Page 1

GESTRA Steam Systems

SPECTORcontrol

Installation Instructions 818494-00

Control, Display and Operating Panel for Boiler Management

Page 2

Contents

Page

Important Notes

Usa ge for the intended purpose.......................................................................................6

Safety notes................................................ .....................................................................6

Explan atory Notes

Scope of supply .......................................... .....................................................................7

Application ............................................................. ..........................................................7

Function............................................ ...............................................................................8

System specification........................................................................................................9

Installation

SPECTORcontrol ...........................................................................................................10

Bus terminal bloc k (I/O module).....................................................................................10

Wiring

SPECTORcontrol ...........................................................................................................10

Bus terminal bloc k (I/O module).....................................................................................10

Commissioning

Technical req u irements..................................................................................................11

Start-up behaviour .........................................................................................................11

Shutdown behaviour.... ..................................................................................................11

Factory settin gs........................................... ...................................................................11

System settings..............................................................................................................12

CAN bus connection ......................................................................................................13

Remote monitoring...................................................................... ...................................14

Integration of third-party equipment.. .............................................................................14

Using the help function ..................................................................................................14

User Interfaces

Des cription of t he browser interface ..............................................................................15

Des cription of t he user interface....................................................................................15

Description of the input masks.......................................................................................16

Description of buttons....................................................................................................17

Menu overview...............................................................................................................21

2

Page 3

Conte nts

Page

System Menu

Sequence of set-up........... .............................................................................................22

System...........................................................................................................................23

Date and time setting........ .......... .......... ........... .......... ..................... ........... .......... ..........2 3

Contrast and backlight setting .......................................................................................24

Language.......................................................................................................................24

Password .......................................................................................................................25

IP addres s settings ........................................................................................................25

Factory settings .............................................................................................................26

Menus of Inputs/Outputs

CAN 1..10 input ..... ........... .......... ..................... .......... ........... .......... ........... .......... ..........2 7

CAN type 1..10 ................. .......... .......... ........... .......... ........... .......... ..................... ..........2 8

NRG 26-40 CAN 1...10..................................................................................................28

NRG 26-40 setup...........................................................................................................29

NRG 26-40 calibration ...................................................................................................30

NRG 16-42 CAN 1...10..................................................................................................30

NRG 16-42 setup...........................................................................................................31

LRG 16-40 CAN 1...10.......................... .........................................................................3 1

LRG 16-40 setup ...........................................................................................................32

LRG 16-40 calibra tion....................................................................................................33

Select standard curve....... .............................................................................................34

Select temperature coefficient .......................................................................................34

Current values of control equipment..............................................................................35

NRS 1-40............... ........... .......... .......... ........... .......... ........... .......... ........... .......... ..........35

NRS 1-41............... ........... .......... .......... ........... .......... ........... .......... ........... .......... ..........36

NRS 1-40/ 41 setup.............................. .........................................................................36

LRR 1-40 ........................................................................................ ...............................37

LRR 1-40 setup ..............................................................................................................37

CAN 1..10 output ........................ .......... ........... .......... ........... .......... ........... .......... ..........3 8

Digital inputs ............................... .......... ........... .......... ........... .......... ........... .......... ..........38

Digital outputs........ ........... .......... .......... ........... .......... ........... .......... ........... .......... ..........39

Digital output 1...10 energised .... .......... ........... .......... ........... .......... ........... .......... ..........4 0

Analog 1..10 input..........................................................................................................41

Analog input 1..10..........................................................................................................41

Analog input 1...10 setup.. .......... .......... ........... .......... ........... .......... ........... .......... ..........4 2

Analog 1..10 output........................................................................................................43

Analog output 1..10............................... .........................................................................43

3

Page 4

Contents

Page

Controller Menu

Controller .......................................................................................................................44

Controller setup..............................................................................................................44

Continuou s controll er setup .... .......... .......... ........... .......... ........... .......... ........... .......... ....45

Continuou s control ler... ........... .......... .......... ........... .......... ........... .......... ........... .......... ....47

2-position controller setup..............................................................................................48

Pump setup....................................................................................................................49

Pump 1...3 setup............................................................................................................ 49

Valve control ..................................................................................................................50

2-pos. controller .............................................................................................................51

Pump status................................................ ...................................................................52

3-position controller setup..............................................................................................52

3-pos. controller .............................................................................................................54

3-element contro ller .......................................................................................................55

3-element contro ller setup .......................... ...................................................................55

3-element continuous controller setup........................................................................... 56

3-element 3-position controller setup.............................................................................58

3-element continuous/3-position controller....................................................................59

Intermittent blowdown....................................................................................................61

Intermittent blowdown setup..........................................................................................61

Boiler Menu

Boiler....................................... .......................................................................................62

Maintenance ..................................................................................................................62

Main tenance 1...5 setu p.......... .......... .......... ..................... ........... .......... ........... .......... .... 63

Signal assignment of digital input ..................................................................................63

Datal ogs.........................................................................................................................64

Datal og 1...5 setup.........................................................................................................64

Select signal channel 1...2............................................... ..............................................64

Datal og 1...5...................................................................................................................65

Edit datalog 1...5............................................................................................................65

Datalog 1...5 range of representation ............................................................................66

Flowrates .......................................... .............................................................................66

Flowrate 1...5 s e tup .......................................................................................................67

Select signal for flowrate 1...2........................................................................................67

Flowrate 1...5 parameter.................................................................................. ..............68

Dai ly log / monthly log........................................................................... .........................68

4

Page 5

Conte nts

Page

Burner Menu

Burner............................................................................................................................69

Fuel gas/oil ....................................................................................................................69

Position of actuator............................... .........................................................................70

Common inputs/outputs.................................................................................................70

Controller .............................................................................. .........................................70

Datalogs............................ .............................................................................................71

Datalog 1...5 setup.........................................................................................................71

Select signal channel 1...2.............................................................................................71

Datalog 1...5 ..................................................................................................................72

Edit datalog 1...5.............................................. ..............................................................72

Datalog 1...5 range of representation .............. ..............................................................73

Flowrates .............................................. .........................................................................73

Flowrate 1...5 setup .............................. ........... .......... ........... .......... ........... .......... ..........7 4

Select signal for flowrate 1...2........................................................................................74

Flowrate 1...5 param eter ... .......... .......... ........... .......... ........... .......... ........... .......... ..........7 4

Daily log / monthly log....................................................................................................75

Malfunction history.........................................................................................................76

Fault history .......................................................................... .........................................76

Burner set-up.................................................................................................................77

Fuel.................................................................. ..............................................................77

Operating hours.............................................................................................................78

Setpoint..........................................................................................................................78

Start-up counter.......................... ...................................................................................79

Clock..............................................................................................................................79

Operating mode.......................... ...................................................................................80

Mode..............................................................................................................................80

Operating mode.......................... ...................................................................................80

Capacity controller.........................................................................................................81

Capacity controller.........................................................................................................81

Targete d capacity specification .....................................................................................81

Alarm

Alarms............................................................................................................................82

Alarm d e tails..................................................................................................................82

Alarm history................................................................................... ...............................83

List of E quipment

Accepted equipment............................. .........................................................................84

Annex

Revision................................................ .........................................................................86

5

Page 6

Important Notes

Usage for the intended purpose

SPECTORcontrol is a visual display and operating panel with integrated programmable

logic controller (PLC).

Apart from GESTRA equipment such as level electrodes, capacitance probes,

temperature limiters and conductivity electrodes, you can also connect equipment

produced by other manufacturers (after consultation with GESTR A) and incorporate it

into the system.

Wa rn in g

The parameters of the high-level and low-level alarm electrodes required by

law can be indicated and monitored.

Note that SPECTORcontrol cannot replace the control units of legally

prescribe d limiters such as low-level alarms, high-level alarms and selfmonitoring temperature limiters.

Such usage is considered as impr oper!

Data can be exchanged safely with equipment tested and approv ed by GESTRA.

Any type of use differing from the usage described a bove must be considered as

improper. The resulting risk will have to be borne by the user alone. The manu facturer

hereby expressly r ejects any claims for any damage resulting from improper usage.

Safety notes

Observe the safety notes of the enclosed specificatio ns concerning equipment and bus

terminals.

Working methods that jeopardise safety must not be used!

6

Page 7

Explanatory Notes

Scope of supply

■ 1 Display and operating panel with CompactFlash™ 32 MB

■ 1 Bus term inal block (I/O module) with connector

■ 1 Installation manual SPECTORc ontrol

■ 1 Specification of the display and operating panel HPG-200

■ 1 Specification of the bus terminal block (I/O module)

Application

SPECTORcontrol is designed for the display, parameterization, monitoring and control of

the following components:

■ CANopen equipmen t

■ Actuators and sensors

All devices that can be used with SPECTORcontrol are indicated in the equipment list.

SPECTORcontrol uses the CANopen protocol and is ready to receive all data transferred

in a CAN bus.

In addition, equipment of Profibus or MODBus systems can also be connected to

SPECTORcontrol

SPECTORcontrol can, if required, be coupled with further SPECTORcontrol equipment

(e. g. follo w-up control of boiler).

The display and operation of SPECTORcontrol can either be effected by means of the

graphical operator panel with a touch screen or, if remote operation is desired, through

the use of Internet browsers via P C or hand-held.

SPECTORcontrol offers the following service functions:

■ Parameter indication,

■ Trend indication,

■ Indication and monitoring of main tenance intervals,

■ Representation of a ccumulated quantity,

■ Indication of the last 512 alarm messages (history function),

■ Remote operation via Intranet (TCP/IP) and Modem,

■ Multi languages,

■ Password protection,

■ Control functions.

7

Page 8

Expl an ato ry No tes – conti nued –

Function

SPECTORcontrol is an operating, indicating and automating device for boiler

management.

The sensors and SPECTORcontrol use the CANopen protocol. At regular intervals the

CANopen devices send data telegrams via CAN bus. The data transfer is in accordance

with ISO 11898.

All transferred process data are continuously received and evaluated by

SPECTORcontrol. If a connected CANopen device interrupts the data transmitting cycle,

an al arm message i s given and a visual signal is indicated by the displ a y.

To establish and monitor the available parameters of CANopen devices you can either

use the operating panel or a PC or handheld.

The configuration is menu driven. Make sure that you only enter correct parameters,

since the CANopen devices do not perform checks regarding consistency and range of

values.

SPECTORcontrol saves the adjusted parameters and received data.

The integrated PLC (programmable logic controller) enables the use of control functions

and di fferent softw are controllers as well as the incorporation of alarm values.

8

Page 9

Expl an ato ry No tes – conti nued –

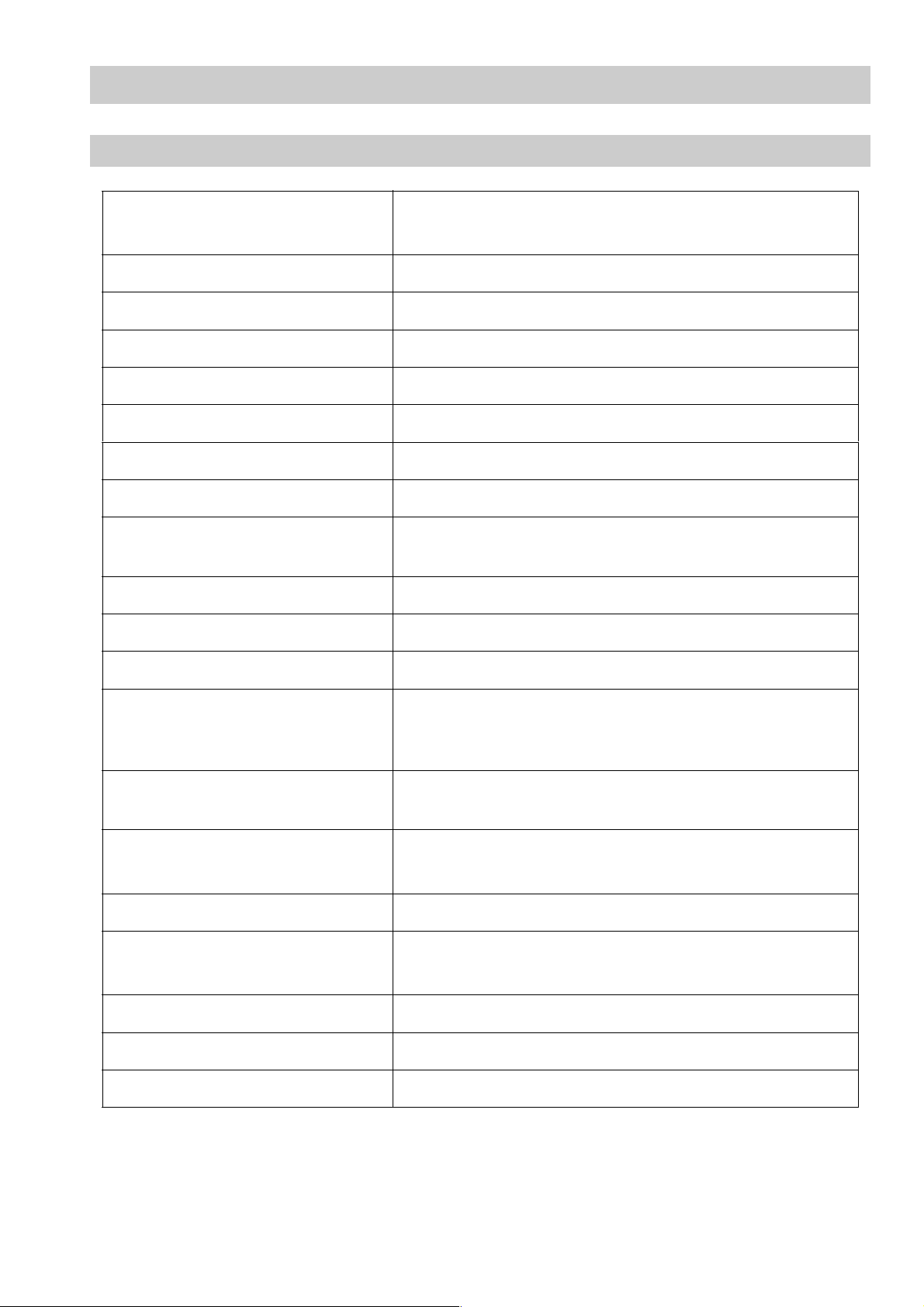

Syst em s pec if ic atio n

Bus terminal block

(I/O module)

Max. inputs an d outpu ts 20 digita l and 10 analogue

CANopen equipment

Max. number of sensors 10

Max. number of actuators 10

Data logs

Number of data logs 5 x 2

Maintenance

Number of counters

(Operating hours/switching cycles)

Qua n tity

Number of quanti ty signal s 5

Controller

Number of controllers

(Continuous / 2-posit ion /

3-position c ontroller)

Number of 3-element controllers

(continuous, 3-position controller)

Intermittent blowdown

control

Number of controls 1

Current and history

messages

5

5

1

Max. number of history messages 512

Password protection

Number of levels 3

9

Page 10

Installation

SPEC TORcontrol

Installation in accordance with the enclosed equipment specification of the visual display

& operating panel HPG-200.

