Franklin Fueling Systems TS 550 Operators Guide

Fuel Management System

Operator’s Guide

TS-550 evo

Franklin Fueling Systems • 3760 Marsh Rd. • Madison, WI 53718 USA

Tel: +1 608 838 8786 • 800 225 9787 • Fax: +1 608 838 6433 • www.franklinfueling.com

Notice

Franklin Fueling Systems (FFS) reserves the right to change this document and specications at any time without notice.

FFS makes no expressed or implied warranty with regard to the contents of this manual. FFS assumes no liability for

errors or omissions, or for any damages, direct or consequential, that may result from the use of this document or the

equipment that it describes.

Trademarks

INCON®, TS-550 evo, Tank Sentinel®, System Sentinel®, SCALD®, Brite®, BriteBox®, BriteBus®, and BriteSensors® are

registered trademarks of Intelligent Controls. All brand and product names are trademarks or registered trademarks of

their respective companies.

Inspection of Materials

Visually inspect all components for defects or damage prior to installation. If any defect or damage is found, do not use the

product and contact FFS for further assistance.

Return Shipping Charges

FFS will not accept shipments of returned products without a Return Material Authorization (RMA) number. RMA’s are

obtained by contacting FFS’s Technical Service division — NO RMA’s will be given without the unit’s serial number(s).

Returned material remains the property of the buyer until replaced or repaired.

Contacting Franklin Fueling Systems (FFS)

Please feel free to contact us by mail at:

Franklin Fueling Systems

3760 Marsh Rd.

Madison, WI 53718 USA

Or contact us by phone, fax or e-mail:

Tel: 1 608 838 8786 E-mail: sales@franklinfueling.com

Fax:

1 608 838 6433 techserve@franklinfueling.com

Tel:

US & Canada 1 800 225 9787

Tel: México 001 800 738 7610

Tel: Europa +49 6571 105 380

Ofce Hours: 8am to 5pm CST - Monday through Friday

Technical Service Hours: 7am to 7pm CST - Monday through Friday

Please visit our web site at www.franklinfueling.com

No part of this publication may be reproduced in any form without the prior written consent of FFS. All rights reserved.

ii

Copyright ©2007 by Franklin Fueling Systems (FFS).

Contents

Important Safety Messages

Approvals ................................................................................................................................2

Related Documentation .......................................................................................................... 2

............................................................ 1

Introduction ...................................................................................... 3

Denitions and Acronyms .............................................................................................................. 3

Applications ............................................................................................................................4

System: ......................................................................................................................................... 4

Fuel Management System (FMS): ................................................................................................ 4

Secondary Containment Monitoring (SCM): ................................................................................. 4

Standard Sensors.......................................................................................................................... 4

BriteSensors™ ........................................................................................................................ 4

Modules ......................................................................................................................................... 4

Standard Modules ......................................................................................................................... 4

Optional Modules .......................................................................................................................... 5

User Interface ................................................................................................................................ 5

Alarms and Warnings .................................................................................................................... 5

Programming and Navigation ........................................................ 6

Console Navigation ................................................................................................................. 6

Navigation Buttons ........................................................................................................................ 6

Quick Jump Menu (QJM) .............................................................................................................. 6

User Role - Access Control .....................................................................................................7

System Identication ............................................................................................................... 7

Quick Jump Menu Selection Description ................................................................................ 8

Tank Inventory Summary Screen .................................................................................................. 8

Tank Inventory Detail Screen ........................................................................................................ 8

Line Status Summary Screen ....................................................................................................... 8

Line Status Detail Screen .............................................................................................................. 9

Sensor Status Summary Screen .................................................................................................. 9

Sensor Status Detail Screen ......................................................................................................... 9

Pump Status Summary Screen ................................................................................................... 10

Pump Status Detail Screen ......................................................................................................... 10

Report Generator Screen ............................................................................................................ 10

Compliance Screen ......................................................................................................................11

Tank Compliance Screen .............................................................................................................11

Alarm Summary Screen ...............................................................................................................11

Active Alarm Detail Screen ...........................................................................................................11

Utilities Screen ............................................................................................................................ 12

Conguration Menu ..................................................................................................................... 12

Secondary Containment Status Summary Screen ...................................................................... 13

Secondary Containment Detail Screen ....................................................................................... 13

Printing Reports .................................................................................................................... 14

Internal Printer ............................................................................................................................. 14

External Printers .......................................................................................................................... 14

Reports Options .......................................................................................................................... 14

Tank Testing ..................................................................................... 15

Why Test the Integrity of a Tank .................................................................................................. 15

Static Testing ............................................................................................................................... 15

Tank Testing Requirements ......................................................................................................... 16

Ideal Testing Conditions .............................................................................................................. 16

