Page 1

GESTRA Steam Systems

OR 52-7

Installation Instructions 818788-00

Oil & Turbidity Detector

OR 52-7

1

Page 2

Contents

Page

Important Notes

Usage for the intended purpose .............................................................................................................4

Safety note ............................................................................................................................................. 4

Danger ...................................................................................................................................................4

Explanatory Notes

Scope of supply ...................................................................................................................................... 5

Description ............................................................................................................................................. 5

Function .................................................................................................................................................5

Technical Data

Measuring transducer ORG 12 ................................................................................................................

Measuring transducer ORT 7...................................................................................................................7

Name plate / marking ............................................................................................................................. 8

Dimensions OR 52-7 ...............................................................................................................................9

Installation

OR 52-7 ................................................................................................................................................10

Example of installation .......................................................................................................................... 11

Electrical Connection

Measuring transducer ORT 7 ................................................................................................................12

Note .....................................................................................................................................................12

Attention ............................................................................................................................................... 12

Tools .....................................................................................................................................................12

Wiring diagram OR 52-7 ....................................................................................................................... 13

Notice .................................................................................................................................................. 13

Functional Elements

Measuring sensor ORG 12 ....................................................................................................................14

Measuring transducer ORT 7.................................................................................................................15

Key .......................................................................................................................................................16

Commissioning Procedure

Factory setting ......................................................................................................................................17

Warning ................................................................................................................................................17

Checking electrical connection .............................................................................................................17

Checking installation .............................................................................................................................17

First commissioning .............................................................................................................................18

Programming mode .............................................................................................................................. 19

Other parameter settings ...................................................................................................................... 20

6

2

Page 3

Contents – continued –

Page

Start, Operation, Alarm and Function Test

Start and operation ............................................................................................................................... 21

Alarm 1 and 2 ...................................................................................................................................... 22

Functional test .....................................................................................................................................22

Data Storage

Memory Card ........................................................................................................................................ 23

Note .....................................................................................................................................................23

Data indication .....................................................................................................................................23

Operating steps – see Fig. 8 ................................................................................................................. 23

Note .....................................................................................................................................................24

Operating flowchart .............................................................................................................................. 24

Malfunctions

OR 52-7 ................................................................................................................................................25

Table listing error codes ........................................................................................................................25

Calibration

OR 52-7 ................................................................................................................................................26

Maintenance

Cleaning the glass cylinder .................................................................................................................. 27

Replacing the drying cartridge ..............................................................................................................27

Replacing the light emitter/receiver ......................................................................................................27

Attention ............................................................................................................................................... 27

Replacing the equipment fuse ...............................................................................................................27

Warning ................................................................................................................................................ 28

Spare parts ........................................................................................................................................... 28

Note .....................................................................................................................................................28

Decommissioning

Warning ................................................................................................................................................ 29

Removal ...............................................................................................................................................29

Disposal................................................................................................................................................29

Annex

Type approval certificate ...............................................................................................................30 – 33

EG-Baumusterprüfbescheinigung (Modul B) .................................................................................... 34, 35

EC Type Examination Certificate (Module B) ....................................................................................36, 37

Declaration of Conformity .....................................................................................................................38

3

Page 4

Important Notes

Usage for the intended purpose

The GESTRA Turbiscope OR 52-7 is designed for the continuous monitoring and detection of oil

contamination of water and used in conjunction with oily water separators as 15 ppm bilge alarm.

The equipment meets the requirements of the International Maritime Organization (IMO) for bilge alarm

monitors, MEPC. 107 (49).

Safety note

The equipment must only be installed and commissioned by qualified and competent staff.

Retrofitting and maintenance work must only be performed by qualified staff who – through adequate

training – have achieved a recognised level of competence.

Danger

The solenoid of the solenoid valve Clw can reach up to 80 °C during operation.

The terminal strips of the measuring transducer ORT 7 can be live during operation.

This presents the risk of electric shock.

Cut off power supply before mounting, removing or connecting the terminal strips.

4

Page 5

Explanatory Notes

Scope of supply

Measuring transducer ORT 7

Measuring sensor ORG 12 with

1 Solenoid valve

1 Drying cartridge (fitted)

1 Light emitter (supplied but not fitted)

1 Spare gasket kit

Description

The oil & turbidity detector OR 52-7 can be used:

■ On board of marine vessels for monitoring the oily water separating equipment for bilge water

according to IMO Resolution MEPC. 107 (49) as 15 ppm oil content alarm.

Function

The measuring sensor is a photometric measuring device consisting of a light source (light emitter)

and a light receiver fitted with two photosensitive elements.

The constant light beam generated in the measuring sensor passes through the transparent liquid. Any

foreign matter which is not dissolved scatters the beam, with emulsified oils scattering the light mainly

in the forward direction. The intensity of the scattered light is converted into an electric current and then

used as measure of the degree of contamination.

