Furuno FR-1760DS User Manual

MARINE RADAR

MODEL

FR-1760DS

A

(

C

9-52, Ashi hara-cho,

Nishinomiya, Japan

Telephone: 0798-65-2111

Telefax: 0798-65-4200

ll rig hts reserved.

Printed in Japan

Your Local Agent/Dealer

FIRST EDITION : NOV. 1998

L : JUL. 9, 2001

PUB. No. IME-34560-L

YOSH)

FR-1760DS

SAFETY INSTRUCTIONS

WARNING

WARNING

WARNING

Radio Frequency Radiation

Hazard

The radar scanner emits electromagnetic

radio frequency (RF) energy which can be

harmful, particularly to your eyes. Never

look directly into the scanner aperture from

a close distance while the radar is in operation or expose yourself to the transmitting

scanner at a close distance.

Distances at which RF radiation levels of

100 and 10 W/m

table below.

Note: If the scanner unit is installed at a

close distance in front of the wheelhouse,

your administration may require halt of

transmission within a certain sector of

scanner revolution. This is possible Ask

your FURUNO representative or dealer to

provide this feature.

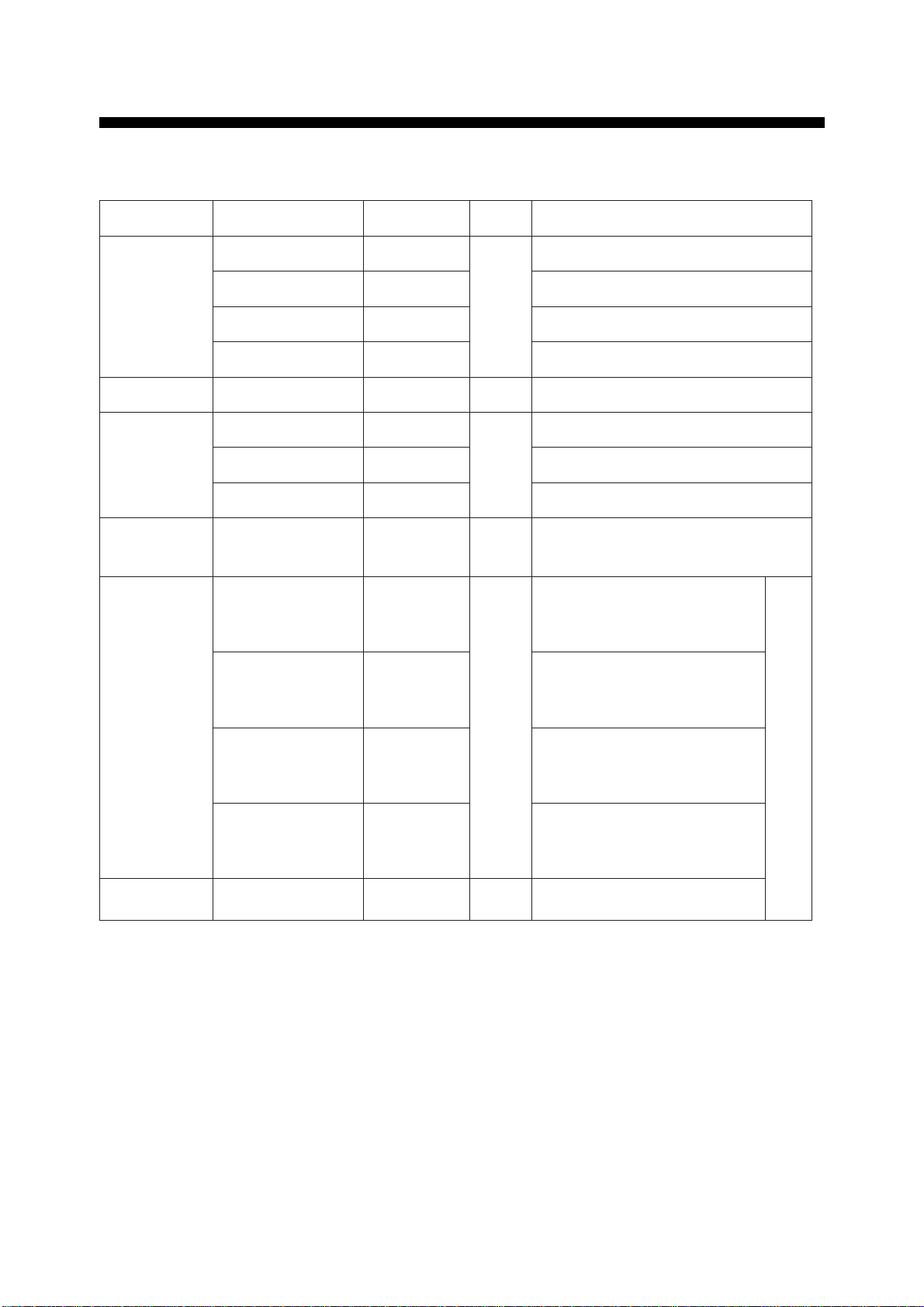

Model

FR-1760DS

2

exist are given in the

Radiator

type

SN4A — 1.2 m

SN5A — 1.0 m

Distance to

100W/m

point

Distance to

2

10W/m

point

WARNING

Do not open the equipment

unless totally familiar with

electrical circuits and

service manual.

ELECTRICAL

SHOCK

HAZARD

Construct a suitable service platform

from which to install the scanner unit.

Serious injury or death can result if someone falls from the radar scanner mast.

Turn off the power at the mains switch-

2

board before beginning the installation.

Fire, electrical shock or serious injury can

result if the power is left on or is applied

while the equipment is being installed.

Only qualified personnel

should work inside the

equipment.

Wear a safety belt and hard

hat when working on the

scanner unit.

Serious injury or death can

result if someone falls from

the radar scanner mast.

Do not install the display unit where it

may get wet from rain or water splash.

Water in the display unit can result in fire,

electrical shock or equipment damage.

i

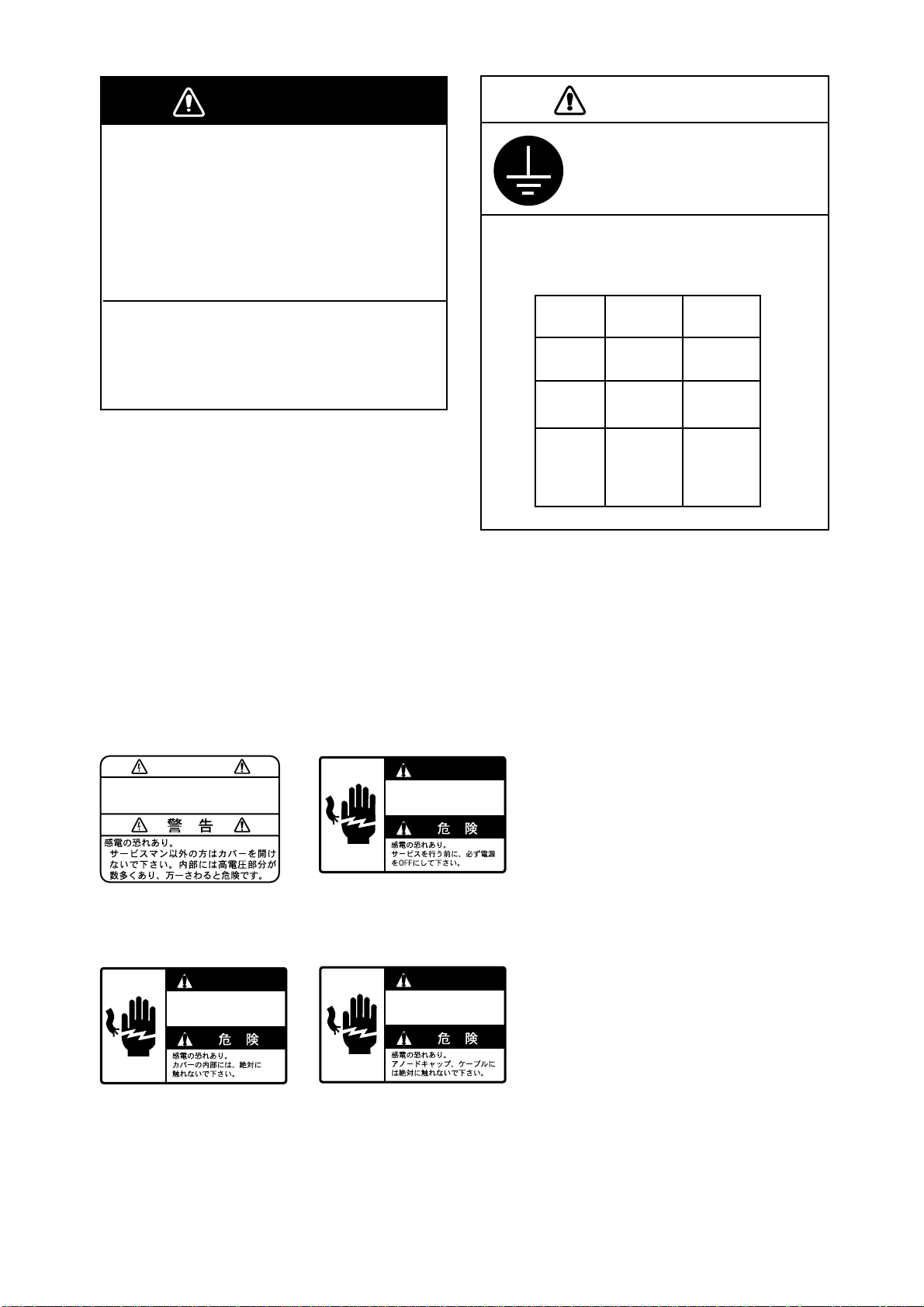

CAUTION

WARNING

WARNING

CAUTION

Be sure that the power supply is

compatible with the voltage rating of

the equipment.

Connection of an incorrect power supply

can cause fire or equipment damage. The

voltage rating of the equipment appears

on the label above the power connector.

Use only the specified power cable.

Fire or equipment damage can result if a

different cable is used.

Ground the equipment to

prevent electrical shock and

mutual interference.

Observe the following compass safe

distances to prevent deviation of a

magnetic compass:

Steering

compass

Display

Unit

Scanner

Unit

Power

supply

unit

PSU-002

Standard

compass

1.15 m 0.90 m

4.8 m 3.6 m

1.2 m 0.9 m

Danger/Warning Labels in Display Unit

This radar system contains the danger/warning labels shown below. Do not remove the

labels. If a label is peeling off or is illegible, contact a FURUNO agent for replacement.

WARNING

To avoid electrical shock, do not

remove cover. No user-serviceable

parts inside.

DANGER

Electrical shock hazard.

Turn off power before

servicing.

Name : Warning Label

Type : 86-003-1011

Code No. : 100-236-230

DANGER

Electrical shock hazard.

Do not touch parts inside

this cover.

Name : Danger Label

Type : 66-022-2012

Code No. : 100-237-730

DANGER

Electrical shock hazard.

Do not touch anode cap

or its cable.

