Page 1

USER INSTRUCTIONS

Installation

Operation

Maintenance

D30 Compact

Digital Positioner

FCD PMENIM0030-01-A5 – 05/18

Page 2

D30 Digital Positioner FCD PMENIM0030-01-A5 – 05/18

2

Contents

1. Introduction 3

2. Storage 6

3. Installation 7

4. Control 17

5. Maintenance/service 34

6. Trouble shooting 39

7. Technical data 40

8. Dimensions 42

9. Spare parts 43

Page 3

D30 Digital Positioner FCD PMENIM0030-01-A5 – 05/18

3

1. Introduction

The D30 is a digital positioner designed

primarily for controlling modulating valves. The

positioner can be used with single or double

acting actuators with either rotary or linear

movement.

The D30 can be equipped with modules for

limit switches and pressure gauges. Pressure

sensors can be installed to offer advanced

diagnostics.

The modules can be factory assembled before

delivery or fitted later.

The modules for limit switches can contain one

of the following:

• Two mechanical contacts

• Two proximity switches

• Two inductive sensors

See page 12 for more options available

Page 4

D30 Digital Positioner FCD PMENIM0030-01-A5 – 05/18

4

Warning!

Special Conditions for Safe Use

The enclosure of PMV D30 Intrinsically safe version is made of aluminium and any impact

or friction caused by external objects shall be avoided in the application.

The surface area of the plastic parts on the cover exceeds the limits specified in EN

60079-0 for II 1G (EPL Ga) for gas group IIC and intensive rubbing or brush charging

should be avoided when used in an IIC explosive atmosphere.

The cable connection of the Remote Unit with the D30 – unit shall be type A or B in

accordance with EN 60079-25. The cable must be adequately mechanically protected in

all instances and have a temperature rating for the ambient temperature range at the site.

Control Drawing D4-086C contains the parameters for intrinsically safety.

The intrinsic safe circuits D30 is insulated from earth and complies with the dielectric

strength test of 500 VAC.

In a hazardous environment where there is a risk of explosion, electrical connections

must comply with the relevant regulations.

Do not disconnect equipment unless area is known to be non-hazardous. or; read,

understand and adhere to the manufacturer’s live maintenance procedures. To prevent

ignition of flammable or combustible atmospheres, disconnect power before servicing,

Substitutions of components may impair suitability for hazardous (classified) locations.

When installing PMV D30 Intrinsically safe unit always consult drawing D4-086C

Page 5

D30 Digital Positioner FCD PMENIM0030-01-A5 – 05/18

5

Maintenance Service

Warning!

When upgrading electronically parts inside a PMV positioner approved for installation in

Hazardous locations special procedures apply, permission from PMV/Flowserve is required

prior to the start of work. Please contact a Flowserve office for information regarding proper

procedures www.pmv.nu or infopmv@flowserve.com

-Always turn off the air and electrical supplies before starting any work.

Safety instruction

Read the safety instructions in this manual carefully before using the product. The

installation, operation, and maintenance of the product must be done by staff with the

necessary training and experience. If any questions arise during installation, contact the

supplier/sales office before continuing work.

Warning

The valve can open or close very quickly when in operation and, if handled incorrectly, it may

cause damages. There may also be unintentional effects due to it fully opening or shutting

off the flow in the process pipe. Please note the following:

• If the input signal fails or is switched off, the valve operates quickly to its default position.

• If the compressed air supply fails or is turned off, rapid movements can occur.

• The valve is not controlled by the input signals when in the Out of Service mode. It will

open/close in the event of an internal or external leak.

• If a high value is set for Cut off, fast movements can occur.

• When the valve is controlled in the Manual mode, the valve can operates quickly.

• Incorrect settings can cause self-oscillation, which can lead to damage.

Important

• Always turn off the compressed air supply before removing or disconnecting the air

supply connection or the integral filter. Remove or disconnect with care as air connection

”C-” is still under pressure even after the air supply is turned off.

• Always work in an ESD (Emergency Discharge) protected area when servicing the Printed

circuit boards (PCB´s). Make sure the input signal is switched off.

• The air supply must be free from moisture, water, oil and particles according to DIN/ISO

8573-1-2001 3.2.3.

Page 6

D30 Digital Positioner FCD PMENIM0030-01-A5 – 05/18

6

2. Storage

General

The D30 positioner is a precision instrument.

Therefore it is essential that it is handled and

stored in the correct way. Always follow the

instructions in this IOM!

Note: As soon as the positioner is connected

and started, internal air venting will provide

protection against corrosion and prevent

the ingress of moisture. For this reason, the

air supply pressure should always be kept

on unless repair/maintenance work of the

positioner, actuator or valve equipment is in

progress.

Keep the cover mounted on the positioner and

replace any damaged window.

Storage indoors

Store the positioner in its original packaging.

The storage environment must be clean, dry,

and cool (15 to 26°C, 59 to 79°F).

Storage outdoors or for a longer period

If the positioner must be stored outdoors,

it is important that all the cover screws are

tightened and that all open ports/connections

are properly sealed and/or plugged.

The red shipping plugs are not intended as a

permanent outdoor plug. The unit should be

packed with a desiccant (silica gel) in a plastic

bag or similar, covered with plastic, and not

exposed to sunlight, rain, or snow.

This is also applicable for long-term storage

(more than 1 month) and for long transport by

sea.

Storage in a warm place

When the positioner is stored - without air

supply pressure applied - in a warm place with

a high relative humidity and is subjected to

daily temperature variations, the air inside the

unit will expand and contract.

This means that air from outside the unit may

be drawn into the positioner. Depending on the

temperature variations, relative humidity, and

other factors, condensation and corrosion can

occur inside the unit, which in turn can give rise

to functional disorders or a failure.

Page 7

D30 Digital Positioner FCD PMENIM0030-01-A5 – 05/18

7

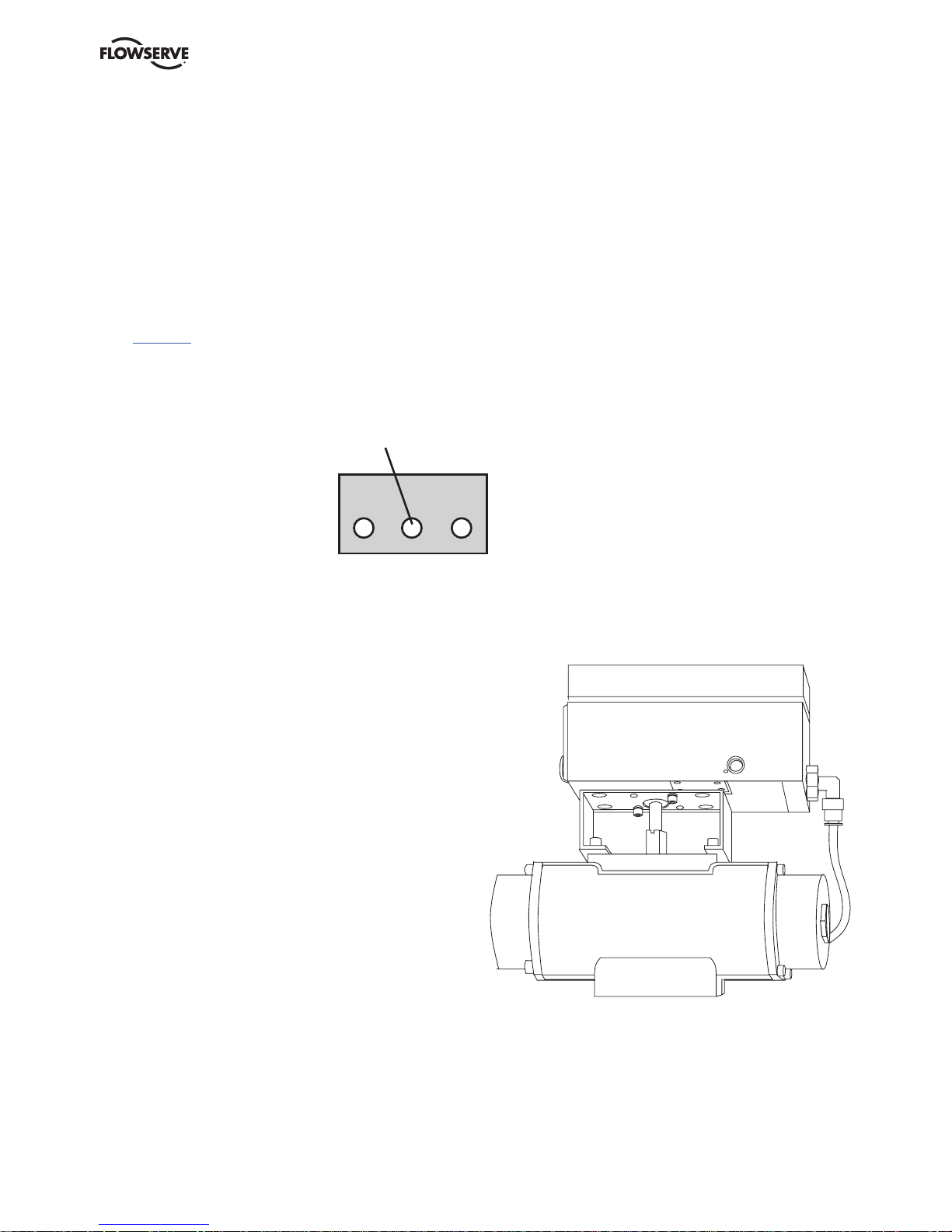

3. Installation

Removal of cover

General purpose / Intrinsically safe

Remove cover by first loosening the screw 1

and then the two screws 2.

