Page 1

Edward Valves

Maintenance Manual for

Edward Pressure-Seal Valves

V-377 R4

Page 2

2

Flow Control Division

Edward Valves

Key to Illustrations...........................................3

Pressure-Seal Valve Figure Numbers..................3

Introduction ....................................................3

Description of Pressure-Seal

Valve Bonnet Types

(Illustration, description and figure numbers)

Type I.........................................................4

Type II ........................................................5

Type III........................................................6

Type IV.......................................................7

Service Problems

Packing Chamber Leak.................................8

Packing Recommendations............................8

Pressure-Seal Gasket Leaks..........................10

Pressure-Seal Leak......................................10

Seat and Disk Joint Leaks............................10

Body Wall Leaks........................................12

Objectionable Vibration, Noise or

Excessive Pressure Drop..............................12

Valve Lubrication........................................12

Repair Procedures

Valve Body Repairs ....................................13

Body Bore Gasket Seal Area Repair.........13

Body Bore Guide Rib Repair ...................13

Seat and Disk Repair ..............................14

Body Wall Repair...................................15

Valve Component Repair ............................15

Disk-Piston Assembly Repair.....................15

Bonnet or Cover Repair ...........................16

Welding Rod Recommendations...................16

Field Repair Equipment...............................17

Disassembly Procedures for

Pressure-Seal Valves

Introduction...............................................18

First Determine the Area of Failure...............18

Disassembly Procedures for

Impactor Handles and Handwheels

Non-Ball Bearing Impactor

Handles and Handwheels........................20

Ball Bearing Impactor Handwheels...........21

Procedures for Removing Limitorque

Operators from Valve Yokes

Revolving Stem Valves or Non-Revolving

Stem Valves with Torque-Only Units...........22

Non-Revolving Stem Valves with

Torque and Thrust Units...........................23

Procedures for Setting Actuator Torque

and Limit Switches

Limitorque Limit Switch and

Torque Switch Setting Procedures .............24

Geared Limit Switch ............................24

Torque Switch .....................................25

Single Torque Switch ...........................25

Double Torque Switch..........................25

Torque Switch Setting...........................26

Disassembly Procedures for Yoke Assemblies

Revolving Stem Valves

with Type I Bonnets.................................27

Revolving Stem Valves

with Type II Bonnets................................28

Non-Revolving Stem Valves

with Type II or III Bonnets.........................28

Valves with Type IV Bonnets.....................28

Procedures for Removing Operator

and Yoke Assembly as a Unit

Revolving Stem Valves

with Type I Bonnets.................................29

Revolving Stem Valves

with Type II Bonnets................................29

Non-Revolving Stem Valves

with Type II, III or IV Bonnets....................30

Disassembly Procedures for

Bonnet Types

Type I Pressure-Seal Bonnets

– Stop and Stop-Check

(Non-Return) Valves..............................31

– Piston-Lift Check Valves.........................32

Type II Pressure-Seal Bonnets

– Stop and Stop-Check (Non-Return)

Valves with Revolving Stems..................33

– Stop and Stop-Check (Non-Return)

Valves with Non-Revolving Stems...........34

Type III Pressure-Seal Bonnets

– Stop and Stop-Check

(Non-Return) Valves..............................36

– Piston- Lift Check Valves........................37

– Tilting Disk Check Valves ......................38

Type IV Pressure-Seal Bonnets

– Stop and Stop-Check

(Non-Return) Valves..............................39

– Piston-Lift Check Valves.........................41

Assembly of Composite Pressure-

Seal Gaskets.................................................42

Reassembly Procedures

for Metal Pressure-Seal Valves

Introduction...................................................43

Type I Pressure-Seal Bonnets

– Stop and Stop-Check

(Non-Return) Valves..............................44

– Piston-Lift Check Valves.........................45

Type II Pressure-Seal Bonnets

– Stop and Stop-Check (Non-Return)

Valves with Revolving Stems..................45

– Stop and Stop-Check (Non-Return)

Valves with Non-Revolving Stems...........45

Type III Pressure-Seal Bonnets

– Stop and Stop-Check

(Non-Return) Valves..............................46

– Piston-Lift Check Valves.........................46

– Tilting Disk Check Valves ......................47

Type IV Pressure-Seal Bonnets

– Stop and Stop-Check

(Non-Return) Valves..............................47

– Piston-Lift Check Valves.........................47

General Information.......................................48

Supplementary Repair Information.......back cover

Ordering Parts...................................back cover

Table of Contents

Page 3

3

Flow Control Division

Edward Valves

Table of Contents (continued)

Illus No.Title Page

I Pressure-Seal Bonnet Type I......................4

2 Pressure-Seal Bonnet Type II.....................5

3 Pressure-Seal Bonnet Type III ....................6

4 Pressure-Seal Bonnet Type IV....................7

5 Typical Globe Valve Nomenclature.........11

6 Pressure-Seal Bonnet Seal Angle.............16

7 Portable Lapping Tool for

Large Valves ........................................17

8 Van Norman Portable

Grinding Machine................................17

9 Van Norman Portable

Boring Machine ...................................17

10 Impactor Handwheel

Non-Ball Bearing Types .........................20

11 Impactor Handwheel

Non-Ball Bearing Types .........................20

12 Impactor Handwheel

Non-Ball Bearing Types .........................20

13 Impactor Handwheel

Ball Bearing Type (with Impactogear)......21

14 Torque-only Limitorque Operator on

Revolving Stem Valve (SMA or SMB) ......22

Illus No.Title Page

15 Torque-only Limitorque Operator on

Revolving Stem Valve (SMB-4T or 5T)......22

16 Torque-only Limitorque Operator on

Non-Revolving Stem Valve.....................22

17 Torque and Thrust Limitorque Operator

on Non-Revolving Stem Valve ................23

18 Limitorque Geared Limit Switch Assy.......24

19 Single & Double Torque

Switch Assemblies ................................25

20 Type I Bonnet on Stop-Check Valve.........27

21 Type I Bonnet on Piston-Lift Check Valve..29

22 Type II Bonnet on Revolving

Stem Stop Valve...................................30

23 Type II Bonnet on Non-Revolving

Stem Stop Valve...................................31

24 Type III Bonnet on Stop Valve.................34

25 Type III Bonnet on Piston-Lift

Check Valve ........................................35

26 Type III Bonnet on Tilting

Disk Check Valve..................................38

27 Type IV Bonnet on Stop-Check Valve.......39

28 Type IV Bonnet on Piston-Lift

Check Valve ........................................41

Key to Illustrations

Introduction

This manual has been prepared to

serve as a guide for the maintenance

of Edward valves of the pressure-seal

bonnet joint construction. It is

designed to help you obtain the most

satisfactory ser vice from these valves.

Although rigid metallurgical, radiographic, physical, and visual inspection is the standard procedure for all

Edward products, it is inevitable that

some valves, after a period of time,

may occasionally require repair.

When this happens, this manual will

assist you so that your valve may be

satisfactorily restored to good working condition with a minimum of time

and expense.

Scope

Before starting, it will be helpful to

have some understanding of the

valve’s physical construction. Consequently, the four basic types of

pressure-seal constructions are discussed and illustrated first. All Edward

pressure-seal valves employ one of

these four basic types, or a minor

modification thereof. Non-pressureseal, or bolted bonnet type valves,

are not included in this manual.

The next major section of this manual

discusses the more common service

problems and failures. It identifies the

problem and explains the reasons for

certain failures. The reason should

be understood before work is

actually started.

602Y

606

606Y

607

607Y

614Y

616

616Y

617

617Y

692Y

694

694Y

695

695Y

702Y

714Y

792Y

970Y

1570Y

1602Y

1614Y

1692Y

1802Y

1814Y

1892Y

2002Y

2006Y

2007Y

2014Y

2016Y

2017Y

2070Y

2092Y

2094Y

2095Y

2570Y

3902Y

3906

3906Y

3907

3907Y

3914Y

3916

3916Y

3917

3917Y

3948Y

3992Y

3994

3994Y

3995

3995Y

4002Y

4006

4006Y

4007

4007Y

4014Y

4016

4016Y

4017

4017Y

4092Y

4094

4094Y

4095

4095Y

4302Y

4306Y

4307Y

4314Y

4316Y

4317Y

4370Y

4392Y

4394Y

4395Y

4402Y

4406Y

4407Y

4414Y

4416Y

4417Y

4448Y

4470Y

4492Y

4494Y

4495Y

4502Y

4514Y

4570Y

4592Y

7502Y

7506

7506Y

7507

7507Y

7514Y

7516

7516Y

7517

7517Y

7548Y

7592Y

7594

7594Y

7595

7595Y

Pressure-seal Valve Figure Numbers

Page 4

4

Flow Control Division

Edward Valves

The procedure to be followed in making

the repair is then explained. This includes

normal valve maintenance as well as major

valve repair. Field repair equipment, available from Edward, is described and

illustrated. Valve lubrication and welding

rod recommendations are also made.

These procedures are adequate for almost

any pressure-seal valve repair or maintenance problem that may arise in the field.

Following is the section describing the

disassembly procedure for the various

valve components; for example, manual of

Limitorque operators, valve yokes, and the

four basic bonnet types. It is very impor-

tant that the Introduction and the paragraphs titled “First Determine the Area of

Failure” be read and understood before

any disassembly work is begun. Several

procedures are described, depending upon

the area of failure. Considerable time can

often be saved by first selecting the proper

disassembly procedure.

The last major section explains how the

various valve constructions are to be

reassembled. Information on how to

contact Edward for additional advice, if

required, and how to order parts is

included.

Description of

Pressure-Seal Valve Types

Edward pressure-seal valves are built with

four basic bonnet arrangements to provide

the most suitable designs for the wide

range of sizes and pressure classes

offered.

