Page 1

OR 42

OR 52

Installation Instructions 810476-00

GESTRA Oil and Turbidity Detector

1

Page 2

OR 42, OR 52

N

∅ 6

1

2

5 4

6 7 8 9 10

3

220 V

231

P

∅ 6

121

151

95

O

N

19 17 15 13 11

18 16 14 12

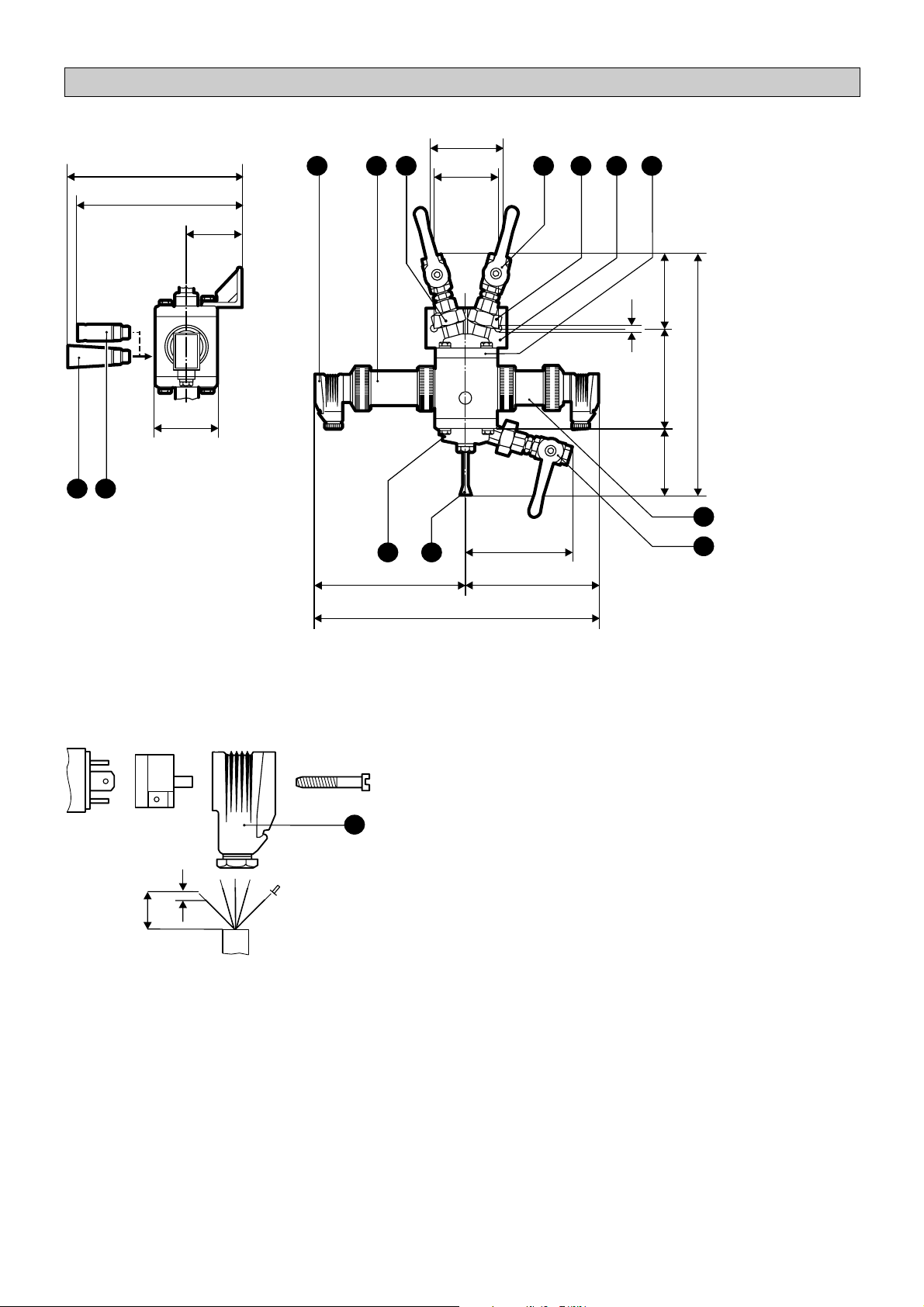

Fig. 1

2

310

220 V

P

7

180

230

110

O

Page 3

OR 42, OR 52

≈85

M L