Name : Danger Label

Type : 14-055-4202

Code No. : 100-245-220

Name : Danger Label

Type : 14-055-4201

Code No. : 100-243-450

ii

TABLE OF CONTENTS

EQUIPMENT LISTS...................................................................................................iv

SYSTEM CONFIGURATION...............................................................vi

MOUNTING

1.1 Scanner Unit ................................................................................................................ 1-1

1.2 Display Unit.................................................................................................................. 1-7

1.3 Power Supply Unit........................................................................................................ 1-8

WIRING

2.1 Scanner Unit ................................................................................................................ 2-1

2.2 Display Unit.................................................................................................................. 2-5

2.3 Power Supply Unit........................................................................................................ 2-8

2.4 Installation and Connection of Rectifier Unit ................................................................ 2-9

EXTERNAL SIGNAL INPUT, OUTPUT

3.1 Input From External Equipment ................................................................................... 3-1

3.2 Output to External Equipment...................................................................................... 3-2

3.3 Connection of External Buzzer .................................................................................... 3-3

3.4 Data Sentences............................................................................................................ 3-4

INITIALIZA TION AND ADJUSTMENT

4.1 Tuning .......................................................................................................................... 4-1

4.2 Accessing Menus for Initialization and Adjustment ...................................................... 4-2

4.3 Heading Alignment ....................................................................................................... 4-3

4.4 Adjusting Sweep Timing............................................................................................... 4-4

4.5 Adjusting Video Signal Level........................................................................................ 4-5

4.6 Suppressing Main Bang............................................................................................... 4-6

4.7 Confirming Magnetron Heater Voltage......................................................................... 4-6

4.8 Initial Settings............................................................................................................... 4-8

4.9 Changing Input Voltage.............................................................................................. 4-10

OPTIONAL EQUIPMENT

5.1 Gyro Converter GC-8................................................................................................... 5-1

5.2 Automatic Tracking Aid ARP-17 ................................................................................... 5-8

5.3 Video Plotter RP-17 ................................................................................................... 5-13

PACKING LISTS....................................................................................................... A-1

OUTLINE DRAWINGS........................................................................................... D-1

INTERCONNECTION DIAGRAM .....................................................S-1

SCHEMATIC DIAGRAMS .................................................................................... S-2

iii

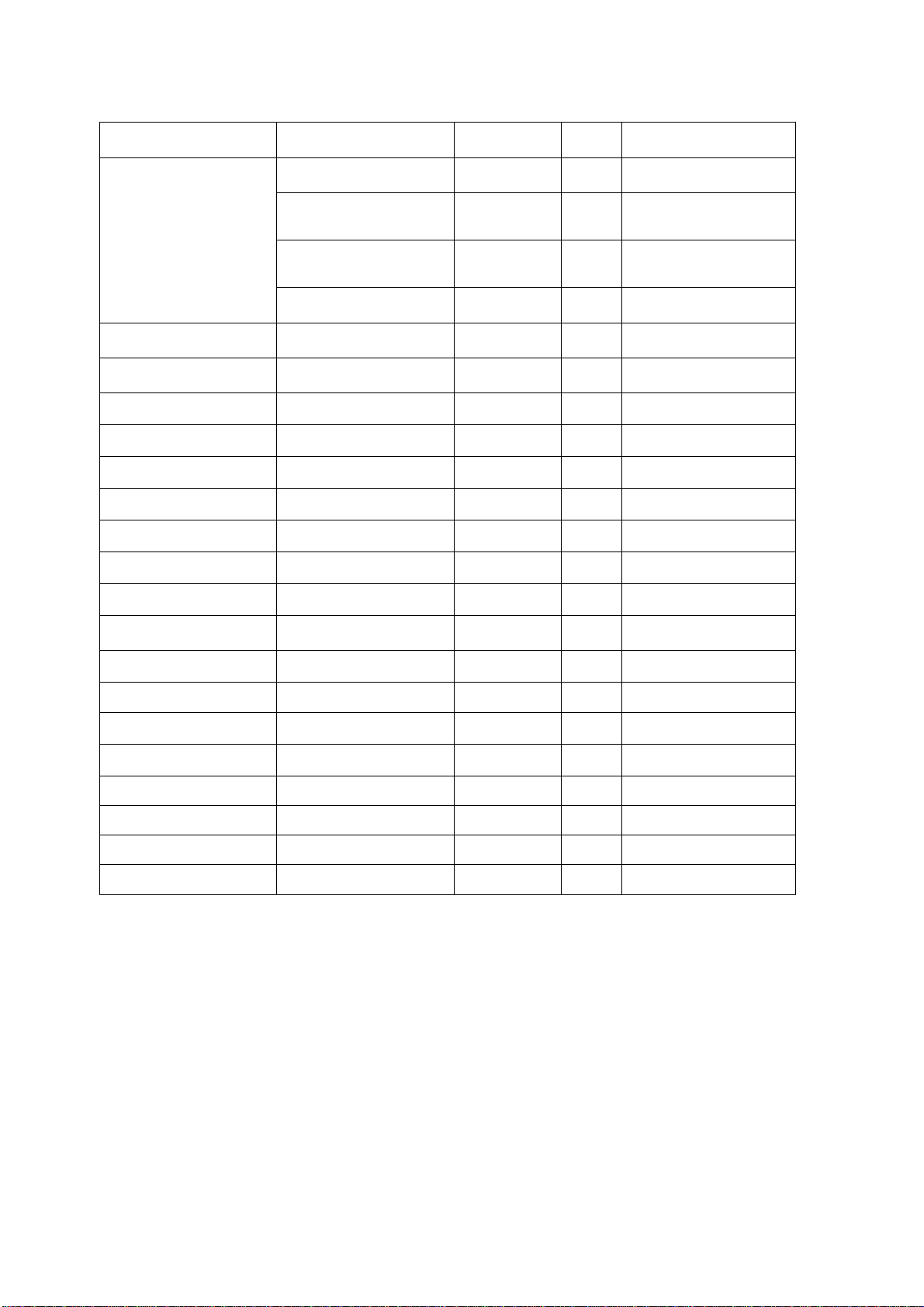

Standard Supply

emaNepyT.oNedoCytQskrameR

EQUIPMENT LISTS

N-1500-BSR-A4NS–

I-1500-BSR-A4NS– reci-ed/w,mm0052

tinUrennacS

N-1500-BSR-A5NS– reci-edo/w,mm0072

I-1500-BSR-A5NS– reci-ed/w,mm0072

tinUyalpsiD021-PDR–1

06-200-USP–

ylppuSrewoP

roftinU

tinUrennacS

straPerapS00721-30PS049-680-0001

noitallatsnI

slairetaM

seirosseccA02560-30PF549-680-0001

16-200-USP–CAV011

26-200-USP–CAV511

06491-30PC149-680-000

07491-30PC249-680-000

08491-30PC349-680-000

09491-30PC449-680-000

tceleS

eno

CAV001

tceleS

eno

tceleS

eno

reci-edo/w,mm0052

tinUyalpsiD:10721-30PS

tinUylppuSrewoP:20290-30PS

tinUrennacS:30290-30PS

tinUyalpsiD:40491-30PC

tinUrennacS:30611-30PC

tinUyalpsiD:40491-30PC

tinUrennacS:30611-30PC

tinUyalpsiD:40491-30PC

tinUrennacS:30611-30PC

tinUyalpsiD:40491-30PC

tinUrennacS:30611-30PC

,)dooH(12560-30PF

22560-30PF

S

tinUylppuSrewoP:20611-30PC

E

)m51(51-87-30SelbaClangiS

E

P

A

tinUylppuSrewoP:20611-30PC

C

)m02(02-87-30SelbaClangiS

K

I

N

tinUylppuSrewoP:20611-30PC

G

)m03(03-87-30SelbaClangiS

L

I

tinUylppuSrewoP:20611-30PC

S

)m06(06-87-30SelbaClangiS

T

S

iv

Optional Equipment

emaNepyT.oNedoCytQskrameR

4243-UR794-030-0001 CAV022,tinUyalpsiD

8571-UR614-030-0001

reifitceR

3081-UR024-030-0001

5033-UR844-030-0001reci-eD

yalpsiDetomeR0108-DMF–1

retrevnoCoryG2-B-8-CG039-005-8001 tnempihsetarapeS

diAgnikcarTcitamotuA71-PRA048-884-8001

revoCtsuD1171-341-30039-562-0011

retliF251-30PO–1

elbaCrewoPc2x8S-VVC436-065-0001m51

rezzuBlanretxE12-30PO790-030-0001

eldnaH07-30PO024-324-8001

yalpsiDetomeR118-DMF–1

retrevnoCDA001-DA–1

CAV022

CAV044

,tinUylppuSrewoP

,tinUylppuSrewoP

elbaClangiS)P5(5-55-30S061-554-8001

elbaCm0161-YCYPM-V066527-521-0001

elbaCm0261-YCYPM-V066627-521-0001

elbaCm0361-YCYPM-V066727-521-0001

elbaCm0561-YCYPM-V066827-521-0001

rettolPoediV2-E71-71-PR989-680-0001

draCMAR511-30PO071-154-80071-PRrof,BK652

draCMAR611-30PO081-154-80071-PRrof,BK215

v

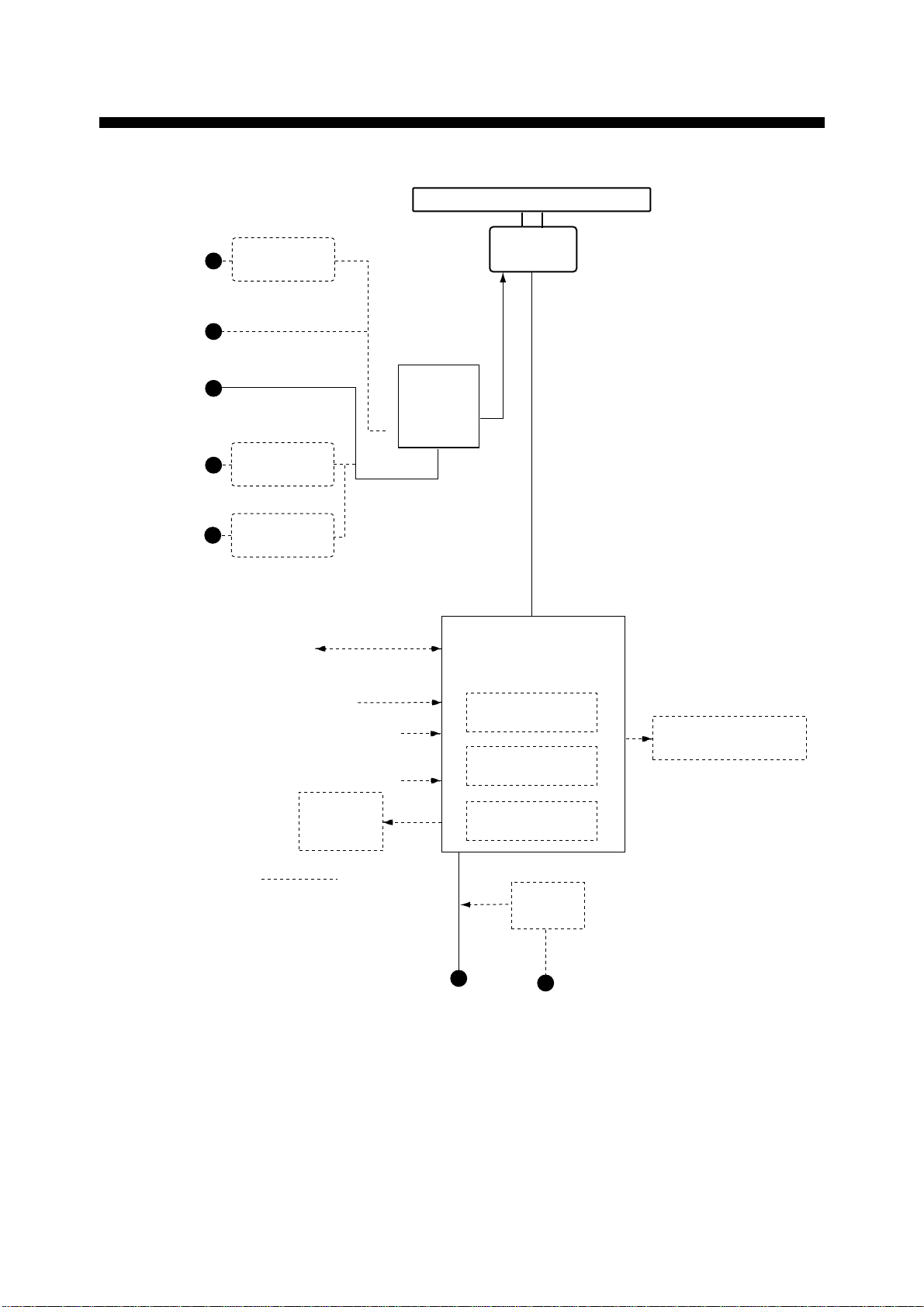

SYSTEM CONFIGURATION

ANTENNA UNIT

110/115/

220 VAC,

1φ, 50/60 Hz

100 VAC,

1φ, 50/60 Hz

100/110/

115 VAC,

1φ, 50/60 Hz

220 VAC,

1φ, 50/60 Hz

440 VAC,

1φ, 50/60 Hz

Rectifier

RU-3305

For de-icer

Rectifier

RU-1758

Rectifier

RU-1803

Serial Data

(I/O)

GPS, etc.

