Page 1

PS 20

Operating instructions

GB

Page 2

2

PS 20 Detector

This operating instructions contains

information on how to use the tool as well

as safety notices (see chapter ”Safety

notices”).

Please read these instructions carefully

before using the tool.

Also place it at the disposal of anyone

who is to use the tool.

We recommend keeping the instructions

and tool together.

Symbols used

Product ID

Type and serial number are on the plate on the

underside of the tool.

Write this information into the manual and always

use it as reference when calling us or our representative for service or other related information.

Type: PS 20

Serial no.: ____________________

The symbols used in the manual have the following

meaning:

Warning:

Operating hazard or health hazard, even

death of the operator if disregarded.

Operating hazard or minor health hazard to

the operator. May however cause

major damage to the equipment and environment. May also cause expensive repairs.

Operator information

Helps in using the equipment properly and

more efficiently.

Content PS 20 Detector

Operating instructions PS 20

1. Product information . . . . . . . . . . . . .3

1.1 Tool overview........................................3

1.2 PS 20 features ......................................3

1.3 Display and keypad ..............................3

1.4 Technical data........................................4

1.5 Items supplied at time of purchase ......5

2. Safety precautions . . . . . . . . . . . . . .6

2.1 Please read now! ..................................6

2.2 Intended purpose..................................6

2.3 Electromagnetic Compatibility (EMC)....7

2.4 FCC statement ......................................7

2.5 Disposal ................................................7

3. Operation . . . . . . . . . . . . . . . . . . . .8

3.1 Inserting the batteries ..........................8

3.2 Switching on/off and calibrating............8

4. Working with the PS 20 . . . . . . . . . .10

4.1 Detecting reinforcement & non-ferrous,

metallic objects..........................................10

4.2 Menu Functions ..............................12

4.2.1 Calibration ......................................12

4.2.2 Setting minimum depth of coverage 12

4.2.3 Switching back light on/off ............13

4.2.4 Setting the offset ............................13

4.2.5 Switching the acoustic beep on/off 14

4.2.6 Localising live electrical cable ........14

5. Settings menu . . . . . . . . . . . . . . . .16

5.1 Set units to mm/in ..............................16

5.2 Test the display....................................16

6. Care, storage, transportation . . . . . .17

6.1 General care ........................................17

6.2 Storage ................................................17

6.3 Transportation ....................................17

7. Displayed notices . . . . . . . . . . . . . .17

8. Accessories . . . . . . . . . . . . . . . . . .18

9. EU-conformity declaration . . . . . . . .18

10. Warranty . . . . . . . . . . . . . . . . . . .19

Page 3

3

1. Product information

1.1 Tool overview

1 Keypad

2 Display

3 Marking hole

4 Sensor head

5 Battery compartment cover

(exchangeable)

6 Sensor head cover (exchangeable)

7 Holes for hand strap

1

6

4

3

7

5

2

1. Product information

The tool is intended for use as a detector. It can

detect ferrous metals (E.g. steel reinforcing

bars), non-ferrous electrical conductive metals

(E.g copper pipe, aluminium) and can detect

the presence of an electrical field, making it

possible to detect live electrical cable. As well

as detecting the position of reinforcing bar

accurately, it can also determine the depth of

the reinforcing bar. It cannot determine the

depth of any other material.

The PS 20 detector can, within certain limitations be used to estimate or localise the position

of a live electrical cable using the special live

electrical cable detection function.

- automatic object recognition and display of

detected reinforcement

- Detection of reinforcing bars within a defined

minimum depth (ignoring any reinforcement

that lie below this depth).

- Adjustment of detected depth for reinforcement containing impurities

- Detection of unshielded, live electrical cable.

1.2 PS 20 features

1.3 Display and keypad

1 Indication light

2 Acoustic beep indication

3 Signal strength bar

4 Live wire symbol

5 Function menu

6 Keypad

7 Battery low symbol

8 Unit of measure

9 Depth of coverage

10 Non-ferrous metal detection.

Typically shows detection of copper or

aluminium

1

7

8

9

3

2

4

10

5

6

Page 4

4

86

280

95

1.4 Technical data

Reinforcement detection

All figures based on bar diameter of 12mm

(0.5 in), round reinforcing bars, magentic permeability 85-105, concrete surface smooth

and flat, reinforcing bars at right angles to

direction of scan, no interfering influences.

