Page 1

OR 52-5

OR 52-6

Installation Instructions 810731-01

Oil & Turbidity Detector OR 52-5, OR 52-6

Page 2

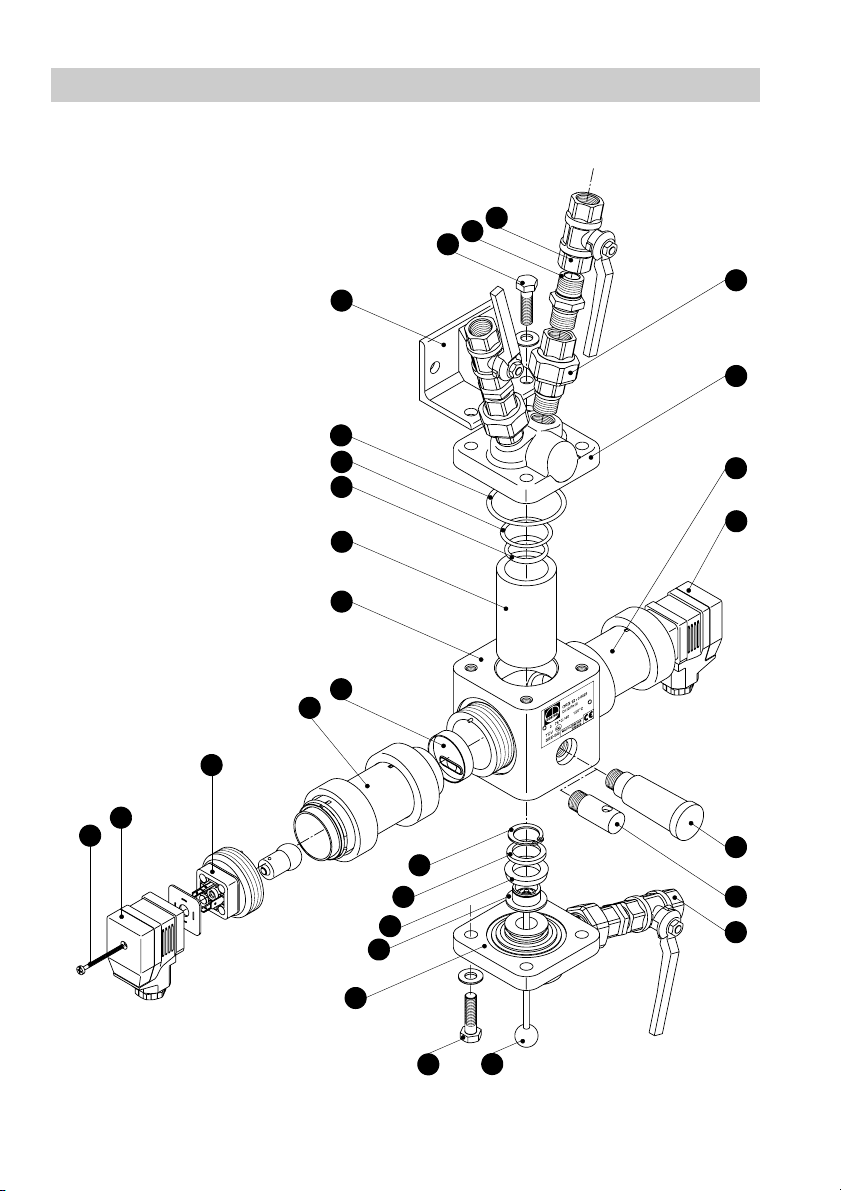

Component Parts

W

B

A

I

Z

Y

C

X

V

U

T

D

P

S

R

Q

P

O

N

M

L

K

J

H

I

2

G

F

E

Page 3

Key

A

Nipple with threaded ends

B

Ball valve ¾“ BSP (DIN ISO 228)

C

Upper cover flange

D

Light receiver with tube

E

Ball valve ¾“ BSP (DIN ISO 228) for purging

F

Vent nipple

G

Drying cartridge

H

Cleaning plunger

I

Hexagon-head screw M8x30 EN 24017

J

Lower flange

K

Support for cleaning ring

L

Cleaning ring (wiper)

M

Ring

N

Retaining ring 19x1.2

O

Screw

P

Connector for light emitter / light receiver

Q

Light emitter

R

Tube

S

Turbidity standard

T

Housing

U

Glass cylinder

O-ring 25x3

V

O-ring 30x2

W

X

O-ring 37x2

Mounting bracket

Y

Z

Screwed union

3

Page 4

Contents

Page

Important Notes

Usage for the intended purpose.......................................................................................6

Safety note.......................................................................................................................6

Warning............................................................................................................................7

Explanatary Notes

Scope of supply ...............................................................................................................8

Application .......................................................................................................................8

Function ...........................................................................................................................9

Technical data................................................................................................................10

Installation

Measuring sensor ORG 12, ORG 22 .............................................................................13

Measuring transducer ORT 6.........................................................................................17

Wiring

Measuring sensor ORG 12, ORG 22 .............................................................................18

Measuring transducer ORT 6.........................................................................................18

Tools ..............................................................................................................................19

Wiring diagram ORG 12, ORG 22, ORT 6.....................................................................19

Wiring diagram ORG 12, ORG 22, ORT 6 with three-way valve ...................................20

Functional Elements

Measuring transducer ....................................................................................................21

Commissioning Procedure

Factory settings..............................................................................................................22

Start-up procedure .........................................................................................................23

0% calibration ................................................................................................................23

100% calibration ............................................................................................................24

Oil / turbidity curves .......................................................................................................25

Detection and indication of various contaminants..........................................................25

Adjusting limit value alarm 1 ..........................................................................................26

Adjusting limit value alarm 2 ..........................................................................................26

Adjusting time delay for alarm 1.....................................................................................27

Adjusting time delay for alarm 2.....................................................................................27

Setting decimal point......................................................................................................28

Establishing actual value output ....................................................................................28

4

Page 5

Contents

Page

Operation

Start ...............................................................................................................................29

Alarm 1 and 2 ................................................................................................................29

Maintenance

Functional check............................................................................................................30

Functional test of relays for alarm 1, alarm 2 and malfunction ......................................30

Malfunctions...................................................................................................................30

Error code – Indication...................................................................................................31

Error Code – Table ........................................................................................................31

Exchanging glass cylinder .............................................................................................33

Cleaning glass cylinder..................................................................................................34

Replacing cleaning plunger ...........................................................................................34

Replacing drying cartridge ............................................................................................. 34

Replacing glow lamp......................................................................................................35

Replacing fuse ...............................................................................................................35

Tools ..............................................................................................................................35

Spare parts ....................................................................................................................36

Annex

Declaration of conformity ............................................................................................... 37

Certificate of type approval ............................................................................................ 40

Type approval certificate................................................................................................44

Updates .........................................................................................................................45

5

Page 6

Important Notes

Usage for the intended purpose

Use oil & turbidity detector OR 52 only for monitoring transparent liquids to detect any

ingress of light-scattering and insoluble foreign matter.

Chemical and corrosive influences have to be taken into account and the equipment must

only be used within its rated pressure and temperature limits. Before installation and

operation make sure that the equipment is resistant to the medium in the operational

conditions that will exist.

Any type of use differing from the usage described above is considered as improper.

The resulting risk will have to be borne by the user alone. The manufacturer hereby

expressly rejects any claims for any resulting damage.

Safety note

The equipment must only be installed, removed, commissioned, operated and serviced

by qualified staff.

Qualified staff are those persons who - through adequate training in electrical

engineering, the use and application of safety equipment in accordance with regulations

concerning electrical systems and circuits, and first aid & accident prevention – have

achieved a recognised level of competence appropriate to the installation and

commissioning of this device.

For installation, removal, commissioning, operation and maintenance, every person

who works with the equipment must have read and understood the complete installation

manual. Furthermore, responsibilities must have been defined clearly and

unambiguously and must be adhered to.

Usage of the equipment for the intended purpose includes compliance with the rules and

notes in this installation manual for installation, removal, commissioning, operation and

maintenance.

The operating company must ensure that, whenever the equipment is being operated,

it is in perfect condition.

Working methods that jeopardise safety must not be used.

6

Page 7

Important Notes

Warning

Danger

If the measuring transducer and sensor are used in an inexpert or

improper manner by unqualified staff, they can cause danger to life and

limb for the user or for third parties, possibly resulting in death.

During operation, the sensor is under pressure. In this condition, screws,

nuts or bolts must not be slackened. Hot water or steam could flow out and

could cause severe scalding over the entire body.

The sensor might be hot during operation. If it is touched when in the

operational condition, severe burns are possible.

Any installation or removal work may only be performed when the

equipment is at zero pressure and has cooled down. When such work is

to be done, the pressure in the pipes upstream and downstream must

have been reduced to zero and the sensor must have cooled down

sufficiently.

The terminal strips of the measuring transducer are live during operation.

This presents the danger of electric shock. Cut off power supply before

opening the cover or mounting/removing the terminal strips.