How to Manually Start Static Tests ....................................................................................... 16

Static Test Results ....................................................................................................................... 16

Statistical Continuous Automatic Leak Detection (SCALD) ................................................. 17

Why Continuously Test Tank Integrity ......................................................................................... 17

SCALD Testing Requirements ..................................................................................................... 17

When SCALD Tests ..................................................................................................................... 17

SCALD Results ........................................................................................................................... 17

Tank Leak Test Reports ........................................................................................................18

Printing Tank Leak Test Reports .................................................................................................. 18

iii

Line Leak Testing ............................................................................ 21

Overview ...............................................................................................................................21

Line Leak Testing Requirements ................................................................................................. 21

Test Cycles & Types .............................................................................................................. 22

How to Manually Start Line Leak Tests ................................................................................. 22

Line Test Results ......................................................................................................................... 23

Line Leak Test Reports ................................................................................................................ 23

Printing Tank Leak Test Reports .................................................................................................. 23

Web Browser Interface ................................................................... 24

How to Manually Start Leak Tests Using Web Browser Interface ......................................... 25

Routine Maintenance ...................................................................... 26

Console Care ........................................................................................................................26

LCD Touch Screen ................................................................................................................ 26

Calibration ................................................................................................................................... 26

Internal Printer ...................................................................................................................... 26

List of Alarms and Troubleshooting .............................................. 27

System Alarms ...................................................................................................................... 27

FMS Alarms .......................................................................................................................... 29

SCM Alarms .......................................................................................................................... 32

Wire Sensor Alarms .............................................................................................................. 33

Line Leak Detector (LLD) Alarms ..........................................................................................34

TPI Alarms ............................................................................................................................ 35

Printer Alarms ....................................................................................................................... 35

Appendix C – Third Party Certications ........................................ 36

iv

Important Safety Messages

Franklin Fueling Systems (FFS) equipment is designed to be installed in association with volatile hydrocarbon liquids

such as gasoline and diesel fuel. Installing or working on this equipment means working in an environment in which these

highly ammable liquids may be present. Working in such a hazardous environment presents a risk of severe injury or

death if these instructions and standard industry practices are not followed. Read and follow all instructions thoroughly

before installing or working on this, or any other related, equipment.

As you read this guide, please be aware of the following symbols and their meanings:

Warning

Caution

Danger

Warning

Warning

This symbol identies a warning. A warning sign will appear in the text of this document when a potentially

hazardous situation may arise if the instructions that follow are not adhered to closely. A potentially hazardous

situation may involve the possibility of severe bodily harm or even death.

This is a caution symbol. A caution sign will appear in the text of this document when a potentially hazardous

environmental situation may arise if the instructions that follow are not adhered to closely. A potentially

hazardous environmental situation may involve the leakage of fuel from equipment that could severely harm

the environment.

This symbol identies an electrical danger. An electrical danger sign will appear in the text of this document

when a potentially hazardous situation involving large amounts of electricity may arise if the instructions that

follow are not adhered to closely. A potentially hazardous situation may involve the possibility of electrocution,

severe bodily harm, or even death.

Alarms and warnings are designed to alert you with specic details when a problem occurs so you can take

appropriate corrective action.

Follow all applicable codes governing the installation and servicing of this product and the entire system.

Always lock out and tag electrical circuit breakers while installing or servicing this equipment and any

related equipment. A potentially lethal electrical shock hazard and the possibility of an explosion or re from

a spark can result if the electrical circuit breakers are accidentally turned on during installation or servicing.

Please refer to the Installation and Owner’s Manual for this equipment, and the appropriate documentation

for any other related equipment, for complete installation and safety information.

Follow all federal, state and local laws governing the installation of this product and its associated systems.

When no other regulations apply, follow NFPA codes 30, 30A and 70 from the National Fire Protection

Association. Failure to follow these codes could result in severe injury, death, serious property damage

and/or environmental contamination.

Warning

Warning

Warning

Warning

Warning

Always secure the work area from moving vehicles. The equipment in this manual is usually mounted

underground, so reduced visibility puts service personnel working on this equipment in danger from moving

vehicles entering the work area. To help eliminate these unsafe conditions, secure the area by using a

service truck to block access to the work environment, or by using any other reasonable means available to

ensure the safety of service personnel.

When the Fuel Management System is used to monitor tanks containing gasoline or other ammable

substances, you may create an explosion hazard if you do not follow the requirements in this manual

carefully.

All wiring must enter the console’s enclosure through the designated knockouts. An explosion hazard may

result if other openings are used.

You must run wiring from probes or sensors to the Fuel Management console in conduits which are

separate from all other wiring. Failure to do so will create an explosion hazard.

