Fisher & Paykel WH8560J1, WH8560P1, WH8060P1, WH7560J1, WH7560P1 Service Manual

479646

Service Manual

Front Load Washer

Models:

WH8560P1

WH8560J1

WH8060P1

WH7560P1

WH7560J1

479646 - OCTOBER 2014

Fisher & Paykel Appliances Ltd

78 Springs Road

East Tamaki

Auckland 2013

PO Box 58-546, Botany

Auckland 2163

New Zealand

Phone: 09 273 0600

Fax: 09 273 0656

Email: customer.care@fp.co.nz

Fisher & Paykel Customer Services Pty Ltd

PO Box 798, Cleveland, QLD 4163

A.C.N. 003 3335 171

19 Enterprise Street

Cleveland, QLD 4163

Australia

Telephone: (07) 3826 9100

Facsimile: (07) 3826 9164

E-mail: customer.care@fp.com.au

Fisher & Paykel Singapore Pte Ltd

150 Ubi Avenue 4

#03-01A

Ubi Biz-hub

Singapore 408825

Telephone: +65 65470100

Facsimile: +65 65470123

COPYRIGHT FISHER & PAYKEL LTD 2014 - ALL RIGHTS RESERVED

2

The specifications and servicing procedures outlined in this manual are subject to change without notice.

The latest version is indicated by the reprint date and replaces any earlier editions

PRODUCT

Brand

Product Code

Model

Fisher & Paykel

92141

92142

92136

92137

93161

95141

95142

95108

95109

WH8560P1 FP AA

WH8560J1 FP AA

WH7560P1 FP AA

WH7560J1 FP AA

WH8060P1 FP AA

WH8560P1 FP SG

WH8560J1 FP SG

WH7560P1 FP SG

WH7560J1 FP SG

479646

3

CONTENTS

1 HEALTH & SAFETY ................................................................................................................................ 5

2 SPECIFICATIONS ................................................................................................................................... 6

2.1 Product Dimensions ............................................................................................................................ 6

2.2 Product weight .................................................................................................................................... 6

2.3 Water Rating ....................................................................................................................................... 6

2.4 Energy Rating ..................................................................................................................................... 7

2.5 Noise Rating ........................................................................................................................................ 7

2.6 Heating Element .................................................................................................................................. 7

2.7 Temperature Sensor ........................................................................................................................... 7

2.8 Detergent/Softener Dispenser ............................................................................................................ 7

2.9 Wash Motor ......................................................................................................................................... 7

2.10 Water Inlet Valves ............................................................................................................................... 8

2.11 Pressure Sensor ................................................................................................................................. 8

2.12 Drain Pump ......................................................................................................................................... 8

2.13 Door Lock ............................................................................................................................................ 8

2.14 Flood Protection .................................................................................................................................. 8

2.15 Motor EMI Filter ................................................................................................................................... 8

2.16 EMI Filter Capacitor ............................................................................................................................ 8

2.17 Product Finish ..................................................................................................................................... 9

2.18 Drain Filter ........................................................................................................................................... 9

3 SERIAL LABEL ..................................................................................................................................... 10

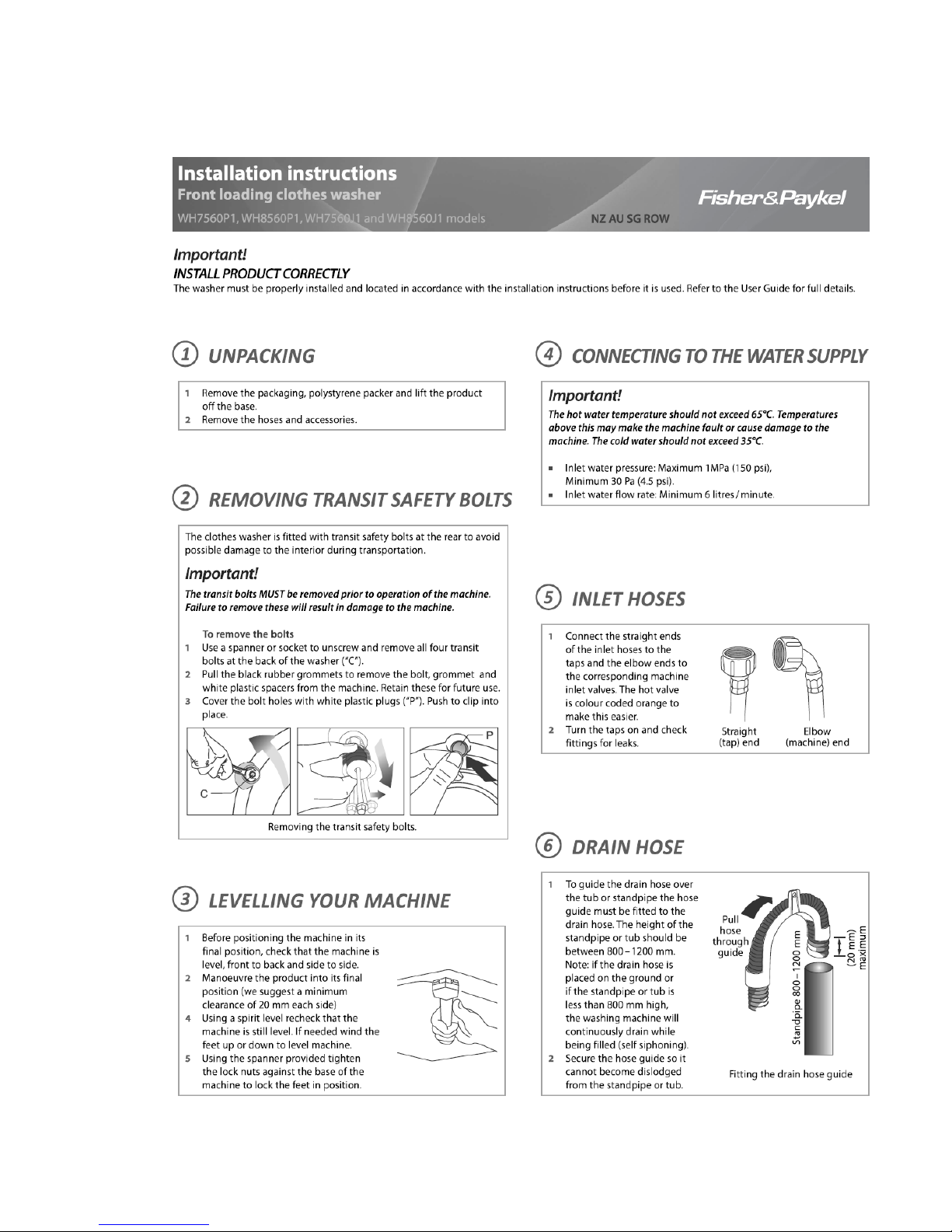

4 INSTALLATION ..................................................................................................................................... 11

