Page 1

#

FANUC AC SPINDLE MOTOR @* series

FANUC AC SPINDLE MOTOR

PARAMETER MANUAL

* series

B-65280EN/05

Page 2

• No part of this manual may be reproduced in any form.

• All specifications and designs are subject to change without notice.

In this manual we have tried as much as possible to describe all the various matters.

However, we cannot describe all the matters which must not be done, or which cannot be

done, because there are so many possibilities.

Therefore, matters which are not especially described as possible in this manual should be

regarded as ”impossible”.

This manual contains the program names or device names of other companies, some of

which are registered trademarks of respective owners. However, these names are not

followed by or in the main body.

Page 3

B-65280EN/05 DEFINITION OF WARNING, CAUTION, AND NOTE

DEFINITION OF WARNING, CAUTION, AND NOTE

This manual includes safety precautions for protecting the user and

preventing damage to the machine. Precautions are classified into

Warning and Caution according to their bearing on safety. Also,

supplementary information is described as a Note. Read the Warning,

Caution, and Note thoroughly before attempting to use the machine.

WARNING

Applied when there is a danger of the user being

injured or when there is a damage of both the user

being injured and the equipment being damaged if

the approved procedure is not observed.

CAUTION

Applied when there is a danger of the equipment

being damaged, if the approved procedure is not

observed.

NOTE

The Note is used to indicate supplementary

information other than Warning and Caution.

- Read this manual carefully, and store it in a safe place.

s-1

Page 4

Page 5

B-65280EN/05 PREFACE

PREFACE

This manual describes the parameters and functions of the FANUC

servo amplifier αi/βi series spindle. This manual is divided into four

parts and appendix. Part I describes the αi series spindle, Part II

describes the βi series spindle, Part III describes the αCi series spindle,

and Part IV describes the Bis series spindle.

Unless otherwise noted, the parameter numbers for FANUC Series 16i

are used in the text. When using any other model, reference the

corresponding parameter numbers.

