Page 1

Automax Valve Automation Systems

Installation, Operation and Maintenance Instructions

Flowserve Corporation 1350 N. Mountain Springs Parkway 1978 Foreman Dr.

Flow Control Division Springville, Utah 84663-3004 Cookeville, TN 38501

www.flowserve .com Phone: 801 489 8611 Phone: 931 432 4021

UltraSwitch™ XL, GL, PL

Description

Automax UltraSwitch™ limit switch enclosures provide

local and remote position indication for automated

valves. They generally feature a Pharos™ visual indicator

with “red=closed” and “green=open” for intuitive local

position determination. The UltraSwitch™ is available

with a number of limit switch options for remote indication in a variety of electrical applications. They may also

be used as a junction box for direct installation of

solenoid valves.

Installation

UltraSwitches may be installed with a variety of mounting

hardware. For best results, specify the NAMUR shaft

option and NAMUR mounting hardware (when possible).

These options allow direct coupling to actuators without

couplings, reducing deadband.

Simply bolt bracket to actuator and UltraSwitch™

to bracket, leaving bolts finger tight. For NAMUR

applications the UltraSwitch™ shaft features an integral

alignment pin. This pin must engage the tapped hole in

your actuator shaft. For non-NAMUR applications, make

sure to properly install a coupler between UltraSwitch™

and actuator. Once the UltraSwitch™ is installed with

fasteners loosely tightened, stroke your actuator

two or three times to align the bracket. Then tighten

all fasteners.

Special Hazardous Location Instructions

UltraSwitch™ XL Series enclosures are explosion proof

which allows them to be used in most Division 1 and 2

hazardous locations. You must install a conduit sealing

fitting within 18 inches of the enclosure to meet NEC

regulations. The AXL series does feature internal potting

wells. Units provided with factory-sealed leads do not

require external sealing fittings.

UltraSwitch™ PL and GL series enclosures are designed

to meet NEMA 4 specifications, but may be used in

Division 2 hazardous locations when supplied with

hermetically sealed magnetic proximity switches. For

Division 2 applications utilizing hermetically sealed

switches, conduit seals are not required. See nameplate

information to verify hazardous location suitability.

Wiring Instructions

UltraSwitch™ enclosures feature prewired switches. All

user connections are made at a numbered terminal strip.

A wiring diagram is located inside the cover and indicates

which terminal numbers correspond to switch contacts:

normally open, normally closed common, etc. Simply follow

the wiring diagram and electric code to connect switches

to your system.

switches, the top switch (top and third switches for

4-switch versions) should only be used to indicate the

clockwise position: the bottom switch (second and fourth

switches for 4-switch versions) should only be used to

indicate the counterclockwise position. Any deviation from

these settings may result in erratic indication.

Solenoids may also be wired through the UltraSwitch™

enclosure. At least two auxiliary terminals are included as

standard. A ground screw is also included. Simply wire the

solenoid to auxiliary terminals, then connect power leads to

the opposite terminal side. Be sure to properly ground the

solenoid at provided ground terminal. Note: PL series

enclosures are non-metallic: be sure to connect a ground

wire to this terminal. When two metal conduits are used

with the APL series, an external grounding strap must be

used to connect to them.

UltraSwitch™ XL and PL series enclosures include two 3/4"

conduit entries. GL series enclosures include two 1/2" entries.

Be sure to follow the National Electric Code regulations for

rigid conduit, or cable systems as applicable.

CAUTION: Substitution of components may impair suitability for Zone 2 Increased Safety.

Do not disconnect equipment unless power has been

switched off or the area is known to be non-hazardous.

Cleaning this housing by rubbing should be done in a nonhazardous area.

DEMKO 02 ATEX 130948X

0518 II 2 G EEx me II T4-T6

-40°C ≤ Tamb ≤ +55°C, T6

-40°C ≤ Tamb ≤ +70°C, T5

-40°C ≤ Tamb ≤ +80°C, T4

Note: for all magnetically tripped proximity

FCD AXAIMO0031-00 (LML0005-1) (AUTO-31) 7/04

©

2004, Flowserve Corporation, Printed in USA

Page 1 of 2

Page 2

Automax Valve Automation Systems

Installation, Operation and Maintenance Instructions

Flowserve Corporation 1350 N. Mountain Springs Parkway 1978 Foreman Dr.

