Page 1

GETINGE 46-SERIES

USER MANUAL

502591900

SEV0840001-

Page 2

<Doc_USR><Doc_5025919000><Rel_A><Lang_EN>

Page 2 of 24

Contents

FOREWORD ____________________________________________3

SAFETY REGULATIONS _________________________________4

Important _________________________________________________ 4

Product liability ____________________________________________ 4

Isolating device ____________________________________________ 4

In an emergency ___________________________________________ 4

INTRODUCTION ________________________________________5

Intended field of application _________________________________ 5

Attention symbols __________________________________________ 5

General ___________________________________________________ 6

Control panel ______________________________________________ 7

Control system _____________________________________________ 8

Door function ______________________________________________8

Dosing system _____________________________________________ 9

OPERATING INSTRUCTIONS_____________________________10

Loading items to be washed into the machine _________________ 10

Positioning the goods _______________________________________ 11

Working with detergents etc _________________________________ 11

Daily inspection ____________________________________________12

If necessary _______________________________________________ 13

Printer (optional) ___________________________________________ 14

PROCESS ______________________________________________ 16

Change parameters ________________________________________ 16

Printing out a program for a machine with printer (optional) ______ 16

FAULT INDICATIONS ____________________________________17

Handling alarms ____________________________________________ 17

Alarms ____________________________________________________ 18

Acknowledging a fault code _________________________________ 18

Fault codes in the machine __________________________________ 18

Detergent ______________________________________________20

Water quality – Washer disinfectors ______________________21

Handling of worn-out washer/flusher disinfectors _________22

Page 3

Page 3 of 24

<Doc_USR><Doc_5025919000><Rel_A><Lang_EN>

FOREWORD

This user manual is intended for users of Getinge 46-series washer disinfectors.

The instruction manual describes the design and operation of the machine and the maintenance for which the user is responsible. The purpose of the information in the manual

is to ensure safe operation and optimum efciency.

Before using the machine for the rst time, users must have read this instruction manual

and familiarized themselves with the operation of the machine and its safety instructions.

Read the user manual before using the machine.

The information in this manual describes the machine as dispatched from Getinge.

There may be differences due to customization.

The machine is accompanied by the following documentation:

User manual (this book)•

Installation manual•

Goods positioning sign•

The following are supplied on CD:

User manual•

Installation manual•

Goods positioning sign•

Technical manual •

Electrical diagrams•

Spare parts list•

Program sheets•

Getinge reserves the right to change the specication and design without prior notice.

The information in this manual was up to date on the date of issue of the manual.

© Copyright

The content of this manual must not be copied, in

whole or in part, without the written consent of Getinge.

Page 4

<Doc_USR><Doc_5025919000><Rel_A><Lang_EN>

Page 4 of 24

SAFETY REGULATIONS

This machine has been designed with a number of built-in safety devices. To avoid

injury, it is highly important not to bypass or disable these safety devices.

The equipment must be used in accordance with the safety instructions

below. If in doubt, contact a representative of the reseller without delay.

Important

Read the user manual thoroughly before using the machine.•

The equipment must only be used by personnel who know about it and are trained •

to use it. Personnel must also receive regular training on this equipment.

Take care when handling the chemical agent used in the machine. Read the details •

on the container or contact the manufacturer:

- what to do if the substance comes into contact with the eyes or skin or if vapors

are inhaled.

- storage of packs and sorting of empty packs for disposal.

Contact the detergent manufacturer for instructions about dosing and washing

temperatures when using a detergent other than that recommended in the

manual (Getinge’s).

Take care, because the machine uses hot water and possibly steam.•

Installation and service work must be done by personnel trained for this machine.•

Never bypass the door switch of the machine.•

Leakage in the system, due to a worn door seal for example, must be repaired •

without delay.

The electric power must be switched off before the machine cabinet is opened. •

(The machine cabinet contains electrical components).

Make sure that there is always detergent in the bottles. This is important both •

for the operation of the machine and for keeping the washing chamber free

from staining .

The machine must be kept clean if it is to work properly.•

Do not wash down or hose down the machine with water.•

Spare parts must be obtained only via Getinge.•

Product liability

Any modication or incorrect use of the equipment without the approval of

Getinge Disinfection AB invalidates Getinge Disinfection AB´s product liability.

This product was manufactured by:

GETINGE DISINFECTION AB

Ljungadalsgatan 11

Box 1505

351 15 Växjö

Sweden

Isolating device

The machine must be tted with a separate isolating device in the electric power supply.

The isolating device must be easily accessible on a wall close to the machine.

In an emergency

• Switch off the main switch

• Close stopcocks in the water and (where present) steam supply lines.

Page 5

Page 5 of 24

<Doc_USR><Doc_5025919000><Rel_A><Lang_EN>

INTRODUCTION

Intended field of application

Getinge 46-series washer disinfectors are intended for cleaning, disinfecting and drying

surgical instruments (solid and tubular), dishes, hand bowls and baby feeding bottles,

containers, anesthesia equipment (critical objects such as surgical instruments and anesthesia equipment must also be sterilized before use), laboratory glass and OP shoes.

The items must be placed in the proper accessories, recommended by

Getinge Disinfection AB.

The customer is responsible for ensuring that an Installation Qualication and a

Performance Qualication according to ISO 15883 are carried out before the product

goes into service.

Attention symbols

Some of the warnings, instructions and advice in this manual are so important that we

use the following special symbols to draw attention to them. The symbols and designs

used are:

This symbol indicates a warning in the text of the manual. It warns of a

hazard that may lead to more or less severe injury and in certain cases mortal

danger . It also highlights warnings of possible damage to the machine.

This symbol indicates a warning in the manual concerning the handling of

components sensitive to ESD. The warning applies to damage that may occur

to circuit boards or hardware.

