Page 1

PR 30-HVS

Bedienungsanleitung de

Operating instructions en

Mode d’emploi fr

Istruzioni d’uso it

Manual de instrucciones es

Manual de instruções pt

Gebruiksaanwijzing nl

Brugsanvisning da

Bruksanvisning sv

Bruksanvisning no

Käyttöohje

Οδηγιεςχρησεως el

Használati utasítás hu

Instrukcjaobsługi pl

Инструкцияпозксплуатации ru

Návod k obsluze cs

Návod na obsluhu sk

Upute za uporabu hr

Navodila za uporabo sl

Printed: 29.11.2013 | Doc-Nr: PUB / 5142593 / 000 / 02

Page 2

1

௺௹

Printed: 29.11.2013 | Doc-Nr: PUB / 5142593 / 000 / 02

Page 3

2

௹

௺

3

4

௹

௹

௺

5

6

௺

ఁ

ఀ

௺

௹

Printed: 29.11.2013 | Doc-Nr: PUB / 5142593 / 000 / 02

ఀ

௺

௹

Page 4

7

8

௺

௹

9

Printed: 29.11.2013 | Doc-Nr: PUB / 5142593 / 000 / 02

35$ 35$ 35$

Page 5

10

11

[

12

$

14

Printed: 29.11.2013 | Doc-Nr: PUB / 5142593 / 000 / 02

13

%

$

15

%

[

[

Page 6

16

17

P

P

P

D

E

P

F G

%

5

Printed: 29.11.2013 | Doc-Nr: PUB / 5142593 / 000 / 02

P

$

P

Page 7

5

18

PP

&

%

$

P

5

Printed: 29.11.2013 | Doc-Nr: PUB / 5142593 / 000 / 02

Page 8

ORIGINAL OPERATING INSTRUCTIONS

PR 30-HVS rotating laser

It is essential that the operating instructions

are read before the tool is operated for the

en

first time.

Always keep these operating instructions to-

gether with the tool.

Ensure that the operating instructions are

with the tool when it is given to other persons.

Contents Page

1 General information 23

2Description 23

3 Accessories 26

4 Technical data 26

5 Safety instructions 28

6Beforeuse 30

7 Operation 31

8 Care and maintenance 38

9 Troubleshooting 39

10 Disposal 40

11 Manufacturer’s warranty - tools 41

12 FCC statement (applicable in US) / IC

statement (applicable in Canada) 41

13 EC declaration of conformity (original) 42

1 These numbers refer to the corresponding illustrations. The illustrations can be found on the fold-out cover

pages. Keep these pages open while studying the operating instructions.

In these operating instructions, the designation “the tool”

or “the rotating laser” always refers to the PR 30-HVS.

“Remote control”, “laser receiver” or "receiver" always

refer to the PRA 30 (03).

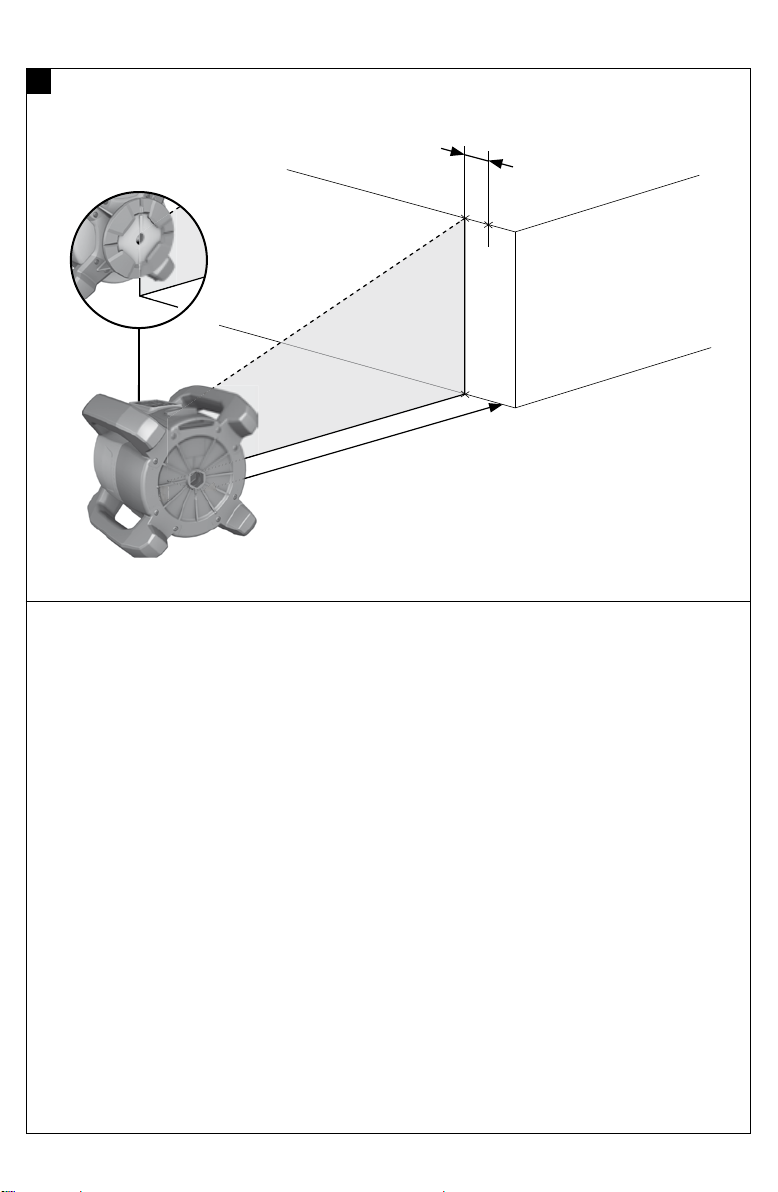

Rotating laser 1

Laser beam (plane of rotation)

@

Rotating head

;

Grip

=

Control panel

%

Base plate with ⁵/₈" thread

&

PRA 84 Li‑ion battery

(

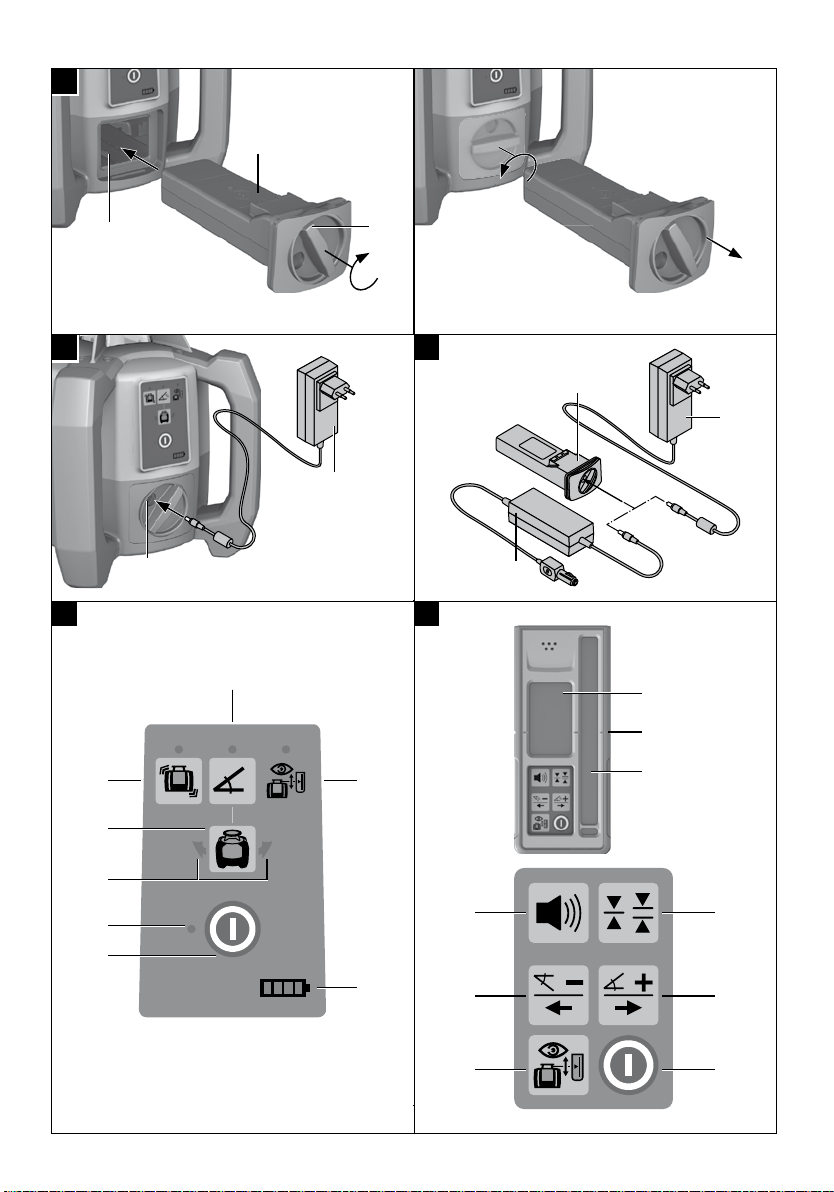

Inserting and removing the battery 2

PRA 84 Li‑ion battery

@

Battery compartment

;

Catch

=

Charging the battery in the tool 3

PUA 81 AC adapter

@

Charging socket

;

Charging the battery after removal from the tool 4

PUA 81 AC adapter

@

PUA 82 motor vehicle power adapter

;