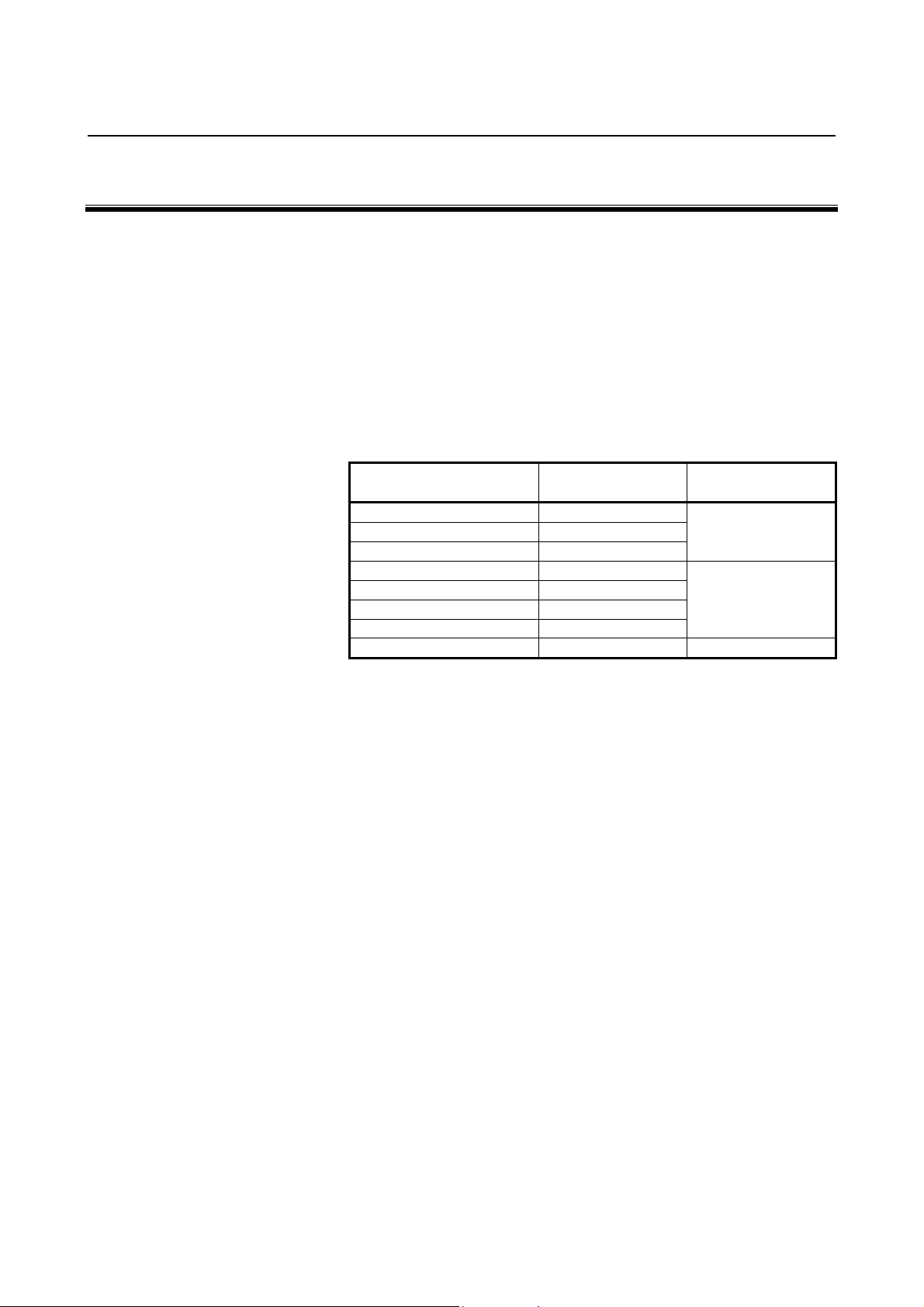

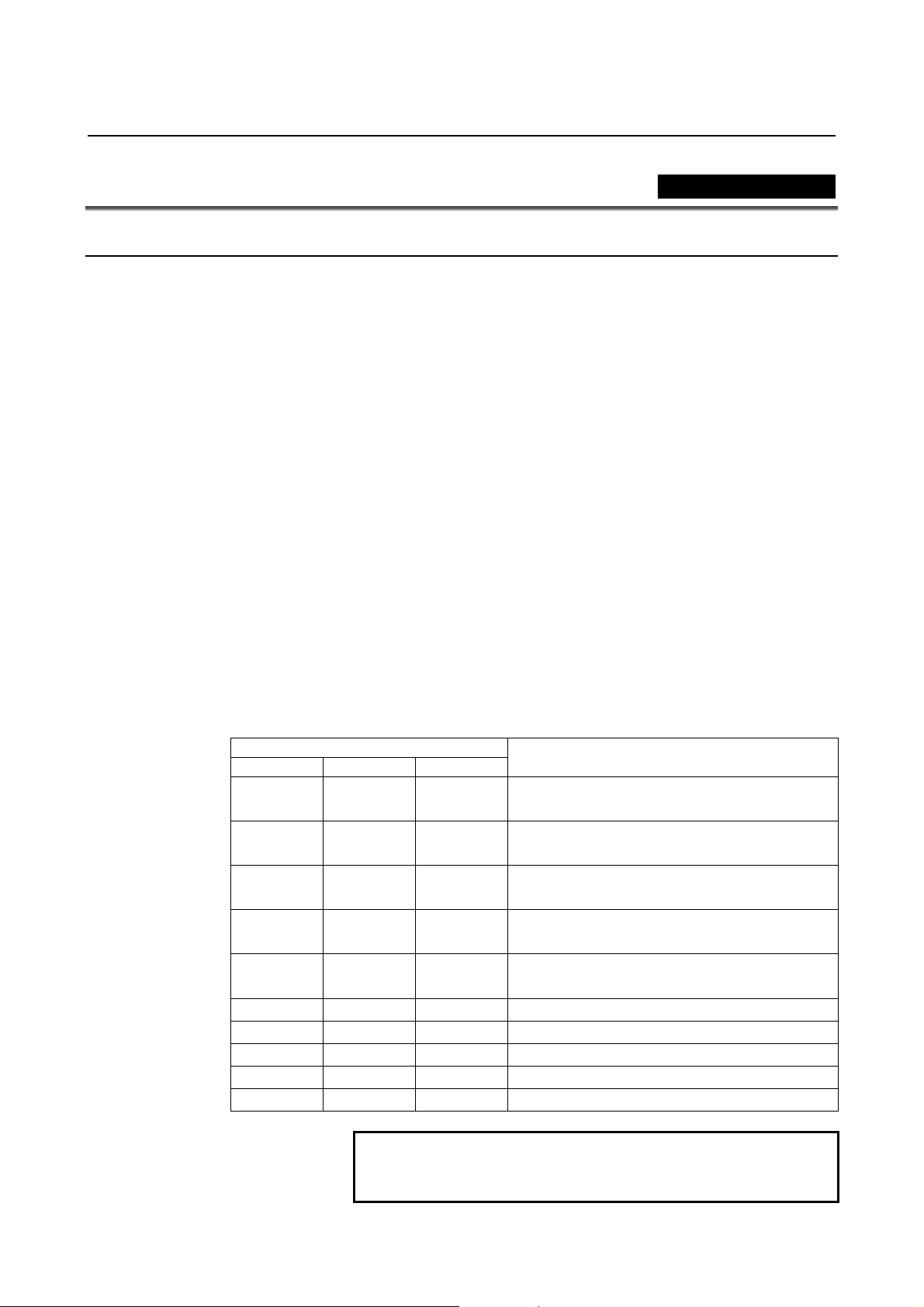

The table below indicates the abbreviated model names used with the

parameter numbers.

Product name

FANUC Series 30i Series 30i

FANUC Series 31i Series 31i

FANUC Series 32i Series 32i

FANUC Series 16i Series 16i

FANUC Series 18i Series 18i

FANUC Series 21i Series 21i

FANUC Series 0i Series 0i

FANUC Series 15i Series 15i 15i

Abbreviated model

name in text

For detailed information indicating which model each function

described in this manual can be used with, refer to the manual of each

CNC. For the package specifications, in particular, refer to the CNC

manual.

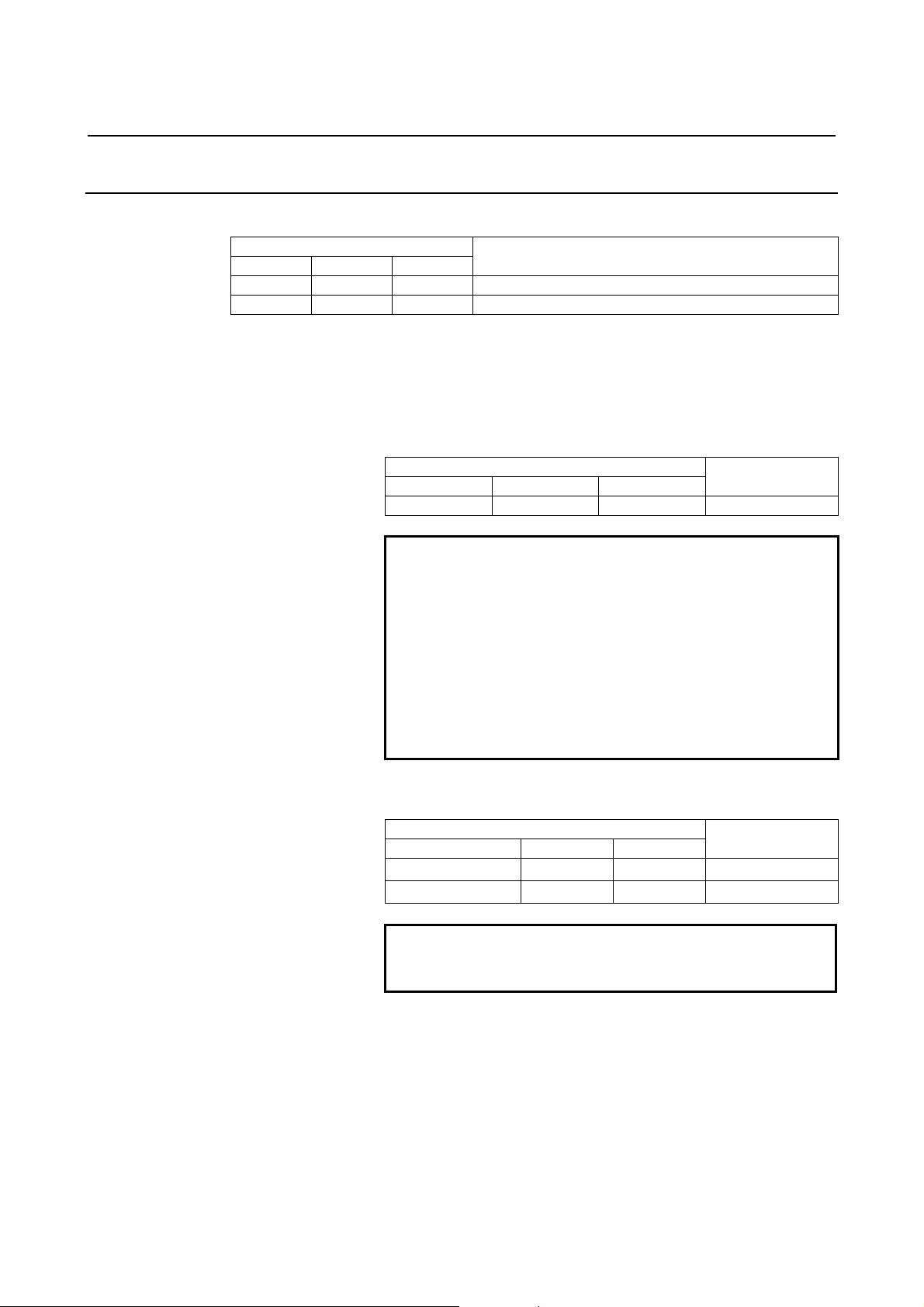

The manuals related to the αi/βi series spindle are listed below.

(1) FANUC AC SPINDLE MOTOR αi series DESCRIPTIONS

(B-65272EN)

(2) FANUC AC SPINDLE MOTOR αCi series DESCRIPTIONS

(B-65372EN)

(3) FANUC AC SPINDLE MOTOR βi series DESCRIPTIONS

(B-65312EN)

(4) FANUC SERVO AMPLIFIER αi series DESCRIPTIONS

(B-65282EN)

(5) FANUC SERVO AMPLIFIER βi series DESCRIPTIONS

(B-65322EN)

(6) FANUC SERVO MOTOR αis/αi series,

FANUC SPINDLE MOTOR αi series,

FANUC SERVO AMPLIFIER αi series

MAINTENANCE MANUAL (B-65285EN)

(7) FANUC SERVO MOTOR βis series,

FANUC SPINDLE MOTOR βi series,

FANUC SERVO AMPLIFIER βi series

MAINTENANCE MANUAL (B-65325EN)

Abbreviated model

name in table

30i

16i

p-1

Page 6

PREFACE B-65280EN/05

(8) FANUC AC SPINDLE MOTOR αi/βi series

PARAMETER MANUAL (B-65280EN)

(9) FANUC AC SPINDLE MOTOR αi

(B-65292EN)