The measuring transducer has the following functions:

■ Control of the measuring sensor and signal evaluation

■ Control of the purging valve

■ Limit ALARM 1 and ALARM 2

■ Analog actual value output 0/4 – 20 mA

■ ALARM 2 indicates a malfunction in the turbidity sensor

■ Indication of actual value / limits

■ Storage and indication of alarm, malfunction and status messages

■ Control of the bilge bypass via output ALARM 2

5

Page 6

Technical Data

Measuring transducer ORG 12

Nominal size

DN 10, connection

3

/8" to DIN ISO 228

Nominal pressure

PN 10

Fluid

Water

pH value

Up to 10.5 (a pH value of 11 and above will lead to wear of the glass, depending on the temperature!)

Fluid temperature range

0 – 60 °C with drying cartridge

Ambient temperature

Max. 60 °C

Materials

Measuring sensor:

Housing cover: 0.6025 galvanised

Wetted parts: 0.6025 galvanised

Throttle: 1.4571

Screwed union: St

Glass cylinder: Duran 50

Internal seal: Silicone

Oil-seal rings: Perbunan

Housing: 0.6025 galvanised

ORG 12

Cleaning ring: EPDM sponge rubber

Light emitter

Glow lamp 12 V / 10 W BA 15s

Electric connection via 4 m connecting cable fitted with four pole connector,

protection IP 65

Light receiver

Two silicon photoelectric cells

Electric connection via 4 m connecting cable fitted with four pole connector,

protection IP 65

Purging valve

2/2 way solenoid valve

Directly controlled, normally closed

Connection:

Valve body: Brass

Internals: Ms 2.0401 / S. S. 1.4104

Internal seal: FKM

Solenoid: Voltage 24 V / 50 Hz, 43 / 24 VA

3

/8" ISO 228

Electric connection via 4 m connecting cable fitted with four pole connector,

protection IP 65

Weight

ORG 12: approx. 6.8 kg

6

Page 7

Technical Data – continued –

Measuring transducer ORT 7

Inputs / outputs

2 Photocells for inputs: directly transmitted light / scattered light,

1 Voltage output for light emitter, 1 – 12 V, pulse-amplitude modulated,

1 Signal input for separator ON/OFF,

1 GPS input RS 485, 4800 Baud, NMEA 183 protocol, data record GPRMC,

3 Volt-free change-over contacts for alarm 1, 2 and purging valve (Clw),

contact material AgNi 0.15,

max. contact rating for switching voltages 24 V AC/DC, 115 V AC and 230 V AC: resistive / inductive 4 A,

1 Current output 0/4 – 20 mA as actual value output, max. load 500 ohm.

Indicators and adjustors

1 LCD display for indicating the actual value, limits, status and malfunctions,

8 Membrane keys,

4 LEDs for indicating alarm, status and malfunction

3 Green LEDs on basic circuit board for monitoring the operating voltages

Data storage

DataFlashcard 8 MB

Measuring range

0 to 25 ppm (ppm = parts per million)

Actual value output

0 or 4 mA = 0 ppm, 20 mA ≥ 25 ppm

Limits for alarm 1 and 2, adjustment range

Adjustable between 0 and 15 ppm

Delay of response for alarm 1 and 2, adjustment range

Adjustable between 0 and 15 sec.

Mains voltage

24 V +10 / –15 %, 50/60 Hz

230 V +10 / –15 %, 50/60 Hz (optional)

115 V +10 / –15 %, 50 / 60 Hz (optional)

Power consumption

50 VA

Fuse

24 V: Thermal fuse M 1.6 A 5 x 20,

230 V: Thermal fuse M 0.2 A 5 x 20

115 V: Thermal fuse M 0.4 A 5 x 20

Housing

Field case for wall mounting,

Case material: die-cast aluminium

Cable gland / Electrical connection

8 cable glands with integrated cable clamps, M 16 x 1.5

3 Three-pole screw-type terminal strips, conductor size 0.75 mm2

8 Multi-pole screw-type terminal strips, detachable, conductor size 1.5 mm

Protection

IP 65 to EN 60529

Admissible ambient temperature

0 – 55 °C

Weight

3.6 kg

2

7

Page 8

Technical Data – continued –

Ser.Nr.: 3923581xxxxx

ORG12

OR 52-7

ORT7

Öl- / Trübungsmelder

Oil- / Turbitity Detector

Détecteur d’huile et de turbidité

ORT 7

250 V ~ T 2,5 A

Range 0 - 25 ppm

Tamb = 55°C (131°F)

Manufacturer

GESTRA AG, Münchener Str.77

D-28215 Bremen

Telefon +49(0)421 3503-0

Telefax +49(0)421 3503-393

E-Mail gestra.ag@flowserve.com

0736 - ....

Oil-content meter OR 52-7 (15ppm Alarm)

approved by SEE-BG

according IMO-Resolution MEPC.107(49)

Approval No. IMO/EC 320030

24 V 50/60 Hz 50VA IP 65

Before removing cover isolate from

power supplies

See installation instructions

Avant d'ouvrir le couvercle dèconnecter

complètement l'appareil

Voir instructions de montage

Vor Öffnen des Deckels Gerät

freischalten!