Fig. 2

140

135

78

70

CBA D E F G

K J

80

135

175200

375

≈90≈125100

7

315

H

I

Fig. 3

A

5

40

3

Page 4

OR 42, OR 52

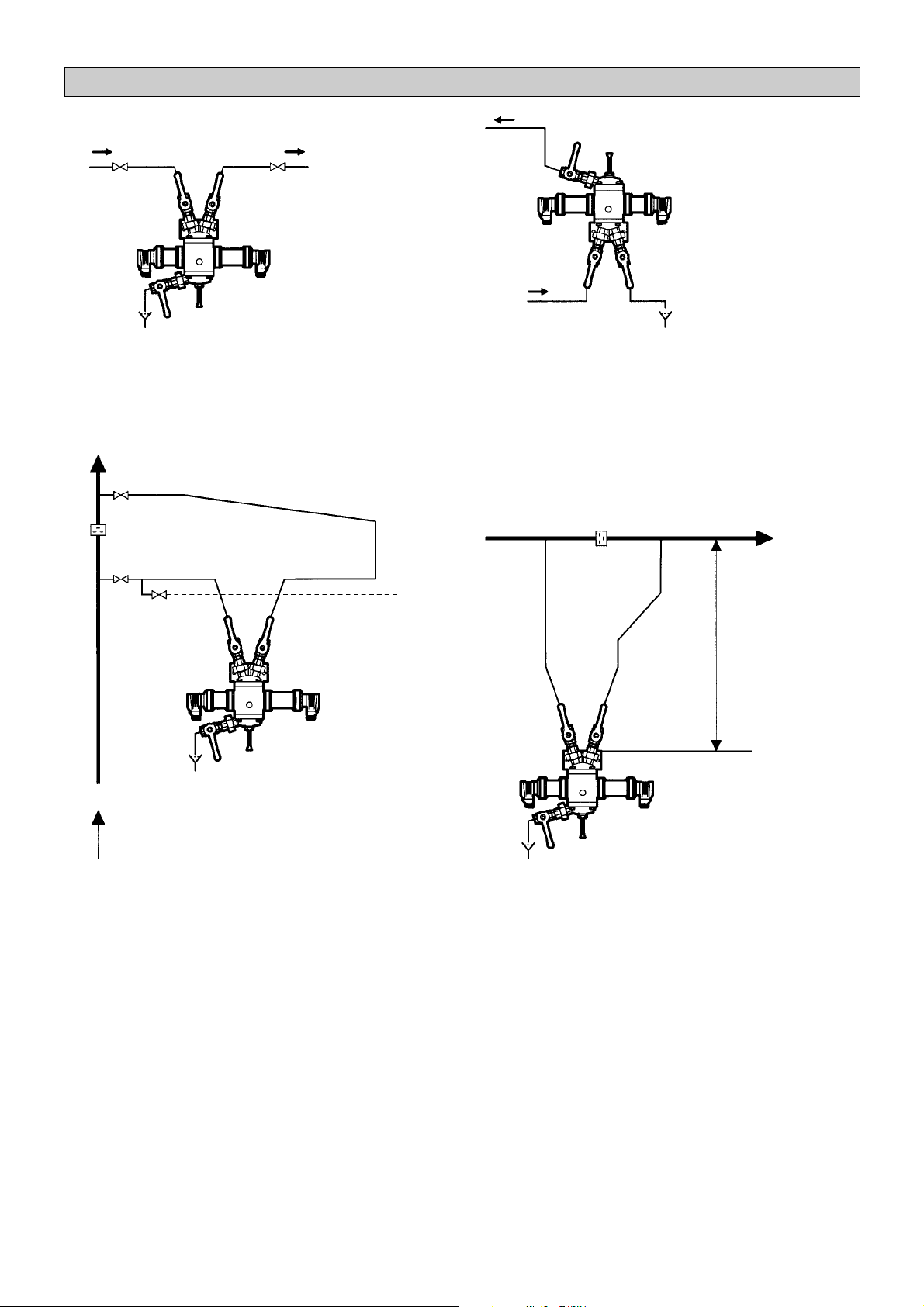

Fig. 4 Fig. 5

*)

H ≥ 500

Fig. 6 Fig. 7

*) T ap product line at the side (angle of 45°) from the bottom to pre vent air and dirt from flowing into the

bypass.