It must be ensured that during the work the system section in which

pressure has been reduced to zero cannot be accidentally put back into

operation. The shut-off valves needed for this purpose must be separately

secured and marked. The connection to the energy supply must be

disconnected and must be secured to prevent it from being operated

accidentally. One or more warning notices, for example containing the text

"DO NOT SWITCH ON" must be displayed in a clearly visible manner at

each operating element.

continued

7

Page 8

Explanatary Notes

Scope of supply

1 Measuring transducer ORT6,

1 Measuring sensor ORG12 or ORG 22 (depending on order),

3Ball valves,

3 Screwed unions and nipples with threaded ends,

1 Vent nipple (screwed in ORG),

1 Turbidity standard 20ppm (supplied but not fitted),

1 Drying cartridge (supplied but not fitted),

1 Installation manual,

Type approval certificates (according to order)

Application

The oil & turbidity detector consists of the measuring sensor ORG 12 or ORG 22 and the

measuring transducer ORT 6 (operating and display unit). The type of measuring sensor

depends on the fluid to be used.

The oil & turbidity detector OR 52-5/-6 is used for monitoring transparent liquids to detect

any ingress of insoluble foreign matter. The equipment is mainly used for industrial

processes and in the foodstuff industry where high level of reliability and ease of

maintenance are required.

The equipment combination can be used for marine applications in order to monitor

microfiltering equipment in accordance with IMO (International Maritime Organization)

resolution MEPC.60(33) and EC directive 96/98/eec (MED) as 15 ppm oil content alarm.

In steam boiler plants condensate and feedwater can be monitored for oil and grease

contamination (according to TRD 604 sheet 1 paragraph 2.1.1 with 3/5 ppm). In addition,

the oil & turbidity detector is well suited for raw water monitoring and water treatment

(sand filters, demineralization plants, reverse-osmosis plants) as well as waste-water

monitoring.

The OR 52 is also used in breweries and the beverage industry (filtration, monitoring of wort,

quality assurance etc.) and in the salad oil production for monitoring filtering processes.

Note

When using the equipment as 15 ppm oil content alarm acc. to IMO please

take the following into consideration:

Microfilter installations usually consist of an oil/water separator followed by

a filter, the so-called coalescer. Gravity coalescer systems cannot split up

stable water/oil emulsions, which are formed with certain cold cleaning

agents and then accumulate in the bilge. We therefore recommend

suitable fast-separating cold cleaning agents which will not produce

stable water-oil emulsions.

8

Page 9

Explanatary Notes

continued

Function

The measuring sensor is a photometric measuring device consisting of a light source

(light emitter ) and a light receiver equipped with two photosensitive elements.

Q

D

A constant light beam passes through the transparent liquid. Insoluble foreign matter

scatters the light, which is then measured using the 15° forward light scattering method.

The light intensity is transformed into an electric current which will be used by the

measuring transducer to determine the concentration of foreign matter. The actual

turbidity value is continuously compared with the adjusted setpoint and the result will be

indicated visually and - if required - acoustically.

The measuring transducer is the operating and indicating unit for signal evaluation and

the control of the measuring sensor. It serves as visual display unit for the measuring

results and the adjustment of the measuring equipment, indicating the actual value,

tripping the limit alarms ALARM 1 and ALARM 2 and releasing messages in the event of

a malfunction in the measuring sensor. The measuring transducer is designed for setting

and indicating the limit values.

ORT 6

ppm

cal

OIL

sec

0

ALARM

12

P

E

Test

ORG 12/22

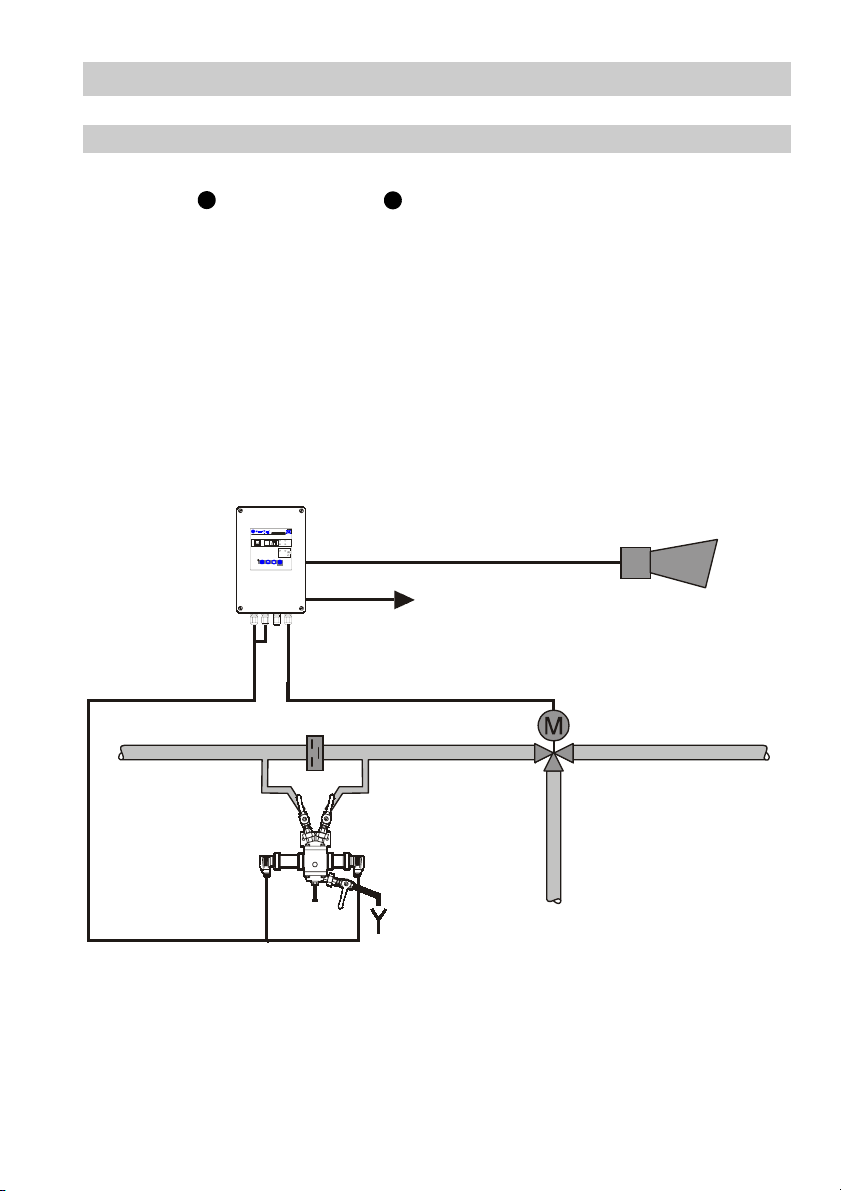

Fig.1

Typical application of an oil & turbidity detector type OR 52-5/-6

9

Page 10

Explanatary Notes

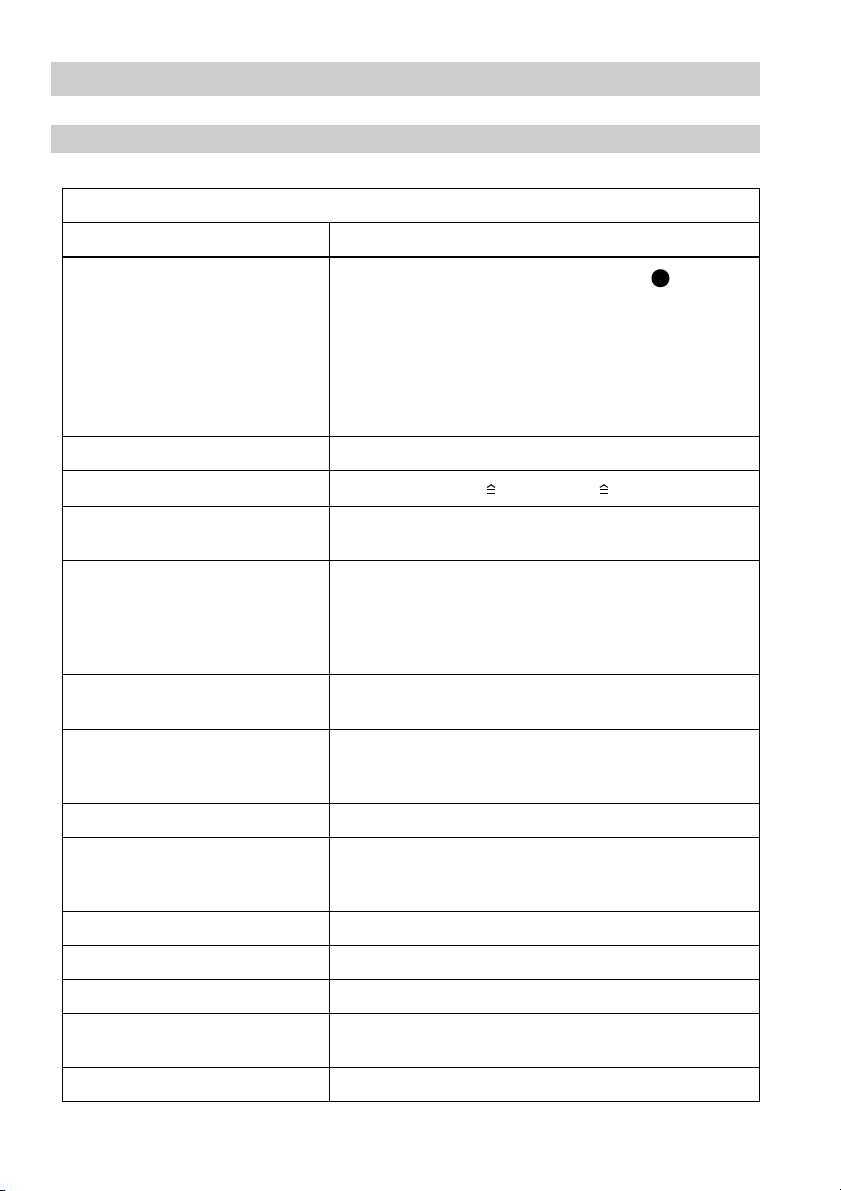

Technical Data

Measuring sensor ORG 12, ORG 22

continued

Nominal pressure PN 10 bar

Nominal size DN 10, screwed “ ¤§8 BSP to DIN ISO 228

Flowrate 0.5– 50 l/ min

1)

Pressure drop

Corrosive resistance Water, condensate, beverages, etc.

