Page 1

PM 24

Operating instructions 2 – 38

Mode d'emploi 32-60

*372696*

372696

en

Page 2

1. Product information

Symbols used

The symbols used in these operating instructions have the

following meanings:

WARNING

Usage risk or improper use which can cause severe personal

injury or a fatal accident.

Information which helps the user to employ the tool efficiently

and in a technically correct manner.

Please read these operating instructions carefully before

operating the tool for the first time. Make the instructions

available to all other users so that they can be read before the

tool is operated.

Always keep these operating instructions with the tool.

The operating instructions should always be with the tool

when it is given to other persons.

3

Page 3

4

1. Product information

1. Product information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Description of functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Operating controls and indicators . . . . . . . . . . . . . . . . . . . . . .7

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Items supplied . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

2. Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Please read this now! . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Intended uses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Warnings and cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Laser classification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Electromagnetic compatibility (EMC) . . . . . . . . . . . . . . . . . . .18

Care, storage and transportation . . . . . . . . . . . . . . . . . . . . . .19

Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

3. Operation and use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Inserting or replacing the batteries . . . . . . . . . . . . . . . . . . . .22

Operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Setting up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Plumbing with the PM 24 . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Setting out 90° with the PM 24 . . . . . . . . . . . . . . . . . . . . . . .26

Horizontal levelling and aligning with the PM 24 . . . . . . . . . .27

Using the accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

4. Accuracy Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5. FCC statement (applicable in US) . . . . . . . . . . . . . . . . . . . . . . . . . 34

6. EC declaration of conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7. Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Page 4

5

PM 24PM 24

1. Product information

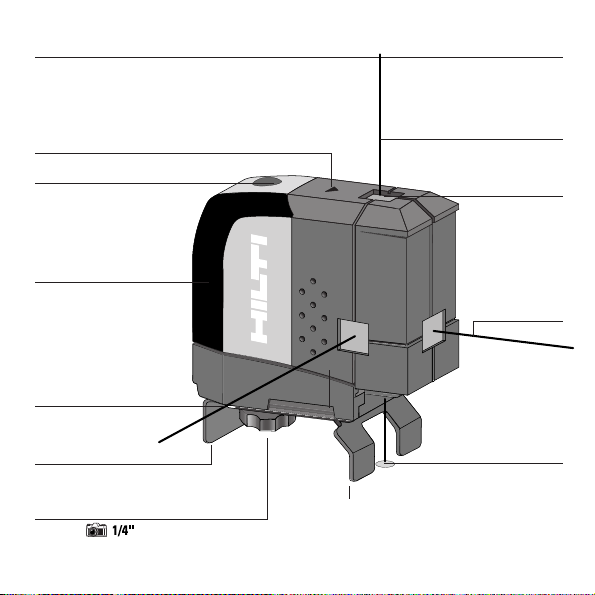

Plumb up beam

(upwards)

ON indicator

1. P roduct information

Tool overview

Laser exit window

Front Beam

90 ° Beam

Battery compartment

(4xtype AA)

Plastic housing

ON/OFF button

Reference beam

(downwards)

Camera tripod

thread

PA 271 Stand

Page 5

6

The Hilti PM 24 is a self-levelling laser tool which allows a single

person to do plumbing, setting out 90° angle, horizontal

levelling and aligning tasks quickly and precisely. It projects four

coincident laser beams (beams with the same point of origin).

All beams have the same operating range of 30 m (100 ft).

However, the maximum recommended distance of the reference

beam (plumb down) is 1 m (3,3 ft), due to its lower accuracy.

Features

– High accuracy of horizontal beams and plumb up beam

(3 mm @ 10 m or 1/8 inch @ 30 ft)

– Additional reference beam downwards

(2 mm @ 1 m or 1/12 inch @ 3 ft)

– Self-levelling within ± 5° in all directions

– Fast self-levelling time: ~ 3 seconds

– Out-of-level warning when the self-levelling range is exceeded

(the laser beams blink)

– Robust, impact-resistant plastic housing

– Small size and light weight - handy to use and transport

– Automatic cut-out: the tool switches off automatically after 15

minutes. Selection of sustained operating mode is also possible.

