Page 1

SETUP & OPERATION MANUAL

FEATURES

Combination riving style splitter and seethrough blade guard with anti-kickback pawls,

and a second European style riving knife also

included.

Extra large precision ground 29” x 42” cast-iron

table including two 11” full cast-iron extension

wings.

Magnetic 2-step safety switch to prevent unwanted or unintentional start-up is equipped

with an extra-large easy access stop panel and

a lock-out key to prevent unauthorized use of

the saw.

Ruggedly built saw carriage with solid cast-iron

cabinet mounted trunnions.

Deluxe Excalibur sliding rip fence system with

50” rails.

Large motor cover door for full, easy access to

motor and belt.

Convenient arbor lock for fast one-tool blade

changes.

Powerful, totally enclosed fan cooled (T.E.F.C.)

industrial motor with multi-groove V-belt drive

for longer belt life and more efficient transfer of

power.

Deluxe cast-iron miter gauge included.

Onboard storage mounts for fence, miter

gauge and arbor wrench.

10" TILTING CABINET SAW

- LEFT TILT

SPECIFICATIONS

• Blade/Arbor diameter

10” (25.4 mm) / 5⁄8” (16 mm)

• Arbor tilt range

0°- 45° (left)

• Maximum depth of cut at 90°/45°

3” (77 mm) / 2 1⁄8” (54 mm)

• Dado capacity

13⁄16” (21 mm)

• Dust port

4” (102 mm)

• Arbor speed

4300 rpm

• Table height

34” (863 mm)

• Table size (w/extension wings)

42” x 29” (1066 x 736 mm)

• Base dimensions (l x w)

21” x 23” (533 x 583 mm)

• Motor

M1 3 HP, 220 V, 1 ph, 11.7 A

M2 5 HP, 220 V, 3 ph, 13 A

M3 5 HP, 600 V, 3 ph, 4.7 A

• Weight

524 lbs (238 kg)

Version 2_Revision 7 - May 2015

© Copyright General International

*Shown with optional table board and legs (50-270KDL)

MODEL

#50-270*

Page 2

GENERAL® INTERNATIONAL

8360 Champ-d’Eau, Montreal (Quebec) Canada H1P 1Y3

Telephone (514) 326-1161 • Fax (514) 326-5555 • www.general.ca

THANK YOU for choosing this General

®

International model 50-270 10”

left tilting cabinet saw. This saw has been carefully tested and inspected before shipment

and if properly used and maintained, will provide you with years of reliable service. For your

safety, as well as to ensure optimum performance and trouble-free operation, and to get

the most from your investment, please take the time to read this manual before assembling,

installing and operating the unit.

The manual’s purpose is to familiarize you with the safe operation, basic function, and features of this saw as well as the set-up, maintenance and identification of its parts and components. This manual is not intended as a substitute for formal woodworking instruction, nor

to offer the user instruction in the craft of woodworking. If you are not sure about the safety

of performing a certain operation or procedure, do not proceed until you can confirm, from

knowledgeable and qualified sources, that it is safe to do so.

Once you’ve read through these instructions, keep this manual handy for future reference.

Disclaimer: The information and specifications in this

manual pertain to the unit as it was supplied from the

factory at the time of printing. Because we are committed to making constant improvements, General

Inter-national reserves the right to make changes to

components, parts or features of this unit as deemed

necessary, without prior notice and without obligation

to install any such changes on previously delivered

units. Reasonable care is taken at the factory to ensure

that the specifications and information in this manual corresponds with that of the unit with which it was

®

supplied. However, special orders and “after factory”

modifications may render some or all information in

this manual inapplicable to your machine. Further, as

several generations of this model of saw and several

versions of this manual may be in circulation, if you

own an earlier or later version of this unit, this manual

may not depict your machine exactly. If you have any

doubts or questions contact your retailer or our support

line with the model and serial number of your unit for

clarification.

Page 3

GENERAL® INTERNATIONAL WARRANTY

All component parts of General® International and Excalibur by General International® products are

carefully inspected during all stages of production and each unit is thoroughly inspected upon completion of assembly.

Limited Lifetime Warranty

Because of our commitment to quality and customer satisfaction, General® International agrees to

repair or replace any part or component which upon examination, proves to be defective in either

workmanship or material to the original purchaser for the life of the tool. However, the Limited Lifetime

Warranty does not cover any product used for professional or commercial production purposes nor for

industrial or educational applications. Such cases are covered by our Standard 2-year Limited Warranty only. The Limited Lifetime Warranty is also subject to the “Conditions and Exceptions” as listed below.

Standard 2-Years Limited Warranty

All products not covered by our lifetime warranty including products used in commercial, industrial

and educational applications are warranted for a period of 2 years (24 months) from the date of purchase. General® International agrees to repair or replace any part or component which upon examination, proves to be defective in either workmanship or material to the original purchaser during this

2-year warranty period, subject to the “conditions and exceptions” as listed below.

To file a Claim

To file a claim under our Standard 2-year Limited Warranty or under our Limited Lifetime Warranty, all

defective parts, components or machinery must be returned freight or postage prepaid to General®

International, or to a nearby distributor, repair center or other location designated by General® International. For further details call our service department at 1-888-949-1161 or your local distributor for

assistance when filing your claim.

Along with the return of the product being claimed for warranty, a copy of the original proof of purchase and a “letter of claim” must be included (a warranty claim form can also be used and can be

obtained, upon request, from General® International or an authorized distributor) clearly stating the

model and serial number of the unit (if applicable) and including an explanation of the complaint or

presumed defect in material or workmanship.

CONDITIONS AND EXCEPTIONS:

This coverage is extended to the original purchaser only. Prior warranty registration is not required but

documented proof of purchase i.e. a copy of original sales invoice or receipt showing the date and

location of the purchase as well as the purchase price paid, must be provided at the time of claim.

Warranty does not include failures, breakage or defects deemed after inspection by General®

International to have been directly or indirectly caused by or resulting from; improper use, or lack of or

improper maintenance, misuse or abuse, negligence, accidents, damage in handling or transport, or

normal wear and tear of any generally considered consumable parts or components.

Repairs made without the written consent of General® International will void all warranty.

Page 4

TABLE OF CONTENTS

Rules for safe operation .....................................................................................................5

Electrical requirements ...................................................................................................... 6

Identification of main parts and components .................................................................. 7

Basic functions ...................................................................................................................8

Installation .........................................................................................................................8

Placement within the shop ................................................................................................................................ 8

Esablishing a safety zone ................................................................................................................................... 8

Unpacking .......................................................................................................................... 9

Clean up ..........................................................................................................................10

Assembly instructions ................................................................................................. 10-12

Install the blade tilt adjustment handwheel .................................................................................................. 10

Install miter gauge & fence storage brackets .............................................................................................. 11

Mount the switch ............................................................................................................................................... 11

Install the table extension wings ..................................................................................................................... 11

Install the motor cover...................................................................................................................................... 11

Install the fence assembly ............................................................................................... 12

Front fence rail .................................................................................................................................................. 12

Rear fence rail ................................................................................................................................................... 12

Connecting to dust collector ...........................................................................................13

Install/remove a saw blade ............................................................................................13

Install and adjust riving knife .......................................................................................... 14

Select a riving knife .......................................................................................................................................... 14

Removal/Installation ........................................................................................................................................ 15

Blade cover and riving knife assembly ......................................................................................................... 15

Adjustment/alignment ..................................................................................................................................... 16

Setting the splitter/knife 90° to the table ........................................................................................................ 16

Setting the splitter/knife parallel and centered on the blade .................................................................... 16

Level the table insert ......................................................................................................................................... 17

Basic adjustments and controls ...................................................................................... 17

Connecting to a power source .......................................................................................................................17

ON/OFF magnetic power switch .................................................................................................................... 17

Overload protection ......................................................................................................................................... 17

Blade height adjustment ................................................................................................................................. 18

Blade tilt(bevel) adjustment ............................................................................................................................ 18

Operating instructions ..................................................................................................... 18

Types of cuts ............................................................................................................... 19-20

Adjusting and using the miter gauge ..............................................................................20

Using a dado blade ......................................................................................................... 22

Maintenance and adjustments .......................................................................................22

Recommended optional accessories ............................................................................. 24

Parts list & diagrams ................................................................................................... 25-33

Contact information ........................................................................................................ 34

Page 5

RULES FOR SAFE OPERATION

To help ensure safe operation, please take a moment to learn the machine’s applications and limitations,

as well as potential hazards. General® International disclaims any real or implied warranty and holds itself

harmless for any injury that may result from the improper use of it’s equipment.

1. Do not operate the saw when tired, distracted, or

under the effects of drugs, alcohol or any medication that impairs reflexes or alertness.

2. The work area should be well lit, clean and free of

debris.

3. Keep children and visitors at a safe distance when

the saw is in operation; do not permit them to operate the saw.

4. Childproof and tamper proof your shop and all

machinery with locks, master electrical switches

and switch keys, to prevent unauthorized or unsupervised use.