This symbol gives warning of hot surfaces.

This is a warning of voltage.

Irritating substances such as acids.

Page 6

<Doc_USR><Doc_5025919000><Rel_A><Lang_EN>

Page 6 of 24

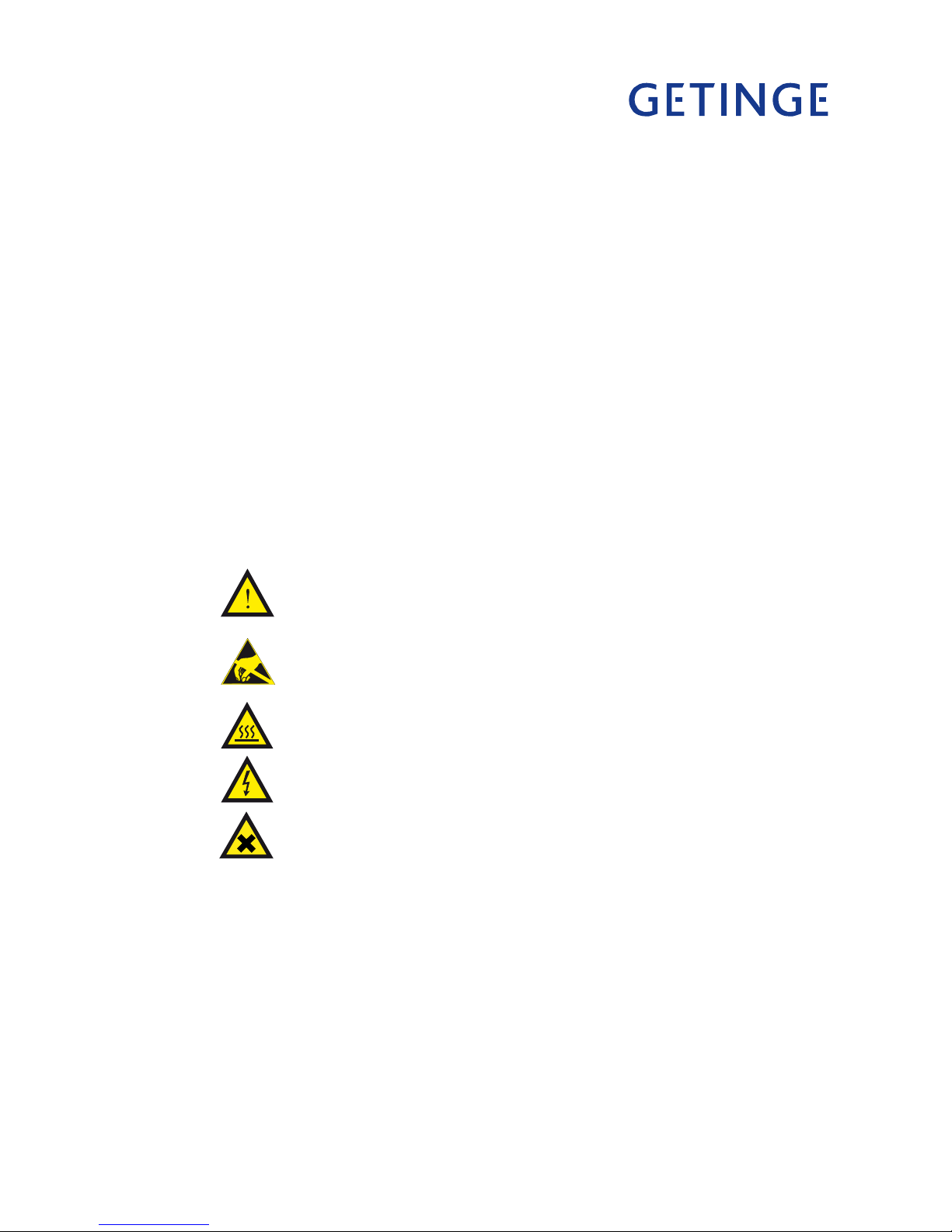

General

The machine has spray arms and dockings as follows:

46-2 has three spray arms and one docking:•

46-3 has three spray arms and one docking:•

46-4 has two spray arms and two dockings:•

46-5 has two spray arms and three dockings:•

The machine can be equipped with several different accessories for different cleaning

requirements.

These accessories are presented in a special accessories catalogue.

There are several possible ways of installing and equipping the machine depending on

its eld of application:

46-2 has electric heating. •

46-3, 46-4 and 46-5 have electric or steam heating.

46-2 and 46-3 are tted with a single door. •

46-4 and 46-5 are tted with a single or double door.

Connection of distilled or de-ionised water.•

Extra dosing pumps which allow chemical disinfection of heat-sensitive goods.•

With or without built-in drying system.•

Audible signal on fault code.•

Dryer module

Main switch

(option)

Control panel

Conductivity

(option)