To install cover, first tighten the screw 1, then

the two screws 2.

Tighten to 1.5 Nm ± 15%.

Supply air should meet requirements specified

on page 5. A coalescing filter/regulator

should be installed in front of the supply air

connection. Now connect the air supply to the

filter, which is connected to the D30 positioner.

Tubing

It is recommended to use tubes with a

minimum inner diameter of Ø 6 mm (¼”).

Air supply requirements

Poor quality air supply is the main cause of

problems in pneumatic systems.

The air supply must be free from moisture,

water, oil and particles and delivered @ 1.4-8

barg (20-115 psi)

Standard: DIN/ISO 8573-1-2001 3.2.3

Filtered to 5 Micron, dew point -40°C/F

Oil 1mg/m³ (0,83 ppm by weight)

The air must come from a refrigeration dried

supply or be treated in such a way that its dew

point is at least 10°C (18°F) below the lowest

expected ambient temperature.

To ensure a stable and problem-free air supply,

we recommend the installation of a

coalescing filter/regulator <5µ as close to the

positioner as possible.

Before the air supply is connected to the

positioner, we recommend the hose is

opened freely for 2 to 3 minutes to allow any

contamination to be blown out. Direct the air

jet into a large paper bag to trap any water, oil,

or other foreign materials. If this indicates that

the air system is contaminated, it should be

properly cleaned before continuing.

2

1

WARNING! Do not direct the open air jet

towards people or objects because it may

cause personal injury or damage.

Page 8

D30 Digital Positioner FCD PMENIM0030-01-A5 – 05/18

8

Mounting

Note: If the positioner is installed in a

hazardous environment, it must be of a type

approved for this purpose.

All versions of the D30 positioner have an ISO

F05 footprint. The holes are used to attach the

D30 to the mounting bracket B. Please contact

PMV or your local distributor representative

with actuator specifics for the proper mounting

bracket and hardware.

The spindle shaft S09 can be changed to suit

various actuators in question by the use of

adaptors.

It is important that the positioner’s spindle

shaft and the lever arms, that transfer the

actuator movements, are correctly mounted.

Any tension between these parts can cause

incorrect operation and abnormal wear.

Spindle shafts

S39 S09

AAssembly examples

Rotary movement Linear movement

C

B

S23

S9

0,354

9

0,079

2

S39

23,2

0,913

0,394

10

S23

5

0,197

4

0,157

0,957

24,3

M3 8

0,236

6

0,394

10

0,354

9

0,189

4,80

M8x1

0,091

2,30

Note: There are many spindle options available depending on the actuator. Please contact your local PMV

supplier for all options available.

Page 9

D30 Digital Positioner FCD PMENIM0030-01-A5 – 05/18

9

Connections

Air:

Port S Supply air, 1.4-8 barg (20-115 psi)

Port C+ Connection to actuator, opening

Port C- Connection to actuator, closing

(only for double action)

Plug for single action, see below

Electrical connection

See page 12.

Dimensions

Air connections: ¼” NPT alt. G ¼”

Electrical connection: M20 x 1.5 alt. NPT ½”

Loctite 577 or equivalent is recommended as a

sealant.

S

Must be plugged when converting

to single action function.

External air

Connection

C+ C-

Rotary actuators VDI/VDE 3485

(Namur)

Fit bracket on actuator and secure

with 4 x screws.

Mount positioner to bracket. Secure with 4 x M6

screws using 2.5 Nm (1.8 lb ft) torque.

Install tubing between actuator and positioner.

Page 10

D30 Digital Positioner FCD PMENIM0030-01-A5 – 05/18

10

Single acting positioner, Direct function

Actuator with closing spring

When the control signal increases, the pressure C+

to the actuator is increased. The valve stem moves

upward and rotates the positioner spindle counter-

clockwise. When the control signal drops to zero,

C+ is vented and the valve closes.

Reverse function

C+

CS

C+

CS

C+

CS

Actuator with opening spring

When the control signal increases the pressure

C+ to the actuator is increased. The valve stem

moves downward and the positioner spindle rotates

clockwise. When the control signal drops to zero,

C+ is vented and the valve opens.

Double acting positioner, Direct function

Double acting actuator

When the control signal increases, the pressure

C+ to the actuator is increased. The valve stem is

pressed upward and rotates the positioner

spindle counter-clockwise. When the control signal

is reduced, the pressure C- to the

actuator increases and the valve spindle is pressed

downward. If the control signal

disappears, the pressure goes to C-, C+ vents, and

the valve closes.

Page 11

D30 Digital Positioner FCD PMENIM0030-01-A5 – 05/18

11

Gauge block

Gauge blocks are available for D30s with ¼” G

or ¼” NPT air connections. To install, ensure

seals are aligned, then use 3 Nm (2.2 lb ft) of

torque when fastening the gauge block to the

positioner using the two screws supplied with

the kit.

Page 12

D30 Digital Positioner FCD PMENIM0030-01-A5 – 05/18

12

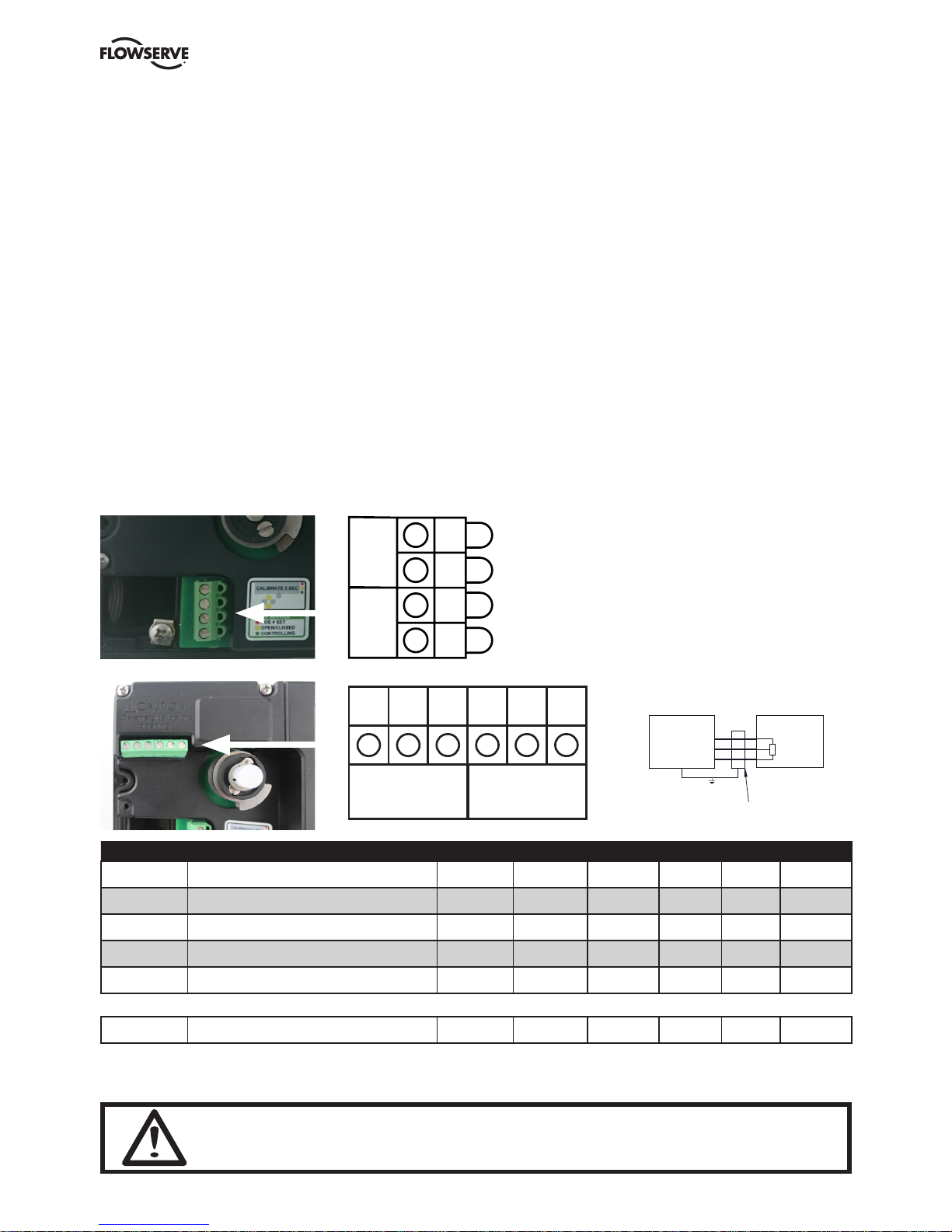

Electrical connections

Terminal block diagram for the D30.

The terminal block for the positioner is

accessible when the aluminum cover is

removed.

The D30 digital positioner has been designed to

operate correctly in electromagnetic (EM) fields

found in typical industrial environments. Care

should be taken to prevent the positioner from

being used in environments with

excessively high EM field strengths (greater

than 10 V/m). Portable EM devices such as

hand-held two-way radios should not be used

within 30 cm of the device.

Ensure proper wiring and shielding techniques

of the control lines, and route control lines

away from electro-magnetic sources that may

cause unwanted noise.

An electromagnetic line filter can be used to

further eliminate noise.

