Page 1

OPERATOR'S MANUAL

ELECTRONIC CHART

DISPLAY AND

INFORMATION SYSTEM

(ECDIS)

FMD-3200

FMD-3200-BB

Model

FMD-3300

www.furuno.com

Page 2

The paper used in this manual

9-52 Ashihara-cho,

A:APR

2012

.

E1:FEB.09, 2015

Pub. No.

(

)

Nishinomiya, 662-8580, JAPAN

is elemental chlorine free.

・FURUNO Authorized Distributor/Dealer

All rights reserved.

DAMI

FMD-3200/3200BB/3300

Printed in Japan

OME-44730-E1

0 0 0 1 7 6 1 2 5 1 4

Page 3

IMPORTANT NOTICES

General

• This manual has been authored with simplified grammar, to meet the needs of international users.

• The operator of this equipment must read and follow the descriptions in this manual. Wrong operation or maintenance can cancel the warranty or cause injury.

• Do not copy any part of this manual without written permission from FURUNO.

• If this manual is lost or worn, contact your dealer about replacement.

• The contents of this manual and equipment specifications can change without notice.

• The example screens (or illustrations) shown in this manual can be different from the screens you

see on your display. The screens you see depend on your system configuration and equipment

settings.

• Save this manual for future reference.

• Any modification of the equipment (including software) by persons not authorized by FURUNO will

cancel the warranty.

• All brand and product names are trademarks, registered trademarks or service marks of their respective holders.

• “C-MAP” means “C-MAP by Jeppesen” in this manual.

How to discard this product

Discard this product according to local regulations for the disposal of industrial waste. For disposal

in the USA, see the homepage of the Electronics Industries Alliance (http://www.eiae.org/) for the

correct method of disposal.

How to discard a used battery

Some FURUNO products have a battery(ies). To see if your product has a battery, see the chapter

on Maintenance. Follow the instructions below if a battery is used. Tape the + and - terminals of

battery before disposal to prevent fire, heat generation caused by short circuit.

In the European Union

The crossed-out trash can symbol indicates that all types of batteries

must not be discarded in standard trash, or at a trash site. Take the

used batteries to a battery collection site according to your national

legislation and the Batteries Directive 2006/66/EU.

In the USA

The Mobius loop symbol (three chasing arrows) indicates that Ni-Cd

and lead-acid rechargeable batteries must be recycled. Take the used

batteries to a battery collection site according to local laws.

In the other countries

Cd

PbNi-Cd

There are no international standards for the battery recycle symbol. The number of symbols can

increase when the other countries make their own recycle symbols in the future.

i

Page 4

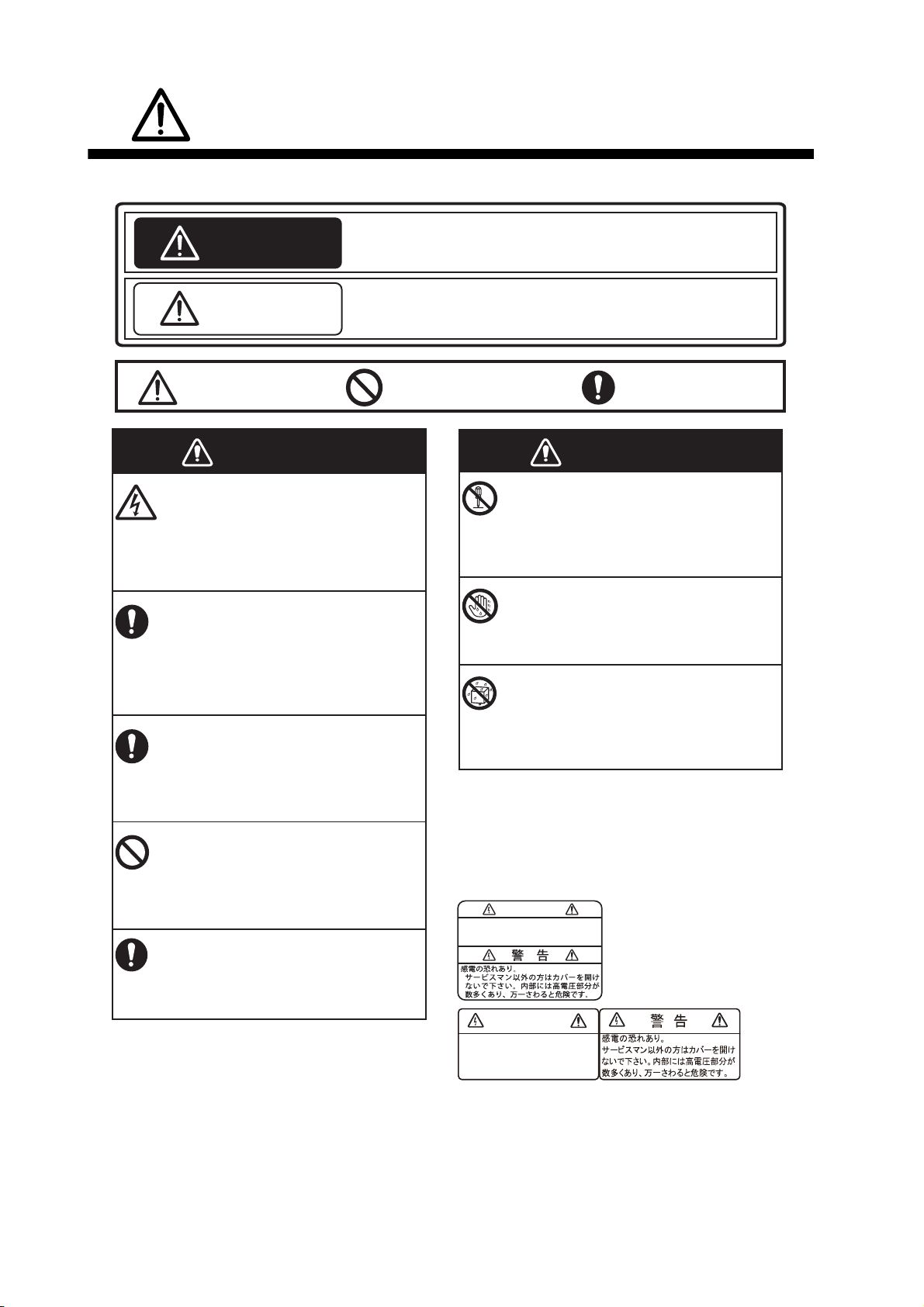

SAFETY INSTRUCTIONS

The operator must read the safety instructions before attempting to operate the equipment.

Indicates a potentially hazardous situation which, if not avoided,

WARNING

CAUTION

could result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided,

could result in minor or moderate injury.

Warning, Caution

Prohibitive Action

WARNING

Do not open the equipment.

This equipment uses high voltage that

can cause electrical shock.

Only qualified persons can work inside

the equipment.

Turn off power at switchboard if the

something is dropped inside the

equipment.

Fire or electrical shock can result if the

power remains on.

Turn off power at switchboard if the

equipment is emitting smoke or fire.

Fire or electrical shock can result if the

power remains on.

Do not place liquid filled containers

on the top of the equipment.

Fire or electrical shock can result if a

liquid spills into the equipment.

Use the correct fuse.

Use of a wrong fuse can cause fire

or damage the equipment.

Mandatory Action

WARNING

Do not dissassemble or modify the

equipment.

Fire, electrical shock or bodily injury can

result.

Do not operate the equipment with

wet hands.

Fire or electrical shock can result.

Keep the equipment away from areas

where contact with water is likely.

Fire or electrical shock can result if

water gets into the equipment.

Warning Label

Warning labels are attached to the Processor

Unit. Do not remove any label. If a label is

missing or damaged, contact a FURUNO

agent or dealer about replacement.

WARNING

To avoid electrical shock, do not

remove cover. No user-serviceable

parts inside.

WARNING

To avoid electrical shock,

do not remove cover.

No user-serviceable parts

inside.

Name: Warning Label (1)

Type: 86-003-1011-3

Code No.: 100-236-233-10

Name: Warning Label (2)

Type: 03-129-1001-3

Code No.: 100-236-743-10

ii

Page 5

TABLE OF CONTENTS

FOREWORD.................................................................................................................. xii

SYSTEM CONFIGURATION ........................................................................................xiv

1. INTRODUCTION.................................................................................................... 1-1

1.1 System Configuration ................................................................................................ 1-1

1.2 Processor Unit EC-3000............................................................................................ 1-1

1.3 How to Turn the Power On/Off .................................................................................. 1-2

1.4 The Standby Mode .................................................................................................... 1-2

1.5 ECDIS Control Unit RCU-024.................................................................................... 1-3

1.5.1 Control description......................................................................................... 1-3

1.6 Trackball Control Unit RCU-026 ................................................................................ 1-5

1.7 How to Select a Color Palette.................................................................................... 1-6

1.8 How to Adjust the Display Brilliance (FURUNO or Hatteland monitor)...................... 1-7

1.8.1 Manual brilliance adjustment......................................................................... 1-7

1.9 How to Select Sensor Settings .................................................................................. 1-8

1.10 How to Enter Ship Speed .......................................................................................... 1-9

1.11 How to Enter Heading ............................................................................................. 1-11

1.12 How to Mark MOB Position ..................................................................................... 1-12

1.13 How to Select Time Format, Set Local Time ........................................................... 1-13

1.14 How to Take a Screenshot of the Display ............................................................... 1-13

1.15 The Settings Menu .................................................................................................. 1-14

1.16 How to Manage User Profiles.................................................................................. 1-14

1.16.1 How to create a profile................................................................................. 1-14

1.16.2 How to disable a profile ............................................................................... 1-14

1.16.3 How to restore default settings to a profile .................................................. 1-14

1.16.4 How to activate a profile .............................................................................. 1-15

1.17 How to View ECDIS Software Version No., ECDIS System Information, and

Operator's Manual ................................................................................................... 1-15

1.18 Split Screen ............................................................................................................. 1-16

1.18.1 How to activate, deactivate the split screen ................................................ 1-16

1.18.2 Function availability ..................................................................................... 1-17

1.18.3 Split screen usage characteristics............................................................... 1-17

1.19 Tips.......................................................................................................................... 1-18

1.20 Printer Information ................................................................................................... 1-18

2. OPERATIONAL OVERVIEW................................................................................. 2-1

2.1 ECDIS Display........................................................................................................... 2-1

2.1.1 Electronic chart area...................................................................................... 2-2

2.1.2 Status bar ...................................................................................................... 2-4

2.1.3 InstantAccess bar.......................................................................................... 2-6

2.1.4 Sensor information box.................................................................................. 2-9

2.1.5 Own ship functions box ............................................................................... 2-10

2.1.6 Route information box ................................................................................. 2-11

2.1.7 Overlay/NAV Tools box ............................................................................... 2-12

2.1.8 Alert box ...................................................................................................... 2-12

2.1.9 Permanent warning box............................................................................... 2-12

2.1.10 EBL, VRM boxes ......................................................................................... 2-13

2.1.11 Context-sensitive menus ............................................................................. 2-13

2.1.12 How to enter alphanumeric data.................................................................. 2-14

2.2 How to Select the Operating Mode.......................................................................... 2-15

2.3 How to Select the ECDIS Operating Mode.............................................................. 2-16

2.4 How to Select the Chart Scale................................................................................. 2-16

iii

Page 6

TABLE OF CONTENTS

2.5 How to Select the Presentation Mode......................................................................2-17

2.6 Cursor Position Box .................................................................................................2-18

2.7 True Motion Reset.................................................................................................... 2-19

2.8 How to Control Route and User Charts in Voyage Navigation and

Voyage Planning Modes ..........................................................................................2-20

2.9 How to Use the VRM and EBL.................................................................................2-21

2.9.1 How to hide/show an EBL, VRM.................................................................. 2-21

2.9.2 How to measure the range and bearing....................................................... 2-21

2.9.3 How to select bearing reference ..................................................................2-21

2.9.4 EBL, VRM functions available with the context-sensitive menu...................2-22

2.10 Datum.......................................................................................................................2-23

2.10.1 General ........................................................................................................2-23

