Page 1

Worcester Controls

MODELS

20 – For AF-17 Boards Mounted Inside 10-23 75 Actuator.

30 – For AF-17 Boards Mounted Inside 25-30 75 Actuator.

AF-17-1K, 120A or 240A, 1000 ohm Resistance Input

AF-17-13, 120A or 240A, 135 ohm Resistance Input

AF-17-1, 120A or 240A, 1 to 5 Milliamp Input

AF-17-4, 120A or 240A, 4 to 20 Milliamp Input

AF-17-10, 120A or 240A, 10 to 50 Milliamp Input

AF-17-5V, 120A or 240A, 0 to 5 VDC Input

AF-17-XV, 120A or 240A, 0 to 10 VDC Input

R – Reverse Action Option

120A-120 VAC Power Circuits

240A-240 VAC Power Circuits

WCAIM2031

AF-17 Electronic Positioner

Installation, Operation and Maintenance Instructions

Page 2

2 AF-17 Electronic Positioner: Installation, Operation and Maintenance WCAIM2031

1.0 GENERAL 3

1.1 Basic Design 3

1.2 Environmental Considerations 4

1.2.1 Temperature 4

1.2.2 Positioner Temperature 4

1.2.3 Humidity 4

1.2.4 Input Circuit Noise Protection 4

2.0 ELECTRONIC CIRCUIT BOARD 6

2.1 General 6

2.2 Circuit Board Configurations 6

2.3 LED Indicators 6

2.4 Controls 6

2.4.1 Range 6

2.4.2 Zero 6

2.4.3 A-H 6

2.5 AC Power Control 6

3.0 INSTALLATION OF AF-17 INTO

3.0 SERIES 75 ELECTRIC ACTUATOR 7

3.1 General 7

3.1.1 Check Kit for Parts 7

3.1.2 Tools Needed 8

3.1.3 Operation Check of Basic Actuator 8

3.2 Mounting Potentiometer 8

3.2.1 Mounting Single

Potentiometer Into

Series 75 Electric Actuator 8

3.2.2 Mounting Dual

Potentiometer Into

Series 75 Electric Actuator 8

3.2.3 Potentiometer Wiring 8

3.2.4 Adjusting Potentiometer 9

3.2.5 Important Note 9

3.3 Mounting Circuit Board 11

3.3.1 For 120/240 VAC 10-23 Size Electric Actuators 11

3.3.2 For 120/240 VAC 25 and 30 Size Electric Actuators 12

3.3.3 For Optional 4-20 mA Position Output Installation 12

3.4 Wiring AF-17 Board to Actuator 13

3.4.1 Terminal Strip 13

3.4.2 Feedback Connections 14

3.4.3 Output Connections 14

3.4.4 For 10-30 AF-17 240 VAC Positioner Wiring 14

3.4.5 Wiring for AF-17 with 4-20 mA Position Output 14

3.5 Actuator Power 15

3.5.1 Wire Size 15

3.5.2 Terminations and Voltage 15

3.5.3 Minimum Fuse Ratings 15

3.6 Input Signal Connections 16

3.6.1 Milliampere 15

3.6.2 Resistive 16

3.6.3 Direct 17

4.0 CALIBRATION AND ADJUSTMENT 17

4.1 Initial Setup and Adjustment 17

4.2 Zero Adjustment 17

4.3 Range Adjustment 17

4.4 AH Adjustment 17

4.5 Adjustment Recheck 18

4.6 Operational Check 18

4.6.1 Increasing Signal 18

4.6.2 Decreasing Signal 18

4.6.3 Attaching Label 18

4.7 If Problems Occur 18

4.7.1 Cam Adjustment 18

4.7.2 Feedback Pot Calibration 18

4.7.3 Reverse Acting 18

4.7.4 Adjustment to Loop Process 18

4.7.5 Check Fuse F1 19

4.7.6 Check Basic Actuator for Proper Operation 19

4.7.7 Check for Noise Problems 19

4.7.8 Replace Circuit Board 19

5.0 OPERATIONAL VARIABLES 19

5.1 Sensitivity 19

5.2 Reduced Travel Operation 19

5.3 Split Range 19

5.4 Reverse Action 19

5.4.1 Milliampere Input 20

5.4.2 Resistive Input 20

5.4.3 Voltage Input 20

5.4.4 240 VAC 20

6.0 TECHNICAL DATA 20

6.1 AC Input Voltage 20

6.2 Input Circuit Specs 20

6.3 Output Circuit Specs 21

6.4 Input Circuit Characteristics 21

6.4.1 Input Circuit Load Resistances 21

6.4.2 Nominal Useable Input Signal Deadband 21

6.5 Controls 21

7.0 APPLICATION NOTES 22

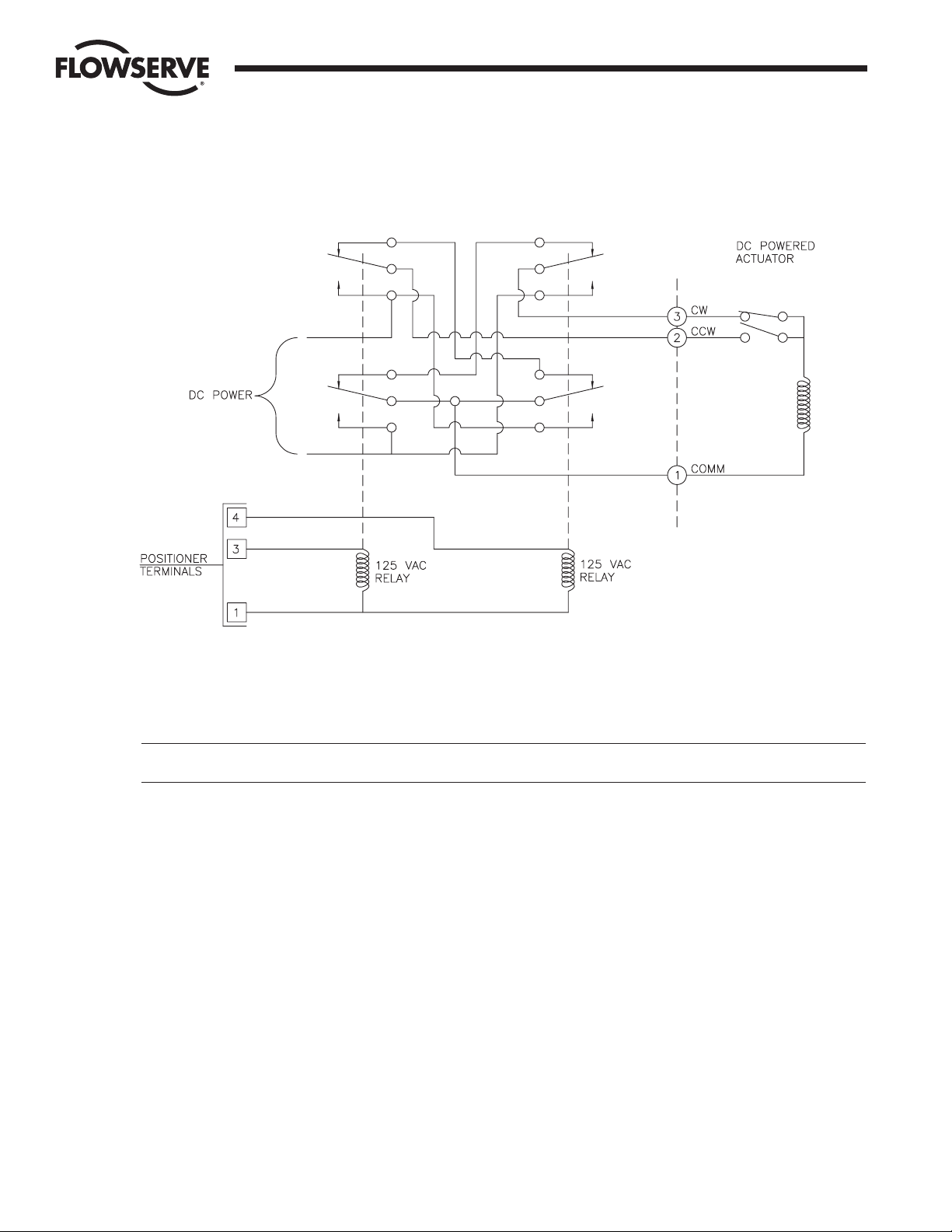

7.1 DC Motor Actuator 22

7.2 Bypass Switch for Manual Control 22

8.0 TROUBLESHOOTING 23

8.1 General 23

8.2 Symptom Table 24

8.3 Troubleshooting Guidelines 25

9.0 SUGGESTED SPARES 27

Flow Control Division

Worcester Controls

TABLE OF CONTENTS

Page 3

WCAIM2031 AF-17 Electronic Positioner: Installation, Operation and Maintenance 3

1.0 GENERAL

1.1 Basic Design

The Worcester AF-17 Electronic Positioner was designed for use with the Worcester Series 75 actuators. However, it may also be

used with other actuators or electrically operated rotary devices, provided the specified load parameters as given in Part 6.3 are

not exceeded.

CAUTION: This positioner is sensitive to electrical noise; please see part 1.2.

PLEASE READ THIS SECTION

A. The AC AF-17 board 4-20 mA signal input circuit is protected with a 62 mA fuse (F1). The fuse is used to protect the input

circuit from an excessively high voltage. The fuse used in the input circuit is a Littlefuse PICO II very fast-acting fuse rated at 62

mA. There is a spare fuse located on the circuit board in the area of the large power resistors.

B. The AF-17 board is designed to receive a floating current input signal. This allows several pieces of equipment to be operated

from the same current loop while at the same time remaining electrically independent of each other.