4.1 Water Connection ............................................................................................................................. 12

4.2 Levelling ............................................................................................................................................ 12

4.3 Drain Hose ........................................................................................................................................ 12

5 OPERATION .......................................................................................................................................... 13

5.1 Control Panel Layout ......................................................................................................................... 13

5.2 Power off Memory Function .............................................................................................................. 14

5.3 Operating Modes ............................................................................................................................... 14

5.3.1 Drain Pump ................................................................................................................................ 14

5.3.2 Filling With Water ...................................................................................................................... 14

5.3.4 Add a Garment (P models only) ................................................................................................ 14

5.3.5 End of Cycle .............................................................................................................................. 14

5.4 Wash Progress Display ..................................................................................................................... 14

6 WASH PROGRAMS .............................................................................................................................. 15

6.1 Wash Program Chart ........................................................................................................................ 15

7 SERVICING PROCEDURES ................................................................................................................. 17

7.1 Component Location ......................................................................................................................... 17

7.2 Dis-assembly Procedure ................................................................................................................... 18

7.2.1 Removal of Top Panel ............................................................................................................... 18

7.2.2 Removal of Rear Cover ............................................................................................................. 18

7.2.3 Removal of Kick Panel .............................................................................................................. 19

7.2.4 Removal of Cabinet Bellows Clamp .......................................................................................... 19

7.2.5 Removal of Control Panel ......................................................................................................... 19

7.2.6 Replacing the Display Module ................................................................................................... 20

7.2.7 Removal of the front Panel ........................................................................................................ 20

7.2.8 Removal of the Drum Assembly ................................................................................................ 21

7.2.9 Replacing Drum Vane ............................................................................................................... 22

7.2.10 Removal of the Door Lock ......................................................................................................... 22

7.2.11 Removal of the Door ................................................................................................................. 23

7.2.12 Pump Blockages........................................................................................................................ 23

7.2.13 Removal of the Drain Pump ...................................................................................................... 23

7.2.14 Removal of Water Valves .......................................................................................................... 24

7.2.15 Removal of the Heater .............................................................................................................. 24

7.2.16 Removal of the Rotor ................................................................................................................ 25

7.2.17 Removal of the Stator ................................................................................................................ 25

7.2.18 Removal of the Motor Controller ............................................................................................... 26

479646

4

8 WIRING DIAGRAM & COMPONENT RESISTANCES .........................................................................27

9 CONNECTOR LAYOUT .........................................................................................................................28

10 MODEL/SIZE SETTING .........................................................................................................................29

11 DIAGNOSTIC MODE .............................................................................................................................30

11.1 Self Test ........................................................................................................................................... 30

11.2 Water Valve Tests ............................................................................................................................ 31

11.3 Drum Rotation Test .......................................................................................................................... 31

11.4 Door Lock Test ................................................................................................................................. 31

11.5 Heater Test ....................................................................................................................................... 31

12 SHOW ROOM MODE ............................................................................................................................32

13 FAULT CODES ......................................................................................................................................33

13.1 Fault Code Flow Charts .................................................................................................................... 34

13.1.1 Door Open .................................................................................................................................34

13.1.2 No Tap .......................................................................................................................................35

13.1.3 Err 7:00 ......................................................................................................................................36

13.1.4 Err 7:01 ......................................................................................................................................37

13.1.5 Err 7:02 ......................................................................................................................................38

13.1.6 Err 7:03 ......................................................................................................................................39

13.1.7 Err 7:04 ......................................................................................................................................40

13.1.8 Err 7:06 ......................................................................................................................................41

13.1.9 Err 7:07 ......................................................................................................................................42

13.1.10 Err 7:08 ......................................................................................................................................43

13.1.11 Err 7:09 ......................................................................................................................................44

13.1.12 Err 10 .........................................................................................................................................45

13.1.13 Err 12 .........................................................................................................................................46

13.1.14 Err 37 .........................................................................................................................................47

13.1.15 Err 74 .........................................................................................................................................48

13.1.16 Err 75 .........................................................................................................................................49

13.1.17 Err 105 .......................................................................................................................................50

13.1.18 Err 235 .......................................................................................................................................51

13.2 Trouble Shooting Flow Charts .......................................................................................................... 52

13.2.1 Unit Will Not Power Up ..............................................................................................................52

13.2.2 No Water ....................................................................................................................................53

13.2.3 Not Draining ...............................................................................................................................54

13.2.4 Abnormal Noise and Vibration ...................................................................................................55

13.2.5 Leaking Water ............................................................................................................................56

14 DIAGNOSTICS LEVELS ........................................................................................................................57

15 SOLVING OPERATING PROBLEMS ...................................................................................................60

15.1 Wash Cycle Time Variations ............................................................................................................ 60

15.2 Detergent/Fabric Softener Remaining in the Dispenser .................................................................. 60

15.3 Washing Comes out Very Wet at Cycle End .................................................................................... 60

16 SOLVING WASH PROBLEMS ..............................................................................................................61

16.1 Creasing ........................................................................................................................................... 61

16.2 Poor Soil Removal ............................................................................................................................ 61

16.3 Dye Transfer ..................................................................................................................................... 61

16.4 Black or Grey Marks on Washing ..................................................................................................... 61