5. Stay alert! Give your work your undivided attention.

Even a momentary distraction can lead to serious

injury.

6. Fine particulate dust is a carcinogen that can be

hazardous to health. Work in a well-ventilated area

and whenever possible use a dust collector and

wear eye, ear and respiratory protection devices.

7. Do not wear loose clothing, gloves, bracelets, neck-

laces or other jewelry while the saw is in operation.

Wear protective hair covering to contain long hair

and wear non-slip footwear.

8. Be sure that adjusting wrenches, tools, drinks and

other clutter are removed from the machine and/

or the feed table surface before operating.

9. Keep hands well away from the blade and all mov-

ing parts. Use a brush, not hands, to clear away

chips and dust.

10. Be sure that the blade is securely installed and in

proper cutting direction before operation.

11. Be sure the blade has gained full operating speed

before beginning to cut.

12. Always use a clean, properly sharpened blade.

Dirty or dull blades are unsafe and can lead to accidents.

13. If using a power feeder, stop the feeder before stop-

ping the table saw.

14. Do not push or force stock into the blade. The saw

will perform better and more safely when working

at the rate for which it was designed.

15. Use suitable support when cutting stock that does

not have a flat surface. Always hold stock firmly

against the fence when ripping, or against the miter

gauge when cross cutting.

16. To minimize risk of injury in the event of workpiece

kickback, never stand directly in-line with the blade

or in the potential kickback path of the workpiece.

17. Avoid working from awkward or off balance posi-

tions. Do not overreach while cutting; keep both

feet on floor. Never lean over or reach over the

blade and never pull the workpiece over the blade

from behind. Use out feed support or have an assistant help when ripping long material.

18. Keep blade guards in place and in working order.

If a guard must be removed for maintenance or

cleaning, be sure it is properly re-attached before

using the tool again.

19. Never leave the machine unattended while it is run-

ning or with the power on.

20. Use of parts and accessories NOT recommended

by GENERAL® INTERNATIONAL may result in equipment malfunction or risk of injury.

21. Never stand on machinery. Serious injury could re-

sult if the tool is tipped over or if the blade is unintentionally contacted.

22. Always disconnect tool from power before servic-

ing or changing accessories such as blades, or

before performing any maintenance, cleaning or

adjustments, or if the machine will be left unattended.

23. Make sure that switch is in “OFF” position before

plugging in the power cord.

24. Make sure the tool is properly grounded. If equipped

with a 3-prong plug it should be used with a threepole receptacle. Never remove the third prong.

25. Do not use this saw for any purpose other than its

intended use. If used for other purposes, GENERAL®

INTERNATIONAL disclaims any real implied warranty

and holds itself harmless for any injury, which may

result from that use.

5

Page 6

ELECTRICAL REQUIREMENTS

BEFORE CONNECTING THE MACHINE TO THE POWER SOURCE, VERIFY THAT THE VOLTAGE OF YOUR POWER SUPPLY

CORRESPONDS WITH THE VOLTAGE SPECIFIED ON THE MOTOR I.D. NAMEPLATE. A POWER SOURCE WITH GREATER

VOLTAGE THAN NEEDED CAN RESULT IN SERIOUS INJURY TO THE USER AS WELL AS DAMAGE TO THE MACHINE. IF IN

DOUBT, CONTACT A QUALIFIED ELECTRICIAN BEFORE CONNECTING TO THE POWER SOURCE.

THIS TOOL IS FOR INDOOR USE ONLY. DO NOT EXPOSE TO RAIN OR USE IN WET OR DAMP LOCATIONS.

Note: voltage requirements and amperage draw for M2 & M3 3-phase motors may not

be fully described in this manual. For complete electrical requirements refer to the motor I.D. name plate on the machine. If in doubt consult a licensed qualified electrician

before proceeding.

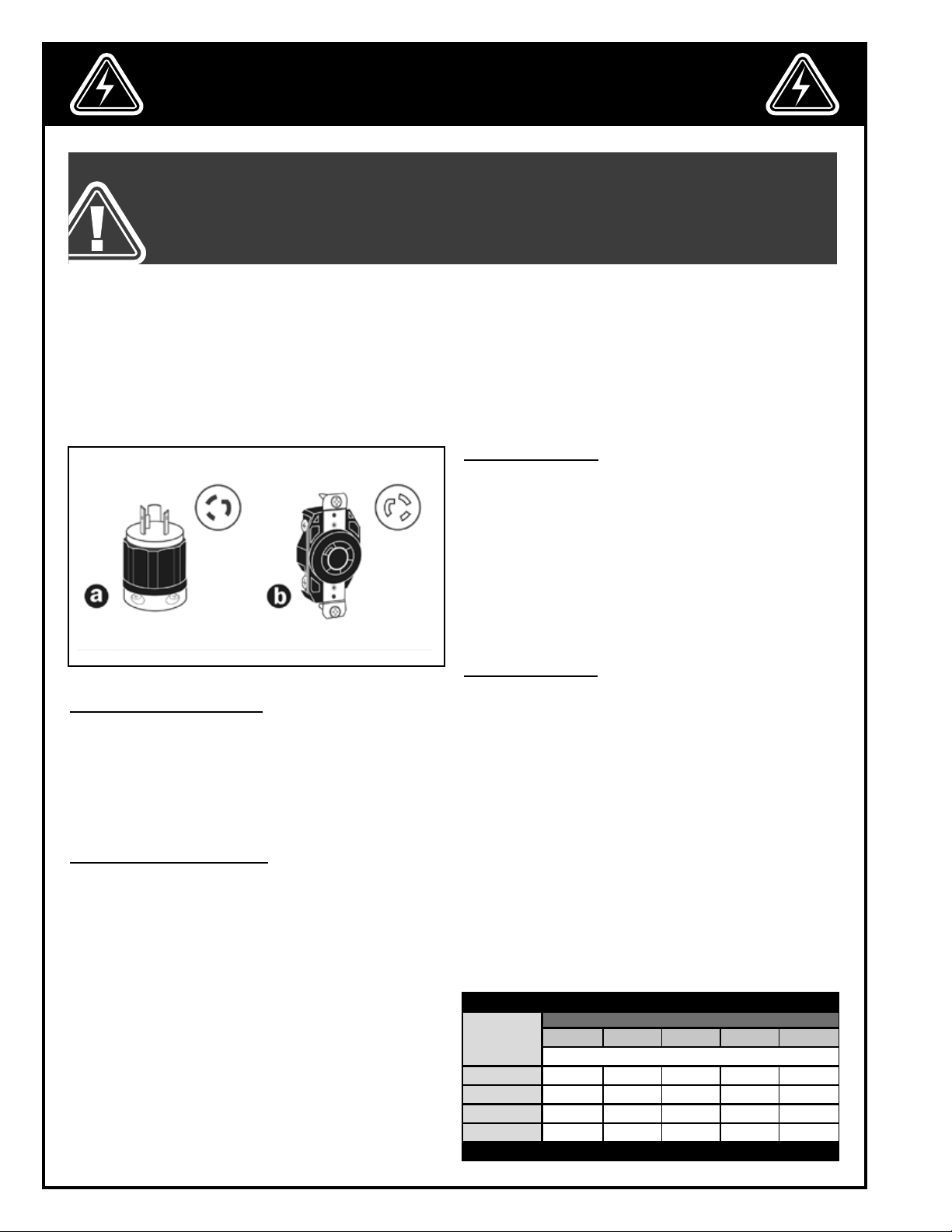

CIRCUIT CAPACITY

Make sure that the wires in your circuit are capable of

handling the amperage draw from your machine, as

well as any other machines that could be operating on

the same circuit. If you are unsure, consult a qualified

electrician. If the circuit breaker trips or the fuse blows

regularly, your machine may be operating on a circuit

that is close to its amperage draw capacity. However, if

an unusual amperage draw does not exist and a power failure still occurs, contact a qualified technician or

our service department.

ELECTRICAL CONNECTIONS

Both a manual circuit breaker (or similar device) as well

as an electrical plug are recommended and should

be installed by a qualified electrician. Use locally approved wire that includes a separate grounding wire

and a 3-prong grounding type plug A with a matching

receptacle B .

GROUNDING INSTRUCTIONS

In the event of an electrical malfunction or short circuit,

grounding reduces the risk of electric shock to the operator. The motor of the “M1” model of this machine is

wired for 220 V single phase operation.

As with many stationary industrial type machines, because each installation situation is unique, this machine

is supplied without a power cord or plug.

The installation of an appropriate power cord and plug

must be performed by a qualified electrician. The machine must be connected to an electrical source using

a power cord that has a grounding wire, which must

also be properly connected to the grounding prong

on the plug. The outlet must be properly installed and

grounded and all electrical connections must be made

in accordance with all local codes and regulations.

