Page 1

Edward Valves

Maintenance Manual for Edward

Forged Steel Valves

Bolted and Screwed Bonnet Types

V-376 R3

V-376 R4

Page 2

Seats and Seat Finishing......................5

Disks and Disk Tack Welds ...................6

Backseat and Packings.........................7

Gland Bolts ........................................8

Reassembly.........................................9

General Information...........................10

Servicing Edward Forged Steel Valves...3

Introduction ........................................4

Contents

Flow Control Division

Edward Valves

3

Page 3

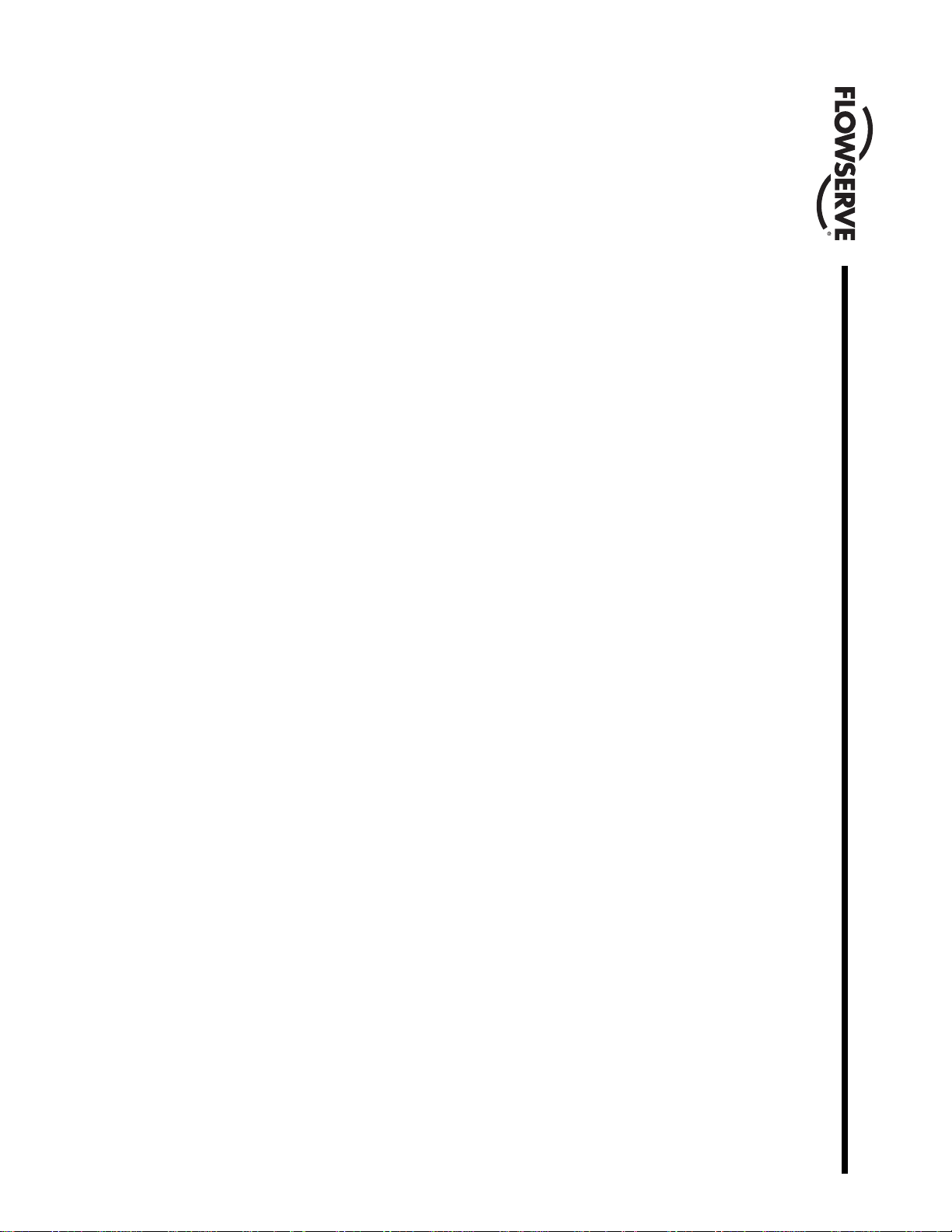

STRAIGHTWAY

Figure 1441

BLOW-OFF

VALVE

Bolted Bonnet, Bolted Gland, O.S.& Y

VALVE

BLOW-OFF

ANGLE

Figure 1443

Bolted Gland, O.S.& Y

Bolted Bonnet Stop,

Fig. 1048Y

Typical

Valve

Designs

Ser vicing Edward Forged Steel Valves

Bolted Cover Piston Check

Fig. 838

4

Screw, Screwed-in Seat

Screwed Gland, Inside

Screwed Bonnet Stop,

Fig. 158

Flow Control Division

Edward Valves

Page 4

Tools

Most Edward Forged Steel valves may be

readily disassembled with ordinary hand

tools. For the removal of screwed-in valve

seats, a special wrench may be necessary.