Speed Log

Pulse Input

Water temperature,

water depth

Gyrocompass

External

Buzzer

OP03-21

POWER

SUPPLY

UNIT

PSU-002

DISPLAY UNIT

RDP-120

ATA Board

ARP-17

Gyro Converter

GC-8-B

Video Plotter

RP-17 Board

SN4A-RSB-0051-N

SN4A-RSB-0051-I

SN5A-RSB-0051-N

SN5A-RSB-0051-I

Remote Display

FMD-8010/FMD-811

Option

Ship’s Mains

24/32 VDC

vi

Rectifier

RU-3424

100/110/115/220/230 VAC,

1φ, 50/60 Hz

MOUNTING

1.1 Scanner Unit

Mounting considerations

• The scanner unit is generally installed either on top of the wheelhouse or on the radar

mast, on a suitable platform. Locate the scanner unit where there is a good all-round

view.

• No funnel, mast or derrick should be within the vertical beamwidth of the scanner in the

bow direction, especially zero degrees ±5°, to prevent blind sectors and false echoes

on the radar picture.

• It is rarely possible to place the scanner unit where a completely clear view in all directions is available. Thus, you should determine the angular width and relative bearing of

any shadow sectors for their influence on the radar at the first opportunity after fitting.

• Locate the antenna of a direction finder clear of the scanner unit to prevent interference

to the direction finder. A separation of more than two meters is recommended.

• To lessen the chance of picking up electrical interference, avoid where possible routing

the signal cable near other onboard electrical equipment. Also avoid running the cable

in parallel with power cables.

• A magnetic compass will be affected if placed too close to the scanner unit. Observe

the following compass safe distances to prevent deviation of a magnetic compass:

Standard compass, 4.8 m, Steering compass, 3.6 m.

• Do not paint the radiator aperture, to ensure proper emission of the radar waves.

• The signal cable run between the scanner and the display is available in lengths of 15

m (standard), 20 m, 30 m and 60 m. Whatever length is used it must be unbroken;

namely, no splicing allowed.

• Deposits and fumes from a funnel or other exhaust vent can adversely af fect the aerial

performance and hot gases may distort the radiator portion. The scanner unit must not

be mounted where the temperature is more than 70°C.

• The scanner base is made of cast aluminum. To prevent electrolytic corrosion of the

scanner base, use the seal washers and corrosion-proof rubber mat and ground the

unit with the ground wire (supplied).

• Leave suf ficient space around the unit for maintenance and servicing. See the scanner

unit outline drawing for recommended maintenance space.

1-1

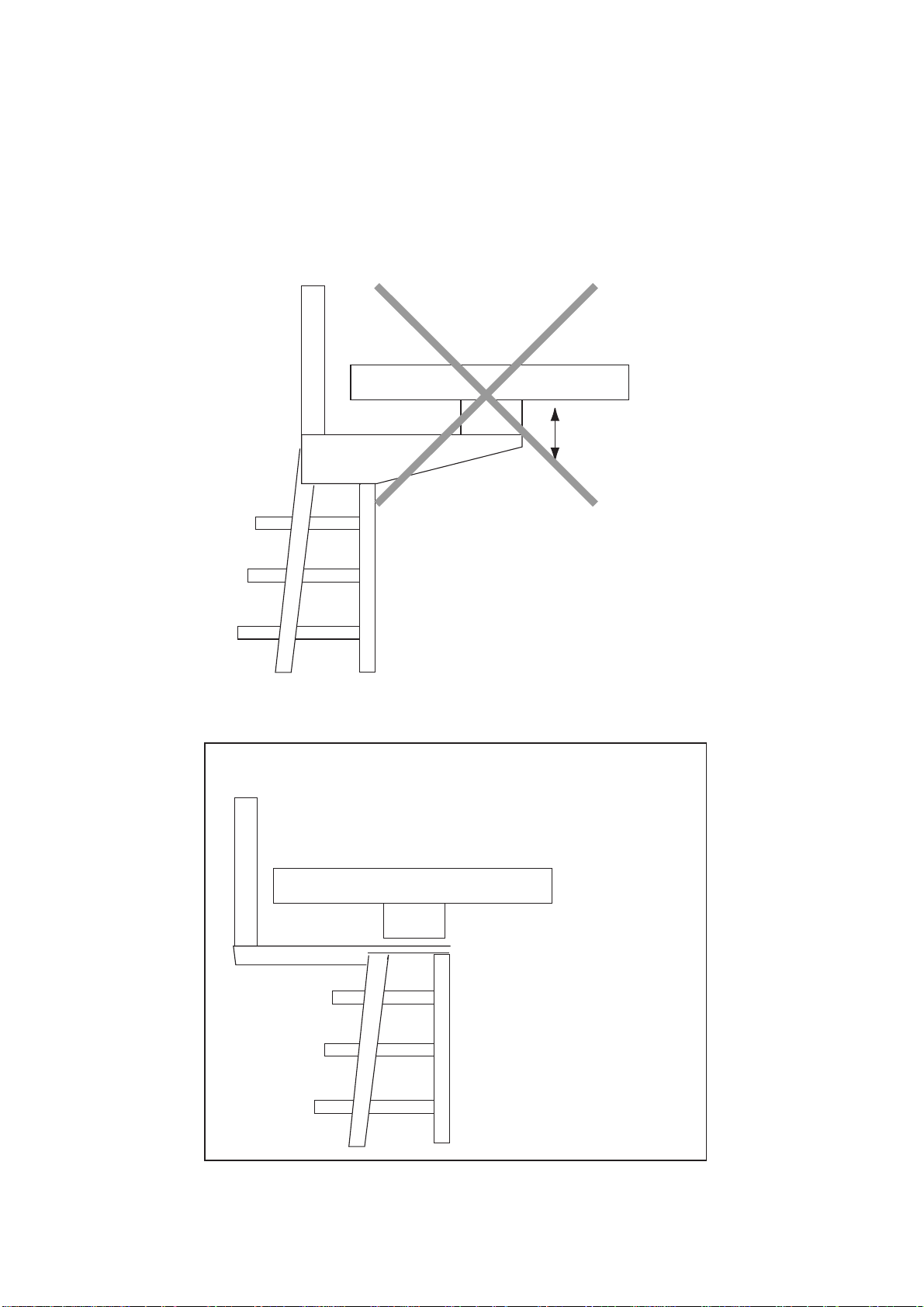

Installation precaution for S-band scanner unit

If an S-band scanner unit is mounted near the end of a platform to provide sufficient

rotation clearance for the radiator, the scanner unit, because of its weight, swings up and

down by ship’s vibration and rolling, exerting excessive levels of stress at the base of the

radiator, which can damage the radiator. To prevent this, relocate the scanner unit, or if

relocation is not possible, reinforce the platform.

Pole for DF, etc.

Remarkable vibration

(pitching)

Mounting

position

EXAMPLE

Pole for DF

Figure 1-1 Mounting of S-band scanner unit

Mount the scanner unit

directly on the mast or

on the platform, as near

as possible to the center

of the mast.

1-2

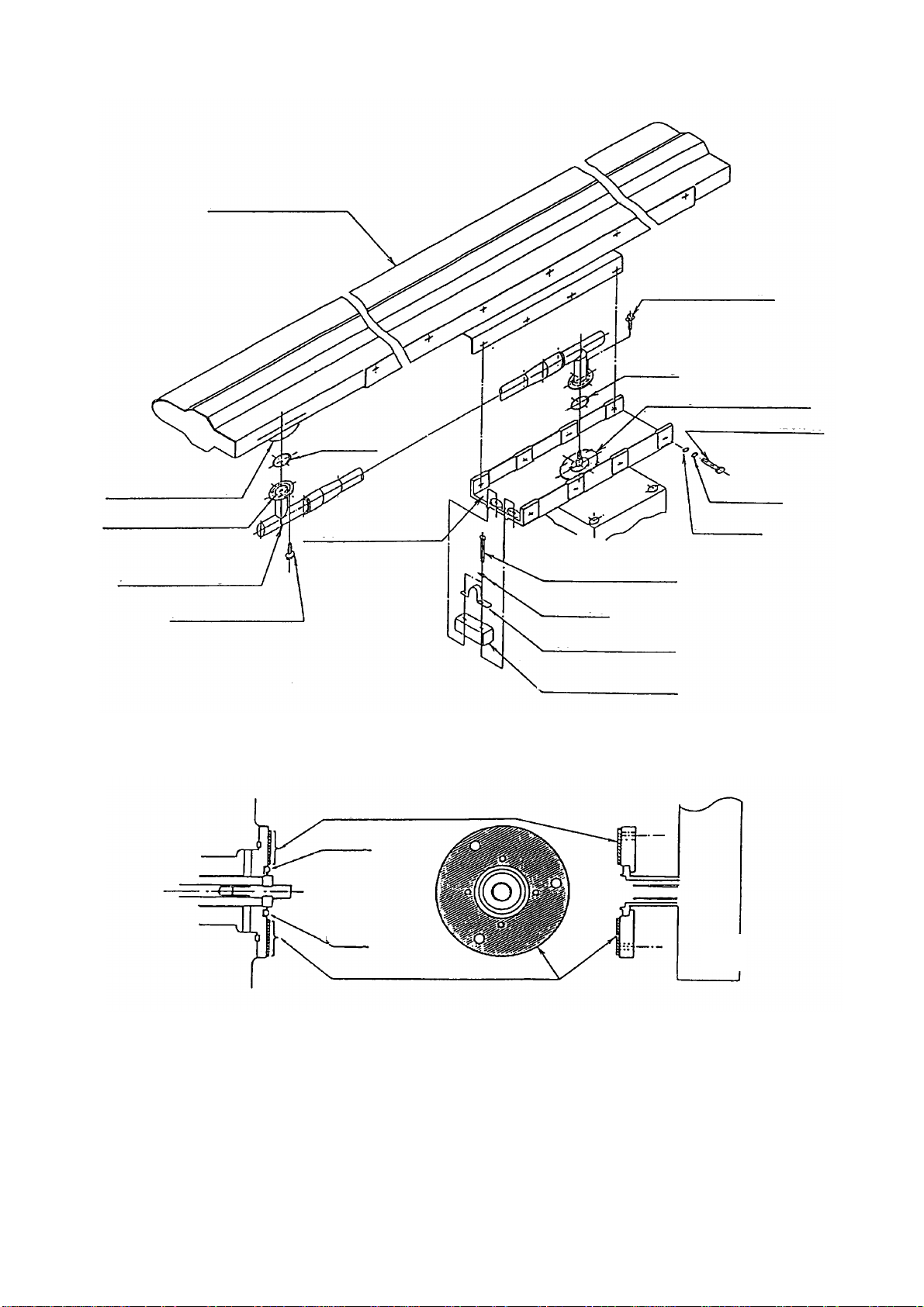

Scanner unit assembling

The scanner radiator and the scanner housing are shipped in separate packages and

must be assembled at installation. Assemble them as below.

