Page 1

DDC-100

Direct-to-Host

Programming Guide

FCD LMAIM4019-00

(Replaces 435-23009)

Network Control Systems

Page 2

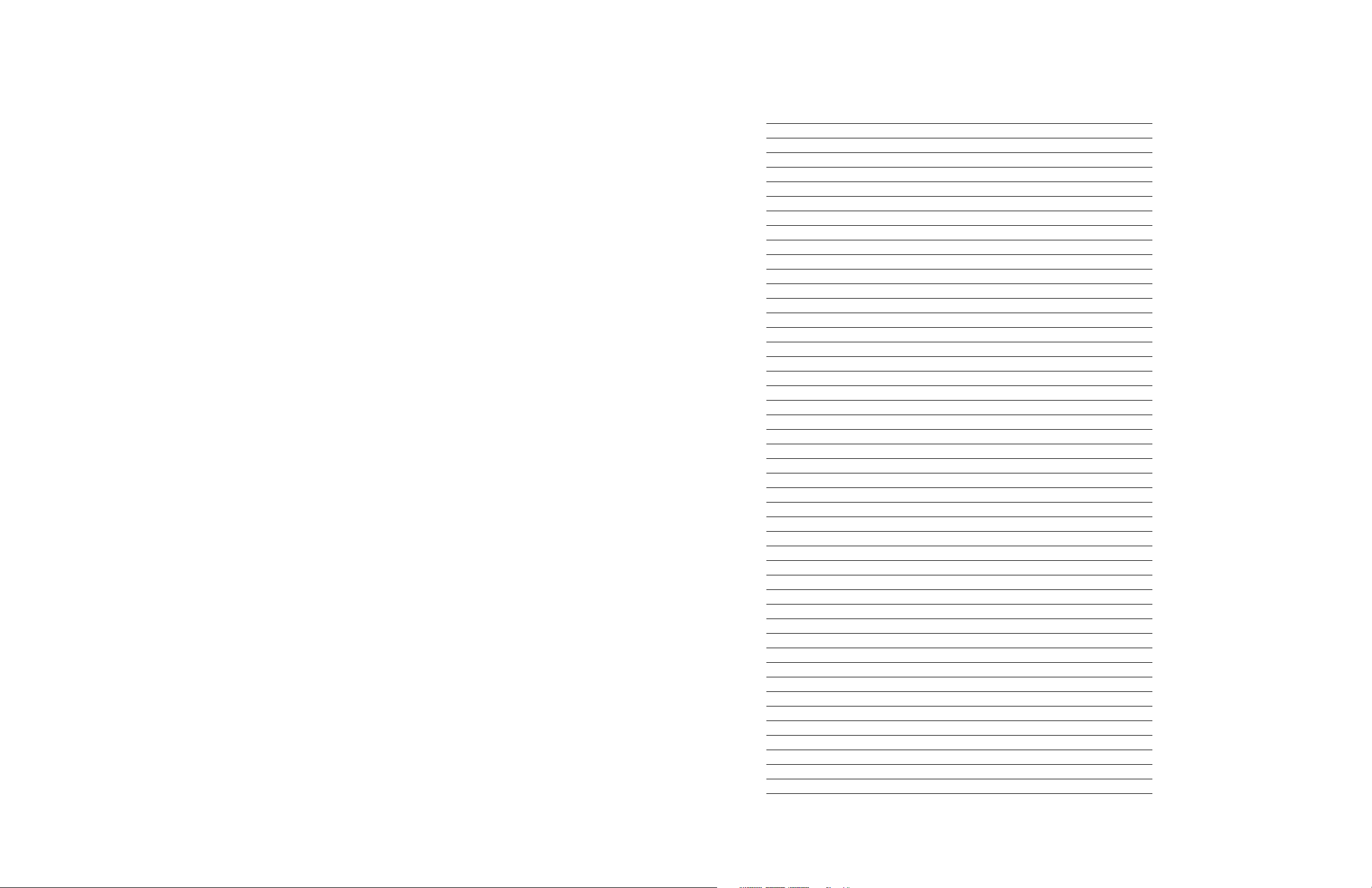

Contents

1 Introduction 1

1.1 Premise 1

1.2 Emphasis 1

1.3 Audience 2

2 Direct-to-Host Valve Control 3

2.1 Advantages of Direct-to-Host Control 3

2.2 Deliverables for Successful Direct-to-Host Implementations 4

3 Field Unit Monitoring and Control 5

3.1 Use of Coils and Registers for Monitoring and Control 5

3.2 Modbus 6

3.2.1 Modbus Function Code 01 (Read Coil Status) 7

3.2.2 Modbus Function Code 02 (Read Input Status) 8

3.2.3 Modbus Function Code 03 (Read Holding Register) 11

3.2.4 Modbus Function Code 04 (Read Input Register) 18

3.2.5 Modbus Function Code 05 (Force Single Coil) 18

3.2.6 Modbus Function Code 06 (Preset Single Register) 19

3.2.7 Modbus Function Code 08 (Diagnostics) 23

3.2.8 Modbus Function Code 15 (Force Multiple Coils) 24

3.2.9 Modbus Function Code 16 (Preset Multiple Registers) 24

4 The DDC-100 Network 27

Belden 3074F Specifications 27

Belden 3105A Specifications 28

Belden 9841 Specifications 28

4.1 Field Unit Network Communication Channels 28

4.1.1 Field Unit Network Bypass Relays 29

4.1.2 Field Unit Repeater Circuits 29

4.2 Network Topologies 29

4.2.1 Redundant Loop 29

4.2.2 Single-Ended Loop 31

4.2.3 Single-Line Multi-drop 32

4.3 Network Polling 33

4.3.1 Network Communication Errors 35

4.3.2 Network Communication Examples 36

4.4 Network Control 38

4.4.1 Ladder Logic Routines 38

4.4.2 Software Control Modules (C++ or Visual Basic Program) 38

4.4.3 Personal Computer with a Graphical User-Interface 39

5 Interfacing Hardware for the DDC-100 Network 41

5.1 RS-232 to RS-485 Converters 41

5.1.1 RS-232/RS-485 Control Line Steered Converter (P/N 61-825-0966-4) 43

5.1.2 RS-232/RS-485 Converter with RS-485 Self-Steering (P/N 61-825-1032-4) 45

5.2 RS-485 Connection Direct to the DDC-100 Field Unit 48

6 Programming Recommendations 49

6.1 Monitoring Field Unit Status 49

6.2 Issuing Control Commands 50

A Typical DDC-100 Network Installation Assignments 53

Project supplier responsibilities 53

FCD LMAIM4019-00 DDC-100 Direct-to-Host Programming Guide i

Page 3

Figures

Figure 4.1 – DDC-100 Redundant Loop Network 30

Figure 4.2 – DDC-100 Single-Ended Loop Network 31

Figure 4.3 – DDC-100 Single-Line Multi-Drop Network 33

Figure 5.1 – RS-232/RS-485 Converter Dimensions and Rack Mount Kit 43

Figure 5.2 – RS-232/RS-485 Cable Diagram 43

Figure 5.3 – Front and Back Panels of Steered Converter 44

Figure 5.4 – Front and Back Panels of Self-Steering Converter 46

Tables

Table 3.1 – Field Unit Communication Parameters 5

Table 3.2 – Modbus Function Codes Supported 7

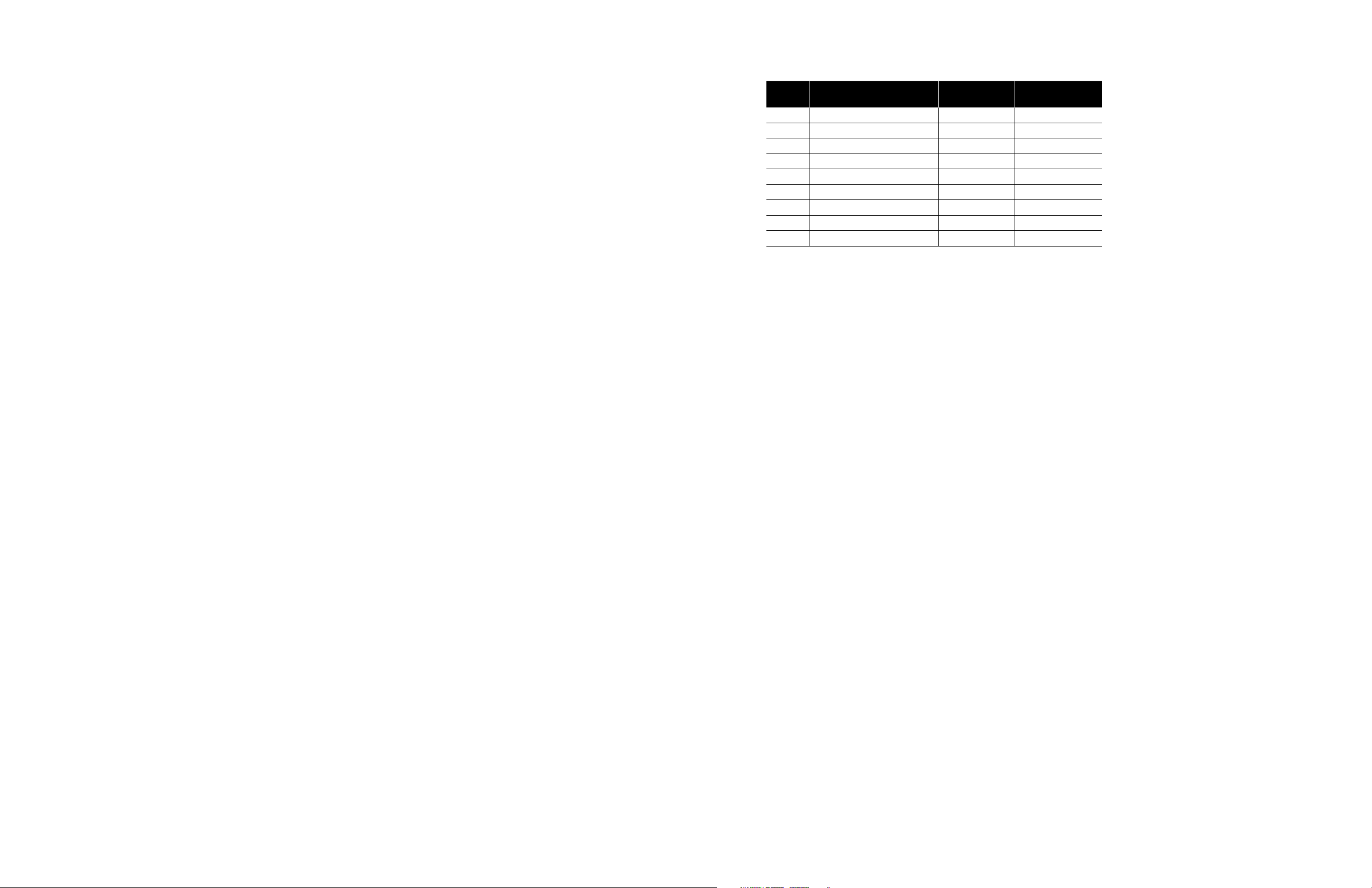

Table 3.3 – DDC-100 Coil Assignments, Modbus Function Code 01 Usage for Digital Outputs 8

Table 3.4 – Status Bit Definitions 8

Table 3.4 – Status Bit Definitions (continued) 9

Table 3.5 – Field Unit Register Definitions 12

Table 3.6 – DDC-100 Coil Assignments Modbus Function Code 05 Usage for Digital Outputs 19

Table 3.7 – Modbus 06 Command and Field Unit Holding Register 40001 20

Table 3.8 – Diagnostic Codes Supported by the DDC-100 Field Unit 23

Table 4.1 – Average Field Unit Response Time 34

Table 4.2 – Average Network Scan Time (seconds) 35

Table 5.1 – RS-232/RS-485 Converter Specifications 42

Table 5.2 – Steered Converter Assembly (P/N 22300-7591) 42

Table 5.3 – Self-Steering Converter Assembly (P/N 22300-7601) 42

Table 5.4 – RS-232/RS-485 Converter (P/N 61-825-0966-4) DIP Switch Functions 44

Table 5.5 – RS-232/RS-485 Converter (P/N 61-825-0966-4) RS-232 Connector 44

Table 5.6 – RS-232/RS-485 Converter (P/N 61-825-0966-4) RS-485 Connector 45

Table 5.7 – RS-232/RS-485 Converter (P/N 61-825-0966-4) Jumpers 45

Table 5.8 – RS-232/RS-485 Converter (P/N 61-825-1032-4) RS-232 Connector 46

Table 5.9 – RS-232/RS-485 Converter (P/N 61-825-1032-4) RS-485 Connector 46

Table 5.10 – RS-232/RS-485 Converter (P/N 61-825-1032-4) Jumpers

Table 6.1 – Sample Tag Table for Direct-to-Host applications 51

1 47

Introduction

1

1.1 Premise

This Programming Guide was written for the user who is connecting Flowserve Limitorque

DDC-100 Network-compatible valve actuators directly to a control system Host computer. These

guidelines provide the information that is necessary to control and monitor the valve actuators

through a serial data communications network.