Disassembly

Be sure line is not under pressure when dis-

assembling valves

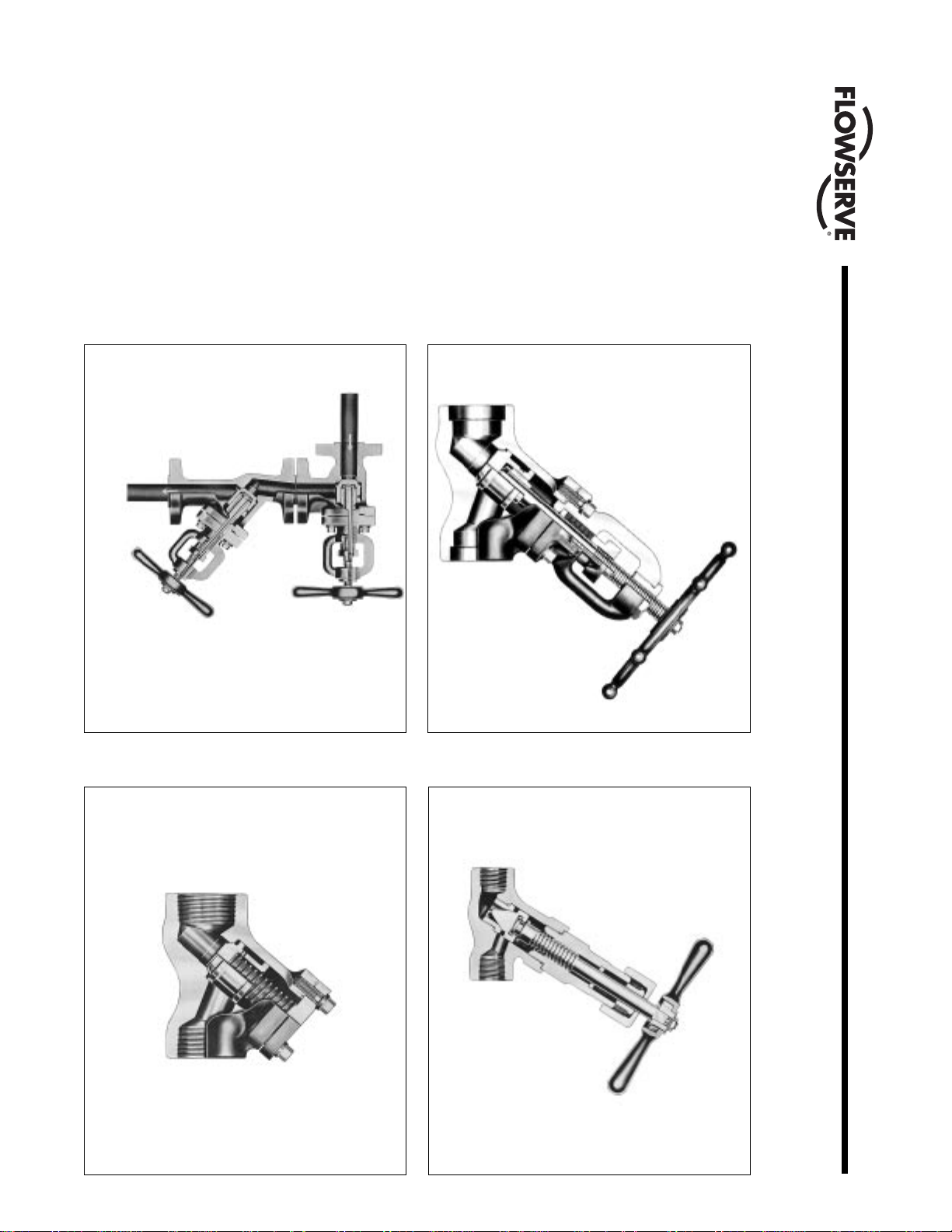

Typical Identification Plates

Bolted Cover Strainer

Fig. 238

This manual is provided to help you

service your Edward Forged Steel valves.

Before disassembling any valve, we recom-

mend that you check the valve identifica-

tion plate and note size, figure number

and pressure class, so that you can identify

it in the appropriate Edward Valve catalog.

This catalog will show typical cross sec-

tions to help identify the various parts.

Introduction

Bolted Bonnet

In bolted bonnet/cover style valves, cap

screws should be removed (see page 3

and below). The bonnet assembly or cover

can then be removed and the interior of

the valve exposed.

Screwed Bonnet

Small valves of the screwed bonnet type

are disassembled by unscrewing the

bonnet.

Screwed Bonnet Construction

Flow Control Division

Edward Valves

5

Page 5

machining. Seats can be cut with high-

speed tool bits. Stellite-faced seats must be

machined with tungsten-carbide tools or by

grinding. In replacing a screwed-in seat in

the valve body, care should be taken that

the face on the body against which the

seat shoulder rests is clean and true to pro-

vide a tight seal. New “O”- Rings should

always be used. Surfaces should be blued

and checked for contact all the way

around when replacing a seat. Care

should be taken that reworking does not

throw the sealing face between body and

seat out of line with the seat threads.

These valves should then be finish-lapped

using the valve disk assembly (see below).

Seat refinishing tools are also available for