Substituting components could impair intrinsic safety. T5 series consoles are intrinsically safe for sensors

installed in – Class I, Division 1, Group D – hazardous locations. Substitution of components could make

the energy limiting circuitry in the system ineffective and could cause an explosion hazard. Repairs to a T5

series console or attached components should only be performed by a qualied, factory-trained technician.

1

Certied Programmer/Service Person: Only a Franklin Fueling Systems certied programmer or service person is

allowed to access both the user interface keypad and areas internal to the Fuel Management System console.

Station Owner/Operator: The station owner or operator of the Fuel Management System console is only allowed to

access the user interface keypad. Access to areas internal to the console is strictly prohibited.

Approvals

All Fuel Management System models are UL and cUL listed 6L79 as Liquid Level Gauge / Leak Detection

Systems. Third party approved leak detection — Pd (probability of detection) = 99.2 % for 0.1 or 0.2 GPH leak

tests (0.1 = annual precision test, 0.2 is the monthly regulatory compliance test).

*The static tank test does not support Manifolded tanks.

**SCALD is 3rd party approved for ONLY two Manifolded tanks.

Related Documentation

The system installation and programming instructions are provided for your use in separate documents. Detailed

installation and testing instructions for each type of leak detection sensor are present in the relevant manual, and,

likewise, the installation, testing and programming of various upgrade kits and optional accessories are also contained in

separate manuals, addenda or in one of this document’s appendices.

TS-550 evo Series Fuel Management Systems Installation Guide (000-2170)

TS-550 evo Series Fuel Management Systems Programming Manual (000-2173)

Manuals can be found on-line at: http://www.franklinfueling.com/service/docs.asp

2

Introduction

The purpose of this manual is to guide installers, operators and technicians through the operation of a TS-550 evo

console. The TS-550 evo console incorporates the monitoring and alarm capabilities of preceding automatic tank gauges

with advanced technologies to supply tank and level data more accurately and efciently. This manual is also designed to

introduce technicians to the optional LCD Graphical User Interface, which is used as an input device to program system

conguration and maintain all applications from the front panel of the console. Overall safety issues, troubleshooting

information, start-up procedures, warranty, service and return policies, as dened in this manual, must be followed.

The TS-550 evo Fuel Management System consists of an open architecture, modular console that can run multiple Fuel

Management Applications simultaneously. It typically contains a color LCD touch screen user interface and a built-in

printer, but it can also be operated by a web-based remote interface. Magnetostrictive Liquid Level Probes inside of

the tanks provide the console with inventory and leak detection information. A variety of optional sensors can be used

to monitor containment spaces. TS-550 evo series consoles combine the power and exibility of computer-based open

architecture with a high speed modular bus design.

Denitions and Acronyms

AST

– Aboveground Storage Tank

Console – The enclosure that houses the Modules.

DHI – Dispenser Hook Isolation

DW/DWT – Double Wall/Double Wall Tank

FAST – Franklin Auto Setup Tool

FMS – Fuel Management Systems

IS – Intrinsically Safe

LCD – Liquid Crystal Display

LON – Echelon Communication Module

LLD – Line Leak Detection

Module – A plug-in card within a T5 series console that is

used to perform various functions for a console.

Modules are used for eld wiring the input and/

or output of electrical signals between different

functional equipment pieces.

NWGLDE – The National Work Group Leak Detection

Evaluations

OTB – One Touch Button

QTB – Quick Jump Button

PC – Personal Computer

STP – Submersible Turbine Pump

TS-ACI – 12 input, AC Input Module

TS-DIMIB – Dispenser Interface Module

TS-2WSNS – 12 input, 2-Wire Sensor Module (Intrinsically

Safe)

TS-3WSNS – 8 input, 3-Wire Sensor Module (Intrinsically

Safe)

TS-420IB – 4-20mA Analog Input Module (Intrinsically

Safe)

TS-RLY – Relay Module

TSSP-CM – Controller Module

TS-PRB – Probe Module (Intrinsically Safe)

TSSP-PS – Power Supply Module

TPI – Turbine Pump Interface

TS-EMS – Environmental Monitoring System

TS-EXPC – Expansion Console

USB – Universal Serial Bus

UST – Underground Storage Tank

XML – eXtensible Markup Language

RS-232 – An EIA standard for serial communication using

either a 9 or 25-pin connector or adapter.

RS-485 – An EIA standard for serial communication.

RTD – Resistance Temperature Detector

RJ-45 – An EIA standard connector for use in

communications with an eight conductor cable.

Usually used in data transmission applications.

RJ-11 –

An EIA standard connector for use in

communications using STP wiring. Usually used in

voice and fax applications.

