Page 1

Limitorque

®

DDC-100 Master Station II

Installation and Operation Manual

FCD LMAIM5001-00

(Replaces 435-11000)

Limitorque Actuation Systems

Page 2

2 DDC-100 Master Station II Installation and Operation Manual FCD LMAIM5001-00

Flow Control Division

Limitorque Actuation Systems

Master Station

Installation and Operation Manual

©2004 Copyright Flowserve Corporation. All rights reserved.

Printed in the United States of America.

Disclaimer

No part of this book shall be reproduced, stored in a retrieval system, or transmitted by any means,

electronic, mechanical, photocopying, recording, or otherwise without the written permission from

Flowserve. While every precaution has been taken in the preparation of the book, the publisher assumes

no responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the

use of the information contained herein.

This document is proprietary information of Flowserve furnished for customer use ONLY. No other uses

are authorized without written permission of Flowserve.

Flowserve reserves the right to make changes, without notice, to this document and the products it

describes. Flowserve shall not be liable for technical or editorial errors or omissions made herein; nor for

incidental or consequential damages resulting from the furnishing, performance or use of this document.

This manual contains information that is correct to the best of Flowserve’s knowledge. It is intended to be

a guide and should not be considered as a sole source of technical instruction, replacing good technical

judgment, since all possible situations cannot be anticipated. If there is any doubt as to exact installation,

configuration, and/or use, please contact Flowserve at 1-800-225-6989.

The choice of system components is the responsibility of the buyer, and how they are used cannot be the

liability of Flowserve Corporation. However, Flowserve’s sales team and application engineers are always

available to assist you in making your decision.

MS-DOS

®

is a registered trademark of Microsoft Corporation.

IBM-PC

®

is a registered trademark of International Business Machines Corporation.

Belden

®

is a registered trademark of Belden, a division of Cooper Industries, Inc.

Page 3

FCD LMAIM5001-00 DDC-100 Master Station II Installation and Operation Manual 3

Flow Control Division

Limitorque Actuation Systems

Page 4

4 DDC-100 Master Station II Installation and Operation Manual FCD LMAIM5001-00

Flow Control Division

Limitorque Actuation Systems

Page 5

FCD LMAIM5001-00 DDC-100 Master Station II Installation and Operation Manual 5

Flow Control Division

Limitorque Actuation Systems

1 Introduction

1.1 Overview

The Limitorque Master Station II is a revolutionary step forward in control technology. The device is

capable of controlling up to 250 actuators, offers full redundancy, provides easy-to-use HMI interfaces,

and allows for high-speed data-transfer via a Modbus DCS port or Modbus Ethernet port. In addition, a

built-in web server can be used for monitoring network status from any remote station using TCP/IP. Web

server operation is covered in Section 18.

1.2 User Rights Overview

The Master Station requires users to login. Three user role levels are provided: View, Control, Configure.

Each role includes the rights of the lesser roles, i.e. Control includes View’s rights, and Configure includes

Control’s rights and View’s rights.

View: the user can view the network status and the activity log. No control or configuration functionality

is available.

Control: in addition to View’s rights, the user has the ability to control MOVs.

Configure: in addition to Control’s rights, the user has the ability to configure the Master Station and

the Network.

The default passwords for each role are:

View: 100

Control: 200

Configure: 300

These passwords can be changed by the Configure user. Changing passwords is discussed in Section 9.

Page 6

6 DDC-100 Master Station II Installation and Operation Manual FCD LMAIM5001-00

Flow Control Division

Limitorque Actuation Systems

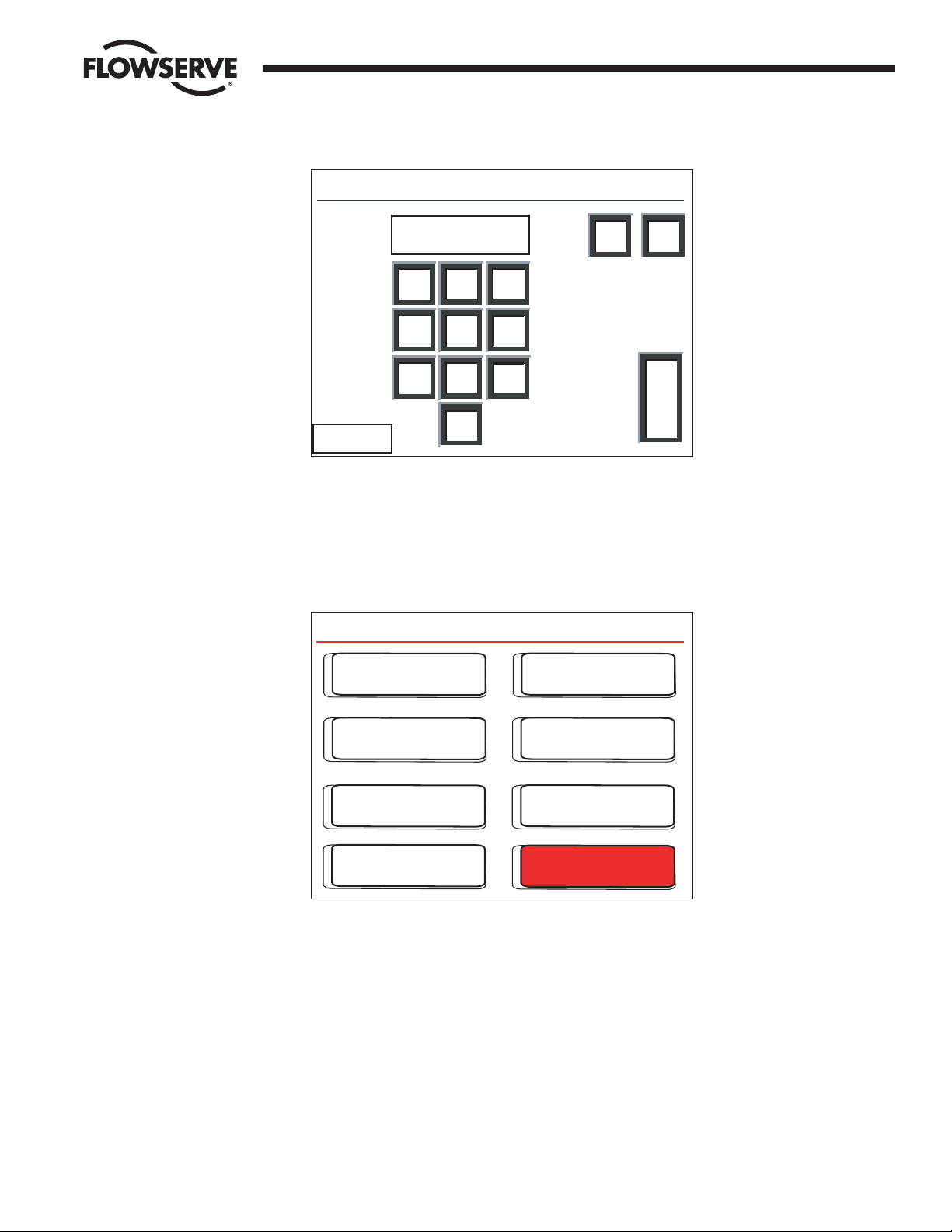

1.3 Login

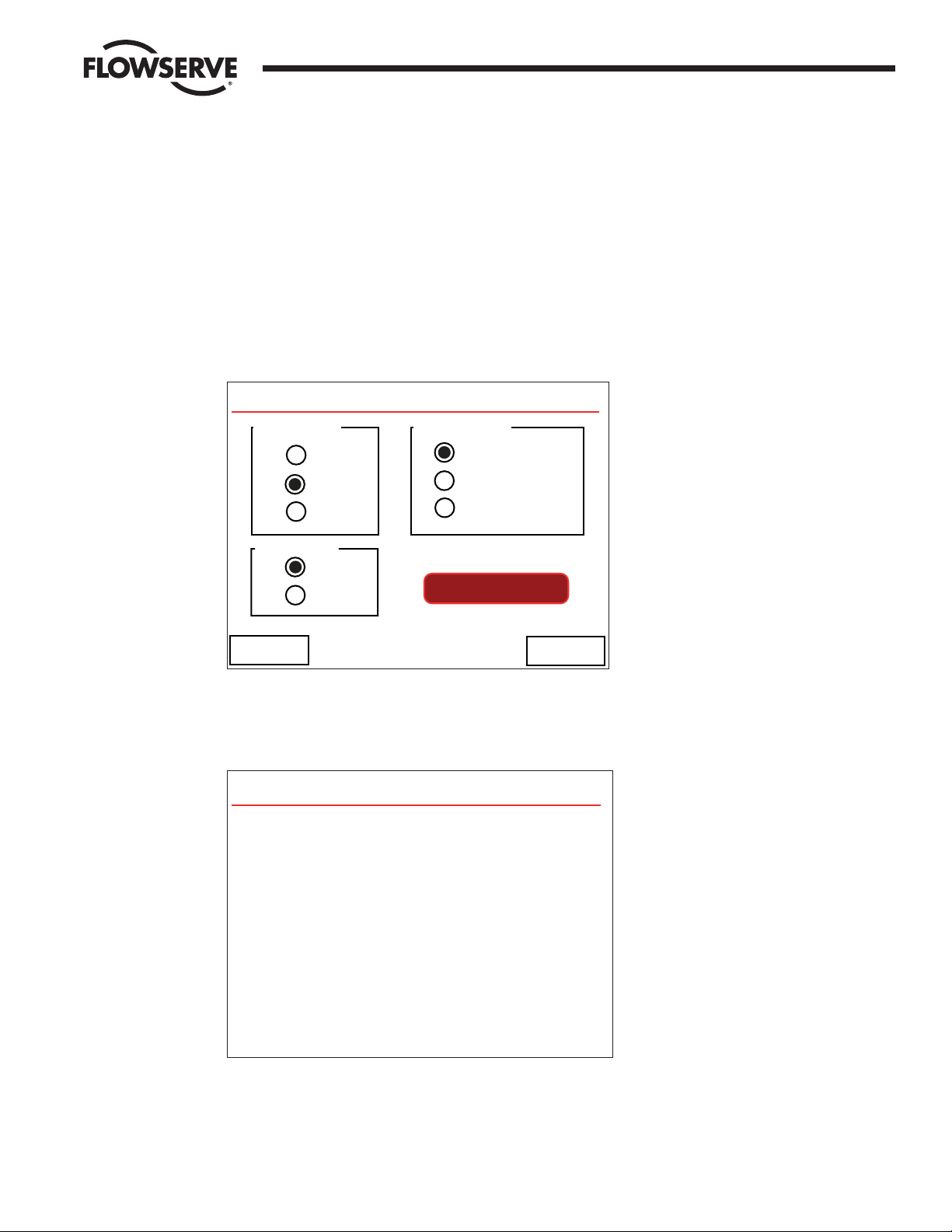

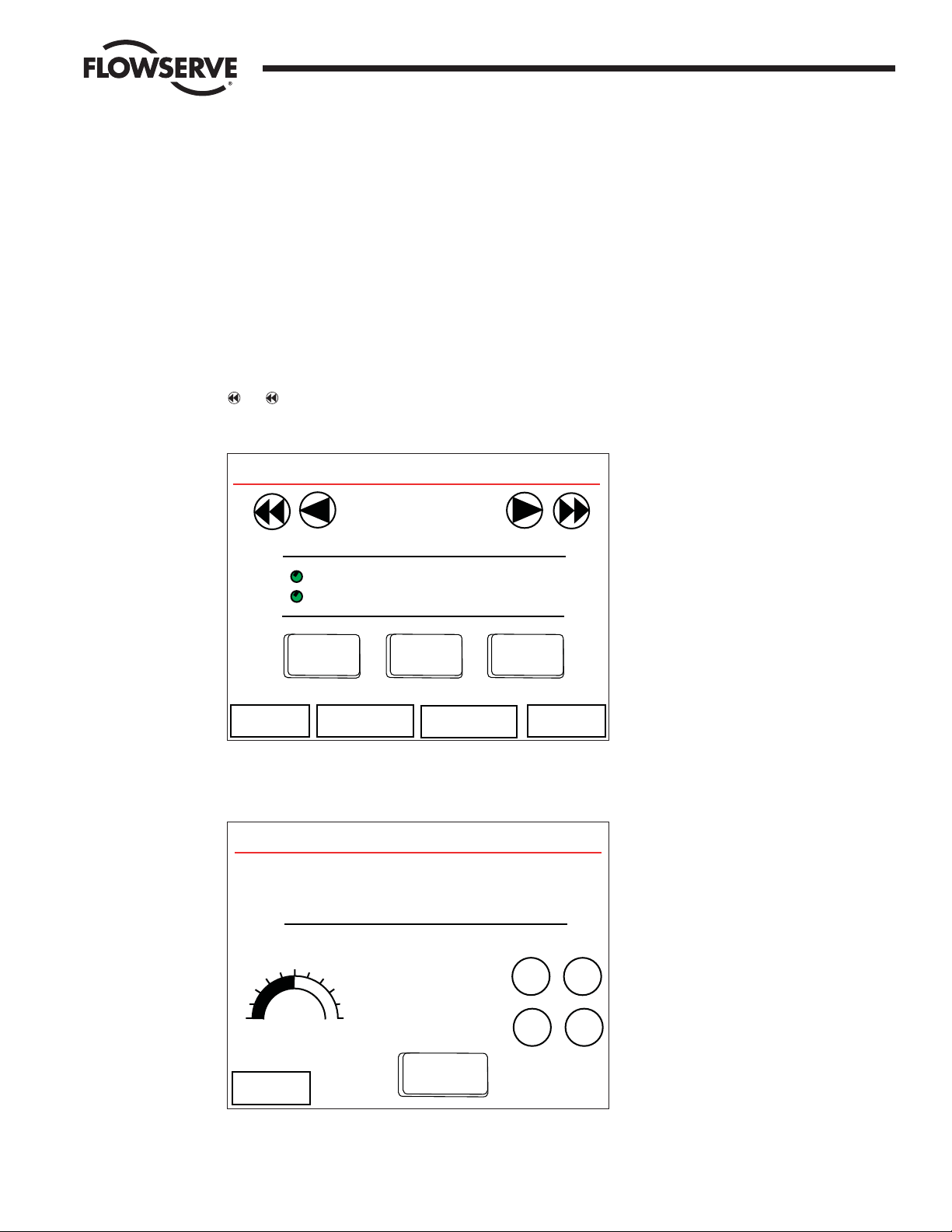

When the Master Station starts, it loads the default startup screen (Figure 1-1).

Figure 1-1: The Introduction screen

Touching any part of the screen will load the login screen (Figure 1-2).

Note: If the screen is blank and the green LED is illuminated, touch the display to exit the screen

saver mode.

Figure 1-2: The Login screen

Note: Each user level must be a unique password.

Passwords can be four digit numbers. The correct password for View, Control, or Configure will take the

user to the Main Menu (Figure 1-4).

If “Help” is pressed on the password screen, the user is given the opportunity to reset all passwords to

the defaults (Figure 1-3). Please contact Limitorque to obtain the reset password.

Passwords are easily configured via the Change Passwords screen (Figure 9-4).