2.10.2 Paper charts.................................................................................................2-23

2.10.3 Electronic sea charts....................................................................................2-23

2.10.4 Positioning devices and datum ....................................................................2-23

2.10.5 ECDIS and datum ........................................................................................2-23

2.11 Set up Before Departure ..........................................................................................2-24

2.11.1 Updates before departure ............................................................................2-24

2.11.2 Create or update a route ..............................................................................2-24

2.11.3 How to check and prepare route to monitor .................................................2-26

2.11.4 Check configuration of navigation sensors ..................................................2-28

2.11.5 How to reset odometer and trip meter..........................................................2-29

3. HOW TO MANAGE CHARTS ............................................................................... 3-1

3.1 How to Install Public Keys for ENC Charts ................................................................3-1

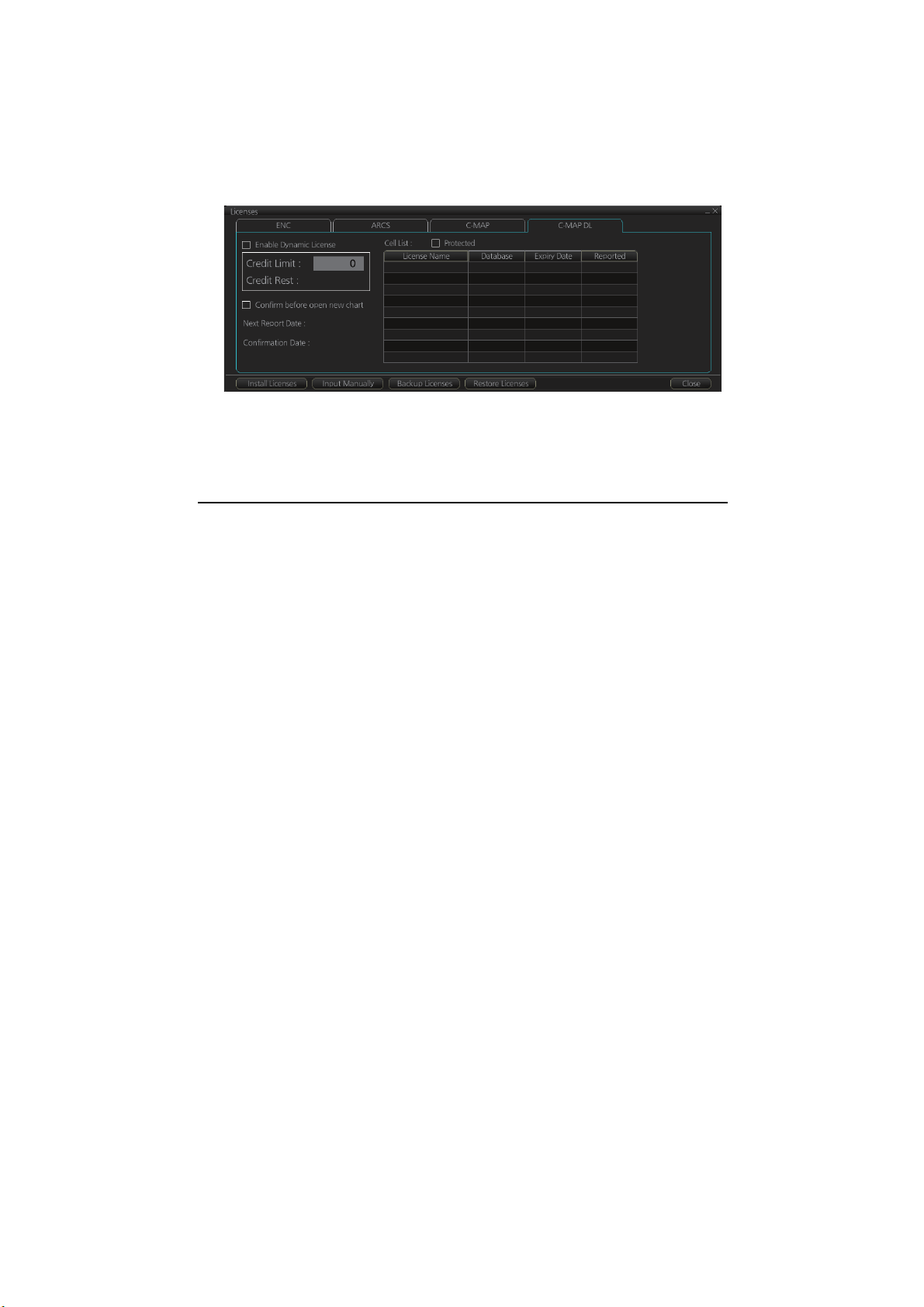

3.2 How to Install ENC Licenses, Charts .........................................................................3-2

3.2.1 How to install an ENC license........................................................................ 3-2

3.2.2 How to install ENC charts ..............................................................................3-3

3.3 How to Install ARCS Licenses, Charts.......................................................................3-5

3.3.1 How to install an ARCS license......................................................................3-5

3.3.2 How to install ARCS charts ........................................................................... 3-6

3.4 How to Delete ENC, ARCS Licenses.........................................................................3-8

3.5 How to Read ENC Judgment Information ..................................................................3-8

3.6 How to Install C-MAP Charts .....................................................................................3-9

3.6.1 How to register the eToken............................................................................ 3-9

3.6.2 How to install the C-MAP database and licenses ..........................................3-9

3.6.3 How to generate, order and apply an update file ......................................... 3-12

3.7 How to Delete a C-MAP Database........................................................................... 3-13

3.8 How to Install C-MAP DL (Dynamic Licensing) Charts ............................................3-13

3.8.1 How to generate, order and apply an update file ......................................... 3-13

3.8.2 How to enable and set up the C-MAP DL .................................................... 3-14

3.9 How to Export a List of Charts .................................................................................3-14

3.10 How to Export a List of Specific Licenses ................................................................3-15

3.11 How to Show the ENC Permit, ARCS License......................................................... 3-15

3.12 How to Backup, Restore Licenses ...........................................................................3-15

3.13 How to View Permit Expiration Date ........................................................................3-16

3.14 How to Display Install/Update History ......................................................................3-17

3.15 Catalog of Chart Cells ..............................................................................................3-18

3.15.1 How to group chart cells...............................................................................3-20

3.15.2 How to view status of chart cells ..................................................................3-21

3.16 How to Open Charts................................................................................................. 3-22

3.17 How to Print Chart List, Cell Status List ...................................................................3-22

3.17.1 How to print the chart list..............................................................................3-22

3.17.2 How to print the cell status list......................................................................3-23

3.18 How to Delete Charts ...............................................................................................3-24

3.19 How to Show Publishers Notes for ENC Charts ......................................................3-24

iv

Page 7

TABLE OF CONTENTS

3.20 How to Find the Chart Type..................................................................................... 3-25

3.21 How to Update ENC, C-MAP Charts Manually........................................................ 3-25

3.21.1 How to insert update symbols ..................................................................... 3-26

3.21.2 How to delete update symbols .................................................................... 3-27

3.21.3 How to modify existing update symbols ...................................................... 3-27

3.22 How to Synchronize Chart Data .............................................................................. 3-28

3.22.1 How to select the units to synchronize ........................................................ 3-28

3.22.2 How to check synchronization status .......................................................... 3-29

3.22.3 Manual updates and synchronization.......................................................... 3-30

3.23 How to Reconvert All SENC Charts ........................................................................ 3-30

4. HOW TO CONTROL CHART OBJECTS ..............................................................4-1

4.1 How to Browse Your Charts ...................................................................................... 4-1

4.2 How to Control Visibility of Chart Objects.................................................................. 4-1

4.2.1 How to set value for shallow contour, safety depth, safety contour and

deep contour.................................................................................................. 4-1

4.2.2 Basic Setting menu........................................................................................ 4-3

4.2.3 Chart Display menu....................................................................................... 4-4

4.2.4 Display base.................................................................................................. 4-5

4.3 How to Control Visibility of Symbols, Features.......................................................... 4-5

4.3.1 General page................................................................................................. 4-5

4.3.2 Tracking page................................................................................................ 4-7

4.3.3 Route page.................................................................................................... 4-8

4.3.4 Mariner page ................................................................................................. 4-8

4.3.5 Targets page ................................................................................................. 4-9

4.4 Control of Predefined IMO Chart Display Settings .................................................. 4-10

5. VECTOR (S57) CHARTS....................................................................................... 5-1

5.1 Introduction to S57 Charts......................................................................................... 5-1

5.1.1 Definitions of terms........................................................................................ 5-2

5.1.2 Chart legend for S57 charts........................................................................... 5-2

5.1.3 Permanent warnings for S57 charts .............................................................. 5-3

5.2 Chart Viewing Dates and Seasonal Features of the S57 Chart ................................ 5-4

5.2.1 Introduction.................................................................................................... 5-4

5.2.2 How to approve and highlight S57 chart updates.......................................... 5-4

5.2.3 How to set Display date and Approved until dates........................................ 5-5

5.2.4 About chart viewing date dependency of S57 standard ................................ 5-5

5.3 Symbology Used in S57 Charts................................................................................. 5-6

5.3.1 Presentation library used for S57 chart features ........................................... 5-6

5.4 How to Find Information about S57 Chart Objects .................................................... 5-6

5.5 Admiralty Information Overlay (AIO).......................................................................... 5-8

5.5.1 Installation ..................................................................................................... 5-8

5.5.2 How to display the AIO.................................................................................. 5-8

5.5.3 Catalog of AIO cells....................................................................................... 5-9

5.5.4 How to find AIO chart object information..................................................... 5-10

5.5.5 How to select the information to display...................................................... 5-11

6. RASTER (ARCS) CHARTS ................................................................................... 6-1

6.1 ARCS Charts ............................................................................................................. 6-1

6.1.1 Chart legend of ARCS chart.......................................................................... 6-1

6.2 Datum and ARCS Charts .......................................................................................... 6-5

6.3 Permanent Warnings of ARCS.................................................................................. 6-5

6.4 ARCS Subscriptions .................................................................................................. 6-6

6.4.1 ARCS Navigator ............................................................................................ 6-6

6.4.2 ARCS license information.............................................................................. 6-6

v

Page 8

TABLE OF CONTENTS

7. C-MAP CHARTS ................................................................................................... 7-1

7.1 C-MAP Cartographic Service .....................................................................................7-1

7.2 How to Register the System at C-MAP Norway.........................................................7-1

7.3 How to Order Charts ..................................................................................................7-1

7.4 How to Apply for Licenses.......................................................................................... 7-1

7.5 Troubleshooting .........................................................................................................7-2

7.6 Chart Subscription Services.......................................................................................7-2

7.6.1 C-MAP Dynamic Licensing (DL) service........................................................ 7-2

7.6.2 What is ENC delivery? ................................................................................... 7-2

7.7 Chart Display.............................................................................................................. 7-3

7.7.1 Introduction ....................................................................................................7-3

7.8 Permanent Warnings .................................................................................................7-4

8. CHART ALERTS................................................................................................... 8-1

8.1 Chart Alerts ................................................................................................................8-2

8.1.1 How to set safety contour...............................................................................8-2

8.1.2 How to select objects used in chart alerts...................................................... 8-3

8.2 How to Activate Own Ship Check ..............................................................................8-4

8.3 Route Planning........................................................................................................... 8-5

8.3.1 Chart alerts for route planning........................................................................8-5

8.4 Route Monitoring........................................................................................................8-7

9. ROUTES................................................................................................................ 9-1

9.1 Route Planning Overview........................................................................................... 9-1

9.2 Main Menu for Route Planning................................................................................... 9-2

9.3 How to Create a New Route ......................................................................................9-2

9.3.1 How to use the Waypoints page ....................................................................9-4

9.3.2 How to use the User Chart page.................................................................... 9-5

9.3.3 How to use the Optimize page....................................................................... 9-6

9.3.4 How to use the Alert Parameters page .......................................................... 9-7

9.3.5 How to use the Check Results page.............................................................. 9-8

9.4 How to Modify an Existing Route ...............................................................................9-9

9.4.1 How to change waypoint position...................................................................9-9

9.4.2 How to change other waypoint data............................................................... 9-9

9.4.3 How to add a new waypoint at the end of a route.......................................... 9-9

9.4.4 How insert a waypoint ................................................................................. 9-10

9.4.5 How to delete a waypoint............................................................................. 9-10

9.4.6 Geometry check of route.............................................................................. 9-10

9.5 SAR Operations .......................................................................................................9-11