EXTENSION CORDS

The use of an extension cord is not generally recommended for 220 V equipment. If you find it necessary,

use only 3-wire extension cords that have 3-prong

grounding plug and a matching 3-pole receptacle that

accepts the tool’s plug. Repair or replace a damaged

extension cord or plug immediately.

Make sure the cord rating is suitable for the amperage listed on the motor I.D. plate. An undersized

cord will cause a drop in line voltage resulting in

loss of power and overheating. The accompanying chart shows the correct size extension cord to be

used based on cord length and motor I.D. plate amp

rating. If in doubt, use the next heavier gauge.

The smaller the number, the heavier the gauge.

TABLE - MINIMUM GAUGE FOR CORD

AMPERE

RATING

< 5

6 TO 10

10 TO 12

12 TO 16

* NR = Not Recommended

220 VOLTS 50 FEET 100 FEET 200 FEET 300 FEET

------->

------->

------->

------->

TOTAL LENGTH OF CORD IN FEET

AWG

18 16 16 14

18 16 14 12

16 16 14 12

14 12 * NR * NR

6

Page 7

IDENTIFICATION OF MAIN PARTS AND COMPONENTS

FRONT VIEW

D

A

C

E

F

B

G

J

H

I

S

P

O

R

N

L

Q

M

K

A. LEFT TABLE EXTENSION WING

B. MITER GAUGE

C. MAIN TABLE

D. SPLITTER/BLADE COVER

E. TABLE INSERT

F. PUSH STICK

G. RIP FENCE

H. RIGHT TABLE EXTENSION WING

I. FENCE LOCKING LEVER

J. EXTENSION TABLE (OPTIONAL)

K. SUPPORT LEGS (OPTIONAL)

L. FRONT FENCE RAIL

M. T-FENCE STORAGE BRACKETS

N. BLADE TILT ADJUSTMENT HANDWHEEL

O. MITER GAUGE STORAGE BRACKET

P. BEVEL ANGLE SCALE

Q. BLADE HEIGHT ADJUSTMENT HANDWHEEL

R. MOTOR COVER

S. MAGNETIC SAFETY SWITCH

7

Page 8

BASIC FUNCTIONS

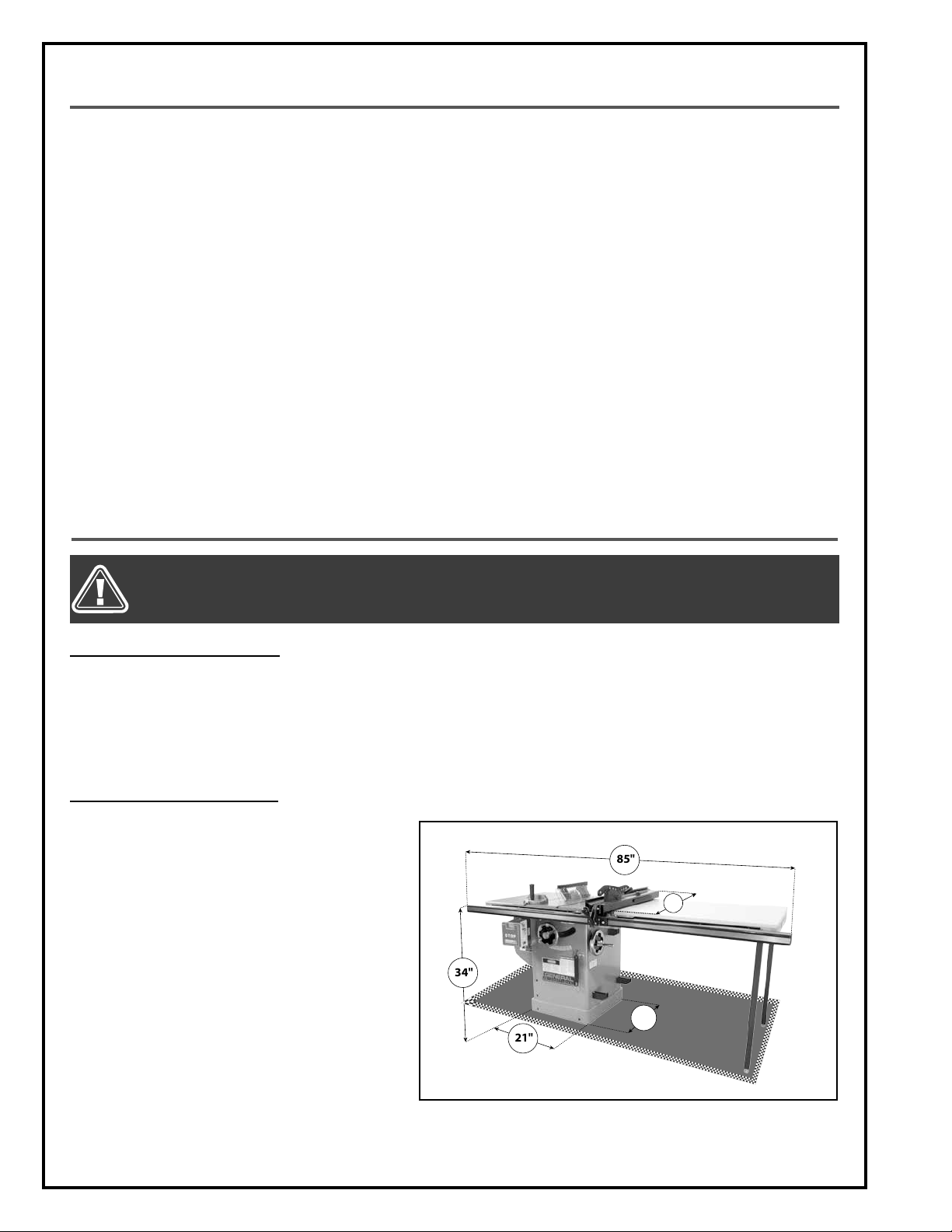

34"

34"

21"

85"

44"

23"

The General International model 50-270 cabinet saw is available with various motor size and electrical voltage

requirement options (see manual coverpage for complete list).

This cabinet saw has been designed for cutting solid wood as well as manufactured wood materials such as plywood, wood paneling, particleboard, mdf and other wood based by-products.

This saw is not designed for cutting metals nor for cutting any materials other than wood or wood based stock.

This saw is designed for use with maximum 10” (254 mm) diameter blades having a center hole diameter of 5/8”.

The blade can be raised to cut a maximum stock thickness of 3” with the blade set 90° to the table. The blade can

be tilted up to 45° to the left for bevel cuts to a maximum stock thickness of 2 1/8”. Using any standard after market

8”diameter stacked dado blade set (not included), the maximum dado cutting capacity of this saw is 13/16”.

Note: for safer dado cutting, an optional dado table insert (#50-302) can be purchased through your General

International distributor.

To encourage safety through the proper use of either the supplied riving style splitter/blade guard assembly or

the European style riving knife the 50-270 is designed with a quick install/quick release feature allowing the user

to install or remove either of these safety components in seconds.

INSTALLATION

THIS MODEL 50-270 10” CABINET SAW IS HEAVY. DO NOT OVER-EXERT. A HOIST OR FORKLIFT WITH STRAPS SHOULD BE

USED TO LIFT THIS MACHINE. TO LIMIT THE RISK OF SERIOUS INJURY OR DAMAGE TO THE MACHINE, ANY EQUIPMENT

USED TO LIFT THIS MACHINE SHOULD HAVE A RATED CAPACITY IN EXCESS OF 524 LBS (238 KG).

PLACEMENT WITHIN THE SHOP

This machine should be installed and operated only on a solid, flat and stable floor that is able to support the

weight of the sander (524 lbs - 238 kg) and the operator.

Using the dimensions shown as a guideline, plan for placement within your shop that will allow the operator to

work unencumbered and unobstructed by foot traffic (either passing shop visitors or other shop workers) or other

tools or machinery.

ESTABLISHING A SAFETY ZONE

For shops with frequent visitors or multiple operators, it is advisable to establish a safety zone

around shop machinery. A clearly defined “nogo” zone on the floor around each machine can

help avoid accidents that could cause injury to

either the operator or the shop visitor.

It is advisable to take a few moments to either

paint (using non-slip paint) or using tape, define

on the floor the limits or perimeter of each machines safety zone.

Take steps to ensure that all operators and shop

visitors are aware that these areas are off limits

whenever a machine is running for everyone but

the individual operating the unit.

*Model 50-270KDL shown

8

Page 9

UNPACKING

Carefully unpack and remove the saw and its components from the shipping crate and check for damaged or

missing items as per the list of contents below.

NOTE: PLEASE REPORT ANY DAMAGED OR MISSING ITEMS TO YOUR GENERAL® INTERNATIONAL DISTRIBUTOR IMMEDIATELY.

