Fisher Management of Change Guide: Replacement of Fisher 685 Actuators with Fisher 785C Double-Acting Springless Actuators Manuals & Guides

Page 1

Management of Change Guide

May 2019

D352798X012

Replacement of Fisher™ 685 Actuators with

Fisher™ 785C Double-Acting Springless Actuators

Table of Contents

Management of Change ..................................2

Background ....................................................2

Question & Answer Checklist ..........................2

Comparison of Fisher 785C and 685 Actuators 5

Basic Design and Features ................................................... 5

Weight ............................................................................... 7

Envelope Dimensions ......................................................... 7

Conclusion ......................................................9

Page 2

Management of Change

Management of Change (MOC) is a procedure used to proactively manage changes

that have the potential to impact safety or the process within a plant. Evaluating

new techniques for improving MOC approval procedures can have an impact on

plant efciency. Historically, upgrading obsolete products or replacing existing

process control equipment had been delayed or abandoned due to the extensive

paperwork involved in completing a complex MOC approval sheet.

Background

The Fisher 785C Series is a double-acting springless or single-acting or doubleacting spring-return actuator that provides accurate, high thrust output for up

to 610 mm (24 inch) travel sliding-stem valve applications. The purpose of this

document is to simplify the transition from existing double-acting springless piston

actuator technologies to the Fisher 785C double-acting springless actuator.

Contained in this guide are two sections, the rst contains questions and answers

and the second compares the Fisher 785C actuator to the Fisher 685 actuator.

The rst section helps users complete MOC approval documents when replacing

existing actuators with the 785C model. The second section helps users better

understand the differences and similarities between the 785C and the 685 actuator.

MOC: Fisher 685 to 785C Actuators

May 2019

D352798X012

Question & Answer Checklist

Q: Does the proposed modication cause any changes to the piping and

1

2

3

4

instrumentation diagram (P&ID)?

A: No.

Q: Does the proposed modication change process chemistry,

technology, or operating and control philosophies?

A: No.

Q: Does the proposed modication change how the existing plant is

operated?

A: No.

Q: Does the proposed modication change process ows?

A: No.