Max. pH value of fluids

Fluid temperature range

Approx. weight 6.8 kg

Housing 0.6025 galvanized 0.6025 galvanized

Cover 0.6025 galvanized 1.4580

Wetted parts 0.6025 galvanized 1.4580

Ball valves Brass 58 1.4436

Screwed unions Steel 1.4571

Glass cylinder Duran 50 Duran 50

Gaskets Silicone Silicone

Cleaning disc EPDM EPDM

2)

0–60 °C

(with drying cartridge)

Materials ORG12 ORG22

g (145 psi g)

5 mbar

10.5

60– 120 °C

(with vent nipple)

Light emitter

Light receiver

1)

At a flowrate of 2 l/min and V-shaped flow through the sensor with a pipe length of 1 m

Glow lamp 12V / 10W BA 15 s

Protection IP 65

2 silicon-type photo-electric cells

Protection IP 65

(DN 10) and 4 bends, ζ=6.1.

2)

A pH value above 10.5 can lead to wear of the glass, depending on the temperature.

3)

Vent nipple screwed in measuring transducer as standard.

F

10

Page 11

Explanatary Notes

continued

Technical Data

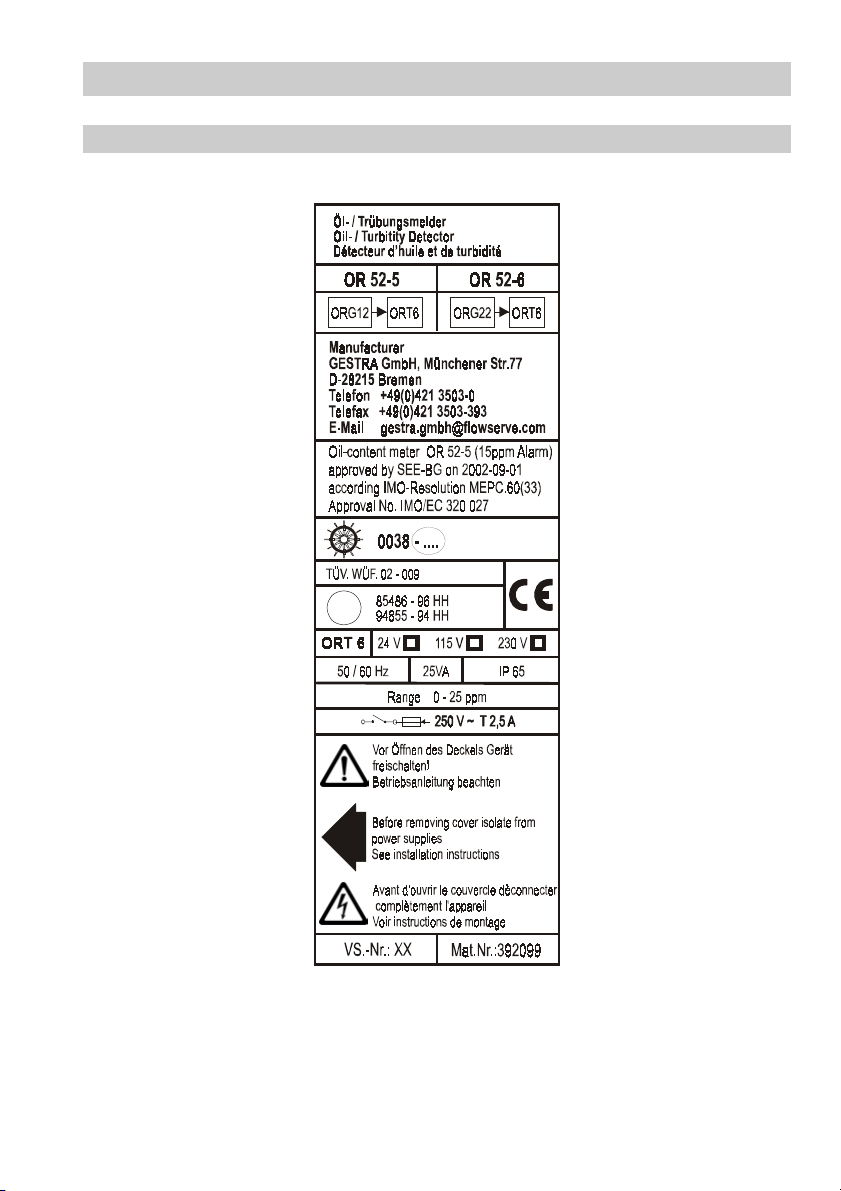

Name plate

contiuned

GL

11

Page 12

Explanatary Notes

continued

Technical Data

continued

Measuring Transducer ORT 6

Inputs Directly transmitted light (D), scattered light (S)

1 voltage output for light emitter ,

Q

1– 12V pulse-amplitude modulated

3 volt-free change-over contacts

Outputs

(alarm 1 + 2 and malfunction),

Contact material AgNi 0.15

Max. contact rating for switching voltages 24V AC / DC,

115V and 230V AC. Resistive / inductive 4 A

1 current output 0/4 – 20 mA, max. load 500 ohm

Measuring range 0– 25 ppm

Actual value output

Adjustment range

Limit value alarm 1 and 2

0/4 mA 0ppm, 20 mA 25ppm

Adjustable between 0 and 15ppm

Other ranges on request

4 membrane keys,

8 LEDs for indicating operating modes and dimensions,

Indicators and adjustors

1 three-digit seven-segment display for actual value,

limit value and fault indication,

3 LEDs for monitoring system voltages

Adjustment range

Time delay alarm 1 and 2

0 to 20 sec.

Other ranges on request

230V + 10 / - 15%, 50 – 60 Hz

Mains voltage

115V + 10 / - 15%, 50 – 60 Hz (optional)

24 V + 10 / -15%, 50–60 Hz (optional)

Power consuption 25 VA

Thermal fuse M 0.2A 5x 20 at 230 V

Fuse

Thermal fuse M 0.4A 5x 20 at 115 V

Thermal fuse M 1.0A 5x20 at 24 V

Housing Field case for wall installation

Housing material Die-cast aluminium

Protection IP 65 (DIN EN 60529)

Admissible ambient

temperature

0–55

°C

Approx. weight 3.6 kg

12

Page 13

Installation

Measuring Sensor ORG 12, ORG 22

It is highly advisable to have the installation work done by qualified staff in the manner

described by these installation instructions. The manufacturer will not accept liability for

damage resulting from improper installation.

The measuring transducer is designed for wall mounting and should be installed close

to the measuring sensor.

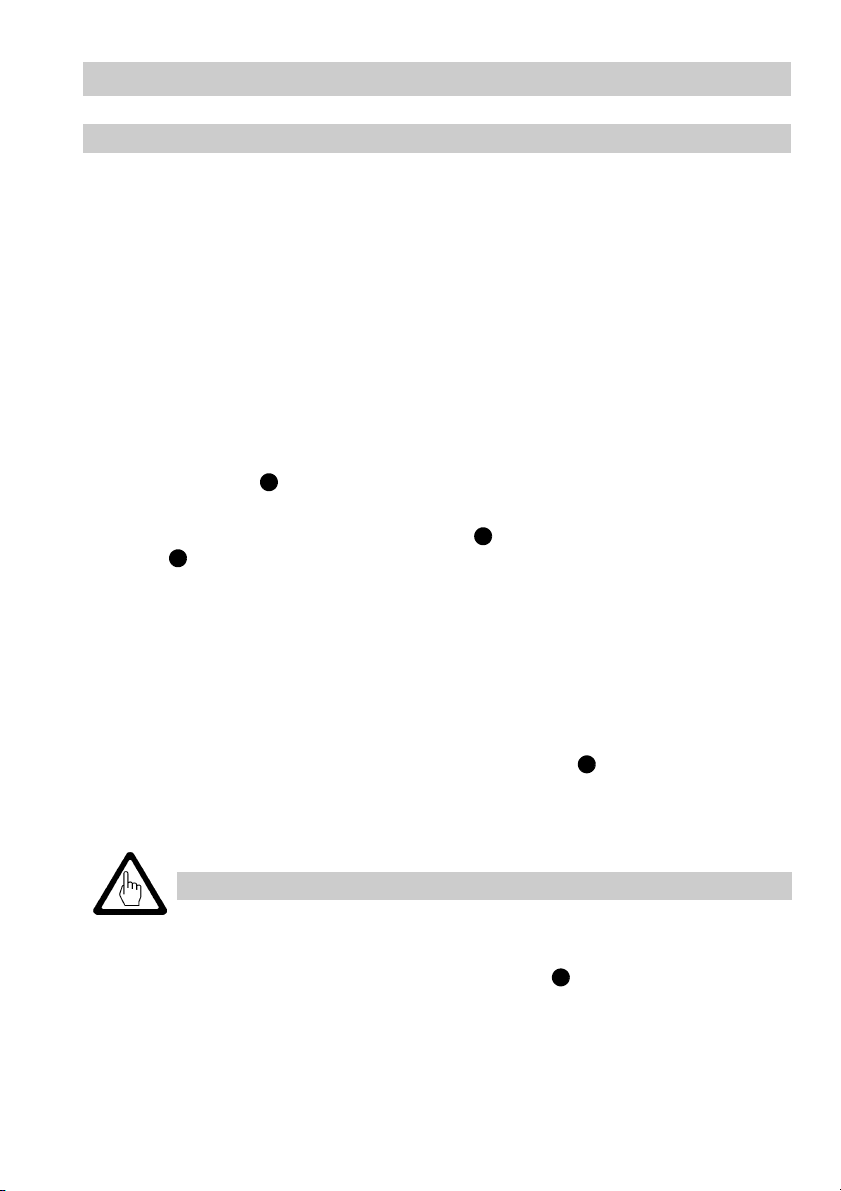

Install the measuring sensor and lines in accordance with the examples given in

figs. 2 to 7.

