Fubag PG 950 T User manual

Мотопомпа для грязной воды

Trash water pump

PG 950 T

Operator'sManual |

Инструкцияпоэксплуатации |

www.fubag.ru

Operator's manual

www.fubag.ru

WARNING! BEFORE USING THE MACHINE READ THE INSTRUCTION MANUAL CAREFULLY!

Our pump FUBAG are designed to give safe anddependable service if operated according to instructions.

Read and understand the manual before operating the pump FUBAG. Failure to do so could result in personal injury or equipment damage.

1. General safety

WARNING!

WARNING!

Exhaust gas contains poisonous carbon monoxide.

Never run the pump in an enclosed area. Be sure to provide adequate ventilation. When installed in ventilated protection are to be observed.

The muffler becomes very hot during operation and remains hot for a while after stopping the engine.

Be careful not to touch the muffler while it is hot. Let the engine cool before storing the pump indoors. The engine exhaust system will be heated during operation and remain hot immediately after stopping the engine.

To prevent scalding, pay attention to the warning marks attached to the pump.

Gasoline is extremely flammable and explosive under certain conditions.

WARNING!

Refuel in a well ventilated area with the engine stopped.

Keep away from cigarette, smoke and sparks when refueling the pump. Always refuel in a well-ventilated location.

Wipe up spilled gasoline at once.

WARNING! |

Caution: The motor pump is supplied without oil. |

|

Before starting up the motor pump, always check the oil level. |

||

|

- 1 -

Operator's manual

www.fubag.ru

WARNING!

-Always make a pre-operation inspection before you start the engine. You may prevent an accident or equipment damage.

-Know how to stop the pump quickly and understand operation of all the controls. Never permit anyone to operate the pump without proper instructions.

-Keep children and pets away from the pump when it is in operation.

-Failure to carry out measurements and checks for early detection of defects.

-The rated speed of the motor has been set during manufacture and may not be changed.

-No naked flames, lights or spark-emitting appliances may be used within the hazard area of the pump.

-Smoking within the hazard area of the pump is strictly forbidden.

-The pump may only be transported when cold.

-The pump may only be lifted using the carry handles intended for this purpose.

-The appliance may not be covered. The air intake may not be blocked or obstructed.

-All other servicing and repair work may only be carried out by personnel who are qualified and licensed for this purpose.

-Always remove spark plug connector prior to commencing servicing and repair work.

-The service intervals set out in these instructions must be observed.

-The pump must be shut down when not required for periods longer than 30 days.

-The pump must be stored in a dry enclosed room.

- 2 -

Operator's manual

www.fubag.ru

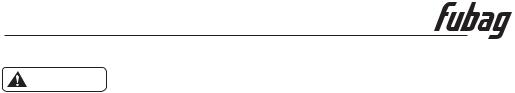

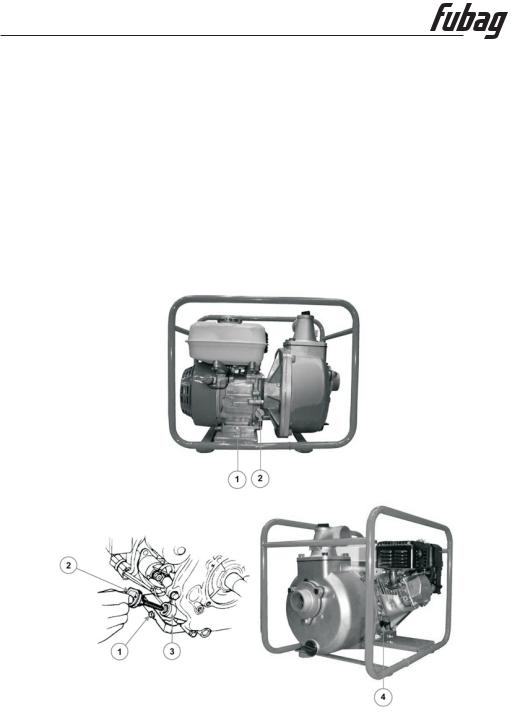

2. Description

START

CHOKE

ON

OFF

1.Fuel tank plug

2.Pump filler cap

3.Choke

4.Motor contactor

5.Throttle lever

6.Fuel tap

7.Recoil starter

8.Pump drain plug

9.Air filter

10.Spark plug

11.Exhaust silencer

- 3 -

Operator's manual

www.fubag.ru

3. Specifications

МODEL |

PG 950 T |

Engine type |

F170 |

Suction diameter, mm |

80 |

Discharge diameter, mm |

80 |

Max. flow rate, L/min |

1300 |

Max. elevation head, m |

26 |

Max. suction head, m |

8 |

Type of liquid |

Trash water |

Particle size of the liquid pumped, mm |

30 |

Fuel tank capacity, L |

3,6 |

Recommended fuel |

Unleaded petrol |

Recommended oil |

SAE 10W30 |

Liquid temperature, ОC |

0 ~ +60 |

Ambient temperature, ОC |

-40 ~ +40 |

Relative humidity (at 40ОС), % |

50 |

Relative humidity (at 20ОС), % |

90 |

Dimensions L х W х H, mm |

562 455 4 72 |

Weight, kg |

43 |

The manufacturer reserves himself the right to make the manual's content or pump function change without any preliminary notification of the users.

