Page 1

COLOR MONIT OR

SER VICE MANUAL

+

CAUTION

BEFORE SERVICING THE UNIT,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

MODEL: Gateway FPD 1500

Page 2

1. LCD CHARACTERISTICS

Type : Color Active Matrix TFT LCD

Size : 15.1inch (38.35cm)

Pixel Pitch : 0.3mm x 0.3mm

Pixel Format : 1024 x 768 pixels (XGA)

RGB Stripe Arrangement

Color Depth : 8-bit, 16 million colors

Active Video Area : 307mm x 230mm

Surface Treatment : Anti-Glare, Hard Coating (3H)

Backlight Unit : Two-CCFL (Cold Cathode

Fluorescent Lamp)

2. OPTICAL CHARACTERISTICS

2-1. Viewing Angle by Contrast Ratio

≥

10

Left : 60° typ., 55° min.

Right : 60° typ., 55° min.

Top : 45° typ., 40° min.

Bottom : 45° typ., 40° min.

2-2. Luminance : 200 cd/m

2

typ.

2-3. Angle at Half Luminance

Left : 50° min.

Right : 50° min.

Top : 40° min.

Bottom : 30° min.

2-4. Contrast Ratio : 250:1 typical

3. SIGNAL (Refer to the Timing Chart)

3-1. Type : TMDS Digital

3-2. Voltage Level : 3.3V

3-3. Input Impedance : 50Ω

3-4. Operating Frequency

Horizontal : 48.363kHz

Vertical : 60Hz

4. POWER SUPPLY

4-1. Power Adaptor

Input : AC 100~240V, 50/60Hz 1.2A

Output : DC 24V 1.9A

4-2. Power Consumption

5. ENVIRONMENT

5-1. Operating Temperature: 10°C~35°C (50°F~95°F)

(Ambient)

5-2. Relative Humidity : 10%~80%

(Non-condensing)

5-3. Altitude : 0~10,000ft (3,030m)

6. DIMENSIONS (with TILT/SWIVEL)

Width : 389.2mm (15.32'')

Depth : 182.4mm (7.18'')

Height : 361.6mm (14.24'')

7. WEIGHT (with TILT/SWIVEL)

Net. Weight : 5.3kg (11.68 lbs)

Gross Weight : 7.2kg (15.87 lbs)

SPECIFICATIONS ................................................... 2

PRECAUTIONS ....................................................... 3

TIMING CHART ....................................................... 4

OPERATING INSTRUCTIONS ................................ 4

WIRING DIAGRAM ................................................. 5

DISASSEMBLY ....................................................... 6

BLOCK DIAGRAM ................................................... 8

TROUBLE SHOOTING GUIDE ............................... 9

PRINTED CIRCUIT BOARD................................... 12

EXPLODED VIEW...................................................14

REPLACEMENT PARTS LIST ...............................17

PIN CONFIGURATION............................................21

PACKING AND ACCESSORIES.............................27

SCHEMATIC DIAGRAM..........................................28

- 2 -

CONTENTS

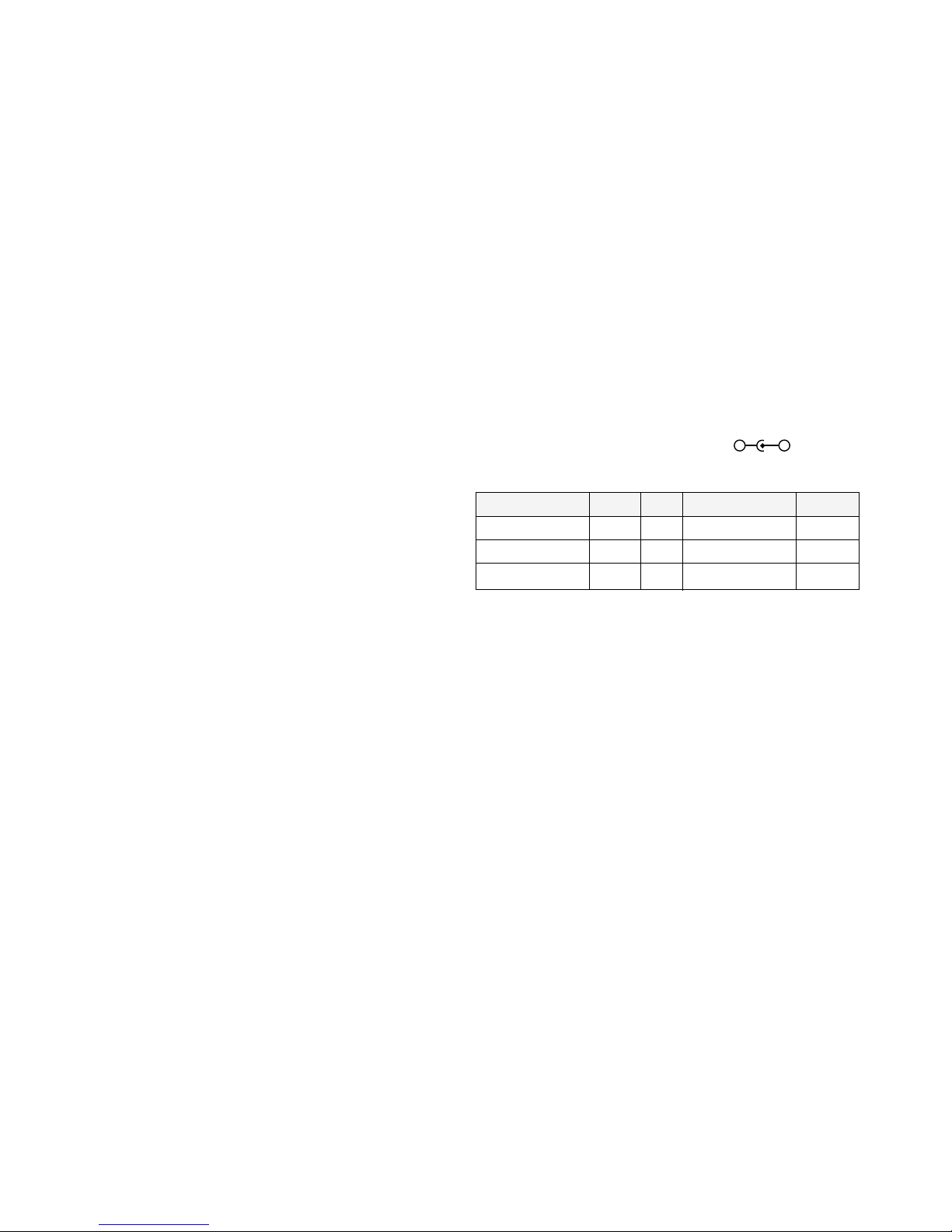

MODE

POWER ON (NORMAL)

DPM

POWER OFF

SIGNAL

ON

OFF

-

POWER CONSUMPTION

less than 30 W

less than 5 W

less than 5 W

LED COLOR

GREEN

ORANGE

OFF

VIDEO

ACTIVE

OFF

-

SPECIFICATIONS

-

+

Page 3

WARNING FOR THE SAFETY-RELATED COMPONENT.

• There are some special components used in LCD

monitor that are important for safety. These parts are

marked on the schematic diagram and the

replacement parts list. It is essential that these critical

parts should be replaced with the manufacturer’s

specified parts to prevent electric shock, fire or other

hazard.

• Do not modify original design without obtaining written

permission from Gateway2000 Inc. or you will void the

original parts and labor guarantee.

TAKE CARE DURING HANDLING THE LCD MODULE

WITH BACKLIGHT UNIT.

• Must mount the module using mounting holes arranged

in four corners.

