Page 1

02236

PK 1000

EDITION 2007

Page 2

Page 3

1

Page 4

2

Page 5

3

Page 6

4

Page 7

GRILLO SERIE PK 1000

Dear customer,

Thank you for choosing our PK 1000; we are sure that your new machine’s performance will meet

your requirements in full.

To ensure optimum service and maintenance of its qualities over time, read this manual carefully

and follow its instructions. This will give you the best results and protect your investment. Please

keep this manual, which must always accompany the machine.

CAUTION! Before starting the engine, read this carefully.

The following warnings are very important in ensuring safety!

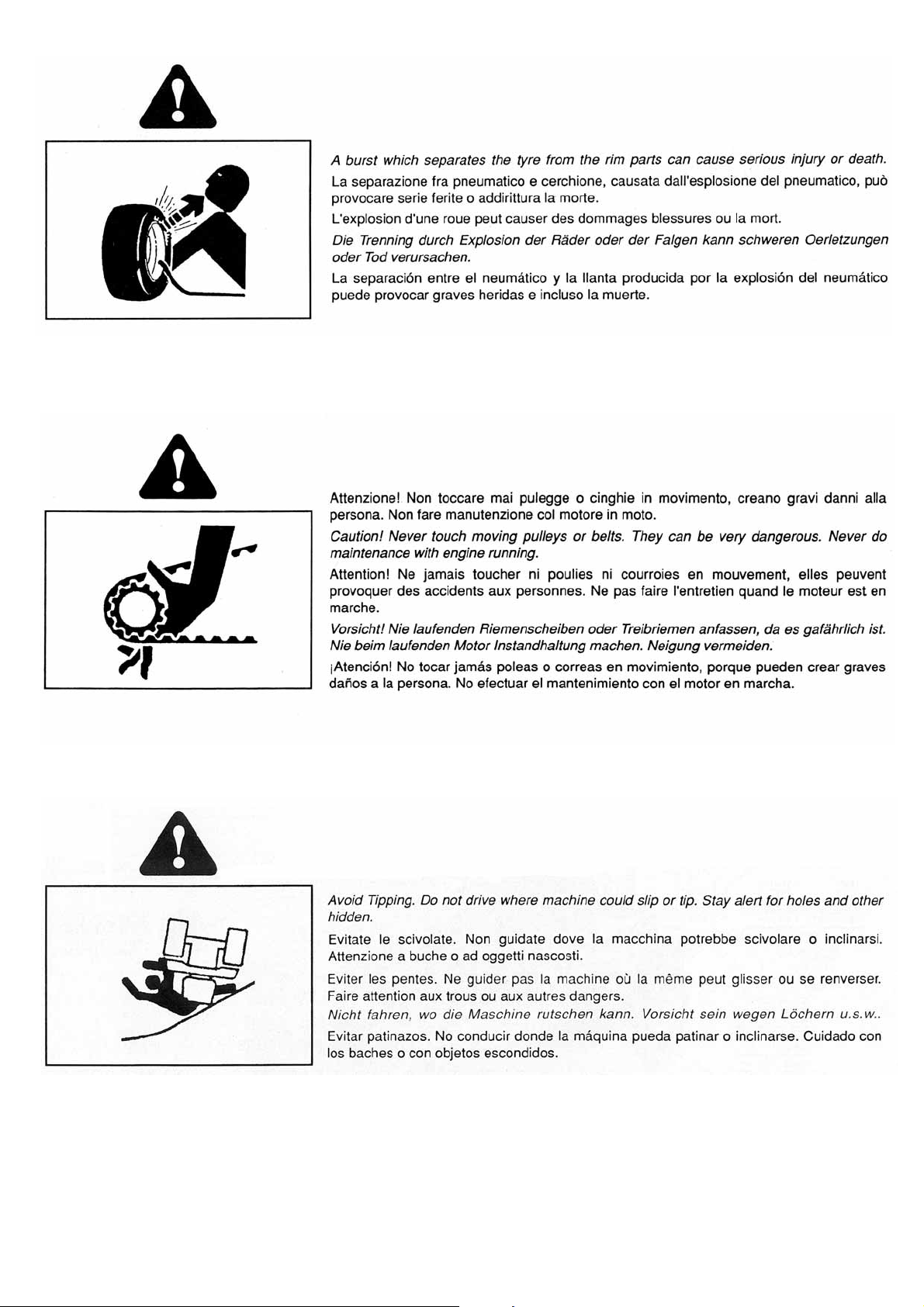

SAFETY REGULATIONS

Caution is the best way for preventing accidents!

We urge you to read carefully the following regulations for use of the machine before

starting working.

Improper use of the machine and its equipment may cause damage; to reduce this risk, read the

following precautions carefully.

1) Read the whole of this manual before starting the machine or putting it in motion.

2) Pay special attention to the safety warnings and labels.

3) Never load weights in excess of the approved capacity – total weight fully loaded 3500 kg.

4) Before other people are allowed to use the machine they must first be informed about the

safety regulations and how to use the vehicle.

5) Before starting the engine, make sure that nobody is nearby, particularly that there are no child

around.

6) Check for people and obstacles before putting the vehicle in motion.

7) Never carry passengers on the machine, next to the driver over the allowed limit.

8) Never use the machine when tired and do not drink alcohol.

9) Secure the load properly with the hooks provided.

10) Before starting work, put on suitable working clothes, gloves and heavy footwear.

11) Before getting off the machine, switch off the engine, remove the ignition key and engage the

parking brake.

12) Travel at low speed over loose ground.

13) Never allow the machine to be used by anyone under 18 years of age.

14) Never reverse with the engine at high throttle.

15) Load the body tidily and evenly.

16) Never load heavy weights in the back of the body or on one side, since a great deal of stability

safety is lost.

17) Never keep the engine running indoors; you may inhale poisonous gases.

18) Always switch off the engine before filling up with fuel, keep away from sparks or flames and do

not smoke.

19) Avoid fuel spills and after filling the tank clean all spills before starting the engine.

20) Never use the vehicle close to ditches or banks which may give way under its weights,

particularly when the ground is loose or wet.

21) Do not turn sharply when going downhill.

22) Never tamper with or deactivate the safety devices.

23) If you have children, hide the ignition keys when you are not using the machine.

24) Never make any adjustments or do any cleaning with the engine running.

25) Never have anyone checking the machine while you are sitting in the driving seat with

running engine.

26) The user is always responsible for injury or damage to third parties.

27) Any improper uses cause the machine to become null and void and the constructor will decline

any liability.

28) Always use original Grillo spare parts.

5

Page 8

DESCRIPTION

The Grillo PK 1000 is a 4-wheel drive vehicle powered by a 4-stroke, water-cooled Diesel engine.

The precise weight distribution provides the maximum stability, while maintenance is reduced to

just a few simple operations.

TECHNICAL DATA with 10.0/75 – 12 wheels

MODEL: wheeled transporter

ENGINE: Lombardini FOCS 1404 Diesel 1372 c.c. 37 HP (27,2 kW), 4 cylinders liquid

cooled.

Kubota 1105 diesel 3 cylinders liquid cooled–3200 rpm – 21 kW, 28 HP.

Lombardini 12LD477 Diesel 2 cylinders air-cooled– 3.200 rpm – 20 HP

(15kW).

STARTING: electric 12V.

CLUTCH: dry, one-plate with pedal control.

GEARBOX: synchronized, 10 gears, 8 forward + 2 reverse.

SPEED (wheels 10.0/80-12: I 2.7 Km/h – II 4.7 Km/h – III 7.2 Km/h – IV 9.9 Km/h – V 10.8 Km/h –

VI 18.9 Km/h – VII 28.9 Km/h – VIII 40 Km/h – I REVERSE 2.8 Km/h – II REVERSE 11.2 Km/h.

WHEELS: pneumatic tractor 10.0/80-12 (6 PR), 10.0/75–15,3 (10 PR); garden 26x12.00/12

(8 PR).

DIFFERENTIAL: on both axles with locking on the rear axle.

FRONT AXLE: steering.

STEERING: hydraulic.

SEATS: sprung and adjustable.

TRACTION: 4 driving wheels with disengageable front wheels

SERVICE BRAKE: hydraulic, acting on the four wheels

EMERGENCY AND PARKING BRAKE: mechanic, acting on the rear wheels.

LOAD BED: three-sided tipping, hydraulic

DRIVER’S PROTECTING GRILL: on front sideboard.

LOAD CAPACITY: max. 1750 kg with 10.0/75 – 15,3 wheels.

MACHINE’S DIMENSIONS: length 4000 hooks included, width 1500, height 2320, distance

between axles 1800, track 1220.

WEIGHT: 1750 KG max with 10.0/75-15,3 wheels (10 PR).

ATTACHMENTS: driver’s protecting cab, 540 rpm PTO.

N.B. TYPE APPROVAL IN PROGRESS, PROVISIONAL DATA.

6

Page 9

IDENTIFICATION

The vehicle’s serial number is punched on the nameplate on the right-hand longitudinal member of

the chassis and on the gearbox nameplate.

SPARE PARTS

We recommended using only original GRILLO spare parts.

PUTTING THE MACHINE INTO SERVICE

1) Make sure the machine is complete and that it has not suffered any damage during transit.

2) Check the levels of the engine oil, the gearbox oil and the radiator liquid.

3) Check the tyre pressures:

10,0 / 75 – 15,3 10PR (5,3 bar)

10,0 / 80 – 12 6PR (2,6 bar)

26 x 12.00 / 12 8PR (2,7 bar)

4) Check the battery voltage, it must not be less than 12 Volts; recharge if necessary.

If a dry battery has been supplied with separate acid, to put the machine into service proceed

as follows:

1) Pour in the acid and wait 2 hours;

2) Charge the battery with a charger set to 12 Volts on a slow charge for 2 hours.

Caution, if this procedure is not observed this could lead to the battery deteriorating and the

acid leaking out during work.

IMPORTANT!!! When fitting the battery be careful not to reverse the poles. Do not start the

engine if the battery is disconnected.

BATTERY – CAUTION!

The gas released by the battery is explosive, so keep it away from naked flames or sparks. Check

the level of the liquid at regular intervals and keep the terminals greased with Vaseline.

RUNNING - IN

During the running-in period (first 70 operating hours), do not work with the engine at high throttle,

taking care not to use more than about 70% of the power available.

After the first 20 operating hours and at the end of the running-in period:

Check the tightness of all the fasteners and connections (screws, nuts and unions).

Check all the units, engine, gearbox and pipelines for oil leaks.

Adjust the handbrake.

Refer to the engine handbook for the specific running-in instructions.