B series DESCRIPTIONS

p-2

Page 7

B-65280EN/05 TABLE OF CONTENTS

TABLE OF CONTENTS

DEFINITION OF WARNING, CAUTION, AND NOTE .................................s-1

PREFACE....................................................................................................p-1

I. FANUC AC SPINDLE MOTOR αi series

1 START-UP............................................................................................... 3

1.1 START-UP PROCEDURE............................................................................. 4

1.2 SPINDLE SERIAL INTERFACE (Optional function) ...................................... 5

1.2.1 Parameters Related to Spindle Serial Output ...........................................................5

1.2.2 Automatic Spindle Parameter Initialization .............................................................6

1.2.3 Diagnosis (Diagnosis Screen)...................................................................................7

1.2.4 Alarm ........................................................................................................................8

1.3 PARAMETERS RELATED TO DETECTORS.............................................. 10

1.3.1 List of Parameters for Detectors.............................................................................10

1.3.2 Details of Parameters for Detectors........................................................................12

1.3.3 Typical Detector Configurations ............................................................................21

2 EXPLANATION OF OPERATION MODES........................................... 28

2.1 VELOCITY CONTROL MODE.....................................................................29

2.1.1 Start-up Procedure..................................................................................................29

2.1.2 Overview ................................................................................................................29

2.1.3 System Configuration.............................................................................................29

2.1.4 List of I/O Signals (CNC↔PMC)..........................................................................30

2.1.5 Related Parameters .................................................................................................34

2.1.6 Details of Related Parameters ................................................................................36

2.1.7 Troubleshooting .....................................................................................................46

2.2 POSITION CODER METHOD SPINDLE ORIENTATION

(Optional function) .......................................................................................50

2.2.1 Start-up Procedure..................................................................................................50

2.2.2 Overview ................................................................................................................51

2.2.3 Feature....................................................................................................................51

2.2.4 System Configuration.............................................................................................52

2.2.5 Stop Position Specification Method .......................................................................54

2.2.6 I/O Signals (CNC ↔ PMC) ...................................................................................55

2.2.7 Examples of Sequences ..........................................................................................59

2.2.8 Related Parameters .................................................................................................62

c-1

Page 8

TABLE OF CONTENTS B-65280EN/05

2.2.9 Details of Related Parameters ................................................................................63

2.2.10 Calculating the Position Gain for Orientation ........................................................68

2.2.11 Adjusting the Orientation Stop Position Shift Parameter.......................................69

2.2.12 Calculating the Orientation Time ...........................................................................71

2.3 RIGID TAPPING (Optional function)............................................................ 73

2.3.1 Start-up Procedure..................................................................................................73

2.3.2 Overview ................................................................................................................73

2.3.3 System Configuration.............................................................................................74

2.3.4 List of I/O Signals (CNC ↔ PMC)........................................................................77

2.3.5 Sequence.................................................................................................................79

2.3.6 Related Parameters .................................................................................................80

2.3.7 Details of Related Parameters ................................................................................82

2.3.8 Parameter Setting Procedure ..................................................................................89

2.3.9 Adjustment Procedure ............................................................................................98

2.3.10 Diagnosis (Diagnosis Screen)...............................................................................104

2.3.11 Alarm ....................................................................................................................106

2.4 Cs CONTOURING CONTROL (Optional function) .................................... 109

2.4.1 Start-up Procedure................................................................................................109

2.4.2 Overview ..............................................................................................................110

2.4.3 System Configuration...........................................................................................110

2.4.4 List of I/O Signals (CNC ↔ PMC)......................................................................112

2.4.5 Examples of Sequences ........................................................................................114

2.4.6 Related Parameters ...............................................................................................115

2.4.7 Details of Related Parameters ..............................................................................117

2.4.8 Diagnosis (Diagnosis Screen)...............................................................................126

2.4.9 Alarm ....................................................................................................................126

2.5 SPINDLE SYNCHRONOUS CONTROL (Optional function)...................... 127

2.5.1 Start-up Procedure................................................................................................127

2.5.2 Overview ..............................................................................................................128

2.5.3 System Configuration...........................................................................................129

2.5.4 Explanation of Operation .....................................................................................136

2.5.5 I/O Signals (CNC ↔ PMC) .................................................................................137

2.5.6 Examples of Sequences ........................................................................................141

2.5.7 Related Parameters ...............................................................................................146

2.5.8 Details of Related Parameters ..............................................................................147

2.5.9 Number of Error Pulses in Spindle Synchronous Control....................................155

2.5.10 Specifying a Shift Amount for Spindle Phase Synchronous Control...................156

c-2

Page 9

B-65280EN/05 TABLE OF CONTENTS

2.5.11 Diagnosis (Diagnosis Screen)...............................................................................156

2.5.12 Alarm ....................................................................................................................157

2.6 SPECIFICATIONS COMMON TO ALL OPERATION MODES.................. 158

2.6.1 Overview ..............................................................................................................158

2.6.2 List of I/O Signals (CNC ↔ PMC)......................................................................158

2.6.3 Parameters ............................................................................................................163

2.6.4 Details of Parameters............................................................................................166

2.6.5 Diagnosis (Diagnosis Screen)...............................................................................176

3 I/O SIGNALS (CNC ↔ PMC) ..............................................................178

3.1 INPUT SIGNALS (PMC→CNC→SPM)...................................................... 179

3.1.1 List of Input Signals .............................................................................................179

3.1.2 Explanation of Input Signals ................................................................................180

3.1.3 Details of Input Signals ........................................................................................182

3.2 OUTPUT SIGNALS (SPM→CNC→PMC).................................................. 192

3.2.1 List of Output Signals...........................................................................................192

3.2.2 Explanation of Output Signals .............................................................................193

3.2.3 Details of Output Signals .....................................................................................195

4 ADJUSTMENT .................................................................................... 202

4.1 VELOCITY LOOP GAIN ADJUSTMENT ................................................... 203

4.1.1 Overview ..............................................................................................................203

4.1.2 Parameters ............................................................................................................203

4.1.3 Adjustment Procedure ..........................................................................................206

4.1.4 Additional Information (Position Gain Adjustment)............................................207

4.2 MACHINE RESONANCE ELIMINATION................................................... 208

4.2.1 TCMD Filter.........................................................................................................208

4.2.2 HRV Filter............................................................................................................209

4.2.3 Disturbance Input Function ..................................................................................212

4.3 AMPLITUDE RATIO/PHASE DIFFERENCE COMPENSATION

FUNCTION ................................................................................................ 217

5 FUNCTION DESCRIPTIONS .............................................................. 222

5.1 SPEED RANGE SWITCHING CONTROL (Optional function)................... 223

5.1.1 Overview ..............................................................................................................223

5.1.2 Series and Editions of Applicable Spindle Software............................................223

5.1.3 Configuration .......................................................................................................223

5.1.4 I/O Signals (CNC ↔ PMC) .................................................................................224

5.1.5 Sequence...............................................................................................................228

c-3

Page 10

TABLE OF CONTENTS B-65280EN/05

5.1.6 List of Related Parameters....................................................................................230

5.1.7 Details of Related Parameters ..............................................................................231

5.1.8 Parameter-specified Switching between High- and Low-speed Characteristics ..233

5.2 SPINDLE SWITCHING CONTROL ........................................................... 235

5.2.1 Overview ..............................................................................................................235

5.2.2 Series and Editions of Applicable Spindle Software............................................235

5.2.3 Configuration .......................................................................................................235

5.2.4 Details of Specifications.......................................................................................236

5.2.5 Restrictions...........................................................................................................236

5.2.6 I/O Signals (CNC↔PMC) ...................................................................................237

5.2.7 Sequence...............................................................................................................240