• Do not press on the panel, edge of the frame strongly

or electric shock as this will result in damage to the

screen.

• Do not scratch or press on the panel with any sharp

objects, such as pencil or pen as this may result in

damage to the panel.

• Protect the module from the ESD as it may damage the

electronic circuit (C-MOS).

• Make certain that treatment person’s body are

grounded through wrist band.

• Do not leave the module in high temperature and in

areas of high humidity for a long time.

• The module not be exposed to the direct sunlight.

• Avoid contact with water as it may a short circuit within

the module.

• If the surface of panel become dirty, please wipe it off

with a softmaterial. (Cleaning with a dirty or rough cloth

may damage the panel.)

WARNING

BE CAREFUL ELECTRIC SHOCK !

• If you want to replace with the new backlight (CCFL) or

inverter circuit, must turn off the power button or

disconnect the AC adapter because high voltage

appears at inverter circuit about 650Vrms.

• Handle with care wires or connectors of the inverter

circuit. If the wires are pressed cause short and may

burn or take fire.

- 3 -

PRECAUTION

CAUTION

Please use only a plastic screwdriver to protect yourself

from shock hazard during service operation.

CAUTION

• There is two backlight, must distinguish between

the top (upper) and the bottom (lower), and be

careful of treatment it.

• MTBF (Mean Time Between Failure) of a backlight

is about 10,000 hours.

Top (Upper) Backlight Ass’y

(P/N: 6913TZZ001A)

Bottom (Lower) Backlight Ass’y

(P/N: 6913TZZ001B)

IF BRIGHTNESS OF THE LCD MODULE DARKEN,

REPLACE THE BACKLIGHT ONE OR ALL.

Page 4

- 4 -

VIDEO

SYNC

C

E

D

F

A

B

TIMING CHART

MODE

1

H

(Pixels)

V

(Lines)

Sync

Polarity

_

_

Dot Clock

65MHz

1024

X

768

48.363KHz

60.0Hz

1344

806

1024 320

768

24

38

136

36

160

29

Frequency

Total

Period

(A)

Video

Active

Time

(B)

Blanking

Time

(C)

Sync

Duration

(E)

Back

Porch

(F)

Front

Porch

(D)

Resolution

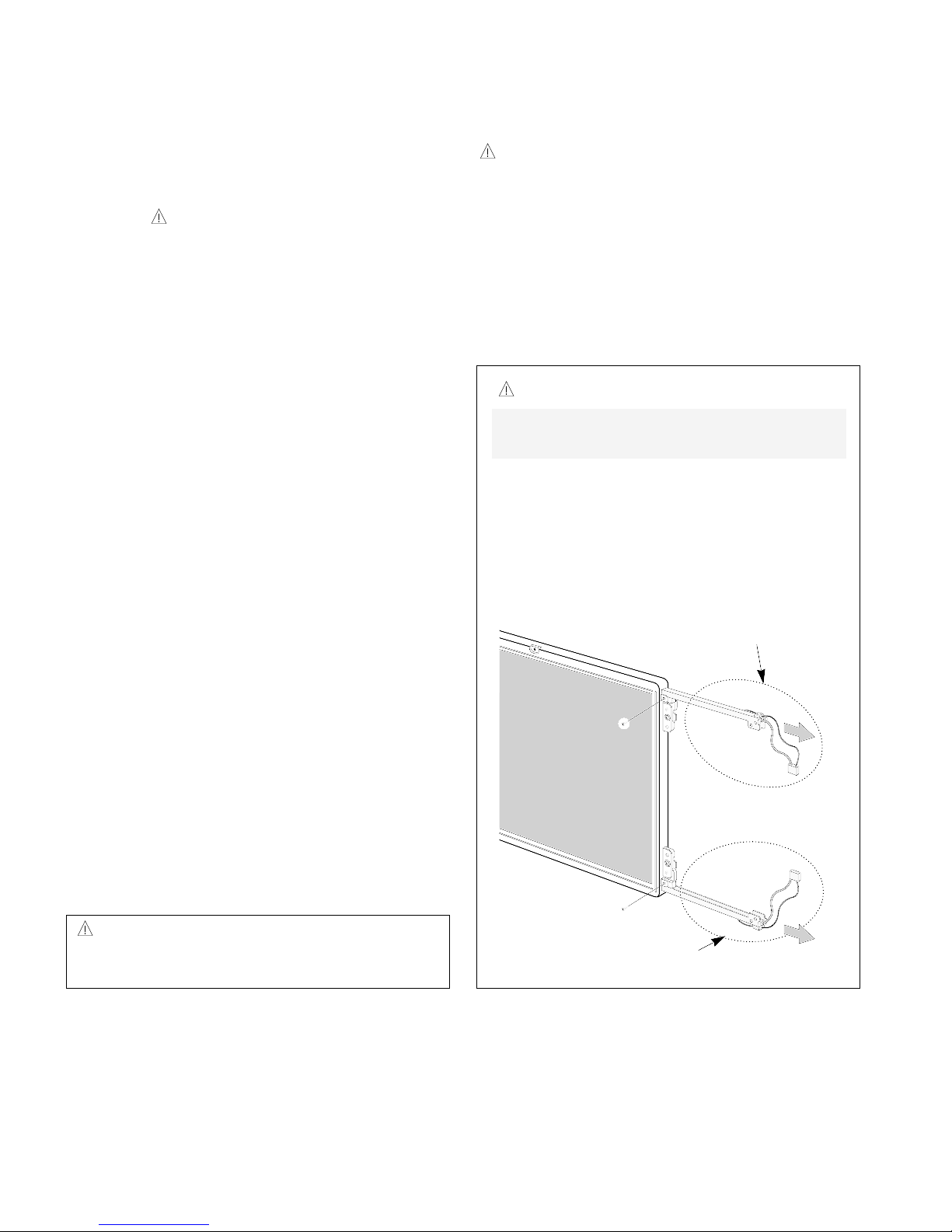

OPERATING INSTRUCTIONS

ID Label

Power ON/OFF Button

This button is used to turn the monitor on and off.

Power Indicator

This indicator lights up green when the monitor operates

normally; in DPMS (Energy Saving) mode, -stand-by,

suspend, or power off mode-its color changes to orange.

Brightness Control Buttons

Use these buttons for adjusting the brightness.