LIST OF CONTENTS QTY

A. SAW (NOT SHOWN) ................................................................. 1

B. MOTOR COVER ....................................................................... 1

C. TABLE EXTENSION ................................................................... 2

D. BLADE COVER/SPLITTER .......................................................... 1

E. RIVING KNIFE ........................................................................... 1

F. BLADE TILT ADJUSTMENT HANDWHEEL .................................... 1

G. MITER GAUGE .......................................................................... 1

H. BLADE TILT HANDWHEEL LOCK KNOB ..................................... 1

I. FENCE STORAGE BRACKET ...................................................... 2

J. MITER GAUGE STORAGE BRACKET.......................................... 1

K. ARBOR WRENCH ..................................................................... 1

Note: The Excalibur SLF35T52 rip fence and rails are packaged separately.

B

ADDITIONAL REQUIREMENTS FOR SET UP

EXTRA PERSON FOR HELP WITH LIFTING

A.

B. PHILLIPS SCREWDRIVER

C. COMBINATION WRENCHES 10 MM AND 7/16”

D. 3 MM AND 4 MM ALLEN KEYS

E. STRAIGHTEDGE

F. MACHINIST SQUARE OR TRIANGLE SQUARE

A

E

B

C

D

C

D

E

F

I

G

H

G

J

K

9

Page 10

CLEAN UP

The protective coating on the saw table prevents rust

from forming during shipping and storage. Remove it

by rubbing with a rag dipped in kerosene, mineral spirits or paint thinner. (Dispose of potentially flammable

solvent-soaked rags according to manufacturer’s safety recommendations).

A putty knife, held flat to avoid scratching the surface,

may also be used to scrape off the coating followed by

clean-up with solvent. Avoid rubbing the saw’s painted

surfaces, as many solvent-based products will remove

paint.

To prevent rust, apply a light coating of paste wax or

use regular applications of any after-market surface

protectant or rust inhibitor.

ASSEMBLY INSTRUCTIONS

BEFORE STARTING THE ASSEMBLY, MAKE SURE THAT THE SWITCH IS IN THE “OFF” POSITION AND THAT THE POWER

CORD IS UNPLUGGED. DO NOT PLUG IN OR TURN ON THE SAW UNTIL YOU HAVE COMPLETED THE ASSEMBLY AND INSTALLATION STEPS DESCRIBED IN THIS SECTION OF THE MANUAL.

TIP: WITH A SCREWDRIVER, PUSH A SOLVENT-SATURATED

RAG INTO THE T-SLOTS TO REMOVE THE GREASE.

INSTALL THE BLADE TILT ADJUSTMENT HANDWHEEL

RIGHT SIDE VIEW

B

C

A

1. Install the blade tilt adjustment handwheel A

ontthe shaft B on the right side of the saw.

Note: First remove the adhesive tape C that holds the

key in the shaft.

Note: To limit the potential for damage in transport, this

table saw is shipped from the factory with the motor sitting on a styrofoam block G for support.

Turn the handwheel H, located on the right side of the

saw, counter-clockwise to raise the motor enough to remove the styrofoam block

F

D

E

2. Tighten the screw D to secure the handwheel on

the shaft using a 4 mm Allen key, then thread the

lock knob E into the handwheel shaft F to secure

the handwheel in place.

H

G

10

Page 11

INSTALL MITER GAUGE & FENCE STORAGE BRACKETS

Install the miter gauge storage bracket J (the smaller one) and the fence storage brackets K on the right

side of the saw as shown in L, using the screws M already mounted on the right side of the cabinet.

MOUNT THE SWITCH

N

O

J

M

K

L

P

Q

1. Loosen the two bolts on front of the saw N and re-

move the two bolts on the left side of the saw O.

INSTALL THE TABLE EXTENSION WINGS

R

Level here

S

T

Flush here

Attach the table extension wings to the main table using the 7/16” mm hex head bolts (3 per wing) already

mounted on both sides of the main table R. Align the

table extensions with the table and loosely attach the

bolts. Place a straightedge on the table and extension

as shown S to align the extension table and then tighten down the bolts.

Note: Be sure that the table extension wings are flush with

front edge of table T.

2. Slide the switch mounting bracket onto the front

bolts P and tighten from inside the cabinet with a

10 mm socket wrench, then re-install and tighten

the side bolts Q.

INSTALL THE MOTOR COVER

V

W

Install the motor cover door on the left side of the saw

by inserting the pins V into the hinge sockets W.

11

Page 12

INSTALL THE FENCE ASSEMBLY

NOTE: THERE ARE DETAILED INSTALLATION AND OPERATING INSTRUCTIONS IN THE SLF35T52 MANUAL SUPPLIED IN THE BOX WITH

THE EXCALIBUR SLF35T52 RIP FENCE.

FRONT FENCE RAIL

1. Install the front guide rail on the front of the saw aligning the holes in the rail with those on the the saw as

shown below.

5/8"

2. Adjust the rail height until the top of the rail is ap-

proximately 5/8” below the top of the table and

level from one end of the table to the other.

Hold the nuts firm with a wrench and tighten the

screws closest to the ends of the table (left and

right) first. Then tighten the center screws only after double-checking the height all along the rail

and at both ends.

REAR FENCE RAIL

1. Install the rear guide rail on the rear of the saw aligning the holes in the rail with those on the saw as shown.

3. Assemble the guide tube A to the front fence rail

using the 8 short hex head bolts with lock washers

and flat washers B to the underside of the rail.

Note: When the tube is attached, there will be a gap of

about 1” between it and the rail, C, in which part of the

fence will ride.

C

A

B

12

Page 13

CONNECTING TO A DUST COLLECTOR

ALWAYS TURN ON THE DUST COLLECTOR BEFORE STARTING THE SAW AND ALWAYS STOP THE SAW BEFORE TURNING OFF

THE DUST COLLECTOR.

1. There is a 4” dust outlet A located on the rear of the

saw cabinet allowing for the connection to a dust

collector (not included).

2. Be sure to use appropriate size hose and fittings

and check that all connections are sealed tightly

to mini-mize airborne dust.

3. If you do not already own a dust collection system-

consider contacting your General® International

distributor for information on our complete line of

dust collection systems and accessories or visit our

website at www.general.ca

A

INSTALL / REMOVE A SAW BLADE

NOTE: This saw is intended for use with 10” (254 mm) diameter or less saw blades having a center hole

diameter of 5/8”. There are many types of blades available to perform specific cutting jobs, such as crosscuts or ripping only, or for use with plywood, panelling and other products. A good quality specialty blade

can produce a finer finish, be more efficient and place less strain on the saw. Use only saw blades designed

for operating speeds of 4300 RPM or higher. Saw blades should be kept clean and sharp. Never store saw

blades by stacking them directly in contact with each other. Place a layer of cardboard or similar material

between the blades to keep them from coming into contact with each other.

BE SURE THE SAW IS UNPLUGGED AND COMPLETELY DISCONNECTED FROM THE POWER SOURCE WHENEVER INSTALLING OR

REMOVING A SAW BLADE!

A B

C

E

D

F

1. Lift the table insert up A and loosen the lock lever B,

then pull the splitter or riving knife up out of its

mounting bracket C.

D

2. Remove the arbor nut D with the supplied arbor

wrench E and remove the flange F.

13

Page 14

BLADE DIRECTION

FRONT

H

E

3. Install a saw blade on the arbor so that the openings

between the teeth face the front of the saw (the blade spins in the counter-clockwise direction), then

replace the flange and arbor nut.

4. Press down on the red arbor lock button G so the

blade and arbor won’t turn as you tighten the arbor

nut clockwise H (toward the rear of the saw) with the

supplied arbor wrench.

5. To remove a saw blade: perform the same procedure turning the arbor nut in the opposite direction.

BEFORE TURNING ON THE SAW, MAKE SURE THE ARBOR LOCK IS DISENGAGED (POPS UP) BY TURNING THE BLADE A

FRACTION TO UNLOCK. TURN THE BLADE BY HAND ONE FULL ROTATION TO MAKE SURE THE ARBOR/BLADE TURNS

FREELY.

NOTE: WHEN TIGHTENING THE ARBOR NUT, TAKE CARE NOT TO OVER TIGHTEN AS THIS WILL MAKE IT VERY DIFFICULT TO REMOVE

LATER. BECAUSE THE ROTATION OF THE BLADE RUNS COUNTER TO THE DIRECTION OF THE THREADS ON THE NUT, THE BLADE IS

ESSENTIALLY TIGHTENING ITSELF TO THE NUT WHENEVER THE SAW IS RUNNING. THOUGH THERE ARE NO HARD AND FAST RULES FOR

HOW MUCH TORQUE IS REQUIRED, THE ARBOR NUT SHOULD BE ALWAYS TIGHTENED HAND-TIGHT AND JUST SLIGHTLY BEYOND

“SNUG”.

INSTALL AND ADJUST RIVING KNIFE

THE BLADE MUST NEVER REMAIN EXPOSED WHEN USING THE SAW. TO PREVENT THE RISK OF SERIOUS INJURIES,

ALWAYS COVER THE BLADE WITH A BLADE GUARD.

SELECT A RIVING KNIFE

Two riving knives are provided:

- A European style riving knife without blade guard A;

- A combination riving style splitter and blade cover with

anti-kickback pawls B.