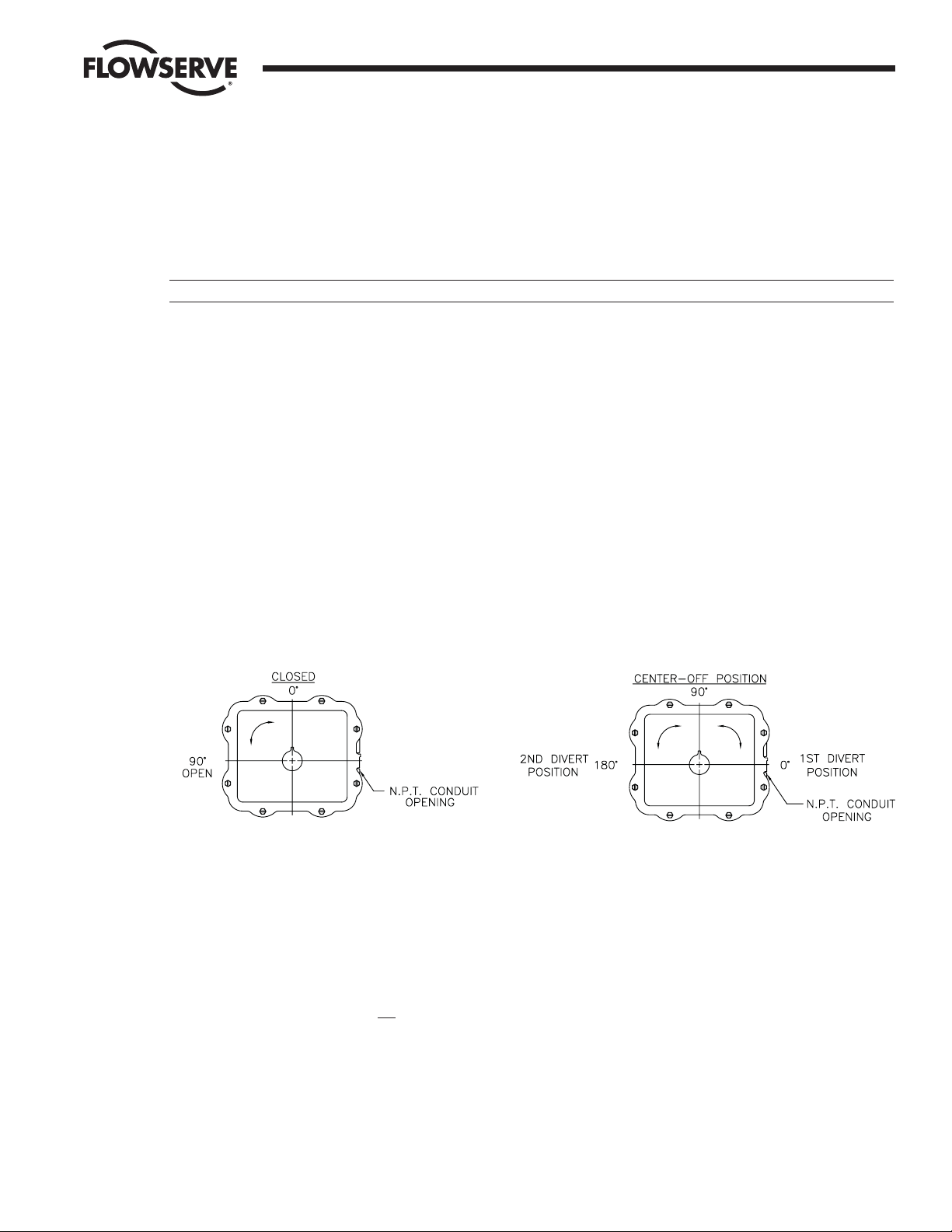

C. The AF-17 board can be set up in several ways for normal operation. The board is designed to control in 90° quadrants only.

The number of quadrants over which the board will control is determined by the number of teeth on the feedback pot pinion

gear. The adjustment trimpots on the board were not set up to reduce actuator travel for a 4-20 mA input span. For example,

trying to adjust the board such that 4 mA is closed and 20 mA is only 60% open is not possible with the standard set up.

The standard setups are:

1. 4 mA for full clockwise rotation, i.e., 0°, and 20 mA for full counter-clockwise rotation, i.e., 90° or 180°.

2. Split range where 4 mA would be full clockwise and 12 mA would be full counter-clockwise or 12 mA would be full clockwise

and 20 mA would be full counter-clockwise.

3. Each of the above standard setups can also be made reverse-acting.

Standard 90° Actuator 180° Center-Off Actuator

Series 75W, X, and Z Shown Series 75W, X, and Z Shown typical

D. Quite often when we receive an actuator for repair at Flowserve we find that the only thing wrong with the unit is that the

feedback potentiometer is out of calibration. It is very important that the feedback pot be properly calibrated for correct

operation of the positioner board. It is also very important that the actuator shaft not be rotated out of the quadrant for which

the feedback pot has been calibrated. Whenever you have a problem with the positioner calibration, always check the feedback

pot calibration first. This must be done with no power applied to the circuit board. If the actuator is in the full clockwise

position, check the resistance between the purple and white/black potentiometer leads. The reading should be 80-90 ohms. If it

is not, rotate the face gear until the proper reading is achieved. If the actuator happens to be in the full counter-clockwise

position then check the resistance between the green and white/black potentiometer leads. If necessary, adjust the face gear for

an 80-90 ohm reading. NOTE: It is not

necessary to loosen or remove face gear snap ring(s) to rotate gear; it is a friction fit.

Flow Control Division

Worcester Controls

Quadrants of Operation

Page 4

4 AF-17 Electronic Positioner: Installation, Operation and Maintenance WCAIM2031

1.2 Environmental Considerations

CAUTION: The AF-17 Electronic Positioner is sensitive to electrical noise on signal or supply lines and in the environment.

For maximum sensitivity, the electrical noise level should not exceed 10mV. Follow installation, calibration and adjustment

guidelines carefully and use shielded wire as stated in paragraph 1.2.4.

Flowserve recommends that all products that must be stored prior to installation be stored indoors, in an environment

suitable for human occupancy. Do not store product in areas where exposure to relative humidity above 85%, acid or alkali

fumes, radiation above normal background, ultraviolet light, or temperatures above 120°F or below 40°F may occur. Do not

store within 50 feet of any source of ozone.

Temperature and humidity are the two most important factors that determine the usefulness and life of electronic equipment.

1.2.1 Temperature

Operating solid-state electronic equipment near or beyond its high temperature ratings is the primary cause for most

failures. It is, therefore, very important that the user be aware of and take into consideration, factors that affect the

temperature at which the electronic circuits will operate.

Operating an electronic device at or below its low temperature rating generally results in a unit operating poorly or not at all,

but it will usually resume normal operation as soon as rated operating temperatures are reached. Low temperature

problems can be easily cured by addition of a thermostatically controlled heater to the unit’s housing.

At high temperatures, some components will destruct completely when their maximum temperature is exceeded; others will

cease operation at temperatures above ratings and will return to operation at normal ratings, but may have been

permanently changed in one or another parameter, causing a device to operate poorly, and may also cause greatly reduced

component life.

1.2.2 Positioner Temperature Considerations

The Worcester AF-17 Electronic Positioner is rated for operation between -40°F and 160°F. When using the positioner inside

the Worcester 75 Series actuators, a maximum ambient temperature of 115°F is required to ensure the circuit board

maximum temperature of 160°F is not exceeded.

1.2.3 Humidity

Most electronic equipment has a reasonable degree of inherent humidity protection and additional protection is supplied by

the manufacturer, in the form of moisture proofing and fungicidal coatings.

Such protection, and the 3 to 4 watts of heat generated by the circuit board assembly will generally suffice for environments

where the average relative humidity is in the area of 80% or less and ambient temperatures are in the order of 70°F average

with only occasional short term exposure to temperatures up to 90°F. Where relative humidity is consistently 80 to 90% and

the ambient temperature is high or subject to large variations, consideration should be given to installing a heater and

thermostat option in the enclosure. The heater should not increase the enclosure temperature to the point where the circuit

board assembly’s temperature rating of 160°F is exceeded.

In those instances where the internal heater would bring the circuit board’s operating temperature near or above its

maximum rating, the user might consider purging the enclosure with a cool, dry gas. The initial costs can usually be paid

off quickly in the form of greatly extended equipment life, low maintenance needs, and much less process downtime.

1.2.4 Input Circuit Noise Protection

Shielded wiring should be used for all signal input circuit wiring regardless of length.

With separately housed positioners, the wiring from the feedback potentiometer to remote positioner, would be considered

as signal input wiring and should also be shielded wire.

The shields should never be used in place of one of the input wires, and the shields normally should be grounded to

equipment housings at one end of the wiring run only. Grounding both ends of shielding can eliminate the shielding benefits

because of current ground loops. If two or more shielded cables come to the positioner from different locations, ground the

shields at the positioner.