– Easy to operate

1. Product information

PM 24 Multi Directional Laser – plumbing, setting out 90° angle,

horizontal levelling and aligning

Description of functions, continued

Page 6

7

Operating controls and indicators

To switch the tool on/ off:

Press and release the ON/OFF button once.

The tool levels itself automatically within 3 seconds each time

it is moved.

The tool levels itself automatically even when not switched on.

The tool switches off automatically after 15 minutes.

Condition

The tool must be placed on a level surface with a maximum

slope of 5°.

To de-activate the automatic cut-out:

Press and hold the ON/OFF button until the green LED begins

to

blink (approx. 3 seconds) and then release the button.

The tool is then in sustained operating mode, i.e. for long

periods of operation.

Note

Press the ON/OFF button to switch off the tool after use in

order to save battery power.

1. Product information

~3s

Continued

Page 7

8

1. Product information

Operating controls and indicators, continued

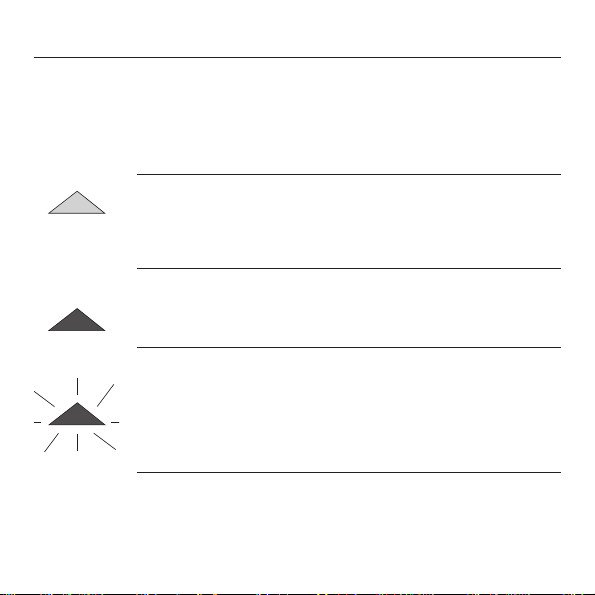

Indicator Status

Off – Laser beams off

– Tool is switched off

– Batteries possibly exhausted

Lit continuously – Laser beams on

– Tool in operation

Blinking – Batteries almost exhausted

– The ON/OFF button has been held in

the depressed position in order to

activate sustained operating mode

Control panel

Page 8

9

1. Product information

Technical data

Measurement range

Level, square, plumb up beam: up to 30 m [100 ft]

Recommendation for reference beam

(downwards): 1 m [3 ft]

Accuracy at 25°C [77°F]:

Level beam (horizontality): ± 60’’ (arc seconds) or

± 3 mm @ 10 m [1/8 inch @ 30 ft]

Square beam (horizontality): ± 60’’ (arc seconds) or

± 3 mm @ 10 m [1/8 inch @ 30 ft]

Angle Level/Square beam: 90° ± 60’’

Plumb up beam: 60’’ (arc seconds) or 3 mm @ 10 m

[1/8 inch @ 30 ft]

Reference beam: 7’ (arc minutes) or 2 mm @ 1 m

[1/12 inch @ 3 ft]

Temperature drift:

The drift of all beams is less than 3’’ (arc seconds)/°C.

Beam diameter

< 7 mm @ 10 m / < 14 mm @ 20 m

[< 1/3 inch @ 30 ft / < 3/5 inch @ 60 ft]

Continued

Page 9

10

Levelling Self-levelling within ±5° in all directions

When the tool is out of it’s self-levelling range, the laser

beams blink

Self-levelling time: ~ 3 seconds

Laser Visible Laser, 635 ±10 nm, laser class 2 (IEC 825-1),

Class II (FDA 21 CFR); power output: < 1 mW

Operating mode indicator

Green LED for on/off, battery condition

Automatic cut-out

The tool switches off automatically after 15 minutes.

To de-activate automatic cut-out: Press and hold the ON/ OFF

button (approx. 3 sec.) until the green LED blinks and then

release the button.