7

Page 10

INSTRUCTIONS FOR USE

DESCRIPTION OF THE CONTROLS (Fig. 1 - Fig. 2)

1) Clutch pedal (Fig. 2 n° 1): disengages the engine from the transmission. It must be operated

whenever various control levers (gearbox, high – low range lever, PTO control lever) are used,

before stopping the machine and before starting the engine.

2) Brake pedal (Fig. 2 n° 2): operates the brakes on the wheels.

3) Throttle pedal (Fig. 2 n° 3).

4) Parking brake lever (Fig. 1 n° 4): acts simultaneously on the brakes of the rear wheels. The

brake is engage by pulling the lever up; to release, press the button on the end of the lever and

lower it.

5) Gear lever (Fig. 1 n° 5):

and two reverse speed.

6) High-low range lever (Fig. 1 n° 6): push forward for high range gears; pull back for a low range

speed.

7) Differential lock lever (Fig. 1 n° 7): pull up to operate.

8) Front axle disengage lever (Fig. 1 n° 8): move forward to release the axle, back to engage. It

may happen that the engage and disengage of the front axle lever is difficult. Do not force the

lever, but move the machine a few cm forward and backward and try again.

9) Dumper control lever (Fig. 1 n° 9).

DESCRIPTION OF THE CONTROLS – Fig. 3

1) Generator warning light (red).

2) Engine oil low pressure warning light (red).

3) Air filter blockage warning light.

4) 4-wheel drive engaged indicator light.

5) Dipped headlight indicator (green).

6) Glow plug preheating indicator.

7) Direction indicator warning light (green).

8) Emergency light switch.

9) Key-switch for switch-on, enabling services, igniting and stopping engine.

10) Direction indicator, horn switch and lights switch.

11) Cooling water temperature indicator.

12) Hour-counter.

13) Rev. Counter.

14) Fuel level indicator.

15) Fuel reserve.

16) Parking lights warning light.

17) Parking brake warning light.

18) Engine oil temperature earning light.

19) Headlights warning light.

in combination with the high – low range lever, this provides eight forward

8

Page 11

BEFORE STARTING UP, CHECK:

Check that the gearbox oil level is in line with the hole on the right-hand side of the gearbox

casing (fig. 4).

Check the engine oil level (follow the instructions in the engine handbook).

Check that the clutch pedal does the first part of its race without actioning it. Regarding the

regulation, operate on the register (fig. 5).

Check the brake fluid level – Fig. 6 The tank is on the right side of the dashboard

Fill the fuel tank, using a funnel with a fine filter (fig. 7).

Make sure that all the levers are in neutral position, then proceed as follows:

1) Starting with engine cold.

2) Depress the clutch pedal.

3) Fit the key into the ignition and turn left for preheating. When the glow-plug indicator light goes

out, turn the key clockwise and release as soon as the engine starts.

To stop the engine, return the key to the central position.

If the engine fails to start, do not keep trying and run down the battery; wait a few minutes before

repeating the starting procedure.

Check the liquid level in the battery often and if necessary add distilled water.

LOAD BED TIPPING USE INSTRUCTIONS

Load bed tipping operations:

Lock with two latches the two load bed frame cross rails, which are located on the tipping

side do you prefer and make you sure that the hinge pins are properly fitted in the load

deck.

To put the load bed upward, operate on the lever (fig. 1 n° 9) keeping it actioned “upward”.

The load deck goes upward only if the lever is continually pressed. You can immediately

stop the tipping releasing the lever.

CAUTION!

The tipping load bed must never be locked in points which are diagonally opposing; to

avoid the wrong location, the two latches are of different shape.

Use only original latches.

Before every lateral tipping make you sure that the sides are opened.

Before beginning the tipping operations, make you sure that the vehicle is located on a

horizontal and not yielding ground and that the charge is uniformly distributed.

NOTES FOR THE LOAD BED USE

The three-sided tipping load bed is built and fitted with some devices, which can assure the total

security, even if the driver is inexperienced. However, it is necessary to follow the fundamental

security rules, here listed:

Before beginning the tipping operations make you always sure that the vehicle is located on

horizontal and not yielding ground and that the charge is uniformly distributed.

Before beginning the tipping make you sure that there are no people, animals or any other

things nearby the vehicle.

Before beginning the tipping operations makes you sure that the latches are locked in order

to allow the tipping in the direction do you prefer.

9

Page 12

When the load bed is charged, above all with no fixed materials, pay attention to the sides

opening, because the materials pressure makes the side open violently and the material

falling down can hit the operator.

Make you sure that during the travel the sides are properly closed and locked.

Pay attention in case of tipping inside enclosed areas, particularly to the possible

interference with beams, ceilings, scaffoldings, installations, or other.

Never lift the load deck near electric aerial lines or similar.

During the maintenance operations, position the strut which must support the load bed in

security conditions (fig. 8). It is forbidden to go under the load deck with every body parts if

the strut is not properly positioned.

In case of engine breakdown you can lift the load deck actioned on the manual pump,

which is located on the right side of the rear frame (Fig. 14 and Fig. 15).

CAUTION!

1. It is absolutely forbidden the improper use of the tipping equipment.

2. The hydraulic system working pressure is regulated by the builder, taking into consideration

the vehicle capacity.

It is absolutely forbidden to change the calibration of the pressure control valve.

3. Never halt under the tipping load bed if it is lifted and if the strut is not properly fixed.

4. It is absolutely forbidden to travel when the load deck is lifted.

MATERIAL CHARGE OPERATION

The charge must be uniformly distributed, in order to avoid the material falling danger on

the street.

Never exceed the allowed charge.

The material must be put in the load bed from the minimum possible height.

Check that the sides are closed, in particular that the rear side is locked by the ratchets.

Big stone blocks or demolition material rubbles must be placed cautiously on the load deck

and you must not make them fall down from strong height.

CAUTION!

Avoid overcharging the vehicle.

Before the travel make you sure that the load bed is completely lowered and avoid to travel

when it is lifted.

STOPPING THE ENGINE

After moving all control levers to the NEUTRAL position, to stop the engine, move the ignition key

to the central position.

MAINTENANCE AND LUBRIFICATION

ENGINE OIL

During the running-in period, make the first oil change after the first 20 hours’ work and the second

80 hours, and then change every 120 operating hours. Use AGIP F.1 D. RANGE SAE 40 engine

summer, and AGIP F.1 D. RANGE SAE 20 in winter. It is essential to check the oil level every 4

hours of work. (Follow the instructions in the engine handbook).

CAUTION!

If the engine oil exceeds the maximum level, the engine performances are reduced and the

functioning may be irregular.

10

Page 13

GEARBOX – REAR RETAINER - HYDRAULIC DUMPER – POWER STEERING OIL

Check the level about every 50 working hours (Fig. 4), placed on the right-hand side of the gearbox

casing. If necessary, add AGIP ROTRA JD, gearbox oil. Change the oil once a year. To drain the

old oil from the casing, unscrew the plug in the centre of the gearbox casing under the differential

(Fig. 11) Quantity 26 lt. The filter cap is under the load bed (Fig. 9).

The hydraulic oil filter is near the gearbox (Fig. 10). Change once a year.

To make the oil refilling or substitution faster, take off the screw which is located on the gearbox

cover (Fig. 9).

FRONT AXLE OIL

Check the level trough of the cap in the front part of the casing (Fig. 19); change the oil every 500

hours using AGIP ROTRA 85 W 90 gearbox oil, quantity 5 litres.

BRAKE FLUID

Check the level of the brake fluid in the tank which is on the right side of the drive seat (Fig. 6)

every 8 hours. Add brake fluid if necessary. Check the braking system periodically for leaks.

A special tool for venting the brake circuit is available. Connect it in the place of the cap of the tank,

and vent first the rear trailer circuit, and then the front circuit.

Users without the tool can try to vent the circuits using the machine’s pump, but this is not always

successful.

BRAKES REGULATION

Take off the plastic plug placed in the low part of the braking system elements (Fig. 16). Turn the

toothed ring nut downwards.

The parking brake can be regulated operating on the registers located on the braking system

elements (Fig. 17).

ATTENTION!

Grease the transmission universal joint, the articulated joint of the machine and the steering

articulations periodically.

RADIATOR LIQUID

Check the level every 8 hours with the engine cold; if hot, the water may cause scalding.

Replace the liquid once a year.

Capacity 16 litres (Fig. 6).

CAUTION!

In case of liquid loss, after repairing the damage, fill the circuit up, purging repeatedly the air from

the plug, which is placed on the engine in correspondence with the superior sleeve (Fig. 18).

FUEL OIL FILTER

The fuel oil (Fig. 12) is fitted with an electrovalve to stop the engine. The air purging from the

conduits is automatic. However on the filter is positioned a purging screw. Regarding the filter

substitution follow the engine handbook. However we advise to substitute it in case of engine

irregularities.

11

Page 14

AIR FILTER

The air filter is placed under the load deck (Fig. 13). It must be substituted when the red warning

light on the dashboard (Fig. 3 n° 3) is switched on.

In case of duster areas it is advised the daily cleaning.

END OF SEASON MAINTENANCE

When the vehicle is to be out of use for a long period, the following procedure is recommended:

Clean the machine in general.

Place it in a position free from dust and damp.

Remove the battery and put it in a dry place without risk of freezing. Recharge it at least

once a month.

Place planks of wood under its wheels to keep it off the ground, cover the vehicle with a

protective sheet.

12

Page 15

GRILLO SERIE PK 1000

Gentile cliente,

nel ringraziarLa per la fiducia e la preferenza accordata al nostro PK 1000, confidiamo che l’uso di

questa sua nuova macchina risponda pienamente alle sue esigenze.

Per l’impiego ottimale e per la sua manutenzione nel tempo, la preghiamo di leggere

attentamente e eseguire scrupolosamente le indicazioni di questo libretto. Ciò le consentirà

di ottenere i massimi risultati e salvaguardare la sua spesa. La preghiamo di conservare questo

libretto, che dovrà sempre accompagnare la macchina.

ATTENZIONE! Prima di avviare il motore leggere attentamente.

Le seguenti avvertenze sono importanti per l’incolumità!

NORME ANTINFORTUNISTICHE

La prudenza è l’arma principale nella prevenzione degli incidenti!

La preghiamo vivamente di leggere con attenzione le seguenti avvertenze nell’uso della

macchina, prima ancora di iniziare il lavoro.

L’uso improprio della macchina e il suo equipaggiamento può risultare dannoso; per impedire che

ciò avvenga osservare le precauzioni necessarie di seguito riportate:

1) Leggere questo manuale interamente prima di accendere e mettere in movimento la

macchina.