Flow Control Division

Worcester Controls

Page 5

WCAIM2031 AF-17 Electronic Positioner: Installation, Operation and Maintenance 5

Flow Control Division

Worcester Controls

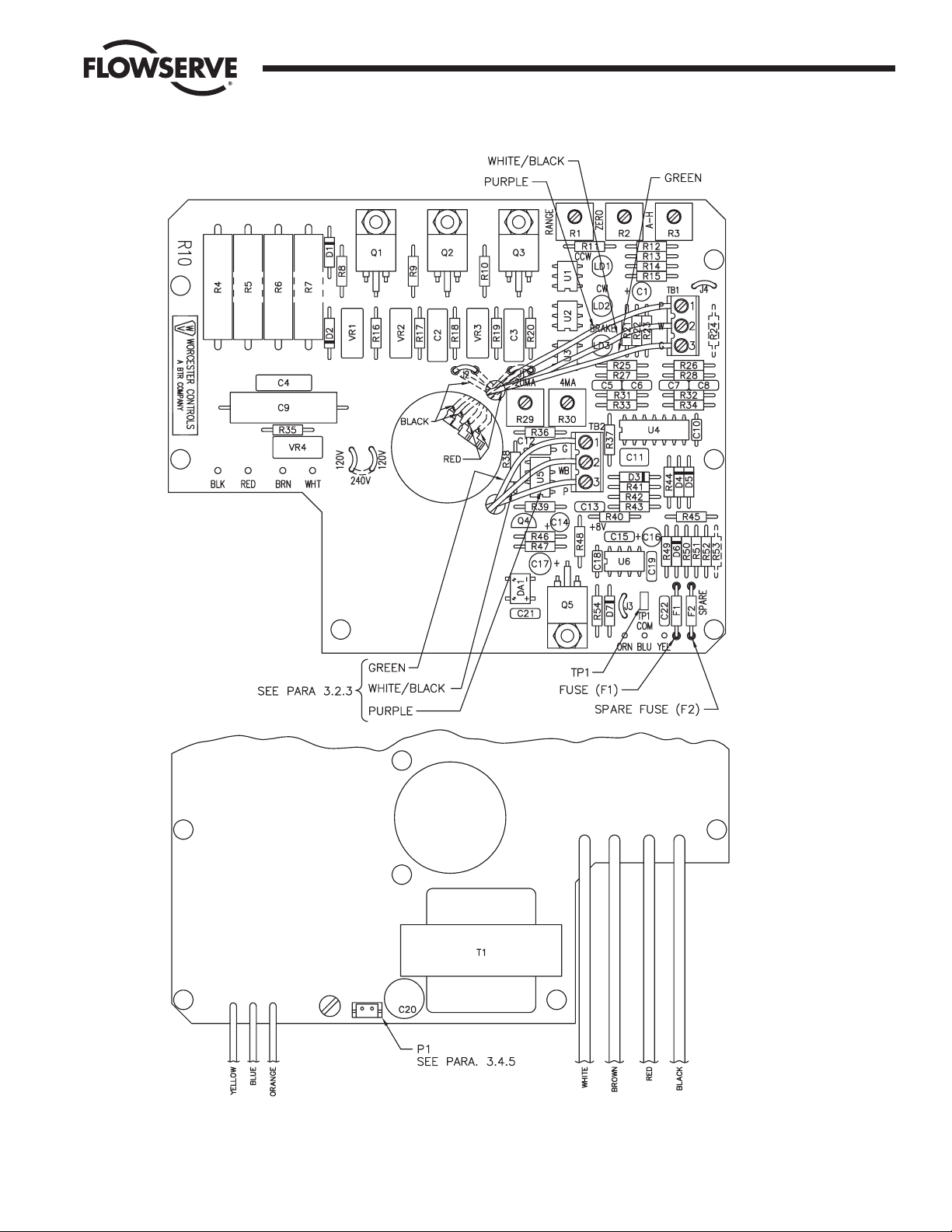

Figure 1 – 120 VAC AND 240 VAC POSITIONER CIRCUIT BOARD

NOTES:

J1 and J2 with red and black wires are

on 240 VAC board only.

Use or values of components R13, R24,

R52, R53, R54, C22, J3, J4 and orange

wire will vary depending on input signal.

R5 and R7 used only for 25 and 30 size

actuators.

Page 6

6 AF-17 Electronic Positioner: Installation, Operation and Maintenance WCAIM2031

2.0 ELECTRONIC CIRCUIT BOARD (120/240 VAC)

2.1 General

Figure 1 defines the location of major components and wires from the positioner to terminal strip connections. The #18 gauge

white wire is the AC power unit “neutral” (or common) in the case of DC input wire. The #20 gauge white/black wire is one of the

connections between the feedback pot and the terminal block (TB-1) on the circuit board.

2.2 Circuit Board Configurations

The positioner board is factory supplied for one of the seven input signal options.

NOTE: Field changes to the positioner board are not advised. Consult Flowserve before attempting any modification.

2.3 LED Indicators

Light emitting diodes (LED) marked LD1, LD2 and LD3 are in the output circuits of amplifier U4. LD1 is tied to pin #13, LD2 to pin

#14, and LD3 to pin #1, and they are each associated with their respective opto-coupler U1, U2 and U3 and indicate when the

input side of the opto-coupler is energized.

2.4 Controls

Three adjustment potentiometers are provided, located on the top side of the board and marked “Range”, “Zero”, and “AH”. See

Figure 1.

2.4.1 Range

The “Range” Control adjusts the positioner’s feedback circuit to cover the same span of voltage as generated by the input

signal.

2.4.2 Zero

The “Zero” adjustment is basically an offset adjustment in that essentially all input signals start at other than a zero signal

condition, i.e., 1, 4 or 12 milliamps.

2.4.3 A-H

The “AH” Control is used primarily to balance the positioner to the dynamic characteristics of the device and media being

controlled. Functionally, it varies the amount of input signal that must be applied to the positioner to cause the actuator to

reverse its direction of rotation. In effect it varies the deadband of the positioner on a reversing signal condition only. The

deadband — the percent change in input signal change that must be applied to initiate a movement of the actuator — on a

signal that is constantly increasing or decreasing, is relatively unaffected by the “AH” control.

The “AH” control can vary the balance point deadband from approximately .3% to 4.0% of signal span. It can therefore be

used to help decrease the effects of signal noise, with a tradeoff in accuracy/sensitivity.

2.5 AC Power Control

The AC output circuits are controlled by solid-state switches (triacs Q1, Q2, Q3), which will provide trouble-free operation for the

life of the equipment they are used with, AS LONG AS THEY ARE OPERATED WITHIN THEIR RATINGS.

The ratings for the solid-state switches used in the Worcester AF-17 Positioner are listed in Part 6.3.

Flow Control Division

Worcester Controls

Page 7

WCAIM2031 AF-17 Electronic Positioner: Installation, Operation and Maintenance 7

3.0 INSTALLATION OF AF-17 INTO SERIES 75 ELECTRIC ACTUATOR

3.1 General

If the actuator was purchased with the AF-17 positioner board factory installed, proceed to section 4.0.

If a 4-20 mA Position Output option is also used with the AF-17 positioner, refer to paragraph 3.3.3 for installation (if not already

installed), and paragraph 3.4.5 for wiring.

3.1.1 Check Kit For Parts

A. Common Parts For Sizes 10-30 Actuators

Additional Parts For 10-23 Actuators:

Additional Parts For 25 and 30 Actuators:

Quantity Name

1 Pot Kit Subassembly

1 Mounting Bracket

2 Mounting Screw (Bracket)

Quantity Name

1 Pot Kit Subassembly

1 Bracket – Right (Long)

1 Bracket – Left (Short)

2 Spacer (Bracket)

2 Mounting Screw (Bracket/Spacer)

1 Support Bracket – Transformer

1 Spacer – Transformer Support Bracket

(for 23 Size Only)

Quantity Name

1 Circuit Board Subassembly

1 Insulating Board

5 or 6 Washers (Nylon)

5 or 6 Grommets (Rubber)

5 or 6 Mounting Screws (Circuit Board)

1 Nameplate – Circuit Board

1 Nameplate – Base

1Wiring Label – Cover

1 Instruction Manual

5 Cable Ties

2 Closed End Splice

1Wire – White

Flow Control Division

Worcester Controls

Page 8

8 AF-17 Electronic Positioner: Installation, Operation and Maintenance WCAIM2031

3.1.2. Tools Needed

1

/

4" nut driver,

1

/

8" screwdriver, needle nose pliers,

1

/

16" Allen wrench (cams and spur gear).

Volt/ohm meter (checking feedback potentiometer resistance, voltages – incoming process signal).

Milliamp source (to check calibration of positioner on actuator).

VAC line cord (to power basic actuator).

3.1.3. Operation Check of Basic Actuator

Set cams for about 1° to 3° of over travel in each direction (full open and full closed). That is, for 0° to 90° operation set

at minus 3° and plus 93°. Power terminals 1 and 3 for CCW rotation, terminals 1 and 4 for CW rotation (reference

paragraph 4.7.6.).

3.2 Mounting Potentiometer

3.2.1 Mounting Single Potentiometer Into Series 75 Actuator

See Figure 2.

A. With the potentiometer mounted to the potentiometer bracket and the spur gear loosely fitted to the potentiometer shaft,

mount the potentiometer bracket (if not already mounted) as follows:

10-23 75 Actuator:

Remove the motor module mounting screws on the side of the module furthest away from the actuator shaft. Position

potentiometer assembly bracket holes over screw holes and line up potentiometer shaft with center of actuator shaft,

replace and tighten screws.

25/3075 Actuator:

Attach potentiometer bracket to motor support plate between the terminal strip and actuator shaft with mounting screws

as shown.

3.2.2 Mounting Dual Potentiometer Into Series 75 Electric Actuator

A dual potentiometer is also available and is required with the AF-17 when external resistance indication is also desired, or

when the 4-20 Position Output option is also used.

Each potentiometer can serve only one function. Remote resistance monitoring and an AF-17, for instance, cannot share a

potentiometer.

Note: Voltage limit of “B” potentiometer is 30 volts maximum.

Mount potentiometer per paragraph A of 3.2.1.

3.2.3 Potentiometer Wiring

A. The feedback potentiometer leads are connected to the terminal block (TB-1) on the AF-17 board. Run the three leads up

through the hole next to potentiometer R29. See Figure 1.

B. Connect the potentiometer leads to the terminal block as follows:

NOTE 1: In the case of a dual potentiometer, “A” (front, close to the bracket) potentiometer wires are wired to the AF-17

board terminal block (TB-1) as stated above, “B” (rear, far from the bracket) potentiometer wires may be wired to terminals 7

(green), 8 (white/black), and 9 (purple) if available and the potentiometer will be used for resistive feedback, or they may be

wired to TB-2 if 4-20 mA position output option is used. The wires are run up through the hole next to Q4 then connected to

TB-2 as follows:

TB-1

Terminal Wire Color

1 Purple

2White/Black

3Green

(DO NOT CUT POTENTIOMETER WIRES!)

Flow Control Division

Worcester Controls

Page 9

WCAIM2031 AF-17 Electronic Positioner: Installation, Operation and Maintenance 9

3.2.4 Adjusting Potentiometer

A. Reference paragraph 4.7.6 for moving the actuator shaft electrically.

B. 10-30 75 Actuator:

Place the large face gear (12) over the actuator shaft with the gear teeth down and secure with snap ring (16).

NOTE: The face gear utilizes a friction fit to the shaft. For best results, wipe off any lubricant that may be on the shaft

before sliding on the face gear.

CAUTION: Do not overstretch the snap ring — use the minimum opening to allow them to slip over the gear.

C. Adjust the potentiometer spur gear until there is approximately 1/

16

" engagement with the large face gear. Ensure there is

minimum backlash between the gears. Tighten the spur gear set screw.

D. Rotate the face gear back and forth to ensure smooth and easy operation of the potentiometer.

E. IMPOR

TANT: For 90° Valves:

Depending on whether the AF-17 board is installed and wired, either measure the resistance directly at the potentiometer

wires if not installed or at the AF-17 terminal block (TB-1) if installed and wired. With the actuator either in the OPEN (full

CCW) or CLOSED (full CW) position, and power off, rotate the face gear, thus turning the potentiometer shaft, until the

resistance between the white/black lead (AF-17 terminal 2) and the green lead (AF-17 terminal 3) or the white/black lead

(AF-17 terminal 2) and the purple lead (AF-17 terminal 1) respectively, as measured by ohmmeter, is between 80 ohms

and 90 ohms.