4

Page 5

OR 42, OR 52

DN 100-300

H ≥ 250

Fig. 8

Fig. 9

5

Page 6

OR 42, OR 52OR 42, OR 52

OR 42, OR 52

OR 42, OR 52OR 42, OR 52

Netz

Mains

Secteur

Red

Rete

Netz

Mains

Secteur

Red

Rete

0 – 20 mA

R ≤ 500Ω

Tv = 0

0 – 1 mA

R ≤ 120Ω

Fig. 10 Fig. 1 1

A

[ppm][TE/F]

25

20

15

10

5

2 4 6 8 10 12 14 16 18 20 2 4 6 8 10 12 14 16 18 20

4

5

3

2

[µl/l] = [ppm]

1

B

A

50

40

30

20

10

Fig. 12 Fig. 1 3

10

8

6

9

7

B

[µl/l] = [ppm]

6

Page 7

ENGLISH

Important Safety Note

Use oil and turbidity detector OR 42/OR 52

only for monitoring of transparent liquids to

detect any ingress of insoluble and

refracting foreign matter, for measuring of

turbidity and signal evaluation for indication

and recording as well as for tripping of

alarms, control valves etc.

The equipment must only be installed by

qualified staff.

Before installing the oil and turbidity detector

cut off power supply.

All repairs must be performed only by the

manufacturer. Misuse or any attempted

modification of the equipment will endanger

plant safety.

Warning

The terminal strip of the ORT4/ORT5 is live

during operation. This presents the danger

of electric shock. Cut off power supply

before opening the equipment or

undertaking any maintenance work

Purpose

The oil and turbidity detector OR 42/OR 52

consists of the sensor ORG 12/ORG 22

and the measuring transducer ORT 4/

ORT 5.

Application:

■

In steam boiler plants: Monitoring of

condensate returned to the boiler for oil

and grease contamination, in particular

for boilers operating without constant

supervision acc. to TRD 604 (2 detectors

are required for 72 h operation)

■

For raw-water monitoring and water

treatment (sand filters, demineralization

plants, reverse-osmosis plants)

■

For waste-water monitoring

■

In breweries and the beverage industry

(filtration, monitoring of wort, quality

assurance etc.)

■

For salad oil production: Monitoring of

filtering process

■

For marine applications: Monitoring of

filtering equipment in accordance with

IMO (International Maritime Organization)

resolution MEPC.60(33) – when certain

cold cleaning agents that split up easily

are used which cannot form stable water/

oil emulsions

Types

Turbidity Detector Transducer Sensor

OR 42/3 ORT 4 ORG 12

OR 42/4 ORT 4 ORG 22

OR 52/3 ORT 5 ORG 12

OR 52/4 ORT 5 ORG 22

Design

■

With three ball valves, three screwed

unions and screwed-in vent nipple

■

Drying cartridge and turbidity standard

20 ppm (OR 52: also turbidity standard

40 TU/F*) are also supplied

■

Spare parts kit separately available, see

“Spare Parts”

*) TU/F = turbidity units of Formazin suspension

Operation

The oil and turbidity detector measures the

intensity of the scattered light produced by

foreign matter that is not dissolved in transparent liquids and exposed to incident light,

with emulsified oils scattering incident light

mainly in the forward direction.

In the oil and turbidity detector the forward

scattered-light principle is applied which

provides a high sensitivity for emulsified

greases and oils and other organic matter.

Tec hnical Data ORG

Approvals

■ Feedwater monitoring

TÜV – approval no. 09-96-0132

■ Feedwater monitoring in marine

applications GL 94855-94 HH

Seeberufsgenossenschaft

GL-OG-94-352002

■ 15 ppm oil detector for bilge monitoring in

engine rooms

GL 85486-94 HH

Seeberufsgenossenschaft

320023

Nominal size

DN 10, connections

BSP to DIN ISO 228

Nominal pressure

PN 10

Flowrate

0.5 ... 50 l/min

3

/8"

Light emitter

At a flowrate of 2 l/min and V-shaped flow

through the sensor with a pipe length of 1 m

(DN 10 mm) and four bends: approx. 5 mbar

(ζ = 6.1)

Fluids

Water, condensate, drinks etc.

pH value

Up to 10.5 (a pH value of 11 and above will

lead to wear of the glass, depending on the

temperature)