5.2.8 List of Related Parameters....................................................................................242

5.2.9 Details of Related Parameters ..............................................................................242

5.2.10 Parameter Setting Procedure ................................................................................245

5.2.11 Supplementary Descriptions about Parameters ....................................................246

5.3 INCRMENTAL COMMAND TYPE SPINDLE ORIENTATION

(SPINDLE ROTATION SPEED CONTROL) (Optional function)................ 247

5.3.1 Overview ..............................................................................................................247

5.3.2 Series and Editions of Applicable Spindle Software............................................247

5.3.3 System Configuration...........................................................................................248

5.3.4 I/O Signals(CNC↔PMC) ....................................................................................251

5.3.5 Examples of Sequences ........................................................................................253

5.3.6 List of Related Parameters....................................................................................256

5.3.7 Details of Related Parameters ..............................................................................256

5.4 HIGH-SPEED SPINDLE ORIENTATION (Optional function)..................... 257

5.4.1 Overview ..............................................................................................................257

5.4.2 Series and Editions of Applicable Spindle Software............................................257

5.4.3 System Configuration...........................................................................................257

5.4.4 I/O Signals (CNC↔PMC) ...................................................................................260

5.4.5 Sequence...............................................................................................................262

5.4.6 List of Related Parameters....................................................................................265

5.4.7 Details of Related Parameters ..............................................................................266

5.4.8 Spindle Data Used in Tuning ...............................................................................271

5.4.9 Tuning Procedure .................................................................................................272

5.5 SPINDLE ORIENTATION DURING SPINDLE SYNCHRONIZATION

CONTROL (Optional function)................................................................... 278

5.5.1 Overview ..............................................................................................................278

c-4

Page 11

B-65280EN/05 TABLE OF CONTENTS

5.5.2 Series and Editions of Applicable Spindle Software............................................278

5.5.3 Specification.........................................................................................................279

5.5.4 I/O Signals (CNC ↔ PMC) .................................................................................281

5.5.5 Sequence...............................................................................................................285

5.5.6 List of Related Parameters....................................................................................287

5.5.7 Details of Related Parameters ..............................................................................288

5.6 SPINDLE FINE ACC./DEC. (FAD) FUNCTION ......................................... 290

5.6.1 Overview ..............................................................................................................290

5.6.2 Series and Editions of Applicable Spindle Software............................................290

5.6.3 Block Diagram .....................................................................................................291

5.6.4 Parameters ............................................................................................................291

5.6.5 Diagnosis (Diagnosis Screen)...............................................................................293

5.6.6 Status Errors .........................................................................................................293

5.6.7 Cautions................................................................................................................294

5.7 UNEXPECTED DISTURBANCE TORQUE DETECTION FUNCTION

(Optional function) .....................................................................................296

5.7.1 Overview ..............................................................................................................296

5.7.2 Series and Editions of Applicable Spindle Software............................................296

5.7.3 I/O Signals (CNC↔PMC) ...................................................................................297

5.7.4 List of Related Parameters....................................................................................298

5.7.5 Details of Related Parameters ..............................................................................298

5.7.6 Parameter Tuning Procedure ................................................................................300

5.8 SPINDLE EGB (SPINDLE ELECTRONIC GEAR BOX)

(Optional function) .....................................................................................302

5.8.1 Overview ..............................................................................................................302

5.8.2 Series and Editions of Applicable Spindle Software............................................302

5.8.3 System Configuration...........................................................................................303

5.8.4 Block Diagram .....................................................................................................306

5.8.5 I/O Signals (CNC ↔ PMC) .................................................................................307

5.8.6 Examples of Sequences ........................................................................................307

5.8.7 List of Related Parameters....................................................................................308

5.8.8 Details of Related Parameters ..............................................................................309

5.8.9 Diagnosis Signal Related to Spindle EGB ...........................................................312

5.8.10 Status Errors Related to Spindle EGB..................................................................312

5.8.11 Alarms ..................................................................................................................313

5.9 DIFFERENTIAL SPINDLE SPEED CONTROL .........................................314

5.9.1 Overview ..............................................................................................................314

c-5

Page 12

TABLE OF CONTENTS B-65280EN/05

5.9.2 Series and Editions of Applicable Spindle Software............................................314

5.9.3 Configuration .......................................................................................................315

5.9.4 Description ...........................................................................................................316

5.9.5 I/O Signals (CNC↔PMC) ...................................................................................316

5.9.6 Examples of Sequences ........................................................................................317

5.9.7 List of Related Parameters....................................................................................318

5.9.8 Details of Related Parameters ..............................................................................318

5.9.9 Status Errors on Differential Spindle Speed Control ...........................................318

5.10 DUAL POSITION FEEDBACK FUNCTION (Optional function) ................. 319

5.10.1 Overview ..............................................................................................................319

5.10.2 Series and Editions of Applicable Spindle Software............................................319

5.10.3 Block Diagram .....................................................................................................320

5.10.4 List of Related Parameters....................................................................................321

5.10.5 Details of Related Parameters ..............................................................................321

5.10.6 SPM Alarm...........................................................................................................325

5.11 TORQUE TANDEM CONTROL FUNCTION (Optional function) ............... 326

5.11.1 Overview ..............................................................................................................326

5.11.2 Series and Editions of Applicable Spindle Software............................................326

5.11.3 System Configuration...........................................................................................327

5.11.4 I/O Signals (CNC ↔ PMC) .................................................................................329

5.11.5 Examples of Sequences ........................................................................................332

5.11.6 Parameters ............................................................................................................336

5.11.7 Alarm and Status Error.........................................................................................339

5.12 MAGNETIC SENSOR METHOD SPINDLE ORIENTATION

(Optional function) .....................................................................................340

5.12.1 Overview ..............................................................................................................340

5.12.2 Series and Editions of Applicable Spindle Software............................................340

5.12.3 System Configuration...........................................................................................340

5.12.4 I/O Signals (CNC ↔ PMC) .................................................................................341

5.12.5 Sequence...............................................................................................................341

5.12.6 Parameters ............................................................................................................342

II. FANUC AC SPINDLE MOTOR βi series

1 START-UP........................................................................................... 349

1.1 START-UP PROCEDURE ......................................................................... 350

1.2 SPINDLE SERIAL INTERFACE (Optional function) .................................. 351

1.2.1 Parameters Related to Spindle Serial Output .......................................................351

c-6

Page 13

B-65280EN/05 TABLE OF CONTENTS

1.2.2 Automatic Spindle Parameter Initialization .........................................................351

1.2.3 Diagnosis (Diagnosis Screen)...............................................................................352

1.2.4 Alarm ....................................................................................................................352

1.3 PARAMETERS RELATED TO DETECTORS............................................ 353

1.3.1 List of Parameters for Detectors...........................................................................353

1.3.2 Details of Parameters for Detectors......................................................................353

1.3.3 Typical Detector Configurations ..........................................................................354

2 EXPLANATION OF OPERATION MODES......................................... 358

2.1 VELOCITY CONTROL MODE................................................................... 359

2.1.1 Start-up Procedure................................................................................................359

2.1.2 Overview ..............................................................................................................359

2.1.3 System Configuration...........................................................................................359

2.1.4 List of I/O Signals (CNC↔PMC)........................................................................359

2.1.5 Related Parameters ...............................................................................................359

2.1.6 Details of Related Parameters ..............................................................................359

2.1.7 Troubleshooting ...................................................................................................359

2.2 POSITION CODER METHOD SPINDLE ORIENTATION

(Optional function) .....................................................................................360

2.2.1 Start-up Procedure................................................................................................360

2.2.2 Overview ..............................................................................................................360

2.2.3 Feature..................................................................................................................360