In the event of a severe electrostatic discharge

near the positioner, the device should be

inspected to ensure correct operability. It may

be necessary to recalibrate the D30 positioner

to restore operation.

1 2 3 4

+ -

4-20mA

in

+ -

4-20mA

out

1. Input signal + 4-20mA DC

2. Input signal - 4-20mA DC

3. 4-20mA + Feedback 13-28 VDC

4. 4-20mA - Feedback 13-28 VDC

Lower

Switch

Upper

Switch

6 7 8 9

10

5

switch es or re mote

Optional board

5 6 7 8 9 10

POSITIONER

Potentiometer

or F5 unit

HAZARDEOU S AREA

8

9

10

Po:0.38W

According

Safety

Barrier

5 or 8

6 or 9

7 or10

Switch

Ui,li,Pi and Li

to table

Scheduled drawing

No modification perm ited without

reference to Notif ied Body

OUT

1 2 3 4

+ -

INPUT

SIGNAL

+ -

4-20mA

Option

D30 Model code

Position B designates certification

3+

Remote Unit

Safety

1+

2-

Ci ≤ 11.3 nF

Substitutions of components may impair suitability for hazardous (classified) locations.

less than 10m or 30 feet

switches

(Position B; B=A or B=E) AND

Reqires shielded cable

4-20mA input signal

HAZARDEOUS AREA UNCLASISIFIED AREA

D30 series terminal configuration

4-20mA Output signal

(Position J; J=4 or J=5)

(Unit has no switches)

Pin 3 and 4

Pin 1 and 2

HAZARDEOUS AREA UNCLASISIFIED AREA

Position H 13 designates Indicator type

Position K designates switch type

(Wher x any character)

Position GG; GG=Rx

Position J designates comunication protokoll

HAZARDEOUS AREA UNCLASISIFIED AREA

or; read, understand and adhere to the manufacturer's live maintenance procedures.

(Position B; B=A or B=E) AND

4-

To prevent ignition of flammable or combustible atmospheres, disconnect power before ser vicing,

Do not disconnect equipment unles s area is known to be non-hazardous.

(Position K; K≠X)

(Position J; J=4 or J=5) AND

Safety

Barrier

is not suitable for Da,Db or Dc enviroments

Warnings:

Barrier

Li ≤ 11.3 µH

If Pos H 13 =D (dome indicator) then product

POSITIONER

Ui ≤ 28 V

Ii ≤ 93 mA

Pi ≤ 653 mW

POSITIONER

Ui ≤ 28 V

Ii ≤ 93 mA

Pi ≤ 653 mW

Ci ≤ 22 nF

Li ≤ 11.3 µH

-

ANNOTATIONDIMENSIONMATERIALDESCRIPTION

HOLE TOL. UNSPECIFIED TOLERANCES ACCORDING TO: SURFACE

PROJECTION EUROPA

-

Control Drawing

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19

A A A B C D E - F G G H H H - I J K L M N

model code positi on

K

model code posit ion

B

A E

Note SWIT CH Type Ci nF Li uH U i V I i mA Pi mW

Min .

temp

T4 (*) T5 (* ) T6 (* )

T

(III C Da)

ATE X iaIECEx

ia

5

2 SJ2-SN NAMUR 30 100 16 25 34 -40 96 68 56 100 Ga ,Da Ga ,Da

6

1 SJ2-N NAMUR 30 100 16 25 34 -25 96 68 56 100 Ga ,Da Ga ,Da

7

1 SC2-N0-GN NAMUR 150 150 16 25 34 -25 95 67 55 100 Ga ,Da Ga ,Da

8

1 SC2-N0-YE NAMUR 150 150 16 25 34 -25 95 67 55 100 Ga ,Da Ga ,Da

G

Mechanical sw itch gold Mec. 1 1 28 45 315 -40 78 60 45 Ga ,Da Ga ,Da

N

3 NJ 2-V3-N NAMUR 40 50 16 25 34 -25 96 68 56 100 Ga Ga

P

Hamli n Proxim ity Reed 1 1 28 45 315 -40 80 - - Ga ,Da Ga ,Da

S

Mechanical sw itch Mec. 1 1 28 45 315 -40 78 60 45 Ga ,Da Ga ,Da

U

3 NCN4-V3-N0 NAMUR 100 100 16 25 34 -25 73 88 100 100 Ga Ga

not e 1 Higher Ui,Li and Pi w ith l ower a mbient temeratures a re alow ed see Certificat e PTB 99 ATEX 2219 X or IECEx PTB 11.0091X

not e 2 Higher Ui,Li and Pi w ith l ower a mbient temeratures a re alow ed see Certificate PTB 00 ATEX 2049 X or IEC Ex PTB 11.0092X

not e 3 Higher Ui,Li and Pi w ith l ower a mbient temeratures a re alow ed see Certificate PTB 00 ATEX 2032 X or IEC Ex PTB 11.0021X

Remote Unit

Order code Switch 5 6 7 8 9 10

S Limit switches Mechanical SPDT NO NC Com NO NC Com

N Namur V3 type sensor, P&F NJ2-V3-N - + Not Used - + Not Used

P Limit switches Proximity SPDT NO NC Com NO NC Com

5 Slot type Namur sensor, P&F SJ2-SN - + Not Used - + Not Used

6 Slot type Namur sensor, P&F SJ2-N - + Not Used - + Not Used

RM Remote Board Not Used Not Used Not Used CCW RA CW

Warning! In a hazardous environment where there is a risk of explosion, electrical

connections must comply with the relevant regulations.

Page 13

D30 Digital Positioner FCD PMENIM0030-01-A5 – 05/18

13

Limit switch calibration

• Losen screws (1) and adjust cams.

• Adjust lower cam first and then upper cam

• Tighten screws (1)

Aproximat switching plase for reed switches

1

Page 14

D30 Digital Positioner FCD PMENIM0030-01-A5 – 05/18

14

Feedback option (cont.)

Calibration of the 4-20 mA transmitter

Connecting the switches/sensors

switche s or rem ote

Optional board

5 6 7 8 9 10

POSITIONER

Potentiometer

or F5 unit

HAZARDEOUS A REA

8

9

10

Po:0.38W

According

Safety

Barrier

5 or 8

6 or 9

7 or10

Switch

Ui,li,Pi and Li

to table

Scheduled drawing

No modification permited w ithout

reference to Notified Body

OUT

1 2 3 4

+ INPUT

SIGNAL

+ -

4-20mA

Option

D30 Model code

Position B designates certification

3+

Remote Unit

Safety

1+

2-

Ci ≤ 11.3 nF

Substitutions of components may im pair suitability for hazardous (classified) locations.

less than 10m or 30 feet

switches

(Position B; B=A or B=E) AN D

Reqires shielded cable

F5ISxx-xxx-P27-xxPVxxx-x

4-20mA input signal

HAZARDEOUS AREA UNCLASISIFIED AREA

D30 series terminal configuratio n

4-20mA Output signal

(Position J; J=4 or J=5)

Terminal 8-9 upper switch

(Unit has no switches)

Pin 3 and 4

Pin 1 and 2

HAZARDEOUS AREA UNCLASISIFIED AREA

Position H 13 designates Indicator t ype

Position K designates switch type

(Wher x any character)

Terminal 5-7 lower switch

Position GG; GG=Rx

Position J designates comunication prot okoll

HAZARDEOUS AREA UNCLASISIFIED AREA

or; read, understand and adher e to the manufacturer's live maintenance procedures.

terminal 7 and 10 not used for Na mur Switches

(Position B; B=A or B=E) AN D

4-

F5ISxx-xxx-POT-xxPVxxx-x

Allowed F5 units are:

To prevent ignition of flammable or combust ible atmospheres, disconnect power before servicing,

Do not disconnect equipment unless area is known to be non-hazardous.

(Position K; K≠X)

(Position J; J=4 or J=5) AND

F5ISxx-xxx-P18-xxPVxxx-x

Safety

Barrier

is not suitable for Da,Db or Dc enviroments

Warnings:

Barrier

Li ≤ 11.3 µH

If Pos H 13 =D (dome indi cator) then product

POSITIONER

Ui ≤ 28 V

Ii ≤ 93 mA

Pi ≤ 653 mW

Potentiometer unit needs an ap ropriate and compatible

Certification for the Hazaredu s area

POSITIONER

Ui ≤ 28 V

Ii ≤ 93 mA

Pi ≤ 653 mW

Ci ≤ 22 nF

Li ≤ 11.3 µH

-

PMV Positioners

-

2017-12-11

imparted to a third party nor be us ed for any unauthorized purpose. Contrave ntion will be prosecuted

DRAWING NO.