NOTE: It is not necessary to loosen or remove face gear snap ring(s) to rotate gear.

F. Power the actuator to the opposite position from where resistance was measured. Reference paragraph 4.7.6 for moving

actuator shaft electrically.

G. At this position, with power off, measure the resistance at the same terminals as stated above. The resistance reading

should be greater than 700 ohms. If not, then power actuator back to original position and adjust potentiometer again, if

necessary, as stated in paragraph E above. If unsuccessful in getting proper resistance readings, potentiometer is

defective and should be replaced.

H. The feedback potentiometer is now adjusted for use in the 75 actuator. Add the potentiometer caution label to the outside

of the actuator cover.

CAUTION: If the actuator shaft is manually rotated a multiple of 360° from its original position, the feedback

potentiometer will no longer be in calibration. It must be recalibrated per paragraphs E-G above, in order for the

AF-17 board to operate properly.

3.2.5 Important Note

The feedback potentiometer is calibrated for only one 90-degree quadrant of valve operation.

If the valve and actuator output shaft is repositioned to another 90-degree quadrant the feedback potentiometer must be

recalibrated as per Section 3.2.4.

The Series 75 actuators offer a manual override feature. Whenever repositioning the valve using the manual override

capability on these actuators, move the valve only within the 90 degrees for which the feedback potentiometer has

been calibrated.

TB-2

Terminal Wire Color

1Green

2White/Black

3 Purple

(DO NOT CUT POTENTIOMETER WIRES!)

Flow Control Division

Worcester Controls

Page 10

10 AF-17 Electronic Positioner: Installation, Operation and Maintenance WCAIM2031

Flow Control Division

Worcester Controls

Figure 2 – NOTE: Illustrations show single potentiometer only.

Item Description

1 Limit Switches

2 Motor Module

3 Motor Module Mounting Screws (2)

4Terminal Strip

5 Actuator Shaft

6 Potentiometer

7 Potentiometer Bracket

8 Spur Gear

9 Spur Gear Set Screw

10 Potentiometer Leads

11 Potentiometer Shaft

12 Face Gear

13 Potentiometer Bracket

14 Mounting Screws (2)

15 Motor Support Plate

16 Snap Ring

17 Lockwashers (2)

18 Nut

Illustrations Show Single Potentiometer Only

Page 11

WCAIM2031 AF-17 Electronic Positioner: Installation, Operation and Maintenance 11

3.3 Mounting Circuit Board

3.3.1 For 120/240 VAC 10-23 Size Electric Actuators

See Figure 3.

A. Mount these brackets to the actuator motors or spacers as provided. The longer bracket is mounted to the right side of

the actuator when facing the terminal strip using the motor mounting screws. Mount transformer support bracket to limit

switch using existing switch screw.

B. Remove and replace motor screws carefully to avoid stripping the threads of these self-tapping screws.

C. Once these motor screws and brackets are firmly secured, firmly tap the motor stator to force realignment of the top

motor bearing.

D. Loosen all actuator terminal strip screws necessary to connect the circuit board’s wiring to the terminal strip. See manual

Part 3.4 for proper wiring of circuit board to the actuator’s terminal strip. Wire routing is important. Ensure that wiring is

not pinched and is not near cams or mechanical brake.

E. Assemble circuit board into actuator. Slide rubber grommets onto insulating board. Put nylon washers under heads of

self-tapping screws. (Six screws will be used to install the circuit board onto the brackets).

F. Place circuit board over brackets. Feed the three feedback potentiometer wires up through the hole in the circuit board

near potentiometer R29. See Figure 3 below and Figure 1 on page 6. Loosely fasten board to brackets using mounting

screws. Use a nylon washer and a rubber grommet on the self-tapping screw securing the left front corner of board to

transformer support bracket when facing terminal strip. NOTE: For 23 size only, use spacer (10) in place of grommet.

Wire potentiometer to the AF-17 board per paragraph 3.2.3.

G. The circuit board is wired to the terminal strip as shown in Part 3.4.

H. Snug down the circuit board and secure mounting screws such that grommets are about half compressed.

View Shown from the capacitor end of the 75 actuator (Capacitor not shown for pictorial clarity)

Flow Control Division

Worcester Controls

Figure 3

10-23 Size 75 Actuators

Item Description

1 Circuit Board Sub-Assembly

2 Insulating Board

3 Bracket-Right (Long)

4Grommet-Rubber

5 Mtg. Screws (Circuit. Board)

6Washer – Nylon

7 Bracket – Left (Short)

8 Mtg. Screws (Bracket)

9 Spacer (Bracket)

10 Spacer (2375 AC Only)

11 Transformer Support Bracket

Page 12

12 AF-17 Electronic Positioner: Installation, Operation and Maintenance WCAIM2031

3.3.2 For 120/240 VAC 25 and 30 Size Electric Actuators

See Figure 4.

A. Assemble circuit board to bracket as shown.

B. Place four of the five rubber grommets onto the insulating board. Put nylon washers on the self-tapping screws and

place screws through the circuit board and insulating board. Start screws into the bracket. Use a nylon washer and a

rubber grommet on the self-tapping screw, securing the lower left corner of circuit board.

C. If no insulating board is used, place a rubber grommet between the board and the bracket. Tighten all screws such that

the grommets are about half compressed.

D. Use two screws to fasten circuit board bracket to the motor mounting plate, component side of the board is facing out.

E. The circuit board is wired to the terminal strip as shown in Part 3.4.

Limit Switch Locations (SW-3 and SW-4 are optional)

NOTE: Standard wiring for switches and capacitor as shown in Figure 4 is the same for 10-23 75 actuators and is for

120 VAC Positioner only. For 240 VAC Positioner, see paragraph 3.4.4.

3.3.3 Installation of Optional 4-20 Position Output (if used and not factory installed)

A. The output of the position output option is suited for a 4-20 mA DC meter with 0-100% scale (such as General Electric

type GE185), which is not part of the package. If properly calibrated, it indicates actuator shaft position from closed (0°,

0%) to open (90°, 100%).

A dual potentiometer has to be used with the AF-17 to achieve the 4-20 mA output. Each potentiometer can serve only

one function. See Part 3.2 for potentiometer installation and wiring procedures.

Flow Control Division

Worcester Controls

Figure 4

25-30 Size 75 Actuators

Item Description

1 Circuit Board Subassembly

2 Insulating Board

3 Circuit Board Bracket

4 Mounting Screw (Bracket)

5Grommet – Rubber

6Washer – Nylon

7 Mounting Screw

(Circuit Board)

Page 13

WCAIM2031 AF-17 Electronic Positioner: Installation, Operation and Maintenance 13

B. Parts Available for Assembly

3.4 Wiring of AF-17 Board to Actuator

NOTE: When there are multiple wires going to terminal 1, use short white wire provided. Connect it to terminal 1 and then

splice it to the other white wires (common) using the closed end splice provided.

3.4.1 Terminal Strip

The AF-17 positioner board is wired to the terminal strip per Figure 5 for 120 VAC or Figure 6 for 240 VAC.

CAUTION: Wiring should be inserted only to mid-point of terminal strip.

NOTE: For all input signal circuit wiring, regardless of length, shielded wiring should be used. See Paragraph 1.2.

Item Qty Description

13Cable Ties

21Potentiometer Kit (Not Shown)

31Connector Assembly (Not Shown)

Flow Control Division

Worcester Controls

Figure 5 Figure 6

Page 14

Figure 7

14 AF-17 Electronic Positioner: Installation, Operation and Maintenance WCAIM2031

3.4.2 Feedback Connections

Actuators shipped with the positioner circuit board installed will have the feedback potentiometer also installed and

connected to the AF-17 terminal block (TB-1) numbers 1, 2 and 3, green wire to 3, white/black wire to 2, and purple wire to

1. (Reference Figure 2.) If not already done, connect the three feedback potentiometer leads as listed above. See Figure 1.

3.4.3 Output Connections

The AC power switching circuits on the circuit board connect to actuator terminals 3 and 4. The circuit board’s CCW power

control circuit connects to terminal 3 via the positioner’s red wire and the CW power control circuit connects to terminal 4

via the positioner’s black wire. (Reference Figures 5 and 6). The actuator’s motor “Common” must connect to the positioner

board’s white wire and AC “neutral” for correct actuator operation.

3.4.4 For 10-30 AF-17 240 VAC Positioner Wiring

For this voltage only, the two limit switches are used to switch off the opto-coupler (U1, U2, U3) outputs at the end of CW

and CCW strokes instead of directly switching off the motor. This protects the triacs (Q1, Q2, Q3) by ensuring that they are

switched off via their gate circuit and do not shut off on full power.

Replace the original gray and blue actuator wires (make a note of which color wire is on which capacitor terminal and then

discard them) with those provided. Connect them to the capacitor as originally wired and to terminals 3 and 4 (gray to no.

3, blue to no. 4) Reference Figure 6.

The two black wires (#20 gauge) from the positioner board connect to the common and normally closed contacts of switch

no. 1 (lower right hand switch), and the two red wires (#20 gauge) from the positioner board connect to the common and

normally closed contacts of switch no. 2 (lower left hand switch). Route the wires so they will not interfere with switch or

feedback potentiometer operation.

The cams, which operate these switches, are adjusted as referenced in paragraphs 3.1.3, 4.1, 4.2, 4.3 and 4.7.1.

NOTE: Securely tighten all terminal screws. Keep wiring away from all rotating parts and ensure it will not be pinched

when the actuator cover is installed.

3.4.5 Wiring for AF-17 with 4-20 mA Output

See Figure 7.

A. The white wire (common) from the AF-17 PC board is wired to terminal no. 1 on internal side; the brown wire (hot) from

the AF-17 PC board is wired to terminal no. 2 on internal side. Feedback potentiometer wires from the “B” section of the

dual potentiometer are wired directly to the AF-17 circuit board terminal block TB-2 (green to terminal 1, white/black to

terminal 2, and purple to terminal 3).

