Page 1

PRS 9

Installation Instructions 810407- 00

Cycling Timer PRS 9

A Siebe Group Product

1

Page 2

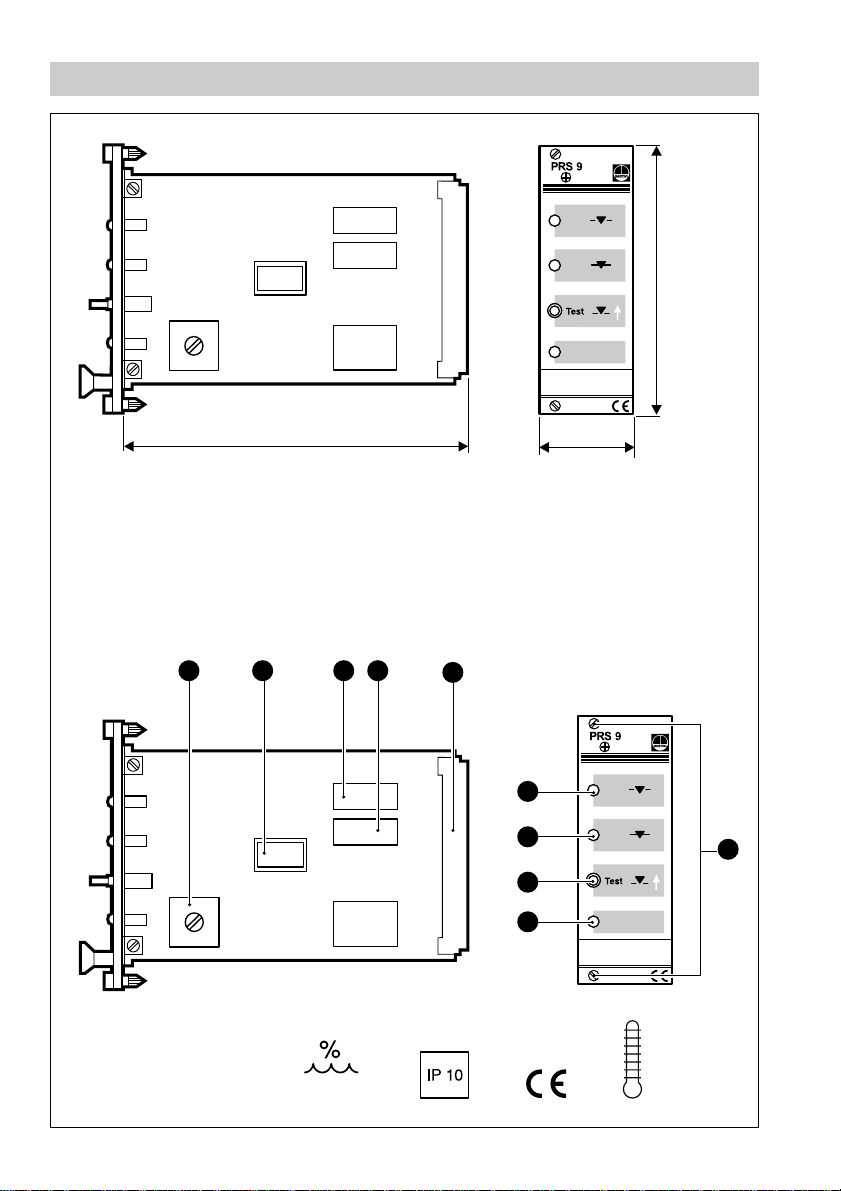

Dimensions/Parts Drawings

1 28.5

Fig. 1

169

A

B C D

E

30.01 (6TE)

I

H

G

F

J

2

Fig. 2

MAX 70°C

MAX 95%

Page 3

Key

A

Switch S1

B

Switch S2 PROGRAM SELECTION

C

Relay 2 ENERGIZED

D

Relay 1 DE-ENERGIZED

E

32 way Euro card connector

F

LED

G

Pushbutton TEST

H

LED VALVE CLOSED

I

LED VALVE OPEN

J

Fixing screws

TIME DELAY

OPERATION

3

Page 4

Contents

Page

Important Notes

Safety note ...................................................................................................................... 6

Warning ...........................................................................................................................6