Fluid temperature ranges

0 ... 60°C with drying cartridge

60 ... 120°C with vent nipple

Protection

IP 65

Max. ambient temperature

60°C

Materials ORG 12 ORG 22

Cover flange GG-25 1.4580

Wetted parts 0.6025 1.4580

galvanized

Ball valves Ms 58 1.4436

Screwed unions St 1.4571

Glass cylinder Duran 50 Duran 50

O-rings EPDM EPDM

Housing 0.6025 0.6025

galvanized galvanized

Cleaning disc EPDM EPDM

Light emitter

Glow lamp 12 V/10 W BA 15 s

cable connection via 4 pole connector

Light receiver

Two silicon photo-electric cells,

cable connection via 4 pole connector

Approx. weight

6.8 kg

Dimensions

See Fig. 2

Spare Parts

The spare parts kit for OR contains:

Designation Number

Glass cylinder 1

O-ring 25 x 3 2

O-ring 30 x 2 2

O ring 37 x 2 4

Glow lamp 2

For cleaning unit:

Cleaning plunger 1

Ring 1

Cleaning disc 1

Retaining ring 19 x 1.2 1

Fixing disc 1

7

Page 8

Tec hnical Data ORT

ORT 4 ORT 5

Wiring 3 cable glands with integral cable clamps PG 11, 3 cable glands with integral cable clamps PG 11,

Mains supply 230 V ± 10 %, 50/60 Hz 230 V ± 10 %, 50/60 Hz

Fuse Thermal fuse M 0.1 A Thermal fuse M 0.2 A

Power consumption 15 VA 25 VA

Measured quantity Turbidity Turbidity

Measuring range 0 – 25 ppm Range I: 0 – 50 TU/F*)

Lamp voltage for light emitter No-load voltage 14 V No-load voltage 14 V

Actual-value output 0 – 1 mA 0 – 20 mA (option 4 – 20 mA)

Output 1 volt-free relay contact 2 volt-free relay contact

Switchpoint Adjustable over complete measuring range Adjustable over complete measuring range

Delay of response 0 s with external wire linke, 10 s 0.5 – 15 min. adjustable, see name plate

Indicators and adjustors 1 LED

Protection IP 54 to DIN 40050 IP 65 to DIN 40050

Max. admissible ambient 0 – 55°C 0 – 55°C

temperature

Housing material Sheet steel, hammer enamel finish Die-cast aluminium, blue enamel finish

Weight 1.6 kg 5.4 kg

Dimensions See Fig. 1 See Fig. 1

*) TU/F = turbidity units of Formazin suspension, ppm = parts per million

screw-type terminals with wire guard, screw-type terminals with wire guard,

max. conductor size 1.5 mm² max. conductor size 1.5 mm²

115 V ± 10 %, 50/60 Hz (option) 115 V ± 10 %, 50/60 Hz (option)

124 V ± 10 %, 50/60 Hz (option) 124 V ± 10 %, 50/60 Hz (option)

Rated voltage see name plate Rated voltage see name plate

Measuring range see name plate Range II: 0 – 25 ppm*)

Measuring range see name plate

with light emitter connected: < 12 V AC, 10 W with light emitter connected: < 12 V AC, 10 W

load 0 ... 120 Ω load 0 ... 500 Ω

Max. contact rating with a switching Max. contact rating with a switching

voltage of 24/115/230 V AC: voltage of 24/115/230 V AC:

resistive 4 A, inductive 0.75 A at cos ϕ = 0.5 resistive 4 A, inductive 0.75 A at cos ϕ = 0.5

Max. contact rating with a switching Max. contact rating with a switching

voltage of 24 V DC: 4 A voltage of 24 V DC: 4 A

Life or relay: 10 x 10

6

switching cycles Life of relay: 10 x 106 switching cycles

Contact material: AgCdO 5 µ hard-gold plated Contact material: AgCdO 5 µ hard-gold plated

without wire link, see name plate

ALARM, 1 LED OPERATION, 1 LED ALARM (INSTANTANEOUS), 1 LED ALARM (DELAYED),

1 LED

MALFUNCTION, 1 potentiometer for switchpoint, 1 LED OPERATION, 1 LED MALFUNCTION,

2 potentiometers for adjustment 0/100 % 1 LED analogue display

RESOLUTION 3 %,

1 potentiometer for switchpoint,

2 potentiometers for adjustment 0/100 %,

1 potentiometer for adjustment of delay of response,

1 change-over switch for measuring range I/II,

1 change-over switch for switchpoint/measured value

Installation

ORG 12/ORG 22

Install and wire ORG 12/ORG 22 in

accordance with the examples given in

figures 4 to 9.