Your safety and satisfaction are very important to Flowserve. Please follow all instructions carefully

and pay special attention to safety.

1.2 Emphasis

The following methods will be used to emphasize text throughout this manual:

WARNING: Refers to personal safety. This alerts the reader to potential danger or harm.

c

Failure to follow the advice in warning notices could result in personal injury or death.

CAUTION: Directs attention to general precautions, which, if not followed, could result in

a

personal injury and/or equipment damage.

NOTE: Highlights information critical to the understanding or use of these products.

Bold text highlights other important information that is critical to system components.

CAPITALIZED text stresses attention to the details of the procedure.

Underlined text emphasizes crucial words in sentences that could be misunderstood if the word is

not recognized.

The purpose of these emphasized blocks of text is to alert the reader to possible hazards associated

with the equipment and the precautions that can be taken to reduce the risk of personal injury and

damage to the equipment.

Read and become familiar with the material in these guidelines before attempting installation,

operation, or maintenance of the equipment. Failure to observe precautions could result in serious

bodily injury, damage to the equipment, or operational difficulty.

ii DDC-100 Direct-to-Host Programming Guide FCD LMAIM4019-00 FCD LMAIM4019-00 DDC-100 Direct-to-Host Programming Guide 1

Page 4

1.3 Audience

These guidelines were written to help you successfully connect Limitorque valve actuators directly

to a control system Host computer. You do not have to be an expert in electronics or digital controls

to utilize this manual. However, this manual assumes that you have a working understanding of

valve actuators and a fundamental understanding of control system programming.

The following manuals should be available before attempting to connect the valve actuators to the

control system:

1) Accutronix Installation and Operation for MX-DDC Field Unit Manual

Bulletin LMAIM1329

2) DDC-100 UEC Field Unit (Modbus®) Installation and Operation Manual

Bulletin LMAIM4029

3) DDC-100 UEC Field Unit Wiring and Startup Guidelines

Bulletin LMAIM4022

4) DDC-100 UEC Field Unit Installation and Commissioning Manual

Bulletin LMAIM4030

5) Modicon Modbus Protocol Reference Guide PI-MODBUS-300 Rev. G

available from Modicon

6) Valve actuator installation manual for the specific model(s) to be installed.

An understanding of valve actuators and digital control systems is beneficial to all system users.

Flowserve assistance and training is available to help you operate your system at top efficiency. It

is recommended that you read this entire manual before attempting to install the valve actuators in

your control system.

Direct-to-Host Valve

2

In this document, Direct-to-Host valve control is defined as the use of a customer-supplied

(possibly pre-existing) Host control system (PLC, DCS, PC, etc.) to directly control the actuation of

valves that are equipped with DDC-100 Network-compatible field units. The field units are microprocessor-based devices that can communicate with the Host and respond to Host commands for

valve motion and status. The DDC-100 Network uses the EIA RS-485 standard for the physical layer

and the A.E.G. Modicon Modbus protocol for the command structure.

The Direct-to-Host solution to valve actuation systems provides distinct advantages for many

users. These benefits range from maximizing system design flexibility to utilizing existing plant

equipment for valve actuator control. The customer can emphasize selecting the best equipment

and software that closely matches the application’s requirements. This solution allows the user to

add valve control while avoiding the need to incorporate new control equipment into the facility.

Direct-to-Host functionality is accomplished through the use of open architecture control and

communications in the valve actuator controls that economically accommodate widely available

interfaces for existing SCADA, PLC, or personal computers.

Control

2.1 Advantages of Direct-to-Host Control

• Freedom to design a valve actuator system to interface directly with customer-preferred supervisory equipment with open-market availability and off-the-shelf components.

• Maximizes valve actuator system exibility by utilizing the industry standard protocol of Modbus,

complemented with the EIA RS-485 electrical standard.

• Increases control room equipment utilization while incorporating a cost savings to the customer

through the elimination of unnecessary hardware.

• Supports the use of control system components familiar to the user and eliminates the requirement to learn third-party interfaces.

• Strengthens control system architecture with components readily available on the open market.

• Encourages parts replacement and support programs favorable to the user.

• Promotes direct downloading of valve actuator data to the supervisory control system without

intervening proprietary hardware or protocols.

2 DDC-100 Direct-to-Host Programming Guide FCD LMAIM4019-00 FCD LMAIM4019-00 DDC-100 Direct-to-Host Programming Guide 3

Page 5

• Provides a safe and reliable communications path between the supervisory control system and

valve actuator network. This eliminates an unnecessary single point of failure that would exist if

the valve control network required a gateway device.

• Enhances the operational relationship between the customer and the customer’s preferred system

integrator.

2.2 Deliverables for Successful

Direct-to-Host Implementations

Each Direct-to-Host installation requires coordination to ensure that every supplier understands

their deliverable responsibilities. When suppliers understand particular obligations and perform

the tasks in an orderly and timely fashion, the DDC-100 Network installation process will progress

very smoothly. Appendix A outlines a “typical” chart detailing areas of responsibility or supplier

deliverables for installing a DDC-100 system. This appendix is a guideline and may vary from

project to project.

Field Unit

3

Monitoring and

Control

Flowserve Limitorque valve actuators that are DDC-100 Network compatible can be controlled and

monitored by sending queries and receiving responses over a serial data network. The DDC-100

Network uses the non-proprietary Modbus message protocol and EIA RS-485 standard for the

physical communication link.

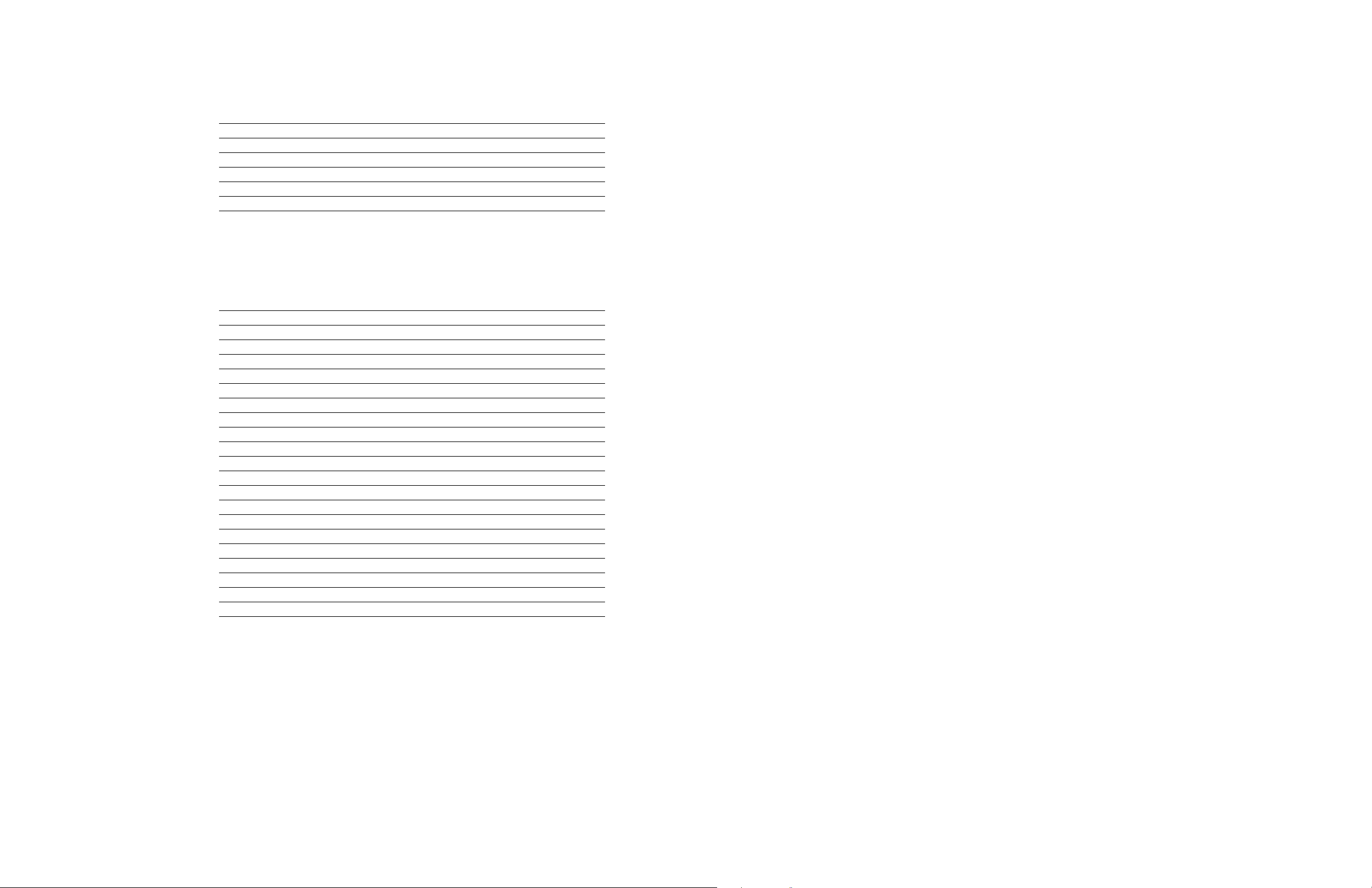

Table 3.1 – Field Unit Communication Parameters

Parameter Options Default

Message Framing RTU, ASCII RTU

Baud Rate 1200, 2400, 4800, 9600, 19,200 9600

Data Bits 8 8

Stop Bits 1 1

Parity None None

Error Checking CRC-16 (RTU), LRC (ASCII) CRC-16 (RTU)

Field Unit Address Range 1–250 Configurable Configurable

3.1 Use of Coils and Registers

for Monitoring and Control

The material in this section is a brief tutorial and general discussion of the use of Modbus queries

and responses to control valve actuators. The detailed discussion of the commands will be given in

Section 3.2.

The Modbus communications protocol allows for working with two types of information—coils

(or bits) and registers (or 16-bit words). Coils are either ON (1) or OFF (0) and are used in direct

relation to relays (that have coils). For example, in a typical actuator, Coil 1 is energized to CLOSE

the actuator and Coil 2 is energized to OPEN the actuator. Register information is used for control

functions that do not involve coils. An example would be to write a command value to energize the

open or close coil or move the actuator to a position of 0 to 100% of open.

4 DDC-100 Direct-to-Host Programming Guide FCD LMAIM4019-00 FCD LMAIM4019-00 DDC-100 Direct-to-Host Programming Guide 5

Page 6

Queries are used to send requests from the Modbus master (Host) to the Modbus slave (DDC-100

Field Unit), and the slave must respond with an appropriate response or an error message.

The Modbus function codes that are supported in the DDC-100 Network are a subset of the

complete Modbus function codes and are listed below:

01 Read Coil Status Reads the ON/OFF status of discrete outputs (coils) in the field units.

02 Read Input Status Reads the ON/OFF status of discrete inputs in the field units.

03 Read Holding Registers Reads the binary contents of holding registers in the field units.

04 Read Input Registers Reads the binary contents of the input registers in the field units.

05 Force Single Coil Forces a single coil to either the ON or OFF state.

06 Preset Single Register Presets a value into a single-holding register.

08 Diagnostics Provides communication tests and checks for internal error conditions in the

field units.