DRW BY Rev. SCALE DATE

ANNOTATIONDIMENSIONMATERIALDESCRIPTION

HOLE TOL. UNSPE CIFIED TOLERANCES ACCORDING TO: SURFACE

-

PROJECTION EUROPA

-

PMV Automation AB

Control Drawing

KORTA GATAN 9 SE-17 1 54 SOLNA SWEDEN - Tel:+46(0)8 555 106 00-Fax:+46(0)8 555 106 01 - www.pmv.nu

-

D4-086C

LRW

-

D30

This document must not be copi ed without our written permissi on and the contents there of must not be

0

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19

A A A B C D E - F G G H H H - I J K L M N

model code po sition

K

model code po sition

B

A E

Note S WITCH Type Ci nF Li u H U i V I i mA Pi mW

Min .

temp

T4 (*) T5 (* ) T 6 (*)

T

(IIIC Da)

ATE X iaIECEx

ia

5

2 SJ2-SN NAMUR 30 100 16 25 34 -40 96 68 56 100 Ga ,Da Ga ,Da

6

1 SJ2-N NAMUR 30 100 16 25 34 -25 96 68 56 100 Ga ,Da Ga ,Da

7

1 SC2-N0-GN NAMUR 150 1 50 16 25 34 -25 95 67 55 10 0 Ga ,Da Ga ,Da

8

1 SC2-N0-YE NAMUR 150 1 50 16 25 34 -25 95 67 55 10 0 Ga ,Da Ga ,Da

G

Mechanical switch go ld Mec. 1 1 28 45 315 -40 78 60 45 Ga ,Da Ga ,Da

N

3 NJ2-V 3-N NAMUR 40 50 16 25 34 -25 96 68 56 100 Ga Ga

P

Hamlin Proximity Reed 1 1 28 45 315 -40 80 - - Ga ,Da Ga ,Da

S

Mechanical switch Me c. 1 1 28 45 315 -40 78 60 45 Ga ,Da Ga ,Da

U

3 NCN4-V3-N0 N AMUR 100 100 16 25 34 -25 73 88 100 100 Ga Ga

not e 1 Higher Ui, Li and Pi w ith low er ambient temerat ures are alowed see Certifi cate PTB 99 ATEX 2219 X or IECEx PTB 11.0091X

not e 2 Higher Ui, Li and Pi w ith low er ambient temerat ures are alowed see Certificat e PTB 00 ATEX 2049 X or IECEx P TB 11.0092X

not e 3 Higher Ui, Li and Pi w ith low er ambient temerat ures are alowed see Certificat e PTB 00 ATEX 2032 X or IECEx P TB 11.0021X

Page 15

D30 Digital Positioner FCD PMENIM0030-01-A5 – 05/18

15

Type sign example

FFH PA

REVISIONS

S/N:

PMV Automation AB

FLOWSERVE, SWEDEN

Temp Range:

Software:

Solna, Sweden

www.flowserve.com

Input Pressure:

Input Signal:

Prod.year:

Ingress protection rati ng

Logo type

Serial.no

Area for switch type

and terminals

Bar Code

Special note

Applicable Certificat

Area for markings, Ex ratings

and associated warnings if applicable

Type and model

H FFPA

No modification permitted without reference

to the Notified Body.

Schedule drawing

Zebra Z-Xtreme 4000

0

2017-11-06

imparted to a third part y nor be used for any unauthor ized purpose. Contravention wi ll be prosecuted

2:1

D4-090C-A

LRW

D30

PMV Positioner

This document must not be copied without our written perm ission and the contents ther e of must not be

Sceduled Drawing

PROJECTION EUROPA

PMV Automation AB

DRAWING NO.

DRW BY Rev.

SCALE

DATE

ANNOTATIONDIMENSIONMATERIALDESCRIPTION

HOLE TOL. UNS PECIFIED TOLERANCES ACCORDING TO: SURFACE

KORTA GATAN 9 SE-171 54 SOLNA SWEDEN - T el:+46(0)8 555 106 00 - www.pmv.nu

D4-090C-2

REVISIONS

REV. DESCRIPTION DATE APPROVED

0470

INTRINSICALLY SAFE

Exia: When installed in accordance with installation

drawing: D4-086C.

WARNING! Avoid intensive rubbing or brush charging of

plastic parts in IIC explosive atmosphere.

Model code Certif ication declaration

DxxAxxxx-xxxxxz-xxyxxx

where z ≠ D and ( y≠N or y≠U)

II 1G Ex ia IIC T4 Ta -40 C to 85 C Ga

II 1D Ex ia IIIC T80 C Da

DxxAxxxx-xxxxxD-xxxxxx or

DxxAxxxx-xxxxxx-xxyxxx

where y=N or y=U

II 1 G Ex ia IIC T4 Ta -40 C to 85 C Ga

D30 Model code

Certification declaration

Serienummer

S/N:

www.flowserve.com

Input Signal:

and terminals

Area for switch type

Prod.year:

Bar Code

FLOWSERVE, SWEDEN

PMV Automation AB

IP 66

Area for logotype

Område för logotype

Software:

Type and model

Typbeteckning och modellkod

Streckkod

Solna, Sweden

Presafe 17 ATEX 11142X

Temp Range:

Special note

Serial.no:

Input Pressure:

NEMA Type

ingressprotection

60

40

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19

A A A B C D E - F G G H H H - I J K L M N

H FFPA

No modification permitted without reference

to the Notified Body.

Scheduled drawing

and terminals

Prod.year:

Area for switch type

Bar Code

Special note

www.flowserve.com

S/N:

Serial.no:

FLOWSERVE, SWEDEN

PMV Automation AB

IP 66

Input Signal:

Temp Range:

Type and model

Typbeteckning och modellkod

Area for logotype

Område för logotype

Software:

Streckkod

Solna, Sweden

Serienummer

IECEx PRE 17.0046X

Certification declaration

Input Pressure:

NEMA Type

ingressprotection

60

40

D4-090C-6

REVISIONS

REV. DESCRIPTION DATE APPROVED

0470

INTRINSICALLY SAFE

Exia: When installed in accordance with installation

drawing: D4-086C.

WARNING! Avoid intensive rubbing or brush charging of

plastic parts in IIC explosive atmosphere.

Model code Certif ication declaration

DxxExxxx-xxxxxz-xxyxxx

where z ≠ D and ( y≠N or y≠U)

II 1G Ex ia IIC T4 Ta -40 C to 85 C Ga

II 1D Ex ia IIIC T80 C Da

DxxExxxx-xxxxxD-xxxxxx or

DxxExxxx-xxxxxx-xxyxxx

where y=N or y=U

II 1 G Ex ia IIC T4 Ta -40 C to 85 C Ga

D30 Model code

Zebra Z-Xtreme 4000

LRW 0

imparted to a third part y nor be used for any unauthor ized purpose. Contravention wi ll be prosecuted

2:1

D4-090C-E

2017-11-06

D30

PMV Positioner

This document must not be copied without our written perm ission and the contents ther e of must not be

Sceduled Drawing

PROJECTION EUROPA

PMV Automation AB

DRAWING NO.

DRW BY Rev.

SCALE

DATE

ANNOTATIONDIMENSIONMATERIALDESCRIPTION

HOLE TOL. UNS PECIFIED TOLERANCES ACCORDING TO: SURFACE

KORTA GATAN 9 SE-171 54 SOLNA SWEDEN - T el:+46(0)8 555 106 00 - www.pmv.nu

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19

A A A B C D E - F G G H H H - I J K L M N

Page 16

D30 Digital Positioner FCD PMENIM0030-01-A5 – 05/18

16

D30 Digital Positioner model code

A Model no

D 3 0 Full LCD menu, LED status

B Approval, Certificate

D General purpose version

E IEC

A ATEX

C Function

H High Flow - Single/double acting - Spool valve

D Connections Air, Electrical

G 1/4” G air, M20 x 1,5 electrical

M 1/4” NPT air, M20x1,5 electrical

N 1/4” NPT air, 1/2”NPT electrical

E Connection feature

2 2 Electrical conduits

T 2 Electrical conduits, threaded Aux. ventilation

F Housing material/ Surface treatment

U Aluminium/Powder epoxy, black

G Mounting options / Shaft

R M Remote mounting (position sensing unit sold separately)

0 9 Double D type, adaptor spindle

2 1 NAF shaft, including Mounting bracket D4-As920

2 3 VDI/VDE 3845 rotar y, Mounting kit not included

3 0 Adaptor shaft, select between 01/06/26/30/36

3 9 IEC 534-6, Flat D t ype, nut incl. Mounting kit not included

H Cover and Indicator

P V A PMV,Black cover, Arrow indicator

P V B PMV, Black cover, No indicator

F W A Flowserve, White, Arrow indicator

F W B Flowserve, White, No indicator

I Temperature/seals

U -40°C to 80°C

J Input signal/Protocoll

4 4-20 mA / none

5 4-20 mA, / HART

P Profibus PA (Only when B = D)

K Feedback option, switches

X No feedback option

T 4-20 mA transmitter only

S Limit switches Mechanical SPDT

N Namur V3 type sensor, P+F NJ2-V3-N

P Limit switches Proximity SPDT

5 Slot t ype Namur sensor, P+F SJ2-SN

6 Slot t ype Namur sensor, P+F SJ2-N

L Options, Add in electronics

0 No pressure sensors

3 3 pressure sensors

M Accessories

X No accessories

M Gauge block 1/4” G (DA, 3 gauges included)

N Gauge block 1/4” NPT (DA, 3 gauges included)

N Special Options

N No special options

S Exhaust silencers

A A A B C D E - F G G H H H - I J K L M N

Page 17

D30 Digital Positioner FCD PMENIM0030-01-A5 – 05/18

17

4. Control

ESC

OK

BASIC MENU

MAN/AUTO

OUT OF SERVICE

MANUAL

UNPROTECTED

FUNC

Menus and pushbuttons

The positioner is controlled using the five

pushbuttons and the display, which are

accessible when the aluminum cover is

removed.

For normal functioning, the display shows the

current value. Press the ESC button for two

seconds to display the main menu.

Use the pushbuttons to browse through

the main menu and the sub-menus.

The main menu is divided up into a basic menu

and a full menu, see page 19.