Depth range for detection

Depth range for detection

0-100mm (0 - 4in)

Depth range for coverage depth

measurement 10 - 80 mm

Accuracy of depth of coverage

measurements

metric:

from 10-30mm - +/-2mm

from 30-60mm - +/-2mm +/-10% of depth

from 60-80mm - +/-5mm +/-10% of depth

imperial:

from 0.4-1.18 in - +/-0.08in

from 1.18-2.36 in - +/-0.08in +/-10% of depth

from 2.36-3.15 in - +/-0.2in +/-10% of depth

Separation of reinforcement

Min 42mm (1.7 in) bewteen bars or

1:1.12, whichever is greater.

Non-ferrous metal detection

0 - 60 mm with 10 - 30 mm (tube-ø)

(0 - 2.4 in with 0.4 - 1.2 in, ( tube-ø)

Localising live electrical cable

Will detect cable 100-240V 50/60Hz.

Accuracy to which cable can be localised on

the surface depends on a variety of factors

such as air humidity, moisture in the material, elements close to the cable.

Smallest unit displayed 1mm (1/32 in)

1. Product information

Power supply and battery

Type: AA (LR6, AM3, Mignon)

Standard: 4 alkaline manganese cells

Optional: rechargeable NiCd, NiMH

Warning symbol when battery charge low

Battery life – 40h continuous operation at

23°C (73°F)

Automatic switch-off

3 minutes after a key press is requested and

not carried out.

Operating temperature

–10° C to +50° C (14° F ... 122° F)

Storage temperature

–20° C to +60° C (-4° F ... +158° F)

Proofing

Dust and splash proof,

IP 54 in accordance with IEC 529 standards.

Relative humidity

Max. 95% in accordance with IEC 68,

DIN EN 60068. Does not apply to live electric

cable detection which is adversely affected

by high levels of relative humidity. Refer to

chapter 4.1 for guidance.

