Garmin Force Trolling Motor Freshwater 50, Force Trolling Motor Freshwater 57 Installation manual

FORCE® TROLLING MOTOR

TA-2019/5242

TA-2019/5243

TA-2019/5244

INSTALLATION

INSTRUCTIONS

Getting Started

WARNING

Do not run the motor when the propeller is out of the water.

Contact with the rotating propeller may result in severe injury.

Do not use the motor in areas where you or other people in the

water may come into contact with the rotating propeller.

Always disconnect the motor from the battery before cleaning or

servicing the propeller to avoid injury.

CAUTION

To avoid possible personal injury, always wear safety goggles,

ear protection, and a dust mask when drilling, cutting, or

sanding.

When stowing or deploying the motor, be aware of the risk of

entrapment or pinching from moving parts, which can result in

injury.

When stowing or deploying the motor, be aware of slick surfaces

around the motor. Slipping when stowing or deploying the motor

may result in injury.

NOTICE

To avoid damage to your boat, this device should be installed by

a qualified marine installer. Specific knowledge of marine

electrical systems is required for proper installation.

When drilling or cutting, always check what is on the opposite

side of the surface to avoid damaging the vessel.

You are required to secure the safety strap when stowing the

trolling motor. Failure to secure the trolling motor in the stowed

position using the safety strap may result in unexpected

deployment, damaging the boat and trolling motor.

After using the motor in salt water or brackish water, you must

rinse off the entire motor with fresh water, and apply a waterbased silicone spray using a soft cloth. You should avoid

spraying jets of water at the cap on the top of the shaft when

rinsing the motor.