Other functions

ESC

Exit the menu without making any changes (as

long as any changes have not been confirmed

with OK).

FUNC

To select function and change parameters.

OK

To confirm selection or change of parameters.

MENU INDICATOR

Displays the position of the current menu row

in the menu.

IN SERVICE

The positioner is following the input signal.

This is the normal status when the positioner is

working.

OUT OF SERVICE

The positioner is not following the input signal.

Critical parameters can be changed.

MANUAL

The positioner can be stroked manually using the

pushbuttons. See section “Man/Auto”, page 25.

UNPROTECTED

Most of the parameters can be changed when

the positioner is in the “Unprotected” position.

However, critical parameters are locked when

the positioner is in the “In service” position.

LED color (R=Red, Y=Yellow, G=Green)

Codes during In Service

R Actual valve position deviates from requested/set

position

Y Fully opened /closed valve using Cut Of f (= OK)

G Controlling valve position (= OK)

Codes during Out of service

R Y Input signal not calibrated

Y G Feedback signal not calibrated

Y Y Out of Service (= OK)

Calibration alarm

R G No feedback movement. Check linkage from actuator

to positioner

R Y No air available. *(alarm available only when

pressure sensors installed)

R G G No pot connection. Check pot cable inside

positioner.

R Y Y No air relay. Check cable inside positioner.

R Y G Pot not calibrated. Go to Calibrate->Expert->Pot

on LCD menu.

Page 18

D30 Digital Positioner FCD PMENIM0030-01-A5 – 05/18

18

Menu indicator

There are indicators at both sides of the display

window and they indicate as follows:

Flashing in position Out of service

Flashing in position Manual

Displayed in position Unprotected

The indicators on the right-hand side show the

position in the current menu.

Menus

To display the menus you can select:

- Basic menu, which means you can browse

through four different menu items

- Full menu, which comprises ten steps. Use

the Shift Menu to browse through the menu

items

Full Menu can be locked out using a passcode.

The main menus are shown on the next page

and the sub-menus on the subsequent pages.

Changing parameter values

Change by pressing

until the desired figure

is flashing.

Press to step to the desired figure.

Confirm by pressing OK.

A change can be undone by pressing the ESC

button, which returns you to the previous

menu.

FULL MENU

CALIBRATE

FULL MENU

MAN/AUTO

FULL MENU

SHIFT MENU

Page 19

D30 Digital Positioner FCD PMENIM0030-01-A5 – 05/18

19

Menu system

The menus are described on

the following pages.

BASIC MENU

READ

BASIC MENU

MAN/AUTO

BASIC MENU

CALIBRATE

BASIC MENU

SHIFT MENU

FULL MENU

READ

FULL MENU

MAN/AUTO

FULL MENU

CALIBRATE

FULL MENU

SHIFT MENU

FULL MENU

STATUS

FULL MENU

SETUP

FULL MENU

TUNING

FULL MENU

ALARMS

FULL MENU

FACT SET

Page 20

D30 Digital Positioner FCD PMENIM0030-01-A5 – 05/18

20

First start

“Calibrate” is displayed in the basic menu

automatically, the first time power is applied. It

can be selected from the basic or full menu at

any time.

A complete auto-calibration will take a few

minutes depending on size of actuator and

includes end limit calibration (zero and

span), auto-tuning (dynamically sets the

control parameters for the actuated package

the positioner is controlling) and a check of

the movement speed. Start the automatic

calibration by selecting Auto-Cal and then

answer the questions in the display by pressing

OK or the respective arrow. More detail about

these questions can be found on page 23.

Calibration error messages

If a fault occurs during calibration, one of the

following error messages can be displayed:

No movement/press ESC to abort

Typically the result of an air delivery issue to the

actuator, a stuck valve or actuator, or incorrect

mounting and/or linkage arrangement. Check

for proper supply air to the positioner, pinched

tubing, proper actuator sizing, proper linkage

and mounting arrangement.

Pot uncalibrated/press ESC to abort

The potentiometer is out of range. The

potentiomenter is aligned using the Calibrate Expert cal - pot Menu. The calibration sequence

must be restarted after the fault is corrected.

Tip! Instant quick calibration

The D30 can be instantly calibrated by pressing

the top + bottom buttons for 5 seconds (see

picture). This function is available from any

menu position.

First start, Profibus PA

For Profibus PA, connect the input signal at pos

1 and 2 on the terminal block. See Electrical

connections in the manual.

In the SETUP/Devicedata/Profibus: change

the address from 126 to any number between

1-125. Never use the same number with more

than one unit. Install values in failsafe mode, for

communication when loss of signal.

Calibrate the unit.

GSD files are available at our web-page

www.pmv.nu

To install the D30_PROFIBUS.DDL file to

Siemens SIMATIC PDM.

1. Move the files to the directory where the

DeviceInstall.exe is located.

2. Run DeviceInstall.exe

BASIC MENU

CALIBRATE

For Expert Calibration

parameters - see page 29!

For further information on

calibrating the pot - see page 38

Instant quick calibration

Page 21

D30 Digital Positioner FCD PMENIM0030-01-A5 – 05/18

21

Parameter Description BYTE

SP Setpoint The SP has 5 bytes, 4 bytes for the float value 4+1=5

and one status byte. The status byte needs to be

128 (0x80Hex) or higher for the D30 to accept it.

READBACK Position The READBACK has 5 bytes, 4 bytes for the 4+1=5

float value and one status byte.

POS_D Digital position Returns actual position as a digital value with 2

definitions as below

0 = Not initialized

1 = Closed

2 = Opened

3 = Intermediate

CHECKBACK Detailed information of the device, coded bit wise. 3

Several messages can occur at the same time.

RCAS_IN Remote Cascade The RCAS_IN has 5 bytes, 4 bytes for the 4+1=5

float value and one status byte.

RCAS_OUT Remote Cascade The RCAS_OUT has 5 bytes, 4 bytes for 4+1=5

the float value and one status byte.

Status Byte Table

MSB LSB Meaning D30 info

0 0 0 0 1 0 x x Not connected

0 0 0 0 1 1 x x Device failure PROFIbus PA module failure

0 0 0 1 0 0 x x Sensor failure No sensor value

0 0 0 1 1 1 x x Out of service AI Function Block in O/S mode

1 0 0 0 0 0 x x Good - Non cascade Measured value OK

All Alarm values used

1 0 0 0 0 0 0 0 OK

1 0 0 0 1 0 0 1 Below low limit Lo Advisory alarm

1 0 0 0 1 0 1 1 Above high limit Hi Advisory alarm

1 0 0 0 1 1 0 1 Lo-Lo Critical alarm

1 0 0 0 1 1 1 1 Hi-Hi Critical alarm

Example SP = 43.7% and 50%

Float Hex Status

43.7 42 2E CC CD 80

50.0 42 48 00 00 80

Page 22

D30 Digital Positioner FCD PMENIM0030-01-A5 – 05/18

22

(FF) Foundation Fieldbus function blocks

Function blocks are sets of data sorted by

function and use. They can be connected to

each other to solve a control process, or to a

controlling DCS. To get a good introduction and

understanding of FF look at www.fieldbus.org

and download the “Technical Overview” from

the About FF pages.

(TB) Transducer Block

The TB contains unit specific data. Most of

the parameters are the same as parameters

found on the display. The data and the order

of data varies between different products. The

AO-block setpoint (SP) and process value (PV)

parameters are transceived to the TB through a

channel. The TB has to be in AUTO for the AOblock to be in AUTO.

The positioner has to be in menu-auto mode

and in service to be controlled from the

fieldbus. If the positioner is placed in menumanual mode then the transducer block will

be forced to (LO) local override. In this way a

person in the field will be able to control the

positioner from the keypad, without collision

with a control loop.

(RB) Resource Block

The RB is a set of parameters that looks the

same for all units and products. The values of

the RB define unit information that concerns

the Fieldbus Protocol such as MANUFAC_ID

which informs the unique manufacturer id. For

Flowserve it is 0x464C53. The RB has to be in

AUTO for the AO-block to be in AUTO.

(AO) Analogue Output Block

The AO follows Fieldbus Foundation’s standard

on content and action. It is used for transferring

(SP) setpoints from the bus to the positioner.

CAS_IN (cascade input) and RCAS_IN (remote

cascade input) are selected as inputs to the AO

block depending on the MODE_BLK parameter.

The selected input will be relayed to the SP

parameter of the AO block. BKCAL_OUT

(back calculated output) is a calculated

output that can be sent back to a controlling

object so that control bumps can be avoided.

Usually the BKCAL_OUT is set to be the (PV)

process value of the AO-block, i.e. the actual

measured position of the valve. OUT is the

primary calculated output of the AO block.

During a limited action (ramping) of the AO

block the RCAS_OUT parameter will supply

the final setpoint and the OUT parameter will

be the limited output. The transducer block is

connected through a channel to the AO block.

Through this channel the OUT value and SP are

transceived.

In order to set the AO block to AUTO, the TB

and the RB have to be in AUTO. Further the

AO block has to be scheduled. Using National

Instruments Configurator; scheduling can be

done by adding the unit to a project and then

click on the “upload to device” icon.

To write a setpoint value by hand, add Man to

MODE->Permitted parameter, and then choose

MODE->Target to Man. Make sure that the unit

is scheduled.

Example

A typical FF block loop control might look

like the following: Where the positioner is

represented by the AO-block.

