Page 1

USER INSTRUCTIONS

Edward Valves

Univalve

Installation

Operation

Maintenance

Experience In Motion

FCD EVENIM2000-02(E)

(Bulletin V-370 R3)

1

Page 2

INTRODUCTION

EDWARD UNIVALVE USER INSTRUCTIONS ENGLISH 12-13

EDWARD CUSTOMER SERVICE

Consult your Edward factory inside sales representative for

information on obtaining repair tools.

As always, field sales and service personnel are available

to assist with maintenance and repairs involving Edward

valves. And they are backed up by factory-trained specialists

to lend additional assistance whenever needed.

An improved low-maintenance Univalve design... tools for

fast in-line repairs...and reliable Edward service!

TABLE OF CONTENTS

Edward Customer Service ..............................................2

Three Tools for Faster In-line Repairs

of Edward Univalves ........................................................2

Exploded View .................................................................3

Disassembling the Univalve ....................................... 4–5

Servicing Edward Univalve Stop and Stop-check Valves

..6

Servicing Edward Univalve Check Valves ........................7

Alternate Weld-cutting Methods for Univalves ................8

Univalve Maintenance Tools ..................................... 9–13

Reassembly of the Univalve ................................... 14–17

Reassembly of Unwelded Bonnet Univalves .............14

Reassembly of Welded Bonnet Univalves .................14

Replacing the Seal Weld Univalves ...............................18

A105 and F22 Univalves ...........................................18

F316 and F347 Univalves ..........................................18

Operational Recommendations .............................. 19–20

General Information ............................................... 21–22

TABLES

Valves With No Prefix in Figure Numbers .............. 10–11

Valves With “B” Prefix Figure Numbers ........................12

Valves With “C” and “D” Prefix Figure Numbers* .........13

Unwelded Univalve Bonnet Gasket Torques ..................15

Welded Univalve Bonnet Torques .................................16

Torque Range for Packing Gland Bolts .........................17

Minimum Torque for Closing Valves —

ft-lb on Main Seat .......................................................................19

Impactor Handle/Handwheel Performance Chart ..........20

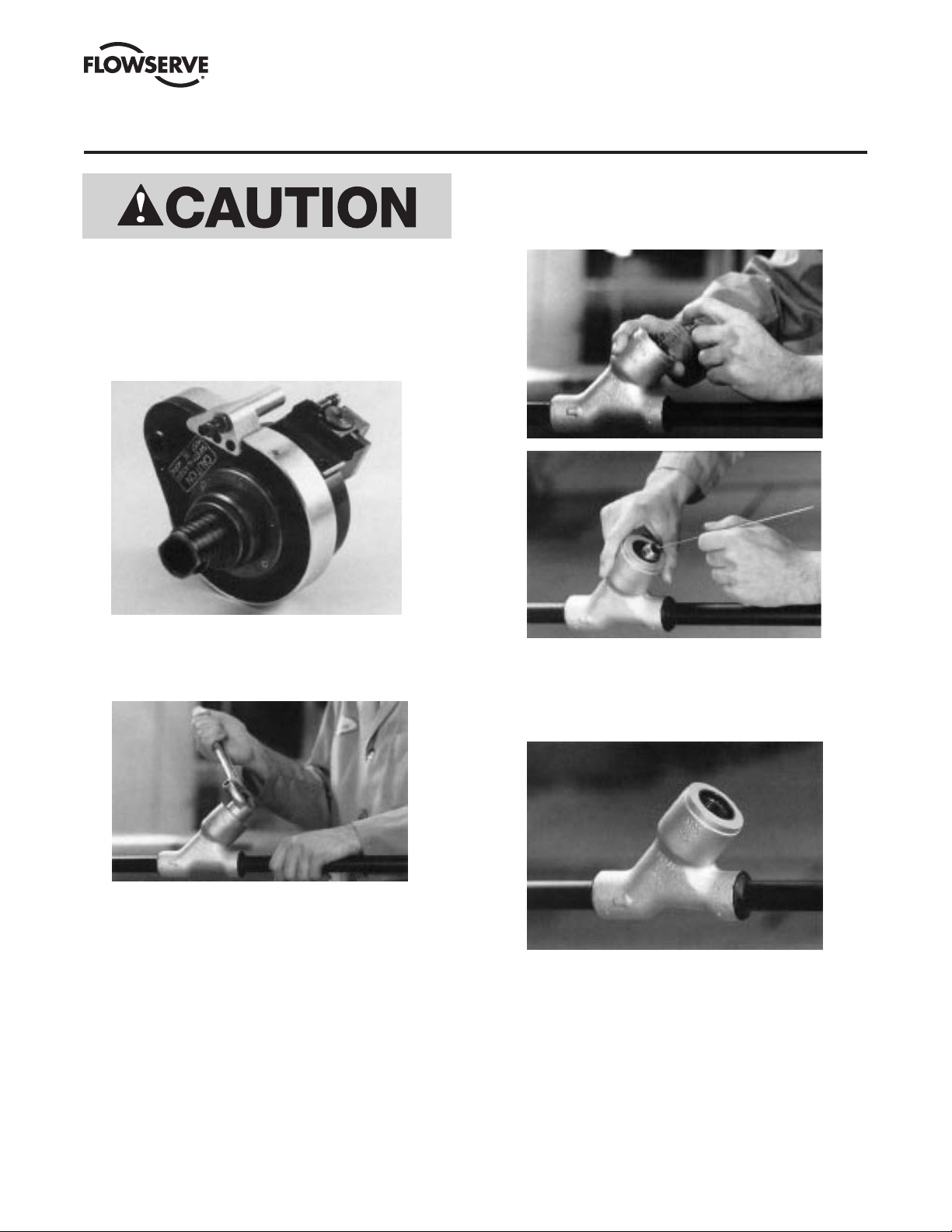

THREE TOOLS FOR FASTER IN-LINE REPAIRS OF

EDWARD UNIVALVES

Edward Univalves aren’t likely to require any maintenance

or repair work until they’ve been in services for quite a few

years. But sooner or later – depending on the nature of the

fluids, frequency of operation and time in service – Univalve

seats and disks may need to be repaired.

The Seat Refinishing Tool has

a self-centering head of multiple

tungsten carbide cutters on a

spindle which is hand-operated

with a speed wrench for complete

seat refinishing. Lapping or other

finishing work is not required to

produce refinished seats.

Seat damage, such as that

Seat Refinishing Tool

produced by foreign materials

in the line fluids, can be repaired

quickly.

The Bonnet Torquing Collar

is essentially a torque wrench

adapter that is used to remove

and reassemble the bonnet of an

unwelded Univalve.

The tool facilitates reassembly

of the bonnet with the required

torque correctly applied to ensure

that the graphitic body-bonnet

Bonnet Torquing Collar

gasket is properly loaded to

establish a leak-tight seal. The tool

may also be used to assemble and

disassemble seal-welded valves.