Betriebsanleitung beachten

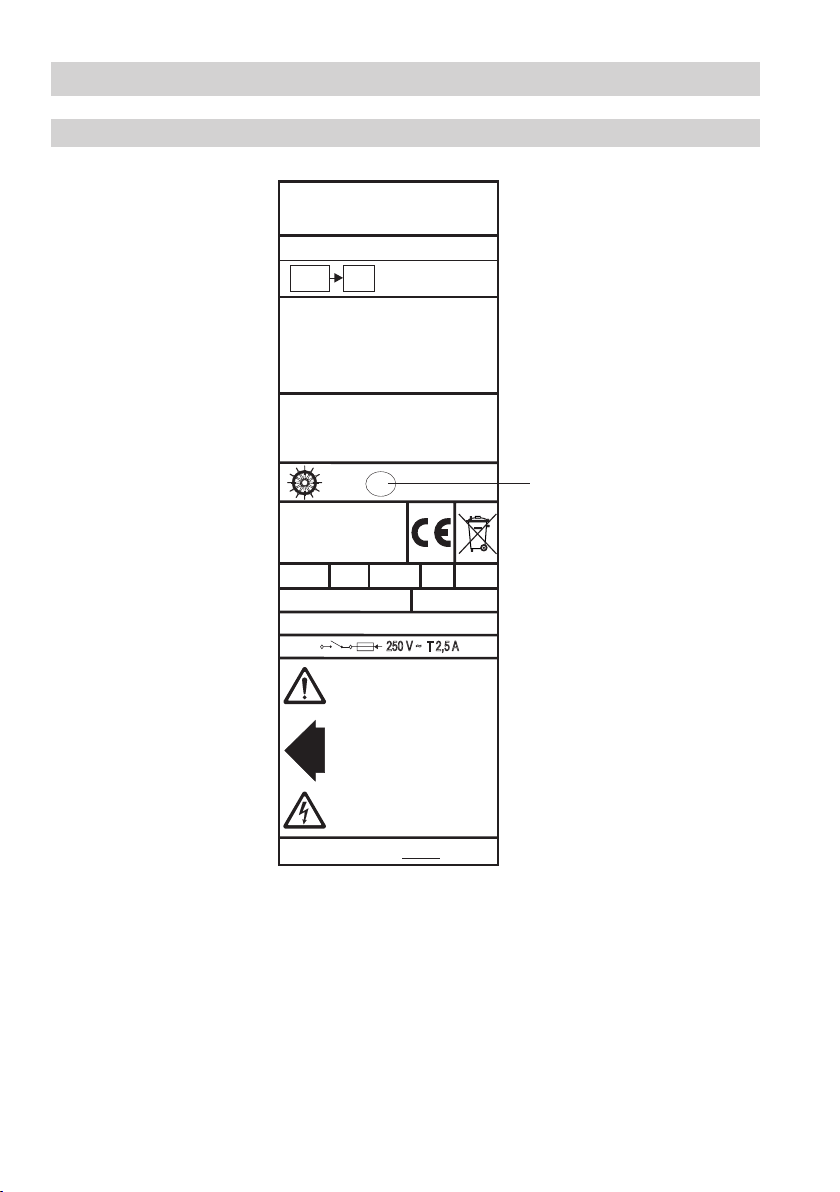

Name plate / marking

Year of manufacture

Fig. 1

8

Page 9

Technical Data – continued –

ON ALARM 1 ALARM2 SYSTEM

GESTRA

ORT 7

OKP

Dimensions OR 52-7

Measuring sensor ORG 12

approx. 225

approx. 200 approx.170

Measuring transducer ORT 7

Fig. 2

240

260

Depth 91 mm

110

160

9

Page 10

Installation

OR 52-7

Use the support and install the measuring sensor ORG 12 as close as possible to the separator in

order to keep the supply delay to a minimum. According to MEPC. 107 (49) in the event of an alarm

(oil content =/> 15 ppm) the contaminated water must be diverted from the separator to the bilge as

quickly as possible, i. e. within no more than 20 seconds.

Use a 10x1 mm copper or stainless steel pipe to connect the measuring sensor ORG 12/22 with the

sampling point of the separator and the clear water supply. The sampling point should be provided in a

vertical section of the separator outlet pipe so as to avoid any impairment caused by air bubbles.

In order to ensure that the arrangement for the extraction of samples gives a truly representative

sample make sure that the fluid flow always passes through the sensor under all operating conditions

and that any by-passing of the oil separator is prevented.

If it is not possible to provide the sampling point in a vertical pipe, a lateral arrangement in a horizontal

pipe is also possible.

For overboard pipes having an outside diameter of up to 75 mm a tee piece for the extraction of

samples can be used. If the size of the pipe exceeds 80 mm, make sure that the sampling arrangement extends approx. 25 % into the overboard line.

Install the vacuum breaker above the highest point of the oil separator.

Attach the measuring transducer ORT 7 to a stable vertical surface. If possible mount the indicator at

eye level for easy viewing and provide sufficient space for service and maintenance work.

The measuring transducer is designed for wall mounting. The distances between the fixing holes are

indicated on the back of the equipment.

To access the fixing holes undo the cover screws and open the cover.