2) Dare particolare attenzione alle ammonizioni e alle etichette di sicurezza.

3) Non caricare pesi superiori alla portata omologata – complessivo a pieno carico Kg 3500

4) Prima di fare lavorare altre persone bisogna metterle al corrente delle norme di sicurezza e di

come si usa la macchina.

5) Prima di accendere il motore verificare che non ci siano persone intorno; specialmente

bambini.

6) Prima di partire con la macchina in marcia indietro controllare che non ci siano persone od

ostacoli.

7) Non trasportare passeggeri sulla macchina oltre a quanto consentito a fianco del guidatore.

8) Non usare la macchina quando si è affaticati e non bere alcolici.

9) Fissare bene il carico negli appositi ganci.

10) Prima di iniziare il lavoro, indossare indumenti appropriati da lavoro, guanti, scarponi.

11) Prima di scendere dalla macchina, spegnere il motore, rimuovere la chiave di avviamento,

inserire il freno di stazionamento.

12) Sui viali sconnessi viaggiare a bassa velocità.

13) Non fare lavorare ragazzi troppo giovani: è vietato l’uso ai minori di 18 anni.

14) Non fare retromarcia col motore accelerato.

15) Caricare il cassone in maniera ordinata e uniforme.

16) Non caricare molto peso nella parte posteriore del cassone oppure su un lato: si perde molto in

stabilità e sicurezza nella guida.

17) Per evitare il pericolo di esalazioni velenose, non adoperare il motore acceso in un locale

chiuso.

18) Spegnere sempre il motore prima di fare rifornimento di combustibile, stare lontano da scintille

o fiamme, non fumare!

19) Evitare fuoriuscite di combustibile e dopo aver riempito il serbatoio pulire ogni fuoriuscita prima

di avviare il motore.

20) Non operare con la macchina vicino a fossati o banchine che si possono rompere sotto il peso

della macchina, specialmente quando la superficie è staccata o bagnata.

21) In discesa curvare sempre lentamente.

22) Non manomettere o disattivare i dispositivi di sicurezza.

23) Se avete dei bambini, quando non usate la macchina nascondete le chiavi di avviamento.

24) Non fare nessun tipo di regolazione o pulizia col motore in moto.

25) Non fare controllare la macchina da nessuno mentre siete seduti alla guida col motore

in moto.

13

Page 16

26) L’utilizzatore è sempre responsabile dei danni arrecati a terzi.

27) Ogni utilizzo improprio comporta il decadimento della garanzia ed il declino di ogni

responsabilità del costruttore.

28) Usare sempre ricambi originali Grillo.

DESCRIZIONE

La motoagricola GRILLO PK 1000 è un veicolo a 4 ruote motrici azionato da un motore Diesel a 4

tempi raffreddato a liquido.

L’esatta distribuzione dei pesi consente di ottenere la massima stabilità. La manutenzione della

macchina è ridotta a poche e semplici operazioni.

CARATTERISTICHE TECNICHE con ruote 10.0/75 - 12

MODELLO: transporter a ruote.

MOTORE: Lombardini FOCS 1404 Diesel 1372 c.c. 37 HP (27,2 kW) potenza massima, (potenza

omologata kW 22,5 a 3000 G/1’), raffreddato a liquido 4 cilindri.

AVVIAMENTO: Elettrico 12V.

FRIZIONE: monodisco a secco con comando a pedale.

CAMBIO: sincronizzato a 10 marce, 8 avanti + 2RM.

VELOCITÀ (con ruote 10.0/75-15,3): I Km/h 2,44 – II Km/h 4,25 – III Km/h 6,56 – IV Km/h 8,93

V Km/h 9,76 – VI Km/h 17,00 – VII Km/h 26,26 – VIII Km/h 35,71 – IRM Km/h 2,54 – IIRM Km/h

10,14

RUOTE:pneumatiche tractor 10.0/80-12 (6 PR); 10.0/75-15,3 (10 PR); garden 26x12.00/12 (8 PR).

DIFFERENZIALE: su entrambi gli assi con bloccaggio sull’asse posteriore.

ASSALE ANTERIORE: sterzante.

STERZO: idraulico.

SEDILI: molleggiati e registrabili.

TRAZIONE: a 4 ruote motrici con le anteriori disinnestabili.

FRENO DI SERVIZIO: idraulico agente sulle 4 ruote.

FRENO DI SOCCORSO E STAZIONAMENTO: meccanico agente sulle ruote posteriori.

CASSONE: ribaltabile trilaterale, idraulico, cm 220 x 134 x 40

ALTEZZA PIANALE CASSONE DA TERRA: cm 85

GRIGLIA PROTEZIONE CONDUCENTE: sulla sponda anteriore del cassone.

PORTATA: 1750 kg con ruote 10.0/75 – 15,3.

DIMENSIONI MACCHINA: lunghezza 4000 compreso di ganci, larghezza 1500, altezza 2320,

passo 1800, carreggiata 1220.

PESO: 1750 kg max con ruote 10.0 / 75 – 15,3 (10 PR).

ACCESSORI: cabina, presa di forza a 540 G/1’.

14

Page 17

IDENTIFICAZIONE DELLA MACCHINA

Il numero di matricola della macchina è stampigliato sulla targhetta posta sul longherone destro del

telaio rimorchio e sulla targhetta cambio.

Il numero di matricola deve essere sempre citato nell’eventuale richiesta delle parti di ricambio.

PARTI DI RICAMBIO

Si consiglia di usare esclusivamente ricambi originali GRILLO.

MESSA IN OPERA DELLA MACCHINA

1) Controllare l’integrità della macchina e accertare che non abbia subito danni durante il

trasporto.

2) Verificare i livelli olio motore, olio cambio e liquido radiatore.

3) Verificare la pressione dei pneumatici:

10,0 / 75 – 15,3 10PR (5,3 bar)

10,0 / 80 – 12 6PR (2,6 bar)

26 x 12.00 / 12 8PR (2,7 bar)

4) Controllare il voltaggio della batteria, non deve risultare inferiore al valore di 12 Volt,

eventualmente provvedere alla ricarica.

Se la batteria è stata fornita a secco con acido a parte, per la messa in opera procedere come

segue:

1) Inserire l’acido e attendere 2 ore;

2) Caricare la batteria con un carica batteria regolato a 12 Volt su carica lenta per 2 ore.

Attenzione, non rispettando questa regola si può avere il deterioramento della batteria e la

fuoriuscita dell’acido durante il lavoro.

IMPORTANTE!!! Durante il montaggio evitare di invertire le polarità della batteria. Non avviare

il motore se la batteria non è collegata.

BATTERIA – ATTENZIONE!

I gas sprigionati dalla batteria sono esplosivi, tenetela lontano da fiamme o scintille. Controllate

periodicamente il livello del liquido e mantenete i morsetti lubrificati con grasso di vaselina.

RODAGGIO

Durante il periodo di rodaggio (prime 70 ore di funzionamento) evitare di operare con il motore a

regimi elevati, limitando lo sfruttamento della potenza a circa il 70% di quella disponibile.

Dopo le prime 20 ore di funzionamento ed al termine del periodo di rodaggio:

Controllare il serraggio di tutti gli organi di fissaggio e di collegamento (viti, dadi, raccordi).

Controllare tutti i gruppi, motore, scatola cambio e le tubazioni, accertandosi che non si

presentino perdite d’olio.

Registrare il freno a mano.

Per quanto riguarda le prescrizioni di rodaggio del motore consultare il rispettivo libretto di

istruzioni.

15

Page 18

ISTRUZIONI D’USO

DESCRIZIONE DEI COMANDI (Fig. 1 - Fig. 2)

1) Pedale comando frizione (Fig. 2 n° 1): serve per disinnestare il motore dalla trasmissione.

Deve essere azionato ogniqualvolta si manovrino le varie leve do comando (leva cambio, leve

ridotte-veloci, leva comando presa di forza), prima di fermare la macchina e prima di avviare il

motore.

2) Pedale comando freni (Fig. 2 n° 2): aziona i freni delle ruote.

3) Acceleratore pedale (Fig. 2 n° 3).

4) Leva comando freno di stazionamento (Fig. 1 n° 4):

ruote posteriori. Il freno viene inserito tirando la leva verso l’alto. Per sbloccare la leva stessa, premere il

pulsante sulla sua estremità e portarla nella posizione più bassa.

5) Leva comando marce (Fig. 1 n° 5):

variatore di velocità, otto velocità in avanti e due in retromarcia.

6) Leva comando variatore di velocità - ridotta e veloce (Fig. 1 n° 6): spingendo la leva in avanti

si ottiene una marcia veloce; tirandola indietro si ottiene una marcia lenta.

7) Leva bloccaggio differenziale (Fig. 1 n° 7): si aziona tirando verso l’alto.

8) Leva disinnesto asse anteriore (Fig. 1 n° 8): girando la leva in avanti l’asse è libero; girandola

indietro è innestato.

Può capitare che l’inserimento o disinserimento dell’asse anteriore sia difficoltoso. Non forzare

mai la leva, ma muovere il veicolo di qualche centimetro avanti o indietro e riprovare.

9) Leva azionamento ribaltabile (Fig. 1 n° 9).

consente di ottenere, in combinazione con la leva comando

agisce contemporaneamente sui freni delle

DESCRIZIONE DEI COMANDI – Fig. 3

1) Spia generatore (rosso).

2) Spia insufficiente pressione olio motore (rosso).

3) Spia intasamento filtro aria.

4) Trazione inserita su tutte le 4 ruote.

5) Spia luci anabbaglianti (verde).

6) Spia preriscaldamento candelette.

7) Spia funzionamento indicatori di direzione (verde).

8) Spia luci di emergenza.

9) Commutatore a chiave per accensione, predisposizione servizi, avviamento e arresto

motore.

10) Deviatore indicatori di direzione e avvisatore acustico, commutatore luci.

11) Spia temperatura liquido di raffreddamento.

12) Contaore

13) Contagiri.

14) Spia livello carburante.

15) Riserva carburante.

16) Spia luci di posizione.

17) Spia freno di stazionamento.

18) Spia temperatura olio motore

19) Spia luci abbaglianti.

CONTROLLI DA ESEGUIRE PRIMA DELL’AVVIAMENTO:

Verificare che l’olio del cambio sia a livello, posto sul lato sinistro del carter cambio (fig. 4).

Controllare il livello olio nel motore (attenersi alle istruzioni del libretto motore).

Controllare che il pedale frizione faccia la prima parte della sua corsa senza azionarla. Per

la regolazione agire sul registro (fig. 5).