3

Applications

Applications are programs designed to function as a

platform for specic Inputs/Outputs. There are three

different applications available to the TS-550 evo console:

System:

This application is standard on all systems and monitors

the console’s operational status and manages software

options and upgrades. All preferences and conguration

settings are controlled by this application (e.g., display

options, clock and calendar). The system application is

standard on every console.

Fuel Management System (FMS):

The Fuel Management System application provides

inventory management and leak detection for tanks, lines

and sensors as well as tank, line and sensor control. This

application also allows users to print reports, tank tests

and line tests.

A broad range of liquid products can be leak-tested and

inventory-monitored using Magnetostrictive LL2 probes.

These probes come in a variety of lengths and typically

contain two oats for indicating both product and water

levels inside the of tank. Programmable limits can be set to

indicate high and low conditions.

Containment sumps, interstitial spaces, monitoring

wells and other areas can be monitored for water and

hydrocarbon intrusion using a wide range of optional

Standard and BriteSensors. These sensors come in 2-wire

(non-discriminating) and 3-wire (typically discriminating)

versions. These models are listed below and can be used

in any combination depending on site specications.

Secondary Containment Monitoring (SCM):

Secondary Containment Monitoring is a continuous

secondary containment monitoring system that monitors

the interstitial spaces of double walled tanks and sumps,

secondarily contained product and vapor return piping.

SCM is a software option that can be added to the TS-550

evo. The Secondary Containment Control Module (SCCM)

consists of a vacuum sensor, solenoid valve, mechanical

bypass valve, and vacuum manifold. SCM uses the

STP siphon port vacuum to evacuate the containment

space and AutoLearn® technology to determine the

characteristics of each secondary containment area that is

monitored. The SCCM unit comes in two models.

Standard Sensors

Standard sensors do not discriminate between liquid and

hydrocarbons and are typically 2-wire sensors.

TSP-EIS – Electro-optic Interstitial Sensors (3-wire,

infrared, liquid sensor)

TSP-HLS – High product Level Sensor (2-wire, oat

switch, liquid level sensor)

TSP-ULS – Universal Liquid Sensor (2-wire, oat switch,

liquid level sensor)

BriteSensors™

BriteSensors™ are 3-wire, discriminating sensors (many of

which may generate multiple alarms).

TSP-DIS – Discriminating Interstitial Sensor (Electro-optic

and conductivity, liquid sensor)

TSP-HIS – Hydrostatic Interstitial Sensor (oat switches,

Brine sensor)

TSP-DDS – Discriminating Dispenser sump Sensor

(conductivity strip and oats, liquid and vapor sensor)

TSP-DTS – Discriminating Turbine sump Sensor

(conductivity strip and oats, liquid and vapor sensor)

TSP-MWS – Discriminating ground water Monitoring

Well Sensor (oat and conductivity strip, liquid and vapor

sensor)

TSP-DVS – Discriminating Vapor well Sensor (vapor

sensor)

TSP-DMS - Discriminating Magnetostrictive Sensor

Modules

A modular bus consists of modules connected by a bus

backplane. Some modules are standard in all units, while

the type and number of other modules are dependent

on the site conguration and options purchased. Most

systems have empty slots available for future expansion or

can be expanded with an expansion console.

Standard Modules

Controller Module

Contains the primary controller and software applications

as well as the user interface and printer controls. The

module contains the Ethernet port, (2) USB ports, COMM

port 1, audible horn and an optional internal modem card.

Power Supply Module

Contains a self-switching (110 & 220 VAC) input and

provides power to the rest of the system. the module

contains two output relays, two backup generator inputs,

a Turbine Pump Interface (TPI) RS-485 connection and

the COMM 2 communications port. An optional Dispenser

Interface Module (TS-DIMIB) or Echelon Communications

Module (TS-LON) can also be added. The Power Supply

Module also has a bus expansion port that can connect a

TS-550 evo console to a TS-EXPC Expansion Console.

4

Optional Modules

2-Wire Sensor Module Provides 12 inputs for 2-wire

Standard sensors.

3-Wire Sensor Module Provides 8 inputs and

supports both 3-wire and

2-wire sensors.

4-20 mA Input Module Provides 8 inputs that can be

used for TS-LS500 line leak

detection transducers and

SCM vacuum transducers.

4-20 mA EXP Explosion-proof module.

Otherwise the same as the

4-20 mA Input Module.

AC Input Module Provides 12 inputs for

dispenser hook signals, which

are also required for LLD. This

module replaces external DHI

boxes.

Probe Module Provides 12 inputs or LL2

probes.

User Interface

LED Indicators – Three LEDs below the front panel give

an “at-a-glance” indication of the system status. These

LEDs are standard on all systems. The green Power LED

indicates that the system power is on. The yellow Warning

LED gives indication that the console has detected a

malfunction or condition that has been deemed a Warning.