10

Page 11

Installation – continued –

ON ALARM1 ALARM 2 SYSTEM

GESTRA

ORT 7

OKP

Example of installation

Three-way control valve Overboard line

Separator

Pressure-

maintaining

valve

(if required)

Separator

outlet

To bilge To bilge

10 x 1 mm

copper or stainless steel pipe

Inlet Outlet

Clear water

inlet (water

pressure

≥ 2.5 bar)

Mount

vacuum

breaker

above

the oil

separator

To

bilge

Fig. 3

11

Page 12

Electrical Connection

Measuring transducer ORT 7

1. Undo cover screws and open cover.

2. Detach all three-pole terminal strips from the base board and pull connecting lines through cable

glands.

3. Mark connecting lines: “Mains”, “Alarm 1”, “Alarm 2”, “Light emitter” and “Light receiver”.

4. Connect all terminal strips in accordance with the wiring diagram. Connect screens only to ORT 7.

5. Connect PE with the earthing screw in the housing.

6. Re-attach terminal strips.

7. Tighten the cable glands in order to seal the cable entry. Use the supplied sealings plugs to seal off

any unused cable glands.

8. Close housing lid and tighten cover screws.

Note

■ The light emitter/receiver and the purging valve are fitted with a 4 m long connecting

cable and only have to be connected to the measuring transducer.

■ The terminal strips on the CPU board of the ORT 7 cannot be detached.

■ Strip off approx. 25 mm of the cable insulation coating and screen of the connecting

cables for the signal input of the separator ON/OFF and for the GPS input.

Attention

■ The oil & turbidity detector has a power consumption of max. 50 VA. Please make sure

that the power supply is rated for 100 VA.

■ To protect the output relay contacts fuse electric circuits with 2.5 A (slow-blow).

■ Provide connected contactors and actuators with RC combinations (in accordance with

manufacturers’ specifications) in order to suppress interferences.

■ Make sure that the disconnecting switch (Fig. 4) is easily accessible and in the close

proximity of the equipment (EN 61010-1).

■ Mark respective switch as disconnecting device for the measuring transducer.

This switch can be dispensed with if the control cabinets are upstream of the equipment

and fitted with a disconnector for the measuring transducer.

Tools

■ Screwdriver for cross-recess screws, size 1 and 2.

■ Screwdriver for slotted screws, size 2.5, completely insulated to VDE 0680

■ Conductor end sleeve pliers

■ Insulation stripper

12

Page 13

Electrical Connection – continued –

DS

1 2 23

3

3

3

3 3 3 3

L N

0/4-20mA

R 500

2

2

2

2 2 2 2 2

1

1

1

1 1 1 1 1

S

D

L

Alarm2 Alarm1

ORT 7

Basis

ORG

ORT 7 CPU

ABS

Separator

GPS

1

1

2233

key “+” :

Clw - On

key “-” :

Clw - Off

Clw

24VAC

Clw

1

2

2

1

3

4

1

- wire no.

1

2

Wiring diagram OR 52-7

External wiring Measuring sensor

To first alarm

Attached in housing

cover

Solenoid valve

Fig. 4 Shown position of contacts: Alarm 1 and 2, separator OFF and power failure

Notice

Fig. 4 shows an example where the water will be run back to the ship‘s bilge in the event of an alarm

(oil content > 15 ppm) or auxiliary power failure.

With different limit settings alarm contact 1 can, for instance, be used for the first alarm and alarm

contact 2 for the main alarm.

For bilge water monitoring a pneumatic three-way valve can be controlled by the alarm contact 2 via a

solenoid valve. If the turbidity of the effluent is too high (alarm caused by ingress of oil or dirt particles

introduced into the system during start-up) the three-way valve will divert the contaminated water to

the bilge tank. The separation continues until the oil content falls below 15 ppm and the cleaned water

can be discharged overboard.

N

Earthing screw

in housing

L

PE L N

Disconnecting switch

Three-way valve

Purging valve

External

wiring

13

Page 14

Functional Elements

ON ALARM 1 ALARM2 SYSTEM

GESTRA

ORT 7

OKP

Measuring sensor ORG 12

6

1

5

2

3

4

Fig. 5

14

7

8

Page 15

Functional Elements – continued –

ON ALARM 1 ALARM 2 SYSTEM

GESTRA

ORT 7

OKP

VDR4

VDR5

VDR3

L3

P2P1 P3

C24

C25

C26

R34

Measuring transducer ORT 7

9

§

"

Fig. 6

0

!

/%&

Fig. 7

$

15

Page 16

Functional Elements – continued –

Key

1 Light emitter

2 Measuring cell

3 Solenoid valve Clew

4 Cleaning device

5 Drying cartridge

6 Throttling device

7 Measuring transducer ORT 7

8 Cable glands

9 LCD display

0 System LED

! Keypad

" LED Mains voltage ON

§ LED Alarm 1 and 2

$ Terminating resistor GPS interface

% Memory card

& Locking piece for Memory Card

/ Circuit board for ORT 7 CPU

16

Page 17

Commissioning Procedure

Factory setting

The measuring transducer features the following factory set default values:

■ Limit alarm 1: 15 ppm

■ Limit alarm 2: 15 ppm

■ Delay of response alarm 1: 1 second

■ Delay of response alarm 2: 1 seconds

Warning

The terminal strips of the measuring transducer ORT 7 may be live during operation!

This presents the risk of severe injuries due to electric shock!

Cut off power supply before opening the housing lid!

