Page 1

User Instructions Logix 520MD - LGENIM0520-01 09/09

®

USER INSTRUCTIONS

Logix 520MD Series

Digital Positioner

FCD LGENIM0520-01

Installation

Operation

Maintenance

Experience In Motion

1

Page 2

User Instructions Logix 520MD - LGENIM0520-01 09/09

STOP!

®

Table of Contents Page

General Information ......................................................................... 2

Unpacking ........................................................................................ 3

Logix 520MD Overview ................................................................... 4

Specifications ................................................................................... 4

Principle of Operation ...................................................................... 5

Tubing .............................................................................................. 6

Wiring .............................................................................................. 6

Cable Requirements ......................................................................... 7

Startup ............................................................................................. 8

Logix 520MD Local Interface Operation ...................................... 8

Operation of Configuration Dipswitch Setup ............................... 8

Calibrations switches .................................................................. 9

Quick-Cal Operation .................................................................... 9

Factory Reset .............................................................................. 10

4-20 mA Analog Output Board .................................................... 10

Error Codes ...................................................................................... 12

Trouble Shooting .............................................................................. 15

Limit switches .................................................................................. 16

Spare parts ...................................................................................... 17

Dimensions ...................................................................................... 18

1 USING FLOWSERVE VALVES, ACTUATORS AND

ACCESSORIES CORRECTLY

1.1 General usage

The following instructions are designed to assist

in unpacking, installing and performing maintenance as required on FLOWSERVE products.

Product users and maintenance personnel should

thoroughly review this bulletin prior to installing,

operating or performing any maintenance.

In most cases FLOWSERVE valves, actuators

and accessories are designed for specific applications with regard to medium, pressure and

temperature. For this reason they should not be

used in other applications without first contacting

the manufacturer.

1.2 Terms concerning safety

The safety terms DANGER, WARNING, CAU-

TION and NOTE are used in these instructions

to highlight particular dangers and/or to provide

additional information on aspects that may not

be readily apparent.

WARNING: indicates that death, severe personal injury

and/or substantial property damage can occur if proper

precautions are not taken.

CAUTION: indicates that minor personal injury and/or

property damage can occur if proper precautions are

not taken.

NOTE: indicates and provides additional technical

information, which may not be very obvious even to

qualified personnel.

Compliance with other, not particularly emphasised

notes, with regard to transport, assembly, operation

and maintenance and with regard to technical documentation (e.g. in the operating instruction, product

documentation or on the product itself) is essential,

in order to avoid faults, which in themselves might

directly or indirectly cause severe personal injury or

property damage.

1.3 Protective clothing

FLOWSERVE products are often used in problematic

applications (e.g. extremely high pressures, dangerous, toxic or corrosive mediums). In particular valves

with bellows seals point to such applications. When

performing service, inspection or repair operations

always ensure, that the valve and actuator are depressurised and that the valve has been cleaned and is free

from harmful substances. In such cases pay particular

attention to personal protection (protective clothing,

gloves, glasses etc.).

1.4 Qualified personnel

Qualified personnel are people who, on account of their

training, experience and instruction and their knowledge of relevant standards, specifications, accident

prevention regulations and operating conditions, have

been authorised by those responsible for the safety of

the plant to perform the necessary work and who can

recognise and avoid possible dangers.

1.5 Installation

DANGER: Before installation check the order-no.,

serial-no. and/or the tag-no. to ensure that the valve/

actuator is correct for the intended application.

Do not insulate extensions that are provided for hot

or cold services.

Pipelines must be correctly aligned to ensure that the

valve is not fitted under tension.

DANGER: indicates that death, severe personal

injury and/or substantial property damage will

occur if proper precautions are not taken.

2

Fire protection must be provided by the user.

Page 3

User Instructions Logix 520MD - LGENIM0520-01 09/09

STOP!

®

1.6 Spare parts

Use only FL O W SERVE ori g inal spar e pa rts.

FLOWSERVE cannot accept responsibility for any

damages that occur from using spare parts or

fastening materials from other manufactures. If

FLOWSERVE products (especially sealing materials)

have been on store for longer periods check these for

corrosion or deterioration before using these products.

Fire protection for FLOWSERVE products must be

provided by the end user.

1.7 Service / repair

To avoid possible injury to personnel or damage to

products, safety terms must be strictly adhered to.

Modifying this product, substituting nonfactory parts,

or using maintenance procedures other than outlined

in this instruction could drastically affect performance

and be hazardous to personnel and equipment, and

may void existing warranties. Between actuator

and valve there are moving parts. To avoid injury

FLOWSERVE provides pinch-point-protection in the

form of cover plates, especially where side-mounted

positioners are fitted. If these plates are removed

for inspection, service or repair special attention is

required. After completing work the cover plates must

be refitted.

1.9 Valve and actuator variations

These instructions cannot claim to cover all details of

all possible product variations, nor can they provide

information for every possible example of installation,

operation or maintenance. This means that the

instructions normally include only the directions to

be followed by qualified personal where the product

is being used for is defined purpose. If there are any

uncertainties in this respect particularly in the event

of missing product-related information, clarification

must be obtained via the appropriate FLOWSERVE

sales office.

2 UNPACKING

Each delivery includes a packing slip. When unpacking,

check all delivered valves and accessories using this

packing slip.

Report transport damage to the carrier immediately.

In case of discrepancies, contact your nearest

FLOWSERVE location.

Apart from the operating instructions and the

obligatory accident prevention directives valid in the

country of use, all recognised regulations for safety

and good engineering practices must be followed.

WA R NING: Before produ c ts ar e ret u rned to

FLOWSERVE for repair or service FLOWSERVE must

be provided with a certificate which confirms that

the product has been decontaminated and is clean.

FLOWSERVE will not accept deliveries if a certificate

has not been provided (a form can be obtained from

FLOWSERVE).

1.8 Storage

In most cases FLOWSERVE products are manufactured

from stainless steel. Products not manufactured

from stainless steel are provided with an epoxy resin

coating. This means that FLOWSERVE products

are well protected from corrosion. Nevertheless

FLOWSERVE products must be stored adequately

in a clean, dry environment. Plastic caps are fitted

to protect the flange faces to prevent the ingress of

foreign materials. These caps should not be removed

until the valve is actually mounted into the system.

3

Page 4

®

3 LOGIX 520MD OVERVIEW

The Logix 520MD is a two-wire, 4-20 mA input digital valve

positioner with HART communication. The Logix 520MD

positioner controls single-acting actuators with linear

and rotary mountings. The Logix 520MD is completely

powered by the 4-20 mA input signal. The minimum input

signal required to function is 3,6 mA.

4 SPECIFICATIONS

User Instructions Logix 520MD - LGENIM0520-01 09/09

Since the positioner is insensitive to supply pressure

changes and can handle supply pressures from 1,5 to 6 barg

(22 to 87 psig), a supply regulator is usually not required;

however, in applications where the supply pressure is

higher than the maximum actuator pressure rating a supply

regulator is required to lower the pressure to the actuator’s

maximum rating (not to be confused with operating range).