Power supply Four alkaline or rechargeable type AA batteries

Battery life at 25°C [77°F]

Alkaline: ≥ 40 h Rechargeable: ≥ 10h

1. Product information

Technical data,continued

Continued

Page 10

11

Operating temperature range

- 10° … + 45°C [+ 14°F … + 113°F]

Storage temperature - 40° … + 63°C [- 40°F … + 145°F], dry

Protection class

IP 52(IEC 529) protection against dust and dripping water

(excluding battery compartment)

Weight 0.5 kg (1.1 lbs), including 4 batteries

Dimensions 109 (L) x 51 (W) x 96 (H) mm

4.3 (L) x 2 (W) x 3.8 (H) inches

1. Product information

Technical data,continued

Page 11

12

PM 24

+20

+10

-10

-20mm

-20mm

-10

+10

+20

PA 211

mm

inch

+10

-10

PA 221

PM 24

PA 240

PA 240

1. Product information

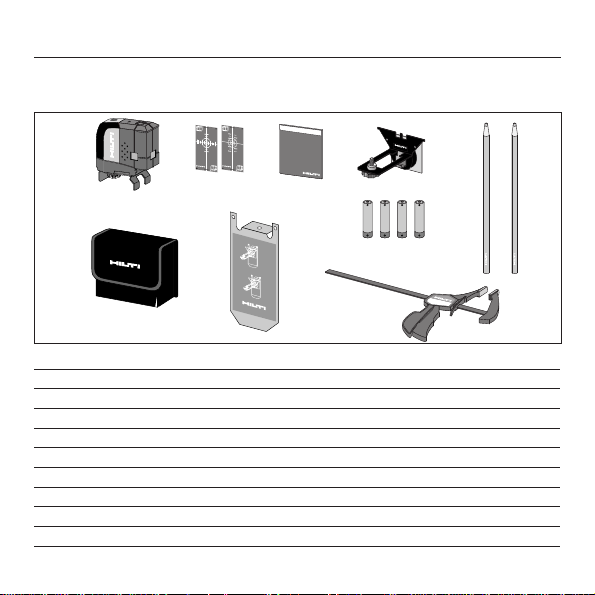

Items supplied - PM 24 Contractor Kit

Packed in a Hilti transport Case

Pos. Pieces Designation

1 1 PM 24 multi directional laser with metal stand PA 271

2 2 PA 211 or PA 221 Target plate

3 1 Operator’s manual

4 1 PA 240 Magnetic bracket

5 1 Soft pouch

6 1 PA 230 Wall bracket

7 4 Batteries

8 1 PA 250 Frame clamp

9 2 Marking pens

1

2

3

4

5

6

9

7

8

0

2

+

+

2

0

0

1

+

+

1

1

0

+

/

2

+

1

0

m

m

i

n

c

h

0

1

-

1

0

1

0

1

/

m

2

m

0

2

-

2

0

PM 24

m

m

P

P

A

A

2

2

2

1

1

1

P

M

2

4

P

A

2

4

0

+

-+-+-+-

P

A

2

3

0

Page 12

13

1. Product information

+20

+10

-10

-20mm

-20mm

-10

+10

+20

PA 211

mm

inch

+10

-10

PA 221

PM 24

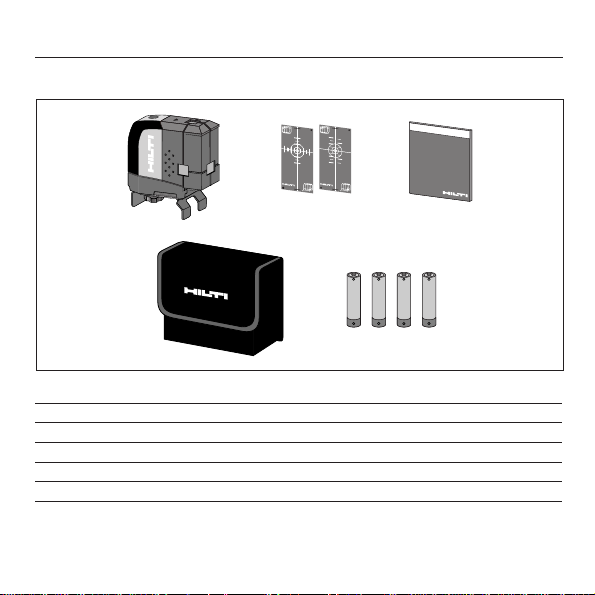

Items supplied - PM 24 Single unit

Pos. Pieces Designation

1 1 PM 24 multi directional laser with metal stand PA 271

2 2 PA 211 or PA 221 Target plate

3 1 Operator’s manual

4 1 Soft pouch

5 4 Batteries

12

3

45

PM 24

P

M

2

0

2

+

+

2

0

0

1

+

+

1

1

0

+

/

2

+

1

0

m

m

i

n

c

h

0

1

-

-

1

0

-

1

0

1

-

/

m

2

m

0

2

-

-

2

0

m

m

P

P

A

A

2

2

1

2

1

1

4

+

-+-+-+-

Page 13

14

Intended uses

2. Safety information

2. Safety information

This information is intended to enable owners and users of the

Hilti PM 24 to identify any operating risks in good time, i.e. to

eliminate any such risks in advance where possible.

The owner of the tool must ensure that these instructions are

understood and followed by all users.

Please read this now!

The Hilti PM 24 is designed to be used indoors for determining

and checking heights or deviations in heigth

at points in the horizontal plane, vertical lines, alignment lines,

the position of partition walls (vertical and at right angles to a

reference line) and for marking plumb points.

For example:

– Transferring datum marks and height marks

– Marking out the position of partitions (at right angles and in

the vertical plane)

– Aligning equipment/installations and other structural