Checking electrical connection

Before commissioning the equipment:

■ Check the connection of the supply voltage

■ The supply voltage is indicated on the name plate

■ Make sure that the connections of the signal inputs and alarm contacts are in accordance with the

wiring diagram.

Checking installation

■ Check all pipe connections for leaks and eliminate any leaks you encounter.

■ Unscrew the drying cartridge and remove the seal. Then screw the cartridge in again.

17

Page 18

Commissioning Procedure – continued –

Device

Certif.

Ser.Nr.

Vers.

: ORT7

: IMO

: MEPC.107(49)

: 392358

: 311137.10

Flowserve Gestra

OIL CONTENT :

ppm

State: WarmUp

8

UTC 10:46 2006-12-06

OIL CONTENT :

ppm

State: ready

8

UTC 10:46 2006-12-06

OIL CONTENT :

ppm

State: ClearWater ON

0

UTC 10:46 2006-12-06

First commissioning

1. Apply supply voltage to the measuring transducer.

The green LED ON will be illuminated and alarm 2 is

signaled.

2. When the equipment is switched on, the system window

appears for approx. 3 seconds, indicating the following:

Name of the equipment,

Certificate,

Serial number,

Number of the software version.

3. After approx 3 seconds the measurement window

appears, indicating the following:

Oil content (in large characters),

State: Warm up

Current time / date in UTC

4. After approx. 30 seconds the actual value in ppm is

indicated in the measurement window. If this value is

below 15 ppm the message Alarm 2 is cancelled and the

equipment state “Ready” is indicated. If, however, the

value continues to exceed 15 ppm, the message Alarm 2

remains active and the equipment state “ppm>Limit” is

indicated.

5. Press now key

indicated. The equipment state “Clear Water ON” appears.

Rinse the measuring transducer ORG 12 for at least

15 minutes with oil-free water and operate the cleaning

device 4 2 – 3 times, Fig. 5. During the rinsing process

with oil-free water the measuring window should show

0 ppm. If this is not the case switch to programming

mode, Parameter Value Offset, and reduce the zero point

by a max. of 5 ppm.

6. To close the purging valve press key

state “Ready” or “ppm>Limit” or any other alarm message

is indicated.

Note that in the measurement window the keys and and “OK” do not have a function. If you

want to enter the programming mode press key P.

+. The purging valve opens and Alarm 2 is

–. The equipment

18

Page 19

Commissioning Procedure – continued –

Parameter

act Value Offset

Value : 0 ppm

= prev = next

= backOKP

= change

Parameter

act Value Offset

Value : 2 ppm

= inc Para = dec Para

= confirmOKP

+

= abort

Parameter

act Value Offset

Value : 2 ppm

= prev = next

= backOKP

= change

Programming mode

The following parameters can be selected and, if required, changed:

Value Offset (reduction of zero point 0-5 ppm),

Output (Output of actual value 0 / 4-20 mA),

Alarm 1 Limit Value (Limit Alarm 1, 0-15 ppm),

Alarm 2 Limit Value (Limit Alarm 2, 0-15 ppm),

Alarm 1 Time Delay (Delay of response for alarm 1, 0-15 sec),

Alarm 2 Time Delay (Delay of response for alarm 2, 0-15 sec),

Datalog Export (transferring the storage data to a PC by means of PC software).

1. Press key

system LED will be illuminated and the window showing

the parameter that was changed last appears.

2. Press

desired parameter is shown.

3. Press key

ge. To quit the programming mode without any changes

press key OK (OK = back). The window that was active

before you switched the mode will reappear.

4. After having activated the parameter change by pressing

key P use the keys +/– to adjust the value within the

permissible limits.

5. To cancel the new setting press key

value will then remain valid.

6. To confirm and activate the new value press key OK

(OK = confirm). The parameter window appears again.

7. Press key OK (OK = back) to quit the programming mode.

The window that was active before you switched the mode

will reappear.

P to enter the programming mode. The amber

or to scroll forwards / backwards until the

P (P = change) to activate the parameter chan-

P (P = abort). The old

19

Page 20

Commissioning Procedure – continued –

Parameter

Output 0/4 . . 20 mA

Value : 4 mA

= prev = next

= backOKP

= change

Parameter

Datalog Export

Start

= prev = next

= backOKP

= change

Parameter

Alarm2 Limit Value

Value : 15 ppm

= prev = next

= backOK

P

= change

Parameter

Alarm2 Time Delay

Value : 5 sec

= prev = next

= backOKP

= change

Other parameter settings

Note

The export of data (Parameter Datalog Export) is described in a separate operating

manual.

20

Page 21

Start, Operation, Alarm and Function Test

Device

Certif.

Ser.Nr.

Vers.

: ORT7

: IMO

: MEPC.107(49)

: 392358

: 311137.10

Flowserve Gestra

OIL CONTENT :

ppm

State: WarmUp

8

UTC 10:46 2006-12-06

OIL CONTENT :

ppm

State: ready

8

UTC 10:46 2006-12-06

OIL CONTENT :

ppm

State: ClearWater ON

0

UTC 10:46 2006-12-06

Start and operation

1. Apply the supply voltage to the measuring transducer.

The green LED will be illuminated and alarm 2 is signaled.