integral Stellite seat valves. Consult your

Edward Valves representative.

Complete instructions for the repair and fin-

ishing of integral Stellite valve seats are

contained in “Univalve Operation and

Maintenance Manual” V-370.

Seat Finishing

After properly installing seats in valve

bodies or reworking integral seat valves, the

seat and disk should be lapped together. To

preclude galling, caution should be taken

not to apply too much pressure in lapping

Screwed-in seats can best be repaired, if

more than lightly damaged, by removal

from the valve. If screwed-in seats are

badly damaged, it may be more economi-

cal to replace them with new seats;

however, if they are repairable, they may

be remachined on a lathe. The part should

be accurately centered in the lathe before

Integral valve seating surfaces cannot be

removed for repair. Once the valve has

been disassembled and thoroughly

cleaned, determine the best procedure

based on the extent of damage. Lightly

damaged seats may simply be repaired by

lapping with the valve disk assembly.

Heavier damage may require the use of

special lapping tools or removal of the

valve body from the line for remachining.

Integral Seat

Edward valve seats are of two types:

screwed-in (with “O”- Ring Seal) or integral

with the valve body.

Seats

Seats and Seat Finishing

6

The effectiveness of valve seat lapping can

best be judged by blueing the disk and

rotating it lightly in the seat. A full contact

should be obtained around the circum-

ference of the seat. A valve that shows

this full contact should be pressure tight

after assembly when proper stem load

is applied.