elements in three axes

– Checking and transferring right angles

– Transferring points marked on the floor to the ceiling

Page 14

15

2. Safety information

WARNING

- Dot not use the product without prior instruction

- Dot not use the product outside its operating limits

- Do not make any conversions or modifications to the product

- Do not render safety devices ineffective or removing notices

and warning signs

- Dot not have inadequate safety measures at the location

where the product is in use (e.g. levelling or alignment work at

a roadside etc.)

- Keep the tool out of reach of children. Laser tools do not

belong in children’s hands.

- Avoid unusual body positions when carrying out alignment

work from ladders. Make sure that your stance is secure and

always stay in balance.

- The battery must be removed from the tool when it is shipped.

- The tools are not designed for use in environments where

there is a risk of explosion.

CAUTION

- Check the tool for possible damage before use. If the tool is

damaged, have it repaired at a Hilti repair centre.

Warnings and cautions

Page 15

16

2. Safety information

- If the tool has been dropped or subjected to other

mechanical forces, its accuracy should be checked. For

safety’s sake, check its accuracy before each use.

- When using adaptors, always ensure that the tool is screwed

on securely.

- When the tool is brought into a warmer environment from a

very low temperature, or vice versa, it should be allowed to

become acclimatised to the ambient temperature before it is

operated.

- Measurements taken through panes of glass or other

objects may be inaccurate.

- To avoid inaccurate measurements, always keep the laser

beam exit windows clean.

- Although the tool is designed for use under arduous

conditions on construction sites, like any other item of

optical equipment (e.g. binoculars, spectacles), it should be

handled with care.

- Although the tool is designed to prevent the entry of moisture, it

should be wiped dry before being put away in its carrying case.

- The tool is not designed for use in rain.

- Do not use damaged batteries.

- The unit may not be opened by unauthorized persons.

Warnings and cautions, continued

Page 16

17

Laser warnings for the USA based on FDA 21 CFR:

2. Safety information

The PM 24 plumb laser corresponds to laser class 2, based on the

standards IEC 825-1 / EN 60825, and class II based on FDA 21 CFR.

The eyelid closure reflex protects the eyes should anyone happen to

look briefly into the laser beam. However, this eyelid closure reflex

can be impaired by medicines, alcohol or drugs. These devices may

be used without further protective measures. Nevertheless, as with

the sun, care should be taken to avoid looking directly into the

light source. Do not direct the laser beam at people.