Weight

600 g (1.32 lbs) not including batteries

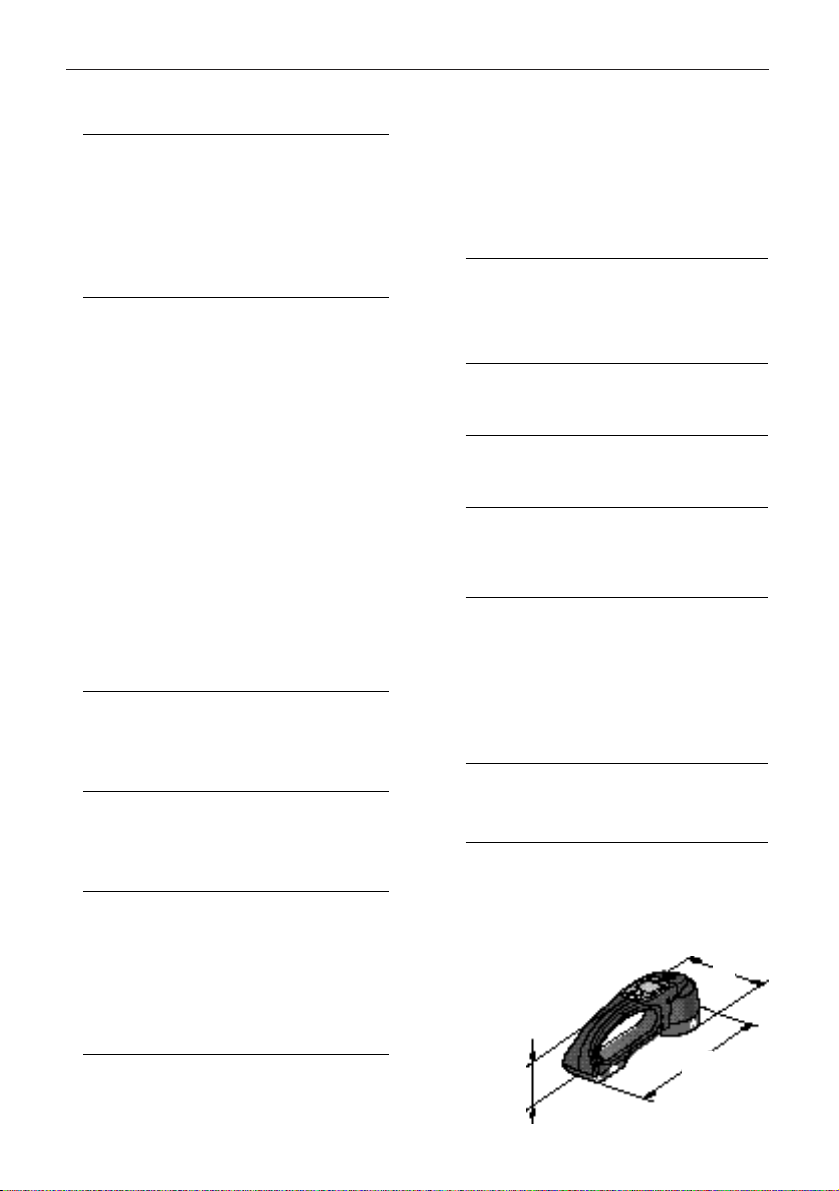

Dimensions (LxWxH)

280 x 95 x 86 mm (11" x 3.7" x 3.4")

Illustration with dimensions [mm]

Page 5

5

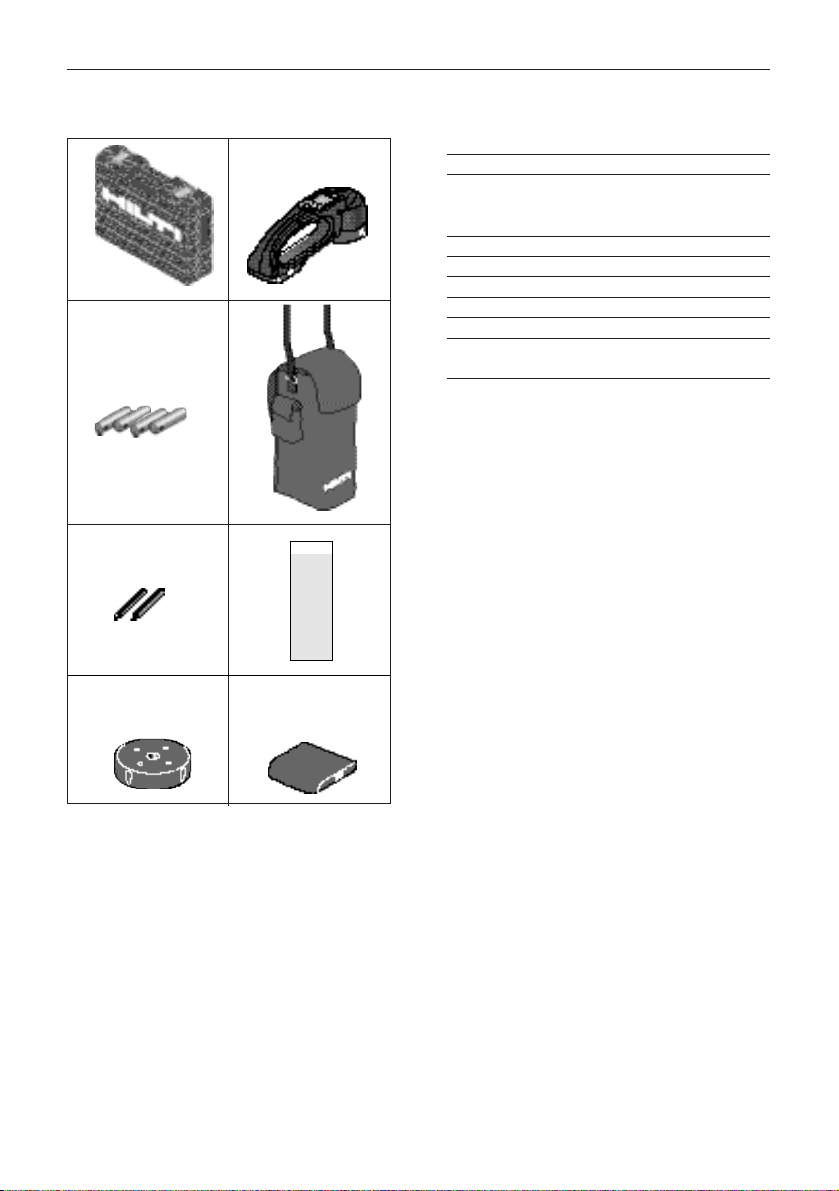

1. Product information

Pos. Pcs. Description

11PS 20 case

21PS 20 detector with sensor head

cover and battery compartment

cover

34AA type batteries

41PS 20 carrying pouch

52Marking pencils

61Operating manual and quick guide

71Replacement sensor head cover

81Replacement battery compartment

cover

1.5 Items supplied at time of purchase

12

34

PS 20

56

78

Page 6

6

2. Safety precautions

2. Safety precautions

2.1 Please read now!

These warnings should put PS 20 owners and

operators in the position where they can recognize possible danger in advance and avoid it,

i.e. prevent it. The owner must make sure all

operators understand and follow these warnings.

