Fresh Indoor Air Quality

R

570 SERIES

INSTALLER: PLEASE FILL OUT AND MAIL WARRANTY CARD AFTER INSTALLATION IS

COMPLETE. LEAVE INSTALLATION INSTRUCTIONS WITH HOME OWNER

PRECAUTION: The installer should be an experienced service technician. Disconnect electrical power before

beginning installation. Do not install where temperatures fall below 32 degrees F or where plenum temperatures

exceed 150 degrees F. When wiring into a multi-speed blower circuit see Step 6.

INSTALLATION: The humidifier may be mounted with the 6" outlet to

the right or left by inverting the cabinet and reversing the positions of

the distributor trough and drain pan. The humidifier may be mounted

on the warm or return air plenum with equal efficiency.

See Typical Installations.

ADDITIONAL MATERIALS THAT MAY BE NECESSARY:

1. 1/4" diameter plastic supply tubing or 1/4" copper

supply tubing for hot water applications

2. 6" diameter galvanized by-pass pipe

3. electrical wire and wire nuts

4. current sensing relay (G.F. Model #GA50 suggested)

5. #8 self piercing sheet metal screws

1

WARM AIR

UP FLOW

3

3

RETURN AIR

DRAIN

GENERALAire AC SERIES

HIGH EFFICIENCY AIR CLEANER

R

WARM AIR

9-1/2”

6”

FLOW-THROUGH

BYPASS HUMIDIFIER

FOR INSTALLATION ON A VERTICAL

PLENUM SURFACE OF ANY

FORCED AIR FURNACE

RETURN AIR

DRAIN

DOWN FLOW

WARM AIR

8-7/8”