Provide a throttling point – e. g. a non-return valve (GESTRA type RK 86) in the main line.

Mount the measuring sensor in a bypass at a lower level than the main line so that any

gas bubbles and flash steam can pass through the main line instead of the sensor. Tap

main line at the side from the bottom to prevent air and dirt particles from flowing into the

bypass.

If the fluid temperature is above the max. ambient temperature:

Screw in vent nipple .

If the fluid temperature is below the ambient temperature:

Remove the plastic lid from the drying cartridge (blue colour) and screw in the drying

cartridge .

G

If the fluid temperature is very high:

Provide a non-insulated pipe upstream of ORG 12/ORG 22 which will allow the fluid to

cool down to 120 °C when reaching the sensor.

In the presence of large amounts of gas:

Tapping point must be at the bottom of the line – use a welding pocket in accordance with

DIN 2618 (see page 14 fig. 5).

If the condensate can be/is highly contaminated:

Ensure downward flow of the fluid through the glass cylinder (glass cylinder may be

scratched), for installation see page 14 fig. 3.

If this does not help and/or a lot of flash steam builds up ahead of the measuring sensor

fit a separator upstream of the equipment (see page 15, fig. 6).

Important

F

G

U

Avoid flashing, outgassing and the presence of air due to a pressure drop

upstream of the measuring sensor.

The additional connection of the cover flange must be reserved for the

C

inlet of either wash water or calibration fluid.

13

Page 14

Installation

continued

Measuring Sensor ORG 12, ORG 22

Inlet Outlet

Cleaning device V-shaped

Fig.2

flow through sensor,

automatic deaeration

Outlet

Cleaning device

Inlet

Fig.3

continued

Sensor installed in a sample line,

e. g. water treatment, beer

filtering, permeate downstream

of reverse osmosis.

Installation of sensor when the

condensate contains suspended

solids. If the sensor is installed in

acc. with figs. 4 – 6, solids could

deposit on the cleaning device

and scratch the glass cylinder .

U

Sensor installed in a bypass of a

product line with upward flow.

Fig.4

Fig.5

14

*)

500

≥

H

Sensor installed below a product

line carrying a slight amount of

gas, e. g. sufficiently sized

condensate line (flashing)

downstream of steam traps.

*) Tap product line at the side

(angle of 45°) from the bottom to

prevent air and dirt from flowing

into the bypass.

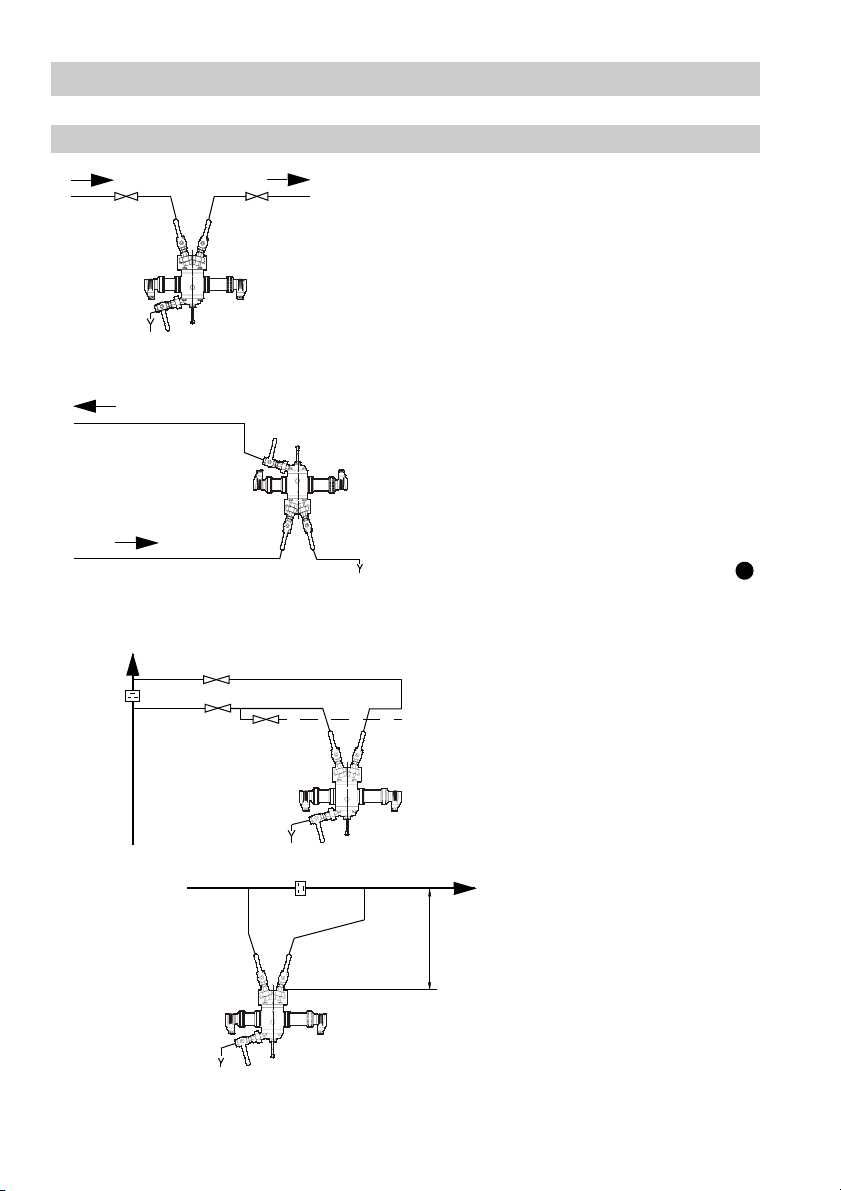

Page 15

Installation

DN>inl

continued

Measuring Sensor ORG 12, ORG 22

Flash steam

Separator

DN100-300

250

≥

H

Condensate

Downward flow

of sample if

condensate is very

contaminated

Fig.6

NRGS 16-1

continued

et

Installation of sensor in a

condensate line with large

amount of flash steam

ppm

cal

OIL

sec

0

ALARM

12

P E

Test

Fig.7

Schematic layout of oily water separation system for bilge water with the oil and turbidity

detector OR 52 as 15 ppm oil content alarm.

15

Page 16

Installation

continued

Measuring Sensor ORG 12, ORG 22

The cover flange and lower flange of the measuring sensor can be screwed turned

C J

continued

through 90°.

1. Screw in nipples with threaded ends , screwed unions and ball valves

supplied with the sensor into upper cover flange and lower flange or directly at

A Z B

C J

the inlet, outlet or purging points. Use teflon tape for sealing.

2. The screwed unions facilitate positioning of the ball valves so that the levers

Z B

can be arranged in one plane (front).

3. Fit the ORG 12/ORG 22 with the mounting bracket provided in an accessible

place. If the sensor is used on ships weld mounting bracket to its support.

Y

Y

4. For the inlet and outlet lines of the sensor use 12 mm OD Ermeto, 10 mm OD gas

pipe or suitable flexible tubes (for rinsing purposes).

5. Fit the light receiver in an accessible place. It can then be easily removed so that

visual inspection of the fluid is possible. The interchange of light emitter and light

receiver is possible after loosening the union nuts (inside) from the housing .

D T

When refitting, take care of correct fit of locating pins of the housing in the grooves

provided in light emitter and receiver . Tighten union nuts.

Be sure the equipment is damp proof – condensate on the outside of glass cylinder

D

Q

T

Q D

U

results in excessively high readings.

Fig.8

80

140

135

70

90

7

16

315

78

135

175200

5

40

375

Page 17

Installation

continued

Measuring Transducer ORT 6

Unscrew cover screws and swing up cover in order to gain access to the holes for

mounting the equipment. The distance between the holes is indicated on the back of the

case. Use suitable screws and wall plugs to mount the measuring transducer.

ppm

110

160

sec

ALARM

12

E

Test

cal

0

260

91

Fig.9

OIL

240

P

17

Page 18

Wiring

Measuring Sensor ORG 12, ORG 22

Before installing the measuring sensor cut off power supply!

Connect light emitter and receiver via connector .