The Seal Weld Cutting Machine

has the ability to cut both fillet

and canopy welds. By removing

the handwheel and yoke, then

installing the machine, seal welds

can be cut, leaving a suitable weld

prep. The machine is operated by

one person and uses conventional

plant air.

Seal Weld Cutting Machine

2

Page 3

EXPLODED VIEW

16

15

14

EDWARD UNIVALVE USER INSTRUCTIONS ENGLISH 12-13

1

2

3

4

13

12

11

10

9

8

1. Stem Nut

2. Washer

3. Handwheel

4. Stem/Disk Assembly

5. Locking Collar

(unwelded bonnet valves only)

(shown turned 90°)

7

6. Body

7. Yoke Nut

8. Graphitic Gasket*

(unwelded bonnet valves only)

9. Bonnet

10. Packing

5

6

11. Yoke Belt

12. Gland

13. Yoke

14. Gland Adjusting Screws

15. Cap Plugs

16. Yoke Bushing

*Class 4500 welded bonnet Univalves have a bonnet insert and graphic gasket seal ring, as shown on page 14.

3

Page 4

DISASSEMBLING THE UNIVALVE

Line pressure must be relieved before disassembling

the valve.

1. Double-check to make sure that line pressure has been

relieved before disassembling the valve.

2. The valve should be in the open position and not

against the body seat or backseat.

EDWARD UNIVALVE USER INSTRUCTIONS ENGLISH 12-13

5. Loosen the yoke clamp bolt and nut. It is not necessary

to completely remove them.

6. Remove the yoke assembly by unscrewing it from

the bonnet. A gentle tap with a hammer might be

necessary before the yoke will unscrew away from

the bonnet. You may find it easier to remove the yoke

by placing the handwheel on the stem to prevent the

stem from rotating. When the yoke is even with the

top of the stem, and you can no longer use the valve

handwheel or handle, you will need to grasp the lower

portion of the stem between the yoke and bonnet. If

the yoke is turning freely, a cloth may be adequate to

hold the stem. If this is not adequate, a strap wrench

that will not damage the stem surface should be used.

If only the packing is to be replaced, this can now

be easily done with no further disassembly of the

Univalve. See Step 14.

3. If the valve is manually operated, remove the lock

nut that attaches the handwheel or impactor handle

to the valve stem. Remove the handwheel or handle.

If the valve is motor operated, remove the actuator

from the valve stem.

4. Loosen the two gland adjustment screws that rest

against the packing gland by threading them higher

into the yoke. A hex allen wrench inserted into the top

of the gland screw thru the holes in the top of the yoke

(remove the dirt protectors first) will speed this up.

7. If the yoke bushing is worn or damaged and must

be removed, insert 1⁄8” (or smaller) abrasive grinding

wheel into the slot on top of the bushing. Using a

standard grinding tool, work the grinder downward

to remove yoke metal that was upset into the bushing

during the valve assembly. Periodically during the

grinding process, try to turn the bushing within the

yoke to test how loose it is becoming. Once loosened,

use a screwdriver in the slot to turn the bushing. To

reinsert a new bushing, thread it into the yoke so that

the top of the bushing is flush with the top of the yoke.

Using a chisel and hammer, tap the yoke metal into the

bushing slot, creating an offset, so that the bushing is

tight within the yoke.

4

Page 5

EDWARD UNIVALVE USER INSTRUCTIONS ENGLISH 12-13

DISASSEMBLING THE UNIVALVE

8. If the valve is unwelded, remove the locking collar.

9. If the valve to be repaired is seal-welded, prepare

the Seal Weld Cutting Machine for the weld cutting

operation. If a cutting machine is not available, use one

of the alternate methods shown on pg. 8.

(continued)

11. Remove the valve bonnet-stem-disk assembly if the

valve being repaired is a stop valve (figure XXX2X).

The disk in a stop-check vaIve (figure XXX6X) and

the bonnet insert in welded Class 4500 vaIves (figure

961XX) may be removed by forming a short piece of

soft wire into the shape of an L and lifting it up in the

disk bore.

10. Refer to the chart on pp. 10–13 to select the proper

torquing collar assembly (consisting of lock nut and

collar). Screw the torquing collar clockwise onto the

bonnet until it bottoms. A left hand threaded lock nut

is used to lock the torquing tool to the bonnet. Use

the appropriate size open end or socket/box wrench

(1-¼", 1-¾" or 2" hex) on the lock nut to turn the tool

counterclockwise to remove the bonnet.

12. Remove the stem from the bonnet. It may be necessary

to rotate the stem through the packing before it can be

removed.

13. If the valve is unwelded, the graphitic gasket must be

replaced. Do so by removing it from the valve body,

but take care not to damage machined surfaces.

14. Using a packing tool, remove the old packing.

Stainless steel Univalves are equipped with a

metal junk ring in the bottom of the packing

chamber. (See pg. 16 for repacking instructions.)

5

Page 6

EDWARD UNIVALVE USER INSTRUCTIONS ENGLISH 12-13

SERVICING EDWARD UNIVALVE STOP AND STOP-CHECK VALVES

3. The Seat Refinishing Tool is now ready for operation.

Use a speed wrench to operate the tool. Because this

manual process is fast, a special air or electric motor

should not be used. The tool assembly can be easily

Line pressure must be relieved before making any

repairs.

If seat damage has occurred, outlined below are step-bystep procedures for fast, in-line repairs using the Edward

Seat Refinishing Tool.

1.

See pp. 4–5 for proper disassembly procedures before

performing repairs on the Univalves. Then, using the

charts on pp. 10–13, select the proper Seat Refinishing

Tool Arrangement for performing repairs on the seat area.

removed to inspect the seat and determine if more seat

refinishing is required. Turn the tool clockwise using

light pressure only on the stellite seat.

Univalves can be reseated several times, assuming

nominal amounts of stellite are removed each

time. A typical resealing operation removes several

thousandths of an inch of stellite; severe seat defects,

of course, would remove more. A total of about

.03 inch of stellite can be removed before the stellite

becomes too thin, or approximately five average

refinishing operations.

2. Take appropriate caution to make sure the inlet and

outlet valve ports are blocked to prevent removed seat

material from entering the line. Then, screw the Seat

Refinishing Tool Assembly into the body while holding

the shaft up to prevent tool and seat contact. The guide

needs only to be hand-tightened. Do not damage the

cutters by dropping the tool on the stellite seat.

4. When a repair of the seat is finished, use a portable

vacuum to remove loose chips.

6

Page 7

SERVICING EDWARD UNIVALVE CHECK VALVES

Line pressure must be relieved before servicing

the valve.

1. If the check valve to be repaired is seal-welded,

prepare the Seal Cutting Machine for the weld-cutting

operation. If a cutting machine is not available, use one

of the alternate methods on pg. 8.