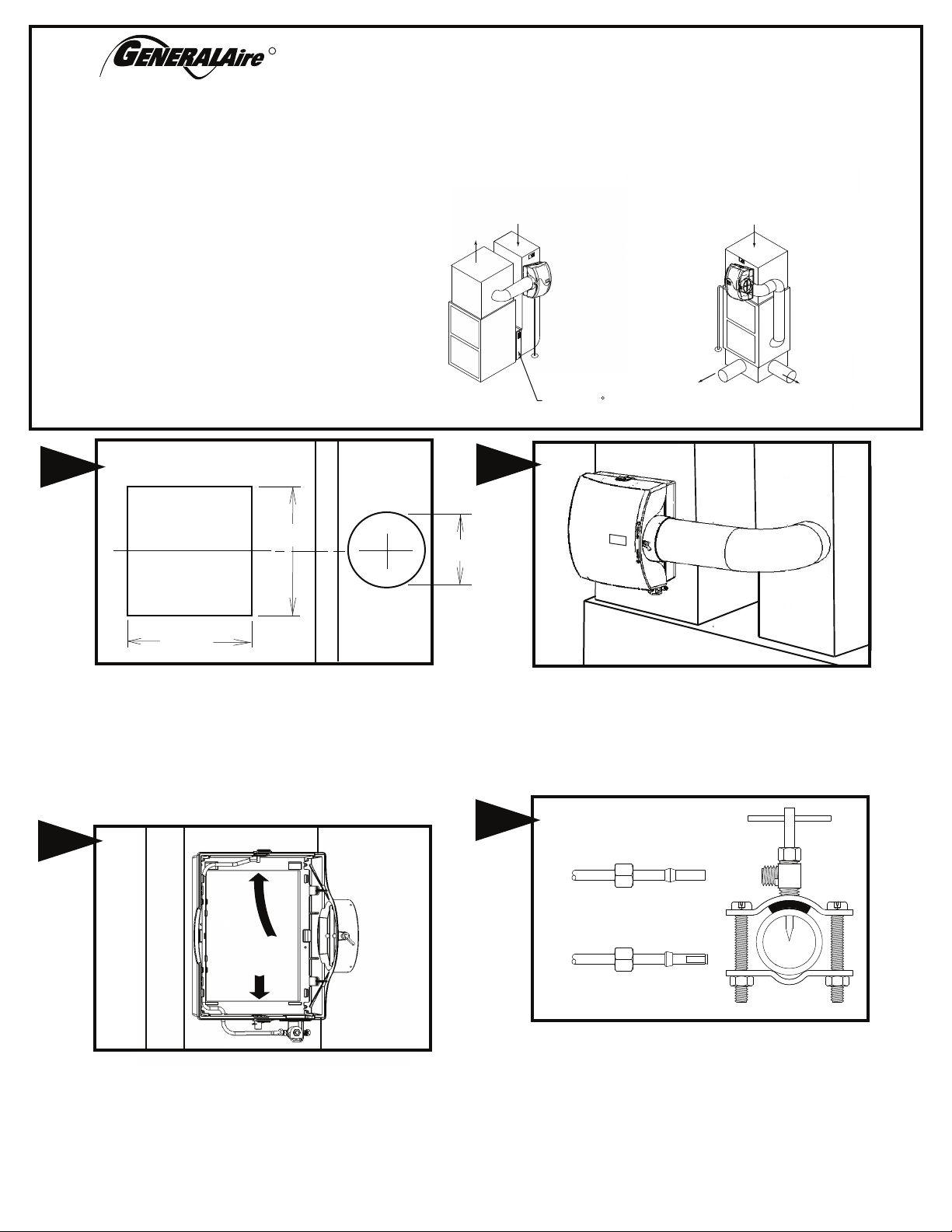

The General Aire model 570 may be installed on either the

supply or return plenum of a forced air handling system. Select

a location for the humidifier that allows for service and

maintenance. Cut out a rectangle 8-7/8” wide by 9-1/2“ tall.

Extend horizontal centerline of cut out to the adjacent plenum.

Cut a 6” hole 10” to 15” from side of humidifier, on cabinet

centerline, using connecting collar as guide. The bypass is

reversible and can be mounted on the right or left side of the

humidifier.

2

1

Humidifier is self retaining. Slide top side in first, then slide

chassis down. Level chassis and install center screws. If

by-pass pipe installs to opposite side of chassis, bend clip on

chassis, remove side discharge, and reinstall discharge to

opposite side of chassis. Install remaining four corner screws.

FORM NO. 570-18 (FILE 15018) REV. E

Connect by-pass pipe to collar and humidifier cabinet. Using

holes at top and bottom of side panel discharge, pierce 2

self tapping screws through by-pass pipe.

4

COPPER

TUBING

PLASTIC

TUBING

2

Mount the self tapping saddle valve or code valve on either a cold

or a hot water pipe. A side or top mount is best to avoid clogging

from pipe sediment. Connect 1/4” O.D. tubing to the saddle valve.

Copper tubing requires a brass compression nut and brass sleeve.

Plastic tubing requires a brass insert inside the tubing, a plastic

sleeve on the outside with a brass compression nut.

NOTE: DO NOT USE PLASTIC TUBING ON HOT WATER OR IN

CONT ACT WI TH ANY H OT PLE NUM SURFACE OR DUCT.

INSTALLATION OF THIS SADDLE VALVE MU ST MEET OR

EXCEED LOCAL CODES AND ORDINANCES.

GCV3412 CODE VALVE INSTALLATION INSTRUCTIONS

Copper Pipe

1. Turn off water supply.

2. Clean pipe, fittings and valve with sandpaper or wire brush.

3. Apply a thin layer of flux to all surfaces to be soldered.

4. Assemble valve to pipe and/or fittings.

5. Cooling the valve by wrapping a wetted rag around the valve is

optional.

6. Heat the joints with a torch. Apply solder to each joint. Continue to

apply heat sufficient to keep solder liquid.

7. After solder has filled entire joint area, remove heat and allow joint

to cool. Do not move or disturb.

8. Slide compression nut over 1/4” copper tube followed by

compression sleeve.

9. Insert tube into valve fully and tighten nut.

10. Turn on water supply and check for leaks.

*CODE VALVE IS INCLUDED WITH AUTOMATIC MODELS ONLY

3/4” TEE

1/2” TEE

5

Connect 1/4" water supply tube to brass filter at inlet of solenoid. DO

NOT USE PLASTIC TUBING IN CONTACT WITH ANY HOT

PLENUM SURFACE OR DUCT. IF USING PLASTIC TUBING, USE

TUBE SUPPORT P189 AND PLASTIC COMPRESSION SLEEVE

P190.

6

Turn damper knob to winter (open) position. Turn on water

supply and check operation of humidifier. Set humidistat to a demand

setting. With the furnace off, the solenoid valve should be closed.

Start the furnace, the solenoid valve should open when the blower or

burner circuit is energized. Check flow of water through distributor

trough and evaporator pad. The standard GA4231 yellow orifice will

supply approximately 3.5 GPH of water at a line water pressure of 60

psi. For low water pressures (20-40 psi) a larger orange orifice

GA4299 is available to provide the same flow. Leave humidistat set

at the recommended setting.