Charging activity LED

=

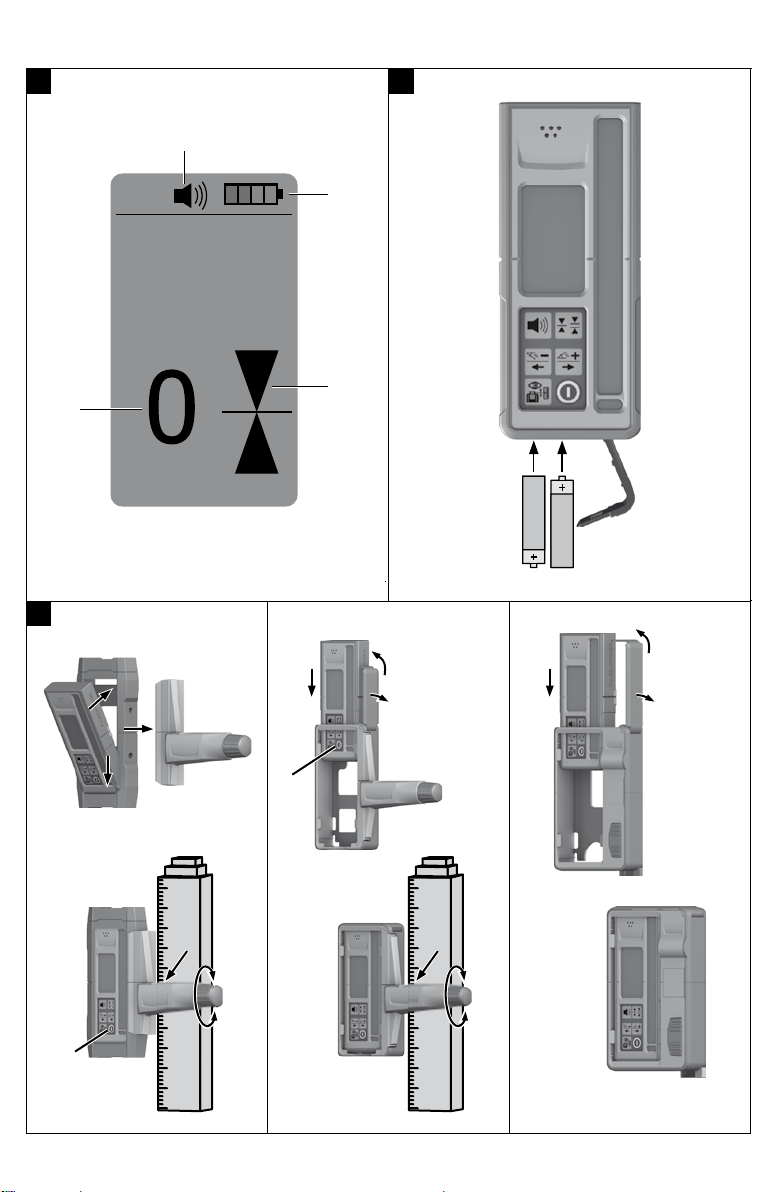

Rotating laser control panel 5

On/off button

@

Auto-leveling LED

;

LED arrow for electronic inclination alignment

=

Electronic inclination alignment button (only in con-

%

junction with inclined plane mode)

Shock warning function button and LED

&

Inclined plane mode button and LED

(

Surveillance mode LED (only with automatic vertical

)

alignment)

Battery charge status LED

+

PRA 30 control panel 6

On/off button

@

Inclination entry button (Plus / Right or Up arrow

;

button) (with the PRA 90)

Units button

=

Volume button

%

Inclination entry button (Minus / Left or Down arrow

&

button) (with the PRA 90:

Automatic alignment / surveillance mode button

(

(vertical) (double click)

Receiving window

)

Marking notch

+

Display

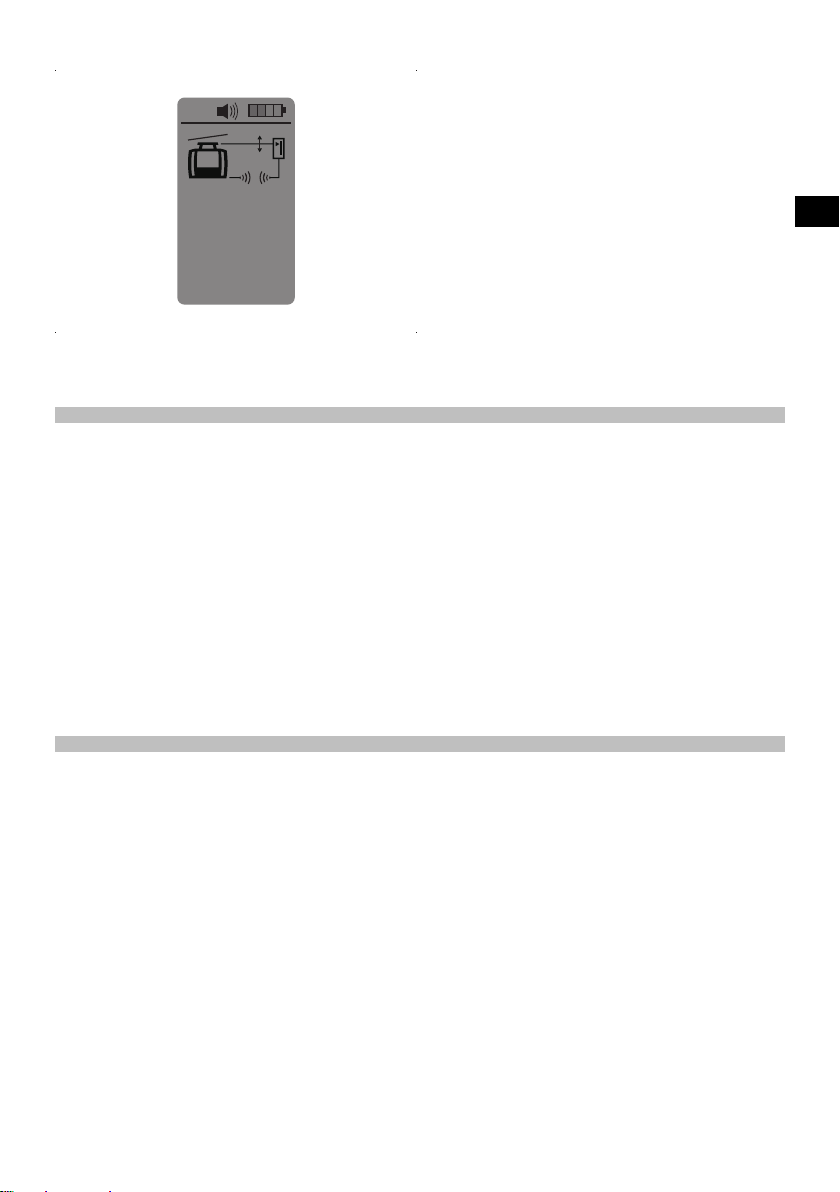

§

PRA 30 display 7

Display showing the position of the receiver relative

@

to the height of the laser plane

Battery status

;

Volume

=

Indication of distance from laser plane

%

22

Page 9

1 General information

1.1 Safety notices and their meaning

DANGER

Draws attention to imminent danger that will lead to

seriousbodilyinjuryorfatality.

WARNING

Draws attention to a potentially dangerous situation that

could lead to serious personal injury or fatality.

CAUTION

Draws attention to a potentially dangerous situation that

could lead to slight personal injury or damage to the

equipment or other property.

NOTE

Draws attention to an instruction or other useful information.

1.2 Explanation of the pictograms and other

information

Symbols

On the tool

Laser Class 2 in accordance with IEC/EN 60825‑1:2007

On the tool

&$87,21

/$6(55$',$7,21'2127

67$5(,172%($0

QP3R P:Ă530

&/$66,,/$6(5352'8&7

Laser Class II according to CFR 21, § 1040 (FDA)

Location of identification data on the tool

The type designation and serial number can be found on

thetypeidentificationplateonthetool.Makeanoteof

this data in your operating instructions and always refer

to it when making an enquiry to your Hilti representative

or service department.

Type:

Generation: 01

en

Read the

operating

instructions

before use.

For indoor

use only

General

warning

Return waste

material for

recycling.

Warning:

caustic

substances

Do not look

into the

beam.

Warning:

electricity

Warning:

explosive

substances

Serial no.:

2 Description

2.1 Use of the product as directed

The Hilti PR 30-HVS is a rotating laser tool with a visible rotating laser beam and a reference beam set at 90° to the

main beam. The rotating laser can be used vertically, horizontally and for inclined planes.

The tool is designed to be used to determine, transfer and check levels, verticals, slopes and right angles. Examples of

its uses are: transferring datums and height marks, determining right angles for walls, vertical alignment on reference

points and setting out slopes.

The tool is designed for professional use and may be operated, serviced and maintained only by trained, authorized

personnel. This personnel must be informed of any special hazards that may be encountered. The tool and its ancillary

equipment may present hazards when used incorrectly by untrained personnel or when used not as directed.

Hilti supplies various accessories which allow the tool to be used with maximum efficiency.

To avoid the risk of injury, use only genuine Hilti accessories and insert tools.

Observe the information printed in the operating instructions concerning operation, care and maintenance.

Take the influences of the surrounding area into account. Do not use the appliance where there is a risk of fire or

explosion.

Modification of the tool is not permissible.

23

Page 10

2.2 Features

Thetoolmakesitpossibleforasinglepersontoleveloraligninanyplanequickly and with great accuracy.

The tool levels itself automatically after switching on. The laser beam is emitted only when the specified accuracy has

been achieved.

LEDs indicate the current operating status.

The tool is powered by a rechargeable Li‑ion battery which can be charged while the tool is in operation.

2.3 Combined use of the PRA 30 remote control / laser receiver

en

The PRA 30 is a combined remote control unit and laser receiver. It can be used to control the PR 30-HVS rotating

laser over great distances. The PRA 30 also serves as a laser receiver and can thus be used to detect and indicate the

laser beam at great distance.

2.4 Digital distance measurement display

The laser receiver displays digitally the distance between the laser plane and the marking notch. This allows the user to

determine the exact position of the receiver relative to the laser plane, with millimeter accuracy, in a single operation.

2.5 Automatic alignment and surveillance

Using the PR 30-HVS and the PRA 30, a person working alone can align the laser plane automatically with a certain

point with great accuracy. The tool detects the applicable alignment (horizontal, inclined or vertical) automatically and

uses the automatic alignment function accordingly (horizontal with the PRA 90 plus inclination) or automatic alignment

with subsequent monitoring of the plane (vertical). With the aid of the PRA 30, the surveillance function checks

alignment of the laser plane at regular intervals in order to avoid possible deviations due to temperature fluctuations,

wind or similar. The surveillance function can be deactivated.