EDWARD UNIVALVE USER INSTRUCTIONS ENGLISH 12-13

3. Remove the check valve spring and disk from the body

bore. A short piece of soft wire formed into an L shape

may be used to assist in disk removal by engaging it in

the groove inside the disk.

2. Once a seal-welded valve has been cut, it is ready for

disassembly. Unscrew vaIve cover from the body using

the flats provided.

4. The check valve is now ready for internal work.

See the section entitled “Servicing Edward Univalve

Stop and Stop-Check Valves” (pg. 6) for correct repair

procedures.

7

Page 8

EDWARD UNIVALVE USER INSTRUCTIONS ENGLISH 12-13

ALTERNATE WELD-CUTTING METHODS FOR UNIVALVES

SCARFING A WELD

(For fillet-welded Univalves) carbon steel and low alloy

valves

Line pressure must be relieved before making any

repairs.

GRINDING A WELD

(For canopy seal Univalves) stainless steel valves

Open valve to backseat. Using a standard grinding wheel,

remove the weld by grinding from the top of the body face

and bonnet outside diameter (see photo). Continue this

process around the valve until all weld is removed where

the body and bonnet are joined together. Clean the valve

with a wire brush. A penetrating oil may be used where

permissible to loosen the threads joining the body and

bonnet.

1. Air-arc method Open valve to backseat.

Using air-arc equipment, make a series of cuts in the

valve weld (see photo and sketch). Continue making

cuts until the valve weld takes on a grooved scarfedout appearance. Clean the valve with a wire brush.

A penetrating oil may be used where permissible to

loosen the threads joining the body and bonnet.

2. Oxyacetylene method Open valve to backseat. Using

an oxyacetylene torch equipped with a scarfing tip,

make a series of cuts in the weld until it takes on a

scarfed-out, grooved appearance. Clean the valve with

a wire brush. A penetrating oil may be used where

permissible to loosen threads joining the body and

bonnet.

This sketch shows the sequence of cuts necessary to remove the fillet weld by both

oxyacetylene and air-arc methods. Place scarfing torch or welding electrode tangent

to the bonnet, as indicated in position A. When metal reaches cutting temperature,

start blowing oxygen or air while moving torch backward. Weld metal should be

blown away. Move torch counterclockwise to position B. Repeat until entire fillet

weld is removed and gap is continuous. DO NOT REMOVE EXCESS MATERIAL

A

FROM BONNET OR UPPER BODY FACE.

B

8

Page 9

UNIVALVE MAINTENANCE TOOLS

SEAT REFINISHING TOOL ASSEMBLY

EDWARD UNIVALVE USER INSTRUCTIONS ENGLISH 12-13

BONNET TORQUING COLLAR ASSEMBLY

9

Page 10

EDWARD UNIVALVE USER INSTRUCTIONS ENGLISH 12-13

UNIVALVE MAINTENANCE TOOLS

(continued)

VALVES WITH NO PREFIX IN FIGURE NUMBERS

Size

1/2 361XX 876111 875920 875929 876744 - - 876678 N/A

3/4 361XX 876111 875920 875929 876744 - - 876678 N/A

1 361XX 876112 975920 875929 876745 - - 876679 N/A

1-1/4 361XX 876113 875922 875930 876746 876703 3 876680 B

1-1/2 361XX 876114 875921 875931 876746 876703 5 876680 A

2 361XX 876115 875924 875933 876747 876703 5 876681 D

2-1/2 361XX 876116 875926 875917 876748 876703 7 876683 E

3 361XX 876116 875926 875917 876748 876703 7 876683 E

4 361XX 876116 875927 875936 876750 876703 7 876684 E

1/2 362XX 876111 875920 875929 876744 - - 876678 N/A

3/4 362XX 876111 875920 875929 876744 - - 876678 N/A

1 362XX 876111 875920 875929 876744 - - 876679 N/A

1-1/4 362XX 876113 875922 875930 876746 876703 3 876680 B

1-1/2 362XX 876113 875922 875930 876746 876703 3 876680 B

2 362XX 876114 875923 875918 876746 876703 5 876681 A

2-1/2 362XX 876115 875925 875934 876749 876703 5 876682 D

3 362XX 876115 875925 875934 876749 876703 5 876682 D

4 362XX 876116 875927 875936 876750 876703 7 876684 E

1/2 661XX 876111 875920 875929 876744 - - 876678 N/A

3/4 661XX 876111 875920 875929 876744 - - 876678 N/A

1 661XX 876112 875920 875929 876745 - - 876679 N/A

1-1/4 661XX 876113 875922 875930 876746 876703 3 876680 B

1-1/2 661XX 876113 875922 875930 876746 876703 3 876680 B

2 661XX 876115 875925 875934 876749 876703 5 876682 D

2-1/2 661XX 876116 875927 875936 876750 876703 7 876684 E

3 661XX 876116 875927 875936 876750 876703 7 876684 E

4 661XX 876116 875927 875936 876750 876703 7 876684 E

Figure

Number

1,6

Tool Head

Assembly

Guide Bushing

For Carbon

Steeel Valves

Guide Bushing

For Stainless

3

Steel Valves

Bonnet

Torquing

Collar

Assembly

Replacement

Cutters

2

No. Of

Cutters

On Head

Assembly

Check

Valve

Adapter

Assembly

4

Torque

Group

5

Notes:

1. First three numbers indicate pressure class and bonnet seal;

remaining two numbers denote valve type and end configuration,

which have no effect on tool selection.

2. Where dashes are indicated, cutters cannot be replaced.

3. Low alloy steel valves use same tools as carbon steel valves.

10

4. Required for using bonnet torqueing collar and seal weld cutting

machine on check valves.

5. To be used to determine the number of impacts required to close

valves with impactor handles/handwheels (see page 19). “N/A”

indicates that the valve(s) have standard handwheel (non-impactor).

6. Four-digit figure number Univalves use different maintenance tools.

Please consult your Edward Valves sales representative.