Lapping with Valve Disk Assembly

Lapping with Lap or Abrasive Disk

seats and disks. Lapping should be done

with a light load, lifting the disk frequently

to a new position and cleaning the lapping

faces as required. See below:

Flow Control Division

Edward Valves

Page 6

Disk Nut Construction - All Univalves and

Post 1991 Bolted Bonnet Valves

Stellite Wire Construction

this contact should be checked, if possible,

to be sure it is in proper condition.

Disk Tack Welds

In body-guided valve disks with disk nuts,

the disk nut is secured to the disk by a

small weld through the side of the disk,

fusing the disk nut threads and preventing

loosening of the disk assembly in service.

Such disks can easily be disassembled if

required by drilling out the fused material

Disk Nut Construction - Bolted

Bonnet Valves - Pre 1991

Disk Nut Construction

radius at the disk contact to give center

loading. If foreign material gets between

this spherical surface and the disk, or if

galling occurs, it may not be possible to

close the valve tightly. In a leaking valve

Valve stems are normally provided with a

Typical Stop-Check Valve with Body-Guided Disk

Fig. 846

T-slot Construction

disk nut, or Stellite wire.

Disks

In all Edward valves, disks are designed to

swivel on the valve stem. They are held in

place by either a “T”-slot connection, a

Disks and Disk Tack Welds

Stop-Check valve disks are not attached to

the stem and respond to the fluid flow in

the same manner as check valve disks

(see below). The disk seating face can be

repaired in a similar manner to that

described for seats.

Valves may be body-guided by rings on

the disk or in the case of “T”-slot disks by

the disk outside diameter. A similar body-

guiding arrangement may be found in

check valves. Some ball check valves are

guided by an extension of the cover (see

Fig. 160). The wear on sliding surfaces

inside valves should be considered and the

surfaces checked to be sure wear has not

resulted in ridges in the guide bore, which

might impair disk movement. Guiding in

check valves is particularly critical.

7

Bolted Cover Piston Check

Fig. 838

at the bottom of the small hole in the disk.

The disk nut can then be unscrewed for

servicing. Care must be taken not to drill

through the disk nut wall or the stem may

be damaged. When repairs are complete,

the parts can be reassembled with care

being taken to screw the disk nut down

until only a few thousandths of an inch in

end play remain in the assembly. The parts

can then be lock-welded again by deposit-

ing weld metal at the bottom of the small

hole in the disk.

Flow Control Division

Edward Valves

Page 7

sized too large for flow condition will

sometimes have excessive wear, chatter

and noise.

Backseat

Edward stop valves have a backseat inte-

gral with the bonnet. The seating face on

the bonnet is generally a bevel and the

seating surface on the disk, disk nut, or

stem is provided with either a radius or a

bevel. Care must be taken of sealing sur-

faces on both the bonnet and the radius,

which seals against it to obtain a tight

backseat.

rings be added. To obtain best results, the

stem should be thoroughly cleaned.

Replacement packing should be the same

as that originally furnished. Edward valve

packings are inhibited to prevent stem

pitting in service.

We recommend packing be purchased

from Edward Valves to assure packing with

the proper density and corrosion inhibitors

is always used.

Foreign material in the flow medium may

wedge between guiding surfaces with the

possibility of making the disk stick. It is

recommended that piston check valves be

used where the fluids are clean and where

tight seating is important. In smaller sizes,

it is recommended that ball type check

valves be used where the problem of stick-

ing open is of serious consideration. Valves

Screwed-Cover, Cover-guided Ball Check,

Screwed-in Set

Fig. 160

Packings

Edward valves are packed with all-purpose

packing sets. This is a combination of

packing using braided rings at the top and

bottom of the packing chamber and flexi-

ble graphite packing in the center section.

Packing glands should be tightened down

enough to prevent leakage but not enough

to develop excessive operating torque.

When the gland has advanced approxi-

mately half way into the packing chamber,

it is recommended that additional packing

Integral Backseat Construction

The guides must be close enough to bring

the disk accurately down into the seat to

make a tight joint.