9.6 Route Bank ..............................................................................................................9-14

9.7 Route Optimization................................................................................................... 9-15

9.7.1 Available route optimization strategies.........................................................9-15

9.7.2 How to optimize a route ...............................................................................9-16

9.7.3 How to plan a speed profile..........................................................................9-17

9.8 How to Import Routes ..............................................................................................9-18

9.8.1 How to import FMD-3xx0, FCR-2xx9 route data.......................................... 9-18

9.8.2 How to import FEA-2x07 route data ............................................................ 9-18

9.8.3 How to import csv, ASCII format route data................................................. 9-19

9.9 How to Export Route Data .......................................................................................9-19

9.9.1 How to export FMD-3xx0 route data ............................................................ 9-19

9.9.2 How to export route data in FEA-2x07, csv, ASCII format........................... 9-20

9.10 How to Delete Routes ..............................................................................................9-20

9.11 Reports.....................................................................................................................9-21

vi

Page 9

TABLE OF CONTENTS

10. USER CHARTS ...................................................................................................10-1

10.1 Introduction.............................................................................................................. 10-1

10.1.1 Objects of user charts.................................................................................. 10-1

10.2 How to Create a User Chart .................................................................................... 10-2

10.3 How to Import a User Chart Created with ECDIS FEA-2x07................................... 10-6

10.4 How to Edit Objects on a User Chart....................................................................... 10-7

10.4.1 How to edit objects on the chart area.......................................................... 10-7

10.4.2 How to edit objects from the User Chart dialog box .................................... 10-7

10.5 How to Delete Objects from a User Chart ............................................................... 10-8

10.6 How to Select the User Chart Objects to Display ................................................... 10-8

10.7 How to Delete User Charts...................................................................................... 10-9

10.8 User Chart Reports.................................................................................................. 10-9

11. HOW TO MONITOR ROUTES.............................................................................11-1

11.1 How to Start Route Monitoring ................................................................................ 11-1

11.2 How to Stop Monitoring a Route (Manual, Automatic) ............................................ 11-3

11.3 How to Select What Parts of a Route to Display ..................................................... 11-3

11.4 How to View Waypoint Information.......................................................................... 11-4

11.5 How to View User Chart Information ....................................................................... 11-5

11.6 How to Change Monitored Route to Planned Route ............................................... 11-5

11.7 How to Use Instant Track to Return to or Deviate from Monitored Route ............... 11-6

11.7.1 Safe off track mode ..................................................................................... 11-6

11.7.2 Back to track mode...................................................................................... 11-7

11.7.3 Instant track messages................................................................................ 11-9

11.7.4 Instant track details.................................................................................... 11-10

11.7.5 How to monitor, stop monitoring an instant track route ............................. 11-10

11.7.6 How to return to a monitored route when following an instant track

route (safe off track mode only)................................................................. 11-12

11.7.7 Button label and equipment state.............................................................. 11-13

11.8 How to Share Route During Route Monitoring ...................................................... 11-14

12. NAVIGATION TOOLS .........................................................................................12-1

12.1 How to Access the Nav Tools in the Overlay/NAV Tools Box ................................. 12-1

12.2 Parallel Index (PI) Lines .......................................................................................... 12-2

12.2.1 How to activate, deactivate PI lines............................................................. 12-2

12.2.2 PI line bearing reference ............................................................................. 12-2

12.2.3 Number of PI lines to display....................................................................... 12-2

12.2.4 PI line mode................................................................................................. 12-2

12.2.5 How to adjust PI line orientation, PI line interval ......................................... 12-3

12.2.6 How to reset the PI lines.............................................................................. 12-3

12.2.7 How to adjust PI line length......................................................................... 12-4

12.3 Check Area.............................................................................................................. 12-5

12.4 Ring ......................................................................................................................... 12-5

12.5 Predictor .................................................................................................................. 12-6

12.6 Anchor Watch .......................................................................................................... 12-7

12.7 UKC (Under Keel Clearance) .................................................................................. 12-8

12.7.1 UKC overview.............................................................................................. 12-8

12.7.2 How to set UKC........................................................................................... 12-8

12.7.3 UKC window................................................................................................ 12-9

12.8 Divider ................................................................................................................... 12-10

12.8.1 How to use the divider............................................................................... 12-10

12.8.2 Usage characteristics, limitations .............................................................. 12-11

12.8.3 How to deactivate and erase the divider ................................................... 12-11

vii

Page 10

TABLE OF CONTENTS

13. TRACKED TARGET (TT) FUNCTIONS.............................................................. 13-1

13.1 How to Show, Hide TT .............................................................................................13-1

13.2 TT Symbols and TT Attributes .................................................................................13-2

13.2.1 TT symbols...................................................................................................13-2

13.2.2 TT symbol color and size .............................................................................13-2

13.3 TT CPA/TCPA Alarm ...............................................................................................13-3

13.3.1 How to set the CPA and TCPA limits, enable, disable the alarm.................13-3

13.4 Lost TT Alarm........................................................................................................... 13-3

13.4.1 How to enable, disable the lost TT alarm.....................................................13-3

13.4.2 How to set the lost TT alarm filter ................................................................13-4

13.5 How to Set Vector Length and Vector Motion ..........................................................13-4

13.6 How to Display TT Data ...........................................................................................13-6

13.6.1 How to display target data for individual TT .................................................13-6

13.7 Displaying Past Positions of TT ...............................................................................13-7

13.7.1 How to enable/disable the past position display, select past

position reference.........................................................................................13-7

13.7.2 Past position point attributes ........................................................................13-7

13.8 TT Source ................................................................................................................13-8

14. AIS TARGET FUNCTIONS................................................................................. 14-1

14.1 Introduction ..............................................................................................................14-1

14.2 AIS Symbols............................................................................................................. 14-2

14.3 Voyage Data ............................................................................................................14-4

14.4 How to Show, Hide AIS Targets............................................................................... 14-5

14.5 How to Filter AIS Targets .........................................................................................14-6

14.6 AIS CPA/TCPA Alarm ..............................................................................................14-6

14.7 Automatic Activation of Sleeping Targets ................................................................14-8

14.7.1 Enabling, disabling automatic activation of sleeping targets........................14-8

14.7.2 Conditions for automatic activation of sleeping targets................................14-8

14.8 How to Sleep All Activated Targets..........................................................................14-9

14.9 AIS Lost Target Alarm..............................................................................................14-9

14.9.1 How to enable, disable the AIS lost target alarm .........................................14-9

14.9.2 How to set the AIS lost target alarm filter...................................................14-10

14.10Vector Length, Vector Stabilization in True Motion Mode .....................................14-10

14.11How to Display AIS Target Data............................................................................14-11

14.12How to Display AIS Target Past Positions.............................................................14-13

14.12.1How to enable/disable the past position display, set past

position reference.......................................................................................14-13

14.13How to Display Own Ship Data .............................................................................14-13

15. AIS SAFETY, NAVTEX MESSAGES.................................................................. 15-1

15.1 AIS Safety Messages...............................................................................................15-1

15.1.1 How to send an AIS safety message ...........................................................15-1

15.1.2 How to manage received and sent AIS safety messages............................15-2

15.2 Navtex Messages..................................................................................................... 15-3

15.2.1 How to receive Navtex messages................................................................15-4

15.2.2 How to manage received Navtex messages................................................15-5

16. RADAR OVERLAY ............................................................................................. 16-1

16.1 Introduction ..............................................................................................................16-1

16.2 How to Setup the Radar Overlay .............................................................................16-2

16.3 Error Between Radar Echo Image and Chart ..........................................................16-3

16.4 Error Sources for Radar Echo Image and TT Mismatch ..........................................16-4

viii

Page 11

TABLE OF CONTENTS

17. WEATHER OVERLAY.........................................................................................17-1

17.1 What is the Weather Overlay?................................................................................. 17-1

17.2 How to Activate, Deactivate the Weather Overlay................................................... 17-1

17.3 How to Select, Playback a Weather Data File......................................................... 17-2

17.4 How to Set up the Weather Overlay ........................................................................ 17-3

17.5 Weather Overlay Examples..................................................................................... 17-5

17.5.1 Wind display ................................................................................................ 17-5

17.5.2 Temperature display.................................................................................... 17-6

17.5.3 Cloud coverage display ............................................................................... 17-6

17.5.4 Precipitation rate display ............................................................................. 17-6

17.5.5 Waves display ............................................................................................. 17-7

17.5.6 Ocean current display.................................................................................. 17-7

17.6 Weather Spot Information........................................................................................ 17-8

17.7 Summary of Weather Overlay Viewability, Operability and Operating Mode .......... 17-8

18. NAVIGATION SENSORS ....................................................................................18-1

18.1 CCRS ...................................................................................................................... 18-1

18.2 How to Select Navigation Sensors .......................................................................... 18-2

18.2.1 Sensors menu description........................................................................... 18-2

18.3 Source of Position ................................................................................................... 18-5

18.4 CCRP, System, Primary, Secondary and Pivot Positions of Own Ship................... 18-6

18.5 Source of Navigation Data....................................................................................... 18-7

18.6 Switching of Sensor and Indication ......................................................................... 18-9

18.7 Filter Status ............................................................................................................. 18-9

18.8 Position Alignment................................................................................................. 18-11

18.8.1 How to align position ................................................................................. 18-11

18.8.2 How to cancel position alignment.............................................................. 18-11

18.9 Wind Sensor .......................................................................................................... 18-12

18.10Depth Sensor........................................................................................................ 18-13

19. RECORDING, PLAYBACK FUNCTIONS............................................................19-1

19.1 How to Record User, Position Events ..................................................................... 19-1

19.1.1 User events ................................................................................................. 19-1

19.1.2 Position events ............................................................................................ 19-2

19.2 Details Log............................................................................................................... 19-5

19.3 Voyage Log ............................................................................................................. 19-6

19.3.1 How to set conditions for voyage logging.................................................... 19-7

19.4 Chart Usage Log ..................................................................................................... 19-8

19.5 Danger Targets Log................................................................................................. 19-9

19.5.1 How to set the conditions for logging danger targets ................................ 19-10

19.6 How to Playback the Log....................................................................................... 19-11

20. ALERTS ...............................................................................................................20-1

20.1 What is an Alert? ..................................................................................................... 20-1

20.2 Alert Box .................................................................................................................. 20-2

20.3 How to Temporarily Silence the Buzzer for an Alarm or Warning ........................... 20-5

20.4 How to Acknowledge an Alarm or Warning ............................................................. 20-5

20.5 Alert List................................................................................................................... 20-6

20.6 Alert Log .................................................................................................................. 20-8

20.7 Alert Reception from Connected Sensors ............................................................... 20-8

20.8 List of Alerts............................................................................................................. 20-9

21. PARAMETERS ....................................................................................................21-1

21.1 Ship and Route Parameters .................................................................................... 21-1

21.2 Forwarding Distances.............................................................................................. 21-2

ix

Page 12

TABLE OF CONTENTS

21.3 Cost Parameters ......................................................................................................21-3

21.4 Instant Track Parameters.........................................................................................21-4

22. CONNING AND MINI CONNING DISPLAYS ..................................................... 22-1

22.1 Conning Display .......................................................................................................22-1

22.2 Mini Conning Display ...............................................................................................22-9

23. SETTINGS MENU ............................................................................................... 23-1

23.1 How to Access the Settings Menu ...........................................................................23-1

23.2 File Export ................................................................................................................23-2

23.3 File Import ................................................................................................................23-3

23.4 File Maintenance......................................................................................................23-4

23.5 Self Test ...................................................................................................................23-5

23.6 Data Sharing ............................................................................................................23-6

23.7 Customize ................................................................................................................23-7

23.8 Display Test .............................................................................................................23-8

23.9 Keyboard Test..........................................................................................................23-9

23.10Screenshots...........................................................................................................23-11

23.10.1How to export screenshots......................................................................... 23-12

23.10.2How to delete screenshots.........................................................................23-12

23.11User Default...........................................................................................................23-13

23.12CCRP ....................................................................................................................23-14