The scanner unit may be assembled before hoisting it to the mounting platform. However,

do not lift the scanner unit by the radiator.

1. Remove two protective caps from the radiator flange and rotary joint flange.

2. Grease an O-ring and place it in the groove of the rotary joint flange. Make sure the

O-ring is not pinched during assembling.

3. Secure the feeder waveguide to the rotary joint flange with four M6x16 hex bolts.

4. Fix the feeder waveguide on the radiator bracket with a waveguide clamp, a clamp

insulator, two flat washers, and two M6x50 hex bolts.

5. Grease other O-ring and set it in the groove of the radiator flange.

6. Set the scanner radiator to the bracket and fix it temporarily with eight M10x20 hex

bolts, spring washers and flat washers.

7. Fasten the feeder waveguide to the radiator flange with four M6x16 hex bolls.

8. Fasten the scanner radiator to the bracket with eight M10x20 bolts.

1-3

Scanner radiator

O-ring

Hex bolt M6x16

O-ring

Rotary joint flange

Hex bolt M10x20

Radiator flange

Waveguide flange

Feeder waveguide

Hex bolt M6x16

Note 1: Coat bolts, nuts, washers and waveguide flanges outside O-ring grooves to prevent

electrolytic corrosion. (Do not allow silicone sealant to touch O-ring and O-ring grooves.)

Radiator

flange

Radiator bracket

Hex bolt M6x50

Flat washer M6

Waveguide clamp

Clamp insulator

Apply silicone sealant here.

O-ring

O-ring

Apply silicone sealant here.

Flat washer M10

Spring washer M10

Waveguide

flange

1-4

Note 2: Do not pinch O-ring and keep it clean.

Note 3: Use grease on scanner covers and O-rings. Do not use silicone sealant.

Figure 1-2 Scanner unit assembling

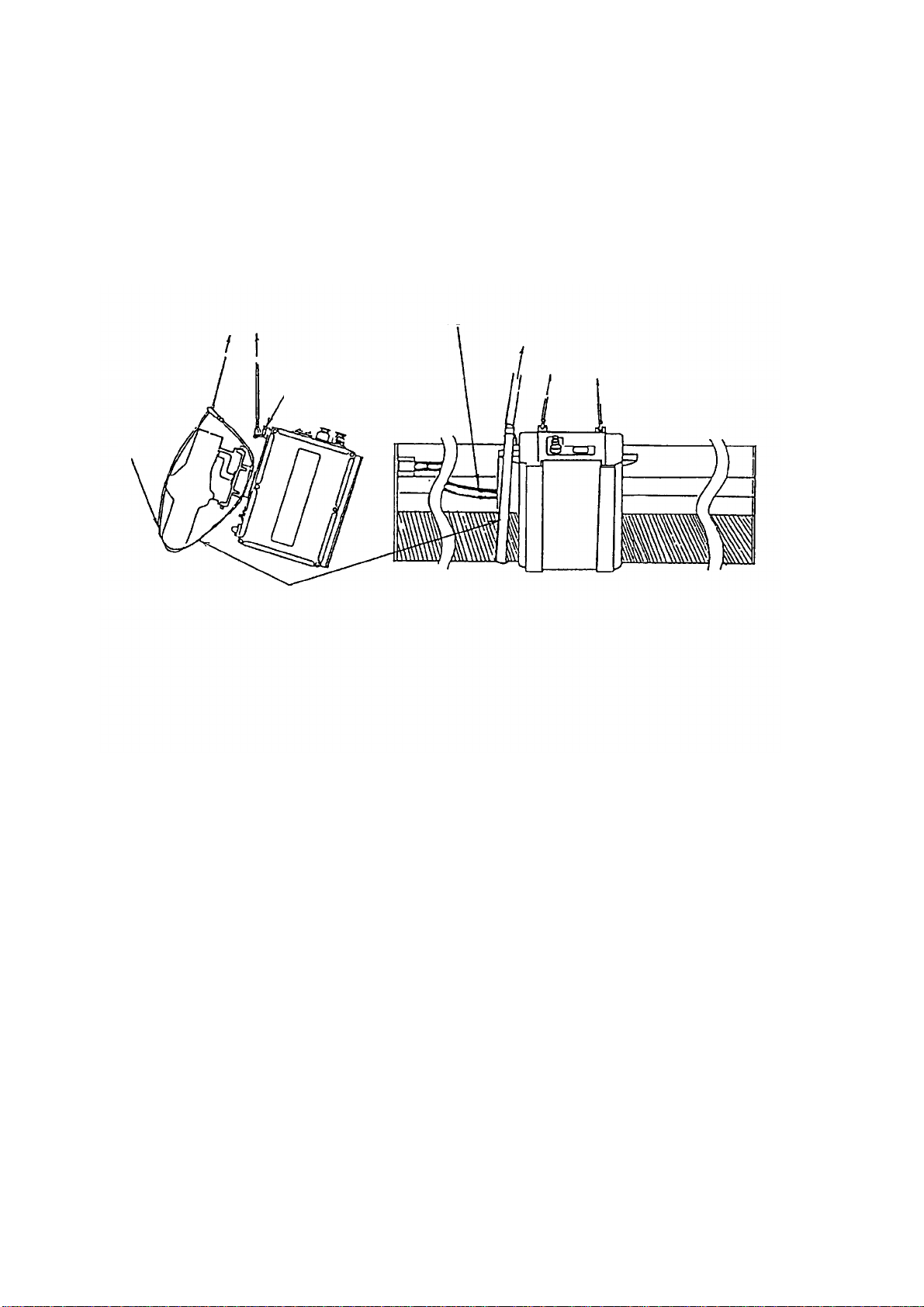

Mounting the scanner unit

1. Referring to the scanner outline drawing, drill four bolt holes (15 mm dia.) in the radar

mast platform or the deck.

2. Place the corrosion-proof rubber mat (supplied) on the mounting platform.

3. Using the two L-angle metal plates on the scanner top, lift the scanner base with the

antenna radiator and place the scanner unit on the rubber mat. Orient the scanner so

its cable glands face the ship’s stern.

Feeder waveguide

Note 2

L-angle

metal plate

Note 1

Place the rope around scanner radiator

(feeder waveguide side) to prevent

scanner from rotating when lifting

the scanner base.

Note 1: Take care not to damage scanner exterior

by the rope.

Note 2: Tensile load should not be applied

to scanner radiator.

Figure 1-3 How to lift the scanner unit

4. Fix the scanner base to the mounting platform with four M12x60 hex bolts, nuts, wash-

ers and seal washers (supplied).

5. Arrange the grounding terminal at the nearest grounding spot with the M6x25 hex bolt,

nut and washers (supplied). Then, fix a ground wire (RW-4747, 340 mm) to the terminal.

6. Connect the other end of the ground wire to the ground terminal of the scanner unit.

7. Coat grounding terminal and fixing bolts on the scanner unit with silicone sealant (sup-

plied).

1-5

ANT MOTOR SW

Seal washer

Corrosion proof

rubber mat

Set seal washer and corrosion-proof

rubber mat, and apply silicone

sealant.

Hex bolt

FW

Ground

wire

Ground

wire

Hex nut

Hex bolt

Welding

Arrange ground terminal at

nearest grounding spot.

Figure 1-4 Mounting of scanner unit

FW

SW

Hex nut

SW

FW

Coat with silicone sealant

after attaching ground

wire.

Ground wire

Scanner body

Ground terminal is fitted to

the scanner body at the factory.

1-6

1.2 Display Unit

Mounting considerations

When selecting a mounting location, keep in mind the following points:

• Select a location where the display unit can be viewed and operated conveniently and

where the screen can be viewed while facing towards the bow.

• Locate the unit out of direct sunlight and away from heat sources because of heat that

can build up inside the cabinet.

• Locate the equipment away from places subject to water splash and rain.

• Be sure the mounting location is strong enough to support the weight of the unit under

the continued vibration which is normally experienced on the ship. If necessary reinforce the mounting location.

• Determine the mounting location considering the length of the signal cable between the

scanner unit and the display unit. (The signal cable comes in lengths of 15, 20, 30 or 60

meters; maximum 100 meters).

• Leave sufficient space on the sides and rear of the unit to facilitate maintenance. Also,

leave a foot or so of “service loop” in cables behind the unit so it can be pulled forward

for servicing or easy removal of connectors.

• A magnetic compass will be affected if placed too close to the display unit. Observe the

following compass safe distances to prevent deviation of a magnetic compass: Standard compass, 1.15 m, Steering compass, 0.90 m.