The riving knife must always be used wit h a blade cover.

If you already own an independently attached blade

cover such as our Excalibur 50-EXBC10, use the riving

BA

knife A. If you do not already own a blade cover, use

the splitter/blade guard assembly B

14

.

Page 15

REMOVAL / INSTALLATION

ALWAYS TURN OFF AND UNPLUG THE SAW BEFORE REMOVING / INSTALLING A RIVING KNIFE.

TABLE INSERT REMOVED FOR CLARITY

B

B

A

Set the blade to 90º and raise it to its highest position (Refer to “Blade height and tilt adjustment” instructions). Lift

the table insert. If already installed, remove the splitter or riving knife by loosening the lock lever A then pulling the

splitter or riving knife up out of its mounting bracket B.

To install: Re-install the table insert and fit the bottom end of the splitter or riving knife into the slot in the mountin g

bracket and push downward until it bottoms out. Lift the table insert and tighten the lock lever to lock it in place.

BLADE COVER AND RIVING KNIFE ASSEMBLY

ALWAYS TURN OFF AND UNPLUG THE SAW BEFORE REMOVING / INSTALLING A RIVING KNIFE.

BA

1. Push and hold in the pin on at the end of the blade

cover and manually remove the blade cover

TIP: FOLLOW THE PREVIOUS STEPS IN REVERSE ORDER TO ASSEMBLE THE BLADE COVER. A “CLICK” OF THE LOCKING PIN

CONFIRMS THAT THE ANTI-KICKBACK FINGERS AND BLADE COVER ARE SECURED PROPERLY ON THE SPLITTER.

2. Push and hold in the pin holding the anti-kickback

fingers A and remove it manually as shown, B.

15

Page 16

ADJUSTMENT / ALIGNMENT

C

A

B

D

D

E

E

ALWAYS TURN OFF AND UNPLUG THE SAW BEFORE PERFORMING ANY ADJUSTMENTS.

The riving knife mounting block is already factory set,

and should not require adjustment out of the box. However with use over time, re-alignment may be required

periodically.

The splitter/knife mounting bracket consists of a rocker

arm A, a spacer B, and a hold-down block C. This assembly is held together by two locking screws D. Both

90º to the table and parallel/centered to the blade

alignments can be achieved by adjusting the four set

screws E. In order to be able to adjust the set screws, the

locking screws D must first be loosened (with a 4 mm

Allen key) – 1/4 turn or more, depending upon how

much adjustment is required.

TIP: TIGHTEN EACH LOCKING SCREW IMMEDIATELY AFTER ADJUSTING ITS CORRESPONDING SET SCREW TO AVOID UNDOING THE PREVIOUS ADJUSTMENT.

SETTING THE SPLITTER/KNIFE 90º TO THE TABLE

1. With the blade set to 90º to the table, using a

square, verify the perpendicular alignment of the

splitter/knife to the table, A.

2. If needed, loosen or tighten (with a 3 mm allen

key) the two upper B and/or lower C set screws on

the splitter/knife mounting bracket, until the splitter/knife is 90º to the table.

SETTING THE SPLITTER/KNIFE PARALLEL TO AND CENTERED ON THE BLADE

A

A

TABLE REMOVED FOR CLARITY ONLY

C

B

D

1. Place a straightedge against the splitter/knife A.

2. If needed, loosen or tighten one or both set screws

on both left B and right C side of the splitter/knifemounting bracket until the splitter/knife is parallel

to the blade D.

3. Use a feeler gauge to measure the clearance be-

tween the straightedge and the blade. The width

of the gap must be more or less the same on

each side of the splitter/knife. If needed, re-adjust

the set screws on both right and left side of the

splitter/knife mounting bracket to increase or decrease the clearance between the straight edge

and the blade.

90º

B

C

B

C

16

Page 17

LEVEL THE TABLE INSERT

STOP

Place the insert into the table and use a straightedge to

determine whether the insert is level with the table top.

Turn each of the 6 adjusting screws A with the a 3 mm

Allen key until done.

Note: If the saw blade has already been installed, use the

raising handwheel to lower the blade below the table surface before leveling the insert.

BASIC ADJUSTMENTS & CONTROLS

CONNECTING TO A POWER SOURCE

TO AVOID UNINTENTIONAL START-UP, MAKE SURE THAT THE POWER SWITCH ON THE SAW IS IN THE OFF POSITION BEFORE

CONNECTING TO A POWER SOURCE. TO AVOID RISK OF SHOCK OR FIRE DO NOT OPERATE THE UNIT WITH A DAMAGED

POWER CORD OR PLUG. REPLACE DAMAGED CORD OR PLUG IMMEDIATELY.

Once the assembly steps have been completed, plug

the power cord into an appropriate outlet. Refer back

to the section entitled “ELECTRICAL REQUIREMENTS” and

make sure all requirements and grounding instructions

are followed. When cutting operations have been

completed unplug the saw from the power source.

A

SWITCH OFF

ON/OFF MAGNETIC POWER SWITCH

This model is equipped with a Magnetic 2-step safety

switch to prevent unintentional start-up and unauthorized use of the saw. The switch assembly is equipped

with a GREEN “START” button A, an extra-large easy

access RED stop panel B, and a lock-out key C.

To start the saw: Insert the lock-out key C and press on

the GREEN “START” button A.

To stop the saw: Press on the RED “STOP” panel, B. Once

the RED “STOP” panel has been pressed, the saw can

only be started by pressing once again on the RED

“STOP” panel to release the green button, then by pressing on the green button.

OVERLOAD PROTECTTION

The magnetic safety switch on this saw is equipped with

an overload protection feature. To prevent an electrical

overload from damaging the motor, in the event of a

spike in line voltage or amperage draw, the internal

overload protector will automatically be tripped, thereby cutting off power to the motor.

To reset the overload protection switch

1. Set the power switch on the saw to the off position,

and disconnect the machine from the power source.

Note: If the saw is permanently connected to a circuit (hardwired), set the wall panel circuit breaker or main circuit interrupter to the off position.

2. Unscrew the 2 screws in the control box front cover.

Remove the cover and press the reset button D. Re-install the control box cover and reconnect the saw to the power source.

A

C

B

D

17

Page 18

BLADE HEIGHT ADJUSTMENT

1/4”

The blade height adjustment handwheel is located on

the front of the saw A and there is a lock knob B on

the handwheel that allows you to lock the wheel and

secure the blade at the desired height.

To raise or lower the blade:

1. Loosen the blade height lock knob B by turning

counter clockwise.

2. To raise the blade: turn the handwheel A clockwise.

To lower the blade: turn the handwheel A counter-

clockwise.

3. With the blade set to the desired height, tighten the

lock knob B by turning clockwise to lock the blade.

BLADE TILT (BEVEL) ADJUSTMENT

B

A

1/4”

The blade tilt (bevel) adjustment handwheel is located

on the side of the saw C and there is a lock knob D on

the handwheel that allows you to lock the wheel and

secure the blade at the desired angle.

To change the angle of the blade:

1. Loosen the bevel lock knob D by turning it counter clockwise.

2. Turn the handwheel C left or right as required to set

the blade to the desired angle. The blade can be tilt ed to the left anywhere from 0° (90° to the table) to

45°.

TO LIMIT YOUR EXPOSURE TO THE BLADE AND ALSO TO MAXIMISE THE EFFECTIVENESS OF THE ANTI-KICKBACK PAWLS (WHEN USING THE RIVING STYLE SPLITTER & BLADE GUARD), NEVER TAKE MORE BLADE HEIGHT

THAN IS REQUIRED TO COMPLETE THE CUT. WHEN SETTING THE BLADE HEIGHT FOR THROUGH-CUTS (CUTS

ALL THE WAY THROUGH THE THICKNESS OF A BOARD) SET THE HEIGHT OF THE BLADE TO ROUGHLY 1/4”

HIGHER THAN THE THICKNESS OF THE BOARD.

3. With the blade tilted to the desired angle, tighten the

lock knob by turning it clockwise to lock the tilting

mechanism and secure the blade.

OPERATING INSTRUCTIONS

D

C

VERIFY ALL CHECK POINTS BEFORE STARTING. FAILURE TO COMPLY CAN RESULT IN SERIOUS INJURIES.

• Make sure that the arbor nut is secure and that the blade is firmly tightened snug on the arbor.

• Make sure that the arbor lock is disengaged and the blade spins unobstructed when rotated by hand.

• Check that the blade angle and height lock knobs are tight. If ripping, make sure the fence lock lever is engaged and that the fence is parallel to the blade.

• If cross cutting, make sure the miter gauge is locked tight.

• While using the saw, be sure to wear safety glasses at all times.

• Make sure that the blade guard/splitter assembly or riving knife is properly installed and aligned with the

blade, and that the anti-kickback pawls are functioning.

• If the saw is installed on a mobile base, make sure that the wheels have been completely locked.