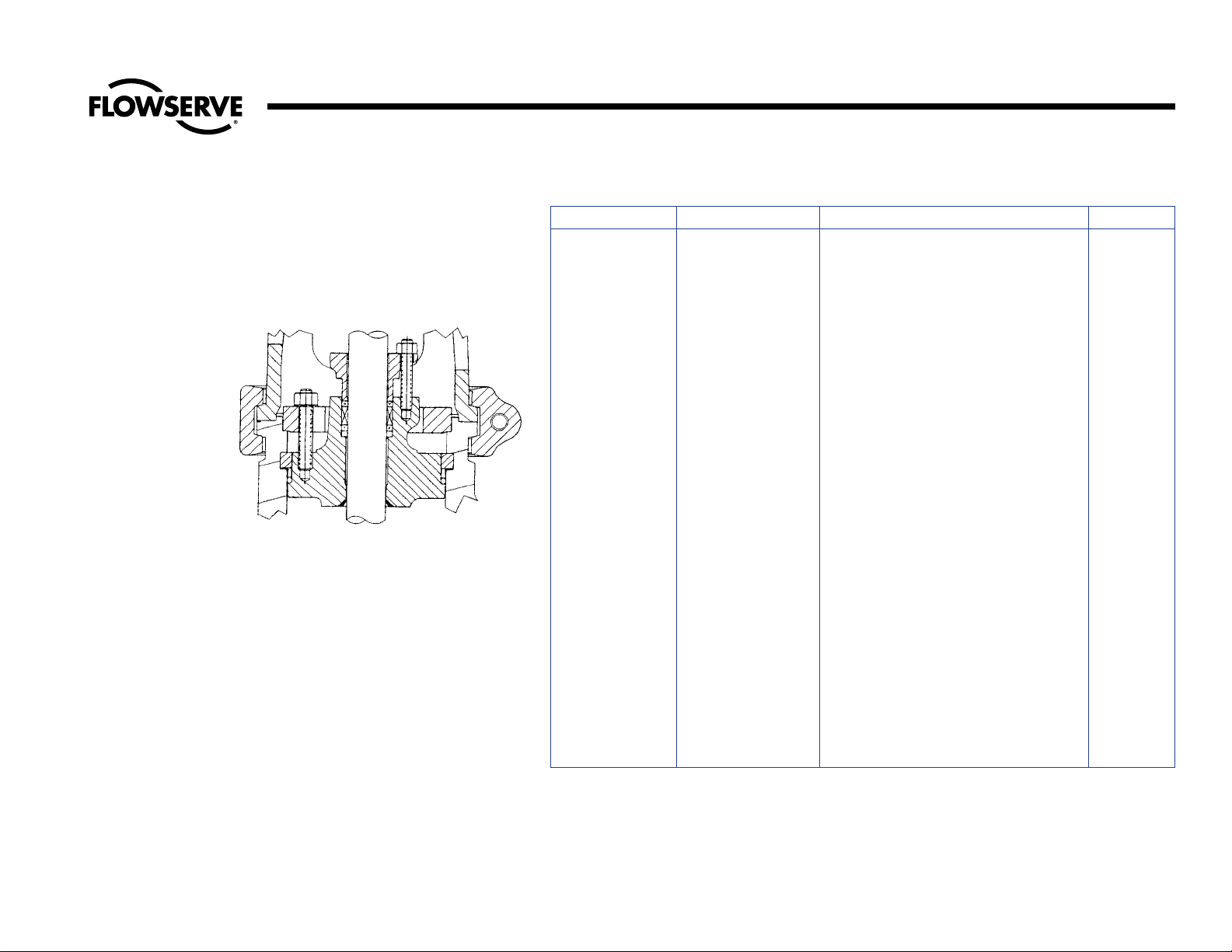

Type I is the studded bonnet design as

shown. It uses the basic pull-up construction

with studs in the bonnet projecting through

the retainer for tightening by use of nuts. It

is a simplified design employed in moderate pressure applications and certain valve

sizes, as shown in the following table.