Mount ORG 12/ORG 22 in a bypass at a

lower level than the main line so that any air

and flash steam can pass through the main

line.

To ensure a flow through the bypass a

throttling point should be provided in the

main line, e. g. GESTRA non-return valve

type RK 66.

Tap product line at the side from the

bottom to prevent air and dirt from

flowing into the bypass.

Any pressure drop upstream of the sensor

which might lead to the release of gases or

to flashing must be avoided.

8

Screw in vent nipple when the fluid

L

temperature is above the max. ambient

temperature (Fig. 2).

When the fluid temperature is below the

ambient temperature remove the plastic lid

from the drying cartridge (blue colour)

M

and screw in the drying cartridge. (Fig. 2)

If the fluid temperature is very high provide

a non-insulated pipe upstream of ORG 12/

ORG 22 which will allow the fluid to cool

down to 120 °C when reaching the sensor.

The second inlet at the lid must be open

for the rinsing water or the calibrating fluid.

In the presence of large amounts of gas

the tapping point must be at the bottom of

the line – use a welding pocket in

accordance with DIN 2618 (Fig. 7, Pos.*)

In the case of very contaminated

condensate: downward flow of the fluid

through the glass cylinder

If the condensate contains suspended

solids (scratching of the glass) installation

as per Fig. 5 should be chosen. If this does

not help and/or a large amount of flash

steam escapes install a separator

upstream of the sensor (Fig. 8)

F K

1. Lid and base can be screwed

turned through 90°.

2. Screw in nipples , screwed unions

E D

and ball valves supplied with the

C

sensor (use teflon tape or hemp for

sealing).

3. They have to be fitted into the lid and

K

base or directly at the inlet, outlet or

F

purging point.

4. The screwed unions facilitate

positioning of the ball valves so that the

levers can be arranged in one plane

(front).

Page 9

5. Fit the ORG 12/ORG 22 with the mounting

bracket provided in an accessible place.

If the sensor is used on ships weld

mounting bracket to its support.

6. Use 12 mm OD Ermeto (screwed

12 mm copper tubing or 10 mm OD gas

pipe (screwed

3

/8") for the inlet and outlet

3

/8") or

lines of the sensor. For rinsing pur poses

suitable flexible tubes should be provided.

7. Fit the light receiver in an accessible

H

place. It can then be easily removed, so

that visual inspection of the fluid is

possible. The interchange of light emitter

and light receiver is possible after

loosening the union nuts (inside). When

refitting, take care of correct fit of locating

pins in the grooves provided in light

emitter and receiver. Tighten union nuts.

Take care of tightness against moisture –

condensate on the outside of glass

cylinder results in too high measured

values.

ORT 4, ORT 5

Wall mounting within reasonable distance

from ORG 12/ORG 22.

Installation dimensions see Fig. 1. The

spacing between the holes is indicated on

the back of the housing. ORT 5: Unscrew lid

N

screw and remove lid to gain access to

the holes for mounting.

Wiring

ORT 4, ORT 5

1. ORT 4: Turn screw through 90° and

open lid, see wiring diagram on operating

panel.

ORT 5: Unscrew lid screw and open

lid, see wiring diagram on the inside of the

lid.

2. Pull cable through cable glands .

3. Connect conductors according to wiring

diagram (Fig. 10/11). Connect control

circuits to output contacts and fuse

separately with T 2.5 A.

4. Tighten cable gland to provide sealing.

5. Seal unused cable glands.

6. Replace lid, tighten screw , in doing so

pay attention to correct position of lid

gasket.or to flashing must be avoided.

ORG 12, ORG 22

Connect light emitter and receiver in

accordance with Fig. 3.

1. Connect light emitter. A two-core cable

(conductor size 1.5 mm²) for distances up

to 90 m can be used.

2. Connect light reciver. A screened fourcore cable, e. g. 2x2x0.8 mm or 4 x 0.5

mm² is required. Max. length 90 m.

N

N

O

O

N

Attention

■ To protect the switching contacts fuse

circuit with T 2.5 A or according to TRD

regulations (1.0 A for 72 hrs operation).

■ Connect screen only to terminal 12

(ORT 4) / terminal 6 (ORT 5).

■ The screen must not make contact with

any metal part of the installation.

■ When switching off inductive loads,

voltage spikes are produced that may

impair the operation of control and

measuring systems. Inductive loads

should be provided with commercial arc

suppressor RC combinations, e. g.