Backseat and Packings

IMPORTANT:

• Stroke the stem and then recheck the

torque on the gland bolts.

• Tighten nuts to the initial values

shown, then loosen and retighten to

the final range.

• IMPORTANT: Apply the recommended

using the gland.

torque to the gland nuts evenly with-

out cocking the gland. See table.

• Clean and lubricate the gland bolts.

• Tamp the packing down by hand

• Position split packing with the ends of

• Standard packing

Top Ring Braided Ring

Center Ring Flexible Graphite Ring

Bottom Ring Same as top

packing.

adjacent rings rotated 90°.

• All parts should be clean and not

• The stem, disk and bonnet should be

in the valve prior to installing the new

repacking.

scored or pitted, especially the stem.

• Long service life from modern

graphitic packing requires that ade-

quate preloads be applied when

Flow Control Division

Edward Valves

8

Page 8

Swing Type

Valves of the Fig. 158, 5158, 9158 (see

pg. 3) type have a packing nut with

threads that should be kept well lubricated

to prevent corrosion and eliminate packing

adjustment difficulties.

Gland Bolts

The removal of glands is accomplished by

removing the nuts. Swing bolts can be

removed by also driving out the pin.

FLEXIBLE

GRAPHITE

RING

BRAIDED

RINGS (2)

Packing Chamber Schematic

Yoke Bushing

valves and reduces wear of yoke bushings.

1046 FINAL 28-38 43-53 43-53 106-116 145-155

ALL TORQUES ARE GIVEN IN INCH-POUNDS EXCEPT WHERE NOTED

1028 INITIAL 40 62 62 153 210

1441,1443 INITIAL 250 287

1641,1643 FINAL 71-81 82-92

1069 FINAL 15-25 28-38 43-53 106-116 145-155

Yoke Bushing

The yoke bushings of small Edward valves

are threaded to the yoke. Bushings are

subject to wear in services where large

amounts of grit accumulate on the valve

threads. Lubrication aids easy operation of

849,868,869 FINAL 8-18 15-25 24-34 59-69 81-91

1029,1047 INITIAL 21 40 62 153 210

1048,1068

847,848

828,829 INITIAL 21 40 62 153 210

5158,9158 FINAL FT-LB FT-LB FT-LB FT-LB FT-LB

158 125-130 140-145 265-270 280-285 435-440

NUMBERS 1/2 3/4 1 1-1/2 2

Gland Bolts

FIGURE 1/4, 3/8 1-1/4

Packing Gland Torque

VALVE SIZE

Flow Control Division

Edward Valves

9

Page 9

NOTE: TORQUE IS MEASURED IN FOOT-POUNDS

9160

5158, 5160

2 158,160, 400-420 300

1-1/4, 1-1/2 158,160 320-340 150

1 158,160 240-260 125

18 30 45 68 90 150 240 370 585 750

3/4 158,160 100-120 60

3/8 7/16 1/2 9/16 5/8 3/4 7/8 1 1-1/8 1-1/4

Torque, Ft. Lbs.

1/4, 3/8, 1/2 158,160 75 40

SIZE NUMBER TORQUE TORQUE

Bolt diameter, Inches

VALVE FIGURE RING COVER

cated and tightened to develop sufficient

gasket compression.

Bolted Bonnet/Cover Torques

A torque wrench should be used for tight-

ening the bonnet, which is used to preload

the spiral-wound gaskets.

The following procedure is recommended:

1. Guard against leakage by having these

2. Capscrews should be tightened to the

torque shown below.

capscrews tight at all times.

mended torque. Sequence:4-3-2

Step #3

Torque to full recommended torque.

Sequence: 1-2-3-4

Note: The above noted method for tighten-

ing cover capscrews is for the purpose of

pulling the cover down evenly. If this objec-

tive can be achieved without following this

suggested method precisely, then some

variation from this method is permissible.