2. When the equipment is switched on, the system window

appears for approx. 3 seconds, indicating the following:

Name of the equipment,

Certificate,

Serial number,

Number of the software version.

3. After approx 3 seconds the measurement window

appears, indicating the following:

Oil content (in large characters),

State: Warm up

Current time / date in UTC

4. After approx. 30 seconds the actual value in ppm is

indicated in the measurement window. If this value is

below 15 ppm the message Alarm 2 is cancelled and the

equipment state “Ready” is indicated. If, however, the

value continues to exceed 15 ppm, the message Alarm 2

remains active and the equipment state “ppm>Limit” is

indicated.

5. Press now key

indicated. The equipment state “Clear Water ON” appears.

Rinse the measuring transducer ORG 12 a few minutes

with oil-free water and operate the cleaning device 4

2 – 3 times, Fig. 5. During the rinsing process with oil-free

water the measuring window should show 0 ppm. If this

is not the case switch to programming mode, Parameter

Value Offset, and reduce the zero point by a max. of

5 ppm.

6. To close the purging valve press key

state “Ready” or “ppm>Limit” will be indicated.

+. The purging valve opens and Alarm 2 is

–. The equipment

21

Page 22

Start, Operation, Alarm and Function Test – continued –

OIL CONTENT :

ppm

State: ppm > Limit

16

UTC 10:46 2006-12-06

Alarm 1 and 2

If the alarm limits 1 and 2 are exceeded, the adjusted time delay is activated.

LED Alarm 1 and LED Alarm 2 are flashing. After the time delay LED Alarm 1 and LED Alarm 2 are

permanently illuminated. The relay contacts Alarm 1 and Alarm 2 open.

Alarm 2 is also indicated when

■ the separator is switched off,

■ the purging valve Clw is opened and

■ if the sensor ORG 12 signals a malfunction

Depending on the reason that caused Alarm 2, the equipment

state “ppm>Limit”, “Separator OFF” or “Clear Water On” will

be indicated in the measurement window.

Functional test

Push cleaning device 4 Fig. 5 slowly into the mid position in order to simulate a malfunction.

The amber system LED is flashing and the relay contact Alarm 2 opens. Error code e1 or e2 is

indicated.

Push cleaning device 4 Fig. 5 back into its initial position.

The equipment must switch back to normal operation.

22

Page 23

Data Storage

Memory Card

The memory card is on the CPU circuit board in the housing lid. Fig. 7. The design of the card ensures

that the recorded time, date, alarm, malfunction and status messages are stored for 18 months as

required by the IMO Resolution MEPC 107 (49).

Once the capacity limit of the card is reached, the oldest message will be overwritten, which means

that the card does not have to be exchanged.

The memory card is encoded with the serial number of the associated oil & turbidity detector OR 52-7

and, as a consequence, only this particular device can write data on the card. All other devices are

only able to read the data stored on the card.

Note

When replacing the oil & turbidity detector OR 52-7 make sure that the memory card

remains on board the ship because it contains the proof that the requirements regarding

oil separation as stipulated by the IMO Resolution were fulfilled.

To take the card out of the card holder unscrew the card locking piece &, Fig. 7.

Data indication

According to the IMO Resolution MEPC 107 (49) the time, date, alarm, malfunction and status

messages must be stored for 18 months. The measuring transducer features therefore a data logging

function.

The state of the equipment (Log MSG: Oil content, Alarm 2, Clear Water and Separator) and, in addition,

every change of state (State change: ON/OFF Alarm 2, geographic position, Clear Water and Separator)

are saved every hour.

Operating steps – see Fig. 8

1 To view the stored data in the log window press key in the measurement window. If you

want to go back press key .

2 To enter the enquiry mode press key or . Depending on the adjusted enquiry interval (dT) the

stored state messages (Log Msg) and changes (State Change) will be indicated.

3 If you want to change the interval press key + / – in the enquiry mode. The following interval

options are available: all, day, week or month.

4 Enquiry interval(dT)

dT: all = When pressing on the arrow key the next entry will be indicated.

dT: day = When pressing on the arrow key the 24

dT: week = When pressing on the arrow key the 5 x 24

dT: month = When pressing on the arrow key the 30 x 24

th

entry will be indicated.

th

entry will be indicated.

th

entry will be indicated.

5 Press key or to view all state messages (Log Msg) and changes (State Change), depending

on the adjusted enquiry interval.

6 Press key or to view only the state changes (State change), depending on the enquiry

interval.