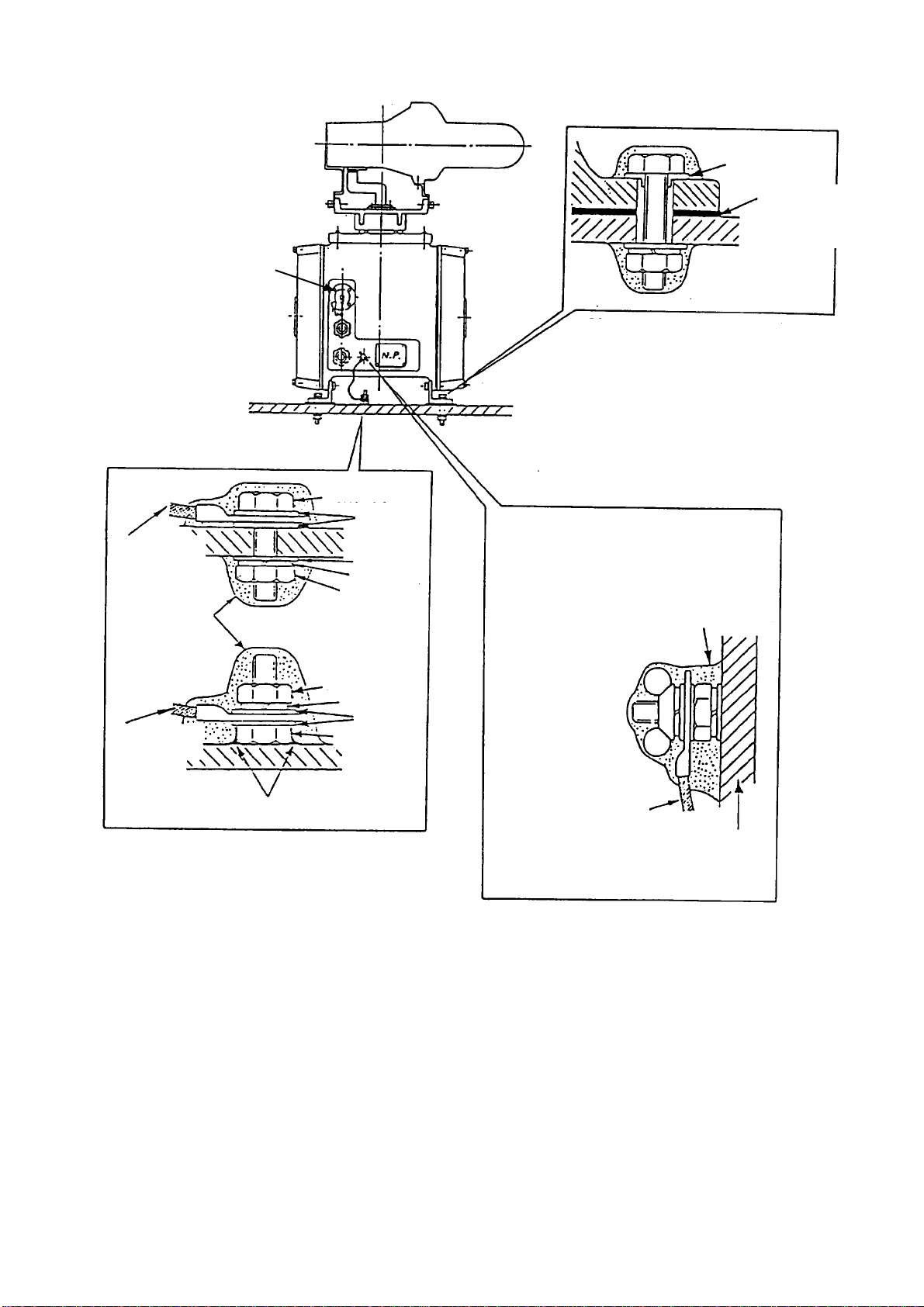

Mounting procedure

1. Loosen the two screws at the front of the display unit.

Screw

Figure 1-5 Display unit, front view

1-7

2. Lift the front panel.

Bolt

Figure 1-6 Display unit, cover opened

3. Unfasten two bolts (M8 x 40) at the bottom front of the display unit, and then remove

the mounting base.

4. Mark screw locations in the tabletop, using the mounting base as a template. For mount-

ing by bolts, nuts and washers, drill four holes of 12 mm diameter in the tabletop.

5. Fasten the mounting base to the tabletop by tapping screws, or M10, bolts, nuts and

washers.

6. Lay the display unit on the mounting base. Fasten the display unit to the mounting

base with the two M8 x 40 bolts removed at step 3.

7. Close the cover and fasten it.

Optional handles

Handles are available. Detach the caps attached to the display unit and fasten the handles.

1.3 Power Supply Unit

The Power Supply Unit PSU-002 does not contain usual operating controls. Therefore,

they can be installed in any recessed place either in vertical or horizontal position. However, select a dry and well-ventilated location and observe the compass safe distances

below to prevent deviation of a magnetic compass.

1-8

dradnatS

ssapmoC

ssapmoC

ecnatsidefas

m2.1m9.0

gnireetS

ssapmoC

WIRING

2.1 Scanner Unit

Two signal cables are terminated at the scanner unit: signal cables S03-78 and

660V-MPYCY-16 (from the power supply unit).

Preparations

Open the port side cover (six bolts) of the scanner unit. Unfasten fixing plates to access

terminal boards.

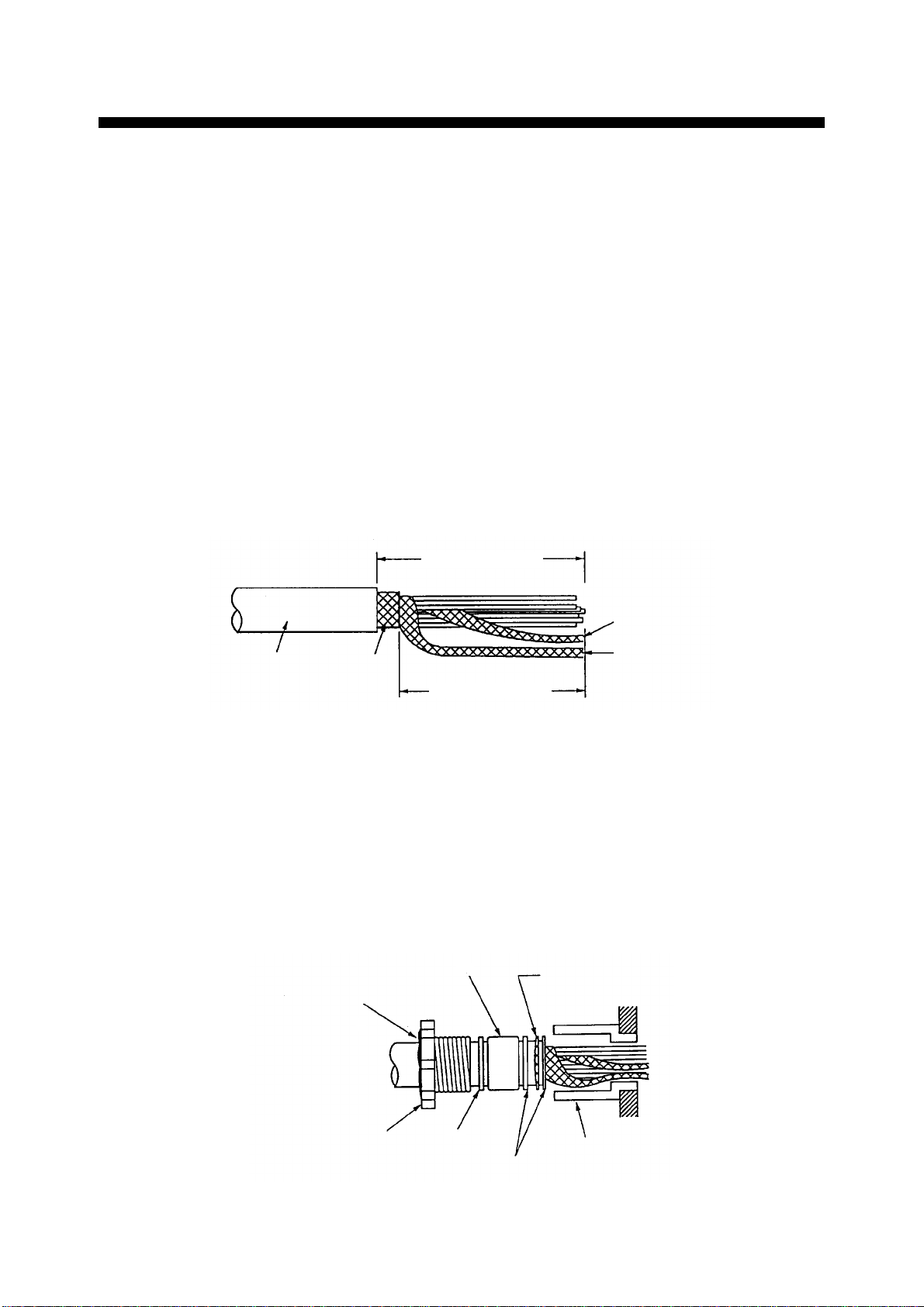

Signal cable S03-78 (JIS cable)

1. Shorten the cable, extending the length actually required by 600 mm. Strip off about

600 mm of the anti-corrosive vinyl sheath and 590 mm of the armor and the inner vinyl

sheath, being careful not to nick the braided shield.

Approx. 600 mm

Inner shield

Anti-corrosive

vinyl sheath

Armor

Approx. 590 mm

Outer shield

Figure 2-1 Fabricating the signal cable S03-78

2. Turn off the ANT MOTOR SW on the scanner unit(Refer to figure 1-4).

3. Unravel the outer shield with a screwdriver or similar tool to expose the cores beneath

the outer shield.

4. Similar to step 2, expose the cores beneath the inner shield. Mark all cores for future

identification.

5. Slide the clamping gland, washers and gasket onto the cable. (Use lower side gland.)

Gasket

Seal with putty

after tightening.

Armor

Clamping gland

Washer

Gland body

Washer

Figure 2-2 Passing clamping gland, washers and gasket on signal cable

2-1

6. Ground the armor through the two washers as shown above. Trim the shields con-

sidering their location on the earth terminal inside the scanner unit. Fit a crimp-on lug

(yellow, FV5.5-4, ø4) to inner and outer shields, then connect them to the ground terminal inside the scanner unit.

7. Determine the length of each core considering its location on STB-1 in the scanner unit

(see the interconnection diagram on page S-1). Remove approx. 6 mm of the vinyl

insulation from the end of each core and fix the crimp-on lug FV1.25-M3 (Red) to each

core.

8. Remove the outer sheath of the coaxial cable (2C-2V) by 75 mm. Pull back the braided

shield to expose the inner core. Remove approx. 25 mm of insulator from the end of

inner core and fold back conductor as illustrated below. Shorten the shield leaving

approx. 45 mm. Fit crimp-on lugs to the conductor (FVD1.25-3, Red) and braided shield

(FV1.25-M3, Red).

50 mm

75 mm

Crimp-on lug

FV1.25-M3

(Red, ∅3)

Fold back the conductor

as illustrated below.

Crimp-on lug

FVD1.25-3

(Red, ∅3)

Inner core

Conductor

6 mm

Coaxial cable

2C-2V

45 mm

Figure 2-3 Fabrication of coaxial cable

9. Lead cable into cable gland, tighten clamping gland and seal with putty.

10.Connect wiring to terminal STB-1 in the scanner unit referring to the interconnection

diagram.