The red Alarm LED indicates that the system has detected

an alarm condition.

LCD Touch Screen – The color LCD touch screen is

the most commonly used user interface for the Fuel

Management System. This bright and colorful display

allows easy viewing in any lighting condition. Touching

certain buttons or segments of the screen will allow access

to menus or more detailed information. Do not use sharp

or pointed objects to operate the touch screen or damage

may result. A “Sleep Mode” screensaver can be activated

under Setup / Conguration / Sleep mode to automatically

turn off the back light after 5 minutes to extend the life of

the display. If improper operation of the touch screen is

noted, it may be necessary to calibrate the touch screen.

Please refer to the Routine Maintenance chapter of this

manual for calibration procedures.

Relay Module Provides 8 relay outputs (2-

Amp) which are typically used

to control the submersible

pump relays to provide pump

or dispenser shutdown when

line leak detection or other

applications are used. Not

used in combination with TPI.

10-Amp Relay Module Provides 6 relay outputs which

are typically used to control

the submersible pump relays

to provide pump or dispenser

positive shutdown upon alarm

conditions.

Input / Output Module Provides 8 AC or DC voltage

inputs that can range from 3

to 240 volts. Typically used for

vapor processors and generic

devices, but not for dispenser

hook signals. In addition, this

module also includes four

4-20 mA signal outputs which

are typically used to interface

to an external device, such

as a SCADA (Supervisory

Control and Data Acquisition),

building monitoring system or

fuel level monitoring.

