Page 1

™

SoftTools

Quick Start Guide for SoftTools 7.0 with support for the

HART Communications Protocol on the Logix

1200/1200e, 3200IQ, and 500/500si Series Positioners

Flowserve Corporation

Suite 7.0

Flow Control Division

VLAUG001-00 ©Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611 1 of 21

Page 2

Table of Contents

Chapter 1: Preface..........................................3

Chapter 2: Software Installation.......................4

System Requirements................................... 4

Installing SoftTools 7.0..................................4

Instrument to Computer Connection ............. 5

Chapter 3: Startup ..........................................6

Using SoftTools 7.0....................................... 6

Using SoftTools TechCheck .........................6

Using the Configurator Tool .......................... 7

Reset........................................................... 10

Using the Calibrator Tool ............................ 10

Using the Condition Tool.............................14

Using the Alert Display................................16

Security Administrator.................................16

Using the Context-Sensitive Help System .. 18

Disabling FIFO Buffers................................18

VLAUG001-00 ©Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611 2 of 21

Page 3

Chapter 1: Preface

Welcome to Flowserve Valtek SoftTools™. This Quick Start Guide is designed to assist the user in

setting up and initiating process control using the combined features of the SoftTools software, the

HART

SoftTools 7.0 is a complete software ‘suite,’ within which communication protocol software and

instrument module software is combined to form a unique process control configuration, calibration

and device monitoring system.

communications protocol, and a Logix™ series "smart" positioner.

VLAUG001-00 ©Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611 3 of 21

Page 4

Chapter 2: Software Installation

System Requirements

The following hardware is required to use SoftTools:

1. A computer using a Pentium, higher, or compatible processor and running

Windows 95, 98, NT, 2000, or XP.

2. CD-ROM drive

3. Mouse or other cursor-pointing device.

4. Memory requirements of 32MB RAM minimum, with 64MB RAM

recommended.

5. Approximately 30MB disk space for installation.

6. Serial communication ports: 1 minimum available with 8 maximum possible.

Installing SoftTools 7.0

1. You must be an administrator on the system. If you do not have administrative

rights, have your system administrator install and run SoftTools one time.

2. Insert the SoftTools 7.0 program CD into the computer CD-ROM drive.

3. Click the Start button on the task bar.

4. Select Run. Type e:\ SoftTools 7 Setup.exe (to install from the E: drive) into the

Run edit box; then click on the OK button.

Application Installation

1. At the Welcome message dialog, click on the Next button.

2. At the Choose Destination Location dialog, the user may accept the default

directory from the dialog box or click on the Browse button to select an

alternate destination folder. After selecting or editing a directory, click on the

Next button.

3. At the Select Program Manager Group, click Next.

4. At the Start Installation dialog, click Next. If a previous installation is

detected, click Yes to preserve data from an earlier version of SoftTools.

Click No to continue without saving previous data.

5. Click Finish to complete the installation.

VLAUG001-00 ©Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611 4 of 21

Page 5

Instrument to Computer Connection

Make the physical connection between the PC and the positioner. Locate an available

serial, PCMICIA or USB communications port on the computer and plug a HART modem

into it. Attach the other end of the HART modem cable to the appropriate device or

interface.

Many new computers (especially laptops) no longer have serial or PCMICIA connections,

but do have USB ports. If the user already has a serial HART modem, a USB to RS 232

adapter is an inexpensive alternative to purchasing a new USB HART modem. Not all USB

to RS 232 adapters communicate properly with the RS 232 HART modems. Flowservesupported USB converters at this time include: Startech – Model #: ICUSB232, Belkin –

Model #: F5U103, and Mactek – Model #: 010031.

USB adapters/modems typically come with driver software (usually on a CD). The user will

be prompted to install the USB driver(s) when the USB adapter/modem is used for the first

time. USB driver software is typically USB port specific. This means that if a laptop has two

USB ports, and the user connects the adapter to USB Port 1 during driver installation, the

adapter will only work on USB Port 1 after the driver(s) are installed. If the adapter/modem

is later connected to USB Port 2, the adapter/modem may not work. To solve this problem,

the USB adapter/modem should be connected to the same USB port every time SoftTools is

used.