1. Wire light emitter with a screened two-core cable

Q D P

Q

(do NOT connect screen),

e. g. LIYIC 2x0.75 mm², max. length 50 m).

2. Wire light receiver with screened four-core cable

D

(do NOT connect screen),

e. g. LIYIC 4x0.5 mm², max. length 50 m).

Measuring Transducer ORT 6

1. Unscrew lid screws and open lid.

2. Remove all three-pole terminal strips and pull connecting cables through

cable glands.

3. Mark connecting cables: "Mains", "Alarm 1" and "Alarm 2".

4. Strip off approx. 40 mm of cable insulation coating and remove approx. 5 mm

of conductor end insulation.

5. Connect terminal strips in accordance with wiring diagram and

connect

screens.

6. Connect PE with earthing screw in case.

7. Re-insert terminal strips.

8. Seal cable glands by tightening screws. Fit plug supplied with equipment to

seal unused cable glands.

9. Close lid and tighten lid screws.

10. Mount disconnecting device (disconnecting switch).

Attention

18

To protect the output contacts fuse circuits with 2.5 A (anti-surge).

Provide connected contactors and actuators with RC combinations

(in accordance with manufacturers' specifications) in order to suppress

interference.

Make sure that the disconnecting switch is easily accessible and in the

close proximity of the equipment (EN 61010-1).

Mark respective switch as disconnecting device for the measuring

transducer.

Page 19

Wiring

Tools

Screwdriver for cross-recess screws, size 1 and 2

Screwdriver for slotted screws, size 2.5, completely insulated to VDE 0680

Conductor end sleeve pliers

Insulation stripper

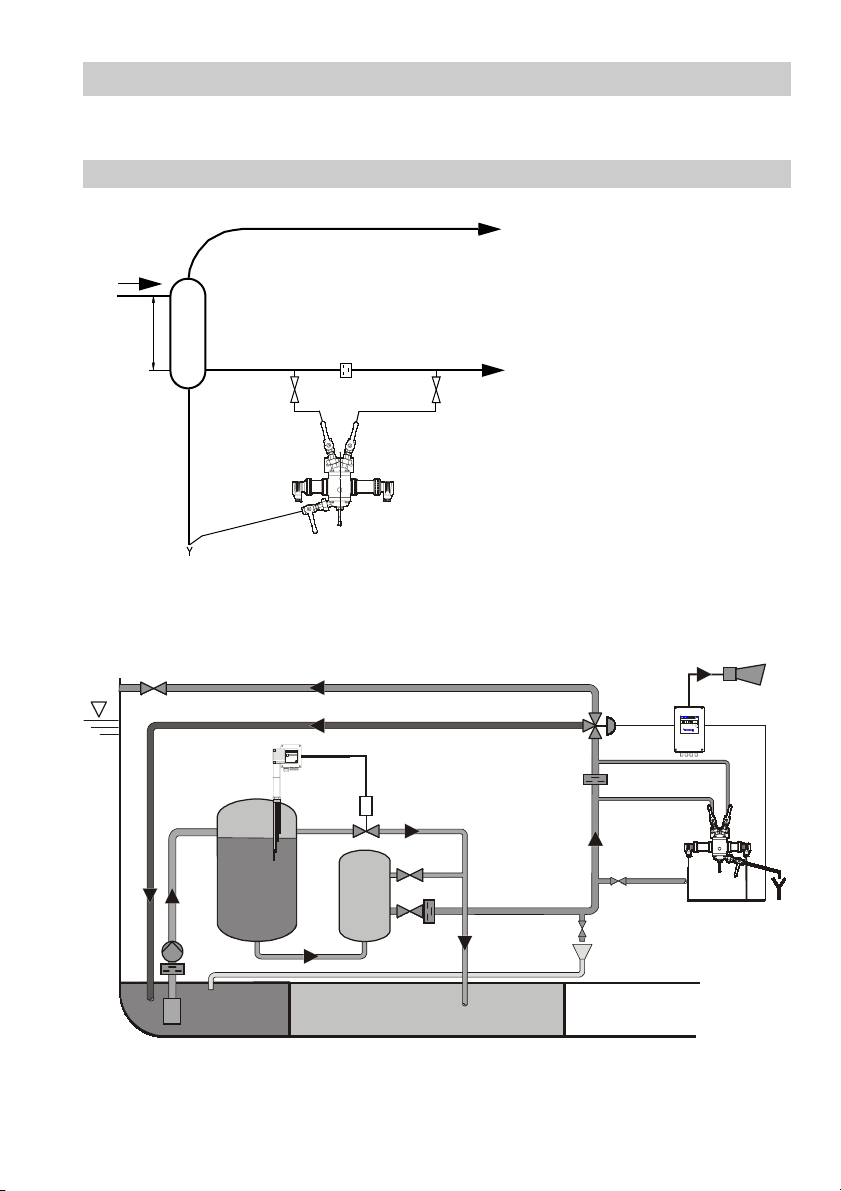

Wiring Diagram ORG 12, ORG 22, ORT 6

0/4–20mA

R≤500

continued

Measuring sensor ORG...

Measuring transducer ORT 6

Ω

Fig.10

S

D

Alarm2 Alarm1

L

Malfunction

Earthing screw

in housing

LN

Disconnecting

switch

PE L N

19

Page 20

Wiring

Wiring Diagram ORG 12, ORG 22, ORT 6 with three-way valve

continued

0/4–20mA

Ω

R≤500

Measuring sensor ORG...

Measuring transducer ORT 6

S

D

L

Valve OPEN: Fluid flowing

through

Valve CLOSED: Fluid is

discharged or

retained

Fig.11

20

Alarm2 Alarm 1

A

Malfunction

PE L N

Z

LN

Disconnecting

switch

Earthing screw

in housing

L

N

Page 21

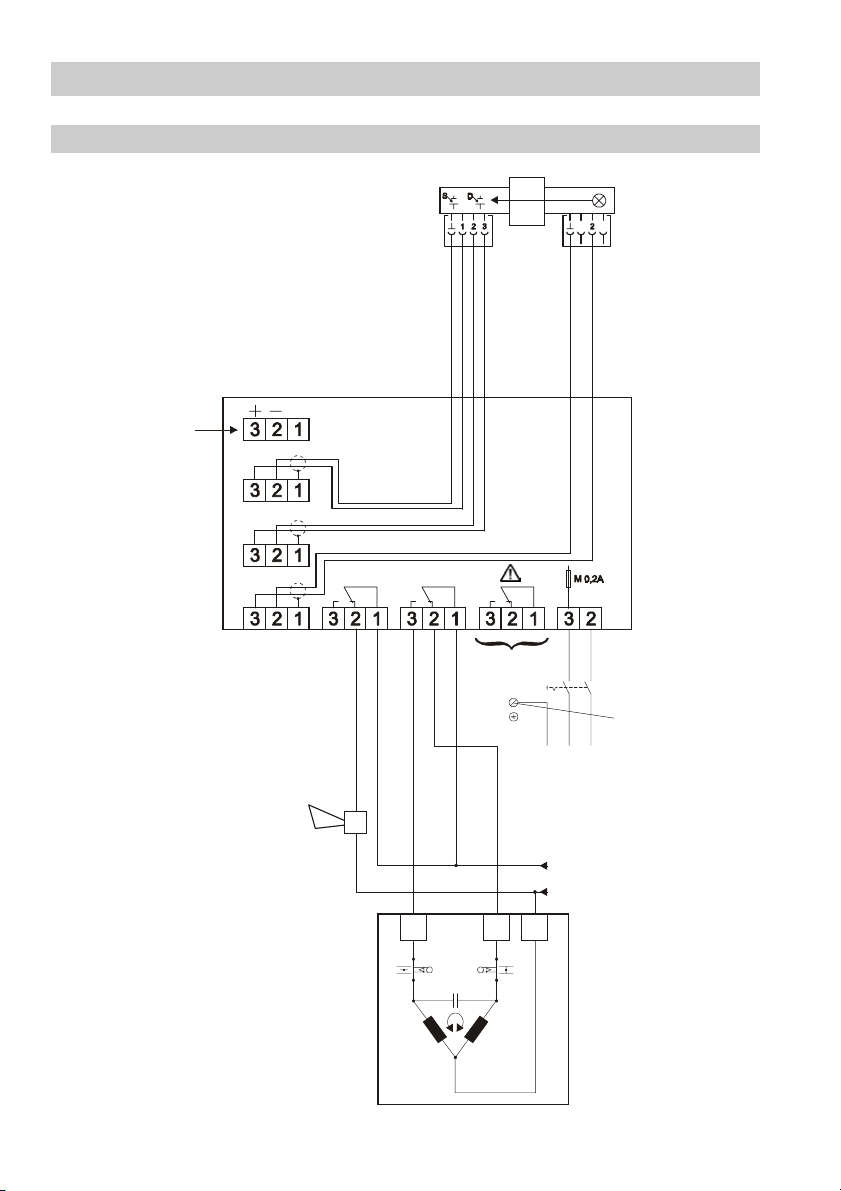

Functional Elements

Measuring Transducer

Seven-

Unit LED

segment

display

OIL

ppm

sec

cal

0

Calibration LED

ALARM

12

Malfunction LED

(yellow)

Yellow P-LED

P

E

Test

The push buttons have the following functions:

P

= Program

= Increase

= Decrease

E

= Enter/Test mode

Partial view of base plate Partial view of front plate

L4

LEDdisplay

Operating

voltage

1

= + 5V

LED1

R16

2K7

L

LED2

LED3

2

= +12V

L

R17

R18

3

= Lamp

L

6K8

6K8

Code switch 7 for

decimal point

ON = with decimal point

OFF = without decimal point

P10

DHL-016- S100-11

Wire link 2 for actual

value output

with wire link: 0-20mA

without wire link: 4-20mA

10uH

L3

10uH

L2

10uH

L1

10uH

S5

1

on

2

34

5

678910

SDIX-10-XS

JP2

JP1

Factory setting: with wire link 1

P1

21

Page 22

Commissioning Procedure

Factory set default values

The measuring transducer features the following factory settings:

Limit value: Alarm 1: 3 ppm

Limit value: Alarm 2: 5 ppm

Delay of response: Alarm 1: 1 sec.