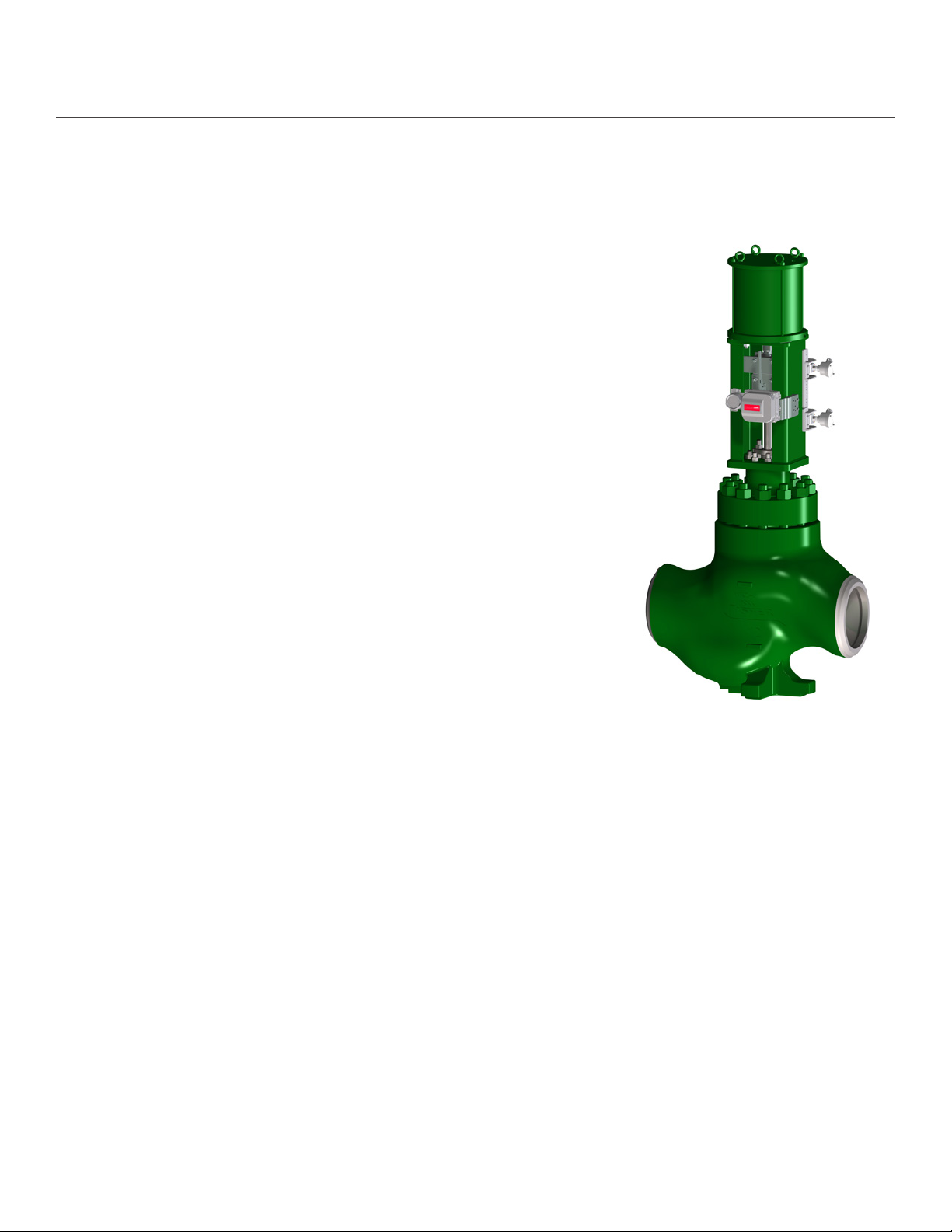

Figure 1. Fisher 785C double-acting

springless actuator

2

Page 3

Q: Does the proposed modication change existing pressure relief cases?

5

A: No.

Q: Does the proposed modication change the process description?

6

A: No.

Q: Have the codes and standards to which the new equipment was

7

8

designed changed?

A: No.

Q: Does the proposed modication change the materials of construction,

such as a change in material form (cast, forged, or alloy)?

A: No. The plant can specify the materials of constructions as desired.

MOC: Fisher 685 to 785C Actuators

May 2019

D352798X012

Q: Does the proposed modication introduce new equipment items that

9

10

11

12

require periodic predictive maintenance?

A: No. The new equipment items will require the same periodic

predictive maintenance required by the old equipment items.

Q: Does the proposed modication change existing operator training

requirements?

A: No. Please refer to the instruction manual when performing

maintenance on the Fisher 785C actuator.

Q: Does the proposed modication introduce new equipment items

that require spare parts, training manuals, maintenance procedures

or training to teach the maintenance department how to maintain

them?

A: Yes, however the new equipment items have the same theory of

operation and maintenance procedures as the old equipment items.

Documentation for training and maintenance can be obtained in the

instruction manual or by contacting your local Emerson sales ofce.

Q: Does the proposed modication introduce new equipment items that

require spares or obsolete spares for existing equipment?

A: Yes. Spares for old equipment items cannot be used with new

equipment items due to differences in dimensions. Documentation

on recommended spares can be obtained by providing the two serial

numbers, located on the actuator, to your local Emerson sales ofce.

3

Page 4

Q: Does the proposed modication permanently remove the spares for

13

14

15

16

existing pieces of equipment?

A: No.

Q: Does the proposed modication change the inspection scope or

inspection interval?

A: No.

Q: Does the proposed modication require welding work to be

performed?

A: No.

Q: Have the materials of construction been reviewed to ensure that the

metallurgy is correct?

A: No.

MOC: Fisher 685 to 785C Actuators

May 2019

D352798X012

4

Page 5

Comparison of Fisher 785C and Fisher 685

Actuators

Even though the Fisher 785C and 685 actuators have identical theories of operation,

there are certain key differences and advantages in the design and feature set of

the 785C actuator. This section provides insight on the differences and similarities

between these two actuators.

Basic Design and Features

The 785C actuator has the same theory of operation, valve-to-actuator mounting

type, and valve stem connection diameters as the 685 actuator. The 785C actuator

can also be mounted and installed onto the same valves that the 685 actuator

is available for and currently installed on. Tables 1, 2, 3 and 4 provide side-byside comparisons of design specications, instrument compatibility, materials of

construction, and certications between the 785C and 685 actuators.

