Great Planes GPMA0214 User Manual

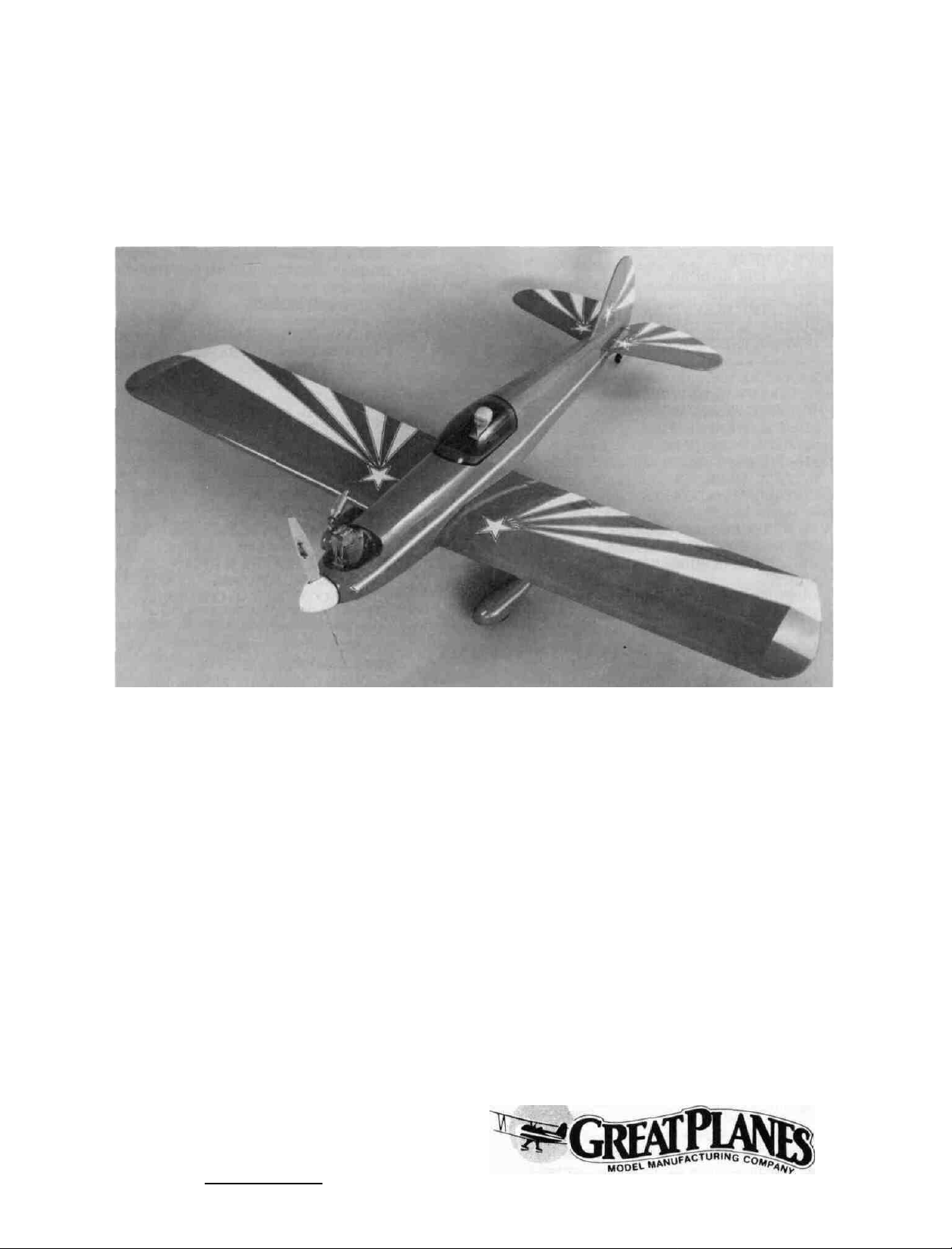

Super Sportster

90/120

Instruction Book

READ THROUGH THIS INSTRUCTION

BOOK FIRST. IT CONTAINS IMPORTANT IN.

STRUCTIONS AND WARNINGS CONCERNING THE BUILDING AND USE OF THIS

MODEL.

INSTRUCTIONS IN BOXES LIKE THIS

ARE VERY IMPORTANT AND SHOULD BE

FOLLOWED CAREFULLY.

WARNING!

This R/C kit and the model you will build is not a toy'. It is capable of serious

bodily harm and property damage. IT IS YOUR RESPONSIBILITY AND YOURS

ALONE — to build this kit correctly, properly install all R/C components and flying

gear (engine, tank, pushrods, etc.) and to test the model and fly it only with experienced, competent help in accordance with all safety standards and common

sense as set down in the Academy of Model Aeronautics Safety Code. It is suggested that you join the AMA and become properly insured before you attempt to

fly this model. IF YOU ARE JUST STARTING R/C MODELING, CONSULT YOUR

LOCAL HOBBY SHOP OR WRITE TO THE ACADEMY OF MODEL AERONAUTICS

TO FIND AN EXPERIENCED INSTRUCTOR IN YOUR AREA.

Academy of Model Aeronautics

1810 Samuel Morse Dr.

Reston, VA 22090

(703) 435-0750

PO BOX 721 URBANA ILLINOIS 61801

TABLE OF CONTENTS

INTRODUCTION ..................... 2

PRECAUTIONS ...................... 3

ENGINE AND MOUNT SELECTION .... 3

LANDING GEAR CONFIGURATION .... 3

CHOOSING YOUR RADIO AND SERVOS . 3

OTHER ITEMS REQUIRED ............ 4

SUPPLIES AND TOOLS NEEDED ...... 4

HARDWARE ......................... 5

TYPES OF WOOD .................... 5

GET READY TO BUILD ............... 6

TAIL

FEATHERS

BUILD THE RUDDER ................. 6

BUILD THE FIN ..................... 8

BUILD THE ELEVATORS ............. 8

BUILD THE STABILIZER .............. 8

INSTALL THE HINGES ............... 8

WING

...................................