Laser classification

Laser warnings based on IEC 825 / EN 60825:

Laser

Do not stare into beam

Laser Class 2

PM 24

Page 17

18

2. Safety information

Electromagnetic compatibility refers to the ability of the Hilti

PM 24 to function correctly in an environment where it is

exposed to electromagnetic radiation and electrostatic discharge,

without causing electromagnetic interference to other devices.

WARNING

There may be a possibility of interference to other equipment

due to electromagnetic radiation.

Although the Hilti PM 24 complies with the strict requirements

of the relevant directives and standards, Hilti cannot entirely

rule out the possibility of interference with other equipment.

CAUTION

Measurements may exceed tolerances where interference is

caused by powerful electromagnetic radiation.

Although the Hilti PM 24 complies with the strict requirements

of the relevant directives and standards, Hilti can not entirely

rule out the possibility of the PM 24 being subject to

interference caused by very intense electromagnetic radiation,

e.g. in the immediate vicinity of radio transmitters, radio

communication equipment, diesel generators etc.

Check the readings for plausibility when the tool is used under

these conditions.

Electromagnetic compatibility (EMC)

Page 18

19

2. Safety information

Cleaning and drying

- Blow dust off the lenses.

- Don’t touch the glass with your fingers.

- Use only clean, soft cloths for cleaning. If necessary,

moisten the cloth slightly with pure alcohol or a little water.

Do not use any other liquids as these may damage the plastic

components.

Observe the temperature limits when storing your equipment. This

is particularly important in winter or summer if the equipment is

kept inside a motor vehicle (-30°C to +60°C / -22°F to +140°F).

Storage

- Remove the tool from its case if it has become wet. The tool,

its carrying case, and accessories should be cleaned and

dried (max 40°C / 108°F). Put the equipment back into its

case only when it is completely dry.

- Check the accuracy of the equipment by taking test

measurements before it is used after a long period of

storage or transportation.

Transportation

Your equipment should be shipped in the Hilti shipping carton

or packaging of similar quality.

Always remove the batteries before shipping.

Care, storage and transportion

Page 19

20

2. Safety information

Disposal

WARNING

Improper disposal of the equipment may lead to the following:

- Burning of plastic components generates toxic fumes which

may present a health hazard.

- If damaged or exposed to very high temperatures, batteries

may explode, causing poisoning, burns, acid burns or

environmental pollution.

- Careless disposal enables unauthorised persons to make

improper use of the equipment. This may lead to serious

injury to themselves or to a third party and to pollution of

the environment.

- Dispose batteries according to national requirements.

Most of the materials from which Hilti tools are manufactured

can be recycled.

The materials must be correctly separated before they can be

recycled.

In many countries, Hilti has already made arrangements for

taking back old tools for recycling.

Please ask your Hilti customer service department or Hilti

representative for further information. Please help to protect

and maintain our environment.

Page 20

21

2. Safety information

Disposal

Part, assembly Main material Recycling

Casing Plastic Plastic recycling

On-off switch Plastic Plastic recycling

Electronics Various Electronics scrap

Screws, small parts Steel Scrap metal

Soft pouch Woven synthetic fiber Plastic recycling

Frame clamp Metal, steel Metal

PA 271 stand Aluminium, metal Metal, plastic

Wall mount Metal, steel Metal

Magnetic bracket Steel Metal

PA 211/221 target plate Plastic Plastic recycling

Page 21

22

3. Operation and use

3. Operation and use

Inserting or replacing the batteries

Green indicator blinks – the laser beams blink for a few

minutes and then switches off automatically ➞ battery voltage

too low ➞ insert new batteries:

Always replace the complete set of batteries!

– Do not mix old and new batteries.

– Do not mix batteries of different makes or use batteries of

different types.

open

close

Page 22

23

3. Operation and use

Operating conditions

1 Observe the operating temperature range.

2 Place the tool on a level, steady surface (the floor).

Accuracy of the tool can only be ensured when the operating

conditions (points 1 and 2) are observed.