Controllare il livello olio freni (fig. 6). La vaschetta si trova sul lato destro del cruscotto.

Riempire il serbatoio di carburante, servendosi di un imbuto munito di filtro molto fine (fig. 7).

Accertarsi che tutte le leve siano in posizione folle, indi operare nel seguente modo:

1) Avviamento con motore freddo.

16

Page 19

2) Abbassare la leva frizione.

3) Inserire la chiave nel commutatore avviamento; ruotarla in senso orario per effettuare il

preriscaldamento quando la spia candeletta si spegne ruotare ulteriormente la chiave e

appena il motore si sarà avviato abbandonarla.

Per spegnere il motore ruotare la chiave in posizione centrale.

In caso di mancato avviamento, non insistere in tentativi inutili, che scaricherebbero la batteria, ma

attendere qualche minuto prima di ripetere l’operazione di avviamento.

Inoltre verificare frequentemente il livello del liquido nella batteria e se occorre aggiungere acqua

distillata.

ISTRUZIONI PER L’USO DEL RIBALTABILE

Operazioni per il ribaltamento del cassone:

Bloccare con i chiavistelli le due traverse del telaio del cassone che si trovano sul lato del

ribaltamento desiderato ed accertarsi che gli spinotti di cerniera siano inseriti correttamente

nell’alloggio.

Per la salita del cassone agire sulla leva (fig. 1 n° 9) tenendola azionata verso il “lato

salita”.

La salita si ottiene solo con la leva continuamente premuta. L’interruzione del ribaltamento

si ha immediatamente rilasciando la leva.

ATTENZIONE!

Il cassone ribaltabile non va mai bloccato in punti diagonalmente opposti; per impedire

l’errato posizionamento i chiavistelli sono di forma diversa.

Usare solo chiavistelli originali.

Prima di ogni ribaltamento laterale accertarsi che le sponde siano aperte.

Prima di iniziare le operazioni di ribaltamento assicurarsi che il veicolo sia posizionato su

terreno orizzontale, non cedevole e con il carico uniformemente distribuito.

AVVERTENZE PER L’IMPIEGO DEL RIBALTABILE

Il ribaltabile trilaterale è costruito e dotato di dispositivi per garantire la massima sicurezza anche

per un operatore inesperto, tuttavia è necessario osservare alcune norme fondamentali di seguito

elencate:

Prima di iniziare le operazioni di ribaltamento assicurarsi che il veicolo sia posizionato su

terreno orizzontale, non cedevole e con il carico uniformemente distribuito.

Prima di iniziare il ribaltamento accertarsi che non vi siano persone, animali o cose nelle

immediate vicinanze del veicolo.

Prima di iniziare le operazioni di ribaltamento assicurarsi che i chiavistelli siano alloggiati in

modo tale da permettere il ribaltamento nella direzione voluta.

È vietata la salita di persone ad attrezzatura ribaltabile sollevata o in corso di sollevamento

per operazioni di livellamento del carico.

A cassone carico, soprattutto con materiali sfusi, prestare la massima attenzione

nell’apertura delle sponde, la pressione dei materiali fa aprire la sponda in modo violento

ed il materiale cadendo può colpire l’operatore.

Assicurarsi che durante la marcia le sponde siano chiuse e bloccate regolarmente.

Prestare molta attenzione, nel caso di ribaltamenti all’interno di locali, all’eventuale

interferenza con travi, soffitti, impalcature, impianti o altro.

Non sollevare mai il cassone in presenza di linee aeree elettriche o similari.

17

Page 20

È vietato abbandonare il posto di manovra con l’attrezzatura ribaltabile alzata.

Per azionare il puntone di sicurezza, l’attrezzatura ribaltabile deve essere vuota.

Durante le operazioni di manutenzione collocare in modo sicuro il puntone atto a sostenere

il cassone (fig. 8). E’ vietato esporsi con alcuna parte del corpo sotto il cassone sollevato

senza che il predetto puntone sia stato accuratamente posizionato.

In caso di avaria del motore è possibile sollevare il cassone agendo sulla pompa manuale

posta sulla parte destra del telaio posteriore (Fig. 14 e Fig. 15).

ATTENZIONE!

1. E’ tassativamente vietato l’uso improprio dell’attrezzatura ribaltabile.

2. La pressione di esercizio dell’impianto idraulico è regolata dal costruttore in funzione della

portata del veicolo

E’ tassativamente vietato modificare la taratura della valvola limitatrice di pressione.

3. Non sostare per nessun motivo sotto il cassone ribaltabile sollevato e non puntellato.

4. E’ tassativamente vietato viaggiare con il cassone, anche minimamente sollevato.

OPERAZIONE DI CARICAMENTO MATERIALE

Caricare il veicolo in modo uniforme e tale da non presentare pericolo di caduta materiale

sul piano stradale.

Mai superare il carico consentito.

Il materiale va versato nel cassone dalla minima altezza possibile.

Controllare che le sponde siano chiuse, in particolar modo che la sponda posteriore sia

bloccata dagli arpioni.

Grossi blocchi di pietra, di detriti di materiale di demolizione vanno disposti cautamente sul

cassone e non lasciati cadere da grande altezza.

ATTENZIONE!

Evitare di sovraccaricare il mezzo

Prima della marcia accertarsi che il cassone sia completamente abbassato ed evitare di

viaggiare con il cassone sollevato.

ARRESTO DEL MOTORE

Dopo aver portato tutte le leve di comando nella posizione di FOLLE, per spegnere il motore

portare la chiave del commutatore nella posizione centrale.

MANUTENZIONE E LUBRIFICAZIONE

OLIO MOTORE

Durante il rodaggio si consiglia di effettuare il primo cambio dopo le prime 20 ore di lavoro, il

secondo dopo 80 ore e successivamente, ogni 120 ore di funzionamento. Utilizzare olio motore

AGIP F. 1D. GAMMA SAE 40 in estate, ed olio AGIP F. 1D. GAMMA SAE 20 in inverno. E’

indispensabile controllare il livello ogni 4 ore di lavoro. (Attenersi al libretto motore).

ATTENZIONE!

Se l’olio è superiore al livello massimo si ha un calo di rendimento del motore e un funzionamento

irregolare.

18

Page 21

OLIO CAMBIO – PONTE POSTERIORE - RIBALTABILE IDRAULICO – IDROGUIDA

Controllare il livello ogni 50 ore circa di lavoro dall’occhio visivo (Fig. 4) posta sul fianco destro del

carter cambio. Se occorre, aggiungere olio per cambio AGIP ROTRA JD. Sostituire l’olio una volta

all’anno. Per togliere l’olio vecchio dal carter cambio svitare il tappo posto al centro del carter

cambio sotto il differenziale (fig. 11). Quantità lt. 23. Il tappo di alimentazione si trova sotto al

cassone (Fig. 9).

Il filtro dell’olio idraulico si trova a lato destro del cambio (Fig. 10). Sostituirlo una volta all’anno.

Per velocizzare le operazioni di rabbocco e di sostituzione dell’olio togliere la vite posta sul

coperchio cambio (Fig. 9).

OLIO PONTE ANTERIORE

Controllare il livello tramite il tappo posto sulla parte anteriore del carter (Fig. 19); sostituire l’olio

ogni 500 ore usando olio per cambio AGIP ROTRA 85 W 90, quantità lt. 5.

LIQUIDO FRENI

Verificare ogni 8 ore il livello del liquido dei freni nella vaschetta posta sul lato destro del posto

guida (Fig. 6). Se occorre aggiungere liquido per freni. Controllare periodicamente l’impianto

frenante per verificare che non vi siano perdite.

Come eseguire lo spurgo qualora se ne verificasse la necessità: se si è in possesso dell’attrezzo

collegarsi al posto del tappo della vaschetta; spurgare prima il circuito posteriore del rimorchio, poi

lo spurgo anteriore.

Dovendo eseguire lo spurgo senza attrezzo agire sulla pompa della macchina, ma non sempre

l’operazione riesce.

REGISTRAZIONE FRENI

Togliere il tappo di plastica posto nella parte bassa della massa frenante (Fig. 16). Girare la ghiera

dentata dal basso verso l’alto.

Il freno di stazionamento si regola agendo sui registri posti sulle masse frenanti (Fig. 17).

IMPORTANTE!

Ingrassare periodicamente il giunto cardanico, di trasmissione, lo snodo oscillante della macchina

e le testine sterzo.

LIQUIDO RADIATORE

Controllare il livello ogni 8 ore a motore freddo, altrimenti il liquido caldo potrebbe causarvi ustioni.

Sostituirlo una volta all’anno.

Capacità 12 litri (Fig. 6).

ATTENZIONE!

In caso di perdite di liquido, una volta riparato il guasto riempire bene il circuito spurgando

ripetutamente l’aria dal tappo posto sul motore in corrispondenza del manicotto superiore (Fig. 18).

FILTRO GASOLIO

Il filtro gasolio (fig. 12) è dotato di elettrovalvola per lo spegnimento.

Lo spurgo dell’aria nelle condutture è automatico; tuttavia sopra al filtro è posizionata una vite di

spurgo.

Per la sostituzione del filtro attenersi al libretto motore. Consigliamo comunque di sostituirlo in caso

di irregolarità del motore.

19

Page 22

FILTRO ARIA

Il filtro aria si trova sotto al cassone (fig. 13) e va sostituito quando si illumina la spia rossa sul

cruscotto (fig. 3 n° 3).

E’ consigliata in caso di ambienti polverosi la pulizia giornaliera.

MANUTENZIONE DI FINE STAGIONE

Quando la macchina deve rimanere inattiva per un lungo periodo si consigliano le seguenti

operazioni:

Eseguire una pulizia generale della macchina.

Collocarla in un ambiente che non sia né polveroso, né umido.

Togliere la batteria, collocarla in un locale asciutto in cui non vi sia pericolo di gelo e

ricaricarla almeno una volta al mese.

Mettere delle assicelle di legno sotto le ruote per isolarla dal suolo, ricoprire la macchina

con un telo protettivo.

20

Page 23

GRILLO SERIE PK 1000

Cher Client,

Nous vous remercions de la confiance et de la préférence que vous avez bien voulu accorder à

notre Grillo PK1000 et nous sommes certains que son usage répondra entièrement à vos

exigences. Pour une utilisation optimale et pour sa maintenance à long terme, nous vous

demandons de lire attentivement et de suivre scrupuleusement les indications contenues dans

cette brochure. Ce qui vous permettra d’obtenir des excellents résultats et de sauvegarder votre

investissement.