7

89

6

5

4

1

2

3

0

DEL

CLR

E

N

T

Cancel

Help

Login: Please Enter Your Password

****

Limitorque

ACTIVEPress Anywhere to Begin

Page 7

FCD LMAIM5001-00 DDC-100 Master Station II Installation and Operation Manual 7

Flow Control Division

Limitorque Actuation Systems

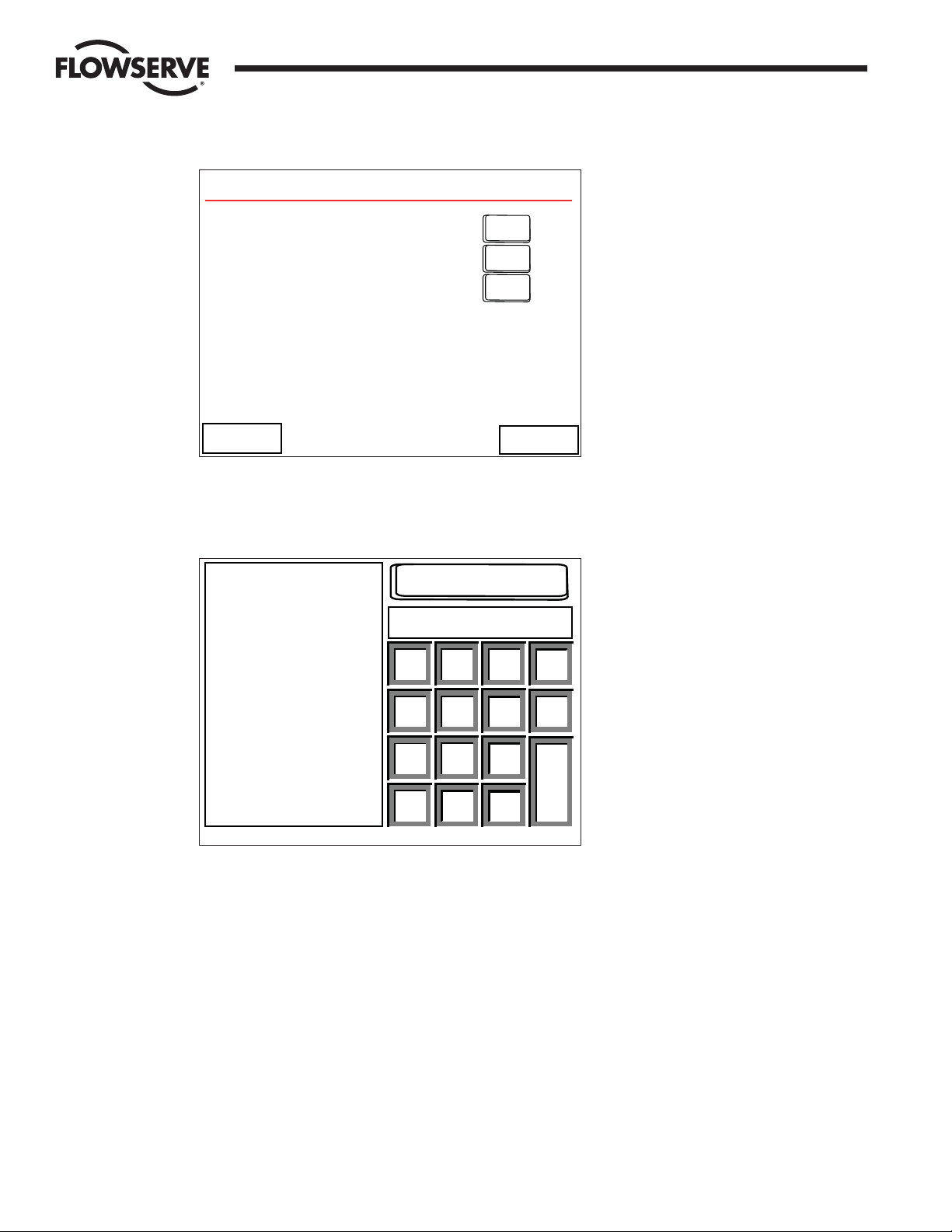

Figure 1-3: The Login Help screen

Note: The keys are outlined in red on this screen.

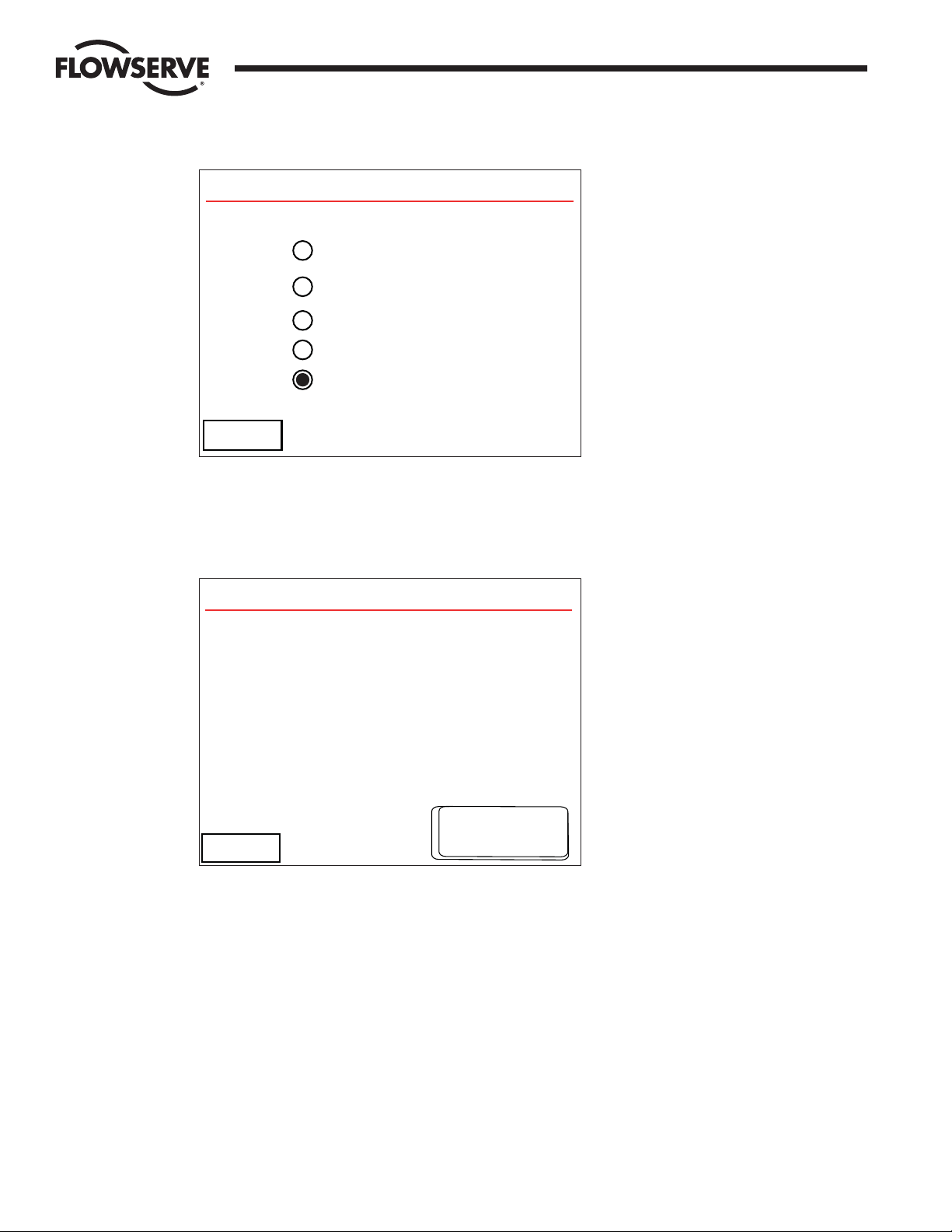

1.4 Main Menu

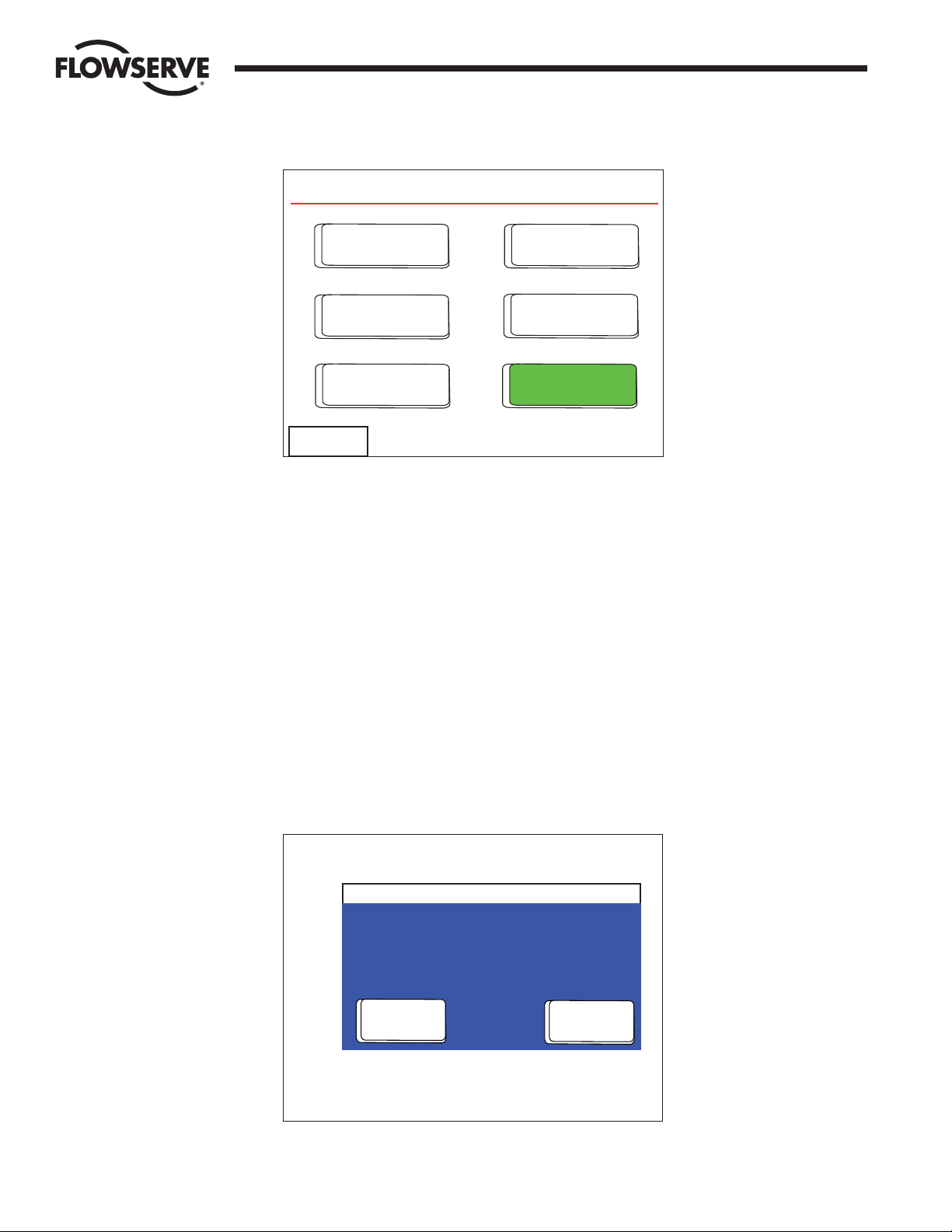

Figure 1-4: The Main Menu screen

From here, the user is restricted by his role. Each button represents a separate logical region of the

Master Station:

Configure: configure the Master Station and the Network.

Network Status: view the Network from a high level to detect communication errors.

Hot Standby: change over of CPU and configure CPU startup status.

View MOV Status: view the detailed status of each MOV.

Logger: activate logging, either for the network or for data analysis. This data will stream out of the

printer port.

Control MOV: control a MOV’s position.

Emergency Shut Down: initiate or clear an emergency shutdown of the network.

Main Menu ACTIVE

Emergency

Shut Down

Control MOV

Exit

Logger

Configure

Hot Standby

View MOV Status

Network Status

7

89

6

5

4

1

2

3

0

DEL

CLR

E

N

T

<< Back

Login Help: Enter the Reset Password

****

Page 8

8 DDC-100 Master Station II Installation and Operation Manual FCD LMAIM5001-00

Flow Control Division

Limitorque Actuation Systems

This page is intentionally blank.