2.2 Intended purpose

The Hilti PS 20 detector is intended to be used

for the following purposes:

• detecting and depth of coverage measurement of steel reinforcement.

• detecting copper tubing and aluminum parts.

• localising live electrical cable.

The PS 20 detects electrically

conductive ferrous and non-ferrous

metals. The presence of small objects

made from such materials or the presence of objects made from other

materials cannot be ruled out.

Never attempt to open up the structure without first turning off the power

supply.

In order to guarantee reliable results,

the tool must not be used during

large temperature changes. Allow the

tool time to adjust to the surrounding

ambient temperature before use.

Measurement and evaluation of the

measurements should be performed

by properly trained personnel.

Use as intended

Misuse

They:

• have read and understood the operating

instructions

•are aware of the special features and limitations of the measuring principle used

• possess sufficient knowledge of reinforcement technology.

• Using the product without following the

instructions in the manual.

• Using the product outside of application limits

or technical specifications.

• Using the product before checking the minimum depth and offset function

settings. When set incorrectly, these will result

in misleading or incorrect measurements.

• Using in areas of electromagnetic anomalies.

This may result in

misleading or incorrect measurements.

• Using in areas where there is a danger of

explosions.

• Using in the proximity of medical

equipment. Use near such equipment may

result in disturbances or failure of it.

• Do not immerse in water or use in very heavy

rain.

• Opening parts of the product other than the

battery compartment cover.

• Modifying and/or adding parts to the product.

• Using third party accessories not explicitly

approved by Hilti.

• Using a damaged product or a product that

returns results that are not plausible.

• Measuring with very worn or dirty sensor head

cover or battery compartment cover.

• Measuring without sensor head cover or battery compartment cover

• Using without first testing the accuracy.

• Using to detect metal in humans or animals.

• Use of measuring results for purposes relating

to safety without control measures and evaluation by qualified specialists. (e.g. civil

engineers)

• Drilling very close to or on marked live electric

cables or pipes.

• Drilling on marked reinforcement deeper than

the depth displayed on the tool, also taking

into account depth accuracy specifications.

Continues

Page 7

7

2. Safety precautions

2.3 Electromagnetic Compatibility (EMC)

Electromagnetic compatibility means the capability of the PS 20 to function smoothly in an environment of electromagnetic radiation and electrostatic discharges, without causing electromagnetic interference to other equipment.

Interference caused by electromagnetic radiation

can cause disturbances in the PS 20.

Although the PS 20 meets the strict regulations

and standards which are in force in this respect,

Hilti cannot completely exclude the

possibility that interference may be

caused to the PS 20 by very intensive

electromagnetic radiation, e.g. near

welding equipment, diesel generators

etc.

Under such conditions, check measurement results for their plausibility.

The PS 20 may cause disturbance in

other equipment through electromagnetic radiation.

Although the PS 20 meets the strict

regulations and standards which are in

force in this respect, Hilti cannot completely exclude the possibility that

interference may be caused by the PS

20, e.g. in electronic measuring equipment.

Possible results of misuse

• Safety hazards to life and limb through faulty

measurement results.

• Structural damage,e.g. from drilling into

loadbearing reinforcing bars.

• Damage to the PS 20.

• Reduction of measuring accuracy.

•Warranty is null and void.

• Safety hazards to life and limb through falling

• Safety hazards to life and limb through electric shock

Misuse, Continued

Hilti products are largely manufactured from

recyclable materials. A prerequisite for recycling

is proper material separation. In many countries

Hilti is already able to accept your used unit for

recycling. Ask your Hilti representative or the

Hilti customer service.

2.5 Disposal

2.4 FCC statement (applicable in U.S.)

WARNING

This equipment has been tested and found to

comply with the limits for a Class II digital

device, pursuant to part 15 of the FCC Rules.