Bus terminal block (I/O module)

Installation in accordance with the enclosed equipment specification of the bus terminal

block (I/O module).

Wiring

SPEC TORcontrol

Wiring in accordance with the enclosed equipment specification of the visual display &

operating panel HPG-200.

Bus terminal block (I/O module)

Wiring in accordance with the enclosed equipment specification of the bus terminal block

(I/O module).

10

Page 11

Commissioning

Technical requirements

All compo nents to be monitored must be connected and operating.

The visual display & operating panel must be provided with a CompactFlash™ card and

the power supply must be switched on.

Start-up behaviour

To commission the display & operating panel switch on the power supply. First a system

test is carried out. Then the hardware is checked.

After that the user program is automatically loaded from the CompactFlash™ and the start

menu is displayed (duration: approx. 4 min.).

Note

Any fault occuring during start-up will be indicated.

Shutdown behaviour

A short power supply failure of up to 10ms will be buffered by the power supply unit. In

the event of a longer power failure you have to reset SPECTORcontrol in order to restore

the power supply.

Factory settings

The graphical screen masks are configured by GESTRA. All adjustable masks are

completely available, no matter whether the indicated instruments are part of the bus

system or not. Subsequent expansion or modification is therefore possible at any time.

The scope of the adjusted values and hence the degree of preadjustments depends

whether a pre-configured OEM version is used or whether SPECTORcontrol will be

connected to an existing bus system and therefore the configuration of the system must

be completely new.

If a pre-configured OEM version is used, the individual components with the adjusted

parameters are stored on the CompactFlash™ card.

11

Page 12

Commissioning – contin ued –

System settings

The system adjustments for the first commissioning are stored on the

CompactFlash™ card. They ensure a trouble-fr ee commissioning procedure.

Grey entry fields or symbols are protected by passw ord.

In every menu that requires a password you can enter your password. The release of the

password protected menus is limited to 1hour (defaul t time setting). After this period of

time the release is automatically terminated and the password must be entered again.

The equipment features the following default settings:

■ Time: Real-time date and clock (battery-backed)

■ Contrast: Contrast = 40%

Backlight = 100%

■ Language: German

■ IP address settings: 194.31.73.1 50

■ Passwords: Level 1 for operating personnel: #####

Level 2 for engineering personnel: #####

Level 3 for commissioning personnel: GESTRA (factory setting)

Note

After commissioning we recommend that you use a new password. Make

sure that the same password is not used twice. Max. length of pass word:

8 characters.

All brand names or pr oduc t nam es are trademarks or registered tra demar ks of the respective manufacturer.

12

Page 13

Commissioning – contin ued –

CAN bus connection

The connection to the CANopen equipment is implemented via the CAN interface.

A D-subminiature plug c onnector in accordance with DIN 41652 must be used for the

connection. Use a multi-core flexible control cable as supply line.

Note that screened multi-core twisted-pair control cable is required as Bus line, e. g.

UNITRONIC® BUS CAN 2x2x. ..mm² or RE-2YCYV-fl 2x2x...mm².

Cable length Number of pairs and conductor size [mm²]

125 m 2 x 2 x 0. 34

250 m 2 x 2 x 0.5

335 m 2 x 2 x 0. 75

500 m

avai lable on demand (depends on bus configuration)1000 m

1000 m

Note

The design and preparation of the data cable is an important factor for the

electromagnetic compatibility (EMC) of SPECTORcontrol.

Connection should therefore be carried out with special care

(see equi pment specific ation of the display and operating panel HPG-20 0).

UNITRONIC® is a r egistered trad emar k of LAP P Kabe lwerke GmbH, Stutt gart.

13

Page 14

Commissioning – contin ued –

Remote monitoring

SPECTORcontrol allows remote monitoring and operation via P C. For this purpose a

browser (Internet Explorer 5.5 or higher) must be installed as frontend. You can also use

a handheld PC.

There are two ways to establish a connection:

1. A direct connection to the network/Intranet can be implemented via the integrated

Ethernet interface using a patch cable (RJ45).

Or, alternati vely, the connection can be established via Hub/switch.

2. An analog modem can be connected to the serial interface CO M3 (RS232). In this

case the connection will be directly established, e. g. via In ternet.

The following device has been tried and tested by GESTRA:

■ devolo-Microlink 56k Fun II serial

The IP address of SPECTORcontrol can be obtained from your system or network

admi nistrator. The IP address must be uniquely defined in the network.

Integration of third-party equipment

Third-party equipment such as Profibus and MODBus can - after prior consultation with

GESTRA - be directly connected to SPECTORcontrol.

Using the help function

You find the help function of the screen mask in the top right corn er of the menu bar.

When you press the button w ith the question mark a new window will pop up, giving

addi tional information on the current screen mask. The window is closed by the user.

14

Page 15

User Inte rfaces

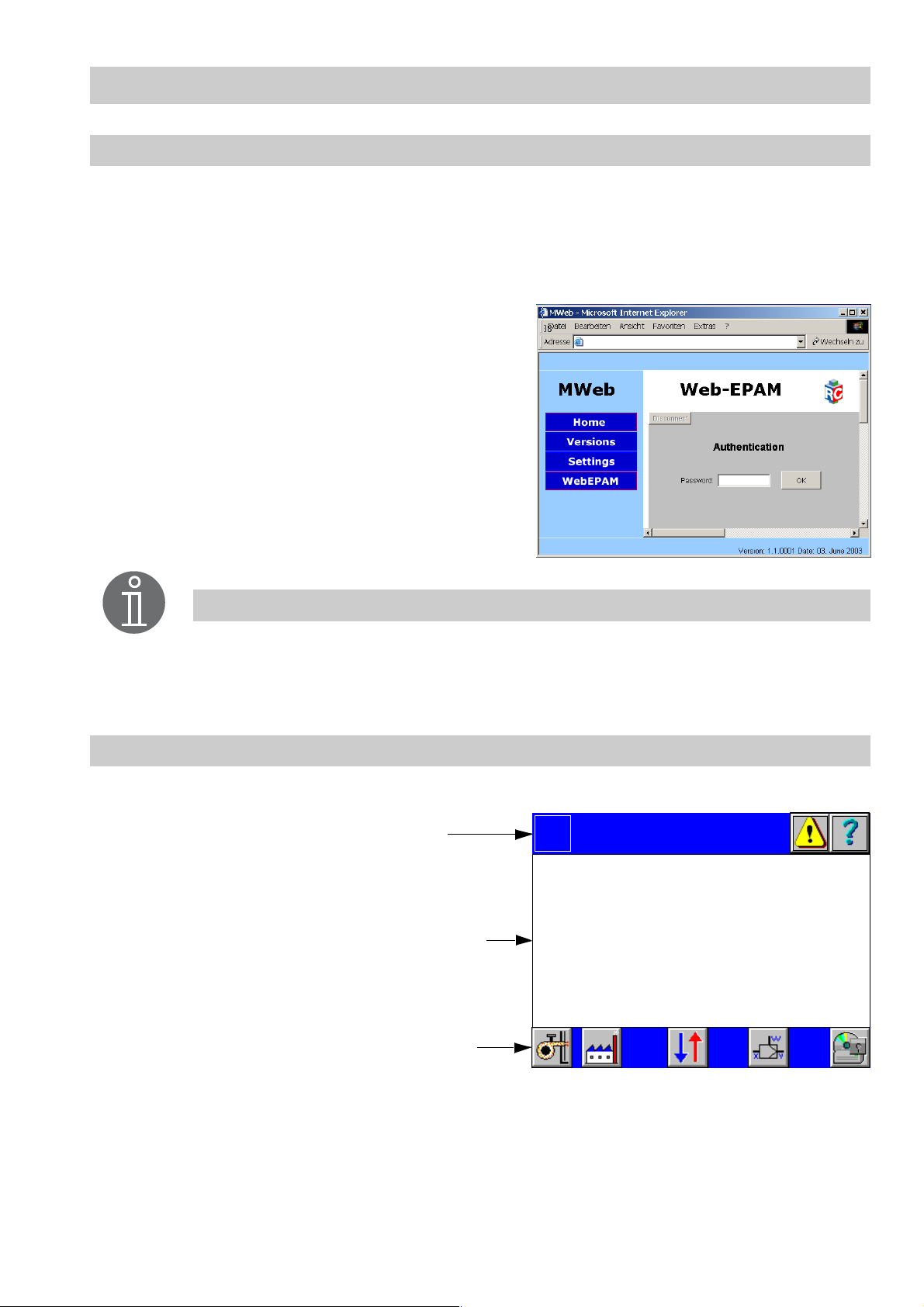

Description of the browser interface

SPECTOR

control

can be operated remotely via Internet Browser.

For the remote access via Intranet a valid IP address is required.

For more information on how to establish an IP address see chapter System, menu

IP addresses. T o call up the page enter http://IP address.

The buttons on the left side of the screen can be

used to show current configuration settings.

http://194.31.73.150

To show th e user int erface o f SPECTORcontrol

press button WebEPAM and enter your

password.

To confirm your input press button OK .

Note

For security reasons only one logged-in user can access the system via

browser. The direct operation of SPECTORcontrol is still pos sible, but a

simultaneous operation (local and remote acces s) should be avoided.

Description of the user interface

The user interface consists of three areas:

Title bar

Logo

Overview

00.00.00 00:00:00

Display field

Symbol bar

The title bar shows the c ompany logo, the title of the menu and two buttons.

All other menus have three buttons.

The display field changes its appearance accor d ing to the indicated menu.

The symbol bar shows the available functions of the indicated menu.

15

Page 16

User Interfaces – continued –

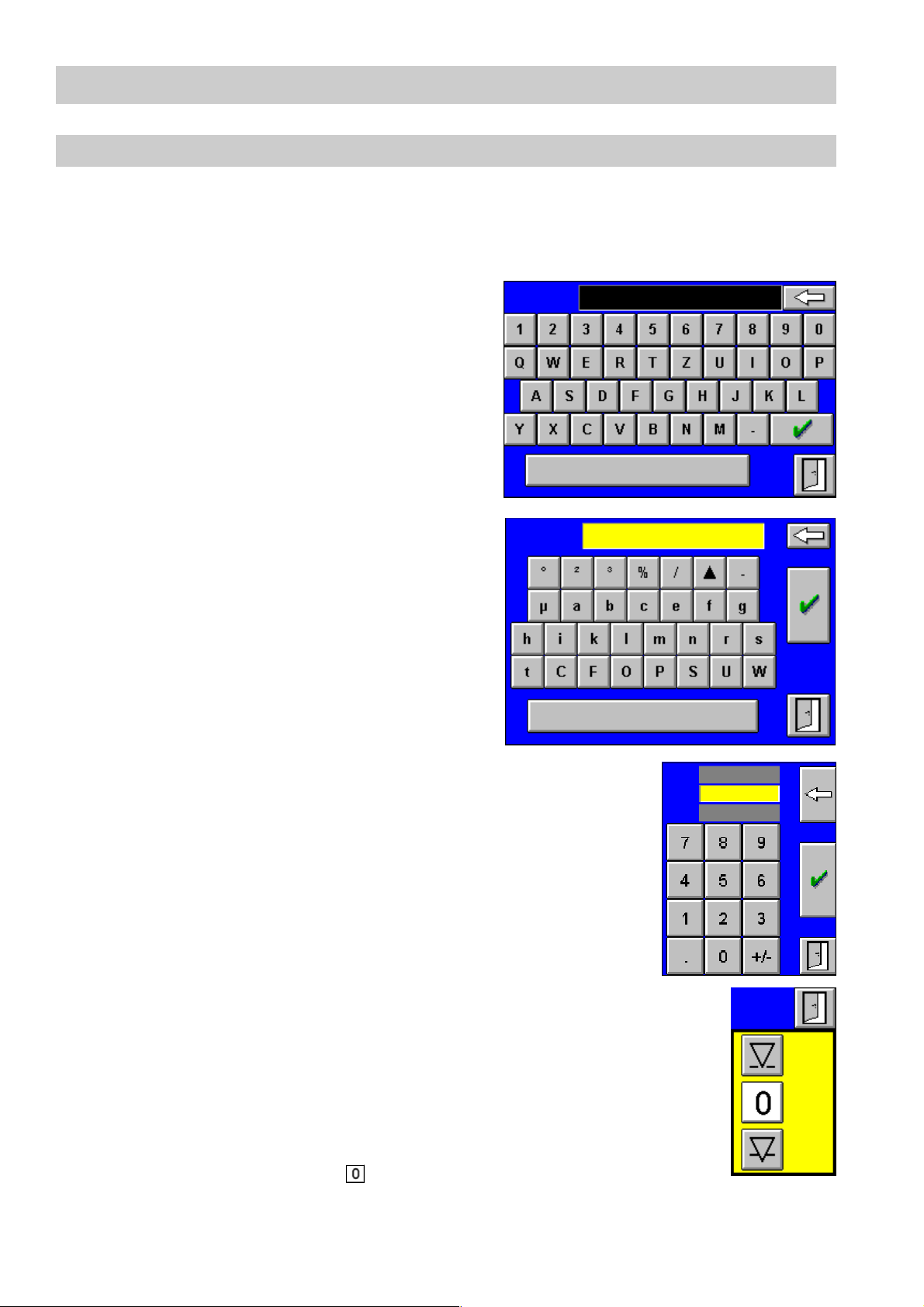

Description of the input masks

The input masks are designed for entering values without a keyboard.

Data is entered directly via touch screen panel and remote input is effected by clicking on

the respective icons of the user interface screen masks with a mouse.

For the input mask only the indicated (limited)

set of characters can be used.

Only upper case letters are indicated and used

(cas e insensitivity).

A plausibility test is not carr ied out.

The input mask is for entering units and

dime nsions.

Note that when changing the l anguage,

country-specific units (e. g. temperature) will

not be changed!

A plausibility test is not carr ied out.