16.5 Tangling ............................................................................................................................................ 61

479646

5

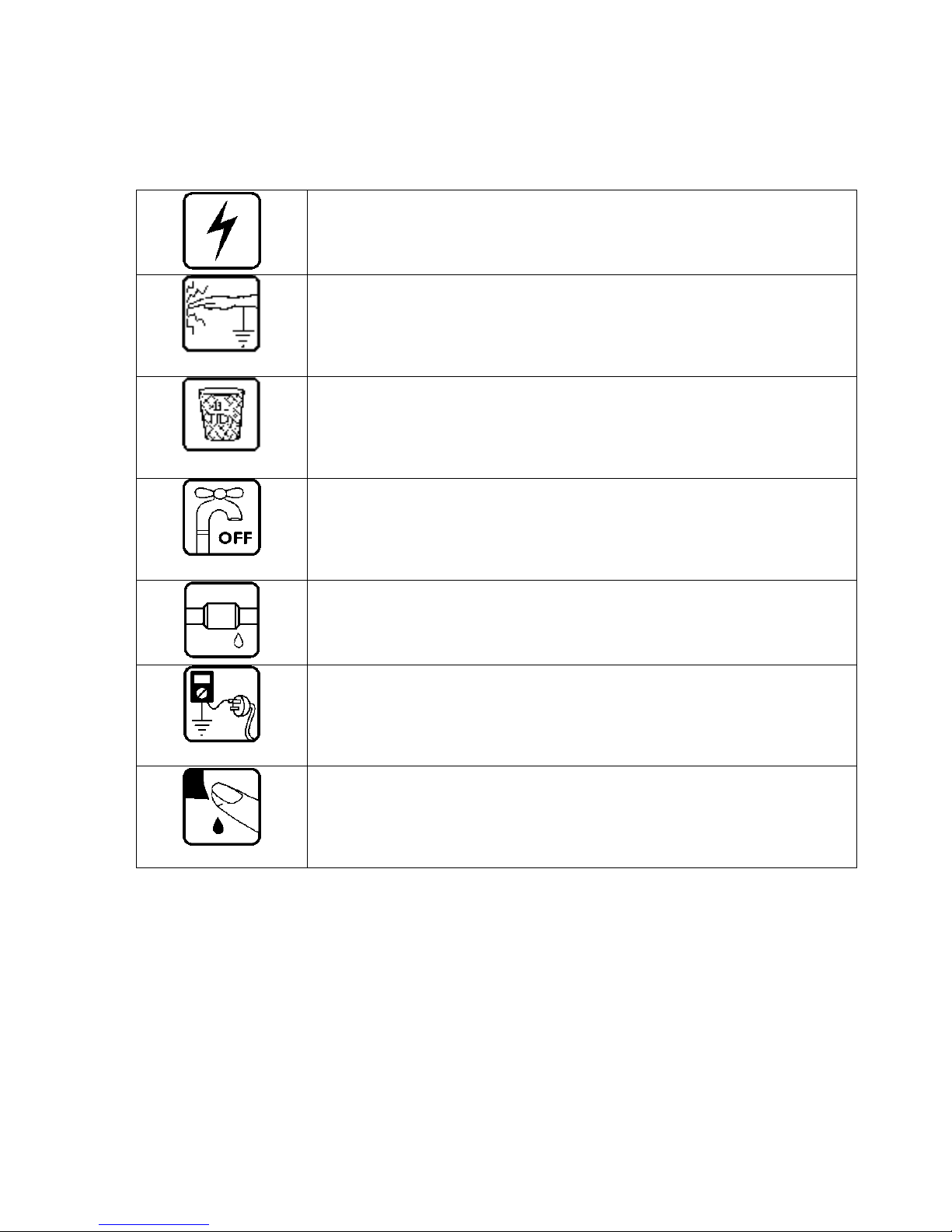

1 HEALTH & SAFETY

When servicing the washer, health & safety issues must be considered at all times. Specific safety issues are

listed below with the appropriate icon.

Electrical Safety

Ensure the mains power has been disconnected before servicing the washer.

If the mains supply is required to be on to service the washer, make sure it is

turned off when removing any electrical component or connection to avoid electric

shock.

Electrostatic Discharge

An anti-static strap is to be used as electrical static discharge (ESD) protection

when servicing electronic components.

Good Working practices

Ensure the work area is in a tidy and orderly condition at all times so as not to

cause a hazard while service work is being completed. Always clean and tidy the

washer and work area after service is completed.

Isolate Water Supply

Turn off the water connection tap before servicing

Water Leak Check

Check for water leaks as part of the testing after the service has been completed.

Insulation test

Megger test to check insulation

Warning: short together the phase and neutral pins on the plug so not to damage

any electronic circuitry.

Sharp Metal Edges

When working around cut sheet metal edges, use appropriate gloves or protection

to eliminate the change of receiving a laceration.