Flow Control Division

Worcester Controls

Page 15

WCAIM2031 AF-17 Electronic Positioner: Installation, Operation and Maintenance 15

B. For 120 VAC board only, remove yellow wire from terminal 5 and brown wire from terminal 6, disconnect them from N.O.

contacts of switches 1 and 2 and discard them. For all AC boards, connect wires of output signal connector assembly

from AF-17 board connector (P1) such that red wire (+) is wired to terminal 5 and black wire (-) is wired to terminal 6 on

internal side of terminal strip.

NOTE: Check for wiring diagram label inside of cover, if it doesn’t have the 4-20 mA output option wiring shown,

mark label for terminals 5 and 6 according to Figure 7.

C. External wiring is between actuator terminal strip and outside power supply and various controls. Common wire of the

power supply is wired to terminal 1 and hot wire of the power supply to terminal 2. An outside position indicator meter is

wired with positive connection to terminal 5 and negative connection to terminal 6.

D. Securely tighten all terminal screws. Secure all wires neatly with the cable ties. Keep wiring away from all rotating parts

and ensure wiring is not pinched when actuator cover is installed.

E. The feedback potentiometer has to be adjusted to obtain the proper resistance range. See paragraph 3.2.4. To obtain

proper 4-20 mA output, the AF-17 board 4-20 mA output has to be calibrated. Using an ammeter connected to actuator

terminals 5 (positive) and 6 (negative) adjust the two potentiometers R29 and R30 on the board. Locate the actuator in

the closed position (0%) and adjust R30 potentiometer (closest to TB-2) to obtain 4 mA on the ammeter. Move the

actuator to the open position (100%) and adjust R29 potentiometer (closest to the shaft hole) to obtain 20 mA. Because

adjustment of one potentiometer affects the other, repeat the procedure several times to obtain proper values.

IMPOR

TANT: The feedback potentiometer is calibrated for only one 90° quadrant of valve operation. If the output shaft is

repositioned to another 90° quadrant or if the output shaft is rotated a multiple of 360° from its original position, or if the

4-20 mA position output option is disconnected from the AF-17 board, the feedback potentiometer will no longer be in

calibration and must be recalibrated. See paragraph C of part 1.1 and paragraph 3.2.4.

3.5 Actuator Power

3.5.1 Wire Size

AC power to the positioner and from the positioner to the actuator should be with wire no smaller than #18 gauge and with

insulation rated for the particular application. The #18 gauge wire size is sufficient for all Worcester Series 75 actuators.

When using the positioner with other makes of actuators, check the manufacturer’s current rating to determine the correct

wire size.

3.5.2 Terminations and Voltage

AC power connections are made to terminals 1 and 2 of the terminal strip. The AC neutral, or common, wire should be

connected to terminal #1 and the AC “Hot” wire to terminal #2. Note that the positioner requires a minimum of 110 VAC,

and a maximum of 130 VAC for the 120 VAC version and a 220 VAC minimum, 250 VAC maximum for the 240 VAC version.

Grounding wires should be connected to green colored grounding screw (if present) on actuator base or to any base plate

mounting screw in the actuator.

3.5.3 Minimum Fuse Ratings

See table below for minimum fuse rating when overcurrent protection is used in motor power circuit.

NOTE: This table shows the minimum rating to prevent inrush current from blowing the fuse.

Minimum Fuse Rating for Overcurrent Protection

Actuator Size Voltage Fuse Rating

10-23 120 VAC 5A

25/30 120 VAC 10A

10-23 240 VAC 3A

25/30 240 VAC 5A

10-23 12 VDC 10A

10-23 24 VDC 5A

Flow Control Division

Worcester Controls

Page 16

3.6 Input Signal Connections

NOTE: The 120/240 VAC AF-17 positioner board signal input circuit is protected by a 1/

16 amp fuse, F1. See Figure 1 and

Paragraph A of Part 1.1.

3.6.1 AF-17-1, AF-17-4, AF-17-10 (Milliamp Input Signal for AF-17)

For a milliampe signal input, the more positive or “High” signal lead should connect to terminal 11. The less positive or

“Common” lead should connect to terminal 10. Terminal 10 is (-), Terminal 11 is (+).

This positioner is available for use with the standard milliamp signals: 1 to 5, 4 to 20, and 10 to 50 milliamps. The

positioner board is factory calibrated for one of the three milliamp signal ranges, and field changes are not advised. A label

on the circuit board indicates the positioner’s signal range.

Paragraph 6.4.1 gives the nominal resistance load, which the positioner presents to the control circuit for the three

signal ranges.

Comparison of resistance measurements made at terminals 10 and 11 (on the yellow and blue wires from the circuit board)

against the resistances shown in paragraph 6.4.1 provides a quick way to determine the milliamp range for which a

particular board is calibrated.

NOTE: If the circuit board has an orange wire (See Figure 1) attached to it, the board is for a Resistive Input. See

Paragraph 3.6.2 and Figure 8.

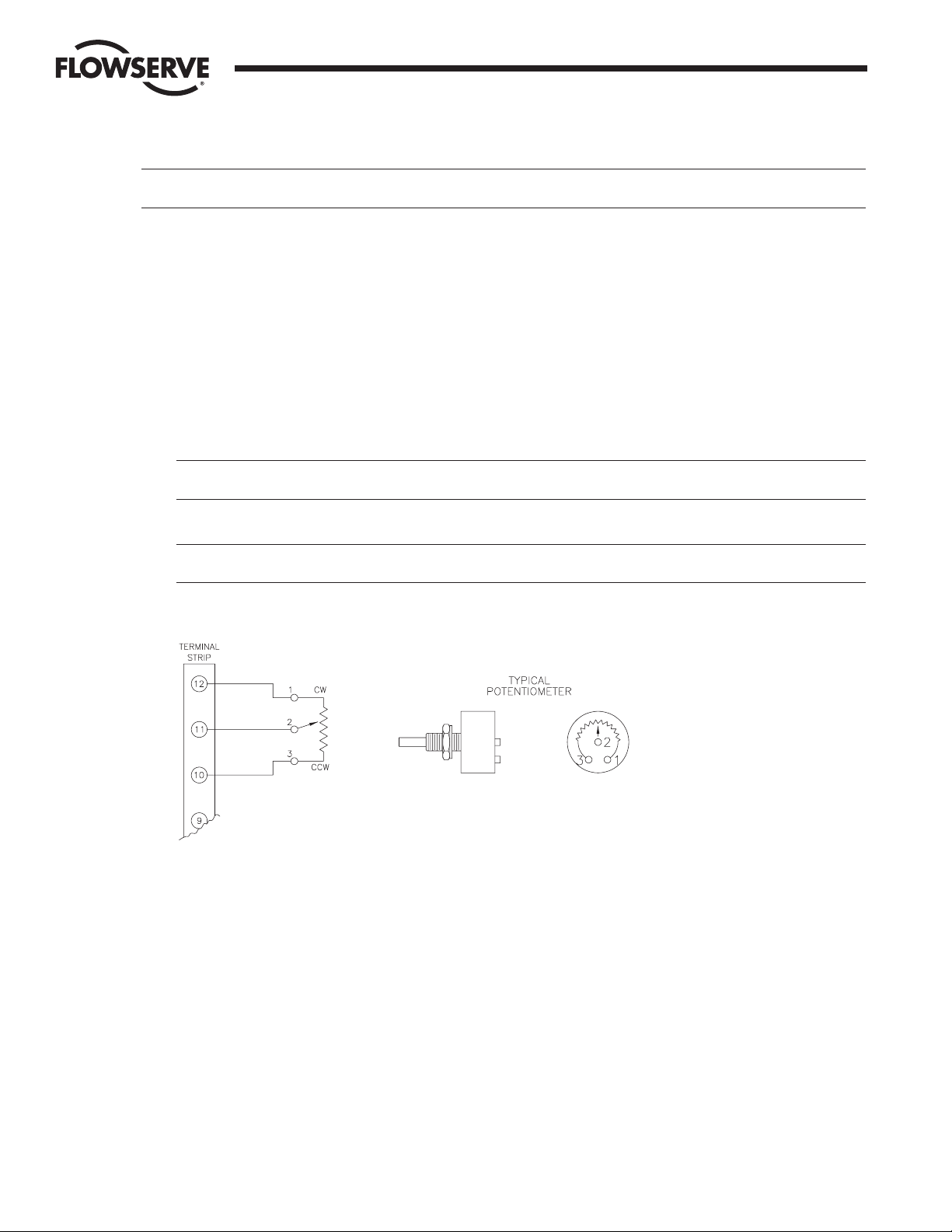

3.6.2 AF-17-13, AF-17-1K (Resistive Input for AF-17)

NOTE: The Resistive Input Potentiometer is not the Feedback Potentiometer, but is an additional Potentiometer

provided and externally located by user.

For a resistance input signal, the usual connections will be similar to that shown in Figure 8 with a “Close” command being

generated where the potentiometer of Figure 8 is rotated to its full CCW position and an “Open” command when it is in the

full CW position.

If the command signal is derived from other than a rotary potentiometer, it is only necessary to keep in mind that a “Closed”

(full CW) valve is called for when the command potentiometer presents the least resistance between terminals 10 and 11

and the most resistance between terminals 11 and 12. A full “Open” (full CCW) valve would be the reverse condition; the

least resistance between terminals 11 and 12 and the most resistance between terminals 10 and 11.

If the “Command” potentiometer is reasonably linear, the actuator/valve will be approximately 50% open when the

resistances between terminals 10 to 11 and 11 to 12 are equal.

Resistive input circuit boards are made in two versions, one for high resistance command circuits – 1000 ohms nominal,

and one for low resistance command circuits – 135 ohms nominal.

Figure 8

16 AF-17 Electronic Positioner: Installation, Operation and Maintenance WCAIM2031

Flow Control Division

Worcester Controls

Page 17

WCAIM2031 AF-17 Electronic Positioner: Installation, Operation and Maintenance 17

3.6.3 AF-17-5V, AF-17-XV (Direct Voltage Input Signal for AF-17)

For a voltage input signal, the more positive or “High” signal lead should connect to terminal 11. The less positive or

“Common” lead should connect to terminal 10. Terminal 10 is (-), Terminal 11 is (+).

This positioner is available for use with the standard direct voltage signals: 0 to 5 VDC and 0 to 10 VDC. The positioner

board is factory calibrated for one of these two signal ranges and field changes are not advised.