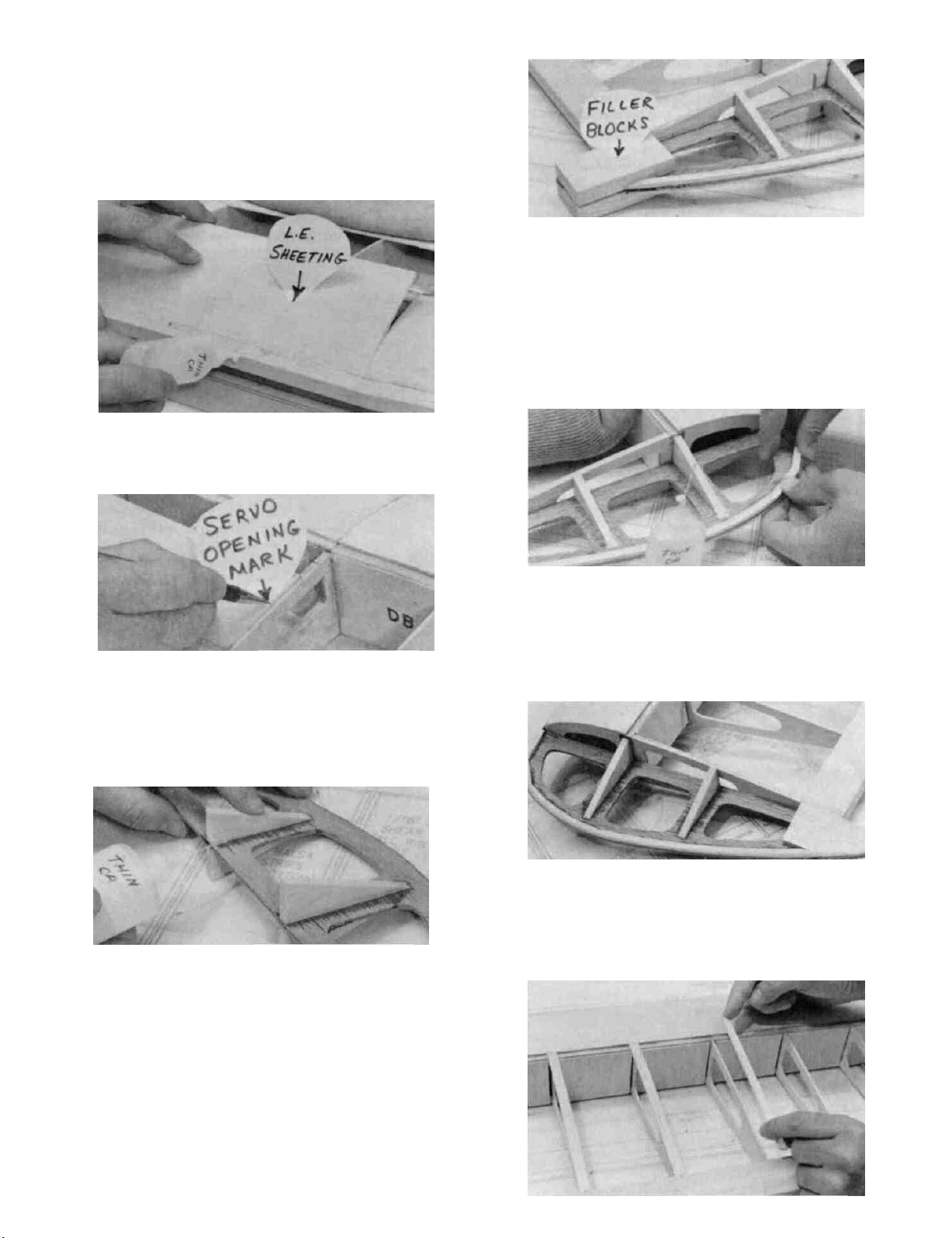

BUILD THE WING PANELS ........... 9

JOIN THE WING PANELS ............ 12

COMPLETING THE WING ............ 13

AILERON TORQUE RODS ............ 14

FIBERGLASS THE CENTER SECTION . 15

INSTALL AILERONS ................ 15

INSTALL WING DOWELS ............ 16

LOWER FUSELAGE ASSEMBLY ......... 16

INSTALL NOSEGEAR BEARING

INSTALL REAR PUSHROD GUIDE

TUBES ............................. 20

INSTALL CHIN BLOCK AND BOTTOM

SHEETING ......................... 21

MOUNT THE WING TO THE FUSE .... 21

MOUNT THE ENGINE ............... 22

INSTALL NOSE GEAR ............... 23

INSTALL FRONT PUSHROD GUIDE

TUBES ............................ 24

INSTALL FUEL TANK ............... 24

UPPER

FUSELAGE STRUCTURE

FORMERS, STRINGERS AND HOOD ... 24

INSTALL COCKPIT FLOOR ........... 25

INSTALL HOOD SHEETING .......... 26

INSTALL REAR STRINGERS ......... 26

...................

......

........

6

9

18

24

COMPLETING THE FUSE AND WING .... 26

CONSTRUCT THE NOSE ............. 26

SAND THE FUSELAGE .............. 28

INSTALL WING FAIRINGS ........... 29

MOUNT THE STABILIZER AND FIN . . 30

LOCK STABILIZER TO FUSELAGE .... 31

FINISH MOUNTING THE STAB

AND FIN .......................... 32

SERVOS, HORNS AND

MOUNT AILERON SERVO AND

PUSHRODS ......................... 33

INSTALL SERVOS ................... 33

INSTALL ELEVATOR AND RUDDER

HORNS ............................ 33

INSTALL PUSHRODS ................ 34

CANOPY AND WHEEL

PREPARE THE CANOPY ............. 34

WHEEL PANTS ..................... 34

FINISHING

PRE.FLIGHT ........................... 39

PARTS

PREVENTING CONTROL SURFACE

.............................

ADDITIONAL FUELPROOFING ....... 36

BALANCE THE AIRPLANE

LATERALLY ........................ 36

FINAL SANDING .................... 36

COVERING ......................... 36

GLUE THE HINGES ................. 37

INSTALL PILOT ..................... 37

GLUE CANOPY IN PLACE ........... 37

WING SEATING TAPE ............... 38

RE-INSTALL ENGINE & RADIO ...... 38

BALANCE YOUR MODEL ............ 38

FINAL HOOKUPS AND CHECKS ..... 38

CHARGE THE BATTERIES ........... 39

FIND A SAFE PLACE TO FLY ........ 39

GROUND CHECK THE MODEL ....... 39

RANGE CHECK YOUR RADIO ........ 39

ENGINE SAFETY PRECAUTIONS ..... 39

AMA SAFETY CODE ................ 39

FLYING ............................ 40

LIST

............................

FLUTTER

.........................

PUSHRODS

PANTS

...........

......

32

34

36

41

43

INTRODUCTION

Pssst! Please don't tell your Super Sportster

90/120 how big it really is, because it thinks it is a

"40-size"! What we mean is that this fantastic

airplane flies with all the smoothness and agility of

our other Super Sportsters (20, 40 and 60), and we

can hardly tell the difference, except for the awe-

some size and power! We think you'll agree that

this is the most exciting Super Sportster yet!

Yes, the Super Sportster 90/120 is a scaled-up

version of our Super Sportster 60, but we have incorporated many major structural improvements to add

strength (without extra weight) and to make it much

easier to build straight and true.

In this book we'll take you, one easy step at a

time, through the construction sequence, plus we'll

give you specific pointers on installing your radio,

engine and accessories, and end up with tips on

finishing, balancing and flying your Super Sportster

90/120.

Before starting to build, we encourage you

to read through these introductory pages very

thoroughly, as they contain a lot of vital information

you need to know, such as decisions you must make

now, engine and radio selection, safety precautions

and additional items you will have to purchase.

This is not a beginner's airplane! While the

Super Sportster 90/120 is easy to build and flies

great, we must discourage you from selecting this

kit as your first R/C airplane. It is fast, highly maneuverable, and lacks the self-recovery characteristics

of a good basic trainer such as the Great Planes

PT Series airplanes. On the other hand, if you have

2

already learned the basics of R/C flying and you are

able to safely handle an "aileron trainer" airplane

such as the Great Planes Trainer Series or Big Stik

Series airplanes, the Super Sportster 90/120 is an

excellent choice

We think you will agree that the Great Planes

Super Sportster 90/120 is the highest quality, best

building and best flying airplane of its type on the

market today!

*********!]<S|!*#*****;i!il!***S|!*S|S***!tl*#****S|S!|!!|!**!|!*

DECISIONS YOU MUST MAKE

NOW

ENGINE AND MOUNT SELECTION:

The recommended engine size range is as fol-

lows:

If you have any questions or problems about

building or flying this airplane, or if any of the kit

parts are badly warped, defective or missing, please

call us at (217) 367-2069 between 8 00 AM and 4 00

PM (central time) and we'll be glad to help If your

call concerns defective or missing parts, please be

ready to give us the 8-digit code (on the box end flap)

and the part numbers

PRECAUTIONS

1 You must build the plane according to the

plans and instructions Do not alter or modify the

model as represented by the plans, as doing so may

result in an unsafe or unflyable model In a few cases

the plans and instructions may differ slightly from

the photos In those instances you should assume the

plans and written instructions are correct

2. You must take time to build straight, true

and strong

3. You must use a proper R/C radio that is in

first class condition, the correct sized engine and

correct components (fuel tank, wheels, etc.)

throughout your building process

4 You must properly install all R/C and other

components so that the model operates properly on

the ground and in the air.

5 You must test the operation of the model

before the first and each successive flight to insure

that all equipment is operating and you must make

certain that the model has remained structurally

sound Be sure to check the nylon clevises often, and

replace if they show signs of wear.

6. You must fly the model only with the com-

petent help of a well experienced R/C pilot if you

are not already an experienced and knowledgeable

R/C pilot at this time.