2.2.4 System Configuration...........................................................................................360

2.2.5 Stop Position Specification Method .....................................................................362

2.2.6 I/O Signals (CNC ↔ PMC) .................................................................................362

2.2.7 Examples of Sequences ........................................................................................362

2.2.8 Related Parameters ...............................................................................................362

2.2.9 Details of Related Parameters ..............................................................................362

2.2.10 Adjusting the Orientation Stop Position Shift Parameter.....................................362

2.3 RIGID TAPPING (Optional function).......................................................... 363

2.3.1 Start-up Procedure................................................................................................363

2.3.2 Overview ..............................................................................................................363

2.3.3 System Configuration...........................................................................................363

2.3.4 List of I/O Signals (CNC ↔ PMC)......................................................................366

2.3.5 Sequence...............................................................................................................366

2.3.6 Related Parameters ...............................................................................................366

2.3.7 Details of Related Parameters ..............................................................................366

2.3.8 Parameter Setting Procedure ................................................................................366

c-7

Page 14

TABLE OF CONTENTS B-65280EN/05

2.3.9 Adjustment Procedure ..........................................................................................366

2.3.10 Diagnosis (Diagnosis Screen)...............................................................................366

2.3.11 Alarm ....................................................................................................................366

2.4 Cs CONTOURING CONTROL (Optional function) .................................... 367

2.4.1 Start-up Procedure................................................................................................367

2.4.2 Overview ..............................................................................................................367

2.4.3 System Configuration...........................................................................................367

2.4.4 List of I/O Signals (CNC ↔ PMC)......................................................................368

2.4.5 Examples of Sequences ........................................................................................368

2.4.6 Related Parameters ...............................................................................................368

2.4.7 Details of Related Parameters ..............................................................................369

2.4.8 Diagnosis (Diagnosis Screen)...............................................................................370

2.4.9 Alarm ....................................................................................................................370

2.5 SPINDLE SYNCHRONOUS CONTROL (Optional function)...................... 371

2.5.1 Start-up Procedure................................................................................................371

2.5.2 Overview ..............................................................................................................371

2.5.3 System Configuration...........................................................................................372

2.5.4 Explanation of Operation .....................................................................................375

2.5.5 I/O Signals (CNC ↔ PMC) .................................................................................375

2.5.6 Examples of Sequences ........................................................................................375

2.5.7 Related Parameters ...............................................................................................375

2.5.8 Details of Related Parameters ..............................................................................375

2.5.9 Number of Error Pulses in Spindle Synchronous Control....................................375

2.5.10 Specifying a Shift Amount for Spindle Phase Synchronous Control...................375

2.5.11 Diagnosis (Diagnosis Screen)...............................................................................375

2.5.12 Alarm ....................................................................................................................375

2.6 SPECIFICATIONS COMMON TO ALL OPERATION MODES.................. 376

2.6.1 Overview ..............................................................................................................376

2.6.2 List of I/O Signals (CNC ↔ PMC)......................................................................376

2.6.3 Parameters ............................................................................................................376

2.6.4 Details of parameters............................................................................................376

2.6.5 Diagnosis (Diagnosis Screen)...............................................................................376

3 I/O SIGNALS (CNC ↔ PMC) ..............................................................377

3.1 INPUT SIGNALS (PMC→CNC→SVPM) ................................................... 378

3.1.1 List of Input Signals .............................................................................................378

3.1.2 Explanation of Input Signals ................................................................................378

3.1.3 Details of input signals .........................................................................................378

c-8

Page 15

B-65280EN/05 TABLE OF CONTENTS

3.2 OUTPUT SIGNALS (SVPM→CNC→PMC) ............................................... 379

3.2.1 List of Output Signals...........................................................................................379

3.2.2 Explanation of Output Signals .............................................................................379

3.2.3 Details of Output Signals .....................................................................................379

4 ADJUSTMENT .................................................................................... 380

4.1 VELOCITY LOOP GAIN ADJUSTMENT ................................................... 381

4.1.1 Overview ..............................................................................................................381

4.1.2 Parameters ............................................................................................................381

4.1.3 Adjustment Procedure ..........................................................................................381

4.1.4 Additional Information (Position Gain Adjustment)............................................381

5 FUNCTION DESCRIPTIONS .............................................................. 382

5.1 INCRMENTAL COMMAND TYPE SPINDLE ORIENTATION

(SPINDLE ROTATION SPEED CONTROL) (Optional function)................ 383

5.1.1 Overview ..............................................................................................................383

5.1.2 System Configuration...........................................................................................383

5.1.3 I/O Signals (CNC↔PMC) ...................................................................................385

5.1.4 Examples of Sequences ........................................................................................385

5.1.5 List of Related Parameters....................................................................................386

5.1.6 Details of Related Parameters ..............................................................................386

5.2 HIGH-SPEED SPINDLE ORIENTATION (Optional function)..................... 387

5.2.1 Overview ..............................................................................................................387

5.2.2 System Configuration...........................................................................................387

5.2.3 I/O Signals (CNC↔PMC) ...................................................................................388

5.2.4 Sequence...............................................................................................................389

5.2.5 List of Related Parameters....................................................................................390

5.2.6 Details of Related Parameters ..............................................................................391

5.2.7 Spindle Data Used in Tuning ...............................................................................391

5.2.8 Tuning Procedure .................................................................................................391

5.3 SPINDLE FINE ACC./DEC. (FAD) FUNCTION ......................................... 392

5.3.1 Overview ..............................................................................................................392

5.3.2 Series and Editions of Applicable Spindle Software............................................392

5.3.3 Block Diagram .....................................................................................................392

5.3.4 Parameters ............................................................................................................393

5.3.5 Diagnosis (Diagnosis Screen)...............................................................................393

5.3.6 Status Errors .........................................................................................................393

5.3.7 Cautions................................................................................................................393

c-9

Page 16

TABLE OF CONTENTS B-65280EN/05

5.4 UNEXPECTED DISTURBANCE TORQUE DETECTION FUNCTION

(Optional function) .....................................................................................394

5.4.1 Overview ..............................................................................................................394

5.4.2 Series and Editions of Applicable Spindle Software............................................394

5.4.3 I/O Signals (CNC↔PMC) ...................................................................................394

5.4.4 List of Related Parameters....................................................................................394

5.4.5 Details of Related Parameters ..............................................................................394

5.4.6 Parameter Tuning Procedure ................................................................................394

III. FANUC AC SPINDLE MOTOR αCi series

1 START-UP........................................................................................... 397

1.1 START-UP PROCEDURE ......................................................................... 398

1.2 SPINDLE SERIAL INTERFACE (Optional function) .................................. 399

1.2.1 Parameters Related to Spindle Serial Output .......................................................399

1.2.2 Automatic Spindle Parameter Initialization .........................................................399

1.2.3 Diagnosis (Diagnosis Screen)...............................................................................400

1.2.4 Alarm ....................................................................................................................400

1.3 PARAMETERS RELATED TO DETECTORS............................................ 401

1.3.1 List of Parameters for Detectors...........................................................................401

1.3.2 Details of Parameters for Detectors......................................................................402

1.3.3 Typical Detector Configurations ..........................................................................406

2 EXPLANATION OF OPERATION MODES......................................... 408

2.1 VELOCITY CONTROL MODE................................................................... 409

2.1.1 Start-up Procedure................................................................................................409

2.1.2 Overview ..............................................................................................................409

2.1.3 System Configuration...........................................................................................409

2.1.4 List of I/O Signals (CNC↔PMC)........................................................................410

2.1.5 Related Parameters ...............................................................................................414

2.1.6 Details of Related Parameters ..............................................................................415

2.1.7 Troubleshooting ...................................................................................................420