Paragraph 6.4.1 gives the nominal resistance load that the positioner presents to the control circuit for the two

signal ranges.

4.0 CALIBRATION AND ADJUSTMENT

4.1 Initial Set-Up and Adjustment (Applies To All Models)

When properly adjusted, the actuator will stop at the full open and full closed points as a result of having reached one of the limits

of the input signal span, and the actuator’s limit switches will be used in a back-up mode to stop the actuator, should an out-ofrange input signal occur.

In case of Series 75, 240 VAC Actuator with AF-17 240 VAC positioner, the two limit switches do not limit actuator travel. Exercise

caution not to override limit switches. Reference paragraph 3.4.4.

Actuators with factory-mounted positioners will be shipped with their limit switches properly adjusted. When the positioner,

whether internally or externally mounted, is installed to an actuator in the field, the actuator limit switches should be initially

adjusted to trip at 1 to 3 degrees AFTER the positioner would normally have shut the actuator off upon reaching the upper or

lower input signal limit. Reference parts 4.2, 4.3 and paragraph 4.7.1. CAUTION: If either the valve or the actuator have mechanical

end of travel stops, the limit switches should be set to trip JUST before a mechanical stop is reached even if this point is

coincident with one of the limits of the input signal.

NOTE: Prior to starting potentiometer adjustment procedure set the AF-17 adjustment potentiometers as follows: “Range”

and “Zero” potentiometers full clockwise, “AH” full clockwise then 1/

4 turn counter-clockwise.

4.2 “Zero” Adjustment [“Zero” Potentiometer Initially Full Clockwise (CW)]

Apply a “full closed” signal to the positioners input, i.e., 4 mA. The actuator should rotate in the CW direction and come to a stop

at or near the CW limit of rotation. Adjust the “Zero” adjustment until the actuator stops in the fully closed position AND the

indicator LD2 is “OFF”. If LD2 is “ON”, this indicates that the “Closed” (SW-1) limit switch has tripped. The “Closed” limit switch

should be adjusted such that it will trip 1° to 3° beyond the full closed position of the actuator. Readjust the “Closed” limit switch

if necessary.

4.3 “Range” Adjustment [“Range” Potentiometer Initially Full Clockwise (CW)]

Apply a “full open” signal to the positioners input, i.e., 20 mA. The actuator should rotate in the CCW direction and come to a stop

at or near the CCW limit of rotation. Adjust the “Range” adjustment until the actuator stops in the fully open position AND the

indicator LD1 is “OFF”. If LD1 is “ON”, this indicates that the “Open” (SW-2) limit switch has tripped. The “Open” limit switch

should be adjusted such that it will trip 1° to 3° beyond the full “Open” position of the actuator. Readjust the “Open” limit switch if

necessary. When 4.2 and 4.3 are complete, ensure that limit switches are set 1° to 3° beyond the electronic travel limits.

Reference CAUTION in 4.1.

4.4 “AH” Adjustment (Anti-Hunt) (“AH” Potentiometer – turn fully clockwise (CW),

then

1

/

4

turn CCW)

This adjustment can be made only after installation is complete and actuator is operational. Apply sufficient input signal to turn the

actuator shaft an amount that would open the valve approximately 10%. If the actuator hunts, adjust the “AH” control in a CCW

direction until the hunting stops. If no hunting occurs, adjust the control towards the CW direction. Increase the input signal in

steps of approximately 10% and reset the “AH” adjustment until no hunting occurs over the entire input signal range.

Flow Control Division

Worcester Controls

Page 18

18 AF-17 Electronic Positioner: Installation, Operation and Maintenance WCAIM2031

4.5 Adjustment Recheck

There is some interaction between adjustments of the “Zero” and “Range” controls, therefore if an adjustment is made at one end

of travel, the opposite end should be rechecked.

Although the “Range” and “Zero” settings are relatively unaffected by fairly large temperature changes, it is suggested that

positioners be checked during a users routine maintenance schedule.

4.6 Operational Check

Once the AF-17’s circuit board zero and span potentiometers are set for the minimum and maximum process signal values,

typically a 4-20 mA signal, do the following checks:

4.6.1 Increasing Signal

Reduce process input signal below the minimum value so that actuator stops on its closed limit switch and closed LD2 is

on. Increasing the input signal in small increments should allow the actuator to move in angular increments proportional to

these small incremental increases in the incoming signal.

4.6.2 Decreasing Signal

Continually adjust the signal until the maximum signal value is reached and actuator is in fully open position. With a signal

over 20 mA, when the positioner is calibrated for 4 to 20 mA, the actuator will operate until the proper cam has actuated the

open limit switch. Note that the open LD1 will be “on” when actuator stops at limit switch.

In similar fashion, decrease the process signal in small values. The actuator should move closed in small steps until the

fully closed position is reached at the minimum signal value, typically 4 mA for a 4-20 mA calibration.

4.6.3 Attaching Label

Attach label to board.

4.7 If Problems Occur

If problems occur while trying to obtain the desired positioner action, check the following:

4.7.1 Cam Adjustment

The actuator cams should actuate the limit switches 1° to 3° after the actuator stops at either the fully open or fully closed

position.

If the actuator is closed at 0 degrees, the limit switch must actuate by the time the actuator is at the minus 1 to 3 degree

position. Similarly, at the open or 90-degree position, the limit switch must actuate by the time the actuator is at the 91 to

93 degree position.

NOTE: See CAUTION in part 4.1.

4.7.2 Feedback Potentiometer Calibration

Check the feedback potentiometer calibration per paragraph 3.2.4 of the manual. At either the full open or the full closed

position, stopping at either limit switch, the potentiometer must still be within its electrical travel. To verify this, check the

resistance at either the full open or full closed position. The resistance measured between terminals 2 and 3 or 2 and 1 on

the AF-17 terminal block, with the power off, must be between 80 ohms and 90 ohms.

Readjust the feedback potentiometer as necessary and check as in the previous steps for proper incremental movement of

the valve actuator from limit switch to limit switch; full closed to full open; -1° to -3°, +91° to +93°.

4.7.3 Reverse-Acting

For a reverse-acting actuator, read part 5.4 in the manual. Simply follow the instructions of part 5.4 and readjust the circuit

board “zero” and “range” potentiometers as needed.

4.7.4 Adjustment to Loop Process

Once the actuator and positioner are installed in the system, further adjustments may be necessary to trim the AF-17 circuit

board/actuator action to the process controller’s action in the process loop. The AH potentiometer on the circuit board may

require adjustment counterclockwise to stop the AF-17 circuitry from reacting to spurious electrical noise signals.

Flow Control Division

Worcester Controls

Page 19

WCAIM2031 AF-17 Electronic Positioner: Installation, Operation and Maintenance 19

4.7.5 Check Fuse F1

For AC boards, check fuse F1 to see if it is blown. If it is, replace with spare fuse F2 attached to PC Board and order another

fuse for spare (Newark part number 94F2146). IMPORTANT: To check fuse - remove it from circuit and test with ohmmeter.

Resistance should be about 6 ohms.

NOTE: If fuse F1 is blown, excessive voltage (possibly 120 VAC) was applied to the signal input circuit. If so, correct

this condition before changing fuse. See Paragraph A of Part 1.1.

For DC boards, check fuse F1 to see if it is blown. If it is, replace it with a 1!?4", 250 volt, 3 amp fuse, available through

any electrical supplier. See Part 2.2 in DCAF17 IOM supplement.

4.7.6 Check basic actuator for proper operation using the proper AC voltage

A. Remove red and black leads coming from circuit board at terminals 3 and 4 (if already installed). Tape stripped ends of

these wires.

B. Alternately energize, with the appropriate AC voltage, terminals 1 and 3 and 1 and 4. The actuator should move clockwise

when energizing terminals 1 and 4, stopping only at the clockwise limit switch. The actuator should move counterclockwise when energizing terminals 1 and 3, stopping only at the counter-clockwise limit switch.

NOTE: For AF-17 240 VAC Positioner only, limit switches do not directly control motor. Therefore, the actuator will

not stop when the limit switches trip. Use care not to drive the actuator past its normal limits. Run the actuator to its

limits in each direction, to assure proper operation of the actuator.

4.7.7 Check for Noise Problems

If the circuit board’s light emitting diodes (LEDs) blink or seem to continuously glow, electrical noise is interfering with the

positioner’s input process signal. (Always use shielded cable for the process signal coming to the AF-17 board. Ground the

shield at only one end.) Adjust AF-17 positioner as necessary. See Section 4.0.

4.7.8 Replace Circuit Board

If problems still occur after taking these remedial steps, replace circuit board in the actuator.

5.0 OPERATIONAL VARIABLES

5.1 Sensitivity

The Worcester AF-17 Electronic Positioner has been designed to a standard sensitivity equivalent to approximately 240 positions

for a 15 second 90 degree shaft movement.

5.2 Reduced Travel Operation

A small amount of travel reduction can be achieved (4-6 degrees). This can be accomplished by applying maximum and minimum

input signals and adjusting the “Range” and “Zero” controls to determine the new rotation end limits. (Limit switch cams should

also be reset. See parts 4.1 and 4.4.)

5.3 Split Range

With AF-17 Positioner circuit board revisions (Revision R10 and later) split range adjustment capability is available with standard

board and may be obtained using the standard calibration procedures.

5.4 Reverse Action

The usual mode of operation of an actuator is to use an increasing signal for the open direction of travel and a decreasing signal

for the close direction of travel. For use in certain types of applications, it may be desirable to operate using a decreasing signal

for the open direction and an increasing signal for the close direction. For some valves this can be done by cross-line mounting

the actuator (mounting the actuator to the valve such that it is rotated 90° from the normal mounting position. This has the effect

of rotating the valve ball 90° with the actuator at its 4 mA position. As the signal is increased toward 20 mA the valve ball will

travel toward its closed position but in a counter-clockwise direction. Therefore, this method will work only with valves with round

seats, not with characterized seats). No positioner wiring changes would be required using this method. If cross-line mounting is

not feasible, the reversal can be accomplished at the positioner as follows:

Flow Control Division

Worcester Controls

Page 20

20 AF-17 Electronic Positioner: Installation, Operation and Maintenance WCAIM2031

5.4.1 Input Reversing – (AF-17-1, AF-17-4, AF-17-10) (mA Input); 120 VAC

Reverse the black and red wires from the positioner board; the red goes to terminal 4 and the black to terminal 3. Change

the feedback potentiometer wires on the board at TB-1 terminals 1 and 3; the purple wire goes to terminal 3 and the green

wire to terminal 1. The positioner will now operate in reverse of the usual manner and the controls “Range” and “Zero” will

also be reversed. The “Range” control should now be used to adjust the closed end of travel and the “Zero” control used to

adjust the open end of travel. Always adjust the “Zero” control first!