AO-block

overview

RCAS_IN

CAS_IN

BKCAL_OUT

AO

RCAS_OUT

OUT

Transducer

AOPIDAI

BKCAL_OUTBKCAL_IN

OUT OUTIN CAS_IN

Page 23

D30 Digital Positioner FCD PMENIM0030-01-A5 – 05/18

23

The contents of the menu are shown on the next page. The various menu texts are described below.

Auto-Cal

Auto-tuning and calibration of end positions

Start tune

Starts the tuning. Questions/commands are displayed during

calibration. Select the type of movement, function, etc. with

and confirm with OK as shown in the chart on the next

page.

Lose prev value? OK?

A warning that the value set previously will be lost (not during

the first auto-tuning).

Direction? Air-to-open.

Select for direct function.

Direction? Air-to-close.

Select for reverse function.

In service? Press OK

Calibration finished. Press OK to start positioner functioning.

(If ESC is pressed, the positioner assumes the ”Out of service”

position but the calibration is retained).

TravelCal

Calibration of end positions

Start cal

Start end position calibration.

Lose prev value? OK?

A warning that the previously set value will be lost. Confirm

with OK. The calibration sequence starts.

In service? Press OK

Calibration finished. Press OK to start positioner functioning.

(If ESC is pressed, the positioner assumes the ”Out of

service”position but the calibration is retained).

Perform

Setting gain

Normal

100% gain

Perform G, F, E, D, C, B, A

Possibility to select a lower gain in steps.

Default setting is D.

Note. Original P. I. D. will always be shown in display

BASIC MENU

CALIBRATE

Page 24

D30 Digital Positioner FCD PMENIM0030-01-A5 – 05/18

24

The menu contents are shown in the figures on the right and the texts are described below:

Current values can be read using the Read Menu and some values can be reset.

Pos Shows current position

Set&pos Set point and position

Set&dev Set point and deviation

Pos graph Shows position graph

Temp Shows current temperature

Statistics

n cycles Shows number of cycles.

1 cycle = [move of valve

+change direction+move

opposite direction] regardless

of size of each move/stroke.

Acc travel Travel = [accumulated % valve

has moved/100].

Example: move 60% up + move

40% down =>Acc travel = 1

mean dev Shows accumulated

deviation in %

m.abs dev Shows accumulated

absolute deviation in %

# of resets Shows number of resets

runtime Shows accumulated runtime

since last reset

Extr temp Shows extreme min and max

temperature

Histogram Shows position and time for

position value

Alarms Displays tripped alarms

READ

S&P Actual

Statistics

pulse rate

READ

pos

READ

set&pos

READ

set&dev

READ

Pos Graph

READ

temp

READ

Statistics

READ

Alarms

Statistics

n cycles

Statistics

mean dev

Statistics

m. abs dev

Statistics

runtime

Statistics

# of resets

Statistics

ex tr. temp

Statistics

histogram

Statistics

Reset stat

Statistics

acc travel

BASIC MENU

READ

Page 25

D30 Digital Positioner FCD PMENIM0030-01-A5 – 05/18

25

The Man/Auto menu is used to change between manual and automatic modes.

The menu contents are shown in the figures on

the right and the various texts are described

below:

AUT, OK = MAN

Positioner in automatic mode

MAN, OK = AUT

Positioner in manual mode

In the MAN mode, the value of POS can be

changed using . The push-buttons

increase/decrease the value in steps. The value

can also be changed in the same way as for the

other parameter values, as described on page

14

Other functions

C+ can be fully opened by pressing and

then immediately OK simultaneously.

C- can be fully opened by pressing and OK

simultaneously.

C+ and C- can be fully opened for blowing clean

by pressing and OK simultaneously.

BASIC MENU

MAN/AUTO

When changing between MAN and AUT

mode, the OK button must be pressed for 3

seconds.

AUT, OK= MAN

POS = 12,3%

OK

MAN, OK= AUT

POS = 12,3%

Page 26

D30 Digital Positioner FCD PMENIM0030-01-A5 – 05/18

26

The Status Menu is used to select whether or not the positioner is in service.

The menu contents are shown in the figures on the right

and the various texts are described below:

o o service Not in service. Flashing

indicator in upper left hand corner of display.

in service Positioner in service.

Critical parameters

cannot be changed.

The Shift Menu is used to choose between the basic menu and the full menu.

The menu contents are shown in the figures on

the right and the various texts are described

below:

No Full menu selected.

Yes Basic menu selected.

The Menu can be locked with a passcode,

see Setup menu.

BASIC MENU

SHIFT MENU

Full menu

no

OK

Full menu

yes

OK

FULL MENU

STATUS

OK

OK

STATUS

o o service

STATUS

in service

When changing between In service and Out

of service, the OK button must be pressed

for 3 seconds.

Page 27

D30 Digital Positioner FCD PMENIM0030-01-A5 – 05/18

27

FULL MENU

SETUP

The Setup Menu is used for various settings.

The menu contents are shown in the chart on the next page and the various texts are described

below:

Actuator Type of actuator Size of actuator Time out

Rotating Rotating actuator. Small 10 s

Linear Linear actuator. Medium 25 s

Large 60 s

Extra large 180 s

Lever Only for linear actuator.

Lever stroke

Stroke length to achieve correct display. Input only needed in case display

value is off

Level cal

Calibration of positions to achieve correct display.

Direction

Direct

Direct function (signal increase opens). Indicator/spindle rotates counterclock wise.

Reverse

Reverse function.

Character Curves that show position as a function of input signal.

Linear

See diagram.

Equal %

Quick open

Sqr root

Custom

Create own curve.

Cust chr

# of point

Specify number of points

(3, 5, 9, 17, or 33)

Cust curve Enter values on X and Y axes.

Curr range (Use this function to split range)

0%= 4.0 mA

100%=20.0 mA Possibility of selecting which input signal values will correspond to

0% and 100% movement respectively. Examples of settings:

4 mA = 0%, 12 mA = 100%, 12 mA = 0%, 20 mA = 100%.

Qo

Sqr

Lin

Eq%

Signal

Movement

x

y

Page 28

D30 Digital Positioner FCD PMENIM0030-01-A5 – 05/18

28

TRVL range Setting end positions

0%=0.0% Select Out of Service.

Set percentage value for

desired end position

(e.g. 3%).

Set 0% Select In Service.

Connect calibrator.

Move forward to desired end

position (0%) and press OK.

100%=100.0% Select Out of Service.

Set percentage value for

desired end position

(e.g. 97%).

Set 100% Select In Service.

Connect calibrator. Move

forward to desired end

position (100%)

and press OK.

Trvl ctrl Behavior at set end position

Set low Choose between Free

(positioner will control until a

mechanical top is reached),

Limit (stop at set end

position), and Cut off (Default

value. Go directly to a

mechanical stop at a

redefined setpoint).

Set high Similar to Set low.

Values Select position for Cut off and

Limit at the respective end

positions.

Passcode Setting passcode for

access to the menu

Numbers between 0000 and 9999 can be used

as passcodes. 0 = no passcode required.

Appearance On display

Language Select menu language.

Units Select units.

Def. Display Select value(s) to be

displayed during service.

The display reverts to this

value 10 minutes after any

change is made.

Start menu Start in Basic menu or

Full menu.

Orient Orientation of text on display.

Par mode Display of control parameters

such as P, I, D or K, Ti, Td.

Devicedata

HW rew

SW rew General parameters.

Capability

HART Menu with HART parameters.

Only amendable with HART

communicator. It is possible

to read from display.

Profibus PA

Status Indicates present status

Device ID Serial number

Address 1-126

Tag Allotted ID

Descriptor ID description

Date SW release date

Failsafe Value = preset pos

Time = Set time +10sec=

time before movement

Valve act = failsafe

(preset pos) or last value

(present pos)

Alarm out= On/Off

Foundation Fieldbus

Device ID Serial number

Nod address Address on the bus provided

by the DCS system

TAG–PD_TAG Name provided by the

DCS system

Descriptor D30 positioner

Date SW release date

Sim jumper Simulate jumper, FF

simulation functionality

activated = ON

Page 29

D30 Digital Positioner FCD PMENIM0030-01-A5 – 05/18

29

FULL MENU

TUNING

The menu contents are shown in the chart on the next page and the various texts are described

below:

Close time Minimum time from fully open to closed.

Open time Minimum time from closed to fully open.

Deadband Setting deadband. Min. 0.1%.

Expert Advanced settings.

Control See explanations below.

Toggles tep Test tool for checking functions. Overlays a square wave on the set value.

Self test Internal test of processor

Undo You can read last 20 changes.

P,I,D and K,Ti,Td parameters

If one of the gains is changed, the

corresponding value in the other gain set is

changed accordingly.

Page 30

D30 Digital Positioner FCD PMENIM0030-01-A5 – 05/18

30

FULL MENU

ALARMS

The menu contents are shown in the chart on the next page and the various texts are described below:

Deviation Alarm generated when deviation occurs

On/Off Alarm on/off.

Distance Allowed distance before alarm is generated.

Time Total deviation time before alarm is generated.

Alarm out Select ON/OFF offers output on terminals.

Valve act Behavior of valve when alarm is generated.

Limit 1 Alarm above/below a certain level.

On/Off Alarm on/off.

Minipos Setting of desired min. position.

Maxpos Setting of desired max. position.

Hysteresis Desired hysteresis.

Alarm on Select ON/OFF offers output on terminals.

Valve act Behavior of valve when alarm is generated.

Limit 2 See Limit 1.

See diagram below!