2.2 POSITION CODER METHOD SPINDLE ORIENTATION

(Optional function) .....................................................................................424

2.2.1 Start-up Procedure................................................................................................424

2.2.2 Overview ..............................................................................................................425

2.2.3 Feature..................................................................................................................425

2.2.4 System Configuration...........................................................................................425

2.2.5 Stop Position Specification Method .....................................................................425

c-10

Page 17

B-65280EN/05 TABLE OF CONTENTS

2.2.6 I/O Signals (CNC↔PMC) ...................................................................................426

2.2.7 Examples of Sequences ........................................................................................426

2.2.8 Related Parameters ...............................................................................................427

2.2.9 Details of Related Parameters ..............................................................................428

2.2.10 Adjusting the Orientation Stop Position Shift Parameter.....................................432

2.3 RIGID TAPPING (Optional function).......................................................... 433

2.3.1 Start-up Procedure................................................................................................433

2.3.2 Overview ..............................................................................................................433

2.3.3 System Configuration...........................................................................................434

2.3.4 List of I/O Signals (CNC ↔ PMC)......................................................................435

2.3.5 Sequence...............................................................................................................437

2.3.6 Related Parameters ...............................................................................................438

2.3.7 Details of Related Parameters ..............................................................................439

2.3.8 Parameter Setting Procedure ................................................................................444

2.3.9 Adjustment Procedure ..........................................................................................450

2.3.10 Diagnosis (Diagnosis Screen)...............................................................................450

2.3.11 Alarm ....................................................................................................................450

2.4 SPINDLE SYNCHRONOUS CONTROL (Optional function)...................... 451

2.4.1 Start-up Procedure................................................................................................451

2.4.2 Overview ..............................................................................................................452

2.4.3 System Configuration...........................................................................................452

2.4.4 Explanation of Operation .....................................................................................452

2.4.5 I/O Signals (CNC ↔ PMC) .................................................................................453

2.4.6 Examples of Sequences ........................................................................................453

2.4.7 Related Parameters ...............................................................................................454

2.4.8 Details of Related Parameters ..............................................................................455

2.4.9 Number of Error Pulses in Spindle Synchronous Control....................................461

2.4.10 Specifying a Shift Amount for Spindle Phase Synchronous Control...................461

2.4.11 Diagnosis (Diagnosis Screen)...............................................................................461

2.4.12 Alarm ....................................................................................................................461

2.5 SPECIFICATIONS COMMON TO ALL OPERATION MODES.................. 462

2.5.1 Overview ..............................................................................................................462

2.5.2 List of I/O Signals (CNC ↔ PMC)......................................................................462

2.5.3 Parameters ............................................................................................................466

2.5.4 Details of parameters............................................................................................468

2.5.5 Diagnosis (Diagnosis Screen)...............................................................................475

3 I/O SIGNALS (CNC ↔ PMC) ..............................................................476

c-11

Page 18

TABLE OF CONTENTS B-65280EN/05

3.1 INPUT SIGNALS (PMC→CNC→SPM)...................................................... 477

3.1.1 List of Input Signals .............................................................................................477

3.1.2 Explanation of Input Signals ................................................................................478

3.1.3 Details of Input Signals ........................................................................................479

3.2 OUTPUT SIGNALS (SPM→CNC→PMC).................................................. 480

3.2.1 List of Output Signals...........................................................................................480

3.2.2 Explanation of Output Signals .............................................................................480

3.2.3 Details of Output Signals .....................................................................................480

4 ADJUSTMENT .................................................................................... 481

4.1 VELOCITY LOOP GAIN ADJUSTMENT ................................................... 482

4.1.1 Overview ..............................................................................................................482

4.1.2 Parameters ............................................................................................................482

4.1.3 Adjustment Procedure ..........................................................................................485

4.1.4 Additional Information (Position Gain Adjustment)............................................486

IV. FANUC BUILT-IN SPINDLE MOTOR Bis series

1 START-UP........................................................................................... 489

1.1 START-UP PROCEDURE ......................................................................... 490

1.2 SPINDLE SERIAL INTERFACE (Optional function) .................................. 491

1.2.1 Parameters Related to Spindle Serial Output .......................................................491

1.2.2 Automatic Spindle Parameter Initialization .........................................................491

1.2.3 Diagnosis (Diagnosis Screen)...............................................................................491

1.2.4 Alarm ....................................................................................................................491

1.3 PARAMETERS RELATED TO DETECTORS............................................ 492

1.3.1 List of Parameters for Detectors...........................................................................492

1.3.2 Details of Parameters for Detectors......................................................................492

1.3.3 Typical Detector Configurations ..........................................................................493

1.4 SUB MODULE SM..................................................................................... 494

1.4.1 Overview ..............................................................................................................494

1.4.2 Series and Editions of Applicable Spindle Software............................................494

1.4.3 Configuration .......................................................................................................494

1.4.4 Related Parameters ...............................................................................................495

1.4.5 Stop Processing When a Sub Module SM Error Occurs......................................496

1.4.6 Alarm and Status Error.........................................................................................497

1.4.7 Caution .................................................................................................................498

1.5 MAGNETIC POLE DETECTION................................................................ 500

1.5.1 Overview ..............................................................................................................500

c-12

Page 19

B-65280EN/05 TABLE OF CONTENTS

1.5.2 Magnetic Pole Detection Operation .....................................................................501

1.5.3 AMR Offset Function...........................................................................................503

1.5.4 I/O Signals (CNC ↔ PMC) .................................................................................505

1.5.5 Related Parameters ...............................................................................................507

1.5.6 Sequence...............................................................................................................512

1.5.7 Causes of SPM Alarm 65 .....................................................................................514

1.5.8 Cautions................................................................................................................514

2 EXPLANATION OF OPERATION MODES......................................... 515

2.1 VELOCITY CONTROL MODE................................................................... 516

2.1.1 Start-up Procedure................................................................................................516

2.1.2 Overview ..............................................................................................................516

2.1.3 System Configuration...........................................................................................516

2.1.4 List of I/O Signals (CNC↔PMC)........................................................................516

2.1.5 Related Parameters ...............................................................................................517

2.1.6 Details of Related Parameters ..............................................................................519

2.1.7 Troubleshooting ...................................................................................................526

2.2 POSITION CODER METHOD SPINDLE ORIENTATION

(Optional function) .....................................................................................527

2.2.1 Start-up Procedure................................................................................................527

2.2.2 Overview ..............................................................................................................527

2.2.3 Feature..................................................................................................................527

2.2.4 System Configuration...........................................................................................527

2.2.5 Stop Position Specification Method .....................................................................527

2.2.6 I/O Signals (CNC ↔ PMC) .................................................................................527

2.2.7 Examples of Sequences ........................................................................................528

2.2.8 Related Parameters ...............................................................................................528

2.2.9 Details of Related Parameters ..............................................................................529

2.2.10 Adjusting the Orientation Stop Position Shift Parameter.....................................532

2.3 RIGID TAPPING (Optional function).......................................................... 533

2.3.1 Start-up Procedure................................................................................................533

2.3.2 Overview ..............................................................................................................533

2.3.3 System Configuration...........................................................................................533

2.3.4 List of I/O Signals (CNC ↔ PMC)......................................................................533

2.3.5 Sequence...............................................................................................................533

2.3.6 Related Parameters ...............................................................................................534

2.3.7 Details of Related Parameters ..............................................................................536

2.3.8 Parameter Setting Procedure ................................................................................540

c-13

Page 20

TABLE OF CONTENTS B-65280EN/05

2.3.9 Adjustment Procedure ..........................................................................................540

2.3.10 Diagnosis (Diagnosis Screen)...............................................................................545

2.3.11 Alarm ....................................................................................................................545