Input:

Cur:

For the input mask only the indicated (limited)

set of characters can be used.

Min. and max. values are indicated above and

below the current entry.

Values that are not within the admissible range

of values will not be accepted .

The mask is used for selecting the type of

manual operation.

In the 3 button menu the controller motors

cont inuously to the selected end position. The

changing value of the manipulated variable is

optically indicated in the previous menu and

the selected mode of operation is shown by the

icon of the button. Press button to interrupt

or terminate the process.

Min.:

Cur.:

Max.:

Manual

Operation

Open

Stop

Close

16

Page 17

User Interfaces – continued –

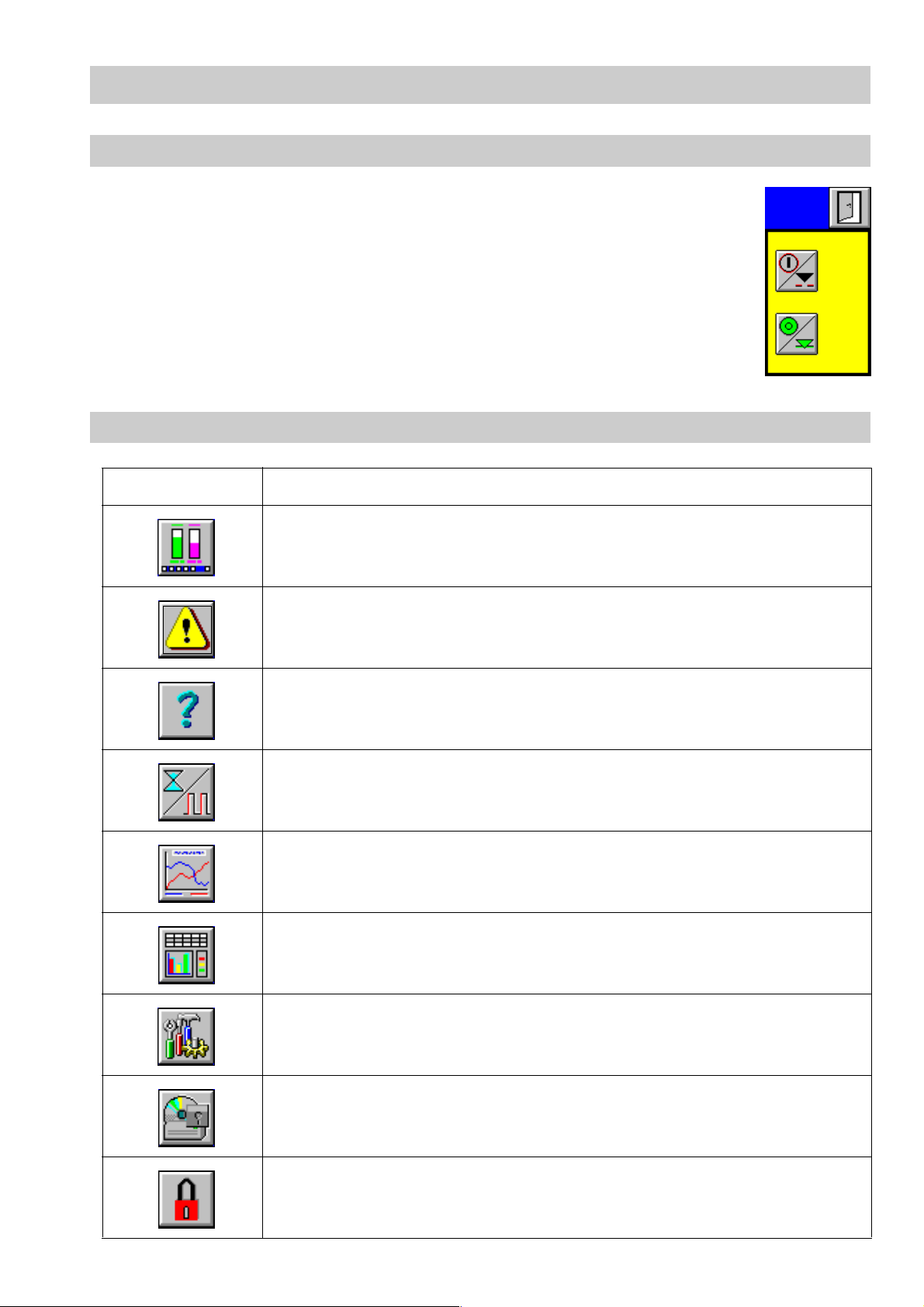

Description of the input masks - continued -

The mask is used for selecting the type of

manual operation.

In the 2 button menu the controller motors

continuously to the selected end position. The

attained mode of operation is optically

indicated in the previous menu. T he selected

mode of operation is indicated by the icon on

the button.

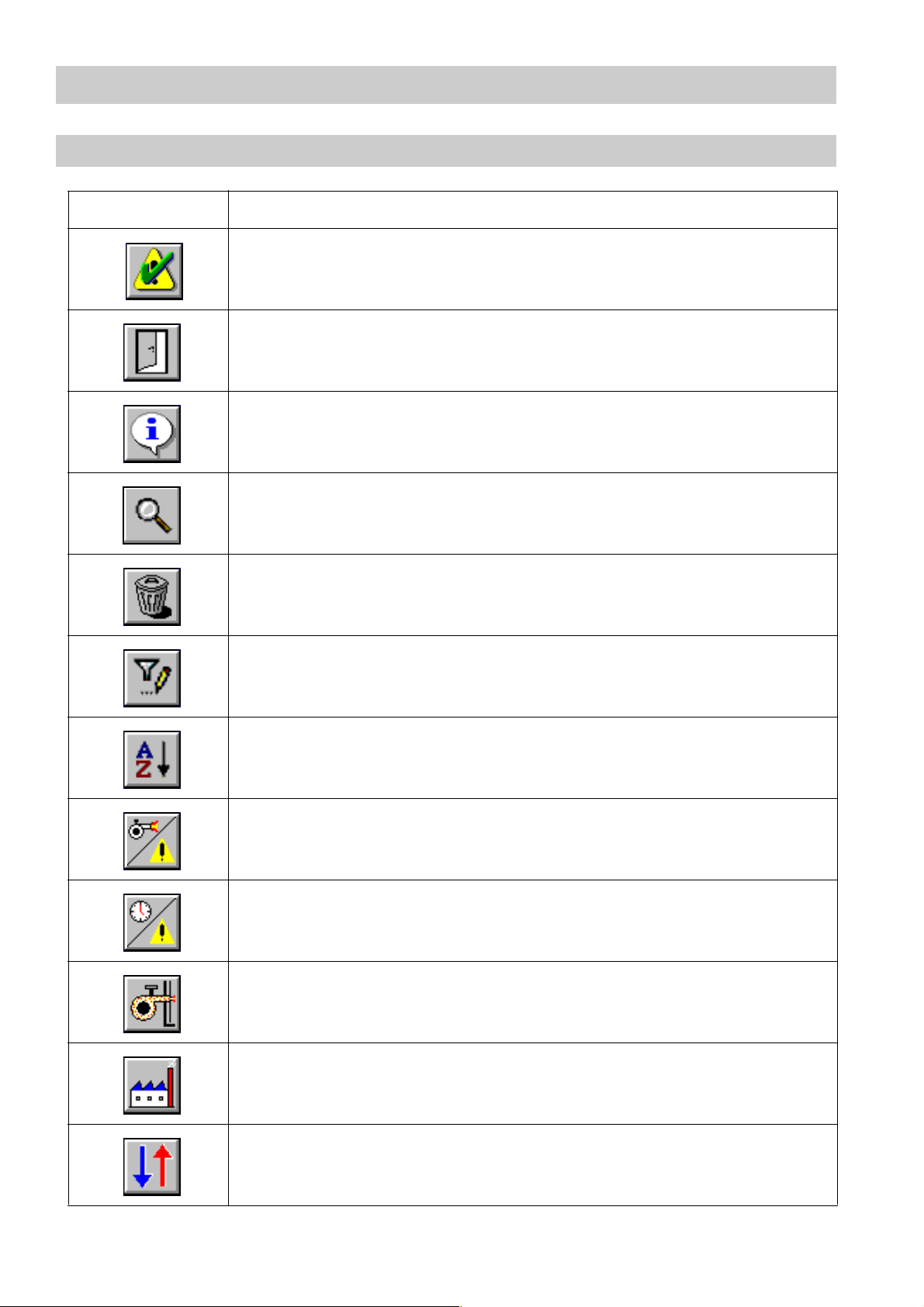

Description of buttons

Button Description

Return to start menu

grey = no alarm activated

Current alarm indication red = alarm acknowledged but still activated

flashing = alarm activated and not acknowledged

Manual

Operation

Open

Close

Indicate he lp text s fo r cu rr en t pa ge

Indicate maintenance

Indicate datalogs

Indicate quantities

Indicate configuration

Indicate system settings

Indicate password entry

17

Page 18

User Interfaces – continued –

Description of buttons - continue d -

Button D escription

Acknowledge alarm

Quit

current menu

Go to source (origin) of malfunction message

Indicate alarm details

Delete all history messages (waste bin)

Indicate filters of alarm history

Indicate sorting of alarm hi sto ry

Indicate malfunction history of the burner

Indicate fault history of th e bu rn e r

Indicate burner menu

18

Indicate boiler menu

Indicate I/O menus

Page 19

User Interfaces – cont inued –

Description of buttons - continued -

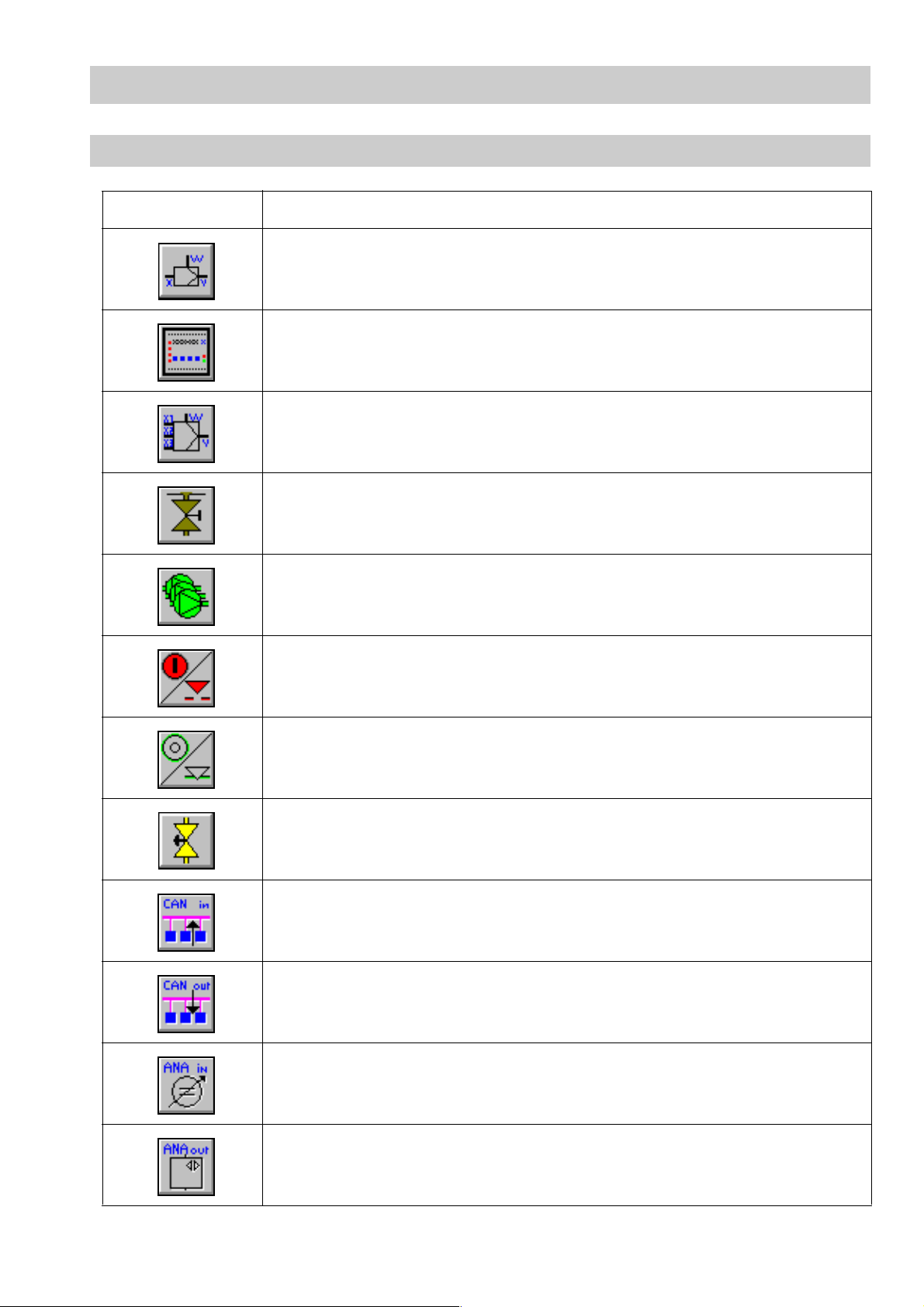

Button Description

Indicate controller menu

Indicate values of c ontrol equipment

Indicate 3-element control menu

Indicate intermittent boiler blowdown

Indicate multiple pump control

Valve position co ntrol OPEN/pump ON

Valve position co ntrol CLOSED/pump OFF

Indicate valve control or single pump control

Indicate CAN inputs

Indicate CAN outputs

Indicate analog inputs (I/O modu le)

Indicate analog outputs (I/O module)