2.6 Digital inclination display with patented electronic inclination alignment

The digital inclination display is capable of indicating an inclination of up to 21.3% when the PR 30-HVS is operating in

inclined mode. This makes it possible to set out and check slopes without having to make any calculations. Electronic

inclination alignment allows optimum inclination accuracy.

2.7 Shock warning

The shock warning function is activated two minutes after the tool has leveled itself after switching on. If a button

is pressed within these two minutes, the two-minute delay begins again. The tool switches to warning mode if it is

brought out of level while in operation (due to vibration or an impact); all LEDs begin to blink and the laser switches

off (the head stops rotating).

2.8 Automatic cut-out

The laser does not switch on and all LEDs blink if the tool is set up outside its self-leveling range (±5°) or if movement

is blocked mechanically.

The tool can be set up on a tripod with a 5/8" thread or stood directly on some other steady surface (free of vibration).

When automaticleveling is activated for one or both axes, the built-in servo system ensures that the specified accuracy

is maintained. The tool switches itself off when automatic leveling cannot be achieved (tool set up outside its leveling

range or physical impediment of the mechanism) or when knocked off level (see “Shock warning” section).

NOTE

If the correct level cannot be achieved, the laser switches itself off and all LEDs blink.

2.9 Items supplied

1 PR 30-HVS rotating laser

1 PRA 30 (03) laser receiver / remote control

1 PRA 80 or PRA 83 laser receiver holder

1 Operating instructions

1 PRA 84 Li‑ion battery

1PUA81ACadapter

2 Batteries (size AA cells)

24

Page 11

2 Manufacturer’s certificates

1 Hilti toolbox

2.10 Operating status indicators

The tool is equipped with the following operating status indicators: Auto-leveling LED, battery charge status LED,

shock warning function deactivation LED, inclined plane mode LED, surveillance mode LED and electronic inclination

alignment LED.

2.11 LED indicators

Auto-leveling LED The green LED blinks. The tool is in the leveling phase.

The green LED lights constantly.

Shock warning deactivation LED The orange LED lights con-

stantly.

Inclined plane mode LED The orange LED blinks. Alignment in the sloping plane.

TheorangeLEDlightsconstantly.

SurveillancemodeLED TheorangeLEDlightscon-

stantly.

The orange LED blinks. The tool is aligning the laser plane with

Electronic inclination alignment LED The orange LED arrows blink. The tool is in electronic inclination align-

Both orange LED arrows light

constantly.

The orange LED arrow on the

left lights

The orange LED arrow on the

right lights

All LEDs All LEDs blink The tool has been bumped, knocked off

The tool has leveled itself / is operating

normally.

The shock warning function is deactivated.

Slope mode is active.

The tool is in surveillance mode. Alignment with the reference point (PRA 30)

is correct.

the reference point (PRA 30).

ment mode, the PRA 30 receives no

laser beam.

The tool is correctly aligned with the

PRA 30.

The tool must be rotated in a clockwise

direction.

The tool must be rotated in a counterclockwise direction.

level or is exhibiting some error.

en

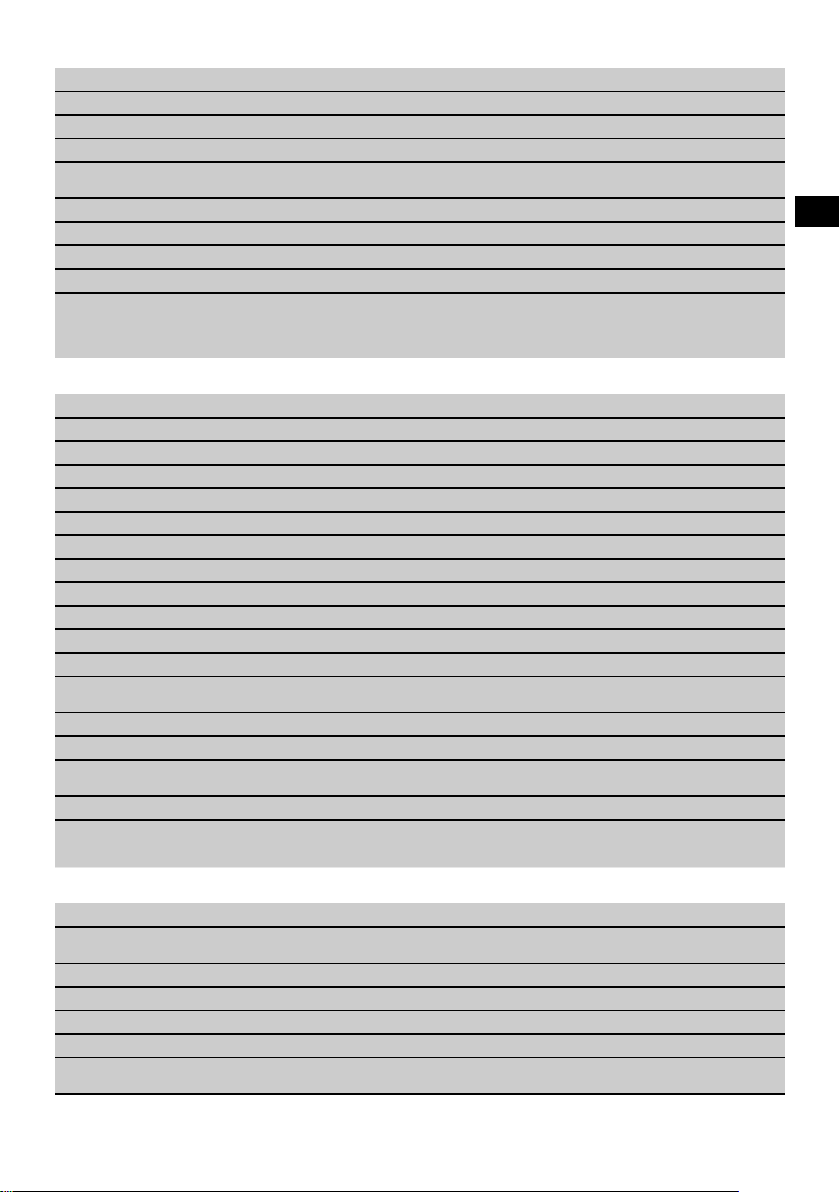

2.12 Charge status of the Li‑ion battery during operation

LEDs light constantly LEDs blink

LED1,2,3,4

LED1,2,3

LED 1, 2

LED 1

-

2.13 Charge status of the Li‑ion battery during charging while inserted in the tool

LEDs light constantly LEDs blink

LED1,2,3,4

LED1,2,3 LED4

LED1,2 LED3

LED1 LED2

-

-

-

-

LED 1

-

LED 1

Charge status C

C≧75%

50 % ≦ C < 75 %

25 % ≦ C < 50 %

10 % ≦ C < 25 %

C<10%

Charge status C

C=100%

75 % ≦ C < 100 %

50 % ≦ C < 75 %

25 % ≦ C < 50 %

C<25%

25

Page 12

2.14 Battery charging activity is shown on the battery display while charging the battery outside the tool.

If the red LED lights constantly, the battery is being charged.

If the red charging activity LED does not light, then either the charging operation is complete or the charger is providing

no current.

3 Accessories

en

Designation

Laser receiver / remote control PRA 30 (03)

Laser receiver PRA 20 (02)

Laser receiver holder PRA 80

Laser receiver holder PRA 83

Height transfer device PRA 81

Slope adapter PRA 79

AC adapter PUA 81

Car charging connector PUA 82

Battery PRA 84

Battery PRA 84G

Vertical angle PRA 770

Batter board adapter PRA 750

Batter board receiver holder PRA 751

Facade adapter PRA 760

Tripod PUA 20

Crank tripod (elevator tripod) PA 921

Crank tripod (elevator tripod) PUA 30

Automatic tripod PRA 90

Telescopic staffs PUA 50, PUA 55

Short designation

4 Technical data

Right of technical changes reserved.

PR 30-HVS

Receiving range (diameter) With PRA 30 (03) (typical): 2…500 m

Range of remote control (circle diameter) With PRA 30 (03) (typical): 0…150m

Accuracy

Plumb beam Continuous, perpendicular to the plane of rotation

Laser class Class 2, 620-690 nm; < 1 mW (EN 60825-1:2007 / IEC

Speed of rotation 600/min, 1,000/min

Slope range

Self-leveling range ±5°

1

otherwise, the tool was adjusted or calibrated under standard ambient conditions (MIL-STD-810G).

2

26

1

Influences such as particularly high temperature fluctuations, dampness, shock, dropping, etc. can affect accuracy. Unless stated

The drop test was carried out from a tripod, dropping onto flat concrete under standard ambient conditions (MIL-STD-810G).

at 10 m: ± 0.75 mm

60825-1:2007); Class II (CFR 21 § 1040 (FDA)); Maximum power < 4.85 mW at ≧ 300 r.p.m.

With the tool pre-inclined: ≤ 21.3%

Page 13

Powersource 7.2V/4.5AhLi‑ionbattery

Battery life Temperature +25°C, Li‑ion battery: ≥ 25 h

Operating temperature range -20…+50°C

Storage temperature range (dry) -25…+60°C

Protection class IP 66 (in accordance with IEC 60529); Not in “charging

during operation” mode

Tripod thread ⁵⁄₈" x 18

Weight (incl. PRA 84) 2.5 kg

Dimensions(LxWxH) 200mmx200mmx230mm

Drop test height

1

Influences such as particularly high temperature fluctuations, dampness, shock, dropping, etc. can affect accuracy. Unless stated

otherwise, the tool was adjusted or calibrated under standard ambient conditions (MIL-STD-810G).

2

The drop test was carried out from a tripod, dropping onto flat concrete under standard ambient conditions (MIL-STD-810G).

