Page 1

PS0003-CV (CVAUTO-200) 05/03 Page: 1 of 4

© 2003, Flowserve Corporation, Printed in USA

Automax Valve Automation Systems

Product Specification

Introduction:

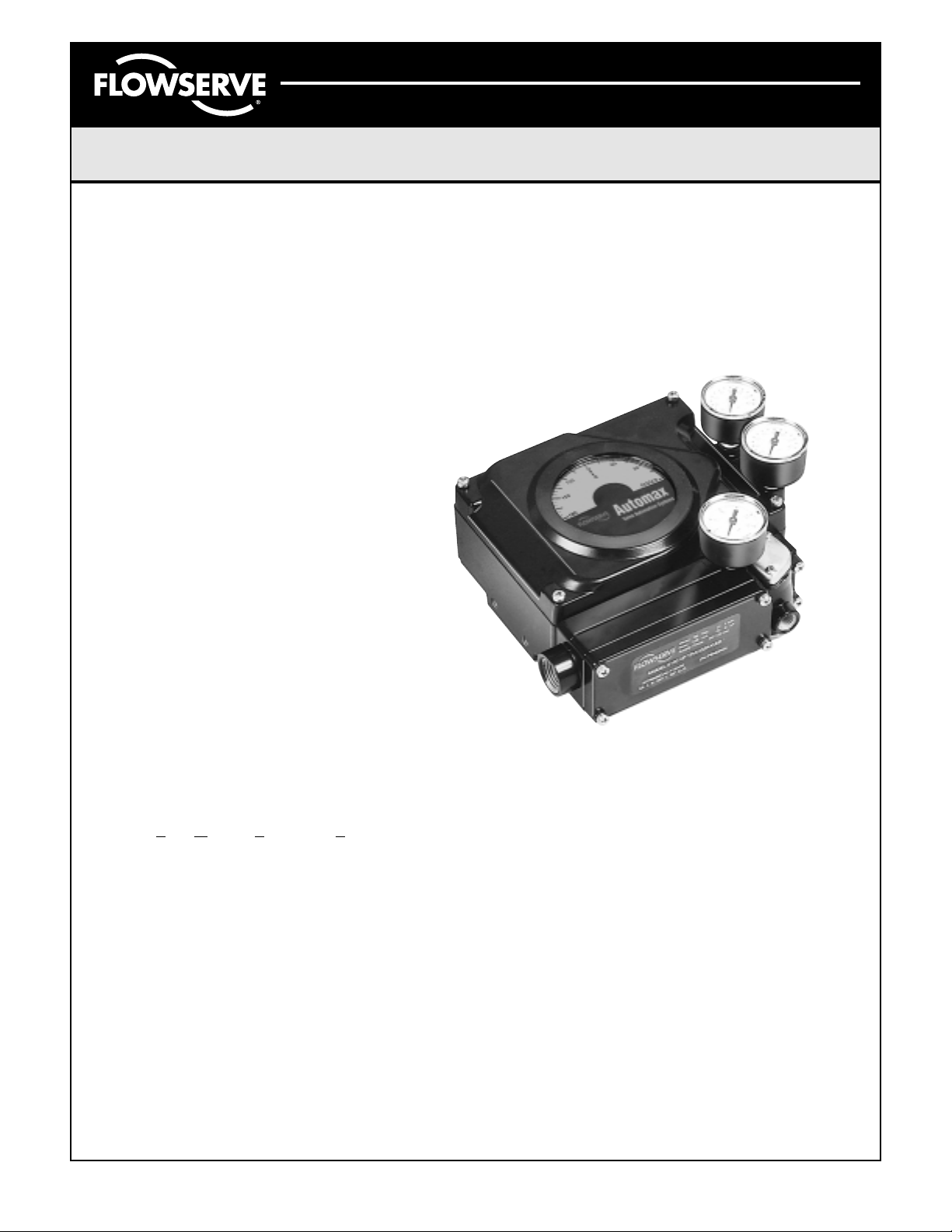

The Apex 5100 I/P Module provides accurate

3-15 psi pneumatic signals for the Apex 5000

Positioner (shown). It receives 4-20 mA current

input and only requires six volts to operate.

The 5100 I/P has many advanced features

including: RFI protection, internal closed loop

control, integral filter (for start-up protection),

and automatic temperature compensation.

Applications:

The Apex 5100 I/P Module’s internal closed loop control system makes it insensitive to installed position. In

addition, this feature enables steady output under the most severe vibration. This transducer may only be used

with the A

pex Modular Positioning System (A.M.P.S.)

