Page 1

MACH 1 TSQV

SEVERE SERVICE PLUG VALVES

Page 2

FOREWORD

The Flowserve Corporation has established this

Installation, Operating and Maintenance Manual to

facilitate field installation, operation and repair of

Triple Seal Mach 1 Valves

Only Flowserve replacement repair parts and

assembly tooling made or designed by Flowserve

should be used. It is recommended that questions

or concerns involving the processes described in

the manual be directed to the local Sales

Representative of Flowerve Corporation.

TABLE OF CONTENTS

Section Title Page

I. Installation Instructions- Flanged and Welded Valves……………….3

II. Operating Instructions, Parts List & Packing Options………………..4

Ill. Materials, Fastener Torques & Figures………………………………6

IV. Valve Disassembly……………………………………………………..8

V. Valve Assembly 1 "-6"………………………………………………… 9

2

Page 3

SECTION I

INSTALLATION INSTRUCTIONS – FLANGED AND WELDED

TSQV PLUG VALVES

FLANGED:

Installation of Flowserve flanged valves is best accomplished by locating valves in

pipeline flanges, assuring all corrosion and foreign materials are removed from pipe

flange, and then centering the gaskets with the valve flanges. Fasteners or taper

pins should be used to align holes and locate gaskets. Fasteners should be

tightened to the corresponding valve and fastener value.

WELDING:

Flowserve Corporation, Flow Control Division recommends using only qualified

welding procedures and personnel for weld installation of TSQV valves.

The following precautions should be observed:

1. The valve should be inspected prior to welding to assure that no foreign materials

obstruct the flow passageway and that the weld preparation area is free of corrosion

and physical damage.

2. The valve should be in the open position while being welded. Open position is

when the flats on the plug stem are parallel with the pipeline.

3. The TSQV valve contains various sleeve and diaphragm materials that have

different maximum temperature limitations. Refer to Table 1.1 for temperature

limitations.

4. The valve body sleeve and diaphragm area must not exceed these temperatures

during welding. This includes preheats, interpasses or post weld heat treatments, as

applicable. Refer to Figure 2 for locations of the sleeve and diaphragm in the center

valve section

5. Welding of the TSQV Valve without disassembly may be accomplished with no

damage to the sleeve and diaphragm. Precautions MUST be taken to cool the valve

bowl and monitor temperature. The temperature of the center or bowl area of the

valve must not exceed the listed temperature of the material. Valves, sizes two inch

and smaller, must be wrapped with water soaked, fire-resistant material to cool the

valve bowl and inlet where the weld is to be made. Use temperature melt crayons

equal to the sleeve and diaphragm rating to mark the body welding end and monitor

the body temperature. Thermocouples may be attached to the welding end of the

body or surface pyrometers may be used to monitor the body bowl temperature.

CAUTION: DO NOT ALLOW WATER

FROM THE SOAKED WRAPPING

MATERIAL TO ENTER THE

WELDMENT.

Table 1.1 – Temperature Limitations

Material

Description

Temperature

UHMWPE 200°F (93°C)

PFA 500°F (260°C)

FEP and Tefzel 275°F (135°C)

Max.

3

Page 4

SECTION II

OPERATION INSTRUCTIONS AND PARTS LIST FOR TSQV VALVES

Part reference cited in this section can be identified

using Figures 1-3 (Section III) and the material list.

Periodic maintenance requirements for TSQV

valves may vary due to operating conditions

of the process. Factors such as operating

temperature and pressure, flowstream, solid

content, and valve cycles can greatly

influence valve performance and

maintenance requirements. Seal wear and

degradation is compensated by correctly

adjusting appropriate parts. For TSQV valves,

three possible leak paths occur; for each leak

path there exists a means of adjustment.

Leak paths are BONNET, STEM and LINE

(through). Each leak path and corresponding

adjustment shall be treated separately.

I. BONNET

Leakage due to thermal cycling (gradients) and

frequent high pressure cycling is stopped by

snugging the top cap fasteners (item 10) in a

"criss-cross" manner (1-3-2-4) per Fig. 3. This

adjustment is most effective when the valve is not

pressurized. It is important that the top cap

fasteners not be torqued above the level specified

in Tables 1a or 1b.