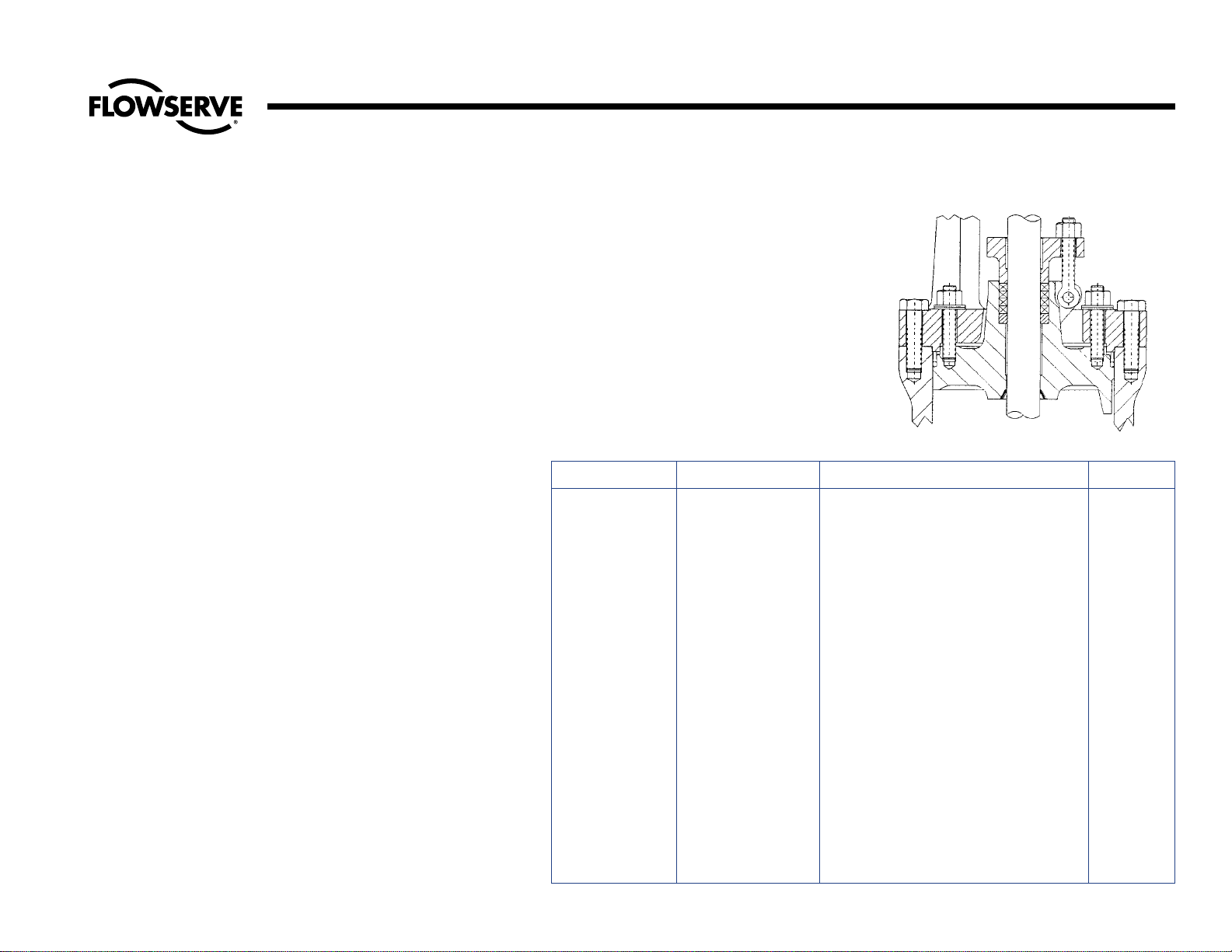

Description of Pressure-Seal Bonnet Types – Type I

Type I

Illustration No. 1

Pressure-Seal Bonnet

Fig. No. Pressure Rating Type of Valve Size

602Y 600 Flite-Flow Globe Stop-Check (Y-Type) 6-20

606 and 606Y 600 Globe Stop-Check 8-14

607 and 607Y 600 Angle Stop-Check 8-14

614Y 600 Flite-Flow Globe Stop (Y-Type) 6-20

616 and 616Y 600 Globe Stop 8-14

617 and 617Y 600 Angle Stop 8-14

692Y 600 Flite-Flow Check (Y-Type) 16-20

694 and 694Y 600 Horizontal Check 8-14

695 and 695Y 600 Angle Check 8-14

702Y 600-SPL Flite-Flow Globe Stop-Check (Y-Type) 16-20

714Y 600-SPL Flite-Flow Globe Stop (Y-Type) 6-20

792Y 600-SPL Flite-Flow Check (Y-Type) 16-20

1602Y Special Flite-Flow Globe Stop-Check (Y-Type) 16-20

1614Y Special Flite-Flow Check Stop (Y-Type) 16-20

1692Y Special Flite-Flow Check (Y-Type) 16-20

1802Y Special Flite-Flow Globe Stop-Check (Y-Type) 16-20

1814Y Special Flite-Flow Globe Stop (Y-Type) 16-20

1892Y Special Flite-Flow Check (Y-Type) 16-20

Type I

Page 5

5

Flow Control Division

Edward Valves

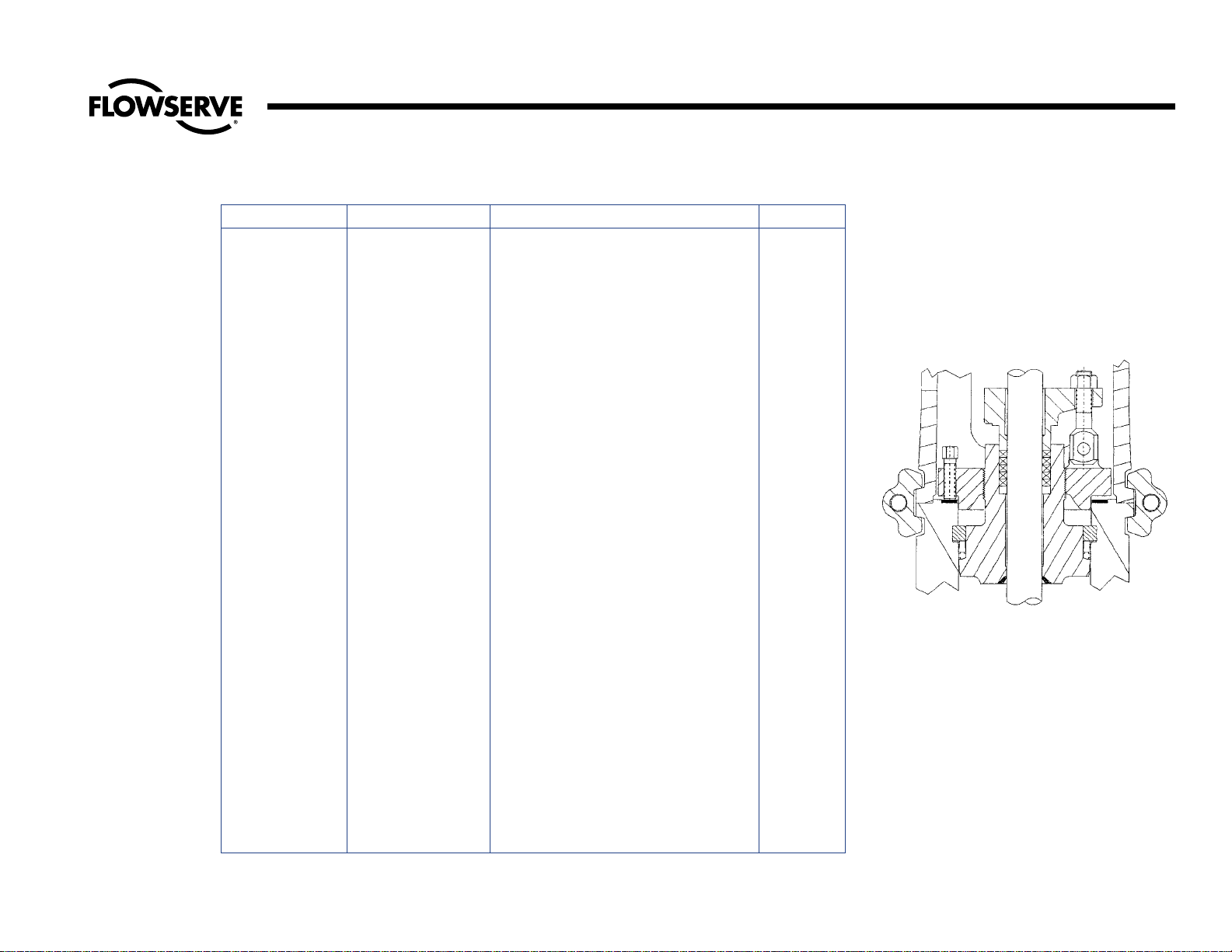

Description of Pressure-Seal Bonnet Types – Type II

Type II

Illustration No. 2

Pressure-Seal Bonnet

Fig. No. Pressure Rating Type of Valve Size

2002Y 1500-SPL Flite-Flow Globe Stop-Check (Y-Type) 3 – 4

2006Y 1500-SPL Globe Stop-Check 2-1/2 – 4

2007Y 1500-SPL Angle Stop-Check 2-1/2 – 4

2014Y 1500-SPL Flite-Flow Globe Stop (Y-Type) 3 – 4

2016Y 1500-SPL Globe Stop 2-1/2 – 4

2017Y 1500-SPL Angle Stop 2-1/2 – 4

3902Y 2500 Flite-Flow Globe Stop-Check (Y-Type) 3-24

3906 and 3906Y 2500 Globe Stop-Check 2-1/2 – 12

3907 and 3907Y 2500 Angle Stop-Check 2-1/2 – 22

3914Y 2500 Flite-Flow Globe Stop (Y-Type) 3-24

3916 and 3916Y 2500 Globe Stop-Check 2-1/2 – 12

3917 and 3917Y 2500 Angle Stop-Check 2-1/2 – 22

3948Y 2500 Elbow Down Stop-Check 10-16

4002Y 900 Flite-Flow Globe Stop (Y-Type) 3 – 4

4006 and 4006Y 900 Globe Stop-Check 2-1/2 – 4

4007 and 4007Y 900 Angle Stop-Check 2-1/2 – 4

4014Y 900 Flite-Flow Globe Stop (Y-Type) 3 – 4

4016 and 4016Y 900 Globe Stop 2-1/2 – 4

4017 and 4017Y 900 Angle Stop 2-1/2 – 4

4302Y 900-SPL Flite-Flow Globe Stop-Check (Y-Type) 3 – 4

4306Y 900-SPL Globe Stop-Check 2-1/2 – 4

4307Y 900-SPL Angle Stop-Check 2-1/2 – 4

4314Y 900-SPL Flite-Flow Globe Stop (Y-Type) 3 – 4

4316Y 900-SPL Globe Stop 2-1/2 – 4

4317Y 900-SPL Angle Stop 2-1/2 – 4

4402Y 2500-SPL Flite-Flow Globe Stop-Check (Y-Type) 3-24

4406Y 2500-SPL Globe Stop-Check 2-1/2 – 12

4407Y 2500-SPL Angle Stop-Check 2-1/2 – 22

4414Y 2500-SPL Flite-Flow Globe Stop (Y-Type) 3-24

4416Y 2500-SPL Globe Stop 2-1/2 – 12

4417Y 2500-SPL Angle Stop 2-1/2 – 22

4448Y 2500-SPL Elbow Down Stop-Check 10-16

4502Y 4500 Flite-Flow Globe Stop-Check (Y-Type) 8-10

4514Y 4500 Flite-Flow Stop (Y-Type) 8-10

4592Y 4500 Flite-Flow Check (Y-Type) 8-10

7502Y 1500 Flite-Flow Globe Stop-Check (Y-Type) 3 – 4

7506 and 7506Y 1500 Globe Stop-Check 2-1/2 – 4

7507 and 7507Y 1500 Angle Stop-Check 2-1/2 – 4

7514Y 1500 Flite-Flow Globe Stop (Y-Type) 3 – 4

7516 and 7516Y 1500 Globe Stop 2-1/2 – 4

7517 and 7517Y 1500 Angle Stop 2-1/2 – 4

Type II

Type II is the push-up design in which the

bonnet retainer ring is screwed onto the

bonnet, and cap screws develop the

upward force. This design is employed on

both intermediate and high-pressure applications. A three-piece construction is used

for the pressure-seal parts.

Page 6

6

Flow Control Division

Edward Valves

Type III also uses the three-piece pressureseal construction but combines it with the

basic pull-up bonnet. This design is utilized

extensively in the larger valves.

Description of Pressure-Seal Bonnet Types – Type III

Type III

Illustration No. 3

Pressure-Seal Bonnet

Fig. No. Pressure Rating Type of Valve Size

602Y 600 Flite-Flow Stop-Check (Y-Type) 24-32

607Y 600 Angle Stop-Check 24-30

614Y 600 Flite-Flow Globe Stop (Y-Type) 24-32

617Y 600 Angle Stop 24-30

692Y 600 Flite-Flow Check (Y-Type) 24-32

695Y 600 Angle Check 24-30

702Y 600-SPL Flite-Flow Globe Stop-Check (Y-Type) 24-32

714Y 600-SPL Flite-Flow Globe Stop (Y-Type) 24-32

792Y 600-SPL Flite-Flow Check (Y-Type) 24-32

970Y 900 Tilting Disk Check 2-1/2 – 24

1570Y 1500 Tilting Disk Check 3-24

1602Y Special Flite-Flow Globe Stop-Check (Y-Type) 24-32

1614Y Special Flite-Flow Globe Stop (Y-Type) 24-32

1692Y Special Flite-Flow Check (Y-Type) 24-32

1802Y Special Flite-Flow Globe Stop-Check (Y-Type) 24-32

1814Y Special Flite-Flow Globe Stop (Y-Type) 24-32

1892Y Special Flite-Flow Check (Y-Type) 24-32

2002Y 1500-SPL Flite-Flow Globe Stop-Check (Y-Type) 6-18

2006Y 1500-SPL Globe Stop-Check 5-14

2007Y 1500-SPL Angle Stop-Check 5-24

2014Y 1500-SPL Flite-Flow Globe 6-18

2016Y 1500-SPL Globe Stop 5-14

2017Y 1500-SPL Angle Stop 5-24

2070Y 1500-SPL Tilting Disk Check 3-24

2092Y 1500-SPL Flite-Flow Check (Y-Type) 3-18

2094Y 1500-SPL Horizontal Check 2-1/2 – 14

2095Y 1500-SPL Angle Check 2-1/2 – 24

2570Y 2500 Tilting Disk Check 3-24

3992Y 2500 Flite-Flow Check (Y-Type) 3-24

3994 and 3994Y 2500 Horizontal Check 2-1/2 – 12

3995 and 3995Y 2500 Angle Check 2-1/2 – 24

4006 and 4006Y 900 Globe Stop-Check 5-14

4007 and 4007Y 900 Angle Stop-Check 5-24

4014Y 900 Flite-Flow Stop (Y-Type) 6-16

4016 and 4016Y 900 Globe Stop 5-14

Type III

Page 7

7

Flow Control Division

Edward Valves

Description of Pressure-Seal Bonnet Types – Type III and Type IV

Fig. No. Pressure Rating Type of Valve Size

4017 and 4017Y 900 Angle Stop 5-24

4092Y 900 Flite-Flow Check (Y-Type) 3-16

4094 and 4094Y 900 Horizontal Check 2-1/2 – 14

4095 and 4095Y 900 Angle Check 2-1/2 – 24

4302Y 900-SPL Flite-Flow Globe Stop-Check (Y-Type) 5-16

4306Y 900-SPL Globe Stop-Check 5-14

4307Y 900-SPL Angle Stop-Check 5-24

4316Y 900-SPL Globe Stop 5-14

4317Y 900-SPL Angle Stop 5-24

4392Y 900-SPL Flite-Flow Check (Y-Type) 3-16

4370Y 900-SPL Tilting Disk Check 2-1/2 – 20

4394Y 900-SPL Horizontal Check 2-1/2 – 14

4395Y 900-SPL Angle Check 2-1/2 – 24

4470Y 2500-SPL Tilting Disk Check 3-24

4492Y 2500-SPL Flite-Flow Check (Y-Type) 3-24

4494Y 2500-SPL Horizontal Check 2-1/2 – 12

4495Y 2500-SPL Angle Check 2-1/2 – 24

4570Y 4500 Tilting Disk Check 6-10

7502Y 1500 Flite-Flow Globe Stop-Check (Y-Type) 6-18

7506 and 7506Y 1500 Globe Stop-Check 5-14

7507 and 7507Y 1500 Angle Stop-Check 5-24

7514Y 1500 Flite-Flow Globe Stop (Y-Type) 6-18

7516 and 7516Y 1500 Globe Stop 5-14

7517 and 7517Y 1500 Angle Stop 5-24

7548Y Special Elbow Down Stop-Check 10-18

7592Y 1500 Flite-Flow Check (Y-Type) 3-18

7594 and 7594Y 1500 Horizontal Check 2-1/2 – 14

7595 and 7595Y 1500 Angle Check 2-1/2 – 24

7598Y Special Elbow Down Check 10-18

Fig. No. Pressure Rating Type of Valve Size

4502Y 4500 Flite-Flow Globe Stop-Check (Y-Type) 4-6

4514Y 4500 Flite-Flow Globe Stop (Y-Type) 4-6

4592Y 4500 Flite-Flow Check (Y-Type) 4-6

Type IV design used in the 4500 lb. valve

is unique in that the gasket retainer segments are located below the bonnet. The

pressure-seal force is derived by pulling the

bonnet retainer down.

Type IV

Illustration No. 4

Pressure-Seal Bonnet

Type III (continued)

Type IV

Page 8

8

Flow Control Division

Edward Valves

Packing Chamber Leak

Where moisture appears or actual dripping

occurs at the packing chamber around the

stem, gland or gland flange, which cannot

be eliminated by retorqueing the gland bolt,

the following points should be considered.

1. The packing may have become hard.

Replace the packing.

2. Gland travel has been fully taken up.

Repack with new packing.

3. The wrong packing is being used.

See packing recommendations shown

on this page.

4. A stem should be replaced when it

has become deeply scratched,

burred,or otherwise mutilated from

careless handling, or where the stem

has worn, tapered or has been bent.

5. The gaps in the rings of split packing

have not been staggered around the

stem. They should be inserted in this

manner.

6. The packing gland may be binding

against the packing chamber or stem

and does not compress the packing

properly. Make certain the gland fits

the packing chamber and is tightened down equally on each side.

Packing Recommendations

Edward valves are packed with all-purpose

packing sets.This is a combination of packing using braided rings at the top and bottom of the packing chamber and flexible

graphite packing in the center section.

Packing glands should be tightened down

enough to prevent leakage but not enough

to develop excessive operating torque.

When the gland has advanced approximately half way into the packing chamber,

it is recommended that additional packing

rings be added. To obtain best results, the

stem should be thoroughly cleaned.

Replacement packing should be the same

as that originally furnished.

We recommend that replacement packing

be purchased from Edward Valves to

assure packing with the proper density and

corrosion inhibitors are always used.

Important:

Long service life from modern graphitic

packing requires that adequate preloads

be applied when repacking.

1. All parts should be clean and not

scored or pitted, especially the stem.

2. The valve internal parts and bonnet

should be assembled prior to

installing the packing.

3. Position split packing rings with the

ends of adjacent rings rotated 90°.

4. Install in the following sequence:

Bottom Ring – Braided Ring

Center Rings – Die formed

expanded graphite

Top Ring – Braided Ring

5. Clean and lubricate the gland eyebolts.

6. Carefully seat each individual packing ring before adding the next ring.

7. Apply the recommended torque to the

gland nuts evenly without cocking the

gland. See Table A for recommended

torques.