0.1 µF/100 Ω.o flashing must be avoided.

Commissioning

1. Switch on ORT 4/ORT 5.

2. Rinse ORG 12/ORG 22 for at least 15

minutes. Operate cleaning device if

J

required.

3. Check visually whether ORG 12/ORG 22

is completely vented. For this purpose

unscrew union nuts (inside) and remove

light receiver . When screwing in light

H

receiver ensure that the locating pin fits

into the groove provided on the front

collar of the light receiver.

4. Calibrate zero point (0 %) and measuring

range (100 %).

5. Adjust switchpoint.

6. Set time delay.

o flashing must be

avoided.

Calibration of Zero Point (0%)

Use tap water (in case of low fluid

temperature) or oil-free condensate as

turbidity zero.

ORT 4

1. Set switchpoint adjustor to 0 ppm.

2. Turn measuring range adjustor (100 %)

2

to medium position.

3. Turn zero point adjustor (0 %) until the

red LED extinguishes and the green

LED just lights up. If the green LED

5

4 4

does not light up clean the pipework.

ORT 5

1. Set change-over switch for measuring

2. Loosen stop screws / of 0 %

3. Loosen stop screw of time delay

4. Turn 0 % adjustor until the LED

5. Slightly tighten stop screws .

19

range to position I and selector switch

10

in position “measured value”.

adjustor and 100 % adjustor by half a

turn.

adjustor and turn the latter against the

13

left stop. Set 100 % adjustor on

graduation 4.5.

analogue display is just no longer

illuminated. If zero indication cannot be

obtained: clean pipework. If this does not

help: add remaining turbidity value when

calibrating measuring range (100 %).

1

3

16 18

14

15

17

6

18

Calibration of Measuring Range (1 00%)

Fitting of turbidity standard

1. Choose turbidity standard supplied with

the equipment:

ORT 4: 20 ppm

ORT 5: Measuring range I: 40 TU/F*)

Measuring range II: 20 ppm

*) TU/F = Turbiditiy units of Formazin

TU/F = suspension

2. Unscrew union nuts (inside) and remove

light emitter from sightglass. Place

B

turbidity standard on black tube so that

the screen fitted in the standard exactly

fits the diaphragm in the tube.

3. Screw in light emitter ensuring that the

locating pin on the sightglass fits into the

groove of the light emitter. Tighten union

nut (inside).

4. Make sure that the liquid used for the

calibration of the zero point stays in the

glass cylinder.

4. Make the following adjustments on the

ORT 4/ORT 5:

ORT 4

6. Set switchpoint adjustor to 20 ppm.

7. Turn 100 % adjustor just until the red

5

LED lights up.

8. Remove turbidity standard and store

carefully. Make sure that it cannot be

scratched.

1

2

ORT 5

6. Set change-over switch for measuring

7. Loosen stop screw of 100 % adjustor

8. Slightly tighten stop screws .

9. Remove turbiditiy standard and store

19

range to position I or II dependent on

the turbidity standard used. Set selector

10

switch to “Measured value”.

16

and turn the adjustor until the LED

analogue display indicates 40 TU/F or

15

6

20 ppm. If required, add remaining

turbidity value – see “Calibration of Zero

Point (0 %)”, item 4.

16

carefully. Make sure that it cannot be

scratched.

Adjustment of Switchpoint

An alarm is given when the actual value

exceeds the adjusted switchpoint.

Tool: Screwdriver

ORT 4

1. Set switchpoint adjustor to the desired

ppm value.

ORT 5

1. Set change-over switch for measuring

2. Set selector switch measured value/

3. Loosen stop screw of switchpoint

4. Turn adjustor until the LED analogue

5. Slightly tighten stop screw.

6. Set selector switch measured value/

19

range to position I (top scale) or

position II (bottom scale) dependent on

the desired switchpoint.

switchpoint to “Switchpoint”.

10

adjustor.

display indicates the turbidity value

11

desired as switchpoint.

switchpoint back to “Measured value”.

10

1

12

9

Page 10

Adjustment of Time Delay

ORT 4

A time-delayed alarm is given when the

switchpoint is exceeded. The time delay

prevents temporary variations in the

turbidity of the fluid from raising an alarm.

Time delay set at our factory: 10 s

To eliminate the time delay provide an exter-

nal wire link between terminals 19 and 20.