2

1.5 m

PRA 30 (03)

Detection range (area diameter) Typical distance with PR 30-HVS: 2…500 m

Signal tone generator 3 volume levels plus mute setting

Liquid-crystal display On both sides

Indicator range, distance from zero ± 52 mm

Laser plane display range ± 0.5 mm

Length of the detection area 120 mm

Casing top edge center indicator

75 mm

Marking notches On both sides

Time without detection before automatic power off 15 min

Dimensions (L × W × H) 160 mm × 67 mm × 24 mm

Weight (including batteries) 0.25 kg

Power source 2 AA batteries

Battery life Temperature +20°C: Approx. 40 h (depending on the

quality of the alkaline batteries used)

Operating temperature range -20…+50°C

Storage temperature range -25…+60°C

Protection class IP 66 (in accordance with IEC 60529), except battery

compartment

Drop test height

1

The drop test was carried out using the PRA 83 receiver holder, dropped onto flat concrete under standard ambient conditions

(MIL-STD-810G).

1

2m

en

PRA 84 Li‑ion battery

Rated voltage (normal mode) 7.2 V

Maximum voltage (during operation or during charging

13 V

while in operation)

Rated current 180 mA

Charging time

Temperature +32°C: 2 h 10 min (battery 80% charged)

Operating temperature range -20…+50°C

Storage temperature range (dry) -25…+60°C

Charging temperature range (also for charging during

+0…+40°C

operation)

27

Page 14

Weight 0.3 kg

Dimensions(LxWxH) 160mmx45mmx36mm

PUA 81 AC adapter

AC supply 115…230 V

AC frequency 47…63 Hz

Rated power 36 W

en

Rated voltage 12 V

Operating temperature range +0…+40°C

Storage temperature range (dry) -25…+60°C

Weight 0.23 kg

Dimensions(LxWxH) 110mmx50mmx32mm

5 Safety instructions

5.1 Basic information concerning safety

In addition to the information relevant to safety given

in each of thesections ofthese operatinginstructions,

the following points must be strictly observed at all

times.

5.2 General safety rules

a) Do not render safety devices ineffective and do

not remove information and warning notices.

b) Stayalert, watchwhat you are doing anduse com-

mon sense when operating the machine. Don’t

use the machine when you are tired or under the

influence of drugs, alcohol or medication. Amo-

ment of inattention while operating machines may

result in serious personal injury.

c) Keep laser tools out of reach of children.

d) Failure to follow the correct procedures when open-

ing the tool may cause emission of laser radiation in

excess of class 2 or, respectively, class 3. Have the

tool repaired only at a Hilti service center.

e) Do not operate the tool in explosive atmospheres,

such as in the presence of flammable liquids,

gases or dust. Tools and appliances create sparks

which may ignite the dust or fumes.

f) (Statement in accordance with FCC §15.21):

Changes or modifications not expressly approved

by the manufacturer can void the user’s authority to

operate the equipment.

g) Use of setting-up / adjusting devices and equipment

or operating procedures other than those specified in

these instructions may lead to exposure to hazardous

radiation.

h) Check the condition of the tool before use. If the

tool is found to be damaged, have it repaired at a

Hilti service center.

i) Maintain the machine carefully. Check for mis-

alignment or binding of moving parts, breakage

of parts and any other condition that may affect

the machine’s operation. If damaged, have the

machine repaired before use. Poor maintenance is

the cause of many accidents.

j) The user must check the accuracy of the tool

after it has been dropped or subjected to other

mechanical stresses.

k) Check the tool before using it for important meas-

uring work.

l) Check the accuracy of the measurements several

times during use of the tool.

m) When the tool is brought into a warm environment

from very cold conditions, or vice-versa, allow it

to become acclimatized before use.

n) If mounting on an adapter, check that the tool is

screwed on securely.

o) Keep the laser exit aperture clean to avoid meas-

urement errors.

p) Although the tool is designed for the tough condi-

tions of jobsite use, as with other optical and electronic instruments (e.g. binoculars, spectacles,

cameras) it should be treated with care.

q) Although the tool is protected to prevent entry

of dampness, it should be wiped dry each time

before being put away in its transport container.

r) Keep the electrical contacts dry (protect from rain

or dampness).

s) Use the AC adapter only for connecting to the AC

supply.

t) Check to ensure that the tool and AC adapter do

not present an obstacle that could lead to a risk

of tripping and personal injury.

u) Ensure that the workplace is well lit.

v) Check the condition of the extension cord and

replace it if damage is found. Do not touch the AC

adapter if the extension cord or AC adapter are

damaged while working. Disconnect the supply

cord plug from the power outlet. Damaged supply

28

Page 15

cords or extension cords present a risk of electric

shock.

w) Avoid body contact with earthed or grounded

surfaces, such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

x) Do not expose the supply cordto heat, oil or sharp

edges.

y) Never operate the AC adapter when it is dirty or

wet. Dust (especially dust from conductive materials) or dampness adhering to the surface of

the AC adapter may, under unfavorable conditions, lead to electric shock. Dirty or dusty tools

should thus be checked at a Hilti Service Center

at regular intervals, especially if used frequently

for working on conductive materials.

z) Avoid touching the contacts.

5.2.1 Battery tool use and care

a) Do not expose batteries to high temperatures or

fire. This presents a risk of explosion.

b) Do not disassemble, squash or incinerate batter-

ies and do not subject them to temperatures over

75°C. A risk of fire, explosion or injury through con-

tact with caustic substances may otherwise result.

c) Avoid ingress of moisture. Moisture in the interior

of the tool may cause a short circuit and chemical

reactions resulting in burns to the skin or fire.

d) Under abusive conditions, liquid may leak from the

battery. Avoid contact. If contact accidentally oc-

curs, flush with water. In the event of the liquid

coming into contact with the eyes, rinse the eyes

with plenty of water and consult a doctor. Liquid

ejected from the battery may cause irritation or burns.

e) Do not use batteries other than those approved

for use with the applicable tool or appliance. Use

of other batteries or use of the battery for purposes

for which it is not intended presents a risk of fire and

explosion.

f) Observe the special guidelines applicable to the

transport, storage and use of Li-ion batteries.

g) When not in use, keep the battery and the charger

away from paper clips, coins, keys, nails, screws

or other small metal objects that could cause a

short circuit at the battery terminals or the charging contacts. A short circuit at the battery terminals

or charging contacts could result in personal injury

(burns) or fire.

h) Avoid short-circuiting the battery.Before inserting

the battery in the tool, check that the terminals of

the battery and the tool are free from foreign objects.

Short-circuiting the battery terminals presents a risk

of fire, explosion or contact with caustic substances.

i) Do not charge or continue to use damaged bat-

teries (e.g. batteries with cracks, broken parts,

bent or pushed-in and/or pulled-out contacts).

j) Use only the PUA 81 AC adapter, PUA 82 motor

vehicle power adapter or other chargers recommended by the manufacturer to power the tool or

charge the battery. Failure to observe these points

may result in damage to the tool. Use of a charger

with batteriesother than the specific type(s) for which

it is designed presents a risk of fire.

5.3 Proper organization of the work area

a) Secure the area in which you are working and

take care to avoid directing the beam towards

other persons or towards yourself when setting

up the tool.

b) Avoid unfavorable body positions when working

from ladders. Make sure you work from a safe

stance and stay in balance at all times.

c) Readings taken in the vicinity of reflective objects or

surfaces, through panes of glass or similar materials

may produce incorrect results.

d) Ensure that the tool is set up on a steady, level

surface (not subject to vibration).

e) Use the tool only within its specified limits.

f) Make sure that your PR 30-HVS is responding only

to your PRA 30 and not to other PRA 30s that may

be in use on the jobsite.

g) When working in “charging during operation”

mode, attach the AC adapter in a secure position,e.g.onatripod.

h) Use of products for applications different from those

intended could result in hazardous situations. Use

the product and its accessories etc. in accordance with these instructions and in the manner

intended for the particular type of product. Take

the working conditions and the work to be performed into account.

i) Use of the telescopic staff in the vicinity of over-

head high voltage cables is not permissible.

5.3.1 Electromagnetic compatibility

Although the tool complies with the strict requirements

of the applicable directives, Hilti cannot entirely rule out

the possibility of the tool being subject to interference

caused by powerful electromagnetic radiation, leading

to incorrect operation. Check the accuracy of the tool

by taking measurements by other means when working

under such conditions or if you are unsure. Likewise, Hilti

cannot rule out the possibility of interference with other

devices (e.g. aircraft navigation equipment).

5.3.2 Laser classification for Laser Class 2 / Class

II appliances

Depending on the version purchased, the tool complies with Laser Class 2 in accordance with IEC8251:2007/EN60825-1:2007 and Class II in accordance with

CFR 21 § 1040 (FDA). This tool may be used without

need for further protective measures. The eyelid closure reflex protects the eyes when a person looks into

the beam unintentionally for a brief moment. This eyelid

closure reflex, however, may be negatively affected by

medicines, alcohol or drugs. Nevertheless, as with the

en

29

Page 16

sun, one should not look directly into sources of bright

light. Do not direct the laser beam toward persons.

6Beforeuse

NOTE

The tool may be powered only by a Hilti PRA 84 or PRA

en

84G battery.

6.1 Fitting the battery 2

CAUTION

Before inserting the battery in the tool, check to

ensure that the battery terminals and the contacts in

the tool are free from foreign objects.

1. Slide the battery into the appliance.

2. Turn the catch in a clockwise direction until the

“locked” symbol appears.

6.2 Removing the battery 2

1. Turn the catch in a counter-clockwise direction until

the “unlocked” symbol appears.

2. Pull the battery out of the appliance.

6.3 Charging the battery

DANGER

Use only the Hilti batteries and Hilti AC adapters listed

under “Accessories”.UseoftoolsorACadapterswhich

show visible signs of damage is not permissible.

6.3.1 Charging a new battery for the first time

Charge the battery fully before using it for the first time.

NOTE

Make sure the system to be charged is standing securely.

6.3.2 Recharging a battery

1. Check that the outer surfaces of the battery are

clean and dry.

2. Insert the battery in the tool.

NOTE Li‑ion batteries are ready for use at any time,

even when only partly charged.

Charging progress is indicated by the LEDs when

the tool is switched on.

6.4 Options for charging the battery

DANGER

The PUA 81 AC adapter is for indoor use only. Avoid

ingress of moisture.

6.4.1 Charging the battery in the tool 3

1. Insert the battery in the battery compartment (see

6.1).