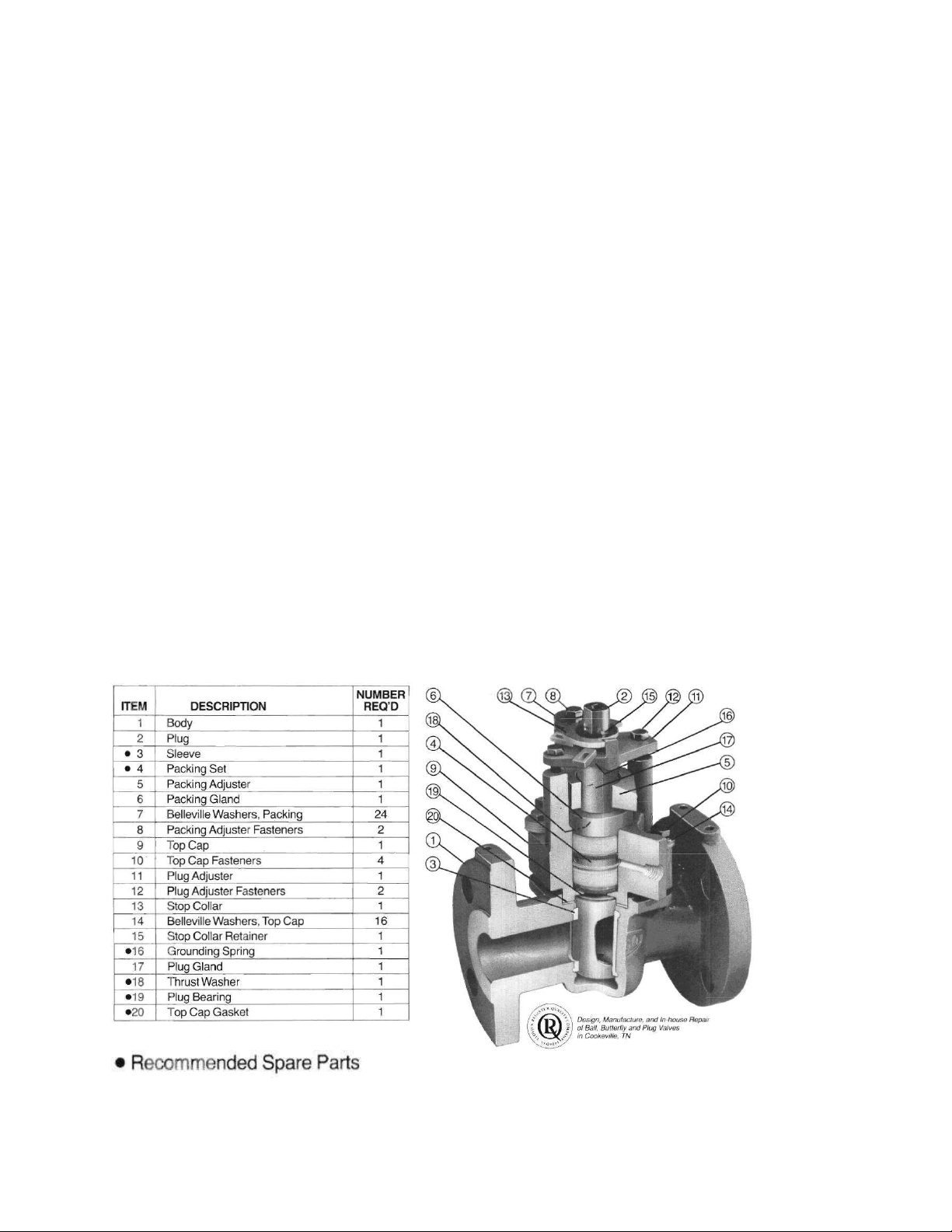

TSQV Assembly and Parts List

2. STEM

Leakage due to wear of the service packing is

stopped by tightening the packing adjuster

fasteners (item 8) in 1/2 turn increments. The

fasteners should be tightened evenly. The

packing adjuster fasteners should not be

tightened above the torque level specified in

Table 3 (pg 6). If possible, the valve should be

operated between adjustments to assure that

the plug stem will not be "frozen" due to

overloading the stem packing. If stem leakage

persists, or the packing adjuster fasteners

bottom out, the stem packing should be

replaced.

3. LINE (through)

Through leakage due to wear or damage to the

valve sleeve, or primary seal can be stopped by

tightening the plug adjuster fasteners (item 12)

in 1/4 turn increments. The fasteners should be

tightened evenly. If possible, the valve should be

operated between adjustments to assure that

the plug has not been forced into the sleeve

excessively, producing an unnecessary high

valve operating torque. Should the valve be

leaking excessively after numerous adjustments,

the sleeve will require replacement.