A coalescing air filter is recommended for all applications

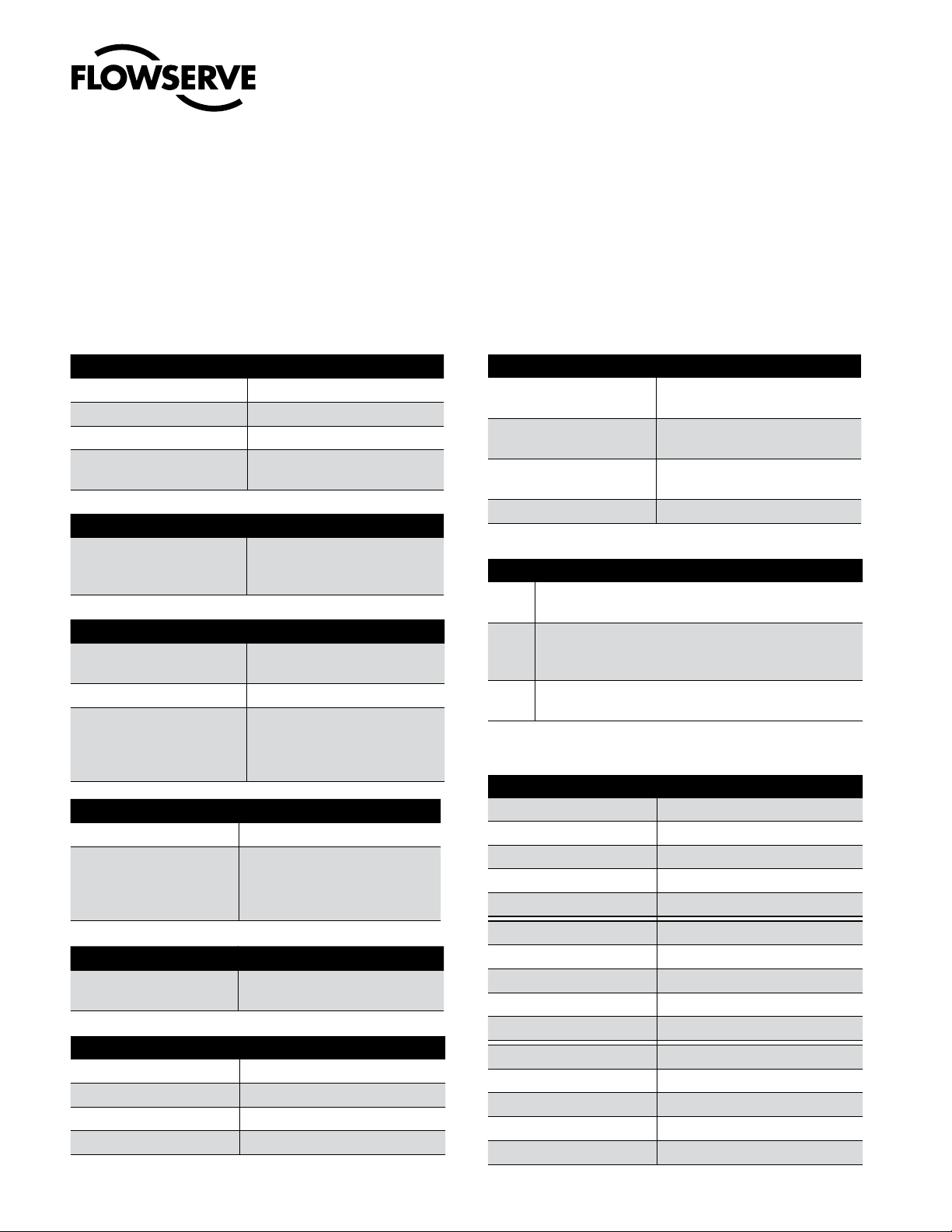

Table 1: Input Signal

Input Signal Range 4 - 20 mA (HART)

Compliance Voltage 10 VDC

Voltage Supply (maximum) 30 VDC

Minimum Required Operating

Current

Table 2: Stroke Output

Feedback Shaft Rotation Min. 15°, max 90°

Table 3: Air Supply

Air Supply Quality Free from moisture, oil and dust

Input Pressure Range 1,5 to 6,0 bar (22 to 87 psi)

Air Consumption (steady state)

Table 4: Output Signal

Output Pressure Range 0 to 100% of air supply pressure

Output Flow Capacity 2,4 Nm³/h @ 1,5 bar

Table 5: Shipping Weights

Base Positioner without

Accessories

Table 6: Performance Characteristics (typical)

Linearity < +/- 1,0%

Resolution < 0,1%

Repeatability < 0,2%

Deadband < 0,2%

3,6 mA without AO

3,83 mA with AO

40° recommended for linear

applications

per IEC 770 and ISA-7.0.01

0,08 Nm³/h @ 1,5 bar

(0,047 SCFM @ 22 psi)

0,12 Nm³/h @ 6,0 bar

(0,071 SCFM @ 87 psi)

(1,41 SCFM @ 22 psi)

7,0 Nm³/h @ 6,0 bar

(4,12 SCFM @ 87 psi)

1,2 kg (2,65 lbs)

Table 7: Environmental Conditions

Operating Temperature

Standard

Operating Temperature

Low

Transport and Storage

Temperature

Operating Humidity 0 to 100% non-condensing

Table 8: Hazardous Area Specifications

ATEX II 1 G Ex ia IIC T5 - T6

II 3 G Ex ic IIC T5 - T6

FM

CSA Class I Division 1, Groups A,B,C,D

Table 9: Limit Switches (optional)

Type P&F SJ2-S1N

Load current < 1 mA < 3 mA

Voltage range 5 - 25 VDC

Hysteresis 0,2 %

Temperature -25

Type P&F SJ2-SN

Load current < 1 mA < 3 mA

Voltage range 5 - 25 VDC

Hysteresis 0,2 %

Temperature -40

Type P&F SJ2-N

Load current < 1 mA < 3 mA

Voltage range 5 - 25 VDC

Hysteresis 0,2 %

Temperature -25

Class I, Division 2, Groups A,B,C,D Temp. Class. T4 Ta = 85°C

Class I Zone = Group IIC T4 Ta = 85°C

Class I, Division 2, Groups A,B,C,D Temp. Class. T4 Ta = 85°C

Class I Division 2, Groups A,B,C,D

-20 °C to +80 °C

(-4 °F to +178 °F)

-40 °C to +80 °C

(-40 °F to +178 °F)

-40 °C to +80 °C

(-40 °F to +178 °F)

°C to

100

°C (

°C to

100

°C (

°C to

100

°C (

-13

-40

-13

°F to

°F to

°F to

212

212

212

°F)

°F)

°F)

4

Page 5

User Instructions Logix 520MD - LGENIM0520-01 09/09

Local

User

Interface

Inner Loop

Piezo Control

Stroke

Inner Loop

Position Feedback

1 Digital Control Circuit

2 Electro-pneumatic

Converter Module

3 Valve Position

Sensor

Filter / Regulator

for Supply Air

1.5 – 6.0 bar (22 – 87 psi)

Air Supply

-

Micro-

Processor

Gain

Pressure Regulator

Piezo Valve

Pneumatic

Amplifier

Control Valve

+

4 – 20 amA

Output

(0ptional)

4 – 20 mA

+ HART

HART

®

Figure 1: Logix 520MD Principle of Operation

due to the close tolerances in the positioner. Optional analog

feedback system as well as limit switch unit and a directly

attachable double acting module complete the Logix 520MD

positioner accessories.

NOTE: The air supply must conform to ISA 7.0.01or IEC 770

(a dew point at least 10 ˚C / 18 ˚F below ambient temperature,

particle size below five microns – one micron recommended

– and oil content not to exceed one part per million).