2.4 Cs CONTOURING CONTROL (Optional function) .................................... 546

2.4.1 Start-up Procedure................................................................................................546

2.4.2 Overview ..............................................................................................................546

2.4.3 System Configuration...........................................................................................546

2.4.4 List of I/O Signals (CNC ↔ PMC)......................................................................546

2.4.5 Examples of Sequences ........................................................................................546

2.4.6 Related Parameters ...............................................................................................547

2.4.7 Details of Related Parameters ..............................................................................549

2.4.8 Diagnosis (Diagnosis Screen)...............................................................................556

2.4.9 Alarm ....................................................................................................................556

2.5 SPINDLE SYNCHRONOUS CONTROL (Optional function)...................... 557

2.5.1 Start-up Procedure................................................................................................557

2.5.2 Overview ..............................................................................................................557

2.5.3 System Configuration...........................................................................................557

2.5.4 Explanation of Operation .....................................................................................558

2.5.5 I/O Signals (CNC ↔ PMC) .................................................................................558

2.5.6 Examples of Sequences ........................................................................................558

2.5.7 Related Parameters ...............................................................................................559

2.5.8 Details of Related Parameters ..............................................................................560

2.5.9 Number of Error Pulses in Spindle Synchronous Control....................................566

2.5.10 Specifying a Shift Amount for Spindle Phase Synchronous Control...................566

2.5.11 Diagnosis (Diagnosis Screen)...............................................................................566

2.5.12 Alarm ....................................................................................................................566

2.6 SPECIFICATIONS COMMON TO ALL OPERATION MODES.................. 567

2.6.1 Overview ..............................................................................................................567

2.6.2 List of I/O Signals (CNC ↔ PMC)......................................................................567

2.6.3 Parameters ............................................................................................................571

2.6.4 Details of Parameters............................................................................................574

2.6.5 Diagnosis (Diagnosis Screen)...............................................................................582

3 I/O SIGNALS (CNC ↔ PMC) ..............................................................583

3.1 INPUT SIGNALS (PMC→CNC→SPM)...................................................... 584

3.1.1 List of Input Signals .............................................................................................584

3.1.2 Explanation of Input Signals ................................................................................585

3.1.3 Details of Input Signals ........................................................................................586

c-14

Page 21

B-65280EN/05 TABLE OF CONTENTS

3.2 OUTPUT SIGNALS (SPM→CNC→PMC).................................................. 590

3.2.1 List of Output Signals...........................................................................................590

3.2.2 Explanation of Output Signals .............................................................................591

3.2.3 Details of Output Signals .....................................................................................592

4 ADJUSTMENT .................................................................................... 594

4.1 VELOCITY LOOP GAIN ADJUSTMENT ................................................... 595

4.1.1 Overview ..............................................................................................................595

4.1.2 Parameters ............................................................................................................595

4.1.3 Adjustment Procedure ..........................................................................................595

4.1.4 Additional Information (Position Gain Adjustment)............................................595

4.2 MACHINE RESONANCE ELIMINATION................................................... 595

4.2.1 TCMD Filter.........................................................................................................595

4.2.2 HRV Filter............................................................................................................595

4.2.3 Disturbance Input Function ..................................................................................595

4.3 AMPLITUDE RATIO/PHASE DIFFERENCE COMPENSATION

FUNCTION ................................................................................................ 595

5 FUNCTION DESCRIPTIONS .............................................................. 596

5.1 SPEED RANGE SWITCHING CONTROL (Optional function)................... 597

5.2 SPINDLE SWITCHING CONTROL ........................................................... 597

5.3 INCRMENTAL COMMAND TYPE SPINDLE ORIENTATION

(SPINDLE ROTATION SPEED CONTROL) (Optional function)................ 598

5.3.1 Overview ..............................................................................................................598

5.3.2 Series and Editions of Applicable Spindle Software............................................598

5.3.3 System Configuration...........................................................................................598

5.3.4 I/O Signals(CNC↔PMC) ....................................................................................599

5.3.5 Examples of Sequences ........................................................................................599

5.3.6 List of Related Parameters....................................................................................600

5.3.7 Details of Related Parameters ..............................................................................600

5.4 HIGH-SPEED SPINDLE ORIENTATION (Optional function)..................... 601

5.4.1 Overview ..............................................................................................................601

5.4.2 Series and Editions of Applicable Spindle Software............................................601

5.4.3 System Configuration...........................................................................................601

5.4.4 I/O Signals (CNC↔PMC) ...................................................................................602

5.4.5 Sequence...............................................................................................................603

5.4.6 List of Related Parameters....................................................................................604

5.4.7 Details of Related Parameters ..............................................................................605

c-15

Page 22

TABLE OF CONTENTS B-65280EN/05

5.4.8 Spindle Data Used in Tuning ...............................................................................610

5.4.9 Tuning Procedure .................................................................................................610

5.5 SPINDLE ORIENTATION DURING SPINDLE SYNCHRONOUS

CONTROL (Optional function)................................................................... 616

5.5.1 Overview ..............................................................................................................616

5.5.2 Series and Editions of Applicable Spindle Software............................................616

5.5.3 Specification.........................................................................................................616

5.5.4 I/O Signals (CNC ↔ PMC) .................................................................................617

5.5.5 Sequence...............................................................................................................618

5.5.6 List of Related Parameters....................................................................................619

5.5.7 Details of Related Parameters ..............................................................................619

5.6 SPINDLE FINE ACC./DEC. (FAD) FUNCTION ......................................... 620

5.6.1 Overview ..............................................................................................................620

5.6.2 Series and Editions of Applicable Spindle Software............................................620

5.6.3 Block Diagram .....................................................................................................620

5.6.4 Parameters ............................................................................................................620

5.6.5 Diagnosis (Diagnosis Screen)...............................................................................620

5.6.6 Status Errors .........................................................................................................620

5.6.7 Cautions................................................................................................................620

5.7 UNEXPECTED DISTURBANCE TORQUE DETECTION FUNCTION

(Optional function) .....................................................................................621

5.7.1 Overview ..............................................................................................................621

5.7.2 Series and Editions of Applicable Spindle Software............................................621

5.7.3 I/O Signals (CNC↔PMC) ...................................................................................622

5.7.4 List of Related Parameters....................................................................................623

5.7.5 Details of Related Parameters ..............................................................................623

5.7.6 Parameter Tuning Procedure ................................................................................623

5.8 SPINDLE EGB (SPINDLE ELECTRONIC GEAR BOX)

(Optional function) .....................................................................................624

5.8.1 Overview ..............................................................................................................624

5.8.2 Series and Editions of Applicable Spindle Software............................................624

5.8.3 System Configuration...........................................................................................625

5.8.4 Block Diagram .....................................................................................................625

5.8.5 I/O Signals (CNC ↔ PMC) .................................................................................626

5.8.6 Examples of Sequences ........................................................................................626

5.8.7 List of Related Parameters....................................................................................627

5.8.8 Details of Related Parameters ..............................................................................627

c-16

Page 23

B-65280EN/05 TABLE OF CONTENTS

5.8.9 Diagnosis Signal Related to Spindle EGB ...........................................................628

5.8.10 Status Errors Related to Spindle EGB..................................................................628

5.8.11 Alarms ..................................................................................................................628

5.9 DIFFERENTIAL SPINDLE SPEED CONTROL .........................................629

5.10 DUAL POSITION FEEDBACK FUNCTION (Optional function).....................629

5.11 TORQUE TANDEM CONTROL FUNCTION (Optional function)...................629

5.12 MAGNETIC SENSOR METHOD SPINDLE ORIENTATION

(Optional function)...............................................................................................629