0%

100%

Alarm Limit 1 on

Alarm Limit 2 on

Alarm Limit 1 off

Alarm Limit 2 off

Alarm Limit 2 on

Alarm Limit 1 on

Alarm Limit 1 off

Alarm Limit 2 off

Travel

Set alarm and hysteresis values

Limit 1, max

Hysteresis

Limit 2, max

Hysteresis

Hysteresis

Limit 2, min

Hysteresis

Limit 1, min

Page 31

D30 Digital Positioner FCD PMENIM0030-01-A5 – 05/18

31

Temp Alarm based on temperature

On/Off Temperature alarm on/off.

Low temp Temperature setting.

High temp Temperature setting.

Hysteresis Allowed hysteresis.

Alarm out Select ON/OFF offers output on terminals.

Valve act Behavior of valve when alarm is generated.

Valve act

No action Alarm generated only. Operations not affected.

Goto open Valve moves to 100%. Positioner changes to position Manual.

Goto close Valve moves to 0%. Positioner changes to position Manual.

Manual Valve stays in unchanged position. Positioner moves to position Manual.

Page 32

D30 Digital Positioner FCD PMENIM0030-01-A5 – 05/18

32

Expert Calibration

When entering “ExpertCal” mode - walk through the list of parameters described below.

Set values where applicable. Confirm by pressing OK.

Set point LO: Use the calibrator set to 4 mA

(or set another value on the display). Press

OK.

Set point HI: Use a calibrator of 20 mA

(or set another value on the display). Press

OK.

Pressure LO: Use a supply of 1.4 bar (20 psi)

(or set another value on the display). Press

OK. Pressure read out only possible on D30

with built in pressure sensor.

Pressure HI: Use a supply of 8 bar (115 psi)

(or set another value on the display). Press

OK. Pressure read out only possible on D30

with built in pressure sensor.

Transmitter: Connect 10 - 28 VDC. Connect

an external mA meter to the loop. Read low

value on mA meter and adjust with up/down

key. Press OK to set low value.

Repeat procedure to set High value.

Also see video on www.pmv.nu

Pot: Potentiometer setting, see section 5.

Also see video on www.pmv.nu

Full reset: Resets all set values and enters

Factory mode. To reset the values only, use

FACT SET in main menu, see below.

FULL MENU

FACT SET

The menu contents are shown in the chart below.

The default values that were set on delivery can be reset using the Fact Set menu.

Values from calibration and from other settings will then be lost.

FACT SET

no

OK

OK

Press OK

for 3 seconds

OK

OK

Discard

settings?

Input

accepted

OK

FACT SET

Done

OK

FACT SET

yes

Page 33

D30 Digital Positioner FCD PMENIM0030-01-A5 – 05/18

33

READ

MAN/AUTO AUT,OK=MAN MAN,OK=AUT

CALIBRATE AutoCal F

TravelCal E C+ & C-**

D default temp

C

Expert cal full reset B statistics runtime

alarms # of reset

normal

Histogram

Reset stat

SHIFT MENU

small

Type medium

O O SERVIC large

STATUS IN SERVICE

SETUP

Lever* Stroke Air To Open

Lever cal Air To Close

Direction

X0=

Y0=

0% =

Set 0%

100%= 0% =

Set 100% Set 0%

100%=

Set 100%

free

Direction

Set high Limit Low

Limit Hi Pos/Set Position

Set Point

Old New 0=Off

Language svenska

Italiano mA

mm

norsk cm mm

cm

bar

Units psi Grad C

Position kPa Grad F

Kelvin

Temp

position

Start Logo On/off

full Tag

LED On/off

Date

Orient. normal Device ID

HW rev

SW rev

Hart

Control (x) On/off

TUNING Close time

Open time K,Ti,Td

Expert

start

Abort step

ALARMS Deviation On/off

Limit On/off Time

Alarm out

On/off On/off

Max diff

Alarm out Alarm out On/off

Low temp no action

Alarm out High temp goto open

Alarm out manual

Temp

FACT SET no

yes

Replacement for page xx in the D30 IOM for software version 1.2

pos

set&pos

set&dev

G Highest Pos Graph

Supply Pr** n cycles

acc travel

Balance mean dev

Perform pot outsignal m. abs dev

A Lowest

extr temp

Basic menu

Full menu rotating single act

linear double act

Function

Size Texas-size

linear

Actuator equal %

quick open

custom

sqr root

Character #of points

Cust chr Cust curve

Curr range

Trvl range

Trvl ctrl Cutoff Low direct

Set low cutoff Cutoff Hi reverse

limited

Values

Transm.

Passcode

english

Appearance

deutsch

français percent

español percent

chinese inch

degrees inch

Setpoint degrees

Pressure**

Def. Displ

Start menu

last value set&pos

basic set&dev Message

menu

Descriptor

flipped Poll adr

Assemblyno

Devicedata Capability Univ cmd

Spec cm

Burst

Togglestep PID params

Self test Run time

Deadband Leakage Spring Adj cycle time

Undo Friction size

Distance

Minpos

Maxpos Valve act

Hysteresis Min Pres

Max Pres

Valve act Valve act Hysteresis

Pos=Pres

Pressure Valve act Hysteresis goto close

Valve act

Valve act

(*) appear if Linear set

(**) appear if pressure sensor exist

(x) Position is show in upper row (PID, KTiTd, Min Pulse)

Page 34

D30 Digital Positioner FCD PMENIM0030-01-A5 – 05/18

34

5. Maintenance/service

When carrying out service, replacing a circuit board, etc., it may be necessary to remove and

refit various parts of the positioner. This is described on the following pages.

Read the Safety Instructions on page 4 and 5 before starting work on the positioner.

Cleanliness is essential when working with the positioner. Contamination in the air ducts

will inevitably lead to operational disturbances. Do not disassemble the unit more than

that described here.

DO NOT take the valve block apart because its function will be impaired.

When working with the D30 positioner, the work place must be equipped with ESD

protection before the work is started.

Always turn off the air and electrical supplies before starting any work.

Please see section for special conditions for safe use and spare parts on page 5!

Please contact a Flowserve office for information regarding proper procedures.

www.pmv.nu or infopmv@flowserve.com

Disassembling D30

Removing cover and inner cover

• Unscrew the screws A and remove the cover. When mounting cover – see page 5.

• Pull off the arrow pointer, B.

• Unscrew the screws C and remove the inner cover.

Note: Removing inner cover will void warranty.

A

B

C

Page 35

D30 Digital Positioner FCD PMENIM0030-01-A5 – 05/18

35

Circuit boards (PCB)

Disconnect or switch off the electric power supply before starting any work.

• Lift off the display PCB..

• Release the cable connections.

• Unscrew the two screws B and lift up the circuit board.

B

Page 36

D30 Digital Positioner FCD PMENIM0030-01-A5 – 05/18

36

Limit Switches

When installing the switch card, make sure it is

placed correctly.Secure the PC board with the

two screws. Make sure the holes are centred

before tightening the screws.

Note! When installing the cam assembly for

mechanical switches, retract both switch arms

first.

Install the cam assembly and tighten the

screws loosely to obtain enough friction to lock

the cams.

Adjust the lower cam first, then the upper cam.

Page 37

D30 Digital Positioner FCD PMENIM0030-01-A5 – 05/18

37

Valve block

Turn off the air and electric power

supply before starting any work.

• Remove the three screws A and lift out the

valve block

N.B. Do not disassemble the valve block

• When installing the valve block — torque the

three screws to 0,4 Nm and seal with

Loctite® 222.

Pressure sensors

Three pressure sensors are available as an

option. They indicate pressure for supply, Cand C+ air,and can be used by ValveSight™ to

enable advanced valve diagnostics.

The sensors are mounted on a circuit board

which mounts next to the air relay on the floor

of the housing at B using three screws.

Pressure sensor PCB - top view

Pressure sensor PCB - bottom view

A

Page 38

D30 Digital Positioner FCD PMENIM0030-01-A5 – 05/18

38

Potentiometer

90° spring loaded potentiometer

The spring-loaded potentiometer can be

removed from the gearwheel for calibration or

replacement.

If the potentiometer is replaced or the setting is

changed, it must be calibrated.

• Select the menu Calibrate - Expert - Cal pot.

The display shows Set gear.

• Turn the spindle shaft clockwise to end

position and press OK. Either turn manually

or use the up/down arrows (with supply

air) to stroke the positioner to turn the shaft

clockwise (see Manual mode page 25).

• Move spring (1) aside and disengage

cogwheels. Turn potentiometer according

to display until OK is shown. Press OK. See

drawing below.

• Move back spring (1) and secure

potentiometer (2) calibration. See drawing

below.

2

1

Page 39

D30 Digital Positioner FCD PMENIM0030-01-A5 – 05/18

39

6. Trouble shooting

Symptom Action

Input signal change to positioner does not

affect actuator position.

• Check air supply pressure, air cleanliness,

and connection between positioner and

actuator.

• Out of service, in manual mode.

• Check input signal to positioner.

• Check mounting and connections of

positioner and actuator.

Change in input signal to positioner makes

actuator move to its end position.

• Check input signal.

• Check mounting and connections of

positioner and actuator.

Inaccurate control. • Perform Auto-calibration and check for

any leaks.

• Uneven air supply pressure.

• Uneven input signal.

• Wrong size of actuator being used.

• High friction in actuator/valve package.

• Excess play in actuator/valve package.

• Excess play in mounting of positioner on

actuator.