+

+

Power Input

Socket

DFP

Signal Connector

Front View

Rear View

Page 5

- 5 -

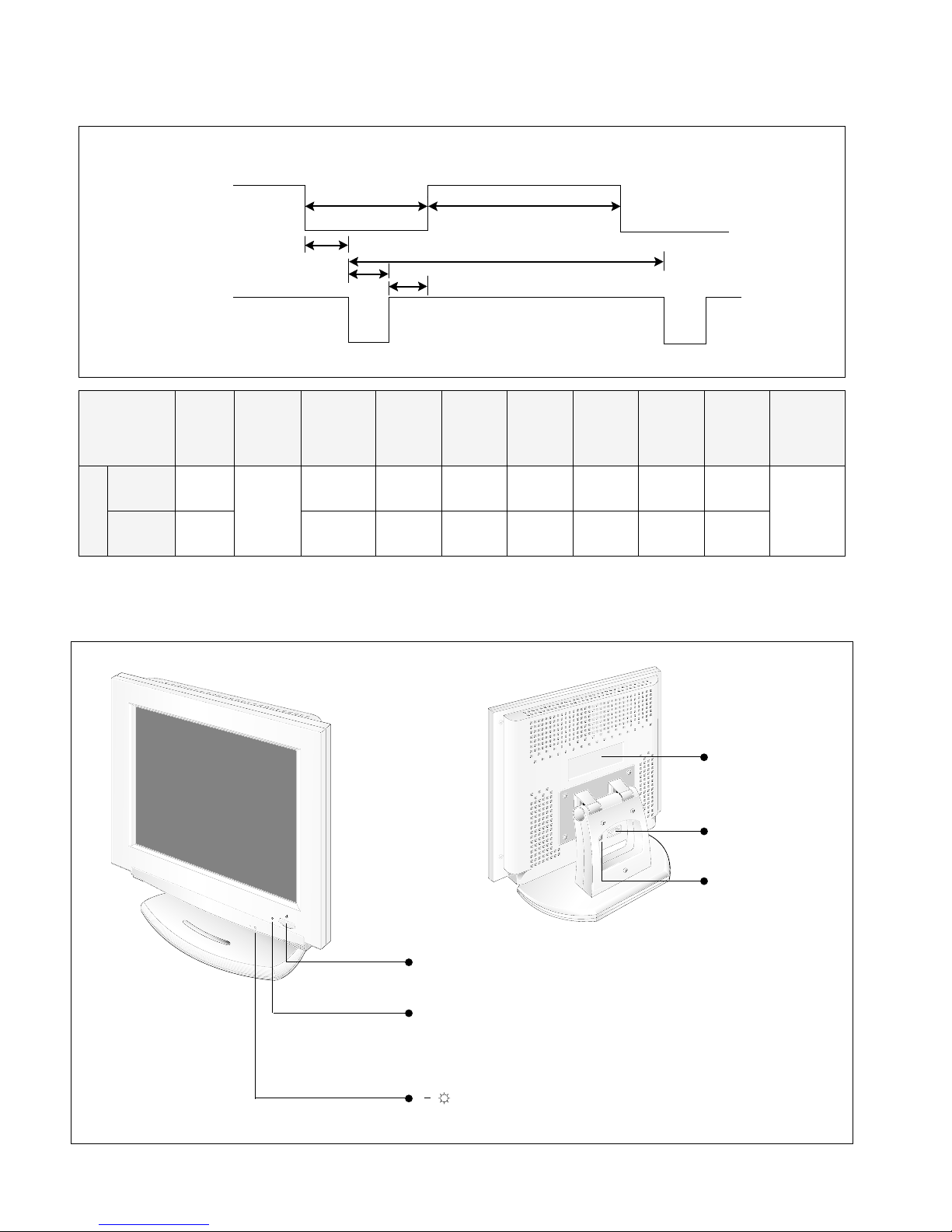

WIRING DIAGRAM

CN1

CN3

J501

CN2

J8-1

J301

J302

J303

J304

CN601

Page 6

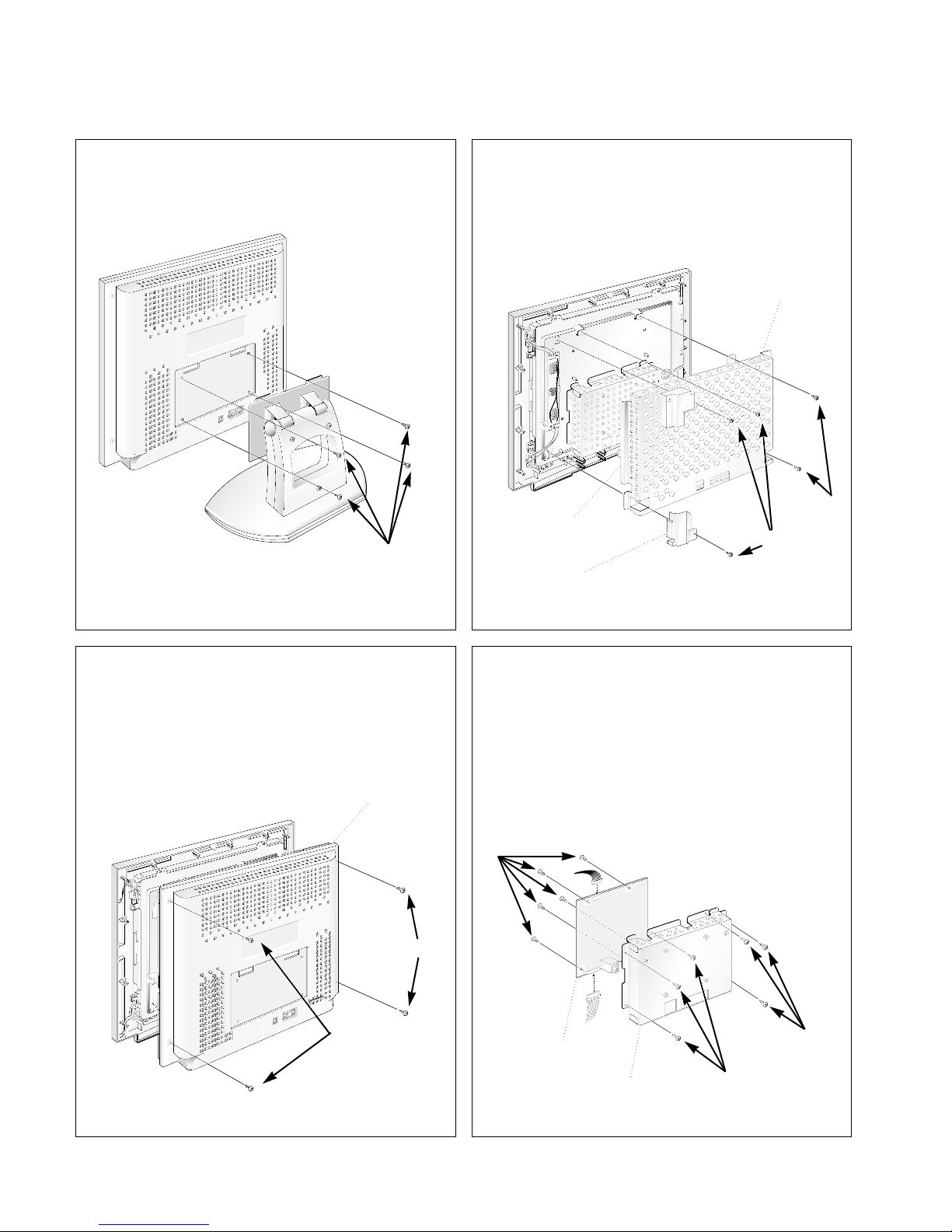

DISASSEMBLY

- 6 -

ⓐ

1. TILT/SWIVEL REMOVAL

①Remove four screws ⓐ.

②Remove the Tilt/swivel.

2. BACK COVER REMOVAL

①Remove four screws ⓐ from the Back Cover.

②Remove the Back Cover.

3. INVERTER CAPS & TOP SHIELD REMOVAL

①Remove five screws ⓐ.

②Remove two Inverter Caps (Upper, Lower).

③Remove the Top Shield.

4. MAIN PCB ASSEMBLY REMOVAL

①Remove six screws ⓐ.

②Disconnect J301 and J501 from the Main PCB.

③Remove the PCB Shield.

④Remove five screws ⓑ.

⑤Remove the Main PCB from the PCB Shield.