Nous vous demandons de conserver ce manuel qui doit toujours accompagner le véhicule.

ATTENTION! Lire attentivement les instructions avant de mettre en

marche le moteur.

Les précautions suivantes sont importantes pour votre

sécurité!

NORMES POUR LA PREVENTION DES ACCIDENTS.

La prudence est la meilleure arme pour la prévention des accidents!

Nous vous demandons de lire attentivement les normes suivantes avant la mise en marche

du véhicule et pentant son utilisation.

L’utilisation inadéquate du véhicule et de son équipement peut être dangereuse. Afin de réduire

ces éventualités de danger, veuillez respecter les précautions nécessaires ci-après:

1) Lire entièrement ce manuel avant l’activation et la mise en mouvement du véhicule.

2) Suivre avec une attention particulière les mises en garde et les étiquettes de sécurité.

3) Ne pas charger de poids supérieurs à la portée maximale homologuée – total à pleine charge:

3500 kg.

4) Avant de confier votre véhicule à d’autres personnes, il faut leur illustrer aussi bien les normes

de sécurité que le mode d’emploi.

5) Avant de mettre en marche le moteur, vérifier qu’il n’y ait personne aux alentours et, en

particulier, qu’il n’y ait pas d’enfants.

6) Avant de faire marche arrière vérifier qu’il n’y ait personne et qu’il n’y ait aucun obstacle.

7) Ne pas admettre plus de passager que prévu à côté du conducteur.

8) Ne pas utiliser le véhicule si vous êtes fatigués et ne pas boire d’alcools.

9) Fixer parfaitement la charge avec les crochets spécialement prèvus à cet effet.

10) Avant de commencer le travail, mettre des vêtements de travail appropriés, des gants et

des bottes.

11) Avant de quitter le véhicule, désactiver le moteur, enlever la clé de démarrage et insérer le

frein de stationnement.

12) Adopter une faible vitesse sur les chemins en mauvais état.

13) Ne pas faire travailler des personnes trop jeunes: l’usage est interdit aux mineurs de 18 ans.

14) Ne pas faire marche arrière avec le moteur accéléré.

15) Charger la benne de manière ordonnée et uniforme.

16) Ne pas charger un poids excessif dans la partie arrière de la benne ou latéralement, afin

d’éviter la perte de stabilité et de sécurité dans la conduite.

17) Pour éviter le danger d’exhalations toxiques, ne pas faire tourner le moteur dans un endroit

fermé.

18) Eteindre toujours le moteur avant de faire le plein de combustible; rester loin des étincelles ou

des flammes et ne pas fumer!

19) Eviter les fuites de combustible; après avoir rempli le réservoir, nettoyer soigneusement les

fuites avant d’activer le moteur.

20) Ne pas utiliser la machine près des fossés ou de accôtements qui pourraient s’effondrer sous

le poids du véhicule, en particulier lorsque la surface est en mauvais état ou mouillée.

21) Aborder toujours lentement les tournants pendant les descentes.

22) Ne pas modifier ni désactiver les dispositifs de sécurité.

23) S’il y a des enfants, il faut cacher les clés de démarrage lorsqu’on n’utilise pas le véhicule.

21

Page 24

24) N’effectuer aucun réglage ou nettoyage avec le moteur en marche.

25) Ne pas faire contrôler le véhicule lorsque le conducteur est au volant avec le moteur en

marche.

26) L’utilisateur est toujours responsable des dégâts occasionnés aux tiers.

27) Toute utilisation impropre annulle la garantie et supprime la responsabilité du Constructeur.

28) Utiliser toujours des pièces de rechange d’origine Grillo.

DESCRIPTION

La machine GRILLO PK 1000 est un véhicule à 4 roues motrices, actionné par un moteur Diesel à

4 temps, avec refroidissement par liquide.

La distribution exacte des poids permet d’obtenir une stabilité maximale; l’entretien du véhicule se

limite à quelques simples opérations.

CHARACTERISTIQUES TECHNIQUES AVEC ROUES 10.0/75-12

MODELE: transporteur à roues.

MOTEUR: Lombardini FOCS 1404 Diesel 1372 c.c. 37 HP (27,2 kW) puissance max,

(puissance homologuée kW 22,5 a 3000 T/1’) refroidissement à eau 4 cylindres.

Kubota 1105 diesel 3 cylindres refroidissement à eau – 3.200 T/1’ - 28 HP (21 kW).

Lombardini 12LD477 diesel 2 cylindres refroidissement à air–3.200 T/1’– 20 HP (15 kW).

DEMARRAGE: électrique, 12V.

EMBRAYAGE: Monodisque à sec avec commande à pédale.

BOITE DE VITESSES: synchronisée à 10 marches, 8 avant + 2 AR.

VITESSE: I Km/h 2,7 – II Km/h 4,7 – III Km/h 7,2 – IV Km/h 9,9 – V Km/h 10,8 –

VI Km/h 18,9 – VII Km/h 28,9 – VIII Km/h 40 – IRM Km/h 2,8 – IIRM Km/h 11,2 avec roues

10.0/80-12.

ROUES: pneumatiques 10.0/80-12.

DIFFÉRENTIEL: sur les deux axes avec blocage sur l’axe AR.

AXE AV: directionelle.

BRAQUAGE: hydraulique.

SIÈGES: suspendus et enregistrables.

TRACTION: à 4 roues motrices avec les roues AV. déconnectables.

FREIN DE SERVICE: hydraulique, intervient sur les 4 roues.

FREIN DE SECOURS ET STATIONNEMENT: méchanique, intervient sur les roues AR.

BENNE: basculeur trilatéral, hydraulique, cm 220 x 134 x 40

HAUTEUR DU PLATEAU DE LA BENNE AU-DESSUS DU NIVEAU DU SOL: cm 85

GRILLE DE PROTECTION DU CONDUCTEUR: sur le bord AV. de la benne.

PORTÉE: 1750 kg max avec roues 10.0/75-15.3.

DIMENSIONS MACHINE: longeur 3750, largeur 1500, hauteur 2030, pas 1800, chaussée 1230.

POIDS: 1650 kg.

ACCESSOIRES: cabine, prise de force à 540 T/1’.

22

Page 25

IDENTIFICATION

Le numéro de série du véhicule est estampillé sur la plaque signalétique placée sur le longeron

gauche du chassis-remorque et sur la plaquette de la boîte de vitesses.

Le numéro de série doit toujours être cité dans les commandes des pièces detachées.

PIECES DETACHEES

Nous conseillons d’utiliser exclusivement des pièces détachées originelles GRILLO.

MISE EN SERVICE DE LA MACHINE

1) Contrôler que la machine soit en bon état et qu’elle n’ait pas été endommagée au cours du

transport.

2) Vérifier les niveaux de l’huile moteur, de l’huile boîte de vitesses et du liquide du radiateur.

3) Vérifier la pression des pneus:

10,0 / 75 – 15,3 10PR (5,3 bar)

10,0 / 80 – 12 6PR (2,6 bar)

26 x 12.00 / 12 8PR (2,7 bar)

4) Contrôler le voltage de la batterie qui ne doit pas etre inférieur à la valeur de 12 V; effectuer

éventuellement la recharge. Si la batterie à été livrée à sec avec de l’acide à part, adopter la

procédure suivante pour la mise en service:

1) Introduire l’acide et attendre 2 heures;

2) Charger la batterie avec un charge-batterie réglé à 12 V sous charge lente pendant 2

heures.

Attention! Si l’on ne respecte pas cette règle on peut détériorer la batterie et il pourrait se

vérifier une fuite d’acide pendant le travail.

IMPORTANT!!! Eviter d’inverser les polarités de la batterie pendant le montage. Ne pas

démarrer le moteur si la batterie n’est pas branchée.

BATTERIE – ATTENTION!

Les gaz qui se dégagent de la batterie sont explosifs; garder la batterie loin des flammes ou des

étincelles. Contrôler périodiquement le niveau du liquide et lubrifier les bornes avec de la graisse

de vaseline.

RODAGE

Durant la période de rodage (les 70 premières heures de fonctionnement) éviter de faire tourner le

moteur à plein régime et exploiter la puissance jusqu’à 70% de la puissance totale disponible.

Après les 20 premières heures de fonctionnement et à l’issue de la période de rodage:

- Contrôler le serrage de tous les organes de fixation et de raccordement (vis, écrous, raccords).

- Contrôler tous les groupes, moteur, boîte de vitesse et conduites, en s’assurant qu’il n’y ait pas

de fuites d’huile.

- Régler le frein à main.

En ce qui concerne les préscriptions à suivre pour le rodage du moteur, consulter le manuel

spécifique.

23

Page 26

MODE D’EMPLOI

DESCRIPTION DES COMMANDES (Fig. 1 - Fig. 2)

1) Pédale de commande embrayage (Fig. 2 n°1): elle sert à déconnecter le moteur de la

transmission. Elle doit etre actionnée toutes les fois que l’on manoeuvre les différents leviers

de commande (levier de changement de vitesse, levier des vitesses réduites-rapides, levier de

commande prise de force), avant d’arrêter la machine et avant de mettre en marche le moteur.

2) Pédale commande freins (Fig. 2 n°2): elle met en fonction les freins des roues

3) Accélérateur pédale (Fig. 2 n° 3)

4) Levier de commande du frein de stationnement (Fig. 1 n°4):

freins des roues arrière. L

levier, presser le bouton-poussoir placé à l’extrémité et conduire le levier vers la position la

plus basse.

5) Levier de commande des vitesses (Fig. 1 n°5):

levier de commande du variateur de vitesse, huit vitesses en avant et deux en marche arrière.

6) Levier de commande du variateur de vitesse (réduite et rapide) (Fig.1 n°6): si l’on pousse le

levier en avant on obtient une vitesse rapide; en le tirant vers l’arrière on obtient une vitesse réduite.

7) Levier de blocage du différentiel (Fig. 1 n°7): on l’actionne en le tirant vers le haut.

8) Levier de désembrayagede l’axe AV (Fig. 1 n°8): si l’on tourne le levier en avant, l’axe est

libre; si l’on tourne le levier en arrière, l’axe est embrayé. Il peut arriver que le levier oppose

résistance empêchant la connexion ou la déconnexion de l’axe. Dans ce cas, ne jamais forcer

le levier mais répéter l’opération après avoir déplacé le véhicule de quelque centimètre.

9) Levier d’actionnement du basculeur.

e frein est inséré lorsqu’on tire le levier vers le haut. Pour débloquer ce

il permet d’obtenir, en synchronisation avec le

il agit simultanément sur les

DESCRIPTION DES COMMANDES – Fig. 3

1) Voyant générateur (rouge).