Note. We, as the kit manufacturer, can provide

you with a top quality kit and great instructions,

but ultimately the quality and flyability of your

finished model depends on how you build it, therefore, we cannot in any way guarantee the performance of your completed model, and no representations

are expressed or implied as to the performance or

safety of your completed model

.61 - .91 cubic inch displacement 2-cycle

.90 - 1.20 cubic inch displacement 4-cycle

Do not power your airplane with an engine

larger than the recommended size ( 91 2-Cycle, 1 20

4-Cycle) Also, if using a 91 2-Cycle, do not use a

tuned pipe

When you start building the fuselage, one of

the first steps will be to cut off a portion of the front

of the fuselage sides and fuselage doublers if you will

be using a 4-cycle engine, due to the increased length

and weight of the 4-cycle engines Therefore, it is

important that you have your engine close at hand

while building.

This kit includes hardwood engine mounting

rails, but you may wish to purchase a custom engine

mount for your engine, and the instructions allow

for that type of installation.

LANDING GEAR CONFIGURATION

The Super Sportster 90/120 may be built with

a "taildragger" or "tricycle" landing gear configuration Some people prefer the tricycle gear setup because they believe it handles better on the ground

Others prefer to build it as a taildragger for the

classic appearance This airplane actually handles

very well in either configuration, so the choice is up

to you Please make this decision now, as it will

affect several things you will do during the construction.

CHOOSING YOUR RADIO AND SERVOS

Most good quality radio systems on the market

today are suitable for this airplane You may, however, have to purchase a 5th servo or a high-torque

servo (see the note below).

IMPORTANT NOTE We have found standard servos which provide approximately 45 oz/in of torque

to be satisfactory for use in the Sportster 90/120 with

the following exception If you are using standard servos you should use one servo for each

elevator (use a "Y"- Connector to plug both elevator

servos into the elevator channel of your receiver) If

you want to use only one servo for the elevators, you

must use two pushrods and a high torque servo providing at least 60 oz/in of torque.

Remember: Take your time and follow directions to end up with a well-built model that

is straight and true

Please make sure you select a radio system

that is on a frequency designated "for aircraft use

only", and one that meets current FCC standards.

OTHER ITEMS REQUIRED

Propellers (see engine instructions for size)

3" diameter Spinner

Fuel Tank (14 - 16 oz. or larger)

(Larger tanks require custom fitting)

2 - 3" diameter Main Wheels

1 - 2-3/4" diameter Nose Wheel

(or)

1 - 1-1/4" diameter Tail Wheel

4 - 3/16" Wheel Collars for Main Wheels

2 - 5/32" Wheel Collars for Nose Wheel

(or)

2 - 3/32" Wheel Collars for Tail Wheel

Iron-on Covering Material

Silicone Fuel Tubing

Foam Wing Seating Tape

Foam Rubber Padding, 1/2" thick

Dummy Pilot Figure (2-1/2" - 3" tall)

2 - DuBro E-Z Connectors (or similar)

"Y"-Connector (for double elevator servos)

SUPPLIES AND TOOLS NEEDED

2-3 oz. - Thin CA Adhesive Pliers

2 oz. - Medium or Thick CA Adhesive Screw Driver

2.5 oz.- 5 Minute Epoxy T-Pins

2.5 oz.- 30 Minute Epoxy Straightedge

Hand or Electric Drill Masking Tape

Drill Bits (No. 53. 1/16", 5/64", 3/32" 7/64", Sandpaper, (Coarse, medium and fine grit)

1/8", 5/32", 3/16", 11/64", 13/64", 1/4", 5/16" T-Bar sanding block, or similar

Sealing Iron Waxed Paper

Heat Gun Balsa Filler

Hinge Slotting Tool 1/4-20 Tap

Hobby Saw (X-Acto Razor Saw) Tap Wrench

X-Acto Knife, #11 Blades Dremel Moto Tool or similar (Optional)

******************************************************

COMMON ABBREVIATIONS USED IN THIS

BOOK AND ON THE PLANS:

Stab = Stabilizer

Rt = Right

Elev = Elevator

LE = Leading Edge (front)

TE = Trailing Edge (rear)

Lt = Left

" = Inches

Fuse = Fuselage

LG = Landing Gear

Ply = Plywood

4

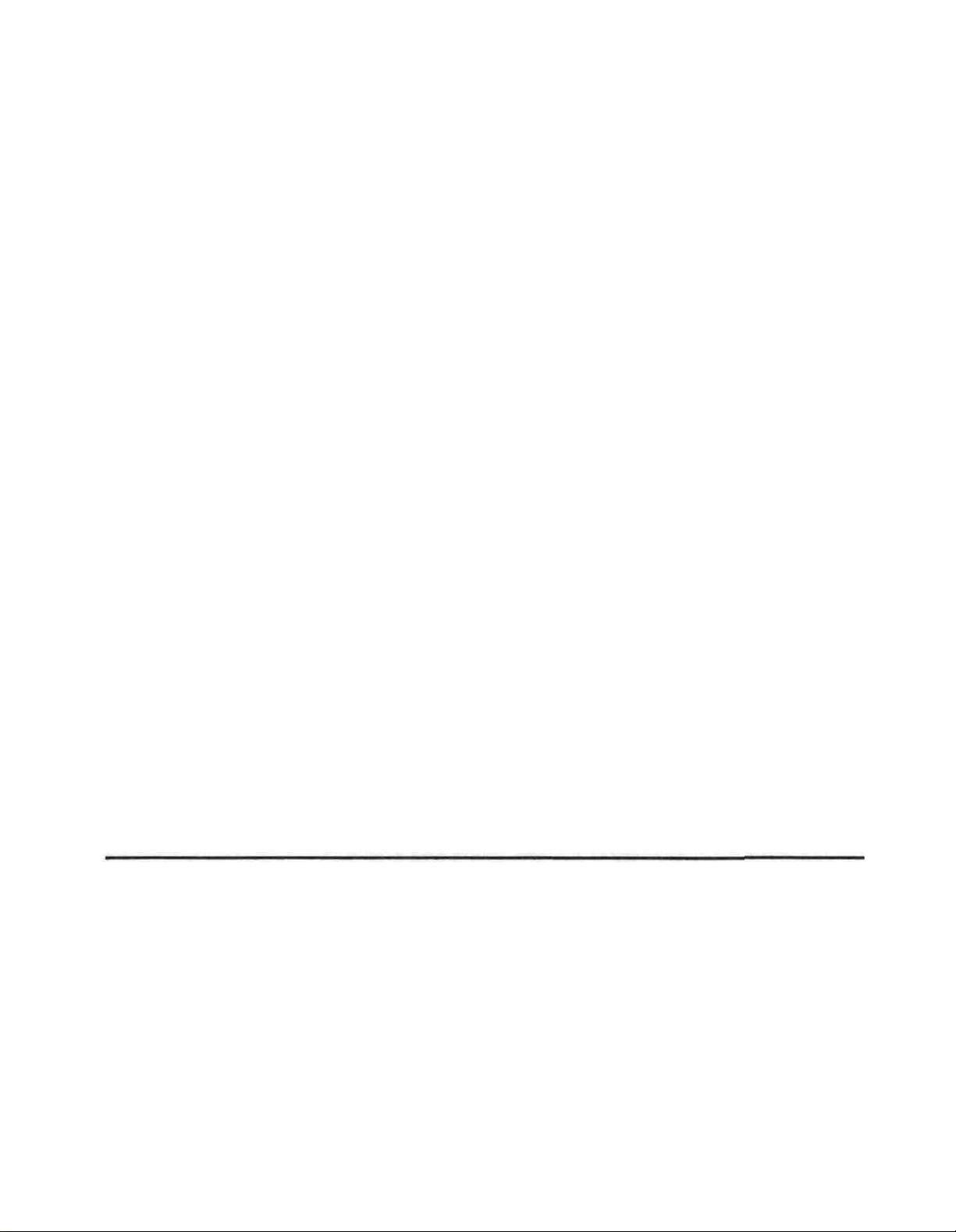

HARDWARE

#2x3/8"

#4x1/2"

2-56 x 5/8" SCREW

SCREW

SCREW

#6 x I SCREW

4-40x1" BOLT

LANDING GEAR CLIP

(NYLON)