23

Page 24

Data Storage – continued –

OIL CONTENT :

ppm

State: ready

8

UTC 10:46 2006-12-06

Time

Date

Pos

Oil

Clw

Data Logger

: UTC 09:55

: 2006-12-06

: N 53° 5´ 36´´

E 008° 48´ 15´´

: 8 ppm Ala : Off

: Off Sep: On

Log Msg (State change)

Time

Date

Pos

Oil

Clw

dT

Time

Date

Pos

Oil

Clw

dT

State change

Time

Date

Pos

Oil

Clw

dT

State change

Clw

dT

Clw

dT

Clw

dT

: UTC 10:00

: 2006-12-06

: 0° 0´ 0´´

000° 0´ 0´´

: 1 ppm Ala : Off

: Off Sep: On

: all

: UTC 09:45

: 2006-12-06

: 0° 0´ 0´´

000° 0´ 0´´

: 16 ppm Ala : On

: Off Sep: On

: all

: UTC 08:15

: 2006-12-06

: 0° 0´ 0´´

000° 0´ 0´´

: 16 ppm Ala : On

: Off Sep: On

: all

: Off Sep: On

: week

: Off Sep: On

: day

: Off Sep: On

: month

OK : backOK : backOK : back

OK : back

OK : back

OK : back

Time

Date

Pos

Oil

Clw

dT

Log Msg + State change

Time

Date

Pos

Oil

Clw

dT

Log Msg + State change

: UTC 09:00

: 2006-12-06

: N 53° 5´ 36´´

E 008° 48´ 15´´

: 8 ppm Ala : Off

: Off Sep: On

: all OK : back

: UTC 08:00

: 2006-12-06

: N 53° 5´ 36´´

E 008° 48´ 15´´

: 8 ppm Ala : Off

: Off Sep: On

: all OK : back

OK

OK

OK

OK

OK

2

Device

Certif.

Ser.Nr.

Vers.

: ORT7

: IMO

: MEPC.107(49)

: 392358

: 311137.10

Flowserve Gestra

Note

If you want to view e. g. an alarm on a particular day, first chose the suitable enquiry

interval and press key

press key or to go to the event in question.

Operating flowchart

to go to this date. Then select the enquiry interval dT and

6 6

55

1

2

3

4

Fig. 8

24

Page 25

Malfunctions

OIL CONTENT :

ppm

State: e1 Light Ctrl ov

8

UTC 10:46 2006-12-06

OR 52-7

In the event of a malfunction the amber system LED is

flashing and the relay contact Alarm 2 is energised.

An error code is indicated in the measurement window.

The equipment is not working – no function, no indication

Fault: The fuse of the equipment is defective.

Remedy: Replace the fuse of the equipment and check the power supply.

Fault: Internal voltage supply failed.

Not all three green LEDs on the basis circuit board are illuminated.

Remedy: Check power supply or replace the measuring transducer.

Measured value increases continuously with 1ppm/day or slower

(ingress of foreign matter can be ruled out)

Fault: Accumulated dirt deposits on glass cylinder.

Remedy: Operate the cleaning device more often.

Table listing error codes

Error code Possibly caused by: Remedy

e1 Light Ctrl ov

Error code Possibly caused by: Remedy

e2 no Light rec

Error code Possibly caused by: Remedy

mem Card err

Glow lamp in light emitter contaminated Replace light emitter

Dirt deposits on glass cylinder Clean glass cylinder

Excessive turbidity

Operating voltage too low Check voltage supply

Cleaning device not in initial position Return the cleaning device into the initial position

Ingress of solid particles in fluid

Glow lamp in light emitter defective Replace light emitter

Connecting line to light emitter interrupted Check connecting line

Cleaning device not it its initial position Return the cleaning device to its initial device

Ingress of solid particles in fluid

No or wrong memory card Insert the right memory card

Once the fault is eliminated the equipment will return to normal operation.

Provide mechanical cleaning device upstream of

equipment

Provide mechanical cleaning device upstream of

equipment

Provide mechanical cleaning device upstream of the

equipment

25

Page 26

Calibration

OR 52-7

According to the IMO Resolution MEPC 107 (49), section 4.2.11, the measuring accuracy of the 15 ppm

bilge alarm must be checked when the equipment is inspected in order to obtain the extension of the

period of validity of the IOPP certificate (5 years) as specified by the manufacturer.

For this inspection the measuring transducer ORG 12 must be exchanged.

Please order a replacement for the measuring transducer ORG 12 (stock code 389 427), indicating the

serial number, in good time before the IOPP certificate expires.

Before exchanging the measuring transducer undo the central screw of the connectors for the light

emitter/receiver and for the purging valve and detach the connectors.

Remove the measuring transducer and mount the replacement equipment.

Attach the connectors to the light emitter/receiver and the purging valve and tighten the central screw.

Repeat the commissioning procedure.

26

Page 27

Maintenance

Cleaning the glass cylinder

1. Push the wiper of the cleaning device

2 or Malfunction may be triggered (depending on the time delay setting) and the amber LED is

flashing.

2. Return the wiper of the cleaning device

70 mm from the equipment).

The cleaning interval (e. g. once a week) depends on the amount of dirt deposits.

Replacing the drying cartridge

Replace drying cartridge when its content turns pink. Should this happen too often check the following

items for tight shut-off:

■ O-rings of light emitter

■ Cable glands of light emitter and light receiver

■ Gaskets of connectors and drying cartridge

Replacing the light emitter/receiver

1. Undo fixing screw and remove connector from light emitter/receiver.

2. Unscrew union nut (outside) of the light emitter/receiver tube and detach the emitter/receiver from

the body of the measuring transducer.

3. Replace the light emitter/receiver. Make sure that the locating pin of the emitter/receiver fits into

the groove of the light emitter/receiver.