Page 9

FCD LMAIM5001-00 DDC-100 Master Station II Installation and Operation Manual 9

Flow Control Division

Limitorque Actuation Systems

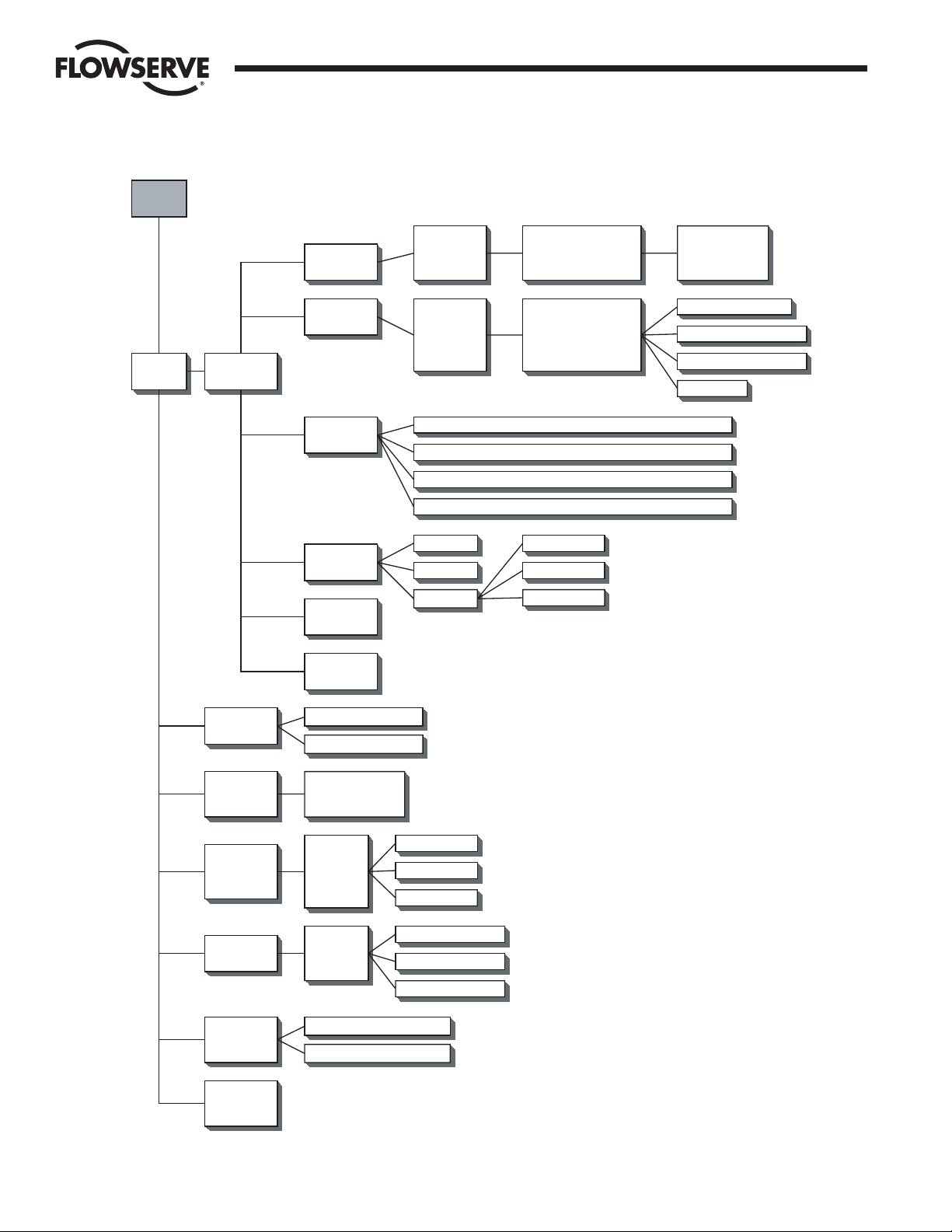

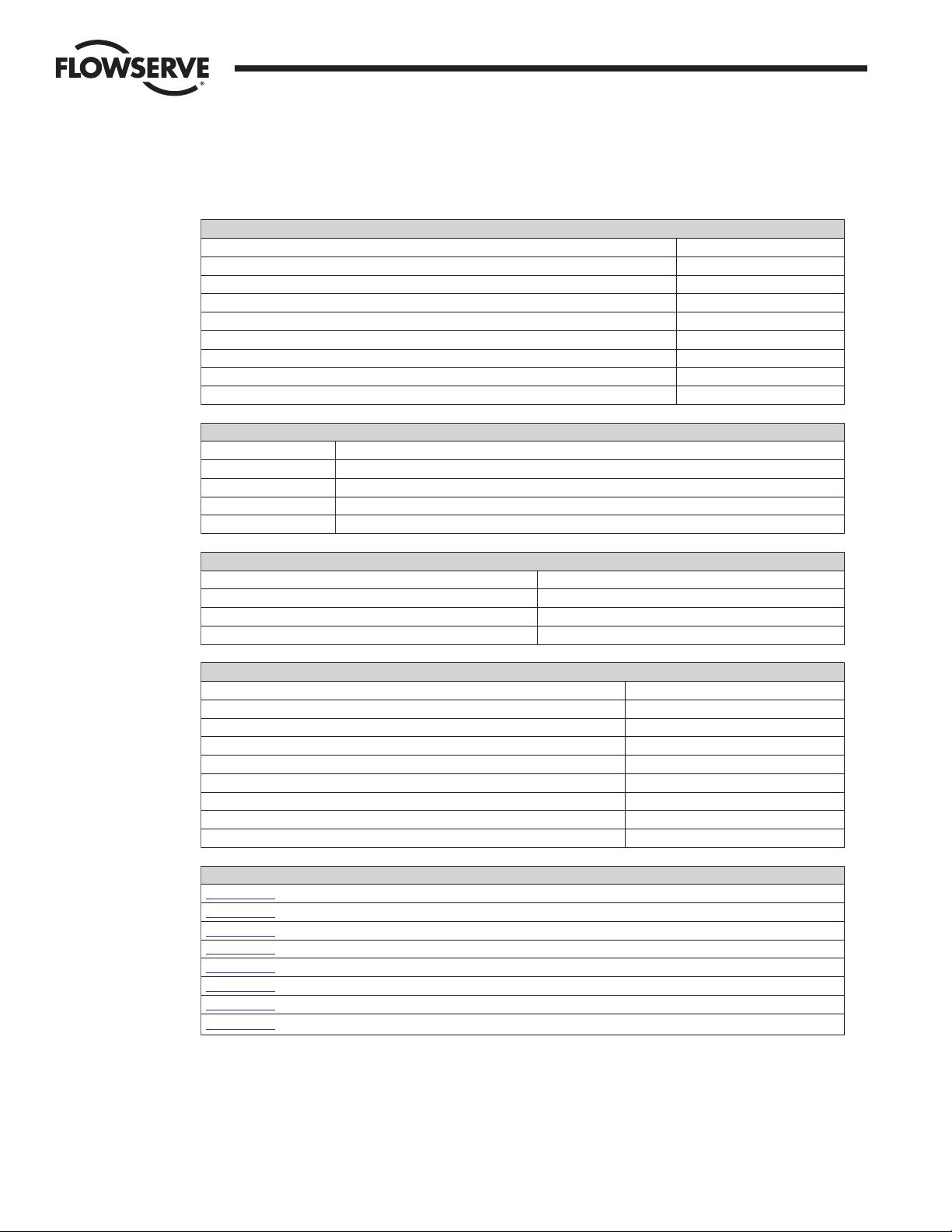

2 Master Station II Screen Flowchart

Figure 2-1 (on the following page) is a flowchart of the Master Station II screens.

Page 10

10 DDC-100 Master Station II Installation and Operation Manual FCD LMAIM5001-00

Flow Control Division

Limitorque Actuation Systems

Figure 2-1: Screen flowchart

Intro

Screen

Main

Menu

Configure

MOV

Network

DCS Port

Ethernet

Port

General

Settings

Change Tags

Save to

Flash

Baud Rate

Retries

Poll Mode

Baud Rate

Stop Bits

Parity

Electrical

IP Address - Octet 1 - Octet 2 - Octet 3 - Octet 4

Mask - Octet 1 - Octet 2 - Octet 3 - Octet 4

Gateway - Octet 1 - Octet 2 - Octet 3 - Octet 4

Standby IP Address - Octet 1 - Octet 2 - Octet 3 - Octet 4

Clock

Version

Password

Timeout

Prop Delay

RTS On Delay

DCS Port Address

RTS On Delay

RTS Off Delay

HMI Control

View

Supervisor

Administrator

Active MOVs 1250

Modbus FC 03 - View

Modbus FC 05/15 - View

Modbus FC 06/16 - View

HMI Control

Hot Standby

Network

Status

View MOV

Status

Control MOV

Emergency

Shutdown

Exit

Change Status

Hot Backup Startup

Communication

Status

MOVs 1-250

Position

MOV Stats

Address 1250

Control

MOVs

1-250

Start Network ESD

Terminate Network ESD

Faults

Alarms

Open/Stop/Close

0-100% Open

Aux Contacts

Page 11

FCD LMAIM5001-00 DDC-100 Master Station II Installation and Operation Manual 11

Flow Control Division

Limitorque Actuation Systems

3 Quick Startup

3.1 Single Master Station Quick Setup Instructions

1. Connect power, earth ground, and network cables per Flowserve recommendations.

2. Turn power on to the Master Station.

3. Wait for the Master Station display to illuminate and the “Press Anywhere To Begin” message.

4. Press the screen and enter the configuration password when prompted. Select Enter.

5. Next select “Configure” then “MOV network”. Select the network baud rate, Time-out, retries, adjust

the Propagation delay and RTS ON delay if required. Next activate the appropriate number of

networked MOVs by making the lamp beside the address green.

6. Select the Back button until the Configuration screen is displayed.

7. From the Configure screen, select “DCS Port.” Select the desired baud rate, stop bits, parity and

electrical standard. Select Next and configure the Master Station DCS port address, adjust the RTS

ON Delay and RTS OFF Delay if required. Select Next for the “Configure DCS Data Table screen”.

8. Configure the data tables for the Master Station.

9. To create the Holding register data table (40000 register block for MOV status) for the Master

Station, select Modbus Fc 03. Select the MOV registers to be available for the DCS by pressing the

toggle switch to illuminate the “green light” on the switch. View the selections and save the changes

and return to the “Configure DCS Data Table” screen.

10. To create the Coils data table (0000 register block for forcing and reading coils) for the Master

Station, select Modbus Fc 05/15. Select the MOV Coils to be available for the DCS by pressing the

toggle switch to illuminate the “green light” on the switch. Save the changes and return to the

“Configure DCS Data Table” screen. Note this feature also creates the Modbus Fc 01 (Read Coils)

data table.

11. To create the Holding register data table (45000 register block for writing holding registers) for the

Master Station, select Modbus Fc 06/16. Select the number of write registers for the MOVs to be

available for the DCS by pressing the toggle switch to illuminate the “green light” on the switch. View

the selections and save the changes and return to the “Configure DCS Data Table screen.”

12. Select Back until reaching the “Configure” screen. Select Back and when prompted to Save,

Select Yes.

13. This will permit a rapid configuration of the Master Station. Further adjustments may be made by

following the procedures outlined in the Master Station Manual.

3.2 Hot Standby Master Station Quick Setup Instructions

Connect power, earth ground, and network cables per Flowserve recommendations.

3.2.1 Configure the Left CPU

1. Turn on power to the left processor of the Master Station. DO NOT apply power to the right half of

the Master Station.

2. Wait for the Master Station display to illuminate and the “Press Anywhere To Continue” message.

3. Press the screen and enter the configuration password when prompted. Select Enter.

Page 12

12 DDC-100 Master Station II Installation and Operation Manual FCD LMAIM5001-00

Flow Control Division

Limitorque Actuation Systems

4. From the Main Menu select Configure.

5. Select Ethernet Port.

6. Complete the setup of the IP address, mask, gateway, and standby address. Select Back from the

Configure window. You will be prompted to Save. Select NO. The Blue window will disappear. Select

Back and return to the Main Menu.

Left unit (default configuration):

IP address: 192.168.0.100

Mask: 255.255.255.0

Gateway: 192.168.0.1

Hot Stby IP: 192.168.0.101

7. From the Main Menu select Hot Standby.

8. Set the Hot Backup Startup as Hot. Select Back.

9. You will be prompted to save the configuration. Select Yes.

10. When the save process is complete turn off the left unit.

3.2.2 Configure the Right CPU

1. Turn on power to the right processor of the Master Station. DO NOT apply power to the left half of

the Master Station.

2. Wait for the Master Station display to illuminate and the “Press Anywhere To Continue” message.

3. Press the screen and enter the configuration password when prompted. Select Enter.

4. From the Main Menu select Configure.

5. Select Ethernet Port.

6. Complete the setup of the IP address, mask, gateway, and standby address. Select Back from the

Configure window. You will be prompted to Save. Select NO. The Blue window will disappear. Select

Back and return to the Main Menu.

Note: The IP address is the standby address of the left processor AND the standby address is the

IP address of the left processor.

Right unit (default configuration):

IP address: 192.168.0.101

Mask: 255.255.255.0

Gateway: 192.168.0.1

Hot Stby IP: 192.168.0.100

7. From the Main Menu select Hot Standby.

8. Set the Hot Backup Startup as Standby. Select Back.

9. You will be prompted to save the configuration. Select Yes.

10. When the save process is complete turn off the right unit.

3.2.3 Configure the Master Station for network control

1. Apply power to the left and right CPUs. Wait for the Master Station display to illuminate and the

“Press Anywhere To Continue” message to appear. One Master Station will display “Active” the other

will display “Standby”.

Left Right

IP IP

Standby Standby

Page 13

FCD LMAIM5001-00 DDC-100 Master Station II Installation and Operation Manual 13

Flow Control Division

Limitorque Actuation Systems

2. Press the screen of the ACTIVE Master Station and enter the configure password when prompted.

Select Enter.

3. From the Main Menu, select Configure

4. Next select Configure the MOV network. Select the network baud rate, Time-out, retries, adjust the

Propagation delay and RTS ON delay if required. Next activate the number of networked MOVs by

making the button beside the address green.

5. Select the Back button until the Configuration screen is displayed.

6. Configure the data tables for the Master Station.

a. To create the Holding register data table (40000 register block for MOV status) for the Master

Station, select Modbus Fc 03. Select the MOV registers to be available for the DCS by pressing

the toggle switch to illuminate the “green light” on the switch. Save the changes and return to

the “Configure DCS Data Table screen.”

b. To create the Coils data table (0000 register block for forcing and reading coils) for the Master

Station, select Modbus Fc 05/15. Select the MOV Coils to be available for the DCS by pressing

the toggle switch to illuminate the “green light” on the switch. Save the changes and return to

the “Configure DCS Data Table” screen. Note this feature also creates the Modbus Fc 01 (Read

Coils) data table.

c. To create the Holding register data table (45000 register block for writing holding registers) for

the Master Station, select Modbus Fc 06/16. Select the number of write registers for the MOVs

to be available for the DCS by pressing the toggle switch to illuminate the “green light” on the

switch. Save the changes and return to the “Configure DCS Data Table screen.”

7. Select Back until reaching the “Configure” screen. Select Back and when prompted to Save,

select Yes.

Note: All network configuration data, MOV data, and Master Station Data table configuration

parameters will be automatically saved to the standby Master Station.

DCS Port configuration data will not be saved as these ports are independently configured.

Items NOT saved to the Standby Master Station:

DCS Address

DCS Baud Rate

DCS Electrical Standard

DCS Stop bits

DCS Parity

DCS RTS On Delay

DCS RTS Off Delay

DCS Startup (Hot or Standby)

IP Address

IP Mask

Gateway

Standby IP Address

8. This will permit a rapid configuration of the Master Station. Further adjustments may be made by

following the procedures outlined in the Master Station Manual.

Page 14

14 DDC-100 Master Station II Installation and Operation Manual FCD LMAIM5001-00

Flow Control Division

Limitorque Actuation Systems

This page is intentionally blank.

Page 15

FCD LMAIM5001-00 DDC-100 Master Station II Installation and Operation Manual 15

Flow Control Division

Limitorque Actuation Systems

4 Connections

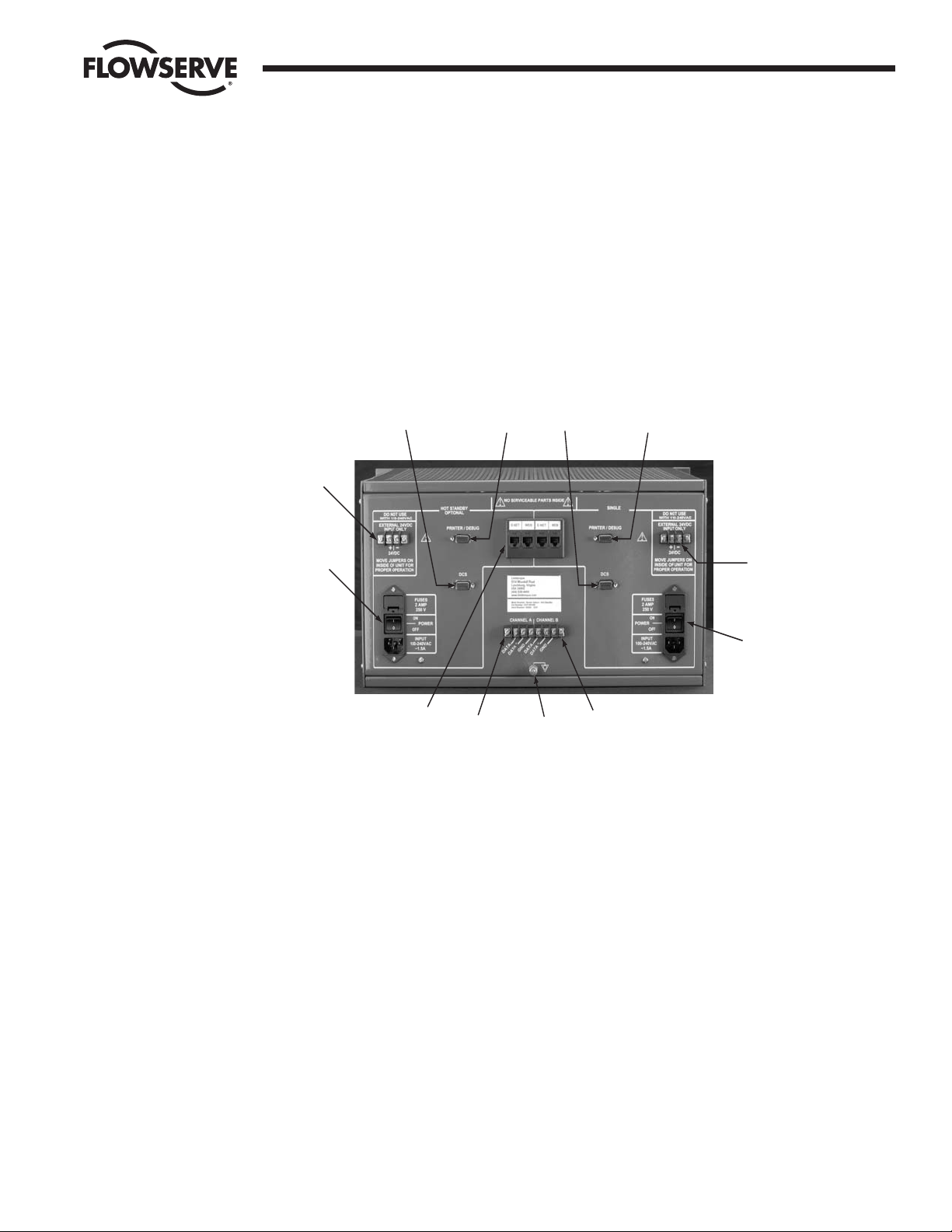

4.1 Master Station Rear Panel Connections

Figure 4-1: Master Station connections

1. Ethernet Ports, RJ-45 connectors. One port is designated for MNET (Modbus Ethernet TCP/IP). The

other port is for the webserver. Either port may be used for either function as they are connected to

the same CPU.

