Franklin Fueling Systems TS-550, TS-5000 User Manual

Secondary Containment Monitoring

Installation & User’s Guide

TS-550/TS-5000 consoles

Franklin Fueling Systems • 3760 Marsh Rd. • Madison, WI 53718 USA

Tel: +1 608 838 8786 • 800 225 9787 • Fax: +1 608 838 6433 • www.franklinfueling.com

Notice

Franklin Fueling Systems (FFS) strives to produce the nest manual possible and to ensure that the information that

it contains is complete and accurate. However, FFS reserves the rights to change this document and specications at

any time without notice. FFS makes no expressed or implied warranty with regard to the contents of this manual. FFS

assumes no liability for errors, omissions or for any damages, direct or consequential, that may result from the use of this

document or the equipment that it describes.

This manual is for use expressly with the TS-550, TS-5000, and TS-SCM at their approved specications.

For further information and installation and programming instructions, please refer to the T5 Series Installation Guide (p/n

000-2150) and/or T5 Series Programming Guide (p/n 000-2142).

Trademarks

INCON®, Tank Sentinel®, System Sentinel®, System Sentinel AnyWare® and Tank Sentinel AnyWare® are registered

trademarks of Intelligent Controls. All brand and product names are trademarks or registered trademarks of their

respective companies.

Inspection of Materials

Visually inspect all components for defects or damage prior to installation. If any defect or damage is found, do not use the

product and contact Franklin Fueling Systems for further assistance.

Warranty Information

Please refer to the FFS Fuel Management Systems & Product Warranty Policy for all warranty information.

Contacting Franklin Fueling Systems (FFS)

Please feel free to contact us by mail at:

Franklin Fueling Systems

3760 Marsh Rd.

Madison, WI 53718 USA

Or contact us by phone, fax or e-mail:

Tel: +1 800 225 9787 E-mail: sales@franklinfueling.com

Fax: +1 608 838 6433 techserve@franklinfueling.com

Ofce and Sales Hours: 8 a.m. to 5 p.m. CST - Monday through Friday

Technical Support Hours: 7 a.m. to 7 p.m. CST - Monday through Friday

Please visit our website at www.franklinfueling.com

Copyright ©2007 by Franklin Fueling Systems (FFS). No part of this publication may be reproduced in any form without the prior written consent of FFS.

ii

All rights reserved.

Contents

Notice..................................................................................................................................ii

Important Safety Messages .............................................................................................. 1

Overview.............................................................................................................................2

Applications ..............................................................................................................................2

Site Requirements .................................................................................................................... 3

Available Congurations .................................................................................................................. 3

Installation ..........................................................................................................................4

SCM Setup (Console Programming) ................................................................................7

AC Input Module .......................................................................................................................7

4-20mA Input Module ................................................................................................................8

Relay Module ............................................................................................................................ 8

Turbine Pump Interface (TPI) Applications (Alternate STP Control) ......................................... 10

Secondary Containment Monitoring Application ....................................................................... 11

SCM Status and Control Screens ....................................................................................12

SCM Status Summary Screen .................................................................................................. 12

SCM Control Screen ................................................................................................................. 13

Status Indicator Table ...................................................................................................................... 13

Control Indicator Table .................................................................................................................... 13

Learn Indicator Table ....................................................................................................................... 13

Pre-Operational Containment Testing ............................................................................. 14

Required Equipment .................................................................................................................14

Containment Tightness and Continuity Test .............................................................................. 14

STP Siphon Flow Rate Test ...................................................................................................... 16

Learn Process .................................................................................................................... 17

When to Learn/Re-Learn .......................................................................................................... 17

Procedure ................................................................................................................................. 17

Learn Messages ....................................................................................................................... 18

SCM Reports ...................................................................................................................... 19

SCM Alarm Reports .................................................................................................................. 19

Application Event Reports ........................................................................................................19

Alarms ................................................................................................................................20

SCM Alarms and Warnings ....................................................................................................... 20

Clearing Alarms ........................................................................................................................21

Enabling/Disabling SCM ...................................................................................................22

Enabling SCM Channels ........................................................................................................... 22

Disabling SCM Channels .......................................................................................................... 22

SCM Annual Functional Testing ....................................................................................... 23

iii

Important Safety Messages

INCON equipment is designed to be installed in association with volatile hydrocarbon liquids such as gasoline and diesel

fuel. Installing or working on this equipment means working in an environment in which these highly ammable liquids

may be present. Working in such a hazardous environment presents a risk of severe injury or death if these instructions

and standard industry practices are not followed. Read and follow all instructions thoroughly before installing or working

on this, or any other related, equipment.