RECOMMENDATION: Users with multiple USB ports on their computers will want to use

the same USB port every time they use SoftTools, and make sure that the proper USB

adapter/modem drivers are installed for this USB port.

VLAUG001-00 ©Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611 5 of 21

Page 6

Chapter 3: Startup

Boot the system in preparation for starting the application:

Using SoftTools 7.0

1. From the Windows Toolbar, click on Start. Select

Programs/Flowserve/SoftTools/TechCheck. The TechBridge splash screen,

followed by the TechCheck splash screen displays. The application will initialize

and install the TechBridge, BridgeEx, and Alert Tool icons into the Windows

System Tray.

2. The Log In dialog will appear. Type “trial” without the quotes into the Password

field. Click OK to finish logging into the system.

Figure 1 TechCheck Login

Using SoftTools TechCheck

Figure 2 TechCheck Main menu

Before attempting the following procedure, see Disabling FIFO Buffers (Page 18).

Please follow these instructions to make your initial connection to a field device on a

HART modem.

VLAUG001-00 ©Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611 6 of 21

Page 7

1. Select Connections from the TechCheck Main menu.

2. Select Set Up Field Network.

3. Select the HART icon.

4. Right-click the HART icon.

5. Select Add.

6. Select and click Server Port.

7. On the ADD SERVER PORT window, use the Com Port pull down box to select

the RS-232 port this connection will use. In the case where you are using a USB

converter, select the communication port created by the installation of the USB

hardware.

NOTE: Some USB converters will require you to check the RTS delay check box.

8. Click OK.

9. A PORT will be added to the Field Network tree.

10. Select the newly added PORT icon.

11. Right-click the PORT icon.

12. Select Scan.

13. Select and click Field Devices.

14. On the Search for a Field Device to Add window, click Start. The program scans

from the Start at Field Address to the Stop at Field Address.

15. Responding devices appear in the grid on the bottom of the window. Usually,

only one device will be attached to a modem.

16. Once the device is found, click Stop to quit scanning in order to avoid a lengthy

search routine.

17. Click the Close just under the Estimated Time Remaining indicator.

18. Click the Add button to add the device to the Field Network Tree.

19. Select the newly added device.

20. Click Install to add the device to the TechCheck device selection list.

21. Click Close to return to TechCheck.

You are now ready to use the TechCheck application tools.

Return to the TechCheck main menu and click on Tools. For the initial use of SoftTools

TechCheck, select Use Configurator and continue with the following instruction titled

Configurator Tool. With a previously configured and calibrated device, select from among

any of the SoftTools Suite application tools.

Using the Configurator Tool

After selecting and establishing communications with a device, configure the positioner. If

the positioner was shipped factory-mounted to a valve, it is pre-configured and calibrated to

work as is.

If working with a new positioner or retrofitting a positioner onto a different valve, parameters

must be set to ensure that it will control the valve properly.

1. From the TechCheck main menu window, click on Tools.

2. Select Use Configurator. Or,

VLAUG001-00 ©Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611 7 of 21

Page 8

3. Click on the Configurator toolbar button for direct access to the Configurator

window.

The Configurator window contains three tabs: Actuator, Positioner, and Valve. Click on

each tab to select and configure the settings for each component.

Figure 3 TechCheck Configurator window (Actuator Configuration Tab shown)

Click on the Actuator tab to display the Actuator Configuration screen. Check to make

certain the actuator information and actions are set correctly.

1. From within the Actuator screen, click on each combo box to ensure that the

selections correspond to the installed actuator information.

2. From within the Mechanical Action screen, click on each combo box to ensure that

the selections correspond to the mechanical configuration of the device.

WARNING! Incorrect settings and/or overriding the DIP switches on the Logix positioner

may cause the valve to stroke suddenly or become unstable.

Click on the Positioner tab to display the Positioner configuration screen. Click on each

representative button to view and/or edit the configurable settings displayed within their

respective windows.

Figure 4 TechCheck Configurator window (Positioner configuration tab shown)

VLAUG001-00 ©Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611 8 of 21

Page 9

For the initial configuration of the device, Flowserve suggests the following configurable

features of the positioner configuration screen receive attention:

1. Click on Minimum Position Cutoff to display its respective window. This feature

prevents the valve from throttling near the seat. If the Control command becomes

less than the Minimum Position Cutoff value, the positioner closes the valve. To

use this feature, enter a desired cutoff value in percent of stroke. Click on the

Apply button.