Seat Ring & Bonnet/Cover Torques

Valves of the screwed bonnet/cover type

construction are sealed at the bonnet by

flat, soft metal gaskets and “O”- Rings.

Screwed-in seats are also sealed by “O”-

Rings. Such seals require smooth clean

surfaces on body, bonnet or seat. Bolted

bonnet valves, such as Fig. 848 type, are

sealed with spiral-wound gaskets. In all

valves, new gaskets (and “O”- Rings) are

recommended for reassembly. Bonnet gas-

kets (and “O”- Rings) are inexpensive and

available out of factory stock.

Valves with screwed bonnet/cover joints

require the bonnet threads to be well lubri-

Step #1

Snug to approximately 10% of full recom-

mended torque. Sequence:1-2-3

Step #2

Torque to approximately 75% of full recom-

Reassembly

10

extreme pressure, extreme temperature

lubricant of high quality. For valves that

are operated infrequently, relubrication

should be at least once a year.

SEAT BONNET/

closed position.

For valves that see frequent operation,

such as motor-actuated, the lubricant

should be replenished every three months.

If extreme service conditions dictate, a

more frequent relube schedule is recom-

mended. Motor-actuated valves have a

lubricant fitting at the yoke flange.

The recommended lubricant for all stem

threads, bonnet, packing nut and bolt

threads is Rykon EP #2, manufactured by

the American Oil Company. This is an

Edward valves into piping, make sure

there is no foreign material on the seat

joint, then close the valve tightly to avoid

distorting the seats.

After welding, open the valve and flush the

line to clean out all foreign matter.

Lubrication

In order to obtain full service life, valves

require periodic lubrication of the stem

threads. Exposed threads should be wiped

clean of old grease and accumulated dirt

and fresh lubricant applied. This is most

effectively done with the valve in the

Welding Edward Valves into Piping

Welding is outside the scope of this manu-

al, but Edward recommends you consult

the appropriate welding procedure in

ASME/ANSI B31, or whatever other codes

apply to your system. When welding

Flow Control Division

Edward Valves

Page 10

to minimize flow disturbances. For addi-

tional information, refer to the “Technical”

section of the Edward Valves Catalog,

Publication No. EV-100.

avoided.

For optimum performance, the orientation

limits shown in Figures 1 and 2 should

be observed even for spring-loaded

check valves.

The orientation limits shown in Figures 1

and 2 must not be exceeded for Edward

stop-check valves and check valves with-

out springs. The limitations given for line

inclination and bonnet roll angle should

not be combined.

All check and stop-check valves should be

installed with 10 or more diameters

of straight pipe upstream of the valve

system to prevent the piping system pressure

from exceeding the maximum rated pressure

of the valve.

PIPING SUPPORT

Piping should be supported sufficiently to

preclude excessive end loads on the valve.

VALVE INSTALLATION GUIDELINES

Except as noted below, Edward stop valves

and stop-check or check valves with springs

can be installed in any position. Installed

positions with the valve cover or bonnet

below horizontal, where dirt and scale can

accumulate in the valve neck, should be

high-pressure side of the valve; continued

flow through an inspection drain on the low-

pressure side; or, in hot water or steam lines,

a downstream pipe that remains hot beyond

the usual length of time and conductivity

range.

Such a leak may be the result of closing on

dirt, scale or other foreign matter in the line.

It may also develop because of the operator’s

failure to close the valve tightly. An increased

velocity is imparted to a flow forced through

a very small opening. This increased velocity

subsequently gives rise to the “cutting” of

both disk and seat, particularly by particles

Edward valves are not provided with a pres-

sure relief device. A pressure relief device

must be provided elsewhere in the piping

WARNING

General Information

SEAT AND DISK JOINT LEAKS

A leak existing between the seat and disk of

a closed valve might be indicated by one of

the following: a definite pressure loss in the

11

11

hard-surfaced material on the seat and disk is

corrosion- and erosion-resistant, grooves, pit

marks, or other surface irregularities may be

formed on the seat and disk joint surfaces

when the disk is closed against a foreign

body on the seat. This sometimes occurs dur-

ing the initial start-up of a piping system.