Page 11

EDWARD UNIVALVE USER INSTRUCTIONS ENGLISH 12-13

UNIVALVE MAINTENANCE TOOLS

(continued)

VALVES WITH NO PREFIX IN FIGURE NUMBERS

Size

1/2 662XX 876111 875920 875929 876744 - - 876678 N/A

3/4 662XX 876111 875920 875929 876744 - - 876678 N/A

1 662XX 876111 975920 875929 876744 - - 876679 N/A

1-1/4 662XX 876113 875922 875930 876746 876703 3 876680 B

1-1/2 662XX 876113 875922 875930 876746 876703 3 876680 B

2 662XX 876115 875925 875934 876749 876703 5 876682 D

2-1/2 662XX 876116 875927 875936 876750 876703 7 876684 E

3 662XX 876116 875927 875936 876750 876703 7 876684 E

4 662XX 876116 875927 875936 876750 876703 7 876684 E

1/2 961XX 876112 876772 876773 876751 - - 876762 N/A

3/4 961XX 876112 876772 876773 876751 - - 876762 N/A

1 961XX 876112 876772 876773 876751 - - 876762 N/A

1-1/4 961XX 876112 876722 876773 876751 - - 876762 N/A

1-1/2 961XX 876112 876772 876773 876751 - - 876762 N/A

2 961XX 876115 875925 875934 876752 876703 5 876763 C

2-1/2 961XX 876115 875925 875934 876752 876703 5 876763 C

3 961XX 876115 875925 875934 876752 876703 5 876763 C

4 961XX 876115 875925 875934 876752 876703 5 876763 C

1/2 962XX 876112 876772 876773 876751 - - 876762 N/A

3/4 962XX 876112 876772 876773 876751 - - 876762 N/A

1 962XX 876112 876772 876773 876751 - - 876762 N/A

1-1/4 962XX 876112 876772 876773 876751 - - 876762 N/A

1-1/2 962XX 876112 876772 876773 876751 - - 876762 N/A

2 962XX 876115 875925 875934 876752 876703 5 876763 C

2-1/2 962XX 876115 875925 875934 876752 876703 5 876763 C

3 962XX 876115 875925 875934 876752 876703 5 876763 C

4 962XX 876115 875925 875934 876752 876703 5 876763 C

Figure

Number

1,6

Tool Head

Assembly

Guide Bushing

For Carbon

Steeel Valves

Guide Bushing

For Stainless

3

Steel Valves

Bonnet

Torquing

Collar

Assembly

Replacement

Cutters

2

No. Of

Cutters

On Head

Assembly

Check

Valve

Adapter

Assembly

4

Torque

Group

5

Notes:

1. First three numbers indicate pressure class and bonnet seal;

remaining two numbers denote valve type and end configuration,

which have no effect on tool selection.

2. Where dashes are indicated, cutters cannot be replaced.

3. Low alloy steel valves use same tools as carbon steel valves.

4. Required for using bonnet torqueing collar and seal weld cutting

machine on check valves.

5. To be used to determine the number of impacts required to close

valves with impactor handles/handwheels (see page 19). “N/A”

indicates that the valve(s) have standard handwheel (non-impactor).

6. Four-digit figure number Univalves use different maintenance tools.

Please consult your Edward Valves sales representative.

11

Page 12

EDWARD UNIVALVE USER INSTRUCTIONS ENGLISH 12-13

UNIVALVE MAINTENANCE TOOLS

(continued)

VALVES WITH “B” PREFIX FIGURE NUMBERS

Size

1/2 B36XXX 876112 499563 499564 876745 - - 166933 N/A

3/4 B36XXX 876112 499563 499564 876745 - - 166933 N/A

1 B36XXX 876112 499563 499564 876745 - - 166933 N/A

1-1/4 B36XXX 876114 875923 494228 876746 876703 5 166934 B

1-1/2 B36XXX 876114 875923 494228 876746 876703 5 166934 B

2 B36XXX 876115 875925 875934 876749 876703 5 166935 D

2-1/2 B36XXX 876116 875927 875936 876749 876703 7 166936 E

3 B36XXX 876116 875927 875936 876749 876703 7 166936 E

4 B36XXX 876116 875927 875936 876748 876703 7 166939 E

1/2 B66XXX 876112 499563 499564 876745 - - 166933 N/A

3/4 B66XYX 876112 499563 499564 876745 - - 166933 N/A

1 B66XXX 876112 499563 499564 876745 - - 166933 N/A

1-1/4 B66XXX 876113 875922 875930 876746 876703 3 166934 A

1-1/2 B66XXX 876113 875922 875930 876746 876703 3 166934 A

2 B66XXX 876115 875925 875934 876749 876703 5 166935 D

2-1/2 B66XYX 876116 875927 875936 876748 876703 7 166939 E

3 B66XXX 876116 875927 875936 876748 876703 7 166939 E

4 B66XXX 876116 875927 875936 876748 876703 7 166939 E

1/2 B96XXX 876112 876772 876773 876746 - - 168554 N/A

3/4 B96XXX 876112 876772 876773 876746 - - 168554 N/A

1 B96XXX 876112 876772 876773 876746 - - 168554 N/A

1-1/4 B96XXX 876112 876772 876773 876746 - - 168554 N/A

1-1/2 B96XXX 876112 876772 876773 876746 - - 168554 N/A

2 B96XXX 876115 875925 875934 876748 876703 5 876683 C

2-1/2 B96XXX 876115 875925 875934 876748 876703 5 876683 C

3 B96XXX 876115 875928 875934 876748 876703 5 876683 C

4 B96XXX 876115 875925 875934 876748 876703 5 876683 C

Figure

Number

1,6

Tool Head

Assembly

Guide Bushing

For Carbon

Steeel Valves

Guide Bushing

For Stainless

3

Steel Valves

Bonnet

Torquing

Collar

Assembly

Replacement

Cutters

2

No. Of

Cutters

On Head

Assembly

4

Check

Valve

Adapter

Assembly

Torque

Group

5

Notes:

1. First three numbers indicate pressure class and bonnet seal;

remaining two numbers denote valve type and end configuration,

which have no effect on tool selection.

2. Where dashes are indicated, cutters cannot be replaced.

3. Low alloy steel valves use same tools as carbon steel valves.

12

4. Required for using bonnet torqueing collar and seal weld cutting

machine on check valves.

5. To be used to determine the number of impacts required to close

valves with impactor handles/handwheels (see page 19). “N/A”

indicates that the valve(s) have standard handwheel (non-impactor).

6. Four-digit figure number Univalves use different maintenance tools.

Please consult your Edward Valves sales representative.

