Page 1

PP 10/11

*233821*

233821

Hilti Corporation

LI-9494 Schaan

Tel.: +423/234 2111

Fax: +423 /234 29 65

www.hilti.com

Hilti = registered trademark of Hilti Corp., Schaan W 3117 0106 00-Pos. 2 1 Printed in Liechtenstein © 2006

Right of technical and programme changes reserved S. E. & O.

233821 / A

Operating instructions en

Bruksanvisning sv

Brugsanvisning da

10 11

12

00_Cover_PP_10_11_P2.qxd 23.1.2006 09:14 Seite 1

Page 2

1 2 3

4 5

6 7

8 9

00_Cover_PP_10_11_P2.qxd 23.1.2006 09:14 Seite 5

Page 3

PP 10 / 11 pipe laser

It is essential that the operating instructions

are read before the tool is operated for the

first time.

Always keep these operating instructions

together with the tool.

Ensure that the operating instructions are

with the tool when it is given to other

persons.

Contents Page

1 General information 1

2 Description 2

3 Accessories 3

4 Technical data 3

5 Safety rules 4

6Beforeuse 5

7Operation 7

8 Care and maintenance 10

9 Troubleshooting 11

10 Disposal 11

11 Warranty 12

12 FCC statement (applicable in US) / IC

statement (applicable in Canada) 12

13 EC declaration of conformity 13

Component parts 1

PP 10/11 pipe laser

Remote control signal receiving window

@

Warning / standby LED

;

Control panel

=

Display

%

Grip

&

Grip mount

(

PPA 84 cable connector

)

Battery compartment cover lock

+

PPA 82 battery incl. mains adaptor

§

Plumb spot

/

PP10/11pipelaser

Laser exit window

:

Remote control signal receiving window

·

Plumb spot

$

Pivot point mark

£

Control panel

Direction control button / auto centering

|

Plumb spot ON button

¡

Laser beam mode button

Q

Remote control signal receiving window

W

Lock button

E

Target plate auto-centering button (only with the

R

PP 11)

Direction control button / auto centering

T

SET button

Z

Laser beam up / down, value-entry button

U

Warning / standby LED

I

Laser beam up / down, value-entry button

O

ON / OFF button

P

en

1. General information

1.1 Safety notices and their meaning

DANGER

Draws attention to imminent danger that could lead

to serious bodily injury or fatality.

CAUTION

Draws attention to a potentially dangerous situation

that could lead to slight personal injury or damage to

the equipment or other property.

NOTE

Draws attention to instructions and other useful information.

1

Page 4

1.2 Explanation of the pictograms and other

information

Warning signs

Laser warning plates for the USA in accordance with

CFR21§1040(FDA)

On the tool

en

General

warning

Symbols

Read the

operating

instructions

before use.

On the tool

DANGER

LASER RADIATION - AVOID DIRECT

675-695nm < 5mW max.

CLASS IIIa LASER PRODUCT

Do not stare into the beam.

Laser warning plates for the USA in accordance with

CFR 21 § 1040 (FDA):

On the tool

DANGER

LASER RADIATION - AVOID DIRECT

520-550nm < 5mW max.

CLASS IIIa LASER PRODUCT

Do not stare into the beam.

EYE EXPOSURE

EYE EXPOSURE

Return waste

material for

recycling.

3R

Laser warning plate in accordance with IEC825 /

EN60825-1:2003

1 These numbers refer to the corresponding illustrations. The illustrations can be found on the fold-out

cover pages. Keep these pages open while studying

the operating instructions.

In these operating instructions, the designation “the

tool” always refers to the PR 10 / 11 pipe laser.

Location of identification data on the tool

The type designation and serial number can be found

onthetypeplateonthetool.Makeanoteofthisdata

in your operating instructions and always refer to it

when making an enquiry to your Hilti representative

or service department.

Type :

Serial no.:

2. Description

2.1 Use of the product as directed

The tool is designed to be used for determining, transferring or checking alignment in the horizontal and

inclined planes, e.g.: Transferring height marks or setting up inclinations. Hilti supplies various accessories

which allow the tool to be used with maximum efficiency.

2.2PP10/11pipelaser

The PP 10 /11 is a pipe laser featuring a visible laser

(spot) that can be used for alignment in the horizontal

or inclined planes.