4. Tighten external union nut.

5. Attach connector to light emitter/receiver and tighten the fixing screw.

6. Correct the zero point when the measuring transducer in programming mode (Parameter Value

Offset).

Please observe the notes on the spare parts kit “Light”.

4 Fig. 5 up and down. When doing so Alarm 1 and/or Alarm

4 to its initial position (the plunger protrudes approx.

Attention

Do not open the measuring transducer!

Replacing the equipment fuse

1. Open the housing lid of the measuring transducer. Observe the warning note!

2. Turn the fuse carrier to the left and take it off.

3. Replace the equipment fuse.

4. Fit fuse carrier in place and turn it to the right. Close housing lid.

27

Page 28

Maintenance – continued –

Warning

The terminal strips of the measuring transducer ORT 7 can be live during operation.

This presents the danger of severe injuries due to electric shock.

Always cut off power supply before mounting, removing or connecting wires to the

terminal strips.

Spare parts

The oil & turbidity detector OR 52-7 comes with a spare parts kit containing the following items:

Spare parts kit “Gaskets”, stock code 389 232

Designation Qty.

Drying cartridge 1

Gasket for connector GDM 3-21

O ring 25 x 3 (housing lid / glass cylinder) 2

O ring 30 x 2 (housing lid / glass cylinder) 2

O ring 37 x 2 (housing lid / glass cylinder) 2

O ring 48 x 2.5 (housing of light emitter / light receiver) 2

If required you can order the following spare parts kit “Light”, stock code 389 333,

containing the following items:

Designation Qty.

Light emitter 1

Light receiver 1

2

28

Note

When ordering please state the stock code no. 389 333 for the spare parts kit and the

equipment serial number.

Please note that you have to replace both the light emitter and receiver when using

the replacement light emitter and receiver.

Page 29

Decommissioning

Warning

The terminal strips of the measuring transducer ORT 7 can be live during operation.

This presents the danger of severe injuries due to electric shock.

Always cut off power supply before mounting, removing or connecting wires to the

terminal strips.

Removal

1. Cut off power supply.

2. Disconnect all wires and draw the cables through the cable gland.

3. Remove the measuring sensor and the measuring transducer.

Disposal

Dismantle the oil & turbidity detector OR 52-7 and separate the waste materials according to the

material specification. Electronic component parts such as the circuit board must be disposed of

separately. For the disposal of the control unit observe the pertinent legal regulations concerning waste

disposal.

29

Page 30

Annex

Type approval certificate

30

Page 31

Annex – continued –

Type approval certificate – continued –

31

Page 32

Annex – continued –

Type approval certificate – continued –

32

Page 33

Annex – continued –

Type approval certificate – continued –

33

Page 34

Annex – continued –

EG-Baumusterprüfbescheinigung (Modul B)

34

Page 35

Annex – continued –

EG-Baumusterprüfbescheinigung (Modul B) – Fortsetzung –

35

Page 36

Annex – continued –

Type Examination Certificate (Module B)

36

Page 37

Annex – continued –

Type Examination Certificate (Module B)

37

Page 38

Annex – continued –

Declaration of Conformity

38

Page 39

For your notes

39

Page 40

Agencies all over the world:

www.gestra.de

GESTRA

España

GESTRA ESPAÑOLA S.A.

Luis Cabrera, 86-88

E-28002 Madrid

Tel. 00 34 91 / 5 15 20 32

Fax 00 34 91 / 4 13 67 47; 5 15 20 36

E-mail: aromero@flowserve.com

Great Britain

Flowserve GB Limited

Abex Road

Newbury, Berkshire RG14 5EY

Tel. 00 44 16 35 / 46 99 90

Fax 00 44 16 35 / 3 60 34

E-mail: gestraukinfo@flowserve.com

Italia

Flowserve S.p.A.

Flow Control Division

Via Prealpi, 30

l-20032 Cormano (MI)

Tel. 00 39 02 / 66 32 51

Fax 00 39 02 / 66 32 55 60

E-mail: infoitaly@flowserve.com

Polska

GESTRA POLONIA Spolka z.o.o.

Ul. Schuberta 104

PL - 80-172 Gdansk

Tel. 00 48 58 / 3 06 10 -02 od 10

Fax 00 48 58 / 3 06 33 00

E-mail: gestra@gestra.pl

Portugal

Flowserve Portuguesa, Lda.

Av. Dr. Antunes Guimarães, 1159

Porto 4100-082

Tel. 0 03 51 22 / 6 19 87 70

Fax 0 03 51 22 / 6 10 75 75

E-mail: jtavares@flowserve.com

USA

Flowserve GESTRA U.S.

2341 Ampere Drive

Louisville, KY 40299

Tel.: 00 15 02 / 267 2205

Fax: 00 15 02 / 266 5397

E-mail: dgoodwin@flowserve.com

GESTRA AG

P. O. Box 10 54 60, D-28054 Bremen

Münchener Str. 77, D-28215 Bremen

Telephone +49 (0) 421 35 03- 0

Fax +49 (0) 421 35 03 - 393

E-Mail gestra.ag@flowserve.com

Internet www.gestra.de

818788-00/1207cm · 2007 GESTRA AG · Bremen · Printed in Germany

40

Loading...

Loading...