2. Printer / Debug Port. DB-9 Female connector. RS-232 port. Used for Master Station diagnostics.

11

10

9

1

12

8

3

7

6

2

4

5

Page 16

16 DDC-100 Master Station II Installation and Operation Manual FCD LMAIM5001-00

Flow Control Division

Limitorque Actuation Systems

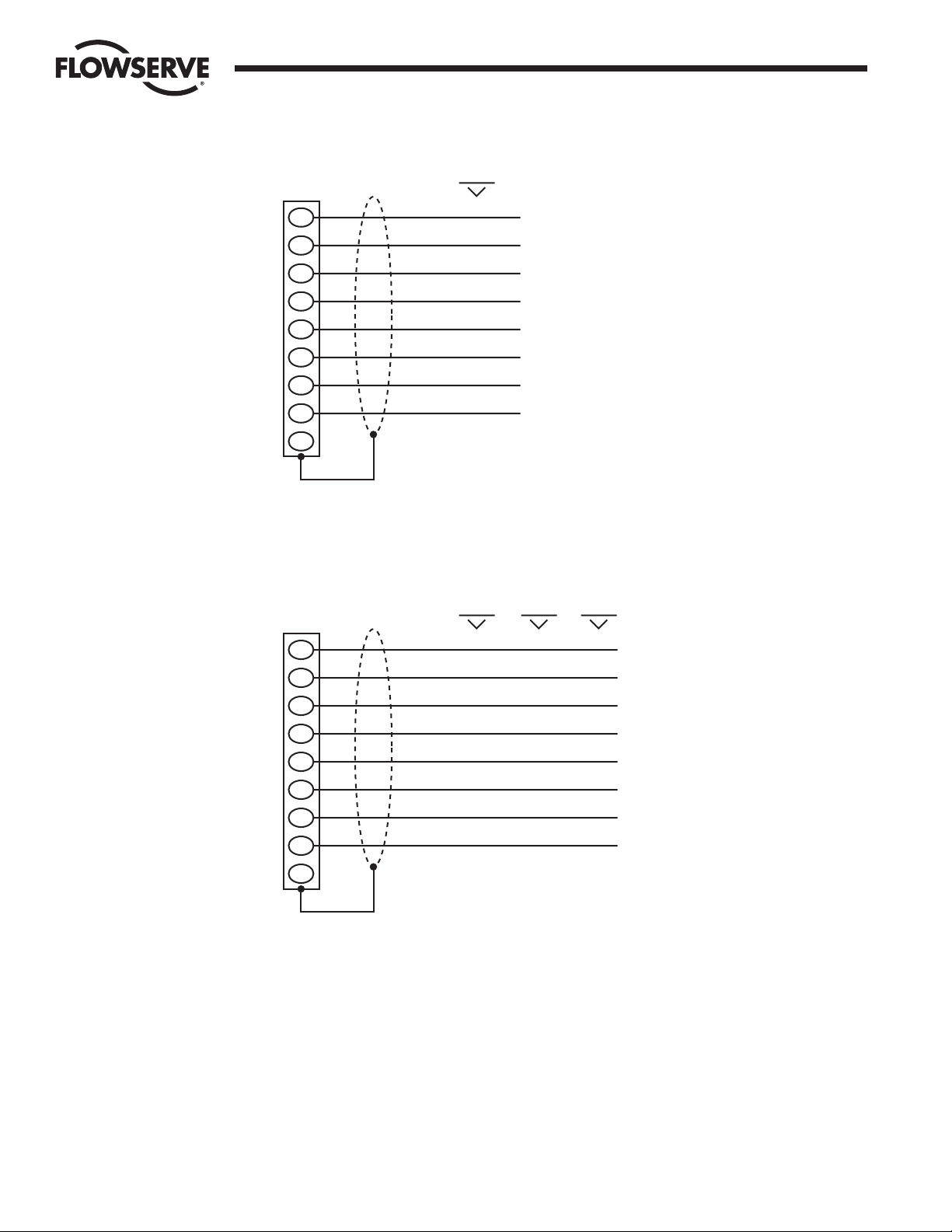

Figure 4-2: Debug Port Connection

3. DCS Port. DB-9 Female connector. Port may be RS-232 or RS-422 or RS-485. Each electrical standard

uses a different wiring convention.

Figure 4-3: DCS Port Connection

4. Auxiliary 24 VDC power connection. Master Station may be configured for 24 VDC power. This will require

the jumpers inside the Master Station to be configured for 24 VDC. DO NOT use 120 VAC when using

24 VDC power.

5. Main power switch and connector for 120 – 240 VAC. DO NOT use when 24 VDC power is applied.

RS 232

DB-9

6

4

7

2

1

8

3

5

9

N/C

DSR

DTR

RTS

RXD

DCD

CTS

TXD

GND

DB-9

6

4

7

2

1

8

3

5

9

RS 232

DSR

DTR

RTS

RXD

DCD

CTS

TXD

GND

N/C

RS 485

TXRXD+

TXRXD-

GND

RS 422

RXD-

RXD+

TXD+

TXD-

GND

Page 17

FCD LMAIM5001-00 DDC-100 Master Station II Installation and Operation Manual 17

Flow Control Division

Limitorque Actuation Systems

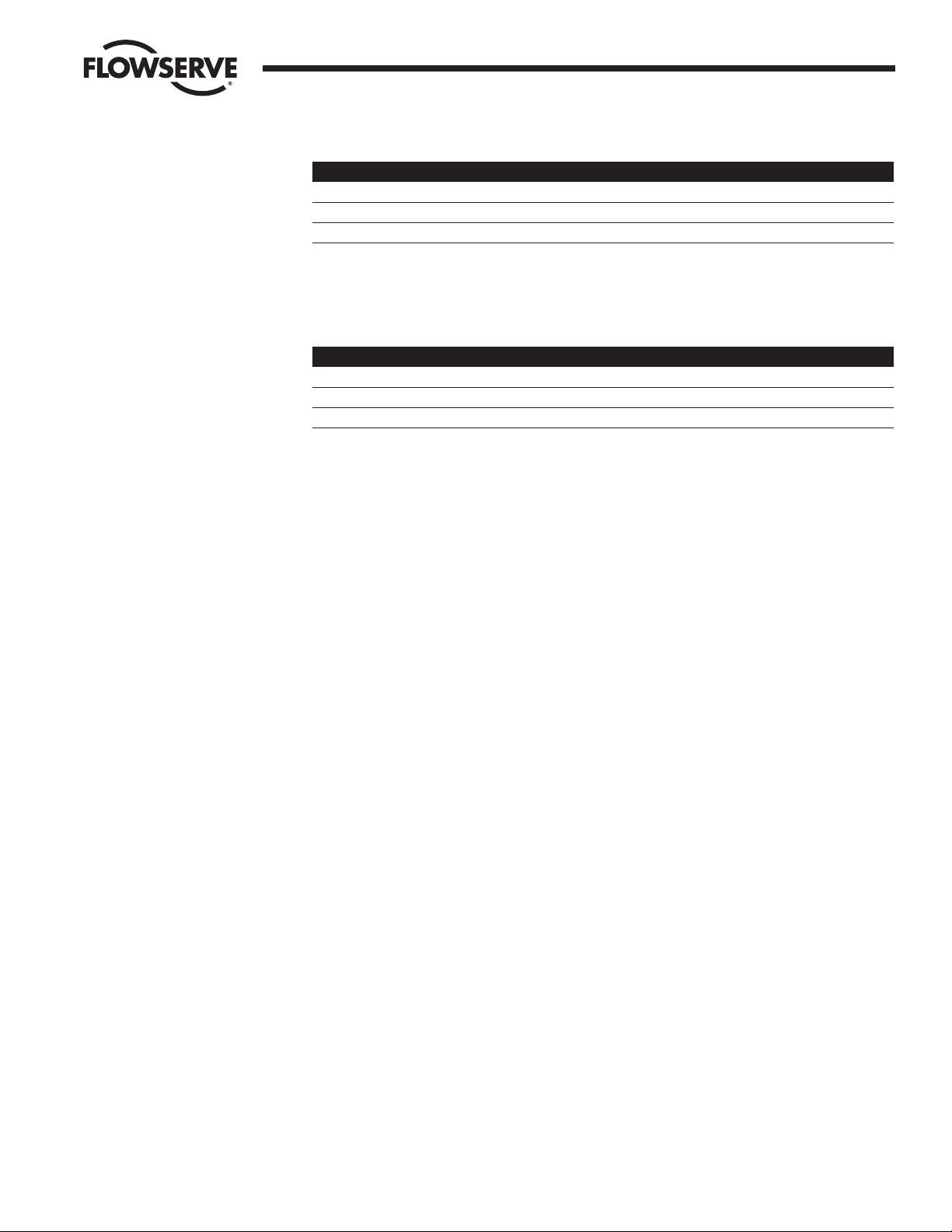

Table 4-1: Network Channel B Connection

Connector MX-DDC UEC-3-DDC

Data 41 TB4 D-S

Data * 29 TB4 D-S*

Shield

6. Electrostatic Ground. A good quality earth ground MUST be attached to the Master Station. An

effective local, low-impedance earth ground (less than 5 ohms) is required.

Table 4-2: Network Channel A Connection

Connector MX-DDC UEC-3-DDC

Data 16 TB3 D-M

Data * 15 TB3 D-M*

Shield

7. Hot Standby unit main power switch and connector for 120 – 240 VAC. DO NOT use when 24 VDC

power is applied.

8. Hot Standby auxiliary 24 VDC power connection. Master Station may be configured for 24 VDC

power. This will require the jumpers inside the Master Station to be configured for 24 VDC. DO NOT

use 120 VAC when using 24 VDC power.

9. Hot Standby DCS Port. DB-9 Female connector. Port may be RS-232 or RS-422 or RS-485. Each

electrical standard uses a different wiring convention.

10. Hot Standby Printer / Debug Port. DB-9 Female connector. RS-232 port. Used for Master Station

diagnostics.

4.2 Master Station Wiring Requirements

The network cable connects the field units to the host controller or Master Station. Belden 3074F, 3105A,

or 9841 shielded, twisted-pair cable should be used. The use of other cables may result in a reduction of

internodal distances or increased error rate, and is the user’s responsibility.

Belden 3074F Specifications

• Total cable length between repeaters or nodes with repeaters: up to 19.2 kbps: 5000' (1.52 km)

For loop mode, this is the total length between operating field units. If a field unit loses power, the relays

internal to the field unit connect the A1 Channel to the A2 Channel, which effectively doubles the length of

the cable (assuming a single field unit fails). To ensure operation within specifications in the event of

power failure to field units, this consideration must be added. Example: To ensure operation within

specification when any two consecutive field units lose power, the maximum length of cable up to 19.2

bkps should not exceed 5000' (1.52 km) per every four field units. See Section 3.1.2.3, Network Cable

Connection to Host Controller or Master Station.

Key Specifications

• Resistance/1000 ft = 18 AWG (7 x 26) 6.92 ohms each conductor (13.84 ohms for the pair)

• Capacitance/ft = 14 pF (conductor-to-conductor)

• Capacitance/ft = 14 pF (conductor-to-shield)

Page 18

18 DDC-100 Master Station II Installation and Operation Manual FCD LMAIM5001-00

Flow Control Division

Limitorque Actuation Systems

Belden 3105A Specifications

• Total cable length between repeaters or nodes with repeaters: up to 19.2 kbps: 4500' (1.37 km)

For loop mode, this is the total length between operating field units. If a field unit loses power, the relays

internal to the field unit connect the A1 Channel to the A2 Channel, which effectively doubles the length of

the cable (assuming a single field unit fails). To ensure operation within specifications in the event of

power failure to field units, this consideration must be added. Example: To ensure operation within

specification when any two consecutive field units lose power, the maximum length of cable up to 19.2

bkps should not exceed 4500' (1.37 km) per every four field units. See Section 3.1.2.3, Network Cable

Connection to Host Controller or Master Station.

Key Specifications

• Resistance/1000 ft = 22 AWG (7 x 30) 14.7 ohms each conductor (29.4 ohms for the pair)

• Capacitance/ft = 11.0 pF (conductor-to-conductor)

• Capacitance/ft = 20.0 pF (conductor-to-shield)

Belden 9841 Specifications

• Total cable length between repeaters or nodes with repeaters: up to 19.2 kbps: 3500' (1 km)

For loop mode, this is the total length between operating field units. If a field unit loses power, the relays

internal to the field unit connect the A1 Channel to the A2 Channel, which effectively doubles the length of

the cable (assuming a single field unit fails). To ensure operation within specifications in the event of

power failure to field units, this consideration must be added. Example: To ensure operation within

specification when any two consecutive field units lose power, the maximum length of cable up to 19.2

bkps should not exceed 3500' (1 km) per every four field units. See Section 3.1.2.3, Network Cable

Connection to Host Controller or Master Station.

Key Specifications

• Resistance/1000 ft = 24 AWG (7 x 32) 24 ohms each conductor (48 ohms for the pair)

• Capacitance/ft = 12.8 pF (conductor-to-conductor)

• Capacitance/ft = 23 pF (conductor-to-shield)

Page 19

FCD LMAIM5001-00 DDC-100 Master Station II Installation and Operation Manual 19

Flow Control Division

Limitorque Actuation Systems

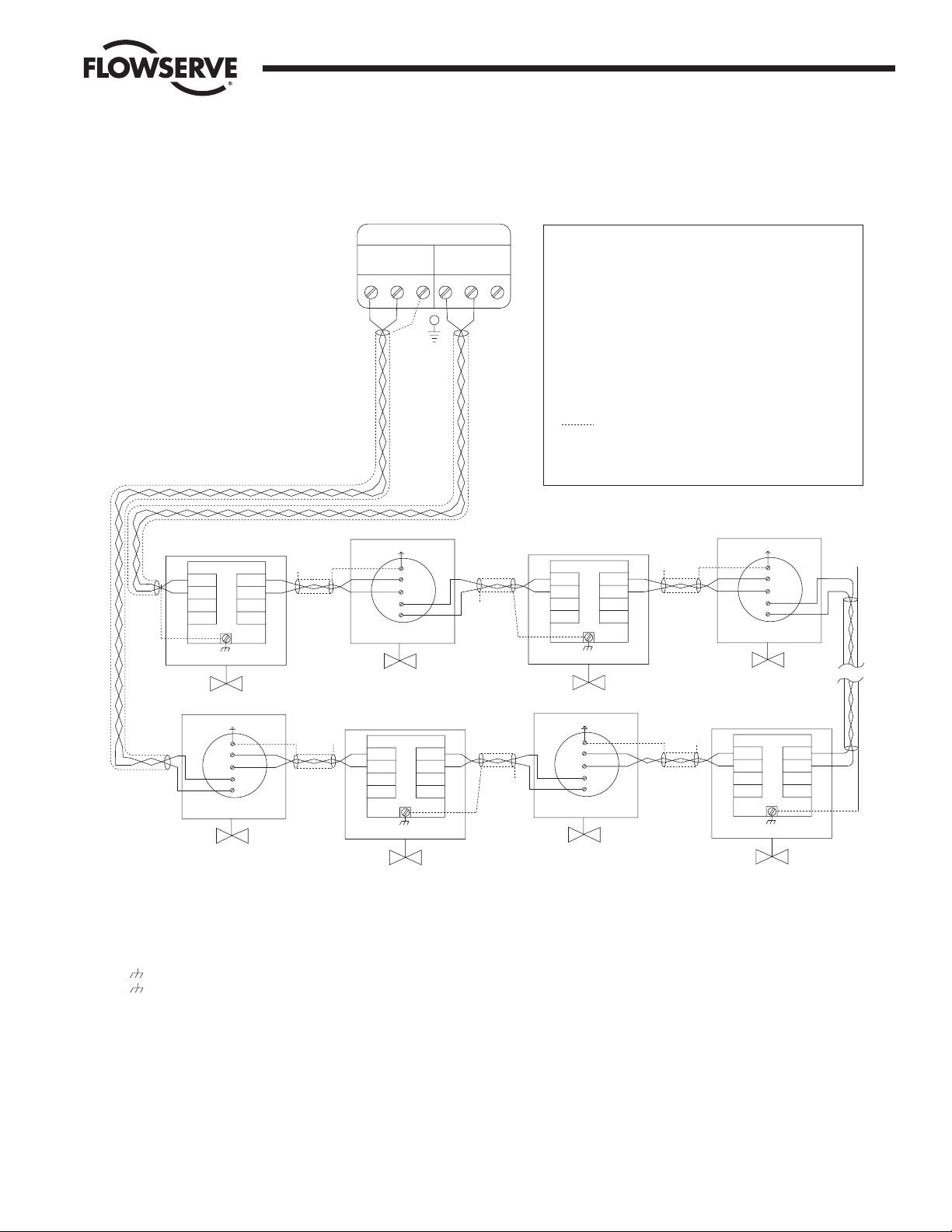

4.3 Master Station Network Schematic

Figure 4-4: DDC-100 Redundant Loop Network

Diagnostic Note:

Earth Ground Note:

MOV-3

A2

A2*

A1

A1*

TB5

MOV-247

A1

A1*

A2

A2*

TB5

N/ C

MOV-249

D-M

D-M*

D-S

D-S*

A1

A1*

A2

A2*

TB4

TB3

TB5

Notes:

Legend

MOV

D-M

D-M*

D-S

D-S*

N/C

Data terminal is positive with respect to data* terminal

See Note 5

See Note 5

See Note 5

1) Belden 3074F, 3105A, or 9841 shielded cable is recommended.