These limits are designed to provide reasonable

protection against harmful interference in a residential installation. This equipment generates,

uses and can radiate radio frequency energy

and, if not installed and used in accordance with

the instructions, may cause harmful interference

to radio communications. However, there is no

guarantee that interference will not occur in a

particular installation. If this equipment does

cause harmful interference to radio or television

reception, which can be determined by turning

the equipment off and on, the user is encouraged to try to correct the interference by one or

more of the following measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and receiver.

- Connect the equipment into an outlet on a circuit different from that to which the receiver

is connected.

- Consult the dealer or an experienced radio/TV

technician for help.

Component/assembly Main material Utilization

Plastic case Plastic Plastic recycling

Case Plastic Plastic recycling

Cable Copper, elastomer Scrap metal

Electronic parts Various Electronic scrap

or (sensor, charger) scrap metal

Screws, small parts Steel, brass Scrap metal

Manual Paper Waste paper

Battery, rechargeable Nickel, cadmium Batter y recycling

(observe special

local regulations)

Page 8

8

3. Operation

3. Operation

3.1 Inserting the batteries

Always replace complete battery set.

- do not mix old with new batteries

- do not use batteries from different

manufacturers or of different types.

- only used checked and undamaged

batteries.

When using rechargeable batteries only

use:

- same brand name and same model.

- of same age and charge level.

Never strike the tool in order to remove

the batteries. Always remove them by

hand.

1. Press the sides of the cover

2. Tilt it upwards

3. Remove old batteries if present

4. Insert new batteries as shown inside the battery compartment

5. Replace the cover by inserting the tab on the

cover into the slot in the tool and clicking

down into place.

Batteries will require replacement when the low

battery symbol shows on the display

- "CA” blinks in the large display and

in the function menu display.

The signal strength bar appears.

A short beep sound follows calibration

(if acoustic beep has not been turned

off).

The screen shows:

The tool is ready for

use.

4

Press On key, ”CA” blinks in the large

display and in the function menu display.

Beep

Hold the tool at least 1m away from

all metallic objects and tools or

machines that emit a large electromagnetic field.

(E.g. other PS 20s, power generators

etc).

Press the On key again:

Continues

3.2 Switching on/off and calibrating

Page 9

9

3. Operation

3.2 Switching on/off and calibrating,

Continued

Calibration:

-results in higher measuring

accuracy by taking account of the

surrounding environment

An automatic calibration request

follows if:

- the temperature changes by ± 3°C

-6 minutes after the last calibration.

When the request occurs, hold the

tool at least 1m away from all metallic

objects and machines that produce a

large electromagnetic field and press

the On key to carry out the calibration.

Then carry on working.

To switch the tool off at any time,

press the On and Function keys simultaneously.

Page 10

10

4. Working with the PS 20

Preconditions:

- tool switched on

- calibration carried out

- Minimum depth of coverage function is

inactive

4.1 Detecting reinforcement &

non-ferrous, metallic objects

Tool:

- place on surface where materials are to be

detected

- move it across the surface with a sweeping

motion. Avoid short, jerking movements as

this can result in erroneous detection.

Detecting reinforcing bar and other ferrous

objects

As a reinforcing bar is approached, the signal

strength shown on the bar increases steadily.

Determining the center of the reinforcing bar:

- the center indication light illuminates.

- the acoustic beep sounds (if active).

- signal strength bar is at a maximum.

- depth of coverage is displayed in [mm] or

[inch]

4. Working with the PS 20

Mark the position through the hole in the sensor

head using a marking pencil supplied.

Note the performance limitations and technical

specifications of the tool regarding depth measurement accuracy where depth of rebar is a

critical factor (E.g. when anchor setting).

When no depth measurement is possible,

”--” is displayed as depth of coverage.

The center, however is detected by the beep

sound, the signal strength bar at maximum and

the center indication light.

Reasons for inability to calculate depth include:

- Object is too deep to determine depth (deeper than 80mm or 3.15in)

- Object is not a standard reinforcing bar

-Iron contains a high level of impurities

The PS 20 detects electrically conductive ferrous and non-ferrous metals.

The presence of small objects made

from such materials or the presence

of objects made from other materials

cannot be ruled out.