NYLON HORN AND NUT PLATE

1/4-20

NYLON

•TO

BOLT

HOLES

BE

DRILLED

NYLON CLEVIS

METAL CLEVIS

RETAINER CUP

5/32" COLLAR

6-32 x 1/4 " SCREW

10-32 SOCKET HEAD

CAP SCREW

BRASS AILERON HORN

2-56

HEX

NUT

TYPES OF WOOD

NYLON L.G. STRAP

BALSA HARDWOOD PLYWOOD

5

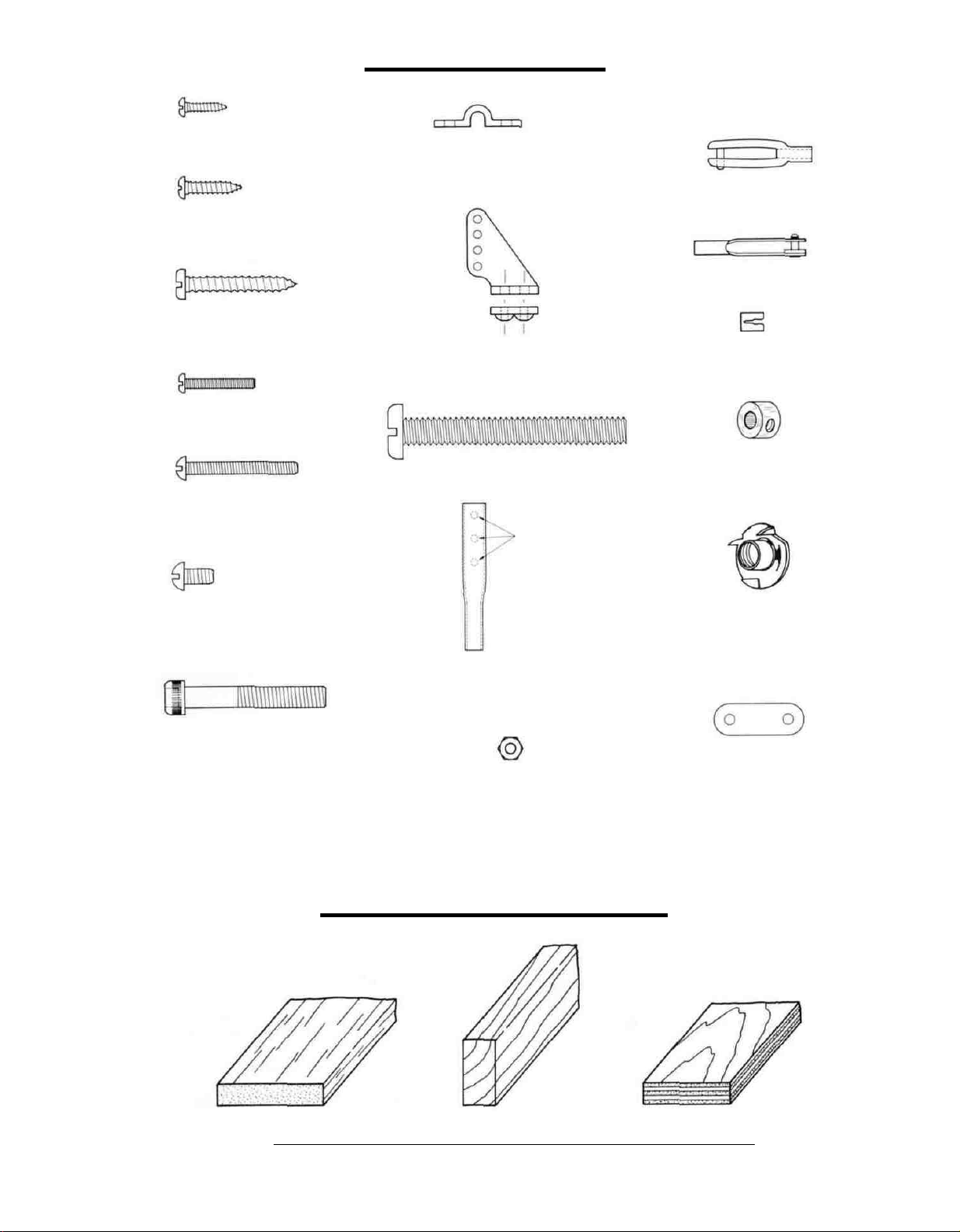

GET READY TO BUILD

D 1. Unroll the plan sheets. Re-roll them inside

out to make them lie flat.

SS90W07 PLY 1/8x4x13-7/8 2 PER KIT

D 2 Remove all parts from the box Figure out

the name of each part by comparing it with

the plans Using a felt tip pen, write the part

name on each piece to avoid confusion later.

Use the die cut patterns shown below to iden-

tify the die cut parts and mark before punch-

ing them out. Save all scraps.

SS90F33 PLY 1/8x4 3/16x12-1/4 2 PER KIT

•UDDER FILLER mil REWIMG H.m\

SS90F37 PLY 1/8x4-7/8x14 PER KIT

A

B

-n

FORMER

Lrf

1

/-

ALIGNMENT

^ BASE

1

SS90F39 PLY l/8x4»10-7/8 I PER KIT

FORMER

/F-5

w

-n

N3

^D

FORMER

FORMER

F2

/

FORMER

F

4

+>

SS90W33

BALSA 3/32x4x18

TAIL FEATHERS

NOTE The Rudder, Fin, Elevators and Stabilizer

are all built in a very similar manner The following

section explains in detail how to build the Rudder

to make you familiar with the procedure, then you

can use the same techniques for building the other

"tail feathers" with very little instruction, except for

a few important comments Here we go!