24. MAINTENANCE AND TROUBLESHOOTING.................................................... 24-1

24.1 Maintenance............................................................................................................. 24-1

24.2 How to Replace the Fuse.........................................................................................24-2

24.3 Trackball Maintenance .............................................................................................24-3

24.4 How to Clean the Filter in the Processor Unit ..........................................................24-3

24.5 Troubleshooting .......................................................................................................24-4

24.6 Consumable Parts.................................................................................................... 24-5

24.7 Color Differentiation Test for S57 Charts .................................................................24-6

25. ALERT MANAGEMENT SYSTEM (option) ....................................................... 25-1

25.1 What is an Alert Management System (AMS)?........................................................ 25-1

25.2 System Configuration...............................................................................................25-1

25.3 Alert Definition, Priority and Category of Alerts........................................................25-1

25.4 Alert Category and Alert acknowledgement From Connected Equipment, AMS .....25-3

25.5 How to Acknowledge an Alert, Stop the Buzzer From the AMS ..............................25-3

25.6 About the ALR and ACK Sentences ........................................................................25-3

25.7 How an Alert is Transferred to the BNWAS .............................................................25-5

25.8 Change of Priority for Unacknowledged Warning ...................................................25-6

25.9 How to Temporarily Silence the Buzzer ...................................................................25-6

25.10Buzzer Patterns .......................................................................................................25-6

25.11Alert Priority, Alert State ..........................................................................................25-7

25.12Alert Icons................................................................................................................25-8

25.13AMS Mode Operations ............................................................................................25-9

25.13.1How to select the AMS mode.......................................................................25-9

25.13.2AMS mode windows................................................................................... 25-10

26. AUTOPILOT OPERATIONS ............................................................................... 26-1

26.1 Configuration............................................................................................................26-1

26.2 Controls....................................................................................................................26-2

26.2.1 EMRI FAP-2000 ...........................................................................................26-2

26.2.2 EMRI FAP-3000 ...........................................................................................26-4

26.2.3 TOKYO KEIKI PR-6000 ...............................................................................26-5

26.2.4 YOKOGAWA PT-500A.................................................................................26-9

x

Page 13

TABLE OF CONTENTS

26.3 Steering Modes ..................................................................................................... 26-10

26.3.1 EMRI FAP-2000, FAP-3000 ...................................................................... 26-10

26.3.2 TOKYO KEIKI PR-6000, YOKOGAWA PT-500A ...................................... 26-11

26.3.3 Summary of steering modes...................................................................... 26-13

26.4 Autopilot Functions at the ECDIS .......................................................................... 26-14

26.5 How to Select the ECDIS to Control the Autopilot................................................. 26-15

26.6 How to Activate, Deactivate the Track Control System (TCS) from the ECDIS .... 26-16

26.6.1 How to activate the TCS............................................................................ 26-16

26.6.2 How to deactivate the TCS........................................................................ 26-16

26.7 Route Steering Related Indications, Alerts and Messages Generated by ECDIS 26-17

26.7.1 Route steering related information in Route Information box .................... 26-17

26.7.2 Alerts and messages when precondition for route steering are

not complete.............................................................................................. 26-18

26.7.3 Alerts given when approaching a waypoint ............................................... 26-20

26.7.4 Other route steering indications and alerts................................................ 26-22

26.8 Route Steering Operations .................................................................................... 26-23

26.8.1 How to stop or change a pre-enabled turn in route steering ..................... 26-23

26.8.2 Collision avoidance maneuver in route steering........................................ 26-24

26.9 Steering Performance............................................................................................ 26-24

26.9.1 Expected steering performance for going ahead....................................... 26-24

26.9.2 Expected steering performance for turns .................................................. 26-25

26.9.3 Expected steering performance under critical failure ................................ 26-26

APPENDIX 1 MENU TREE .......................................................................................AP-1

APPENDIX 2 ABBREVIATIONS, SYMBOLS...........................................................AP-5

APPENDIX 3 DIGITAL INTERFACE ......................................................................AP-18

APPENDIX 4 DATA COLOR AND MEANING........................................................AP-31

APPENDIX 5 ALERT LIST ...................................................................................... AP-33

SPECIFICATIONS ..................................................................................................... SP-1

INDEX ......................................................................................................................... IN-1

xi

Page 14

FOREWORD

Congratulations on your choice of the FURUNO ECDIS (Electronic Chart Display and Information

System) FMD-3200, FMD-3200-BB, FMD-3300. We are confident you will see why the FURUNO

name has become synonymous with quality and reliability.

Since 1948, FURUNO Electric Company has enjoyed an enviable reputation for innovative and

dependable marine electronics equipment. This dedication to excellence is furthered by our extensive global network of agents and dealers.

This equipment is designed and constructed to meet the rigorous demands of the marine environment. However, no machine can perform its intended function unless installed, operated and

maintained properly. Please carefully read and follow the recommended procedures for operation

and maintenance.

Features

The FMD-3000 series ECDIS is the product of FURUNO’s extensive experience in computer technology and marine electronics. The ECDIS displays electronic charts, nav lines, TT data, AIS targets and other navigation data on a high-resolution 19-inch (FMD-3200) or 23.1-inch display

(FMD-3300). The FMD-3200-BB is supplied without a monitor, permitting use of the commercial

monitor of your choice.

The main features of this ECDIS series are

• Complies with IMO MSC.232(82), IMO A.694(17), IEC 61174 Ed. 3, IEC 61162-1 Ed. 4 2010-11,

IEC 61162-2 Ed. 1, IEC 62288, IEC 60945 Ed. 4.

• Continuous monitoring of ship’s position through multi-sensor Kalman filter processing using GPS,

DGPS, SDME.

• Route planning and route monitoring facilities.

• Radar image can be overlaid on electronic charts. (Requires FURUNO FAR-2xx7 or FCR-2xx9 series radar.)

• Grounding warnings, safe depth contours.

• Chart database loaded and updated using DVD ROMs or CD ROMs.

• Target data from TT (Tracked Target) and AIS transponder to aid in collision avoidance.

Standards Used in this Manual

• The keys and controls of the ECDIS Control Unit RCU-024 are shown in bold face; for example,

the ENTER key.

• The buttons on the InstantAccess bar and Status bar and menu items are shown in brackets; for

example, the [PLAN] button.

• Context-sensitive menus are available with many buttons and boxes and objects within the display

area. Right-click those items to display the related context-sensitive menu.

• Unless noted otherwise, "click" means to push the left button on a trackball module (in order to do

a function).

• There are two types of Control Units: ECDIS Control Unit RCU-024 (alphabet keyboard, controls,

trackball module) and Trackball Control Unit RCU-026 (trackball module only). Unless noted otherwise, "Control Unit" refers to the RCU-024.

• "Keyboard" refers to the alphabet keyboard of the ECDIS Control Unit RCU-024.

• The system can be operated with the controls of the ECDIS Control Unit or a trackball module. The

descriptions in this manual use the trackball module.

• The color mentioned in this manual are the default colors. Your colors may vary.

xii

Page 15

Program No.

ECDIS: 2450074-01.xx, Conning: 2450079-01.xx (xx is version no.)

Data protection scheme

FOREWORD

Product

FMD-3xx0 01.xx IEC 61174

Software

Version

Testing

Std.

Ed.3

Elec. Nav.

Chart (ENC)

S-57 Ed. 3.1,

S-57 Ed.

3.1.1, and S57 Maint.

Doc. (Cumulative) No. 8

Raster

Nav. Chart

(RNC)

S-61 Ed.1.0 S-52 PresLib

ECDIS

Presentation

Library

Ed.3.4

Data

Protection

Scheme

S-63

Ed.1.1.1

Virus Prevention

The ECDIS is not equipped with a virus checker. The ECDIS operates in real time; therefore, having a virus checker that periodically checks the equipment for viruses would increase the processing load, which can affect operation. However, you can avoid viruses by following the instructions

in this section.

When you update a chart

The PC and medium (USB flash memory, etc.) used to download and store an update for an existing chart or a new chart may be infected with a virus. Check the PC and the medium for viruses

with a commercial virus checker - BEFORE you connect them to the ECDIS. Be sure the virus

checker contains the latest virus definition files.

Network connection

The ECDIS receives and displays information from various navigation equipment and radar via a

LAN. A PC and other equipment connected to a network can carry viruses. To prevent the introduction of a virus to the LAN, DO NOT connect the ECDIS or HUB to an external network, including other shipboard LAN.

Do not install 3rd party programs in the ECDIS

Do not install any 3rd party software.

Open source software

This product includes software to be licensed under the GNU General Public License (GPL), GNU

Lesser General Public License (LGPL), BSD, Apache, MIT and others. The program(s) is/are free

software(s), and you can copy it and/or redistribute it and/or modify it under the terms of the GPL

or LGPL as published by the Free Software Foundation. Please access to the following URL if you

need source codes: https://www.furuno.co.jp/cgi/cnt_oss_e01.cgi.

This product uses the software module that was developed by the Independent JPEG Group.

Reverse engineering

Reverse engineering (reverse assemble, reverse compiler) of the software of this equipment is

strictly prohibited.

xiii

Page 16

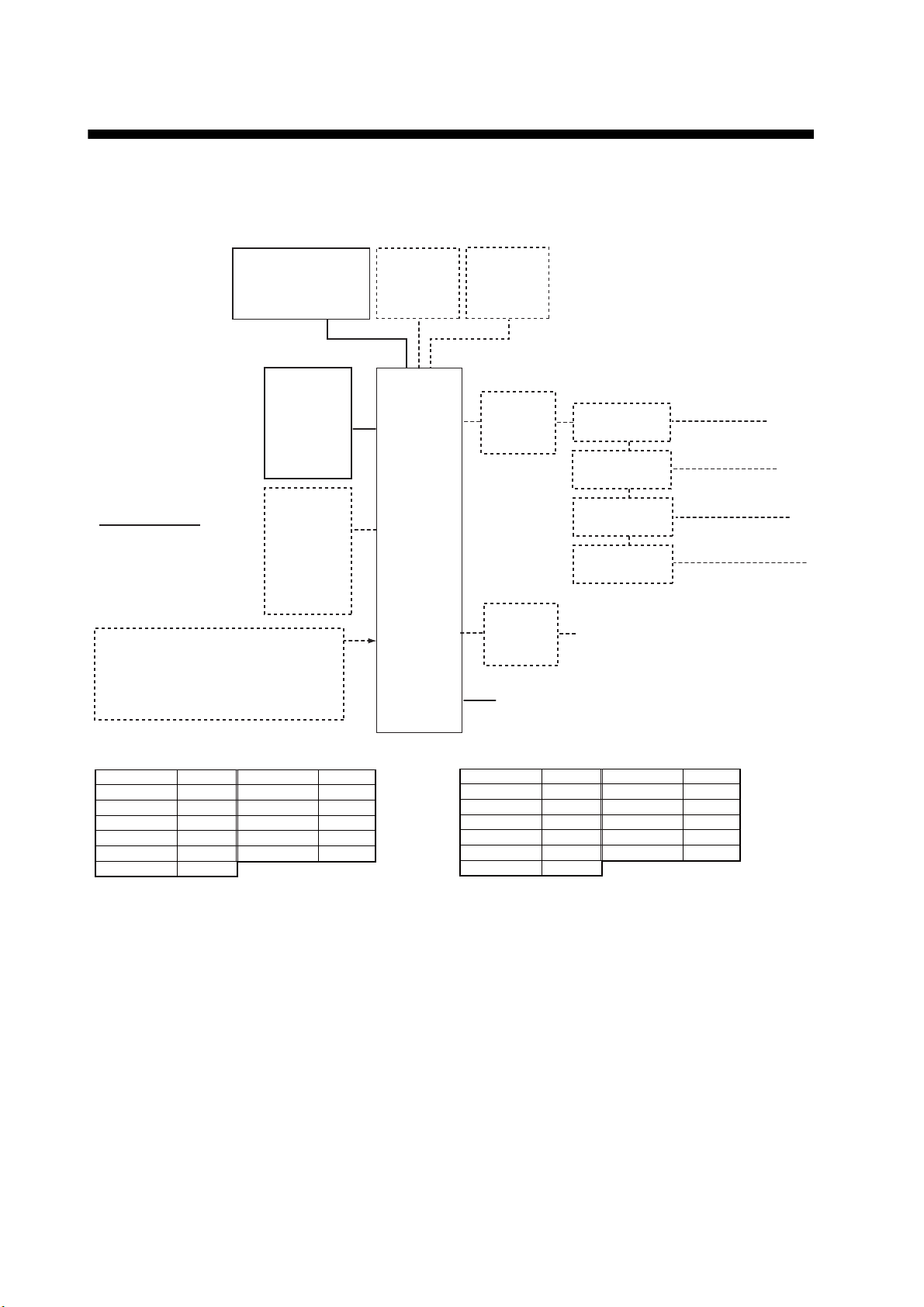

SYSTEM CONFIGURATION

Single workstation

Main Monitor Sub Monitor

Monitor Unit

MU-190

MU-231

HD26T21-MMD-MA4-FAGA

Monitor Unit

MU-190

MU-231

ECDIS

Control Unit

RCU-024

or

Trackball

Control Unit

RCU-026

ECDIS

Category of units

All units protected

from the weather.