2) Correct polarity for field unit and network controller

connection is necessary for proper operation.

3) Connections shown are typical. The number of

MOVs shown may not indicate true system size.

4) Earth ground: ground rod

5) Earth gro

und: ground rod or lug in

actuator if actuator is grounded.

Polarity and level of the network’s data connection can

be checked by measuring voltage between data and

data* terminals. This voltage should be greater than

+200mVDC with network controlle

r network ports

disconnected.

If low impedance earth ground is not available at

each actuator, contact engineering for alternative

earth ground surge protection strategies.

A1*

MOV-2

See Note 5

N/C

A2*

N/C

MOV-248

See Note 5

N/C

MOV-4

See Note 5

N/C

16

15

41

29

29

41

D-S

D-S*

D-M

D-M*

TB3

TB4

MOV-1

A2

A2*

A1

A1*

TB5

See Note 5

D-S

D-S*

D-M

D-M*

TB3

TB4

D-M

D-M*

D-S

D-S*

TB4

TB3

15

16A2A1

A1*

A2*

29

41

15

16A2A1

A1*

A2*

29

41

15

16A2A1

Motor-Operated Valve

Data A1

Data A1*

Data A2

Data A2*

Data A1 (UEC-3-DDC)

Data A1*(UEC-3-DDC)

Data A2* (UEC-3-DDC)

Shield

No Connection

Data A2 (UEC-3-DDC)

N/C

MOV-250

See Note 5

A1*

A2*

29

41

15

16A2A1

N/C

Channel A Channel B

MASTER STATION II

Page 20

20 DDC-100 Master Station II Installation and Operation Manual FCD LMAIM5001-00

Flow Control Division

Limitorque Actuation Systems

This page is intentionally blank.

Page 21

FCD LMAIM5001-00 DDC-100 Master Station II Installation and Operation Manual 21

Flow Control Division

Limitorque Actuation Systems

5 Configuration

5.1 Login

From the Main Menu, touching the Configure button will prompt for the Configure password if the user is

not already logged in as the Configure user (Figure 5-1). This screen will not be displayed if the initial

password entered is the configure password.

Figure 5-1: The Configure Password screen

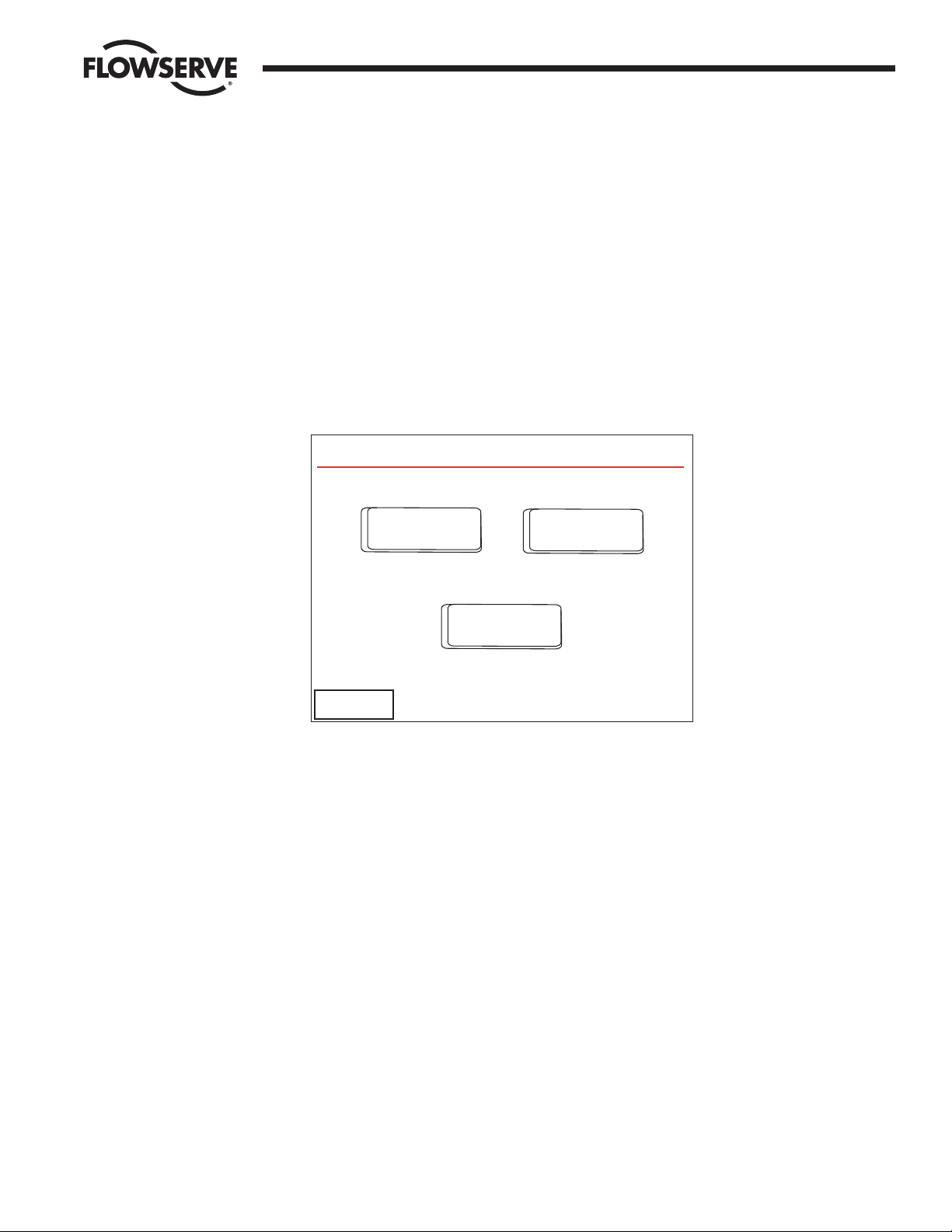

5.2 Configure Main Screen

After successfully logging in as the Configure user, the Configure main screen will be presented

(Figure 5-2).

7

89

6

5

4

1

2

3

0

DEL

CLR

E

N

T

<< Back

Login: Enter Configuration Password

****

Page 22

22 DDC-100 Master Station II Installation and Operation Manual FCD LMAIM5001-00

Flow Control Division

Limitorque Actuation Systems

Figure 5-2: The Configure main screen

The Configure main screen allows the user to configure five areas of the Master Station:

MOV Network: includes baud rate for network, retries, poll mode, timeout, propagation delay, RTS ON

delay, and screens to allow the user to graphically select the active MOVs.

DCS Port: includes baud rate for DCS communication, stop bits, parity, electrical standard, DCS address,

RTS ON delay, RTS OFF delay, HMI state during DCS communication traffic, and selectable register

maps for Modbus function code 3, Modbus function code 5/15, and Modbus function code 6/16.

Ethernet Port: includes IP Address, Mask, Gateway, and Hot Standby IP Address.

General Settings: includes Clock, Passwords, and Version information.

Hot Standby: includes buttons for forcing a state switch from Hot to Standby or Standby to Hot, indicates

the current state, and the Hot Backup Startup state.

Note: CONFIGURATION CHANGES WILL BE LOST UNLESS SAVED TO FLASH. It is important that desired

configuration changes are saved to flash by pushing the green “Save Config to Flash” button before

exiting. Attempting to exit without saving will cause a prompt to save changes.

Figure 5-3: Confirmation to Change configuration screen

Yes

No

Do you wish to save changes

made to this configuration?

Configuration Changed

MOV

Network

DCS Port

Ethernet

Port

General

Settings

Change Tags

Save Config

to Flash

Configure ACTIVE

<< Back

Page 23

FCD LMAIM5001-00 DDC-100 Master Station II Installation and Operation Manual 23

Flow Control Division

Limitorque Actuation Systems

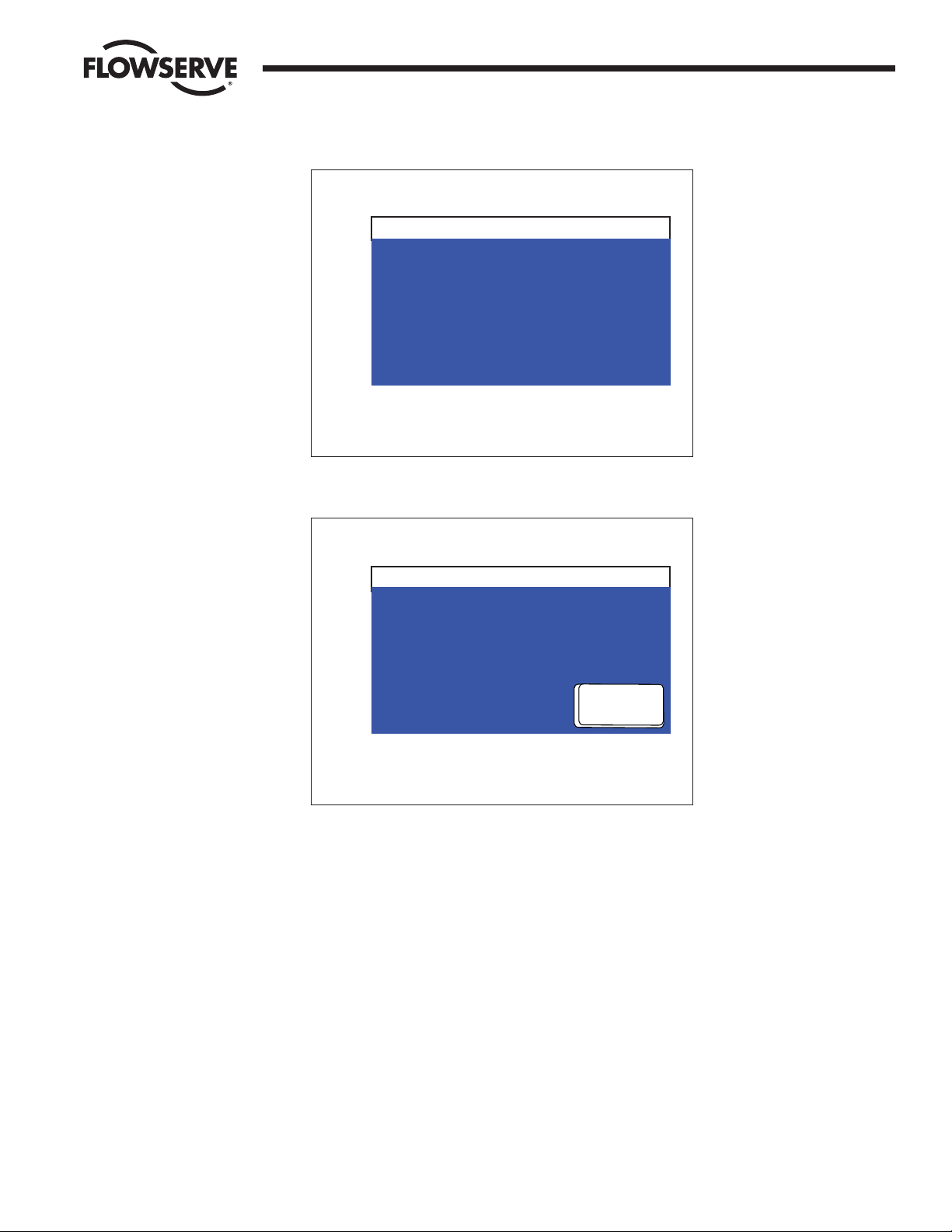

Figure 5-4: Saving Changes to Flash screen

Figure 5-5: Configuration Not Changed screen

OK

There have been no changes

made to the configuration.

Configuration Not Changed

Please wait while the

configuration is saved to

flash.

This operation requires

approximately 20 seconds.

Please Wait

Page 24

24 DDC-100 Master Station II Installation and Operation Manual FCD LMAIM5001-00

Flow Control Division

Limitorque Actuation Systems

5.3 Change Tags

Each MOV has a Tag name associated with it to provide a user-friendly identification. These tags can be

edited by the user via the Change Tags screen (Figure 5-6).

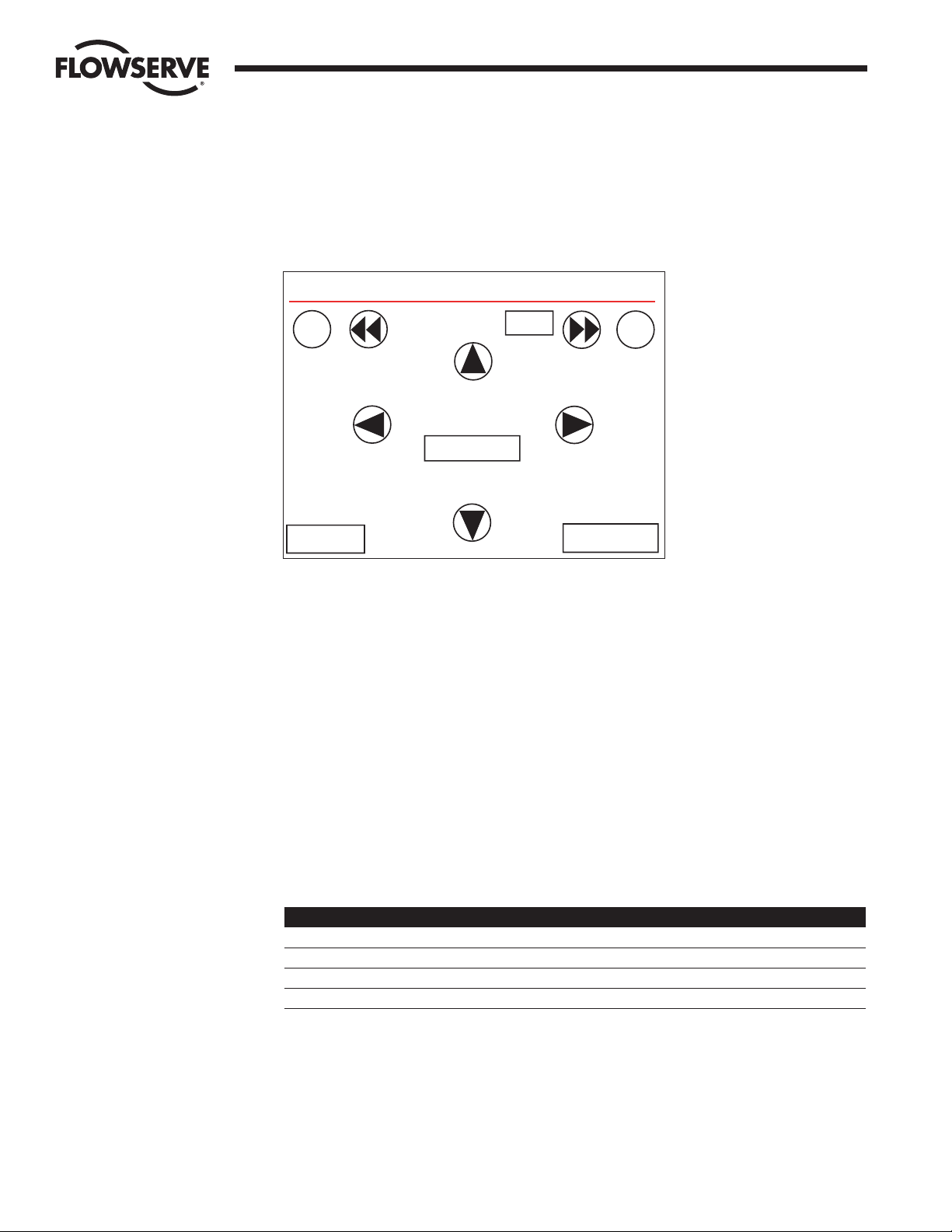

Figure 5-6: Change Tag Name screen

The MOV Address indicates the MOV currently being edited. The arrows to the left and right of the MOV

Address allow the user to navigate between MOVs. The +10 and -10 buttons allow the user to rapidly skip

between MOVs.