2) Voyant pression de l’huile moteur insuffisante (rouge).

3) Indicateur de l’obstruction du filtre de l’air.

4) Traction activée sur les 4 roues.

5) Voyant feux de croisement (vert).

6) Voyant de préchauffage des bougies.

7) Voyant de fonctionnement des indicateurs de direction (vert).

8) Voyant des feux de detresse.

9) Commutateur à clé pour l’allumage, la prédisposition des services, le démarrage et

l’arrêt du moteur.

10) Commutateur des indicateurs de direction et avertisseur sonore, commutateur

lumières.

11) Voyant température liquide de refroidissement.

12) Compte-heures.

13) Compte-tours.

14) Voyant du niveau de carburant.

15) Reserve de carburant.

16) Voyant feux de position.

17) Voyant frein de stationnement.

18) Voyant température huile moteur.

19) Voyant feux de route.

CONTROLES A EFFECTUER AVANT LE DEMARRAGE:

Vérifier que l’huile de la boîte de vitesses atteigne le niveau indiqué sur le côté gauche du

carter de la boîte de vitesse (fig. 4).

Contrôler le niveau de l’huile dans le moteur (respecter les instructions du manuel du

moteur).

Contrôler que la pédale d’embrayage n’actionne pas l’embrayage pendant le premier trait

de sa course. Pour le réglage modifier le registre (fig. 5).

24

Page 27

Contrôler le niveau d’huile des freins (fig. 6). La cuvette se trouve à la droite du tableau de

bord.

Remplir le réservoir de carburant par le biais d’un entonnoir muni d’un filtre très fin (fig. 7).

S’assurer que tous les leviers soient au point mort, ensuite adpter la procédure suivante:

1) Démarrer avec le moteur froid;

2) Abaisser le levier d’embrayage;

3) Introduire la clé dans le commutateur de démarrage; tourner la clé en sens horaire pour

effectuer le préchauffage; lorsque le voyant de la bougie s’éteint tourner encore la clé et la

laisser dès que le moteur démarre.

Pour éteindre le moteur tourner la clé sur la position centrale.

Dans le cas où la machine ne démarre pas, il ne faut pas insister en faisant des tentatives inutiles

qui déchargeraient la batterie, mais attendre quelques minutes avant de répéter l’opération de

démarrage.

Vérifier fréquemment le niveau du liquide dans la batterie et ajoter de l’eau distillée si nécessaire.

MODE D’EMPLOI DU BASCULEUR

Opérations pour le basculement de la benne:

Par le biais des verrous, bloquer les deux traverses du châssis de la benne placées sur le

côté intéréssé par le basculement et s’assurer que les goujon des charnière soient

correctement insérés.

Pour faire monter la benne, régler le levier (fig. 1 n°9) sur le “côté montée”.

La benne continue de monter jusqu’à ce que l’on fait pression sur le levier. Pour

interrompre le basculemet, laisser le levier.

ATTENTION!

La benne ne doit jamais être bloquée à des points diagonalement opposés; afin

d’empêcher une position incorrecte de la benne, les verrous sont de différentes formes.

N’utiliser que des verrous originels.

Avant tout basculement latéral, s’assurer que les ridelles soient ouvertes.

Avant de commencer les opérations de basculement, s’assurer que le véhicule se trouve

sur un terrain horizontal, non pas mouvant, et avec la charge distribuée de manière

uniforme.

AVERTISSEMENTS POUR L’EMPLOI DU BASCULEUR

Le basculeur est équipé de dispositifs particuliers et conçu afin de garantir la meilleure sécurité

pour tous les utilisateurs jusqu’aux moins experts. Il est néanmoins nécessaire d’observer les

normes fondamentales suivantes:

Avant de commencer les opérations de basculement, s’assurer que le véhicule se trouve

sur un terrain horizontal, non pas mouvant, et avec la charge distribuée de manière

uniforme.

Avant de commencer les opérations de basculement, s’assurer que toute personne, animal

ou chose soient éloignés du véhicule.

Avant de commencer les opérations de basculement, s’assurer que les verrous soient

positionnés de façon à permettre le basculement dans la direction désirée.

Il est interdit aux opérateurs de monter sur la benne pour distribuer les matériaux, pendant

la phase de basculement ou lorsque la benne est soulevée.

25

Page 28

Quand la benne est pleine, sourtout lorsque les matériaux y sont chargés en vrac, il faut

porter une attention particulière pendant l’ouverture des ridelles, car la pression des

matériaux pousse violemment la ridelle et les matériaux qui tombent peuvent frapper

l’utilisateur.

S’assurer que pendant la marche les ridelles soient régulièrement fermées et bloquées.

Lorsque on effectue le basculement dans des locaux fermés, il faut porter une attention

particulière aux poutres, plafonds, échafaudages, installations etc.

Ne jamais soulever la benne tout près de lignes électriques aériennes ou similaires.

Il est interdit d’abandonner le poste de manoeuvre lorsque la benne est soulevée.

Pour pouvoir insérer l’étai de sécurité, la benne doit être vide.

Pendant les opérations d’entretien, bien assurer l’étai qui soutient la benne (fig. 8). Il est

interdit de s’exposer avec toute partie du corps sous la benne sans avoir préalablement

bien positionné l’étai.

Dans les cas de panne du moteur, il est toutefois possible de soulever la benne, en

actionnant la pompe manuelle placée sur le côté droit du châssis postérieur

(Fig. 14 et Fig. 15).

ATTENTION!

1. Toute utilisation inadéquate de l’équipement basculeur est absolument interdite.

2. La pression d’exploitation de l’installation hydraulique est réglée par le constructeur en

fonction de la portée du véhicule.

Il est absolument interdit de modifier le tarage de la soupape de retour.

3. Ne jamais demeurer, pour toute raison que ce soit, au dessous de la benne soulevée et

non fixée avec l’étai.

4. Il est absolument interdit de voyager avec la benne ne serait-ce que légèrement soulevée.

OPERATIONS DE CHARGEMENT MATERIAUX

Charger uniformément le véhicule et de façon à éviter tout danger de chute des matériaux

sur la route.

Ne jamais dépasser la charge maximale.

Les matériaux doivent être versés dans la benne à partir de la moindre hauteur possible.

Contrôler que les ridelles soient fermées et tout particulièrement que la ridelle arrière soit

bloquée avec les cliquets.

Les gros blocs de pierre et les matériaux de démolition doivent être déposés prudemment

dans la benne. Eviter de les laisser tomber d’une grande hauteur.

ATTENTION!

Eviter de charger eccessivement la machine.

Avant de la mise en marche, s’assurer que la benne soit bien abbaissée et éviter de

voyager avec la benne soulevée.

EXTINCTION MOTEUR

Après avoir conduit tous les leviers de commande sur la position POINT MORT, pour éteindre le

moteur tourner la clé du commutateur sur la position centrale.

26

Page 29

ENTRETIEN ET LUBRIFICATION

HUILE MOTEUR

Pendant le rodage, nous vous conseillons d’effectuer la première vidange après 20 heures de

travail, la deuxième après 80 heures et ensuite toutes les 120 heures d’exploitation. Utiliser de

l’huile moteur AGIP F. 1D. GAMME SAE 40 en été , et l’huile AGIP F. 1D. GAMME SAE 20 en

hiver. Il est indispensable de contrôler le niveau de l’huile toutes les 4 heures de travail (suivre les

indications du manuel du moteur).

ATTENTION!

Si l’huile dépasse le niveau maximum, on accuse une détérioration des performances du moteur et

un fonctionnement irrégulier.

HUILE DE LA BOITE DE VITESSES – PONT ARRIERE – BASCULEUR HYDRAULIQUE

– DIRECTION HYDRAULIQUE

Contrôler le niveau toutes les 50 heures de travail en regardant à travers l’oeil (Fig. 4) placé sur le

côté droit du carter de la boîte de vitesses. Si nécessaire, rajouter de l’huile pour boîte de vitesse

AGIP ROTRA JD. Vidanger l’huile une fois par an. Pour effectuer l’opération de vidange du carter,

dévisser le bouchon placé au milieu du carter de la boîte de vitesses sous le différentiel (fig. 11).

Quantité Lt. 23. Le bouchon d’alimentation se trouve sous la benne (Fig. 9).

Le filtre de l’huile hydraulique se trouve à la droite de la boîte de vitesses (Fig. 10). Le remplacer

une fois par an.

Si l’on désire que l’appoint et la vidange de l’huile soient plus rapides, dévisser la vis placée sur le

couvercle de la boîte de vitesses (Fig. 9).

HUILE PONT AVANT

Contôler le niveau par le bouchon placé sur la partie avant du carter (Fig. 19); vidanger l’huile

toutes les 500 heures et utiliser l’huile pour boîtes de vitesses AGIP ROTRA 85 W 90, quantité Lt.

5.

LIQUIDE DES FREINS

Toutes les 8 heures, vérifier le niveau du liquide des freins de la cuvette placée à la droite du poste

de condudite (Fig. 6). Si nécessaire, rajouter du liquide. Contrôler périodiquement le groupe de

freinage pour vérifier qu’il n’y ait pas de fuites.

Comment purger en cas de nécessité: si l’on dispose de l’outil approprié, se relier au poste du

bouchon de la cuvette; purger tout d’abord le circuit arrière de la remorque, et ensuite le circuit

avant.

Si l’on ne dispose pas de l’outil approprié, on peut essayer d’intervenir sur la pompe du véhicule,

mais cette opération ne réussit pas toujours.

REGLAGE FREINS

Enlever le bouchon de plastique placé dans la partie basse de la masse de freinage (Fig. 16).

Faire tourner l’anneau denté du bas vers le haut.

Pour régler le frein de stationnement, intervenir sur les mécanismes de réglement placés sur les

masses de freinage (Fig. 17).

IMPORTANT!

Graisser périodiquement les joints de cardan, les joints de transmission, le joint oscillant du

véhicule et les têtes de la barre de direction.

27

Page 30

LIQUIDE RADIATEUR

Contrôler le niveau toutes les 8 heures avec le moteur froid, le liquide chaud pourrait en effet

provoquer des brûlures à l’opérateur.

Effectuer la vidange une fois par an.

Capacité 12 litres (Fig. 6).

ATTENTION!

En cas de pertes de liquide, après la réparation, bien remplir le circuit, purgeant plusieurs fois l’air

par le bouchon placé sur le moteur en correspondance du manchon supérieur (Fig. 18).

FILTRE GASOIL

Le filtre gasoil (fig. 12) est équipé d’une soupape électrique pour l’extinction.