2. Click on Model to display its respective window. The Logix 1200e and 3200IQ

series positioner is available in two models: The standard model with HART

communications and no pressure sensors. The advanced model with Port 1 and

Port 2 actuator pressure sensors and HART communications. Selecting the

incorrect model prevents SoftTools from using all of its features.

3. Click on Soft Limits to display its respective window. When soft limits are applied,

the positioner restricts Control Command to the given limits. If soft limits are to be

used, enter the High Limit and Low Limit set-points to the desired level and click on

the Apply button.

4. Click on Stroke Characterization to display its respective window. Custom

Characterization enables the positioner to change its output signal as a function of

the input signal. This allows the stroke movement of the closure member to be

customized.

Click on the Valve tab to display the Valve Configuration screen. Click on each

representative button to view and/or edit the configurable settings displayed within their

respective windows.

Figure 5 TechCheck Configurator window (Valve configuration tab shown)

1. Use the Body and Trim selections to display their respective windows and ensure the

selections correspond to the installed valve body and trim information.

2. Preventive Maintenance and User Information selections allow user-defined

configuration of closure member travel and cycling limits and units of measure

throughout the device.

VLAUG001-00 ©Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611 9 of 21

Page 10

Reset

If it becomes desirable to reset the device to the factory default settings, proceed as follows:

From the TechCheck Configurator menu, click on Configurator and select Reset

Configuration.

From the Reset window, you may set all non-volatile memory to factory defaults. Any

custom configurations or settings are lost and the positioner will operate as a standard

model (read the warning within the window). To reset the device, click on the Reset

checkbox and click Apply.

Using the Calibrator Tool

The Calibrator Tool consists of several separate calibration windows and allows calibration

of the actuator pressure sensors, the 4-20 mA current loop, and the closure member stroke

position sensor. Select and perform each of the calibrations to ensure correct operation of

the device. An additional function provides a means to check the device calibration.

1. From the main TechCheck window menu, click on Tools.

2. Select Use Calibrator. Or,

3. Click on the Calibrator toolbar button for direct access to the main Calibrator

window.

Figure 6 TechCheck Calibrator main menu window

To select a specific calibration type:

1. From the main TechCheck Calibrator window menu, click on Subsystem.

2. Select the type of calibration desired. Or,

3. Click on a toolbar button for direct access to the desired calibration type.

Click on Calibrate Actuator Pressure Sensor to display the Calibrate Actuator Pressure

Sensor window. This calibration procedure is available only on 121X and 321X (advanced)

models of the Logix positioners, and effects the calibration of the actuator pressure sensors.

VLAUG001-00 ©Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611 10 of 21

Page 11

Figure 7 TechCheck Calibrator (Calibrate Actuator Pressure Sensor window)

To perform an actuator pressure sensor calibration:

1. Type in the supply pressure if the displayed pressure differs from the actual

pressure.

2. Click on the Start button. The attached device automatically performs the

calibration using the embedded internal calibration data.

NOTE: You must complete the entire procedure. The positioner is "offline" during

calibration and does not return to service until the procedure is complete.

Click on Calibrate Current Loop to display the Calibrate Current Loop window. Perform

this procedure to correctly calibrate the 4-20 mA input signal. This is a linear two-point range

calibration on the input signal sensed by the Logix positioner. It requires that you set both

the minimum and maximum current levels the positioner will sense as a command signal.

Figure 8 TechCheck Calibrator (Calibrate Current Loop window)

VLAUG001-00 ©Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611 11 of 21

Page 12

To perform a current loop calibration, follow the directions in the calibration wizard:

1. Set the variable current source to the desired absolute 0% command signal

(usually 4 mA). Click the 0% level Accept button.

2. Set the variable current source to the desired minimum (usually 4 mA). If split-

ranged application, minimum may be different (e.g. 12 mA).

3. Set the variable current source to the desired 100% command signal (usually 20

mA). Click the 100% level Accept button.

NOTE: You must complete the entire procedure. The positioner is "offline" during

calibration and does not return to service until the procedure is complete.