7

SNSR

HUM

AC N

AC L

SNSR

HUM

AC N

AC L

HUMIDISTAT

HUMIDISTAT

OUTDOOR TEMP. SENSOR

WIRE JUMPER

WIRE JUMPER

OUTDOOR TEMP. SENSOR

WIRE

JUMPER

727-58 24 V. TRANSFORMER

24 V. TRANSFORMER

ON-OFF SWITCH

FURNACE

CONTROL BOARD

C

24v.

60CY.

R

N

115v.

(HOT)

60CY.

FURNACE

CONTROL BOARD

C

24v.

60CY.

HUM

ON-OFF SWITCH

W

W

FURNACE

BOARD

FURNACE

BOARD

(HOT)

ACC

EAC

24v.

60CY.

24V. SOLENOID VALVE

24V. SOLENOID VALVE

24V. SOLENOID VALVE

24V. SOLENOID VALVE

C

115v.

60CY.

7A

7C

7E

7G

SNSR

HUM

AC N

AC L

SNSR

HUM

AC N

AC L

HUMIDISTAT

Connect drain hose to 1/2" spout on humidifier cabinet using hose

clamp. Run 1/2" hose to suitable drain such as floor drain, sewer or

laundry sink. Be sure hose has continuous slope and is not kinked at

any point.

L2

115v.

60CY.

(HOT)

L1

FURNACE

COMMON LEAD

C

(HOT)

L2

115v.

60CY.

(HOT)

L1

FURNACE

COMMON LEAD

C

(HOT)

115v.

60CY.

24V. SOLENOID VALVE

7B

C

MULTI

SPEED

HI

BLOWER

LO

MOTOR

115v.

60CY.