2. Rotate the socket cover until the charging socket on

the battery becomes visible.

3. Plug the cord from the AC adapter or motor vehicle

power adapter into the battery.

The battery will be charged.

4. Switch the tool on in order to display the charging

status while charging is in progress.

6.4.2 Charging the battery outside the tool 4

1. Remove the battery (see 6.2).

2. Connect the cord from the AC adapter or the motor

vehicle power adapter to the battery.

The red LED on the battery indicates charging activity.

6.4.3 Charging the battery while the tool is in

operation

DANGER

Operation in “charging during operation” mode is not

permissible for outdoor use or in damp surroundings.

CAUTION

Avoid ingress of moisture. Moisture in the interior of

the tool may cause a short circuit and chemical reactions

resulting in burns to the skin or fire.

1. Rotate the socket cover until the charging socket on

the battery becomes visible.

2. Plug the cord from the AC adapter into the battery.

The tool continues to operate while charging and

battery charging status is indicated by the LEDs on

the tool.

6.5 Battery use and care

Store the battery in a cool, dry place. Never store the

battery where it is exposed to direct sunlight or sources

of heat, e.g. on heaters / radiators or behind glass.

Batteries that have reached the end of their life must be

disposed of safely and correctly to avoid environmental

pollution.

NOTE

Make sure that the recommended temperature range is

observed when charging (0 to 40°C).

30

6.6 Switching the tool on

Press the on/off button.

NOTE

After switching on, the tool begins to level itself automatically. After completion of the leveling process, the laser

Page 17

beam is switched on and begins to rotate in the normal

direction.

6.7 LED indicators

Please refer to section 2 “Description”.

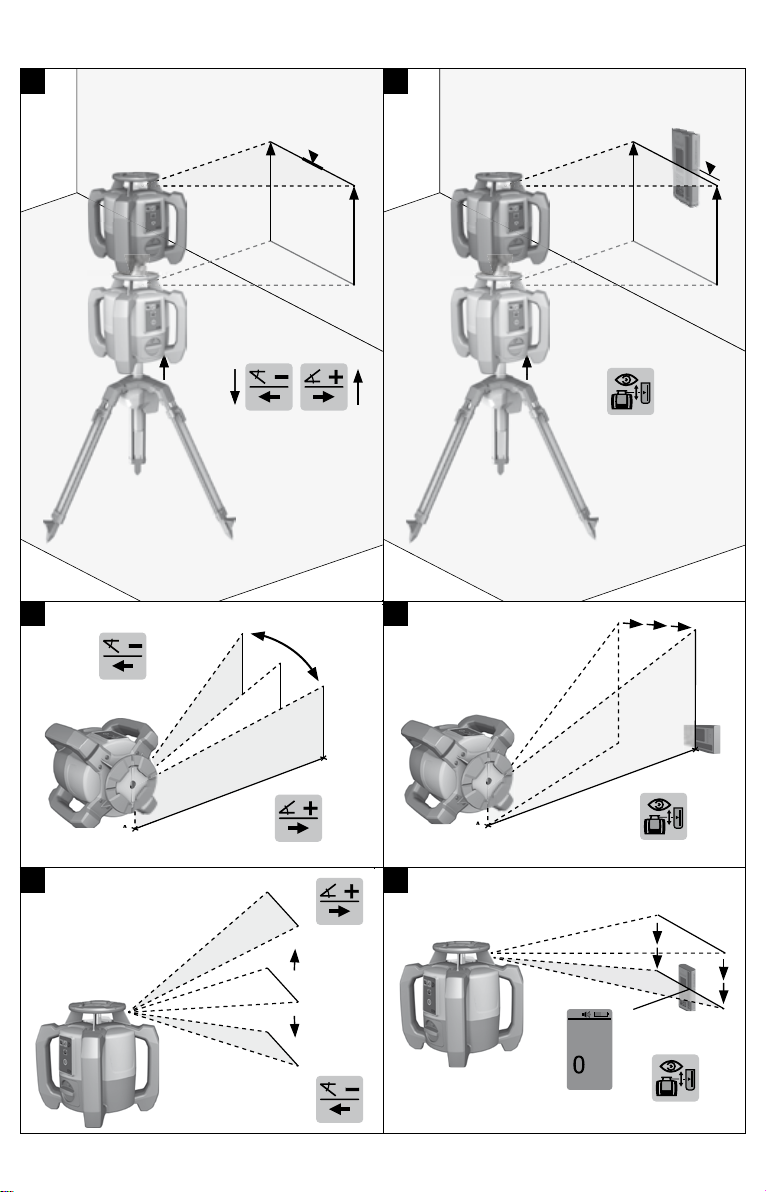

6.8 Inserting batteries in the PRA 30 8

DANGER

Do not use damaged batteries.

DANGER

Do not mix old and new batteries. Do not mix batteries of

different makes or types.

NOTE

The PRA 30 may be powered only by batteries manufactured in accordance with the applicable international

standards.

1. Open the laser receiver battery compartment.

2. Insert the batteries in the laser receiver.

NOTE Check to ensure correct polarity when inserting the batteries.

3. Close the battery compartment cover.

6.9 Pairing

The rotating laser and the remote control / laser receiver

are already paired when supplied. Additional laser receivers of the same type or PRA 90 automatic tripods are

not ready for use until they have been paired. The rotating laser and these accessories must be paired before

they can be used together. Pairing tools and appliances

means that they are explicitly assigned to each other.

The rotating laser and the PRA 90 automatic tripod then

receive only signals from the remote control units / laser

receivers with which they have been paired. The pairing

enables appliances to work close to other rotating lasers

without the risk that their settings will be altered by these

other lasers.

6.9.1 Pairing the rotating laser and the laser

receiver

en

1. Press the on/off buttons on the rotating laser

and laser receiver simultaneously and keep them

pressed for at least 3 seconds.

Successful pairing is indicated by a signal tone emitted by the laser receiver and all LEDs blinking on the

rotatinglaser.Atthesametime,the“Paired”symbol

appears briefly in the laser receiver display. The rotating laser and the receiver switch off automatically

after pairing.

2. Switch the paired appliances on again.

The “Paired” symbol appears in the display.

6.9.2 Pairing the PRA 90 and the receiver

1. Press the on/off buttons on the PRA 90 automatic

tripod and laser receiver simultaneously and keep

them pressed for at least 3 seconds.

Successful pairing is indicated by a signal tone

emitted by the laser receiver and all LEDs blinking

on the PRA 90 automatic tripod. At the same time,

the “Paired” symbol appears briefly in the laser

receiver display. The tripod and the receiver switch

off automatically after pairing.

2. Switch the paired appliances on again.

The rotating laser with the tripod is shown in the

display on the laser receiver.

7Operation

7.1 Checking the tool

Check the accuracy of the tool before using it for important tasks, especially if it has been dropped or subjected

to unusual influences or impacts etc. (see 8.6).

7.2 Switching the tool on

Press the on/off button.

NOTE

After switching on, the tool begins to level itself automatically.

7.3 Working with the PRA 30

The PRA 30 is a combined laser receiver and remote control unit. The remote control makes working with the rotating

laser more convenient and is required in order to make use of certain functions. The laser beam is indicated by visual

and audible signals.

7.3.1 Working with the laser receiver as a hand-held unit

1. Press the on/off button.

2. Hold the laser receiver with the detection area directly in the plane of the rotating laser beam.

31

Page 18

7.3.2 Working with the laser receiver in the PRA 80 receiver holder 9

1. Open the catch on the PRA 80.

2. Place the receiver in the PRA 80 receiver holder.

3. Close the catch on the PRA 80.

4. Switch the receiver on by pressing the on/off button.

5. Turn the rotating grip to the open position.

6. Secure the PRA 80 receiver holder on the telescopic staff or leveling staff by tightening the clamping knob.

7. Hold the laser receiver with the detection area directly in the plane of the rotating laser beam.

en

7.3.3 Working with the laser receiver in the PRA 83 receiver holder 9

1. Push the receiver into the rubber sleeve of the PRA 83 at an angle until it fully encloses the receiver. Take care to

ensure that the detection area and the buttons are facing the front.

2. Fit the receiver, complete with the rubber sleeve, onto the grip section. The cover and grip section are joined

together by the magnetic holder.

3. Switch the receiver on by pressing the on/off button.

4. Turn the rotating grip to the open position.

5. Secure the PRA 83 receiver holder on the telescopic staff or leveling staff by tightening the clamping knob.

6. Hold the laser receiver with the detection area directly in the plane of the rotating laser beam.

7.3.4 Working with the PRA 81 height transfer device 9

1. Open the catch on the PRA 81.

2. Insert the laser receiver in the PRA 81 height transfer device.

3. Close the catch on the PRA 81.

4. Switch the laser receiver on by pressing the on/off button.

5. Hold the laser receiver with the detection area directly in the plane of the rotating laser beam.

6. Position the laser receiver so that the distance display shows “0”.

7. Use the measuring tape to measure the desired distance.

7.3.5 Setting the measuring unit 6

The “Units” button can be used to set the desired accuracy of the digital display (mm/cm/off).

7.3.6 Volume adjustment 6

The laser receiver is set to “Normal” volume when switched on. The volume can be adjusted by pressing the “Volume”

button. One of four settings can be selected: “Low”, “Normal”, “High” or “Off”.

32

Page 19

7.3.7 Menu options 6

1. Press and hold the on/off button for two seconds when switching the laser receiver on.

The menu then appears in the display.

2. Use the “Units” button to select metric or imperial measuring units.

3. Use the “Volume” button to assign the more rapid signal tone to the detection area above or below the marking

notch.

4. Use the arrow buttons (Left / Right) to select further points as necessary.

NOTE The arrow buttons (Left / Right) can be used to select settings. The “Units” button is used to change the

applicable settings. The following settings can be made: Display software version (no adjustment possible), PR

30-HVS sleep mode (off / on), units for inclined plane mode (%/°), pairing the PR 30-HVS (pair / separate), pairing

the PRA 90 (pair / separate), sensitivity of shock warning function (high / medium / low), wireless connection (on

/ off). Settings that affect the rotating laser only become effective when the rotating laser is switched on and a

wireless connection has been established.