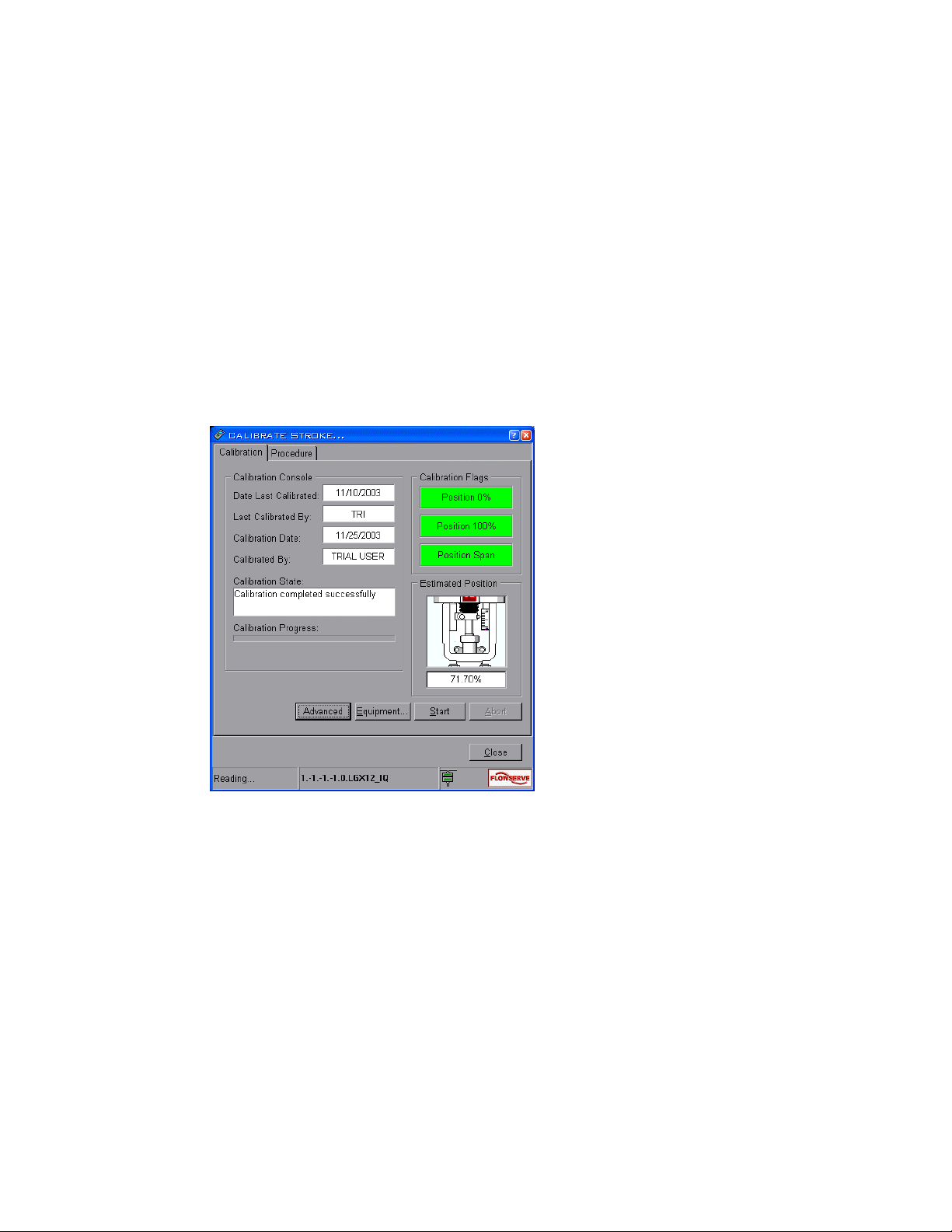

Click on Calibrate Stroke to display the Calibrate Stroke window. The stroke calibration

procedure moves the valve to a closed position and then to an open position. The positioner

measures closure member position at the two points to ascertain each exact position,

thereby correctly calibrating the stroke position sensor.

Figure 9 Stroke calibration window

To perform a stroke calibration on a "double-acting" actuator:

WARNING! This procedure causes stroke movement to occur. Follow your company

guidelines to assure the safety of personnel and processes before proceeding.

1. Click on the Start button. The stroke calibration procedure is performed

automatically.