Page 13

EDWARD UNIVALVE USER INSTRUCTIONS ENGLISH 12-13

UNIVALVE MAINTENANCE TOOLS

(continued)

VALVES WITH “C” AND “D” PREFIX FIGURE NUMBERS*

Size

1/2 X36XXX 876112 499564 499564 876745 - - 166933 N/A

3/4 X36XXX 876112 499564 499564 876745 - - 166933 N/A

1 X36XXX 876112 499564 499564 876745 - - 166933 N/A

1-1/4 X36XXX 876114 494228 494228 876746 876703 5 166934 B

1-1/2 X36XXX 876114 494228 494228 876746 876703 5 166934 B

2 X36XXX 876115 875934 875934 876749 876703 5 166935 D

2-1/2 X36XXX 876116 875936 875936 876749 876703 7 166936 E

3 X36XXX 876116 875936 875936 876749 876703 7 166936 E

4 X36XXX 876116 875936 875936 876748 876703 7 166939 E

1/2 X66XXX 876112 499564 499564 876745 - - 166933 N/A

3/4 X66XXX 876112 499564 499564 876745 - - 166933 N/A

1 X66XXX 876112 499564 499564 876745 - - 166933 N/A

1-1/4 X66XXX 876113 875930 875930 876746 876703 3 166934 A

1-1/2 X66XXX 876113 875930 875930 876746 876703 3 166934 A

2 X66XXX 876115 875934 875934 876749 876703 5 166935 D

2-1/2 X66XXX 876116 875936 875936 876748 876703 7 166939 E

3 X66XXX 876116 875936 875936 876748 876703 7 166939 E

4 X66XXX 876116 875936 875936 876748 876703 7 166939 E

1/2 X96XXX 876112 876773 876773 876746 - - 168554 N/A

3/4 X96XXX 876112 876773 876773 876746 - - 168554 N/A

1 X96XXX 876112 876773 876773 876746 - - 168554 N/A

1-1/4 X96XXX 876112 876773 876773 876746 - - 168554 N/A

1-1/2 X96XXX 876112 876773 876773 876746 - - 168554 N/A

2 X96XXX 876115 875934 875934 876748 876703 5 876683 C

2-1/2 X96XXX 876115 875934 875934 876748 876703 5 876683 C

3 X96XXX 876115 875934 875934 876748 876703 5 876683 C

4 X96XXX 876115 875934 875934 876748 876703 5 876683 C

Figure

Number

1,6

Tool Head

Assembly

Guide Bushing

For Carbon

Steeel Valves

Guide Bushing

For Stainless

3

Steel Valves

Bonnet

Torquing

Collar

Assembly

Replacement

Cutters

2

No. Of

Cutters

On Head

Assembly

4

Check

Valve

Adapter

Assembly

Torque

Group

5

*Prefix examples: X36220 = C36220 or D36220.

Notes:

1. First three numbers indicate pressure class and bonnet seal;

remaining two numbers denote valve type and end configuration,

which have no effect on tool selection.

2. Where dashes are indicated, cutters cannot be replaced.

3. Low alloy steel valves use same tools as carbon steel valves.

4. Required for using bonnet torqueing collar and seal weld cutting

machine on check valves.

5. To be used to determine the number of impacts required to close

valves with impactor handles/handwheels (see page 19). “N/A”

indicates that the valve(s) have standard handwheel (non-impactor).

6. Four-digit figure number Univalves use different maintenance tools.

Please consult your Edward Valves sales representative.

13

Page 14

REASSEMBLY OF THE UNIVALVE

EDWARD UNIVALVE USER INSTRUCTIONS ENGLISH 12-13

REASSEMBLY OF UNWELDED BONNET UNIVALVES

GENERAL: Be sure all parts are clean of dirt, rust or scale.

• Always install a new stem-disk assembly into the bonnet

if the one is damaged, e.g., the disk seat damaged or

stem scratched, worn or pitted. Make sure all dirt is

removed from old stems.

• Apply a light coating of a good high-temperature

lubricant to the bonnet-body threads, such as Bostik

Never-Seez™ – Regular Grade; stainless Univalves

should use Nickel Special Nuclear Grade. Do not use

excessive amounts, and keep it off the gasket seal faces

of unwelded Univalves.

• Next, install a new graphitic gasket seal ring – it should

always be replaced – by slipping it onto the bonnet and

placing it snugly against the off-set. A light film of oil (not

Never-Seez™) helps hold it in place.

• Slip the locking collar over the bonnet from the body end,

with the lug toward the body. Install the capscrew and

nut on the collar, but do not tighten.*

• Next carefully screw the bonnet and stem-disk assembly

into the body, making certain the disk is off the body

seat (valve is open). Using the Bonnet Torquing Collar

assembly, tighten the threads to the torque shown for

unwelded bonnet Univalves.

THIS IS VERY IMPORTANT FOR UNWELDED BONNET

UNIVALVES.

• Verify that the bonnet shoulder does not bottom out on

the body.

• Rotate the locking collar counterclockwise so the lug is

against one of the body lugs. Tighten nut to the torque

value for the yoke bolts, as shown in the next column.

• Install the packing if the original is to be replaced. See

“Packing Installation,” pg. 16.

• Making sure the stem is clean, apply a light coat of

extreme pressure grease, such as American Oil Rycon

EP-2 or equivalent on the threads. Screw the yoke onto

the stem, then onto the bonnet, turning it down snugly

against the bonnet shoulder. Lubricate and then tighten

the yoke bolt as follows:

3/8 dia. bolt 16/20 ft-lb

25/30 N-M

7/16 dia. bolt 30/35 ft-lb

45/50 N-M

• Tighten the gland bolts. IMPORTANT: per “Torque Range

for Packing Gland Bolts,” pg. 17.

• Install the handwheel or actuator. For safety reasons,

make sure the self-locking stem nut is tight on the

handwheel valves.

NOTE: Univalves with “B” prefix or no prefix have a different

type of locking collar which is installed after the bonnet has

been tightened into the body.

REASSEMBLY OF WELDED BONNET UNIVALVES

GENERAL: Be sure all parts are clean of dirt, rust or scale.

• Always install a new stem-disk assembly into the bonnet

if the old one is damaged, e.g., the disk seat is damaged

or stem scratched/worn or pitted. Make sure all dirt is

removed from old stems.

• Class 4500 welded bonnet Univalves (only) should have

both the bonnet insert and graphitic gasket seal ring

replaced. Do this by removing the stem-disk assembly

from the bonnet, placing the new bonnet insert and

graphitic gasket seal ring over the stem, then installing

the stem back into the bonnet.

• Apply a light coating of a good high-temperature

lubricant to the bonnet-body threads, such as Bostik

Never-Seez™ Regular Grade; stainless Univalves should

use Nickel Special Nuclear Grade. Do not use excessive

amounts.

• Next, carefully screw the bonnet and stem-disk assembly

into the body, making certain the disk is off the body seat

(valve is open). Apply a nominal torque, as specified on

pg. 16 for welded bonnet Univalves.

• Seal weld the bonnet; refer to pg. 18.

• Install the packing if the original is to be replaced. See

“Packing Installation,” pg. 16.

• Making sure the stem is clean, apply a light coat of

extreme pressure grease, such as American Oil Rycon

EP-2 or equivalent, on the threads. Screw the yoke onto

the stem, then onto the bonnet, turning it down snugly

against the bonnet shoulder. Lubricate and then tighten

the yoke bolt as follows:

3/8 dia. bolt 16/20 ft-lb

25/30 N-M

7/16 dia. bolt 30/35 ft-lb

45/50 N-M

• Tighten the gland bolts. IMPORTANT: per “Torque Range

for Packing Gland Bolts,” pg. 17.

• Install the handwheel or actuator. For safety reasons,

make sure the

self-locking

stem nut is tight

on handwheel

valves.