479646

6

2 SPECIFICATIONS

2.1 Product Dimensions

Model

Width

Depth

Height

WH8560

600mm

650mm

850mm

WH8060

600mm

650mm

850mm

WH7560

600mm

590mm

850mm

2.2 Product weight

Model

Kgs

WH8560

69

WH8060

69

WH7560

69

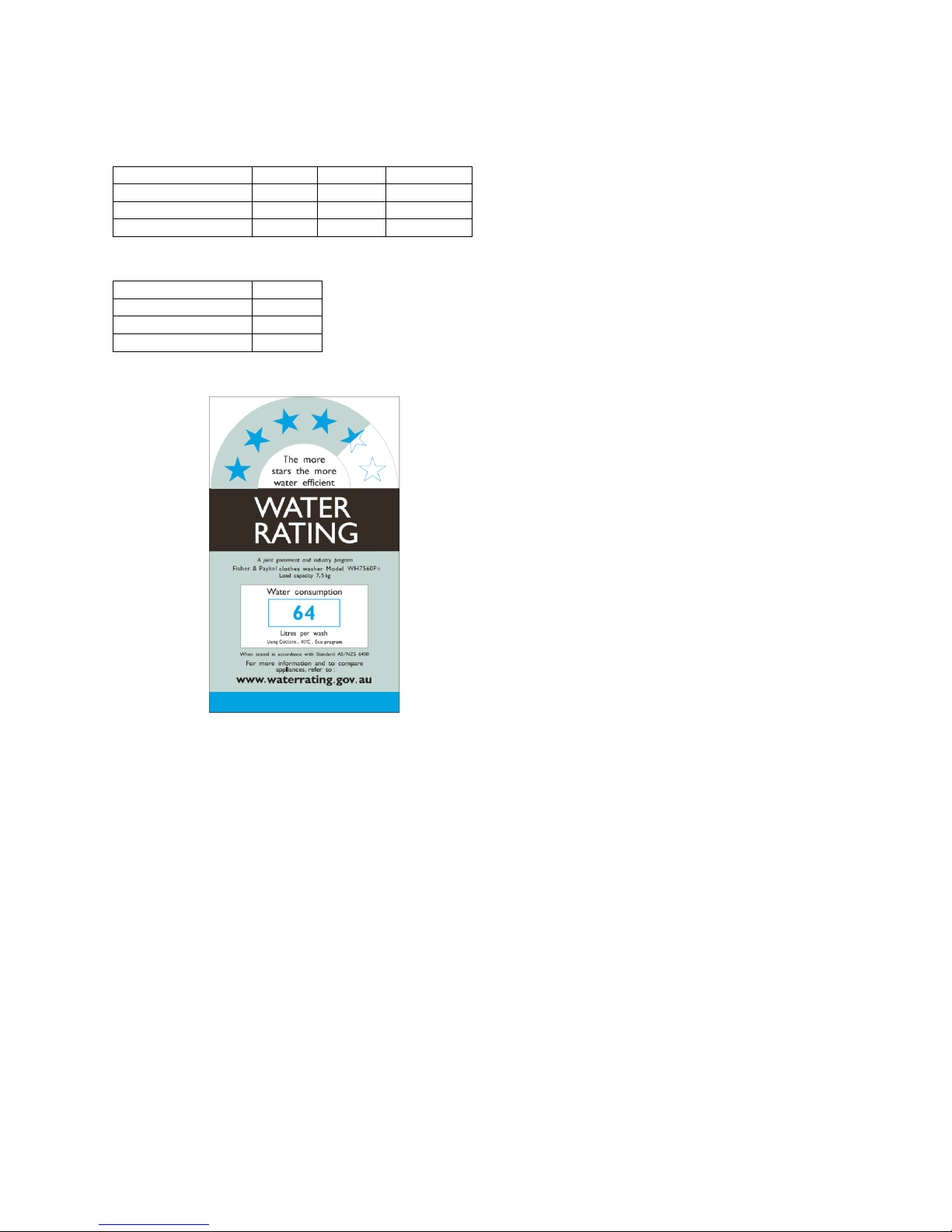

2.3 Water Rating

4.5 Star Water rating using the Cotton 40OC cycle.

479646

7

2.4 Energy Rating

220V - 240V AC, 50Hz, 2000W, 10Amp maximum

4 Star rating

2.5 Noise Rating

72 dB

2.6 Heating Element

1800 Watts.

Resistance 30Ω.

Overheat protection thermal link 167OC.

2.7 Temperature Sensor

NTC type: Reduces in resistance as temperature rises.

Resistance 13K Ω @ 25 oC.

2.8 Detergent/Softener Dispenser

Compartments: There are three: Prewash, Main Wash and Softener

Pre Wash and Main wash are for powder detergent only DO NOT USE LIQUIDS.

2.9 Wash Motor

Electronically commutated 27 pole direct drive 3 phase brushless DC motor.

Motor Resistance @20oC (68oF): 14.5Ω +/- 10% (28Ω +/- 1.95Ω phase to phase).

479646

8

2.10 Water Inlet Valves

Cold Valve dual type.

Hot valve single type.

220V – 240V AC 50Hz.

Resistance 4 KΩ +/- 5%.

Cold maximum inlet temperature 35OC.

Hot maximum inlet temperature 65OC.

2.11 Pressure Sensor

The machine is fitted with a pressure sensor, which controls the fill to any water level. The pressure sensor

is a stand alone component which is replaceable and is connected to the tub air chamber via the pressure

tube.

2.12 Drain Pump

220V – 240V AC 50Hz.

Total power 30W.

Resistance 212 Ω.

Pump out rate 15litres/min.

Overheat protection thermal link 105OC.

2.13 Door Lock

Type Solenoid Activated.

With mechanical release.

Resistance Terminal 2 & 3 190Ω 10%.

Nominal Voltage Terminal 2&3 230V.

2.14 Flood Protection

Pressure sensor activated.

The drain pump will run when pressure switch is activated and fault code 12 will be displayed.

2.15 Motor EMI Filter

Inductor – 7.8mH

2.16 EMI Filter Capacitor

X Capacitor 0.47uF

Y Capacitor 470nF

L Inductor > 4mH

479646

9

2.17 Product Finish

Cabinet - sheet metal powder coated.

Inner drum - stainless steel.

Outer tub – plastic.

Outer door frame – plastic.

Inner door – glass.

Front panel – plastic.

Kick panel – plastic.

Detergent dispenser – plastic.

2.18 Drain Filter

Recommended to be cleaned once a month.

Open the filter compartment cover in the lower right hand corner and unhook the pump outlet hose

pulling it out (about 150mm), remove the plug and drain residual water into a shallow dish.

Replace the plug into the hose and refit hose back into housing.

Remove filter by turning counter-clockwise.

Flush clean with running water.

Refit it the reverse procedure

479646

10

3 SERIAL LABEL

The serial label is located on the front panel top centre of the door porthole.

.

The last 9 digits of serial number indicate where manufactured, date of manufacture and sequential number.