La purge de l’air dans les conduites est automatique; cependant, il y a une vis de purge au dessus

du filtre.

Pour le remplacement du filtre, suivre les instructions contenues dans la brochure du moteur. Le

remplacement de ce filtre est, néanmoins, conseillé en cas d’irrégularités du moteur.

FILTRE AIR

Le filtre de l’air se trouve au dessous de la benne (fig. 13) et il doit être remplacé quand le voyant

rouge du tableu de bord est allumé (fig. 3 n° 3).

Si le véhicule est utilisé dans des endroits poussiéreux, on conseille le nettoyage une fois par jour.

ENTRETIEN DE FIN DE SAISON

Lorsque l’on prévoit une longue période d’inactivité du véhicule, nous conseillons d’exécuter les

opération suivantes:

Effectuer un nettoyage général de la machine.

Placer la machine dans un endroit sec et non poussiéreux.

Démonter la batterie, la placer dans un local sec, sans qu’elle soit exposée au danger de

gel et la recharger au moins une fois par mois.

Placer des planches de bois sous les roues pour les isoler du sol, recouvrir le véhicule avec

une bâche.

28

Page 31

GRILLO SERIE PK 1000

Sehr geehrter Kunde,

wir danken Ihnen für Ihr Vertrauen und sind sicher, daß Sie mit Ihrem neuen “Grillo PK 1000” voll

und ganz zufrieden sein werden.

In diesem Handbuch finden Sie alles, was Sie für den Gebrauch und die Wartung Ihrer Maschinen

wissen müssen. Lesen Sie es daher aufmerksam durch, und halten Sie sich genau an die

Anleitungen, damit Sie auch wirklich immer optimale Resultate erzielen und lange Freude an Ihrer

Maschine haben werden. Bewahren Sie dieses Handbuch immer zusammen mit der Maschine

auf.

ACHTUNG! Vor dem Anlassen des Motors die folgenden

sicherheitstechnischen Hinweise genau durchlesen.

UNFALLVERHÜTUNGSMASSNAHMEN!

Vorsicht ist immer die beste Maß´nahme, um Unfälle zu vermeiden!

Lesen Sie die folgenden Hinweise genau durch, bevor Sie mit der Arbeit beginnen.

Ein unsachgemäßer Gebrauch der Maschine und Ihrer Ausrüstung kann Personen- oder

Sachschäden zur Folge haben. Um alle eventuellen Risiken zu vermeiden, sind die folgenden

Hinweise genaustens zu beachten:

1) Lesen Sie das gesamte Handbuch vor der ersten Benutzung der Maschine sorgfältig und

ganz durch.

2) Die auf der Maschine angebrachten Hinweise bzw. Plaketten beachten.

3) Niemals die zulässige Nutzlast überschreiten – das maximal zugelassene Gesamtgewicht in

vollbeladenem Zustand beträgt 3500 kg.

4) Soll die Maschine von einer anderen Person benutzt werden, ist diese vorher genaustens im

Gebrauch und über die Unfallsverhütungsmaßnahmen zu unterweisen.

5) Vergewissern Sie sich vor dem Einschalten der Maschine, daß sich keine anderen Personen

und vor allem keine Kinder in der Nähe befinden.

6) Vergewissern Sie sich vor dem Rückwärtsfahren, daß sich keine Personen oder Hindernisse

hinter der Maschine befinden.

7) Nicht mehr Passagiere mitnehmen, als auf dem Beifahrersitz erlaubt.

8) Das Gerät auf keinen Fall benutzen, wenn Sie unter Alkoholeinfluß stehen und/oder müde

sind.

9) Die Last immer gut mit den dafür vorgesehenen Haken befestigen.

10) Beim Aqrbeiten immer geeignete Arbeitskleidung, Handschuhe und Arbeitsschuhe

tragen.

11) Vor dem Absteigen von der Maschine immer den Motor abstellen, den Zündschlüssel abziehen

und die Feststellbremse anziehen.

12) Auf holprigen und unwegsamen Straßen/Wegen angemessen langsam fahren.

13) Das vorgeschriebene Mindestalter für die Benutzung der Maschine beträgt 18 (achtzehn)

Jahre.

14) Im Rückwärtsgang nur langsam fahren.

15) Die Ladefläche ordentlich und gleichmäßig beladen.

16) Die Ladefläche nicht einseitig oder nur hinten mit großen Gewichten belasten, da dadurch die

Stabilität der Maschine und die Sicherheit beim Lenken beeinträchtigt werden.

17) Den Motor nicht in geschlossenen Räumen laufen lassen (Vergiftungsgefahr – gefährliche

Abgase)

18) Beim Nachtanken den Motor immer abschalten, nicht rauchen und offene Flammen bzw.

Funken aus dem Gefahrenbereich entfernen.

19) Keinen Treibstoff verschütten, und beim Tanken ausgetretenen/verschütteten Treibstoff vor

dem Anlassen des Motors entfernen.

20) Nicht in der Nähe von Gräben oder Banketten arbeiten, die unter dem Gewicht der Maschine

nachgeben könnten, vor allem dann, wenn das Erdreich naß oder brüchig ist.

29

Page 32

21) Beim Bergabfahren immer vorsichtig und langlam lenken.

22) Die Sicherheitsvorrichtungen auf der Maschine niemals außer Funktion setzen bzw.

entfernen.

23) Wird die Maschine nicht benutzt, sind die Schlüssel immer an einem für Kinder unerreichbaren

Ort aufzubewahren.

24) Niemals bei laufendem Motor Reinigungsarbeiten bzw. Einstellungen durchführen.

25) Die Maschine niemals von einer anderen Person kontrollieren lassen, während Sie

selbst auf dieser sitzen und der Motor läuft.

26) Der Benutzer ist immer für anderen Personen zugefügte Schäden verantwortlich.

27) Jeder unsachgemäße Gebrauch hat den Verfall des Garantieanspruches und der Haftung des

Herstellers zur Folge.

28) Ausschließlich Original-Grillo-Ersatzteile verwenden.

BESCHREIBUNG

Der Transporter GRILLO PK 1000 ist ein Nutzfahrzeug mit vier Antriebsrädern und einem 4-TaktDieselmotor mit Flüssigkeitskühlung.

Dank der exakten verteilung der Gewichte ist das Fahrzeug besonders stabil. Die Wartung

beschränkt sich auf wenige, einfache Handgriffe.

TECHNISCHE DATEN mit Bereifung 10.0/75 - 12

MODELL: Transporter

MOTOR: Lombardini FOCS 1404 Diesel 1372 ccm. 37 HP (27,2 kW) Maximalleistung,

(homologierte Leistung kW 22,5 bei 3000 U/1’), 4 Zylinder mit Flüssigkeitskühlung

ANLASSER: Ellektrisch 12V

KUPPLUNG: Einscheiben-Trockenkupplung mit Pedalbedienung

GETRIEBE: Synchrongetriebe mit 10 Gängen, davon 8 Vorwärts- und 2 Rückwärtsgänge

GESCHWINDIGKEIT (mit Bereifung 10.0/75-15,3): I Km/h 2,44 – II Km/h 4,25 – III Km/h 6,56

– IV Km/h 8,93 V Km/h 9,76 – VI Km/h 17,00 – VII Km/h 26,26 – VIII Km/h 35,71 – I RG Km/h

2,54 – II RG Km/h 10,14

BEREIFUNG: pneumatische Traktorbereifung 10.0/80-12 (6 PR); 10.0/75-15,3 (10 PR);

Gartenbereifung 26x12.00/12 (8 PR)

DIFFERENZIAL: Auf beiden Achsen mit Sperrung auf Hinterachse

VORDERACHSE: gelenkt

LENKUNG: Hydraulisch

SITZE: Einstellbar und gefedert

ANTRIEB: Allradantrieb, abschaltbar für Vorderräder

BETRIEBSBREMSE: Hydraulisch, auf alle 4 Räder wirkend

FESTSTELL- UND NOTBREMSE: Mechanisch, auf die Hinterräder wirkend

PRITSCHE: Hydraulisch dreiseitig Kippbar; cm 220 x 134 x 40

PRITSCHENHÖHE VOM BODEN: 85 cm

FAHRER-SCHUTZGITTER: Auf dem Vorderrand der Pritsche

NUTZLAST: Max.1750 kg mit Bereifung10.0/75 – 15,3.

MASCHINEN-ABMESSUNGEN: Länge 4000 mm einschließlich Anhängerkupplung, Breite

1500mm, Höhe 2320mm, Radstand 1800mm, Spurweite mm.

GESAMTGEWICHT: Max 3500 kg con ruote 10.0 / 75 – 15,3 (10 PR).

ZUBEHÖR: Kabine, Zapfwelle mit 540 U/1’.

30

Page 33

IDENTIFIKATION DER MASCHINE

Auf dem rechten Längsträger des Anhängerrahmens und auf dem Getriebe befinden sich jeweils

eine Plakette mit der Seriennummer der Maschine, die für die Bestellung von Ersatzteilen und bei

allen die Maschine betreffenden Anfragen dem Hersteller anzugeben ist.

ERSATZTEILE

Benutzen Sie ausschließlich Original-GRILLO-Ersatzteile.

INBETRIEBNAHME DER MASCHINE

1) Unversehrtheit der Maschine überprüfen und nachsehen, ob Transportschäden bestehen.

2) Öl-Niveau des Motors und Gertriebes sowie Kühlflüssigkeit überprüfen.

3) Reifendruck prüfen:

10,0 / 75 – 15,3 10PR (5,3 bar)

10,0 / 80 – 12 6PR (2,6 bar)

26 x 12.00 / 12 8PR (2,7 bar)

4) Die Batteriespannung überprüfen; sie darf nicht unter 12 Volt liegen. Bei Bedarf die Batterie

ans Ladegerät hängen.

Wenn die Batterie trocken, mit bder Säure separat geliefert wurde, bitte wie folgt vorgehen:

1) Säure einfüllen und 2 Stunden warten;

2) Mit einem Batterieladegerät, welches auf 12 Volt eingestellt ist, 2 Stunden langsam laden.

Achtung, bei Nicht-Befolgung dieser Regel, kann die Batterie beschädigt werden, und die

Säure während der Arbeit austreten.

WICHTIG!!! Bei der Montage die Polung der Batterie nicht verwechseln. Den Motor nicht

starten, wenn die Batterie nicht angeschlossen ist.

BATTERIE – ACHTUNG!