7D

24V. SOLENOID VALVE

7F

C

MULTI

SPEED

HI

BLOWER

LO

MOTOR

OUTDOOR TEMP. SENSOR

WIRE

JUMPER

727-58 24 V. TRANSFORMER

24V. SOLENOID VALVE

OUTDOOR TEMP. SENSOR

WIRE

JUMPER

727-58 24 V. TRANSFORMER

C

12500 AIR

PRESSURE SWITCH

24V. SOLENOID VALVE

24 V. TRANSFORMER

NO

C

12500 AIR

PRESSURE SWITCH

ON-OFF SWITCH

24 V. TRANSFORMER

HUMIDISTAT

ON-OFF SWITCH

NO

ON-OFF SWITCH

CURRENT

SENSING

RELAY

ON-OFF SWITCH

CURRENT

SENSING

RELAY

GA50

GA50

7H

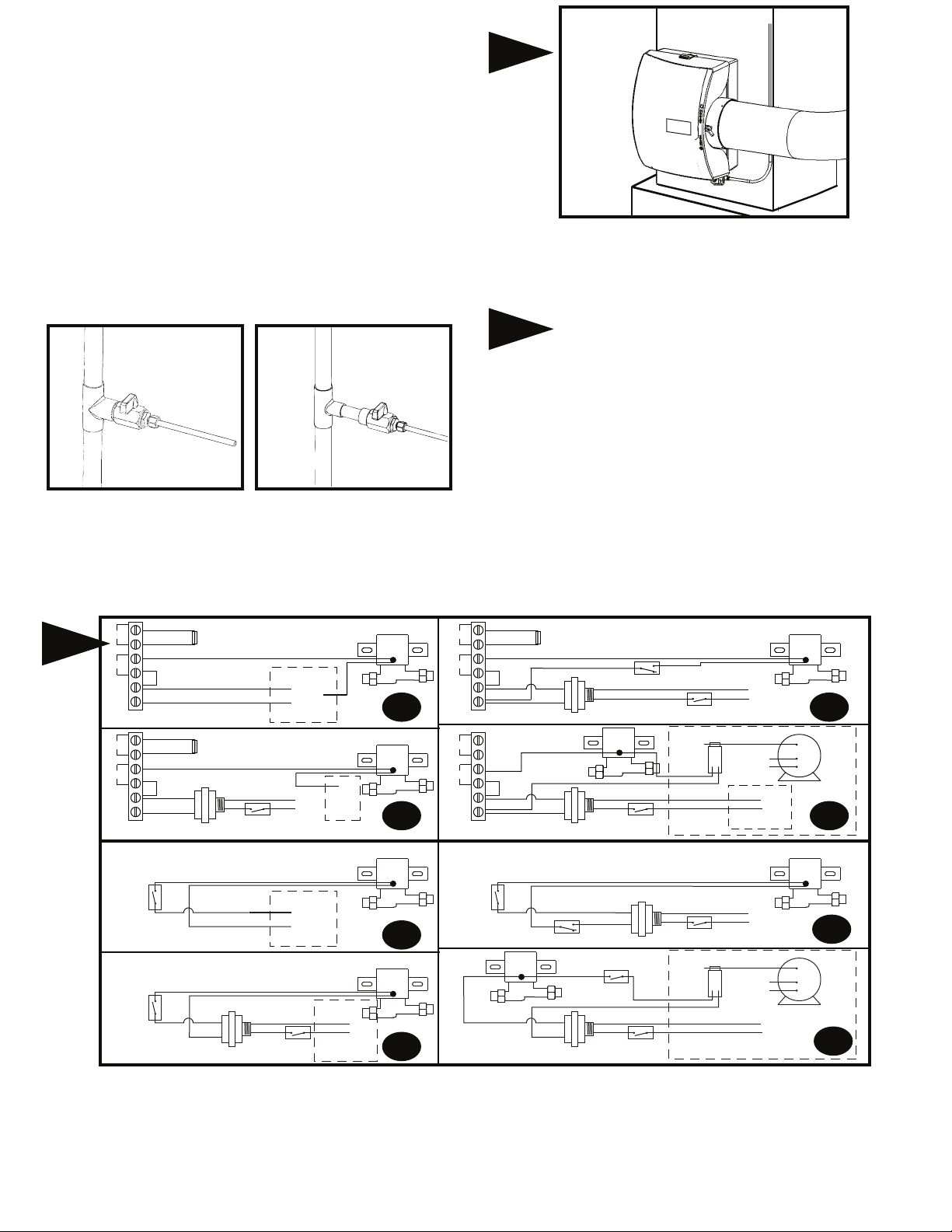

7A-7D Electronic Humidistat

7A - To furnace control board 24 volts

7B - To constant power using 24V transformer and pressure switch

7C - To furnace control board 115 volts with 24V transformer

7D - To constant power using 24V relay and current sensing relay

7E-7H Manual Humidistat

7E - To furnace control board 24 volts

7F - To constant power using 24V transformer and pressure switch

7G - To furnace control board 115 volts with 24V transformer

7H - To constant power using 24V relay and current sensing relay

570-1 CHASSIS

900-9 NOZZLE

900-10 SPOUT

GA4226 DISTRIBUTOR TUBE

PARTS LIST FOR HUMIDIFIER

570-40 PAD RAIL

GA-10 EVAPORATOR PAD

900-15 DISTRIBUTOR TROUGH

900-11 DAMPER KNOB

900-28 DAMPER DISK

570-2 SIDE PANEL

DISCHARGE

900-71 BADGE

570-13 COVER

900-14 DRAIN PAN

GA4040 SOLENOID VALVE ASM

GA4004 STAINER SCREEN

P102 COMPRESSION SLEEVE

P101 COMPRESSION NUT

P189 BRASS TUBE INSERT

747-38 TUBING KIT (AVAILABLE)

GA4231 YELLOW ORIFICE

P190 COMP. SLEEVE (PLASTIC)/P102 COMP. SLEEVE (BRASS)

P101 COMPRESSION NUT

LIMITED WARRANTY

This humidifier, if properly registered by the return of the warranty registration card to the manufacturer, is warranted to the consumer against defects in

materials and workmanship for a period of ten years from the date of installation. Evaporator pads, water strainers or metering orifices are not covered by this

limited warranty or any other warranties. Any other defective parts will be repaired without charge except for removal, reinstallation and transportation costs.

To obtain repair service under this limited warranty, the consumer must send the defective part or the complete humidifier to the manufacturer.

THERE ARE NO EXPRESS WARRANTIES COVERING THIS HUMIDIFIER OTHER THAN AS SET FORTH ABOVE, THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE EXPRESSLY EXCLUDED. THE MANUFACTURER ASSUMES NO LIABILITY IN

CONNECTION WITH THE INSTALLATION OR USE OF THIS PRODUCT, EXCEPT AS STATED IN THIS LIMITED WARRANTY. THE MANUFACTURER

WILL IN NO EVENT BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES.