Washing chamber

Bottom strainer

with handle

Dosing pumps

Hinged door

Suction pipe

with container

alarm

Detergent

container

V1627

Page 7

Page 7 of 24

<Doc_USR><Doc_5025919000><Rel_A><Lang_EN>

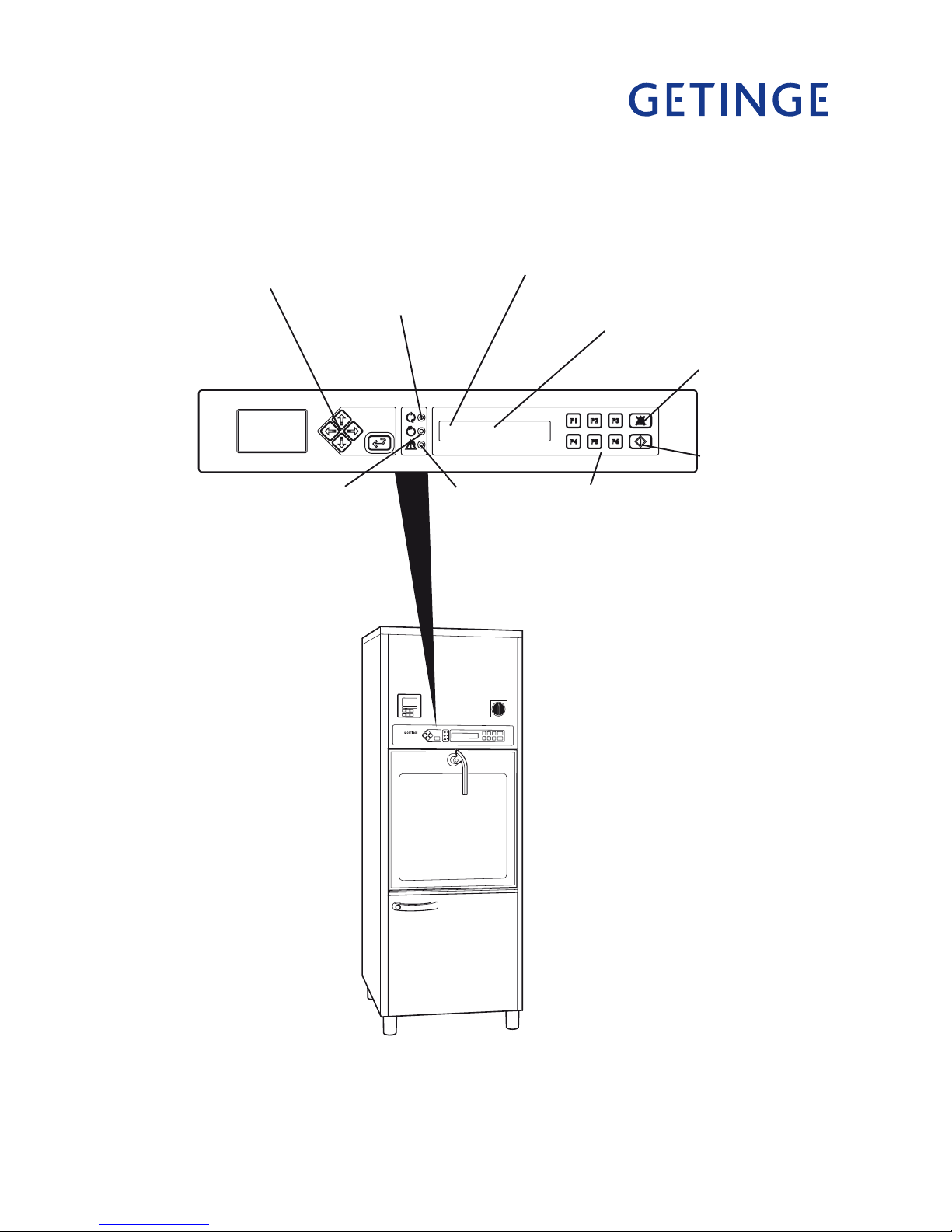

Control panel

The machine is operated from the control panel above the soiled-side door. The picture

below shows the location of buttons and indicators.

Menu selection buttons

(see “Technical manual”)

Yellow lamp:

Program running

P01 OP-SHORT-D

47.0℃

Program number

Before starting: Chosen program

While running: Program phase (eg

“Rinsing”)

Alarm reset

button

Start button

for washing

programs

Program

selection

buttons

Red lamp:

Fault indication

Green lamp:

Program

complete

V1624

V1762

Page 8

<Doc_USR><Doc_5025919000><Rel_A><Lang_EN>

Page 8 of 24

Control system

The machine has an electronic controller which can hold various programs. Six of these

programs can be chosen with the program selection buttons. Other programs are chosen

with the menu buttons; see Operating instructions.

The machine comes with a number of standard programs in the control system (see the

separate program sheet). Contact the your reseller for customized programs.

Programming may only be done by authorized personnel.

Door function

46-2 and 46-3 are tted with a single door. 46-5 and 46-5 are tted either with a single

door or with double doors.

Machines with double doors have a system of interlocks to ensure that only one door

can be opened at a time. This means that the clean-side door must be closed and locked

before the soiled-side door can be opened.

Pressing V locks the door. When the program is complete, a green lamp lights up on

both sides (if there are double doors) and the clean-side door is unlocked. When the door

has been opened manually, the green lamp goes out. With double doors, the clean-side

door must be closed before the soiled-side door can be unlocked.

Clean side Soiled side

V398

Page 9

Page 9 of 24

<Doc_USR><Doc_5025919000><Rel_A><Lang_EN>

Dosing system

In standard form, the machine has two dosing systems. One is for alkaline detergent and

one is for rinse-aid or acid detergent.

The machine cannot be started until detergent has been added. If the detergent container

is empty, “DOS 1 LOW LEVEL” (for example) appears on the display.

A third and a fourth dosing system for chemical disinfection of heat-sensitive goods or

instrument milk (for example) can be installed.

Important!

When installing and starting the machine, check that the detergent

reaches the dosing pump.

If the machine is not fitted with flow monitoring, the dosing must be

checked visually.

If the type of detergent is changed, the dosing system must be recalibrated

for the new detergent.

Drying

If the machine does not have a dryer, we recommend that the goods are dried in a

separate drying cabinet.

Empty container alarm Containers for detergent/rinse-aid

V1627

Page 10

<Doc_USR><Doc_5025919000><Rel_A><Lang_EN>

Page 10 of 24

OPERATING INSTRUCTIONS

Loading items to be washed into the machine

Load the items to be washed on to the trolley and run the trolley into the machine. •

Examples showing how to load the trolley are shown on the goods positioning sign.