19

Page 20

User Interfaces – cont inued –

Description of buttons - continue d -

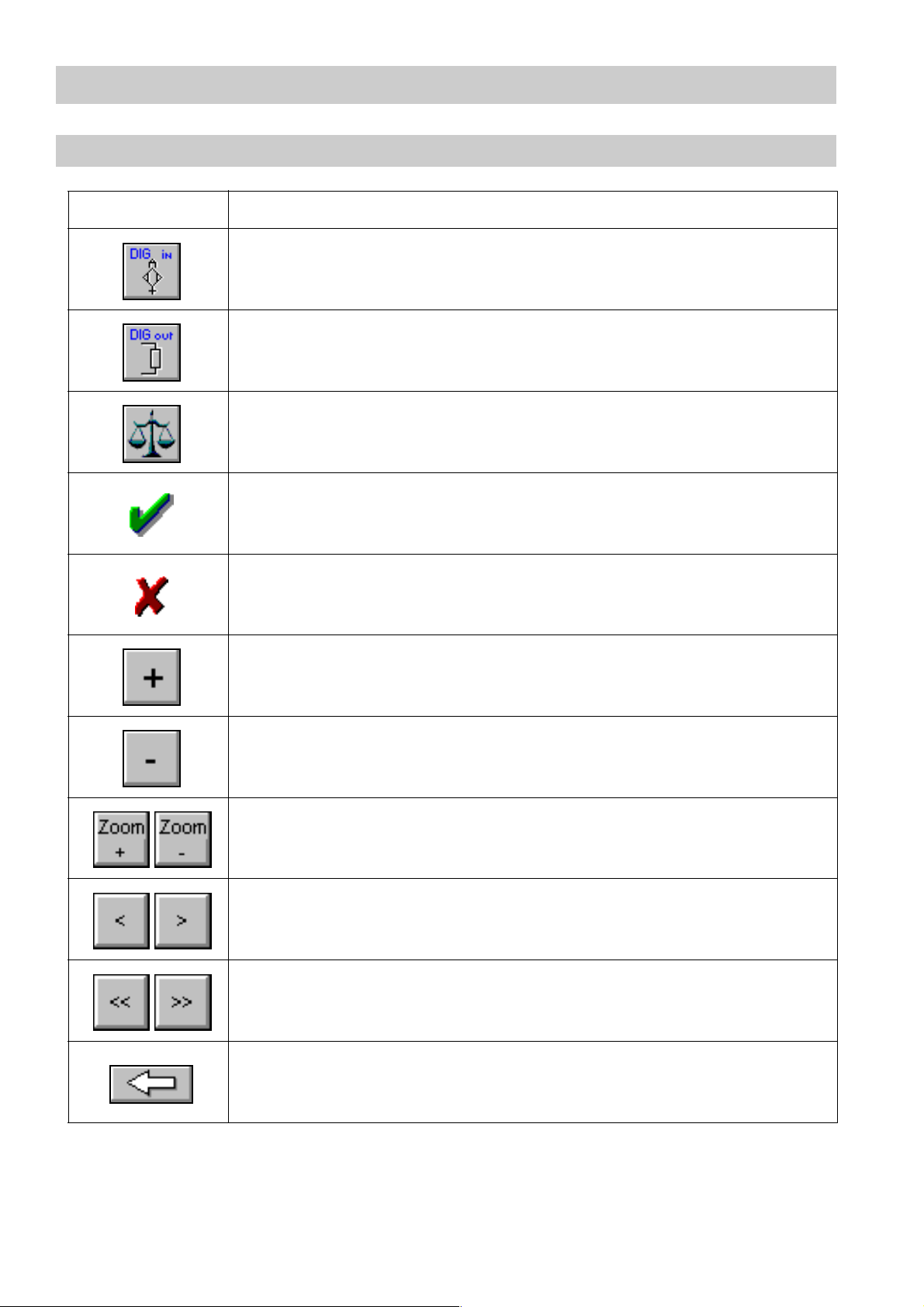

Button D escription

Indicate digital inp uts (I/O module)

Indicate digital outputs (I/O module)

Indicate calibration

Acknowledge / accept

Delete

Plus (time)

Minus (time)

Zoom plus/ minus (in datalog)

Forwards/backwards in steps of 3 min. (in datalog)

Forwards/backwards in steps of 10 min (i n datalog)

20

Backspace

Page 21

User Interfaces – cont inued –

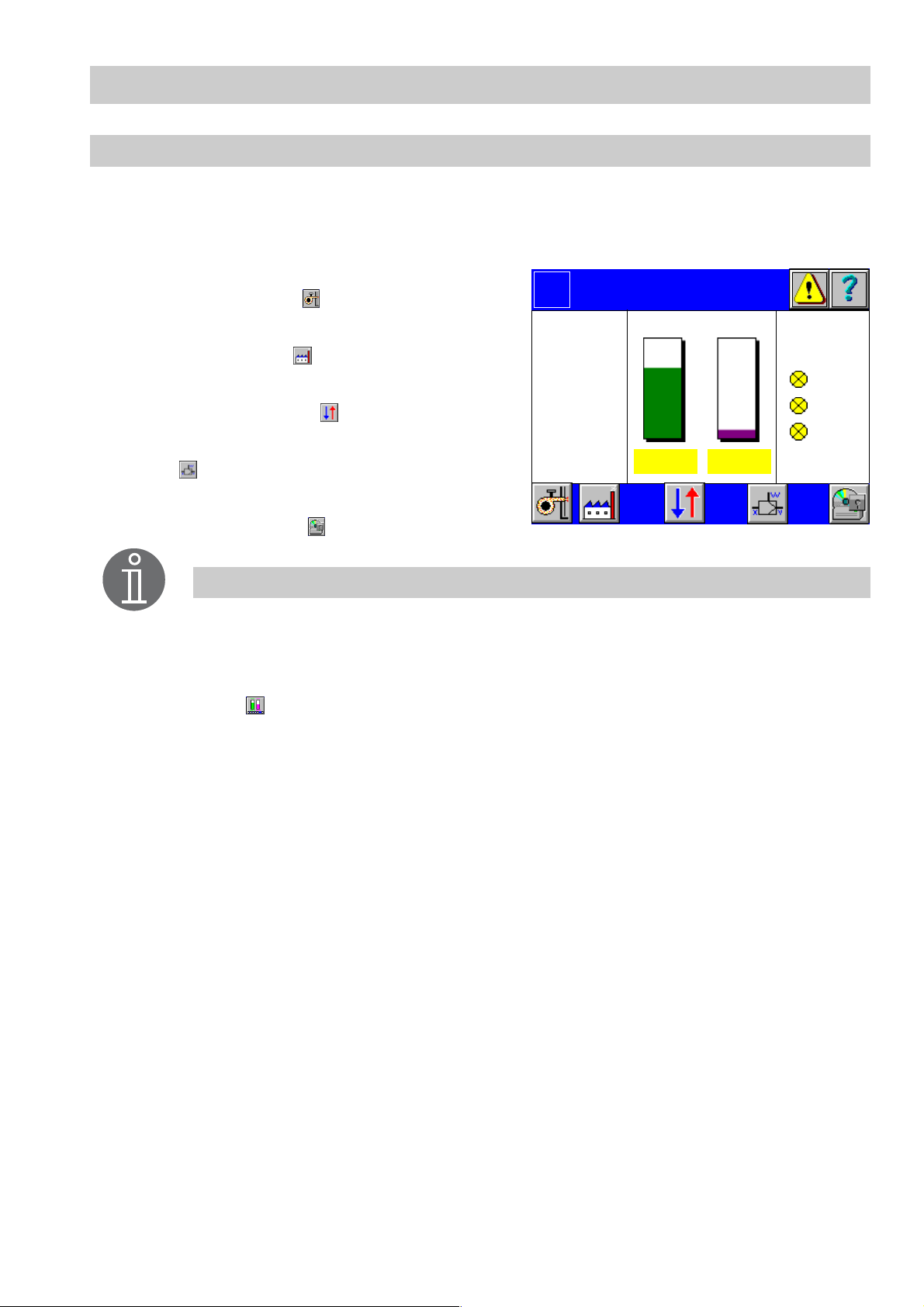

Menu o vervi ew

The display field shows all important current parameters of the boiler, e. g. level (CAN

input 1) and conductivity (CAN input 2) as well as specific burner data. The display is

made to the customer's specification and therefore serves here only as an example.

■ To show the configuration or current values

of the burner, press .

■ To show the configuration or current values

of the boiler, press .

■ To show the values or configuration of

inputs/ outputs, press .

■ To show or configure values of the controller,

press .

■ To show the configuration or current values

of the system, press .

Note

CAN input 1 is linked wi th level indication and CAN input 2 with conductivity

indication in the menu Overview. The values of equipment configured for

these inputs are shown in the menu Overview.

Use , which is not shown in this menu, to jump from all submenus directly

to the menu Overview. If no inputs are made within a certain period of time,

the system automatically returns to the overview menu.

Logo

Burner

P 20.0%

Actual 87.0 °C

Setp. 88.0 °C

O² - 0.1%

Overview

Level

Conductivity

492.9 µs71%

Boiler

LW 1

LW 2

HW

21

Page 22

System Menu

Sequence of set-up

Before starting the set-up procedure, make sure that all devices are interconnected via

CAN bus . The CANopen protocol is used for the data exchange between the equipment

groups.

To be able to access the CANopen equipment of the plant you must first check and, if

necessary, modify the basic settings.

Pre-configured installa tions will be completely parameterized by GESTRA. The data are

stored on the CompactFlash™ card. Modifications are therefore not necessary.

For a subsequent installation or expansion of SPECTORcontrol follow the configuration

step s described below.

Note

Any modification of t he basic settings has a direct effect on the boiler

monitoring system and the operating functions .

We recommend the following configuration sequence:

1. Check/configure system settings

2. Check/configure connected CANopen equipment

3. Check/configure connected analog equipment (I/O module)

4. Check/configure connected digital equipment (I/O modul e)

5. Check/configure connected controller

6. Check/configure boiler parameter settings

7. Check/configure burner parameter settings

8. After finishing the configuration restart the system.

(Only applicable if settings of CANopen equipment - cf. item 2 - were modified)

Note

SPECTORcontrol does not have an own on/off switch. To turn the equipment

on/off, switch on/off the power supply in the control cabinet or connect/strip

off the plug-in connection of the equipment.