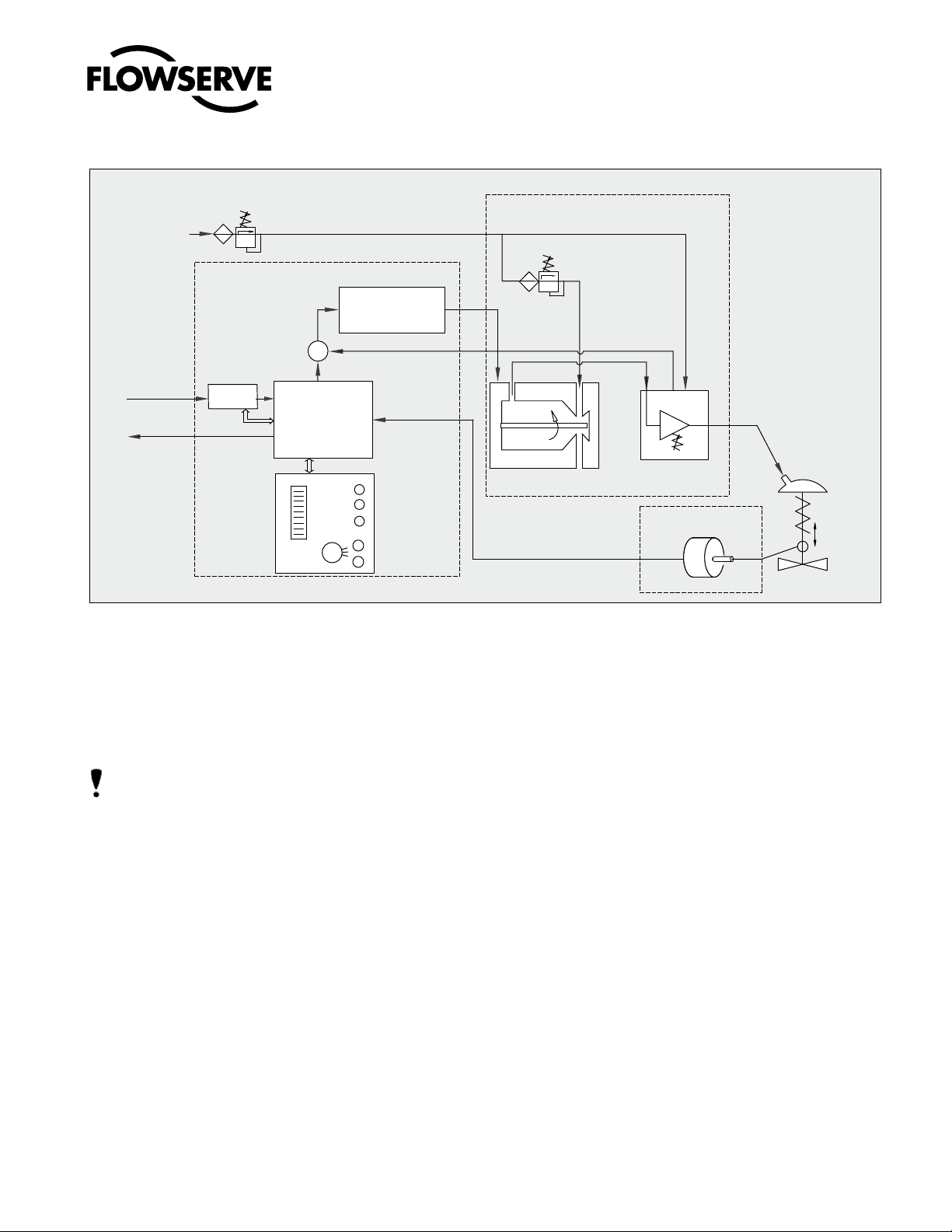

5 PRINCIPLE OF OPERATION

The Logix 520MD positioner is a digital positioner that incor-

porates HART protocol for communication. The positioner

consists of three main modules:

1. T he m ic rop ro ces so r- ba sed e le ct r on ic con tr ol

module includes HART communications and direct local

user interface switches

2. The piezo valve-based electro-pneumatic converter module

3. The infinite resolution valve position sensor.

The basic positioner operation is best understood by refer-

ring to Figure 1. The complete control circuit is powered

by the two-wire, 4-20 mA command signal. The HART

module sends and receives the superimposed FSK HART

digital communications over the 4-20 mA signal wires

providing two-way remote digital communications to

the microprocessor. The analog 4-20 mA command is

passed to the microprocessor, where it is compared to

the measured valve stem position. The control algorithm in the processor performs control calculations

and produces an output command to the piezo valve,

which drives the pneumatic amplifier. The position of

the pilot valve in the pneumatic amplifier is measured

and relayed to the inner loop control circuit. This twostage control provides for more responsive and tighter

control than is possible with a single stage control

algorithm. The pneumatic amplifier controls the airflow

to the actuator. The change of pressure and volume of

the air in the actuator causes the valve to stroke. As the

valve approaches the desired position, the difference

between the commanded position and the measured

position becomes smaller and the output to the piezo

is decreased. This, in turn, causes the pilot valve to

close and the resulting flow to decrease, which slows

the actuator movement as it approaches, the new

commanded position. When the valve actuator is at the

desired position, the pneumatic amplifier output is held

at zero, which holds the valve in a constant position.

5

Page 6

User Instructions Logix 520MD - LGENIM0520-01 09/09

®

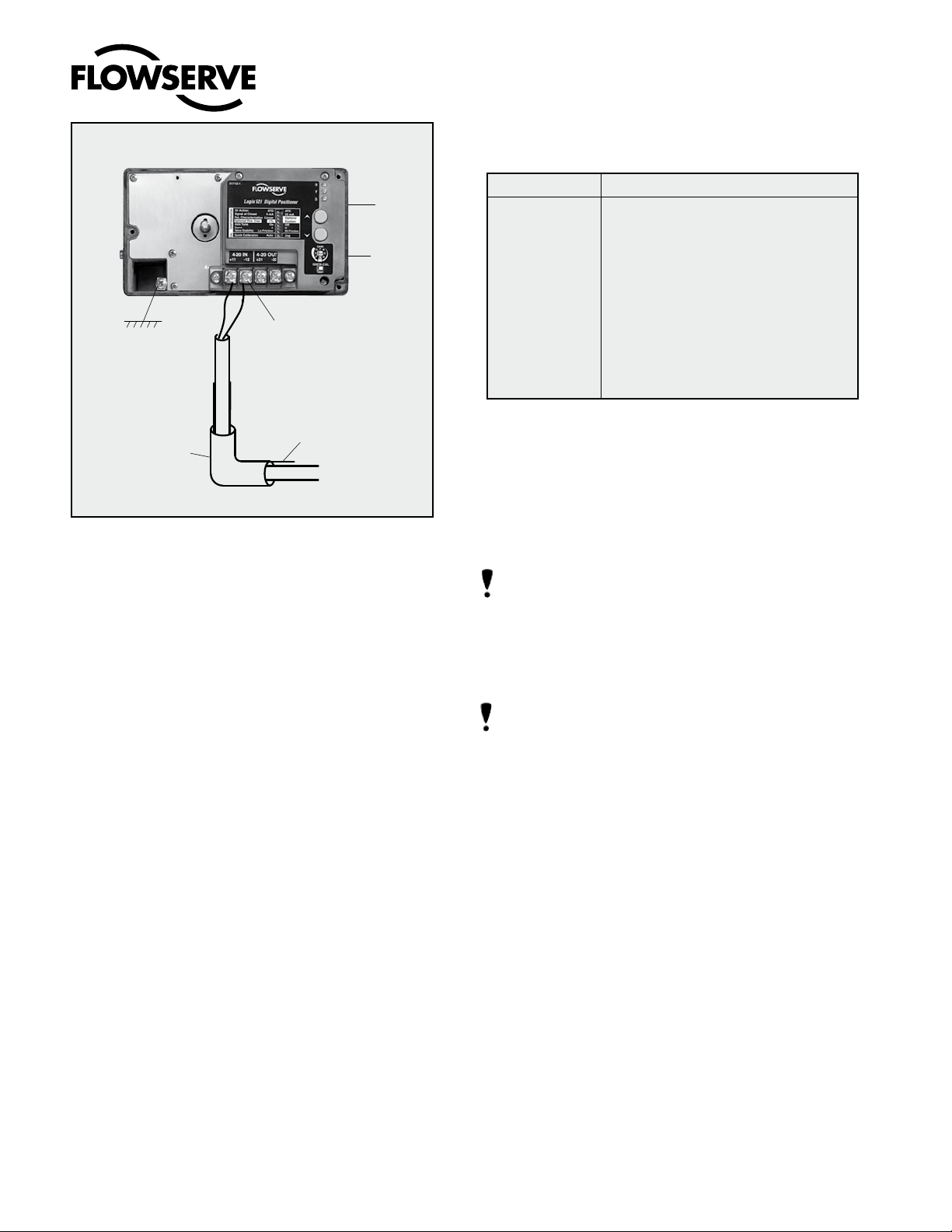

Table 10: Connection Table

Internal Housing

EARTH Terminal

Shielded Cable

4-20 mA Signal

Connect Shield at Source Ground

-

4-20 mA Current Source

+

Figure 2: Wiring Diagram

6 TUBING POSITIONER TO ACTUATOR

After mounting has been completed, tube the positioner

to the actuator using the appropriate compression fitting

connectors:

Air connections: 1/4” NPT (standard air connection)

Auxiliary power: Pressurized air or permissible

gases, free of moisture and dust in according with

IEC 770 or ISA 7.0.01.

Pressure range: 1,5 – 6,0 bar (22 – 87 psi)

For connecting the air piping, the following notes should

be observed:

1. The positioner passageways are equipped with filters,

which remove medium and coarse size dirt from the

pressurized air. If necessary, they are easily accessible

for cleaning.

2. Supply air should meet IEC 770 or ISA 7.0.01 requirements. A coalescing filter should be installed in front of

the supply air connection Z. Now connect the air supply

to the filter, which is connected to the Logix 500si series

positioner.

3. With a maximum supply pressure of 6 bar (87 psi) a

regulator is not required.

4. With an operating pressure of more than 6 bar (87 psi),

a reducing regulator is required. The flow capacity of

the regulator must be larger than the air consumption

of the positioner (7 Nm

psi).

5. Connect the outlet connector Y of the positioner to the

actuator with tubing, independent of the action (direct

6

or reverse).