NOTE:

Maximum weight of items to be washed and wash trolley:

46-2: 35 kg

46-3: 35 kg

46-4: 50 kg

46-5: 60 kg

Make sure that the washer arms can rotate freely without touching the goods.•

Close the door and make sure that the handle is in the locked position.•

Choose program

Choose a program in one of the following ways: •

- Press one of the program selection buttons 1 - 6

- Press S.

Choose a program from the list with • H and J.

Press S to conrm your choice.

You can see the machine programs on the separate program sheet.

Press • V.

A fine filter must be used when cleaning and disinfecting tubular instruments

with a passage smaller than 1 mm, to prevent particles getting stuck in the

instruments. Blocked or reduced water flow may result in ineffective cleaning

and disinfection.

If the program is aborted after starting, the goods will not be properly washed

or disinfected.

While a program is running

While the program is running, a yellow lamp at M is lit and the program phase

(eg “Rinse”) and the current temperature are shown on the display. Press S to see how

much time remains.

When the program is complete

When the program is complete, a green lamp lights up at • N. The door (on the clean

side if the sterilizer has two doors) is unlocked and can be opened.

If the items are still hot after a program, handle them with care to avoid burns.

Empty the machine (and if the machine has double doors, close the clean-side door).•

If the same program is to be used again, there is no need to select the program •

again. Simply press V directly.

NOTE:

The lighting in the chamber and in the display switches to standby mode after 30 minutes

and returns automatically when a program is started or selected.

J058

Page 11

Page 11 of 24

<Doc_USR><Doc_5025919000><Rel_A><Lang_EN>

Positioning the goods

NOTE:

All vessels must be thoroughly emptied before they are loaded into the machine.

Use inserts and special inserts correctly and only for the items and utensils that are •

to be washed.

Make sure that the water jets reach all surfaces of the goods. Any surfaces that are •

covered will not be completely clean.

Do not block the spray arm.•

Make sure that the strainers in the machine are clean and that water can ow •

through them. It is important to clean and check the strainers regularly.

Empty all vessels to be washed before they are placed in the machine.•

Position sharp and pointed utensils in such a way that they cannot cause injury or •

damage during loading and unloading.

Make sure that utensils are not lying on top of each other, preventing water from •

reaching all surfaces.

Position vessels with their openings downwards in the correct inserts. Water must •

be able to ow freely into and out of the vessels.

Goods with a convex bottom must be positioned on a tilt so that water does not •

collect in the convex surface.

Anodised aluminium and nickel-plated instruments are not suitable for washing in •

a washer disinfector.

Rigid endoscopes must be dismantled in accordance with the manufacturer’s •

instructions before washing.

Open all valves and remove covers and seals so that the channels can be thoroughly •

ushed out to achieve the desired cleaning result.

Optics and light guides must be approved by the manufacturer for thermal •

disinfection .

Working with detergents etc

Empty out all residue of acid, especially hydrochloric acid, solvents and chloridecontaining solvents from the vessels before placing them in the machine.

Pre-treatment with detergent or disinfectant and certain types of dirt may •

result in increased lather formation. The lather may affect the washing and

disinfection result .

Follow carefully the manufacturer’s instructions for detergents and special products. •

To avoid chemical reactions (eg oxy-hydrogen gas) and damage to materials, the

detergent must only be used for the purpose stated by the manufacturer.

Handle liquid agents (for cleaning, rinsing, disinfection and neutralizing) with care. •

The substances often consist of acids or caustic solutions.

Do not add organic solvents as this may result in an explosion. Use safety

glasses and protective gloves when handling these substances. Always follow the

manufacturer’s safety instructions when handling chemical agents.

Do not use domestic dishwasher detergent.•

Follow the dosing instructions of the detergent manufacturer. Different detergents •

may have different cleaning effects. If cleaning results are not satisfactory, try

changing to a detergent of a different quality before contacting Getinge.

Page 12

<Doc_USR><Doc_5025919000><Rel_A><Lang_EN>

Page 12 of 24

Remove and clean the strainer in the bottom of the washing chamber. A dirty •

coarse strainer may prevent water from circulating and create the conditions for the

growth of bacteria.

The heating coils under the coarse strainer may be hot.

If necessary for cleaning, open the strainer with the two nuts.•

Open the detergent access panel and check that there is detergent/rinse-aid in the •

containers and the hoses.

Check that the trolley docks properly with the water connections. If the wash •

trolley does not dock properly, adjust the spring.

Check the accessories of the machine visually with regard to their intended use and •

function. For example, blocked channels, worn and missing parts that might affect

the performance of the machine. Water must be able to ow freely through the

ducts in hollow instruments.

Check the cleaning instructions of the goods manufacturer. •

To achieve the intended level of performance and safety, distribute the load evenly •

over the washing surface.

Check the cleaning result visually when the process is complete.•

Check that the dockings move easily.•

The spray arm journal must be checked daily and replaced every ve years.•

Daily inspection

Check that no objects have fallen down into the bottom of the washing chamber. •

Loose objects may cause blockages and seriously reduce the performance of the

washer disinfector.

Check that the spray arms can rotate freely. Check that the holes in the washing •

arms are not blocked. Blocked spray holes may adversely affect the cleaning result.

Check that the goods to be cleaned are retained in the insert.•

If the arms need cleaning, remove them by unscrewing the central nut. The arms can then •

be lifted off and washed clean. Check that the arm can rotate freely when re-installed.

Centre nut

Coarse strainer

Fine strainer

Detergent/rinse-aid container

Page 13

Page 13 of 24

<Doc_USR><Doc_5025919000><Rel_A><Lang_EN>

If necessary

The spray arm

Clean the spray arms when necessary by unscrewing the central nut, lifting off the spray

arm and rinsing it until it is clean. Take off the plastic end pieces by pressing the metal

bar over the edge of the spray arm and removing them. Using a washing brush, clean the

inside of the spray arm.