2-2

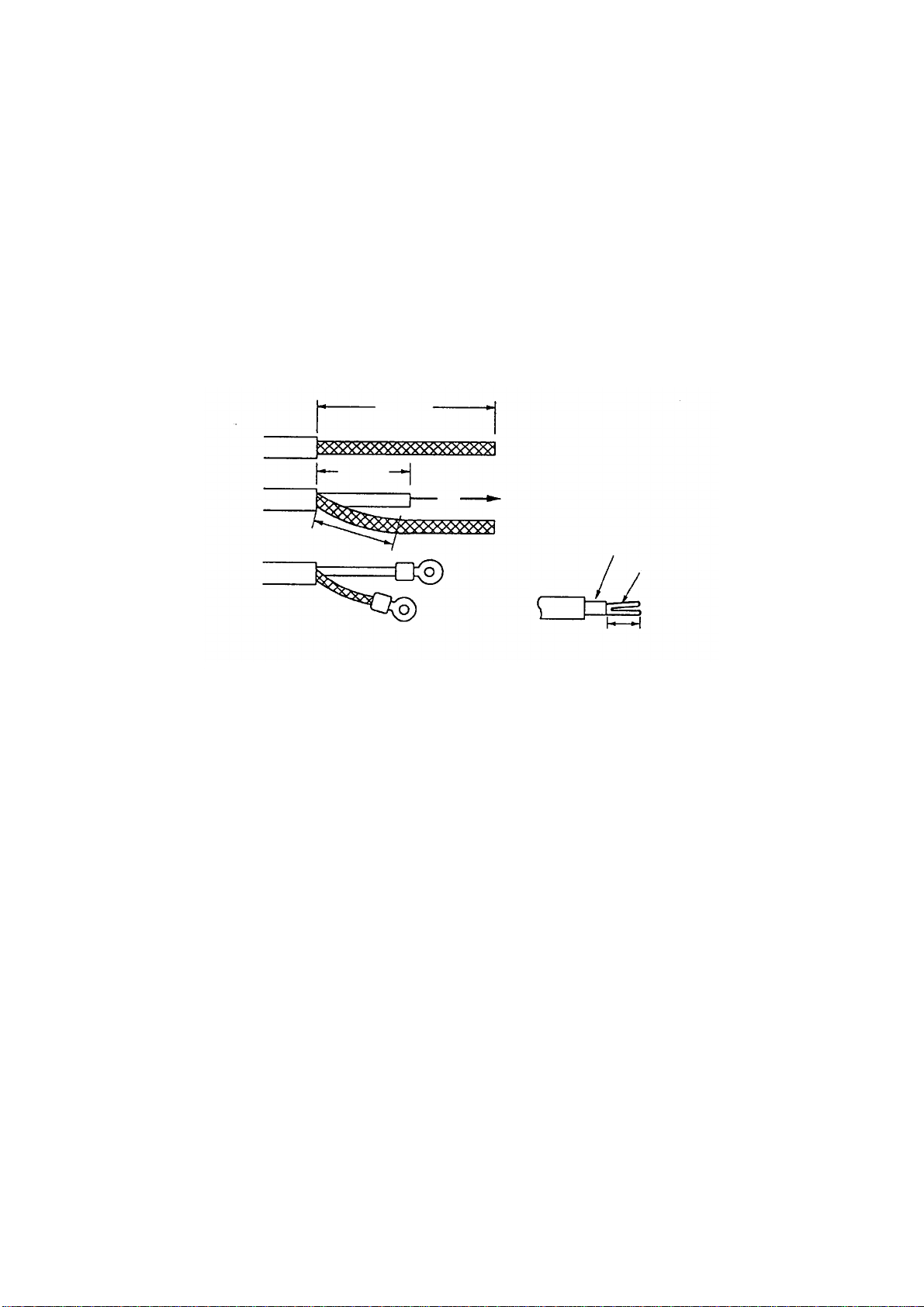

Signal cable 660V-MPYCY-16 (JIS cable)

1. Unfasten the clamping gland from the upper cable gland, and remove the gasket and

flat washers.

2. Shorten the cable as appropriate. Remove the vinyl sheath by 600 mm. Remove the

armor by 590 mm.

Armor

590 mm

Conductors

600 mm

Armor

Core

φ = 1.25 mm

2

Vinyl sheath

Figure 2-4 Fabrication of signal cable 660V-MPYCY-16

3. Slide the clamping gland, washers and gasket on the power cable. Fold back the armor

by 5 mm, then put it between washer and cable gland body as below.

Gasket

Seal with putty

after tightening.

Vinyl sheath

Clamping gland

Flat

washer

Armor (folded back)

Cable gland

Flat

washer

Flat

washer

Figure 2-5 Passing clamping gland, washers and gasket on the signal cable

4. Determine the length of the cores considering their location on STB-2 and STB-3. Trim

conductors as appropriate.

5. Ground the armor by inserting it through the two flat washers near the cable gland.

6. Remove the sheath of each core by 6 mm. Fix crimp-on lug FV1.25-4 (Blue, ø4) to

each conductor. Make sure each connection is secure both electrically and mechanically.

7. Lead cable into cable gland, tighten clamping gland and seal with putty.

8. Connect the conductors to STB-2 and STB-3, referring to the interconnection diagram

on page S-1.

9. Check for loose screws and poor contact on crimp-on lugs. Close terminal boards.

10.Grease the fixing bolts for the cover, gasket and tap holes in the scanner chassis.

Attach cover.

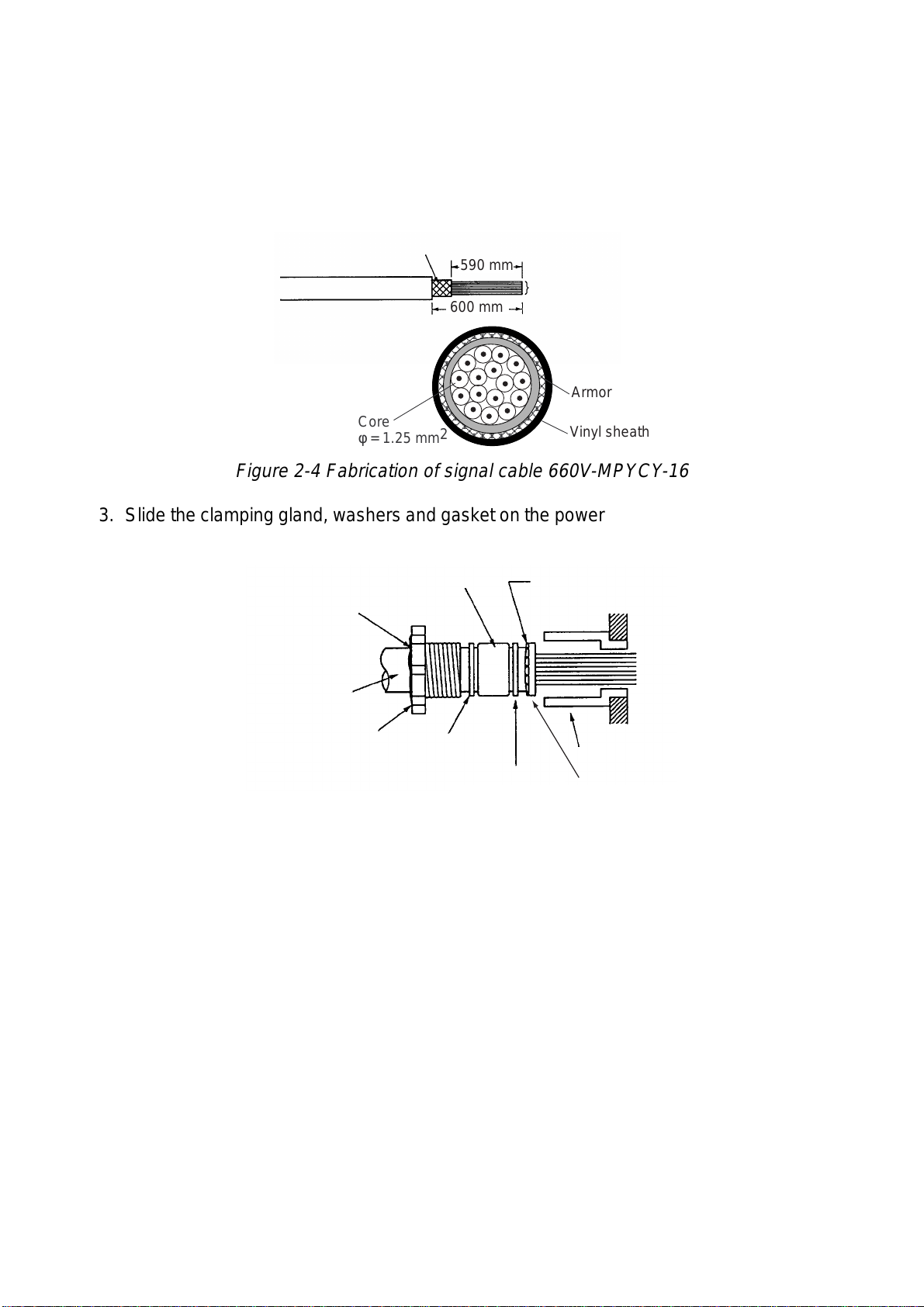

2-3

STB-2

STB-3

Cable

gland

Photo No. 2919

Cable clamp (3 pcs.)

TB fixing plate (1)

Figure 2-6 Scanner unit, port side view

STB-1

TB fixing plate (2)