3

/hr @ 6 bar / 4,12 scfm @ 87

Y

Connection Description

+11 Input+ 4..20 mA

-12 Input- 4..20 mA

Z

+31* Output+ 4..20 mA

-32* Output– 4..20 mA

Limit switch 1 - separate board

Limit switch 2 - separate board

Y (0⇒) Pneumatic output signal (outlet)

Z (0⇐) Air supply

* 0ptional

7 WIRING AND GROUNDING GUIDELINES

Electrical connections: signal cable with cable passage

(NPT or M20 x 1,5) to terminals 2 x 2,5 mm

Input signal: 4 – 20 mA

NOTE: Observe the minimum requirements of voltage

and equivalent electrical load: 10,0 VDC / 500 Ω / at

20 mA

The performance is ensured only for a minimum input cur-

rent of 3,6 mA.

For wiring, the following notes should be observed:

NOTE: The input loop current signal to the Logix

520MD should be in shielded cable. Shields must

be tied to a ground at only one end of the cable to

provide a place for environmental electrical noise to

be removed from the cable. In general, shield wire

should be connected at the source. (Figure 2)

Connect the 4-20 mA current source to terminals +11 and

-12 (Figure 2).

Grounding Screw

The grounding screw, located inside the positioner cover,

should be used to provide the unit with an adequate and

reliable earth ground reference. This ground should be tied

to the same ground as the electrical conduit. Additionally, the

electrical conduit should be earth grounded at both ends of

its run. The grounded screw must not be used to terminate

signal shield wires.

Compliance Voltage (Figure 3)

Output compliance voltage refers to the voltage limit the

current source can provide. A current loop system consists

of the current source, wiring resistance, barrier resistance

(if present), and the Logix 520MD impedance. The Logix

520MD requires that the current loop system allow for a 10 VDC

drop across the positioner at maximum loop current.

Page 7

User Instructions Logix 520MD - LGENIM0520-01 09/09

510

Controller

Voltage

Compliance

Voltage

12V

®

Figure 3: Compliance Voltage

CAUTION: Never connect a voltage source directly across

the positioner terminals. This could cause permanent

circuit board damage.

In order to determine if the loop will support the Logix

520MD, perform the following calculation:

Available Voltage = Controller Voltage (@Current

- Current

MAX

*(R

barrier

+ R

wire

)

The calculated available voltage must be greater than 10

VDC in order to support the Logix 520MD.

Example:

DCS Controller Voltage = 19 V

R

R

CURRENT

barrier

= 25 Ω

wire

= 300Ω

MAX

= 20 mA

Voltage = 19 V - 0,020 A*(300Ω + 25 Ω)

= 12,5 V

The available voltage 12,5 V is greater than the required

10.0

V; therefore, this system will support the Logix 520MD.

The

Logix 520MD has an input resistance equivalent to 500 Ω

at a 20 mA input current.

8 CABLE REQUIREMENTS

The Logix

520MD

digital positioner utilizes the HART

communication protocol. This communication signal is

superimposed on the DC 4-20 mA current signal. The two

frequencies used by the HART protocol are 1200 Hz and

2200 Hz. To prevent distortion of the HART communication,

cable capacitance and cable length restrictions must be calculated. The cable length must be limited if the capacitance

is too high. Selecting a cable with lower capacitance/mm

MAX

)

10V

rating will allow longer cable runs. In addition to cable

capacitance, the network resistance also affects the

allowable cable length.

65Ω

C

(µF) < - 0,0032

network

(R

barrier

+ R

+ 390Ω)

wire

Example:

R

= 300 Ω (if present)

barrier

R

C

Max. Cable Length =

Max. Cable Length = = 1111 m

= 50 Ω

wire

72 ρF 0.000072 µF

= =

cable

m m

65

(300 + 50 + 390)

- 0,0032 = 0,08 µF = C

C

(µF)

network

C

cable

0,08 µF

0.000072 µF/m

To control cable resistance, No. 24 AWG cable can be

used for runs less than 1500 m. For cable runs longer

than this, No. 20 AWG cable should be used.

Electromagnetic Compatibility

The Logix 520MD digital positioner has been designed

to operate correctly in electromagnetic (EM) fields

found in typical industrial environments. Care should

be taken to prevent the positioner from being used in

environments with excessively high EM field strengths

(greater than 10 V/m). Portable EM devices such as

hand-held two-way radios should not be used within

30 cm of the device.

520MD

(µF)(Max)

network

7

Page 8

®

Configuration Switches

User Instructions Logix 520MD - LGENIM0520-01 09/09

LED Status

Lights

Jog Calibrate

Buttons

Gain Selector

4-20 mA Input 4-20,mA Feedback

Figure 4: Logix 520MD Local Interface

Ensure proper wiring and shielding techniques of the

control lines, and route control lines away from electromagnetic sources that may cause unwanted noise.

An electromagnetic line filter can be used to further

eliminate noise (FLOWSERVE Part Number 10156843).

In the event of a severe electrostatic discharge near

the positioner, the device should be inspected to

ensure correct operability. It may be necessary to

recalibrate the Logix 520MD positioner to restore

operation.

9 STARTUP

9.1 Logix 520MD Local Interface

The Logix 520MD local user interface allows the user

to configure the basic operation of the positioner, tune

the response, and calibrate the positioner without

additional tools or configurators. The local interface

consists of a Quick-Cal™ button for automatic zero and

span setting, along with two jog buttons for spanning

valve/actuators with no fixed internal stop in the open

position. There is also a switch block containing eight

switches. Six of the switches are for basic configuration

settings, two are for calibration options. There is also

a rotary selector switch for adjusting the positioner

gain settings. For indication of operational status or

alarm conditions there are three LEDs on the local user

8

interface.

Quick-Cal Button

(Optional)

9.2 Initial DIP Switch Setting

Before placing the unit in service, set the DIP switches in

the “Configuration” and “Cal” boxes to the desired control

options.

NOTE: The switch settings in the Configuration box are

activated only by pressing the Quick-Cal button or by

utilizing the stroke calibration features provided by a

handheld or by Flowserve PC software.

9.2 Operation of Configuration DIP Switches Setup

The first six DIP switches are for basic configuration

1. Air Action – Must be set to match the configuration of

the valve/actuator mechanical configuration.

ATO (air-to-open) – Select ATO if increasing output pres-

sure from the positioner is tubed so it will cause the valve

to open.

ATC (air-to-close) – Select ATC if increasing output pres-

sure from the positioner is tubed so it will cause the valve

to close.

2. Signal at Closed – Normally this will be set to 4 mA for

an air-to-open actuator, and 20 mA for an air-to-close

actuator configuration.

Selecting 4 mA will make the valve fully closed when the

signal is 4 mA and fully open when the signal is 20 mA.

Selecting 20 mA will make the valve fully closed when the

signal is 20 mA and fully open when the signal is 4 mA.

Page 9

User Instructions Logix 520MD - LGENIM0520-01 09/09

STOP!

®

3. Pos. Characterization

Select Linear if the actuator position should be directly

proportional to the input signal.

Select Optional if another characteristic is desired, which

is set in conjunction with the next switch, labeled Optional

Pos. Char.

4. Optional Pos. Char. – If the Pos. Characterization switch

is set to optional, this switch is active with the following

options:

The =% op tion wi ll cha r acte r ize th e actua tor

response to the input signal based on a standard 30:1 equal

percent rangability curve.

If Custom is selected, the positioner will be characterized to

a custom table that must be set-up ValveSight DTM software

or a HART handheld.

5. Auto Tune – This switch controls whether the positioner will

auto tune itself every time the Quick-Cal button is pressed

On enables an auto tune feature that will automatically de-

termine the positioner gain settings every time a Quick-Cal

is performed based on the setting of the rotary Gain switch.

NOTE: there is a small black arrow indicating the selection.

The slot does not indicate the chosen gain.

Indicator arrow

If the rotary Gain selector switch is set to E with

th e Auto Tune switch On, a Flowserve nominal

response tuning set will be calculated and used.

If the rotary Gain selector switch is set to D, C, B, or A with

the Auto Tune switch On, progressively lower gain settings

will be calculated and used.

If the rotary Gain selector switch is set to F, G, or H with

the Auto Tune switch On, progressively higher gain settings

will be calculated and used.

Off forces the positioner to use one of the factory preset

tuning sets determined by the rotary Gain selector switch.

Settings A through H are progressively higher gain prede-

fined tuning sets. The positioner is preset to Autotune - On

at the factory. This is the recomended setting.