After cleaning, press the metal bar back into the groove in the plastic end piece.

Check that the arm can rotate freely when re-installed.

Washing chamber

Do not allow deposits to form in the wash chamber. Remove any deposits as follows:

Open the door and dispense 200 ml NEODISHER BU descaler (sold by •

Dr. Weigert) into the washing chamber.

Close the door and run the descaling program. •

NOTE: There must not be any items in the machine with this program. It is only used to

descale the machine and insert.

The outside

The front and side walls can be cleaned and disinfected with an alcohol-based cleaning

agent, medical spirit or an ordinary cleaner. The control panel can be cleaned in the same

way. To remove stains, use ordinary stainless steel cleaner.

If the washer disinfector is used without automatic descaling for incoming water, the

heating element must be checked regularly for limescale deposits.

It is important to maintain a good level of hygiene around the machine.

V1627

V2026

V2027

Page 14

<Doc_USR><Doc_5025919000><Rel_A><Lang_EN>

Page 14 of 24

Printer (optional)

Replacing the paper roll

Open the front door of the printer.•

Remove any paper residue.•

Fold down the printing mechanism by pressing the latch marked PUSH (• A).

Cut the end of the new roll square (• B). (This makes it easier to thread the paper into

the printer mechanism.)

Insert the paper into the opening of the print mechanism and press the FEED (• C) but-

ton on the printer. The paper is now automatically fed through the printer mechanism.

Fold away the printing mechanism and lock it with the latch (• D).

Tear off the paper and close the front panel of the printer.•

The printer is now ready to use again.•

Never use the printer without paper and/or ink ribbon.

Do not pull on the printer feed when the printer is on.

A

B

D

C

V1972

V1973

V1973

Page 15

Page 15 of 24

<Doc_USR><Doc_5025919000><Rel_A><Lang_EN>

Ribbon cassette replacement

Open the front door of the printer.•

Remove the ink ribbon by pressing gently on the left-hand side of the ribbon cassette.•

Insert the new ribbon cassette. The printer is now ready to use again.•

Never use the printer without paper and/or ink ribbon.

A

V1973

Page 16

<Doc_USR><Doc_5025919000><Rel_A><Lang_EN>

Page 16 of 24

PROCESS

Change parameters

Normally the preset parameter settings of the installed programs are used, but in special

cases it may be necessary to adjust certain parameters for matching to a specic wash

process. Information about the parameters that can be changed and their limit values can

be found under heading “A- or P-parameters” in Chapter 4 of the Technical manual.

Printing out a program for a machine with printer (optional)

An example of a program printout is shown below. In the example, program P02 OP-D,

programmed on menu selection button 2 is used.

46-Series

DATE : 2008/06/02

SIGNALS

PROCESS START : 13:28:45

AI07 TEMP INDEPENDENT

MACHINE NAME : 46-Series

CYCLE COUNTER : 12

PARAMETERS

WASH1 TEMP SP 60.0 C

WASH1 TIME 00:01:00

F RINSE TEMP SP 90.0 C

FR TIME 00:01:00

DRY TIME 00:13:00

PROGRAM: P1 OP-SHORT

----------------------------------------------------PROGTIME AI07

00:00:00 73.8

START

00:00:00 73.8

DRAIN

WASH 1

00:00:11 73.8

FILL

00:00:21 73.5

HEAT

00:01:20 38.2

DOS START

00:01:21 38.0

DOS STOP

00:01:50 37.9

WASH START

00:06:00 60.1

WASH STOP

00:07:01 60.9

DOS PUMP 1 53.2ml

DRAIN

00:07:02 60.9

RINSE 1

00:08:23 59.8

FILL

00:08:29 59.9

RINSE START

00:09:27 56.2

RINSE STOP

00:10:28 56.2

DRAIN

00:10:28 56.2

FINAL RINSE

00:11:49 55.5

FILL

00:11:59 55.4

HEAT

00:12:58 54.8

DOS START

00:18:29 79.8

DOS STOP

00:18:33 80.1

DISINF START

00:21:01 89.7

DISINF STOP

00:22:02 91.7

DOS PUMP 2 8.8ml

DRAIN DRYING

00:22:03 91.7

DRAIN

00:22:04 91.7

DRY

00:22:43 90.9

PROCESS COMPLETE

00:35:44 70.8

PROCESS OK

Page 17

Page 17 of 24

<Doc_USR><Doc_5025919000><Rel_A><Lang_EN>

FAULT INDICATIONS

Handling alarms

Handling alarms appear on the display in plain text.

The machine cannot be started until the fault has been put right.

The following handling alarms can be displayed:

Dos 1 low level Empty container alarm 1. If detergent 1 is finished, a handling code is

generated. The alarm is reset automatically when detergent is added.

Dos 2 low level Empty container alarm 2. If detergent 2 is finished, a handling code is

generated. The alarm is reset automatically when detergent is added.

Dos 3 low level Empty container alarm 3. If detergent 3 is finished, a handling code is

generated. The alarm is reset automatically when detergent is added.

Dos 4 low level Empty container alarm 4. If detergent 4 is finished, a handling code is

generated. The alarm is reset automatically when detergent is added.

NOTE:

When the handling alarm Add detergent 1-4 is activated (appears on the display) there is

always enough detergent left for one run; in other words, if you have started a program it

can run to the end.

Red lamp: Alarm indication Handling alarm or fault code

P01

DOS 1 LOW LEVEL

DOS 1 LOW LEVEL

Page 18

<Doc_USR><Doc_5025919000><Rel_A><Lang_EN>

Page 18 of 24

Alarms

If the red lamp at O lights up, the process has been aborted because of a fault.