8. Tighten the nuts to the initial values

shown, then loosen and retighten to

the final torque.

9. Stroke the valve, then recheck the

gland nut torques.

NOTE: The torque values given are for

sealing full-rated pressure. For line pressures less than the full CWP rating of the

valve, the final torques may be reduced by

the ratio of P

actual

/CWP down to a mini-

mum of P

actual

= 1500 psig. This will

reduce packing drag and extend packing

life.

Service Problems

Page 9

9

Flow Control Division

Edward Valves

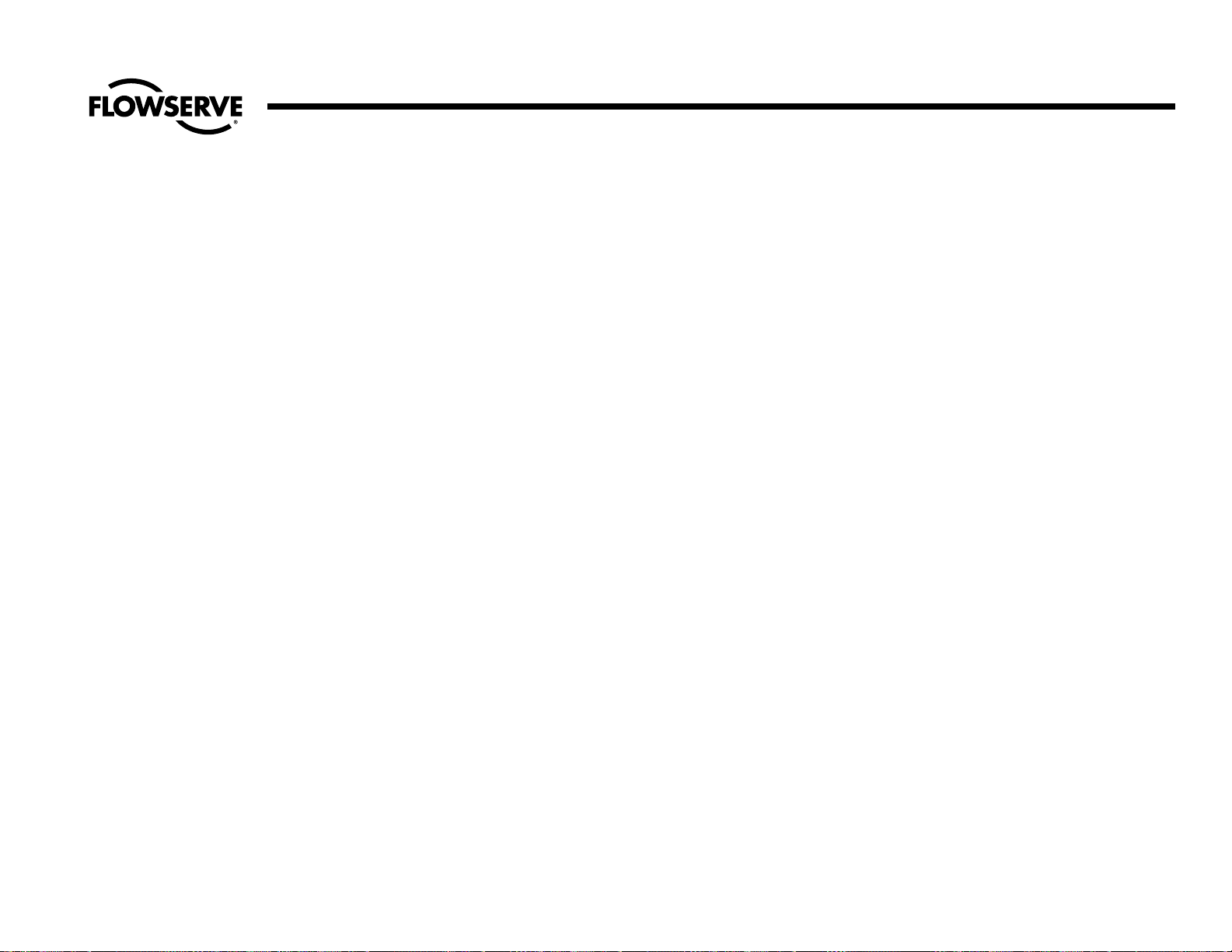

Service Problems (continued)

Initial Final

Figure Numbers Size Torque Torque

2.5 27 8

3278

604, 605, 606, 607 4 41 12

616, 617, 618, 619 5 55 16

704, 705, 706, 707 6 60 17

716, 717, 718, 719 8 89 26

10 143 41

12 209 60

14 233 67

64814

85516

10 62 18

602, 614, 702, 714 12 84 24

14 84 24

16 353 102

20 571 165

Table A

Gland Bolt Torques, ft.-lbs.

Class 600 Valves

Initial Final

Figure Numbers Size Torque Torque

65825

86930

4002, 4014, 4302, 4314 10 115 50

12 185 80

14 185 80

16 206 89

35524

47934

4006, 4007, 4016, 4017 5 84 36

4306, 4307, 4316, 4317 6 89 39

8 143 62

10 199 86

12 252 109

4006, 4016, 4306, 4316 14 266 115

14 252 109

4007, 4017, 4307, 4317 16 331 143

20 633 274

Table A (continued)

Gland Bolt Torques, ft.-lbs.

Class 900 Valves

Initial Final

Figure Numbers Size Torque Torque

7506, 7507, 7516, 7517 2.5 29 21

2006, 2007, 2016, 2017 3 55 40

47857

58461

7502, 7506, 7507, 7514 6 90 65

7516, 7517, 2002, 2006, 8 200 145

2007, 2014, 2016, 2017 10 159 114

12 353 255

7502, 7514 14 353 255

7506, 7507, 7516, 7517 14 378 273

2006, 2007, 2016, 2017

7502, 7507, 7514, 7517 16 672 484

2002, 2007, 2014, 2017 18 672 484

Table A (continued)

Gland Bolt Torques, ft.-lbs.

Class 1500 Valves

Initial Final

Figure Numbers Size Torque Torque

3906, 3507, 3916, 3917 2.5 29 29

4406, 4407, 4416, 4417 3 51 51

460 60

590 90

3902, 3906, 3907, 3914, 6 143 143

3916, 3917, 4402, 4406, 8 267 267

4407, 4414, 4416, 4417 10 286 286

12 473 473

3902, 3907, 3914, 3917 14 479 479

4402, 4407, 4414, 4417 16 479 479

19 269 269

20 269 269

Table A (continued)

Gland Bolt Torques, ft.-lbs.

Class 2500 Valves

Page 10

10

Flow Control Division

Edward Valves

Pressure-Seal Gasket Leak

Edward valves have been produced with

two types of pressure-seal gasket: Earlier

valves had metal gaskets, while later

designs have composite expanded graphite

gaskets. The valves with composite gaskets

can be identified by a “B” prefix on the figure number. Assembly and disassembly of

the two gasket types are essentially the

same except the composite gasket designs

may have belleville spring washers under

the nuts (or capscrews) of the pull-up bolting, and the tightening torque requirements

for the pull-up bolting are different.

To guard against leakage, the bolts should

be kept tightened at all times.

A torque wrench should be used for tightening the bonnet or cover retainer stud nuts or

capscrews, which are used to preload the

pressure-seal gasket.

All nuts/capscrews should be tightened in

an alternating star pattern to ensure even

tightening.

The bolting should be tightened to the

torque values shown in Table B while the

valve is under full line pressure.

Pressure-Seal Leak

Should the leak fail to stop after tightening,

it must be concluded that there is an imperfect pressure-seal, and the valve will have

to be opened for examination. (Note:

Regardless of the cause of failure, opened

pressure-seal bonnets should always be

reassembled with a new gasket. These are

available from stock via Air Express from

Raleigh, North Carolina.) Such a leak may

result from any of the following causes:

1. Incomplete Seal Between Bonnet and

Gasket. An incomplete seal around

the gasket seating surface of the bonnet (or cover on check valves) may be

caused by corrosion, dirt, chips, or

other foreign matter on the mating surfaces of the sealing angle.

2. Incomplete Seal Between Body I.D.

and Gasket. An incomplete seal in

the area of the gasket and body I.D.

contact may be caused by surface

imperfections in the body wall in the

form of pin holes, extended cracks, or

indentations where the metal has

failed sometime after valve installation

and use. Such imperfections may be

surface indications of deeper flaws in

the body casting that may cause a bypass around the pressure-seal.

Seat and Disk Joint Leak

A leak existing between the seat and disk

of a closed valve might be indicated by

one of the following: a definite pressure

loss in the high-pressure side of the valve;

continued flow through an inspection drain

on the low-pressure side; or, in hot water or

steam lines, a downstream pipe that

remains hot beyond the usual length of time

and conductivity range.

Such a leak may be the result of a distorted

seat caused by uneven welding and stressrelieving temperatures that were present in

the body when mounting the valve in the

pipe line. It may also develop because of

the operator’s failure to close the valve

tightly. An increased velocity is imparted to

a flow forced through a very small opening. This increased velocity subsequently

gives rise to the “cutting” of both disk and

seat, particularly by particles of line scale

or rust in suspension or normal solids in

solution; or, in spite of the fact that the stellited hard-facing material on the seat and

disk is corrosion and erosion resistant,

grooves, pit marks, or other surface irregularities may be formed on the seat and disk

joint surfaces when the disk is closed

against a foreign body on the seat. This

sometimes occurs during the initial start-up

of a piping system.

Service Problems (continued)