Delay of response: Alarm 2: 1 sec.

Actual value output: wire link 2 established = 0 - 20 mA

Seven-segment display without decimal point

Warning

The terminal strips of the measuring transducer are live during operation.

This presents the risk of electric shock.

Cut off power supply before opening the housing lid!

Before commissioning rinse the measuring sensor. Do not use caustic

agents for flushing unless the use of such agents is explicitly permitted by

the manufacturer.

22

Note

Adjust two different limit values if you want to use for instance alarm

contact 1 for a first alarm and alarm contact 2 for the main alarm.

For condensate and bilge water monitoring alarm contact 1 can then be

used to control a three-way valve, which will discharge the unusable

condensate if the level of turbidity is too high (alarm caused by ingress of

oil or start-up protection). Alarm contact 2 will trigger the main alarm / shutdown.

Valves with single-phase A.C. motor, max. power rating 50 VA (see wiring

diagram on page 20, fig. 11) can be connected directly. If a three-phase

actuator is used fit a reversing contactor in between. Pneumatically

operated valves can be controlled via solenoid valves.

Page 23

Commissioning Procedure

continued

First Commissioning

1. Switch on measuring transducer

(disconnecting switch).

2. Rinse measuring transducer ORG 12/22 for at

least 15 minutes and operate cleaning device

H

if necessary.

3. Make sure that the ORG 12/22 is completely free of

OIL

ppm

cal

sec

0

ALARM

12

air. For visual inspection undo union nuts (inside) and

remove light receiver . When screwing the light

receiver in again make sure that the locating pin

D

P

E

Test

fits exactly in the corresponding groove at the front

collar of the light receiver .

D

0% Calibration

Use tap water (with low fluid temperature) or oil-free condensate as turbidity zero.

1. Press until yellow P-LED lights up.

P

2. Use to change the LED display until the

calibration LED 0 lights up. The calibration value

(digits) saved last will be indicated.

3. Press , the yellow P-LED and the 7-segment

P

display are flashing.

4. Press , the 0 % value is saved as basic turbidity.

E

The P-LED and the 7-segment display are illuminated.

If the basic turbidity is too high an error message

OIL

P

ppm

cal

sec

0

ALARM

12

E

Test

will pop up.

5. Press , the equipment returns to normal operation, 0 ppm is indicated and the LED

E

for ppm is illuminated.

To cancel press twice, the yellow P-LED will light up again.

P

23

Page 24

Commissioning Procedure

100% Calibration

continued

Fit turbidity standard 20 ppm supplied with the equipment to the light emitter .

Unscrew union nut (inside) from tube and remove light emitter from housing of

the sightglass. Place turbidity standard on black tube so that the screen fitted in

the standard is exactly congruent with the screen of the tube . Screw in light emitter

Q T R

, making sure that the locating pin of the housing fits into the groove of the tube .

S R

S R

R Q T

S R

Tighten union nuts (inside).

Make sure that the liquid used for the calibration of the zero point stays in the glass

cylinder.

Further adjustments of the measuring transducer:

1. Press , the yellow P-LED lights up.

2. Press to change the LED display until the

3. Press , the yellow P-LED and the 7-segment display

P

calibration LED cal lights up. The calibration value

(digits) saved last will be indicated.

P

ppm

OIL

cal

sec

0

ALARM

12

are flashing.

4. Press , the 100 % value is saved. The P-LED and

E

P

E

Test

the 7-segment display are illuminated.

5. Press , the equipment returns to normal operation, 20 ppm is indicated and the LED

E

for ppm is illuminated.

To cancel press twice, the yellow P-LED will light up again.

P

Remove turbidity standard from measuring transducer and store carefully. Make sure that

it cannot be scratched.

24

Page 25

Commissioning Procedure

continued

Oil / Turbidity Curves

A light beam shines through the liquid and any foreign matter which is not dissolved scatters the beam. The scattered light intensity increases in proportion to the concentration

of suspended particles, the degree of turbidity depending on:

size of the particles (degree of emulsification)

shape and composition of the particles

optical properties of the particles

In the case of oils, fats and greases the degree of emulsification is a decisive factor.

Different suspended particles in the fluid

Indication [ppm]

2

25

345

20

15

10

5

2 4 6 8 10 12 14 16 18 20

Concentration [µl/l] = [ppm]

1

Fuel oil EL, 15°C, coarse emulsification Xylene, 80 °C, fine emulsification

2

Fuel oil EL, 15°C, fine emulsification Red-berry juice, concentrated

3 9

Fuel oil EL, 80°C, fine emulsification Black-berry juice, concentrated

4

Engine oil (medium), 15

fine emulsification

5

Vegetable oil, 15°C fine emulsification Turbine oil T68, gear oil M 68

6

Xylene, 20°C, fine emulsification

°C,

7

8

10

Skimmed milk, fat content 0.1% referred

to fat concentration

11

11

1

10

8

6

9

7

25

Page 26

Commissioning Procedure

Adjusting Limit Alarm 1

continued

1. Press , the yellow P-LED lights up.

P

2. Use to change the LED display until LED Alarm 1

and LED ppm light up. The value saved last is shown.

3. Press , the yellow P-LED and the second digit of the

P

7-segment display are flashing.

4. Use to change the digit, press to save the

E

OIL

ppm

cal

sec

0

ALARM

12

setting and move to the third digit. The third digit is

now flashing.

5. Use to change the digit, press to save the

E

P

E

Test

setting. The P-LED and the 7-segment display are

illuminated. A limit value of max. 15 ppm can be adjusted.

6. Press , the equipment returns to normal operation, the actual value is indicated and

E

the LED ppm is illuminated.

Adjusting Limit Alarm 2

1. Press , the yellow P-LED lights up.

P

2. Use to change the LED display until LED Alarm 2

and LED ppm light up. The value saved last is shown.

3. Press , the yellow P-LED and the second digit of the

P

7-segment display are flashing.

4. Use to change the digit, press to save the

E

OIL

ppm

cal

sec

0

ALARM

12

setting and move to the third digit. The third digit is now

flashing.

5. Use to change the digit, press to save the

E

P

E

Test

settings. The P-LED and the 7-segment display are

illuminated. A limit value of max. 15 ppm can be adjusted.

6. Press , the equipment returns to normal operation, the actual value is indicated and

E

the LED ppm is illuminated.

26

Page 27

Commissioning Procedure

Adjusting time delay for alarm 1

continued

1. Press , the yellow P-LED lights up.

P

2. Use to change the LED display until LED Alarm 1

and LED ppm light up. The value saved last is shown.

3. Press , the yellow P-LED and the second digit of the

P

7-segment display are flashing.

4. Use to change the digit, press to save the

E

OIL

ppm

cal

sec

0

ALARM

12

setting and move to the third digit. The third digit is

now flashing.

5. Use to change the digit, press to save the

E

P

E

Test

setting. The yellow P-LED and the 7-segment display

are illuminated. A max. time delay of 20 sec. can be adjusted.

6. Press , the equipment returns to normal operation, the actual value is indicated and

E

the LED ppm is illuminated.

Adjusting time delay for alarm 2

1. Press , the yellow P-LED lights up.

P

2. Use to change the LED display until LED Alarm 2

and LED ppm light up. The value saved last is shown.

3. Press , the yellow P-LED and the second digit of the

P

7-segment display are flashing.

4. Use to change the digit, press to save the

E

OIL

ppm

cal

sec

0

ALARM

12

setting and move to the third digit. The third digit is

now flashing.

5. Use to change the digit, press to save the

E

P

E

Test

setting. The yellow P-LED and the 7-segment display

are illuminated. A max. time delay of 20 sec. can be adjusted.

6. Press , the equipment returns to normal operation, the actual value is indicated and

E

the LED ppm is illuminated.

27

Page 28

Commissioning Procedure

continued

Indicating decimal point

The 7-segment display can show a decimal point.

This setting does not have any effect on the adjusted limit

values and time delays.

Cut off power supply!

OIL

Decimal point

ppm

sec

cal

0

Open housing lid of the measuring transducer and set code switch 7 on lid plate to ON.

Setting actual value output

The actual value output can be changed from 0–20 mA to 4–20 mA.

Cut off power supply!

Open the housing lid and remove wire link 2 from the lid plate.

Wire link 2 set: actual value output 0–20 mA

Wire link 2 removed: actual value output 4–20 mA

Danger

The terminal strips of the measuring transducer are live during operation.

This presents the risk of severe injuries due to electric shock. Cut off

power supply before opening the housing lid.

28

Page 29

Operation

Start

Apply power.