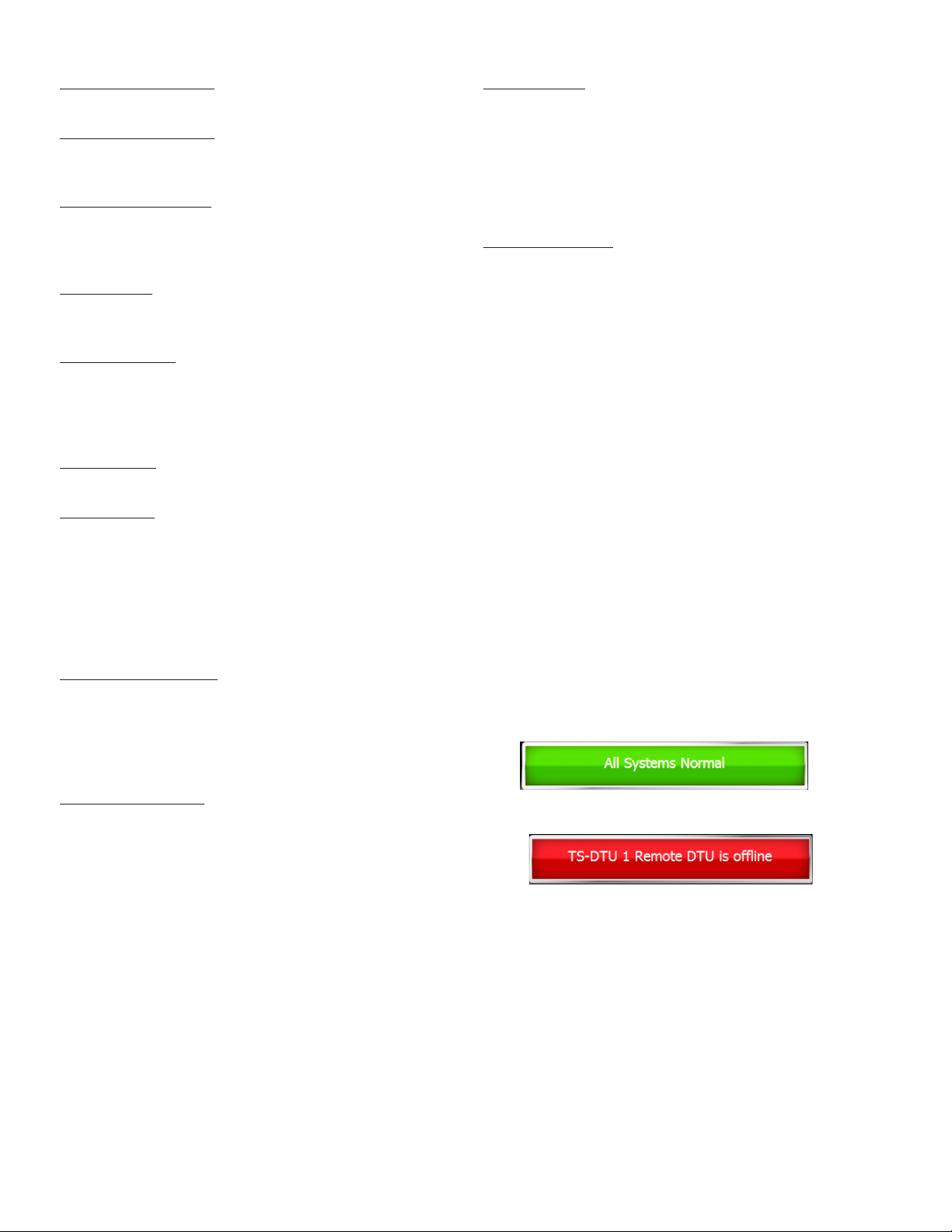

Alarms and Warnings

Alarms and warnings are designed to alert you with

specic details when a problem occurs so that you can

take appropriate corrective action. System hardware

failure warnings, tank related alarms, leak detection sensor

alarms, and line leak alarms will always notify the user in

certain ways, other notication options are programmable.

Alarms and Warnings will always:

• Cause the red Alarm light or yellow Warning light to

ash (standard).

• Change the alarm button from showing normal:

to showing the alarm. i.e.:

.

Optionally, on alarm the system can:

• Sound the console’s internal alarm horn.

• Activate relay outputs and sound external alarm

devices.

• Print alarm reports.

• E-mail alarm reports to a specied destination.

• Notify remote monitoring software via optional

internal modem or Ethernet.

For help with troubleshooting alarms, refer to the

Troubleshooting chapter of the TS-550 evo Series

Programming Manual (000-2173).

5

Programming and Navigation

Console Navigation

The operating system is designed for easy navigation. Applications allow the user to modify programming options by

responding to on-screen commands. The following instructions show various operating system functions, so that issues

can be corrected efciently without interrupting dispensing or sales.

One-Touch Buttons – Run

customized and site-specic rules

for various console functions.

Shows which

screen is

displayed.

Home – This will return to

the screen shown here.

Navigation Buttons

There are many ways to navigate the applications of the TS-550 evo console. Listed below are buttons that will help you

navigate the functions of the console.

Back – Returns to

the previous screen.

Quick Jump Menu –

Allows rapid access

to console functions.

Shows current

system time and

date.

Help – Displays

context-sensitive

help information.

Status – When in Alarm, bar

turns red and describes alarm.

Quick Jump Menu (QJM)

The Quick Jump Menu was developed to simplify system navigation. From the Quick Jump Menu you can access sections

of the TS-550 evo with a few quick selections.

Quick Jump Menu

Note: Your console will display selections depending upon installed equipment.

Selecting the icon will take you to the summary screen for that item and allow you to access more detailed information.

Tank

s – The Tanks selection provides inventory information and control functions for the tanks and manifolds at a site

Lines – The Lines selection provides Line Status, Line Leak Test status, as well as Line control & calibration functions for

each line at a site.

Sensors – The Sensors selection provides Sensor status, and control functions for the sensors at a site.

Pumps – The Pump selection provides the status and control functions for all Pumps connected to the system using the

Turbine Pump Interface.

Reports – The Reports selection allow the user to generate any number of system and application reports.

Compliance – The Compliance selection provide detailed information regarding the compliance status of: Tanks, Manifolds,

Lines, and Sensors monitored by the system.

Alarms – The Alarms selection provide a list of current active alarms, as well as an alarm history and an application event

history.

Utilities – The Utilities selections provides access to the various setup, conguration, and system tools used to congure and

maintain the site.