Dashed lines indicate

optional or local supply

equipment.

Control Unit

RCU-024

or

Trackball

Control Unit

RCU-026

(Max. 2)

EC-3000

PROCESSOR

IF Signal:

- Serial Interface x2 (IEC 61162-1/2)

- Serial Interface x6 (IEC 61162-1)

- Digital Out x6

(power fail/system fail/ NO x2, NC x2)

- Digital In (ack in)

Note: The following monitors are

available with the FMD-3200-BB:

Model Maker Model Maker

MU-190 FURUNO JH23T12FUD Hatteland

MU-231 FURUNO JH23T14FUD Hatteland

MU-201CE FURUNO HD24T21MMD Hatteland

MU-231CE FURUNO JH26T11MMD Hatteland

JH19T14FUD Hatteland HD26T21MMD Hatteland

JH20T17FUD Hatteland

For information about a Hatteland monitor, see its

Operator’s Manual.

UNIT

Conning

Monitor

Monitor Unit

MU-190

MU-231

Switching

Hub

HUB-100

Sensor Adapter

MC-3000S

Sensor Adapter

Serial interface

Analog interface

MC-3010A

Sensor Adapter

Digital IN interface

MC-3020D

Sensor Adapter

Digital OUT interface

MC-3030D

Intelligent

Hub

HUB-3000

Gateway network equipment

(radar, ECDIS, etc.)

100-115/

220-230 VAC,

1ø, 50/60 Hz

Monitor viewing distance (m):

Model

MU-190 1.0138 JH23T12FUD 1.0138

MU-231 1.0138 JH23T14FUD 1.0138

MU-201CE 1.0759 HD24T21MMD 0.9517

MU-231CE 1.0138 JH26T11MMD 0.9879

JH19T14FUD 1.0138 HD26T21MMD 0.9879

JH20T17FUD 0.8793

Viewing Dist.

Model

Viewing Dist.

xiv

Page 17

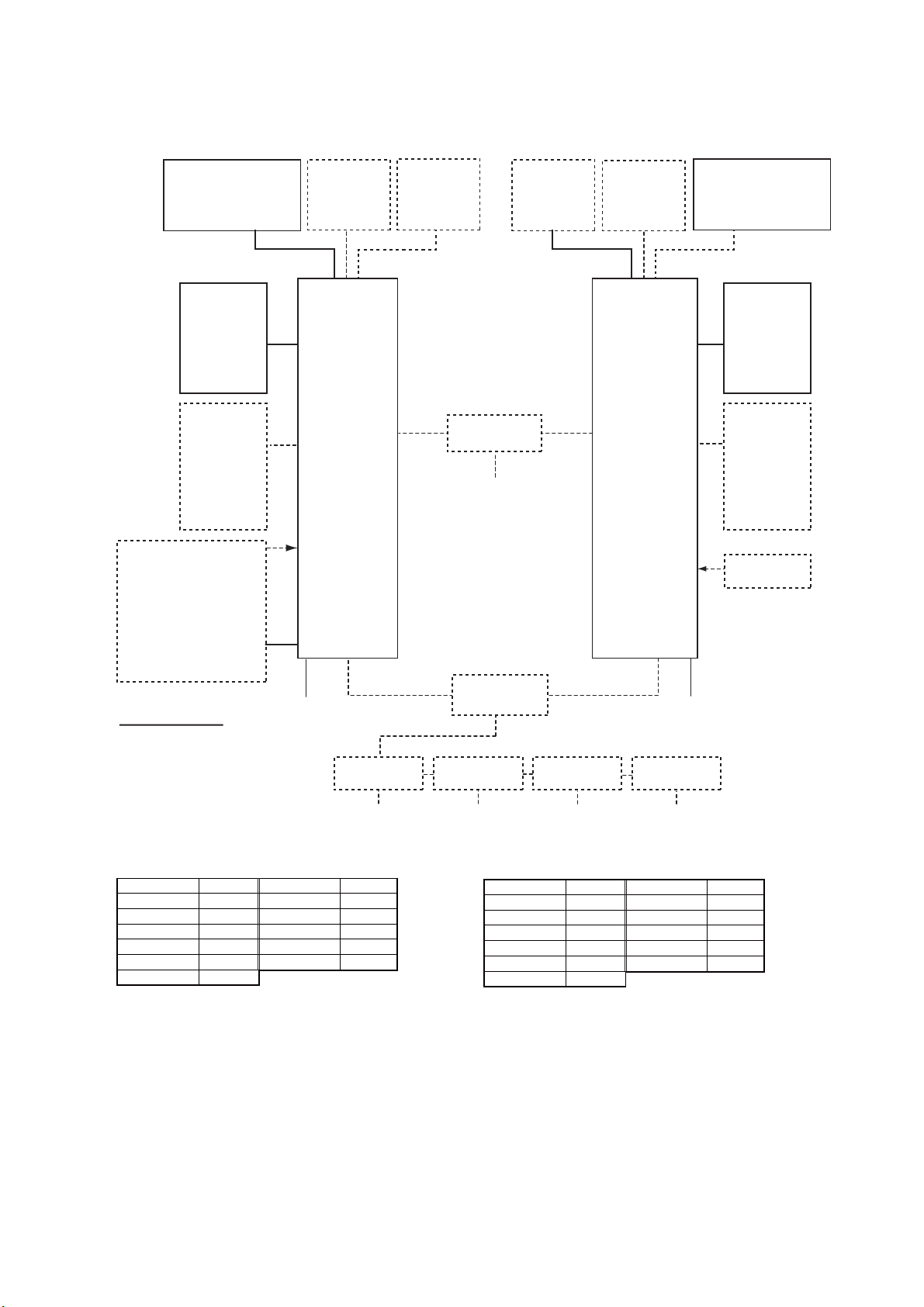

Multiple workstation

SYSTEM CONFIGURATION

Main Monitor Sub Monitor

Monitor Unit

MU-190

MU-231

HD26T21-MMD-MA4-FAGA

Monitor Unit

MU-190

MU-231

Conning

Monitor

Monitor Unit

MU-190

MU-231

ECDIS

Control Unit

RCU-024

or

Trackball

Control Unit

RCU-026

ECDIS

Control Unit

RCU-024

or

Trackball

Control Unit

RCU-026

EC-3000

PROCESSOR

UNIT

(Max. 2)

IF Signal:

- Serial Interface x2

(IEC 61162-1/2)

- Serial Interface x6

(IEC 61162-1)

- Digital Out x6

(power fail/system fail/

NO x2, NC x2)

- Digital In (ack in)

100-115/

220-230 VAC,

1ø, 50/60 Hz

Category of units

All units protected

from the weather.

Dashed lines indicate

optional or local supply

100-115/

220-230 VAC,

1ø, 50/60 Hz

Sensor Adapter

MC-3000S

equipment.

Serial

interface

Note: The following monitors are

available with the FMD-3200-BB:

Model Maker Model Maker

MU-190 FURUNO JH23T12FUD Hatteland

MU-231 FURUNO JH23T14FUD Hatteland

MU-201CE FURUNO HD24T21MMD Hatteland

MU-231CE FURUNO JH26T11MMD Hatteland

JH19T14FUD Hatteland HD26T21MMD Hatteland

JH20T17FUD Hatteland

For information about a Hatteland monitor, see its

Operator’s Manual.

Conning

Monitor

Monitor Unit

Intelligent Hub

HUB-3000

Gateway network

equipment

(radar, ECDIS, etc.)

Switching Hub

HUB-100

Sensor Adapter

MC-3010A

Analog

interface

* Monitor viewing distance (m):

Model

MU-190 1.0138 JH23T12FUD 1.0138

MU-231 1.0138 JH23T14FUD 1.0138

MU-201CE 1.0759 HD24T21MMD 0.9517

MU-231CE 1.0138 JH26T11MMD 0.9879

JH19T14FUD 1.0138 HD26T21MMD 0.9879

JH20T17FUD 0.8793

Main Monitor

Monitor Unit

MU-190

MU-231

HD26T21-MMD-MA4-FAGA

MU-190

MU-231

Sub Monitor

Monitor Unit

MU-190

MU-231

ECDIS

Control Unit

RCU-024

or

Trackball

Control Unit

RCU-026

ECDIS

Control Unit

RCU-024

EC-3000

PROCESSOR

UNIT

or

Trackball

Control Unit

RCU-026

(Max. 2)

IF Signal:

(Same as left.)

100-115/

220-230 VAC,

1ø, 50/60 Hz

Sensor Adapter

MC-3020D

Digital IN

interface

Viewing Dist.

Sensor Adapter

MC-3030D

Digital OUT

interface

Model

Viewing Dist.

xv

Page 18

SYSTEM CONFIGURATION

This page is intentionally left blank.

xvi

Page 19

1. INTRODUCTION

1.1 System Configuration

This ECDIS series is comprised of the components shown in the illustration on the

System Configuration page.

The Processor Unit is connected to various sensors, and performs navigation calculations, route planning and route monitoring. The Sensor Adapters interface between

the Processor Unit and external equipment.

The operator controls the ECDIS with the ECDIS Control Unit RCU-024 or the Trackball Control Unit RCU-026. Both units are equipped with a trackball module (trackball,

right and left mouse buttons and a scrollwheel). The RCU-024 is additionally equipped

with an alphabet keyboard. All functions of the ECDIS can be accessed from the trackball module.

1.2 Processor Unit EC-3000

The Processor Unit is the heart of the ECDIS system, and is mainly responsible for the

chart management, route planning and route navigation.

The Processor Unit has two power switches. The Mains switch controls the power

from the switchboard, and the Power switch controls the power to the ECDIS system.

DVD

drive

Mains switch

Note 1: Do not operate the system with a medium inserted in the DVD drive when its

use is not required, to prevent damage to the drive and medium. After use of a medium

is completed, remove the medium from the drive and store it in its case.

Power switch

Note 2: To keep the system stable, restart the unit at least once every two weeks.

Note 3: Close the lid of the DVD drive when the drive is not in use.

Note 4: The DVD ROM provided with this equipment contains the ECDIS program.

Store the DVD in a place where the temperature and humidity are moderate. The recommended storage temperature is -10°C(50°F) to 40°C(104°F).

1-1

Page 20

1. INTRODUCTION

1.3 How to Turn the Power On/Off

Normally, leave the power switches at the front of the Processor Unit on and control

the power with the power key on a Control Unit (RCU-024, RCU-026). The Monitor

Unit is powered independently.

How to power the system

Push the Mains switch on the Processor Unit for the "I" position. Turn on the power

switch on the Processor Unit or the power key on the Control Unit. The start-up display

appears on the monitor.

Note: If the ambient temperature is less than 0°C (32°F) when the power is applied,

nothing appears on the display. This is because the heater is warming the Processor

Unit. The display appears after the Processor Unit becomes warm, in approx. two minutes.

How to power off the system

Press the power switch on the Processor Unit or the power key on the Control Unit.

Then, push the Mains switch for the "O" position.

