Page 1

Accord Controls

Installation, Operation and Maintenance Instructions

Flowserve Corporation

1350 N. Mountain Springs Parkway

Phone: 801 489 2234

Flow Control Division

Springville, Utah 84663-3004

Facsimile: 801 489 2228

www.flowserve.com

FCD ACAIM0073-00 (AC-73) 06/04 Page 1 of 2

© 2004, Flowserve Corporation, Printed in USA

NOTE:

1. Both resistive and current feedback signals are geared for quarter turn operation. Consult factory for other rotations.

2. The ‘TX’ option is a loop powered transmitter. For ‘TT’ options (transmitter with servo) see IOM for electronic servo position.

Caution: To Pr

event ignition of hazardous atmospheres, keep unit tight

while circuits are alive. Disconnect supply circuit before opening.

Division 1 applications must be calibrated in a secured area.

Calibration

Resistive Feedback:

1. Remove cover and rotate actuator/valve to fail or start position.

2. Note desired resistance values at fail or start position.

3. Connect an ohmmeter to feedback terminals.

4. Using a 0.035 allen hex driver, loosen the set screw on the potentiometer gear. With a flat blade screwdriver,

rotate the end of the potentiometer shaft to yield desired resistance.

5. Alternatively, the jam nut holding the potentiometer to the bracket may be loosened. Slide the potentiometer and

gear away from the camshaft gear and rotate to desired resistance. Re-align and tighten.

6. Rotate actuator/valve to end position. Check that resistance increases (or decreases) over stroke and that the

potentiometer does not rotate past maximum (or minimum) resistance.

7. Replace cover.

4-20 mA Current Transmitter:

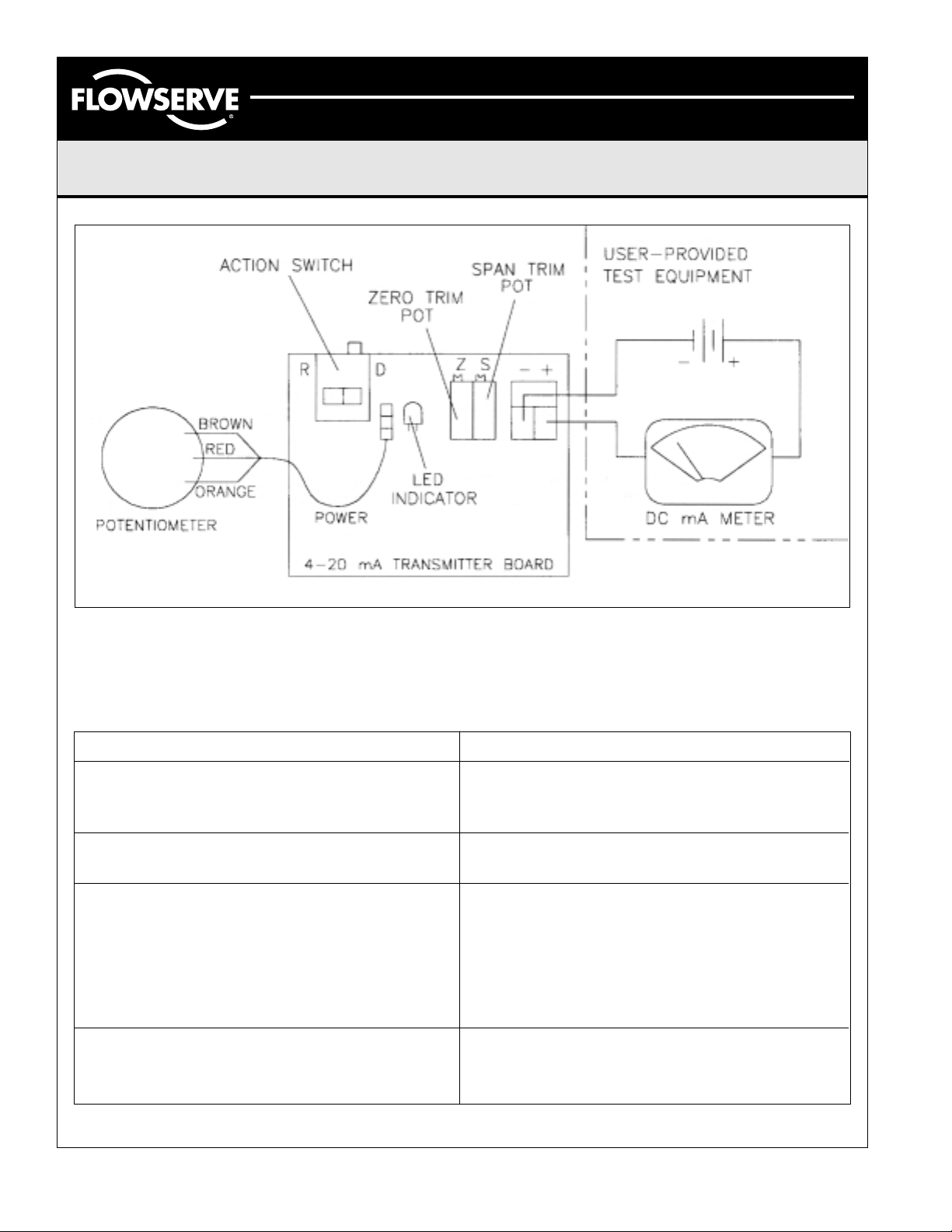

Figure 1 shows a diagram of the transmitter board and all necessary current loop components for calibration.

1. The controller board action DIP switch selects direction. For 4 mA in the full clockwise direction, select “D”.

For 4 mA in the full counterclockwise direction, select “R”. The factory setting is “D”.

Note:

Steps 2 through 4 are normally not necessary.

2. Rotate actuator/valve to mid position (45 degrees or 50%).

3. Using a 0.035 allen hex driver, loosen the set screw on the potentiometer gear. With a flat blade screwdriver, rotate the

end of the potentiometer shaft to yield desired resistance.

4. Alternatively, the jam nut holding the potentiometer to the bracket may be loosened. Slide the potentiometer and gear

from the camshaft gear and rotate to desired resistance. Re-align and tighten.

5. Rotate actuator/valve to fail or start position.

6. Adjust controller board zero trim pot. to yield 4 mA.

7. Rotate actuator/valve to end position.

8. Adjust controller board span trim pot. to yield 20 mA.

9. The zero and span adjustments are interactive. Repeat steps 5 through 8 until further zero adjustment does not affect

span and vice versa.

10. Disconnect test equipment (if necessary) and replace cover.

Note:

If transmitter adjustment gets difficult (i.e., trim pots do not have desired effect) start over by “centering” the trim pots.

This is accomplished by turning in one direction 20 turns or until a clicking is heard. Turn in the opposite direction 10 turns.

Repeat for other trim pot. Start calibration over at step 2.

Centura Analog Output Options

Calibration and Operating Instructions

TYPE TX TYPE P2 TYPE P3 TYPE P4

4-20 mA Current Transmitter 0-1 K ohm resistive 0-5K ohm resistive 0-10 K ohm resistive

Voltage required: 6-30 Vdc 1 Watt max. Ioad 1 Watt max. Ioad 1 Watt max. Ioad

Input resistance: 750 ohms max. Temp. range: 32 to 158°F Temp. range: 32 to 158°F Temp. range: 32 to 158°F

@ 24 Vdc

Temp. range: 32 to 158°F

Electrical Specifications

Resistive feedback modules use a 1% linearity precision potentiometer operated by precision gears. The current feedback option combines

the potentiometer with a 4-20 mA transmitter card.

Page 2

Flowserve Corporation

1350 N. Mountain Springs Parkway

Phone: 801 489 2234

Flow Control Division

Springville, Utah 84663-3004

Facsimile: 801 489 2228

www.flowserve.com

Accord Controls

Installation, Operation and Maintenance Instructions

FCD ACAIM0073-00 (AC-73) 06/04 Page 2 of 2

© 2004, Flowserve Corporation, Printed in USA

Figure 1 – 4-20 mA Transmitter Diagram

Probable Cause/Solution

Potentiometer is out of adjustment (see “Resistive Feedback

Calibration” or 4-20 mA Current Transmitter Calibration”

steps 2-4).

Zero or span trim potentiometer is out of adjustment

(see 4-20 mA Current Transmitter Calibration).

Circuit Board LED not lit:

1. Loose or shorted signal connection (no loop power).

2. Controller board not responding (replace board).

Circuit Board LED lit:

1. Potentiometer disengaged.

2. Defective potentiometer or controller board. Replace

defective component.

Input signal not linear. Linkage or drive mechanism is

introducing non-linearity. Zero span trim potentiometer is

out of adjustment (see 4-20 mA Current Transmitter Calibration).

Problem

Output is not continuous throughout actuator/valve stroke

(experience a band of max. output)

Transmitter does not out 4 or 20 mA at desired end of travel.

Transmitter module does not provide current signal or provide

constant signal.

Output not linear or does not track valve position/rotation

Troubleshooting

Loading...

Loading...