14

Page 15

EDWARD UNIVALVE USER INSTRUCTIONS ENGLISH 12-13

REASSEMBLY OF THE UNIVALVE

(continued)

UNWELDED UNIVALVE BONNET GASKET TORQUES

Figure Number

36220, 36224

36228, 36264

36268, 36270

36274, 36278

66220, 66224,

66228, 66264

66268, 66270

66274, 66278

96224, 96228

96264, 96268

96274, 96278

Figure Number

B, C & D

1/2 3/4 1 1-1/4 1-1/2 2 2-1/2 3 4

50-60

70-80

50-60

70-80

110-120

150-165

1/2 3/4 1 1-1/4 1-1/2 2 2-1/2 3 4

50-60

70-80

50-60

70-80

110-120

150-165

50-60

70-80

50-60

70-80

110-120

150-165

Valve Size (No Prefix Figure Numbers)

90-105

125-145

90-105

125-145

110-120

150-165

Valve Size (Prefix B, C & D Figure Number)

90-105

125-145

90-105

125-145

110-120

150-165

140-155

190-210

260-290

355-395

430-475

585-645

260-290

355-395

400-440

545-600

430-475

585-645

260-290

355-395

400-440

545-600

430-475

585-645

400-440

545-600

400-440

545-600

430-475

585-645

X36220, X36224,

X36228, X36260

X36264, X36268

X36270, X36274

X36278

X66220, X66224

X66228, X66260,

X66264, X66268,

X66270, X66274,

X66278

X96224, X96228

X96264, X96268

X96274, X96278

*Prefix examples: X36220=B36220, C36220 or D36220.

ft-lb: Bold face numerals are feet-pounds.

N-M: Regular face numerals are in newton-meters.

70-80

95-110

70-80

95-110

110-120

150-165

70-80

95-110

70-80

95-110

110-120

150-165

70-80

95-110

70-80

95-110

110-120

150-165

140-155

190-210

90-105

125-145

110-120

150-165

140-155

190-210

90-105

125-145

110-120

150-165

260-290

355-395

260-290

355-395

430-475

585-645

400-440

545-600

400-440

545-600

430-475

585-645

400-440

545-600

400-440

545-600

430-475

585-645

400-440

545-600

400-440

545-600

430-475

585-645

15

Page 16

EDWARD UNIVALVE USER INSTRUCTIONS ENGLISH 12-13

REASSEMBLY OF THE UNIVALVE

(continued)

WELDED UNIVALVE BONNET TORQUES

Figure Number

All

ft-lb: Bold face numerals are feet-pounds.

N-M: Regular face numerals are in newton-meters.

1/2 3/4 1 1-1/4 1-1/2 2 2-1/2 3 4

50

70

GENERAL: Be sure all parts are clean of dirt, rust or scale.

Packing Installation

If the Univalve packing was sealing well and has not been

removed, it can be reused. However, if leaking, or if it has

been removed from the bonnet, it should be replaced. We

recommend packing be purchased from Edward Valves

to assure packing with the proper density and corrosion

inhibitors is always used.

IMPORTANT: Long service life from modern graphitic

packing requires that adequate preloads be applied when

repacking.

• All parts should be clean and not scored or pitted,

especially the stem.

• The stem, disk and bonnet should be in the valve prior

to installing the new packing.

• Position split packing with the ends of adjacent rings

rotated 90°.

• Standard packing:

– Top Ring: Braided Carbon Fiber Ring

Note: Class 4500 valves use two (2) top rings

– Center Ring: Flexible Graphite Ring

– Bottom Ring: Same as top (Class 4500 has only one

[1] ring on bottom).

• Clean and lubricate the gland screws.

• Tamp the packing down by hand using the gland.

• IMPORTANT: Apply the recommended torque to

the gland bolts evenly without cocking the gland.

See pg. 15 for torques.

• Stroke the stem and then recheck the torque on the

gland bolts.

Valve Size

100

135

Packing Chamber Schematic

16

Page 17

EDWARD UNIVALVE USER INSTRUCTIONS ENGLISH 12-13

REASSEMBLY OF THE UNIVALVE

TORQUE RANGE FOR PACKING GLAND BOLTS

Figure Number

36120, 36124,

36128, 36164,

36168

36220, 36224

36228, 36264,

36368

66120, 66124,

66128, 66164,

66168

66220, 66224,

66228, 66264,

66268

96124, 96128,

96164, 96168

1/2 3/4 1 1-1/4 1-1/2 2 2-1/2 3 4

8-13

11-18

8-13

11-18

9-14

12-19

9-14

12-19

18-23

24-31

8-13

11-18

8-13

11-18

9-14

12-19

9-14

12-19

18-23

24-31

(continued)

10-15

14-20

8-13

11-18

11-16

15-22

9-14

12-19

18-23

24-31

Valve Size (No Prefix Figure Numbers)

19-24

26-33

19-24

26-33

21-26

29-35

21-26

29-35

25-30

34-41

18-23

24-31

19-24

26-33

21-26

29-35

21-26

29-35

25-30

34-41

23-28

31-38

18-23

24-31

30-35

41-47

30-35

41-47

63-72

85-98

26-31

35-42

27-32

37-43

41-47

56-64

41-47

56-64

63-72

85-98

26-31

35-42

27-32

37-43

41-47

56-64

41-47

56-64

63-72

85-98

37-42

50-57

37-42

50-57

41-47

56-64

41-47

56-64

63-72

85-98

96224, 96228,

96264, 96268

Figure Number B,

C & D*

X36120, X36124,

X36128, X36160,

X36164, X36168,

X36220, X36224,

X36228, X36264,

X36268

X66120, X66124,

X66128, X66160,

X66164, X66168,

X66220, X66224

X66228, X66264,

X66268

X96124, X96128,

X96164, X96168,

X96224, X96228,

X96264, X96268

18-23

24-31

1/2 3/4 1 1-1/4 1-1/2 2 2-1/2 3 4

10-15

14-20

13-18

18-24

22-27

30-37

18-23

24-31

10-15

14-20

13-18

18-24

22-27

30-37

18-23

24-31

10-15

14-20

13-18

18-24

22-27

30-37

25-30

34-41

Valve Size (Prefix B, C & D Figure Number)

21-26

29-35

21-26

29-35

22-27

30-37

25-30

34-41

21-26

29-35

21-26

29-35

22-27

30-37

63-72

85-98

33-38

45-52

38-43

52-58

63-72

85-98

63-72

85-98

37-42

50-57

41-47

56-64

63-72

85-98

63-72

85-98

37-42

50-57

41-47

56-64

63-72

85-98

63-72

85-98

37-42

50-57

41-47

56-64

63-72

85-98

*Prefix examples: X36220=B36220, C36220 or D36220.

ft-lb: Bold face numerals are feet-pounds.