ⓐ

ⓐ

ⓐ

ⓐ

ⓐ

ⓑ

ⓐ

Inverter Cap (Upper)

Inverter Cap (Lower)

Main PCB

PCB Shield

Back Cover

Top Shield

J501

J301

Page 7

- 7 -

ⓒ

ⓐ

ⓐ

ⓑ

ⓐ

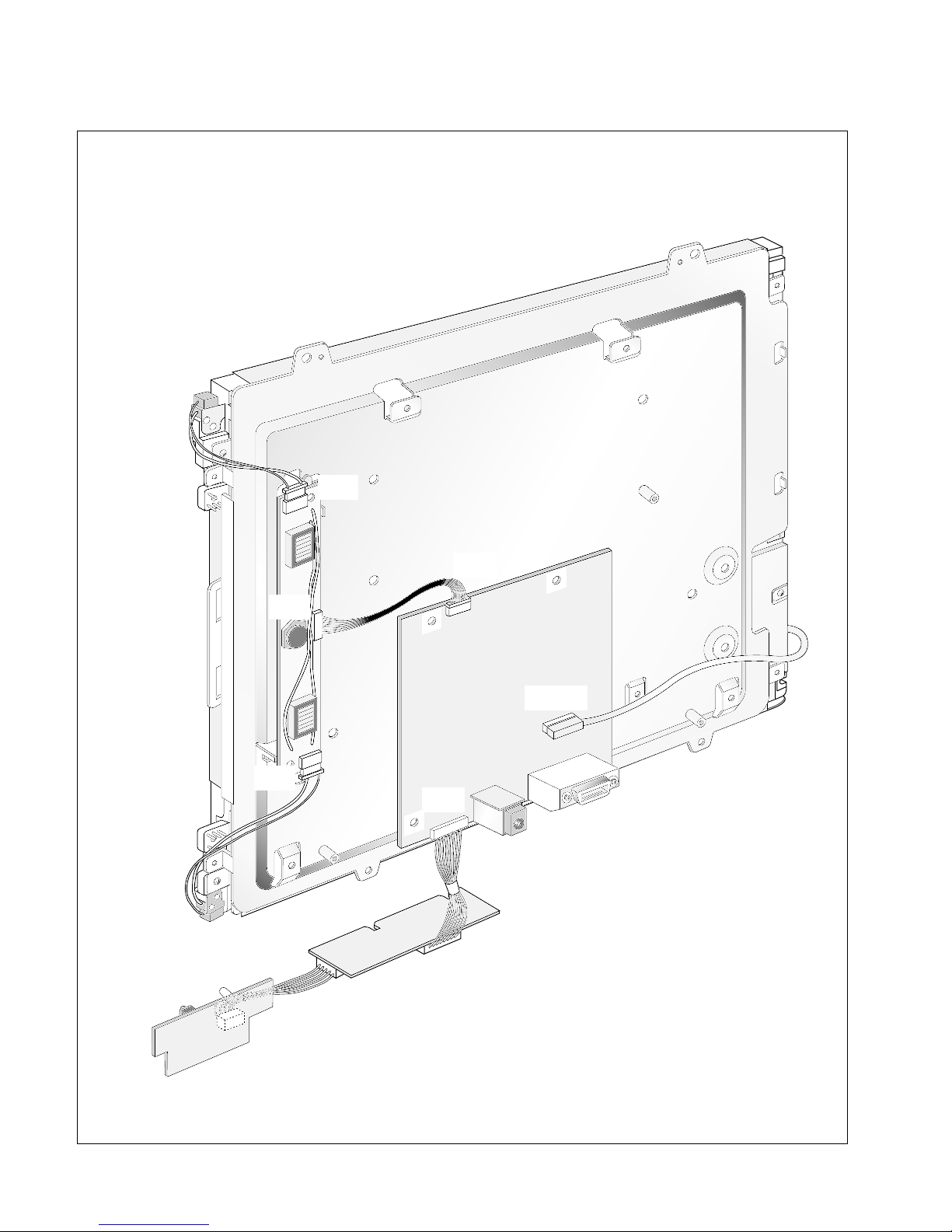

5. INVERTER, POWER, CONTROL PCB

AND MAIN FRAME REMOVAL

①Remove two screws ⓐ.

②Disconnect CN1 and CN2.

③Remove Inverter PCB.

④Remove two screws ⓑ.

⑤Remove the Power and the CONTROL PCB.

⑥Remove four screws ⓒ.

⑦Remove the Front Cabinet.

6. BACKLIGHT REMOVAL

①Remove two screws ⓐ.

②Remove two Sponge Tapes.

③Remove the Backlight from the LCD Module.

ⓐ

7. LCD MODULE REMOVAL

①Remove four screws ⓐ.

②Divide the LCD Module and the Main Frame.

Bottom (Lower) Backlight Ass’y

Top (Upper) Backlight Ass’y

Front Cabinet

Power PCB

CONTROL PCB

Inverter PCB

LCD Module

LCD Module

Main Frame

Page 8

BLOCK DIAGRAM

Description of Block Diagram

- 8 -

DFP 20Pin

Connector

PanelLink

Connector

EMI Filter

To LCD Module

T

X

0

T

X

1

T

X

2

T

X

C

2

From PC

DPM_det

I2C

Power Connector

From AC/DC

Adapter

DC/DC

Converter

(Max785)

GND

+24V

Inverter

Connecter

To

Inverter

Power switching

(SI4925)

System

Controller

(68HC05BD1)

To key button

Voltage

Regulator

(78M12,05)

+5Vst

+5V

Voltage

Regulator

+5Vmod

+3.3Vcc

+3.3Vcc

+24Vinv

+24Vinv

Inv_onoff

PWM_in

Inv_onoff

PWM_in

P_ctrl

EEPROM

(24C02)

EEPROM

(24C02)

2 2 2

2 2 2 2

System Block Diagram

Block Diagram for Main Logic Board

1.DC/DC Converter

This curcuit supplies stand-by 5V(+5Vst) and regular

5V(+5V) for using MAX785 from AC/DC adapter(+24V).

The +5V voltage supply to power swichng IC(SI4925)

and 3.3V voltage regulator.

The state of power down makes all voltage except

+5Vst down using SHDN pin from system controller

(68HC05BD1).

2. System Controller

This curcuit consists of two EEPROM IC(24C02)

which stores the control data for system and

communicates

DDC(Display Data Channel) and oscillator(X201).

The operating procedures of system controller and its

associated circuit are as follows:

1) The system controller detects frequency of vertical

sync through DFP(Digital Flat Panel) 20 pin

connector.

This controller controls the power swiching

IC(SI4925) by the detection of verticalsync(HVsync).

2) The system controller controls the brightness of

inverter by using the key control button and store

the data to EEPROM(24C02).

3. Power Swiching Circuit

This block supplies +24V(+24Vin) to the inverter for

the backlight voltage of the LCD module and +5V

(+5Vmod) for data control of the LCD module.

4. Signal Transmission

The digital video signals(R,G,B) and clock signals(CLK)

by differencial signals(Tx0,Tx1,Tx2,Txc), are transmitted

to LCD module through EMI filter from PC system which

has digital video card.

LCD Module

Inverter PCB

Main Logic PCB

Button PCB

Power

Supply

Power

Cord

DFP Signal Cable

20Pin

Page 9

- 9 -

NO POWER

(POWER INDICATOR OFF)

TROUBLE IN

U101

TROUBLE IN

AC/DC ADAPTER

CHECK

J101 PIN1

INPUT VOLTAGE

24V ?

NO

YES

YES

YES

YES

YES

YES

YES

TROUBLE IN

J101, J102

CHECK

U50 PIN 1

INPUT VOLTAGE

24V ?

NO

TROUBLE IN

U102, U103

CHECK

5VST VOLTAGE

5V ?

NO

TROUBLE IN

Q101, Q102

CHECK

+5V VOLTAGE

5V ?

NO

TROUBLE IN

U104

CHECK

+3.3V VOLTAGE

3.3V ?

NO

TROUBLE IN

Q403, Q401

CHECK

+24V_INV VOLTAGE

24V ?