Note: You must complete the entire procedure. The positioner is "offline" during calibration

and does not return to service until the procedure is complete.

VLAUG001-00 ©Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611 12 of 21

Page 13

Click on Check Calibration to display the Check Calibration window. The check calibration

procedure verifies the completed calibration performed to the attached device.

Figure 10 TechCheck Calibrator (Check Calibration window)

Before performing this procedure, it is important to have performed the Actuator Pressure

Sensor, Current Loop, and Stroke calibrations. This procedure will stroke the closure

member to five separate positions, wait for the selected Settling Time, and then compare

Command to Position to affect a Pass/Fail calibration rating.

To perform a Check Calibration on a "double-acting" actuator:

WARNING! This procedure causes stroke movement to occur. Follow your company

guidelines to assure the safety of personnel and processes before proceeding.

1. Using the spin button, select the desired Settling Time for each position.

2. Click on the Start button to initiate the procedure.

Calibration reports may be generated using additional functionality built into the Calibrator

Tool.

1. From the main TechCheck Calibrator window menu, click on Report.

2. Click on Create Report to display the Create Report window.

3. Using the available combo boxes within the window, select the desired criteria with

which to generate a calibration report.

VLAUG001-00 ©Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611 13 of 21

Page 14

Using the Condition Tool

While the positioner controls the device, you may monitor the ongoing status of its

relationship with the closure member.

1. From the main TechCheck window menu, click on Tools.

2. Select View Condition. Or,

3. Click on the Condition toolbar button for direct access to the Condition window.

4. The Condition window contains dual functions: Within the Monitor Status tab,

monitor the closure member position and positioner action in real time, while the

valve is functioning in a process loop. Within the View Variables tab, alternately

select among and view individual variables.

Figure 11 Condition window (Monitor Status tab selected)

Within the Device Status panel, the 4-20 mA dynamic display indicates the analog command

to the positioner (in percentage). Changing the current loop level will cause the value

indicated in the 4-20 mA display to change. The 4 mA should read approximately 0% and

20 mA should read approximately 100%. Perform a loop calibration to eliminate any error

(refer to the Calibrator tool).

VLAUG001-00 ©Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611 14 of 21

Page 15

The Position indicator bar on the left side of the panel represents the position of the closure

member in percent of full stroke. The indicator tracks the closure member position as the

valve is stroked. If a large deviation exists between Command In and Control command (the

actual command the positioner is using to position the valve), check to see if Custom

characterization is active. If not, two options are available to correct it.

• Wait a few minutes. The positioner has an integrator built into its control algorithm

that will slowly take out any deviation between the Command In and Control

commands.

• Tune the positioner. Refer to “Positioner Tuning” in the Configurator tool for

detailed information and instruction.

Selecting a Command Source

The positioner operates using either an analog or a digital command source. Analog

command source indicates that the Control command originates from a 4-20 mA current

source. Digital command source indicates that the Control command originates from a

computer or other source that is capable of sending the command via the HART

communication connection. Select the command source as follows:

1. Click the combo box labeled Source.

2. Select Digital or Analog as desired. The program indicates the success of the

source change.

Entering a Digital Command

For fine adjustments to the digital positioner, use the Command In spin button edit control.

1. Use the spin buttons within the control labeled Command In to

increment/decrement the current value.

2. Highlight the value in the control box. Type in a new digital command percentage

and press ENTER to transfer the new value to the positioner.

Selecting a Step Size

Set the step size as follows:

1. Click the combo box labeled Step Size.

2. Select the step size desired for the particular application. Sizes range from 10

through 1 to 0.1, as a percent of stroke. Press ENTER to transfer the new value

to the positioner.

The program uses the newly selected step size for all subsequent adjustments made to the

digital command percentage.

Viewing Individual Variables

To view individual variables, select the View Variables tab.

1. Choose a variable to view by alternately clicking on each button edit control

beneath the Variable # label.

VLAUG001-00 ©Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611 15 of 21

Page 16

2. Select from a grid containing a list of variables available for viewing. Each choice

made displays the variable number with its corresponding description and current

value.