8

PER

KIT

D B DIHEDRAL BRACE

SS90W34

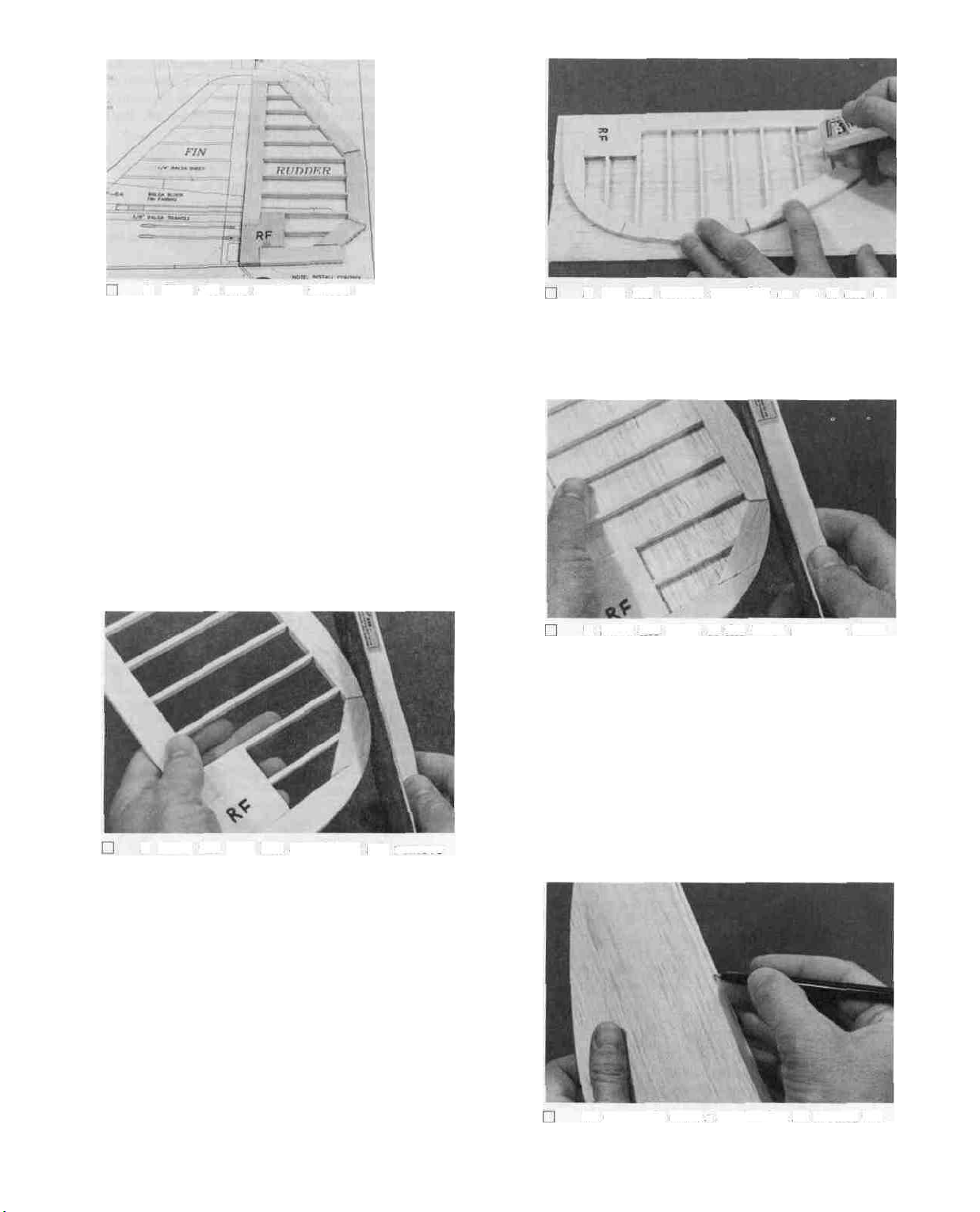

BUILD THE RUDDER

To build the rudder you'll need the following:

LANDING GEAR DOUBLERS

3

PER

BALSA 3/32x4x18

KIT

1/4" x 3/4" x 36" balsa sticks (set aside the

straightest hard stick for the stabilizer TE)

1/8" x 1/4" x 36" balsa sticks (set aside the two

softest sticks to be used later on the wing tips)

1/16" x 3" x 36" balsa sheets

Two 1/8" die-cut ply rudder filler (RF) pieces

D 1. Tape the fuselage plan down to your flat

work surface Tape a piece of waxed paper over

the fin and rudder portion of the plan.

2. Glue the two rudder fillers (RF) together

using thick CA glue, making one piece 1/4"

thick.

3. Using a razor saw, cut pieces of 1/4" x 3/4"

balsa (from the 36" sticks) to make the rudder

framework. Working right on the plan, glue

these pieces together along with the ply RF

piece, using thin CA glue.

4. From the 1/8" x 1/4" x 36" sticks, cut "ribs"

to fit between the rudder framework, and glue

them in place. NOTE: It is not necessary to

get these ribs in the exact position shown on

the plan.

8. Lay the rudder assembly on top of one of

your 6" x 12" sheets. Hold the rudder assembly

down and apply thin CA glue along the edges

of the framework and ribs.

9. Sand the edges of the 1/16" sheeting flush

with the edges of the framework.

D 10. Apply thick (slow setting) CA glue (or 30-

minute epoxy if you need more time) to the

rudder framework and ribs, then lay the other

6" x 12" balsa sheet in place. Hold the sheeting

in place with your hands or with books until

the glue has set.

5. After the glue has completely set, remove

the rudder assembly from the plan and using

a T-bar sander or a sanding block with coarse

grit sandpaper, sand the outside edge of the

rudder to the approximate shape as shown on

the plan.

6. Examine the rudder framework and add

thick CA glue to any open joints, then use your

T- bar with medium grit sandpaper to sand

both sides of the rudder framework smooth.

7. From the 1/16" x 3" x 36" balsa sheets, cut

four pieces 12" long. Edge glue these pieces

together in pairs, using thin CA glue, to make

two sheets 6" x 12". Sand the surfaces of these

sheets smooth, using a T-bar with medium to

fine grit sandpaper.

D 11. Sand the edges of the sheeting flush with

the edges of the framework.

12. Carefully draw a centerline all around the

edges of the rudder.

D 1. Tape waxed paper over the separate elevator

drawing on the fuse plan Glue the two EF

pieces together, then in the same manner as

the rudder, build the inner framework. Build

two identical elevators.

D 2. Sand the framework to the shape as shown

on the plan.

D 3. Glue 1/16" balsa sheeting to both sides of

the elevators, with the grain running the long

way.

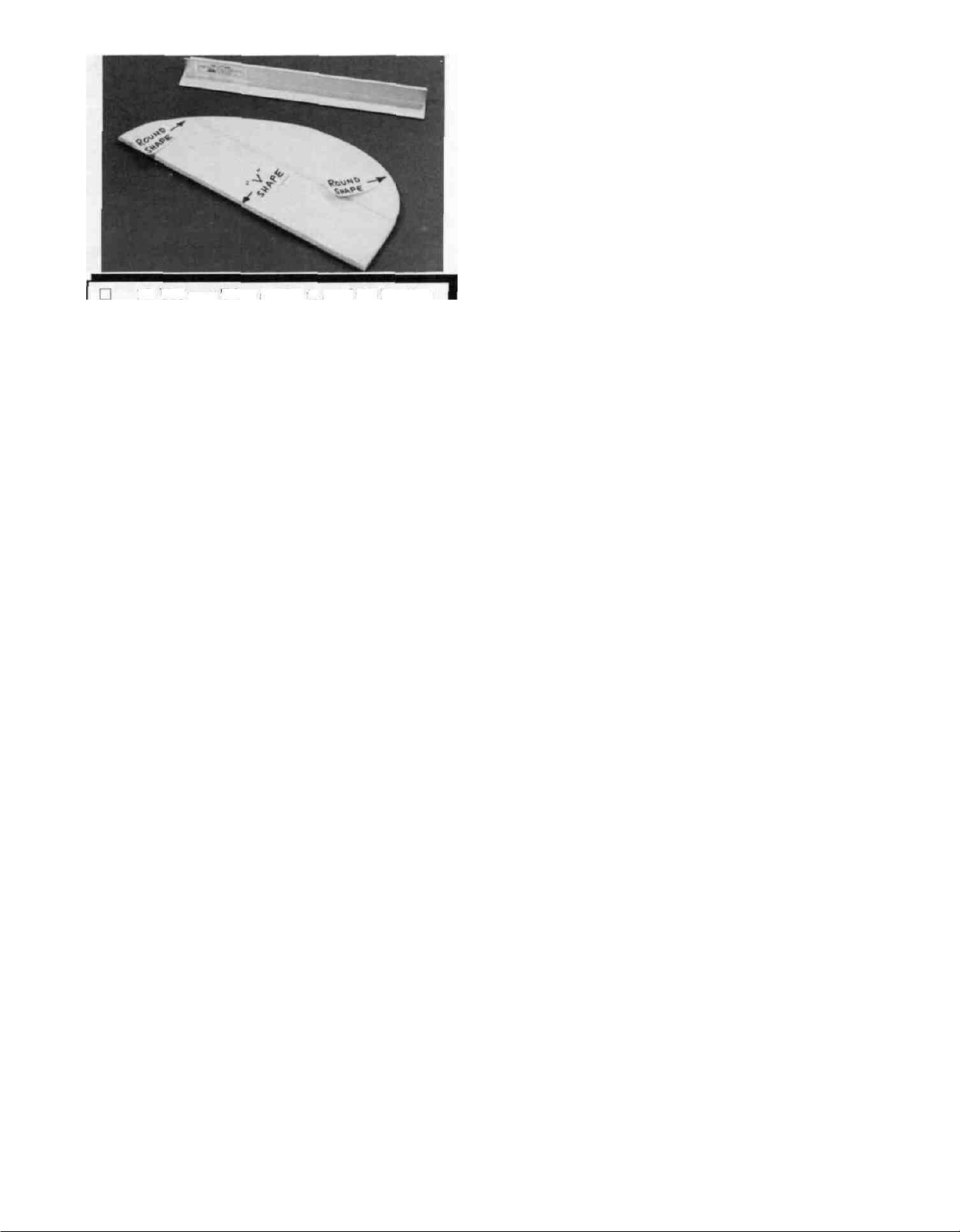

13. Use your T-bar sander to sand the leading

edge of the rudder to a "V" shape (take a look

at the top view of the rudder on the plan to

determine the proper angle of the "V")

D 14 Sand all other edges of the rudder to a

round shape NOTE The centerline you previously drew will help you to sand the same

amount from both sides.