The 7-segment display shows briefly the version number

of the software.

Then the indicator counts until the actual value is

reached.

The LED ppm is illuminated.

Alarm 1 and 2

When the limit value for alarm 1 or 2 is exceeded the

adjusted time delay is activated. The LED alarm 1 or

LED alarm 2 is flashing.

After the time delay has elapsed LED alarm 1 or LED

alarm 2 will light up.

The relay contact for alarm 1 or 2 opens.

Note

When the limit values are exceeded the measuring transducer will not

interlock automatically. If the installation requires a lockout function, the

latter must be implemented in the sequence circuit (burner protection

circuit). This circuit must comply with the requirements of the DIN VDE

0116 regulations.

ppm

OIL

OIL

cal

sec

0

ALARM

12

ppm

cal

sec

0

ALARM

12

29

Page 30

Maintenance

Functional Test

1. Push cleaning device slowly into mid-position to simulate a malfunction.

H

2. The LED "Malfunction" lights up and the relay contact "Malfunction" opens.

First error code E 03 is indicated and then error code E 08.

3. Push cleaning device back to its initial position.

H

The equipment must return to normal operation.

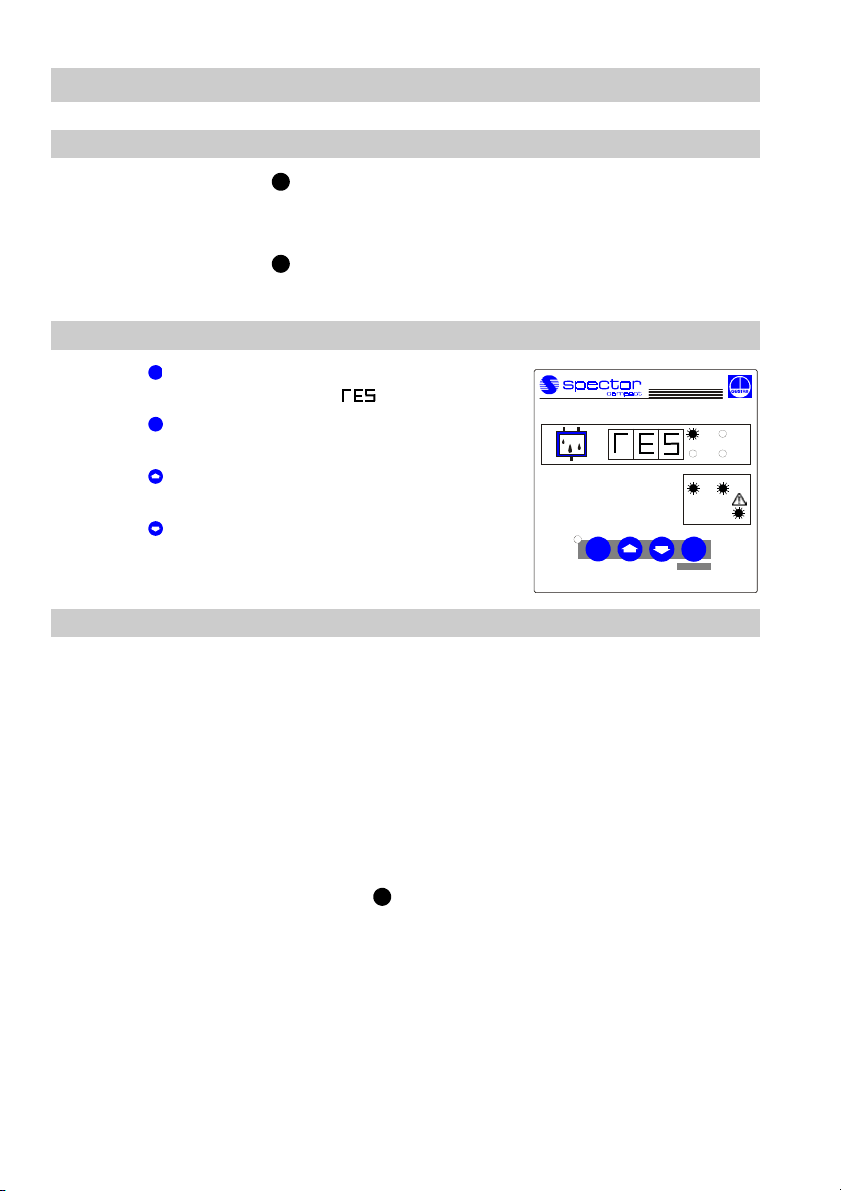

Functional Test Relay Alarm 1, Alarm 2 and Malfunction

1. Press briefly to activate the test mode for 10 sec.

E

The 7-segment display shows .

2. Press . While the button is held down LED Alarm 1

P

lights up and relay contact Alarm 1 opens.

OIL

3. Press . While the button is held down LED Alarm 2

lights up and relay contact Alarm 2 opens.

4. Press . While the button is held down the LED

Malfunction lights up and the relay contact Malfunction

P

opens.

Malfunctions

1. The measuring transducer does not work – no function, no display

Fault: Equipment fuse defective.

Remedy: Replace equipment fuse with a new one. Check power supply.

Fault: Power failure. Not all three green LEDs on the base plate are

illuminated at the same time.

Remedy: Check power supply or replace measuring transducer.

2. Measured value increases steadily by 1 ppm per day (or slower) –

ingress of foreign matter can be ruled out

Fault: Growing contamination of glass cylinder.

Remedy: Operate cleaning device more often.

H

ppm

cal

sec

0

ALARM

12

E

Test

30

Page 31

Maintenance

continued

Indication of Error Code

In the event of a malfunction the yellow LED Malfunction

lights up, the relay output Malfunction opens and the

7-segment display indicates the error code.

The raising of an alarm is not effected by a malfunction.

ppm

OIL

cal

sec

0

ALARM

12

Error Code Table

Error code

E01

P

E

Test

Possible reason Remedy

Q

Glow lamp in light emitter

contaminated

Glass cylinder contaminated Clean or replace glass cylinder

U U

Turbidity of fluid too high

Replace glow lamp

Provide mechanical cleaning stage

ahead of equipment

Operating voltage too low Check supply voltage

Cleaning device not in its initial

H H

position

Ingress of solids

Return cleaning device to its

initial position

Provide mechanical cleaning stage

ahead of equipment

31

Page 32

Maintenance

continued

Error Code Table

Error code

E03

Error code

E05

continued

Possible reason Remedy

Glow lamp in light emitter

defective. A frequent occurrence

of this problem indicates heat

accumulation in light emitter

(despite fluid temp. > 60 °C

Q

Replace glow lamp. Remove

Q

drying cartridge and install

vent nipple

G

F

drying cartridge mounted)

Cable connection to light

Q

emitter interrupted

Cleaning device not in its

H H

initial position

Ingress of solids

Check connecting cables

Return cleaning device to its

initial position

Provide mechanical cleaning stage

ahead of equipment

Possible reason Remedy

Basic turbidity > 10 ppm

Glass cylinder scratched

U

(ingress of solids)

Glass cylinder contaminated Clean or replace glass cylinder

U U

Provide mechanical cleaning stage

ahead of equipment

Replace glass cylinder .

U

Install sensor acc. to installation

example fig. 3

Error code

E06

32

Ingress of solids

Presence of gas or steam

bubbles (flashing)

Provide mechanical cleaning stage

ahead of equipment

Throttle outlet

Possible reason Remedy

Light receiver defective or

incorrectly connected.

D D

Replace light receiver or check

connecting cables

Measuring transducer defective Replace measuring transducer

Page 33

Maintenance

continued

Error Code Table

Error code

E08

continued

Possible reason Remedy

Glow lamp or light emitter

Q

defective.

Connection to light receiver /

Q

emitter interrupted

Cleaning device not in its initial

H H

D

position

Ingress of solids

Replace glow lamp

Check connecting cables

Return cleaning device to its

initial position

Provide mechanical cleaning stage

ahead of equipment

Once the fault is eliminated the equipment will return to normal operation.

Replacing Glass Cylinder

1. Close ball valves for inlet and outlet. Open ball valve for rinsing .

2. Slacken (but do not remove) the eight hexagon head screws . Insert the cleaning

device into the housing (for fitting pull out the cleaning device as shown on

H T

page 14, fig. 3), unscrew the four hexagon head screws on top and remove the

housing .

T

3. Pull out the cleaning device and remove the glass cylinder . If the equipment

has not been used for a longer period of time, the glass cylinder might be stuck

due to dirt accumulated on the upper cover flange .

4. Check whether housing , upper cover flange and lower flange are completely

dry inside. If not, dry housing with compressed air as any moisture remaining in

the housing would lead to the glass cylinder becoming covered with mist when

B E

I

I

H U

U

C

T C J

T

U

cold fluids are used and this would lead to faulty measurements.

5. Undo the four hexagon head screws at the bottom.

6. Take out the O-rings , clean seating surfaces and insert new

O-rings .

V W X

V W X

7. Hold new and dry glass cylinder at the rim and push it over the seat of the

upper cover flange .

8. Attach the housing to the upper cover flange using screws .

9. Insert the plunger of the cleaning device into the glass cylinder and screw

the lower flange to the housing .

10. Close ball valve for rinsing , open ball valves for inlet and outlet.

C

T C I

K H U

J T

E B

I

U

Check 0 % and 100 % settings of the measuring transducer.