Explanatory Notes

Scope of supply .............................................................................................................. 7

System description ......................................................................................................... 7

Function .......................................................................................................................... 7

Design ............................................................................................................................. 7

Technical data ................................................................................................................. 8

Installation

Design “c”/ “d” .................................................................................................................9

Attention..........................................................................................................................9

Tools ................................................................................................................................9

Wiring

Design “c”/ “d” ...............................................................................................................10

Wiring diagram ..............................................................................................................10

Key to wiring diagram ...................................................................................................10

Attention........................................................................................................................ 1 1

Note ..............................................................................................................................11

Basic Adjustments

Select opening mode of the valve ................................................................................ 12

Table 1 Opening mode of the valve ..............................................................................12

Adjust time delay ..........................................................................................................12

Table 2 Time delay........................................................................................................12

Commissioning

Warning .........................................................................................................................13

Check valve function .....................................................................................................13

Check wiring .................................................................................................................13

Apply mains voltage......................................................................................................13

Check test function .......................................................................................................13

Check switching function ..............................................................................................13

4

Page 5

Contents – continued –

Page

Annex

Warning.........................................................................................................................14

Fault finding list .............................................................................................................14

Declaration of conformity ..............................................................................................14

5

Page 6

Important Notes

Safety note

Use the cycling timer PRS 9 only in combination with GESTRA level switches

NRS 2-4. Installation must only be performed by qualified staff.

Qualified staff are those persons who – through adequate training in electrical

engineering, the use and application of safety equipment in accordance with

regulations concerning electrical safety systems, and first aid & accident

prevention – have achieved a recognised level of competence appropriate

to the installation and commissioning of this critical safety device.

Warning

The terminal strip of the PRS 9 is live during operation. This presents the

danger of electric shock. Cut off power supply before opening the

equipment and before inserting or removing the 19" slide-in unit.

6

Page 7

Explanatory Notes

Scope of supply

PRS 9, design “c”

1 Cycling timer type PRS 9

2 Guide rails

1 32pole screw-type connector

1 Installation instructions

PRS 9, design “d”

1 Cycling timer type PRS 9

1 Installation instructions

System description

The PRS 9 is an analogue/digital cycling timer. In combination with up to four level

switches type NRS 2-4/NRS 2-5 and a position-controlled limit switch the cycling

timer can, as part of a controlled draining system in a power station, control drain

valves as a function of time.

Function

Signals coming to the inputs of the level switches and the position-controlled limit

switch will be processed electronically, with the time delay adjusted in the equipment

being taken into account. Dependent on the adjustment the drain valve will be

controlled in one or two steps with a time delay.

Design

Design “c”

19" slide-in unit with guide rails and 32pole screw-type connector for installation in

19" magazine acc. to DIN 41494, part 5.

Design “d”

19" spare slide-in unit

7

Page 8

Technical data

Supply voltage

24 V DC

Power consumption

4 V A

Input

Three control inputs (volt-free relay contacts)

Control voltage 12 V DC

Output

2 volt-free relay contacts

Max. contact rating with a switching voltage of 24 V, 115 V and 230 V AC: 4 A

resistive, 0.75 A inductive at cos ϕ 0.5.

Max. contact rating with a switching voltage of 24 V DC: 4 A.

Service life of the relays: 30x10

6

switching cycles.

Indicators and adjustors

1 green LED

OPERATION, 1 red LED VALVE OPEN, 1 red LED VALVE CLOSED

1 pushbutton TEST (simulating alarm signalled by P1)

1 switch (on the circuit board) for program selection

1 switch (on the circuit board) for time delay setting

Protection

IP 10 to DIN 40050

Admissible ambient temperature

0°C to +70°C

Case

19" slide-in unit with front panel to DIN 41494 part 5 and rear 32 way Euro card

connector to DIN 41612 for installation onto 19" magazine.

Front panel: Aluminium

Wiring

via 32 pole screw-type connector at the back of the 19" magazine, max. conductor

size 1.5 mm

2

Weight

approx. 0.6 kg

8

Page 9

Installation

Design “c”/“d”

1. Install the guide rails and the screw-type connector in the 19" magazine.

2. Introduce the 19" slide-in unit onto the guide rails until it hits the stop.

3. Tighten the fixing screws .

Attention

To provide sufficient ventilation, ensure a minimum spacing of 20 mm

between adjacent units.