Installation Preparation

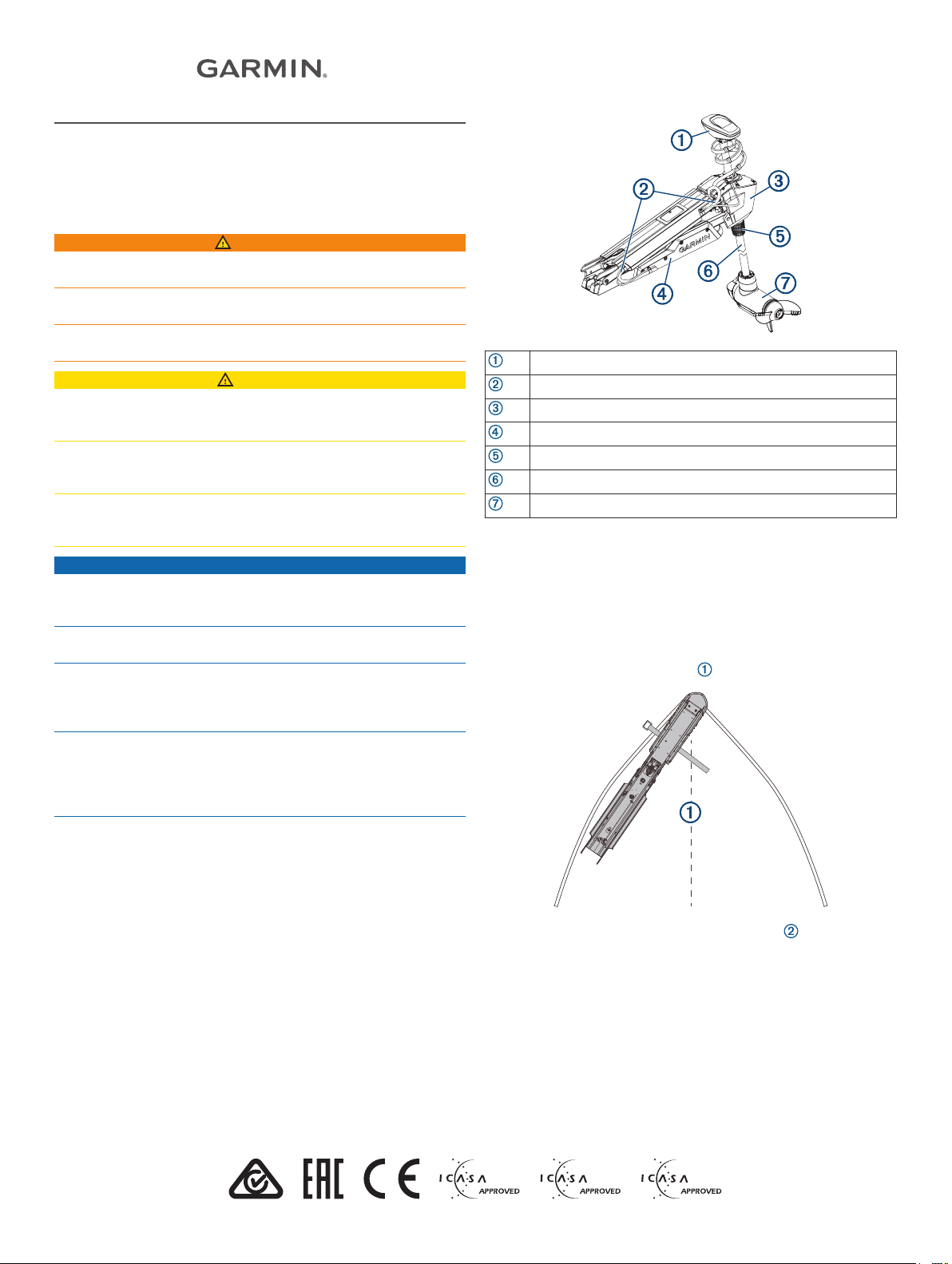

Device Overview

Shaft cap

Power and transducer cables

Steering system

Mount

Depth-adjustment collar

Shaft

Propeller drive motor

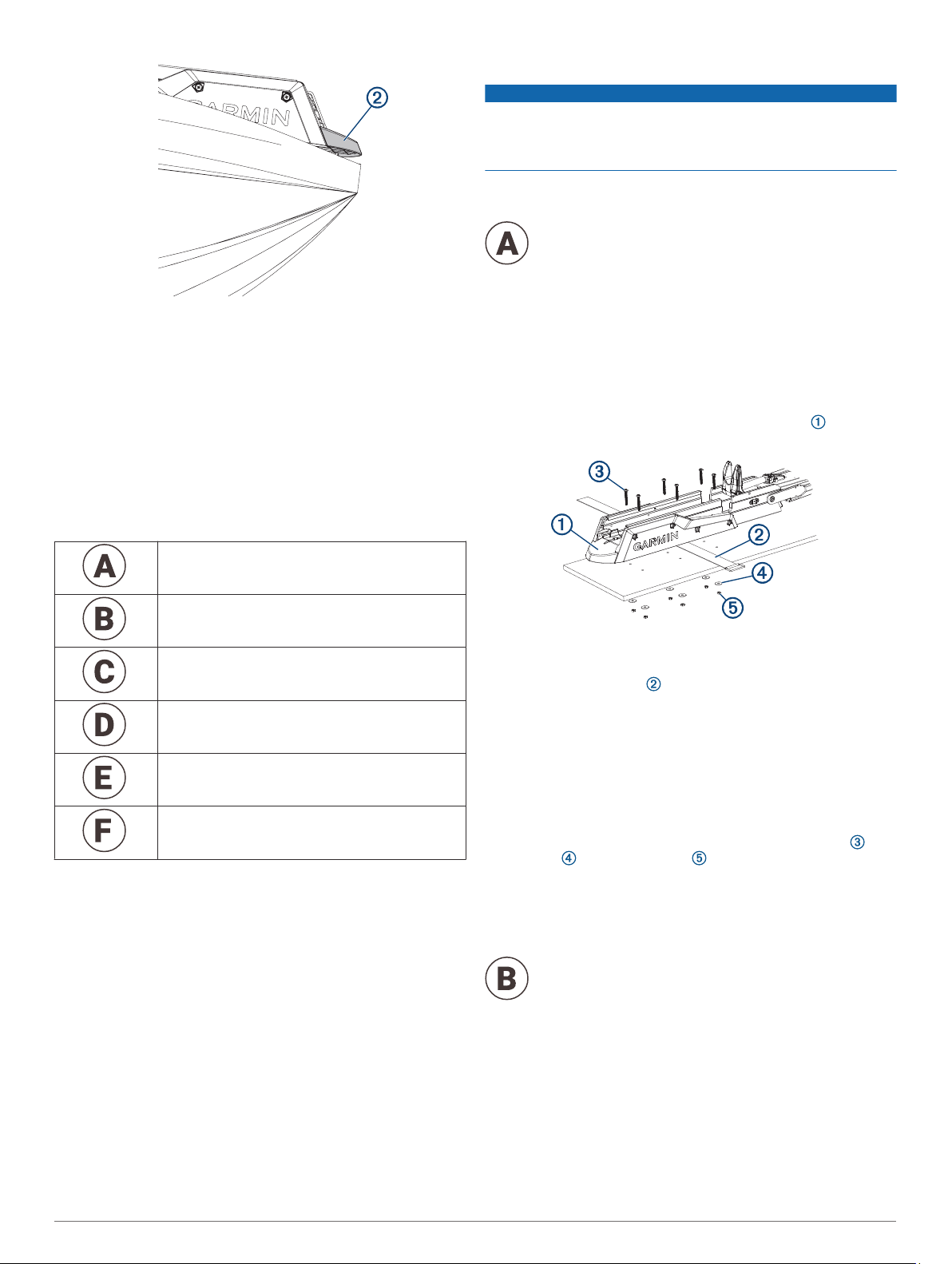

Mounting Considerations

When selecting a mounting location, observe these

considerations.

• You must install the motor on the bow of your boat.

• It is recommended to install the motor on the port side of the

bow, but you can install it on the starboard side if necessary.

• You should install the mount so the deployed motor is as

close to the center of the boat as possible.

Tools and Supplies Needed

• Drill and a 5/16 in. (8 mm) drill bit

• #1 and #2 Phillips screwdrivers

• 3 mm and 4 mm hex bits or wrenches (two 4 mm

recommended)

•9/16 in. (14 mm) socket

• Torque wrench

• Circuit breaker rated for continuous 60 A

• Trolling motor plug and receptacle rated for 60 A or greater

(optional)

• 6, 4, or 2 AWG (16, 25, or 35 mm2) wire for extended runs of

the power cable

• Solder and heat-shrink tubing, if extending the power cable

• Stainless steel pan head 1/4-20 (M6x1) bolts (if the included

bolts are not long enough to mount the motor to the deck)

• You must install the mount with the bumper overhanging

the gunwale of the boat.

GUID-6360FBE3-F330-46AA-85ED-65D27799C5BC v5October 2020

• The motor secures to the deck of the boat using bolts, so you

must have room to secure the mount from the underside

using washers and nuts.

• The motor must have clearance to move from the deployed

to the stowed position and back again, so the installation

location must be clear of obstacles.

Parts Bags

The installation hardware for the trolling motor is included in

labeled bags. As you complete the installation process, each

procedure begins with a reference to the label on the parts bag

needed to complete the procedure. You can use this table to

review or verify the parts bags needed for the installation

procedures.

Contains the safety strap and the hardware used to

secure the mount base to the boat deck.

Installation Procedures

NOTICE

When assembling the motor, you must use hand tools to install

all of the parts, observing the torque specifications when

provided. Using power tools to assemble the motor may damage

the components, and voids the warranty.