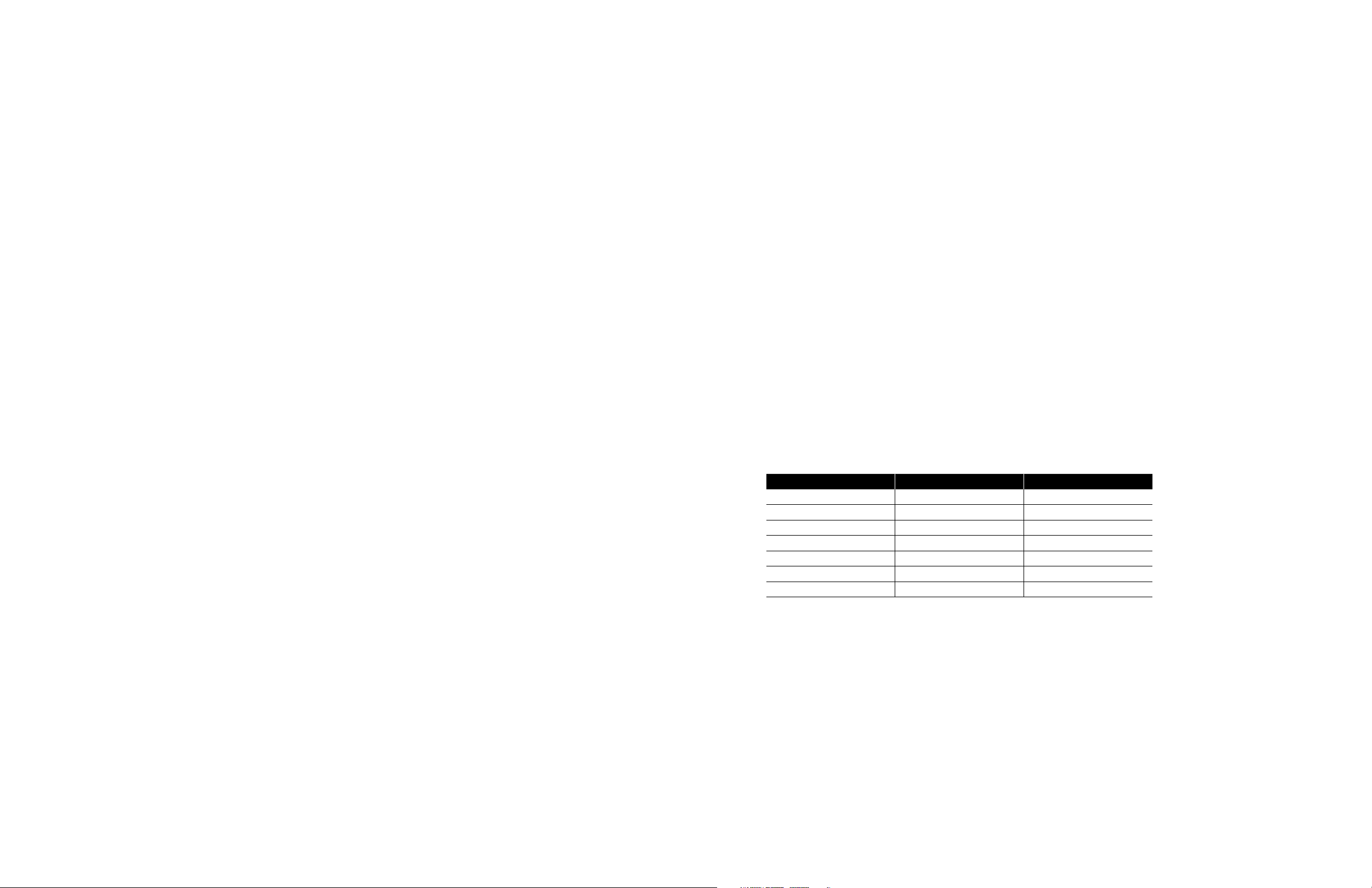

Table 3.2 – Modbus Function Codes Supported

Function

Code

Note: MX-DDC does not support Modbus function code 02.

Name

01 Read Coil Status Bit 0,000 - 9,999

02 Read Input Status Bit 10,000 - 19,999

03 Read Holding Register Register 40,000 - 49,999

04 Read Input Register Register 30,000 - 39,999

05 Force Single Coil Bit 0,000 - 9,999

06 Preset Single Register Register 40,000 - 49,999

08 Diagnostics N/A N/A

15 Force Multiple Coils Bit 0,000 - 9,999

16 Preset Multiple Registers Register 40,000 - 49,999

Modbus function codes 15 and 16 are supported in:

UEC-3-DDC Modbus Firmware 2.00 and greater

MX-DDC Firmware 02/01.00 and greater

Bit/Register

Addressing

Extended

Addressing Range

15 Force Multiple Coils Forces multiple coils to either the ON or OFF state.

16 Preset Multiple Registers Presets a value into multiple holding registers.

NOTE: All data in Modbus messages are referenced to zero. The first occurrence of a data item is

addressed as item number zero. This includes Coils, Inputs, and Registers. For example, coils 1-8

would be addressed as 0-7, inputs 1-16 would be addressed as 0-15, and registers 1-16 would be

addressed as 0-15.

3.2 Modbus

The Modbus protocol was developed by A.E.G. Modicon for communicating to various networked

devices. The relationship between these devices and a central controller is called a master-slave

relationship in which the master (Host device) initiates all communications. The slave devices (field

units in the actuators) respond to the queries from the master. Modbus only permits one master to

communicate at any given time (simultaneous communication is prohibited) for assuring process

control integrity.

The controlling device (master) must conform to the Modbus protocol as defined in the Modicon

Modbus Protocol Reference Guide PI-MODBUS-300 Rev. G and support Modbus function codes

01 through 06, 08, 15 and 16. These function codes are a subset of the complete protocol and are

defined in Table 3.2.

The choice of which query to use in a particular situation can significantly affect the efficiency of the

network. As an example, consider the situation where the Host requires the status of the coils, the

status of the digital inputs, the status of the faults, and the status of the timers and analog channels. This information can be obtained by using the 01 - Read Coil Status query, the 02 - Read Input

Status query, and 04 - Read Input Register query. To obtain this information, the Host would have

to send three separate queries, and the field unit would have to respond to each query separately.

A more efficient way to accomplish this same request for information would be through the use of

the 03 - Read Holding Register query. The Host would issue the 03 query (specifying the registers

to read), and the field unit would respond with one response that would contain all of the requested

information. The latter approach would generate considerably less network traffic than the former

approach, improving network capacity and response times.

In the strict sense, all transmissions from the Modbus master are called commands. In this manual,

a request for information, however, may be referred to as a query. Usually the term query will only

be used in conjunction with function codes (01), (02), (03), (04), and (08), which typically request

data. Commands are used in conjunction with function codes (05), (06), (15) and (16), which

typically initiate field unit action.

Examples

• The coil known as “coil 1” in the eld unit is addressed as coil 0000 in the data address eld of a

Modbus message.

• Digital input 129 decimal is addressed as digital input 0080 hex (128 decimal).

• Holding register 40001 is addressed as register 0000 in the data address eld of the message.

The function code field already specifies “holding register” operation. Therefore the reference

“4XXXX” is implicit.

• Holding register 40009 is addressed as register 0008 hex (8 decimal).

3.2.1 Modbus Function Code 01 (Read Coil Status)

This function code is used to read the coil status in the DDC-100 Field Unit. There are nine coils

available to be read on DDC-100 Field Units as shown in Table 3.3. For the MX/DDC or UEC-3-DDC

Field Unit, Coil 1 indicates CLOSE contactor and is interlocked with Coil 2, Coil 2 indicates OPEN

contactor and is interlocked with Coil 1. When the I/O Module is used in non-MOV (motor-operated

valve) mode, relays 1 through 6 or coils 3 through 8 are available for user configuration.

6 DDC-100 Direct-to-Host Programming Guide FCD LMAIM4019-00 FCD LMAIM4019-00 DDC-100 Direct-to-Host Programming Guide 7

Page 7

Table 3.3 – DDC-100 Coil Assignments, Modbus Function Code 01 Usage for Digital Outputs

Coil

Number

1 00 Close / Stop Close / Stop Close / Stop Do Not Use

2 01 Open / Stop Open / Stop Close / Stop Do Not Use

3 02 AS-1 Lockout or Relay #3 Lockout or Relay #3 Relay #3

4 03 AS-2 Do Not Use Relay #4 Relay #4

5 04 AS-3 Do Not Use Relay #5 Relay #5

6 05 AS-4 Relay #6 Relay #6 Relay #6

7 06 AR-1 (Opt) Do Not Use Do Not Use Relay #21

8 07 AR-2 (Opt) Do Not Use Do Not Use Relay #12

9 08 AR-3 (Opt) Do Not Use Do Not Use Do Not Use

Note 1: Relay #2 is physical Relay K2.

Note 2: Relay #1 is physical Relay K1.

Bit

Number

MX/DDC UEC-3-DDC DDC-100 Clamshell I/O Module

Example

Poll field unit number 3 for 8 coils starting at coil 1.

Query 0301000000083C2E

Response 03010118503A

Message Breakdown

Query Response

03 Slave (Field Unit) Address 03

01 Function 01 Function

00 Starting Address Hi 01 Byte Count

00 Starting Address Lo 18 1 Data (Coils 8 - 1)

00 No. of Points Hi 503A Error Check (CRC)

08 No. of Points Lo

3C2E Error Check (CRC)

Note 1: 18h equals 00011000 or coils 4 and 5 are ON.

Slave (Field Unit)

Address

3.2.2 Modbus Function Code 02 (Read Input Status)

This function code is used to read the discrete input status bits in the DDC-100 Field Unit. The use

of this function code will provide the user with the input status bits that are used to develop holding

registers 9 through 13. The status bit inputs are contained in locations 10129-10208 for each

DDC-100 Field Unit and are defined in Table 3.4.

Table 3.4 – Status Bit Definitions

Bit Number

129 128 Opened Not Used

130 129 Closed Not Used

131 130 Stopped Not Used

132 131 Opening Not Used

133 132 Closing Not Used

134 133 Valve jammed Not Used

135 134 Actuator switched to local mode Not Used

136 135 Combined fault Not Used

Modbus

Bit

Address

UEC-3-DDC and DDC-100 Clamshell I/O Module

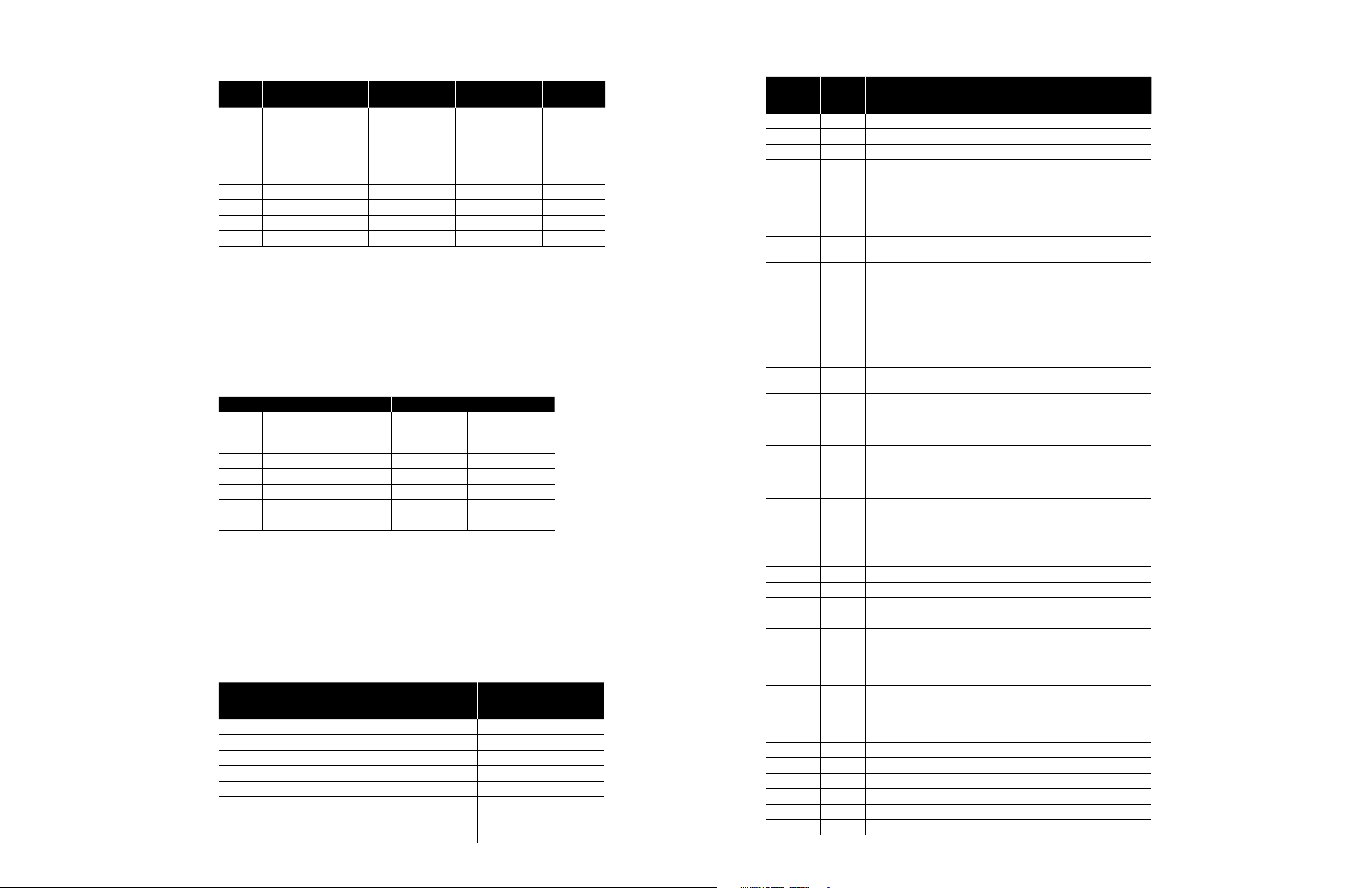

Table 3.4 – Status Bit Definitions (continued)