This limited warranty gives you specific legal rights, and you may also have other rights which vary from state to state. Some states do not allow either

limitations on implied warranties, or exclusions from incidental or consequential damages, so the above exclusion and limitation may not apply to you.

Any questions pertaining to this limited warranty should be addressed to the manufacturer. (U.S.A.: The manufacturer has elected not to make available the

informal dispute settlement mechanism which is specified in the Magnuson-Moss Warranty Act.)

CARE AND MAINTENANCE

Your humidifier is engineered to give helpful and trouble-free humidification. For maximum efficiency the following cleaning procedures should be carried out at

the end of each heating season:

1. Turn off water supply and electrical power to humidifier.

2. Remove water cover, distributor trough, evaporator pad and drain pan. Clean excessive mineral deposits from the

distributor trough, drain pan, pad rails, and humidifier cabinet. A solution of 1/2 vinegar & 1/2 water will help loosen mineral

deposits.

Replace humdifier evaporator pad if necessary. (Part number GA10) Install trough and drain pan.

3.

Replace cover. Replace evaporator pad yearly for peak performace.

4. In heavy mineral areas or if the solenoid valve fails to function disconnect the 1/4” water supply line from the solenoid valve.

Carefully pull the strainer screen (P.N. GA4004) from the valve body (P.N. 900-6). Clean the mineral deposits from all

parts. If the orifice is clogged, it may be opened by inserting a small pin. Reinsert the filter into the orifice fitting and screw

the brass strainer body into the solenoid valve.

5. Reconnect the 1/4” water line to the solenoid valve if necessary. Turn on the water supply and check all points for leakage.

The operation of the unit may be checked by starting the furnace. The humidifier operates only when the furnace blower is

running or the burner circuit is energized. The humidifier is now ready for operation.

6. During the summer, turn off water supply and electrical power to humidifier. Close air damper.

AT

OUTSIDE

TEMPERATURE

-20°F -29°C

-10°F -23°C

0°F -18°C

+10°F -12°C

+20°F - 7°C

+30°F - 1°C

RECOMMENDED

SETTING

15%

20%

25%

30%

35%

40%

HOW THE HUMIDIFIER WORKS

The operating principle of the humidifier is based on the most efficient and economical means of evaporating water to the air. The humidifier uses only 2.5

watts of electrical power during operation, less than the smallest household light bulb. The heat necessary for evaporating water is produced by the furnace.

The water supply to the humidifier is controlled by the electric solenoid valve. The humidistat connected in series with the solenoid provides low voltage control

of the humidifier. The humidistat is designed for wall mounting in the living area or surface mounting on the return air duct. ELECTRICAL RATING: 24 VAC /

60 Hz.

Water flows through a strainer, is metered through an orifice to provide the proper amount of water, and is supplied to the evaporator pad by the distributor

trough. Approximately 200 CFM of air is by-passed from the warm air plenum through the humidifier and returned to the cold air plenum. Moisture is

evaporated to the air passing through the evaporator pad. Minerals are not blown into the air stream as occurs in atomizing humidifiers; they are left on the

evaporator pad where a high percentage is carried off with the waste water. When the humidifier is installed and operating, no adjustments are necessary other

than setting the control knob on the humidistat to the desired level of humidification. Leave knob on the humidifier in "HI" or "WINTER" position. To turn the

humidifier off, close water supply valve, switch electrical power off and turn humidistat off. If furnace is used for summer cooling or ventilating set air damper on

"LOW" or "SUMMER".

DO NOT SET RELATIVE HUMIDITY TOO HIGH DURING COLD WEATHER. EXCESSIVE HUMIDITY MAY CAUSE CONDENSATION ON WINDOWS OR IN

WALLS. REFER TO RECOMMENDED SETTINGS AS DESCRIBED IN THE HUMIDISTAT OWNERS MANUAL.

TROUBLESHOOTING

SYMPTOMS

Humidier will not operate

Proper voltage present at solenoid

valve (24 VAC) but no water ow

Humidier runs without

furnace operation or humidier

never shuts o

Too much humidity in home and/or

condensation on windows

Where can I purchase

replacement parts?

DIAGNOTIC STEP

1. Set thermostat to operate both furnace burner and blower. Operation may be necessary for system power.

2. Humidity level in home may be higher than humidistat setting. Increase humidity setting on humidistat.

(humidistat usually located on the return plenum of the furnace or on an interior wall in the living space)*

3 . Verfy water supply is on.