BUILD THE FIN

You'll need the following parts:

1/4" x 2-7/8" x 1-1/2" shaped balsa front fin

filler

1/4" x 3" x 1-1/2" balsa rear fin filler

1/4" x 3/4" balsa sticks

1/8" x 1/4" balsa sticks

1/16" x 3" balsa sheets

D 1. In the same manner as the rudder, build the

inner framework, including the 1/4" fin filler

sheets, the 1/4" x 3/4" sticks and the 1/8" x 1/4"

sticks (for ribs).

D 2. Sand the top front comer to the shape as

shown on the plan.

D 3. Glue 1/16" balsa sheeting to both sides (ver-

tical grain).

D 4. Sand the leading edge (only) to a round

shape.

NOTE: The trailing edge, bottom edge and lower

front edge must not be rounded or V-shaped, instead,

just sand these edges flat.

BUILD THE ELEVATORS

You'll need the following parts:

4 1/8" die-cut ply elevator filler (E F) pieces

1/4" x 3/4" balsa sticks

1/8" x 1/4" balsa sticks

1/16" x 3" balsa sheets

D 4 Sand the leading edge to a "V'-shape, and

the other edges to a round shape.

BUILD THE STABILIZER

You'll need the following parts:

1/4" x 3/4" balsa sticks

1/8" x 1/4" balsa sticks

1/16" x 3" balsa sheets

Shaped 1/4" ply front stab brace

1/4" x 1/2" x 6" ply rear stab brace

1/4" x 3-7/32" x 3" balsa stab center sheet

D 1. Tape waxed paper over the separate

stabilizer'drawing on the fuse plan In the same

manner as the rudder, build the inner

framework, including the front stab brace, rear

stab brace, 1/4" balsa center sheet, 1/4" x 3/4"

sticks and 1/8" x 1/4" sticks.

D 2. Sand the outside edges to the shape as shown

on the plan.

D 3. Glue 1/16" balsa sheeting to both sides, with

the grain running the long way.

D 4. Sand the leading edge and the ends to a

round shape.

NOTE- The trailing edge must not be rounded or

V-shaped. Instead, just sand this edge flat

INSTALL THE HINGES (Do Not Glue)

NOTE: The large one-piece molded hinges supplied

in this kit are strong, easy to install, and provide a

good dampening effect to help prevent dangerous

control surface flutter We recommend that you use

these hinges in your Super Sportster 90/120.

D 1 Lay the rudder and elevators on the plan

and mark the hinge locations Place the rudder

against the fin TE (trailing edge) and transfer

the marks over to the fin. Place the elevators

against the stab TE and transfer the marks

over to the stab.

D 2. Cut the hinge slots on the accurate center-

lines which you previously drew, using a

standard slotting fork and slotting hook. Because the hinges are wider than normal, you

should use the following procedure: When first

inserting the slotting fork, push it in only part-

way along one side of the hinge location, then

push it in the full depth along the other side

of the hinge location, finally, go back and complete the push in the original position. Clean

out the slot with the slotting hook.

D 3. IMPORTANT! Condition or "break-in" the

hinges by folding them tightly back and forth

several times.

D 4. Insert the hinges into the slots and trial fit

the rudder and elevators in place on the fin

and stab. Do not glue the hinges until after

you have covered the model.

WING

BUILD THE WING PANELS

Lt. Rt.

D D 5. Glue two W-3 ribs together to make one tip

rib.

D D 6. Draw an accurate centerline along the rear

edge of the notched balsa trailing edges.

D 1. Tape the wing plan to your flat building

surface, and tape a sheet of waxed paper over

the wing panel portion of the plan.

Q 2. Punch out all the wing ribs from the die-cut

sheets. Compare the ribs with the wing rib patterns on the wing plan and arrange them into

stacks of the same kind of ribs.

D 3. Note that the drawing of rib W-2 shows the

two alternate locations for the main landing

gear blocks. Note also that the W-2 ribs have

partial cutouts for each of the two locations.

If you are building your plane as a taildragger,

cut out the front notches in the W-2 ribs. If

you are building your plane with a tricycle

gear, cut out the rear notches. Trim the die-cut

1/16" ply doublers, and glue them to the W-2

ribs as shown on the plan.

D 4. The notched balsa leading and trailing edges

are supplied in one shaped piece and are held

together by thin strips of balsa. Break these

apart now, and break off any remaining pieces

of the thin balsa. Sand the edges straight with

your T-Bar sanding block.

NOTE: Follow steps 5 through 28 to build the

RIGHT wing panel, then repeat these steps to

build the LEFT wing panel UPSIDE DOWN.

D D 7. Pin one of the notched balsa trailing edges

to the 1/4" x 1-5/32" x 33" balsa jig stick as

shown in the following sketch. Note that the

top of the jig stick must be on the centerline

which you have drawn on the trailing edge.

Notched Balsa

Trailing Edge

Table

Top

T-Pin

_Balsa

Jig Slick

D D 8. Place one of the 3/8" x 1/2" basswood main

spars on the wing plan, line up the right end

with the outside edge of the tip rib and pin the

spar down with crossed T-pins as shown in the

following sketch. NOTE: If you prefer not to

use pins, you may hold the spar firmly in place

using "shot bags" as shown in the photos, which

are made by partially filling a sock with lead

shot.

T-PINS

SPAR

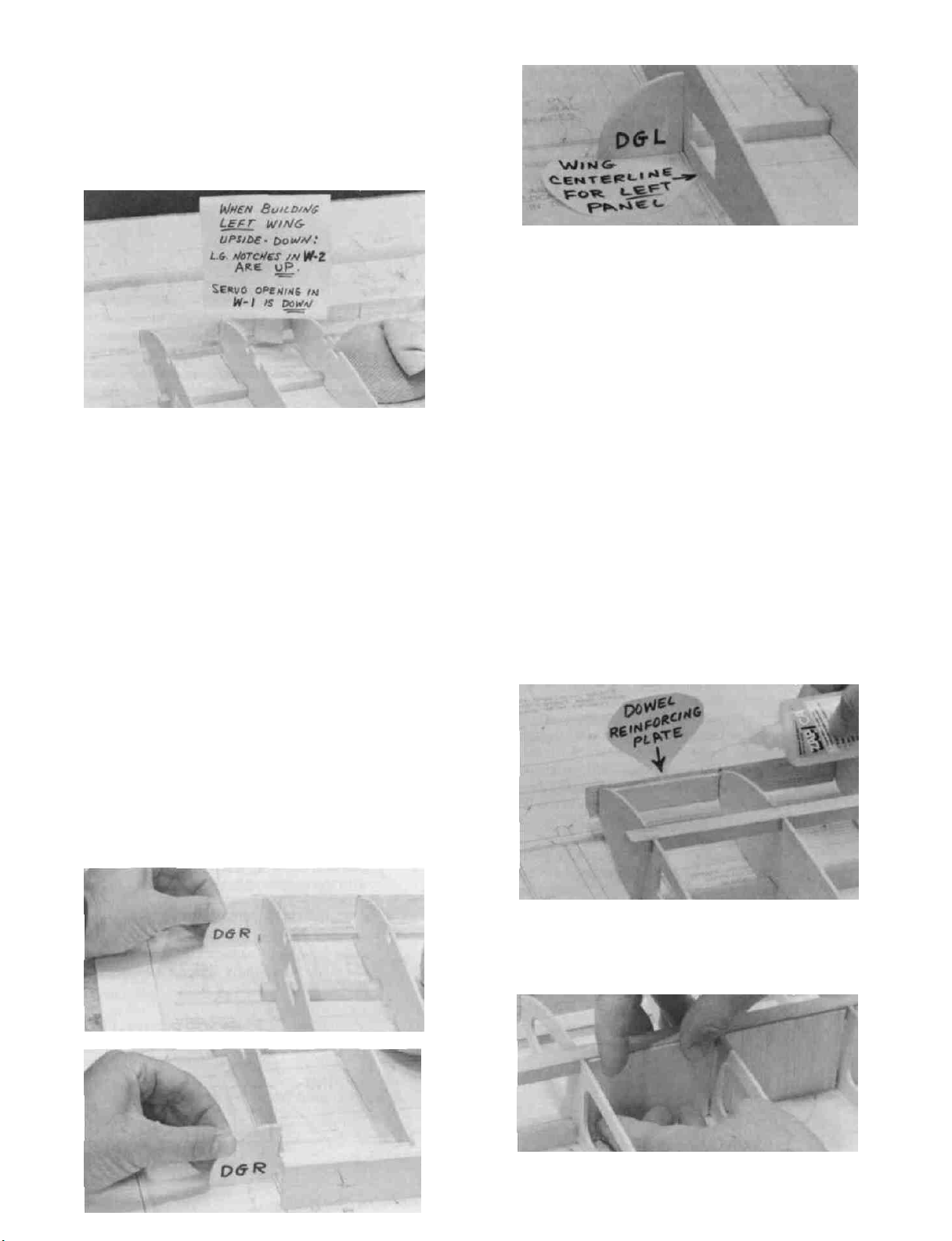

IMPORTANT NOTE!!!!!!!!!!!!!!!!!!