Page 11

11

4. Working with the PS 20

4.1 Detecting objects, Continued

Detecting non-ferrous metallic objects

(copper and aluminium)

Limitations of rebar detection and depth

measurement

The problem of shading can occur

when trying to detect a second layer

of reinforcement. The top layer shades

the magnetic field. Any reinforcement

below the top layer that is shaded will

not be detected.

1.Shading

Although such a situation rarely

occurs, a reinforcing mat that lies up

to 60mm deeper than the reinforcing

bar can influence the magnetic field

produced by the tool and result in an

incorrect measurement.

Retaining the measured depth value on the

display

To retain the measured depth value on

the display after a rebar has been

detected, press and hold the On key.

This aids easy reading of the display

when working in restricted areas. After

releasing the key, the display is reset.

2.Influence of reinforcement mats on

depth measurements

Localising live electrical cable

See chapter 4.2.6

Determining the center of the pipe:

- the center indication light illuminates.

- the acoustic beep sounds (if active).

- signal strength bar is at a maximum.

- the non-ferrous metal symbol appears on the

display

Mark the position through the hole in the sensor

head using a marking pencil supplied.

Note that depth cannot be calculated.

Mark the likely area through the hole in the

sensor head using a marking pencil supplied.

To return to the metal detection mode, press the

On key.

Page 12

12

If you suspect a recalibration is required before

it is automatically requested, carry it out by:

1. Press the function key. ”CA” blinks in the

main display and in the function menu.

2. Hold the tool at least 1m away from any

metal objects.

3. Press the On key to carry out the calibration.

4. Working with the PS 20

4.2.1 Calibration

4.2 Menu Functions

Calibrating the tool enables it to ensure

accuracy regardless of temperature change or

surrounding magnetic influences.

Calibration is automatically required when the

tool is first switched on. Thereafter it will also

automatically be requested either when the temperature in the tool changes by ±3°C (+26/37°F)

or 6 minutes after the previous calibration.

You will not be able to carry on working until

this calibration is carried out. See chapter 3.2

Switching on and calibrating.

Continues

4.2.2 Setting minimum depth

of coverage

This function is used for checking minimum

concrete coverage depth for:

- quality control

- assessment of cover on concrete areas prior

to renovation

- check before drilling holes for anchors

To set the minimum coverage depth and

activate the function:

With the minimum coverage depth

set, the tool will only sound the visual

and audible alarm when reinforcing

bar is detected closer to the surface

than the defined minimum depth.

1. Select the minimum coverage function from the menu by pressing the

function key twice. The minimum

coverage icon flashes in the

function menu.

2. Press the right arrow key to set the

desired depth. Keep the key pressed

to quickly scroll to the value you

require. Use the left arrow key to

descend to a lower value if required.

Press both arrow keys together to

reset to zero.

3. Press the On key to confirm your

choice and return to the detection

mode.

The minimum coverage icon is displayed in the function menu, signifying that the function is active. Nonferrous metals will still be detected

in the normal way. This setting is

saved when the tool is switched off.

2x

Page 13

13

4. Working with the PS 20

Continues

4.2.3 Switching back light on/off

To operate in poorly lit areas (e.g. a cellar)

switch the back light on.

To switch the backlight on or off:

1. Press the function key three times.

The back light icon flashes.

2. Use the left or right arrow key to

switch the backlight on or off.

3. Press the On key to continue.

This setting is not saved when the

tool is switched off.

3x

To deactivate the function:

1. Repeat step 1 above.

2. Press both arrow key

simultaneously to reset the depth to

zero.

3. Press the On key to confirm and

continue.

The minimum coverage icon

disappears, signifying that the function

is now inactive. To ensure that the

function remains inactive switch the

tool off and then back on.

Before use, ensure that the minimum

cover setting is still valid for the area

you wish to scan. Misleading results

may be obtained if this is not done.

4.2.2 Setting minimum depth of coverage,

Continued

4.2.4 Setting the offset

Offset

The PS 20 contains a database of almost all

known standard reinforcing bars and their

magnetic characteristics. When the reinforcing

bar contains too many impurities, a false depth

of coverage may be displayed. Such problems

usually occur either in older structures or where

building standards are not enforced as a matter

of practice.

The offset function provides a solution to this

problem. However, it does rely on the operator

recognising that such a problem exists. A test

hole is drilled to the reinforcing bar and the

depth measured. Then the PS 20 is used to

measure the depth and the difference calculated. The difference will likely remain reasonably

constant for all reinforcing bar in the structure.