2

2.3 Features

A single person working with the tool can set out any

desired inclination (within the -15% to +40% range)

with great accuracy. The tool levels itself automatically

when set up within 10% of the horizontal plane.

2.4 Automatic cut-out

The laser beam and the LED on the control panel blink

if the tool is set up outside its self-leveling range. The

direction in which the tool requires to be tilted is also

shown in the display.

Page 5

2.5 PPA 82 battery

Battery performance drops at low temperatures.

2.6 Automatic charging cut-out

The charging operation is stopped automatically to

protect the battery when the temperature exceeds the

specified charging temperature range.

NOTE

Charge the battery every 3 to 4 months. Store the

battery at a maximum temperature of 30°C (86°F).

Allowing the battery to become fully discharged may

have a negative effect on its future performance.

Charging may take less than 9 hours if the battery

was not previously fully discharged.

2.7 Use of various power sources

Three different power sources may be used: the

standard PPA 82 battery supplied or the PPA 83

battery holder or PPA 84 external 12V cable which

are available as accessories.

2.8 Items supplied

1 PP 10 or 11 pipe laser (depending on version

purchased)

1 PPA 20 remote control unit

1Targetplate,short

1 Target plate, long

1 Target plate holder

1 PPA 81 charging adaptor

1 PPA 82 battery incl. mains adaptor

1 Set of 4 screw feet, 150 mm

1 Set of 4 screw feet, 200 mm

1 Set of 4 screw feet, 250 mm

1 Set of 4 screw feet, 300 mm

1 Centering screw

1 PP 10 / 11 operating instructions

1 PPA 20 operating instructions

4 Batteries (size AAA cells)

1 Manufacturer’s certificate

1 Hilti toolbox

3. Accessories

PP 10 / 11 accessories

PPA 83 battery holder (size D cells) PPA 83 (size D cells)

PPA 84 connecting cable (12V) PPA 84 (12V)

Vertical and horizontal adaptors

PPA73tripodadaptor PPA73

PPA 40 telescopic sight PPA 40

en

4. Technical data

NOTE

Right of technical changes reserved.

Wavelength, PP 10 633 mm

Wavelength, PP 11 532 mm

Accuracy (at 24 °C) ±0.5 mm @ 10 m horizontal

Laser class Class IIIa, visible, < 5 mW (IEC825-1 / EN60825-

1:2003; FDA 21 CFR 1040)

Laser beam diameter 12 mm

Self-leveling range ±10°

Inclinationrange -15to40%

Min. inclination setting 0.001 %

PP10batterylifeat20°C[+68°F] Alkaline:70h;NiMH:>48h

PP11batterylifeat20°C[+68°F] Alkaline:45h;NiMH:>32h

3

Page 6

Operating temperature range -20 to 50 °C

Storage temperature range -30 to 60 °C

Wateranddustresistant Yes(submersiontoadepthofupto5m/24h)

Weight Including 4 batteries 3.8 kg

Dimensions Without grip

en

Dimensions With grip

Automatic target plate detection (only PP 11)

Range 5 to 150 m

330mmx122mmdia.

330 mm x 122 mm dia.

5. Safety rules

5.1 Basic information concerning safety

a) In addition to the information relevant to safety

given in each of the sections of these operating

instructions, the following points must be strictly

observed at all times.

5.2 Misuse

a) The tool and its ancillary equipment may present

hazards when used incorrectly by untrained personnel or when used not as directed.

b) To avoid the risk of injury, use only genuine Hilti

accessories and additional equipment.

c) Modification of the tool is not permissible.

d) Observe the information printed in the operating

instructions concerning operation, care and main-

tenance.

e) Do not render safety devices ineffective and do not

remove information and warning notices.

f) Keep laser tools out of reach of children.

g) Failure to follow the correct procedures when

opening the tool may cause emission of laser

radiation in excess of class 3. Have the tool repaired

only at a Hilti service center.

h) Take the influences of the surrounding area into

account.Donotusethetoolwherethereisarisk

of fire or explosion.

i) (Statement in accordance with FCC §15.21):

Changes or modifications not expressly approved

by Hilti could limit the user’s right to operate the

equipment.