Bit Number

137 136 Over-temperature fault Not Used

138 137 Actuator failing to de-energize Not Used

139 138 Channel A fault Channel A fault

140 139 Channel B fault Channel B fault

141 140 Open torque switch fault Not Used

142 141 Close torque switch fault Not Used

143 142 Valve operated manually fault Not Used

144 143 Phase error Not Used

145 144

146 145

147 146

148 147

149 148

150 149

151 150

152 151

153 152

154 153

155 154

156 155 Local emergency shutdown is active Not Used

157 156

158 157 Wrong rotation Not Used

159 158 Opening in local mode Not Used

160 159 Closing in local mode Not Used

161 160 Close contactor (interlocked) Not Used

162 161 Open contactor (interlocked) Not Used

163 162 Lockout or user, Relay 3 Relay 3

164 163

165 164

166 165 User, Relay 6 Relay 6

167 166 Close contactor (non-interlocked) Relay 2 (K2)

168 167 Open contactor (non-interlocked) Relay 1 (K1)

169 168 Field unit software vs. ID Field unit software vs. ID

170 169 Field unit software vs. ID Field unit software vs. ID

171-176 170-175 Field unit software vs. ID Field unit software vs. ID

177 176 Remote switch User Input 8

178 177 Thermal overload User Input 9

Modbus

Bit

Address

UEC-3-DDC and DDC-100 Clamshell I/O Module

Input “open verify” is not active after open

command is initiated

Input “close verify” is not active after close

command is initiated

Input “open verify” is active after open

command is de-energized

Input “close verify” is active after close

command is de-energized

“Ph_det” (Phase Detect) input is active.

One or more phases is missing

“Ph_seq” (Phase Sequence) input is active.

Reverse phase sequence is occurring

Valve manually moved from mid-travel to

open

Valve manually moved from open to

mid-travel

Valve manually moved from mid-travel to

close

Valve manually moved from close to

mid-travel

Network emergency shutdown (ESD) is

active

Field unit microprocessor has reset since

the last poll

Local pushbutton switch LED (UEC-3)

Relay 4 (Clamshell)

Local pushbutton switch LED (UEC-3)

Relay 5 (Clamshell)

Not Used

Not Used

Not Used

Not Used

Not Used

Not Used

Not Used

Not Used

Not Used

Not Used

Not Used

Relay 4

Relay 5

8 DDC-100 Direct-to-Host Programming Guide FCD LMAIM4019-00 FCD LMAIM4019-00 DDC-100 Direct-to-Host Programming Guide 9

Page 8

Table 3.4 – Status Bit Definitions (continued)

Bit Number

179 178 Open torque switch User Input 10

180 179 Open limit switch User Input 11

181 180 Close torque switch User Input 12

182 181 Close limit switch User Input 13

183 182 Aux. Open Input User Input 14

184 183 Aux. Close Input User Input 15

185 184 User Input 0 User Input 0

186 185 User Input 1 User Input 1

187 186 User Input 2 User Input 2

188 187 User Input 3 User Input 3

189 188 User Input 4 User Input 4

190 189 User Input 5 User Input 5

191 190 Input 6 User Input 6

192 191 Input 7 User Input 7

193 192 Analog Input 1 lost Analog Input 1 lost

194 193 Analog Input 2 lost Analog Input 2 lost

195 194 Analog Input 3 lost Analog Input 3 lost

196 195 Analog Input 4 lost Analog Input 4 lost

197 196 Network Channels A/B timed out Network Channels A/B timed out

198 197 Reserved Reserved

199 198 Reserved Reserved

200 199 Reserved Reserved

201 200 Reserved Reserved

202 201 Reserved Reserved

203 202 Reserved Reserved

204 203 Reserved Reserved

205 204 Lost Phase Input User Input 18

206 205 Phase Reverse Input User Input 19

207 206 Input 8 User Input 16

208 207 Input 9 User Input 17

Modbus

Bit

Address

UEC-3-DDC and DDC-100 Clamshell I/O Module

Example

Poll field unit number 22 for 16 inputs starting at input 129 with the actuator opening.

Query 1602008000107B09

Response 1602020108CDED

Message Breakdown

Query Response

16 Slave (Field Unit) Address 16 Slave (Field Unit) Address

02 Function 02 Function

00 Starting Address Hi 02 Byte Count

1

80 Starting Address Lo 01

00 No. of Points Hi 08

10 No. of Points Lo CDED Error Check (CRC)

7B09 Error Check (CRC)

Note 1: 01h equals 0000 0001 (actuator open input bit is ON).

Note 2: 08h equals 0000 1000 (actuator Channel B Fail bit is ON).

Data (Inputs 10136 - 10129)

2

Data (Inputs 10144 - 10137)

3.2.3 Modbus Function Code 03 (Read Holding Register)

This function code is used to read the binary contents of holding registers in the DDC-100 Field

Unit. This function code is typically used during the network polling cycle. A network poll should

consist of field unit registers 9 (Status) and 10 (Fault) as a minimum. Holding register 8 should

also be polled when the actuator is configured for the analog feedback option or position control.

See Table 3.5 for a complete listing of the holding registers.

10 DDC-100 Direct-to-Host Programming Guide FCD LMAIM4019-00 FCD LMAIM4019-00 DDC-100 Direct-to-Host Programming Guide 11

Page 9

Table 3.5 – Field Unit Register Definitions

Register

Number

Register Name MX/DDC Meaning UEC-3-DDC Meaning

1 Command

2 Argument

3 Analog Output

4 Analog Output

5 Analog Input Main Power Value (Volts) Analog Input 4

6 Analog Input

7 Analog Input

8 Position

Status Register

(Field Units as

9

MOV - MotorOperated Valve)

Status Register

I/O Module only

9

(Non-Valve

Service)

Registers 1 and 2 are write-only

registers used for Modbus Function

Code 06

Registers 1 and 2 are write-only

registers used for Modbus Function

Code 06

APT Scaled Output Value

(Default 0-100)

ATT Scaled Output Value1

(Default 0-100)

Analog Input 1 (Default 0-100) User

4-20 mA Input (Heavy Smoothing)

Analog Input 2 (Default 0-100) User

4-20 mA Input

Valve Position, Scaled Value (Default

0-100) (0-100, 2-255, 0-4095)2

16 Bits of Field Unit Status 16 Bits of Field Unit Status

Bit 0 Opened Bit 0 Opened

Bit 1 Closed Bit 1 Closed

Bit 2 Stopped Bit 2 Stopped

Bit 3 Opening Bit 3 Opening

Bit 4 Closing Bit 4 Closing

Bit 5 Valve jammed Bit 5 Valve jammed

Bit 6 Actuator switched to local

mode1

Bit 7 Combined fault3 Bit 7 Combined fault3

Bit 8 Over-temperature fault Bit 8 Over-temperature fault

Bit 9 Future Implementation

Bit 10 Network Channel A fault4 Bit 10 Network Channel A fault

Bit 11 Network Channel B fault4 Bit 11 Network Channel B fault

Bit 12 Open torque switch fault Bit 12 Open torque switch fault

Bit 13 Close torque switch fault Bit 13 Close torque switch fault

Bit 14 Valve-operated manually

fault

Bit 15 Phase error Bit 15 Phase error

N/A

Registers 1 and 2 are write-only

registers used for Modbus Function

Code 06

Registers 1 and 2 are write-only

registers used for Modbus Function

Code 06

N/A

Average Torque

(version 2.00 and greater)

Analog Input 3

Analog Input 2

Valve Position, Scaled Value (Default

0-100) OR Analog Input 1

Bit 6 Actuator switched to local

Bit 9 Actuator failing to de-ener-

Bit 14 Valve-operated manually

16 Bits of Field Unit Status

Bits 0-9 Not Used

Bit 10 Network Channel A fault

Bit 11 Network Channel B Fault

Bits 12-15 Not Used

mode

gize

fault

Table 3.5 – Field Unit Register Definitions (continued)

Register

Number

Register Name MX/DDC Meaning UEC-3-DDC Meaning

16 Bits of Field Status 16 Bits of Field Status

Bits 0-3 Not Used

Bit 4 One or more phases are

missing

Bit 5 Reverse phase sequence is

occurring

Bits 6-9 Not Used

Bit 10 Network emergency

shutdown is active

Bit 11 Local PB emergency

shutdown is active

Bit 12 MX microprocessor has

reset since the last poll

Bit 13 Local Stop

Bit 14 Opening in local mode

Bit 15 Closing in local mode

10

Fault Register

(Not Used for I/O

Module)

Bit 0 Input “open verify” is not

active after open command

is initiated

Bit 1 Input “close verify” is not

active after close command

is initiated

Bit 2 Input “open verify” is active

after open command is

de-energized

Bit 3 Input “close verify” is active

after close command is

de-energized

Bit 4 “Ph_det” input is active. One

or more phases are missing

Bit 5 “Ph_seq” input is active.

Reverse phase sequence is

occurring

Bit 6 Valve manually moved from

mid-travel to open

Bit 7 Valve manually moved from

open to mid-travel

Bit 8 Valve manually moved from

mid-travel to close

Bit 9 Valve manually moved from

close to mid-travel

Bit 10 Network emergency

shutdown is active

Bit 11 Local emergency shutdown

is active

Bit 12 Field Unit microprocessor

has reset since the last poll

Bit 13 Wrong rotation

Bit 14 Opening in local mode

Bit 15 Closing in local mode

12 DDC-100 Direct-to-Host Programming Guide FCD LMAIM4019-00 FCD LMAIM4019-00 DDC-100 Direct-to-Host Programming Guide 13