Tools

■

Screwdriver for slotted screws, size 5, completely insulated according to VDE 0680.

J

9

Page 10

Wiring

Design “c”/ “d”

Wiring is effected via the 32 pole screw-type connector.

Wiring diagram

PRS 9

4

5

1

Fig. 3

Key to wiring diagram

1

P2 Level switch NRS 2-4 or NRS 2-5 (24 V DC) from corresponding level electrode 2

2

Position-controlled limit switch of the drain valve

3

P1 Level switch NRS 2-4 or NRS 2-5 (24 V DC) from level electrode 1

4

Rel 2 for opening the drain valve

5

Rel 1 for closing the drain valve

10

2 3

Page 11

Attention

■

Fuse supply cable with T 2.5 mA.

■

When switching off inductive loads, voltage spikes are produced

that may impair the operation of control and measuring systems.

Inductive loads should be provided with commercial arc suppressor

RC combinations, e. g. 0.1 µF/100 Ω.

Note

Connect only volt-free relay contacts to the control inputs. The cycling

timer PRS 9 supplies a 12 V DC control voltage.

11

Page 12

Basic Adjustments

Select opening mode of the valve

Use switch S2 for selecting the opening mode, see table 1.

B

Table 1 Opening mode of the valve

Switch position Opening mode of the valve

1 Two-step opening of the valve

2 One-step opening of the valve

Adjust time delay

Use switch S1 for setting the time delay, see table 2.

A

Table 2 Time delay

Switch position Time delay

1 5 sec.

2 7.5 sec.

3 10 sec.

4 15 sec.

5 22.5 sec.

6 30 sec.

12

Page 13

Commissioning

Warning

The terminal strip of the PRS 9 is live during operation. This presents the

danger of electric shock. Cut off power supply before undertaking any work

at the equipment and before inserting or removing the 19" slide-in unit.

Check valve function

1. Drive drain valve manually into the mid-position.

2. Apply mains voltage for about 10 sec. – P1 and P2 must not give a signal – and

check whether the valve moves into the closed position.

Check wiring

1. Check whether the 19" slide-in unit has been properly introduced into the magazine.

2. Check whether the equipment has been wired in conformity with the mains voltage.

Apply mains voltage

1. Switch on the mains voltage and check the equipment for power supply.

The LED functions as visual check.

F

Check test function

1. Push button and check whether the valve is opening.

2. Press and hold down button until the valve has reached the position of the limit

G

G

switch and the actuator has been switched off.

3. Release button and check whether the valve returns to the closed position

G

after the preset time delay has elapsed.

Check switching function

To check the switching functions raise or lower the water level until the switchpoints

are reached or simulate the corresponding signals by disconnecting the control inputs

3

of P1 and P2 , Fig. 3

1. P1 and P2 are not giving signals: Check whether LED is illuminated, REL1 is

1

H D

energized and the valve is closing.

2. P1 or P2 is giving a signal: Check whether the LED is illuminated, REL2 is

I C

energized and the valve is opening.

3. P2 or – if the valve is controlled only by P1 – P1 is not giving a signal or the valve is

in the intermediate position, no LED illuminated: Check whether the LED lights

up after the time delay, REL 1 is energized and the valve is closing.

D

H

13

Page 14

Annex

Warning

The terminal strip of the PRS 9 is live during operation. This presents the

danger of electric shock. Cut off power supply before opening the

equipment and before inserting or removing the 19" slide-in unit.

Fault finding list

The LED is not illuminated after applying the mains voltage

F

Fault: The mains voltage has not been switched on.

Remedy: Switch on the mains voltage. Check the 19" slide-in unit for correct installation.

No or incorrect functions

Fault: The internal circuitry is defective.

Remedy: Replace the cycling timer.

Declaration of conformity

We hereby declare that the equipment PRS 9 conforms to the following European

guidelines:

■

LV guideline 73/23/EWG version 93/68/EWG

■

EMC guideline 89/336/EWG version 93/68/EWG

which are based on the following harmonised standards:

■

LV standard EN 60947-5-1: 1991

■

EMC standard EN 50 081-2, EN 50 082-2

This declaration is no longer valid if modifications are made to the equipment without

consultation with us.