Freigesetzte Batteriegase sind explosiv! Halten Sie sie von Feuer oder Funken fern. Kontrollieren

Sie regelmäßig den Flüssigkeitsstand und halten Sie die Anschlußklemmen mit Vaselin-Fett

eingefettet.

EINFAHREN

In der Einfahrzeit (die ersten 70 Arbeitstunden) Fahren mit hohen Drehzahlen vermeiden, indem

nur mit 70% der zur Verfügung stehenden Leistung gefahren wird.

Nach den ersten 20 Arbeitsstunden und nach der Einfahrzeit:

Überprüfung und Anzug aller Befestigungs- und Verbindungsstücke (Schrauben, Muttern,

Verbindungsteile)

Überprüfung aller Aggregate, Motor, Getriebegehäuse und Leitungsrohre, um sich zu

versichern, daß nirgends Öl austritt

Handbremse einstellen

Für die Einfahranforderungen des Motors betrifft, sehen Sie im entsprechenden MotorenHandbuch nach.

31

Page 34

GEBRAUCHSANWEISUNG

BESCHREIBUNG DER BEDIENUNGSELEMENTE (Fig. 1 - Fig. 2)

1) Kupplungspedal (Fig. 2 n° 1): dient zur Auskupplung des Motors von der Übersetzung. Sie

muss jedesmal vor dem Einsatz verschiedener Bedienungselemente getätigt werden

(Gangschaltung, Untersetzte Gänge, Zapfwelleneinschaltung); Betätigung auch vor dem

Anhalten der Maschine und vor dem Starten des Motors.

2) Bremspedal (Fig. 2 n° 2): Betätigt die Bremsen der Räder.

3) Gaspedal (Fig. 2 n° 3).

4) Feststellbremse (Fig. 1 n° 4):

betätigt, indem der Hebel nach oben gezogen wird. Um die Bremse wieder zu lösen, Knopf am Ende

des Hebels betätigen und Hebel nach unten führen.

5) Gangschaltung (Fig. 1 n° 5):

acht Geschwindigkeiten vorwärts und zwei Rückwärtsgänge.

6) Geschwindigkeitsreglungshebel - reduziert und schnell (Fig. 1 n° 6): den Hebel nach vorne

drückend erhält man die schnellen Gänge; den Hebel nach hinten ziehend erhält man die langsamen

Gänge.

7) Hebel für Differenzialsperrung (Fig. 1 n° 7): wird aktiviert, indem Hebel nach oben gezogen wird.

8) Abschalthebel für Vorderachsenantrieb (Fig. 1 n° 8): den Hebel zur Freisetzung der Achse

nach vorne drehend; zum Einschalten nach hinten drehen.

Es kann passieren, daß das Ein- oder Ausschalten der Vorderachse schwierig geht. Auf

keinen Fall mit Gewalt den Hebel betätigen, sondern das Fahrzeug einige Zentimeter nach

vorne oder hinten bewegen und nochmals versuchen.

9) Hebel zur Pritschenkippung (Fig. 1 n° 9).

Wirkt gleichzeitig auf die Bremsen der Hinterräder. Die Bremse wird

verfügt, in Kombination mit dem Hebel zur Geschwindigkeitsregelung,

BESCHREIBUNG DES ARMATURENBRETTS – Fig. 3

1) Lichtmaschinenkontroll-Leuchte (rot)

2) Öldruck-Kontroll-Leuchte (rot)

3) Luftfilterverstopfungs-Anzeige

4) Antrieb auf allen 4 Rädern (Allrad)

5) Abblendlichtanzeige (grün)

6) Vorglühleuchte des Dieselmotors

7) Blinkerfunktionsanzeige (grün)

8) Warnblinklicht-Anzeige

9) Zündschloß; Anlassen und Ausschalten des Motors

10) Schalter für Blinker, Licht und Hupe

11) Temperatur-Kontroll-Leuchte der Kühlflüssigkeit

12) Stundenzähler

13) Drehzahlmesser

14) Tankanzeige

15) Reservetank-Anzeige

16) Standlicht-Anzeige

17) Feststellbrems-Anzeige

18) MotorenölTemperaturanzeige

19) Fernlicht-Anzeige

VOR DEM STARTEN SIND FOLGENDE KONTROLLEN DURCHZUFÜHREN:

Überprüfung des Getriebeöl-Niveaus; befindet auf der linken Seite des Getriebegehäuses

(fig. 4)

Überprüfung des Motorenöl-Niveaus (an die Anweisungen des Motoren-Handbuchs halten)

Überprüfung des Kupplungspedals, so daß es den ersten Teil des Weges ohne Aktion

zurücklegt. Zur Regulierung die Einstellung verändern (fig. 5)

Überprüfung des Bremsöl-Niveaus (fig. 6). Der Behälter befindet sich auf der rechten Seite

des Armaturenbretts

32

Page 35

Den Treibstofftank mit Hilfe eines Trichters mit sehr feinem Sieb füllen (fig. 7).

Vergewissern Sie sich, daß sich alle Hebel im Leerlauf befinden und dann wie folgt vorgehen:

1) Starten bei kaltem Motor.

2) Das Kupplungspedal drücken.

3) Den Zündschlüssel ins Zündschloß stecken; Schlüssel zum Vorglühen im Uhrzeigersinn

drehen; wenn die Vorglühleuchte erlischt, den Schlüssel weiter drehen bis der Motor startet

und dann sofort loslassen.

Zum Ausschalten des Motors den Schlüssel in zentrale Position zurückdrehen.

Wenn der Motor nicht startet nicht unnötig weiterversuchen, da sich dabei nur die Batterie entleert,

sondern einige Minuten warten und dann nochmals den Start versuchen.

Außerdem in regelmäßigen Abständen das Niveau der Batterieflüssigkeit kontrollieren und

gegebenenfalls destilliertes Wasser nachfüllen.

ANWEISUNGEN ZUR BENUTZUNG DES KIPPERS

Vorgehensweise für das Kippen der Pritsche:

Mit den Riegeln die zwei Traversen des Pritschenrahmens, welche sich auf der

gewünschten Kippseite befinden, blockieren und sich versichern, daß die Bolzen des

Scharniers richtig in die Buchsen positioniert wurden.

Für das Anheben der Pritsche den Hebel (fig. 1 n° 9) betätigen und ihn in “Richtung

Anstieg” in Aktion halten.

Die Pritsche steigt nur bei ständiger Betätigung des Hebels. Durch loslassen des Hebels

stoppt der Kippvorgang sofort.

ACHTUNG!

Die Pritsche niemals an zwei diagonal gegenüberliegenden Punkten blockieren; um eine

Fehlpositionierung zu verhindern sind die Riegel verschiedenartig geformt

Nur Original-Riegel verwenden

Vor jedem seitlichen Kippvorgang überprüfen, ob die Seitenwände geöffnet sind

Vor dem Kippvorgang sich vergewissern, daß das Fahrzeug auf ebenem, nicht

nachgiebigem Untergrund steht und die Ladung gleichmäßig verteilt ist.

GEBRAUCHSANWEISUNG FÜR DEN EINSATZ DER KIPP-PRITSCHE

Die dreiseitig kippbare Pritsche ist mit Vorrichtungen konstruiert und ausgerüstet, welche die

maximale Sicherheit auch für nicht Experten bietet; trotzdem ist es Notwendig einige fundamentale

Richtlinien zu befolgen, welche folgend aufgezeigt werden:

Vor dem Kippvorgang sich vergewissern, daß das Fahrzeug auf ebenem, nicht

nachgiebigem Untergrund steht und die Ladung gleichmäßig verteilt ist.

Vor dem Kippvorgang sich vergewissern, daß sich keine Personen, Tiere oder

Gegenstände in unmittelbarer Nähe des Fahrzeugs befinden.

Vor dem Kippvorgang sich vergewissern, daß die Riegel richtig positioniert sind um in die

gewünschte Richtung zu kippen.

Bei beladener Pritsche, vorallem bei losen Materialien, dem Öffnen der Seitenwände die

höchste Aufmerksamkeit widmen, da der Druck der Materialien die Seitenwände

gewaltsam öffnen kann und herabfallende Materialien den Bediener treffen und verletzen

können.

Sich versichern, daß während des Betriebs die Seitenwände geschlossen und

ordnungsgemäß verriegelt sind.

33

Page 36

Besondere Obacht wird gefordert beim Kippen der Pritsche im Inneren von Räumlichkeiten,

wegen Interferenz von Trägern, Decken, Baugerüsten, Anlagen oder anderem.

Niemals die Pritsche anheben, wenn sich elektrische Leitungen oder ähnliches in der Nähe

befinden.

Während der Wartungsarbeiten den roten Sicherheitshebel (Fig. 8) auf sichere Weise

anbringen, daß die Pritsche nicht herunterkommen kann. Es ist Verboten irgendein

Körperteil unter die angehobene Pritsche zu stecken, ohne daß der obengenannte

Sicherheitshebel sorgfältig positioniert wurde.

Im Falle eines Ausfalls des Motors kann man die Pritsche auch mittels Betätigung der

Handpumpe auf der rechten Seite des hinteren Ramens anheben (Fig. 14 e Fig. 15).

ACHTUNG!

1. Es ist absolut Verboten die Kippausrüstung unsachgemäß zu verwenden.

2. Der Arbeitsdruck der hydraulischen Anlage wurde vom Hersteller unter Berücksichtigung

der Nutzlast des Fahrzeugs eingestellt. Es ist absolut Verboten irgendwelche Einstellungen

an dieser Kallibrierung des Drucksicherheitventils zu verändern.

3. Unter keinen Umständen unter der angehobenen Pritsche ohne Sicherung verweilen.

4. Es ist absolut Verboten sich mit auch nur im geringsten angehobener Pritsche mit dem

Fahrzeug fortzubewegen.

BELADUNG VON MATERIALIEN

Das Fahrzeug gleichmäßig beladen, daß keine Gefahr durch herunterfallendes Material auf

die Fahrbahn entsteht.

Nie zulässiges Gesamtgewicht überschreiten.

Das Material aus geringst möglicher Höhe in die Pritsche einladen.

Kontrolle der Seitenwände, daß sie geschlossen, und vorallem daß die Heckwände mit den

Sperrklinken blockiert wurden.

Große Steinblöcke und Bauschutt müssen vorsichtig auf die Pritsche geladen und nicht aus

großer Höhe fallen gelassen werden.

ACHTUNG!

Überladung des Fahrzeugs vermeiden

Vor dem in Gang setzen sich vergewissern, daß die Pritsche komplett abgesenkt wurde

und vermeiden Sie sich mit angehobener Pritsche fortzubewegen.

AUSSCHALTEN DES MOTORS