2-4

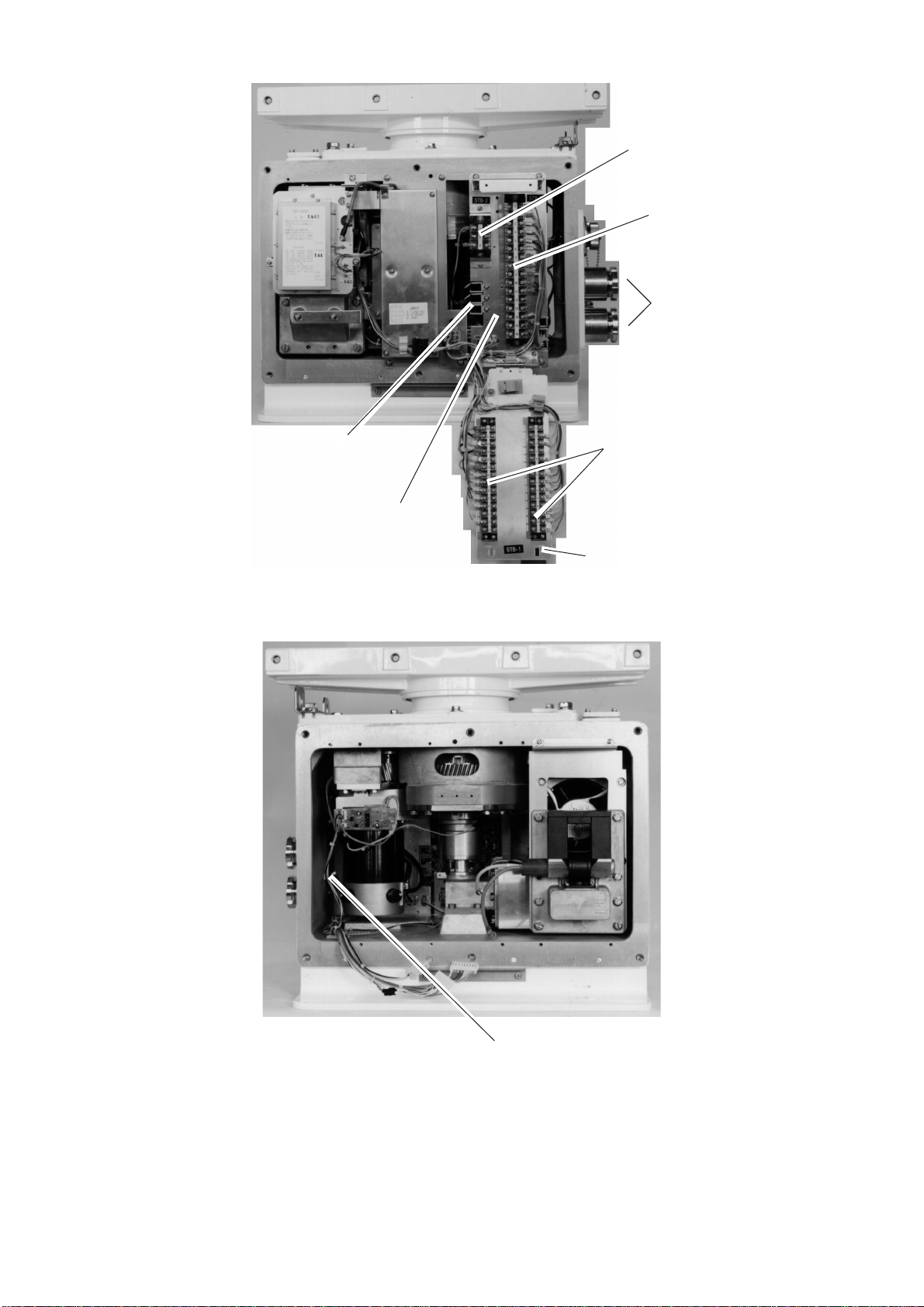

Photo No. 2918

Ground terminal

Figure 2-7 Scanner unit, starboard side view, Rf chassis removed

2.2 Display Unit

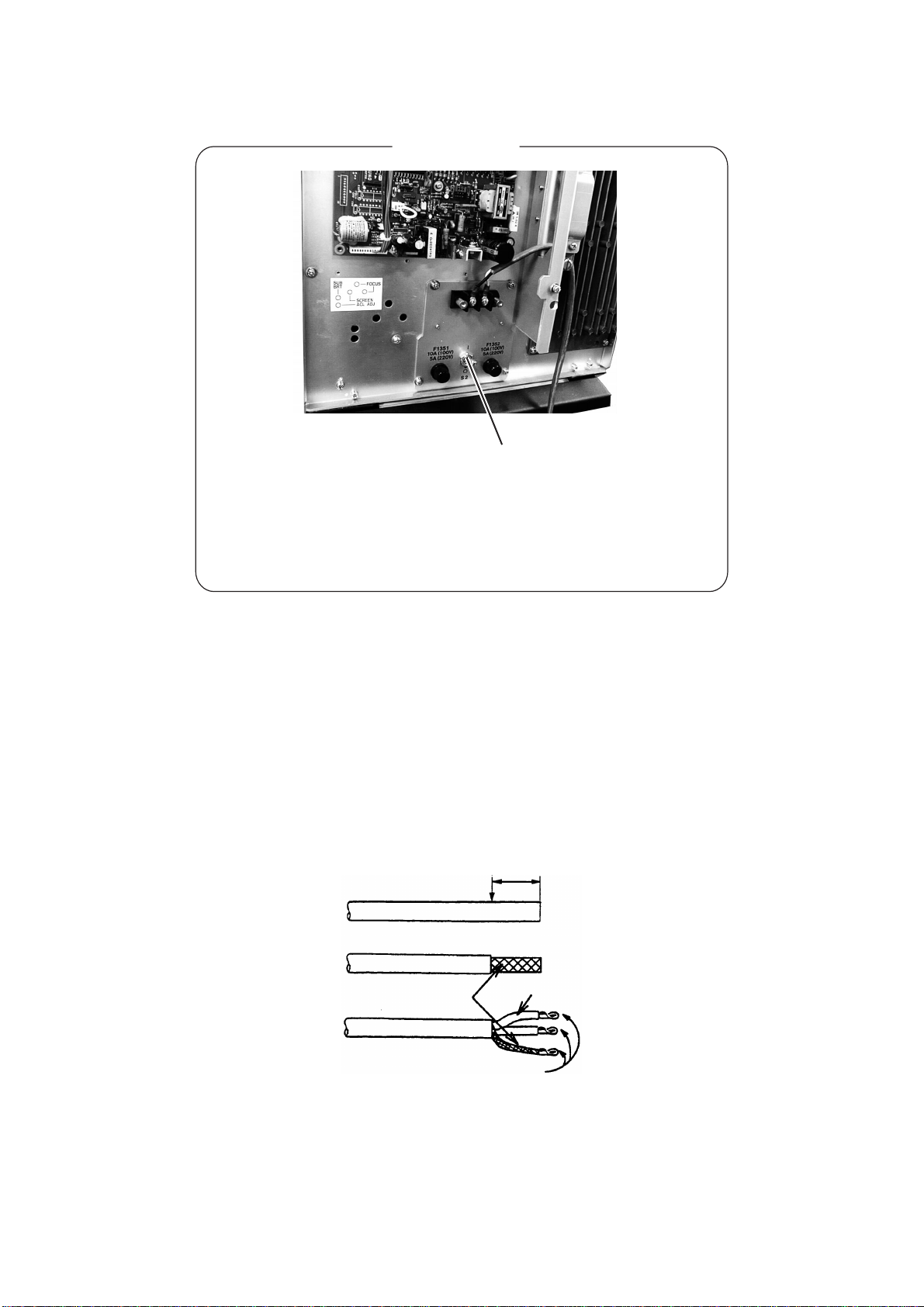

The display unit designed to run on AC power has a switch (S2)

at its rear to cut off 100/200 VAC power to the display unit. To

access the switch, unscrew two screws and then slide cover

to remove it. TURN THE SWITCH OFF WHENEVER ACCESSING

INSIDE THE DISPLAY UNIT.

Switch S2

Switch S2 (AC spec. only)

Fabricating the power cable CVV-S 8X2C (option)

1. Remove the vinyl sheath by 40 mm.

2. Cut off jute tape wrapped around the armor.

3. Unravel the armor to expose the cores.

4. Remove insulation of cores by about 10 mm. Fix crimp-on lugs to the cores and armor.

5. Cover the armor with vinyl tape, leaving the portion which will lie inside the cable clamp

untaped.

About 40 mm

CVV-S 8X2C

Braided shield

Crimp-on lug

Core

Figure 2-8 Fabrication of power cable CVV-S 8X2C

2-5

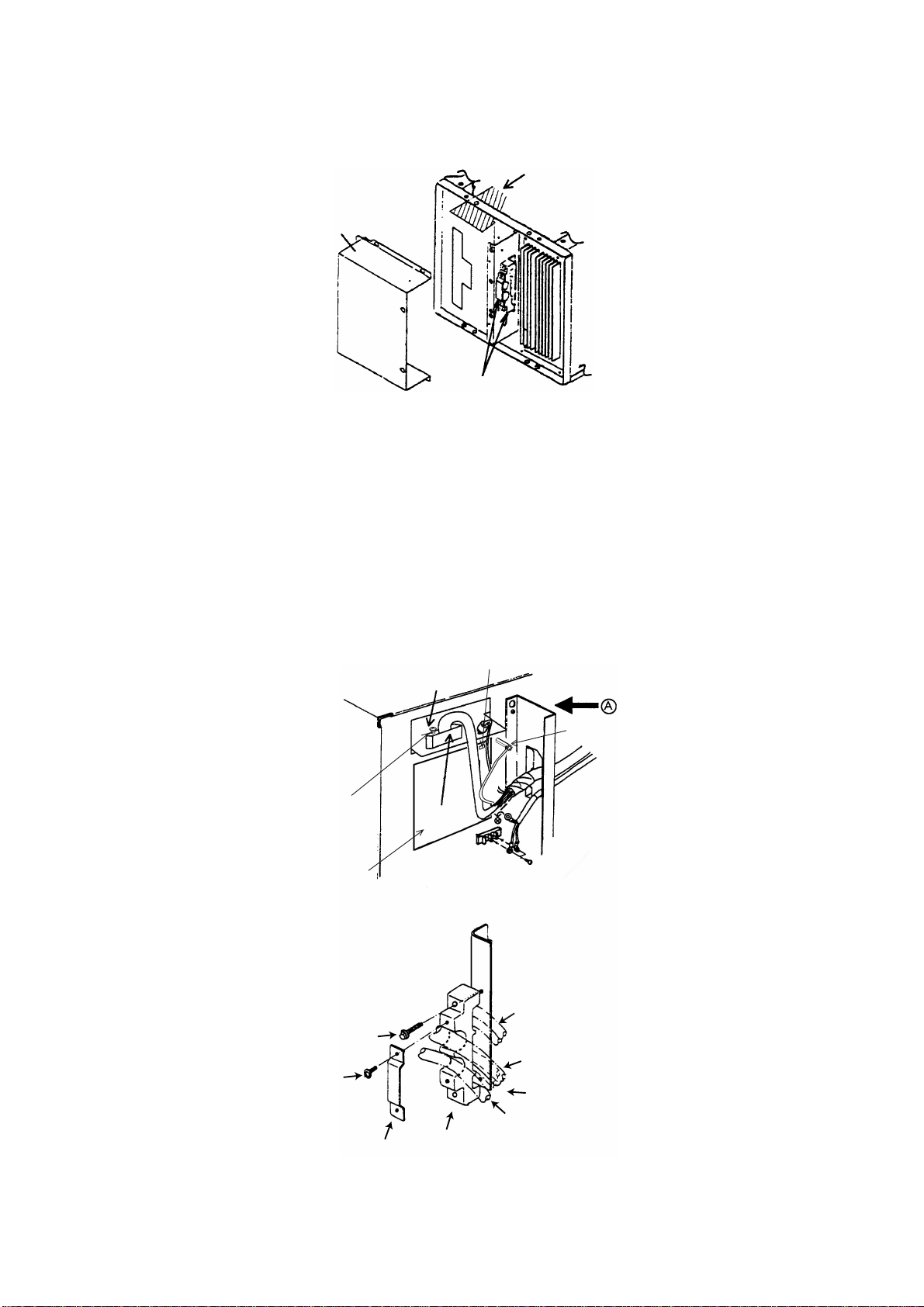

Wiring

All wiring of the display unit is done on the SPU Board at the rear of the display unit.

SPU Board

Cover

Cable clamp,

clamp plate

Figure 2-9 Display unit, rear view

1. Unfasten the cover.

2. Unfasten the clamping plate from the cable clamp.

3. Lay the copper tape part (armor part for signal cable with armor) of the signal cable and

anticorrosive shield part of power cable in the cable clamp and then fasten with the

clamping plate. For cables of optional equipment, loosen M6x35 bolt (2 pcs.) on cable

clamp, lay cables in appropriate location in clamp and then tighten clamp.

J5

Ground wire

Screw

(M3, 2 pcs.)

GYRO PROCESSOR

Board 64P1106A

* Lay gyrocompass

signal cable beneath

cables of optional

equipment.*

SPU Board

To DJ-1

2-6

Cables of optional

M6X35

M4X15

Cable clamp

Clamp plate

equipment

Signal cable

(from scanner)

Gyrocompass signal

cable

Power cable

Figure 2-10 Cable clamp at rear of display unit

4. Connect wiring to the SPU Board as shown in the interconnection diagram and Chap-

ter 3. Fasten shields of cables to chassis.

5. Cover the cable clamp with aluminum tape (about 50 mm in width) to keep foreign

objects out of the display unit.

Aluminum tape

(About 50 mm in width)

Cable clamp

Cable

(Power, signal, etc.)