4. Preparation before use

Positioning for operation

Place the motor pump on a sufficiently strong, flat and horizontal surface so that the electric pump cannot sink in (the inclination must not exceed 10° in any direction).

Select a clean location, ventilated and protected from inclement weather, and provide an oil and fuel supply close to the place of motor pump usage, while still maintaining a safe distance.

Select a location which will not impede the movement of people or vehicles.

Make sure that the motor pump remains stable and immobile while in operation. Don't forget that the suction hose tends to pull the motor pump towards the water source during pumping.

Place the motor pump as close as possible to the liquid being drawn-in. The shorter the vertical distance between the motor pump and the liquid surface, the more rapid the priming and the greater the volume of liquid pumped.

Submerge the strainer completely within the liquid, taking care that it is not blocked.

- 4 -

Operator's manual

www.fubag.ru

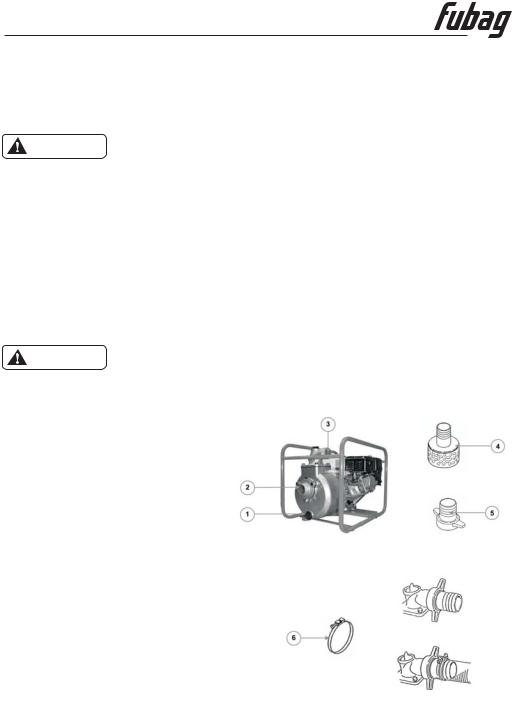

Oil level

1.Remove the filler plug-dipstick (no. 2) by unscrewing it, and wipe the dipstick.

2.Insert the dipstick into the filler neck (no. 3) without screwing it. N.B.: A second black plug (no. 4) without a dipstick, is available if necessary on the other side of the engine.

3.Visually check the level and top up if necessary.

4.Tighten the filler plug-dipstick (no. 2) completely onto the filler neck (no. 3).

5.Check that there are no leaks.

6.Wipe off excess oil with a clean cloth.

- 5 -

Operator's manual

www.fubag.ru

Fuel level

WARNING!

Only use clean fuel without any water. Do not overfill the tank (there should not be any fuel in the filler neck).

After filling, always check that the plug is fitted properly on the tank. If fuel has been spilled, make sure that it has dried and that the fumes are dissipated before starting the motor pump set.

Visually check the fuel level. Top up if necessary:

1.Close the fuel tap.

2.Remove the fuel tank plug.

3.Fill the fuel tank with a funnel, taking care not to spill any fuel.

4.Tighten the plug on the tank.

5.Open the fuel tap.

Assembly of pipings

Never use the motor pump without the appropriate strainer (risk of pump

deterioration).

WARNING! Always ensure that the sealing joints of the couplings are firmly in place (risk of poor suction of the liquid).

1.Pass the pipe fixing clamps (no. 6) around the suction & discharge hoses.

2.Mount the hose couplings (no. 5) on the suction (no. 2) & discharge of the pump (no. 3).

3.Fix the suction & discharge hoses on their respective couplings using the pipe fixing clamps.

4.Place one of the pipe fixing clamps around the other end of the suction hose.

5.Attach the strainer (no. 4) at the end of the suction hose.

6.Fix the strainer with a pipe fixing clamp.

- 6 -

Operator's manual

www.fubag.ru

5. Usage of the motor pump

Starting-up

Always top up the pump housing before starting the engine.

WARNING! Presence of liquid is necessary to prime & lubricate a pump (risk of deterioration).

1.Fully immerse the strainer in the liquid to be drawn-in. If there is a risk of blockage, place the strainer on a rock bed.

2.Unscrew the pump filler plug.

3.Top up the pump housing with water.

4.Screw the pump filler plug back on.

5.Move the choke knob into position  .

.

N.B: Do not use the starter when the engine is hot or when the atmospheric temperature is high.

6.Set the engine switch to “I” and activate the gas lever.

7.Slowly pull the recoil starter handle once until encountering resistance, allow it to return back gently.

8.Pull the recoil starter firmly & strongly until the engine starts.

9.Gently set the choke knob to  and wait for an engine temperature increase before releasing the gas lever.

and wait for an engine temperature increase before releasing the gas lever.

If the engine does not start, repeat the operation until the engine starts-up. If the pump does not discharge, stop the motor pump and check the suction circuit.

Operation

WARNING!

During the operation, don't allow any foreign bodies to block the suction or the discharge.

Don't block the discharge pipe: don't allow any vehicle to park on the pipe.

Never close a valve abruptly: water-hammer action can seriously damage the pump.

When the speed of the motor pump has stabilised (around 3 min), move the gas lever into position for the desired speed.

The motor pump discharges the liquid not only according to the speed but also the elevation height for suction & discharge, and the quality of liquid to be drawn-in.

- 7 -

Loading...

Loading...