MOC: Fisher 685 to 785C Actuators

May 2019

D352798X012

Specication

Fisher 785C Actuator

(1)

Fisher 685 Actuator

(1)

Actuator Type Double-Acting Piston for Sliding Stem (Globe) Valves

Yoke Boss Diameter 5, 5H, or 7 inch 5H or 7 inch

Valve Stem

Connection

Manual Override

Capability

Top Mounted Handwheel (280 - 385)

1, 1 1/4, or 2 inch 1 1/4 or 2 inch

Manual Handpump (435 - 685)

Side Mounted Handwheel

Cylinder Diameter 280 to 685 mm (11 to 27 inches) 304 to 660 mm (12 to 26 inches)

Travel 25 to 609.6 mm (1 to 24 inches) 25 to 610 mm (1 to 24 inches)

Operating Pressure 2.7 to 12 bar (40 to 174 psig) 2.7 to 10.3 bar (40 to 150 psig)

Operating

Temperature Limits

(2)

Thrust

Standard: -20 to 100°C (-4 to 212°F)

Low Temp: -60 to 100°C (-76 to 212°F)

High Temp: -20 to 200°C (-4 to 392°F)

1600 KN (359,000 lbs.) 354 KN (79,639 lbs.)

Standard: -40 to 93°C (-40 to 200°F)

Low Temp: -54 to 93°C (-65 to 200°F)

High Temp: -29 to 204°C (-20 to 400°F)

Pressure Connections 3/4, 1/2, 1, or 1 1/4 NPT 3/4, 1, or 1 1/4 NPT

1. Representative of standard constructions

2. Thrust varies depending on supply pressure, cylinder diameter, and stroke direction (push or pull). Values listed are for the push stroke

direction.

Table 1. Design specications comparison

5

Page 6

MOC: Fisher 685 to 785C Actuators

May 2019

D352798X012

Instrument

Fisher 785C Actuator Fisher 685 Actuator

Compatible (Yes/No)

Fisher FIELDVUE™ DVC6000 Series Positioners No Yes

Fisher FIELDVUE DVC6200 Series Positioners Yes Yes

Fisher 2625 Volume Booster Yes Yes

Fisher SS-263 Volume Booster No (Available by Request) Yes

Fisher 377 Trip Valve Yes Yes

TopWorx™ GO Switch™ Position Sensor Yes Yes

Table 2. Instrument compatibility comparison

Part Fisher 785C Actuator Fisher 685 Actuator

Yoke Carbon Steel Carbon Steel

Piston Carbon Steel Carbon Steel

Cylinder Carbon Steel Carbon Steel

Upper/Lower Heads Carbon Steel Carbon Steel

Tie Bolt Carbon Steel or Stainless Steel Carbon Steel

Piston Rod Stainless Steel Stainless Steel

Stem Connector Carbon Steel or Stainless Steel Carbon Steel

Nameplate and

Travel Scale

Table 3. Materials of construction comparison for standard temperature range

Stainless Steel —

Certication Fisher 785C Actuator Fisher 685 Actuator

PED PED 2014/68/EU PED (97/23/EC)

ATEX ATEX Group II Category 2 Gas and Dust ATEX Group II Category 2 Gas and Dust

SIL

CUTR

Table 4: Certications comparison

Customs Union Technical Regulations

(CUTR) 010/2011 and 012/2011

Safety Instrumented System,

SIL 3 Capable

Customs Union Technical Regulations (CUTR)

Safety Instrumented System,

SIL 2 Capable

010/2011 and 012/2011

6

Page 7

Weight

See Table 5 for side-by-side comparisons of design weight without manual override

between the Fisher 785C and 685 actuators. For complete weight comparisons

check the Fisher 785C product bulletin and Fisher 685 product bulletin.