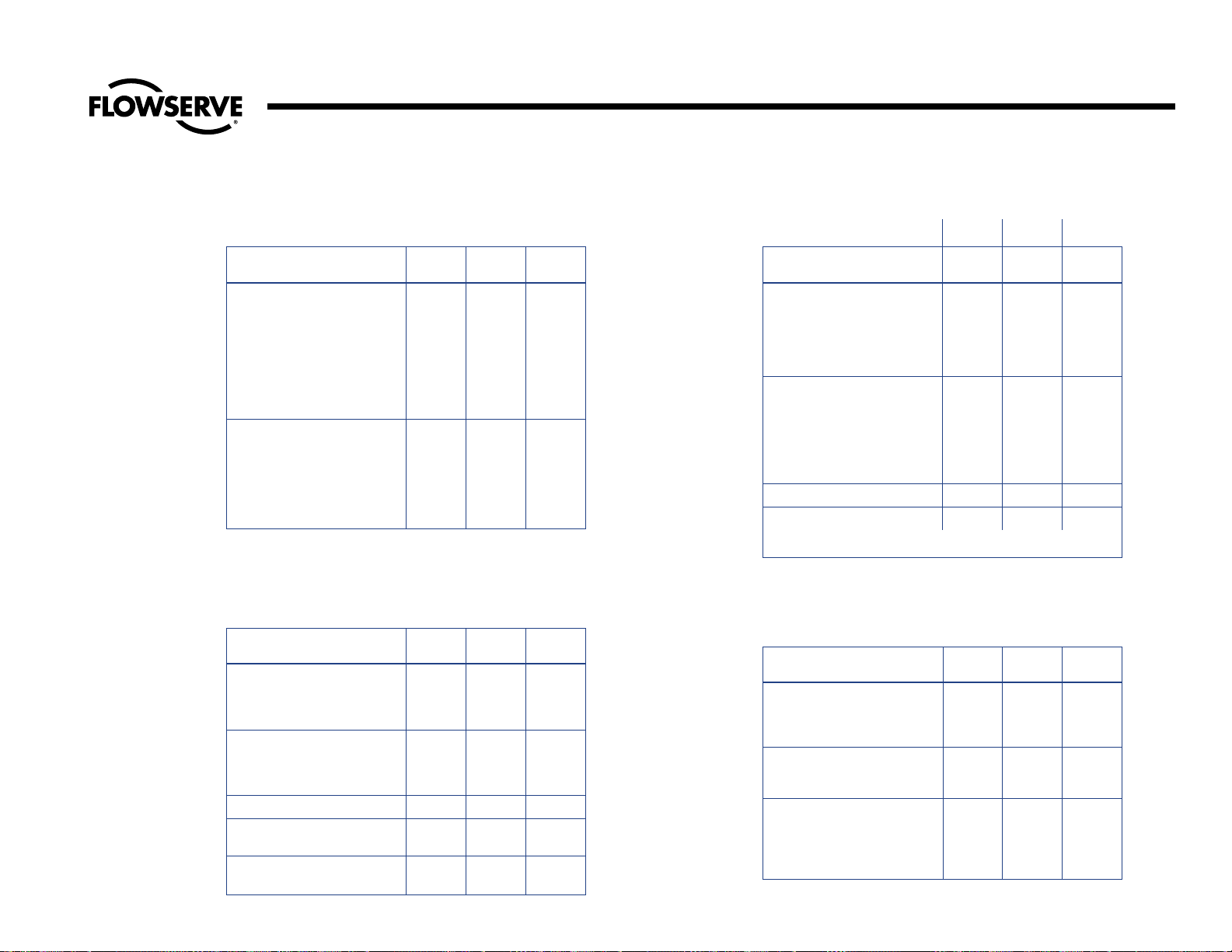

Table B

Bonnet/Cover Bolt/Nut Pull-Up

Torques

(With Valve Under Pressure)

REQUIRED TORQUE, FT-LBS

BOLT SIZE METAL COMPOSITE

GASKET GASKET

3/8 18 5

7/16 30 5

1/2 45 7

9/16 68 10

5/8 90 15

3/4 150 25

7/8 240 35

1 370 55

1-1/8 533 80

1-1/4 750 110

1-3/8 1020 150

1-1/2 1200 170

1-5/8 1650 230

1-3/4 2250 320

1-7/8 3000 420

2 3300 460

Page 11

11

Flow Control Division

Edward Valves

Leakage of steam through a valve that is

badly steam-cut has a whistling or

sonorous sound. If the valve is only slightly

steam-cut, however, leakage is identified

by subdued gurgling or weak popping

sounds. These sounds can be heard

through a stethoscope or by placing one

end of a stick against the valve body while

holding the other end between the teeth,

with hands over the ears.

To check for a properly closed valve, on

valves with nonrising type handwheels

(non-revolving stem), an indicator is

attached to the lower side of the yoke

bushing that coincides with a pointer

attached to the yoke, when the valve is

tightly closed. This can be viewed through

one of the yoke windows and it represents

the same relative position between the

yoke and yoke bushing, as when the valve

was hydrostatically seat-tested and found

to be tight at the factory. The hydrostatic

pressure is stamped on the indicator. It is

only natural that the indicator will travel

past this mark after repeated closings.

Some operators hesitate to force the valve

crossarm under the handwheel further than

this button, but no harm will be done even

if the indicator travels more than an inch

past the mark when holding a desired

pressure. If a tight seal is not made after

repeated impact blows, it must be concluded that the pressure is bypassing either at

the seat joint or body diaphragm between

the inlet and the outlet passage. Inspection

of the interior of the valve now is advisable.

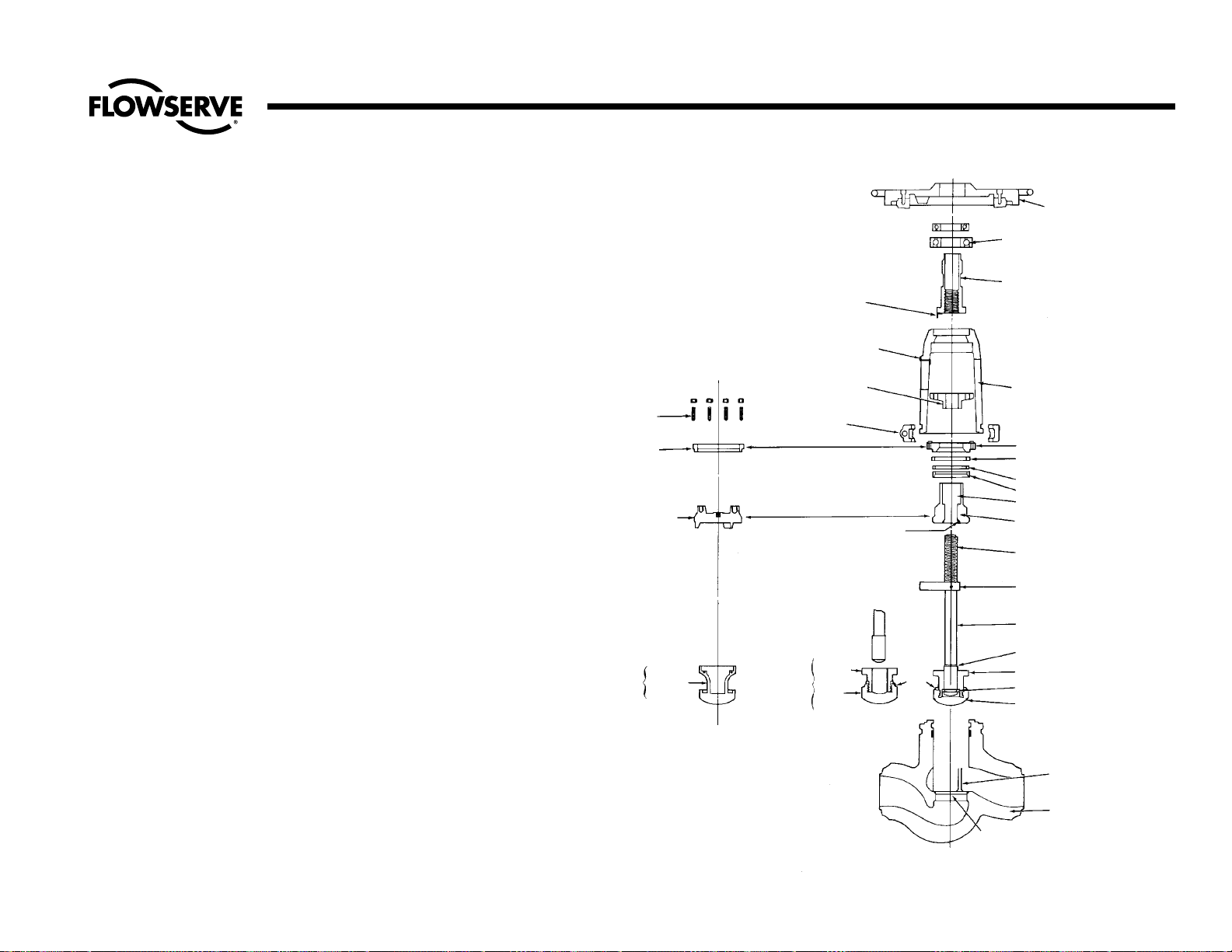

HANDWHEEL–

IMPACTOR TYPE

BEARINGS–USED ON NONREVOLVING STEM VALVES ONLY;

TAPERED AND SPHERICAL ROLLER

BEARINGS ALSO USED

LOCATION OF “INDICATOR” ON

YOKE BUSHING TO INDICATE

WHEN VALVE IS TIGHTLY SEATED

LOCATION OF “POINTER”

ON YOKE TO INDICATE WHEN

VALVE IS TIGHTLY SEATED

ONE-PIECE PACKING GLAND

(OR 2-PIECE GLAND FLANGE

AND GLAND ASSEMBLY)

YOKE LOCK RING

(2 PIECES)

BONNET BACKSEAT

COVER RETAINER

STUDS OR

CAP SCREWS

COVER RETAINER

USED ON

CHECK VALVES

PRESSURE-SEAL

COVER, USED ON

CHECK VALVES

YOKE BUSHING USED ON VALVES

WITH NON-REVOLVING STEMS

(CALLED STEM BUSHING ON

LIMITORQUE OPERATED VALVES)

TYPICAL YOKE–USED ON VALVES

WITH NON-REVOLVING STEMS

(YOKES USED ON OTHER VALVE

TYPES DIFFER)

BONNET RETAINER

SPACER RING

PRESSURE-SEAL GASKET

PACKING CHAMBER

STEM THREADS

STEM GUIDE COLLAR ON

NON-REVOLVING STEMS

STEM

STEM BACKSEAT

DISK NUT

STEM COLLAR

DISK

LOCK

WELD

BODY GUIDE RIBS

(ONLY ONE SHOWN)

SEAT WITH STELLITE

HARD FACING

FOR STOP

CHECK

VALVES

DISK PISTON

ASSEMBLY

PISTON

PISTON

FOR

CHECK

VALVES

DISK

BODY

FOR STOP

VALVES

DISK STEM

ASSEMBLY

TYPICAL PRESSURE-SEAL

BONNET AS USED ON STOP &

STOP-CHECK VALVES

GASKET RETAINER SEGMENTS

(SEVERAL PIECES)

}

Illustration No. 5

Typical Globe Valve Nomenclature

Service Problems (continued)

Page 12

12

Flow Control Division

Edward Valves

Body Wall Leak

This is a visual leak through the body wall,

welding end or end flanges and may be the

result of a shrink cavity or other void in the

casting. If small at first, such a leak may go

unnoticed for a time, particularly if the valve

is heavily insulated and the pipe line at that

point is sufficiently warm to keep the insulation dry enough to escape notice.

Objectionable Vibration, Noise or

Excessive Pressure Drop

Excessive vibration noise or humming coming from within a stop-check, non-return or

check valve indicates the possibility that

the disk-piston assembly is wedged inside

the body. Such sticking may be caused by

uneven body guide rib wear on the downstream side induced by oversizing the

valve, or by corrosion, by flakes of line

scale, or by particles of weld spatter that

may have entered the valve during construction of the piping, and which later

washed up into the piston bearing area of

the body I.D.

On stop-check and non-return valves, the

stem position is indicated by the stem

guide collar on non-revolving stems, or by

the position of the handwheel on revolving

stems; the stem should normally be fully

open against the bonnet backseat in order

that the disk-piston can lift the full amount.

When the disk is not touching the bottom

of the stem or the bottom stop lugs on the

bonnet (due to a wedged disk-piston or

insufficient flow, for example), then the disk

assembly is free to move laterally within

the body. This motion in most cases causes

a slight vibration which can be felt through

the body, yoke and handwheel.

Screwing the stem down slowly to contact

the disk first increases the intensity of vibration to the hand and to the ear, but further

downward, movement of the stem builds

sufficient contact pressure and eliminates

the vibration. This also tends to dislodge

any foreign particles that may have been

the initial cause for disk-piston wedging.