• Page 8 list further information about these menu items

6

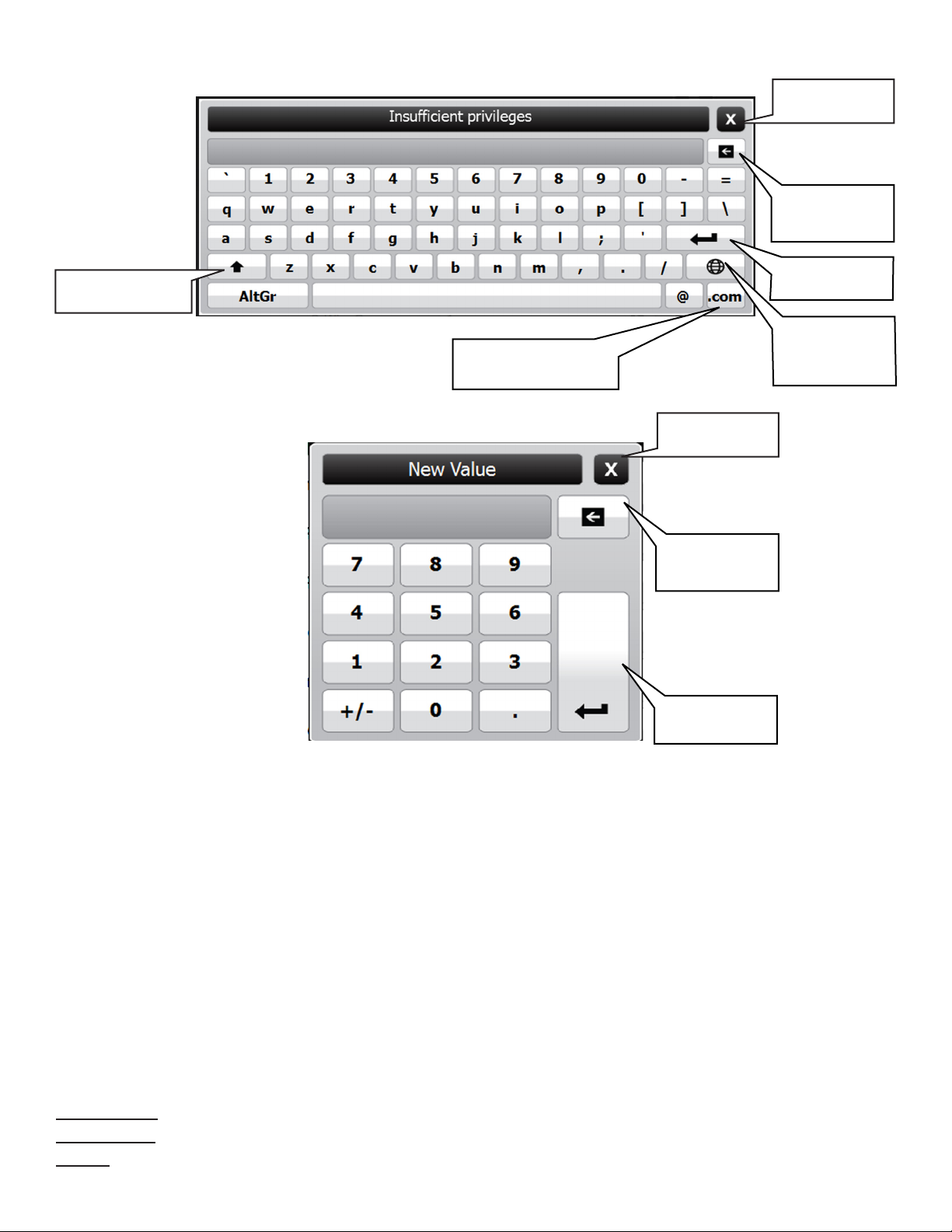

Text Entry Screen

Close Without

Saving

Erase Individual

Characters

Use Upper-Case

Characters

Number Entry Screen

Adds the .com extension

to an e-mail address

Save and Enter

Text

Use

International

Characters

Close Without

Saving

Erase Individual

Characters

Save and Enter

Numerals

User Role - Access Control

There are three levels of access into the console’s operating system: Guest, User, and Administrator. Each level will

allow an operator to access different features and controls of the console. This security feature prevents unauthorized

access to critical information and settings. The password for each access level can be adjusted by the Administrator. The

Administrator level is typically reserved for an Franklin Fueling Systems certied technician. User’s will be automatically

prompted for a password to access or change data as required.

The User Role icon displays the current access level allowed. White bars displayed in this icon indicate the access level.

Pressing the User Role indicator on your LCD display will return the system to Guest access level.

GUEST level: Guests are allowed to access menu options, check the system conguration and print reports. A GUEST

will not be able to modify the console’s settings.

USER level: Users are given access to more functions of the operating system so that they can perform line/tank leak

tests and reset line alarms.

ADMINISTRATOR: This level grants access to all areas of programming and setup conguration. The administrator

privilege is usually reserved for Franklin Fueling Systems certied technicians.

System Identication

In order to understand what sections of this manual apply to your system, you must be able to identify what Fuel

Management System you have and what Options and Applications it is running.

Model Number – Located on the front of the console.

Serial Number – Located on a sticker on the left side panel (along with Model number).

Options – To see what Applications and Options the system is running, press QJM>Utilities>System

7

Quick Jump Menu Selection Descriptions

Tank Inventory Summary Screen

The Tank Inventory Summary screen displays a

graphical representation of the product and water levels in

the tanks and indicates any alarm conditions. The Product

name and current Volume are also displayed for each tank.

An alarm condition on the tank is also indicated here, if

present. Pressing the print button while on this screen will

print an Inventory Report for all tanks.

To access the Tank Inventory Summary screen select

Tanks from the Quick Jump Menu (QJM).

Tank Controls feature can be accessed using the Control

Button on the Tank Inventory Detail Screen. This will allow

authorized users and technicians to start tank tests or

autocalibration.