NOTE: If the 4-20 mA signal output (if installed) is to be reversed also, then the wires at TB-2 terminals 1 and 3 must

also be reversed. The AF-17 board must be recalibrated after switching the wires at TB-2 and/or TB-1.

5.4.2 Input Reversing – (AF-17-1K, AF-17-13) (Resistance Input); 120 VAC

Make the same changes as in 5.4.1. If the input is from a manual control station and it is desired that the direction for

“Closed” and “Open” also be reversed at the “Command” potentiometer, change additionally the wires from the circuit board

to terminals 10 and 12. Connect the orange wire to terminal 10 and the yellow wire to terminal 12. The operation of

adjustments “Range” and “Zero” will be reversed, as in paragraph 5.4.1. Recalibrate the AF-17 board.

5.4.3 Input Reversing – (AF-17-5V, AF-17-XV) (Direct Voltage Input); 120 VAC

Follow same procedure as paragraph 5.4.1.

5.4.4 Input Reversing, 240 VAC Only

In addition to performing the steps in paragraphs 5.4.1, 5.4.2, or 5.4.3, it is also necessary to swap the two black wires

from limit switch 1 to limit switch 2 and the two red wires from limit switch 2 to limit switch 1.

6.0 TECHNICAL DATA

6.1 AC Input Voltage:

All voltages ........................................................................................... ±10%

Power Consumption (Circuit Board Only).........................................2.5 watts

6.2 Input Circuit Specifications

Maximum Noise Level at Maximum Positions............................Approx. 7mV

Resistance Input

AF-17-1K.........................................................................Nominal 1000 ohms

AF-17-13 ...........................................................................Nominal 135 ohms

Current Input

AF-17-1 ................................................................................ 1 to 5 milliamps

AF-17-4 .............................................................................. 4 to 20 milliamps

AF-17-10............................................................................10 to 50 milliamps

Voltage Input

AF-17-5V........................................................................................0 to 5 VDC

AF-17-XV......................................................................................0 to 10 VDC

Flow Control Division

Worcester Controls

Page 21

WCAIM2031 AF-17 Electronic Positioner: Installation, Operation and Maintenance 21

6.3 Output Circuits Specifications

All Models

Maximum Surge Current ...............................................100 amps for 1 cycle

Maximum Normal Starting or In-Rush Current ............10 amps for 1 second

Maximum Stall Current ..................................................8 amps for 1 minute

Maximum Running Current – Resistive Load......................................5 amps

90% Duty Cycle

Maximum Running Current – Inductive Load......................................3 amps

90% Duty Cycle

Maximum Peak Voltage on Load Circuit............................................800 VAC

All 120 VAC and 240 VAC

4-20 mA output will drive 20 mA into a 600 ohm maximum load.

6.4 Input Circuit Characteristics

6.4.1 Input Circuit Load Resistances

Approximate

1 to 5 milliamp Models.......................................................................1000 ohms

4 to 20 milliamp Models.......................................................................220 ohms

10 to 50 milliamp Models.....................................................................100 ohms

0 to 5 VDC Models................................................................................800 ohms

0 to 10 VDC Models............................................................................1100 ohms

6.4.2 Nominal Useable Input Signal Deadband

1000 ohm Input .....................................................................................5.5 ohms

135 ohm Input..................................................................................... .75 ohms

1 to 5 milliamp Input.................................................................20 microamperes

4 to 20 milliamp Input...............................................................80 microamperes

10 to 50 milliamp Input...........................................................200 microamperes

0 to 5 VDC Input................................................................................25 millivolts

0 to 10 VDC Input..............................................................................50 millivolts

NOTE: Above “Useable” deadband figures are “NORMS” determined by multiple tests of various actuator/valve

combinations. All actuators used a permanent split phase motor, with an output shaft speed of 1 RPM (15-second

cycle time). Electronic braking was employed on all tests. Results may differ in applications where different shaft

speeds are used.

6.5 Controls – All Models

Zero – Adjustment for Low End of Control Signal +60% Span

Range – Adjustment for High End of Control Signal -60% Span

AH – Adjustment for Hysteresis (Anti-Hunt) 0.3% to 4.0% of full scale

4 mA – Adjust 4 mA Output

20 mA – Adjust 20 mA Output

Flow Control Division

Worcester Controls

Page 22

7.0 APPLICATION NOTES

7.1 DC Motor Actuator

Typical wiring to operate DC motor actuators from Worcester AF-17 120 VAC electronic positioner. Terminal numbers in schematic

are for Worcester 75 actuators, but wiring arrangement is applicable to other makes. Relay contact ratings should be based on

switching a highly inductive load at the actuator’s maximum current rating (stalled current).

Motor is automatically braked when either relay goes from the “on” to the “off” position.

NOTE: The electronic brake on the positioner board should be made inoperative for this application (clip out U3 from circuit

board – See Figure 1 for location).

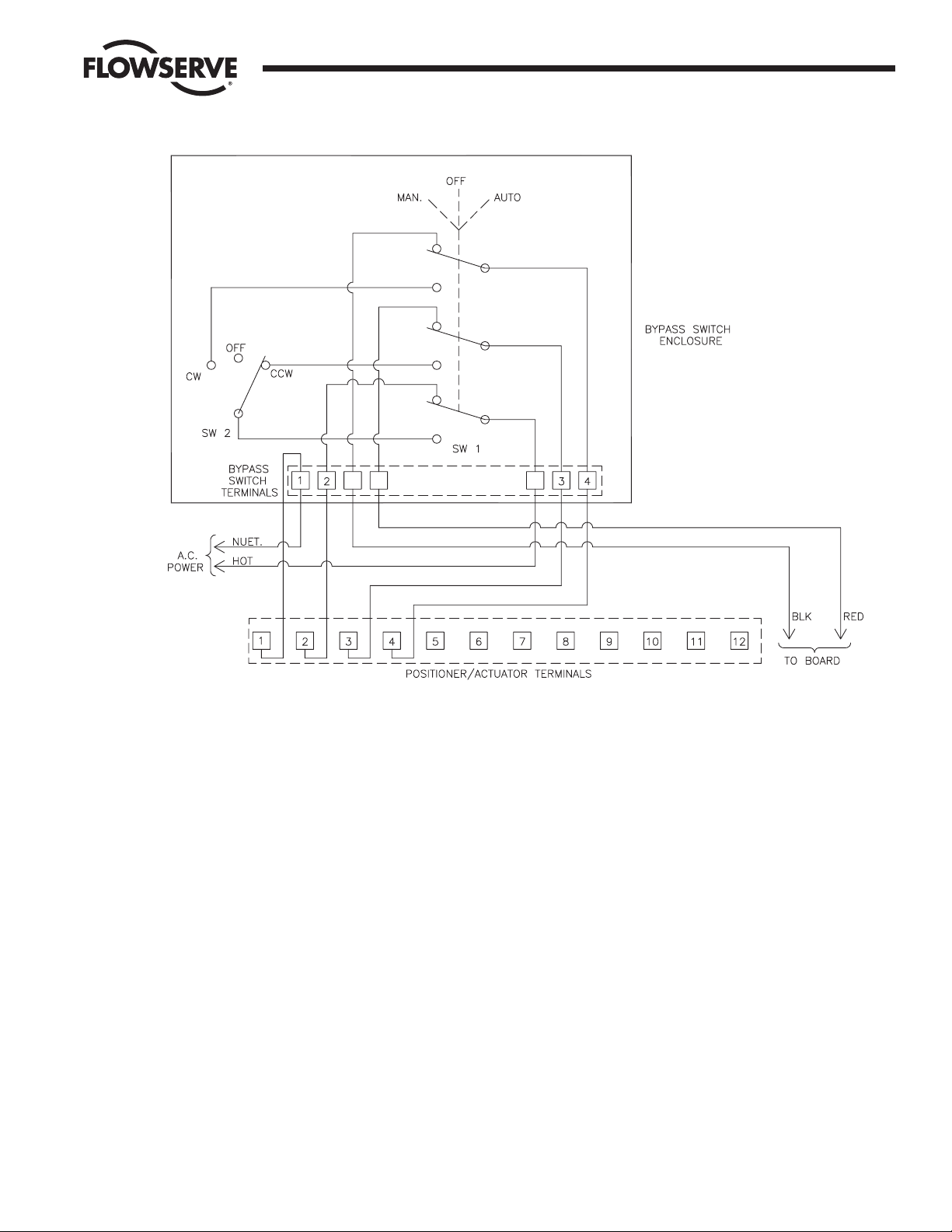

7.2 Bypass Switch for Manual Control (For 120 VAC Only)

This application is offered as a non-standard option through Flowserve’s Custom Products Department or may be altered by end

user. Figure 10 on the next page shows a schematic diagram of two switches for controlling the following functions:

One triple-pole, double-throw (TPDT) switch with center-off, switching from automatic to manual operation.

One single-pole, double-throw (SPDT) switch with center-off position for manually controlling clockwise (CW), counter-clockwise

(CCW) directions of actuator.

Figure 9

22 AF-17 Electronic Positioner: Installation, Operation and Maintenance WCAIM2031

Flow Control Division

Worcester Controls

Page 23

8.0 TROUBLESHOOTING

8.1 General

The following charts are a troubleshooting guide for servicing the positioner, should a malfunction occur. If the problem cannot be

solved, the unit should be returned to the factory for service.

The first thing to be checked, before proceeding to the troubleshooting guide, is to determine if the malfunction is in the

positioner, or in the actuator. To do this, remove the red and black positioner leads from terminals 3 and 4 of the actuator, and the

AC line connections from terminals 1 and 2. Tape these leads. Using a test cable, apply power to actuator terminals 1 and 3. The

actuator should rotate CCW until stopped by the CCW limit switch. Then apply power to terminals 1 and 4 to check CW actuation

and the CW limit switch.