CR D 2 G 0001

CR= Manufacture code 0959= Product number

D= Year 2013 G= 16th Day

2= 2nd Month

Year

2013

2014

2015

2016

2017 D E F G

H

Month

Jan

Feb

Mar

Apr

May

Jun

Jul

Aug

Sep

Oct

Nov

Dec

1 2 3 4 5 6 7 8 9 A B

C

Day

1 2 3 4 5 6 7 8 9

10

11

12

13

14

15

1 2 3 4 5 6 7 8 9 A B C D E F

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31 G H J K L M N P Q R S T U V W X

479646

11

4 INSTALLATION

479646

12

4.1 Water Connection

Hot & cold inlet valves.

30 kPa (4.3PSI) Minimum water pressure.

1000 kPa (145PSI) Maximum water pressure.

4.2 Levelling

50mm Adjustment height

Level within – 2 degrees side to side & front to back.

4.3 Drain Hose

1.2M Length of standard hose

2.5M Max length if extended

1200mm Max pump from floor

800mm Minimum

479646

13

5 OPERATION

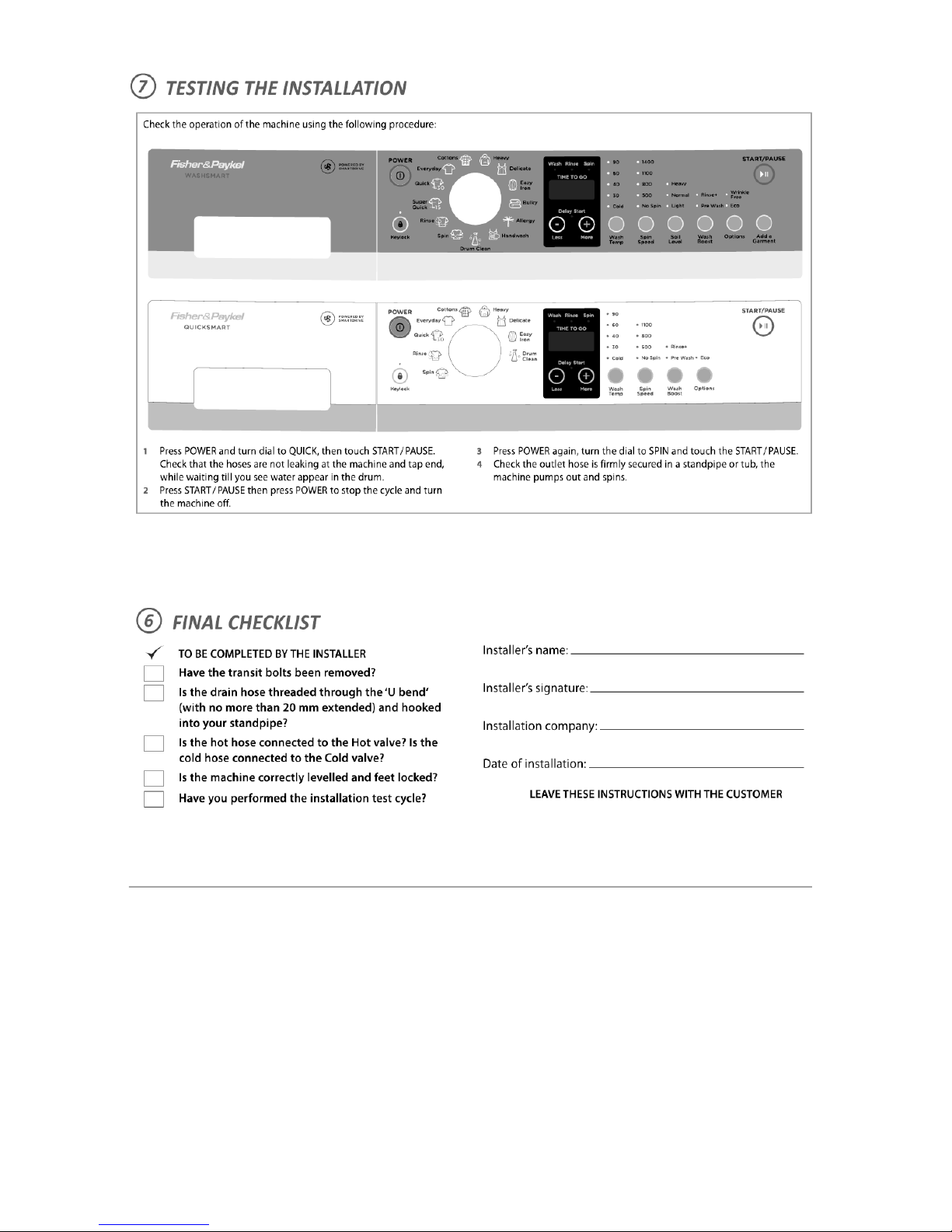

5.1 Control Panel Layout

WH8560J1/WH75J1 (QuickSmart)

Power Button

Used to switch washer on and off.

Key Lock

Activated and deactivated by pressing the KEY LOCK button for 2 seconds. Once activated, the light above

the button is illuminated.

Program Knob

Rotary action with up to 13 programs dependent on model.

Delay Start

Enables delay of the the start of the wash cycle from between 5 minutes and 12 hours. To program the

delay start time simply use the MORE button to increase and the LESS button to decrease the time or

to turn the delay start off.

Display Screen

Displays the remaining wash time, user warning, any error messages and wash progress.

Wash Temperature

Used to select wash temperatures which are adjustable from cold to 90 oC but is dependent on wash cycle

selected.

Spin Speed

Used to select desired spin speed between no spin and 1400 rpm but is dependent on model and the wash

cycle selected.

Soil Level (P models only)

Used for adjusting the wash to suit the amount of soil in the load. Heavy for dirty clothes, Light for lightly

soiled clothes. These adjust the wash time accordingly.

Wash Boost

Allows the selection of an extra rinse (Rinse +) to the program and/or a Pre Wash for extra dirty loads.

WH85/7560P1 (WashSmart) WH8060P1

479646

14

Options

Press this button to select the ECO and Wrinkle free functions.

Wrinkle free (P models only) is for loads that are not going to be removed after the completion of the wash

cycle and will tumble the clothes every 15 minutes for up to 12 hours.