Page 10

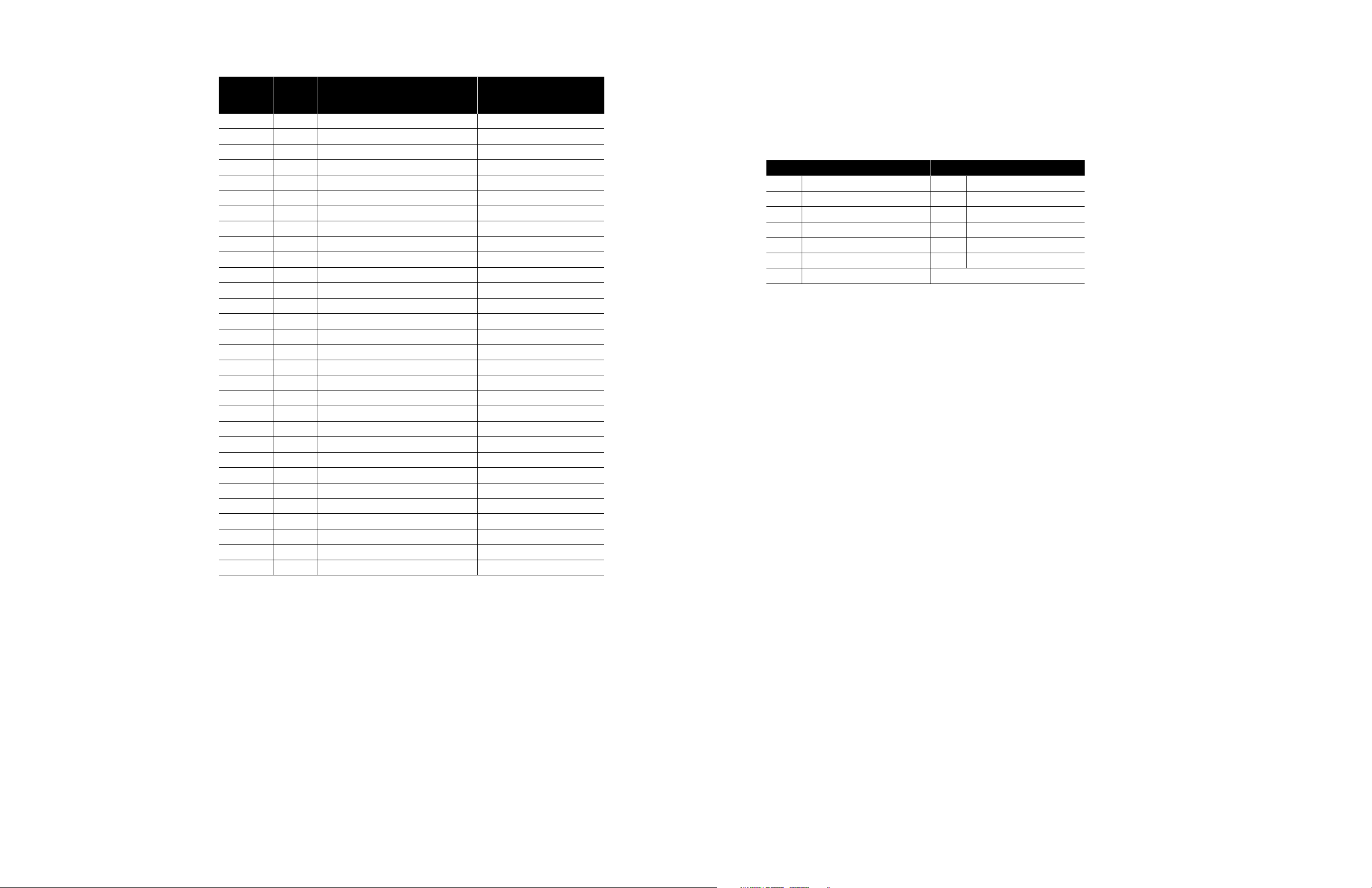

Table 3.5 – Field Unit Register Definitions (continued)

Register

Number

Register Name MX/DDC Meaning UEC-3-DDC Meaning

Value of 16 Digital Outputs Value of 16 Digital Outputs

Bit 0 Close contactor (interlocked)

Bit 1 Open contactor (interlocked)

Bit 2 AS-1 Bit 2 Lockout or User Relay 3

Bit 3 AS-2

11 Digital Outputs

12 Digital Inputs 1

Bit 4 AS-3

Bit 5 AS-4

Bit 6 AR-1 (Opt)

Bit 7 AR-2 (Opt)

Bit 8 AR-3 (Opt) Bits 8-15 Field Unit Software vs. ID

Bit 9 Network Relay

Bits 10-15 Not Used

Value of 16 Digital Inputs Value of 16 Digital Inputs

Bit 0 Remote Switch

Bit 1 Thermal Overload

Bit 2 Open Torque Switch

Bit 3 Open Limit Switch

Bit 4 Close Torque Switch

Bit 5 Close Limit Switch

Bit 6 Not Used

Bit 7 Not Used

Bit 8 User Input 0, terminal 21

Bit 9 User Input 1, terminal 10

Bit 10 User Input 2, terminal 9

Bit 11 User Input 3, terminal 6

Bit 12 User Input 4, terminal 7

Bit 13 User Input 5, terminal 5

Bit 14 Opt User Input 6,

terminal 23

Bit 15 Opt User Input 7,

terminal 24

Bit 0 Close contactor (interlocked),

I/O Module as MOV (MotorOperated Valve)

Bit 1 Open contactor (interlocked),

I/O Module as MOV

Bit 3 UEC-3-DDC Local push-

button switch LED, Relay 4

Clamshell and I/O Module

Bit 4 UEC-3-DDC Local push-

button switch LED, Relay 5

Clamshell and I/O Module

Bit 5 Relay 6 Clamshell and I/O

Module

Bit 6 Relay 2 (K2), I/O Module

(non-interlocked)

Bit 7 Relay 1 (K1), I/O Module

(non-interlocked)

Bit 0 Remote Switch, I/O Module

Input 8

Bit 1 Thermal Overload, I/O

Module Input 9

Bit 2 Open Torque Switch, I/O

Module Input 10

Bit 3 Open Limit Switch, I/O

Module Input 11

Bit 4 Close Torque Switch, I/O

Module Input 12

Bit 5 Close Limit Switch, I/O

Module Input 13

Bit 6 Aux. Open Input, I/O Module

Input 14

Bit 7 Aux. Close Input, I/O Module

Input 15

Bit 8 User Input 0, I/O Module

Input 0

Bit 9 User Input 1, I/O Module

Input 1

Bit 10 User Input 2, I/O Module

Input 2

Bit 11 User Input 3, I/O Module

Input 3

Bit 12 User Input 4, I/O Module

Input 4

Bit 13 User Input 5, I/O Module

Input 5

Bit 14 Input 6, I/O Module Input 6

Bit 15 Input 7, I/O Module Input 7

Table 3.5 – Field Unit Register Definitions (continued)

Register

Number

Register Name MX/DDC Meaning UEC-3-DDC Meaning

Value of 16 Digital Inputs Value of 16 Digital Inputs

Bit 0 Not Used Bit 0 Analog Input 1 lost

Bit 1 Not Used Bit 1 Analog Input 2 lost

Bit 2 Analog input 1 lost Bit 2 Analog Input 3 lost

Bit 3 Analog input 2 lost Bit 3 Analog Input 4 lost

Bit 4 Network Channels A/B

timed out

Bit 5 Not Used Bit 5 Reserved

Bit 6 DDC board present Bit 6 Reserved

Bit 7 I/O option board present Bit 7 Reserved

13 Digital Inputs 2

Timers and

14

Analog Channels

Bit 8 Not Used Bit 8 Reserved

Bit 9 Not Used Bit 9 Reserved

Bit 10 Not Used Bit 10 Reserved

Bit 11 Not Used Bit 11 Reserved

Bit 12 Phase lost

Bit 13 Phase reverse

Bit 14 Opt User Input 8,

terminal 25

Bit 15 Not Used

Bit 15 Input 9, I/O Module Input 17

Bits 0-15 – Not Used

Bit 4 Network Channels A/B

timed out

Bit 12 Phase lost input, I/O Module

Input 18

Bit 13 Phase reverse input, I/O

Module Input 19

Bit 14 Input 8, I/O Module Input 16

Value of 16 Bits

Bit 0 Analog Channel 1 Low

Bit 1 Analog Channel 2 Low

Bit 2 Analog Channel 3 Low

Bit 3 Analog Channel 4 Low

Bit 4 Analog Channel 1 High

Bit 5 Analog Channel 2 High

Bit 6 Analog Channel 3 High

Bit 7 Analog Channel 4 High

Bit 8 Open reversal time-out

Bit 9 Close reversal time-out

Bit 10 Jammed valve time-out

Bit 11 Network Channel A time-out

Bit 12 Network Channel B time-out

Bit 13 User 1 time-out

Bit 14 User 2 time-out

Bit 15 User 3 time-out

14 DDC-100 Direct-to-Host Programming Guide FCD LMAIM4019-00 FCD LMAIM4019-00 DDC-100 Direct-to-Host Programming Guide 15

Page 11

Table 3.5 – Field Unit Register Definitions (continued)

Register

Number

24-44 Reserved Special Applications Only Special Applications Only

45-47 Not Named Special Applications Only Special Applications Only

Register Name MX/DDC Meaning UEC-3-DDC Meaning

Value of 16 Bits

Bit 0 User Fault 0

Bit 1 User Fault 1

Bit 2 User Fault 2

Bit 3 User Fault 3

15 User Faults Bits 1-15 – Not Used

16 Current State Bits 0-15 – Not Used

Field Unit

17

Holding Register

Field Unit

18

Holding Register

Field Unit

19

Holding Register

Field Unit

20

Holding Register

Field Unit

21

Holding Register

Field Unit

22

Holding Register

Field Unit

23

Holding Register

TP_START_

48

POSITION

TP_STOP_POSI-

49

TION

50 TP_SAMPLE Special Applications Only Special Applications Only

51 TP_MID_T_HIGH Special Applications Only Special Applications Only

52 TP_MID_T_POS Special Applications Only Special Applications Only

Special Applications Only Special Applications Only

Special Applications Only Special Applications Only

Special Applications Only Special Applications Only

Special Applications Only Special Applications Only

Special Applications Only Special Applications Only

Special Applications Only Special Applications Only

Special Applications Only Special Applications Only

Special Applications Only Special Applications Only

Special Applications Only Special Applications Only

Bit 4 User Fault 4

Bit 5 User Fault 5

Bit 6 User Fault 6

Bit 7 User Fault 7

Bit 8 User Fault 8

Bit 9 User Fault 9

Bits 10-15 Reserved

Value of 16 Bits

Bit 0 Waiting to Open

Bit 1 Waiting to Close

Bit 2 Running Backward

Bit 3 Invalid Configuration

Bit 4 Reverse Switches

Bit 5 OK to Modulate

Bits 6-15 Reserved

Table 3.5 – Field Unit Register Definitions (continued)

Register

Number

Note 1: Torque will be expressed proportionally as a reference only from 40-100% inclusive. Initial indication

may read 0% until torque exceeds 40% minimum.

Note 2: Default value is scaled 0-100 of span. Changes made to “Scale Analog” affect Analog registers (3, 4,

6, 7, 8) and “move-to” commands.

Note 3: Combined Fault bit is a value of 1 or true when bit 5 or 8 or 9 or 15 or (bits 10 and 11) is a value of 1

or true.

Note 4: Channel A is physical connection A1. Channel B is physical connection A2.

MX/DDC actuators shipped prior to 2nd QTR, 1999, have the following definition for Register 9 bit 6. When

this bit has a value of 1 or true, the actuator selector switch is in LOCAL mode. This bit does not indicate

STOP or REMOTE. The actuator selector switch in REMOTE (available for network control) is indicated by

Register 12 bit 00 having a value of 1 or true. Register 9 bit 6 value 0 (zero) or false AND Register 12 bit 00

value 0 (zero) or false indicates selector switch is in the STOP position.

MX/DDC actuators shipped after 2nd QTR, 1999, have the following definition of Register 9 bit 6. When this

bit has a value of 1 or true, the actuator is in LOCAL or STOP (unavailable for network control). The actuator

selector switch in REMOTE (available for network control) is indicated by Register 12 bit 00 having value

of 1 or true.

IMPORTANT: Verify Host program when installing an MX/DDC actuator shipped after 2nd QTR, 1999, on a

network commissioned before 2nd QTR, 1999, for indication of selector switch values. Proper selector switch

indication at the Host will ensure safe conditions at the facility.

Register Name MX/DDC Meaning UEC-3-DDC Meaning

TP_MID_T_AV_

53

VAL

54 TP_STOP_VAL Special Applications Only Special Applications Only

TP_BEFORE

55

MID_T_HIGH_

TP_AFTER

56

MID_T_HIGH

Special Applications Only Special Applications Only

Special Applications Only Special Applications Only

Special Applications Only Special Applications Only

Example

Poll field unit number 125 for 3 registers starting at register 8 with the actuator stopped between

the limits and in local mode.

Query 7D0300070003BFF6

Response 7D0306003D084400003E07

Message Breakdown

Query Response

7D Slave (Field Unit) Address 7D Slave (Field Unit) Address

03 Function 03 Function

00 Starting Address Hi 06 Byte Count

07 Starting Address Lo 00 Data Hi (Register 40008)

00 No. of Points Hi 3D

03 No. of Points Lo 08 Data Hi (Register 40009)

BFF6 Error Check (CRC) 44

Note 1: 003Dh equals 61 Decimal (actuator Analog Input 1 in percent format).

Note 2: 0844h equals 2116 Decimal or 0000 1000 0100 0100 Binary (actuator stopped between limits, local

mode, and Channel B Fail bit is ON).