The gain selector operates as a “live” switch. This means

that changes to the switch position while the positioner is in

normal operation will have immediate effect on the control

algorithm.

6. Stability Switch – This switch adjusts the position control

algorithm of the positioner for use with low friction control

valves or high friction automated valves

Placing the switch to the left optimizes the response

for low friction, high performance control valves. This

setting provides for optimum response times when used

with most low friction control valves.

Placing the switch to the right optimizes the response

for valves and actuators with high friction levels. This

setting slightly slows the response and will normally

stop limit cycling that can occur on high friction valves.

9.3 Calibration switches

9.3.1 Setup of the Cal DIP Switch for the Quick

Calibration operating mode

Select Auto if the valve/actuator assembly has an internal

stop in the 100% stroke position. In Auto mode the

positioner will fully close the valve and register the 0%

position and then open the valve to the stop to register

the 100% position when performing a self-calibration.

See detailed instructions in the next section on how to

perform an auto positioner calibration.

Select Jog if the valve/actuator assembly has no cali-

bration stop in the open position. In the Jog mode the

positioner will fully close the valve for the 0% position

and then wait for the user to set the open position using

the Jog buttons labeled with the up and down arrows.

See the detailed instructions in the next section on how

to perform a manual calibration using the Jog buttons.

WARNING: During the Quick-Cal operation the valve

may stroke unexpectedly. Notify proper personnel

that the valve will stroke, and make sure the valve is

properly isolated.

9.4 Quick-Cal Operation

The Quick-Cal button is used to locally initiate a

calibration of the positioner. Pressing and holding the

Quick-Cal button for approximately three seconds will

initiate the calibration. If the Config-Switches option is

enabled, the settings of all the configuration switches

are read and the operation of the positioner adjusted

accordingly. The Gain Selector switch is also read and

action will be taken to adjust the gain according to the

settings of the calibration switches as described in the

previous section. A Quick-Cal can be aborted at any

time by briefly pressing the Quick-Cal button and the

previous settings will be retained.

If the Quick calibration switch (not to be confused

with the Quick-Cal button) is set to Auto and the valve/

actuator assembly has the necessary internal stops, the

calibration will complete automatically. While the calibration is in progress you will notice a series of different

lights flashing indicating the calibration progress. When

the lights return to a sequence that starts with a green

light, the calibration is complete. (See the appendix for

an explanation of the various light sequences.)

9

Page 10

User Instructions Logix 520MD - LGENIM0520-01 09/09

STOP!

STOP!

®

WARNING: When operating using local control of the

valve, the valve will not respond to external commands.

Notify proper personnel that the valve will not respond

to remote command changes, and make sure the valve

is properly isolated.

If the Quick calibration switch is set to Jog, the calibra-

tion will initially close the valve then cause a small jump

in the valve position. The jog calibration process will

only allow the user to manually set the span; zero

position is automatically always set at the seat. If an

elevated zero is needed a handheld or other PC based

configuration software is required. The LEDs will then

flash in a sequence of Y-G-Y-R (yellow-green-yellowred) which indicates the user must now use the Jog

keys to manually position the valve to the desired 100%

position. Now press both Jog buttons simultaneously to

proceed to the next step. The valve will then stroke and

then wait while flashing the Y-G-Y-R sequence again,

allowing the user to adjust the valve position a second

time to exactly 100% using the Jog buttons. When the

stem is properly positioned press both Jog buttons

simultaneously again to register the 100% position and

proceed. No more user actions are required while the

calibration process is completed. When the lights return

to a sequence that starts with a green light the calibration is complete. (See the appendix for an explanation

of the various light sequences.)

9.5 Local control of valve position

Can be done from the user interface by holding both jog

buttons and then simultaneously pressing the Quick-Cal

button. While in this mode the LEDs will flash a Y-G-Y-Y

(yellow-green-yellow-yellow) sequence. To exit the local

control mode and return to normal operation, briefly

press the Quick-Cal button.

9.6 Factory reset

Hold Quick-Cal button while applying power and all of

the internal variables including calibration will be reset

to factory defaults. The positioner must be re-calibrated

after a factory reset. Tag names and other user configured limits, alarm settings, and valve information will

also need to be restored. A factory reset will always

reset the command source to analog 4-20 mA.

9.7 Special settings

Several adjustments to the Logix 520 such as split-

range, MPC, soft stop, etc. cannot be set using the local

interface.

To set these parameters please use ValveSight DTM

software or a HART handheld.

This option can also be retrofitted in the field. The 4-20 mA

analog output board is wired in series with a 12.5 to 40 VDC

power supply (see Figure 5). This position feedback option

has the following features and specifications:

Does not interfere with positioner operation.

Calibration of the analog output signal is performed using a

HART 375 Handheld Communicator or configuration software

such as ValveSight.

Output follows actual position of valve, including all failure

modes of positioner except loss of power. An output of <3.15

mA is transmitted with loss of power to the positioner.

Immune to RFI/EMI disturbances.

Available for intrisically safe applications (ATEX, FM, CSA ).

10.1 Replacing the 4-20 mA Analog Output Board

To replace the 4-20 mA analog output board, refer to Figures

5 and 6 and proceed as outlined below. The following tools

are required:

Phillips screwdriver

WARNING: Observe precautions for handling

electrostatically sensitive devices.

1. Make sure the valve is bypassed or in a safe condition.

2. Disconnect the power and air supply to the unit.

3. Remove the main cover.

4. Remove the plastic board cover by removing the three retaining screws.

5. Remove the configuration board

6. Disconnect the two wire connection from the side of the

4-20 mA analog output board.

7. Gently lift the 4-20 mA analog output board off the main PCB

assembly.

8. Align the two connectors on the new 4-20 mA analog output

board with the mating sockets on the main PCB board and

gently press the connectors together.

9. Connect the two wire connection coming from the User

Interface board to the side of the 4-20 mA analog output

board.

10. Replace the configuration board

11. Install the plastic board cover. Insert the three retaining screws

through the plastic cover into the threaded boss and tighten

evenly, using a Phillips screwdriver. Do not overtighten.

12. Connect the Analog Output wiring to the Analog Output

terminals on the User Interface board (see Figure 5.)

13. Reinstall all covers.

10 4-20 MA ANALOG OUTPUT BOARD

The Logix 520MD digital positioner can be supplied to

provide an analog feedback signal of the stem position.

10

Page 11

User Instructions Logix 520MD - LGENIM0520-01 09/09

®

4 - 20 IN

+11 -12 +31 -32

CAUTION: Isolated Power Sources Required.

4 - 20 OUT

Position Feedback

Current Loop

(Logix Output)

Position Command

Current Loop

(Logix Input)

–

+

12 VDC

–

to 40 VDC

Spannungs-

+

quelle

4 to 20 mA

Current Source

Figure 6: 4-20 mA Analog Output BoardFigure 5: Analog Output Board Power

11

Page 12

11 LIMIT SWITCH UNIT

STOP!

User Instructions Logix 520MD - LGENIM0520-01 09/09

®

CAUTION: The installation of hazardous location electrical

equipment must comply with the procedures contained in

the certificates of conformance. Country specific regulations

may apply. Electrical safety is determined only by the power

supply device. (Positioner operation with limited voltage

only).

11.1 General

The Logix 520MD digital positioner can be equipped with

an additional limit switch unit.

11.2 Principle of Operation

The lever / coupling moves the vane into the slot of the

limit switches LS1 or LS2. The sensors are designed as a

proximity vane type switch. The switching function is triggered if a ferromagnetic object (vane) is inserted between

the coils. The switching point can be set by adjustment of

the vane.

11.3 Installation (Figure 7)

The limit switch unit is fitted to the positioner when delivered

but can be retrofitted. Fit 3 spacer screws (1) to positioner

housing. Place PC board (2) on spacer screws (1), secure

with 3 mounting screws (3).

11.4 Adjusting switches

Use the following procedure to adjust the switches

1. Loosen the two screws on the vane (4), figure 7.

2. Stroke the valve to the first switching position.

3. Set the switching point of the limit switch by adjusting

the lower vane for the lower switch (LS2).

4. Stroke the valve to the second switching position

(LS1).

5. Set the switching point of the limit switch by adjusting

the vane for the upper switch.

6. Tighten the two screws on the vane (4), figure 7.

7. Check the two switching points and repeat the adjustment steps 1 to 6, if necessary.

Switches (Figure 8)

Install vane assembly (4) and secure with 2 screws. For

electrical connect see Figure 8.