As you read this guide, please be aware of the following symbols and their meanings:

Warning

Caution

Danger

Warning

Warning

This symbol identies a warning. A warning sign will appear in the text of this document when a potentially

hazardous situation may arise if the instructions that follow are not adhered to closely. A potentially hazardous

situation may involve the possibility of severe bodily harm or even death.

This is a caution symbol. A caution sign will appear in the text of this document when a potentially hazardous

environmental situation may arise if the instructions that follow are not adhered to closely. A potentially

hazardous environmental situation may involve the leakage of fuel from equipment that could severely harm

the environment.

This symbol identies an electrical danger. An electrical danger sign will appear in the text of this document

when a potentially hazardous situation involving large amounts of electricity may arise if the instructions that

follow are not adhered to closely. A potentially hazardous situation may involve the possibility of electrocution,

severe bodily harm, or even death.

Follow all applicable codes governing the installation and servicing of this product and the

entire system. Always lock out and tag electrical circuit breakers while installing or servicing

this equipment and any related equipment. A potentially lethal electrical shock hazard and the

possibility of an explosion or re from a spark can result if the electrical circuit breakers are

accidentally turned on during installation or servicing. Please refer to the Installation and Owner’s

Manual for this equipment, and the appropriate documentation for any other related equipment, for

complete installation and safety information.

Follow all federal, state and local laws governing the installation of this product and its associated

systems. When no other regulations apply, follow NFPA codes 30, 30A and 70 from the National Fire

Protection Association. Failure to follow these codes could result in severe injury, death, serious

property damage and/or environmental contamination.

Warning

Warning

Warning

Warning

Warning

Warning

Always secure the work area from moving vehicles. The equipment in this manual is usually

mounted underground, so reduced visibility puts service personnel working on this equipment in

danger from moving vehicles entering the work area. To help eliminate these unsafe conditions,

secure the area by using a service truck to block access to the work environment, or by using any

other reasonable means available to ensure the safety of service personnel.

When the Tank Sentinel system is used to monitor tanks containing gasoline or other ammable

substances, you may create an explosion hazard if you do not follow the requirements in this

manual carefully.

All wiring must enter the console’s enclosure through the designated knockouts. An explosion

hazard may result if other openings are used.

All wiring from probes or sensors to the Tank Sentinel console must be run in conduit separate

from all other wiring. Failure to do so will create an explosion hazard.

Substituting components could impair intrinsic safety. T5 series consoles are intrinsically safe

for sensors installed in – Class I, Division 1, Group D – hazardous locations. Substitution of

components could make the energy limiting circuitry in the system ineffective and could cause

an explosion hazard. Repairs to a T5 series console or attached components should only be

performed by a qualied, factory-trained technician.

TS-SCCM contains aluminum, care must be taken to avoid ignition due to impact.

1

Overview

The TS-SCM (Secondary Containment Monitoring) system is a continuous secondary containment monitoring system that

monitors the interstitial spaces of double walled tanks and sumps, secondarily contained product and vapor return piping.

This product can be ordered as an available option with Franklin Fueling Systems’s TS-550 and TS-5000 FMS consoles.

The TS-SCM system is comprised of an application running on a T5 series FMS console and all necessary input and

output modules with installation kits. The Secondary Containment Control Module (SCCM) consists of a vacuum sensor,

solenoid valve, mechanical bypass valve, and vacuum manifold. SCM uses the STP siphon port vacuum to evacuate the

containment space and AutoLearn® technology to determine the characteristics of each secondary containment area that

is monitored.

Warning

SCM equipment operates at a standard 2" to 6" Hg and should only be used to monitor containments that are designed to withstand these vacuum levels. Refer to the containment manufacturer

for further information.