ORT 5

The ORT 5 features two alarm channels:

■ Channel A 1 operates without delay:

The corresponding relay contact can be

used for triggering a three way valve,

so that contaminated fluid is immediately

discharged from the system.

■ Channel A 2 operates with a delay which

is adjustable between 0.5 and 15 minutes

for start-up and purging purposes, when

at the beginning the turbidity is very high

without representing a case of alarm.

Tool: Screwdriver

1. Loosen stop screw of adjustor and

set required time delay.

2. Slightly tighten stop screw .

14 13

14

Functional T est

1. After applying mains voltage the green

2. Operate cleaning device . The green

3. Set cleaning device back to its initial

4 9

LED / must be permanently

illuminated (Fig. 1). ORT 5: If a three-way

valve is connected the fluid must flow

straight through.

4 9

LED / must extinguish.

ORT 4: The red LED must light up.

ORT 5: The red LED and after the set

time delay the red LED must light up. If

J

5

8

7

a three-way valve is connected it must

open to discharge the fluid.

position. The red LEDs must extinguish.

J

Maintenance

Clean glass cylinder at regular intervals – at

least once a week, dependent on the

degree of contamination of the fluid.

Replace glass cylinder if it is strongly

contaminated.

st lightup.

ORT 5: The red LED and after the set

time delay the red LED must light up. If

a three-way valve is connected it must

open to discha

With fluids having a normal transparency the

service life of the glow lamp is more than

10 000 hrs. It is, however, recommended to

replace the glow lamp each time the glass

cylinder is being cleaned.

When the content of the drying cartridge

M

has assumed a pink colour it can no longer

absorb moisture and must be replaced.

If frequent replacing is necessary check

equipment for tightness:

■

O-rings on light emitter and receiver .

■

Cable entries on light emitter and

receiver .

■

Gaskets of terminal boxes , gaskets of

H

B H

B

A

glass cylinder, oil-seal rings.

Cleaning of Glass Cylinder

1. Move the disc of the cleaning device

up and down. Note that dependent on the

adjusted time delay a temporary alarm

may be given.

2. Move the disc of the cleaning device

back to its initial position (operating bar

protrudes approx. 70 mm from the

sightglass). In case of strong

contamination of glass cylinder replace

plunger of the cleaning device.

J

J

Exchange of Glass Cylinder

1. Close ball valves for inlet and outlet.

Open ball valve for rinsing .

2. Loosen hexagon head screws and

remove base with cleaning device.

3. Remove glass cylinder from below.

4. Check whether housing, lid and base are

completely dry inside. If not, dry with

compressed air. In case of cold fluids,

any moisture remaining in the housing

would lead to the glass cylinder becoming

covered with mist and therefore faulty

measurements.

5. Loosen screws and withdraw housing

from lid .

F

6. Remove O-rings, clean sealing surfaces

and insert new O-rings.

7. Replace housing and fix lid with

G

screws .

8. Hold new and dry glass cylinder at the

rim and push into housing from below until

it is located in the upper O-ring.

9. Insert plunger of the cleaning device

into glass cylinder. Screw base to

housing by using hexagon screws.

D

I

K

G

F

J

K

10.Close ball valve for rinsing , open ball

D

valves for inlet and outlet.

I

11. Check zero-point adjustment and

calibration of the ORT 4/ORT 5.

Replacement of Glow Lamp

1. Unscrew union nut (outside) of the lid

of the light emitter and remove lid.

2. Exchange glow lamp.

3. Replace lid of the light emitter. Take care

that locating pin fits the groove provided

on the light emitter. Tighten union nut.

4. Repeat calibration of zero point (0%) and

measuring range (100 %).

A

Replacement of Mains Fuse

1. Turn fuse carrier to the left and take off

(Fig. 1).

2. Exchange fuse. Required types:

230 V M 0.1 A 5 x 20 M 0.2 A 5 x 20

115 V M 0.2 A 5 x 20 M 0.4 A 5 x 20

3. Replace fuse carrier and turn to the

right.

P

ORT 4 ORT 5

P

Replacement of Cleaning Device

T ools: Spanner

Screwdriver

1. Close ball valves for inlet and outlet.

Open ball valve for rinsing .

2. Loosen hexagon head screws and

remove base with cleaning device.

3. Use screwdriver for bending open the

inside serrations of the fixing disc and

remove fixing disc.

4. Withdraw plunger and insert new plunger.

5. Mount new fixing disc. Make sure that the

serrations do not point towards the

plunger.