WARNING: For units installed in Hazardous areas special

installation cautions and procedures are required.

4

3

1

2

Figure 7: Limit switches Figure 8: Switch connections

12

Page 13

User Instructions Logix 520MD - LGENIM0520-01 09/09

®

12 STATUS CODES

Blink

Code

GGGG

GGGY

GGYG LOCAL INTERFACE DISABLED/ENABLED when DISABLED, in-

GGYY DIGITAL COMMAND SOURCE indicates a HART signal is needed

GGRR SQUAWK MODE ON/OFF (user set) When ON, this indicates a

GYGG POSITION LIMIT ALERT (user set) indicates the position has

GYGY SOFT STOP LIMIT ALERT (user set) indicates the unit is being

GRGG CYCLES or TRAVEL LIMIT ALERT (user set) indicates that one of

YGGY SIGNATURE IN PROGRESS MODE indicates that a test has been

YGGR INITIALIZING MODE displays a blink sequence 3 times when the

YGYG CALIBRATION IS IN PROGRESS indicates a calibration is pro-

YGYY JOG COMMAND STATE indicates the unit has been placed in a

YGYR JOG CALIBRATION STATE indicates that during a jog calibration,

YYGG POSITIONER TEMPERATURE WARNING (user set) indicates the

YYGY PRESSURE OUT OF RANGE WARNING indicates that during a

YYGR SUPPLY PRESSURE HIGH WARNING indicates the positioner

Description Recommendations

NORMAL OPERATION indicates normal, healthy operation

MPC ACTIVE MODE

is active. The command is beyond the user set limit for tight

shutoff feature. This is a normal condition for all valves when

closed. The factory default setting triggers this at command signals below 1%. This indication may also occur on 3 way valves

at both ends of travel if the high MPC value has been set.

dicates PC software has been used to disable the local interface.

This code is only present for a short time when the Quick Cal

button is pressed.

to change the position command and the analog 4-20 mA input

signal is ignored.

user has set the positioner to flash a special sequence so that it

can be visually located.

reached or is exceeding a user defined upper or lower position

indicator similar to a limit switch indicator.

commanded to exceed a user defined upper or lower position

limit and the internal software is holding the position at the limit.

The function is similar to a mechanical limit stop except it is not

active if the unit is un-powered.

the cycle or travel limits has been exceeded. The criterion and

count limit are set by the user to track the usage of the valve.

There are accumulators for total valve travel, total valve cycles,

total spool valve travel, and total spool valve cycles. Flowserve

supplies software can identify the specific limit that has been

reached.

initiated by Flowserve supplied software

unit is powering up.

cess. Calibrations such as stroke may be initiated locally with

the Quick-Cal button or remotely. Other calibrations for the inputs and outputs or pressure sensors are only initiated remotely.

local override mode where the valve can only be stroked using

the two local jog buttons.

the unit is waiting for the user to manually adjust the valve position to the desired 100% open position.

internal electronics have exceeded a temperature limit. The

mum limit of the electronics and the default setting is -40°F (-40°C).

Low temperature may inhibit responsiveness and accuracy. The

maximum limit of the electronics and default setting is 185°F (85°C).

High temperature may limit the life of the positioner.

pressure sensor calibration, the range of applied pressures to

port 1 was too small for optimum performance.

has determined that the supply pressure is above the user set

warning limit.

(user set) indicates that tight shutoff (MPC)

mini-

If tight shutoff is not desired reset the tight shutoff limits to the correct values or

adjust the command signal inside of the specified MPC value. See DTM screen:

Configuration/Custom/Position Cutoff.

If local control is desired then the local interface must be re-enabled from the

remote software. See DTM screen: Configuration/Basic Local Interface.

A manual Command Source Reset is provided to change the command back to

analog control mode from the local interface if a PC or hand held configurator

is not available. This is done while a QUICK-CAL is in progress by holding

down both the Jog buttons (up and down) while briefly pressing the QUICKCAL button. A new QUICK-CAL must be done after resetting. See DTM screen:

Dashboard.

This mode is canceled if the Quick-cal button is briefly pressed, the Squawk

mode is selected again remotely, or more than one hour has passed since the

command was issued. See DTM screen: Configuration/Custom/LED.

Reset the indicator if more travel is needed or adjust the command signal back

in the specified range. See DTM screen: Configuration/Custom/Position Cutoff.

This indicator can be disabled.

Reset the limit if more travel is needed or adjust the command signal back in the

specified range. See DTM screen: Configuration/Custom/Soft Limits.

For valve accumulators indications follow routine procedures for maintenance

when the limit is reached such as checking the packing tightness, and checking

linkages for wear, misalignment, and tightness. After maintenance, reset the

cycle accumulator. See DTM screen: Health Status/Positioner Health. This

indicator can be disabled. For spool valve accumulators inspect for high air consumption and signs of wear. See DTM screen: Health Status/Positioner Health.

This indicator can be disabled.

Signatures can only be canceled by Flowserve supplied software. See DTM

screen: Diagnostics.

Wait for power up to complete.

Local calibration may be canceled by briefly pushing the quick-cal button. Remote calibrations can only be canceled by the software.

Control the valve using the jog buttons. This mode may be canceled by briefly

pushing the quick-cal button.

Use the buttons on the positioner to adjust the valve to the desired fully open

position. See the explanation of Jog Calibrate in the Quick-Cal section of main

document for operation.

Regulate the temperature of the positioner. If the temperature reading is in error,

replace the main board. See DTM screen: Health Status/Positioner Health. This

indicator can be disabled.

Adjust the supply pressure to a proper value (30-150 psig) so the positioner

can properly calibrate the sensors. Then recalibrate. Briefly push the quick-cal

button to acknowledge this condition and the positioner will operate using the

current short stroke calibration values if valid.

Regulate the supply pressure at the positioner below the maximum limit recommended for your actuator. Recalibrate pressure sensors. Check the pressure

sensor board connections. Replace pressure sensor board if necessary. See

DTM screen: Health Status/Actuator Health. This indicator can be disabled.

13

Page 14

User Instructions Logix 520MD - LGENIM0520-01 09/09

®

Blink

Code

YYYG SUPPLY PRESSURE LOW WARNING (user set) indicates that the

YYYY ACTUATION RATIO WARNING (user set) indicates a decreased

YRGG PILOT RELAY RESPONSE WARNING (user set) indicates that the

YRGY FRICTION LOW WARNING (user set) indicates the friction has

YRGR PNEUMATIC LEAK WARNING (user set) indicates that the positi-

YRYG

YRRY ELECTRONIC INABILITY TO FAIL SAFE WARNING indicates that

YRRR PNEUMATIC INABILITY TO FAIL SAFE WARNING indicates that

RGGY FEEDBACK READING PROBLEM DURING CALIBRATION ALARM

RGGR

RGYG

Description Recommendations

supply pressure is below the user set warning limit. Low supply

pressure can cause poor valve response or positioner failure.

The minimum recommended supply pressure is 30 PSI (2.1 bar)

for proper operation. The unit will fail at less than approximately

17 PSI (1.2 bars). Low supply pressure indications can also be

caused by pneumatic leak.

ability of the system to actuate the valve. It is based on the ratio

of available force to required force to actuate. It is affected by the

process load, friction, spring force, and available supply pressure.

pilot relay is sticking or slow to respond. This affects the responsiveness, increases the chance of limit cycling and excessive air

consumption. The pilot relay is part of the inner loop and consists of the driver module assembly with piezo (I-P relay) which

is coupled to the poppet. The value of this indicator corresponds

with inner loop lag. Delayed response can be caused by a partially clogged piezo or debris, oil, corrosion or low supply pressure.

passed below the user set limit.

oner has detected a leak in the actuation assembly. Leakage from

the actuator can cause decreased responsiveness and excessive

air/gas consumption. Low supply pressure can also trigger this

warning.

FRICTION HIGH WARNING

friction has passed the user set limit. High friction can cause

loop oscillations, poor position control, jerky motion, or valve

sticking. It can be caused by build-up from the process on the

stem, trim or seat , by a failing bearing or guides in the valve

and actuator, galling of the trim or stem, excessively tightened

packing, linkages, or other valve/actuator mechanical issues.

the piezo may be damaged. This may prevent the proper failure

position upon loss of signal/power. This condition may occur

briefly on an air-to-close valve that is held for long periods of

time in the closed position, or and air-to-open valve held in the

open position.

upon loss of air supply, the valve may not move to the fail-safe

position. The spring alone is not adequate to overcome the friction and process load in the system. The failsafe spring may have

failed, or it was not sized properly for the application. Friction or

process load may have increased.

indicates that during calibration, the range of motion of the position feedback arm was too small for optimum performance, or the

position sensor was out of range.