18

Page 19

TYPES OF CUTS

NEVER REACH IN TOWARDS THE BLADE WHILE THE BLADE IS STILL SPINNING! WHENEVER A RIP CUT IS COMPLETED,

TURN OFF THE SAW AND WAIT FOR THE BLADE TO COME TO A COMPLETE STOP BEFORE REACHING IN TO REMOVE THE

WORKPIECE OR THE WASTE MATERIAL.

RIPPING

Cutting a wood plank or sheet of plywood lengthwise to

reduce its width is called “ripping.” To rip stock, hold the

work with both hands pushing it into the blade as well as

firmly against the rip fence so that it is cut straight A.

• The work to be cut must have a straight edge to ride

the fence and must be flat to make solid contact

with the table during the cut in order to avoid “kickback” (a blade jam causing the wood to fly backwards and hit you).

• Never rip or cut wood without using the fence or miter gauge to guide it because the stock could kickback.

• Always use the blade guard and splitter/riving knife

assembly when cutting wood. The anti-kickback fingers and splitter/riving knife prevent the saw “kerf” (the slit

cut by the blade) from closing and binding the blade, which can overload and/or stall the motor or cause

the blade to lift and eject the workpiece towards the front of the saw at very high speeds. The blade guard

keeps your fingers away from the blade and also reduces the amount of sawdust flying free.

• Although certain operations require the removal of the blade guard and splitter assembly, it should always be

replaced for regular cutting.

• Never stand in the line of the blade when ripping.

• Raise the saw blade only about 1/4” higher than the workpiece to be cut.

As you complete the rip, the wood will either remain on the table, tilt up to be caught on the end of the guard,

or fall onto the floor (or outfeed table). The waste part of the stock remains on the table to be removed only after

the saw is stopped (unless it is large enough for immediate safe removal).

A

A

NEVER REACH IN TOWARDS THE BLADE WHILE THE BLADE IS STILL SPINNING! WHENEVER A RIP CUT IS COMPLETED,

TURN OFF THE SAW AND WAIT FOR THE BLADE TO COME TO A COMPLETE STOP BEFORE REACHING IN TO REMOVE THE

WORKPIECE OR THE WASTE MATERIAL.

If the work to be ripped is narrow, it is safer to use the

supplied push stick, rather than hands, to feed it into the

blade B.

When ripping extremely narrow stock that may not clear

the width of the blade guard, or very thin material such

as paneling, which may slip between the underside of

the fence and the table surface, a strip of wood as an

auxiliary guide can be attached to the fence.

BEVEL RIPPING

Bevel ripping is performed the same as ripping but with the saw blade set to an angle not perpendicular to the

table surface. After changing the bevel angle verify the alignment of the guard and splitter; make sure there is

clearance with the saw blade.

RIPPING SMALL WORK PIECES

Do not attempt rip cuts if the work piece is too small, as this will oblige you to place your hands too close to the

blade and put you at serious risk of injury. When ripping narrower widths; use a push block or a push stick in order

to avoid placing hands near the blade.

B

19

Page 20

CROSS CUTTING

Cutting against the grain, to shorten the length of a

board is crosscutting. With some smaller-sized and rectangular pieces, you often have the choice of ripping

or crosscutting.

Always use the miter gauge C when crosscutting; never

cut a piece unsupported. The miter gauge may be

used in either slot, but most operators prefer the left

groove for typical work. When the blade is tilted for

bevel cutting, use the table slot that does not cause

interference with your hand or the blade guard.

To begin crosscutting, place the work on the miter

gauge and, with the motor OFF, slide it up close to the

blade to align the outer edges of the teeth with your

cut mark D.

Keep a firm grip as you pull the miter gauge and the

wood back away from the blade. Turn on the saw and

make the cut. When the work is cut through, move one

or both cut pieces — if long enough to handle without

danger — immediately off to the side, away from the

turning blade. Turn off the motor.

BEVEL CROSS CUTTING

This procedure is the same as cross cutting except that the blade is set to an angle other than 0. After changing

the bevel angle, verify the alignment of the blade cover and splitter and verify that there is clearance with the

saw blade.

C

D

ADJUSTING AND USING THE MITER GAUGE

ADJUSTING THE MITER GAUGE

The miter gauge supplied with your saw has accurately

adjusted index stops at 90° and 45° to the right and left,

with a 30° maximum.

To use a setting other than 90°, loosen the lock knob A

by turning it counterclockwise, flip down the stop-lock

tab B and rotate the miter head to 45°, or any angle

shown on the numerical guide. Turn the lock knob

clockwise to tighten it.

To check the accuracy of the miter gauge’s factory

settings, set it at 90° and check it with an L-square or

T-square. To verify the setting, make a test cut in scrap

stock and then use a square to check the cut piece.

If the miter gauge needs adjusting, manually turn

the head so the pointer is where you think it ought to

be, tighten the lock knob and loosen the nut C. Turn

the adjusting screw until it touches the stop-lock tab.

Tighten down the nut. Recheck the angle by making

another test cut. Repeat, if necessary, until a true 90° is

achieved.

A

B

C

20

Page 21

ADDING AN AUXILIARY FENCE TO THE MITER GAUGE

To ensure a true 90° cross cut, especially with longer

pieces of wood that need more support than the narrow miter gauge head can provide, an auxiliary wood

fence can be attached.

Make sure the wood for the fence is straight, not bowed.

It should be about 2” wide and extend about 12” from

either side of the miter head. Drill 2 holes in the wood

corresponding to those on the miter head and use bolts

and nuts to secure the wood fence to the head A.

To use the miter gauge with an auxiliary fence, first

notch the fence with the saw blade a bit higher than

the workpiece B. Measure and draw a cutline on your

wood C then place it on the miter fence. Position your

cutline against the notch. Turn on the saw, slide the work

up until it is cut through (but don’t cut off the fence).

Marking Wood. If you measure a cut for 24”, line up the

blade on the waste side of the mark.

Don’t cut through the middle of the measurement line

or you’ll reduce your desired board length by half the

width of the saw blade! For accurate work, don’t mark

your cut with a fat pencil line D. A narrow dash, with a

sharp pencil point is best E.

FOCUS

A

B

C

FRONT VIEW

G

F

Encircle the dash so you’ll find it again and add a small

“x” to indicate the waste or cut-off side F. Pencils, like

saw blades, have thickness.

When squaring off from the cut mark, align your square

to allow for pencil clearance, which will be about 1/16”

away from the drawing edge of the square G.

MITER CUTS

This operation is the same as cross cutting, except the

miter gauge is set to an angle other than 0. Hold the

workpiece firmly against the miter gauge and feed the

workpiece slowly into the blade to prevent it from moving during the cut I.

D

E

I

COMPOUND MITERING

This is a combination of bevel cross cutting and mitering. It is infrequently used. Follow instructions for both bevel

cutting and mitering.

21

Page 22

USING A DADO BLADE

ALWAYS VERIFY THE DADO BLADE CLEARANCE BEFORE CONNECTING THE SAW TO THE POWER SOURCE. RE-ATTACH THE

GUARD AND ADJUST AFTER DADO CUT IS FINISHED. THE MAXIMUM DADO HEAD WIDTH FOR THIS SAW IS 13/16” AND THE

MAXIMUM DADO BLADE DIAMETER IS 8”.

Dadoing is cutting a “rabbet” or a wide groove into

the work. A dado blade A (not supplied with your saw)

usually consists of two outer blades and several interior

cutters. These can be adjusted to cut grooves from 1/8”

to 13/16” for making shelves, joints and tenoning. Set the

blade’s width according to the instructions supplied with

your dado blade.

After adjusting its width, mount the dado blade on your

saw just like a regular blade. You’ll need an optional

dado insert B (Item #50-302) to replace the standard

one that comes with your saw. Use the fence to line up

the cut. The blade guard/splitter must be removed when

dadoing. Never use the dado blade in a bevel position.

A B

MAINTENANCE & ADJUSTMENTS

MAKE SURE THE SAW HAS BEEN TURNED OFF AND UNPLUGGED FROM THE POWER SOURCE BEFORE PERFORMING ANY MAINTENANCE.

PERIODIC MAINTENANCE

• Inspect/test the ON/OFF switch before each use. Do not operate the saw with a damaged switch - replace a

damaged switch immediately

• Inspect the saw blade for damage or chipped teeth before each use. Replace a damaged or chipped blade

immediately. Never operate the saw with a damaged or chipped blade

• Keep the saw table clean and free of dust, pitch or glue. An occasional light coating of paste wax can be used

to protect the cast-iron surface. Ask our local distributor for suggestions on table top cleaners and cast-iron sur face protection based on what is readily available in your area.

• Occasionally open the cabinet door and brush off and vacuum out accumulated dust from inside the cabi net and on the blade tilting gears, and on or around the motor.

• Periodically inspect the power cord and plug for damage. To minimize the risk of electric shock or fire, never

operate the saw with a damaged power cord or plug. Replace a damaged power cord or plug at the first

sign of damage.