1

2

00 Data Hi (Register 40010)

00 Data Lo (Register 40010)

3E07 Error Check (CRC)

Data Lo (Register 40008)

Data Lo (Register 40009)

16 DDC-100 Direct-to-Host Programming Guide FCD LMAIM4019-00 FCD LMAIM4019-00 DDC-100 Direct-to-Host Programming Guide 17

Page 12

3.2.4 Modbus Function Code 04 (Read Input Register)

This function code is used to read the binary contents of input registers in the DDC-100 Field

Unit. The typical use of this function code is to read the analog input registers. If the field unit is

configured for scaled analog data, the register information will be returned as a percent from 0 to

100 (see NOTE below). The first analog input register (Analog 4) will start at register 30005 through

(Analog 1) Input Register 30008.

This function code may also be used to read the information available in registers 9 through 16.

NOTE: Limitorque field units can be configured to report analog data in several formats. See the

appropriate field unit manual for details.

Example

Poll field unit number 70 for 4 registers starting at register 5 (Analog Input Registers 1-4).

(This example assumes that the field unit is configured for scaled analog data.)

Table 3.6 – DDC-100 Coil Assignments Modbus Function Code 05 Usage for Digital Outputs

Coil

Number

1 00 Close / Stop Close / Stop Close / Stop Do Not Use

2 01 Open / Stop Open / Stop Open / Stop Do Not Use

3 02 AS-1 Lockout or Relay #3 Lockout or Relay #3 Relay #3

4 03 AS-2 Do Not Use Relay #4 Relay #4

5 04 AS-3 Do Not Use Relay #5 Relay #5

6 05 AS-4 Relay #6 Relay #6 Relay #6

7 06 AR-1 (Opt) Do Not Use Do Not Use Relay #21

8 07 AR-2 (Opt) Do Not Use Do Not Use Relay #12

9 08 AR-3 (Opt) Do Not Use Do Not Use Do Not Use

Note 1: Relay #2 is physical Relay K2.

Note 2: Relay #1 is physical Relay K1.

Bit

Number

MX/DDC UEC-3-DDC DDC-100 Clamshell I/O Module

Query 460400040004BF7F

Response 460408FFFFFFFF002B001EDBA8

Message Breakdown

Query Response

46 Slave (Field Unit) Address 46 Slave (Field Unit) Address

04 Function 04 Function

00 Starting Address Hi 08 Byte Count

04 Starting Address Lo FF Data Hi (Register 40005)

1

00 No. of Points Hi FF

04 No. of Points Lo FF Data Hi (Register 40006)

BF7F Error Check (CRC) FF

00 Data Hi (Register 40007)

2B

00 Data Hi (Register 40008)

1E

DBA8 Error Check (CRC)

Note 1: FFFFh equals 65535 Decimal (actuator Analog Input 4 value).

Note 2: FFFFh equals 65535 Decimal (actuator Analog Input 3 value).

Note 3: 002Bh equals 43 Decimal (actuator Analog Input 2 value).

Note 4: 001Eh equals 30 Decimal (actuator Analog Input 1 in percent format).

Data Lo (Register 40005)

2

Data Lo (Register 40006)

3

Data Lo (Register 40007)

4

Data Lo (Register 40008)

The normal response to the (05) command is an echo of the command.

Example of force coil command

Force coil 1 of field unit 49 ON. This will CLOSE the valve controlled by field unit 49.

Query 31050000FF0089CA

Response 31050000FF0089CA

Message Breakdown

Query Response

31 Slave (Field Unit) Address 31

05 Function 05 Function

00 Coil Address Hi 00 Coil Address Hi

001 Coil Address Lo 00 Coil Address Lo

FF Force Data Hi FF Force Data Hi

002 Force Data Lo 00 Force Data Lo

89CA Error Check (CRC) 89CA Error Check (CRC)

Note 1: 0000h equals Coil Address 00000001 (field unit coil 1).

0001h equals Coil Address 00000010 (field unit coil 2).

Note 2: FF00h requests the coil to be ON. (0000h requests the coil to be OFF)

Slave (Field Unit)

Address

3.2.5 Modbus Function Code 05 (Force Single Coil)

This function code is used to force a single coil in the DDC-100 Field Unit. Forcing the individual coil

either ON (1) or OFF (0) will energize or de-energize a coil (digital output) in the field unit. Coil 1 in

the field unit closes the actuator and Coil 2 opens the actuator. If the actuator is opening or closing,

changing the status of coil 1 or 2 from a value of 1 to 0 will stop the actuator (the coil will automatically be set to zero when the actuator reaches the full open or full close position).

Available digital outputs for DDC-100 Field Units are listed in Table 3.6. Force-coil commands

should be issued only once for the desired field unit control. Repeated issuance of an acknowledged command will degrade network performance.

3.2.6 Modbus Function Code 06 (Preset Single Register)

This function code is used to preset a single register in the field unit. The function code is typically

used to command the DDC-100 Field Unit by writing values to the 40001 and 40002 registers. A

predetermined value may be used to open/stop/close the actuator, move the actuator to a preset

position, activate/deactivate network ESD, reset the field unit, etc.

The Modbus function code 06 is also used to command a throttling actuator to “move-to” a position of 0-100% of open. The field unit will compare the new position value with the current position

and open or close the valve to meet the new position requirement. This is a two-step command: the

first step is to write the desired position value to the field unit register 40002, then write the value

of 6656 to field unit register 40001. This sequence of commands loads the desired position, then

NOTE: See Bulletin LMAIM1329, Accutronix Installation and Operation for MX-DDC Field Unit to

instructs the field unit to execute the command.

configure AS and AR Relays for DDC control.

For UEC-3-DDC field units containing Modbus Firmware 2.00 or greater and MX-DDC field units

containing Firmware 02/01.00 or greater, the “move-to” command may be executed with a one-step

command.

18 DDC-100 Direct-to-Host Programming Guide FCD LMAIM4019-00 FCD LMAIM4019-00 DDC-100 Direct-to-Host Programming Guide 19

Page 13

Modbus function code 06 command values for controlling the DDC-100 Field Unit are given in Table

3.7. Each command should be issued only one time for the desired field unit control. Repeated

issuance of an acknowledged command will degrade network performance.

Example of Field Unit Command

Write the command to open an actuator (actuator open) to field unit number 179. This corresponds to writing the value 256 into field unit register 40001.

The normal response to the (06) command is an echo of the command.

NOTE:

1) Only use values listed in table 3.7 For field unit register 40001.

2) Field Unit Register 40002 should only be used for “move-to” position input.

3) The Host MUST issue “move-to” commands in the proper sequence. Failure to issue this

two-step command in the correct sequence will result in the field unit waiting for the proper

command sequence execution before performing the “move-to” function.

4) The “move-to” command should only be used with field units that include the position control

option.

5) Do not write to Field Unit Registers 5-16.

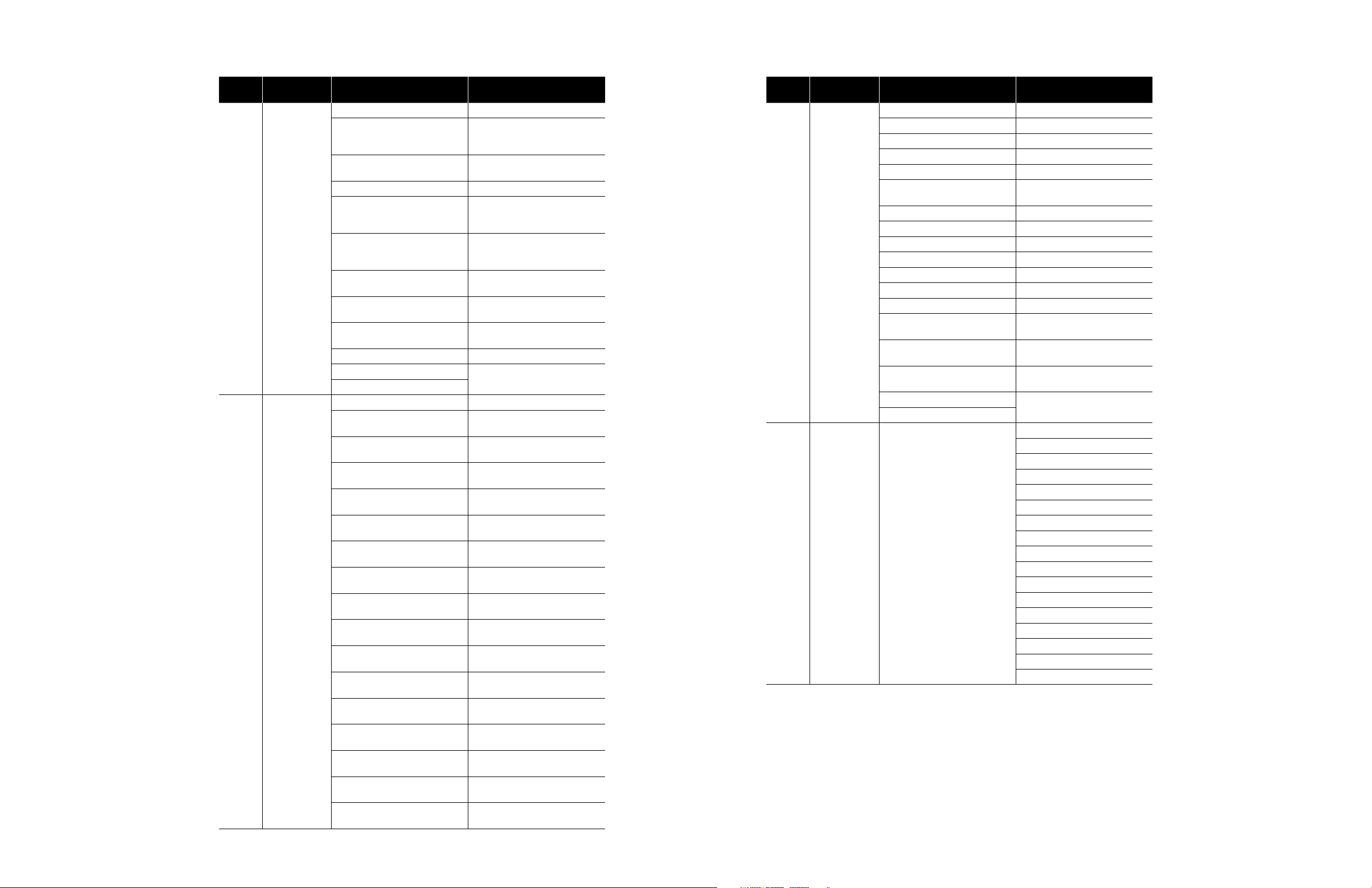

Table 3.7 – Modbus 06 Command and Field Unit Holding Register 40001

Host Commands to

Field Unit Register 1

Null Command 0 Yes Yes Yes Yes

Open 256 Yes Yes Yes Do Not Use

Stop 512 Yes Yes Yes Do Not Use

Close 768 Yes Yes Ye s Do Not Use

Start Network ESD 1280 Yes Yes Ye s Do Not Use

Stop Network ESD 1536 Yes Yes Yes Do Not Use

Engage Relay #1 2304 Yes (AS-1) Do Not Use Do Not Use Yes, K21

Engage Relay #2 2560 Yes (AS-2) Do Not Use Do Not Use Yes, K12

Engage Relay #3 2816 Yes (AS-3) Yes Yes Yes

Engage Relay #4 3072 Yes (AS-4) Do Not Use Yes Ye s

Engage Relay #5 3328 Yes (AR-1) Do Not Use Yes Yes

Engage Relay #6 3584 Yes (AR-2) Yes Ye s Yes

Engage Relay #7 3840 Yes (AR-3) Do Not Use Do Not Use Do Not Use

Disengage Relay #1 4352 Yes (AS-1) Do Not Use Do Not Use Yes, K21

Disengage Relay #2 4608 Yes (AS-2) Do Not Use Do Not Use Yes, K12

Disengage Relay #3 4864 Yes (AS-3) Yes Yes Yes

Disengage Relay #4 5120 Yes (AS-4) Do Not Use Yes Ye s

Disengage Relay #5 5376 Yes (AR-1) Do Not Use Yes Yes

Disengage Relay #6 5632 Yes (AR-2) Ye s Yes Ye s

Disengage Relay #7 5888 Yes (AR-3) Do Not Use Do Not Use Do Not Use

Move-To (enable) 6656 Yes Yes Ye s Do Not Use

Note 1: Engage and disengage Relay #1 control physical Relay K2.