5.3 Proper organization of the work area

a) Secure the area in which you are working and take

care to avoid directing the beam towards other

persons or towards yourself when setting up the

tool.

b) Avoid unfavorable body positions when working

on ladders or scaffolding. Make sure you work

from a safe stance and stay in balance at all times.

c) Measurements taken through panes of glass or

other objects may be inaccurate.

d) Ensure that the tool is set up on a steady, level

surface (not subject to vibration).

e) Use the tool only within its specified limits.

f) Check that your PP 10 / 11 is responding only to

your PPA 20 and not to other PA 350s that may be

in use on the jobsite.

5.3.1 Electromagnetic compatibility

a) Although the tool complies with the strict re-

quirements of the relevant directives, Hilti cannot

entirely rule out the possibility that the tool may

cause interference to other equipment (e.g. aircraft

navigation equipment) or that the tool may be sub-

ject to interference caused by powerful radiation,

possibly leading to incorrect operation. Check the

accuracy of the tool by taking measurements by

other means when working under such conditions

or if you are unsure.

5.3.2 Laser classification for tools of the classes

3A and 3R

a) Depending on the version purchased, the tool

conforms to laser class 3 in accordance with CFR

21 § 1040 (FDA). Do not stare into the beam and

do not direct the beam toward other persons.

b) Laser Class 3A tools may be operated only by

appropriately trained persons.

4

Page 7

c) Theareainwhichthetoolisinusemustbemarked

with laser warning signs.

d) The plane of the laser beam should be well above

or well below eye height.

e) Precautions must be taken to ensure that the

laser beam does not unintentionally strike highly

reflective surfaces.

f) Precautions must be taken to ensure that persons

do not stare directly into the beam.

g) The laser beam must not be allowed to project

beyond the controlled area.

h) When not in use, laser tools should be stored in

an area to which unauthorized persons have no

access.

5.4 General safety rules

a) Check the condition of the tool before use. If the

tool is found to be damaged, have it repaired at a

Hilti service center.

b) The accuracy of the tool must be checked after it

has been dropped or subjected to other mechanical

stresses.

c) When the tool is brought into a warm environment

from very cold conditions, or vice-versa, allow i t

to become acclimatized before use.

d) If mounting on an adaptor, ensure that the tool is

screwed on securely.

e) Keep the laser exit aperture clean to avoid meas-

urement errors.

f) Although the tool is designed for the tough condi-

tions of jobsite use, as with other optical and electronic instruments (e.g. binoculars, spectacles,

cameras) it should be treated with care.

g) Although the tool is protected to prevent entry of

dampness, it should be wiped dry each time before

being put away in its transport container.

h) Check the tool before using it for important meas-

uring work.

i) Check the accuracy of the measurements several

timesduringuseofthetool.

5.4.1 Electrical

a) Keep the batteries out of reach of children.

b) The batteries may explode or release toxic sub-

stances. Do not allow the batteries to overheat and

do not expose them to fire.

c) Do not charge the batteries.

d) Do not solder the batteries into the tool.

e) Do not discharge the batteries by short circuiting

as this may cause them to overheat and swell up.

f) Do not attempt to open the batteries and do not

subject them to excessive mechanical stress.

en

6. Before use

NOTE

The tool may be powered only by the PPA 82 battery

or by batteries manufactured in accordance with IEC

285.

6.1 Switching the tool on

Press the ON / OFF button.

NOTE

The PP 10 / 11 is capable of leveling itself within a

range of +/- 10%.The tool levels itself automatically

when set up within this range. The LED begins to

blink when the inclination of the tool is more than +/10% from the set inclination. The tool should then be

tilted in the direction indicated by the arrow.

6.2 Battery warning indicator 2

1 Battery power is adequate

2 Battery power is low, the laser

maycontinuetobeused.

NOTE

When this status is reached, the

laser transmits a battery warning

signal to the laser receiver.

3 The battery is discharged.

NOTE

Recharge the NiMH battery or

insert new alkaline batteries.

4 The display blinks

NOTE

The laser tool is charged using

the PPA 84 12V connecting

cable.

5

Page 8

6.3 Removing the PPA 83 battery holder or PPA 82

battery

1. Turnthebatterylockingknobto“OPEN”and

remove the battery holder.

2. Turn the knob on the battery compartment cover

en

to the “OPEN” position.

6.4 Replace the batteries.

1. Replace the used batteries in the battery holder

with new ones.

6.5 Fitting the PPA 83 battery holder or PPA 82

battery

1. Refit the battery holder after replacing the batteries.

NOTE The PPA 83 can be inserted into the tool

only in one position.