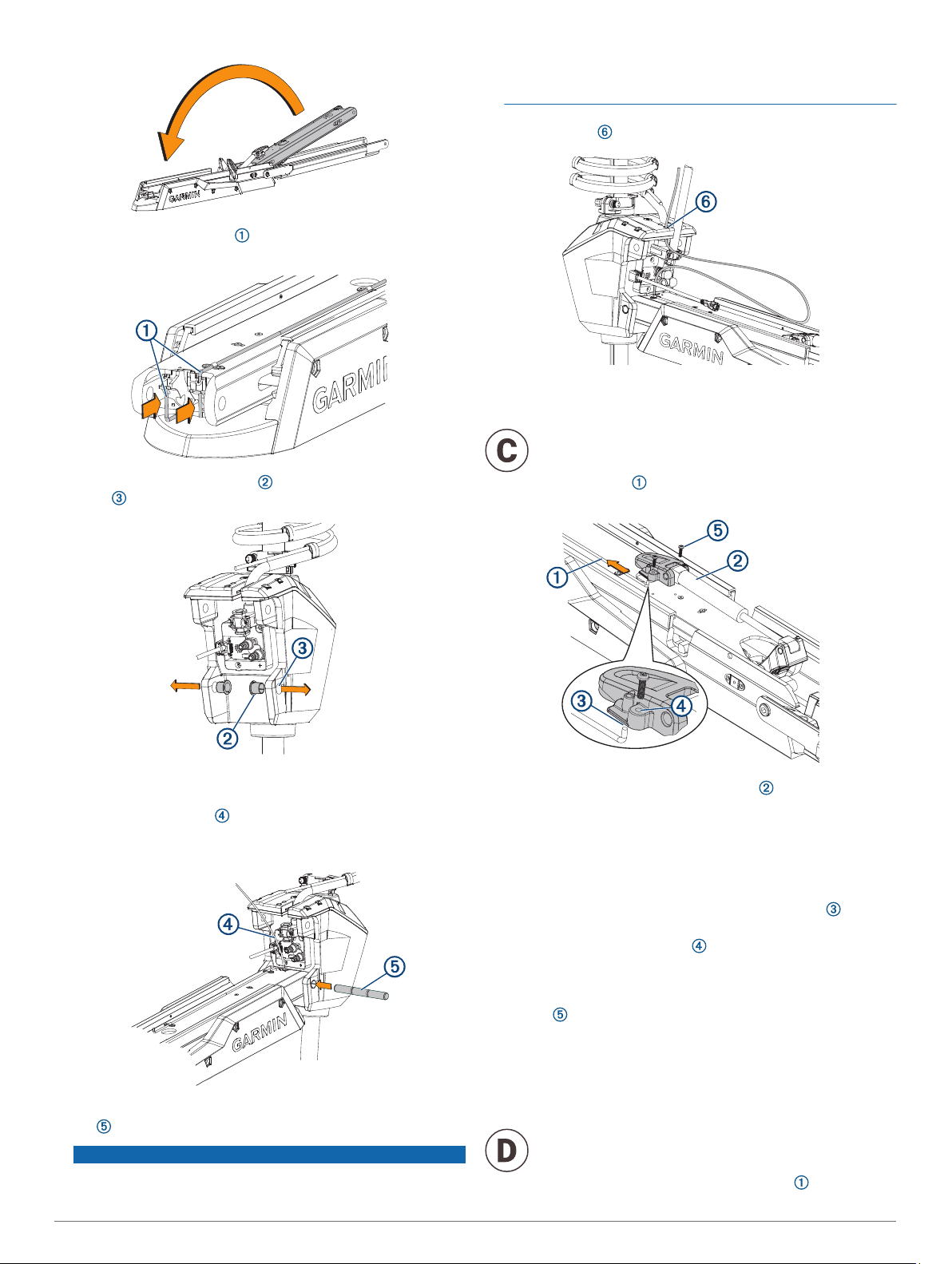

Installing the Mount on the Deck

Label identifying the parts bag required for this procedure:

NOTE: If the supplied bolts are not long enough for the

mounting surface, you must obtain the appropriate length

stainless steel pan head 1/4-20 (M6x1) bolts.