Note 2: Engage and disengage Relay #2 control physical Relay K1.

Do Not Use–This command is not intended for use in this configuration.

Other registers may also be preset to control or change other functions but care must always be taken to

properly change these values. An improper value written to a register can cause undesirable actions from the

DDC-100 Field Unit.

NOTE: Null Command–The field unit takes no action when this command is received. This command is

typically used by a Host to reset the Host output register when required.

Value

(dec.)

MX-DDC UEC-3-DDC DDC-100

Clamshell

I/O Module

Query: B306000001009388

Response: B306000001009388

Message Breakdown

Query Response

B3 Slave (Field Unit) Address B3

06 Function 06 Function

00 Register Address Hi 00 Register Address Hi

001 Register Address Lo 00 Register Address Lo

01 Force Data Hi 01 Preset Data Hi

002 Force Data Lo 00 Preset Data Lo

9388 Error Check (CRC) 9388 Error Check (CRC)

Note 1: 0000h equals Register Address 40001 (field unit register 1, command register).

Note 2: 0100h requests the register to be preset with 256 Decimal (engage open contactor).

Slave (Field Unit)

Address

Example of “Move-To” Command

Move an actuator at address 179 to 42% of open by first writing the value of 42 to the field unit

40002 register. After receiving a response from the field unit, write the value of 6656 to the field

unit 40001 register. The actuator will then move to a position of 42% of open.

First Command

Query: B3060001002A4207

Response: B3060001002A4207

First Command Message Breakdown

Query Response

B3 Slave (Field Unit) Address B3

06 Function 06 Function

00 Register Address Hi 00 Register Address Hi

011 Register Address Lo 01 Register Address Lo

00 Force Data Hi 00 Preset Data Hi

2A2 Force Data Lo 2A Preset Data Lo

4207 Error Check (CRC) 4207 Error Check (CRC)

Note 1: 001h equals Register Address 40002 (field unit register 2, argument register).

Note 2: 002Ah equals 42.

Slave (Field Unit)

Address

20 DDC-100 Direct-to-Host Programming Guide FCD LMAIM4019-00 FCD LMAIM4019-00 DDC-100 Direct-to-Host Programming Guide 21

Page 14

Second Command

Query B30600001A009978

Response B30600001A009978

Second Command Message Breakdown

Query Response

B3 Slave (Field Unit) Address B3

06 Function 06 Function

00 Register Address Hi 00 Register Address Hi

1

00

1A Force Data Hi 1A Preset Data Hi

2

00

9978 Error Check (CRC) 9978 Error Check (CRC)

Note 1: 0000h equals Register Address 40001 (field unit register 1, command register).

Note 2: 1A00h equals 6656.

Register Address Lo 00 Register Address Lo

Force Data Lo 00 Preset Data Lo

Slave (Field Unit)

Address

Example of single register write “move-to” command

This command allows a Host to issue the “move-to” command with a single write utilizing the

Modbus function code 06. Register 1 will be used to complete this command.

Message Breakdown

Query Response

01 Slave Address 01 Slave Address

06 Function 06 Function

00 Starting Address Hi 00 Starting Address Hi

00 Starting Address Lo 00 Starting Address Lo

4B Preset Data Hi 4B Preset Data Hi

32 Preset Data Lo 32 Preset Data Lo

3EEF Error Check (LRC or CRC) 3EEF Error Check (LRC or CRC)

3.2.7 Modbus Function Code 08 (Diagnostics)

This function code provides a series of tests for checking the communication system between

the Host and field units (slaves), or for checking various error conditions within the field unit.

This function code uses a two-byte subfunction code field in the query to define the type of test

to be performed. The field unit echoes both the function code and subfunction code in a normal

response. It does not affect the field unit in any way. If this exchange is successful, then the

communication is successful.

A listing of the supported diagnostic two-byte subfunction codes is given in Table 3.8.

Rules for utilizing this command:

• Field unit scaling must be congured for 0-100.

• To use the hexadecimal method of determining a single write “move-to” command, 0x4B is

always placed into the Hi Byte of Register 1.

• The desired position value is always placed into the Lo Byte of Register 1.

To move the actuator to a position of 50%, place the value 0x4B in the high byte and the value of

0x32 (50 decimal) into the low byte.

Example:

Hex format: 0x4B32

To use the decimal method of determining a single write “move-to” command, add the desired

position value to 19200.

Example:

Desired position: 50%

19200 + 50 = 19250

Example of single write “move-to” command

Move an actuator at address 1 to 50% of open by writing the value of 19250 (0x4B32) to the field

unit 40001 register. The actuator will then move to a position of 50% open.

Example

Query: 010600004B323EEF

Response: 010600004B323EEF

Example

Request a loopback (return query data) from the field unit at network address 3.

Query 030800000000E1E9

Response 030800000000E1E9

Message Breakdown

Query Response

03 Slave (Field Unit) Address 03 Slave (Field Unit) Address

08 Function 08 Function

00 Subfunction Hi 00 Subfunction Hi

00 Subfunction Lo 00 Subfunction Lo

00 Data Hi 00 Data Hi

00 Data Lo 00 Data Lo

E1E9 Error Check (CRC) E1E9 Error Check (CRC)

Table 3.8 – Diagnostic Codes Supported by the DDC-100 Field Unit

Code Name

00 Return Query Data

01 Restart Communication Option

02 Return Diagnostic Register1

03 Change ASCII Input Delimiter

04 Force Listen-Only Mode

10 (0A Hex) Clear Counters and Diagnostics Register

11 (0B Hex) Return Bus Message Count

12 (0C Hex) Return Bus Communication Error Count

13 (0D Hex) Return Bus Exception Error Count

14 (0E Hex) Return Slave Message Count

Note 1: Contains DDC-100 Field Unit diagnostic information. For engineering use only.

22 DDC-100 Direct-to-Host Programming Guide FCD LMAIM4019-00 FCD LMAIM4019-00 DDC-100 Direct-to-Host Programming Guide 23

Page 15

3.2.8 Modbus Function Code 15 (Force Multiple Coils)

This function code allows the user to force multiple coils with a single command and uses the same

coil assignments as the function code 05.

It should be noted that the coils are operated from the lowest coil number to the highest. Forcing

coil 1 or 2 OFF (0) is considered a stop command, sending a 15 command to force two coils

starting with coil 1, with coil 1 ON and coil 2 OFF, would result in the unit stopping, since coil 2 is

forced OFF after coil 1 is forced ON.

To prevent inadvertent Stop commands from being issued, it is recommended to force one coil at a

time.

Available digital outputs for DDC-100 Field Units are listed in Table 3.6. Force multiple coil

commands should be issued only once for the desired field unit control. Repeated issuance of an

acknowledged command will degrade network performance.

NOTE: This function code is implemented in UEC-3-DDC Modbus Firmware 2.00 and greater and

MX-DDC Firmware 02/01.00 and greater

Example of force coil command

Force coil 1 of field unit 1 ON. This will CLOSE the valve controlled by field unit 1.

Query: 010F000000010101EF57

Response: 010F00000001940B

Message Breakdown

Query Response

01 Slave Address 01 Slave Address

0F Function 0F Function

00 Coil Address Hi 00 Coil Address Hi

00 Coil Address Lo 00 Coil Address Lo

00 Quantity of Coils Hi 00 Quantity of Coils Hi

01 Quantity of Coils Lo 01 Quantity of Coils Lo

01 Byte Count 940B Error Check (LRC or CRC)

01 Force Data Lo

EF57 Error Check (LRC or CRC)

Note: 000000010101h equals Coil Address 00000001 (field unit coil 1)

000100010101h equals Coil Address 00000010 (field unit coil 2)

3.2.9 Modbus Function Code 16 (Preset Multiple Registers)

This function code is used to preset single or multiple registers in the field unit and uses the same

predetermined register values as the function code 06. This function code is typically used to

command the DDC-100 Field Unit by writing values to the 40001 and/or 40002 registers.

Modbus function code 16 command values for controlling the DDC-100 Field Unit are given in Table

3.7. Each command should be issued only one time for the desired field unit control. Repeated

issuance of an acknowledged command will degrade network performance.

Example of Field Unit Command

Write the command to open an actuator (actuator open) to field unit number 1. This corresponds to

writing the value 256 into field unit register 40001.

Query: 011000000001020100A7C0

Response: 01100000000101C9

Message Breakdown

Query Response

01 Slave Address 01 Slave Address

10 Function 10 Function

00 Starting Address Hi 00 Starting Address Hi

00 Starting Address Lo 00 Starting Address Lo

00 Number of Registers Hi 00 Number of Registers Hi

01 Number of Registers Lo 01 Number of Registers Lo

02 Byte Count 01C9 Error Check (LRC or CRC)

01 Preset Data Hi

00 Preset Data Lo

A7C0 Error Check (LRC or CRC)

Example of “Move-To” Command

Move an actuator at address 1 to 50% of open by presetting registers 40001 with the value 6656,

and register 40002 with the value 50 in a single write command. The actuator will receive this

message and move to a position of 50% open.

Query: 011000000002041A0000327562

Response: 01100000000241C8

Message Breakdown

Query Response

01 Slave Address 01 Slave Address

10 Function 10 Function

00 Starting Address Hi 00 Starting Address Hi

00 Starting Address Lo 00 Starting Address Lo

00 No. of Registers Hi 00 No. of Registers Hi

02 No. of Registers Lo 02 No. of Registers Lo

04 Byte Count 41C8 Error Check (LRC or CRC)

1A Preset Data Hi

00 Preset Data Lo

00 Preset Data Hi

32 Preset Data Lo

7562 Error Check (LRC or CRC)

Note: The single register write “Move-to” command may also be used with the function code

16. This function code may also utilize the Single Register write “move-to” command.

The normal response returns the slave address, function code, starting address, and quantity of

registers preset.

NOTE: This function code is implemented in UEC-3-DDC Modbus Firmware 2.00 and greater and

MX-DDC Firmware 02/01.00 and greater.

24 DDC-100 Direct-to-Host Programming Guide FCD LMAIM4019-00 FCD LMAIM4019-00 DDC-100 Direct-to-Host Programming Guide 25

Page 16

This page is intentionally blank.

The DDC-100

4

The Flowserve Limitorque DDC-100 Network is a digital communications network based on

non-proprietary hardware and protocols. This network is capable of maintaining up to 250 valve

actuators or other devices over a simple shielded, twisted-pair connection. The network consists

of a master (Host PLC, Host Computer, Limitorque Master Station, or some other Master-capable

device) and a number (up to 250) of field units. The EIA RS-485 standard is used for the physical

interface between devices to provide reliable communications over long distances.

Two protocols are supported by Limitorque Field Units—Modbus® and BITBUS®. The protocol

must be specified when the units are ordered; however, the protocol may be changed in the field

(requires new EPROM). The Modbus protocol was developed by AEG Modicon and the BITBUS

protocol was developed by the Intel Corp. Modbus protocol is more widely used, has a simpler

implementation, and satisfies most applications that are not extremely time-critical. Therefore, this

document addresses only the Modbus protocol. BITBUS protocol information is available upon

request.

Network

NOTE: The MX-DDC does not support Bitbus protocol.

The network cable connects the field unit to the Host System. Belden 3074F, 3105A, and 9841

shielded, twisted-pair cable should be used. The use of other cables may result in a reduction of

internodal distances or increased error rate. Other individually shielded, twisted-pair cables with

electrical properties within 5% of the recommended Belden cables may be used but have not been

performance-tested with the DDC-100 Network.

Belden 3074F Specifications

• Total cable length between repeaters or nodes with repeaters: up to 19.2 kbps: 5000' (1.52 km)

For loop mode, this is the total length between operating field units. If a field unit loses power,

relays internal to the field unit connect the A1 Channel to the A2 Channel, which effectively doubles

the length of the cable (assuming a single field unit fails). If you need to assure operation within

specifications in the event of power failure to field units, then this consideration must be added.

Example: To assure operation within specification when any two consecutive field units lose power,

then the maximum length on cable up to 19.2 kbps: 5000' (1.52 km) per every four eld units.