INNER LOOP OFFSET TIME OUT ALARM during calibration the

Inner Loop Offset value did not settle. This could result in less

accurate positioning.

NON-SETTLE TIME OUT ALARM indicates that during calibration,

the position feedback sensor did not settle.

(user set) indicates the valve/actuator

Regulate the supply pressure at the positioner above 30 PSI (2.1 bar). Recalibrate pressure sensors. Ensure system air/gas supply is adequate. Repair

kinked supply tubing. Check the pressure sensor board connections and replace

pressure sensor board if necessary. Check for pneumatic leaks in the actuator

and actuator tubing. See DTM screen: Health Status/Actuator Health. This

indicator can be disabled.

Increase the supply pressure. Reduce the friction. Check the actuator spring.

Resize the actuator. Adjust user set limits. See DTM screen: Health Status/

Actuator Health. This indicator can be disabled.

Check response of the valve. If OK, adjust Pilot Relay Response limits. Check

supply pressure. Replace the piezo or driver module assembly. Maintain a clean,

water-free air/gas supply. See DTM screen: Health Status/Positioner Health.

This indicator can be disabled.

Low friction is usually an indication of improperly loaded packing or seals in the

valve and actuator. See DTM screen: Health Status/Valve Health. This indicator can

be disabled.

Repair pneumatic leaks at the tubing junctions and actuator seals. Ensure proper

supply pressure. See DTM screen: Health Status/Actuator Health. This indicator

can be disabled.

Determine if the friction is significantly interfering with the valve control. If not,

consider increasing the friction warning limit. Consider the following to reduce

friction: Stroke the valve to clear off build-up. Clear any external mechanical obstruction, loosen the packing, clean the stem, repair or replace the actuator. Highly

localized friction or very jerky travel can indicate internal galling. Repair or replace

internal valve components. See DTM screen: Health Status/Valve Health. This

indicator can be disabled.

If alarm persists for more than 30 minutes, the Piezo assembly is damaged and

should be replaced. This indicator can be disabled.

Check for high friction. Repair or replace actuator spring. Reduce process load.

This indicator can be disabled.

Check for loose linkages and/or adjust the feedback pin to a position closer to

the follower arm pivot to create a larger angle of rotation if the feedback rotation

is less than 15 degrees for the total valve travel and recalibrate. Briefly pushing

the quick-cal button acknowledges this condition and the positioner will operate

using the current short stroke calibration if otherwise a good calibration. If the

condition does not clear then adjust the positioner mounting, linkage or feedback

potentiometer to move the position sensor back into range then restart the calibration. This error may be cleared by briefly pushing the quick-cal button, which

will force the positioner to use the parameters from the last good calibration.

Repeat the stroke calibration to get a more accurate ILO value. To proceed using

the less accurate ILO value, this error may be cleared by briefly pushing the

quick-cal button. Lowering the gain setting may help if the actuator is unstable

during the calibration. Gain settings can be physically adjusted on the device. A

lower letter represents lower gain.

Check for loose linkages or a loose positioner sensor. This error may be cleared

by briefly pushing the quick-cal button, which will force the positioner to use

the parameters from the last good calibration. This error may appear on some

very small actuators during the initial calibration. Recalibrating may clear the

problem.

14

Page 15

Blink

Code

RGYY

RGRR

RYYG

RRGG

RRGY

RRGR

RRYG

RRYR

RRRY

RRRR

User Instructions Logix 520MD - LGENIM0520-01 09/09

®

Description Recommendations

NO MOTION TIME OUT ALARM indicates that during calibration,

there was no motion of the actuator based on the current stroke

time configuration.

FACTORY RESET STATE indicates the unit has had a factory reset

and has not yet been calibrated. The unit will not respond to

commands and will remain in the failsafe position until a calibration is successfully completed.

SUPPLY PRESSURE LOW ALARM (user set) indicates that the

supply pressure is below the user set alarm limit. Low supply

pressure can cause poor valve response or positioner failure.

The minimum recommended supply pressure is 30 PSI (2.1 bar)

for proper operation. The unit will fail at less than approximately

17 PSI (1.2 bars). Low supply pressure indications can also be

caused by pneumatic leak.

PILOT RELAY RESPONSE ALARM (user set) indicates that the

pilot relay is sticking or extremely slow to respond. This affects

the responsiveness, increases the chance of limit cycling and

excessive air consumption. The pilot relay consists of the driver

module assembly with piezo (I-P relay) which is coupled to

the spool valve. Delayed response can be caused by a partially

clogged piezo or debris, oil, corrosion, or ice on the spool, or low

supply pressure.

FRICTION LOW ALARM (user set) indicates the friction has

passed below the user set limit. The alarm indicates a more

severe condition than the warning.

FRICTION HIGH ALARM (user set) indicates the valve/actuator

friction has passed the user set limit. The alarm indicates a more

severe condition than the warning. High friction can cause loop

oscillations, poor position control, jerky motion, or valve sticking.

It can be caused by build-up from the process on the stem, trim

or seat, by a failing bearing or guides in the valve and actuator, galling of the trim or stem, excessively tightened packing,

linkages, or other valve/actuator mechanical issues.

PIEZO VOLTAGE ALARM indicates the portion of the circuit board

that drives the piezo is bad, or piezo valve itself is bad.

PILOT RELAY POSITION LIMIT ALARM indicates the pilot relay

(spool) appears to be fixed at a limit and is not responding. This

could be due to low supply pressure, a hall sensor that is out

of calibration, a broken piezo, stuck spool, or a wire connection

problem.

ELECTRONICS ERROR OR ALARM indicates the internal data

was not updated correctly. This may affect the function of the

positioner in various ways or not at all. This can be caused when

intermittent operation occurs when connecting power.

POSITION DEVIATION ALARM (user set) indicates the difference

between the command and the actual position has been greater

than the user-set limit for longer than a user-set time.

Check linkages and air supply to make sure the system is properly connected.

If the time out occurred because the actuator is very large then simply retry the

Quick cal and the positioner will automatically adjust for a larger actuator by

doubling the time allowed for movement. This error may be cleared by briefly

pushing the quick-cal button, which will force the positioner to use the parameters from the last good calibration.

Calibrate. Proper Valvesight operation will require stroke, actuator, and friction

calibration to be completed. This indicator can be disabled.

Regulate the supply pressure at the positioner above 30 PSI (2.1 bar). Recalibrate pressure sensors. Ensure system air/gas supply is adequate. Repair

kinked supply tubing. Check the pressure sensor board connections and replace

pressure sensor board if necessary. Check for pneumatic leaks in the actuator

and actuator tubing. See DTM screen: Health Status/Actuator Health.

Check response of the valve. If OK, adjust Pilot Relay Response limits. Check

the supply pressure. Check the spool for debris, oil, corrosion, ice on the spool.

Clean or replace the spool assembly. Replace the piezo or driver module assembly. Maintain a clean, water-free air/gas supply. See DTM screen: Health Status/

Positioner Health. This indicator can be disabled.

Check for a packing leak. Tighten or replace the valve packing. See DTM screen:

Health Status/Valve Health. This indicator can be disabled.

Determine if the friction is significantly interfering with the valve control. If not,

consider increasing the friction warning limit. Consider the following to reduce

friction: Stroke the valve to clear off build-up. Clear any external mechanical

obstruction, loosen the packing, clean the stem, repair or replace the actuator.

Highly localized friction or very jerky travel can indicate internal galling. Repair

or replace internal valve components. See DTM screen: Health Status/Valve

Health This indicator can be disabled.

If the unit is functioning and controlling replace the piezo, if it does not operate

replace the main circuit board. This indicator can be disabled.

Check for adequate supply pressure. A hall sensor problem may be cleared by

briefly pushing the quick-cal button, which will force the positioner to use the

parameters from the last valid calibration. Check the internal wiring harnesses

for good connections. Check the spool valve for sticking problems. If the

positioner still does not operate replace the piezo, driver module assembly, and/

or spool assembly.

Error may self clear with time. If error persists, cycle power and complete a

Quick-Cal. If the error still persists, Check internal wiring and connectors for

electrical shorts or opens. If no problems are found and alarm persists, replace

the main circuit board.