6. Remove O-rings from base, clean sealing

surfaces and insert new O-rings.

7. Push plunger of the cleaning device

into glass cylinder. Screw base to

housing by using hexagon screws.

8. Close ball valve for rinsing , open ball

D

valves for inlet and outlet.

9. Check zero-point adjustment and

calibration of the ORT 4/ORT 5.

D

I

K

J

K

I

10

Page 11

Fault Finding

Fault Finding

Fault Possible reason Remedy

No lighting up of LEDs Mains fuse defective Replace mains fuse

Lamp “Malfuncion” on Basic turbidity of fluid too high Refer to “Basic turbidity too high” in this table

Glass cylinder highly contaminated Clean or replace glass cylinder

Glass cylinder scratched (solids in condensate) Replace glass cylinder. Install ORG 12/ORG 22

Glow lamp in light emitter defective Replace glow lamp

Cable leading to light emitter defective Check cable

Calibration of zero point Cable leading to light receiver defective Measuring of lamp voltage < 12 V only possible

(0 %) not possible if lamp intact

Glass cylinder highly contaminated Clean or replace glass cylinder

Glass cylinder scratched (solids in condensate) Replace glass cylinder. Install ORG 12/ORG 22

Glass cylinder covered with condensation Check gaskets of terminal boxes and glass cylinder,

Drying cartridge assumed pink colour ? Replace drying cartridge

Extremely eccentric position of glow lamp filament Insert glow lamp with central filament position

Basic turbidity of fluid too high Add indicated value of 100 % calibration to turbidity

No indication of measured Cable leading to light receiver defective Check cable

value

Basic turbidity too high Presence of gas or steam bubbles (flashing) Throttle outlet (indication must drop)

Basic turbidity specific of fluid To measure basic turbidity: Repeat calibration of 0 %

Measured value rises If ingress of foreign matter can be excluded, Operate cleaning device more frequently

continually 1 ppm/day growing contamination of glass cylinder

Glow lamp often defective Heat accumulation in light emitter since fluid Remove drying cartridge and install vent nipple

temperature > 60 °C and drying cartridge mounted

acc. to mounting suggestion Fig. 5

acc. to mounting suggestion Fig. 5

O-rings of light emitter and light receiver

standard value

and 100% with distilled water

If faults occur that are not listed above,

please contact our subsidiary or agency

in your country.

11

Page 12

GESTRA Gesellschaften · GESTRA Companies · Sociétés GESTRA · Sociedades Gestra · Società GESTRA

Vertretungen weltweit · Agencies all over the world · Représentations dans le monde entier · Representaciones en todo el mundo · Agenzie in tutto il mondo

®

GESTRA GmbH

Postfach 10 54 60

D-28054 Bremen

Münchener Strasse 77

D-28215 Bremen

Tel. + 49 (0) 421 35 03 -0

Fax +49 (0) 421 35 03- 393

Internet www.gestra.de

E-mail

gestra.gmbh@flowserve.com

A Unit of Flowserve Corporation

12

810476-00/999c · ©1996 GESTRA GmbH · Bremen · Printed in Germany

España

GESTRA ESPAÑOLA S.A.

Luis Cabrera, 86-88

E-28002 Madrid

Tel. (091) 5152 032

Fax (091) 4 136 747; (091) 5152 036

France

Flowserve Flow Control S.A.S.

10 Avenue du Centaure, BP 8263

F-95801 CERGY PONTOISE

Tél. (01) 34.43.26.60

Fax (01) 34.43.26.87

Great Britain

Flowserve Flow Control UK

Burrel Road, Haywards Heath

West Sussex RH 16 1TL

Tel.00 44 14 44 / 31 44 00

Fax00 44 14 44 / 31 45 40

Italia

Flowserve S.p.A.

Divisione Italgestra

Via Prealpi, 30 - 20032 Cormano (Mi)

Tel.00 39 02 / 66 32 51

Fax00 39 02 / 61 51 863

Polska

GESTRA POLONIA Spolka z o.o.

Ul. Schuberta 104

PL-80-172 Gdansk

Tel. (058) 306 10 02

Fax (058) 306 1003

Portugal

Flowserve Portuguesa, Lda.

Av. Dr. Antunes Guimarães, 1159

P-4100 Porto

Tel.0 03 51 22 / 6 19 87 70

Fax0 03 51 22 / 6 10 75 75

Loading...

Loading...