Leakage of steam through a valve that is

badly steam-cut has a whistling or sonorous

sound. If the valve is only slightly steam-cut,

however, leakage is identified by subdued

gurgling or weak popping sounds. These

sounds can be heard through a stethoscope

or by placing one end of a stick against the

valve body while holding the other end

between the teeth, with hands over the ears.

of line scale or rust in suspension or normal

solids in solution. In spite of the fact that the

Flow Control Division

Edward Valves

Page 11

© 2003 Flowserve Corporation, Irving, Texas, USA. Flowserve and Edward Valves are registered trademarks of Flowserve Corporation. V-376 R3 3/03 Printed in USA

FLOWSERVE CORPORATION

FLOW CONTROL DIVISION

Edward Valves

1900 South Saunders Street

Raleigh, NC 27603 USA

Toll- Free Telephone Service

(U. S. and Canada)

Day: 1-800-225-6989

After Hours Customer Service

1-800-543-3927

US Sales Offices

Phone: 919-832-0525

Facsimile: 919-831-3369

Facsimile: 919-831-3376

Visit Our Website

www.edwardvalves.com

www.Flowserve.com

For more information about Flowserve Corporation, contact www.flowserve.com or call USA 1-800-225-6989.

one of its worldwide operations or offices.

While the information and specifications contained in this literature are believed to be accurate, they are supplied for informative purposes only and should not be considered certified or as a guarantee of satisfactory results by

reliance thereon. Nothing contained herein is to be construed as a warranty or guarantee, express or implied, regarding any matter with respect to this product. Because Flowserve is continually improving and upgrading its product

design, the specifications, dimensions and information contained herein are subject to change without notice. Should any question arise concerning these provisions, the purchaser/user should contact Flowserve Corporation at any

Flowserve products in connection with the specific application.

backseat a valve. This can result in damage

to the valve stem and bonnet backseat.

in blowout of the packing.

valves require the B/M number to properly

identify your valve.

cate the correct torque switch setting for

the valve. Exceeding these torque switch

settings can cause damage to the valve.

Never use an electric motor actuator to

Failure to torque the gasket properly will

result in gasket failure. When replacing the

valve stem packing, never machine the

packing chamber oversize. This will result

the correct parts for your Edward valve,

include the valve size, the figure number,

including any prefix and/or suffixes and,

if available, the B/M number. All nuclear

NOTES ON VALVE OPERATION

Valves equipped with electric motor actua-

tors have special tags attached, which indi-

NOTES ON VALVE MAINTENANCE

When replacing the bonnet gaskets, follow

the torque requirements on page 9 closely.

HOW TO ORDER PARTS

During normal working hours, call

800-225-6989 or 919-832-0525. To assure

Flowserve Corporation has established industry leadership in the design and manufacture of its products. When properly selected, this Flowserve product is designed to perform its intended function safely during its useful life.

However, the purchaser or user of Flowserve products should be aware that Flowserve products might be used in numerous applications under a wide variety of industrial service conditions. Although Flowserve can (and often does)

provide general guidelines, it cannot provide specific data and warnings for all possible applications. The purchaser/user must therefore assume the ultimate responsibility for the proper sizing and selection, installation, operation,

and maintenance of Flowserve products. The purchaser/user should read and understand the Installation Operation Maintenance (IOM) instructions included with the product, and train its employees and contractors in the safe use of

V-376 R4 7/10

This information is located on the valve

nameplate. The nameplate is attached to a

yoke leg via a cable. If the nameplate is

inaccessible, you can use your Edward

sales drawing; please include the drawing

number as well.

SERVICE

If you have any further questions on valve

repair or part replacement, your Edward

Valves representative will be happy to

assist you. Edward Valves catalogs are

available on request.

Edward Valves

Flow Control Division

Loading...

Loading...