4. Check for voltage at the solenoid valve. Voltage should be 24VAC. Bypass the humidistat if necessary to isolate

the solenoid valve circuit.

5. Verify wiring of humidier and humidistat.

1. Verify water supply is on

2. Verify metering orice is not obstructed. Very hard water with high mineral content may restrict the metering

orice in as little as one heating season. Replace metering orice if restriced. (part number GA4231)

1. Verify humidier and humidistat wiring. Humidier should operate with furnace burner or blower cycle.

1. Reduce the setting on the humidistat. Refer to CARE AND MAINTENANCE section of this manual to estimate a

humidity setting for the home based on outside temperature. *

1. Replacement parts can purchased through your authorized General Aire contractor or visit www.GeneralAire.com

for more information.

* Humidistat is generally located on furnace return plenum or on an inside wall in the living space.

TECHNICAL SUPPORT

USA CUSTOMERS

General Filters, Inc.

43800 Grand River Ave.

Novi, MI 48375

www.GeneralAire.com

Engineering@generalfilters.com

Toll Free (866) 476-5101

CANADIAN CUSTOMERS

Canadian General Filters, Ltd.

400 Midwest Rd.

Toronto, ON M1P3A9 Canada

www.CGFProducts.com

Sales@cgfproducts.com

Tel. (416) 757-3691

ELITE 570 HUMIDIFIER SPECIFICATIONS

Expected Humidity Performance Coverage in Square Feet Based on Construction Type

Model No.

Elite 570

Elite 900

Elite 1000

13-1/4”

GPD

12

17

18

Loose (0.75 AC/H)

800 sq. ft.

1115 sq. ft.

1175 sq. ft.

Average (0.50 AC/H) Tight (0.30 AC/H)

1200 sq. ft.

1650 sq. ft.

1770 sq. ft.

Humidifier Performance Baseline Criteria

Outside Design Temp 0° F (-18° C)

Outside Design R.H. 70% R.H.

Inside Design Temp. 70° F (21° C)

Inside Design R.H. 30% R.H.

Air Changes/hour (AC/H) 0.30

Ceiling Height 8 ft

Furnace Plenum Temp. 120° F (49° C)

Furnace run time for 8hr/1 day

calculating sq. ft.

2000 sq. ft.

2800 sq. ft.

3000 sq. ft.

8-7/8”

13-3/4”

15-1/2”

9-1/2”

Humidier Chassis with plenum

cut out shown as dashed lines

HUMIDIFIER PACKAGED COMPONENT ACCESSORIES

Model 570A (GFI#5710) includes:

Humidier components: GA10 Vapor pad, GA4040 solenoid assembly, Integral Bypass Damper

Accessories: GFX3 Automatic Digital Humidistat, 24V Transformer, Code Valve, Saddle Valve

Model 570M (GFI#5705) includes:

Humidier Components: GA10 Vapor Pad, GA4040 Solenoid Assembly, Integral Bypass Damper

Accessories: Manual Humidstat, 24V Transformer, Saddle Valve

WARRANTY REGISTRATION

You may register online at www.GeneralAire.com or mail form below

Product Information:

Serial Number: _____________________________________________________________

Model: ____________________________________________________________________

Install Date: Month _______________ Day ______________ Year _____________

Owner Information:

Name: _____________________________________________________________________

Address: ___________________________________________________________________

Address 2: __________________________________________________________________

City: _______________________ State: ___________ Zip Code: ____________________

Phone: _____________________________________________________________________

Email: ______________________________________________________________________

Contractor Information:

Contractor Name: _____________________________________________________________

Address: ____________________________________________________________________

Address 2: ___________________________________________________________________

City: _____________________ State: ___________ Zip Code: _______________________

Contractor Phone: ____________________________________________________________

Contractor Email: _____________________________________________________________

R

Fresh Indoor Air Quality

Mail Form To:

General Filters, Inc

Attn: Warranty Dept.

43800 Grand River Ave.

Novi, MI 48375

cut along dashed line

cut along dashed line

USA CUSTOMERS

General Filters, Inc.

43800 Grand River Ave.

Novi, MI 48375

www.GeneralAire.com

Engineering@generalfilters.com

Toll Free (866) 476-5101

TECHNICAL SUPPORT

CANADIAN CUSTOMERS

Canadian General Filters, Ltd.

400 Midwest Rd.

Toronto, ON M1P3A9 Canada

www.CGFProducts.com

Sales@cgfproducts.com

Tel. (416) 757-3691

Loading...

Loading...