NO

TROUBLE IN

Q402, Q401

CHECK

+5V_MOD VOLTAGE

5V ?

NO

TROUBLE-SHOOTING GUIDE

1. NO POWER

Page 10

- 10 -

CHECK PC

or SIGNAL CABLE

CHECK

CN602 PIN 1, 2, 5, 6

11, 12, 15, 16

SIGNAL ?

NO

TROUBLE IN

CMF601, 602, 603, 604

CHECK

CN601 PIN 9, 10, 12, 13,

15, 16, 18, 19

SIGNAL ?

NO

TROUBLE IN

CN601, TMDS CABLE,

LCD MODULE

CHECK

CN601 PIN 20

Vsync ?

NO

TROUBLE IN

U601

CHECK

U201 PIN 28

Vsync ?

NO

REFER TO NO POWER

CHECK

POWER LINE ?

NO

YES

YES

YES

YES

YES

YES

2. NO RASTER

NO RASTER

TROUBLE IN

INVERTER

Page 11

- 11 -

3. TROUBLE IN DPM

CHECK PC

CHECK

CN602 PIN 1, 2, 5, 6

11, 12, 15, 16

SIGNAL ?

NO

TROUBLE IN

DPM MODE

RECHECK PC

& SIGNAL CABLE

TROUBLE IN

LCD MODULE

CHECK

CN601 PIN 20

Vsync ?

NO

TROUBLE IN

U601

CHECK

U201 PIN 28

Vsync ?

NO

TROUBLE IN

U201(MICOM)

CHECK

U201 PIN 12, 15

HIGH ?

NO

YES

YES

YES

YES

Page 12

- 12 -

PRINTED CIRCUIT BOARD

1. MAIN BOARD (Component Side)

2. MAIN BOARD (Solder Side)

Page 13

- 13 -

3. CONTROL BOARD (Component Side)

4. CONTROL BOARD (Solder Side)

5. INTERFACE BOARD (Component Side)

6. INTERFACE BOARD (Solder Side)

Page 14

1

2

3

4

13

14

7

8

9

5

6

A

15

16

10

11

12

EXPLODED VIEW

- 14 - - 15 -

Page 15

- 16 -

EXPLODED VIEW PARTS LIST

Ref. No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

A

Part No.

3091TKL005A

6304TLT151B

6633TZA003A

4950TKS072D

4950TKK060A

4950TKK061A

4950TKK047A

3809TKL005A

6871TST085A

332-095C

3043TKK023D

332-105F

6871TMT078A

4950TKK048B

6866TDM001A

6634TBZ004A

3313TL5004A

Description

CABINET ASS’Y, LG501, NO BRAND

LCD MODULE, LGE TFT LCD LM151X1-G 15.1”

INVERTER PCB ASS’Y

MAIN FRAME

INVERT CAP (UP)

INVERT CAP (DOWN)

MAIN SHIELD

BACK COVER ASS’Y

CONTROL BUTTON PCB ASS’Y

SCREW, PZP+3x12

TILT SWIVEL ASS’Y

SCREW, PVS+4x10

MAIN PCB ASS’Y

PCB SHIELD

SIGNAL CABLE

ADAPTER, AC-DC

MAIN TOTAL ASS’Y

Q'ty

1

1

1

1

1

1

1

1

1

4

1

4

1

1

1

1

1

Material

LGC LUPOY GN5001TF

LGC LUPOY GN5001TF

LGC HIPS 60HR

Page 16

REPLACEMENT PARTS LIST

CAUTION:BEFORE REPLACING ANY OF THESE COMPONENTS,

READ CAREFULLY THE SAFETY PRECAUTIONS IN THIS MANUAL.

* NOTE :S SAFETY Mark

AL ALTERNATIVE PARTS

MODEL: Gateway FPD 1500 DATE: 1998 . 9. 20.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION REMARK

C101 0CH8107J611 CAPACITOR, CHIP[AL. ELECTROLYTIC], 100UF 35V M 85STD

C102 0CH7106F621 CAP ACITOR, CHIP[TANTALUM], 10UF 16V M 3528MM TP(-)

C103 0CH3103K516 CAPACITOR, CHIP[CERAMIC LD-LESS HD], 10000PF 50V K B

C104 0CH3104K566 CAPACITOR, CHIP[CERAMIC LD-LESS HD], 0.1UF 50V K X

C105 0CH3224K944 CAPACITOR, CHIP[CERAMIC LD-LESS HD], 0.22UF 50V Z F

C106 0CH3104K566 CAPACITOR, CHIP[CERAMIC LD-LESS HD], 0.1UF 50V K X

C107 0CH3103K516 CAPACITOR, CHIP[CERAMIC LD-LESS HD], 10000PF 50V K B

C108 0CH6102K406 CAPACITOR, CHIP[CERAMIC LD-LESS TC], 1000PF 50V J SL

C109 0CH7227C661 CAPACITOR, CHIP[TANTALUM], 220UF 6.3V M 7343 TP(-)

C110 0CH7107F661 CAPACITOR, CHIP[TANTALUM], 100UF 16V M 7343 TP(-)

C111 0CH3104K566 CAPACITOR, CHIP[CERAMIC LD-LESS HD], 0.1UF 50V K X

C112 0CH3103K516 CAPACITOR, CHIP[CERAMIC LD-LESS HD], 10000PF 50V K B

C113 0CH7476F661 CAPACITOR, CHIP[TANTALUM], 47UF 16V M 7343 TP(-)

C114 0CH3104K566 CAPACITOR, CHIP[CERAMIC LD-LESS HD], 0.1UF 50V K X

C115 0CH3103K516 CAPACITOR, CHIP[CERAMIC LD-LESS HD], 10000PF 50V K B

C116 0CH6102K406 CAPACITOR, CHIP[CERAMIC LD-LESS TC], 1000PF 50V J SL

C117 0CH6221K416 CAPACITOR, CHIP[CERAMIC LD-LESS TC], 220PF 50V J NP0

C118 0CH6221K416 CAPACITOR, CHIP[CERAMIC LD-LESS TC], 220PF 50V J NP0

C119 0CH8107J611 CAPACITOR, CHIP[AL. ELECTROLYTIC], 100UF 35V M 85STD

C120 0CH6101K416 CAPACITOR, CHIP[CERAMIC LD-LESS TC], 100PF 50V J NP0

C121 0CH3104K566 CAPACITOR, CHIP[CERAMIC LD-LESS HD], 0.1UF 50V K X

C123 0CH7106F621 CAP ACITOR, CHIP[TANTALUM], 10UF 16V M 3528MM TP(-)

C124 0CH3103K516 CAPACITOR, CHIP[CERAMIC LD-LESS HD], 10000PF 50V K B

C125 0CH7106F621 CAP ACITOR, CHIP[TANTALUM], 10UF 16V M 3528MM TP(-)

C126 0CH3103K516 CAPACITOR, CHIP[CERAMIC LD-LESS HD], 10000PF 50V K B

C127 0CH8107J611 CAPACITOR, CHIP[AL. ELECTROLYTIC], 100UF 35V M 85STD

C129 0CH8107J611 CAPACITOR, CHIP[AL. ELECTROLYTIC], 100UF 35V M 85STD

C130 0CH3104K566 CAPACITOR, CHIP[CERAMIC LD-LESS HD], 0.1UF 50V K X

C131 0CH3103K516 CAPACITOR, CHIP[CERAMIC LD-LESS HD], 10000PF 50V K B

C201 0CH7226F651 CAP ACITOR, CHIP[TANTALUM], 22UF 16V M 6032 TP(-)