Bremen, 28th April 1997

GESTRA GmbH

Dr. Anno Krautwald

Dr. Christian P olitt

14

Page 15

15

Page 16

GESTRA Gesellschaften · GESTRA Companies · Sociétés GESTRA · Sociedades Gestra · Società GESTRA

GESTRA Gesellschaften · GESTRA Companies · Sociétés GESTRA · Sociedades Gestra · Società GESTRA

Vertretungen weltweit · Agencies all over the world · Représentations dans le monde entier · Representaciones en todo el mundo · Agenzie in tutto il mondo

Vertretungen weltweit · Agencies all over the world · Représentations dans le monde entier · Representaciones en todo el mundo · Agenzie in tutto il mondo

España

España

GESTRA ESPAÑOLA S.A.

GESTRA ESPAÑOLA S.A.

Luis Cabrera, 86-88

Luis Cabrera, 86-88

E-28002 Madrid

E-28002 Madrid

Tel. 003491/5152032

Tel. (+34) 915152032

Fa x0 0349 1/41367 47 ; 515 203 6

Fax (+34) 914136747; (+34) 915 152 036

E-mail: gestra@gestra.es

Polska

Polska

GESTRA POLONIA Spolka zo.o.

GESTRA POLONIA Spolka z.o.o.

Ul. Schuberta 104, P.O. Box 71

Ul. Schuberta 104, P. O.B. 727

PL-80-172 Gdansk

PL-80-958 Gdansk 50

Tel. 004858/3061002 oder 30610 10

Tel. (58) 306 10 02

Fax 004858/3061003 oder 3063300

Fax (58) 306 10 03

E-mail: gestra@gestra.pl

France Portugal

France Portugal

GESTRA S.A.R.L.

10 Avenue du Centaure, BP 8263 CERGY

Flowserve Flow Control S.A.S.

F-95801 CERGY PONTOISE Cedex

10 Avenue du Centaure, BP 8263

Tél. (00 33) 01.34.43.26.60

F-95801 CERGY PONTOISE CEDEX

Fax (00 33) 01.34.43.26.87

Tél. 00331/3443 2660

Fax 00331/34432687

Great Britain

E-mail: gnation@flowserve.com

GESTRA (U.K.) LTD.

9-11 Bancroft Court

Italia

Hitchin, Hertfordshire, SG5 1PH

Tel. (0 14 62) 4316 81

Italgestra S.r.l.

Fax (0 14 62) 4203 96

Via Carducci 125

l-20099 Sesto San Giovanni (MI)

Italia

Tel. 003902/2410 12.1

Fax 003902/241012.460

ITALGESTRA S.r.l.

E-mail: info@italgestra.it

Via Carducci 125

l-20099 S.S. Giovanni (MI)

Tel. (02) 2 6297-0

Fax (02) 26 297460

GESTRA PORTUGUESA VALVULAS LDA.

Av. Dr. Antunes Guimarães, 1159

GESTRA PORTUGUESA V ALVULAS LDA.

P-4100 Porto

Av. Dr. Antunes Guimarães, 1159

Tel. (2) 6 1075 51

Porto 4100-082

Fax (2) 6 1075 75

Tel. 00351 22/6 19 8770

Fax 0035122/61075 75

USA

E-mail: gestra@gestra.pt

GESTRA Division

10 York Avenue

West Caldwell, NJ 07006

Tel. (9 73) 403-15 56

Fax (9 73) 403-15 57

®

®

GESTRA GmbH

Postfach 10 54 60

GESTRA GmbH

D-28054 Bremen

Münchener Str. 77

Hemmstraße 130

D-28215 Bremen

D-28215 Bremen

Tel. +49 (0) 421 35 03-0

Tel. + 49 (0) 421 35 03-0

Fax+49 (0) 421 3503-39 3

Fax +49 (0) 421 35 03-393

E-mail

gestra.gmbh@gestra.de

Internet www.gestra.de

Internet www.gestra.de

E-mail

gestra.gmbh@gestra.de

A Unit of Flowserve Corporation

A Siebe Group Company

810407-00/199c · ©1997 GESTRA GmbH · Bremen · Printed in Germany

16

Loading...

Loading...