33

Page 34

Maintenance

continued

Cleaning Glass Cylinder

1. Move ring of the cleaning device up and down. Note that dependent on the

L H

adjusted time delay Alarm 1 and/or Alarm 2 may be triggered off.

2. Move ring of the cleaning device back to its initial position (operating bar

L H

protrudes approx. 70 mm from the sightglass). If the glass cylinder is very

contaminated replace the wiping ring of the cleaning device .

Clean glass cylinder at regular intervals - at least once a week, dependent on the de-

U

gree of contamination of the fluid. Replace glass cylinder if it is strongly contaminated.

L H

U

Replacing Cleaning Plunger

1. Close ball valves for inlet and outlet. Open ball valve for rinsing .

2. Pull out cleaning device and unscrew the four hexagon head screws of the

lower flange . Remove lower flange with cleaning device .

B E

H I

J J H

3. Use screwdriver for bending open the inside serrations of the fixing disc and remove

the fixing disc.

4. Take out plunger and insert new plunger .

K K

5. Mount new fixing disc. Make sure that the serrations point in the opposite direction

of the plunger .

6. Remove O-rings from the lower flange, clean seating surfaces and insert

new O-rings .

7. Push plunger of the cleaning device into the glass cylinder and screw lower

flange firmly to housing .

8. Close ball valve for rinsing , open ball valves for inlet and outlet.

K

V W X

V W X

K H U

J T

E B

9. Check 0 % and 100 % settings of the measuring transducer.

Replacing Drying Cartridge

Replace drying cartridge when its content turns pink. Should this happen too often

G

check the following items for tightness;

O-rings at light emitter and receiver

Gaskets at connectors , front gaskets of glass cylinder

Cable glands at connectors of light emitter and receiver

Q H

P U

P Q D

34

Page 35

Maintenance

continued

Replacing Glow Lamp

1. Unscrew and remove union nut (outside) of tube of light emitter .

R Q

2. Replace glow lamp (12 V 10 W) with a new one.

3. Fit light emitter . Take care that the locating pin of the light emitter fits the groove

provided on the tube . Tighten union nut.

Q Q

R

4. Repeat calibration of zero point (0 %) and measuring range (100 %) at measuring

transducer.

Replacing Equipment Fuse

1. Open housing cover of the measuring transducer.

2. Turn fuse carrier to the left and take it off.

3. Replace equipment fuse with a new one:

Type (anti-surge) 0.2 A 5x20 at 230 V, (anti-surge) 0.4 A 5x20 at 115 V, (anti surge)

M 1.0 A 5x20 at 24 V.

4. Fit fuse carrier in place and turn it to the right. Close housing cover.

Warning

The terminal strip of the measuring transducer is live during operation.

This presents the danger of severe injuries due to electric shock.

Cut off power supply before opening the housing cover.

Tools

Spanner for hexagon head screws, A. F. 13

Screwdriver for slotted head screws, size 2.5

35

Page 36

Maintenance

continued

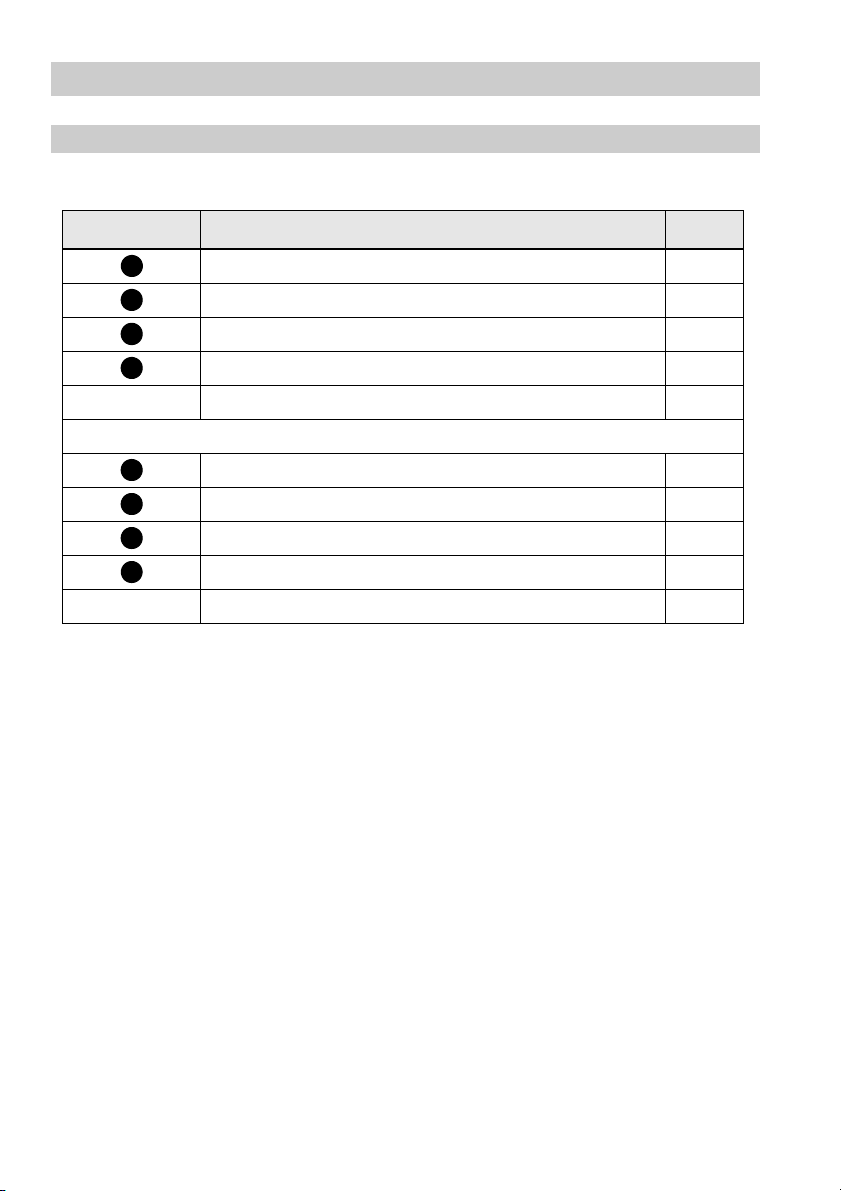

Spare Parts

A spare parts kit containing the following items is available on request:

Item

U

V

W

X

K

M

L

N

Designation Qty.

Glass cylinder 1

O-ring 25x 3 2

O-ring 30x 2 2

O-ring 37x 2 4

Glow lamp 2

For cleaning device

Plunger 1

Ring 1

Cleaning ring (wiper) 1

Retaining ring 19x 1.2 1

Fixing disc 1

36

Page 37

Annex

Declaration of Conformity

37

Page 38

Annex

continued

Declaration of Conformity

continued

38

Page 39

Annex

continued

Declaration of Conformity

continued

39

Page 40

Annex

Certificate of Type Approval

continued

40

Page 41

Annex

continued

Certificate of Type Approval

continued

41

Page 42

Annex

continued

Certificate of Type Approval

continued

42

Page 43

Annex

continued

Certificate of Type Approval

continued

43

Page 44

Annex

Type Approval Certificate

continued

44

Page 45

Annex

Updates

continued

Index

00 New installation manual 04-08-2003

Description Date

45

Page 46

46

Page 47

47

Page 48

GESTRA Gesellschaften • GESTRA Companies • Sociétés GESTRA • Sociedades Gestra • Società GESTRA

Vertretungen weltweit • Agencies all over the world • Représentations dans le monde entier • Representaciones en todo el mundo • Agenzie in tutto il mondo

Great Britain

Flowserve Flow Control (UK) Ltd.

Burrel Road, Haywards Heath

West Sussex RH 16 1TL

Tel. 00 44 14 44 / 31 44 00

Fax 00 44 14 44 / 31 45 40

E-mail: sales@flowserve.com

France

Flowserve Flow Control S.A.S.

10 Avenue du Centaure, BP 8263

F-95801 CERGY PONTOISE CEDEX

Tél. 0 03 31 / 34 43 26 60

Fax 0 03 31 / 34 43 26 87

E-mail: gnation@flowserve.com

España

GESTRA ESPAÑOLA S.A.

Luis Cabrera, 86-88

E-28002 Madrid

Tel. 00 34 91 / 5 152 032

Fax 00 34 91 / 4 136 747; 5 152 036

E-mail: gestra@gestra.es

Italia

Flowserve S.p.A.

Divisione Italgestra

Via Prealpi, 30 – 20032 Cormano (MI)

Tel. 00 39 02 / 66 32 51

Fax 00 39 02 / 66 32 55 60

E-mail: info@italgestra.it

Portugal

Flowserve Portuguesa, Lda.

Av. Dr. Antunes Guimarães, 1159

Porto 4100-082

Tel. 0 03 51 22 / 6 19 87 70

Fax 0 03 51 22 / 6 10 75 75

E-mail: gestra@gestra.pt

GESTRA

®

P.O.Box 10 54 60, D-28054 Bremen, Münchener Str. 77, D- 28215 Bremen

Telephone +49 (0) 421 35 03-0, Fax +49 (0) 421 35 03-393

E-Mail gestra.gmbh@flowserve.com, Internet www.gestra.de

An Unit of Flowserve Corporation

810731-01/903c · © 2003 GESTRA GmbH · Bremen · Printed in Germany

GmbH

Loading...

Loading...