• To minimize airborne dust particles periodically inspect all dust collection fittings – re-tighten as needed.

LUBRICATION

Keep the blade height adjustment mechanism A as well

as the blade tilt mechanism B (both accessible by the

motor cover door) well lubricated and free of dust or debris. Clean and remove dust, debris, and old grease as

needed depending on frequency of use. After cleaning,

re-apply grease as needed. The motor and all bearings

are sealed and permanently lubricated – no further

lubrication is required. No other part of this table saw

needs lubrication.

Note: Use any all-purpose grease, available at any hardware store.

A

B

22

Page 23

ADJUSTING THE 90° BEVEL STOP

1. Raise the blade to its highest position and lift the

blade guard.

2. Loosen the bevel lock knob and turn the blade tilting

handwheel clockwise until it stops.

3. Verify the 90° angle of the blade with a combina-

A

D

C

tionsquare from the left side of the blade, keep the

square flat against the table and against the flat part

of the blade - Do not touch the teeth or the table

insert A.

If the blade angle is incorrect, adjust the 90° stop located

inside the cabinet, on the left side of the saw. Proceed as

90°

follows:

1. Loosen the jam-nut C using a 5/8” open end wrench.

2. Adjust the height of the 90° stop bolt D until the blade is 90° to the table when the 90° stop bolt touches the

stop. Re-tighten the jam-nut.

ADJUSTING THE BEVEL ANGLE POINTER

The bevel pointer should read “0” when the blade is at 90° to the table. If not, proceed as follows:

A

1. With the blade set 90° vertical to the table, loosen

the set screw on the front handwheel shaft using

a Allen key, remove the handwheel lock knob A

and pry the handwheel off its shaft.

ADJUSTING THE 45° BEVEL STOP

Verify the 45° setting by tilting the blade as far as possible

to the left and using a square to check the angle A. If

needed adjust as for the 90° stop, this time using the stop

screw B inside the cabinet, at the front of the saw.

C

B

2. Once the handwheel has been removed, loosen

the screw B on the pointer mounting bracket (us ing a 10 mm wrench) and manually align the

pointer with the zero on the bevel scale C, then re tighten the screw and re-attach the handwheel.

A

B

23

Page 24

RECOMMENDED OPTIONAL ACCESSORIES

We offer a large variety of products to increase convenience, productivity, accuracy and safety when using your

saw. Here’s a small sampling of optional accessories available from your local General International dealer.

For more information about our products, please visit our website at www.general.ca

item #50-301

ZERO CLEARANCE INSERT

Eliminates space between the blade and insert to

help reduce tear-out and airborne dust. Raise the

blade through the insert and custom cut to your

blade kerf.

item #50-050

TENONING JIG

Solid cast iron. Fits left or

right tilt saws for safe and

accurate tenoning.

item #50-106 & #50-115

29” X 36” MELAMINE EXTENSION TABLE AND STEEL

ADJUSTABLE SUPPORT LEG SET (2)

item #50-SLT60P or 50-SLT 40P

SLIDING TABLE

For accurate cross cutting or mitering of wide

panels; 49” for SLT40P or

up to 72” for SLT60P. Featuring a stable rock solid design that runs on

smooth roller bearings

allowing the user to walk

large panels through the

cut with ease.

item #50-302

DADO INSERT

Fits left tilt models 50-270, 50-300 & 50-305 only. For

use with dado blades up to 13/16” (21 mm) maximum width.

DUST COLLECTORS

We have a wide selection

of dust collectors to suit

all your shop needs. Dust

collectors contribute to a

cleaner and more healthful workshop en- vironment.

item #50-EXBC10

BLADE COVER – WITH DUST COLLECTION CAPABILITY

Maximize dust collection without compromising

safety. Easy to install and simple to use, see-through

blade cover. Unique design mounting bracket: pivots away or removes completely in seconds

item #55-185

7 PIECE DELUXE 8”

DADO BLADE SET

(2) 24 tooth exterior

blades. Standard 5/8”

(16 mm) bore. Maximum 6000 RPM. Makes

1⁄8” to 13⁄16” (3 to 21 mm)

grooves. Anti-kickback

design. Convenient &

sturdy wooden storage

case included.

.

24

Page 25

DIAGRAM

CABINET AND TABLE - LEFT TILT (#50-270)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15L

21

20

19

16

17

18

27

26

23

23

24

23

25

49

22

30

31

32N

33N

28

29

38

37

53

52

35

34

36

40

41

42

18

39

48

23

26

43

44

45

46

47

1A

54

DIAGRAM

CABINET AND TABLE (#50-460R)

51

50

16

17

18

15R

DIAGRAM

CABINET AND TABLE (#50-270)

25

Page 26

PARTS LIST

10” CABINET SAW - LEFT TILT (#50-270)

IMPORTANT: When ordering replacement parts, always give the model number, serial number of the

machine and part number. Also a brief description of each item and quantity desired.

PART# REF. # DESCRIPTION SPECIFICATIONS QTY

1A 50-145 MITER GAUGE ASSEMBLY 1

1 50175-032 HANDLE 1

2 50175-035 MITER GAUGE BODY 1

3 50175-033 HEX NUT M5 3

4 50175-040 POINTER 1

5 50175-039 STOP PLATE 1

6 50175-041 SET SCREW M5 X 5 1

7 50175-041A PIN M3 X 6 1

8 50175-034 SET SCREW M5 X 20 3

9 50175-038 GUIDE BAR 1

10 50175-037 GUIDE WASHER 1

11 50175-036 FLAT HEAD SCREW M6 X 8 11

12 50300-012 SET SCREW 1/4” X 3/8” 6

13 50300-013 TABLE INSERT 1

14 50300-014 MAIN TABLE 1

15R 50300-015R EXTENSION WING RIGHT 1

15L 50300-015R EXTENSION WING LEFT 1

16 50300-016 HEX HEAD BOLT 7/16” X 1-1/2” 6

17 50300-017 LOCK WASHER 7/16” 6

18 50300-018 FLAT WASHER 7/16” 6

19 50300-019 MOTOR COVER DOOR 1

20 50300-020 FLANGE NUT M6 1

21 50300-021 HANDLE 1

22 50300-022 FOAM STRIP 1

23 50300-023 FLAT WASHER 1/4” 12

24 50300-024 SPRING 1

25 50300-025 HEX HEAD BOLT M6 X 50 1

26 50300-026 LOCK WASHER 1/4” 10

27 50300-027 HEX NUT 1/4” 4

28 50300-028 ANGLE INDICATOR SCALE 1

29 50300-029 LOGO PLATE 1

30 50300-030 POWER CORD 1

31 50300-031 CARRIAGE BOLT 1/4” X 3/4” 4

32N 50300-032N SWITCH MOUNTING PLATE 1

33N 50300-131NM1 MAGNETIC SWITCH ASSEMBLY (50-270 M1 ONLY) 3HP.1PH.220V 1

33N 50300-131NM2 MAGNETIC SWITCH ASS’Y (50-270 M2 ONLY) NOT SHOWN 5HP.3PH.220V 1

333 50300-131NM3 MAGNETIC SWITCH ASS’Y (50-270 M3 ONLY) NOT SHOWN 5HP.3PH.600V 1

34 50300-034 PHILLIPS HEAD SCREW 3/16” X 3/4” 2

35 50300-035 FLAT WASHER 3/16” 2

36 50300-036 POWER CORD TO MOTOR 1

37 50300-037 STRAIN RELIEF 3

38 50300-038 CORD BUSHING 1/2” 2

39 50300-039 NYLON NUT 1/4” 3

40 50300-040 WARNING LABEL 1

41 50270TC-41 CABINET 1

42 50300-042 FENCE STORAGE BRACKET 2

43 50300-043 SOCKET SCREW 1/4” X 3/4” 6

44 50300-044 MITER GAUGE STORAGE BRACKET 1

45 50300-045 DUST COLLECTION FITTING 1

46 50300-046 HEX HEAD BOLT 1/4” X 5/8” 3

47 50300-047 SOCKET SCREW 7/16” X 3/4” 4

48 50300-048 THREADED INSERT 1/4” 6

49 50300-049 CORD CONNECTION BOX 1

50 50300-050 DUST TRAY 1

51 50300-051 SELF-TAPPING SCREW M5 X 10 4

52 50270-052 PUSH STICK STORAGE HOOK 1

53 50270-053 HEX NUT 1

54 50270-054 LOCK-OUT SAFETY KEY 2

26

Page 27

DIAGRAM

MOTOR AND TRUNNION (#50-270)

27

Page 28

PARTS LIST

MOTOR AND TRUNNION (#50-270)

IMPORTANT: When ordering replacement parts, always give the model number, serial number of the

machine and part number. Also a brief description of each item and quantity desired.