Fisher 785C Actuator Fisher 685 Actuator

Cylinder Size, mm (inch) Weight

280 (11) 142 (313)

335 (13) 173 (381)

385 (15) 240 (529)

435 (17) 283 (624)

485 (19) 325 (717) 508 (20) 430 (947)

535 (21) 373 (822) 558 (22) 505 (1114)

585 (23) 490 (1080) 609 (24) 702 (1548)

635 (25) 561 (1237) 660 (26) 804 (1771)

685 (27) 660 (1455) — —

1. Representative of actuator without handwheel.

2. Representative of actuator with 5H yoke boss.

(1,2)

, kg (lbs.) Cylinder Size, mm (inch) Weight

Cylinder sizes not available for maximum travel of

203 mm (8 inch)

MOC: Fisher 685 to 785C Actuators

May 2019

D352798X012

(1,2)

, kg (lbs.)

Table 5: Weight comparison

Envelope Dimensions

Refer to Tables 6, 7, and 8 with Figure 2 for a comparison of envelope dimensions

between the 785C and 685 actuators.

Width, mm (Inches)

785C Size 485 (19) 685 Size 508 (20) 785C Size 535 (21) 685 Size 558 (22)

Without Manual

Override

Table 6: Width envelope dimensions

Travel, mm

(inch)

785C Size 485 (19.09) 685 Size 508 (20) 785C Size 535 (21.06) 685 Size 558 (22)

102 (4) 767 (30.20) 754 (29.69) 798 (31.42) 754 (29.69)

203 (8) 952 (37.48) 941 (37.06) 994 (39.13) 941 (37.06)

Table 7: Height envelope dimensions for actuators with 5H yoke boss diameter

630 (25) 591 (23) 680 (27) 654 (26)

Height for a 127 mm (5H) Yoke Boss Diameter, mm (inches)

Without Manual Override

7

Page 8

MOC: Fisher 685 to 785C Actuators

May 2019

D352798X012

Travel, mm

(inch)

Without Manual Override

785C Size 485 (19.09) 685 Size 508 (20) 785C Size 535 (21.06) 685 Size 558 (22)

102 (4) 797 (31.38) 786 (30.94) 799 (31.46) 786 (30.94)

203 (8) 1028 (79.84) 1018 (40.06) 1030 (40.55) 1018 (40.06)

Table 8: Height envelope dimensions for actuators with 7 yoke boss diameter

Height for a 178 mm (7 inch) Yoke Boss Diameter, mm (inches)

Figure 2: Fisher 785C Double-Acting Springless

Without Manual Override Actuator

8

Page 9

on dark backgroundson light backgrounds

standard

no gradients

watermark

stacked logo (for sharing only)

standard

no gradients

watermark

stacked logo (for sharing only)

Conclusion

Introducing the Fisher 785C actuator in addition to the Fisher 685 actuator will not

affect Fisher 685 actuators currently installed in plants. The Fisher 785C actuator

offers new sizes and features in addition to the previous 685 actuator offerings and

will offer at least the same application coverage range as the 685 actuators.

Please contact your local Emerson sales ofce for additional details or questions

regarding Fisher 785C actuators.

MOC: Fisher 685 to 785 Actuators

May 2019

D352798X012

Visit Fisher.com to

nd an Emerson sales

contact in your area.

http://www.Facebook.com/FisherValves

http://www.Twitter.com/FisherValves

Emerson Automation Solutions

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Cernay, 68700 France

Dubai, United Arab Emirates

Singapore 128461 Singapore

http://www.YouTube.com/user/FisherControlValve

http://www.LinkedIn.com/groups/Fisher-3941826

© 2019 Fisher Controls International LLC. All rights reserved.

Fisher, FIELDVUE, TopWorx, and GO Switch are marks owned by one of the companies in the Emerson

Automation Solutions business unit of Emerson Electric Co. Emerson and the Emerson logo are

trademarks and service marks of Emerson Electric Co. All other marks are the property of their

respective owners.

The contents of this publication are presented for informational purposes only, and while every

effort has been made to ensure their accuracy, nothing herein is to be construed as a warranty

or guarantee, express or implied, regarding the products or services described herein or their

use, performance, merchantability or tness for a particular purpose. Individual results may vary.

All sales are governed by our terms and conditions, which are available upon request. We reserve

the right to modify or improve the designs or specications of our products at any time without

notice. Responsibility for proper selection, use and maintenance of any product or service remains

solely with the purchaser and end user.

Loading...

Loading...