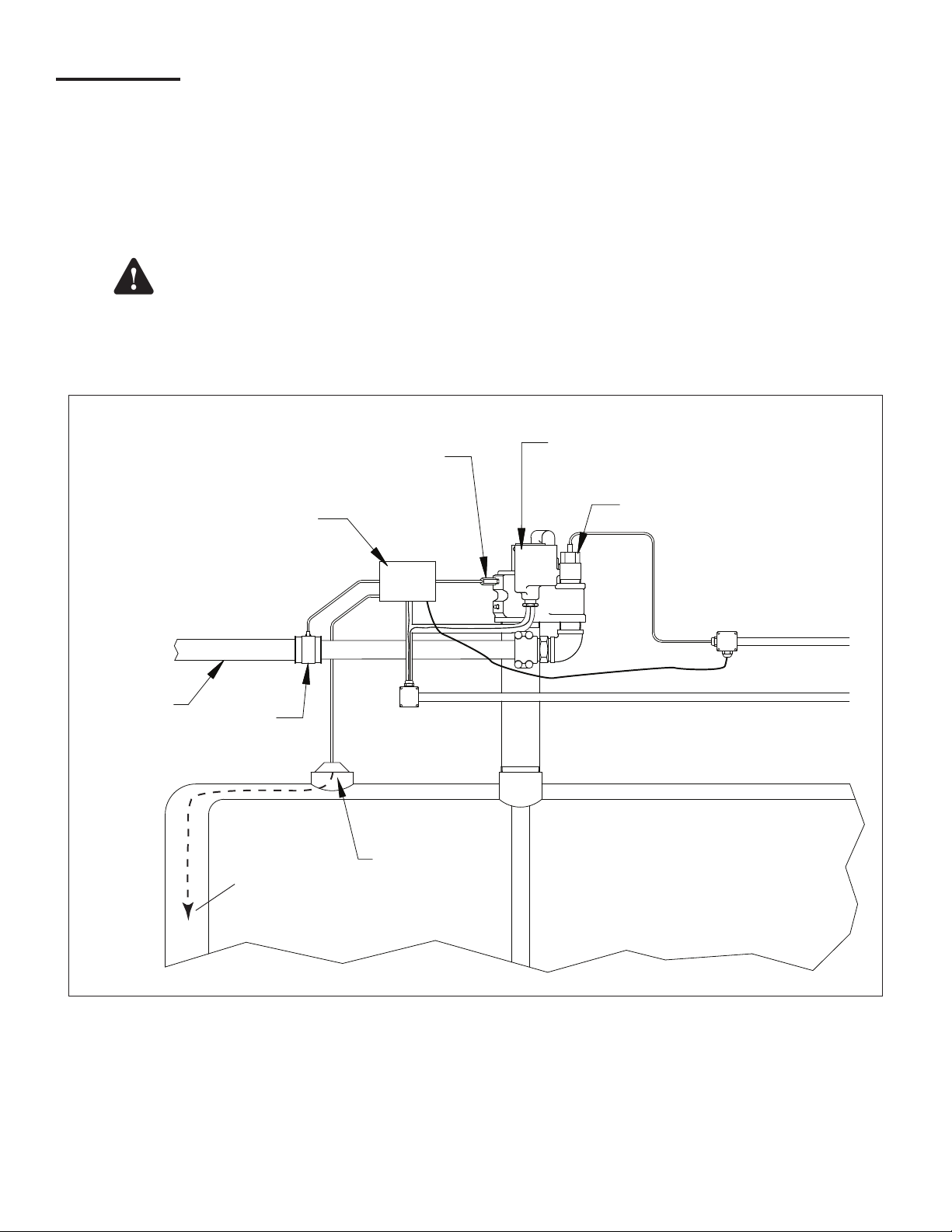

Applications

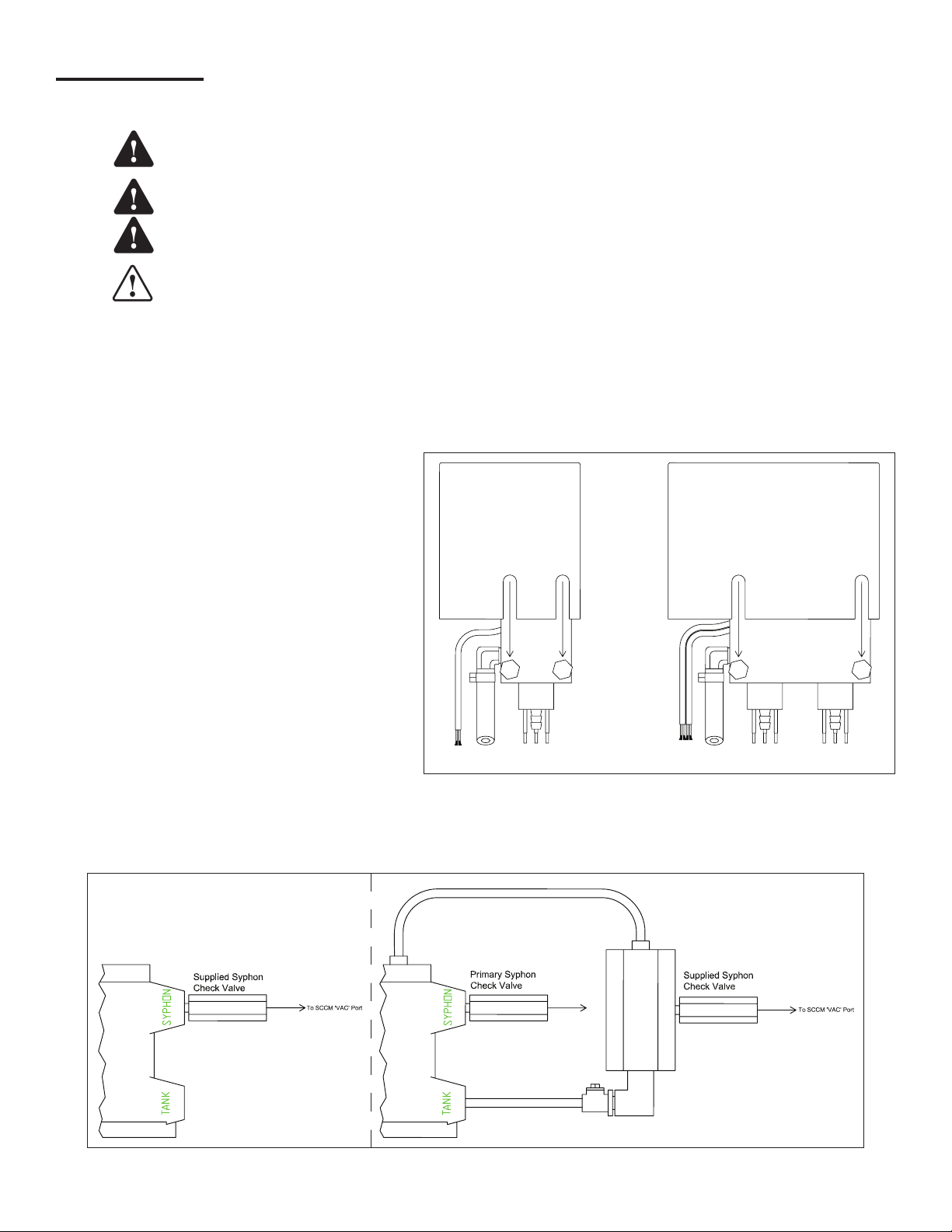

The following diagram illustrates a typical installation of SCM equipment inside of a STP sump.

FE Petro

Submersible

Pump

TS-LSU500

High Voltage Conduit

APT

Double Wall

Product Pipe

Syphon

Check Valve

Integral Solenoid

Vacuum Sensor

TS-SCCM/1

APT

Test

Boot

Intrinsically

Safe Conduit

To Bottom

of Tank

Tank

Containment

Install Kit

Figure 1 – TS-SCM System Overview

2

Site Requirements

Total Containment Volume*

Normal Operating Vacuum 2" – 6" Hg (1 – 3 PSIG)

Pre-Programmed Maximum

Shutdown (Alarm Condition)

Mechanical Relief Valve

Vacuum**

Jumper Tubing Use only supplied vacuum tubing

Vacuum Sensor Wiring

Solenoid Wiring

Minimum - 0.25 gallons (1 L)

Maximum - 500 gallons (1879 L)

9" Hg (4.5 PSIG)

10" Hg (5 PSIG)

Belden No. 87761(0.12" OD) to 400 ft.

Belden No. 89182(0.31" OD) to 500 ft. (maximum distance)

600 V, 18 AWG minimum, UL approved

refer to ANSI/NFPA70 or CEC electrical codes

*Refer to manufacturers’ installation

guides or data sheets to calculate

containment area volumes.

**All containment areas MUST be

compatible with the vacuum levels

listed.