22

Page 23

System Menu – continued –

System

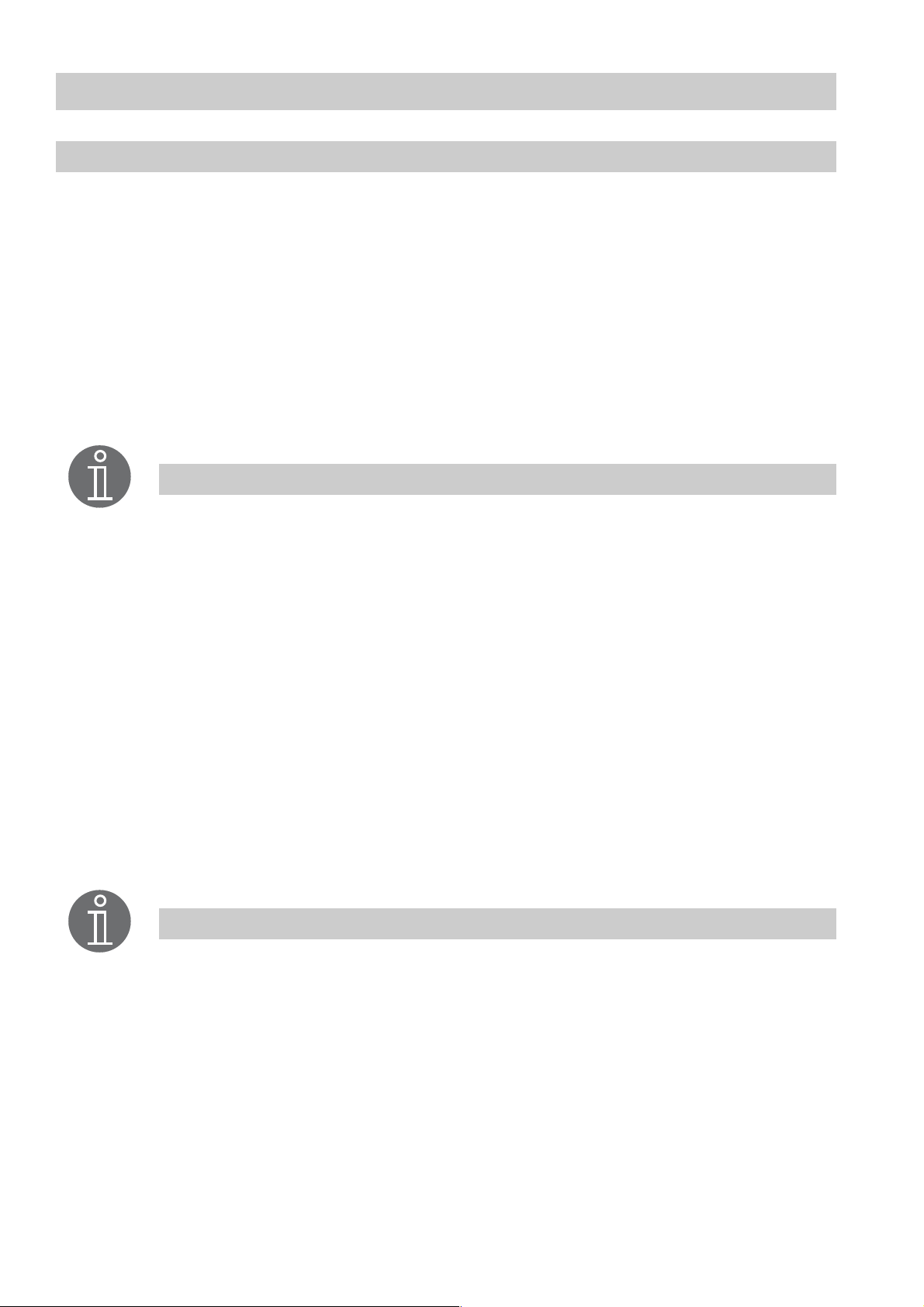

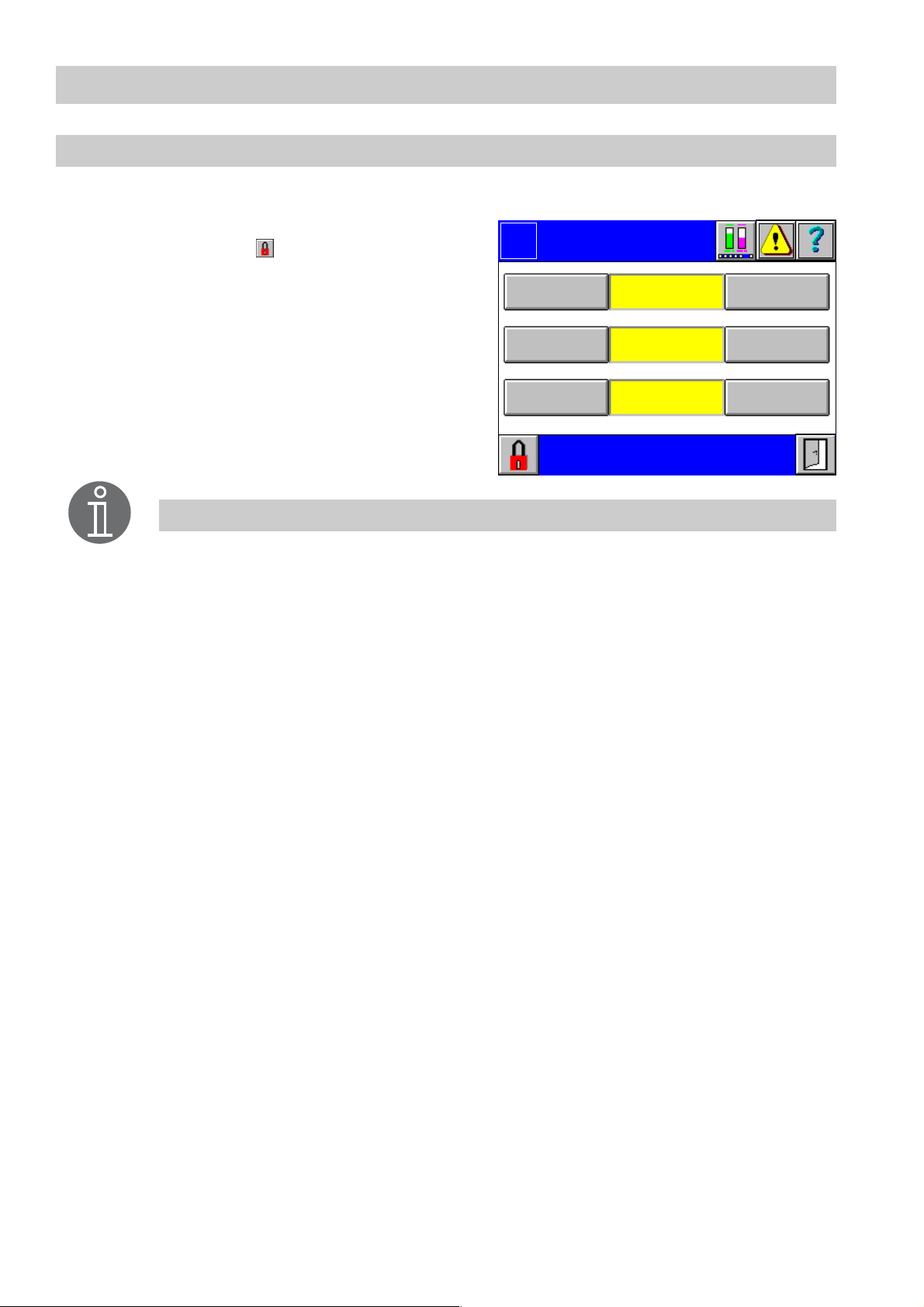

To configure the system press button in the menu O verview.

■ To set the time, press button Set time.

■ To change the contrast and the brightness of

the screen, press button Change contrast.

■ To change the language, press button

Language.

■ To change the password, press button

Change password.

■ To change the IP address, press button

Change IP.

■ To save or restore the default plant configu-

ration, press button Factory settings.

Note

All changes of the configuration take an immediate effect. However, changes

of the IP address and/or the node ID will only become effective after a restart.

Date and time setting

Logo

Change contrast

Set time

Language

System

Change password

Change IP

Factory settings

Canalyzer

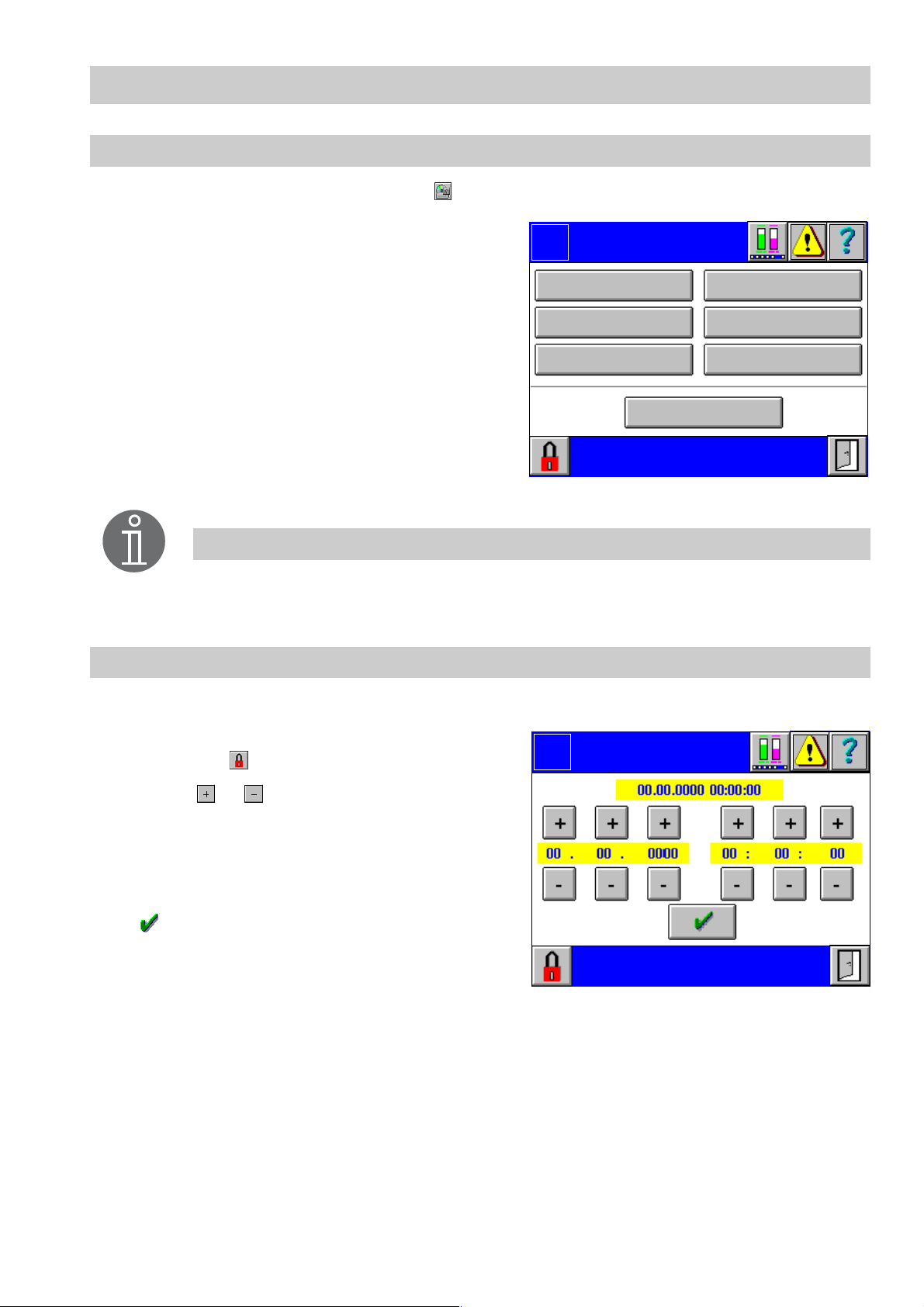

1. To set the t ime, click button Set time in the menu System.

2. The date/tim e setting is password protect-

Logo

ed. Press and enter your password.

3. Press or above and below the date

and time settings to change the indicated

values. The values are changed incrementally.

4. To accept the date and time settings press

.

Date

Time

23

Page 24

System Menu – continued –

Contrast and backlight setting

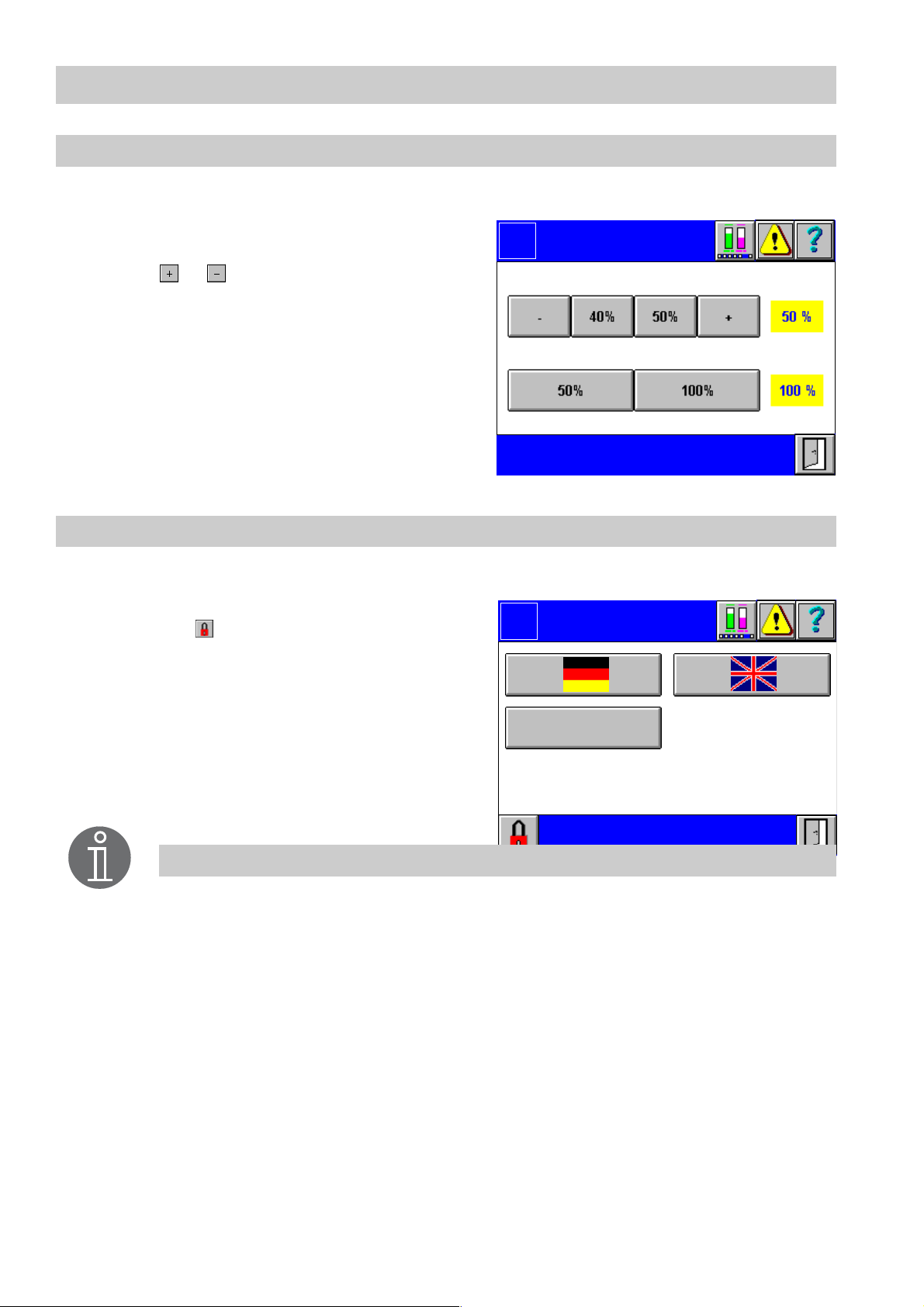

1. Press button Change contrast in the menu System.

2. To change th e contrast (difference between light and dark areas of the screen),

press or to the left an d right sides of

the fixed values of 40 % and 50 %. The

current value takes immediate effect and

is highlighted in yellow.

3. The backlight (brightness of the screen

display) can be set to 50 % or 100 % by

pressing the respective button.

The selected value takes immediate effect

and is highlighted in yellow.

Language

1. Press button Language in the menu System.

2. The language setting is password protected. Press and enter your password.

3. To change the language press the button

with the country flag in question. The selected language takes immediate effec t

and is shown in the menu bar.

Logo

Contrast

Backlight

Logo

Contrast

Backlight

Language

24

Note

Additional languages can be use d.

Page 25

System Menu – continued –

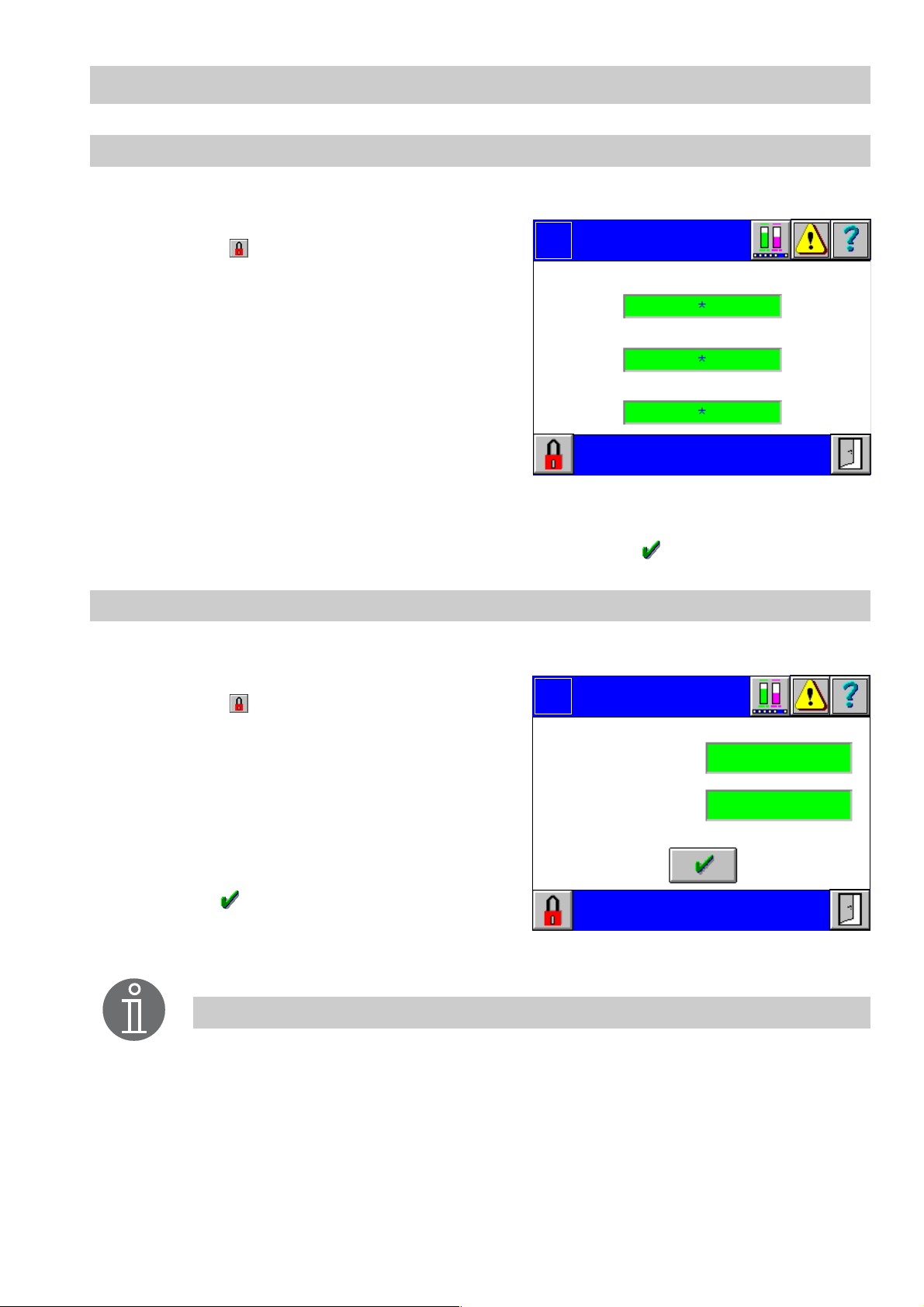

Passwor d

1. Press button Change password in the menu System.

2. The menu Password is password protected. Press and enter your password.

Logo

Password

3. According to the level of authorization one

or more green inpu t fields are shown. An

Level 1:

asterisk appears fo r each character you

enter.