4

Page 5

Stuffing Box Options:

The Durco TSQV valve will accommodate standard packing of most manufacturers.

A. Standard Polymer Cup and Cone

B. Fire Sealed Options

5

Page 6

SECTION III

MATERIALS, FASTENER TORQUES & FIGURES

Durco Material Code Cross-Reference

6

Page 7

SECTION III (CONT.)

7

Page 8

SECTION IV TSQV VALVE DISASSEMBLY

Recommended Precautionary Measures

1. Valves must be relieved of process fluid and

pressure prior to disassembly. Plug should be in

the open position.

2. Personnel performing disassembly must be

suitably protected and alert for emission of

hazardous process fluid.

3. If there is a pipe plug located at the bottom

bowl of the valve, DO NOT remove the pipe plug

until the valve plug has been removed.

Disassembly Steps

NOTE: Refer to Figures 1-3 for parts

identification. If an actuator or gearbox

operates the valve, alignment marks should

be noted to assure correct orientation when

reassembled. This may best be

accomplished by making matching marks

on the plug stem and operator housing with

no burrs on the plug stem permitted.

1. Gradually loosen plug adjuster fasteners

(Part 12)-DO NOT REMOVE.

2. Turn plug (Part 2) in order to raise the

plug to vent any material trapped in the

valve (see note below). NOTE: If there is

no upward movement of the plug (Part 2),

it will be necessary to devise a method of

lifting the plug upward. This may require

removal of the valve operator (Step 3).

This operation should be undertaken

noting the above precautionary measures.

Methods of plug removal must include

protective measures on plug stem and

plug end.

3. WARNING: Do not loosen or remove top

cap fasteners (Part 10) when removing an

operator or accessory. Remove the

operator by unfastening it from the

bracket.

4. Once the plug (Part 2) has lifted, the

adjuster fasteners (Part 12) can be

completely removed.

5. Loosen and remove the packing adjuster

fasteners (Part 8).

6. Gradually loosen but DO NOT REMOVE

all of the top cap fasteners (Part 10). Turn

the plug until it is loose from the sleeve

(Part 3) and all pressure has been vented.

8

(Again, it may be necessary to use a

mechanical means to move the plug

upwards.)

7. Remove the top cap fasteners (Part 10)

and top cap (Part 9).

8. Remove the plug (Part 2) from the body

(Part 1).

9. Remove the grounding spring (Part 16)

from the plug.

10. lnspect the valve sleeve (Part 3) for

wear or damage, especially scratches

near the top, bottom, and port areas. If

wear or damage is excessive, the sleeve

should be replaced.

11. Remove sleeve (Part 3) as follows:

NOTE: Care should be taken not to

damage the internal body bore.

To remove the sleeve, use a wooden

dowel and pry the sleeve upward by

engaging the dowel in the sleeve at the

top of the port. A sharp blow may be

necessary to unseat the sleeve. Both

sides may need to be pried upward for

removal. (See Figure 4)

12. Thoroughly clean all valve parts with an

acceptable cleaner.

13. lnspect parts for damage. Look for

marred, scratched, or rough sealing

surfaces on the valve plug (Part 2).

NOTE: Reinstallation of damaged or

unclean parts will ruin any replacement

seals installed into the valve.

Figure 4

Page 9

SECTION V

VALVE ASSEMBLY 1”-6” TSQV WITH SLEEVE

NOTE: Part number reference is shown

in Figures 1-3, Sec III.

1. Mount body (Part 1) on arbor press

or table vise holding one flange.

Weld-in bodies are repaired in-line.

Place sleeve (Part 2) in position in

body. Align sleeve ports with body

ports. (Figure 5)

Figure 5

2. Apply a thin film of lubricant on the

plug (Part 2). Then place the plug in

the closed position into the sleeve

which is in the body. (Figure 6).

Figure 6

3. Check that the top seal of the sleeve

is seated into the body counterbore. It

may be necessary to tap sleeve with

soft mallet. Push the plug downward,

while still in the closed position, until

the top of the plug taper is 1/16” above

the top of the sleeve surface. Use an

arbor press or c-clamp. Allow the plug

to remain in this position for time listed

in Table 4. Remove plug.