Select a mounting location on the bow of your boat,

1

according to the mounting considerations.

Pivot the top parts of the mount up and back so you can

2

access the mounting holes on the mount base.

Place the included mounting template on the mounting

3

location with the mount bumper on the template

overhanging the gunwale or the edge of the boat deck.

Contains the pin needed to secure the steering

system to the lower half of the mount.

Contains the hardware needed to secure the upper

and lower gas springs.

Contains the pin needed to secure the steering

system to the upper half of the mount.

Contains the pull-cable handle hardware.

Contains the hardware needed to secure the cables

to the mount.

Connection Considerations

When making the wiring connections, observe the following

considerations.

• You must connect the trolling motor to a 24 or 36 Vdc battery

bank capable of supplying 60 A continuously.

• You must connect to the power source through a circuit

breaker rated for continuous 60 A (not included).

• If necessary, you can extend the power cable using the

appropriate wire gauge based on the length of the extension

(Power Cable Extension, page 6).

• For convenience, you can install a trolling motor plug and

receptacle rated for 60 A or greater (not included) in the

bulkhead to make it easier to disconnect the motor from the

power source.

Mark the mounting hole locations on the boat deck.

4

Using a 5/16 in. (8 mm) drill bit, drill the mounting holes.

5

Place the safety strap under the mount base near the

6

center, with the hook and loop fasteners facing downward.

NOTE: You must place the safety strap under the mount

before you secure it to the surface. If you do not install the

safety strap at this time, you may need to partially

disassemble the motor later to install it correctly.

Place the mount base on the boat deck on top of the safety

7

strap, aligning the holes on the mount with the mounting

holes.

Secure the mount to the deck using the included bolts ,

8

washers , and locking nuts .

Tighten the nuts to 10.85 N m (8 lbf-ft.).

9

Installing the Steering Servo on the Lower Link of the Mount

Label identifying the parts bag required for this procedure:

Pivot the lower link of the mount forward until it locks into the

1

base.

2

Push the two safety rods into the lower link as far as

2

possible.

completely when pushed by hand. Damage caused by

hammering the pin or modifying the holes is not covered

under warranty.

Route the pull cable upward through the top of the steering

6

servo housing .

Securing the Upper Gas Spring

Label identifying the parts bag required for this procedure:

Make sure that the bushings are installed in the lower

3

holes on the steering servo housing.

If the bushings were removed, you can re-insert them from

the inside out.

Holding the pull cable up, place the steering servo housing

4

onto the lower link of the mount, aligning the lower holes on

the housing with the holes on the link.

While lifting up on the steering servo housing, push the pivot

5

pin through the housing and the link to hold it in place.

NOTICE

Do not hit the pin with a hammer or other object. Do not drill

or modify the holes. Although it is a snug fit, the pin slides in

Push the safety rod toward the steering servo housing as

1

far as possible to lock the lower pivot pin in place.

If necessary, pivot the upper gas spring toward the lower

2

link of the mount so the base of the gas spring aligns with the

safety rod and mounting holes.

NOTE: If you must rotate the gas spring so the base aligns

with the mount, rotate the spring in a clockwise direction only.

Rotating the gas spring in a counter-clockwise direction may

loosen the fittings.

Align the single hole on the base of the gas spring with the

3

safety rod, and press down.

The screw holes on the base should align with the holes

on the bottom of the mount.

Using a #2 Phillips screwdriver, secure the base of the gas

4

spring to the lower link of the mount using the included

screws .

Keep the remaining screws in the parts bag. You must use them

when securing the other gas spring in a later procedure.

Connecting the Upper Link of the Mount to the Steering Servo Housing

Label identifying the parts bag required for this procedure:

Remove the tape that secures the data cable to the

1

steering servo housing.

3

Loading...

Loading...