This difference is entered in the PS 20 and is

automatically added or subtracted from the

measured depth.

To enter the offset and activate the function:

1. Press the function key four times.

The offset icon flashes.

2. Press the left or right arrow key to

set the desired offset (Maximum

±10mm). Keep the key pressed to

quickly scroll to the value you require. Use the left arrow key to descend to a lower value if required.

Press both arrow keys together to

reset to zero.

3. Press the On key to confirm your

choice and continue.

4x

The offset icon appears in the display signifying

that the function is active. This setting is saved

when the tool is switched off.

Page 14

14

4.2.5 Switching the acoustic beep

on/off

The acoustic beep signifies either that

the centre of a reinforcing bar or

non-ferrous object has been reached.

To switch the acoustic beep on/off:

1. Press the function key five times.

The acoustic beep icon flashes.

2. Use the left or right arrow key to

switch the beep on or off.

3. Press the On key to continue.

When switched off, the corresponding symbol

appears in the display. This setting is saved

when the tool is switched off. To ensure that

the function remains inactive switch the tool

off and then back on.

5x

4. Working with the PS 20

To deactivate the function:

1. Repeat step 1 above.

2. Press both arrow key

simultaneously to reset the offset

to zero.

3. Press the On key to confirm and

continue.

The minimum coverage icon disappears, signifying that the function is

now inactive. To ensure that the function remains inactive switch the tool

off and then back on.

Before use, ensure that the offset setting is still valid for the area you wish

to scan. Misleading results may be

obtained if this is not done.

4.2.4 Setting the offset, Continued

4.2.6 Localising live electrical cable

1. Press the function key until the live

wire symbol is displayed as below.

2. Place the detector on the area of

interest. If the indication light illuminates, a cable has been found.

3. Reduce the sensitivity level by

pressing the left arrow key until the

light goes out.

4. Increase the sensitivity by one level

so that the light illuminates again

and scan the immediately surrounding area.

5. Repeat steps 3 and 4 until the area

over which the cable is found is

acceptably small.

Live electrical cable is located by first determining that a cable is nearby and then narrowing

down the area over which it is detected by reducing the sensitivity of the tool.

Use the Function menu to access the live cable

function:

Continues

To return to metal detection,

press the On key.

Page 15

15

4.2.6 Localising live electrical cable,

Continued

The following factors must be taken

into account and observed:

The cable detection function localises

the area in which a live cable lies and

gives a most likely position within this

area based on the information available.

Shielded cable and cable running in

metal conduit cannot be detected or

localised. However, metal conduit

lying within the detection range of the

PS 20 will be detected as metal and

shown accordingly on the display.

Moist or damp materials and/or a

humid atmosphere act in a similar

way to an antenna for the electric field

produced by the cable and spread it

over a large area. Therefore, live electric cables cannot be localised in

damp materials or when the surrounding air is very humid.

If a rough surface is scanned using

the live cable detection function on the

higher sensitivity levels (i.e. level 9-6),

use gentle scanning movements over

a small area. Quick, rough movements

over a large area may lead to misleading detection of live electric cables.

4. Working with the PS 20

Page 16

16

5.1 Set units to mm/in

This setting changes the units used

when displaying the depth or reinforcing bar, setting the minimum coverage depth and setting the offset. The

units may be set to millimetres or

inches and fractions of an inch. The

smallest displayed unit is 1mm or

1/32 inch.

To set the units used:

1. Ensure the tool is switched off.

2. Switch on by pressing the On and

function keys simultaneously. The

tool switches on in Settings mode

and the current unit used is displayed.

3. Use the left or right arrow key to

select the desired unit (mm or inch)

4. Press the On and function keys

simultaneously to confirm your

choice and switch the tool off.

The new settings take effect the next

time the tool is switched on.

To avoid confusion, always reset the

minimum cover and offset functions

to zero after changing units.

5. Settings menu

5. Settings menu

5.2 Test the display

All LCD segments in the display may be

activated at once to check that all are

working properly.

To test the display:

1. Ensure the tool is switched off.

2. Switch on by pressing the On and

function keys simultaneously. The

tool switches on in Settings mode

and the current unit used is displayed.

3. Press the function key to test the

display. All LCD segments are activated.

4. Press the On and function keys

simultaneously to switch the tool off.