The display shows a fault code.

Acknowledging a fault code

Acknowledge the fault code as follows:

Note the fault code•

Cancel the acoustic signal by pressing • U. The machine remains locked but the

program has been stopped. The display shows the password entry menu.

Correct the fault or call service personnel.•

Enter the password (558387) using the arrow keys and press • S. All liquid is

drained from the machine and the soiled-side door is unlocked*.

Open the door and remove the items.•

The items in the machine are not clean and must be washed again from the

beginning with a new program.

If the items are still hot, handle them with care to avoid burns.

* If the drain pump is faulty, water cannot be drained from the machine and the fault cannot be put

right until the door has been opened. The soiled-side door is unlocked as soon as the password

is conrmed.

F01

Fault codes in the machine

Fault codes indicate that a serious fault has occurred in the machine or the washing

process . The fault must be put right by an authorized service technician.

The following fault codes may occur:

Fault code Description of fault

A00 POWER FAIL Power failure

A01 MCCB TRIP Tripped overload protection

A02 CH SLOW FILL Chamber tank slow to fill. The chamber tank takes more than 10 minutes to fill.

A03 SLOW DRAIN The chamber takes more than 5 minutes to drain.

A04 W LEAK DRYER Water leakage in the dryer

A05 LOCK SS Soiled-side door does not lock within 3 seconds of program start or the door is

unlocked while a program is running.

The soiled-side breakers for locked and unlocked are activated at the

same time.

A06 UNLOCK SS Soiled-side door does not unlock within 3 seconds after the end of a program.

A07 CLOSED SS The soiled-side door did not close within 20 seconds of program start or the

door is open while a program is running or the crush protection was activated

while a program was running.

The soiled-side breakers for open and closed are activated at the same time.

A09 LOCK CS Clean-side door does not lock within 3 seconds of program start or the door is

unlocked while a program is running.

The clean-side breakers for locked and unlocked are activated at the

same time.

Page 19

Page 19 of 24

<Doc_USR><Doc_5025919000><Rel_A><Lang_EN>

Fault code Description of fault

A10 UNLOCK CS Clean-side door does not unlock within 3 seconds after the end of a program.

A11 CLOSED CS The clean-side door did not close within 20 seconds of program start or the

door is open while a program is running or the crush protection was activated

while a program was running.

The clean-side breakers for open and closed are activated at the same time.

A13 DOSING 1 Low flow, detergent 1.

The amount of detergent has not decreased by 5 ml within 10 seconds

of dosing .

A13 DOSING 2 Low flow, detergent 2.

The amount of detergent has not decreased by 5 ml within 10 seconds

of dosing .

A13 DOSING 3 Low flow, detergent 3.

The amount of detergent has not decreased by 5 ml within 10 seconds

of dosing .

A13 DOSING 4 Low flow, detergent 4.

The amount of detergent has not decreased by 5 ml within 10 seconds

of dosing .

A18 CONDUCTIV H The conductivity is above 4 µS/cm after three final rinse attempts.

A19 CIRC PRESS L The pressure from the circulation pump is below 20 kPa. There is a delay of

five seconds from the starting of the circulation pump.

A20 CIRC PRESS H The pressure from the circulation pump is higher than 130 kPa.

A21 DRY PRESS L Drying pressure below 150 Pa. There is a delay of five seconds from the start-

ing of the dryer fan.

A22 DRY PRESS H Drying pressure above 750 Pa.

A23 DRYER TEMP L Low temperature in dryer. The temperature in the dryer has not increased to

80 °C within four minutes of the dryer starting.

A24 DRYER TEMP H The temperature in the dryer is above 130 °C.

A25 CHAMB TEMP L Low temperature in the chamber The temperature in the dryer has not in-

creased by 10 degrees C within four minutes of the dryer starting.

A26 CHAMB TEMP H The temperature in the chamber is more than 5 degrees C above the highest

chosen reference point.

A27 T DIFF CHAMB The pressure difference between the chamber sensors is more than 3 degrees

C. Delay of 3 seconds. An alarm is activated only when the reference point has

been reached.

A28 DISINF TEM L The final rinse time + 60 seconds has passed.

A29 ROT FLUSH W Low spray arm rotation speed.

A31 COND SENS Conductivity sensor faulty.

A32 CIRC PR SENS Circulation pump pressure sensor faulty.

A34 T SENS DRYER Dryer temperature sensor faulty.

A35 T SENS CHAMB Chamber temperature sensor faulty

A36 I SENS CHAMB Independent temperature sensor in the chamber.

A37 HUMIDITY SEN Humidity sensor faulty

A38 CONFIG ERROR Configuration error

A41 I/O FAULT I2C communication bus or I/O card faulty.