When building the right wing panel, position

the ribs so the landing gear block notches in the W-2

ribs are down, and the servo opening in rib W-1 is

up.

When building the left wing panel, position

the ribs so the landing gear block notches in the W-2

ribs are up, and the servo opening in rib W-1 is

down.

Note that the leading and trailing edges do not have

a notch for the W-1 rib. Use the 1/8" die-cut ply

dihedral gauges "DGR" and "DGL" to position rib

W-1 at the proper angle. When building the right

wing panel, use dihedral gauge DGR to position W-1,

setting the rib's location and tilt with the point of

DGR on the "Right Wing Panel Centerline". When

building the left wing panel (upside down), use dihedral gauge DGL to position W-1, with the point

of DGL on the "Left Wing Panel Centerline".

***********************************************************************

D D 11. Insert the top spar into the notches in the

top of the ribs, with the right end even with

the outside edge of the tip rib.

DO NOT BUILD TWO RIGHT WING

HALVES!!!!!!!!!!!!!!

D D 9. Place the ribs on the spar in their approxi-

mate positions, but do not glue.

D D 10. Hold the notched balsa trailing edge in

place (with jig attached) and carefully work

the ribs into the notches, centering each rib up

and down. In the same manner, insert the ribs

into the notches in the balsa leading edge. Note

that one end of the leading and trailing

edge stock has a notch at the end, and this

notch must be at the wing tip. Do not glue

anything yet.

***********************************************************

PLEASE STUDY THE FOLLOWING NOTE

AND THE ACCOMPANYING PHOTOS

BEFORE PROCEEDING!

D D 12. Make sure the tip rib is vertical (90 degrees

to the work surface), that the spars are lined

up with the outside edge of the tip rib, that rib

W-1 is set at the proper angle, and that all

parts are properly aligned. Apply thin CA glue

to all joints (but do not glue the "jig stick" to

the TE!). Then apply thick CA glue to all joints

which are not tight-fitting.

D D 13. Glue the 1/8" ply dowel reinforcing plate

to the back of the leading edge, between W-1

and W-2.

D D 14. Glue the pre-cut 1/16" balsa shear webs

to the rear edge of the spars in all rib bays

except between W-1 and W-2.

10

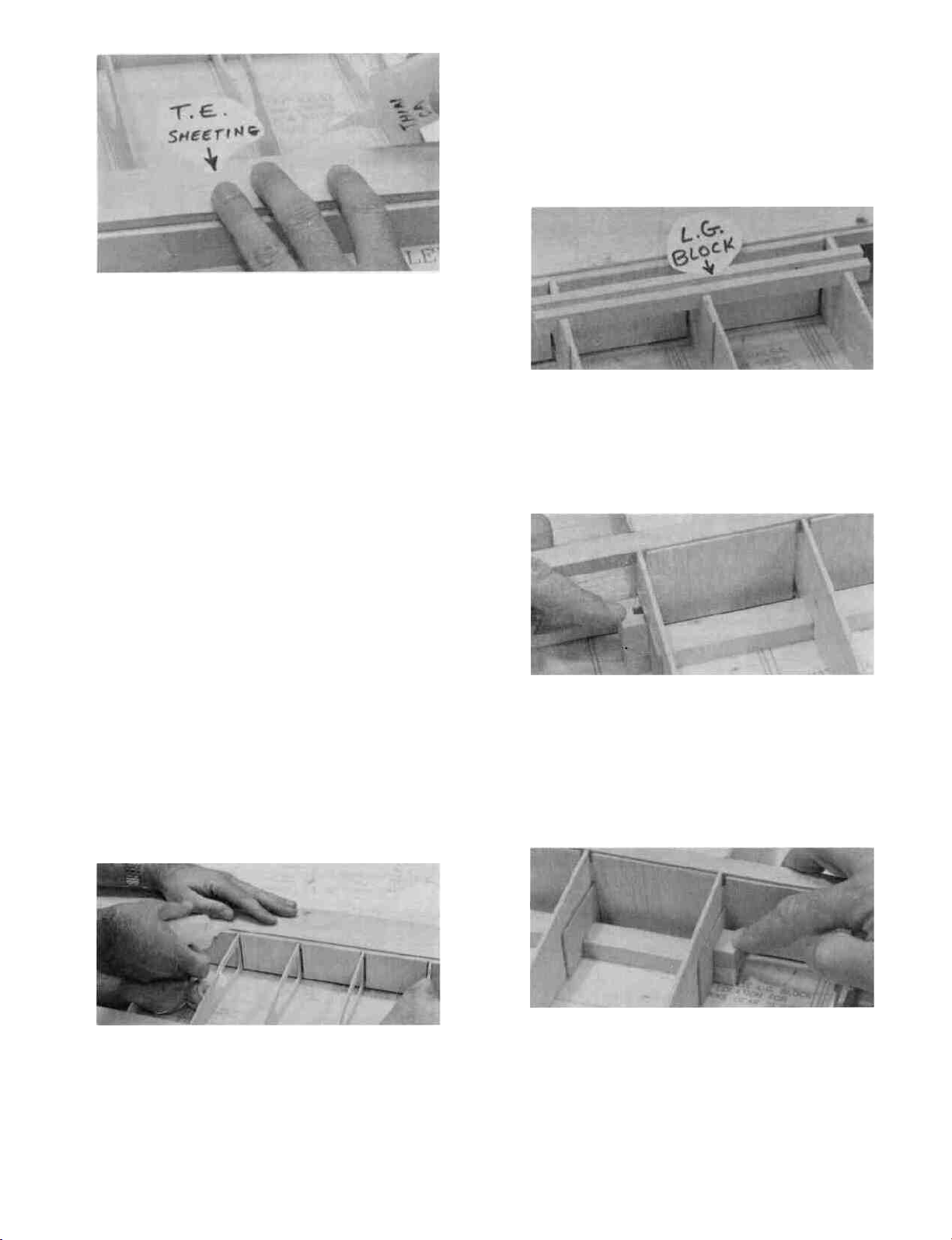

D D 15. Lightly sand the tops of the ribs to blend

with the notched trailing edge, if necessary;

then position one of the 3/32" x 1-13/32" x 33"

balsa trailing edge sheets so the Rt. end is

even with the outside edge of the tip rib and

glue it in place.

D D 16. If you are building a taildragger, you should

install the grooved hardwood landing gear

block at this time. Refer to steps 20 - 23 for

the correct procedure.

bend the sheeting down onto the ribs and spar.

Hold the sheeting down with masking tape,

pins and your hands until the glue has set.

NOTE: Do not install the TOP leading edge

sheeting until after joining the left and right

wing panels.

D D 20. Trial fit the long grooved hardwood land-

ing gear block into the notches in the W-2

ribs (see the landing gear detail drawing on

the wing plan for proper positioning). File the

notches if necessary for a good fit. Now use

epoxy to securely glue the block in place.

LI D 17. Before applying the leading edge sheeting

in the next step, use your T-bar to lightly sand off

the edges of the shear webs and the rear corners of

the spars to blend with the ribs.