PM 24

PM 24

PM 24

PM 24

Page 23

24

3. Operation and use

Setting up

Marking the reference point – the possibilities

1 Mark the laser reference beam point by hand.

Set up the laser plumbline with the spot on the mark.

2 For other applications, e.g. alignment with the edge of a dry

wall track or board, etc., position the PM 24 against the track.

The laser reference beam spot is positioned exactly on the

edge of the track and at the center of the tool.

PM 24

PM 24

1

2

Page 24

25

PM 24PM 24

Plumbing with the PM 24

3. Operation and use

Procedure

1 Position the tool on the marked reference point.

2 Switch on the tool.

The ON indicator lights (green), the laser beam lights up and

the tool levels itself automatically.

3 The reference beam spot must coincide with the mark.

Correct the position of the tool if necessary.

4 Mark the plumb up beam spot or use the PA 211 target

plate, for example, to check for plumb along a wall.

Note: The other beams have been omitted from illustration for clarity.

PM 24 PM 24

Page 25

26

Setting out 90° angle with the PM 24

Procedure:

1. Place PM 24 against the reference wall.

2. Using the target plate, adjust the front beam so that it is

parallel to the wall.

3. Now with the right, 90° beam and the target plate mark off

your points.

3. Operation and use

+1/

2

+10

mm inch

-10

-1/

2

PA 221

y

x

x

1

2

x

x

3

4

Page 26

27

Horizontal Levelling and aligning with the PM 24

The PM 24 can do horizontal levelling and aligning in two ways:

1. Directly over the surface ➪ Place the PM 24 over the reference

surface. Level the other surface using the target plate.

2. Mounted with an accessory ➪ Mount the PM 24 with an

appropriate accessory at the desired height. Rotate the

PM 24 and mark the points or perform the installation directly.

When performing levelling and aligning applications with the

PM 24 mounted on the PA 271 stand, first check the

reference by holding the target plate directly in front of the

tool. This reference may or may not be on the center of the

target plate and will apply to all further levelling points.

3. Operation and use

Page 27

28

3. Operation and use

Using the accessories

a) Frame clamp

When using the Frame clamp (e.g. at a door frame), the magnetic bracket can

be slid onto the stationary jaw of the clamp by way of the rail at the rear. The

protective cover should be fitted over the magnet.

b) Magnetic bracket

The protective cover should be removed from the magnets before using the

magnetic bracket.

Page 28

29

c) Wall bracket

The wall bracket is used for mounting the PM 24 on a non-magnetic surface.

Screws or nails can be used to fasten the wall bracket to surfaces of this kind.

The PM 24 can be set up on the wall bracket with the magnetic holder

(protective cover removed).

d) Tripod Head

Tripod Head with 1/4 “ thread.

3. Operation and use

Page 29

30

The tool should be checked on regular intervals at room temperatures

(25˚C or 77˚F) to ensure compliance with the technical specifications.

Plumb Up Beam

1. Mark a point (a cross) on the floor of a high room (e.g. a

stairwell, (5-10m or 15-30 ft)).

2. Put the tool on a level floor and switch it on.

3. Bring the reference beam point on top of the center of the cross.

4. Mark the corresponding up beam on the ceiling (easier if paper is

taped there)

5. Turn the tool 90° so that the reference beam stays on the same

point and mark again on the ceiling.

6. Repeat the same at 180° and at 270°.

7. The 4 resulting points on the ceiling define a circle of which the

crossing point of the diagonals d

1

(1– 3) and d2(2– 4) mark the

exact plumb point.

8. Calculate accuracy:

The result of the formula refers to the accurcy in “mm @ 10 m” (equation

(1)) or the accuracy in “inch @ 30 ft (equation (2)). The result shall be

within the PM 24 specification: 3 mm @ 10 m [1/8 inch @ 30 ft].

4. Accuracy check

4. Accuracy check

Result =

10

Room height [m]

.

(d1+ d2) [mm]

4

(1) or

Result =

30

Room height [ft]

.

(d1+ d2) [inch]

4

(2)

Page 30

31

Page 31

32

Level and Square Beam (horizontality)

1. Place the PM 24 on the floor near wall (A). Mark the center

of the laser spot (1) with a cross. Turn the tool through

180 °. Mark the center of the laser spot (2) with a cross.