Table 4

Sleeve Material

UHMWPE, FEP,

Tefzel

PFA

NOTE: After sizing the sleeve, the

TSQV top works are to be assembled

onto the plug prior to pushing the

plug into the sleeved valve body

4. The plug bearing is to be placed on

the plug as shown in Figure 7. The

plug stem and the stuffing box

counterbore of the top cap must be repolished, if necessary, until a surface

finish of 16 RMS is achieved.

5. The top cap is placed on the plug as

shown in Figure 7. Care must be

exercised to insure that the plug stem

is not scratched as the top cap is

lowered onto the plug.

Sizing Time

1"-3" 4"-6"

30 sec 60 sec

5 min 8 min

9

Page 10

6. Install the diaphragm over the plug stem.

The diaphragm guide must be used to

install the diaphragm. Make sure there are

no nicks on the guide. Place the diaphragm

over the guide and push downward over the

guide. See Figure 7. Push the diaphragm

down using the diaphragm pusher.

Figure 7

press is required to load the pusher.)

See Figure 8.

8. At this time, tap pusher with soft

mallet for weld-end valves. Then

apply a light coat of silicone, or

approved lubricant, to the packing

area of the plug stem and the seat

area of the top cap stuffing box.

Figure 8

7. Remove the diaphragm guide and

pusher from the stem. Place the

diaphragm gland over the plug stem.

Now locate and seat the diaphragm

gland by pushing downward with the

diaphragm gland pusher. (An arbor

9. The packing is then placed into the

stuffing box as shown in Figure 9.

Several packing orientations are

shown in an earlier section. Under no

circumstances shall sharp objects

such as screw drivers, cold chisels or

knives be used to force the packing

into the stuffing box. The packing

gland may be used to start the packing

into the stuffing box.

10

Page 11

10. Following insertion of the packing set,

the diaphragm gland pusher is placed

over the plug stem. Seat the packing by

loading the gland pusher with an arbor

press. The packing may be seated in

sections but the gland pusher will only fit a

cone ring. It must not be used to seat

against a cup. See Figure 9. The packing

gland is now placed over the plug stem

and seated with the arbor press.

Figure 9

finger tight. Care should be taken such

that the packing adjuster remains level

with respect to the top cap.

12. The thrust washer is placed over the

plug stem and should lay flat against

the plug stem bearing surface as

shown in Figure 10.

Figure 10

11. The packing adjuster is placed over the

plug stem. Each fastener may have on

optional twelve Belleville washers placed

as shown in Figure 10. The packing

adjuster fasteners should be tightened

13. The plug gland is placed over the

plug stem. Next, the grounding spring

is pushed onto the plug stem. The

adjuster with fasteners is placed over

the plug stem and secured by the

adjuster fasteners shown in Figure 11.

The adjuster fasteners should be

tightened to position the top cap

gasket surface in line with the flat

surface which the plug bearing rests

on as shown in Figure 11.

11

Page 12

Figure 11

Figure 12

14. Place the top cap gasket into the valve

body flange counterbore.

15. Apply a thin, even film of silicone, or

approved lubricant, to the entire outside

surface of the plug taper.

16. The top works are then placed onto the

valve body and oriented as shown in

Figure 12. The plug is then pressed into

the sleeve with the aid of an arbor press

or c-clamp until the top of the plug

adjuster falls ¼’’ below plug adjuster

fasteners. The press must provide

sufficient force to depress the plug,

allowing the gasket surface of the top cap

to bottom against the gasket counterbore.

The valve must remain in the arbor press

for steps 16 thru 19.

17. The top cap fasteners with four optional

Belleville washers each (Figure 12 for top

cap Belleville washer orientation) should

be installed at this time. Do not tighten the

top cap fasteners more than finger tight.

18. Tighten the packing adjuster fasteners

in a manner such that the packing

adjuster does not "tilt". The torque on the

packing adjuster fasteners should be per

Table 3. (Fig 12).

19. Tighten the top cap fasteners in a

crisscross fashion to values listed in

Table 1a or 1b.

20. At this time, remove the valve from

press or c-clamp.

21. Loosen the plug adjuster fasteners

and operate the plug several times.

22. Tighten the plug adjuster fasteners

per Table 2. Install stop collar and

retainer ring.

23. Operate the plug several times. It

will be difficult to turn at first, but will

then loosen and turn freely.

24. Pressure testing of the assembled

valve should be done at this time. Any

additional valve adjustment that might

be needed to hold the specified

pressure should be made at this time.

The valve is now ready for installation

12

Loading...

Loading...