Page 20

<Doc_USR><Doc_5025919000><Rel_A><Lang_EN>

Page 20 of 24

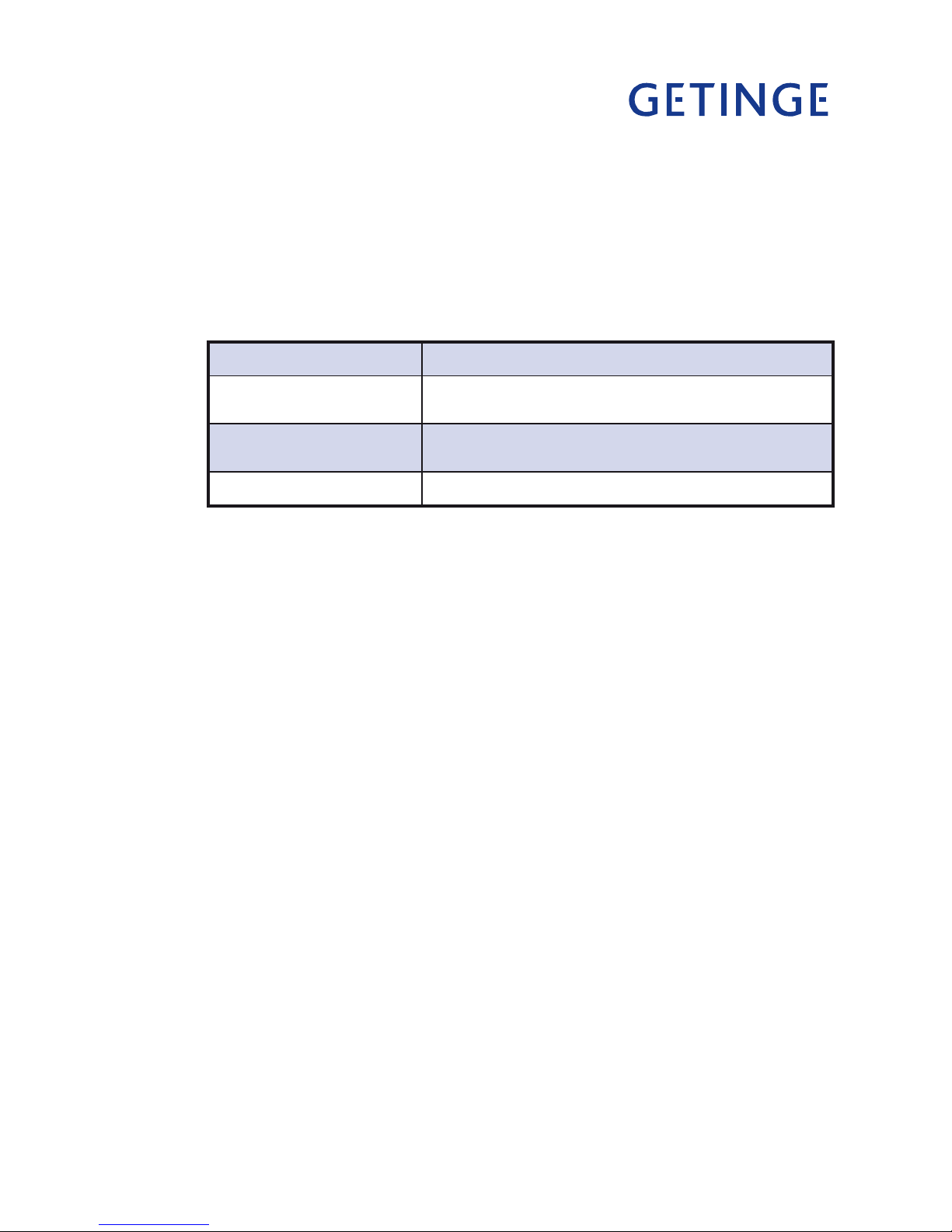

Detergent

The machine has been proven and tested with Getinge detergent. We recommend using

Getinge detergent or an equivalent detergent from a reputable manufacturer.

Do not use domestic dishwasher detergent.

Recommendation of chemical agents does not mean that the manufacturer is liable

for the effect of these agents on the goods to be washed. Changes in the composition,

conditions etc. not notied by the manufacturer may affect the quality of the washing

process.

Getinge detergent for mechanical washing of:

A - Surgical instruments B - MIS-instruments C - Anesthesia equipment

D - OP-shoes E - Containers F - Baby-bottles

G - Lab glassware

Products Alkalinity Surfactants Phosphates Enzymes Suitable for optics

and anodized Alu.

Goods to be

washed

Getinge Power Wash Amines + - + + A, B, C, D, E

Getinge Wash Extra Alkaline salts - + - (+) A, C, D, (E), F

Getinge Wash Intensive Caustic soda + - - - A, C, D, F

Getinge Wash Enzyme - + - + + A, B, C, D, E

Getinge Wash LAB Caustic soda - - - - G

Acidic detergents and neutralizing agents

Products Acids Effects Prewash for Dosage lab glassware

Getinge Neutralization P Phosphoric

acid, Citric

acid

Neutralization of alkaline

residues, removal of mineral

residues, e.g. rust and lime

Removal of

mineral residues

First rinse after the alkaline wash

for neutralization or prewash

Getinge Neutralization Citric acid Neutralization of alkaline

residues

First rinse after the alkaline wash

Lubricants and rinse aids

Products Ingredients Effects Dosage

Getinge Instrumentmilk Paraffinum perliquidium

emulsifying agents

Lubrication of instruments Final rinse

Getinge Rinse Surfactants Reduction of surface tension

of water, improved drying

Final rinse

Getinge agents can be ordered from your Getinge products reseller.

Page 21

Page 21 of 24

<Doc_USR><Doc_5025919000><Rel_A><Lang_EN>

Water quality – Washer disinfectors

The quality of the water used in all stages of cleaning is important for good results.

The water used in each stage must be compatible with:

* The material that the washer disinfector is made of

* The chemicals used in the process

* Process requirements for the various stages of the process

The main factors for good water quality are:

Hardness High hardness will cause limescale deposits in the washer disinfector, lead-

ing to poor cleaning results.

Ionic contaminants A high concentration of ionic contaminants may cause corrosion and pitting

on stainless steel. Heavy metals such as iron, manganese or copper cause

instruments to tarnish.

Microbial contaminants The water used should not increase the biological load on the equipment

that is being treated against micro-organisms and their residual products

which may cause fever-like symptoms when they get into the human body.

Sanitary chemicals High concentrations of and high exposure to sanitary chemicals may cause

corrosion and pitting on stainless steel.

Getinge Disinfection AB therefore recommends that water used in the pre-rinsing,

washing and nal rinsing phases should be of drinkable quality in accordance with

the guidelines .

Detailed information about acceptable water quality can be found in “Guidelines for

Drinking Water Quality, 3rd Edition” published by WHO.