The Apex 5100 is designed to NEMA 4 specifications. It requires only 6 volts minimum DC power, enabling

series operation with other devices on 24 VDC current loops.

The I/P housing is constructed of durable die-cast aluminum and treated with a dichromate undercoat and

polyester powder top coat for protection against the toughest applications in all process industries including:

1. Chemical and Petro-Chemical

2. Power

3. Food and Beverage

4. Pharmaceutical

5. Municipal

6. Wastewater treatment

APEX 5100 Current-to-Pressure Transducers

(I/P Modules)

Flowserve Corporation 1350 N. Mountain Springs Parkway 1978 Foreman Dr.

Flow Control Division Springville, Utah 84663-3004 Cookeville, TN 38501

www.flowserve.com Phone: 801 489 8611 Phone: 931 432 4021

Page 2

PS0003-CV (CVAUTO-200) 05/03 Page: 2 of 4

© 2003, Flowserve Corporation, Printed in USA

Automax Valve Automation Systems

Product Specification

Flowserve Corporation 1350 N. Mountain Springs Parkway 1978 Foreman Dr.

Flow Control Division Springville, Utah 84663-3004 Cookeville, TN 38501

www.flowserve.com Phone: 801 489 8611 Phone: 931 432 4021

Features:

1. RFI immunity to both externally radiated RF and cable-conducted RF is provided by a conductive housing

and signal input filters.

2. Current loop connections are highly accessible and deplugable simplifying installation.

3. LED loop power indication simplifies troubleshooting.

4. Sensors automatically compensate for temperature fluctuations.

5. Internal regulator compensates for supply pressure changes.

6. Pressure feedback for precise output control, regardless of position, even under heavy vibration.

7. Internal zero and span calibration.

8. Integral filter provides initial startup protection against tubing scale or dirt.

Note: the integral filter is not designed to act as a permanent source of clean, dry air.