2. Turn the knob to the “LOCK” position.

6.6 Connecting the PPA 84 cable

NOTE

If using a battery that is fitted to a motor vehicle,

please first switch off the engine.

NOTE

Take care to ensure correct polarity when connecting

both terminals.

NOTE

Switch the tool off before connecting or disconnecting

the external power cable.

The connecting cable is designed for connecting to a

12 V battery.

1. Connect the red clip to the positive (+) pole.

2. Connect the black clip to the negative (-) pole.

6.7 Charging the PPA 82 battery

When charging the battery, the ambient temperature

should be between + 10ºC and + 40ºC.

Exceedingthespecifiedchargingtimemayshorten

the life of the battery. The battery is charged automatically when the laser is operated at a temperature

of [+10ºC to +40ºC] with an external battery.

1. Fit the PPA 81 charging adapter to the PPA 82

battery.

2. Connect the power supply unit to the charging

adapter.

3. Plug the power supply unit into a power outlet.

4. Check that the correct voltage has been set on the

power supply unit.

The charging control lamp lights green when the

charging operation is complete.

6.8 Charging status

Charging

status

Red LED lights

Charging

Green LED lights

Charging completed

Blinks green

Error during charging

Blinks red

The protective cut-out has been

activated. The PP 10 / 11 may be

used while in this status.

6

Page 9

7. Operation

7.1 Button functions 3

1. Switching

on the plumb

spot

2. Laser beam

mode

3. Lock This button locks all data entry

4. Target plate

auto-centering

button (only

PP 11)

5. Direction

control

5. Parameter

selection

5. Automatic

centering

6. Laser beam

up and down

6. Value entry Positive or negative values may

7. SET button This button is used to confirm

8. ON / OFF

button

The plumb spot can be switched

on or off by pressing the laser

beam mode button (switches

itself off automatically after 30

minutes).

The laser beam can be switched

over by pressing the laser beam

mode button. PP 10: constant

beam or blinking beam PP 11:

constant beam, blinking beam,

high-power mode

functions. Values can then no

longer be changed. The data

entry functions can be unlocked

by pressing the LOCK button

again.

The laser beam finds the center

of the target plate automatically.

Moves the laser beam to the left

or right.

Used to select the parameters to

be set.

The laser beam centers itself

automatically when both direction control buttons are pressed

at the same time.

Moves the laser beam up or

down.

be entered. When both buttons

are pressed at the same time,

inclination is set automatically to

00.000% .

the selected parameters.

Thisbuttonisusedtoswitchthe

tool on or off.

7.2 Symbols in the display 4

1 Plumb spot indicator.

2 Direction indicator (shows the

direction of the laser beam).

3 Battery status indicator (shows

the remaining battery capacity in

3stages).

4 Self-leveling indicator (blinks

while the laser is leveling itself,

the display then changes to the

laser mode set).

5 Inclination indicator

6 Percentage

7 Lock indicator (the data entered

cannot be changed)

8 Electronic bubble level

9 Laser mode display

7.3 Warnings 5

1. Battery

warning indicator

2. Level warning indicator

3. Lateral inclination warning indicator

7.4 Switching the tool on

Press the ON / OFF button.

NOTE

The PP 10 / 11 is capable of leveling itself within a

range of +/- 10%.The tool levels itself automatically

when set up within this range. The LED begins to

blink when the inclination of the tool is more than +/-

Operation is no longer possible.

Replace / recharge the battery

or connect an external power

source.

The laser is tilted beyond its

self-leveling range. T ilt the laser

tool in the direction of the arrow

shown in the display.

The laser has been rotated

beyond its self-leveling range.

Rotate the laser tool in the

direction of the arrow shown in

the display.

en

7

Page 10

10% from the set inclination. The tool should then be

tilted in the direction indicated by the arrow.

7.5 Setting the inclination 7

Inclination can be set either manually or automatically.

en

Inclination can be set within the -15% to +40% range

(for inclination of over 10%, the adaptor or some

other aid should be used to provide initial inclination

of the laser tool).

7.5.1 Automatic entry of inclination 7

1. Switch the tool on by pressing the ON / OFF

button.

2. Press the SET button. The set value is displayed

andthe±indicatorblinks.

3. Press the laser beam UP or DOWN button to

change the sign.

4. Press the right-hand direction control button in

order to reach the correct position (the left direction control button can be used to move back).

5. Press the laser beam UP or DOWN button to

change the value.