5. To save the settings, switch the laser receiver off.

NOTE Each setting that has been made becomes effective the next time the tool is switched on.

7.3.8 Double-click

When operating the tool, the “automatic alignment” and “surveillance” commandsmustbeconfirmedwithadoubleclick in order to avoid incorrect operation.

en

7.4 Deactivating the shock warning function

1. Switch the tool on (see 7.2).

2. Press the “Deactivate shock warning” button.

The shock warning deactivation LED lights constantly, indicating that the function has been deactivated.

3. To return to standard operating mode, switch the

tool off and then switch it back on again.

33

Page 20

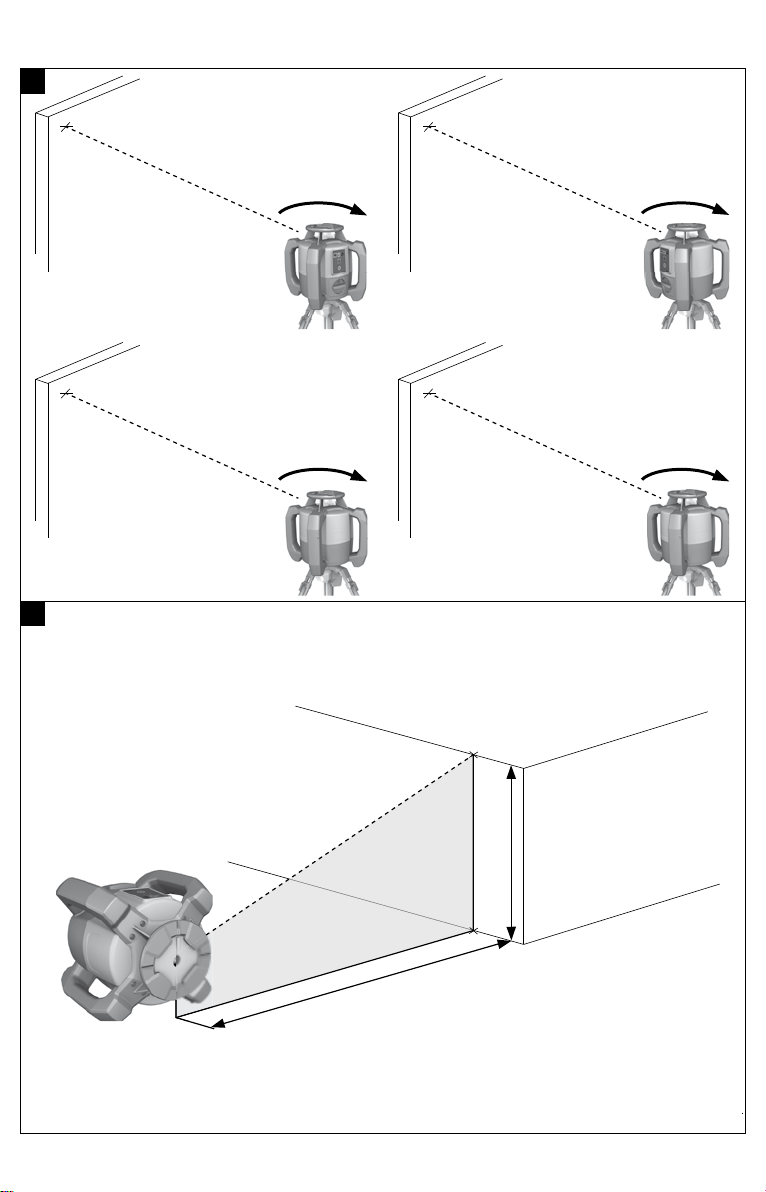

7.5 Working in the horizontal plane

7.5.1 Setting up

1. Set up the tool in a suitable position for the application, e.g. on a tripod. Alternatively, the rotating laser may be

mounted on a wall bracket. The angle of inclination of the surface on which it stands should not exceed ± 5°.

2. Press the on/off button.

The auto-leveling LED blinks green.

The laser switches on, the beam begins to rotate and the “auto leveling” LED lights as soon as the tool has

en

leveled itself.

7.5.2 Alignment using the PRA 90 automatic tripod

NOTE

This function is available only with the PRA 90 automatic tripod.

When used for the first time, the PRA 30 laser receiver must be paired with thetripod(see6.9.2).

With the optional PRA 90 automatic tripod you can set the height of the laser plane to the desired level manually or

automatically.

1. Mount the tool on the PRA 90 automatic tripod.

2. Switch on the rotating laser, the automatic tripod and the laser receiver.Settheheightofthelaserplanemanually

(see 7.5.3) or automatically (see 7.5.4).

7.5.3 Manual alignment 6

Press the +/- buttons on the laser receiver or the arrow buttons on the PRA 90 to shift the horizontal plane up or down

(parallel).

7.5.4 Automatic alignment 6

1. Hold the laser receiver at the desired height with the detection area facing the PRA 90 control panel. Hold the

laser receiver still while alignment is taking place and take care to ensurethatthelineofsightbetweenthelaser

receiver and the tool is not obstructed.

2. Press the “Automatic alignment” button on the laser receiver twice in quick succession(double-click). Double-click

the button again to complete the procedure.

This double-click starts the process of bringing the laser plane into alignment, i.e. the tripod elevates or lowers

itself to the required height. A constant signal tone is emitted while this is taking place. As soon as the laser beam

strikes the detection area of the laser receiver, the beam moves to the position of the marking notch (reference

plane).

After the position has been reached and the rotating laser has leveled itself, a signal tone with a duration of 5

seconds indicates that the process is complete. The “Automatic alignment” symbol is then also no longer shown.

PP

3. Check the height settings in the display.

4. Remove the laser receiver.

NOTE If the automatic alignment process was not successful, short signal tones are emitted and the “Automatic

alignment” symbol goes out.

34

Page 21

7.6 Working in the vertical plane

1. When working in the vertical plane, mount the tool on a suitable tripod, facade adapter, batter board adapter or

wall bracket, with the control panel facing upwards. Alternatively, the tool can be stood on the rubber feet on the

rear grips.

NOTE The best wireless connection with the PRA 30 is provided by the side of the tool to the right of the control

panel.

NOTE In order to ensure that the tool’s specified accuracy can be maintained, make sure that it is set up on a

level surface or mounted sufficiently level on the tripod or other accessory.

2. Use the visual sighting aids to adjust the tool so that its vertical axis is aligned in the required direction.

3. Press the on/off button.

After the tool has leveled itself automatically, it projects a stationary laser beam vertically downwards. This

projected point is a reference point (not a plumb point) and can be used to help position the tool.

4. Align the tool so that the projected laser point coincides exactly with a reference point (e.g. nail on a batter board).

5. Now line up the laser plane with the second reference point manually (see 7.6.1) or automatically (see 7.6.2).

The laser begins to rotate automatically as soon as you begin the alignment operation.

7.6.1 Manual alignment 6

1. Press the arrow buttons (Left / Right) on the laser receiver to bring the vertical plane manually into alignment.

7.6.2 Automatic alignment and surveillance 6

1. Hold the laser receiver with the marking notch at the desired alignment point and facing the rotating laser.

2. Double-click the “Automatic alignment” button. Double-click the button again to complete the procedure.

This double-click starts the process of bringing the laser plane into alignment. A constant signal tone is emitted

while this is taking place.

The direction of the search can be changed by pressing the “Automatic alignment” button.

As soon as the laser beam strikes the detection area of the laser receiver, the beam moves to the position of the

marking notch (reference plane).

Once the position is reached (i.e. the marking notch is found), a signal tone with a duration of 5 seconds indicates

that the process is complete.

The laser receiver switches automatically to surveillance mode and checks at regular intervals whether the laser

plane has shifted. If it is found to have shifted, the laser plane will be readjusted to the original marking plane as

far as possible. If the marking plane is outside the leveling range of ±5°, direct line of sight between the rotating

laser and the laser receiver is obstructed for a long period or the alignment process is not completed successfully

within a time of 2 minutes, then short signal tones are emitted, the laser stops rotating and the “Automatic

alignment” symbol goes out. This indicates cancellation of the automatic alignment process.

en

PP

3. Double-click the “Automatic alignment” button to leave surveillance mode.

7.7 Working with slopes

7.7.1 Setting up

NOTE

The slope can be set manually, automatically, or by using the PRA 79 slope adapter.

35

Page 22

NOTE

Inclination can be set and displayed on the PRA 30 in percent (%) or in degrees (°). For instructions on how to set the

desired unit, please refer to section 7.3.7 “Menu options”.

1. Set up the tool in a suitable position for the application, e.g. on a tripod.

2. Position the rotating laser either at the upper edge or lower edge of the inclined plane.

3. Position yourself behind the tool, facing the control panel.

4. With the aid of the target notch on the head of the tool, bring the tool roughly into alignment with the inclined

en

plane (parallel to the plane). For more precise adjustment, first set the inclination and then carry out electronic

inclination alignment (see 7.7.4).

5. Switch the tool on and then press the “Inclined plane mode” button. The “Inclined plane mode” LED then lights.

The laser beam switches on as soon as the tool has leveled itself. The PR 30-HVS can be inclined as soon as

“inclined plane mode” appears in the display on the PRA 30.

7.7.2 Setting the slope manually 6

NOTE

If the tool measures a change in temperature of more than 10 degrees, laser rotation stops for about 40 seconds.

During this time the tool corrects all errors that may have been caused by the temperature change. After this automatic

correction the tool resets the laser plane to the previous inclination and the laser again begins to rotate.

Depending on by how much the rotating laser is already inclined, inclination values of up to 21.3 % can be entered.

The display on the laser receiver shows the angle of inclination.

7.7.2.1 Positive inclinations

The positive inclination entry button (“Plus” button) raises the laser plane ahead of the rotating laser and lowers it

behind the rotating laser.

1. Press the positive inclination entry button (“Plus” button) on the remote control.

NOTE If no button is pressed for three seconds, the tool will be set to the most recently displayed inclination

value. The inclined plane mode LED then blinks.

The display on the laser receiver shows the angle of inclination.