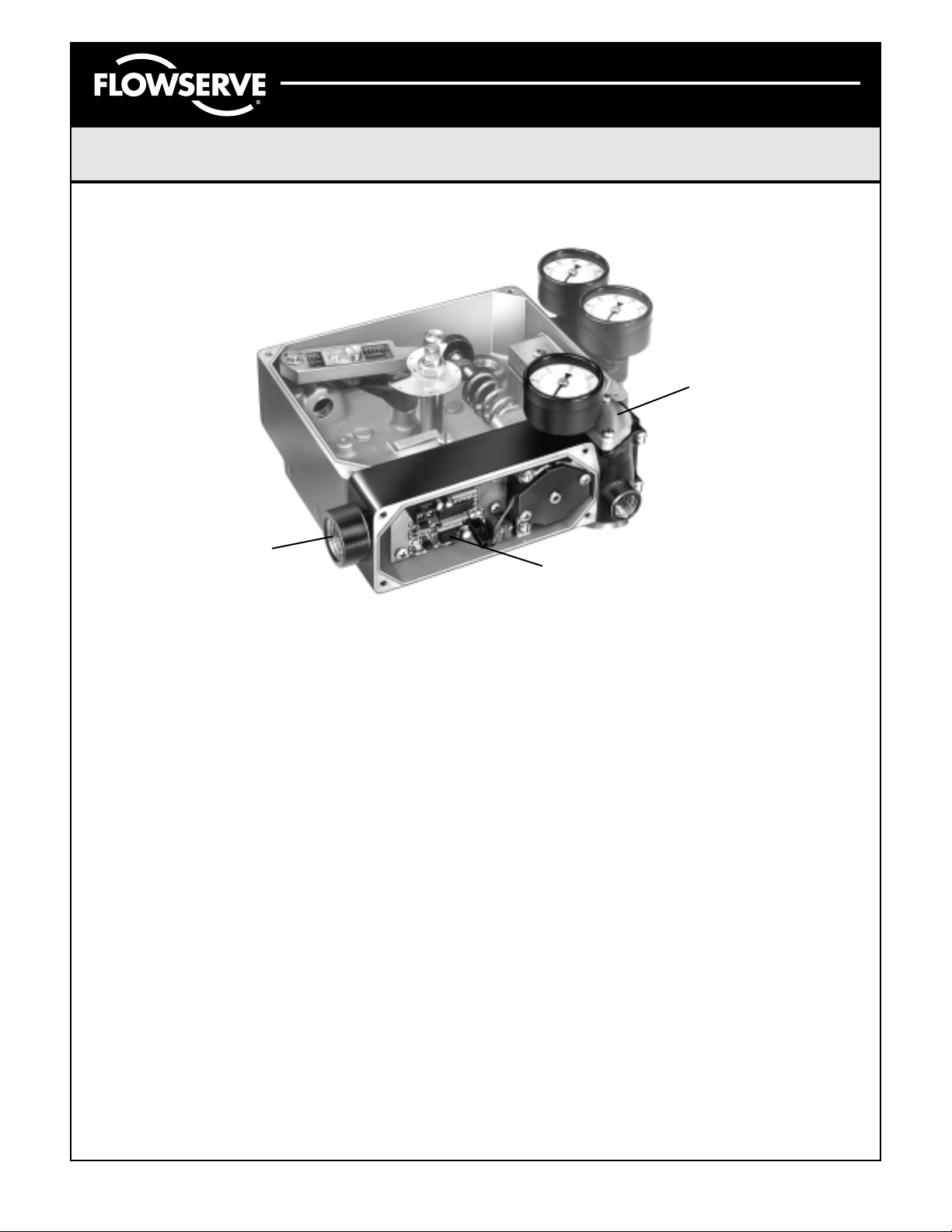

1/2" NPT

Conduit Hub

EMF and RFI

Protected

Built-In

Filter/Regulator

Page 3

PS0003-CV (CVAUTO-200) 05/03 Page: 3 of 4

© 2003, Flowserve Corporation, Printed in USA

Automax Valve Automation Systems

Product Specification

Flowserve Corporation 1350 N. Mountain Springs Parkway 1978 Foreman Dr.

Flow Control Division Springville, Utah 84663-3004 Cookeville, TN 38501

www.flowserve.com Phone: 801 489 8611 Phone: 931 432 4021

Part Materials

Housing/Cover

Anodized Aluminum

w/Dichromate/Powdercoat

Regulator Plated Steel

Regulator and Filter Covers Stainless Steel

Coil/Nozzle Assembly Plated Steel

Coil Retainer Anodized Aluminum

All Fasteners Stainless Steel

All O-ring Seals and Gaskets Nitrile Rubber

Parameter Units Value

Resolution % Full Scale 0.5

Deadband % Full Scale 0.5

Repeatability % Full Scale 0.5

Hysteresis % Full Scale 0.5

Linearity % Full Scale 1

Gain - Low Flow %/% 15-50

High Flow %/% 30-110

Max Flow %/% 50-150

Supply Pressure Effect %/1 PSIG 0.05

Supply Pressure Range PSIG 30-120

Air Consumption SCFM 0.3

Ambient Temp. Range Degrees F -40 to 180

Temperature Effect %/1 Deg. F 0.5

Input Signal mA 4-20

Signal Voltage VDC 6-30

Materials of Construction: Performance Specs:

Apex 5000 w/ 5100 I/P Module

Dimensions: Apex 5000 w/ 5100 I/P Module

Optional NAMUR Shaft

1.120

0.156

0.50

0.155 FLATS

ALIGNMENT SCREW

Page 4

PS0003-CV (CVAUTO-200) 05/03 Page: 4 of 4

© 2003, Flowserve Corporation, Printed in USA

Automax Valve Automation Systems

Product Specification

The Apex 5100 I/P Module converts 4-20 mA current signals into 3-15 psi pneumatic signals needed by the

Apex 5000 Positioner. A controller card compares the input signal with an electrical pressure feedback signal

and outputs voltage, which is applied to a coil.

The coil voltage varies a magnetic field strength which influences a metallic diaphragm. This diaphragm

throttles air flow out of the positioner input chamber (supplied by the internal regulator). As voltage and field

strength increase, the diaphragm moves closer to the coil nozzle, reducing air flow and increasing positioner

input chamber pressure.

The controller circuit board features temperature compensation and input signal filtration to provide accurate

3-15 psi output signals.

Principles of Operation:

Representative:

Flowserve Corporation 1350 N. Mountain Springs Parkway 1978 Foreman Dr.

Flow Control Division Springville, Utah 84663-3004 Cookeville, TN 38501

www.flowserve.com Phone: 801 489 8611 Phone: 931 432 4021

AMBIENT

TEMP

SENSOR

REGULATOR

XMTR

AMP

DRIVE

AMP

INPUT

AMP

RFI

FILTER

Loading...

Loading...