26 DDC-100 Direct-to-Host Programming Guide FCD LMAIM4019-00 FCD LMAIM4019-00 DDC-100 Direct-to-Host Programming Guide 27

Page 17

Key Specs

• Resistance/1000 ft = 18 AWG (7x26)

6.92 ohms each conductor (13.84 ohms for the pair)

• Capacitance/ft = 14 pF (conductor-to-conductor)

• Capacitance/ft = 14 pF (conductor-to-shield)

Belden 3105A Specifications

• Total cable length between repeaters or nodes with repeaters: up to 19.2 kbps: 4500' (1.37 km)

For loop mode, this is the total length between operating field units. If a field unit loses power,

relays internal to the field unit connect the A1 Channel to the A2 Channel, which effectively doubles

the length of the cable (assuming a single field unit fails). If you need to assure operation within

specifications in the event of power failure to field units, then this consideration must be added.

Example: To assure operation within specification when any two consecutive field units lose power,

then the maximum length on cable up to 19.2 kbps: 4500' (1.37 km) per every four eld units.

Key Specs

• Resistance/1000 ft = 22 AWG (7x30)

14.7 ohms each conductor (29.4 ohms for the pair)

• Capacitance/ft = 11.0 pF (conductor-to-conductor)

• Capacitance/ft = 20.0 pF (conductor-to-shield)

The optional channel, Channel B, is used in network topologies that feature dual redundant

communication paths. Please contact Flowserve for further information about dual redundant

communication paths with the DDC-100 Network.

4.1.1 Field Unit Network Bypass Relays

Every Limitorque DDC-100 Field Unit is equipped with a set of network bypass relays designed

to isolate the individual field unit from the network in the event of a field unit power failure. These

normally closed relays are energized on field unit power-up allowing the network data transmissions to enter the field unit repeater circuitry and UART (Universal Asynchronous Receive Transmit

circuit). When the field unit power is turned off, these relays close, shorting the signal through the

field unit network board so the signal may pass to the next field unit. This isolates the powereddown field unit from the network while allowing the remainder of the network to function normally.

Care must be taken in the design of the DDC-100 network cable routing. This is necessary so

maintenance programs or other group power outage conditions do not add more physical cable

distance between two functional field units than the RS-485 electrical signal can support.

NOTE: The MX-DDC Field Unit will not energize the network bypass relays until the field unit is fully

operational and ready to communicate. UEC-3-DDC Field Units revision 1.57 and greater will “fast

start” the UART, preventing network communication disruption during the field unit reboot cycle.

4.1.2 Field Unit Repeater Circuits

Belden 9841 Specifications

• Total cable length between repeaters or nodes with repeaters: up to 19.2 kbps: 3500' (1 km)

For loop mode, this is the total length between operating field units. If a field unit loses power,

relays internal to the field unit connect the A1 Channel to the A2 Channel, which effectively doubles

the length of the cable (assuming a single field unit fails). If you need to assure operation within

specifications in the event of power failure to field units, then this consideration must be added.

Example: To assure operation within specification when any two consecutive field units lose power,

then the maximum length on cable up to 19.2 kbps: 3500’ (1 km) per every four field units.

Key Specs

• Resistance/1000 ft = 24 AWG (7x32)

24 ohms each conductor (48 ohms for the pair)

• Capacitance/ft = 12.8 pF (conductor-to-conductor)

• Capacitance/ft = 23 pF (conductor-to-shield)

4.1 Field Unit Network Communication Channels

Before proceeding with discussions of network polling, network error monitoring, and network

control, it is necessary to explain some network terminology with respect to field unit communication channels, ports, and hardware features.

All Limitorque DDC-100 Field Units are provided with a dual port network communication channel.

This channel is designated Channel A and the ports are designated ports A1 and A2. Both ports are

capable of bi-directional serial communications and comply with the EIA RS-485 standard.

In addition, some field units can optionally be ordered or retrofitted with a second dual port network

communication channel. This channel is designated Channel B and the ports are designated ports

B1 and B2. Channel B is implemented by adding a Granddaughter Board and an additional Network

Board to the standard field unit (not available with MX-DDC).

Every Limitorque DDC-100 Field Unit communications channel contains a repeater circuit that

recenters, reclocks, and amplifies the incoming signal and sends it out the opposite port. The circuit

is bi-directional, so it will repeat the received signals from port A1 out A2 or from port A2 out A1.

When the optional Granddaughter Board (not available with the MX-DDC) is added, the repeater

also recenters, reclocks, and amplifies the incoming signal received from B1 out B2 or from B2 out

B1. Although the circuit resends the entire message, there is less than a one-bit time delay before

retransmission out the corresponding port.

4.2 Network Topologies

Three network topologies are commonly used and supported by Limitorque—redundant loop,

single-ended loop (or half loop), and single-line multi-drop. The recommended cable types for

all three topologies are Belden 3074F, Belden 3105A, or Belden 9841. Other individually shielded,

twisted-pair cables with electrical properties within 5% of Belden 3074F, Belden 3105A, or Belden

9841 may be used but have not been performance-tested with the DDC-100 Network.

4.2.1 Redundant Loop

The redundant loop topology requires two serial communication ports on the Host device.

Because each field unit can be accessed by two ports, redundant access paths are supported. The

connections from the serial ports to the field units and between field units are made with shielded,

twisted-pair cable in a loop configuration. This topology tolerates a single-line break or short

while maintaining communications to all field units. Figure 4.1 shows the redundant loop network

topology.

With redundant loop topology, serial data is transmitted from Host port 1 through an RS-232 to

RS-485 converter to port A1 of the first field unit. The field unit passes the data that comes in

port A1 out through port A2 to the next field unit A1 port. Each subsequent field unit receives data

through its A1 port then passes the data out through its A2 port to the next field unit. The looped

communication continues in this manner until the last field unit port A2 relays the serial data to port

28 DDC-100 Direct-to-Host Programming Guide FCD LMAIM4019-00 FCD LMAIM4019-00 DDC-100 Direct-to-Host Programming Guide 29

Page 18

2 on the Host. The Host is not required to act on the data received at the second port. Note that,

because of the bi-directional nature of the serial ports, the direction of data flow can be reversed.

Communications can be initiated by port 2 of the Host to port A2 of the first field unit. This data is

then transmitted out port A1 to port A2 of the next field unit. The data then continues in this direction until it reaches port 1 of the Host. In either direction, the signal is regenerated in each field unit

to permit longer-distance communications with reduced noise sensitivity and improved reliability.

Figure 4.1 – DDC-100 Redundant Loop Network

Legend

MOV

- Motor-Operated Valve

16

- Data A1

- Data A1*

15

- Data A2

41

29

- Data A2*

D-M

- Data A1 (UEC-3-DDC)

- Data A1*(UEC-3-DDC)

D-M*

D-S

- Data A2 (UEC-3-DDC)

- Data A2* (UEC-3-DDC)

D-S*

- Shield

N/C

- No Connection

Data terminal is positive with respect to data* terminal

MOV-2

TB3

A1

D-M

A1*

D-M*

TB5

See Note 5

N/C

TB4

A2

D-S

A2*

D-S*

MOV-3

See Note 5

A1*

29

41

15

16A2A1

A2*

RS-232

RS-232 to RS-485

converter with

surge suppression

Data 1

Data* 2

Ground 3

RS-485

N/C

Earth Ground

(See Note 4)

Host

RS-232

PORT 1

Network Port A

MOV-1

See Note 5

A1*

29

41

Network Port B

15

16A2A1

A2*

RS-232

PORT 2

N/C

4.2.2 Single-Ended Loop

The single-ended loop topology is the loop topology described above except that only one end of

the loop is connected to the Host as shown in Figure 4.2. The single-ended loop is wired by cabling

from the Host port to the first field unit port A1. Port A2 of this field unit is then connected to port

A1 of the next field unit. This continues until the last field unit is connected. (If a stub cable is run

from port A2 of the last field unit to a planned field unit location, or the last field unit is disconnected, the end of the cable must be terminated with a 120 ohm resistor to prevent unacceptable

signal reflections.) The connection of the single-ended loop is identical to the redundant loop except

that in the single-ended loop the connection from the last field unit to port 2 of the Host is omitted.

The single-ended loop topology utilizes the field unit repeater circuitry that maximizes the number

of field units and distance inherent with the loop topology. The single-ended loop is inherently less

reliable than the redundant loop topology because the Host can only reach the field units from one

direction. It is, however, more reliable than the single-line multi-drop because a break or a short will

only prevent communication with the field units beyond the break or short.

Figure 4.2 – DDC-100 Single-Ended Loop Network

Legend

MOV

- Motor-Operated Valve

16

- Data A1

- Data A1*

Host

RS-232

PORT 1

N/C

Network Port A

15

- Data A2

41

29

- Data A2*

D-M

- Data A1 (UEC-3-DDC)

- Data A1*(UEC-3-DDC)

D-M*

D-S

- Data A2 (UEC-3-DDC)

- Data A2* (UEC-3-DDC)

D-S*

- Shield

N/C

- No Connection

Data terminal is positive with respect to data* terminal

RS-232 to RS-485

converter with

surge suppression

RS-232

Data 1

Data* 2

Ground 3

RS-485

Earth Ground

(See Note 4)

N/C

TB4

A2

D-S

A2*

D-S*

Notes:

1) Belden 3074F, 3105A, or 9841 shielded cable is recommended.

2) Correct polarity for field unit and network controller

connection is necessary for proper operation.

3) Connections shown are typical. The number of

MOVs shown may not indicate true system size.

4) Earth ground: ground rod

5) Earth ground: ground rod or lug in

actuator if actuator is grounded.

MOV-250

TB5

See Note 5

MOV-249

See Note 5

TB3

A1

D-M

A1*

D-M*

N/C

15

A1*

16A2A1

29

A2*

41

Diagnostic Note:

Polarity and level of the network’s data connection can

be checked by measuring voltage between data and

data* terminals. This voltage should be greater than

+200 mVDC with network controller network ports

disconnected.

Earth Ground Note:

If low impedance earth ground is not available at

each actuator, contact engineering for alternative

earth ground surge protection strategies.

MOV-248

N/C

TB4

TB3

TB5

See Note 5

A1

D-M

A1*

D-M*

Notes:

1) Belden 3074F, 3105A, or 9841 shielded cable is recommended.

2) Correct polarity for field unit and network controller

connection is necessary for proper operation.

3) Connections shown are typical. The number of

MOVs shown may not indicate true system size.

4) Earth ground: ground rod

5) Earth ground: ground rod or lug in

RS-232 to RS-485

converter with

surge suppression

RS-232

Data 1

Data* 2

Ground 3

RS-485

actuator if actuator is grounded.

N/C

Earth Ground

(See Note 4)

TB4

D-S

D-S*

MOV-1

See Note 5

A1*

29

41

MOV-250

TB5

See Note 5

MOV-3

MOV-2

15

16A2A1

A2*

N/C

TB3

A1

D-M

A1*

D-M*

TB3

A1

D-M

A1*

D-M*

TB5

See Note 5

MOV-249

See Note 5

15

A1*

16A2A1

29

N/C

A2*

41

N/C

TB4

A2

D-S

A2*

D-S*

See Note 5

15

A1*

16A2A1

29

A2*

41

MOV-248

N/C

TB4

A2

D-S

A2*

D-S*

TB5

See Note 5

N/C

TB3

A1

D-M

A1*

D-M*

Diagnostic Note:

Polarity and level of the network’s data connection can

be checked by measuring voltage between data and

data* terminals. This voltage should be greater than

+200 mVDC with network controller network ports

disconnected.

Earth Ground Note:

If low impedance earth ground is not available at

each actuator, contact engineering for alternative

earth ground surge protection strategies.

A2

D-S

A2*

D-S*

30 DDC-100 Direct-to-Host Programming Guide FCD LMAIM4019-00 FCD LMAIM4019-00 DDC-100 Direct-to-Host Programming Guide 31

Page 19

4.2.3 Single-Line Multi-drop

The single-line multi-drop topology is shown in Figure 4.3. Single-line multi-drop is wired by

cabling from the Host and connecting to the first field unit port A1. The cable to the next field unit

is attached to the same terminals on the first field unit and then run to port A1 on the second field

unit. This continues until the last field unit is connected.

A single-line multi-drop topology can simplify installation (especially when pre-existing wiring

is used), but it does not offer the extra reliability of a looped communication path. A line break

prevents communication with field units beyond the break, and a line short will cause a loss of

communication with all field units.

The maximum number of field units that can be accommodated by the single-line multi-drop

network is 28 units and the maximum distance between the Host and the last field unit is 1800

feet (550 m) without the use of repeaters. Note that all Limitorque field units can be wired to act as