Figure 2-11 Covering the cable clamp with aluminum tape

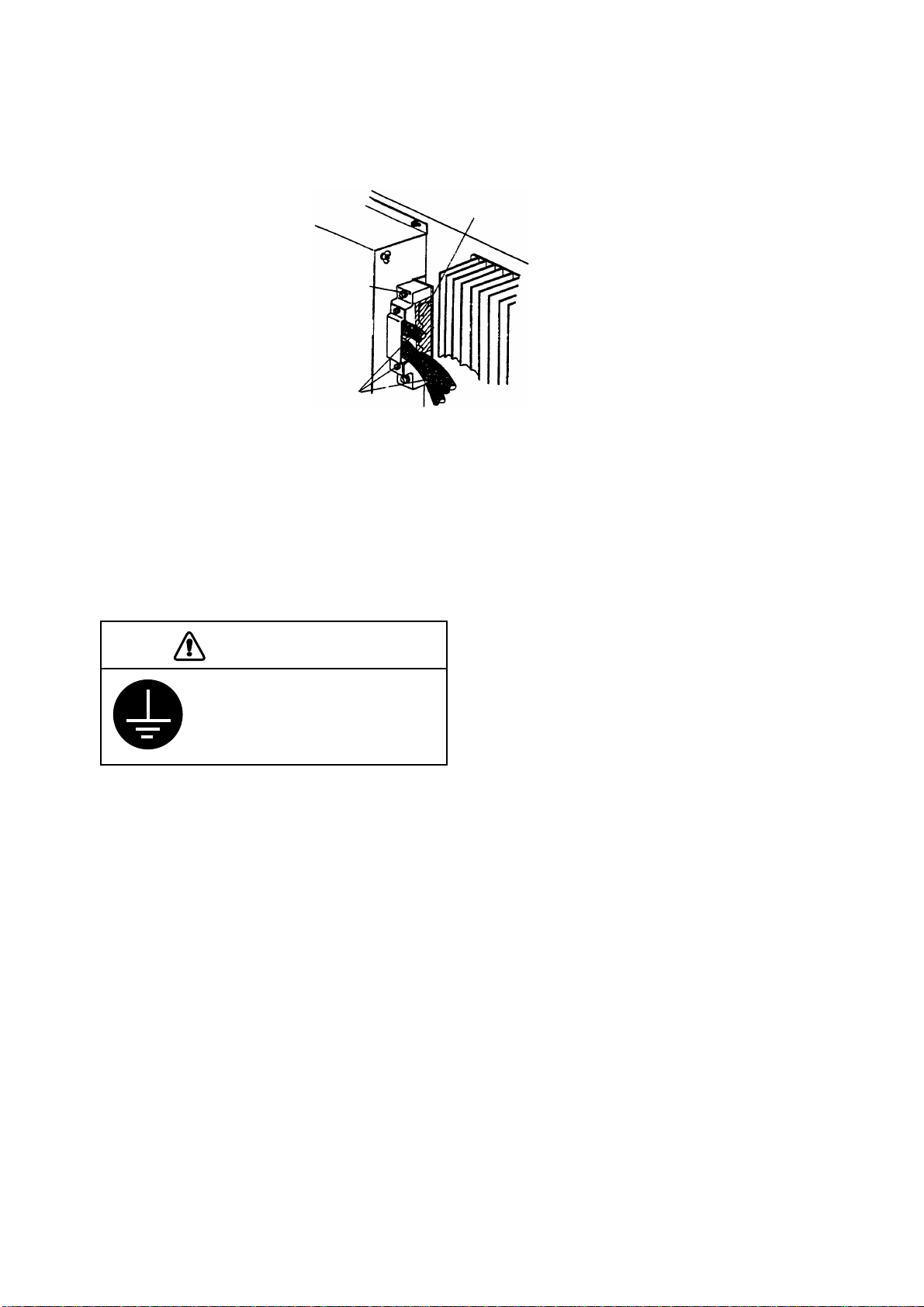

Ground

Run a ground wire (IV -8sq or equivalent) between ground terminal on the display unit and

ship’s superstructure.

CAUTION

Ground the equipment to

prevent electrical shock

and mutual interference.

2-7

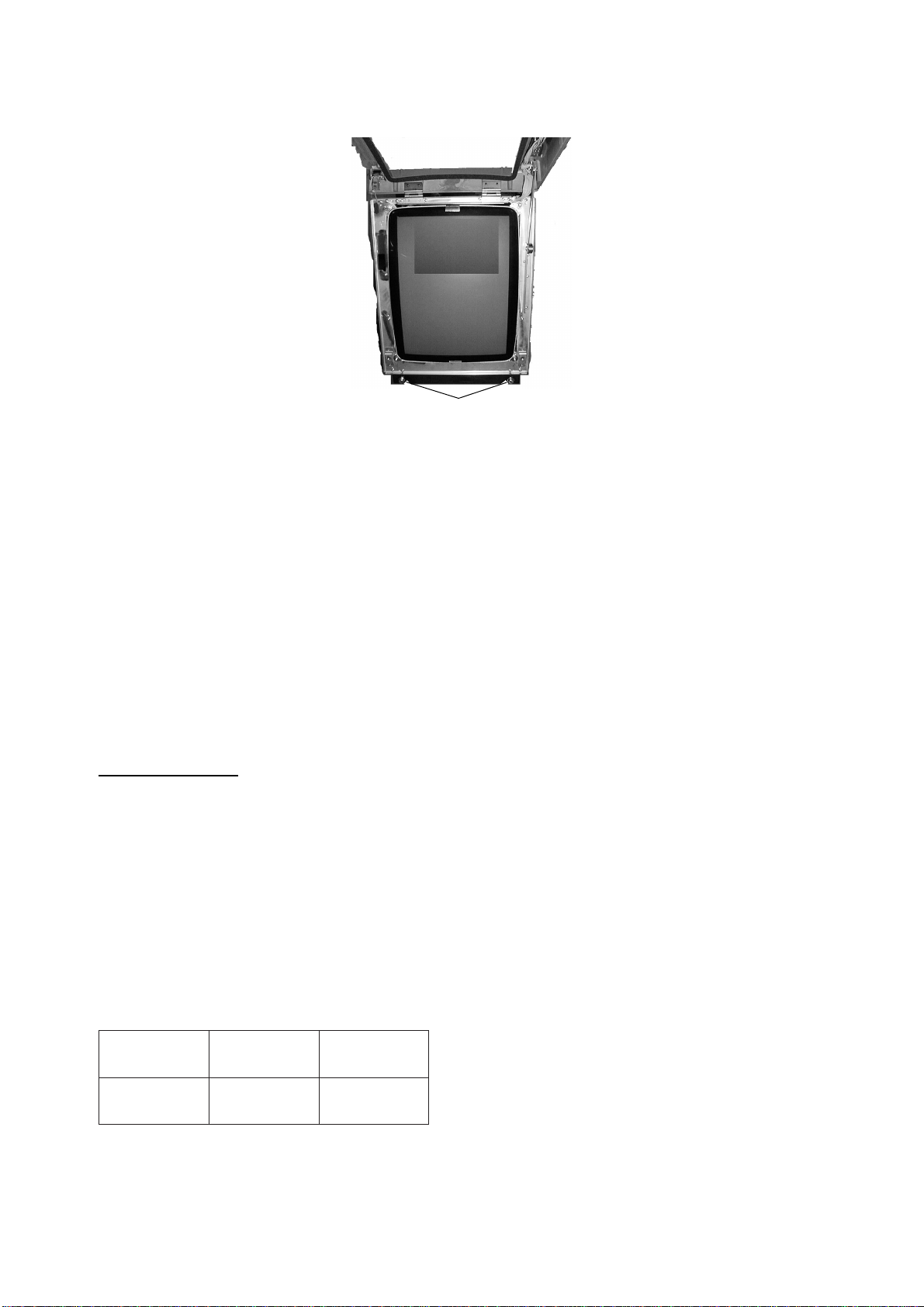

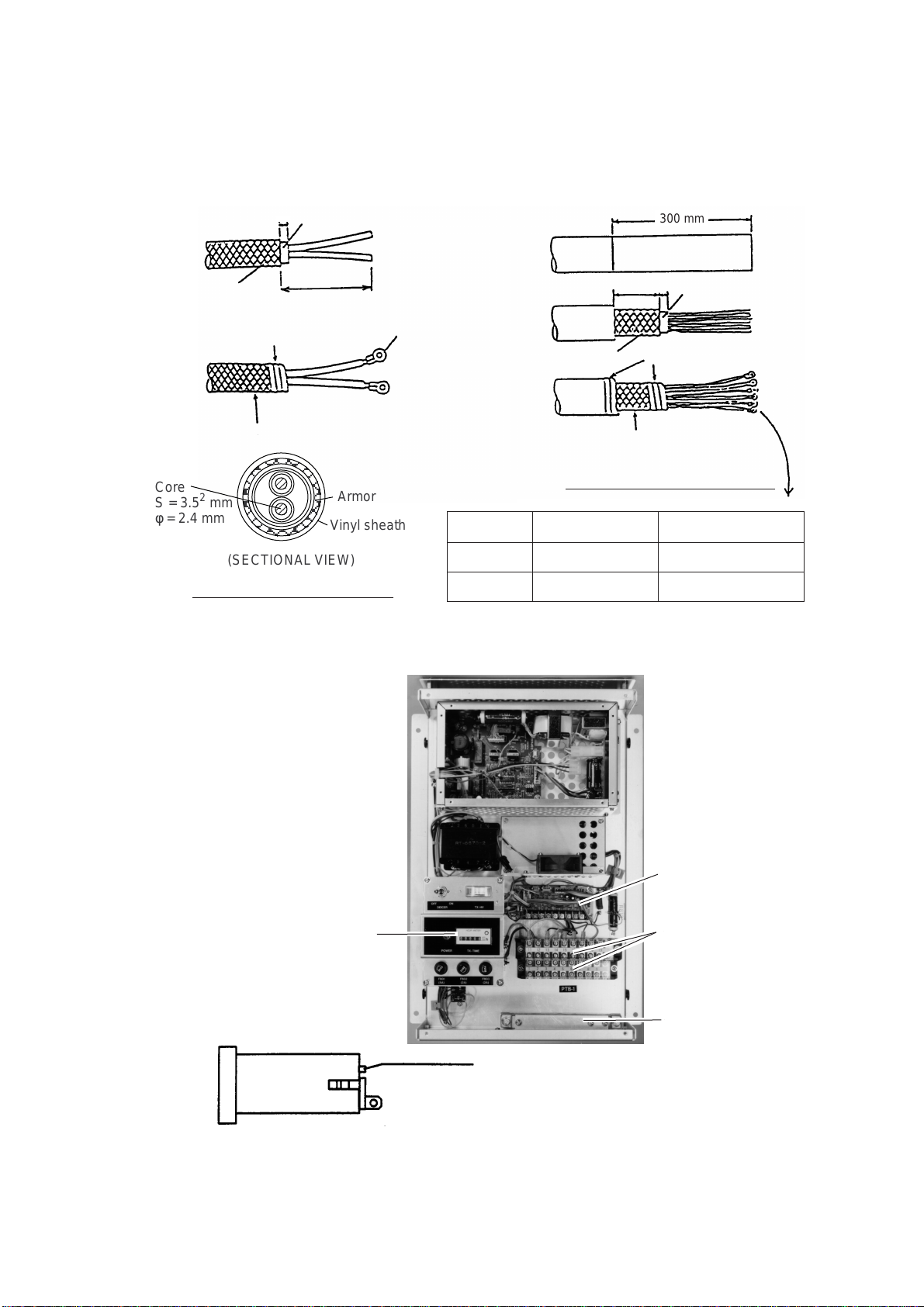

2.3 Power Supply Unit

Two cables run to the Power Supply Unit PSU-002: the power cable (250V-DPYC-3.5)

from AC power supply and the signal cable (660V-MPYCY-16) from the scanner unit.

5 mm

Armor

Vinyl sheath

150 mm

Vinyl tape

Crimp-on lug

FV5.5-4

Armor

300 mm

ANTI-CORROSIVE

SHEATH

5 mm

50 mm

Vinyl sheath

Vinyl tape

Clamp here.

Clamp here.

Core

2

S = 3.5

φ = 2.4 mm

mm

(SECTIONAL VIEW)

Power Cable 250V-DPYC-3.5

Armor

Vinyl sheath

.oNeroCotdetcennoCguLno-pmirC

9ot12-BTP)deR(3M-52.1VF

61ot011-BTP)eulB(4-2VF

Signal Cable 660V-MPYCY-16

Figure 2-12 Fabrication and connection of power cable and signal cable

Tap selection of T804:

connection of two

yellow wires should be

selected according to

supply voltage.

100VAC---tap"1"

110VAC---tap"5"

115VAC---tap"6"

Frequency setting of

HM801: Select the slide

switch position "60Hz" or

"50Hz". The slide switch is

located rear side of the

hour meter.

Front Rear

Hour Meter Slide view

Figure 2-13 Power supply unit PSU-002

PTB-2

PTB-1

Cable clamp

Slide Switch

2-8

Loading...

Loading...