Page 17

17

6. Care, storage, transportation / 7. Displayed notices

6.1 General care

6.2 Storage

6. Care, storage, transportation

Do not use any other liquids as they

may damage the plastic components.

Pay attention to the temperature the

tool is exposed to, especially in summer when keeping it in a vehicle.

(Storage temperatures:

-20°C to +70°C / -4°F to +158°F)

When sensor head or battery covers

are dirty:

-remove and clean.

-replace if necessary.

Signal holes will appear in the Sensor

head cover when it needs replacing.

Similarly, replace the battery cover

immediately when a hole begins to

appear. Delayed replacement may

result in irreparable damage to the tool.

Worn Sensor head and battery compartment covers can also lead to a

degradation of depth measurement

accuracy of between -1 to -4mm.

- clean with soft dry cloth. Only if necessary

dampen cloth with pure alcohol or water.

Clean and dry the tool. Do not repackage equipment until totally dry

Storage temperatures:

-20°C to +60°C / -4°F to +140°F .

Remove batteries when storing tool

for a long period of time.

Take a test measurement after long storage or

long transportation period.

7. Displayed notices

Batteries almost empty.

- replace

Sensor malfunction

Measure:

Ensure the calibration conditions have

been fulfilled as described in chapter

3.2. Switch off and back on. If error

remains, contact Hilti Service

Error codes:

E1

Temperature outside of safety range

Measure:

Switch off and allow to adjust to

surrounding temperature for one

hour. Ensure surrounding temperature

is within specifcation. Switch back on.

If error remains, contact Hilti Service

E2

Calibration cannot be carried out

Measure:

Ensure the calibration conditions have

been fulfilled as described in chapter

3.2. Switch off and back on. If error

remains, contact Hilti Service

E3

6.3 Transportation

Use the Hilti case when shipping the

tool. Always ship without batteries

inserted. In this way, any disturbance

of vehicle or aircraft systems through

unintended activation of the tool are

ruled out.

Page 18

18

9. EU-conformity declaration

Designation: PS 20

Serial numbers: 00000001 - 50000000

Year of design: 2000

-conform

We declare under sole responsibility that this

product corresponds to the following standards

or standard documents.

EG guideline 89/336/EWG and the corresponding standards DIN EN50081-1 (03.93), DIN EN

50082-2(03.95),authorized certification issued:

no. 010b/00-d.

Hilti Corporation

Armin Spiegel

Positioning Systems

Manager

Head of Business Unit

Bodo Baur

Quality Manager

Positioning Systems

Quality Manager of

Business Unit

Positioning Systems 07/2001

8. Accessories / 9. EU-conformity declaration

8. Accessories

12 red markers packaged in a plastic

storage tube

-1 replacement Sensor Head Cover

-1 replacement battery cover

Sensor Head and Battery Covers. (340807)

Markers (340806)

Replacement parts available from Hilti:

Page 19

19

10. Warranty

10. Warranty

Hilti warrants that the tool supplied is free of

defects in material and workmanship. This warranty is valid so long as the tool is operated and

handled correctly, cleaned and serviced properly

and in accordance with the Hilti Operating

Instructions, all warranty claims are made within

12 months from the date of the sale (invoice

date), and the technical system is maintained.

This means that only original Hilti consumables,

components and spare parts may be used in the

tool.

This warranty provides the free-of-charge repair

or replacement of defective parts only. Parts

requiring repair or replacement as a result of

normal wear and tear are not covered by this

warranty.

Additional claims are excluded, unless stringent national rules prohibit such exclusion. In

particular, Hilti is not obligated for direct, indirect, incidental or consequential damages,

losses or expenses in connection with, or by

reason of, the use of, or inability to use the

tool for any purpose.

Implied warranties of merchantability or fitness for a particular purpose are specifically

excluded.

For repair or replacement, send tool and/or related parts immediately upon discovery of the

defect to the address of the local Hilti marketing

organization provided.

This constitutes Hilti’s entire obligation with

regard to warranty and supersedes all prior or

contemporaneous comments and oral or written

agreements concerning warranties.

Page 20

340809

Hilti Corporation

FL-9494 Schaan

Tel.: +423 / 236 2111

Fax: +423/2362965

www.hilti.com

Hilti = reg. trademark of Hilti Corp., Schaan W2630 0801 2-Pos. 1 9 Printed in Liechtenstein © 2001

Right of technical and programme changes reserved S.E.&O.

Loading...

Loading...