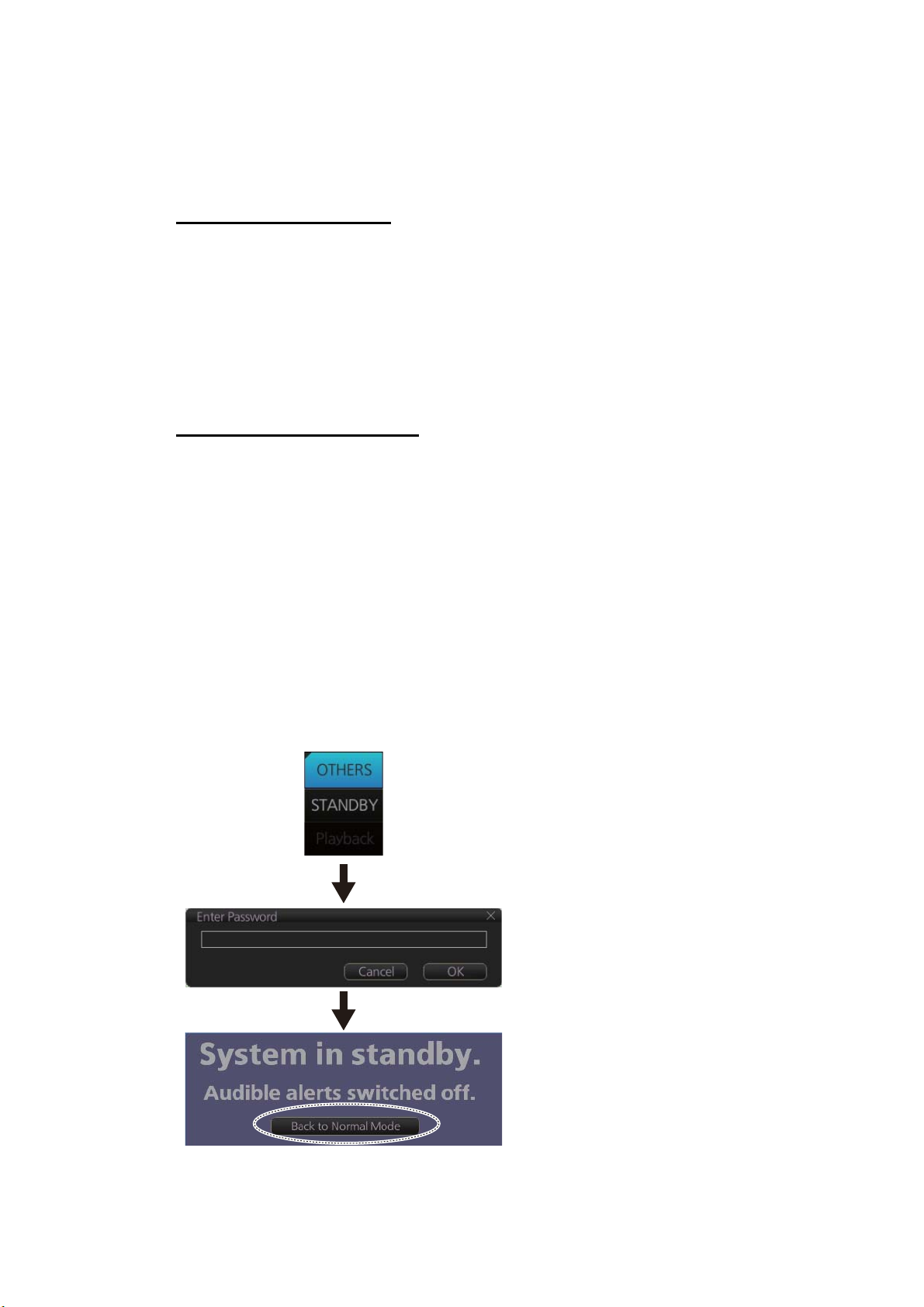

1.4 The Standby Mode

The standby mode, which requires a password to activate, deactivates the audio

alarms from the ECDIS. Use this mode when the ECDIS is not required, like in a harbor.

To go to the standby mode, first click the [OTHERS] button on the Status bar then click

[STANDBY]. Have the holder of the password enter the password then click the [OK]

button.

Click OTHERS,

STANDBY.

Playback

Enter password;

click OK button.

1-2

Click to return to normal operation.

To return to normal operation, click [Back to Normal Mode].

Page 21

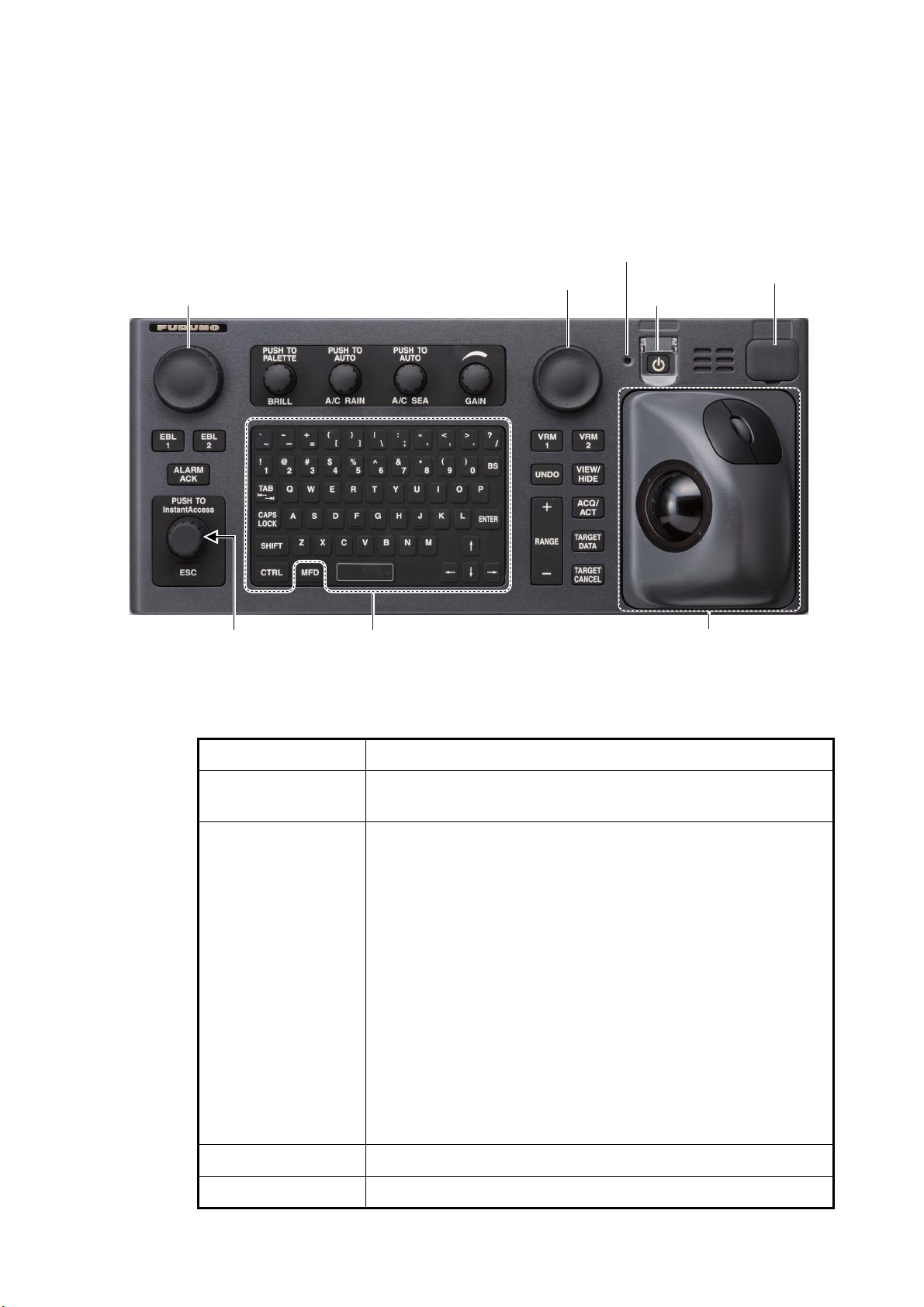

1.5 ECDIS Control Unit RCU-024

The RCU-024 consists of controls, keys, alphabet keyboard and trackball module

(trackball, scrollwheel and left and right mouse buttons). The trackball module functions like a PC mouse. The operator rolls the trackball and operates the left and right

mouse buttons and the scrollwheel to do various functions.

Rotary encoder

for EBL

Rotary encoder

for VRM

1. INTRODUCTION

Status LED

USB port

POWER key

InstantAccess

knob

Keyboard

1.5.1 Control description

Key Description

POWER key Turns the system on or off. (With a FURUNO or Hatteland mon-

itor unit, the monitor is also turned on or off with this key.)

Status LED The color and state of the LED change according to system or

alert status.

Green, lighting: Normal operation status; no alerts generated.

Red, lighting: Acknowledged alert (but not rectified) or SYS-

TEM FAIL. SYSTEM FAIL occurs when there is trouble in the

Processor Unit or communication failure between the Processor

Unit and an ECDIS Control Unit. Each Control Unit detects trouble and its lamp flashes in red and the buzzer sounds. If this

condition occurs at the No. 1 ECDIS Control Unit, the SYSTEM

FAIL signal is output.

Red, flashing rapidly: Alert not acknowledged nor rectified.

Red, flashing slowly: Alert not acknowledged but rectified.

OFF: The heater on the CPU board is on, because the ambient

temperature is not at least 0°C. The heater takes about two minutes to warm the equipment. The LED lights green after the

heater goes off.

Trackball module

EBL rotary encoder Adjusts active EBL.

EBL 1 Activates or deactivates EBL 1.

1-3

Page 22

1. INTRODUCTION

EBL 2 Activates or deactivates EBL 2.

ALARM ACK Alert acknowledgement for alerts generated by chart, naviga-

Key Description

tion, etc.

InstantAccess knob,

ESC key

BRILL Rotate: Adjusts the brilliance of a FURUNO or Hatteland moni-

A/C RAIN No use.

A/C SEA No use.

GAIN No use.

Alphabet keyboard Enter alphanumeric data. The CTRL key has no function.

VRM rotary encoder Adjusts active VRM.

MFD Switches between the ECDIS and CONNING modes.

VRM 1 Activates or deactivates VRM1.

VRM 2 Activates or deactivates VRM2.

UNDO Undo the last operation, when creating a route or user chart.

Selects and processes the functions on the InstantAccess bar.

Rotate: Selects item.

Push: Confirms selection.

ESC key: Goes back one step in the current operating se-

quence on the InstantAccess bar.

tor.

Push: Selects a color palette.

VIEW/HIDE Shows or hides the Instant Access bar, [Route Information] box,

VRMs, EBLs, [Overlay/NAV Tools] box.

RANGE Selects the display scale.

ACQ/ACT Activates cursor-selected sleeping AIS target.

TARGET DATA Displays detailed target data for selected TT, AIS target.

TARGET CANCEL Sleeps cursor-selected activated AIS target.

USB port For connection of USB flash memory (FAT16 or FAT32 format

only). Do not connect a USB HDD or PC keyboard. The DVD

drive (Maker: TEAC, Type: PU-DRV10) is for chart updates.

Trackball module See the description in section 1.6.