The ECO function saves energy and water. This function reduces the wash temperature slightly and

increase the wash time by approximately 10 minutes.

Add a Garment (P models only)

Used to add or remove items during the wash stage of the cycle under certain conditions. It will only operate

during the wash cycle and if the wash temperature is less than 60OC.

Start/ Pause

Press this button to start the selected wash cycle. Operation can be paused at any time by pressing the

button. The display will begin to blink and the operation will stop. To continue, press the button again.

5.2 Power off Memory Function

The machines have a built in memory function. If the power goes off, the washing machine will remember

the current settings and place in the wash cycle. It will automatically return to the same place in the cycle

and continue when the power is restored.

5.3 Operating Modes

5.3.1 Drain Pump

The filter of the drain pump requires cleaning approximately once a month. The pump will automatically

activate if the machine over fills.

5.3.2 Filling With Water

The machine fills with a combination of cold & hot water for the main wash e.g. Cotton 60, with the rinse

being of cold water.

5.3.3 Washing and Heating

When the wash requires a wash temperature that is greater than the mixed inlet temperature, the machine

heats the water with an on board element. The temperature is subject to the program selection and is

monitored by the temperature sensor.

5.3.4 Add a Garment (P models only)

This function is only available during a wash cycle with a selected wash temperature below 60 degrees.

When the ADD A GARMENT button is activated, the machine will pause and the start/pause LED will flash.

The pump will turn on and pump out some of the wash water if the level is above the door seal. To continue

the wash, press the start/pause button.

5.3.5 End of Cycle

At the end of cycle the machine stops automatically with the screen displaying the word END.

5.4 Wash Progress Display

The display has LED indicators that illuminate as the machine progresses through each of the steps of the

cycle: Wash, Rinse and Spin.

479646

15

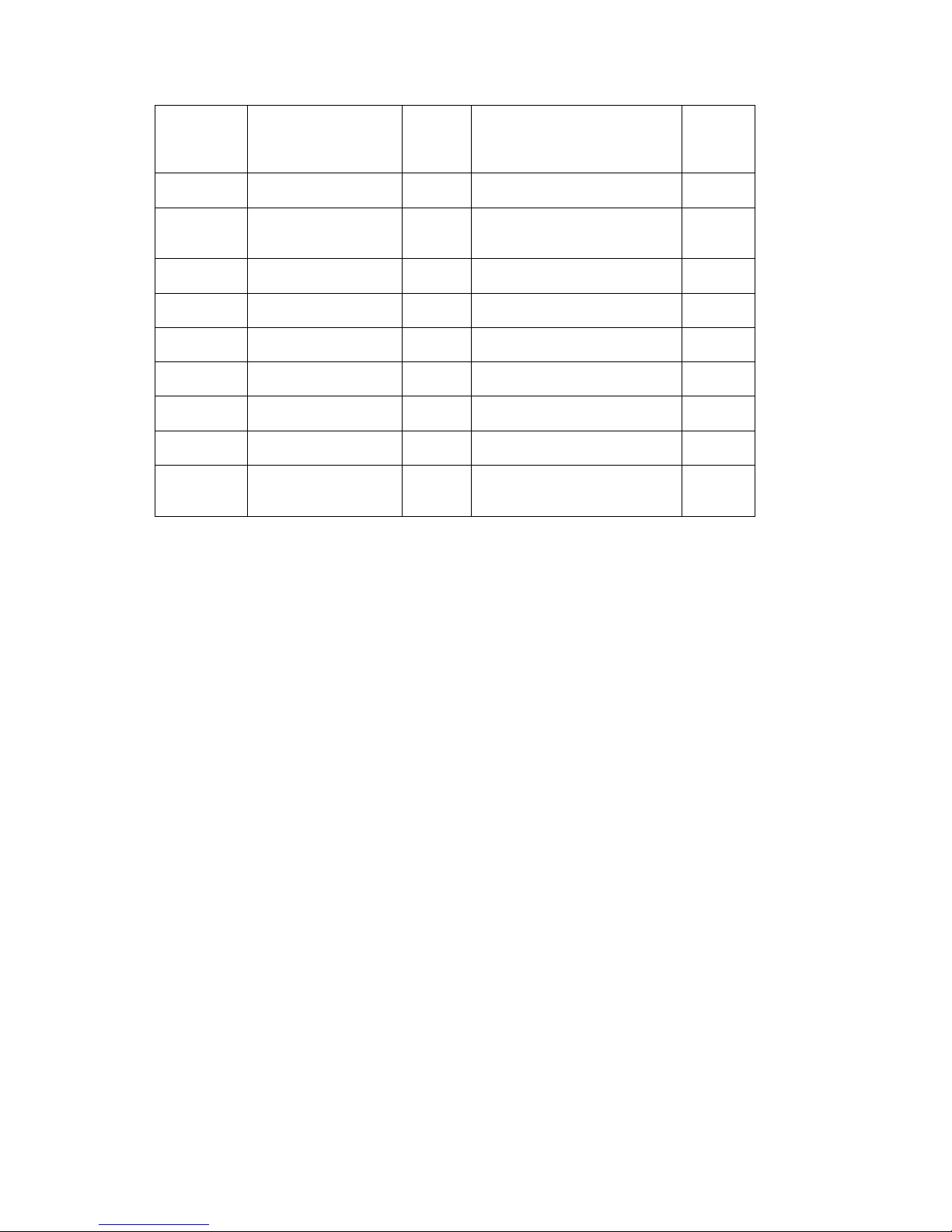

6 WASH PROGRAMS

6.1 Wash Program Chart

WASHSMART

Cycle

Designed for

Max.