6. Press the right-hand direction control button to

move to the next position.

7. Press the laser beam UP or DOWN button to

change the value. Repeat the steps described

above to change other numerical values.

8. Press the SET button when the value entered is

correct.

The laser beam then begins to move to the specified setting.

7.5.2 Manual entry of inclination

NOTE

Inclination can also be set directly by moving the laser

beam. Check that the locking function has not been

activated.

The value indicated becomes higher or lower as the

laser beam is moved.

1. Press the laser beam UP or DOWN button. The

laser beam then moves up or down.

2. Press the laser beam UP and DOWN buttons at

the same time to move the laser beam to the zero

position.

The laser beam moves immediately to the 0.000%

position.

7.7 Beam position indicator 6

1 Beam position indicator

2 End position left

3 End position right

7.8 Adjusting the position of the beam 6

The maximum lateral adjustment range is 9m at a

distance of 30m. The speed of movement can be

varied.

If the button is pressed briefly, the laser beam moves

slowly.

If the button is pressed for longer, the laser beam

moves quickly.

The current position of the beam can be read from

the display at any time.

7.8.1 Adjusting the beam end position left / right

The display informs the operator when the beam has

reached the left or right end position and cannot

be moved further. The display blinks to i nform the

operator of this status.

If this position is reached frequently it is recommended that the tool is pivoted slightly to the left or right

and the beam then realigned.

7.9 Automatic centering

Press both direction control buttons (left and right) at

the same time to center the laser beam automatically.

7.10 Target plate auto-centering (only PP 11) 8

NOTE

This feature is particularly useful for setting up the

laser tool the next working day.

1. Set up the target plate with the reflective stripes

facing the laser tool.

2. Press the target plate auto-centering button. The

laser then finds the horizontal center of the target

plate automatically.

7.6 Aligning the target line 6

Use the direction control buttons on the PP 10 / 11 or

PPA 20 remote control unit to move the laser beam

horizontally to the right or left.

8

Page 11

7.11 Display while searching

1 The tool has not yet completed

the self-leveling procedure.

NOTE

This procedure will first be

completed.

2 The display indicatesstabilization

of the laser beam after selfleveling.

3 Searching (auto centering) then

begins.

NOTE

The display indicates that

searching (auto centering) is in

progress.

4 Automatic alignment has been

completed.

NOTE

Check the position of the laser

spot on the target plate. If

necessary, the remote control or

the direction control buttons (left

/ right) can be used to readjust

the position of the beam.

5 If the beam loses contact with

the target plate while searching,

theproceduremustberestarted.

7.12 Selecting the laser beam mode

Press the laser beam mode button as often as necessary until the desired display mode is shown in the

display.

7.13 Operating modes

1 Constant beam

2 Blinking beam

3 High-power mode (only with the

PP 11)

7.14 Adjusting the electronic bubble level 9

When the tool is pivoted, the electronic bubble level

appears clearly in the display.

Adjust the tool until the “bubble” is in the center of

the display.

The LED begins to blink as soon as the tool’s selfleveling range is exceeded.

7.15 Fitting the screw feet and centering screw

Fit the appropriate screw feet for the pipe diameter

before setting up the laser in the pipe.

NOTE

Screw feet of the following sizes are supplied: 150

mm, 200 mm, 250 mm and 300 mm.

7.16 Setting the target plate size

Setthetargetplatesizetoavaluesuitableforthepipe

diameter you are working with.

7.17 Target plate, front (1)

1 Locking screw

2Targetplate,small

3 Bubble level

4 Target plate holder

7.18 Target plate, rear (2)

2 Reflective stripes (only for the

PP 11)

7.19 Setting parameters

7.19.1 Setting units of measurement to % or ‰

1. Press the ON / OFF button and the LOCK button

at the same time.

The set values are shown in the display.

2. Use the laser beam UP / DOWN button to move

to the “unit” line.

3. Press the SET button to enter the correct mode.

4. Select the value you wish to change by pressing

the direction control button.

5. Press the SET button to confirm the entry.

The tool then returns to the normal operating

mode.

7.19.2 Setting and activating the security code

Unauthorized persons can be prevented from using

the laser tool by entering a 4-digit security code.

Please note that once the security code has been

activated, the laser tool can no longer be operated

without entering this code. The code will be requested

automatically after the tool is switched on.

en

9

Page 12

1. Press the ON / OFF button and the LOCK button

at the same time.