N-M: Regular face numerals are in newton-meters.

17

Page 18

REPLACING THE SEAL WELD UNIVALVES

EDWARD UNIVALVE USER INSTRUCTIONS ENGLISH 12-13

A105 AND F22 UNIVALVES

Seal weld of A105 (Carbon) and F22 (Low-alloy) Univalves

are made using a “Fillet” weld.

RE-WELDING

• To allow welding gases to escape, do not fully seat or

backseat valve.

• Weld surfaces shall be clean and dry.

• Preheat to 300°F – 400°F.

• Weld A105 Univalves with SFA 5.1 E7018 electrodes and

F22 Univalves with SFA 5.5 E9018-B3 electrodes.

• Deposit weld metal to meet dimensions shown in table

below.

Univalve Size Min. Leg

1-1/2 and smaller 3-16 1/8 2

2 (except Class 4500) 1/4 3/16 2

2 (Class 4500 and valves over 2) 3/8 1/4 2

Min.

Throat

Min.

Passes

F316 AND F347 UNIVALVES

JOINT

Seal welds of F316, F316L and F347 (Stainless Steel)

Univalves are made using a “Canopy” weld.

• Univalves should be prepared for the Joint design shown

below.

RE-WELDING

• To allow welding gases to escape, do not fully seat or

backseat the valve.

• Weld surfaces shall be clean and dry.

• Preheat to 70°F – 150°F.

• Maintain an interpass temperature of 350°F maximum.

• Weld F316 Univalves using SFA 5.9 ER316L bare rod,

F316L Univalves using SFA 5.9 ER308L bare rod and

F347 Univalves using SFA 5.9 ER347 bare rod.

• Deposit weld metal to meet dimensions shown in sketch

below.

18

Page 19

EDWARD UNIVALVE USER INSTRUCTIONS ENGLISH 12-13

OPERATIONAL RECOMMENDATIONS

RECOMMENDED CLOSING TORQUES

To assure long seat life and seat tightness, it is very

important to close the Univalve with enough seat

stress/stem load.

The torques in this table should be applied when closing

against the maximum (100°F) valve pressure. The impactor

handle/handwheel performance chart on pg. 20 will achieve

these stem loads.

Overtorquing can, on the other hand, damage seats and

bend stems, so torques greatly in excess of these should

not be applied.

MINIMUM TORQUE FOR CLOSING VALVES — FT-LB ON MAIN SEAT (Do Not Apply This Load to Backseats.)

Figure Number

36120, 36124,

36128, 36160

36164, 36168

36220, 36224,

36228, 36260,

36264, 36268

66120, 66124,

66128, 66160,

66164, 66168

66220, 66224,

66228, 66260,

66264, 66268

96124, 96128,

96164, 96168

96224, 96228,

96264, 96268

All Valves With Five-Digit Figure Numbers

1/2 3/4 1 1-1/4 1-1/2 2 2-1/2 3 4

30 30 30 95 95 155 275 275 275

30 30 30 95 95 155 275 275 275

45 45 45 85 85 230 395 395 395

45 45 45 85 85 230 395 395 395

70 70 70 70 70 350 350 350 350

70 70 70 70 70 350 350 350 350

Torques are for valves with stem packing tightened – see page 17.

19

Page 20

EDWARD UNIVALVE USER INSTRUCTIONS ENGLISH 12-13

Impactor

OPERATIONAL RECOMMENDATIONS

(continued)

Correct Use of Impactor Handles/Handwheels to Close Applicable Univalves (Sizes 1-1/4 Through 4)

IMPACTOR HANDLE/HANDWHEELS

Impactor handle/handwheels increase the closing

effectiveness and eliminate the need for cheater bars.

Impactor handles/handwheels used on Edward Univalves

have the proven ability to achieve tight sealing, eliminating

leakage past the seats.They allow the recommended stem

loads on pg. 19 to be easily achieved.

Since they are smaller in diameter than standard

handwheels, they must be impacted multiple times to

The values listed in the chart below are based on a standard

rating for the ability of plant personnel to accelerate the

handle/handwheel against the the stem adaptor. In addition,

these values assume that all parts are in good working

order (no binding or heavy dirt build-up on stem). The

figures given represent the minimum number of required

impacts, and exceeding them will not damage valves.

Failure to close these valves tightly, on the other hand, will

cause leakage, with resulting degradation of the sealing

surfaces over time.

develop the required torque. The number of impacts

required depends upon the size of the handle/handwheel,

the stem and seat size, and the differential pressure against

which the valve is being closed.

IMPACTOR HANDLE/HANDWHEEL PERFORMANCE CHART

Maximum Shut-Off Pressure < 1000 PSIG

Maximum Shut-Off Pressure < 1500 PSIG

Maximum Shut-Off Pressure < 2000 PSIG

Maximum Shut-Off Pressure < 3000 PSIG

Maximum Shut-Off Pressure < 3500 PSIG

Maximum Shut-Off Pressure < 4000 PSIG

3

Maximum Shut-Off Pressure < 2500 PSIG

22

2

20

18

16

14

12

10

8

6

4

Number of Impacts Required for Tight Closure

2

0

Torque Group A

1

Torque Group B

1

Torque Group C

1

Torque Group D

1

Torque Group E

1

1.) See pages 10–13 for identification of torque groups A through E.

2.) Number of impacts listed are “minimum” values for corresponding shut-off pressure range.

3.) For shut-off pressures greater than 4000 PSIG, double the number of impacts recommended at 4000 PSIG for the applicable valve group.

22

20

18

16

14

12

10

8

6

4

2

0

20

Page 21

GENERAL INFORMATION

EDWARD UNIVALVE USER INSTRUCTIONS ENGLISH 12-13

WARNING

The Edward Univalve® is not provided with a pressure

relief device. A pressure relief device must be provided

elsewhere in the piping system to prevent the piping system

pressure from exceeding the maximum rated pressure of

the Univalve.

CONVERTING UNIVALVES

Welded bonnet carbon steel and F22 Univalves, Class 1690

and 2680, can be converted to unwelded types by removing

the seal weld and bonnet, and adding a graphitic gasket and

a locking collar to assure the bonnet will remain locked to

the body. Torque the bonnet per pg. 15.

Unwelded bonnet carbon steel and F22 Univalves, Class

1690 and 2680, can be converted to welded types by adding

a seal weld. Edward Valves does not recommend adding

a seal weld to Univalves with the graphitic bonnet gasket

installed, because of the possibility of over-pressurizing the

threaded region with fluid trapped between the seal weld

and graphitic gasket; remove the gasket before welding.

WELDING UNIVALVES INTO PIPING

WeIding is outside the scope of this manual, but Edward

recommends you consult the appropriate welding

procedure in ASME/ANSI B31, or whatever other codes

apply to your system. When welding Univalves into piping,

make sure there is no foreign material on the seat joint, then

close the valve tightly to approximately 50% of the torque

values in the chart on pg. 19, to avoid distorting the seats.