4. Click in the input field that you want to

change .

Level 2:

Commissioning

Level 3:

5. The current value appears as plain text in

the inp u t mask. Use the on-screen keyboard to overwrite or modify the value.

Note that at most 8 characters can be enter ed.

6. Confirm the input of the password by pressing the button .

IP add ress se ttin gs

1. Press button Change IP in the menu System.

Operator

Engineer

2. The menu Change I P is password protect-

ed. Press and enter your password.

3. Click in the input field that you want to

change .

4. The current value appears in the input

mask. Use the on-screen keyboard to

overwrite or modify the value.

5. Confirm the input of all IP addresses by

pressing .

6. After finishing the configuration restart the

system.

Note

All changes of the configuration take an immediate effect. However, changes

of the IP address and/or the node ID will only become effective after a restart.

Logo

IP address Target:

IP address Gateway:

IP address

25

Page 26

System Menu – continued –

Fa ctory se ttin gs

1. Press button Factory settings in the menu System.

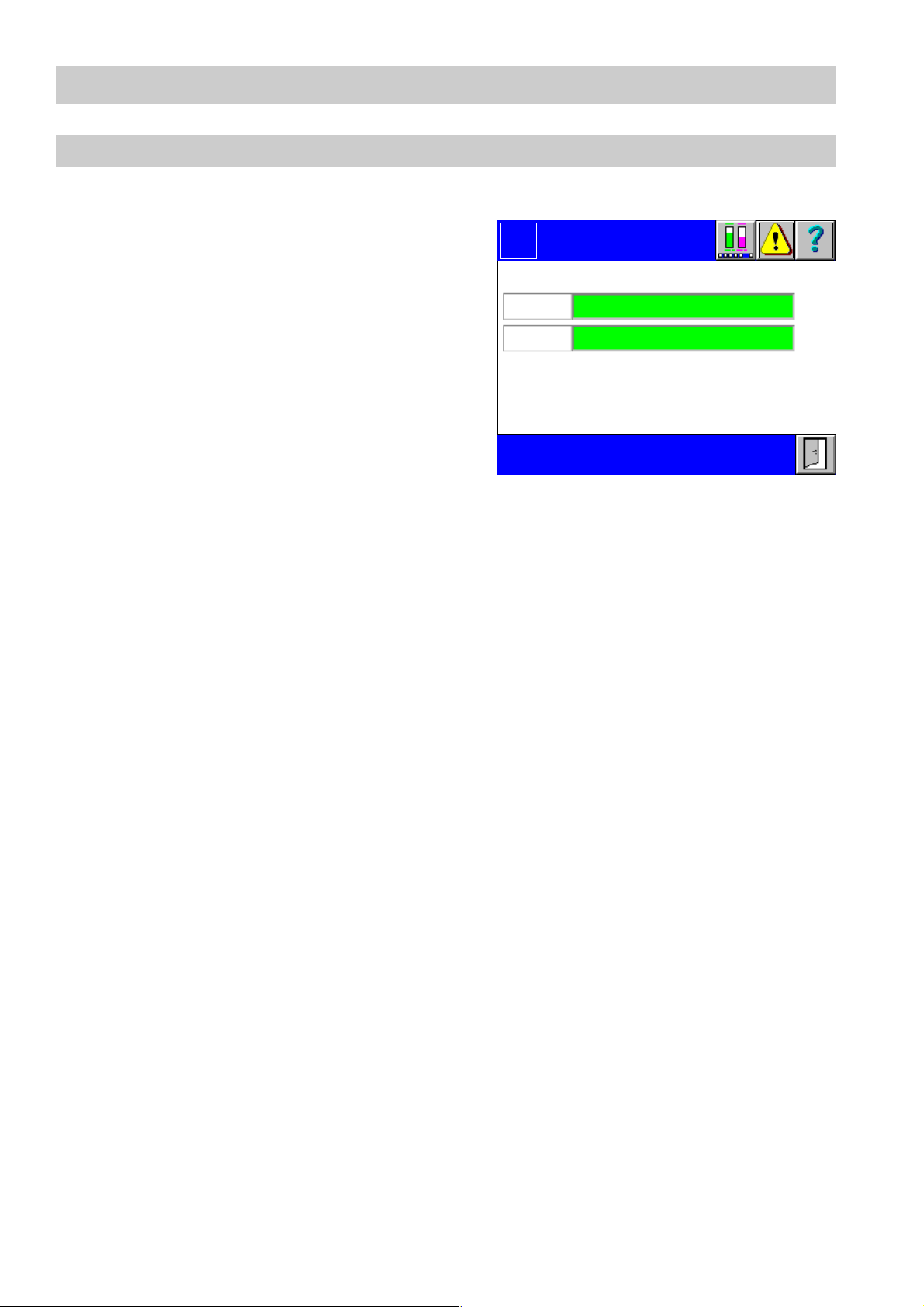

2. The menu Factory settings is password

protected. Press and enter your password.

3. According to the level of authorization one

or more yellow input fields with the "Saved

on" date are shown.

4. Click on the button of the settings that you

want to save or load.

Note

The accumulated maintenance and quantity data will not be over written. All

adjusted parameters remain stored.

Logo

Save

Save

Save Load

Factory

settings

Setting s 3

00.00.0000 00:00

Settings 2

00.00.0000 00:00

Settings 1

00.00.0000 00:00

Load

Load

26

Page 27

Menus of Inputs/Outputs

CAN 1..10 input

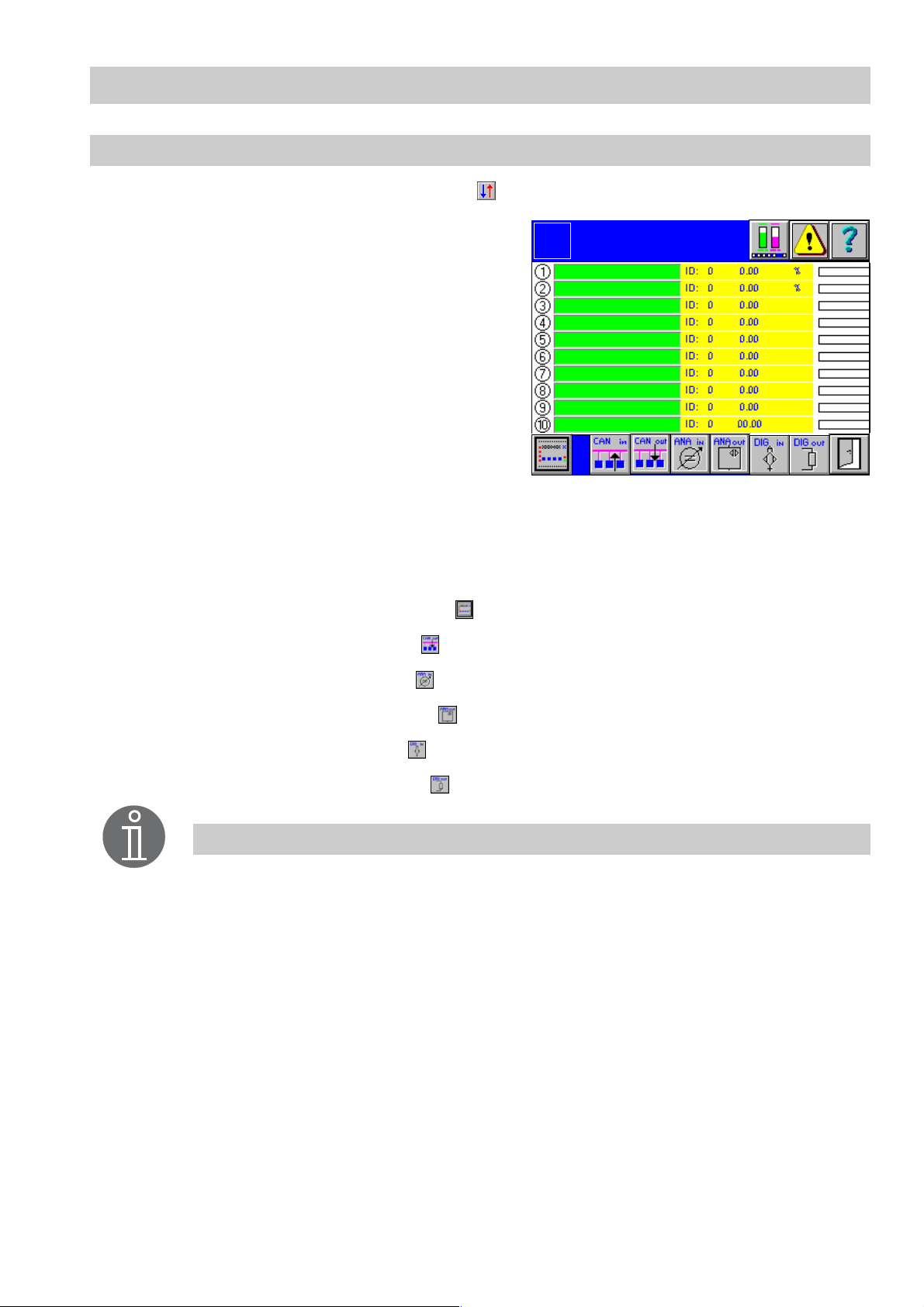

To adjust the inputs / outputs press button in the menu Overview.

1. The green input fields list the names of the

current CAN inputs. Active inputs are indi-

Logo

CAN 1 ..10

Input

cated by the illumina ted yellow number on

the left side. A node I D conflict is indicated

by a mark at the left side of the ID setting.

At the right side the currently measured value, the as sociated unit and the graphical

representation is sh own. Current alarms

are indicated for each individual input by a

mark at the left side of the graphical representation.

2. To re-configure an input click in the green input field. The menu CAN Typ e 1...10

pops up.

If one input has already been configured its designation will appear in the input field.

Click in the input field to call up the corresponding menu directly.

■ To show the control equipment press .

■ To call up the CAN outputs press .

■ To show the analog inputs press .

■ To call up the analog outputs press .

■ To show the digital inputs press .

■ To call up the digital outputs press .

Note

CAN input 1 is linked with leve l indication and CAN input 2 with co nductivity

indication in the menu Overview.

The values of these devices are currently indicated in the menu Overview.

27

Page 28

Me nus o f In pu ts/O utp uts – conti nue d –

CAN type 1..10

1. Click in the menu CAN 1..10 Input in the new input field that you want to configure.

2. Select the device to be configured.

CAN type 1..10

3. To delete an entry press .

NRG 26-40

NRG 16-42

LRG 16-40

Note

All devices that can be used with SPECTORcontrol are indicated in the

equipme nt list.

NRG 26-40 CAN 1...10

1. Click in the menu CAN 1..10 Input in the green input field of the device in question.

2. The display field shows the current values

of the equi pment.

Logo

NRG 26-4 0

CAN 1

3. The menu NRG 26-40 CAN 1..10 is password protected. Press and enter your

password.

4. To show the setup menu press .

5. To access the menu NRG 26-40 Calibra-

tion press .

Reading

Name

0

0%

0 %

0 %

0 %

0 %

Node

Electrode online

Temp.in terminal box OK

OffNode ID

28

Page 29

Me nus o f In pu ts/O utp uts – conti nue d –

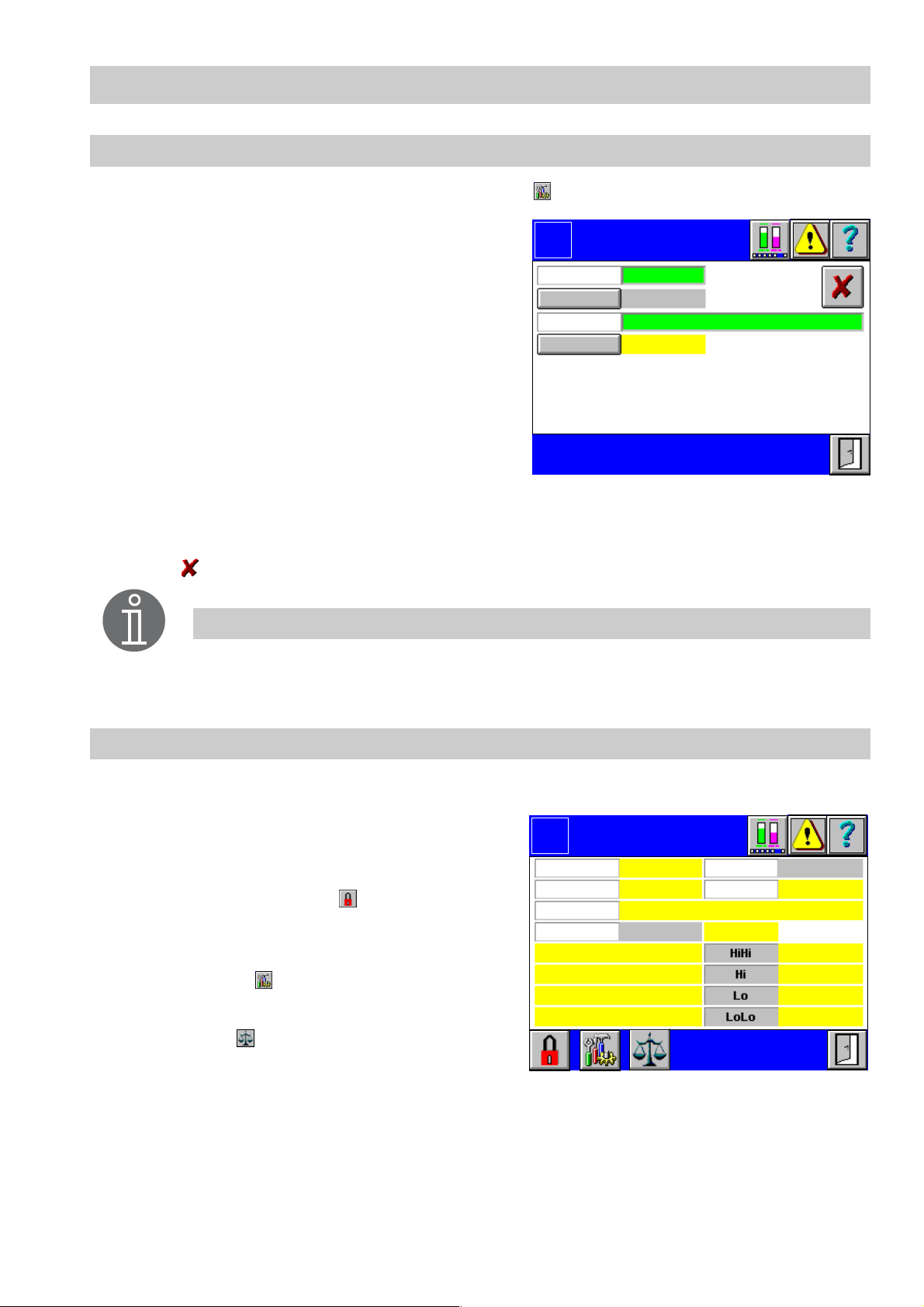

NRG 26- 40 setu p

1. In the menu NRG 26-40 CAN 1...10 press .

2. To establish or change the node ID click in

the green input field.