The set values are shown in the display.

2. Use the laser beam UP/DOWNbuttontomove

en

to the “input S code” line.

3. Press the SET button to enter the correct mode.

4. The laser beam UP / DOWN button and direction

control button can be used to navigate to the

corresponding number. Press the SET button

to confirm the number selected. Press the SET

button to confirm the code as soon as the four

desired digits are displayed in the “code” area of

the display.

5. The display then returns to the previous mode.

The security code can then be activated (“on”

by pressing the SET button) or deactivated later

(“off” by pressing the SET button again).

The tool then returns to the normal operating

mode.

7.19.3 Entering the name of the company

These instructions describe how to enter or change

the name of the company. A maximum of 32 characters (16 characters in 2 rows) can be entered.

1. Press the ON / OFF button and the LOCK button

at the same time.

The set values are shown in the display.

2. Use the laser beam UP / DOWN button to move

to the “change name” line.

3. Press the SET button to enter the correct mode.

4. Use the laser beam UP / DOWN button and

direction control button to navigate to the corresponding characters / digits. Press the SET button

to confirm the character selected. Press the SET

button to confirm the entry as soon as the correct

name / designation is displayed.

The tool then returns to the normal operating

mode.

7.20 Checking the tool’s accuracy

1. Set the laser to an inclination of 0.000%.

2. Set up a leveling staff at a distance of 1m and a

second leveling staff at a distance of 60m. Note

the heights at which the laser beam strikes the

staffs.

3. Set up an optical level in the middle between the

twolevelingstaffsandreadtheheightsfromboth

staffs.

4. Calculate the difference between the readings

from the optical level and the laser at staffs 1

and 2. If the two values are identical, the laser is

correctly adjusted.

NOTE If the differences X1 and X2 are not equal,

please contact your nearest Hilti representative.

8. Care and maintenance

8.1 Cleaning and drying

1. Blow dust off the lenses.

2. Do not touch the glass with your fingers.

3. Use only a clean, soft cloth for cleaning. If necessary, moisten the cloth slightly with pure alcohol

oralittlewater.

NOTE Do not use any other liquids as these may

damage the plastic components.

4. Observe the temperature limits when storing your

equipment. This is particularly important in winter

/ summer if the equipment is kept inside a motor

vehicle (-30°C to + 60°C).

8.2 Storage

Remove the tool from its case if it has become wet.

The tool, its carrying case and accessories should be

cleaned and dried (at maximum 40°C / F). Repack the

equipment only once it is completely dry.

10

Check the accuracy of the equipment before it is used

after a long period of storage or transportation.

Remove the batteries from the tool before storing it

for a long peri od.

8.3 Transport

Use the Hilti toolbox or packaging of equivalent quality

for transporting or shipping your equipment.

CAUTION

Always remove the batteries before shipping the tool.

8.4 Hilti calibration service

We recommend that the tool is checked by the Hilti

calibration service at regular intervals in order to

verify its reliability in accordance with standards and

legal requirements.

Page 13

Use can be made of the Hilti calibration service

at any time, but checking at least once a year is

recommended.

The calibration service provides confirmation that the

tool is in conformance, on the day it is tested, with

the specifications given in the operating instructions.

The tool will be readjusted if deviations from the

manufacturer’s specification are found. After check-

ing and adjustment, a calibration sticker applied to

the tool and a calibration certificate provide written

verification that the tool operates in accordance with

the manufacturer’s specification.

Calibration certificates are always required by companies certified according to ISO 9 00x.

Your local Hilti Center or representative will be pleased

to provide further information.

9. Troubleshooting

Fault Possible cause Remedy

E02/03 An internal measurement problem has

occurred.

E99 An internal memory problem has oc-

curred.

ERROR The tool was moved while in standby

mode.

Switch the tool off and then on again. An

error message may be displayed if the

tool is knocked or shaken. In this case,

eliminate the cause of the disturbance.

Switchthetooloffandthenonagain.

Switch the tool off and then on again and

check that it is set up correctly.

NOTE

Contact your nearest Hilti Service Center

if the fault persists.