C202 0CH3104K566 CAPACITOR, CHIP[CERAMIC LD-LESS HD], 0.1UF 50V K X

C203 0CH6220K416 CAPACITOR, CHIP[CERAMIC LD-LESS TC], 22PF 50V J NP0

C204 0CH6220K416 CAPACITOR, CHIP[CERAMIC LD-LESS TC], 22PF 50V J NP0

C205 0CH3104K566 CAPACITOR, CHIP[CERAMIC LD-LESS HD], 0.1UF 50V K X

C206 0CH3103K516 CAPACITOR, CHIP[CERAMIC LD-LESS HD], 10000PF 50V K B

C401 0CH8106J611 CAPACITOR, CHIP[AL. ELECTROLYTIC], 10UF 35V M 85STD

C402 0CH3104K566 CAPACITOR, CHIP[CERAMIC LD-LESS HD], 0.1UF 50V K X 2012

- 17 -

MAIN BOARD

CAPACITORs

Page 17

MODEL: Gateway FPD 1500 DATE: 1998 . 9. 20.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION REMARK

C403 0CH8106J611 CAPACITOR, CHIP[AL. ELECTROLYTIC], 10UF 35V M 85STD

C404 0CH3104K566 CAPACITOR, CHIP[CERAMIC LD-LESS HD], 0.1UF 50V K X

C406 0CH7226F651 CAP ACITOR, CHIP[TANTALUM], 22UF 16V M 6032 TP(-)

C407 0CH3103K516 CAPACITOR, CHIP[CERAMIC LD-LESS HD], 10000PF 50V K B

C408 0CH6101K416 CAPACITOR, CHIP[CERAMIC LD-LESS TC], 100PF 50V J NP0

C410 0CH8106J611 CAPACITOR, CHIP[AL. ELECTROLYTIC], 10UF 35V M 85STD

C411 0CH3104K566 CAPACITOR, CHIP[CERAMIC LD-LESS HD], 0.1UF 50V K X

C412 0CH3103K516 CAPACITOR, CHIP[CERAMIC LD-LESS HD], 10000PF 50V K B

C501 0CH6221K416 CAPACITOR, CHIP[CERAMIC LD-LESS TC], 220PF 50V J NP0

C502 0CH6221K416 CAPACITOR, CHIP[CERAMIC LD-LESS TC], 220PF 50V J NP0

C503 0CH6221K416 CAPACITOR, CHIP[CERAMIC LD-LESS TC], 220PF 50V J NP0

C504 0CH6221K416 CAPACITOR, CHIP[CERAMIC LD-LESS TC], 220PF 50V J NP0

C505 0CH6221K416 CAPACITOR, CHIP[CERAMIC LD-LESS TC], 220PF 50V J NP0

C601 0CH3104K566 CAPACITOR, CHIP[CERAMIC LD-LESS HD], 0.1UF 50V K X

CMF601 6140TBZ007C COIL, CHOKE, COMMON-MODE CHOKE,ZCYS51R5-2PAT(TDK)

CMF602 6140TBZ007C COIL, CHOKE, COMMON-MODE CHOKE,ZCYS51R5-2PAT(TDK)

CMF603 6140TBZ007C COIL, CHOKE, COMMON-MODE CHOKE,ZCYS51R5-2PAT(TDK)

CMF604 6140TBZ007C COIL, CHOKE, COMMON-MODE CHOKE,ZCYS51R5-2PAT(TDK)

CN301 366-184F WAFER, 53015-0710 MOLEX 2.0mm R/A

CN501 6602T10001D WAFER, SM10B-SRSS-TB JST 1.0mm R/A

CN601 6602T11001A WAFER, FI-TWE21P-VF JAE 1.0mm S/T

CN602 6602T20007B WAFER, 87089-2016 MOLEX 2.0MM BOARD

D101 0DS181009AA DIODE, SWITCHING, KDS181 TP KEC SOT-23 80V 300MA 2A

D102 0DR190309AA DIODE, RECTIFIER, MBRS190T3 TP MOTOROLA 403A-03 90V

L101 6210TCT002C CORE (CIRC), BEAD, HF50ACC575018-T TDK , CHIP BEAD,LCD

L102 6140TBZ016A COIL, CHOKE, DR10*5 22UH 0.45MM 20.5T LG501

L103 6200TEZ007A FILTER(CIRC), CAPACITOR, STC-B SERIES(104B) NIIGATA(FILMAC)

L104 6140TBZ016A COIL, CHOKE, DR10*5 22UH 0.45MM 20.5T LG501

L105 6210TCE001G CORE (CIRC), BEAD, HH-1M3216-501 CERATEC 3216MM R/TP

L106 6210TCE001G CORE (CIRC), BEAD, HH-1M3216-501 CERATEC 3216MM R/TP

L401 6200TEZ007A FILTER(CIRC), CAPACITOR, STC-B SERIES(104B) NIIGATA(FILMAC)

L501 6210TCE001C CORE (CIRC), BEAD, HB-1T3216-500JT CERATEC , CHIP-BEAD

L502 6210TCT002B CORE (CIRC), BEAD, ACB2012M-300-T TDK , CHIP BEAD,LCD

L503 6210TCT002B CORE (CIRC), BEAD, ACB2012M-300-T TDK , CHIP BEAD,LCD

U101 0IMX785000B IC, MAXIM, MAX785CAI 28P,SSOP TP DUAL OUTPWRSUPPLY

U102 0ISS781200J IC, SAMSUNG ELECTRONICS,KA78M12R 3P,D-PAK TP VOL.

U103 0ISS780500H IC, SAMSUNG ELECTRONICS, KA78M05-R 3P,D-PAK TP 5V 0.5A

U104 0IRH033200A IC, ROHM, BA033FP-E2 MOLD-3 TP REGULATOR

U201 0IZZTSZ011A IC [HYBRID], 28P DIP BK, MC68HC705BD1A, LG501

- 18 -

DIODEs

COILs & COREs

ICs

Page 18

MODEL: Gateway FPD 1500 DATE: 1998 . 9. 20.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION REMARK