The position of the lift indicator on the

yoke, where vibration ceased, should be

noted and any increase in pressure drop

indicated on available gauges recorded. It

may be that when the stem is screwed

back to the full open position, the disk will

again remain in a floating position, which

could indicate oversizing of the valve for

the flow conditions. It is always recommended that check valve size selection be

governed by flow conditions rather than by

adjacent piping. Oversizing induces vibration or noise and causes excessive, uneven

guide rib wear, giving rise to greater diskpiston assembly clearance on one side of

the body.

By means of other valves in the line, it may

be possible to vary the rate of flow through

a noisy check valve sharply enough (in a

short period of time) to dislodge the piston

from its wedged position.

Valve Lubrication

In order to obtain full service life, valves

require periodic lubrication of the bearings

and stem threads, as does any rotating

machinery.

On valves where the stem bushing and

bearings are in the motor operator, the

bearings are lubricated by the operator

lube supply, which should be maintained

at the recommend level.

Valves that have bearings in the top of the

yoke have lube fittings on the valve yoke

for convenient relubrication.

Stem threads also require periodic replenishment of the lubricant. Exposed threads

should be wiped clean of old grease and

accumulated dirt and fresh lubricant

applied. This can be most effectively done

with the valve in the closed position.

For valves that see frequent operation, the

lubricant should be replenished on bearings and stem threads every three months.

If extreme service conditions dictate, the

plant operating engineer should establish

a more frequent relube schedule.

For valves that are operated infrequently,

relubrication at least once a year is recommended. The recommended lubrication for

both bearings and stem threads is Rykon EP

#2, manufactured by The American Oil

Company. This is an extreme-pressure,

extreme-temperature lubricant of high

quality.

Valves equipped with automatic stem lubricators should be maintained in accordance

with the above instructions for the bearings

and as required to maintain the lube level

in the stem lubricator reservoir.

Service Problems (continued)

Page 13

13

Flow Control Division

Edward Valves

VALVE BODY REPAIRS

Body Bore Gasket Seal Area Repair

with Metal Gasket Only

Pressure-seal valves made prior to 1952

were made with a 47° bonnet seal angle

and the body bore seal was in the parent

metal of the body castings. In 1952 the

design was changed to a 25° seal angle

and the body castings were inlayed with

18-8 stainless at the seal area. When a leak

developed on the older valves, the gasket as

well as the body bore were wire drawn.

If the depth of defects are .010” or less,

the seal area can be honed using a

portable Sunnen Hone. This device is

adjustable for different bore sizes and can

be operated by one man using a portable

electric drill of 1/2“ to 3/4“ capacity.

When the defects are greater than .010”,

welding will be required to cut down the

repair time.

First make visual inspection all around this

area, noting, if possible, where flaws may

occur. Next wash the area with a suitable

solvent, drying with clean rags and, if necessary, polishing with a fine grade of

emery cloth to remove any undesirable

scale or foreign matter that may have been

deposited on the area suspected of having

flaws. Use a dye penetrant test if cracks

are suspected.

Where it is necessary to repair the body

inlay by welding, note the following:

1. Prior to any cutting or welding operations being performed on the valve, it

is necessary that adequate seat joint

protection be provided and some

means of insurance against getting

chips, weld spatter or other foreign

matter into the pipe line if the valve is

permanently mounted. A round piece

of sheet metal placed over the seat

and taped in place will furnish

adequate protection.

2. Chip out the defective area in the

body, being careful to remove the

affected portion to its end, inside

the casting, and to thoroughly clean

it away.

3. With a small hand grinder, grind the

chipped area smooth.

4. Preheat an area large enough

around the imperfection so that during the entire welding operation heat

will be retained at approximately

400°F.

5. Use a stainless steel inlay selected

from either 18-8 stainless steel rod,

Harstain 18-8, Stainlend “K” 18-8,

Stainweld 18-8 or equivalent.

6. Lay the weld in thin, even layers,

peening each layer before proceeding with the next, and being careful

to maintain a temperature above

400°F in the area being repaired.

Peening the bead actually stretches it

and counteracts its tendency to contract and shrink as it cools. The last

layer of weld must overlap onto the

sound metal to ensure a weld without

an undercut at the edges. The overlapping should be done along this

edge by using a welding rod of 1/8”

maximum diameter. The last layer

should bring the height of the welded

area up to 1/16” above the original

surface, as checked with a straight

edge along the body bore.

For this type of weld repair, it is recommended that the last layer be

pounded while still hot with the flat

face of the hammer. Thermal stress

relieving is not recommended.

With a hand grinder, rough grind the

welded surface to within about .010”

of the finished surface. A simple

template cut from thin sheet metal

and having the same arc as the body

bore diameter, and a straight edge

laid along the body bore can be

used as a guide. A final cut then can

be made, using a fixture similar to

the one shown in Illustration No. 9.

Final finishing can be done with the

adjustable Sunnen hone described on

page 17.

After removing all dirt, chips, slag,

spatter, and grinding dust from the

body, the bore should be polished

with fine emery cloth and then thoroughly cleaned before reassembly of

the valve.

It is best that a new pressure-seal gasket be used upon reassembly.

Body Bore Guide Rib Repair

Where more than one guide rib is

involved, each rib should be preheated

and welded before proceeding to the next.

1. Follow steps 1 through 3 of the section titled “Body Bore Gasket Seal

Area Repair” on this page.

Repair Procedures

Page 14

14

Flow Control Division

Edward Valves

2. Heat the body area adjacent to the

guide rib to approximately 200°F.

This can be done locally with an oxyacetylene torch.

3. Select the proper welding rod to suit

the body material (1/8” maximum

size rod is recommended here). See

page 16 for weld rod recommendations. Using the same welding procedure as described for step 6 in the

previous section, build up the guide

rib at least 1/16” above the original

finished surface. The welding should

be started at the bottom so as to create a small shelf, and then proceeded up the guide rib.

If stainless steel inlay is desired on

the guide ribs, use AWS 5.4, E309L

stainless electrodes.

4. Finishing after welding is also similar

to that described in the previous section and in addition, the edges of the

guide ribs should be rounded off

smooth. Check the progress of the

grinding by using a straight edge

and feeler gauges. As the bonnet

bore and guide rib approach alignment a light can be placed on one

side of the straight edge and the high

spots in the guide rib observed on

the other. Where a check valve or

stop-check (non-return) body is being

repaired, the progress of the finishing

cuts can also be measured by slipping some long pieces of shim stock

between the I.D. of the body guide

ribs and the O.D. of the disk-piston

assembly, which has been placed

centrally in position on the seat joint.

A shim should pass around the disk

at all three guide ribs with equal

clearance. The original design clearance is .020 to .030 inches on the

diameter. The disk-piston assembly

should also be moved up and down

to make sure that it is free.

It is recommended that where guide

rib repairs have been made, the seat

and disk joint be checked for distortion and relapped, if necessary.

Seat and Disk Repair

The following description does not apply to

tilting-disk check valves. For repair information on these valves, contact your local

Edward Sales representative.

A valve seat joint will require repairing in

any instance where the seating surface permits a leak because it has been altered

from the original state in which it was

shipped from the factory; where corrosion

has set in to cause pit marks on the seating

surfaces of either the body or disk; where

the seat has become distorted because of

an abnormal heating condition; or, where

a groove has been formed on the seat or

disk by closing the valve against a foreign

body. Verification of such a faulty condition

may be obtained by a seat blueing test or

by careful visual examination.

The stellited seats in these pressure-seal

valves are not easily scored, but where

reconditioning is necessary, the following

points should be observed:

Where an indentation or pit marks on

the valve seat joint are deep (.010 or

greater), a cast iron lap with suitable

lapping compound will speed up

repair. The included angle of the valve

seat is 90° and the cast iron lap should

be closely guided in the body bore during the lapping.

Lap first with the cast iron lap and finish

with the valve disk, which has been

reground or relapped, if necessary. For

initial lapping, use Clover compound

“A.” Norton 320 mixed with olive oil

or sperm oil to a molasses consistency

is also recommended for finish lapping.

For rough lapping, Carborundum H20

coarse is recommended.

In the lapping operation, lap against

the seat with a small quantity of the lapping compound placed between the

mating surfaces. It is important that not

too much pressure be applied on the

lap or disk against the seat. With the

lapping compound in place between

the mating surface, the lap or disk

should be reciprocally rotated as far as

arm movements will permit while standing in one position; the strokes should

be light, and the lap or disk should be

lifted frequently and turned to a new

position circularly around the valve

body so that lapping will be rotated

over a new area. To make cer tain the

pressure strokes are light, it is necessary on large valves to suspend the disk

and stem assembly from a coil spring in

such a manner as to allow the disk to

bear, but lightly, against the seat. See

Figure A on page 17; for another type

see Illustration No. 7.

Repair Procedures (continued)

Page 15

15

Flow Control Division

Edward Valves

For smaller size valves, a driving handle can be easily made of 3/8” diameter wire bent as per Fig. B on page 17.

These small assemblies, being much

lighter, do not require a supporting

spring. Stellited seating faces are hard

and lapping time is variable, depending on the extent of flaws on the surface

and the position of the valve in the line.

If a seat requires machining prior to

lapping, a fixture similar to that shown

in Illustrations 8 and 9 on page 17,

can be used.

The disk of stop valves will also require

refinishing. When the only defects that can

be found on the disk-stem assembly occur

on the seating surface, it becomes very

convenient to push the stem into a lathe

spindle and chuck on the disk nut diameter

without taking the assembly apart. (However, if the stem is too large to fit through the

lathe spindle, it will have to be taken apart

as described in the following paragraph).

Hold the disk using a four jaw chuck so

that the large O.D. and seating surface run

true. Grind the seating surface using a tool

post grinder. Just go deep enough to clean

the surface. Polish the seating surface with

fine emery cloth.

If, when checking the disk-stem assembly,

it is found that the assembly is tight or does

not swivel freely, it will be necessary to

disassemble. Occasionally it is possible to

cut the lock welds with a hack saw and

unscrew the disk from the disk nut. However, it will usually be found expedient to

chuck the disk O.D. in a lathe and cut the

lock welds, including the weld that penetrates the first thread. After this weld metal

has been cleaned away, the disk nut will

readily unscrew. Repair any damaged surfaces on the stem, disk nut, stem collars or

disk. Then proceed to repair the disk seating surface as described above. When finishing the disk in this manner, it will not be

necessary to lap it to the seat.

Body Wall Repair

There are five basic steps in repairing a

casting defect:

1. Cut out to sound metal. Attempting to

weld over the defect will only leave a

notch that may reintroduce the defect.

Cutting may be done by chipping,

grinding or flame gouging. The amount

of metal removed should be held to a

minimum to avoid distortion during subsequent welding.

2. Preheat, using the minimum temperature

specified by the material specification

and/or the design code. Use at least

400F on WC9 or C5 material, 300F on

WC6. Although cast carbon steels such

as WCB or WCC do not require preheat, it may be advantageous to

remove any moisture or other contaminants from the area to be welded. This

may also identify any leak paths. There

are also disadvantages to preheat,

especially localized preheat, that must

be considered when working in areas

of the casting with finish machined

dimensions. Distortion may result in

more damaging problems than those

concerns created by the original defect.

Lower preheats and the control of interpass temperature are two methods used

to minimize distortion.