PART # REF. # DESCRIPTION SPECIFICATIONS QTY

101 50300-204 ARBOR NUT 1

102 50300-205 ARBOR FLANGE 1

104 50300-207 ARBOR 1

105 50300-208 KEY M5 X 44 1

106 50300-106 BEARING 6203ZZ 2

107 50300-107 BEARING LOAD SPRING 4

108 50300-108 BEARING LOAD SPACER 1

109 50300-109 SET SCREW 1/4” X 3/8” 10

110 50300-110 ARBOR PULLEY 1

111 50300-111 COLLAR 1

112 50300-112 KEY 1/4” X 1/4” X 45 1

113 50300-113 LOCK WASHER 3/8” 9

114 50300-114 ARBOR BRACKET 1

115 50300-115 ARBOR BUSHING 1

116 50300-116 ARBOR RETENTION NUT 5/8” 1

117 50300-117 SPRING PIN M6 X 50 1

118 50300-118 KEY 1/4” X 1/4” X 2-5/16” 1

119 50300-119 FLAT WASHER 7/16” 1

120 50300-120 CAP SCREW 7/16” X 1” 2

121 50300-121 SHAFT 1

122 50300-122 MOTOR BRACKET 1

123 50300-123 PIN 1

124 50300-124 COTTER PIN 2

125 50300-125 POLY V-BELT PJ260 1

126 50300-126 MOTOR MOUNTING PLATE 1

127 50300-127 MOTOR PULLEY 1

128 50300-128 FLAT WASHER 5/16” 14

129 50300-129 LOCK WASHER 5/16” 10

130 50300-130 HEX HEAD BOLT 5/16” X 3/4” 4

131 50300-131M1 MOTOR (50-270 M1 ONLY) 3HP. 1PH. 220V 1

131 50305-131M2 MOTOR (50-270 M2 ONLY) 5HP. 3PH. 220V 1

131 50305-131M3 MOTOR (50-270 M3 ONLY) 5HP. 3PH. 600V 1

132 50300-132 CAP SCREW 3/8” X 1-1/2” 7

133 50300-133 REAR TRUNNION BRACKET 1

134 50300-134 HEX NUT 3/8” 5

135 50300-135 CAP SCREW 3/8” X 1” 4

136 50300-136 SPRING PIN M8 X 25 4

137 50300-137 HEX NUT 3/4” 1

138 50300-138 FIBER WASHER 3/4” 4

139 50300-139 REAR TRUNNION 1

140 50300-140 BUSHING 1

141 50300-141 YOKE 1

142 50300-142 SET SCREW 5/16” X 1/4” 2

143 50300-143 COLLAR 2

144 50300-144 SHAFT 1

145 50300-145 SPRING PIN M5 X 30 2

146 50300-146 WORM GEAR 1

146-1 50300-146-1 LIFTING WORM GEAR 1

147 50300-147 LOCK PIN 4

148 50300-148 KEY M5 X 35 2

149 50300-149 CAP SCREW 5/16” X 1/2” 2

150 50300-150 DUST SHROUD 1

151 50300-151 HOSE CLAMP M100 2

152 50300-152 FRONT TRUNNION 1

153 50300-153 HEX HEAD BOLT 5/16” X 5/8” 2

154 50300-154 HEX NUT 5/16” 2

155 50300-155 LOCK KNOB 2

156 50300-156 FIBER WASHER 3/4” 2

28

Page 29

PARTS LIST

MOTOR AND TRUNNION (#50-270)

IMPORTANT: When ordering replacement parts, always give the model number, serial number of the

machine and part number. Also a brief description of each item and quantity desired.

PART # REF. # DESCRIPTION SPÉCIFICATIONS QTY

157 50300-157 CAP SCREW 5/16” X 1” 4

158 50300-158 FRONT TRUNNION BRACKET 1V

159 50300-159 HANDWHEEL HANDLE 2

160 50300-160 HANDWHEEL 2

161 50300-161 GUIDE PLATE 1

162 50270MT-162 HEX HEAD BOLT 1/4” X 3/8” 1

163 50270MT-163 POINTER 1

164 50300-164 POINTER BRACKET 1

165 50300-165 PHILLIPS HEAD SCREW 3/16” X 2” 2

166 50300-166 GUIDE BLOCK 1

167 50300-167 FLAT WASHER 3/8” 1

168 50300-168 BUSHING 1

169 50300-169 TILT SHAFT 1

170 50300-170 ARBOR WRENCH 1

171 50300-171 DUST HOSE 1

172 50300-172 L BRACKET 1

173 50300-173 CAP SCREW 5/16” X 3/4” 3

174 50300-174 DUST PLATE 1

175 50300-175 FLAT WASHER 3/16” 3

176 50300-176 LOCK WASHER 3/16” 3

177 50300-177 HEX HEAD BOLT 3/16” X 3/8” 3

178 50300-178 HEX HEAD BOLT 1

179 50300-179 LOCK PIN 1

180 50300-180 SPRING 1

181 50300-181 NYLON NUT 1/4” 3

182 50300-182 SPRING 2

183 50300-183 GUIDE BRACKET 1

184 50300-184 FLAT HEAD SCREW 1/4” X 1” 2

185 50300-185 SCREW 1

186 50300-186 LINK PLATE 1

187 50300-187 NYLON NUT M6 1

188 50300-188 PLATE 1

189 50300-189 RIVING KNIFE SUPPORT PLATE 1

190 50300-190 FLAT HEAD SOCKET SCREW M5 X 12 2

191 50300-191 RIVING KNIFE HOLDER 1

192 50300-192 SPRING 1

193 50300-193 CLAMPING PLATE 1

194 50300-194 FLAT HEAD SOCKET SCREW M6 X 20 2

195 50300-195 LOCK LEVER 1

196 50300-196 NYLON NUT M8 1

197 50300-197 SHIM RING 1

198 50300-198 SNAP RING S52 1

199 50300-199 SET SCREW M5 X 12 4

200 50300-200 GUIDE BLOCK 1

201 50300-201 LOCK PIN BRACKET 1

202 50300-202 SET SCREW M4 X 8 1

203 50300-203 CAP SCREW M5 X 20 2

29

Page 30

14A

DIAGRAM - PARTS LIST

RIVING KNIFE AND BLADE GUARD

19

16

17

19

10

11

16

14

17

9

17

16

15

19

8

27

2

20

19

16

24

23

17

17

11

13

151213

28

16

15

6

5

19

16

17

19

7

5

17

15

16

16

18

4

3

19

17

14

19

1

21

22

26

7

25

IMPORTANT: When ordering replacement parts, always give the model number, serial number of the

machine and part number. Also a brief description of each item and quantity desired.

PART # REF # DESCRIPTION SPECIFICATIONS QTY

1 50270BG-01N SPLITTER 1

2 50270BG-02N BLADE GUARD BODY 1

3 50270BG-03N BUSHING (L) 1

4 50270BG-04N BUSHING (R) 1

5 50270BG-05N FLAT HEAD SCREW M3 X 10 4

6 50270BG-06N LOCK PIN 1

7 50270BG-07N SPRING 2

8 50270BG-08N FRONT SHIELD 1

9 50270BG-09N ROLL PIN M5 X 25 1

10 50270BG-10N TOP SIGHT SHIELD 1

11 50270BG-11N ROUND HEAD SCREW M4 X 8 2

12 50270BG-12N BUSHING 1

13 50270BG-13N ROLL PIN M5 X 8 2

14 50270BG-14N BLADE GUARD SIDE SHIELD 2

14A 50270BG-14NA BLADE GUARD ASSEMBLY 1

15 50270BG-15N LINKING PLATE 4

16 50270BG-16N FLAT HEAD SOCKET SCREW M6 X 16 8

17 50270BG-17N FLAT WASHER M6 8

18 50270BG-18N SET SCREW M4 X 10 1

19 50270BG-19N NYLON INSERT LOCK NUT M6 8

20 50270BG-20N ROLL PIN M4 X 30 1

21 50270BG-21 RIVING KNIFE 1

22 50270BG-22N ANTI-KICKBACK PAWL (R) 1

23 50270BG-23N ANTI-KICKBACK PAWL (L) 1

24 50270BG-24N FLANGE(L) 1

25 50270BG-25N LOCK PIN 1

26 50270BG-26N FLANGE 1

27 50270BG-27N E-CLIP E5 1

28 50270BG-28N PAWL BASE 1

30

Page 31

220 V, 1 P hase

WIRING DIAGRAM

WIRING DIAGRAM

A1

A2

31

Page 32

5HP, 220 V, 3 P hase

WIRING DIAGRAM

POWER CORD

WIRING DIAGRAM

32

220

Page 33

5HP, 600 V, 3 P hase

POWER CORD

WIRING DIAGRAM

600

33

Page 34

34

8360 Champ-d’Eau, Montreal (Quebec) Canada H1P 1Y3

Tel.: (514) 326-1161

Fax: (514) 326-5565 - Parts & Service / (514) 326-5555 - Order Desk

orderdesk@general.ca

www.general.ca

*Model 50-270KDL shown

Follow us:

Loading...

Loading...