During subsequent stress relief of the welds, leave the

valve closed to avoid distorting the valve seat. Also, during

stress relief, assure that the valve upperstructure is not

overheated. After welding, open the valve and flush the line

to clean out all foreign matter.

PIPING SUPPORT

Piping should be supported sufficiently to preclude

excessive end loads on the valve.

VALVE INSTALLATION GUIDELINES

Except as noted below, Univalve stop valves and check

valves with springs can be installed in any position.

Installed positions with the valve cover or bonnet below

horizontal, where dirt and scale can accumulate in the valve

neck, should be avoided.

For optimum performance, the orientation limits shown in

Figures 1 and 2 should be observed, even for spring-loaded

check valves.

The orientation limits shown in Figures 1 and 2 must not be

exceeded for Univalve Stop-Check valves and Check valves

without springs. The limitations given for line inclination

and bonnet roll angle should not be combined.

All Check and Stop-Check valves should be installed with

10 or more diameters of straight pipe upstream of the valve

to minimize flow disturbances. For additional information,

refer to the “Technical” section of the Flowserve-Edward

catalog FCD EVENCT0001 or FCD EVENCT0002.

Figure 1

45° Inclined Bonnet Piston-Lift Check Valves

Maximum Check Valve Orientation Limits

Figure 2

Angle Piston-Lift Check Valves

Orientation Limits

21

Page 22

EDWARD UNIVALVE USER INSTRUCTIONS ENGLISH 12-13

GENERAL INFORMATION

NOTES ON VALVE OPERATION

Valves equipped with electric motor actuators have special

tags attached which indicate the correct torque switch

setting for the valve. Exceeding these torque switch settings

can cause damage to the valve.

Never use an electric motor actuator to backseat a valve.

This can result in damage to the valve stem and bonnet

backseat.

NOTES ON VALVE MAINTENANCE

When replacing the bonnet gasket in the unwelded Univalve,

follow the torque requirements on page 15 closely. Failure

to torque the gasket properly will result in gasket failure.

When replacing the valve stem packing, never machine the

packing chamber oversize. This will result in blowout of the

packing.

LUBRICATION

In order to obtain full service life, valves require periodic

lubrication of the stem threads. Exposed threads should be

wiped clean of old grease and accumulated dirt and fresh

lubricant applied. This is most effectively done with the

valve in the closed position.

For valves that see frequent operation, such as motor

actuated, the lubricant should be replenished every three

months. If extreme service conditions dictate, a more

frequent re-lube schedule is recommended. Motor actuated

valves have a lubricant fitting at the yoke flange.

The recommended lubricant for all stem threads is Rykon

EP #2, manufactured by the American Oil Company. This

is an extreme pressure, extreme temperature lubricant

of high quality. For vaIves that are operated infrequently,

relubrication should be at least once a year.

(continued)

SEAT AND DISK JOINT LEAKS

A leak existing between the seat and disk of a closed valve

might be indicated by one of the following: a definite

pressure loss in the high-pressure side of the valve;

continued flow through an inspection drain on the lowpressure side; or, in hot water or steam lines, a downstream

pipe that remains hot beyond the usual length of time and

conductivity range.

Such a leak may be the result of closing on dirt, scale

or other foreign matter in the line. It may also develop

because of the operator’s failure to close the valve tightly.

An increased velocity is imparted to a flow forced through

a very small opening. This increased velocity subsequently

gives rise to the “cutting” of both disk and seat, particularly

by particles of line scale or rust in suspension or normal

solids in solution. In spite of the fact that the hard surfaced

material on the seat and disk is corrosion and erosion

resistant, grooves, pit marks, or other surface irregularities

may be formed on the seat and disk joint surfaces when

the disk is closed against a foreign body on the seat. This

sometimes occurs during the initial startup of a piping

system.

Leakage of steam through a valve which is badly steam

cut has a whistling or sonorous sound. If the valve is

only slightly steam cut, however, leakage is identified by

subdued gurgling or weakly popping sounds. These sounds

can be heard through a stethoscope or by placing one end

of a stick against the valve body while holding the other end

between the teeth, with hands over the ears.

HOW TO ORDER PARTS

During normal working hours, call 800/225-6989 or

919/832-0525. To assure the correct parts for your

Univalve, include the valve size, the figure number ñ

including any prefix and/or suffixes and if available, the

B/M number. All nuclear valves require the B/M number to

properly identify your Univalve.

This information is located on the valve nameplate. The

nameplate is attached to a yoke leg via a cable. If the

nameplate is inaccessible, you can use your Edward sales

drawing; please include the drawing number as well.

22

Page 23

NOTES

EDWARD UNIVALVE USER INSTRUCTIONS ENGLISH 12-13

23

Page 24

FLOWSERVE CORPORATION

FLOW CONTROL DIVISION

Edward Valves

1900 South Saunders Street

Raleigh, NC 27603 USA

Toll-Free Telephone Service

(U.S. and Canada)

Day: 800 225 6989

After-Hours Customer Service

1 800 543 3927

U.S. Sales Offices

Phone: 919 832 0525

Fax: 919 831 3369

Visit Our Website

www.edwardvalves.com

For more information about Flowserve Corporation,

contact www.flowserve.com or call USA 1-800-225-6989.

FCD EVENIM2000-02 (E) 12/13 © 2013 Flowserve Corporation.

Flowserve Corporation has established industry leadership in the design and manufacture of its products. When properly selected, this Flowserve product is designed to perform

its intended function safely during its useful life. However, the purchaser or user of Flowserve products should be aware that Flowserve products might be used in numerous

applications under a wide variety of industrial service conditions. Although Flowserve can (and often does) provide general guidelines, it cannot provide specific data and warnings

for all possible applications. The purchaser/user must therefore assume the ultimate responsibility for the proper sizing and selection, installation, operation, and maintenance of

Flowserve products. The purchaser/user should read and understand the Installation Operation Maintenance (IOM) instructions included with the product, and train its employees

and contractors in the safe use of Flowserve products in connection with the specific application.

While the information and specifications contained in this literature are believed to be accurate, they are supplied for informative purposes only and should not be considered

certified or as a guarantee of satisfactory results by reliance thereon. Nothing contained herein is to be construed as a warranty or guarantee, express or implied, regarding any

matter with respect to this product. Because Flowserve is continually improving and upgrading its product design, the specifications, dimensions and information contained herein

are subject to change without notice. Should any question arise concerning these provisions, the purchaser/user should contact Flowserve Corporation at any one of its worldwide

operations or offices.

© 2013 Flowserve Corporation, Irving, Texas, USA. Flowserve is a registered trademark of Flowserve Corporation.

flowserve.com

Loading...

Loading...