In the center of the screen the MOV tag name is displayed. The Pos and Pos arrows allow the user to edit

different characters in the tag name. The Character + and Character - arrows allow the user to increase a

character, for example A to B to C or to decrease a character, C to B to A. In this manner, the user may

rapidly create custom tags for each MOV.

It is important to touch the “Save Tag” button before the user edits a different MOV or exits the screen.

“Save Tag” must be touched for each tag changed. Failing to touch “Save Tag” will result in loss of data.

5.3.1 Altering Tag Names with Microsoft Excel

1. Attach a PC to the Master Station Ethernet port. Configure the PC Ethernet port to communicate with

the Master Station.

Example:

Master Station PC

IP 192.168.0.100 192.168.0.101

Mask 255.255.255.0 255.255.255.0

Gateway 192.168.0.1 192.168.0.1

Standby IP 0.0.0.0 0.0.0.0

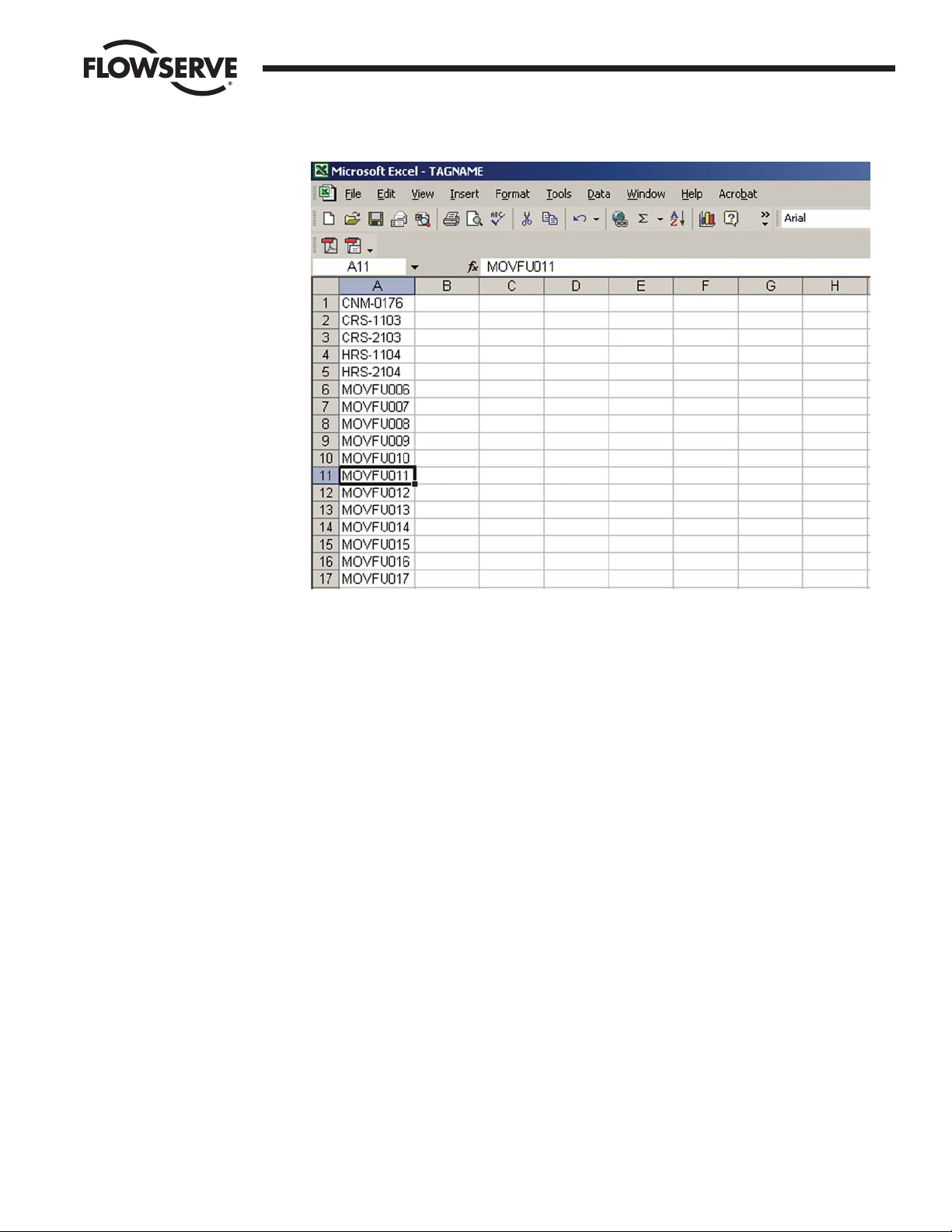

2. Copy the TAGNAME file to a PC using a FTP (File Transfer Protocol).

3. Open the TAGNAME file with Excel.

4. Column A will contain 250 rows corresponding to the 250 allowable addresses for the Master Station.

5. Example Row 1 is MOV Address 1, Row 2 is MOV Address 2, etc.

6. Edit the tag name for each address.

7. The Master Station supports the ASCII character set.

Change Tag Name

MOV Address

Character -

Tag Value

MOVFU001

Character +

Pos -

Pos +

<< Back

Save Tag

1

-10

+10

Page 25

FCD LMAIM5001-00 DDC-100 Master Station II Installation and Operation Manual 25

Flow Control Division

Limitorque Actuation Systems

8. Tag names are limited to 8 characters. Spaces and other symbols are considered a character.

9. Save the file in .CSV (comma separated value) format.

10. Using FTP, copy the TAGNAME file to the Active Master Station.

11. Power cycle the Master Station to load the new TAGNAME file. On power-up the new tag names will

appear on the ACTIVE Master Station.

12. For a Hot Standby Master Station, after the Active unit has been power cycled, enter the

configuration screens and save the current configuration. This will transfer the new TAGNAME file to

the Standby Master Station.

Page 26

26 DDC-100 Master Station II Installation and Operation Manual FCD LMAIM5001-00

Flow Control Division

Limitorque Actuation Systems

This page is intentionally blank.

Page 27

FCD LMAIM5001-00 DDC-100 Master Station II Installation and Operation Manual 27

Flow Control Division

Limitorque Actuation Systems

6 MOV Network Configuration

These screens allow the user to configure the MOV network for operation. The first screen presented allows the user to

configure Baud Rate, Retries, and Poll Mode (Figure 6-1).

Figure 6-1: The Configure MOV Network screen

Once these parameters are configured, the “Auto Search” button can be pressed. This will cause the Master Station to

poll the network, searching for active MOVs. All inactive MOVs will be disabled in its configuration (Figure 6-2).

Figure 6-2: Auto-configuring Network screen

Touching “Next >>” will take the user to the next configuration screen on which the Timeout, First Active MOV, Last

Active MOV, Total MOVs, Propagation Delay, and RTS ON Delay can be configured (Figure 6-3).

Auto-Configuring Network

The Network is being auto-configured.

This process can take several minutes.

Please wait.

Estimated Time Remaining: # minutes

Baud Rate

4800

9600

19200

Retries

1

2

Redund. Loop

A Port Only

B Port Only

Configure MOV Network

Poll Mode

<< Back

Next >>

Auto Search

Page 28

28 DDC-100 Master Station II Installation and Operation Manual FCD LMAIM5001-00

Flow Control Division

Limitorque Actuation Systems

Figure 6-3: The second Configure MOV Network screen

Touching an “Edit” button will take the user to a screen similar to Figure 6-4. Each screen provides information about the

parameter being configured, the current value, and the valid values or range.

Figure 6-4: The Timeout Edit screen

The remaining eight screens under the Configure MOV Network section allow the user to select, graphically, which MOVs

are active (Figure 6-5).

Timeout

Current Value:

350

200-5000 (ms)

Valid Range:

MOV response

time-out period.

1 ms increments

(Min. 200 msec.)

350

<< Back

7

89

6

5

4

1

2

3

0.

CLR

DEL

-

E

N

T

EDIT

EDIT

EDIT

EDIT

EDIT

EDIT

Timeout (ms): 350

Prop. Delay (ms): 10

RTS ON Delay (ms): 10

Total Active MOVs: 32

First Conf. MOV: 1

Last Conf. MOV: 32

Configure MOV Network

<< Back

Next >>

Page 29

FCD LMAIM5001-00 DDC-100 Master Station II Installation and Operation Manual 29

Flow Control Division

Limitorque Actuation Systems

Figure 6-5: The Active MOVs screen

MOVs are represented by green/red lamps. Active MOVs are green, while inactive MOVs are red. Touching the number of

an MOV will toggle its state from Active to Inactive or Inactive to Active.

By selecting the Next button, the Master Station screen will advance to the next screen to enable/disable additional

MOVs. There are eight screens for activating all 250 MOVs.

Table 6-1: MOV activation pages

Page MOVs

1 of 8 1-32

2 of 8 33-64

3 of 8 65-96

4 of 8 97-128

5 of 8 129-160

6 of 8 161-192

7 of 8 193-224

8 of 8 225-250

Next >>

<< Back

001 002 003 004 005 006 007

008 009 010 011 012 013 014

015 016 017 018 019 020 021

022 023 024 025 026 027 028

029 030 031 032

Press on a MOV to toggle activation

MOV Not Active

MOV Active

LEGEND

Active MOVs MOVs 1-32 Page 1 of 8

Page 30

30 DDC-100 Master Station II Installation and Operation Manual FCD LMAIM5001-00

Flow Control Division

Limitorque Actuation Systems

This page is intentionally blank.

Page 31

FCD LMAIM5001-00 DDC-100 Master Station II Installation and Operation Manual 31

Flow Control Division

Limitorque Actuation Systems

7 DCS Port Configuration

7.1 Introduction

DCS Port: includes baud rate for DCS communication, stop bits, parity, electrical standard, DCS address,

RTS ON delay, RTS OFF delay, HMI state during DCS communication traffic, and selectable register maps

for Modbus function code 3, Modbus function code 5/15, and Modbus function code 6/16.

These screens allow the user to configure the DCS port for operation. The first screen presented allows

the user to configure Baud Rate, Retries, Parity, and Electrical connection (Figure 7-1).

Figure 7-1: The Configure DCS Port screen

Touching “Next >>” will take the user to the next DCS Port configuration screen on which the DCS Port

Address, RTS ON Delay, RTS OFF Delay, and HMI control may be disabled when DCS communication

traffic is active (Figure 7-2).

Configure DCS Port

Baud Rate

Stop Bits

Electrical

1

2

RS-232

RS-422

RS-485

None

Even

Odd

Parity

4800

9600

19200

38400

57600

115200

<< Back

Next >>

Page 32

32 DDC-100 Master Station II Installation and Operation Manual FCD LMAIM5001-00

Flow Control Division

Limitorque Actuation Systems

Figure 7-2: The DCS Port Configuration screen

Touching “EDIT” next to “DCS Address,” “RTS ON Delay (ms)” or “RTS OFF Delay (ms)” will allow the

user to enter new values.

Figure 7-3: DCS Port Address screen

DCS Port Address

Current Value:

1

1-247

Valid Range:

Modbus node

address for this

Master Station

for communication

to DCS or PLC.

1

<< Back

7

89

6

5

4

1

2

3

0.

CLR

DEL

-

E

N

T

DCS Port

DCS Address:

RTS ON Delay (ms):

RTS OFF Delay (ms):

HMI State during DCS Comm Traffic

HMI Control On

<< Back

1

0

0

EDIT

EDIT

EDIT

EDIT

EDIT

EDIT

Next >>

Page 33

FCD LMAIM5001-00 DDC-100 Master Station II Installation and Operation Manual 33

Flow Control Division

Limitorque Actuation Systems

Figure 7-4: RTS ON Delay screen

Press Back after editing values.

Figure 7-5: RTS OFF Delay screen

Press Back after editing values.

Touching “Next >>” on the DCS Port Configuration screen will take the user to the next DCS Data Table

Configuration screen.

7.2 Data Table Configuration

The Master Station data table is configurable for the Modbus Function codes 01, 05, 03, 05/15, 06/16.

The Modbus function codes 02 and 04 have a fixed data table and do not permit user alteration

(Figure 7-6).

RTS Off Delay

Current Value:

0

1-65535

Valid Range:

Time delay

(1 ms each incr.)

after the last

char. transmit

and before RTS

is dropped.

0

<< Back

7

89

6

5

4

1

2

3

0.

CLR

DEL

-

E

N

T

RTS On Delay

Current Value:

0

1-65535

Valid Range:

Time delay

(1 ms incr.)

between asserting

RTS and the

transmission of

data.

0

<< Back

7

89

6

5

4

1

2

3

0.

CLR

DEL

-

E

N

T

Page 34

34 DDC-100 Master Station II Installation and Operation Manual FCD LMAIM5001-00

Flow Control Division

Limitorque Actuation Systems

Figure 7-6: The Select Data Table screen

Touching the “View/Edit” button for Modbus 03 will take the user to a screen similar to Figure 7-7. This

screen permits the user to select the MOV parameters for holding register status.

<< Back Top Screen

Configure DCS Data Table

View/Edit

View/Edit

View/Edit

View/Edit

View/Edit

View/Edit

Read Only

Read/Write

Modbus Fc 03:

Modbus Fc 05/15:

Modbus Fc 06/16:

MNET Status

Page 35

FCD LMAIM5001-00 DDC-100 Master Station II Installation and Operation Manual 35

Flow Control Division

Limitorque Actuation Systems

03 —Read Holding Registers

Reads the binary contents of holding registers in the field units. The Master Station will allow the user to

select the number of registers to be visible per field unit up to a maximum of 10 (registers 4 – 13). Default

setting will display field unit registers 8 and 9.

Figure 7-7: The Register Selection screen

When the user selects the register(s) to be mapped into the DCS Data table, the toggle switch will display

a green dot. All registers between the first selected toggle switch and the last toggle switch selected will

be displayed. Once the selections have been completed, touching the “View >>” button will display a

sample Data Table for the first 12 registers (Figure 7-8).

Note: Once the selection is made, the “Store” button must be pressed for the configuration to be

stored.

Figure 7-8: The Sample Data Table screen

Touching the “<< Back” button will take the user to the register selection screen where the chosen register

format may be saved or altered to another configuration. (Figure 7-7).