3. Use the on-screen keyboard to overwrite

or modify the value in the input mask.

4. Use button Node On/Off to activate or deactivate the node ID.

5. To name the NRG 26-40 click in the input

Logo

Node ID

Node On

Name

NRG 26-40

Setup

0

Node Off

0 %

0 %

0 %

0 %

Delete

electrode?

field Name.

6. Use the on-screen keyboard to overwrite

or modify the value in the input mask.

7. To change the values of the NRG 26-40 click in the i nput field.

8. Use the on-screen keyboard to overwrite or modify the value in the input mask.

9. Use to delete the adj usted equipment or to change the type of CAN electrode.

Note

The HiHi and LoLo settings can be used for alarms and the Hi and Lo settings

for switchpoints of 2-position controllers.

The alarm monitoring function is de-activated when all HiHi to LoLo values

have been set to 0%.

The node ID settings of SPECTORcontrol must agree with the settings of the

respective devices.

29

Page 30

Me nus o f In pu ts/O utp uts – conti nue d –

NRG 26-40 calibration

1. In the menu NRG 26-40 CAN 1...10 press .

2. Choose a reference point at the boiler

(e. g. bottom edge of sightglass), fill the

boiler up to this point and then press button 0% Calibration to acknowledge.

3. After calibrating the zero point, 100% must

Logo

Level

NRG 26-4 0

Calibration

100 %

0

Cali. value

be calibrated. F o r this purpose click in the

green input fi eld.

4. Use the on-screen keyboard to overwrite

0%

0% Calibratio n

or modify the value in the input mask.

5. Choose a value between >50% ( e . g. m i d dle of sightglass) and <100% ( e. g. top

edge of s ightglass).

Fill the boiler until the set marking is reached an d press button 100% Calibration to

acknowledge.

NRG 16-42 CAN 1...10

1. Click in the menu CAN 1..10 Input in the green input field of the device in question.

2. The display field shows the current values

of the equi pment.

3. The menu NRG 16-42 CAN 1..10 is password protected. Press and e nter your

password.

4. To show the setup menu click button .

Logo

Reading

Name

NRG 16-42

CAN 1...10

0

0 %

Node

Electrode online

Temp. interminalboxOK

OffNode ID

0.5 µSSense

30

Page 31

Me nus o f In pu ts/O utp uts – conti nue d –

NRG 16- 42 setu p

1. In the menu NRG 16-42 CAN 1...10 press .

2. To establish or change the node ID

click in the green input field.

3. Use the on-screen keyboard to overwrite

or modify the value in the input mask.

4. Use button Node On/Off to activate or de-

Logo

Node ID

Node On

Name

S e ns e 10 µS

NRG 16-42

Setup

0

Node Off

0.5 µ S

Delete

electrode?

activate the node ID.

5. To name the NRG 16-42 click in the input

field Name.

6. Use the on-screen keyboard to overwrite

or modify the value in the input mask.

7. Use button Sen se 10/ 0.5 µS to toggle between the two values. The adjusted value

is highlighted in yel low.

8. Use to delete the adj usted equipment or to change the type of equipment.

Note

The node ID s ettings of SPECTORcontrol must agree with the settings of the

respective devices.

LRG 16 -40 CAN 1...10

1. Click in the menu CAN 1..10 Input in the green input fi eld of the device in question

2. The display field shows the current values

of the equi pment.

3. The menu LRG 16-40 CAN 1..10 is password protected. Press and enter your

password.

4. To show the menu LRG 16-40 Set up

press button .

5. To access the menu LR G 16-40 Calibra-

Logo

Node ID

Readin g

Name

Ele ct r od e on lin e

Tem p. in ter m inal box OK

PT1000 OK

LRG 16-40

CAN 1

0

0.0 µ S

OffCompens.

Temperature

1234567890

Node

Off

0 °C

0 µS

0 µS

0 µS

0 µSElect rode OK

tion press .

31

Page 32

Me nus o f In pu ts/O utp uts – conti nue d –

LRG 16-40 setup

1. In the menu LRG 16-40 CAN 1...10 press .

2. To establish or c hange the node ID

click in th e green input field.

3. Use the on-screen keyboard to overwrite

or modify the value in the input mask.

4. Use button Node On/ Of f to activate or deactivate the node ID .

5. To name the LRG 16-40 click in the input

Logo

Node ID

Node On

Name

Range 100%

Range 0%

LRG 16-40

Setup

0

Node Off

0.00

0.00

Delete

electrode?

0 µS

0 µS

0 µS

0 µS

field Name.

6. Use the on-screen keyboard to overwrite

or modify the value in the input mask.

7. To change th e values of the LRG 16-40 click in the input field. First establish the

0% -100% range and then enter further values.

8. Use the on-screen keyboard to overwrite or modify the value in the input mask .

9. Use to delete the adjusted equipment or to change the type of equipment.

Note

The HiHi and LoLo settings can be used for alarms and the Hi and Lo settings

for switchpoints of 2-position controllers.

For the 72 hrs operation according to TRD 604 the switchpoint HiHi does not

replace t he independent equipme n t in the safety chain

The alarm monitoring function is de-activated when all HiHi to LoLo values

have been set to 0 µS.

The node ID settings of SPECTORcontrol must agree with the settings of the

respective devices.

32

Page 33

Me nus o f In pu ts/O utp uts – conti nue d –

LRG 16 -40 ca libra tion

1. In the menu L RG 16-40 C AN 1 .. .10 pres s .

2. Use button Compensation On/Off to activate or de-activate the temperature compensation. All indicated readings are here

Logo

Compensation Off

LRG 16-40

Calibration

Autoscan

Auto activ.

absolute readings of the current conductivity.

3. To carry out an autoscan press button Au-

Standard curve

Linear

toscan. The auto-curve temperature com-

pensat ion is suitable for boilers operating

Cell constant

0.000

with variable pressure, which means that

the boiler does not have a fixed working

pressure (e. g. low l oad 10 bar, full load 15

bar). The system detects in steps of 10 °C

all temperature and conductivity values from 100 °C to the service temperature. For

this purpose the boiler must reach its working pressure (with variable pressure operation: ma x. allowable working pressure). If the standard curve is not suitable for variable pressure operation, use can be made of the recorded curve.

4. If you want to use the autoscan values, e. g. because the standard curve is not suitable, press button Auto activ.. The previously recorded auto-curve will be activated.

The auto-curve can be overwritten by a newly recorded curve at any time.

5. To adjust the standard-curve temperature compensation click in the green input field.

Th e menu Select standard curve appears. The standard curve temperature compensat ion is suitable for boilers o perating with variable pressure, which means that

the boiler d oes not have a fixed working pressure (e. g. low load 10 bar, full load 15

bar). The standard c urves of feedwater condi tioning agents with different basic conductivities compensate for the influence of the temperature on readings within the operating range.

6. To adjust the linear temperature compensation click in the input field next to the button Linear. The menu Select temperatur e coefficient appears. The gradient (de-

fault setting: 2.1%/°C) is normally used for steam boilers operating with constant

pressure. The con ductivity is ascertained a t an ambient temperature of 25 °C. The

cell constant can be modified in order to calib rate the value measured by the electrode. The gradient can be verified at operating pressure with the aid of a calibrated

conductivity meter .

7. Click in the green input field to enter the cell constant C of the conductivity electrode

(values must be within the admissible range).

8. Use the on-screen keyboard to overwrite or modify the value in the input mask.

33

Page 34

Me nus o f In pu ts/O utp uts – conti nue d –

LRG 16-40 calibration - conti nued -

Note

With increasing press u re and temperature the conductivity i s no longer a

linear function. Choose a suitable temperature compensa tion method.

Sele ct sta ndard cu rve

1. Click in the green input field of the menu LRG 16-40 Calibration

2. Select in the menu Select standa rd curve the

corresponding standard temperature curve. The

curves are applicable for various feedwater condi-

Select standard curve

NaHO+H2O 260µS

tioning agents with different basic conductivities.

For more information refer to the installation manual of the equipment.

NaHO+H2O 1080µS

NaHO+H2O 5400µS

NaHO+H2O 11200µS

Na3PO4+H2O 190µS

Na3PO4+H2O 1100µS

Select temperature coefficient

1. Click in the green input field of the menu LRG 16-40 Calibration

2. Select in the menu Select temperature coef-

ficient the corresponding gradient.

Selec t temp. coefficie nt

0

34

1.6 % / °C

1.7 % / °C

....

2.9 % / °C

3.0 % / °C

Page 35

Me nus o f In pu ts/O utp uts – conti nue d –

Current v alues of control equipment

To adjust the control equipment press button in the menu CAN 1..10 Input.

1. The display f ield shows the current name

and node ID of the control equipment. Active equipment is indicated by a signal at

the left side. If there is a malfunction the

buttons or the text boxes are highlighted in

red.

2. To show the configuration of the control

equipment press the respective button.

Note

All devices that can be used with SPECTORcontrol are indicated in the

equipme nt list.

NRS 1- 40

Logo

Current values

Control Equipment

NRS 1-40

NRG 16-40

NRG 16-40

NRS 1-41

NRS 1-41

LR R 1- 40

Name

ID

0

0

0

0

0

0

To adjust the control equipment pr ess button NRS 1-40 in the menu Current values of

control equipment.

1. The display field shows the current parameters of the control equipment. Malfunctions ar e indicated in red.

2. The menu NRS 1-40 is password protected. Press and enter your password.

3. To show the setup menu press button .

Logo

Name

Node

Control equipment online

Relay (de)energ. OK

Relay A OK Relay D OK

El ectrod e 1 Online

Ele ctrod e 1 OK

Electr. 1 term. temp. OK

NRS 1-40

Low le vel lim iter

Off

Relay C OK

Node ID

NRS 1-40 OK

El ectrod e 2 Online

Ele ctrod e 2 OK

Electr. 2 term. temp. OK

0

35

Page 36

Me nus o f In pu ts/O utp uts – conti nue d –

NRS 1-41

To adjust the control equipment press button NRS 1-41 of the menu Current values of

control equipment.

1. The display field shows the current parameters of the c o ntrol equipment. Malfunctions are indicated in red.

2. The menu NRS 1-41 is password protected. Press and enter your password.

3. To show the setup menu press button .

NRS 1-40/ 41 setup

1. In the menu NRS 1-40 or NRS 1 -41 press .

2. To establish or c hange the node ID

click in th e green input field.

3. Use the on-screen keyboard to overwrite

or modify the value in the input mask.

4. Use button Node On/ Of f to activate or deactivate the node ID .

Logo

Name

Node

Contr ol equipment online

Relay (de)energ. OK

Relay A OK

Relay C OK

Relay D OK

Logo

Node ID

Node On

Name

NRS 1-41

NRS 1-40

Setup

0

Node Off

Low level limiter

Off

Node ID

Electrode online

Electrode OK

Electrode term. temp. OK

NRS 1-41 OK

0

5. To name the control equipment click in the

input field Name.

6. Use the on-screen keyboard to overwrite

or modify the value in the input mask.

Note

The node ID settings of SPECTORcontrol must agree with the settings of the

respective devices.

36

Page 37

Me nus o f In pu ts/O utp uts – conti nue d –

LRR 1-40

1. Press button LRR 1-40 in the menu Current values of control equipment.

2. The display field shows the current values

of the equi pment.

3. The menu LRR 1-40 Setup is password

protected. Press and enter your password.

4. To show the setup menu click button .

LRR 1-40 setup

1. In the menu LRR 1-40 press .

2. To establish or change the node ID

click in the green input field.

3. Use the on-screen keyboard to overwrite

or modify the value in the input mask.

4. Use button Node On/Off to activate or deactivate the node ID.

Logo

Name

Node

Node ID

Max. lim it

Control equipment online

Logo

Node ID

Node On

Name

Write

max. li mit

LRR 1-40

LRR 1-40

Node Off

Conductivity

Off

0

0

Setup

0

0

5. To name the LRR 1-40 click in the input

Read

max. limit

0

field Name.

6. Use the on-screen keyboard to overwrite

or modify the value in the input mask.

7. The current limit value is highlighted in yellow. To change the max. limit click in the

corresponding input fi eld.

8. Use the on-screen keyboard to overwrite or modify the value in the input mask.

9. When the entered limit value is accepted, it will be sent to the equipment. The value

is immediately active and displayed in the menu.

Note

The node ID s ettings of SPEC TORcontrol must agree with the settings of the

respective devices.

37

Page 38

Me nus o f In pu ts/O utp uts – conti nue d –

CAN 1..10 output

1. In the menu Inputs or Outputs press .

Digital inputs

1. In the menu Inputs or Outputs press .

2. The display field shows the c onnected

signals. Active connections are indi cated

by a yellow signal at the left side.