Note: SCM should be tested annually after installation.

The term containment (in secondary containment) refers to the interstitial spaces of double walled piping, sumps and

tanks that serve as a secondary containment if the primary containment is damaged.

Individual containment sections of a given product pipeline may be jumpered together via a vacuum line to form one larger

single containment. An example of ‘jumpered’ containment spaces is the secondary containment layer of product piping

from the turbine containment to the rst dispenser, and then jumpered to the secondary containment layer of the same

product piping on the other side leading to the next dispenser containment area.

Several containment areas may be grouped together and used with a single Secondary Containment Control Module (TSSCCM). No more than four (4) SCM groups should be used per pump siphon. The combination of any containment group

may not exceed the volume limits listed for SCM.

Note: DO NOT jumper tank interstitials with other tank interstitials or other containments.

Note: DO NOT jumper containment areas of unlike product pipelines together.

Note: If grouping multiple containment areas together, the installer will need to purchase and use the vacuum hose,

ttings, and clamps to secure the connection as specied by FFS.

Note: Both intrinsically safe and explosion proof conduits need to be available inside of the turbine containment for the

TS-SCCM.

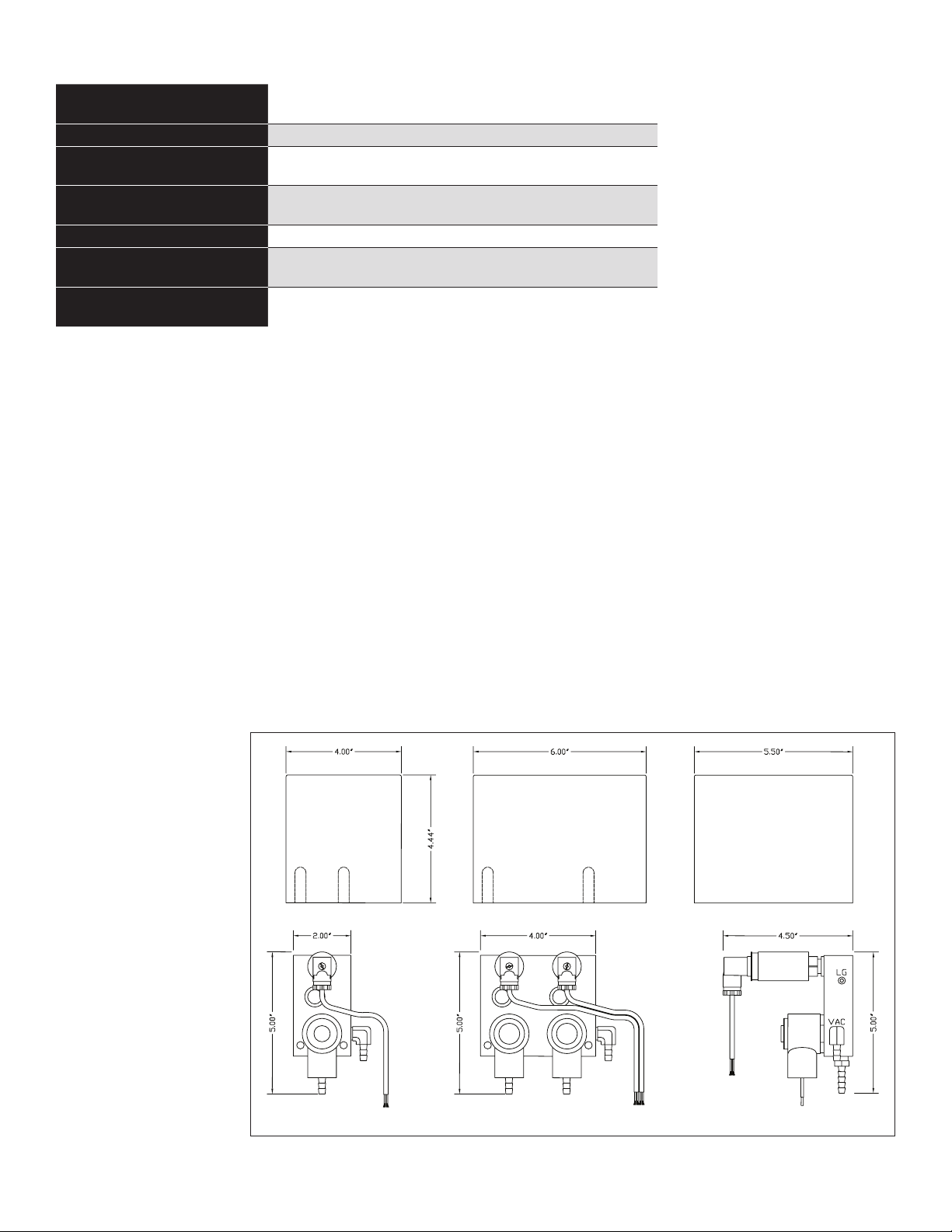

Available Congurations

Refer to Franklin Fueling

Systems’s current Fuel

Management Systems

Product Catalog for

a complete listing

of the current SCM

congurations offered.

Note: The SCCM 1 (as

pictured in Figure

2) can monitor one

containment group

and the SCCM

2 can monitor

two containment

groups.

TS-SCCM/1 TS-SCCM/2 TS-SCCM Side View

Figure 2 – SCCM 1 and SCCM 2 Dimensions

3

Installation

Before starting installation, conduct a site survey to identify potential containment groups. Based on that survey, plan out

which STP sump the equipment will be installed in and how containment areas will be grouped together.

Warning

Lockout and tag circuit breakers, and disconnect console power wiring before installing or servicing

any system wiring.

Warning

Warning

Caution

DO NOT make solenoid and/or sensor wiring connections with live power connected to the console

or any module.

TS-SCCM contains aluminum, care must be taken to avoid ignition due to impact.

Do not run intrinsically safe (IS) wiring and non-intrinsically safe (non-IS) wiring in the same

conduit.

Note: TS-SCCM must be installed in accordance with the national electrical code, ANSI/NFPA 70, CEC or other