1-4

Page 23

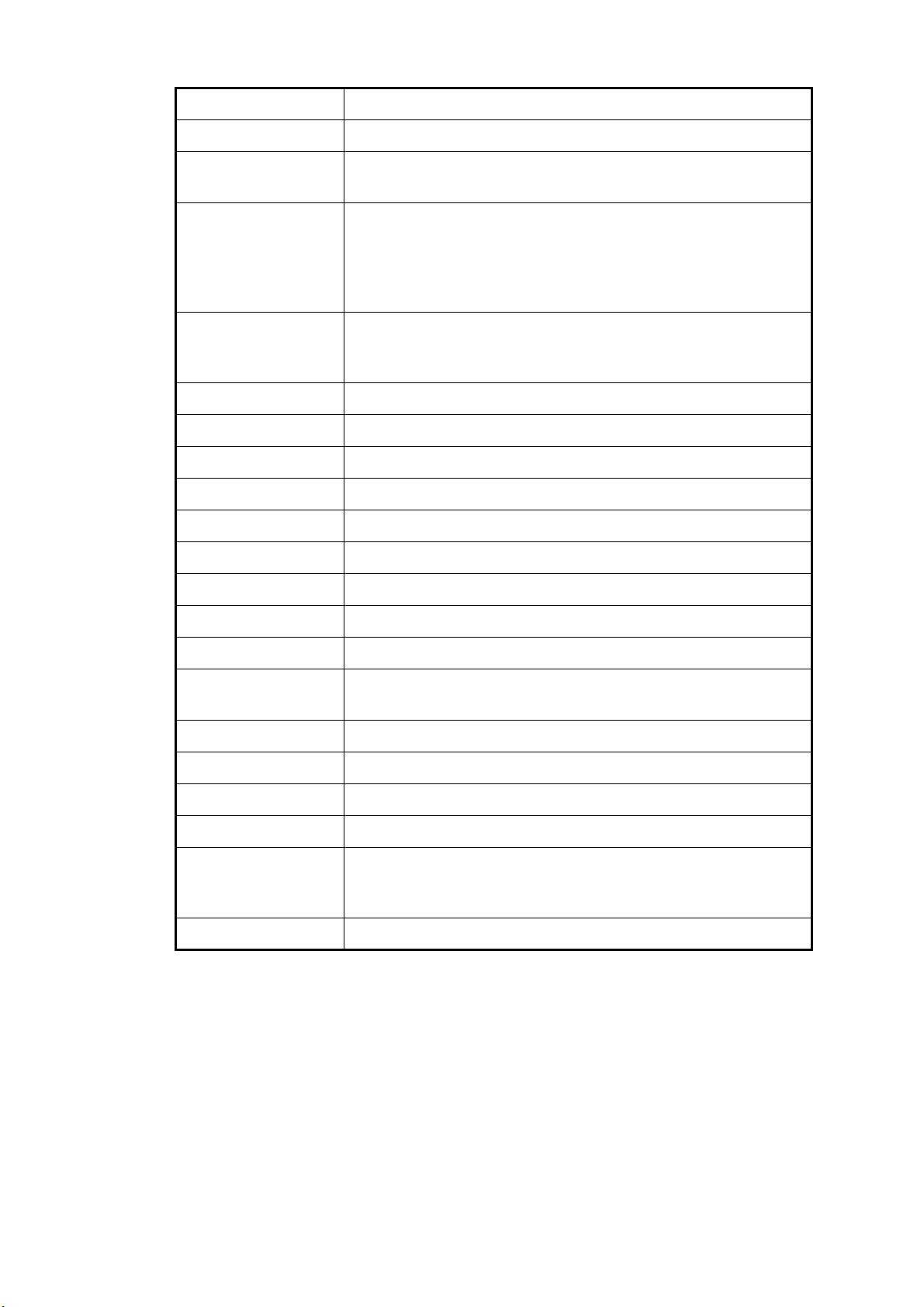

1.6 Trackball Control Unit RCU-026

The RCU-026 has a power key, a trackball module (trackball, scrollwheel and left and

right mouse buttons), a status LED, and a USB port. The trackball module functions

like a PC mouse; the user rolls the trackball and operates the left and right buttons and

the scrollwheel to do various functions.

1. INTRODUCTION

Status

LED

Trackball

Power

key

Left

button

Scrollwheel

USB port

Right

button

Control Description

Power key Turns the system on or off. (With a FURUNO or Hatteland monitor unit, the mon-

itor is also turned on/off with this key.)

Status

LED

Left

button

Scrollwheel • Select options.

Right

button

Trackball • Moves the cursor.

USB port For connection of USB flash memory (FAT16 or FAT32 format). Do not connect a

The color and state of the LED change according to system or alert status. See

the LED status description on page 1-3.

• Does the operation related to the object selected.

• Confirms the operation done for the object selected.

• Selects chart scale.

• Sets numeric data.

The scrollwheel does not have a “push” function.

• Displays context-sensitive menu when cursor is put in the display area.

• Cancels operation done on the object selected.

• Selects an object.

USB HDD or PC keyboard. The DVD drive (Maker: TEAC, Type: PU-DRV10) is

for chart updates.

1-5

Page 24

1. INTRODUCTION

1.7 How to Select a Color Palette

The system provides three sets of color and brilliance sets (palette), day, dusk and

night, to match any ambient lighting condition. The default specifications of each set

are as shown in the table below. The panel dimmer setting is automatically changed,

and the number of steps depends on the color palette selected.

Palette Brilliance

19”

display unit

Day-gray

Day-blue

Dusk-gray

Dusk-blue

Night-gray

Night-blue

110 cd/m

110 cd/m

50 cd/m

50 cd/m

5 cd/m

5 cd/m

2

2

2

2

2

2

To select a palette, do the following:

1. Click the [Palette] button.

[Palette]

button

23”

display unit

120 cd/m

120 cd/m

50 cd/m

50 cd/m

5 cd/m

5 cd/m

2

2

2

2

2

2

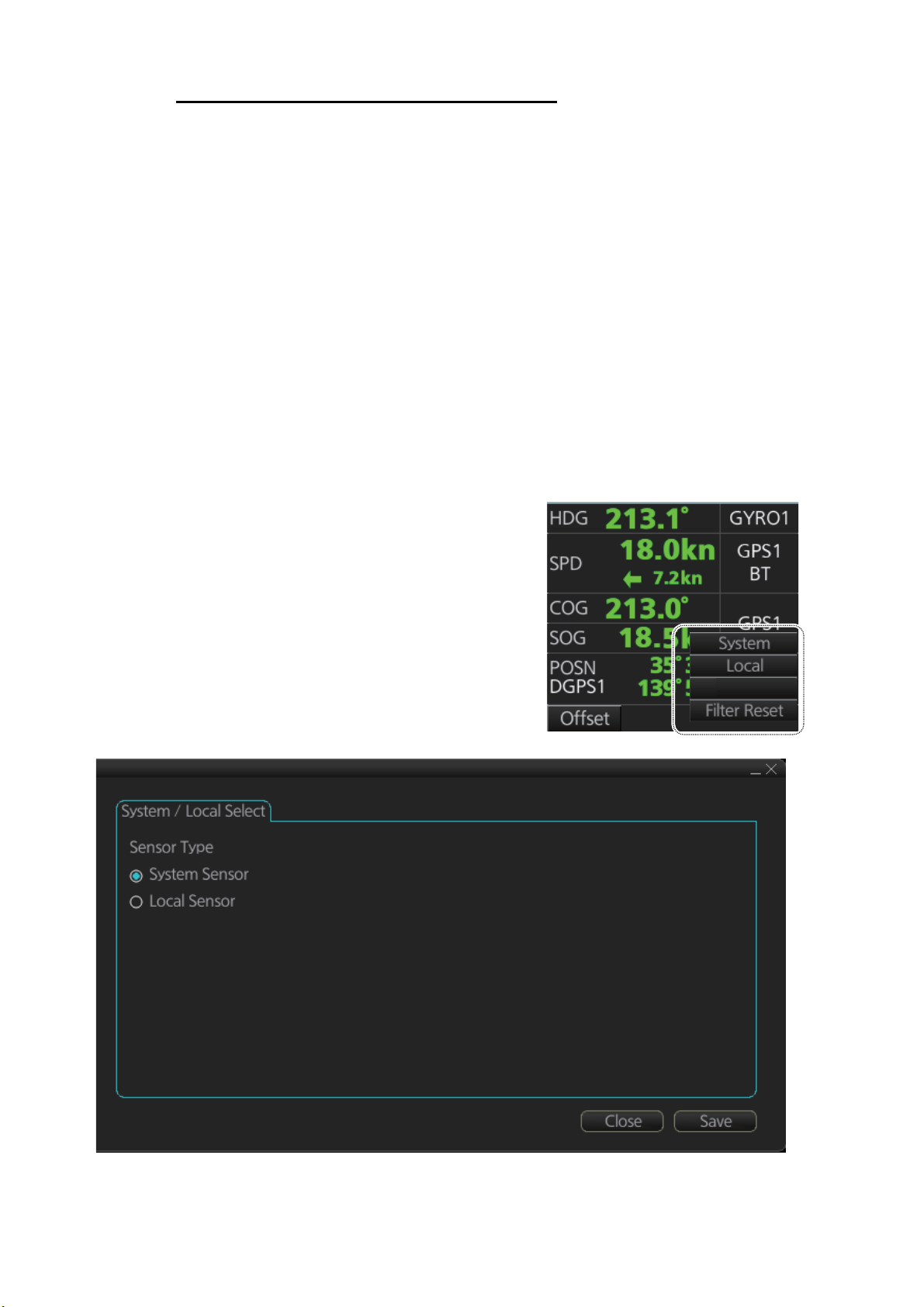

Panel dimmer

(step)

Text

color

15 White Gray

15 White Blue

7 Light gray Dark gray

7 Light gray Dark blue

3 Orange Dark gray

3 Light gray Dark blue

Background

color

2. Select [Day], [Dusk] or [Night] as appropriate. For example, select [Day] to show

its options.

3. Click the palette desired.

Note 1: A palette can also be selected by pushing the BRILL control on the Control

Unit.

Note 2: If the display cannot be seen when switching from a Night to Day palette, push