10. Disposal

CAUTION

Improper disposal of the equipment may h ave serious consequences: The burning of plastic components

generates toxic fumes which may present a health hazard. Batteries may explode if damaged or exposed to

very high temperatures, causing poisoning, burns, acid burns or environmental pollution. Careless disposal

may permit unauthorized and improper use of the equipment. This may result in serious personal injury, injury

to third parties and pollution of the environment.

en

Most of the materials from which Hilti tools or machines are manufactured can be recycled. The materials must

be correctly separated before they can be recycled. In many countries, Hilti has already made arrangements

for taking back your old tools for recycling. Please ask your Hilti customer service department or Hilti

representative for further information.

For EC countries only

Disposal of electric tools together with household waste is not permissible!

In observance of European Directive 2002/96/EC on waste electrical and electronic equipment

and its implementation in accordance with national law, electric tools that have reached the end

of their life must be collected separately and returned to an environmentally compatible recycling

facility.

11

Page 14

Dispose of the batteries in accordance with national regulations.

en

11. Warranty

Hilti warrants that the product supplied is free from

defects in material and workmanship. This warranty

is valid as long as the product is operated and

handled correctly, cleaned and serviced properly and

in accordance with the Hilti operating instructions,

all warranty claims are made within 12 months (unless other mandatory national regulations prescribe

a longer minimum period) from the date of sale (invoice date) and the technical system is maintained,

i.e. only genuine Hilti consumables, accessories and

spare parts are used with the product.

This warranty provides the free-of-charge repair or

replacement of defective parts only. Parts requiring

repair or replacement as a result of normal wear and

tear are not covered by this warranty.

Additional claims are excluded, unless mandatory national regulations prohibit such exclusion. In

particular, Hilti is not obligated for direct, indirect,

incidental or consequential damages, losses or expenses in connection with,orbyreasonof,theuse

of, or inability to use the product for any purpose.

Implied warranties of merchantability or fitness for

a particular purpose are specifically excluded.

Send the product and/or related parts immediately

upon discovery of a defect to the local Hilti marketing

organization for repair or replacement.

This constitutes Hilti’s entire obligation with regard

to warranty and supersedes all prior or contemporaneous comments and oral or written agreements

concerning warranties.

12. FCC statement (applicable in US) / IC statement (applicable in Canada)

CAUTION

This equipment has been tested and found to comply

with the limits for a Class B digital device, pursuant

to part 15 of the FCC rules. These limits are designed

to provide reasonable protection against harmful interference in a residential installation. This equipment

generates, uses and may radiate radio frequency

energy. Accordingly, if not installed and used in accordance with the instructions, it may cause harmful

interference to radio communications.

However, there is no guarantee that interference will

not occur in a particular installation. If this equipment

does cause harmful interference to radio or television

reception, which can be determined by turning the

equipment off and on, the user is encouraged to try

tocorrecttheinterferencebytakingthefollowing

measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and

receiver.

Connect the equipment to a power outlet on a circuit

different from that to which the receiver is connected.

Consult your dealer or an experienced TV/radio technician for assistance.

NOTE

Changes or modifications not expressly approved

by Hilti could limit the user’s right to operate the

equipment.

This device complies with part 15 of the FCC Rules

and RSS-210 of the IC.

Operation is subject to the following two conditions:

(1) This device may not cause harmful interference.

(2) This device must accept any interference received,

including interference that may cause undesired operation.