APPENDIX

A SPINDLE PARAMETER TABLE......................................................... 633

A.1 αi SERIES SPINDLE PARAMETER TABLE ............................................. 634

A.2 αCi SERIES SPINDLE PARAMETER TABLE........................................... 650

A.3 Bis SERIES SPINDLE PARAMETER TABLE............................................ 654

B LIST OF SPINDLE PARAMETER NUMBERS....................................661

C PARAMETER TABLE FOR EACH MOTOR MODEL .........................667

C.1 SPINDLE MOTOR αi series ...................................................................... 668

C.2 SPINDLE MOTOR αiP series..................................................................... 672

C.3 SPINDLE MOTOR αiT series..................................................................... 674

C.4 SPINDLE MOTOR α(HV)i series............................................................... 676

C.5 SPINDLE MOTOR α(HV)iP series ............................................................. 678

C.6 SPINDLE MOTOR α(HV)iT series ............................................................. 679

C.7 SPINDLE MOTOR βi series ...................................................................... 681

C.8 SPINDLE MOTOR αCi series.................................................................... 682

D LISTS OF ALARMS/STATE ERRORS ............................................... 683

D.1 LIST OF SPINDLE ALARMS ..................................................................... 684

D.2 LIST OF SPINDLE STATE ERRORS ........................................................ 686

E TABLE OF I/O SIGNALS RELATED TO SPINDLE CONTROL......... 689

E.1 αi SERIES SPINDLE ................................................................................. 690

E.1.1 Input Signals (PMC→CNC).................................................................................690

E.1.2 Output Signals (CNC→PMC)..............................................................................692

E.2 αCi SERIES SPINDLE ..............................................................................695

E.2.1 Input Signals (PMC→CNC).................................................................................695

E.2.2 Output Signals (CNC→PMC)..............................................................................697

E.3 Bis SERIES SPINDLE ............................................................................... 699

E.3.1 Input Signals (PMC→CNC).................................................................................699

c-17

Page 24

TABLE OF CONTENTS B-65280EN/05

E.3.2 Output Signals (CNC→PMC)..............................................................................701

F OBSERVING DATA USING THE SERVO GUIDE ..............................704

F.1 SERIES AND EDITIONS OF APPLICABLE SPINDLE SOFTWARE......... 705

F.2 SPINDLE DATA THAT CAN BE OBSERVED USING THE SERVO

GUIDE ....................................................................................................... 706

F.2.1 Data List ...............................................................................................................706

F.2.2 About the Spindle Speed Control and Spindle Status Signals .............................707

F.3 EXAMPLE OF OBSERVING DATA ........................................................... 708

G PARAMETER SPECIFICATION DIFFERENCES BETWEEN THE αi

SERIES AND αCi SERIES.................................................................. 710

G.1 PARAMETERS WITH DIFFERENT MEANINGS....................................... 711

H PARAMETER SPECIFICATION DIFFERENCES BETWEEN THE αi

SERIES AND Bis SERIES.................................................................. 713

H.1 PARAMETERS WITH DIFFERENT MEANINGS....................................... 714

c-18

Page 25

I. FANUC AC SPINDLE MOTOR αi series

Page 26

Page 27

B-65280EN/05 FANUC AC SPINDLE MOTOR αi series 1.START-UP

1 START-UP

- 3 -

Page 28

1.START-UP FANUC AC SPINDLE MOTOR αi series B-65280EN/05

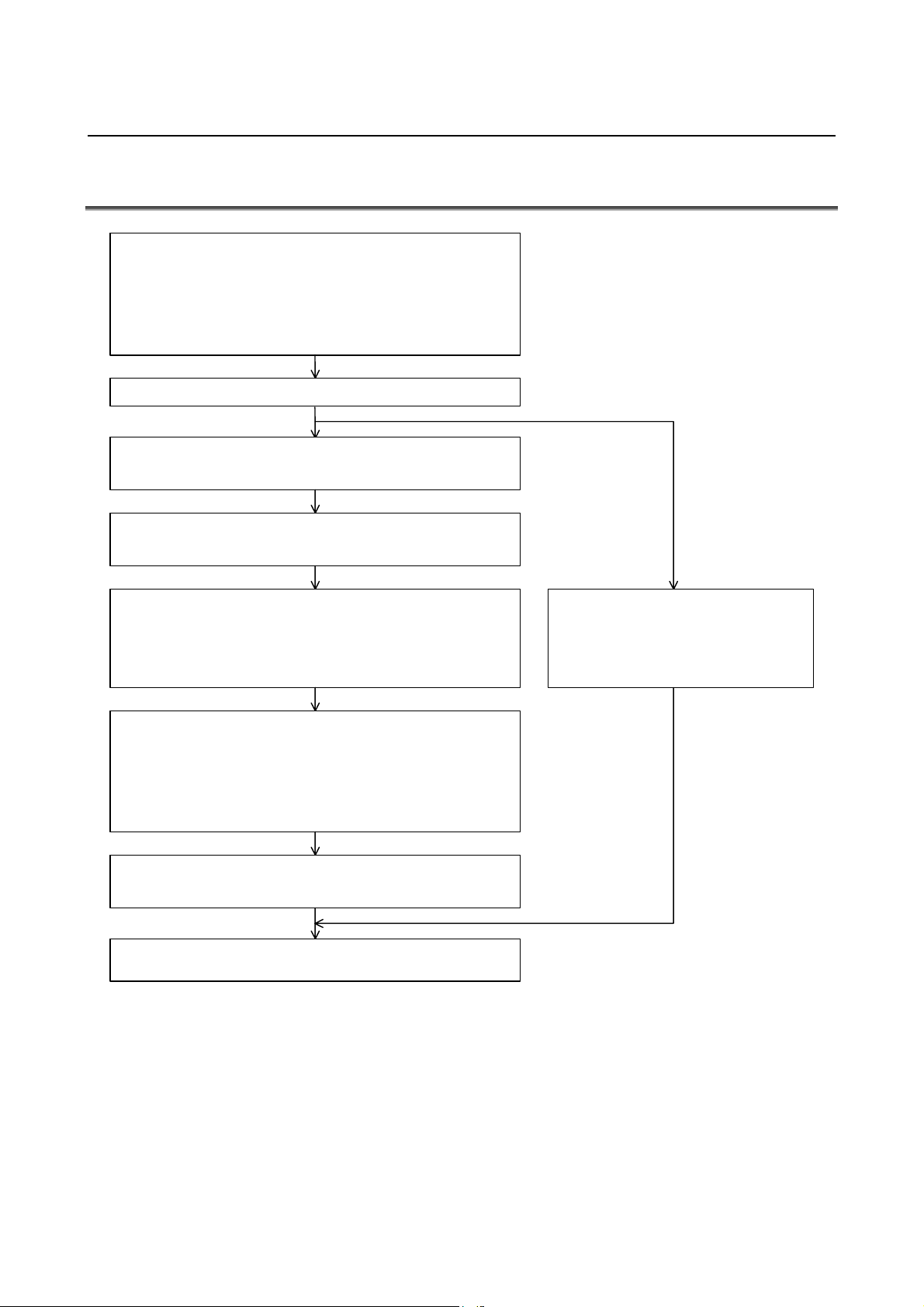

1.1 START-UP PROCEDURE

A. Check the spindle-related specifications.

- CNC model

- Spindle motor

- Power supply module

- Spindle amplifier module

- Detector system

B. Check all connections. (See DESCRIPTIONS (B-65272EN).)

C. Prepare and check the PMC ladder program.

D. Check the CNC parameter setting for using the αi series

(Serial) spindle. (See Subsection 1.2.1.)

E. Perform automatic αi series (Serial) spindle parameter

initialization. (See Subsection 1.2.2.)