3. Welding should be done by qualified

welders, using qualified procedures and

weld material of a chemistry matching

the casting (see Table on page 16 for

welding rod recommendations). The

final weld should be blended into the

contour of the casting.

4. Stress relieving is generally recommended. Decisions to not stress-relieve should

factor in piping code rules. The temperatures must be based on material specification and piping code recommendations. Again, since temperatures are

much higher than those experienced in

welding, there are also disadvantages

that must be considered. Distortion may

result in more damaging problems.

Lower temperature post-weld heat treatment is sometimes an option for carbon

steels.

5. The final weld should receive any needed nondestructive testing. This should

include a visual examination and liquid

penetrant or magnetic particle examination. Some major weld repairs could

even mandate radiography to ensure a

sound weld.

VALVE COMPONENT REPAIR

Disk-Piston Assembly Repair

It is possible that the bearing surfaces on

the O.D. of the disk-piston assembly and

I.D. of the body can become scored

deeply enough to cause a binding or

wedging of the piston assembly in a full, or

partially, open or closed position. Such

scores and resulting burrs may be caused

by particles of weld spatter, flakes of hard

Repair Procedures (continued)

Page 16

Flow Control Division

Edward Valves

Repair Procedures (continued)

line scale or other foreign matter that has

inadvertently gotten into the line. Upon disassembly, any body and disk-piston assembly burrs must be removed with emery

cloth, and the bearing surfaces otherwise

made smooth and clean again. Where the

burrs on the piston are very large, it may

be more convenient to chuck the assembly

in an engine lathe and file them off.

Bonnet or Cover Repair

In late 1951 and early 1952 important

changes were made in the pressure-seal gasket design. These changes have greatly

reduced the likelihood of gasket seal leakage. In any case of gasket or bonnet leakage necessitating repair or replacement, it is

strongly recommended that the valve be converted to the new style by replacing the bonnet, or cover, and the pressure-seal gasket.

Where foreign matter of any sort is responsible for a gasket seal leak on the outer

angular sealing surface of the bonnet, it is

very likely that it has caused an impression

in this same sealing surface that must be

removed completely before reassembling.

This can be done by taking a shaving or

skin cut on the sealing surface. In so

doing, it is mandatory that the work be

chucked concentric and square to all existing diameters and surfaces and that the

angle be remachined at 25°, plus 1/2°,

minus 0° as shown in Illustration No. 6.

For old style valves the angle should be

47°, plus 1/2°, minus 0°. When finished,

this surface must be smooth and free from

any marks or surface blemishes, and the

circumferential point where the largest

O.D. meets the angular seal surface must

be lightly honed to remove any sharp

edges or fins.

Welding Rod Recommendations

PRESSURE

SEAL

GASKET

25° +1/2°

–0°

Illustration No. 6

Pressure-Seal Bonnet Seal Angle

Material to be Welded

Weld Rod

Recommendations

ASME IX

Material ASTM Grade AWS Classification

P-Numbers

P-1 Carbon Steel 1. ASTM A216, Grade WCB AWS 5.1

2. ASTM A105 E7018

P-4 1-1/4% Chromium, 1. ASTM A217, Grade WC6 AWS 5.5

1/2% Molybdenum 2. ASTM A182, Grade F11 E8018-B2

Low Alloy Steel

P-5 2-1/4 Chromium, 1. ASTM A217, Grade WC9 AWS 5.5

1% Molybdenum 2. ASTM A182, Grade F22 E9018-B3

Low-Alloy Steel

P-8 18% Chromium, 1. ASTM A351, Grade CF8M AWS 5.4

8% Nickel 2. ASTM A182, Grade F316 E316

Stainless Steel

P-8 18% Chromium, 1. ASTM A351, Grade CF8C AWS 5.4

8% Nickel 2. ASTM A182, Grade F347 E347

Stainless Steel

Welding Edward Valves In-Line

When welding a valve in-line, the installer should apply the specific technical rules imposed by the jurisdictional

authority of the area where the valve is installed. In the absence of such rules, following are suggested practices

for welding Edward Valves in-line:

1. Welding should be done using procedures and personnel qualified in accordance with ASME Section IX. Rules

for preheat and postheat are stated in Chapter V of ASME B31.1 (Power Piping).

2. The valve should be welded in-line, one end at a time, in a closed position (approximately a half-turn after the

seat in the body comes in contact with the disk). This is suggested to preclude warpage between seating surfaces caused by temperature-induced stresses during welding or subsequent heat treat. It also protects the seat

from weld spatter that might coat the lapped seat and disk. When post-weld heat treat is required, each weld

end should be heat-treated one at a time, to minimize impact of heat on valve internals. Do not heat treat an

Edward Valve with a piping attached as a unit in a furnace, as warpage of parts may occur. After welding,

open the valve and flush the line to clean out all foreign matter.

16

Page 17

17

Flow Control Division

Edward Valves

Field Repair Equipment

Available from the Edward Manufacturing

plant in Raleigh, N.C., are some basic

tools for repairing valves in the field. This

equipment was developed for customer use

on a rental basis. Of course, an emphasis

has been placed on large valve repairs

where economics justify extensive repairs

in the field rather than removing the valve

from the pipe line for return to the factory.

Contact your local Edward Valves sales

representative for more information. A list

of this equipment follows:

1. Lapping equipment for all pressureseal valves from 2-1/2 to 18” in all

pressure classes. See Figs. A, B and

Illustration No. 7 on this page.

2. Self-centering, lap-guide fixtures for

lapping valve seats in valves 8” and

up in all pressure classes. See Figs.

C, D on this page. This fixture can be

used when the valve is installed in

any position, and is suggested in

place of (1) above, when the stem is

horizontal or mounted down.

3. Sunnen Portable Hone for honing

pressure-seal bores from 4” to

14-1/2“ diameter. (Not illustrated)

4. Van Norman portable boring

machine for reboring valves in the

field. Grinding attachments are also

available to some sizes for grinding

seat joints. See Illustrations No. 8

and No. 9 on this page.

5. Air-driven portable boring machine

for reboring guide ribs and seats of

valve bodies in the line. (Not

illustrated)

SPRING

GUIDE PLATE

GUIDE PLATE

FRICTION CLAMP

FRICTION CLAMP

SPRING

SPRING

SOFT STEEL

BUSHING

SOFT STEEL

BUSHING

YOKE LOCK

RING

STEEL PILOT

PLATE

STEEL PILOT

PLATE

DISK DRIVER FOR

LAPPING LARGE VALVES

DISK DRIVER FOR

LAPPING SMALL VALVES

SEAT AND DISK LAPPING

FIXTURE FOR VALVES

MOUNTED WITH STEM

DOWN OR HORIZONTAL

(SHOWING VALVE WITH YOKE

LOCK RING CONNECTION

TO BODY)

SEAT AND DISK LAPPING

FIXTURE FOR VALVES

MOUNTED WITH STEM

DOWN OR HORIZONTAL

(SHOWING VALVE WITH

STUDDED YOKE CONNECTION

TO BODY)

Fig. A

Fig. C

Fig. D

Fig. B

Illustration No. 7

Portable Lapping Tool

for Large Valves

Illustration No. 8

Van Norman

Portable

Grinding Machine

Illustration No. 9

Van Norman

Portable

Boring Machine

Page 18

18

Flow Control Division

Edward Valves

Introduction

Step-by-step disassembly procedures are

described for all types of Edward pressureseal bonnet valves, including those with

manual and motor operators. It is impor-

tant that the following paragraphs be read

and understood before any specific

disassembly work is started.

First Determine the Area

of Failure

Failures or maintenance problems, for

other than check valves, can be divided

into three major areas. The area involved

will affect the disassembly procedure to be

followed. These areas, in general, are:

Area 1 The impactor Handwheel or

Handle, or the Limitorque

Operator.

Area 2 The yoke assembly, including the

yoke and yoke bushing, and in

addition on non-revolving stem

valves, the yoke bearings and

stem guide collar.

Area 3 The valve internals, including the

bonnet, body, stem, disk, disk-nut,

gland and seats.

If failure is indicated in Area 1, refer to the

applicable section “Disassembly Procedure

for Impactor Handles” on page 19, or

“Disassembly Procedure for Removing Limitorque Operators from Valve Yokes” on

page 20.

If failure is indicated in Area 2, it will be

necessary to first remove the valve operator. Therefore, refer first to the applicable

operator disassembly procedure described

in the above paragraph. Then proceed to

the section “Disassembly Procedure for

Yoke Assemblies” on page 27, for the

actual disassembly of Area 2.

If failure is indicated in Area 3, two methods are available. In method 1, the operator and yoke assembly may be removed

from the valve body as a unit. This requires

less time but requires adequate clearance

area above the valve. Also, large handwheels, say 48” diameter and above, are

massive and sometimes difficult to handle

when attached to the yoke assembly. For

these reasons, the second method is to first

remove the operator from the yoke, and then

the yoke from the body, in separate steps.

Disassembly Procedures for Pressure-Seal Valves

CAUTION

As a general reminder, make sure all pressure is removed from

valves, both upstream and downstream, before any disassembly

work is started. An exception to this is valves requiring service

only on the operator (Area 1) or Yoke Assembly (Area 2),

where the valve can remain in service. NOTE: Removal of the

yoke assembly under pressure does not apply to revolving stem

valves, only non-revolving. The following stem positions should

be observed:

1. For service in Area 1:

a. If pressure is to be maintained in the valve, back seat to the full

open position. On Limitorque operated valves, only torque-only

operators will permit service in Area 1 under pressure. See

definition of “torque-only” units on page 22.

b. If no pressure is to be maintained in the valve, close the

valve fully and open approximately 1/8”.

2. For service in Area 2:

a. For non-revolving stems only, if pressure is to be main-

tained in the valve, back seat to the full open position.

Never service revolving stem valves in Area 2 while

under pressure.

b. If no pressure is to be maintained in the valve, close the

valve fully and open approximately 1/8”.

3. For service in Area 3:

Close the valve fully and open approximately 1/8”.

Service Area 3 only without pressure in the valve.

Page 19

19

Flow Control Division

Edward Valves

For Method 1, first remove the operator-

yoke assembly combination as described

in “Procedure for Removing Valve Opera-

tor and Yoke Assembly as a Unit” on page

29. Then proceed to the section “Disassembly Procedure of Bonnet Types” on page

31, omitting any steps preceded by an

asterisk (*) for the actual disassembly of

Area 3. On all revolving stem and Type IV

bonnets, only method 2, as follows, should

be used.

For Method 2, first remove the operator by

following the applicable section, “Disas-

sembly Procedure for Impactor Handwheels

and Handles” on page 19, or “Disassembly Procedure for Removing Operators

from Valve Yokes” on page 22. Then, pro-

ceed to the section “Disassembly Procedure

of Bonnet Types” on page 31, for actual

disassembly of Area 3. On Type IV bonnets, reverse this procedure and complete

steps 1 through 9 on pages 39 & 40,

before beginning operator disassembly.

If failures are indicated in any combination

of Areas 1, 2, or 3, then each of the

respective procedures must be followed.

For check valves without stems or operators, simply use the proper section under

“Disassembly Procedure of Bonnet Types”

on page 31.