U202 0IMP240200A IC, MICRO CHIP TECHNOLOGY, 24LC02BT/SN 3.3K/ TP

U203 0IMP240200A IC, MICRO CHIP TECHNOLOGY, 24LC02BT/SN 3.3K/ TP

U601 0IMO741420B IC, MOTOROLA, MC74HCT14ADR2 14P,SOIC TP LEVEL

Q101 0TF993609AA FET, SI9936DY TP TEMIC 30V 5A SO-8

Q102 0TF941009AA FET, SI9410DY TP TEMIC 30V 7A SO-8

Q401 0TF492509AA FET, SI4925DY TP TEMIC 30V 6.1A SO-8

Q402 0TR162309CA TRANSISTOR, KSC1623 TP SAMSUNG SOT23 NPN EPI

Q403 0TR162309CA TRANSISTOR, KSC1623 TP SAMSUNG SOT23 NPN EP

R101 0RH1003D422 RESISTOR, CHIP, 100K 1/10W 1% D R/TP

R102 0RH0000D622 RESISTOR, CHIP, 0 1/10W P-TYPE TAPPING

R103 0RH4701D622 RESISTOR, CHIP, 4.7K 1/10W 5 D.R/TP

R104 0RHZTJZ001B RESISTOR, CHIP, 0.025 OHM 1 W 2% 2512 R/TP ,IRC

R201 0RH1000D622 RESISTOR, CHIP, 100 1/10W 5 D.R/TP

R202 0RH4701D622 RESISTOR, CHIP, 4.7K 1/10W 5 D.R/TP

R203 0RH4701D622 RESISTOR, CHIP, 4.7K 1/10W 5 D.R/TP

R204 0RH0000D622 RESISTOR, CHIP, 0 1/10W P-TYPE TAPPING

R205 0RH0000D622 RESISTOR, CHIP, 0 1/10W P-TYPE TAPPING

R206 0RH0000D622 RESISTOR, CHIP, 0 1/10W P-TYPE TAPPING

R207 0RH0000D622 RESISTOR, CHIP, 0 1/10W P-TYPE TAPPING

R208 0RH3300D622 RESISTOR, CHIP, 330 1/10W 5 D.R/TP

R209 0RH3300D622 RESISTOR, CHIP, 330 1/10W 5 D.R/TP

R210 0RH4701D622 RESISTOR, CHIP, 4.7K 1/10W 5 D.R/TP

R211 0RH4701D622 RESISTOR, CHIP, 4.7K 1/10W 5 D.R/TP

R212 0RH1000D622 RESISTOR, CHIP, 100 1/10W 5 D.R/TP

R213 0RH1000D622 RESISTOR, CHIP, 100 1/10W 5 D.R/TP

R214 0RH4701D622 RESISTOR, CHIP, 4.7K 1/10W 5 D.R/TP

R401 0RH6802D622 RESISTOR, CHIP, 68K 1/10W 5 D.R/TP

R402 0RH1002D622 RESISTOR, CHIP, 10K 1/10W 5 D.R/TP

R403 0RH1002D622 RESISTOR, CHIP, 10K 1/10W 5 D.R/TP

R404 0RH1002D622 RESISTOR, CHIP, 10K 1/10W 5 D.R/TP

R405 0RH6802D622 RESISTOR, CHIP, 68K 1/10W 5 D.R/TP

R406 0RH6802D622 RESISTOR, CHIP, 68K 1/10W 5 D.R/TP

R407 0RH1002D622 RESISTOR, CHIP, 10K 1/10W 5 D.R/TP

R408 0RH1002D622 RESISTOR, CHIP, 10K 1/10W 5 D.R/TP

R603 0RH1002D622 RESISTOR, CHIP, 10K 1/10W 5 D.R/TP

R604 0RH1002D622 RESISTOR, CHIP, 10K 1/10W 5 D.R/TP

R605 0RH1002D622 RESISTOR, CHIP, 10K 1/10W 5 D.R/TP

R606 0RH5100D622 RESISTOR, CHIP, 510 1/10W 5 D.R/TP

R607 0RH5100D622 RESISTOR, CHIP, 510 1/10W 5 D.R/TP

R608 0RH5100D622 RESISTOR, CHIP, 510 1/10W 5 D.R/TP

R609 0RH5100D622 RESISTOR, CHIP, 510 1/10W 5 D.R/TP

- 19 -

RESISTORs

TRANAITORs

Page 19

MODEL: Gateway FPD 1500 DATE: 1998 . 9. 20.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION REMARK

X201 6202TST001B CRYSTAL, SX-1 SUNNY ,SMD, 4.0MHZ ,30PPM, 18PF, TP

CN302 366-184F WAFER, 53015-0710 MOLEX 2.0mm R/A

CN303 366-184D WAFER, 53015-0510 MOLEX 2.0mm R/A

CN304 366-183D WAFER, 53014-0510 MOLEX 2.0mm S/T

LD301 0DL571300AA LED, SPR571MVW3 TP ROHM GREEN/RED 10,10MCD

R301 0RD1801Q609 RESISTOR, FIXED CARBON FILM, 1.80K 1/4W(3 5% TA52

R302 0RD4700Q609 RESISTOR, FIXED CARBON FILM, 470 OHM 1/4 W (3.4) 5%

R303 0RD1001Q609 RESISTOR, FIXED CARBON FILM, 1K 1/4W(3 5% TA52

S301 140-058E SWITCH, TACT, SKHV10910B LGEC NON 12V 20A HORIZENTAL

S302 140-058E SWITCH, TACT, SKHV10910B LGEC NON 12V 20A HORIZENTAL

S303 140-058E SWITCH, TACT, SKHV10910B LGEC NON 12V 20A HORIZENTAL

ZD301 0DZ560009CE DIODE, ZENER, MTZJ5.6B TP ROHM-K DO34 500MW 5.6V 5MA

J101 6612TAH002A JACK,AC/DC POWER, DC-001 UNITOP DC-001 2.0MM (UNITOP)

J102 6602T25007A WAFER, GC250-3P-LS-SO LGC 2.5mm R/A

J603 6602T20007A WAFER, 87264-2050 MOLEX 2.0MM BOARD

J604 6630TGA002A CONNECTOR (CIRC), D-SUB, 10220-55F3JL 3M 20PIN 1.27MM

LCD 6304TLT151B LCD, LGE TFT LCD LM151X1-G 15.1” 1024X768

ADAPTER

6634TBZ004A ADAPTER,AC-DC, PSCV450106A SAMSUNG 100V 24V 1.875A

INVERTER

6633TZA003A INVERTER ASSY, SAMSUNG LG1501 FOR 15.1” LCD MNT

or

INVERTER

6633TZA001A INVERTER ASSY, AMBIT REV.1, (UO4.32.C.00) LCD

P/CORD 174-206F POWER CORD, UL/CSA 1830MM WALL IVORY

or P/CORD

174-240A & 174-240A

POWER CORD, WALL OUT, 6FT, BK, FOR JAPAN ONLY

S/CABLE 6866TDM001A SIGNAL CABLE, UL20276 DT 2000MM COOL GRAY 3C

M-INVERTER

6631T10001C CONNECTOR ASSY, 10P H-H 130MM UL 1571 28

M-MODULE

6631T11006C CONNECTOR ASSY, 21P H-H 220MM UL20276SB10P+2C

M-CTRL 6631T20005E CONNECTOR ASSY, 7P H-H 60MM UL1061 AWG 26 TW

C-

POWER

6631T20005B CONNECTOR ASSY, 5P,H-H,L60,UL1061 26

- 20 -

MISCELLANEOUS

CONTROL BOARD

INTERFACE BOARD

OTHERs

Page 20

PIN NAME FUNCTION

1 CS3 Current-sense input for +3.3V; +100mV = current limit level referenced to FB3.

2 SS3 Soft-start input for +3.3V. Ramp time to full current limit is 1ms/nF of capacitance to GND.

3 ON3 ON/

OFF

control input disables the +3.3V PWM. Tie directly to VL for automatic start-up.

4 D1 #1 level-translator/comparator noninverting input, threshold = +1.650V. Controls Q1. Tie to GND if unused.

5 D2 #2 level-translator/comparator noninverting input (see D1)

6 VH External positive supply-voltage input for the level translators/comparators

7Q2

#2 level-translator/comparator output. Sources 20µA from VH when D2 is high. Sinks 500µA to GND

when D2 is low, even with VH = 0V.

8 Q1 #1 level translator/comparator output (see Q2)

9 GND Low-current analog ground

10 REF 3.3V reference output. Sources up to 5mA for external loads. Bypass to GND with 1µF/mA of load or

0.22µF minimum.

11 SYNC

Oscillator control/synchronization input. Connect to VL or GND for 200kHz; connect to REF for

300kHz. For external clock synchronization in the 240kHz to 350kHz range, a high-to-low transition

causes a new cycle to start.

12

SHDN

Shutdown control input, active low. Tie to VL for automatic start-up. The 5V VL supply stays active in

shutdown, but all other circuitry is disabled. Do not force

SHDN

higher than VL + 0.3V.

13 ON5 ON/

OFF

control input disables the +5V PWM supply. Tie to VL for automatic start-up.