• Dirty/humid supply air.

Slow movements, unstable regulation.

• Implement auto-tuning.

• Increase the deadband (Tuning menu).

• Adjust Performance (Calibrate menu).

Page 40

D30 Digital Positioner FCD PMENIM0030-01-A5 – 05/18

40

7. Technical data

Rotation angle min 25° max 100°

Stroke From 5 mm (0.2¨)

Input signal 4-20 mA DC

Air supply 1.4-8 barg (20-115 psi) DIN/ISO 8573-1 3.2.3

Free from oil, water and moisture.

Air delivery Up to 760 nl/min @ 6 bar (29.3 scfm @ 87 psi)

Air consumption 8 nl/min @ 6 bar (0.31 scfm @ 87 psi)

Air connections ¼” G or NPT

Cable entry 2x M20x1.5 or ½” NPT

Electrical connections Screw terminals 2.5 mm2 /AWG14

Linearity <0.4%

Repeatability <0.5%

Hysteresis <0.3%

Dead band 0.1-10% adjustable

Display Graphic, view area 15 x 41 mm (0.6 x 1.6¨)

UI 5 push buttons

CE directives 93/68EEC, 89/336/EEC, 92 /31/EEC

Voltage drop, w/o HART 8 V

Voltage drop, with HART 9.4 V

Vibrations < 0.25% FS 10-500 Hz 2g max

Enclosure IP66

Material Die-cast Aluminum

Surface treatment Powder epoxy

Temperature range –40°C to +80°C (-40˚F to 176˚F)

Weight 1.8 kg (4 lbs)

Mounting position Any

Communication protocols Hart, Profibus PA, Foundation Fieldbus

Page 41

D30 Digital Positioner FCD PMENIM0030-01-A5 – 05/18

41

Mechanical switches

Type SPDT

Size V3

Rating 3 A/125 VAC / 2 A/30 VDC

Temperature range -40°C to 80°C (–22°F to 180°F)

NAMUR sensors

(NJ2-V3-N)

Type Proximity DIN EN 60947-5-6:2000

Load current

1 mA ≤ I ≤ 3 mA

Voltage range 8 VDC

Hysteresis 0.2%

Temperature range –25°C to 85°C (–13°F to 185°F)

Proximity switches

Type SPDT

Rating 0.4 A @ 24 VDC, Max 10 W

Operating time Max 1.0 ms

Max voltage 200 VDC

Contact resistance

0.2 Ω

Temperature range -40°C to 80°C (–22°F to 180°F)

Slot NAMUR switches

(SJ2-SN, SJ2-N)

Type Proximity DIN EN 60947-5-6:2000

Load current

1 mA ≤ I ≤ 3 mA

Voltage 8 VDC

Hysteresis 0.2%

Temperature range –25°C to 85°C (–40°F to 185°F) SJ2-N

–40°C to 85°C (–40°F to 185°F) SJ2-SN

4-20 mA transmitter

Supply 11-28 VDC

Output 4-20 mA

Resolution 0.1%

Linearity full span +/–0.5%

Output current limit 30 mA DC

Load impedance 800 Ω @ 24 VDC

Page 42

D30 Digital Positioner FCD PMENIM0030-01-A5 – 05/18

42

8. Dimensions

100

173,5

53

63

M6 (4x)

17,7

17,7

17,7

17,7

28,6

28,6

28,6

M8 (3x) alt.

5/16"-18 UNC (3x)

1

17,5

32,5

47,5

62,5

77,5

9(2x)

11(3x)

M8(2x)

G1/4" alt.

1/4" NPTF

16

46

63

103

M20x1.5 alt.

1/2" NPT

33

29

24,5

10

9

4,8

24

12

10

164

126

70

50

55

2,3

M8x1

4

10

9,5

7

6

M3

REV.

MODIFICATION

DATE

MOD.BY

1

New cover implemented. New gauge block implemented. M8 was M6.

180321

KBM

Page 43

D30 Digital Positioner FCD PMENIM0030-01-A5 – 05/18

43

9. Spare parts

No Part no Description

1 D4-SP37PVA Black cover incl. screws and flat indicator

1 D4-SP37FWA White cover incl. screws and flat indicator

2 D4-SP40 Internal cover incl. screws

3 D4-SP1516 External covers SST, 2, incl screws

4 3-SXX Spindle adaptor (XX = 01, 02, 06, 26, 30, 36)

5 D4-SP05-09 S09 shaft compl. incl. gear wheel, friction clutch, spring

5 D4-SP05-21 S21 shaft compl. incl. gear wheel, friction clutch, spring

5 D4-SP05-23 S23 shaft compl. incl. gear wheel, friction clutch, spring

5 D4-SP05-39 S39 shaft compl. incl. gear wheel, friction clutch, spring

6 D4-SP400 Air relay complete, incl. cable, seal, screws

7 D4-SP08 Potentiometer compl. incl. spring, bracket, cable

8 3-SP37HR PCB LCD assembly

9 D4-SP7-80H PCB mother board 4-20 mA / HART

9 D4-SP7-80P PCB mother board Profibus PA

9 D4-SP7-80F PCB mother board Fieldbus

10 D4-SP84-3 Pressure sensor assembly complete

11 D4-SPGB Bag with screws, O-rings, seals, pair of sintered brass silencers, cable

gland

12 D4-SP940M Gauge block G, complete incl. screws, seals, 3 gauges / SST, Brass

12 D4-SP940N Gauge block G, complete incl. screws, seals, 3 gauges / SST, Brass

13 D4-SP45S Limit switches Mechanical SPDT compl.

13 D4-SP45N Limit switches Namur V3 P&F NJ2-V3-N compl.

13 D4-SP45P Limit switches Proximity SPDT compl.

13 D4-SP455 Limit switches Namur slotted P&F SJ2-SN compl.

13 D4-SP456 Limit switches Namur slotted P&F SJ2-N compl.

Note: PMV does not offer spare parts for certified units

Page 44

D30 Digital Positioner FCD PMENIM0030-01-A5 – 05/18

44

1

2

8

9

5

11

10

12

7

6

13

Page 45

Page 46

47

PMV Automation AB

Korta Gatan 9

SE-171 54 SOLNA

SWEDEN

Phone: +46 (0)8-555 106 00

E-mail: infopmv@flowserve.com

PMV USA

14219 Westfair West Drive

Houston, TX 77041, USA

Phone: +1 281 671 9209

Fax: +1 281 671 9268

E-mail: pmvsales@flowserve.com

Flowserve Flow Control

Burrell Road, Haywards Heath

West Sussex RH16 1TL

Phone: +44(0)1444 314400

E-mail: pmvuksales@flowserve.com

Flowserve Flow Control Benelux

Rechtzaad 17

4703 RC Roosendaal

THE NETHERLANDS

Phone: +31 (0) 30 6771946

Fax: +27 (0) 30 6772471

E-mail: fcbinfo@flowserve.com

Flowserve Flow Control GmbH

Rudolf-Plank Strasse 2

D-76275 Ettlingen

GERMANY

Phone: +49 (0) 7243 103 0

Fax: +49 (0) 7243 103 222

E-mail: argus@flowserve.com

Flowserve Corporation

No. 35, Baiyu Road

Suzhou Industrial Park

Suzhou 215021, Jiangsu Province,

PRC

Phone: +86-512-6288-1688

Fax: +86-512-6288-8737

Flowserve (China)

585, Hanwei Plaza

7 Guanghau Road

Beijing, China 100004

Phone: +86 10 6561 1900

Flowserve Pte Ltd

No. 12 Tuas Avenue 20

Singapore 638824

Phone: +65 6879 8900

Fax: +65 6862 4940

Flowserve do Brasil Ltda

Rua Tocantins, 128 - Bairro Nova Gerti

São Caetano do Sul,

São Paulo 09580-130 Brazil

Phone: +5511 4231 6300

Fax: +5511 4231 6329 - 423

Flowserve Corporation has established industry leadership in the design and manufacture of its products. When

properly selected, this Flowserve product is designed to perform its intended function safely during its useful life.

However, the purchaser or user of Flowserve products should be aware that Flowserve products might be used

in numerous applications under a wide variety of industrial service conditions. Although Flowserve can provide

general guidelines, it cannot provide specific data and warnings for all possible applications. The purchaser/user

must therefore assume the ultimate responsibility for the proper sizing and selection, installation, operation, and

maintenance of Flowserve products. The purchaser/user should read and understand the (D3 Digital Positioner

User Instructions) instructions included with the product, and train its employees and contractors in the safe use of

Flowserve products in connection with the specific application.

While the information and specifications contained in this literature are believed to be accurate, they are supplied

for informative purposes only and should not be considered certified or as a guarantee of satisfactory results by

reliance thereon. Nothing contained herein is to be construed as a warranty or guarantee, express or implied,

regarding any matter with respect to this product. Because Flowserve is continually improving and upgrading its

product design, the specifications, dimensions and information contained herein are subject to change without

notice. Should any question arise concerning these provisions, the purchaser/user should contact Flowserve

Corporation at any one of its worldwide operations or offices.

For more information about Flowserve Corporation, contact www.flowserve.com or call USA 1-800-225-6989.

FCD PMENIM0030-01-A5 – 05/18

To find your local Flowserve

representative:

To find your local Flowserve representative

please use the Sales Locator

System found at www.flowserve.com30

© May 2018, Flowserve Corporation, Irving, Texas

flowserve.com

Loading...

Loading...