Review active alarms and warnings to find root causes of this alarm. See DTM

screen: Alerts/Command Deviation. This indicator can be disabled.

13 VERSION NUMBER CHECKING

The version number of the embedded code may be checked at any time except during a calibration by holding down the

Δ button. This will not alter the operation of the unit other than to change the blink sequence to 3 blinks indicating the

major version number. Holding the ∇ button will give the minor version number without affecating operation. The version codes are interpreted by adding up the numbers assigned according to the following table:

Color First blink value Second blink value Third blink value

Green 0 0 0

Yellow 9 3 1

Red 18 6 2

For example if holding the Δ button gave a G-G-R code, and holding the ∇ button gave a Y-Y-G code then the resulting

version number would be (0+0+2).(9+3+0) or version 2.12.

15

Page 16

User Instructions Logix 520MD - LGENIM0520-01 09/09

®

14 TROUBLE SHOOTING

Logix 520MD Symptoms and Solutions

Failure Probable Cause Corrective action

No LED is blinking 1. Current source below 3,7 mA 1. Verify current source supplies at least 3,7 mA

2. Incorrect wiring polarity 2. Check wiring for correct polarity

Erratic communications 1. Current source bandwidth not 1. Maximum allowable current source rate of

limited to 25Hz change is 924 mA per second

2. Maximum cable length or cable 2. Check cable conductor size, length and

impedance exceeded capacitance. Refer to ‘Cable Requirements’ on

page 11.

3. HART modem connected to PC RS-232 3. Verify laptop battery is not low

port not receiving enough power

4. Interference with I.S. barrier 4. Must use HART compatible I.S. barrier

5. Current source stripping (filtering) 5. Use the HART filter (VHF) available from

HART signal Flowserve (FLS part-No. 10156843)

Alternatively a 250Ω and a 22 µF capacitor,

installed according to the following schematic

drawing can be used to establish communication

22 µF

250Ω

Control system

Unit does not respond 1. Unit is in digital command mode 1. Switch to analog command mode with ValveSight

to analog commands DTM software or handheld communicator.

2. Error occurred during calibration 2. Correct calibration error. Recalibrate

Valve position reading 1. Stem position sensor mounting 1. Reposition sensor

is not what is expected is off 180 degrees

2. Stroke not calibrated 2. Calibrate stroke

3. Tight shutoff MPC (Minimum 3. No action

position cutoff) is active

4. Custom characterization or soft 4. No action

stops active

Position is driven fully 1. Stroke not calibrated 1. Calibrate valve stroke

open or closed and will 2. Inner-loop hall sensor not connected 2. Verify hardware connections

not respond to command 3. Wrong air action entered in software 3. Check ATO (Air-to-open) and ATC (Air-to-Close)

settings. Recalibrate

4. Actuator tubing backward 4. Verify ATO/ATC actuator tubing

5. Electro-pneumatic converter 5. Replace electro-pneumatic converter

malfunctioning

6. Control parameter inner-loop offset 6. Adjust inner-loop and see if proper control

is too high/low resumes

Sticking or hunting 1. Contamination of the 1. Check air supply for proper filtering and meeting

operation of the positioner electro-pneumatic converter. ISA specifications ISA-7.0.01

2. Control tuning parameters not correct 2. Lower proportional gain settings

16

Page 17

User Instructions Logix 520MD - LGENIM0520-01 09/09

®

1

2

3

4

Figure 9: Exploded drawing for spare parts

15 SPARE PARTS KITS

Item No. Description Part-No.

1 Cover Assembly Yellow 255240.999.000

White 218771.999.000

Black 218772.999.000

2

PC Board Assembly Logix 520MD

PC Board Assembly analog feedback board

Relay Module Assembly: -20ºC to 85ºC (-4ºF to 185ºF) 230103.999.000

3

Relay Module Assembly: -40ºC to 85ºC (-40ºF to 185ºF) 218773.999.000

4 Repair kit for Potentiometer Assembly 218774.999.000

5 Position Feedback Assembly 218774.999.000

8 Follower Arm Assembly Max. stroke 65 mm 214323.999.000

Max. stroke 110 mm 214322.999.000

Mounting Kits

Description Part-No.

– IEC 534 part 6 (FloTop, Kämmer KA, Kämmer KP, and standard NAMUR linear valves) 213619.999.000

– Rotary VDI/VDE 3845 (DIN ISO 5211) 188151.999.000

– Flowserve direct mounting 214004.999.000

– Linear VDI / VDE 3847 255242.999.000

255349.999.000

255350.999.000

17

Page 18

®

EXTERIOR

GROUNDING

SCREW

User Instructions Logix 520MD - LGENIM0520-01 09/09

LED WINDOW

22.95

.90

"D" SHAFT OPTION

(STANDARD)

M8

10.00

.39

2.31

57.20

2.25

.09

28.60

1.13

35.40

1.39

M20X1,5 OR

1/2" NPT

64.10

2.52

FRONT VIEW

174.10

6.85

28.60

1.13

G1/4" OR

1/4" NPT

98.14

3.9

10.00

53.00

2.09

4.00

4.80

.2

.4

100.00

.2

"N" SHAFT OPTION

(VDI/VDE 3845, NAMUR)

3.94

32.00

1.3

4.00

.2

17.70

.70

17.70

.70

35.40

1.39

57.20

2.25

M6

M8X1,25 OR 5/16"-18UNC

BACK VIEW

MM

INCH

Figure 10: Dimensional Drawing for the Logix 520MD Series Digital Positioner

18

Page 19

User Instructions Logix 520MD - LGENIM0520-01 09/09

FIG. 6 - DIMENSIONAL DRAWING FOR OPTIONS

®

216.18

8.51

AUXILIARY OPTIONS - “GA” (GAUGE ADAPTER)

SINGLE PRESSURE GAUGE

1/4" NPT

100.00

3.94

TWO PRESSURE GAUGES

47.63

1.88

100.00

3.94

1/4" NPT

63.50

2.50

216.87

8.54

AUXILIARY OPTIONS - “GM”

DOMED

INDICATOR

100.00

3.94

173.50

6.83

(GAUGE MANIFOLD)

POSITION INDICATOR - “D” (DOMED INDICATOR)

127.69

5.03

MM

INCH

Figure 11: Dimensional Drawing for the Logix 520MD with options

19

Page 20

Contact:

User Instructions Logix 520MD - LGENIM0520-01 09/09

®

Flowserve Headquarters

5215 N. O'Connor Blvd.

Suite 2300

Irving, Tx. 75039

Phone: +1 972 443 6500

Flowserve Corporation

Flow Control

1350 N. Mt. Springs Parkway

Springville, UT 84663

USA

Phone: +1 801 489 8611

Fax: +1 801 489 3719

Flowserve (Austria) GmbH

Control Valves - Villach Operation

Kasernengasse 6

9500 Villach

Austria

Phone: +43 (0)4242 41181 0

Fax: +43 (0)4242 41181 50

Flowserve Australia Pty Ltd.

14 Dalmore Drive

Scoresby, Victoria 312020

Australia

Phone: 61 7 32686866

Fax: 61 7 32685466

China

585, Hanwei Plaza

7 Guanghau Road

Beijing, China 100004

Phone: +86 10 6561 1900

Flowserve India Controls Pvt. Ltd

Plot # 4, 1A, E.P.I.P, Whitefield

Bangalore Kamataka

India 560 066

Phone: +91 80 284 10 289

Fax: +91 80 284 10 286

Flowserve Essen GmbH

Manderscheidtstr. 19

45141 Essen

Germany

Phone: +49 (0)201 8919 5

Fax: +49 (0)201 8919 662

Flowserve S.A.S.

7, Avenue del la Libération - BP 60

63307 Thiers Cedex

France

Phone: +33 (0)4 73 80 42 66

Fax: +33 (0)4 73 80 14 24

Flowserve Pte Ltd.

12 Tuas Avenue 20

Singapore 638824

Singapore

Phone: 65 6868 4600

Fax: 65 6862 4940

NAF AB

Gelbgjutaregatan 2

SE-581 87 Linköping

Sweden

Phone: +46 (0)13 31 61 00

Fax: +46 (0)13 13 60 54

Kämmer Valves INC.

1300 Parkway View Drive

Pittsburgh, Pa 15205

USA

Tel.: +1 412 787 8803

Fax: +1 412 787 1944

All data subject to change without notice

© ©04.2009 Flowserve Corporation. Flowserve and Kämmer are trademarks of Flowserve Corporation

20

Loading...

Loading...