14 SS5 Soft-start control input for +5V. Ramp time to full current limit is 1ms/nF of capacitance to GND.

15 CS5 Current-sense input for +5V; +100mV = current-limit level referenced to FB5.

16 DH5 Gate-drive output for the +5V high-side MOSFET

17 LX5 Inductor connection for the +5V supply

18 BST5 Boost capacitor connection for the +5V supply (0.1µF)

19 DL5 Gate-drive output for the +5V low-side MOSFET

20 PGND Power ground

21 FB5 Feedback and current-sense input for the +5V PWM

22 VL 5V logic supply voltage for internal circuitry. VL is always on and can source 5mA for external loads.

23 V+ Supply voltage input from battery, 5.5V to 30V

24 DL3 Gate-drive output for the +3.3V low-side MOSFET

25 BST3 Boost capacitor connection for the +3.3V supply (0.1µF)

26 LX3 Inductor connection for the +3.3V supply

27 DH3 Gate-drive output for the +3.3V high-side MOSFET

28 FB3 Feedback and current-sense input for the +5V PWM

PIN CONFIGURATION

28

27

26

25

24

23

22

21

1

2

3

4

5

6

7

8

FB3

DH3

LX3

BST3

D1

ON3

SS3

CS3

DL3

V+

VL

FB5

Q1

Q2

VH

D2

20

19

18

17

9

10

11

12

PGND

DL5

BST5

LX5

SHDN

SYNC

REF

GND

16

15

13

14

DH5

CS5

SS5

ON5

MAX785 Dual-Output Power-Supply Controller

28

1

PIN CONFIGURATION

Page 21

P

+5V LDO

LINEAR

REGULATOR

V+

VL

REF

SHDN

GND

+3.3V

REFERENCE

ON

3.3V

5V

4V

2.8V

SYNC

300kHz/200kHz

OSCILLATOR

ON

STANDBY

4.5V

FAULT

ON

3.3V

PWM

CONTROLLER

(SEE FIG. 3)

FB3

CS3

BST3

DH3

LX3

DL3

SS3

FB5

CS5

BST5

DH5

LX5

DL5

SS5

PGND

ON3

5V

PWM

CONTROLLER

(SEE FIG. 3)

ON

D1

D2

1.65V

1.65V

ON5

VH

Q1

Q2

BLOCK DIAGRAM FOR MAX785

Page 22

PA1/PWM9

PA0/PWM8

PA2/PWM10

PB5*/PWM5*

PC2/CLAMP

PB3/PWM3**

PC5/AD0

PC3/HSYNCO

PC4/VSYNCO

PB4*/PWM4*

VSYNC

HSYNC

PB1/PWM1**

PB2/PWM2**

MC68HC(7)05BD1A

28-PIN DIP

1

2

3

4

5

6

7

8

9

10

11

12

13

14

28

27

26

25

24

23

22

21

20

19

18

17

16

15

XTAL

PA5/PWM13

PA6/PWM14

PA4/PWM12

PA7/PWM15

EXTAL

IRQ/VPP

VDD

VSS

RESET

SDA/PC0/PWM6***

SCL/PC1/PWM7***

PB0/PWM0**

PA3/PWM11

28

MC68HC705BD1A HCMOS Microcontroller

1

PIN CONFIGURATION

BLOCK DIAGRAM

PA0/PWM8

PA1/PWM9

PA2/PWM10

PA3/PWM11

PA4/PWM12

PA5/PWM13

PA6/PWM14

PA7/PWM15

SDA/PC0/PWM6***

SCL/PC1/PWM7***

PC2/CLAMP

PC3/HSYNCO

PC4/VSYNCO

PC5/AD0

PORT

A REG

DDC12AB/

PORT

C REG

DATA

DIR

REG

IIC

DATA

DIR

REG

EXTALXTAL

OSCILLATOR

AND DIVIDE

BY 2

CPU CONTROL

68HC05 CPU

CPU REGISTERS

COND CODE REG 1 1 1 I N Z CH

3.75K/7.75K bytes

for HC05BD1A

(7.75K bytes for

HC705BD1A)

000 1100000

PROGRAM COUNTER

ROM

VDD

VSS

RESET IRQ/VPP

CORE

TIMER

(COP)

ALU

ACCUM

INDEX REG

STK PTR

128/256 bytes

(256 bytes for

HC705BD1A)

RAM

Pulse

Width

Modulation

(PWM)

6-bit ADC

SYNC

PROCESSOR

PB0/PWM0**

PB1/PWM1**

PB2/PWM2**

PB3/PWM3**

PB4*/PWM4*

PB5*/PWM5*

PORT B REG / DIR REG

HSYNC

VSYNC

Page 23

MC54/74HC14A Hex Schmitt-Trigger Inverter

1314 12 11 10 9 8

21 34567

VCCA6 Y6 A5 Y5 A4 Y4

A1 Y1 A2 Y2 A3 Y3 GND

I/O

Control

Logic

Memory

Control

Logic

XDEC

HV Generator

EEPROM

Array

Write Protect

Circuitry

YDEC

Vcc

Vss

SENSE AMP

R/W CONTROL

SDA

SCL

A0 A1 A2

WP

OUT

Reference Voltage

Vcc

1

2

3

GND

FUNCTION TABLE

14

1

PIN CONFIGURATION

24LC02 2K 2.5V I2C™ Serial EEPROM

Inputs

A

L

H

Outputs

Y

H

L

1

3

A2

5

A3

9

A4

11

A5

13

A6

BLOCK DIAGRAM

10

12

2

Y1A1

4

Y2

6

Y3

Y = A

8

Y4

Pin 14 = V

Pin 7 = GND

Y5

Y6

CC

8

1

A0

A1

A2

Vss

1

2

3

4

24LC024

Vcc

8

WP

7

SCL

6

SDA

5

PIN CONFIGURATION

BA033FP Low Saturation Voltage type 3-terminal Regulator

1

2

3

1. Vcc

2. GND

3. OUTPUT

BLOCK DIAGRAM

BLOCK DIAGRAM

- 24 -

Page 24

- 25 -

SI4925DY Dual P-Channel 30-V (D-S) Rated MOSFET

SI9410DY N-Channel Enhancement-Mode MOSFET

S

1

G

1

D1D

1

S

2

G

2

D2D

2

PIN CONFIGURATION BLOCK DIAGRAM

PIN CONFIGURATION BLOCK DIAGRAM

SI9936DY N-Channel Enhancement-Mode MOSFET

1

8

D

D

D

G

S S

D

1

8

BLOCK DIAGRAM

D

6

1

4

R1

R1

3

2

LD=4nH

DBDDY

LS=6nH

LG=6nH

CGD

DMAX DMIN

CGS

RG=6Ω

G

S

1

8

S

1

1

G

2

1

S

3

2

G

4

2

D

8

1

D

7

1

D

6

2

D

5

2

N/C

1

2

S

3

S

4

G

8

D

7

D

6

D

5

D

Page 25

PARTSTYPE

PARTSTYPE

KDS181

MBRS190T3

12

3

- 26 -

KA78M05R

KA78M12R

1. INPUT

2. GND

3. OUTPUT

1. CATHODE 1

2. CATHODE 2

3. ANODE

1

3

2

1

3

2

KSC1623

1. BASE

2. EMITTER

3. COLLECTOR

2

3

1

1

2

1

2

0CH7106F621

10uF/16V

0CH7107F661

100uF/10V

0CH7226F651

22uF/16V

0CH7227F661

220uF/6.3V

0CH7476F661

47uF/10V

_

+

Regulator

Schottky Diode

Diode

Transistor

Tantalum Capacitor

Page 26

Loading...

Loading...