Tank Inventory Detail Screen

The Tank Inventory detail screen will provide detailed

information on product volume, level, temperature and

ullage space available in a particular tank. The level and

volume of any water will also be displayed. The hash

marks on the graphic indicate the various programmed

high and low alarm limits. An alarm condition on the tank is

also indicated here, if present.

The Tank Inventory Detail screen also provides details

regarding the tanks Static Leak Test status, Autocalibration

status, and Delivery history using the four tabs at the top of

the left hand column. Pressing the print button while on the

page will print an Inventory Report for just this tank.

To access the Tank Inventory Detail Screen select a tank

from the Tank Inventory Summary screen.

Line Status Summary Screen

The Line Status Summary screen displays a graphical

representation of the line pressures in each line and will

indicate any alarm conditions. The Line name and current

pressure reading are also displayed for each line.

To access the Lines Status Summary screen select Lines

from the Quick Jump Menu (QJM).

8

Line Status Detail Screen

The Line Status Detail screen will provide detailed

information on Line Leak Testing and the Line Status. The

Line status, Pump status, number of Gross Leak Tests

performed, Line Learn Messages, and the date and time

of the last line test completed. An alarm condition on the

Line is also indicated here, if present. From the Line Detail

screen Line Control can be accessed. To access the Line

Status Detail Screen select a line from the Line Status

Summary screen.

Sensor Status Summary Screen

The Sensor Status Summary screen displays a graphical

representation of a sensor, the name of the sensor and

will indicate any alarm conditions. Pressing the print button

from the screen will print a sensor status report for all of the

sensors.

To access the Sensor Status Summary screen select

Sensors from the Quick Jump Menu (QJM).

Line Controls feature can be accessed using the Line

Control Button on the Line Status Detail Screen. This will

allow authorized users and technicians to start line leak

tests, reset the line, and learn the line.

Sensor Status Detail Screen

The Sensor Status Detail screen will provide details on

the sensor type and the sensors current status. Any alarm

condition on the Sensor is also indicated here, if present.

Pressing the print button from this screen will print a sensor

report for that tank. To access the Sensor Status Detail

Screen select a sensor from the Sensor Status Summary

screen.

9

Pump Status Summary Screen

This screen displays a graphical representation of the

submersible pumps, the name of the pump, and an

indication whether the pump is running or not. An alarm

condition on the pump is also indicated here, if present.

Pressing the print button while on this screen will print a

Pump Status Report for all Pumps.

Report Generator Screen

The Report Generator screen is used to create a variety of

reports. The report options available depend on software

options and system conguration. The available reports

include: Alarm History, Application Event History, Setup,

Inventory, Delivery, Tank Test, SCALD, Line Test, Pump

Status, Reconciliation, Regulatory, and Sensor Status.

To access the Pump Status Summary screen select

Pumps from the Quick Jump Menu (QJM).

Pump Status Detail Screen

This screen provides a variety of information regarding the

pump and it settings. Information including: Pump Name,

Enabled/Disabled, Controller Type, Controller Address, the

tank the pump is installed in, and Pump Group. The screen

also includes status information such as Pump Running, has

the pump been forced off, and if a hook signal is present.

Pressing the print button while on the page will print a Pump

Status Report for just this tank.

To access the Report Generator screen select Reports

from the Quick Jump Menu (QJM).

Pump Controls feature can be accessed using the Control

Button on the Pump Status Detail Screen. This will allow

authorized users and technicians to reset the Pump

hardware and software.

10

Compliance Screen

The Compliance screen displays regulatory status

information for Tanks, Manifolds, Lines, and Sensors.

Each page lists every device, the number of days

remaining and the date when that specic device will be

out of compliance. The screen will indicate compliance

concerns with a color coded status indicator.

Compliance Status

Compliant – The device is in compliance.

Compliance Alert – The device will be out of

compliance in 8 to 14 days.

Compliance Warning – The device will be out of

compliance in 1 to 7 days.

Compliance Alarm – The device is out of

compliance.

Tank Compliance Screen

Alarm Summary Screen

The Alarm Summary screen displays active alarms, an

alarm history, and an application event history. From the

alarm summary screen users can view currently active

alarms and review alarm and application event histories,

as well as access more details about active alarms.

To access the Alarm Summary screen select Alarms from

the Quick Jump Menu (QJM).

Active Alarm Detail Screen

The Active Alarm Detail screen provides detailed

information regarding an active alarm. These details

include the device, the date and time the alarm occurred,

and a description of the alarm. It will also provide hints for

recommended actions and precautions. Many alarms will

also have a “Go To Device” link which directs users straight

to the device to allow users to perform corrective actions.

Pressing help from this screen will provide further details

regarding the specic alarm. To access the Alarm Detail

Screen select an Alarm from the list of active alarms.

11

Loading...

Loading...