3. The menu Digital Inputs is password protected. Press and enter your password.

4. To designate a signal click in the green input field.

5. Use the on-screen keyboard to overwrite

or modify the value in the input mask.

6. The Alarm buttons feature three different

indicating functi ons:

Alarm with signal value 0 (O FF) (yellow)

Alarm with signal value 1 (O N) (yellow)

Alarm OFF (grey)

7. To go to the CAN input press .

8. To go to the CAN output press .

9. To go to the analog input press .

Logo

Sig. 1

Sig. 2

Sig. 3

Sig. 4

Sig. 5

Designation

Designation

Digital

Inputs

Alarm

with 0

Alarm

with 1

Alarm

Off

Alarm

Off

Alarm

Off

10. To go to the analog output press .

11. To go to the digital output press .

38

Page 39

Me nus o f In pu ts/O utp uts – conti nue d –

Digital outputs

1. In the menu Inputs or Outputs press .

2. The display f ield shows the connected

signals. Active outputs are indicated by a

yellow signal at the left side.

3. The menu Digital Outputs is password

protected. Press and enter your pass-

Logo

Sig. 1 Designation

Sig. 2

Sig. 3

Digital

Outputs

Alarm

Alarm

Alarm

word.

Sig. 4

Alarm

4. To designate a sig nal click in the green input field.

Sig. 5

Alarm

5. Use the on-screen keyboard to overwrite

or modify the value in the input mask.

6. To show the status of a signal press button Signal 1...10 at the left side. A new menu

will pop up.

7. Press button Alarm to link the digital output with an alarm (HiHi/LoLo) of the CAN

inputs or with analog inputs.

8. Select the signal that indicates the required parameters. For more information on the

setup and configuration of the equipment see chapters CAN Input and Analog Input.

After selecting an input establish the alarm limit HiHi or LoLo. W hen the alarm is

raised t he digital output will be switched off.

9. To go to the CAN input press .

10. To go to the CAN output press .

11. To go to the analog input press .

12. To go to the analog output press .

13. To go to the digital input press .

39

Page 40

Me nus o f In pu ts/O utp uts – conti nue d –

Digital output 1...10 energised

1. Press button Signal 1...10 in the menu Digit al Outputs.

2. The display field shows the parameters of

the digital output.

3. The menu Digital Outputs is password

protected. Press and enter your password.

Logo

Signal from

Type

Signal

DO 1

energised

2-position controller

Controller 2

Open

40

Page 41

Me nus o f In pu ts/O utp uts – conti nue d –

Analog 1..10 input

1. In the menu Inputs or Outputs press .

2. The green input fields list the names of the

current analog inputs. Active inputs are indicated by the illuminated yellow number

on the left side. At the right side the currently measured value, the associated unit and

the graphical representation are shown.

Current al arms are indicated for each individual input by a mark at the left side of the

graphica l representation .

3. To configure an input click in the green input field. The menu Analog Input 1...10

pops up.

■ To show the CAN inputs press .

■ To call up CAN outputs press .

■ To call up the analo g outputs press .

■ To show the digital inputs press .

Logo

Analog 1..10

Input

■ To call up the digital outputs press .

Analog input 1..10

1. Click in the menu Analog 1..10 Input in the green input field.

2. The display field shows the par ameters of

the anal og input.

3. To configure the analog inputs press .

Logo

Type

AI Status

Name

Reading 0.00

Range 100%

Range 0%

Analog

Input 1

PT100

Off

0.00

0.00

PT 100

OK

0.00

0.00

0.00

0.00

41

Page 42

Me nus o f In pu ts/O utp uts – conti nue d –

Analog input 1...10 setup

1. In the menu Analog Input 1...10 press .

2. The menu Analog Input 1...10 Setup is

password protected. Press a nd enter

your password.

3. To select the type of sensor press button

Logo

Type

AI On

Name

AI 1

Setup

PT100

Off

Unit

PT 100

Type. The available types of sensor are

shown in a list.

4. To activate or de-activate the analog input

press but ton A I On/Off.

Range 100%

Range 0%

0.00

0.00

0.00

0.00

0.00

0.00

5. To select the unit of the measured value

click in th e green input field.

6. Use the on-screen keyboard to overwrite or modify the unit in the input mask.

7. To name the analog input click in the input field Name.

8. Use the on-screen keyboard to overwrite or modify the value in the input mask .

9. To change the range limits click in the corresponding input field. First establish the

0% -100% range and then enter further values.

10. Use the on-screen keyboard to overwrite or modify the val ue in the input mask.

Note

The HiHi and LoLo settings can be used for alarms and the Hi and Lo settings

for switchpoints of 2-position controllers.

The alarm monitoring function is de-activated when all HiHi to LoLo values

have been set to 0%.

42

Page 43

Me nus o f In pu ts/O utp uts – conti nue d –

Analog 1..10 output

1. In the menu Inputs or Outputs press .

2. The green input fields list the names of the

current analog inputs. Active inputs are indicated by the illuminated yellow number

on the left side. At the right side the currently measured value, the associated unit and

the graphical representation are shown.

Current al arms are indicated for each individual input by a mark at the left side of the

graphica l representation .

3. To configure an input click in the green input field. The menu Analog Output 1...10

pops up.

■ To show the CAN inputs press .

■ To call up the CAN outputs press .

■ To show the analog inputs press .

■ To show the digital inputs press .

Logo

Analog 1..10

Output

0.00 %

0.00 %

0.00 %

0.00 %

0.00 %

0.00 %

0.00 %

0.00 %

0.00 %

0.00 %

■ To call up the digital outputs press .

Analog output 1..10

1. Click in the green input field of the menu A nalog 1..10 Output.

2. The menu Analog Output 1...10 is pass-

word protected. Press and enter your

password.

3. To name the analog output click in the i nput field Name.

4. Use the on-screen keyboard to overwrite

or modify the value in the input mask.

Logo

Name

Type

Name

Range 100

Range 0

Analog

Output 1

specifie d by:

Off

NC

0.0

0.0

0.0 %

0

AO On

5. To select the type of sign al press button

Type. The available types of actual value

signal are shown in a list. After the sele ction the values of the sensing element will

be indicated.

Control outputs are established in the setup menu of the c ontinuous controller. The

controller has always top priority.

AO OffOutput value

6. To activate or de-activate the analog output press button AO On/O ff.

43

Page 44

Controller Menu

Controller

To set up the controller press button in the menu Overview .

■ The menu Controller is password protect-

Logo

Controller

ed. Press button and enter your password.

■ The green input fields list the names of the

Controller 1

Controller 2

controllers in question.

■ The yellow signal to the left indicates that the

controller is activated. CC stands for continuous controller, 2P for 2-posi tion controller

Controller 3

Controller 4

Controller 5

and 3P for 3-posi tion controller.

■ To configure a controller press button Con-

troller 1...5 Setup.

■ To show the adjusted controller values c lick in the respective input field. The menu

Continuous controller setup, 2-pos. controller setup or 3-pos. controller setup

appears.

■ To call up the menu 3-element co ntroller press .

■ To configure the intermittent boiler blowdown press button .

Con tro ller s etup

1. Press button Controller 1...5 Setup in the menu Controller.

2. The green input field at the top shows the

name of the controll er in question. To

change the name of the controller click in

the input field.

3. The current name appears in the input

Logo

Off

Enabled

Controller

Setup

Name of controller 1Status

NC

mask. Use the on-screen keyboard to

overwrite or modify the name.

Continuous

controller

2 pos.

controller

3 pos.

controller

4. The controller can be enabled or disabled

by a digital input. Click in the green input

field at the bottom to go to the selec tion

menu.

5. Select the signal that shall enable (1) or disable (0) the controller. You will find more

information on equipment setup in the menu Digital Inpu ts. If no signal has been selected, the acronym NC (not connected) is indicated. This means that the co ntroller

is permanently enabled. The field Enabled/disabled indicates the status.

44

Page 45

Controller Menu – conti nued –

Cont roll er setup - continued -

6. Use the three controller buttons to a ctivate the controller. An activated controller is

visually indicated in the menu Controller.

7. Use button Off to de-activate the controller.

8. If no controller type has been selected, the status indicator indicates Off. If a controller has been selected, the respec tive button is highlighted in yellow and the status

indicator indicates On.

9. To configure the controller press button Continuous controller, button 2-pos. con-

troller or button 3-pos. controller.

Continuous controller setup

1. Press button Continuous controller in the menu Controller Setup.

2. The name of the controller is highlighted in

yellow.

3. The green input field Actual value shows

the actual value. Click in the input field to

show all es tablished si gnals.

4. Select the signal that indi cates the required parameters. For more information

Logo

Controller 1

Actual value

Int. setpoi nt

Manip. variable

Position

Offset MIN limit

Continuous

controller setup

NC

NC

NC

NC

MAX lim it

on the setup and configuration of the

equipment see menu CAN Input and Analog Input.

5. The green input field Setpoint shows the

setpoint element. The setpoint can be adjusted directly in the equipment or externally, e. g. via a potentiometer.

6. To toggle between internal and external setpoint press button Internal setpoint/ Ex-

ternal setpoint.

7. To enter the signal for an external setpoint click in the green input field. All established sensing elements will be indicated.

8. Select the signal that indicates the required parameters. For more information on the

setup and configuration of the equipment see menu CAN Input and Analog Input.

9. The green input field Manip. variable shows the manipulated variable element. To

select a signal for the manipulated variable click in the green input field. All adjusted

signals will be indicated.

10. Select the s ignal to which the manipulated variable shall be sent.

You will find the settings in the menu Analog Outputs.

45

Page 46

Controller Menu – conti nued –

Continuous controller setup - continue d -

11. The green input field Position shows the position indicator. To select a position feedback signal, click in the green input field. All adjusted signals will be indicated.

12. Select the signal that indicates the required parameters. For more information on the

setup and configurati on of the equipment see menu CAN Input and Analog Input.

13. The green input field Offset shows the current value. To enter or change a value click

in the input field.

14. The adjusted value appears in the inp ut mask. Use the on-screen keyboard to o verwrite or modify the value.

15. The green input field MIN limit shows the current limit. To enter or change a value

click in the input field.

16. The adjusted value appears in the inp ut mask. Use the on-screen keyboard to o verwrite or modify the value.

17. The green input field MAX limit shows the current limit. To enter or change a value

click in the input field.

18. The adjusted value appears in the inp ut mask. Use the on-screen keyboard to o verwrite or modify the value.

19. To config ure the controller press button .

Note

The MIN and MAX limit values specify the admissible manipulated variable.

46

Page 47

Controller Menu – conti nued –

Continuous controller

1. Press button in the menu Continuous controller setup.

2. The menu Continuous controller is

password protected. Press button and

enter your password.

3. The name of the controller is highlighted in

yellow. Below that the current actual value,

the setpoint as well as the current controller position are indicated.

4. To change the internal setpoint click in

Logo

Controller 1

Actual

Enabled

Continuous

TEST 2

0.0 %

Int. setpoint

Position

Manual:

0.0

0.0NC

0.0

0.0

0.0

0.0

the green input field.

5. The current value appears in the input

mask. Use the on-screen keyboard to

overwrite or modify the value.

6. W hen you switch to manual operation you can enter a manipulated variable in the

input field Manual. For this purpose click in the green input field.

7. The current value appears in the inpu t mask. Use the on-screen keyboard to overwrite or modify the value.

8. Use the button to activate either automatic operation, off or manual operation. The

adjusted mode of operation will be indicated by a larger ic on next to the button.

9. Use the input fields P (proportional), I (integral) and D (differential) to enter the control

parameters of the PID controller.

10. The current value appears in the input mask. Us e the on-screen keyboard to over write or modify the value.

11. Below the status indicator Enabled/Disabled and the ad justed controller the actual

value (X), the setpoint (W) and the manipulated variable (Yx) as well as the position

feedback (Yx) are graphically represented in the form of a bar chart.

Note

In this menu only an internal setpoint can be established.

If you change the switch setting from automatic operation to Off, the current

manipulated variable (Yw) of the controller will appear in the field Manual.

If the controller features an external setpoin t element that is defective, the

internal setpoint will become active and can be adjusted.

47

Page 48

Controller Menu – conti nued –

2-position controller setup

1. Press button 2-pos. controller in the menu Cont rolle r Setup .

2. The name of the c ontroller is highlighted in

yellow.

3. The green input field Actual value shows

the actual value. Click in the input field to

show all es tablished signals.

4. Select the signal that indicates the required parameters. For more information

on the setup and configuration of the

Logo

Controller 1

Actual value

Discharge control

Parameterised as

Pump control

2-pos. controller

Setup

NC

Fill c on tr ol

parameterisedVal ve control

equipmen t see menu CAN Input and Analog Input .

5. To toggle between fill and discharge control press button fill or discharge control. The selected control mode is indicated in

the right hand field.

6. The bottom field specifies the actuator. This field is highlighted in yellow if pump and/

or valve control has been adjusted.

7. To set the valve control press button Valve control.

8. To set the pump control press button Pump control.

9. To parameterise the controller press button .

48

Page 49

Controller Menu – conti nued –

Pump setup

1. Press button Pump control in the m enu 2-pos. contro ller setup.

2. To adjust the pump press button Pump

1...3.

3. Use the buttons to specify the mode of operation (automatic / off / on) for eac h

pump. The lamp signal indicates that the

pump is operating.

4. The total operating time of the pump is

highlighted in yellow.

5. To delete the operating t ime press .

Note

If several pumps are used and automatic operation is activated, first the

pump with the shortest operating ti me is selected, provided i t is ready for

operation.

Pump 1...3 setup

Logo

Pump 1 Pump 2 Pump 3

Ready

Run time: hh:mm Run time: hh:mm

Pump

Setup

Ready

Ready

Run time: hh:mm

00000:0000000:0000000:00

1. Press button Pump 1...3 in the menu Pump Control.

2. The adjusted sensing element is indicated

in the green input field Ready for opera-

tion. Click in the in put field to show all es-

Logo

Ready for operation

Pump 1

Setup

NC

tablished signals.

Pump ON

NC

3. Select the signal that indi cates the required parameters. You will find more information on equipment setup in the menu

Digital Input.

4. The adjusted signal receiver is indicated in

the green input field Pump ON. Click in t he

input field to show all established signals.

5. Select the signal that indicates the required parameters. You will find more in formation on equipment setup in the menu Digital Output.

49

Page 50