Load

size

(Kg)*

Default Setting

Default

Cycle

Time

Cottons**

Normally Soiled

everyday cotton loads

7.5 , 8.0

or 8.5

1400 rpm

40OC

2:17

Everyday

Normally or lightly

soiled everyday

items

7.5, 8.0

or 8.5

1400 rpm

40OC

1:00

Heavy

Heavy soiled durable

garments

7.5, 8.0

or 8.5

1400 rpm

60OC

2:10

Delicate

Delicate lightly soiled

items

4

500 rpm

40OC

0:45

Easy Iron

Minimising creasing

4

800 rpm

40OC

1:04

Bulky

Washing bulky items

4

800 rpm

40OC

1:50

Allergy

Asthma sufferers &

people with skin

sensitivities

7.5, 8.0

or 8.5

1400 rpm

60OC

2:30

Handwash

Very delicate lightly

soiled garments

2

500 rpm

30OC

0:45

Quick

Lightly soiled

garments

4

800 rpm

40OC

0:30

Super

Quick

Freshening up small

musty or lightly

soiled items

2

800 rpm

40OC

0:15

Rinse

Items that require

rinsing only

7.5, 8.0

or 8.5

1400 rpm

Cold

0:25

Spin

Spinning of wet

items

7.5, 8.0

or 8.5

1400 rpm

N/A

0:12

Basket

Clean

Maintaining the

cleanliness of your

washer

N/A

1400 rpm

90OC

0:59

* Depends on your model of washer (7.5kg or 8.5 kg capacity).

** Cottons, 40

o

C, 1400rpm, normal soil level and Eco option selected is the recommended water and

energy saving cycle for normally soiled, everyday washing.

479646

16

QUICKWASH

Cycle

Designed for

Max.

Load

size

(Kg)*

Default Setting

Default

Cycle

Time

Cottons**

Normally Soiled

everyday cotton loads

7.5 or

8.5

1100 rpm

40OC

2:17

Everyday

Normally or lightly

soiled everyday

items

7.5 or

8.5

1100 rpm

40OC

1:00

Heavy

Heavy soiled durable

garments

7.5 or

8.5

1100 rpm

60OC

2:10

Delicate

Delicate lightly soiled

items

4

500 rpm

40OC

0:45

Easy Iron

Minimising creasing

4

800 rpm

40OC

1:04

Quick

Lightly soiled

garments

4

800 rpm

40OC

0:30

Rinse

Items that require

rinsing only

7.5 or

8.5

1100 rpm

Cold

0:25

Spin

Spinning of wet

items

7.5 or

8.5

1100 rpm

N/A

0:12

Basket

Clean

Maintaining the

cleanliness of your

washer

N/A

1100 rpm

90OC

0:59

* Depends on your model of washer (7.5kg or 8.5 kg capacity).

** Cottons, 40 oC, 1100rpm, normal soil level and Eco option selected this is the recommended water and

energy saving cycle for normally soiled, everyday washing.

479646

17

7 SERVICING PROCEDURES

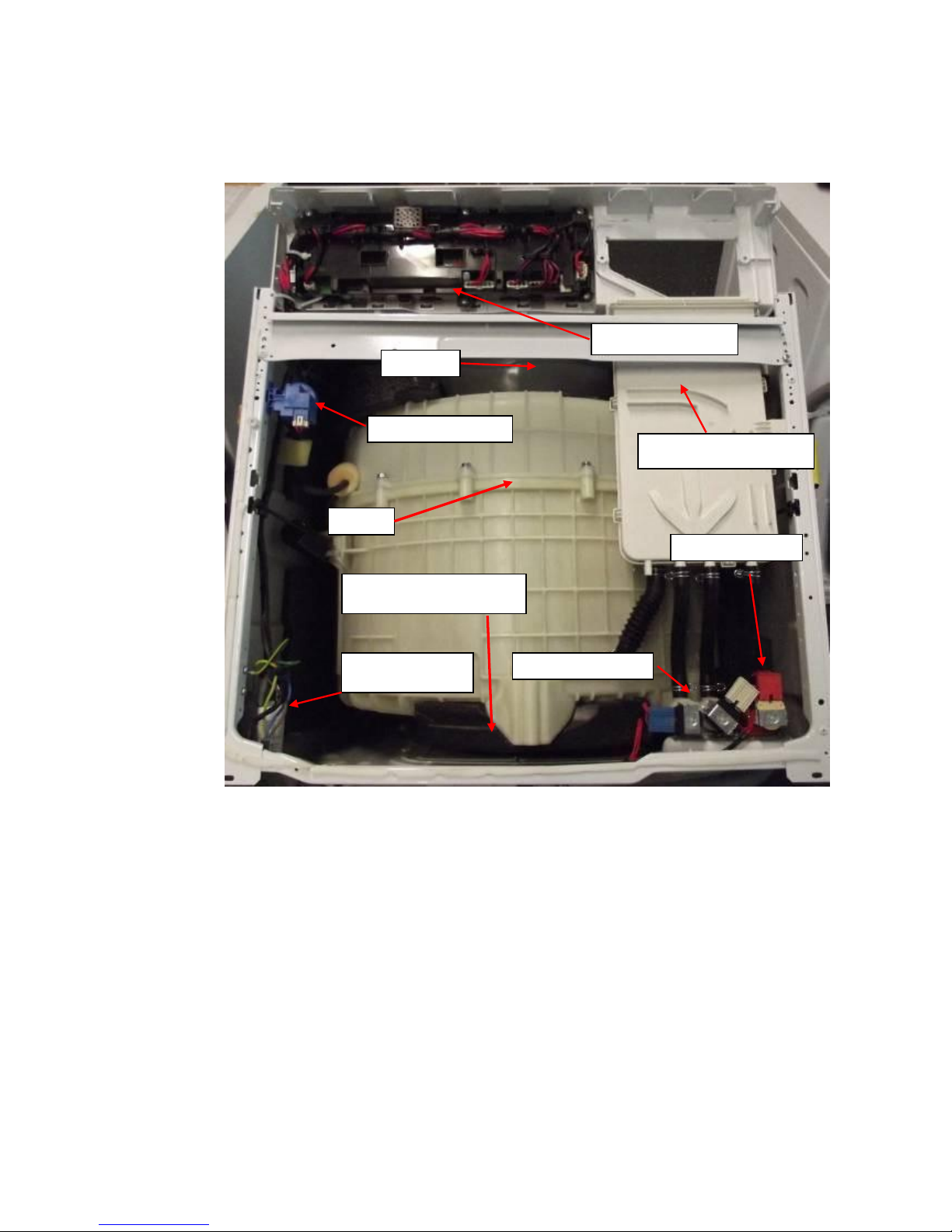

7.1 Component Location

Pressure Sensor

Detergent Dispenser

Cold inlet valves

Hot inlet valve

RFI Capacitor

Tub

Upper Counter weight

Bellows

Display Module

479646

18

7.2 Dis-assembly Procedure

7.2.1 Removal of Top Panel

1. Remove the 2 self-tapping screws securing

the top panel to the rear of the cabinet. Slide

the top panel toward the rear to clear the

side locators and then upwards to take off.