Data Table Modbus Function Code 03

Reg.# MOV# Meaning

40001 1 Pos

40002 1 Status

40003 2 Pos

40004 2 Status

40005 3 Pos

40006 3 Status

40007 4 Pos

40008 4 Status

40009 5 Pos

40010 5 Status

40011 6 Pos

40012 6 Status

Reg.# MOV# Meaning

<< Back

Modbus Holding Registers

Select Desired Registers/MOV

Torque

Volts Analog #1 Analog #2

D. outFaultStatusPosition

DI #1 DI #2

Always

On

Store

View >>

<< Back

Page 36

36 DDC-100 Master Station II Installation and Operation Manual FCD LMAIM5001-00

Flow Control Division

Limitorque Actuation Systems

Selecting a register for a specific field unit follows the convention listed below.

Name MX-DDC UEC-3-DDC

Torque Torque (current) Average Torque (Opt)

Volts Actual Volts Not Used

Analog #1 Analog Input (User) Analog Input (User)

Analog #2 Analog Input (User) Analog Input (User)

Position Valve Position (0 - 100%) Valve Position (0 - 100%)

Status Register

Bit 00 Opened Opened

01 Closed Closed

02 Stopped Stopped

03 Opening Opening

04 Closing Closing

05 Valve Jammed Valve Jammed

06 Local Mode Selected Local Mode Selected

07 Combined Fault * Combined Fault *

08 Thermal Overload Fault Thermal Overload Fault

09 Future Use Fail De-Energize

10 Channel A Fault Channel A Fault

11 Channel B Fault Channel B Fault

12 Open Torque Switch Fault Open Torque Switch Faul

13 Close Torque Switch Fault Close Torque Switch Fault

14 Manual Operation Manual Operation

15 Phase Error Phase Error

Fault Register

Bit 00 Not Used Open Verify Fault

01 Not Used Close Verify Fault

02 Not Used Open De-Energize Fault

03 Not Used Close De-Energize Fault

04 Phases Missing Phases Missing

05 Phase Reversed Phase Reversed

06 Not Used Manual Mid to Open

07 Not Used Manual Open to Mid

08 Not Used Manual Mid to Close

09 Not Used Manual Close to Mid

10 Network ESD is ON ** Network ESD is ON**

11 Local ESD is ON Local ESD is ON

12 Unit Reset since last poll Unit Reset since last poll

13 Local Stop Selected Wrong Rotation

14 Opening in Local Opening in Local

15 Closing in Local Closing in Local

Page 37

FCD LMAIM5001-00 DDC-100 Master Station II Installation and Operation Manual 37

Flow Control Division

Limitorque Actuation Systems

Name MX-DDC UEC-3-DDC

Digital Output

Bit 00 Close Contactor Close Contactor

01 Open Contactor Open Contactor

02 AS-1 User (K3)

03 AS-2 SW-93 LED

04 AS-3 SW-93 LED

05 AS04 User (K6)

06 AR-1, Opt N/A

07 AR-2, Opt N/A

08 AR-3, Opt Bits 08-15

09 Network Relay Field Unit Software

10 - 15 Not Used Version ID

Digital Inputs 1

Bit 00 Remote Mode Selected Remote Mode Selected

01 Thermal Overload Fault Thermal Overload Fault

02 Open Torque Switch Open Torque Switch

03 Open Limit Switch Open Limit Switch

04 Close Torque Switch Close Torque Switch

05 Close Limit Switch Close Limit Switch

06 Not Used Aux. Open Input

07 Not Used Aux. Close Input

08 User 0, Terminal-21 User 0, TB2-1

09 User 1, Terminal-10 User 1, TB2-2

10 User 2, Terminal-9 User 2, TB2-3

11 User 3, Terminal-6 User 3, TB2-4

12 User 4, Terminal-7 User 4, TB2-5

13 User 5, Terminal-5 User 5, TB2-6

14 User 6, Opt, Terminal-23 User 6, I/O Module Only

15 User 7, Opt, Terminal-24 User 7, I/O Module Only

Digital Inputs 2

Bit 00 Not Used Analog in 1 Lost

01 Not Used Analog in 2 Lost

02 Analog in 1 Lost Analog in 3 Lost

03 Analog in 2 Lost Analog in 4 Lost

04 Network A/B Lost Network A/B Lost

05 Not Used Reserved

06 DDC Bd. Present Reserved

07 I/O Opt Board Present Reserved

08 Not Used Reserved

09 Not Used Reserved

10 Not Used Reserved

11 Not Used Reserved

12 Phase Lost Phase Lost

13 Phase Reverse Phase Reverse

14 User 8, Opt, Terminal-25 User 8, I/O Module Only

15 Not Used User 9, I/O Module Only

Page 38

38 DDC-100 Master Station II Installation and Operation Manual FCD LMAIM5001-00

Flow Control Division

Limitorque Actuation Systems

DCS Requested Register = [(field unit address –1) * number of registers per unit] + desired register

Touching the “View/Edit” button for Modbus 05/15 will take the user to a screen similar to Figure 7-9.

This screen permits the user to select desired coils/MOV.

01 —Read Coil Status

Reads the ON/OFF status of discrete outputs (coils) in the field units. This data table is configured with the

Modbus Function code 05/15 parameters.

05 —Force Single Coil / 15 —Force Multiple Coil

Forces only a single coil to either the ON or OFF state (15 Forces multiple coils to either the ON or OFF

state). This is a configurable value.

Figure 7-9: The Force Coils screen

When the users selects the coils to be mapped into the DCS Data table, the toggle switch will display a

green dot. All coils between the first selected toggle switch and the last toggle switch selected will be

displayed. Once the selections have been completed, touching the “View >>” button will display a sample

Data Table for the first 12 coils (Figure 7-10).

Modbus Coils

AS-1

Close/Stop

Select Desired Coils/MOV

Open/Stop

AS-2

AS-3 AS-4

AR-3

AR-2AR-1

Store

View >>

<< Back

Always

On

Always

On

Page 39

FCD LMAIM5001-00 DDC-100 Master Station II Installation and Operation Manual 39

Flow Control Division

Limitorque Actuation Systems

Figure 7-10: The Data Coils screen

Available Coils for each MOV

Coil Bit Slave

Number Number Address MX-DDC UEC-3-DDC I/O Module

1 0 1 Close / Stop Close / Stop Do Not Use

2 1 1 Open / Stop Open / Stop Do Not Use

3 2 1 AS-1 Lockout / K3 Relay #3

4 3 1 AS-2 Do Not Use Relay #4

5 4 1 AS-3 Do Not Use Relay #5

6 5 1 AS-4 K6 Relay #6

7 6 1 AR-1 Do Not Use Relay #2

8 7 1 AR-2 Do Not Use Relay #1

9 8 1 AR-3 Do Not Use Do Not Use

Touching the “<< Back” button will take the user to the coil selection screen where the chosen coil format

may be saved or altered to another configuration. (Figure 7-9).

Note: Once the selection is made, the “Store” button must be pressed for the configuration to be stored.

Selecting a coil for a specific field unit follows the convention listed below.

DCS Requested Coil = [(field unit address –1) * number of coils per unit] + desired coil

06 —Preset Single Register / 16 —Preset Multiple Register

Presets a value into a single-holding register. (16 Presets a value into multiple-holding registers) The data

table for this function code only permits one or two write registers per field unit. A unique data table is

created starting at register 45001.

Touching the “View/Edit” button for Modbus 06/16 will take the user to a screen similar to Figure 7-12.

This screen permits the user to select the MOV parameters for holding register status.

Data Table Modbus Function Code 05

Coil# MOV# Meaning

0001 1 Close

0002 1 Open

0003 2 Close

0004 2 Open

0005 3 Close

0006 3 Open

0007 4 Close

0008 4 Open

0009 5 Close

0010 5 Open

0011 6 Close

0012 6 Open

Coil# MOV# Meaning

<< Back

Page 40

40 DDC-100 Master Station II Installation and Operation Manual FCD LMAIM5001-00

Flow Control Division

Limitorque Actuation Systems

Figure 7-11: The Writer Holding Register screen

When the users selects the number of command registers to be mapped into the DCS Data table, the

toggle switch will display a green dot. Once the selections have been completed, touching the “View >>”

button will display a sample Data Table for the first 12 control or command registers (Figure 7-13).

Figure 7-12: Sample Data Table for Modbus Function Code 06/16

Limited to two registers per write with the Modus Function code, 16. Touching the “<< Back” button will

take the user to the Write Register selection screen where the chosen register format may be saved or

altered to another configuration (Figure 7-12). Selecting a register for a specific field unit follows the

convention listed on the next page.

DCS Requested Write Register = [(field unit address –1) * number of registers per unit] + desired register

Data Table Modbus Function Code 06

Reg.# MOV# Meaning

45001 1 CMD

45002 2 CMD

45003 3 CMD

45004 4 CMD

45005 5 CMD

45006 6 CMD

45007 7 CMD

45008 8 CMD

45009 9 CMD

45010 10 CMD

45011 11 CMD

45012 12 CMD

Reg.# MOV# Meaning

<< Back

Modbus Holding Registers

Select Desired Number of

Write Holding Registers

1/MOV

2/MOV

Store

View >>

<< Back

Page 41

FCD LMAIM5001-00 DDC-100 Master Station II Installation and Operation Manual 41

Flow Control Division

Limitorque Actuation Systems

Valid Command Register Operations

Values MX-DDC Definition UEC-3-DDC Definition

256 Open Open

512 Stop Stop

768 Close Close

1280 Start / Terminate Network ESD Start / Terminate Network ESD

2304 Engage AS-1 Engage #1 (I/O Module Only)

2560 Engage AS-2 Engage #2 (I/O Module Only)

2816 Engage AS-3 Engage #3

3072 Engage AS-4 Engage #4 (I/O Module Only)

3328 Engage AR-1 Engage #5 (I/O Module Only)

3584 Engage AR-2 Engage #6

4352 Disengage AS-1 Disengage #1 (I/O Module Only)

4608 Disengage AS-2 Disengage #2 (I/O Module Only)

4864 Disengage AS-3 Disengage #3

5120 Disengage AS-4 Disengage #4 (I/O Module Only)

5376 Disengage AR-1 Disengage #5 (I/O Module Only)

5632 Disengage AS-2 Disengage #6

6656 Enables “move-to” for units Enables “move-to” for units

requiring the 2 register writes. requiring the 2 register writes.

19200 + Value Position Value for units capable of Position Valve for units capable of

accepting 1 write “move-to” accepting 1 write “move-to”

Valid Argument Register Operations

Values MX-DDC Definition UEC-3-DDC Definition

0 - 100 Desired Valve Position Desired Valve Position

Page 42

42 DDC-100 Master Station II Installation and Operation Manual FCD LMAIM5001-00

Flow Control Division

Limitorque Actuation Systems

02 —Read Input Status

Reads the ON/OFF status of discrete inputs in the field units. This function code provides information

from field unit holding registers 9 – 13.

Read Input Status Data Table

Digital Slave Register / bit MX-DDC

Input Number Address MX-DDC UEC-3-DDC I/O Module

1 1 9/00 Opened

2 1 9/01 Closed

3 1 9/02 Stopped

4 1 9/03 Opening

5 1 9/04 Closing

6 1 9/05 Valve Jammed

7 1 9/06 Local Mode

8 1 9/07 Combined Fault

9 1 9/08 Thermal O/L

10 1 9/09 Fail De-Energize

11 1 9/10 Channel A Fault Channel A Fault

12 1 9/11 Channel B Fault Channel B Fault

13 1 9/12 Open Torque Switch

14 1 9/13 Close Torque Switch

15 1 9/14 Operated Manually

16 1 9/15 Phase Error

17 1 10/10 Network ESD Active

18 1 10/11 Local ESD Active

19 1 10/12 Microprocessor reset

20 1 10/13 Local Stop

21 1 10/14 Local Opening

22 1 10/15 Local Closing

23 1 12/00 Remote Mode User 8

24 1 12/08 User 0 User 0

25 1 12/09 User 1 User 1

26 1 12/10 User 2 User 2

27 1 12/11 User 3 User 3

28 1 12/12 User 4 User 4

29 1 12/13 User 5 User 5

30 1 12/14 User 6 User 6

31 1 12/15 User 7 User 7

32 1 13/14 User 8 User 19

Page 43

FCD LMAIM5001-00 DDC-100 Master Station II Installation and Operation Manual 43

Flow Control Division

Limitorque Actuation Systems

04 —Read Input Registers

Reads the binary contents of the input registers in the field units. This function code will map the

following field unit registers 4 – 8 into a data table.

Read Input Registers Data Table

Master Field Unit Field Unit

Station Register Register Address MX-DDC UEC-3-DDC

30001 4 1 Torque Scaled Output* Average Torque Output

30002 5 1 Main Volts Analog Input

30003 6 1 Analog Input Analog Input

30004 7 1 Analog Input Analog Input

30005 8 1 Valve Position (Scaled) Valve Position (Scaled)

30006 4 2 Torque Scaled Output* Average Torque Output

30007 5 2 Main Volts Analog Input

30008 6 2 Analog Input Analog Input

30009 7 2 Analog Input Analog Input

30010 8 2 Valve Position (Scaled) Valve Position (Scaled)

Page 44

44 DDC-100 Master Station II Installation and Operation Manual FCD LMAIM5001-00

Flow Control Division

Limitorque Actuation Systems

This page is intentionally blank.

Page 45

FCD LMAIM5001-00 DDC-100 Master Station II Installation and Operation Manual 45

Flow Control Division

Limitorque Actuation Systems

8 Ethernet Port Configuration

The Master Station includes support for several TCP/IP protocols, including Modbus Ethernet and HTTP (web server).

Each Master Station processing unit must be configured with a unique IP address, mask, gateway, and Hot Standby IP

Address if Hot Standby is installed (Figure 8-1). The Hot Standby IP Address is discussed in detail in Chapter 10.

Note: If Hot Standby is not installed, the Hot Standby IP Address must be 0.0.0.0.

Figure 8-1: The Configure Ethernet Port screen

Touching the “Edit” button for each row will allow the user to edit the octets of the addresses, one octet at a time, from

left to right (Figures 8-2, 8-3, 8-4, 8-5).

Use the “Next” and “Back” buttons on each editing screen to navigate between screens.

Figure 8-2: Edit Octet One screen

<< Back

IP Address 1

Current Value:

192

1-255

Valid Range:

1st octet of

IP Address for

this CPU

### ___ ___ ___

192

7

89

6

5

4

1

2

3

0.

CLR

DEL

-

E

N

T

Next >>

EDIT

EDIT

EDIT

EDIT

EDIT

EDIT

EDIT

EDIT

<< Back Top Screen

IP Address

192 168 0 100

Mask

255 255 255 0

Gateway

192 168 0 1

Hot Standby IP Address

0 0 0 0

Configure Ethernet Port

Page 46

46 DDC-100 Master Station II Installation and Operation Manual FCD LMAIM5001-00

Flow Control Division

Limitorque Actuation Systems

Figure 8-3: Edit Octet Two screen

Figure 8-4: Edit Octet Three screen

Figure 8-5: Edit Octet Four screen

<< Back

IP Address 1

Current Value:

100

1-255

Valid Range:

4th octet of

IP Address for

this CPU

___ ___ ___ ###

100

7

89

6

5

4

1

2

3

0.

CLR

DEL

-

E

N

T

Next >>

<< Back

IP Address 1

Current Value:

0

1-255

Valid Range:

3rd octet of

IP Address for

this CPU

___ ___ ### ___

0

7

89

6

5

4

1

2

3

0.

CLR

DEL

-

E

N

T

Next >>

<< Back

IP Address 1

Current Value:

168

1-255

Valid Range:

2nd octet of

IP Address for

this CPU

___ ### ___ ___

168

7

89

6

5

4

1

2

3

0.

CLR

DEL

-

E

N

T

Next >>

Page 47

FCD LMAIM5001-00 DDC-100 Master Station II Installation and Operation Manual 47

Flow Control Division

Limitorque Actuation Systems

9 General Settings Configuration

9.1 Overview

General settings include the Clock, Passwords, and Version (Figure 9-1).

Figure 9-1: The Configure General Settings screen

9.2 Clock

The clock is configured on the Clock screen (Figure 9-2). Touching an up arrow will increase a value,

while the down arrow will decrease the value.