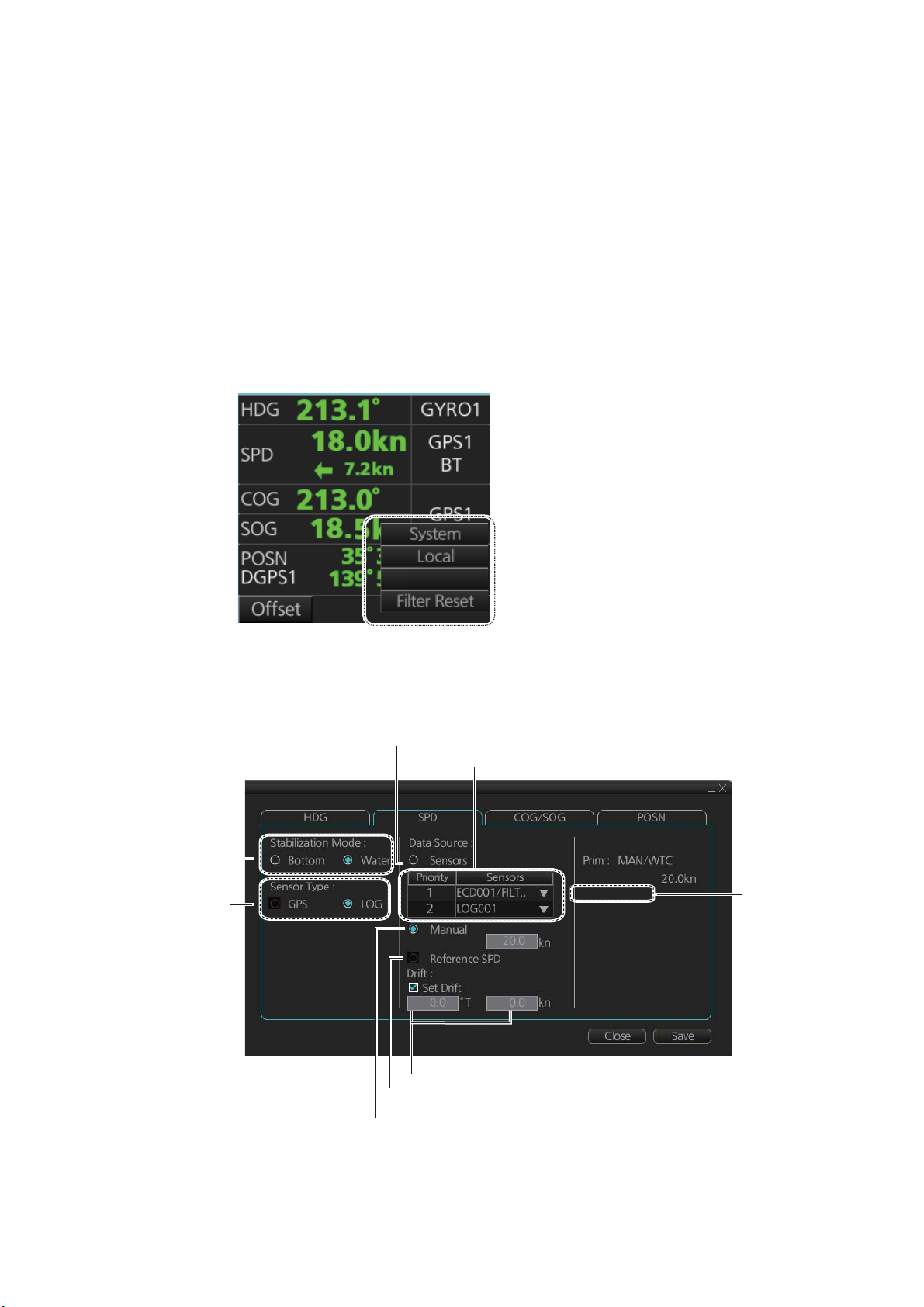

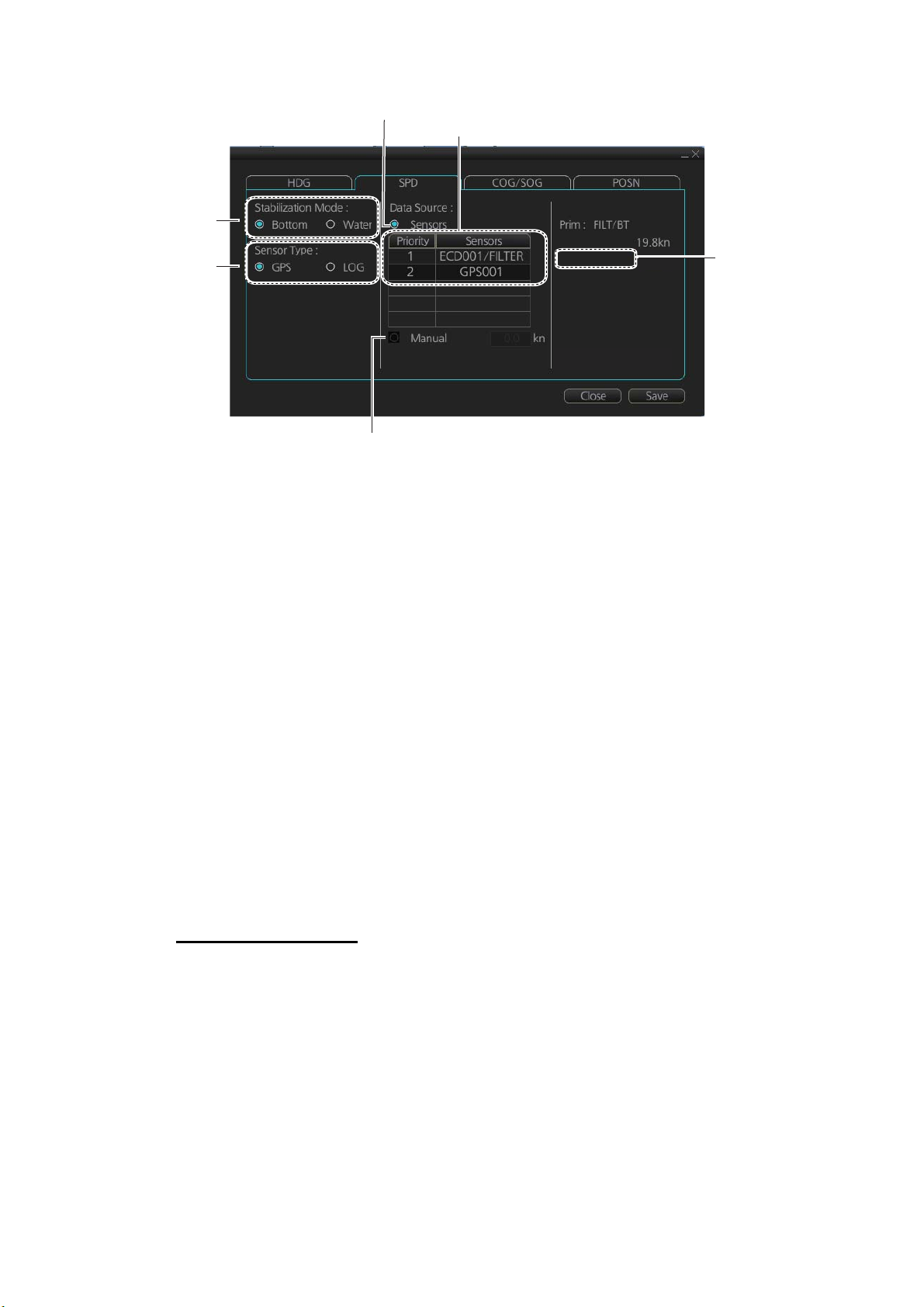

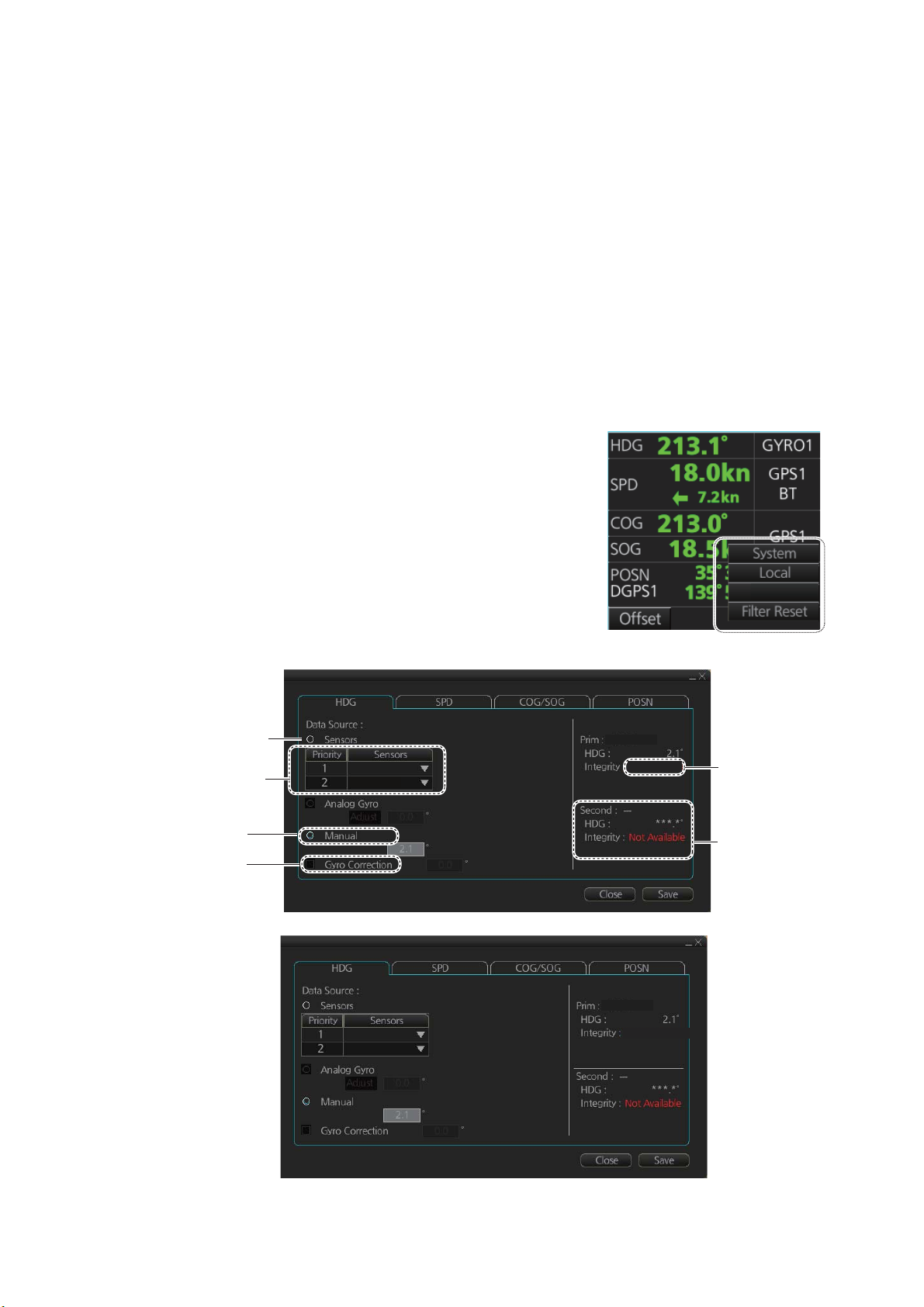

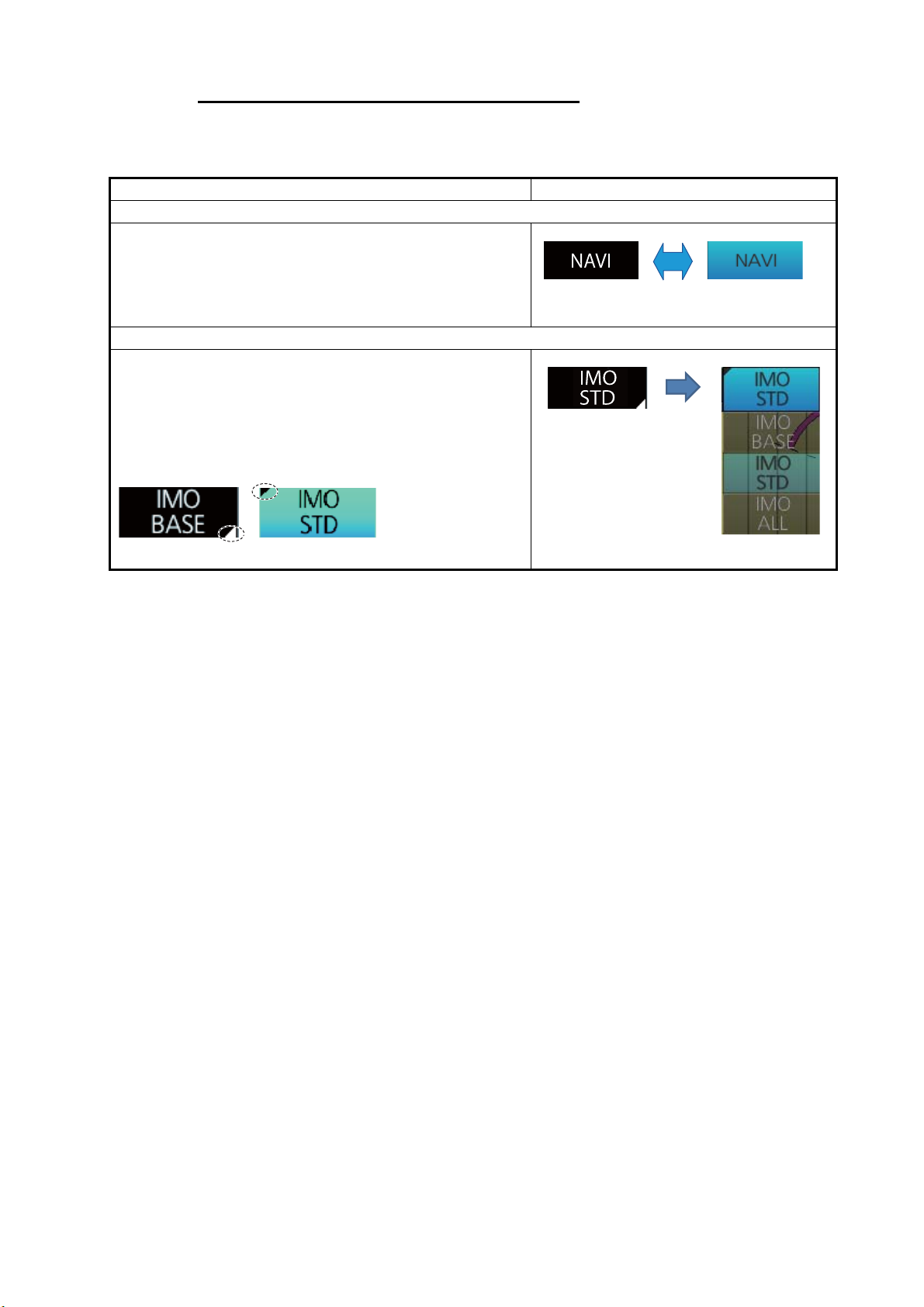

and hold the right button (approx. 2 seconds) to switch to the dusk-gray mode.