12

Page 15

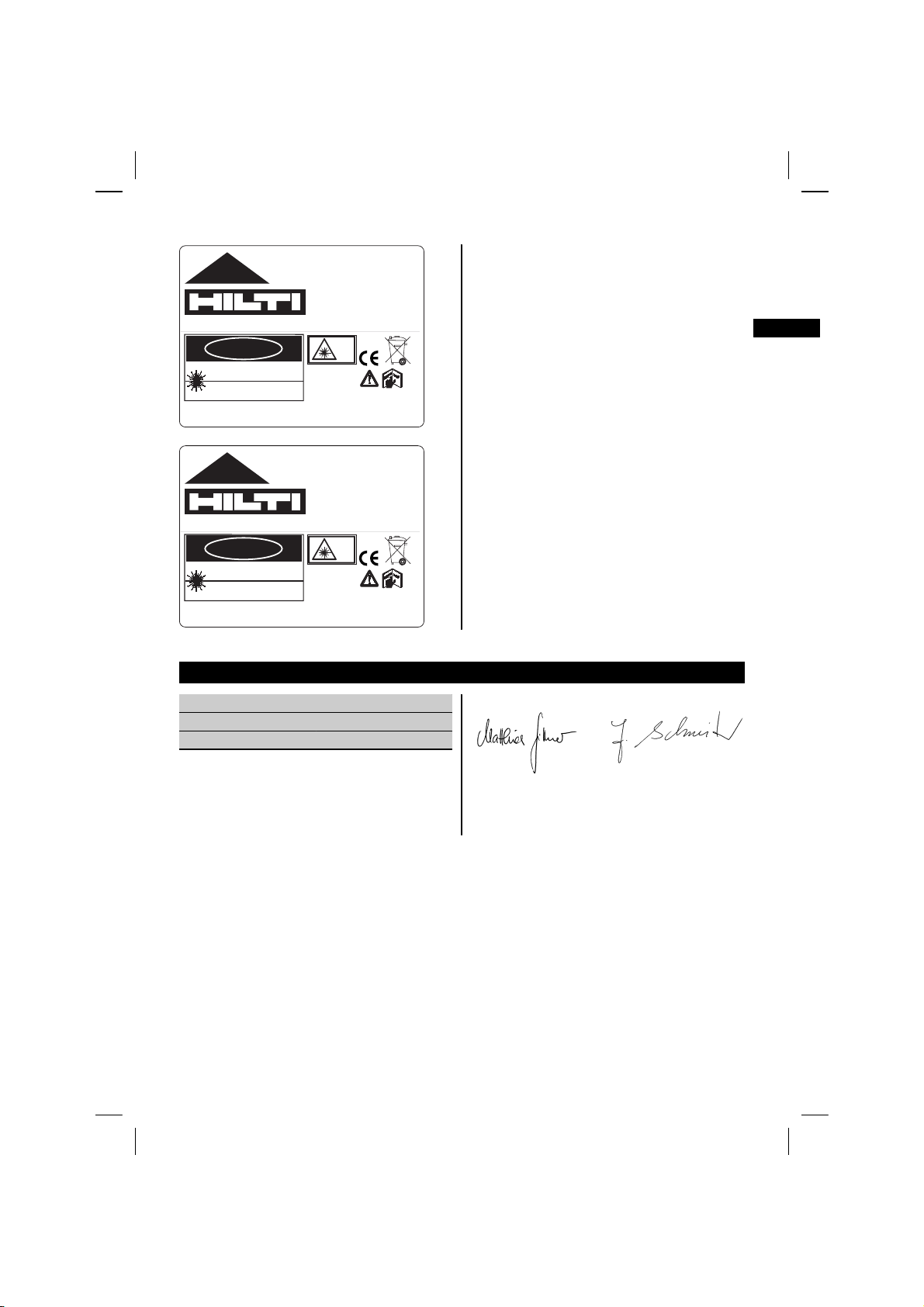

AVOID EXPOSURE

LASER LIGHT IS EMITTED

FROM THIS APERTURE

PP 10

Made in Japan

Hilti= registered trademark of the Hilti Corporation, Schaan, Liechtenstein

DANGER

LASER RADIATION - AVOID DIRECT

620-690nm < 5mW max.

CLASS IIIa LASER PRODUCT

Item No.: 319781

Date .:

EYE EXPOSURE

AVOID EXPOSURE

LASER LIGHT IS EMITTED

FROM THIS APERTURE

3R

EN 60825-1:2003

This Laser Product

complies with 21CFR

1040 as applicable

Power: 6.0V=nom./250 mA

319789

PP 11

Made in Japan

Hilti= registered trademark of the Hilti Corporation, Schaan, Liechtenstein

DANGER

LASER RADIATION - AVOID DIRECT

520-550nm < 5mW max.

CLASS IIIa LASER PRODUCT

Item No.: 319791

Date .:

EYE EXPOSURE

3R

EN 60825-1:2003

This Laser Product

complies with 21CFR

1040 as applicable

Power: 6.0V=nom./250 mA

319795

13. EC declaration of conformity

Designation: Pipe laser

Type: PP 10 / 11

Year of design: 2005

We declare, on our sole responsibility, that this

product complies with the following directives and

standards: EN 61000-6-2, EN 61000-6-3.

Hilti Corporation

Matthias Gillner Dr. Heinz-Joachim Schneider

Head BU Measuring Systems Executive Vice President

BU Measuring Systems Business Area Electric

07 2005 07 2005

Tools & Accessoires

en

13

Loading...

Loading...