D D 18. Prepare the 3/32" x 3-27/32" x 33" balsa

bottom leading edge sheeting by sanding

one edge to a slight bevel so it will fit snugly

against the back of the leading edge. If you are

building a taildragger, carefully cut out an

opening in the leading edge sheeting for the

landing gear block.

NOTE: It will be helpful to have the following items

handy for the next step . . . thin CA, thick CA, a wet

cloth, masking tape and T-pins.

D D 21. Glue the short grooved hardwood block to

the landing gear block and to the 1/16" ply

doubler as shown on the plan and in the photo,

using 5-minute epoxy. After the glue has firmly

set, insert a 3/16" diameter drill bit down into

the groove in the short hardwood block, then

continue drilling through the long hardwood

block.

D D 19. Position the leading edge sheeting so the

Rt. end is even with the outside edge of the tip

rib. Using thin CA, glue the front (beveled)

edge of the leading edge sheeting to the back

edge of the leading edge. Wet the top surface

of the sheeting so it will bend easier. Apply

thick CA glue to the top edge of the ribs and

to the front half of the spar, then immediately

D D 22. Glue the 1/2" x 3/4" x 1/2" hardwood block

to the other end of the landing gear block and

to the 1/16" ply doubler, using 5-minute epoxy.

D D 23. Trial fit the 3/16" diameter main landing

gear wire into the landing gear block at this

time. Cut or file the groove and hole in the

landing gear block as necessary for a good fit.

11

NOTE: Most standard wheels have a 5/32" diameter

axle hole, so you'll have to drill the hubs of your

wheels to fit the 3/16" diameter landing gear wire

supplied in this kit. Start by using a 3/16" drill bit,

but because the nylon hub material is somewhat flexible, it may be necessary to use a 13/64" drill bit to

get the hole large enough to allow the wheel to turn

freely.

D D 24. Glue the 3/32" balsa trailing edge sheeting

to the other side of the wing in the same manner as described in step 15.

L] D 25. Find the 8 balsa center section sheets

(3/32" x 2-5/8" x 10-1/8") and the 4 balsa center

section sheets (3/32 x 1-3/8 x 10-1/8). Glue 2 of

the 2-5/8 wide sheets and one of the 1-3/8 sheets

to the W-l and W-2 ribs on the bottom of the

wing only Now glue just one 2-5/8 piece of

top center section sheeting in place at the trailing edge (the balance of the top sheeting will

be installed after joining the wing panels).

D D 27. Carefully cut out the center portion of the

W-l ribs (1/8" in front and back of the spars),

to make room for the plywood dihedral braces.

D 28. Now go back and repeat steps 5 through

27 to build the left wing panel. Remember,

you will build the left wing panel UPSIDE

DOWN!

JOIN THE WING PANELS

NOTE: Read Steps 1-5, then make a "dry run"

through these steps before actually proceeding.

1. Lay a piece of waxed paper down at the center

of the wing, place the two wing panels together

at the center, and block up both wing tips 11/2".

D 2. Trial fit the 1/8" ply dihedral braces to

make sure they will readily slide into place.

NOTE: Due to the extremely high stresses which

occur at the center of this wing, you must use

30 minute epoxy in the next step to insure

adequate strength.

D D 26. Using a razor saw, carefully cut off all ex-

cess sheeting, spars, LE and TE even with W-l.

Now sand the ends of the parts you just

trimmed until they are smooth and flush with

the face of W-l. Also sand the outside face of

the tip rib at this time.

D 3. Mix up a batch of 30 minute epoxy and spread

it liberally on the front and back of the spars

between ribs W-l and W-2, on the spar ends,

and on one surface of each of the dihedral

braces. Slide the dihedral braces into place and

immediately proceed to the next step.

D 4. Carefully align the leading and trailing

edges of both wing panels at the centerline and,

while holding them in correct alignment, apply

thin CA glue to the center joint to "lock" the

panels together. Do not apply CA glue to

any area that is already coated with epoxy.

Immediately proceed to the next step.

12

D 5. Clamp the dihedral braces together as shown

in the photo, wipe away any excess epoxy, then

allow the epoxy to fully harden before disturb-

ing the wing.

COMPLETING THE WING

D 1. In the same manner as in Steps 18 and 19

above, glue the top leading edge sheeting in

place.

D 5. Glue the 1/2" x 1-1/2" x 2-15/16" balsa rear

tip fairing blocks in place at the trailing edge

of the wing tips.

D 6. Find the two softest 1/8" x 1/4" x 36" balsa

sticks that you previously set aside when building the rudder.

D 2. Glue the top center section sheeting in

place (Note: As you do so, it will be helpful to

mark the location of the aileron servo opening on the top of the sheeting for future reference).

D 3. From the 1/4" x 1" x 7" balsa sheet and the

1/4" x 7/8" x 5-7/8" balsa sheet, cut out the triangular tip braces using the pattern on the wing

plan, then glue them to the 1/8" ply wing tips.

D 7. Glue 1/8" x 1/4" balsa strips to the top and

bottom of the wing tips as shown in the photos.

Do not be concerned if the sticks break when

they are bent around the curve. Just glue them

down and-sand them to a rounded shape later.

D 8. Use a sanding block with coarse (#60 or

#80) sandpaper to blend the rear tip fairing

blocks to the wing tips, as shown. Also sand

the outside edge of the wing tips to a smooth,

rounded shape.

D 4. Glue the wing tip and tip brace assemblies

to the tip ribs.

13

D 9. From the six 3/32" x 3/8" x 36" balsa sticks,

cut cap strips to fit between the trailing edge

sheeting and leading edge sheeting. Glue these

cap strips to the top and bottom edges of all

exposed ribs as shown on the plan.

D 10. Temporarily install the main landing gear

wires into the wing. Now fill the unused portion

of the slot in the landing gear block with pieces

cut from the 3/16" x 3/16" balsa stick. Glue

these pieces in place.

D 11. Temporarily secure the landing gear in

place with the nylon straps and #2 x 3/8"

screws as shown in the landing gear detail

drawing and the cross-section drawing of W-2

on the wing plan.

AILERON TORQUE RODS

D 6. Drill holes in the flattened portion of the

brass horn for the clevis pin (Note: The proper

size drill bit to use here is a #53 bit, available

at most hardware stores. You may, however,

use a 1/16" bit, but a slight amount of "slop"

may result). After drilling, carefully remove

the sharpness from the edge of the holes with

an Xacto knife.

D 7. Repeat the above process for the other torque

rod. You should now have a right and a left

torque rod.

D 1. Sand the short end of the torque rod with

320 grit sandpaper.

D 2. Roughen the surface of the brass bearing

tube with 100 grit sandpaper.

D 3. Clean the torque rod and bearing tube with

degreasing solvent or thinner.

D 4. Apply a small amount of soldering flux to

the short end of the torque rod, push on the

brass tube which has been flattened at one end

and rotate it to the proper position.

D 5. Heat the brass tube with a soldering gun or

iron while applying solder to the joint. When

the assembly becomes hot enough the solder

will melt and flow freely into the joint. Then

remove the heat and allow to cool without disturbing.

D 8. Find the two grooved, tapered balsa center

trailing edge pieces, and trial fit the torque

rods into them. Determine from the plan where

to cut the clearance notches in the center trailing edges and the wing trailing edge, which

permit the torque rod horns to travel freely.

Note: The torque rod horns must exit the

TOP of the wing!

D 9. Slide the brass torque rod bearings toward

the brass horns, then use a toothpick to apply

a small amount of petroleum jelly to the ends

of the brass tubes. This will help prevent glue

from locking up the torque rods.

D 10. Use 5-minute epoxy to glue the brass torque

rod bearings into the grooves in the center

trailing edge pieces. Wipe off any excess glue

and allow to harden.

14

D 11. Trial fit the trailing edge/torque rod assem-

bly onto the wing trailing edge. Sand the center

trailing edge pieces slightly where they join,

for a good fit. Glue these pieces in place with

epoxy. Also check to make sure the top and

bottom of the TE pieces line up with the top

and bottom of the wing.

Loading...

Loading...