2. Place the tool near wall (B) and direct the beam towards

wall (B). Mark the center of the laser spot (3) with a cross.

Pivot the tool trough 180 °. Mark the center of the laser

spot (4) with a cross.

3. Measure the distance d1 and d2. Mark the middle point in

d1 and d2. If the reference points 1 and 3 are on different

sides of the middle point (see the example), subtract d2

from d1. If they are on the same side of the middle point,

add d1 to d2. Divide the result by twice the length of the

room.

For PM 24: max. error = 3mm / 10m or 1/4” at 60feet.

Example: d1 = 6mm, d2 = 4mm, room length = 10m,

points 1 and 3 are on different sides of the real level line.

6mm-4mm =2mm

=

1mm / 10m

10m X 2 20 m

Level / Square Beam Angle

An effective test of the accuracy of the angle between level and

square beams can only be carried out in a Hilti Repair Center.

Page 32

33

1

Room must have 10 to 20 m (60 to 100 ft)

AB

1

180

2

2

AB

180

4

3

3

AB

1

d

1

4

D

2

d

2

3

Page 33

34

5. FCC statement (applicable in U.S.)

WARNING

This equipment has been tested and found to comply with the

limits for a class B digital device, pursuant to part 15 of the

FCC rules.

This device complies with part 15 of the FCC Rules. Operation

is subject to the following two conditions:

(1) This device may not cause harmful interference, and (2)

this device must accept any interference received, including

interference that may cause undesired operation. However,

there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of

the following measures:

– Reorient or relocate the receiving antenna.

– Increase the separation between the equipment and receiver.

– Connect the equipment into an outlet on a circuit different

from that to which the receiver is connected.

5. FCC statement (applicable in U.S.)

Continued

Page 34

35

5. FCC statement (applicable in U.S.)

5. FCC statement (applicable in U.S.), continued

PM 24

– Consult the dealer or an experienced radio/TV technician for

help.

WARNING

Changes or modifications not expressly approved by Hilti for

compliance could void the user’s authority to operate the

equipment.

Label

PM 24

Page 35

36

6. EC declaration of conformity

6. EC declaration of conformity

Designation: PM24

Serial no.: 500000 –800000

Year of design: 2001

-conform

We declare, on our sole responsibility, that this product

complies with the following standards or standardisation

documents: 89/336/EWG

Hilti Corporation

Armin Spiegel

Head of Business Unit

Positioning Systems

12/2001

Bodo Baur

Quality Manager of Business

Unit

Positioning Systems

12/2001

Page 36

37

7. Warranty

7. Warranty

Hilti warrants that the tool supplied is free of defects in

material and workmanship. This warranty is valid so long as

the tool is operated and handled correctly, cleaned and

serviced properly and in accordance with the Hilti Operating

Instructions, all warranty claims are made within 12 months

from the date of the sale (invoice date), and the technical

system is maintained. This means that only original Hilti

consumables, components and spare parts may be used in the

tool. (Unless stringent national rules stipulate a longer

minimum warranty period.)

This warranty provides the free-of-charge repair or

replacement of defective parts only. Parts requiring repair or

replacement as a result of normal wear and tear are not

covered by this warranty.

Additional claims are excluded, unless stringent national

rules prohibit such exclusion. In particular, Hilti is not

obligated for direct, indirect, incidental or consequential

damages, losses or expenses in connection with, or by

Continued

Page 37

38

7. Warranty, Addresses

7. Warranty,continued

reason of, the use of, or inability to use the tool for any

purpose. Implied warranties of merchantability or fitness for

a particular purpose are specifically excluded.

For repair or replacement, send tool and / or related parts

immediately upon discovery of the defect to the address of the

local Hilti marketing organization provided.

This constitutes Hilit’s entire obligation with regard to warranty

and supersedes all prior or contemporaneous comments and

oral or written agreements concerning warranties.

Hilti Corporation

FL-9494 Schaan, Principality of Liechtenstein

Internet: www.hilti.com

Loading...

Loading...