Configure General Settings

Clock

Passwords

Version

<< Back

Page 48

48 DDC-100 Master Station II Installation and Operation Manual FCD LMAIM5001-00

Flow Control Division

Limitorque Actuation Systems

Figure 9-2: The Configure Clock screen

9.3 Passwords

Figure 9-3: The Login screen

Note: Each user level must be a unique password.

Passwords can be four digit numbers. The correct password for View, Control, or Configure will take the

user to the Main Menu (Figure 1-4).

If “Help” is pressed on the password screen, the user is given the opportunity to reset all passwords to

the defaults (Figure 1-3). Please contact Limitorque to obtain the reset password.

Passwords are easily configured via the Change Passwords screen (Figure 9-4).

7

89

6

5

4

1

2

3

0

DEL

CLR

E

N

T

Cancel

Help

Login: Please Enter Your Password

****

Clock

Current Date and Time

Month Day Year Hour Minute

<< Back

Top Screen

1 / 1 / 2003 12 : 30

Page 49

FCD LMAIM5001-00 DDC-100 Master Station II Installation and Operation Manual 49

Flow Control Division

Limitorque Actuation Systems

Figure 9-4: The Change Passwords screen

Touching the “Edit” button will take the user to an editing screen (Figure 9-5) which will allow them to

enter a new value for the password.

Figure 9-5: The Edit View Password screen

'View' Password

Current Value:

100

000-9999

Valid Range:

This password

permits the user

to VIEW network

conditions. Does

not allow control

or configuration.

100

<< Back

7

89

6

5

4

1

2

3

0.

CLR

DEL

-

E

N

T

<< Back

Top Screen

EDIT

EDIT

EDIT

EDIT

EDIT

EDIT

Change Passwords

'View' Role: 100

'Supervisor' Role: 200

'Administrator' Role: 300

Page 50

50 DDC-100 Master Station II Installation and Operation Manual FCD LMAIM5001-00

Flow Control Division

Limitorque Actuation Systems

9.4 Version

The Version information provided is read-only and may be requested by technical support to help

troubleshoot the Master Station (Figure 9-6).

Figure 9-6: The Master Station Revisions screen

<< Back Top Screen

Master Station Revisions

HMI Application Version 03/05.01

CPU Application Version 5163

Page 51

FCD LMAIM5001-00 DDC-100 Master Station II Installation and Operation Manual 51

Flow Control Division

Limitorque Actuation Systems

10 Hot Standby Configuration

10.1 Overview

The Master Station is capable of Hot Standby Operation. Two identical processing units communicate with

each other via an Ethernet 10-BaseT connection. One processing unit is configured to be “Hot” while the

other unit is configured to be “Standby.”

10.2 Configuration

Each unit must be configured for TCP/IP communication. This is accomplished via the HMI interface on

the “Configure Ethernet Port” screen (Figure 10-1).

Figure 10-1: The Configure Ethernet Port screen

In addition, the “Hot Standby IP Address” must be configured with the other processing unit’s IP address.

For example, the Hot processing unit must have the Standby processing unit’s IP address in the “Hot

Standby IP Address” section, and the Standby processing unit must have the Hot processing unit’s IP

address in the “Hot Standby IP Address” section.

IP addresses are configured by touching the “Edit” button on the row of the address to be configured.

This will allow the user to set the octets of the IP address from the left to the right, one octet at a time.

Use the “Next” and “Back” buttons on each editing screen to navigate between screens.

Following the successful configuration of the IP address information for each unit, further configuration is

necessary.

The “Configure Hot Standby” screen of the HMI (Figure 10-2) allows the user to configure the startup

mode of each processing unit, displays the current state of each processing unit (i.e. Idle, Standby, or

EDIT

EDIT

EDIT

EDIT

EDIT

EDIT

EDIT

EDIT

<< Back Top Screen

IP Address

192 168 0 100

Mask

255 255 255 0

Gateway

192 168 0 1

Hot Standby IP Address

192 168 0 101

Configure Ethernet Port

Page 52

52 DDC-100 Master Station II Installation and Operation Manual FCD LMAIM5001-00

Flow Control Division

Limitorque Actuation Systems

Hot) and allows the user to force the units to switch roles such that the Hot unit becomes the Standby

unit and the Standby unit becomes the Hot unit (Figure 10-3).

Figure 10-2: Configure Hot Standby screen

When configuration changes are saved in the Hot processing unit, these changes are transfered to the

Standby processing unit. Therefore, the network configuration, DCS configuration, and other

configurations only need to be performed once. The configuration for the Hot Standby Parameters are

unique for each processing unit, however, and as such must be completed independently for each

processing unit. The Hot Standby configuration is not transferred from the Hot unit to the Standby unit

when the configuration is saved.

Figure 10-3: Edit Hot Standby screen

Change State

Active/Standby

Configure Hot Standby

Hot Backup State

Idle

Standby

Active

Hot Backup Startup

Hot

Standby

Change State

Active/Standby

Configure Hot Standby

Hot Backup State

Idle

Standby

Active

Hot

Edit

Hot Backup Startup

Page 53

FCD LMAIM5001-00 DDC-100 Master Station II Installation and Operation Manual 53

Flow Control Division

Limitorque Actuation Systems

10.3 Operation

Under normal operating conditions, the Hot processing unit will transmit incremental data updates to the

Standby processing unit via the Ethernet connection.

The Standby unit will also monitor the communication on the network to ensure that the Hot processing

unit is viable.

In the event of a Hot unit failure, the Standby unit will smoothly transition into the Hot role. In addition, a

forced switch may be imposed. The transition period from Hot to Standby and Standby to Hot takes under

20 milliseconds to complete.

Each processing unit is capable of three states: Idle, Standby, and Hot.

Idle state: the processing unit is active, will accept incremental updates from a Hot unit, but will not perform

the Hot unit’s duties nor will the processing unit switch to Hot state should a Hot failure be detected.

Standby state: the processing unit is active, will accept incremental updates from a Hot unit, and will

switch to Hot state should a Hot failure be detected.

Hot state: the processing unit is the Hot unit and will perform the Hot duties of Network polling and

incremental updating of the Standby processing unit.

A state change can occur in any of the following conditions:

Hot Unit Failure: the Hot unit fails to send incremental updates to the Standby unit and there is no

network traffic.

Hot-Standby communication failure: the Standby unit is not receiving incremental update information

from the Hot unit but detects Network traffic. The Standby unit will zero its database and set an alert error.

The HMI will detect this state and will display “Idle” instead of “Standby”.

Page 54

54 DDC-100 Master Station II Installation and Operation Manual FCD LMAIM5001-00

Flow Control Division

Limitorque Actuation Systems

This page is intentionally blank.

Page 55

FCD LMAIM5001-00 DDC-100 Master Station II Installation and Operation Manual 55

Flow Control Division

Limitorque Actuation Systems

11 Network Status

The Network Status screens (Figure 11-1) present an overview of the entire network, 25 MOVs per page. There are ten

pages total. Use the “<< Back” and “Next >>” buttons to navigate between the screens.

Figure 11-1: Network Status Page 1 screen

There are two levels of information presented on this screen.

The first colored bar (left) indicates communication status. Green is good communication on both channels A and B.

Yellow indicates Channel A communication failure. Blue indicates Channel B communication failure. Red indicates failure

on both channels.

The second colored bar indicates MOV Fault status. A green bar indicates no fault, while a red flashing bar indicates

MOV fault.

Touching a MOV will take the user to the View MOV Status screen. The View MOV Status screens are discussed in

Chapter 13.

Network Status MOVs 1-25 Pg 1 of 10

<< Back Next >>

ACTIVE

No Comm Faults

Channel A Channel B

MOV Fault

Press on a MOV to view status detail

001 002 003 004 005

006 007 008 009 010

011 012 013 014 015

016 017 018 019 020

021 022 023 034 025

Channel A and B

No MOV Fault

Page 56

56 DDC-100 Master Station II Installation and Operation Manual FCD LMAIM5001-00

Flow Control Division

Limitorque Actuation Systems

This page is intentionally blank.

Page 57

FCD LMAIM5001-00 DDC-100 Master Station II Installation and Operation Manual 57

Flow Control Division

Limitorque Actuation Systems

12 View MOV Status

The View MOV Status screens allow the user to see detailed information regarding the MOV’s current status (Figure 12-1).

Figure 12-1: View MOV Status Page 1 screen

The first page allows the user to navigate between MOVs using the arrows to the left and right of the MOV Address. The

Tag name for each MOV is displayed for reference. A convenient “Control MOV” button is provided which allows the user

to jump to the Control MOV screen. Control MOV functionality is discussed in Chapter 14.

Gray lamps indicate an off or clear condition, while Red lamps indicate an on or active condition.

Figures 12-2, 12-3, 12-4, and 12-5 provide an overview of the comprehensive status information these screens provide

the user.

Figure 12-2: View MOV Status Page 2 screen

<< Back

More >>

MOV Address 1

View Status (page 2 of 5)

Tag MOVFU001

Opened Jammed

Local

Fault

Future

Th O/L

Phase

Channel A

Channel B

Open T/S

Close T/S

Manual Move

Closed

Stopped

Remote Mode

Opening

Closing

View Status (page 1 of 5)

MOV Address 1

Tag MOVFU001

ACTIVE

<< Back

More >>

0 % Open

Opened

Closed

Stopped

Opening

Closing

Fault

Channel A

Channel B

Control MOV

Type: MX

Page 58

58 DDC-100 Master Station II Installation and Operation Manual FCD LMAIM5001-00

Flow Control Division

Limitorque Actuation Systems

Figure 12-3: View MOV Status Page 3 screen

Figure 12-4: View MOV Status Page 4 screen

Figure 12-5: View MOV Status page 5 screen

<< Back

More >>

MOV Address 1

View Status (page 5 of 5)

Tag MOVFU001

Lost AI#1

Remote Mode

Lost AI#2

I/O Board

Analog Input #1 12345

Analog Input #2 12345

View Torque

Status Info

<< Back

More >>

MOV Address 1

View Status (page 4 of 5)

Tag MOVFU001

Remote

Remote Mode

Close L.S.

Future

Future

User #1

User #0

User #3

User #4

User #5

User #6

User #7

Th O/L

Open T.S.

Open L.S.

Close T.S.

User #2

User #8

<< Back

More >>

MOV Address 1

View Status (page 3 of 5)

Tag MOVFU001

Phase Lost

Remote Mode

Lcl Stop

Lcl Open

Lcl Close

AS-2

AS-1

AS-3

AS-4

AR-1 (Opt)

AR-2 (Opt)

AR-3 (Opt)

Phase Rev

Net ESD

Lcl ESD

Reset

Page 59

FCD LMAIM5001-00 DDC-100 Master Station II Installation and Operation Manual 59

Flow Control Division

Limitorque Actuation Systems

Page 5 (Figure 12-5) provides a link to Torque Status information (Figure 12-6).

Figure 12-6: MOV Torque Status screen

Start % Open 0

Stop % Open 0

Time (ms) 0

High Mid Tq 0

High Tq Pos 0

Avg. Tq 0

Remote Mode

Hi Tq @ Stop 0

Hi Start Tq 0

Hi Stop Tq 0

<< Back

MOV Address 1

MOV Torque Status

Tag

MOVFU001

Page 60

60 DDC-100 Master Station II Installation and Operation Manual FCD LMAIM5001-00

Flow Control Division

Limitorque Actuation Systems

This page is intentionally blank.

Page 61

FCD LMAIM5001-00 DDC-100 Master Station II Installation and Operation Manual 61

Flow Control Division

Limitorque Actuation Systems

13 Control MOV

MOVs can be controlled from these screens. This includes opening, stopping, closing, and opening to a set position

(such as 50%).

Control MOV Page one (Figure 13-1) allows the user to open, stop, and close a MOV. Navigation between MOVs is

accomplished via the arrows at the top of the screen. The MOV Address and Tag indicate the MOV being controlled. The

and arrow buttons move the address in increments of 10.

Figure 13-1: Control MOV Page 1 screen

Control MOV page two (Figure 13-2) allows the user to set a MOV to an arbitrary position.

Figure 13-2: Control MOV Page 2 screen

Control MOV

MOV ID: 1

Tag MOVFU001

SET

POSITION

Percent Open Set Position

50%

Local Mode

50%

SHUT OPEN

+1

+10

-1

-10

<< Back

Control MOV

MOV Address 1

Tag MOVFU001

Channel A

Channel B Closed

OPEN

LOCAL MODE

STOP

CLOSE

<< Back

More >>

AR Relays

AS Relays

Page 62

62 DDC-100 Master Station II Installation and Operation Manual FCD LMAIM5001-00

Flow Control Division

Limitorque Actuation Systems

Figure 13-3: Control Auxillary Coils screen 1

Figure 13-4: Control Auxillary Coils screen 2

Control Aux. Coils

<< Back

MOV Address: 1 Tag MOVFU001

Note: Relays must be configured for

DDC Control at the MOV.

Feedback to User Inputs

is recommended

AS-1 AS-2 AS-3 AS-4

User #0 User #2 User #4 User #6

User #1 User #3 User #5 User #7

1

111

0

0

00

Control Aux. Coils

<< Back

MOV Address: 1 Tag MOVFU001

Note: Relays must be configured for

DDC Control at the MOV.

Feedback to User Inputs

is recommended

AS-1 AS-2 AS-3

User #0 User #2 User #4 User #6

User #1 User #3 User #5 User #7

1

11

0

00

Page 63

FCD LMAIM5001-00 DDC-100 Master Station II Installation and Operation Manual 63

Flow Control Division

Limitorque Actuation Systems

14 Emergency Shut Down

Should it be necessary to initiate an Emergency Shut Down of the networked MOVs, this can be accomplished by

accessing the Emergency Shut Down screen from the Main Menu (Figure 14-1).

Figure 14-1: Emergency Shut Down screen

Two options are available: Initiate a shutdown and Clear a shutdown. Once an Emergency Shut Down has completed and

is no longer necessary, the Emergency Shut Down state is cleared by pressing the Clear button.

When an Emergency Shut Down is Initiated, the Emergency Shut Down in Progress screen will be displayed

(Figure 14-2).

Figure 14-2: Emergency Shut Down in Progress screen

Emergency Shut Down In Progress

The Emergency Shut Down Procedure

has been initiated.

Main Menu

Procedure Complete

Emergency Shut Down ACTIVE

Pressing the red button will initiate

an Emergency Shut Down procedure

for the Network.

Once Initiated, the Emergency Shut

Down Procedure cannot be revoked.

Clear

Emergency

Shut Down

Initiate

Emergency

Shut Down

Cancel

Page 64

64 DDC-100 Master Station II Installation and Operation Manual FCD LMAIM5001-00

Flow Control Division

Limitorque Actuation Systems

When an Emergency Shut Down is Cleared, the Emergency Shut Down Termination in Progress screen will be displayed

(Figure 14-3).

Figure 14-3: Emergency Shut Down Termination screen

Emergency Shut Down Termination

The Emergency Shut Down Procedure

termination is in progress.

Main Menu

Procedure Complete

Page 65

FCD LMAIM5001-00 DDC-100 Master Station II Installation and Operation Manual 65

Flow Control Division

Limitorque Actuation Systems

15 Logger

The Logger allows the user to monitor the status of the network or communication traffic. The Logger Menu provides

two options: Data Analyzer and Network Status (Figure 15-1).

Figure 15-1: Logger Menu screen

Note: In a Hot Standby configuration, the Standby unit does not report logger functions.

The Data Analyzer screen allows the user to monitor communication traffic (Figure 15-2). Several monitoring options

are available:

Channel A: monitor communication on Channel A port

Channel B: monitor communication on Channel B port

DCS Port: monitor communication on DCS port

MNET Port: monitor communication on Modbus ethernet port

Activity Log Disabled: no logging

Logger

Data Analyzer

Logger Menu ACTIVE

<< Back

Page 66