Flow Control Division Springville, Utah 84663-3004 Cookeville, TN 38501

www.flowserve .com Phone: 801 489 8611 Phone: 931 432 4021

Adjusting Limit Switches

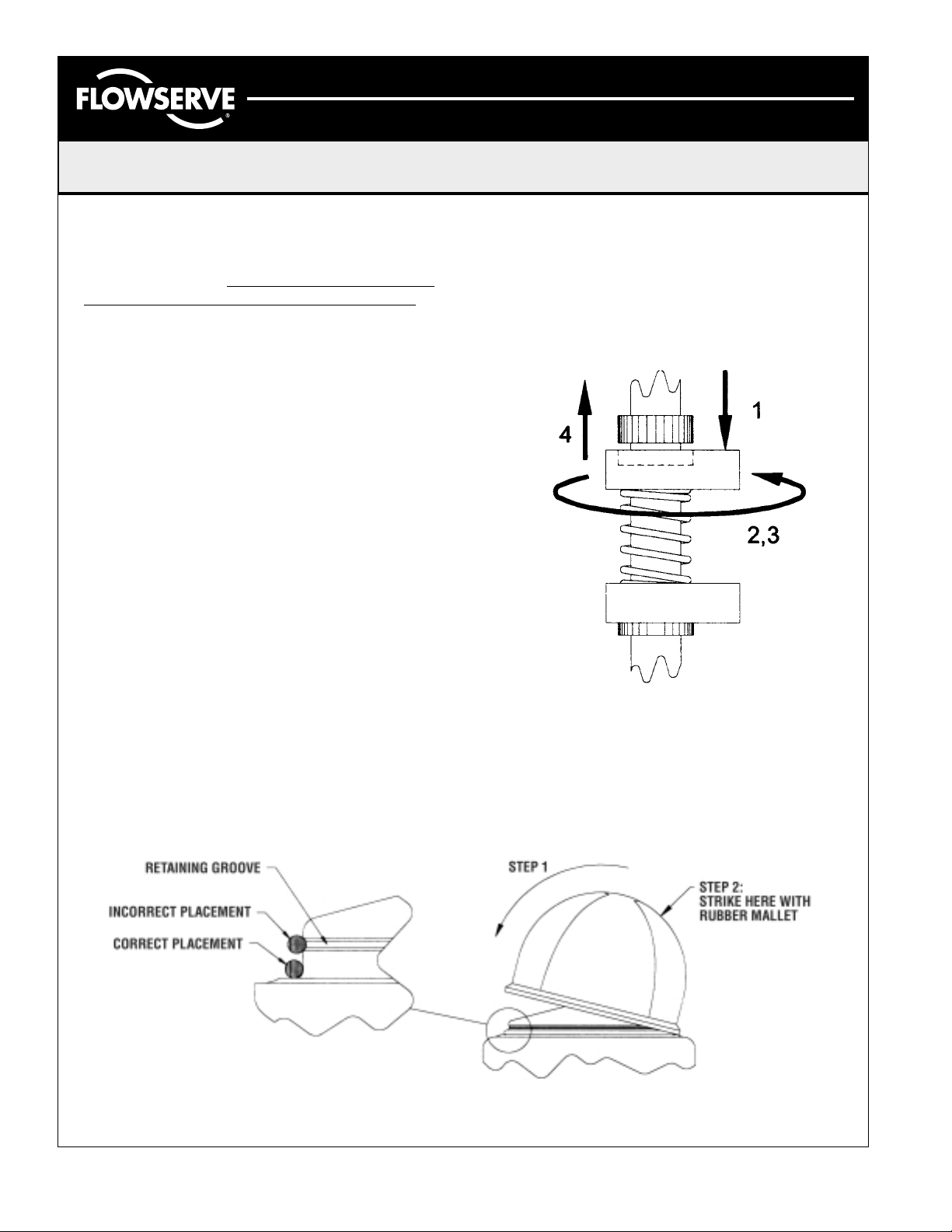

UltraSwitch™ enclosures feature quick-set cams which

are used to trip the limit switches. These cams are easily

adjusted without tools.

Caution: disconnect power before

removing cover when installed in hazardous locations.

Remove cover and set aside. Rotate actuator/valve to full

clockwise (CW) position. Adjust cam(s) associated with CW

as follows:

1. Push or pull cam against spring to disengage it

from splines.

2. Rotate cam CW breaking contact with switch

(or moving magnet away from switch).

3. Continue rotating cam CW just until switch trips.

4. Release cam and reengage it with splines.

Rotate actuator/valve to full counterclockwise (CCW)

position. Adjust cam(s) associated with CCW as

described in steps 1 through 4, except rotate cam(s) CCW.

Note: factory setting is top switch = CW (closed), second

switch = CCW (open), third switch = CW, and fourth

switch = CCW.

Adjusting Pharos™ Position Indicator

Pharos visual indicators are easily adjusted to match

the dome’s clear windows to the rotor’s red and green

quadrants. Simply pry upward under dome “flange” with a

large, flat-bladed screwdriver to remove. Make sure o-ring

is fully seated against the flat dome sealing surface, not in

the dome retaining groove, as shown. Then install dome in

a tilted fashion, engaging one of the dome locking tabs in

the dome retaining groove. Make sure dome windows line

up with rotor quadrants. Finally, using a rubber mallet,

strike dome as shown to engage all locking tabs.

FCD AXAIMO0031-00 (LML0005-1) (AUTO-31) 7/04

©

2004, Flowserve Corporation, Printed in USA

Page 2 of 2

Loading...

Loading...