Getinge Disinfection AB also recommends following local standards. RO (reverseosmosis) water (or similarly treated water) is used for the nal washing/disinfection

phase. A typical specication for RO water is:

pH 5.5 till 8

Conductivity <30 µs.cm

-1

TDS <40 mg/l

Maximum hardness <50 mg/l

Chlorine <10 mg/l

Heavy metals <10 mg/l

Phosphates <0.2 mg/l as P2O

5

Silicates <0.2 mg/l som SiO

2

Endotoxins <0.25 EU/ml

Total number of micro-organisms <100 per 100 ml

Further advice should also be obtained from the manufacturers of chemical and

medical equipment.

Where local standards are stricter than Getinge Disinfection AB’s recommendations,

they should be followed. Note that it is the customer’s responsibility to supply the

washer disinfector with suitable water.

Page 22

<Doc_USR><Doc_5025919000><Rel_A><Lang_EN>

Page 22 of 24

Handling of worn-out washer/flusher disinfectors

Worn-out electrical and electronic machines consist of recyclable materials.

However, they also contain materials that are harmful but necessary in order for the

machines to function in a proper and secure way. If these materials are placed among the

domestic waste or handled in the wrong way, it could lead to health hazards or damage

to the environment.

The machine might be contaminated. This means it must be disinfected before it can be

recycled.

Therefore you should never, not under any circumstances, place the worn-out washer/

usher disinfector among the domestic waste.

Instead, take worn-out electrical and electronic machines to a recycling plant.

Ask your reseller if required.

Make sure the worn-out washer/usher disinfector is kept out of reach of children before

it is taken away for recycling.

All plastic parts of the washer/ usher disinfector have international markings on them.

Therefore it is possible to recycle the parts of the washer/ usher disinfector in an environmentally friendly way by means of proper waste sorting.

Page 23

Page 23 of 24

<Doc_USR><Doc_5025919000><Rel_A><Lang_EN>

Page 24

Australia

Getinge Australia Pty ltd

PO Box 50, Bulimba QLD 4172

Unit 1, 205 Queensport Rd.

Murarrie QLD 4173

info@getinge.com.au

Phone:+61-7 3399 3311

Belgium

Getinge NV

Vosveld 4 B-2

B-2110 Wijnegem

info@getinge.be

Phone: +32-33 542 865

Canada

Getinge Canada Ltd

1575 South Gateway Road,

Unit C Mississauga

Ontario L4W 5J1

info@getingecastle.ca

Phone: +1-905 629 8777

China

Getinge (Suzhou) Co.Ltd

No.158,Fang Zhou Road, Suzhou

Industrial Park 15021 Suzhou,

Jiangsu Province P.R.China

info@getinge.com.cn

Phone: +86- 51 262 838 966

Getinge Shanghai Trading Co. Ltd.

Rm 1988 Tower B,

CityCentr, 100 Zunyi Rd.

200051 Shanghai P.R.

info@getinge.com.cn

Phone: +86- 21 623 72 408

Denmark

Getinge Danmark A/S

Firskovvej 23

DK-2800 Lyngby

getinge.danmark@getinge.com

Phone: +45-45 93 27 27

Finland

Getinge Finland AB

Ängsgatan 8

FI-02200 Esbo

getinge@getinge.fi

Phone: +35-89 6824 120

France

Getinge France SAS

BP 49, avenue du Canada

ZA de Courtaboeuf

Les Ulis, FR-91942

getinge.france@getinge.fr

Phone: +33-1 64 86 89 00

Germany

Getinge Vertrieb & Service GmbH

Kehler Strasse 31

764 37 RASTATT

TYSKLAND

Tel: +49-7222 932 306

Fax: +49-7222 932 597

e-mail: info.inco-de@getinge.com

Italy

Getinge S.p.A

via Poggio Verde, 34

00148 Roma

info@getinge.it

Phone: +39-06 656 631

Netherlands

Getinge B.V.

Fruiteniersstraat 27, Zwijndrecht

Postbus 1004

NL-3330 CA Zwijndrecht

info@getinge.nl

Phone: +31-78 610 24 33

Norway

Getinge Norge A/S

Ryenstubben 2

0679 Oslo

info@getinge.no

Phone: +47-23 051 180

Poland

Getinge Poland

Ul. Lirowa 27

02-387 Warszawa

offi ce@getinge.pl

Phone: +48-22 882 06 26

Singapore

Getinge International Far East Pte. Ltd.

20 Bendemeer Road,

#06-02, Cyberhub Building

Singapore, SG-339914

Phone: + 65- 6396 7298

South Africa

Getinge South Africa (Pty) Ltd

P O Box 48492

Hercules

Pretoria SA 0002

getinge@mweb.co.za

Phone: +27-123 721 370

Spain

Getinge Iberica SL

P.E. San Fernando, Avda. Castilla 2,

Edif. Francia 1era planta

San Fernando de Henares

Madrid ES-28830

administracion@getinge.es

Phone: + 34-916 78 26 26

Sweden

Getinge International AB

P O Box 69

SE-310 44 Getinge

info@getinge.com

Phone: +46-35 15 55 00

Switzerland

Getinge ALFA AG

Weidenweg 17

4310 Rheinfelden

info@alfa.ag

www.getingealfa.ch

Phone: +41-61 836 15 15

United Kingdom

Getinge UK Ltd

Orchard Way

Calladine Park

Sutton-In-Ashfi eld

Notts NG 17 1JU

sales@getinge.co.uk

Phone: +44-1623510033

USA

Getinge USA Inc.

1777 East Henrietta Road

Rochester, NY 14623-3133

info@getingeusa.com

www.getingeusa.com

Phone: +1-5,854,751,400

www.getinge.com

Loading...

Loading...