applicable national or local codes.

Note: Maximum torque on supplied hose clamps is 20 inch-lbs.

1. Pull all wiring through the conduits that will be used for the TS-SCCM vacuum sensor and solenoid valve. The

intrinsically safe (IS) sensor wiring must be run in an IS conduit. The non-IS solenoid wiring must be run in an

approved explosion proof rigid metal conduit.

2. Mount the TS-SCCM inside of the turbine

containment area, supported by rigid,

explosion proof conduit. Then orientate the

units to allow enough clearance to make the

vacuum line connections without stretching,

kinking, or creating sharp bends in vacuum

hoses. The SCCM cover is installed with the

label upwards. See Figure 3.

3.

Connect the solenoid wiring to the eld wiring

using wire nuts to secure the connections.

Replace the explosion proof junction box cover.

4. Connect the vacuum sensor wiring to the IS

eld wiring using epoxy wire seals to secure

the connections. Replace the IS junction box

cover.

5. Install the supplied Siphon Check Valve with

the inscribed Flow Arrow pointing to the STP.

Apply a non-hardening, thread sealing

TS-SCCM/1 TS-SCCM/2

Figure 3 – Cover Installation (rear view)

compound to the threads, then thread the valve body into the submersible turbine’s siphon port. If necessary, use a

FFS Secondary Syphon Assembly to connect the SCCM to the syphon port of the STP.

Single Syphon (typical)

Secondary Syphon

Assembly

STPSTP

Secondary Syphon Kit

Figure 4 – Secondary Syphon Assembly Installation

4

6. Plumb the siphon hose from the VAC port of the TS-SCCM to the siphon check valve. Secure the hose to the ttings

Earth Ground

using one of the supplied hose clamps at each end.

7. Plumb the containment vacuum hose from the INT port of the TS-SCCM to the containment area to be monitored.

Secure the hose to the tting using one of the supplied hose clamps per tting. Install T-ttings and clamps where

necessary to connect the hoses if more than one containment area will be monitored as a group.

Note: The containment vacuum hose must be placed in the lowest point of the containment space. For double walled

tanks, this means ensuring that the vacuum line rests at the bottom most part of the tanks interstitial space. Use

the same industry procedures used to install any sensor at the bottom of a double walled tank.

8. Secure all containment boots, lids and caps. Clean pipe surfaces to clear debris or foreign objects prior to tightening

secondary test boots on secondary containment product or vapor return piping. Make all jumper connections inside of

dispenser sumps by using supplied hardware.