Figure 12 Condition window (View Variables tab selected)

Using the Alert Display

All windows involved in communication with the instrument contain the Alert Display LED

visible within the status bar to the left of the Flowserve logo. If it becomes active, it blinks

red. Place the cursor over it and right click the mouse. The Alert Display window shows

and allows the user to view additional information and/or acknowledge any errors.

Security Administrator

If you wish to establish separate levels of access for users, proceed with the following:

1. Right-click on the TechBridge tray icon (this icon is usually located in the bottom

right hand corner of the screen on the windows taskbar), and select Open

Security Administrator from the pop-up menu. The Security Check window

displays. Select Admin from the Administrator ID: combo box, and type your

user password into the Password: edit box. The Security Administrator window

displays.

VLAUG001-00 ©Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611 16 of 21

Page 17

Figure 13 Security Administrator window

5. To insert a new user, click on the Insert tool button. The Insert User window

displays.

Figure 14 Security Administrator Insert User window

6. Type a name into the User Name edit box. Using the Security Level combo box,

select a user level designating access permissions. Type a password for the new

user into the Password edit box and re-type the same password into the Verify

Password edit box. Click on OK.

7. To edit a user, click on the Edit button. The Edit User window displays.

VLAUG001-00 ©Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611 17 of 21

Page 18

Figure 15 Security Administrator Edit User window

8. Type a name into the User Name edit box. Using the Security Level combo box,

select a user level designating access permissions. Type a password for the

edited user into the Password edit box and re-type the same password into the

Verify Password edit box. Click on OK.

9. To delete a user, click on the Delete tool button. A confirmation window displays.

Click on Yes to delete the user.

Figure 16 Security Administrator Confirm window

Using the Context-Sensitive Help System

To access the SoftTools 7.0 help system:

From any SoftTools menu, click on the Help menu item.

Click on Contents and Index to view the Contents and Index window of the help

system, or…

Select a control on which you wish to receive help and press F1 (it must be a control

that can receive focus). A pop-up window containing help displays.

From the keyboard, access the Contents and Index window of the help system by

pressing F1.

Disabling FIFO Buffers

With the advent of advanced serial port hardware, Microsoft

the user the ability to configure how data is transferred out a serial port. A

communication port works in units of characters. A single character is represented by

a variable number of bits. The new hardware is capable of caching several characters

before actually transmitting them out the port. The concept works well for devices that

can handle more than one character at a time. Here-in lies the problem. Due to timing

constraints in the HART protocol, the Logix positioner can only receive one character at

®

Windows gives

VLAUG001-00 ©Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611 18 of 21

Page 19

a time. In order for the positioner to receive data correctly, the user must turn off the

FIFO buffers. The following procedure assists the user in turning off FIFO buffers.

Microsoft Windows NT

1. Click Start.

2. Click Settings.

3. Double click Ports.

4. Click Advanced on the Ports dialog.

5. Uncheck the FIFO check box.

6. Click OK.

7. Close the Port dialog.

8. Close the Control Panel.

9. Reboot the computer.

Microsoft Windows 98, 2000, and XP

1. Click Start.

2. Click Control Panel or Settings.

3. Double click System.

4. Click the Hardware tab.

5. Click the Device Manager button.

VLAUG001-00 ©Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611 19 of 21

Page 20

6. From the device selection list, expand the Ports item.

10. Right click the communication port you desire to use with SoftTools.

NOTE: USB adapter cables and modems will have their own COM ports

assigned when the driver(s) are installed. This installation typically occurs the

first time the adapter or modem is connected, and the drivers are installed

using the manufacturer’s installation software (typically on a CD). This is not

usually COM Ports 1 or 2. Care must be taken to ensure that the correct COM

port is selected, or the FIFO buffers will be disabled for the incorrect COM Port.

11. Click Properties.

VLAUG001-00 ©Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611 20 of 21

Page 21

9. Click the Port Settings tab.

10. Click the Advanced button.

11. Uncheck the Use FIFO buffers check box.

12. Click OK.

13. Click OK on the Properties dialog.

14. Close the Device Manager.

15. Click OK on the System Properties window.

16. Restart the computer.

Flowserve Corporation, Flow Control Division

1350 North Mountain Springs Parkway

Springville, UT, 84663

U.S.A.

801.489.8611

www.flowserve.com

VLAUG001-00 ©Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611 21 of 21

Loading...

Loading...