2. If you wish to change the value quickly, press and hold the inclination entry button until the desired value is

reached.

7.7.2.2 Negative inclinations

The negative inclination entry button (“Minus” button) lowers the laser plane ahead of the rotating laser and raises it

behind the rotating laser.

1. Press the negative inclination entry button (“Minus” button) on the remote control.

NOTE If no button is pressed for three seconds, the tool will be set to the most recently displayed inclination

value. The inclined plane mode LED then blinks.

The display on the laser receiver shows the angle of inclination.

2. If you wish to change the value quickly, press and hold the inclination entry button until the desired value is

reached.

7.7.3 Setting the inclination (slope) automatically 6

With this function you can create an inclined laser plane between 2 points automatically and determine the angle of

inclination between these points.

1. Set up the rotating laser at the top edge of the inclined plane like as described in 7.7.1.

2. Mount the laser receiver with the PRA 80/PRA 83 receiver holder, for example, on the PUA 50 telescopic staff.

3. Position the receiver immediately in front of the rotating laser, bring it into alignment with the laser plane at the

correct height, and then secure it on the telescopic staff.

4. Position the receiver on the telescopic staff at the lower edge of the inclined planeand double-click the “Automatic

alignment” button. Double-click the button again to complete the procedure.

The laser plane alignment procedure then begins. A constant signal tone is emitted while this is taking place. The

direction of the search can be changed by pressing the “Automatic alignment” button.

As soon as the laser beam strikes the detection area of the laser receiver, the beam moves to the position of the

marking notch (reference plane). Once the position is reached (i.e. the marking notch is found), a signal tone with

a duration of 5 seconds indicates that the process is complete.

The “Automatic alignment” symbol is no longer shown in the display on the laser receiver and the receiver

switches automatically to normal operating mode.

The inclination is shown in the display of the laser receiver for 5 seconds.

36

Page 23

PP

5. Read the inclination between the two points (positions of the rotating laser and the laser receiver) from the display

of the laser receiver.

NOTE After 5 seconds, the inclination value disappears from the display on the laser receiver.

7.7.4 Optional electronic inclination alignment

After aligning the rotating laser approximately and setting the slope as described above, alignment of the PR 30-HVS

can be optimized through use of Hilti’s patented electronic alignment system.

1. Position the PRA 30 centrally opposite the PR 30-HVS at the end of the inclined plane. You can either hold it still

by hand or fix it in place with the aid of the PRA 80 / PRA 83 .

2. Activate electronic inclination alignment on the PR 30-HVS by pressing the “Electronic inclination alignment”

button.

When the arrows for electronic inclination alignment are blinking, the PRA30isreceivingnolaserbeamfromthe

PR 30-HVS.

3. When the left arrow lights, turn the PR 30-HVS clockwise.

4. When the right arrow lights, turn the PR 30-HVS counter-clockwise.

When both arrows light, the PRA 30 is correctly aligned.

After successful alignment (both arrows light constantly for 10 seconds), the function ends automatically.

5. Then secure the rotating laser on the tripod so that it cannot be inadvertently moved out of position.

6. You can also end electronic inclination alignment by pressing the “Electronic inclination alignment” button.

NOTE There may be deviations between the results obtained by approximate alignment with the sighting notches

and fine alignment with the aid of electronic inclination alignment. As the electronic method is more accurate

than the visual method, we recommend that electronic inclination alignment is always used as the reference.

7.7.5 Setting the inclination with the aid of the PRA 79 slope adapter

NOTE

Check that the slope adapter is fittedcorrectly betweenthe tripod and the tool (please refer to the operating instructions

for the PRA 79).

1. Set up the PRA 79 slope adapter in a suitable position for the application,e.g.onatripod.

2. Position the tripod either at the upper edge or lower edge of the inclined plane.

3. Mount the rotating laser on the slope adapter and, with the aid of the targetnotchontheheadofthePR30-HVS,

adjust the tool and slope adapter so that they are parallel to the inclined plane. The control panel of the PR 30-HVS

should face away from the direction of inclination.

4. Make sure that the slope adapter is in the zero position (0°).

5. Switch the tool on (see 7.2).

6. Press the “Inclined plane mode” button.

The “Inclined plane mode” LED then lights on the control panel of the rotating laser.

The tool then begins automatic self-leveling. The laser switches on and begins to rotate as soon as this is

complete.

7. Set the slope adapter to the desired angle of inclination.

NOTE When the angle of inclination is set manually, the PR 30-HVS levels the laser plane once and then

subsequently fixes it. Vibration, changes in temperature or other influences that may occur during the course of

thedaymayaffectthepositionofthelaserplane.

en

37

Page 24

7.8 Returning to standard mode

To return to standard operating mode, switch the tool off

and then switch it back on again.

7.9 Sleep mode

The PR 30-HVS can save power when in sleep mode.

The laser is switched off, thereby extending battery life.

en

7.9.1 Activating sleep mode

1. When the PRA 30 is switched off, press and hold the

on/off button of the PRA 30 for approx. 3 seconds.

8 Care and maintenance

8.1 Cleaning and drying

1. Blow dust off exit windows.

2. Donottouchtheglasswiththefingers.

3. Use onlya clean,soft clothfor cleaning.If necessary,

moisten the cloth slightly with pure alcohol or a little

water.

NOTE Abrasive cleaning materials may scratch the

glass and impair the accuracy of the laser tool.

NOTE Do not use any other liquids as these may

damage the plastic components.

4. Dry the equipment, observing the maximum temperatures given in the technical data.

NOTE Especially in summer and winter, take care

that the given maximum and minimum temperatures

are not exceeded, e.g. when the equipment is stored

in a motor vehicle.

8.2 Care of the Li-ion battery

NOTE

A conditioning charge (as is required with NiCd or NiMH

batteries) is not necessary with Li-ion batteries.

NOTE

Interruption of the charging procedure has no negative

effect on battery life.

NOTE

Charging can be started at any time with no negative

effect on battery life. There is no memory effect (as with

NiCd or NiMH batteries).

NOTE

For best results, batteries should be stored fully charged

in a cool dry place. Storing the battery in places subject

to high ambient temperatures (e.g. at a window) has an

adverse effect on battery life and increases the rate of

self-discharge.

NOTE

Batteries lose capacity due to aging and overstressing.

They can then no longer be fully charged. You may

continue to work with a battery that shows signs of

aging, but the battery should be replaced in good time.

2. Press the “Right” arrow button twice to access

“Sleep mode” in the menu.

3. Press the “Units” button to activate the sleep mode

on the PR 30-HVS.

7.9.2 Deactivating sleep mode

1. When the PRA 30 is switched off, press and hold the

on/off button of the PRA 30 for approx. 3 seconds.

2. Press the “Right” arrow button twice to access

“Sleep mode” in the menu.

3. Press the “Units” button to deactivate the sleep

mode on the PR 30-HVS.

4. To ensure working accuracy, check the laser settings after the PR 30-HVS has been reactivated.

1. Avoid ingress of moisture.

2. Charge the battery fully before using it for the first

time.

3. Charge the battery as soon as its performance begins to drop significantly.

NOTE Recharging in good time will increase the

service life of the battery.

NOTE If use of the tool continues, further battery

discharge will be stopped automatically before the

battery cells suffer damage.

4. Charge the battery with the Hilti charger approved

for use with Li-ion batteries.

8.3 Storage

1. Remove the appliance from its case if it has become wet. Dry and clean the tool, its transport

container and accessories (while observing the permissible temperature range). Repack the equipment

only once it is completely dry.

2. Check the accuracy of the equipment before it is

used after a long period of storage or transportation.

3. Remove rechargeable and non-rechargeable batteries from the tool or the laser receiver before storing

the units for long periods. The tool or laser receiver may suffer damage caused by leakage from

rechargeable or non-rechargeable batteries.

8.4 Transport

Use the Hilti toolbox or packaging of equivalent quality

fortransportingorshippingyourequipment.

CAUTION

Remove the batteries from the tool and receiver before

transport or shipping.

8.5 Calibration by the Hilti Calibration Service

We recommend that the tool is checked by the Hilti Calibration Service at regular intervals in order to verify its

reliability in accordance with standards and legal requirements.

Use can be made of the Hilti Calibration Service at any

time, We recommend that the tool is calibrated at least

once a year

38

Page 25

Thecalibrationserviceprovidesconfirmationthatthe

tool is in conformance, on the day it is tested, with the

specifications given in the operating instructions.

In the event of deviation from the manufacturer's specification, the used tool will be readjusted. After checking and

adjustment, a calibration sticker applied to the tool and

a calibration certificate provide written verification that

the tool operates in accordance with the manufacturer’s

specification.

Calibration certificates are always required by companies

certified according to ISO 900x.

The Hilti representative in your localregion will be pleased

to provide further information.

8.6 Checking accuracy

NOTE

In order to ensure compliance with the technical specifications, the tool should be checked regularly (at least

before each major / relevant job).

NOTE

After falling and suffering an impact it can be presumed

that the tool will continue to operate faultlessly, with

the accuracy it achieved prior to the impact, when the

following conditions are met:

The height of the fall did not exceed the height given in

the technical data.

The tool suffered no obvious mechanical damage from

the impact (e.g. breakage of the pentaprism).

The tool projects a rotating laser beam when in operation.

The tool operated faultlessly before the impact.

8.6.1 Checking the main and transverse horizontal

axes

1. Set up the tripod approx. 20 m from a wall and level

the tripod head with a spirit level.

2. Mount the tool on the tripod and use the aiming

notch to aim the tool at the wall.

3. Use the receiver to catch the laser beam and mark

a point (point 1) on the wall.

4. Pivot the tool clockwise through 90° about its own

axis. In doing so, ensure that the height of the tool

does not change.

5. Use the laser receiver to catch the laser beam and

mark a second point (point 2) on the wall.

6. Repeat steps 4 and 5 twice and mark points 3 and

4 on the wall with the aid of the laser receiver.

When this procedure is carried out carefully, the

vertical distance between the two marked points 1

and 3 (main axis) or, respectively, points 2 and 4

(transverse axis) should be less than 3 mm (at 20 m).