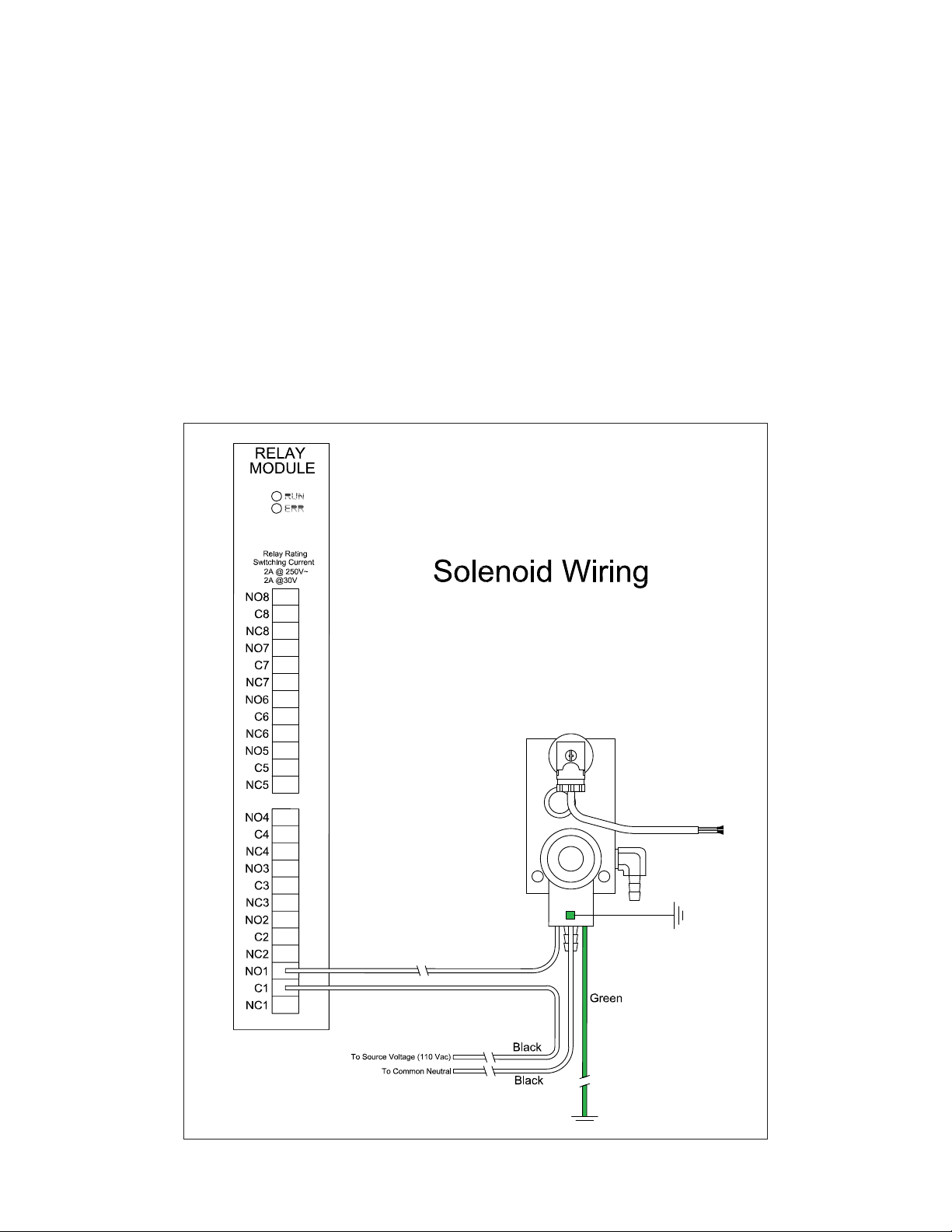

9. Inside the console, the TS-SCCM solenoid wiring must enter the console from the explosion proof rigid conduit through

a designated knockout on the non-IS side of the barrier inside. Connect the line, neutral, and ground wire of the

solenoid to a single unused channel on the Relay Module (RLY). The solenoid should be wired to the Common (C) and

Normally Open (NO) contacts of the channel selected. Source voltage (110 VAC) will need to be provided to the dry

contact relay.

Figure 5 – Solenoid Wiring

5

Warning

console is positively shut down during installation and service. Failure to remove power may result

in damage to equipment, personal injury or even death.