Disassembly Procedures

for Impactogear Handles

and Handwheels

(With or Without Impactogear

Air Wrench Operators)

AREA 1

Edward pressure-seal valves use several

designs of Impactor handles or handwheels, depending upon the valve size

and pressure class.

Handwheels can be removed while the

valve is pressurized, but caution must be

observed to make certain that it’s first in

the back-seated or fully opened position.

See “Caution” on page 18.

Valves equipped with Impactogear air

wrench operators do not require disassembly of the Impactogear itself. However, during regular impactor handwheel disassembly, the Impactogear pinion gear and the

handwheel gear will be separated.

All of the following handwheel disassembly

procedures are arranged in accordance

with the general comments on page 18.

Study these pages carefully before beginning disassembly.

To disassemble, first determine the type of

handwheel on the valve by measuring its

diameter or referring to the valve dimension drawing. Then select the proper

procedure, as listed below.

Disassembly Procedures for Pressure-Seal Valves (continued)

Page 20

20

Flow Control Division

Edward Valves

Non-Ball Bearing Type Impactor

Handles and Handwheels

All have 12, 14, 16, 20, 26, or 30 inch

diameters. See Illustrations No. 10, 11,

and 12 on this page.

These handwheels are of relatively simple

design and utilize fewer parts than the ball

bearing type. (Not to be confused with ball

bearings in the valve yoke.) Not illustrated,

but of similar construction to Illustration

No. 10 on this page, are Impactor handles. The following instructions apply, in

general, to all non-ball bearing types.

1. Remove the handwheel locknut,

which is the uppermost part on the

top of the valve stem. On some

designs, it is a friction device and is

merely unscrewed. On others, a roll

pin must first be driven out. On

another design, a small lock screw

must be unscrewed.

2. Mark the relative position of the handwheel and cross arm so the original

relationship can be restored when

reassembling. If this is not done, the

handwheel could be reassembled

180° out of the original position.

3. Lift the handwheel off the valve, using

a suitable capacity chain hoist for

large handwheels. If the stem of the

valve is mounted vertically, position

the hoist directly above the handwheel. Otherwise, the hoist should be

positioned slightly away from the

handwheel in line with the stem.

4. Crossarm Removal: For all valves

being serviced in Area I or revolving

stem valves in Area 2, the crossarm

can be removed by tapping lightly

with a hammer on the underside. If

the crossarm is keyed to the yoke

bushing, as in non-revolving stem

valves, the handwheel bushing is first

removed by unscrewing the cap

screws holding the handwheel bushing to the handwheel, and then

unscrewing the handwheel bushing

from the yoke bushing. The keyed

crossarm can now be removed by

tapping the underside with a hammer

and lifting off.

Illustration No. 12

Impactor Handwheel

Non-Ball Bearing Types

Illustration No. 11

Impactor Handwheel

Non-Ball Bearing Types

Illustration No. 10

Impactor Handwheel

Non-Ball Bearing Types

CROSSARM

ROLL PIN

HANDWHEEL LOCKNUT

HANDWHEEL LOCKNUT

ADAPTER (EQUIVALENT

TO CROSSARM

IMPACTOR

HANDWHEEL

IMPACTOR

HANDWHEEL

IMPACTOR HANDWHEEL

VALVE YOKE BEARING

HANDWHEEL LOCK NUT

LOCKSCREW

HANDWHEEL BUSHING

CROSSARM

KEY

Disassembly Procedures for Impactor Handles & Handwheels

Page 21

Flow Control Division

Edward Valves

Disassembly Procedures for Impactor Handles & Handwheels (continued)

BEARING NUT

BALL BEARING

GEAR COVER ASSEMBLY

(VALVE YOKE)

CROSSARM

(VALVE YOKE BUSHING)

(VALVE YOKE BEARING)

SHOWN WITH

IMPACTOGEAR

IMPACTOR

HANDWHEEL

LOCKING

SCREWS

KEY

Ball Bearing Impactor Handwheels

(With or without Impactogears)

All have 28, 36, 48 or 72” diameters. See

Illustration No. 13 on this page.

These impactor handwheels differ in diam-

eter and design from the non-bearing type

in that the handwheel turns on ball bearings. The following instructions apply to all

sizes.

1. Remove the cover plate screws and

the cover plate.

2. Back off all of the locking screws.

3. Mark the relative position of the

handwheel and crossarm so the original relationship can be restored when

reassembling. If this is not done, the

handwheel could be reassembled

180° out of the original position.

4. Provide a suitable capacity chain

hoist, at least 1500 lb., to remove

the handwheel. If the stem of the

valve is mounted vertically, position

the hoist directly above the handwheel. Otherwise the hoist should be

placed slightly away from the handwheel in line with the stem.

a. The handwheel bearing nut and

handwheel are removed as an

assembly.

b. Unscrew the handwheel bearing

nut using a tool to engage the two

drive holes in the top of the nut or

a strap wrench on the O.D. To

prevent the yoke bushing from

turning, hold it with a strap

wrench or other suitable tool.

c. Begin with all slack out of the

hoist, and retain a taut chain by

simultaneously taking up the slack

as the handwheel bearing nut is

fully unscrewed and lifted off the

valve.

5. Crossarm Removal: For all valves

being serviced in Area I or revolving

stem valves in Area 2, the crossarm

can be removed by tapping lightly

with a hammer on the underside until

it is free of the key(s).

6. If malfunction is indicated within the

handwheel bearing, the balls can be

removed by unscrewing the filler hole

set screw, tipping the handwheel so

the hole is down, and ‘fishing’ out

the individual balls. Need for this

should be rare, if ever.

Illustration No. 13

Impactor Handwheel Ball Bearing Type (w/Impactogear)

21

Page 22

22

Flow Control Division

Edward Valves

Edward pressure-seal valves use various

types of Limitorque operators, depending

upon the size and pressure class, which

determines the torque requirements,

whether the stem is revolving or non-revolving, and whether the valve takes the stem

thrust (torque-only unit) or the operator

takes the stem thrust (torque and thrust

unit). The procedures below describe the

removal of these various types from the

valve yoke. Also included are complete

instructions for resetting the torque and

limit switches. Disassembly procedures for

the Limitorque operators themselves are not

included and appropriate instructions

should be obtained before starting.

On torque-only Limitorques, the operator

can be removed while the valve is pressurized, but caution must be observed to

make certain that the valve is first in the

back-seated or fully open position. See

“Caution” on page 18.

All of the following disassembly procedures

are arranged in accordance with the

general comments on page 18. Study these

pages carefully before beginning.

First, determine whether the valve stem is

revolving or non-revolving. For non-revolving stem valves, several procedures are

shown, depending upon the operator type.

Then determine whether the operator is a

torque-only or torque and thrust unit.

Revolving Stem Valves or NonRevolving Stem Valves with Torqueonly Units

All revolving stem valves use torque-only

units. The operator drive nut is connected

to the stem through a key. See Illustration

No. 14. Non-revolving stem valves using

torque-only units, have their drive nut

splined to the valve yoke bushing. See

Illustration No. 15.

1. Disconnect the electrical wiring to the

operator.

2. Position a sling on the motor operator

and attach a chain hoist of suitable

capacity to the sling.

3. Remove the nuts from the underside

of the yoke flange.

Procedures for Removing Limitorque Operators from Valve Yokes

Illustration No. 14

Torque-Only Limitorque Operator on

Revolving Stem Valve (SMA or SMB)

Illustration No. 15

Torque-Only Limitorque Operator on

Revolving Stem Valve (SMB-4T or 5T)

Illustration No. 16

Torque-Only Limitorque Operator on

Non-Revolving Stem Valve

Page 23

23

Flow Control Division

Edward Valves

4. Lift the operator up and completely

off the stem and stem key or the yoke

bushing splines.

5. Position the operator away to a clean

area for further disassembly, if

required.

Non-Revolving Stem Valves with

Torque and Thrust Units

See Illustration No. 17 on this page.

1. Disconnect the electrical wiring to the

operator.

2. Make certain the packing gland nuts

are tight.

3. Position a chain hoist of suitable

capacity so the operator is supported

in such a manner that the handwheel

can still be rotated. If the valve is

installed with its stem other than

vertical, the hoist should be positioned slightly away from the handwheel in line with the stem.

4. Remove the nuts from the underside

of the yoke flange.

5. Turn the operator handwheel in a

direction to close the valve, thus

unscrewing the operator from the

stem. Try to keep the weight on the

hoist as the handwheel is turned.

6. With the hoist, lift the operator clear

of the stem and place down on a

clean area for further disassembly, if

required.

Procedures for Removing Limitorque Operators from Valve Yokes (continued)

Torque and Thr ust Limitorque Operator on

Non-Revolving Stem Valve

Page 24

Limitorque Limit Switch and Torque

Switch Setting Procedures

The following descriptions apply only to

Limitorque valve controls. If another type

valve control is used, the appropriate manual should be consulted to determine the

proper setting of the limit switch and

torque switch.

Geared Limit Switch

See Illustration No. 18.

Numbers in parenthesis ( ) refer to callouts on Illustration No. 18 on this page.

When reassembling the Limitorque valve

control, the rotor type geared limit switch

should be reset as follows:

1. Make certain the electric current is

off.

2. Open the valve by hand until the

valve disk strikes the back seat. Note

the direction the intermittent gear

shaft (D) is turning. This slotted shaft

is extended through the gear case

and can be seen just above the rotor

connected to the open coil.

3. Back the valve off to allow for coast

of the moving parts.

4. With the valve in this position,

declutch the drive pinion (A) by

inserting a screwdriver in the drive

pinion setting rod (B) and turning

clockwise until it is tight.The intermittent gear shaft (D) can now be turned

by inserting a screwdriver in its slot.

5. a. Turn the intermittent gear shaft (D)

in the same direction as noted

when the valve was opened until

the contact on the rotor (C) connected to the open contactor circuit opens.

b. In the event this contact is already

open, turn this shaft in the opposite direction until it closes; then

back off on the shaft until the contact opens.

6. Unscrew the drive pinion setting rod

(B) until it reaches a firm stop, but do

not jam. This train of gears and contacts is now set.

Illustration No. 18

Limitorque Geared Limit Switch Assembly

WARNING

SHOULD IT BECOME NECESSARY TO

CHANGE THE TORQUE SWITCH SETTING

FOR ANY REASON, THE LOCAL EDWARD

REPRESENTATIVE SHOULD BE CONTACTED

AND HE WILL OBTAIN FROM THE FACTORY

THE CORRECT NEW SETTING.

THE TORQUE SWITCH FOR THE

MOTOR -OPERATED VALVE IS SET DURING

FACTORY ASSEMBLY TO CLOSE THE VALVE

AGAINST THE SPECIFIED UNBALANCED

PRESSURES AND REQUIRES THE SAME

ATTENTION FOR RESETTING.

24

Flow Control Division

Edward Valves

Procedures for Setting Actuator Torque and Limit Switches

Page 25

25

Flow Control Division

Edward Valves

7. Connect the electric current and

check this setting as follows:

a. Run the valve to mid-position by

hand.

b. Press the “open” pushbutton -

make sure moving the valve is in

the “open” direction.

c. Allow the limit switch to stop the

motor.

d. After the motor has stopped, turn

the valve by hand to make sure

their is sufficient clearance

between the valve backseat and