If the deviation is greater than this, the tool should

be returned to a Hilti Service Center for calibration.

8.6.2 Checking the vertical axis

1. Place the tool in the vertical position on a flat floor

approx. 20 m from a wall.

2. Adjust the position of the tool so that the grips are

parallel to the wall.

3. Switch the tool on and mark the reference point (R)

on the floor.

4. With the aid of the receiver, mark point (A) low on

the wall. Select medium speed.

5. With the aid of the receiver, mark point (B) at a

height of approx. 10 m.

6. Pivot the tool through 180° and realign it with the

reference point (R) on the floor and with point (A) at

thebaseofthewall.

7. With the aid of the receiver, mark point (C) at a

height of approx. 10 m.

8. Check the distance between points (B) and (C).

When the procedure has been carried out carefully,

the horizontal distance between the two points (B)

and (C) marked at a height of 10 meters should be

less than 1.5 mm (at 10 m).

NOTE If the deviation is greater: Please return the

tool to a Hilti Service Center for calibration.

en

9 Troubleshooting

Fault Possible cause Remedy

The display shows this symbol The PRA 30 has not been paired with

the PR 30-HVS.

The display shows this symbol Invalid entry; the command is not

possible.

Pair the tools (see section 6.9)

Press a valid button.

39

Page 26

Fault Possible cause Remedy

The display shows this symbol The command is valid but the tool

doesn’t react.

en

The display shows this symbol The tool is in surveillance mode. Re-

alignment was not possible.

The display shows this symbol The tool is in sleep mode (the tool

will remain in sleep mode for max.

4hours).

Switch on all tools and make sure

they are within wireless communication range.

Check to ensure there are no obstructions between the tools. Do not exceed the maximum wireless communication range. For good wireless

communication, the PR 30-HVS and

PRA 30 should be positioned ≧ 10 cm

(4 in) above floor level.

Check the positions of the PR 30HVS and PRA 30 and make sure that

the line of sight between the PR 30HVS and PRA 30 is unobstructed. Restart automatic alignment (see section

on automatic alignment and surveillance mode).

Activate the tool (see section “Deactivating sleep mode”)

The display shows this symbol The state of charge of the PR 30-HVS

battery is low.

Charge the battery, use a different

battery or use the PR 30-HVS in

“charging during operation” mode

(not suitable outdooors or in damp

conditions).

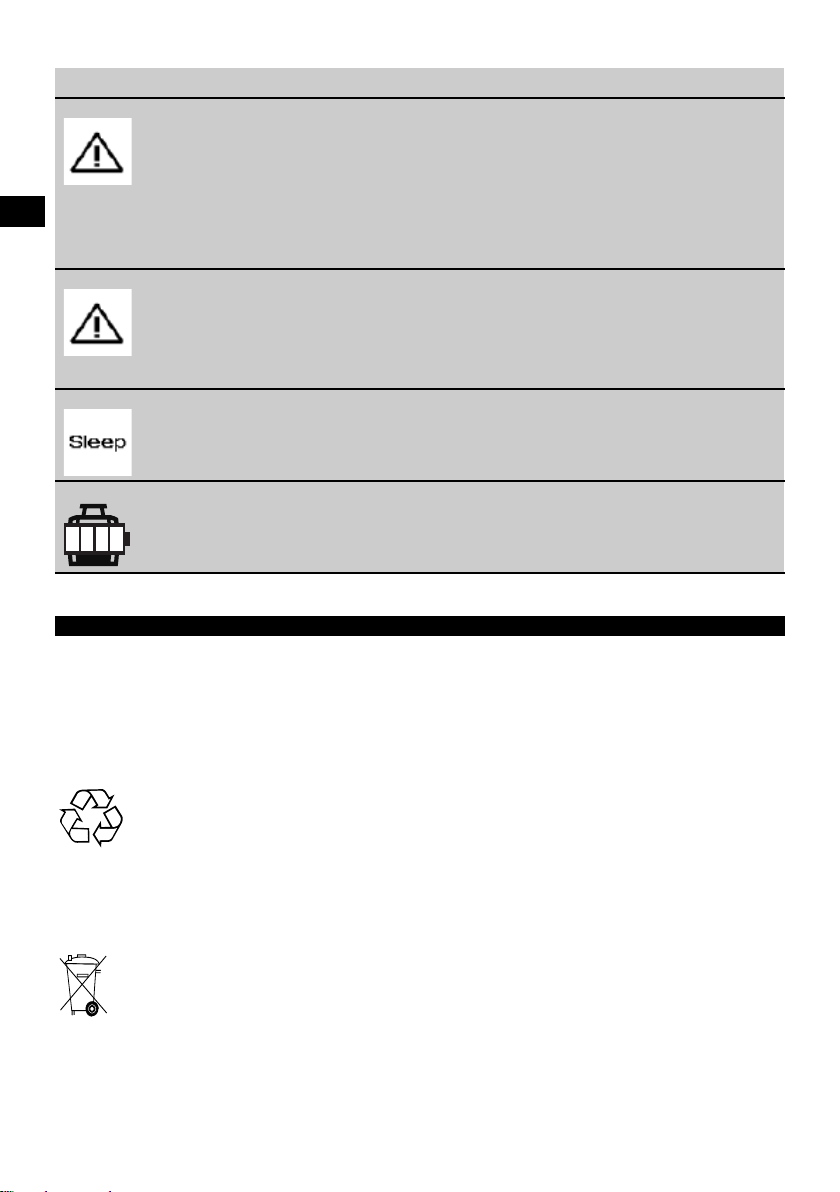

10 Disposal

WARNING

Improper disposal of the equipment may have serious consequences:

The burning of plastic components generates toxic fumes which may present a health hazard.

Batteries may explode if damaged or exposed to very high temperatures, causing poisoning, burns, acid burns or

environmental pollution.

Careless disposal may permit unauthorized and improper use of the equipment. This may result in serious personal

injury, injury to third parties and pollution of the environment.

Most of the materials from which Hilti tools or appliances are manufactured can be recycled. The materials must

be correctly separated before they can be recycled. In many countries, Hilti has already made arrangements for

taking back old tools and appliances for recycling. Ask Hilti customer service or your Hilti representative for further

information.

For EC countries only

Disposal of electric tools together with household waste is not permissible.

In observance of the European Directive on waste electrical and electronic equipment and its imple-

mentation in accordance with national law, electrical appliances that have reached the end of their life

must be collected separately and returned to an environmentally compatible recycling facility.

40

Page 27

Dispose of the batteries in accordance with national regulations.

11 Manufacturer’s warranty - tools

Hilti warrants that the tool supplied is free of defects in

materialandworkmanship.Thiswarrantyisvalidsolong

as the tool is operated and handled correctly, cleaned

and serviced properly and in accordance with the Hilti

Operating Instructions, and the technical system is maintained. This means that only original Hilti consumables,

components and spare parts may be used in the tool.

This warranty provides the free-of-charge repair or replacement of defective parts only over the entire lifespan

of the tool. Parts requiring repair or replacement as a

result of normal wear and tear are not covered by this

warranty.

Additional claims are excluded, unless stringent national rules prohibit such exclusion. In particular, Hilti

is not obligated for direct, indirect, incidental or consequential damages, losses or expenses in connection with, or by reason of, the use of, or inability to

use the tool for any purpose. Implied warranties of

merchantability or fitness for a particular purpose are

specifically excluded.

For repair or replacement, send the tool or related parts

immediately upon discovery of the defect to the address

of the local Hilti marketing organization provided.

This constitutes Hilti’s entire obligation with regard to

warranty and supersedes all prior or contemporaneous

comments and oral or written agreements concerning

warranties.

12 FCC statement (applicable in US) / IC statement (applicable in Canada)

CAUTION

This equipment has been tested and found to comply

with the limits for a class B digital device, pursuant to

part 15 of the FCC rules. These limits are designed to

provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses and may radiate radio frequency energy.

Accordingly, if not installed and used in accordance with

the instructions, it may cause harmful interference to

radio communications.

However, there is no guarantee that interference will not

occur in a particular installation. If this equipment does

cause harmful interference to radio or television reception, which can be determined by turning the equipment

off and on, the user is encouraged to try to correct the

interference by taking the following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment to a power outlet on a circuit

different from that to which the receiver is connected.

ConsultyourdealeroranexperiencedTV/radiotechnician for assistance.

NOTE

Changes or modifications not expressly approved by

Hilti may restrict the user’s authorization to operate the

equipment.

This device complies with part 15 of the FCC Rules and

RSS-210 of the IC.

Operation is subject to the following two conditions:

This device should cause no cause harmful interference.

This device must accept any interference received, including interference that may cause undesired operation.

en

41

Page 28

13 EC declaration of conformity (original)

Designation: Rotating laser

Type: PR 30-HVS

Generation: 01

Year of design: 2013

en

We declare, on our sole responsibility, that this product

complies with the following directives and standards:

2011/65/EU, 2006/95/EC, 2006/66/EC, 2004/108/EC,

1999/5/EC, EN ISO 12100, EN 300 440‑2 V1.4.1,

EN 301 489‑1 V1.9.2, EN 301 489‑17 V2.2.1.

Hilti Corporation, Feldkircherstrasse 100,

FL‑9494 Schaan

Paolo Luccini Matthias Gillner

Head of BA Quality and Process Management

Business Area Electric Tools & Accessories

03/2013 03/2013

Head BU Measuring Systems

BU Measuring Systems

Technical documentation filed at:

Hilti Entwicklungsgesellschaft mbH

Zulassung Elektrowerkzeuge

Hiltistrasse 6

86916 Kaufering

Deutschland

42

Page 29

Hilti Corporation

LI-9494 Schaan

Tel.: + 423/234 2111

Fax: +423/234 29 65

www.hilti.com

Hilti = registered trademark of Hilti Corp., Schaan

W 4271 | 1113 | 00-Pos. 1 | 1

Printed in Germany © 2013

Right of technical and programme changes reserved S. E. & O.

Printed: 29.11.2013 | Doc-Nr: PUB / 5142593 / 000 / 02

2065552 / A3

*2065552*

2065552

Loading...

Loading...