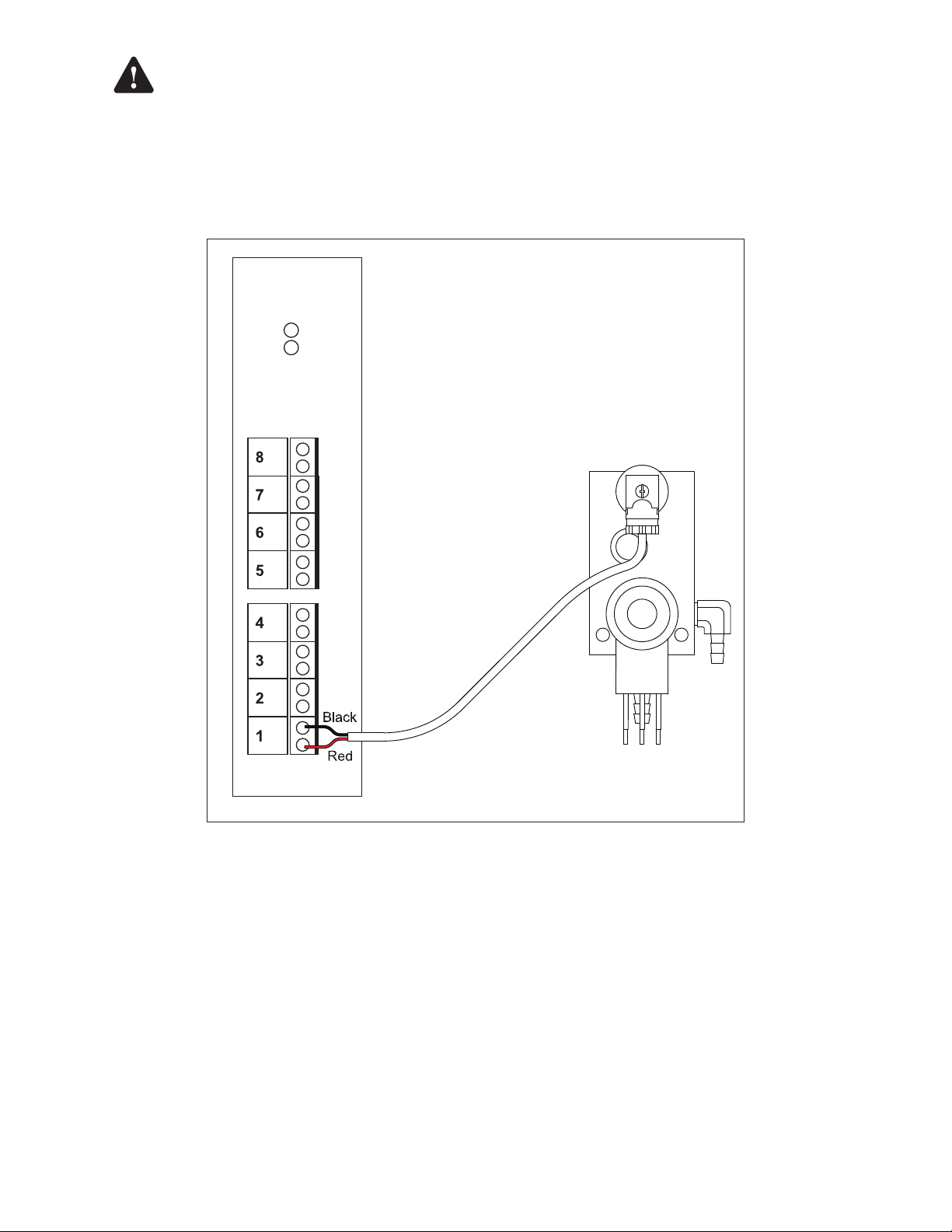

10. The TS-SCCM sensor wiring must enter the console in IS conduit through a knockout on the IS side of the barrier.

Secure each pair of sensor wires to a single channel on the 4-20mA Analog Input Module. Always use the next

available channel when wiring; for example, if Channels 1 – 3 are being used, Channel 4 must be used next. Pay

close attention to the polarity (+/-) of the wires.

4-20mA Input

Module

RUN

ERR

–

+

–

+

–

+

–

+

If using console power wires to provide power to a dry contact relay channel, ensure that the

–

+

–

+

–

+

–

+

Figure 6 – Vacuum Sensor Wiring

6

Loading...

Loading...