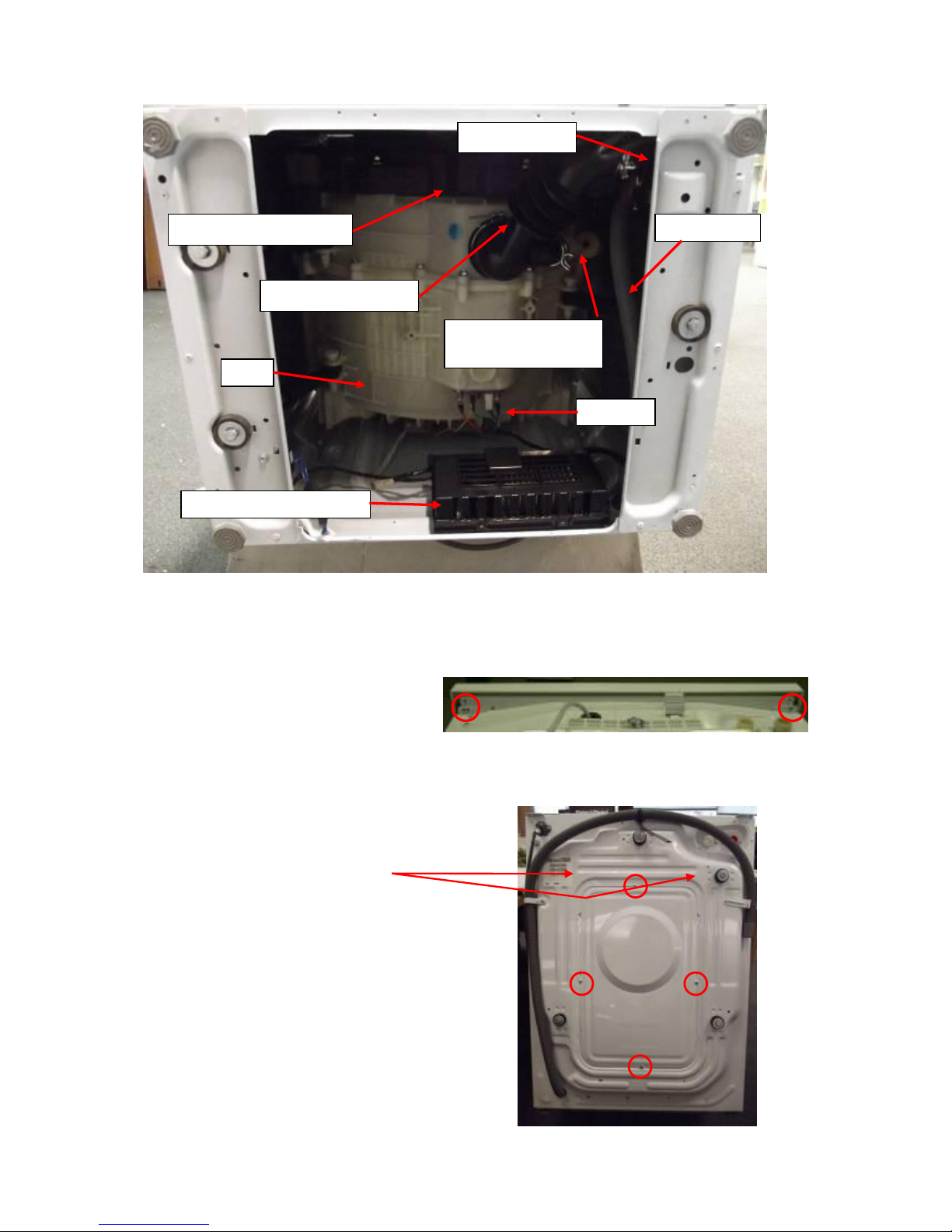

7.2.2 Removal of Rear Cover

1. Remove 4 self-tapping screws holding the rear

cover to the rear of the cabinet.

2. To remove the rear cover, slide it down and out

from the locating slots.

Reassemble in the reverse order.

Drain Pump

Tub to Pump Hose

Air chamber for

pressure sensor

Motor controller module

Heater

Front counter weights

Drain Hose

Tub

479646

19

7.2.3 Removal of Kick Panel

1. To remove the kick panel, open the pump cover

and drain the pump of any water (refer to

Section 2.18).

2. Remove the screw.

3. Carefully unclip the kick plate from its locking

clips.

NB. If too tight to free, then remove the base panel

and release the 5 clips from the inside of the front

panel.

Reassemble in the reverse order

7.2.4 Removal of Cabinet Bellows Clamp

1. Undo the screw holding the clamp in position.

2. Unhook the wire clamp to separate and remove.

3. Remove bellows from cabinet.

Reassemble in the reverse order

7.2.5 Removal of Control Panel

1. Follow the procedure for removal of top panel

(refer to Section 7.2.1).

2. Remove dispenser drawer by pressing down on

the area indicated by the word push on the

siphon inside the dispenser.

3. Remove the 2 screws securing the control panel

to the dispenser housing.

4. Remove the 2 screws securing the top edge of

the control panel to the cabinet.

5. Remove the control panel from the front of the

cabinet. Lift up to release the locating spigots

then forward to clear the dispenser housing.

6. Remove the wiring harness from the display

module.

Reassemble in the reverse order.

Loading...

Loading...