For AF-17-240 VAC positioner only, switches do not directly limit travel. Exercise caution not to override limit switches. Operate

the unit to its limits in each direction, to assure that the basic actuator is functional.

If the actuator does not operate, check wiring from the terminal strip, through the limit switches to the motor and capacitor. For

240 VAC actuator with AF-17 positioner, check wiring from the terminal strip to the capacitor and to the motor. Check switch

continuity. Check for an open motor winding, and check for a shorted capacitor. If the problem in the actuator still cannot be

determined, return the unit for service. If the actuator functions properly, then proceed to the troubleshooting guide.

To facilitate troubleshooting a positioner, it would be advantageous on resistive input units to connect a potentiometer directly to

the signal input terminals in place of the standard process input. Use a 150 ohm or 1000 ohm potentiometer depending on which

model is used. Figure 11 on next page shows a schematic of a simple test unit that can be connected to the input terminals to

stimulate the process signal for a milliamp rating.

Figure 10

WCAIM2031 AF-17 Electronic Positioner: Installation, Operation and Maintenance 23

Flow Control Division

Worcester Controls

Page 24

24 AF-17 Electronic Positioner: Installation, Operation and Maintenance WCAIM2031

8.2 Symptom Table

Test Unit for Milliamp Input Positioner – Set R1 all the way toward the plus end. Adjust R2 for a 20 mA reading. Varying R1 will

now provide input signals between 4 and 20 milliamps.

Sympton Guidlines to Follow

8.2.1 Actuator will not operate in either direction 8.3.1, 8.3.2, 8.3.3, 8.3.4, 8.3.5, 8.3.6, 8.3.7,

[no sound from motor(s)]. 8.3.10

8.2.2 Actuator will not operate in either direction 8.3.2, 8.3.3, 8.3.4, 8.3.5, 8.3.6, 8.3.9, 8.3.10,

[humming or buzzing sound from motor(s)]. 8.3.11, 8.3.12

8.2.3 Actuator slowly moves in one direction on its own. 8.3.4

8.2.4 Actuator runs normally for 7° to 8° while coming off 8.3.4, 8.3.15

limit switch, then slows down or stops

[motor(s) hum or buzz].

8.2.5 Actuator oscillates intermittently or upon 8.3.2, 8.3.8, 8.3.13

reaching a new position.

8.2.6 Actuator runs slowly in one or both directions, . 8.3.2, 8.3.4, 8.3.9, 8.3.10, 8.3.11, 8.3.12

but otherwise operates normally

8.2.7 Actuator works intermittently. 8.3.2, 8.3.10, 8.3.12

8.2.8 Actuator runs normally in one direction but will not 8.3.2, 8.3.4, 8.3.7

operate in the other direction

[no hum or buzz from motor(s)].

8.2.9 Actuator will not move valve after a stop when signaled 8.3.14

to travel in same direction as previous command.

Flow Control Division

Worcester Controls

Figure 11

Page 25

WCAIM2031 AF-17 Electronic Positioner: Installation, Operation and Maintenance 25

8.3 Use the following troubleshooting guidelines to isolate problems/bad components

Prior to beginning any procedure, read all of Check, Action, and Notes and Cautions sections.

Flow Control Division

Worcester Controls

Check Action Notes and Cautions

8.3.1 Check for proper AC/DC power Correct as necessary.

to actuator and circuit board.

See Figures 5 or 6 for AC or

Figure 3 in DCAF17 IOM

supplement for DC.

8.3.2 With power off, check for broken Repair broken wires and

wires and/or loose connections. tighten loose connections.

8.3.3 With power off, check to see Remove F1 from socket pins Before restoring power, try to

if fuse F1 is blown. or fuse clips. For AC boards determine what caused F1 to blow

only, check for continuity and correct problem. See part 3.6

through fuse with an ohmmeter. and paragraph 4.7.5 Notes and

If F1 is bad, replace it. AC Paragraph A of Part 1.1 for AC

boards have a spare fuse (F2) boards. See part 2.2 in DCAF17

located on board. IOM supplement for DC boards.

8.3.4 Check operation of basic See Part 8.1. This check will isolate the problem

actuator per Part 8.1. to either the actuator or the circuit

board.

8.3.5 Check for proper range Use ammeter, voltmeter or See models listed at beginning of

of input signal. ohmmeter to verify input IOM for ranges. 4-20 mA is

signal range. standard.

8.3.6 With power off, check calibration A quick check to see if this is the When trying to move the valve

of feedback potentiometer per problem is to declutch the actuator manually with the clutch

Paragraph 3.2.4. shaft and reposition the shaft to disengaged, be certain that the

about 45° (if valve torque permits). wrench fits properly on the flats of

If the actuator now runs normally the actuator shaft. Improper fit can

in each direction (after clutch cause shaft damage with

re-engages), recalibrate the consequent damage to cover

feedback potentiometer. bearing surface. Stay within the

preset quadrant of operation. See

Paragraph C of Part 1.1.

8.3.7 Check to see that varying input If LEDs do not turn on and off, The turning on and off of the LEDs

signal from 4-20 mA causes the replace board. is indicative that the input side of

light emitting diodes (LEDs) to the circuit board is OK.

turn on and off individually.

8.3.8 Check the operation of the If intermittent or jittery operation Turning the A-H control CCW may

positioner with a portable, stops, it is indicative of a noisy help to alleviate the problem.

battery-operated signal source. on-line signal input. To avoid

damaging the actuator, it is

necessary to "clean up" the signal.

Also, follow the shielding guidelines

of Paragraphs 1.2 and 1.2.4.

8.3.9 Check the motor run capacitor Replace as necessary. Disconnect all leads from capacitor

for a short, excessively high leakage (power off) prior to testing. Do not

and low capacitance. Use a exceed rated voltage of capacitor.

capacitance meter to check. Make certain that capacitor is

(AC boards only) terminals discharged before reconnecting.

Page 26

26 AF-17 Electronic Positioner: Installation, Operation and Maintenance WCAIM2031

Flow Control Division

Worcester Controls

Check Action Notes and Cautions

8.3.10 Check temperature of motor(s). Allow the motor(s) to cool so that Duty cycle is specified at an

Each AC motor has a thermal the thermal switches can reset. ambient temperature of 70°F, 60 Hz.

cutout switch built in that opens at Normally the thermal switches will

about 210°F (winding temperature). not open unless the motor's rated

If the thermal cutout in one motor duty cycle is exceeded and/or the

has opened, the other motor by ambient temperature is very high.

itself may not be strong enough to Correct the problem.

move the valve (20-2375 sizes).

8.3.11 Check the operating torque of the If operating torque of valve exceeds If the actuator is removed from a

valve. If necessary, remove the the specified torque for the seats three-piece valve that requires the

actuator from the valve. Measure used and the DP across the valve, body bolts to also be removed, the

valve torque with an accurate determine cause and correct. If valve body bolts must be retorqued to

torque wrench. Check torque under torque falls within normal range, it specification before checking valve

actual operating conditions if possible. is possible that the actuator is torque. See Valve IOM.

undersized.

8.3.12 Check ambient temperature. Actuator duty cycles are specified Higher ambient derates duty cycle.

at an ambient temperature of 70°F.

8.3.13 Check to see that mechanical Replace defective mechanical brake. All 2" CPT valves with positioner

brake is operating correctly. If one was never installed, order a boards in actuator must have

kit and install it in actuator. mechanical brake installed to prevent

oscillation.

8.3.14 Check to see if actuator can move If motor(s) cannot start, go to

a high torque valve from a stop next larger size actuator.

under load when moving in the

same direction as last command

(mechanical brake does not allow

motor(s) to unwind).

8.3.15 Check to see which direction of Replace circuit board.

travel causes problem. If actuator is

coming off open limit switch

(traveling CW) when it slows down

or stops, then either Q1 or U1 is bad.

If actuator is coming off closed limit

switch (traveling CCW), then either

Q2 or U2 is bad. (AC boards only)

Page 27

WCAIM2031 AF-17 Electronic Positioner: Installation, Operation and Maintenance 27

9.0 SUGGESTED SPARE PARTS

It is suggested that where 10 or more units are in service, one or more complete circuit boards be stocked as spares for ease of

maintenance and minimum downtime. All circuit boards are wired directly to screw type terminal strips (no solder connections) and can

be easily changed on location.

Fuse F2 is a spare fuse attached to AC circuit boards but not wired in the circuit. See Figure 1. If fuse F2 is used to replace fuse F1, it is

recommended that another be purchased and attached to circuit board as a spare.

Flow Control Division

Worcester Controls

Page 28

Flow Control Division

Worcester Controls

Flowserve Corporation has established industry leadership in the design and manufacture of its products. When properly selected, this Flowserve product is designed to perform its intended function

safely during its useful life. However, the purchaser or user of Flowserve products should be aware that Flowserve products might be used in numerous applications under a wide variety of industrial

service conditions. Although Flowserve can (and often does) provide general guidelines, it cannot provide specific data and warnings for all possible applications. The purchaser/user must therefore

assume the ultimate responsibility for the proper sizing and selection, installation, operation, and maintenance of Flowserve products. The purchaser/user should read and understand the Installation

Operation Maintenance (IOM) instructions included with the product, and train its employees and contractors in the safe use of Flowserve products in connection with the specific application.

While the information and specifications contained in this literature are believed to be accurate, they are supplied for informative purposes only and should not be considered certified or as a guarantee of

satisfactory results by reliance thereon. Nothing contained herein is to be construed as a warranty or guarantee, express or implied, regarding any matter with respect to this product. Because Flowserve

is continually improving and upgrading its product design, the specifications, dimensions and information contained herein are subject to change without notice. Should any question arise concerning

these provisions, the purchaser/user should contact Flowserve Corporation at any one of its worldwide operations or offices.

For more information about Flowserve Corporation, contact www.flowserve.com or call USA 1-800-225-6989.

FLOWSERVE CORPORATION

FLOW CONTROL DIVISION

1978 Foreman Drive

Cookeville, Tennessee 38501 USA

Phone: 931 432 4021

Facsimile: 931 432 3105

www.flowserve.com

© 2003 Flowserve Corporation, Irving, Texas, USA. Flowserve and Worcester Controls are registered trademarks of Flowserve Corporation. WCAIM2031 10/03 Printed in USA

Loading...

Loading...