Page 1

FANUC AC SPINDLE MOTOR

@*

DESCRIPTIONS

series

B-65272EN/04

Page 2

Ȧ No part of this manual may be reproduced in any form.

Ȧ All specifications and designs are subject to change without notice.

In this manual we have tried as much as possible to describe all the

various matters.

However , we cannot describe all the matters which must not be done,

or which cannot be done, because there are so many possibilities.

Therefore, matters which are not especially described as possible in

this manual should be regarded as ”impossible”.

Page 3

B-65272EN/04 SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

This "Safety Precautions" section describes the precautions which

must be observed to ensure safety when using FANUC spindle

motors.

Users of any spindle motor model are requested to read this manual

carefully before using the spindle motor.

The users are also requested to read this manual carefully and

understand each function of the motor for correct use.

The users are basically forbidden to do any behavior or action not

mentioned in this manual. They are invited to ask FANUC previously

about what behavior or action is prohibited.

For matters that are not described in this manual, a machine must be

designed and assembled in accordance with EN60204-1 to ensure the

safety of the machine and compliance with European specifications.

For details, refer to the specification.

Contents

1.1 DEFINITION OF WARNING, CAUTION, AND NOTE.........s-2

1.2 WARNING ................................................................................s-3

1.3 CAUTION..................................................................................s-5

1.4 NOTE ...................................................................................s-7

s-1

Page 4

SAFETY PRECAUTIONS B-65272EN/04

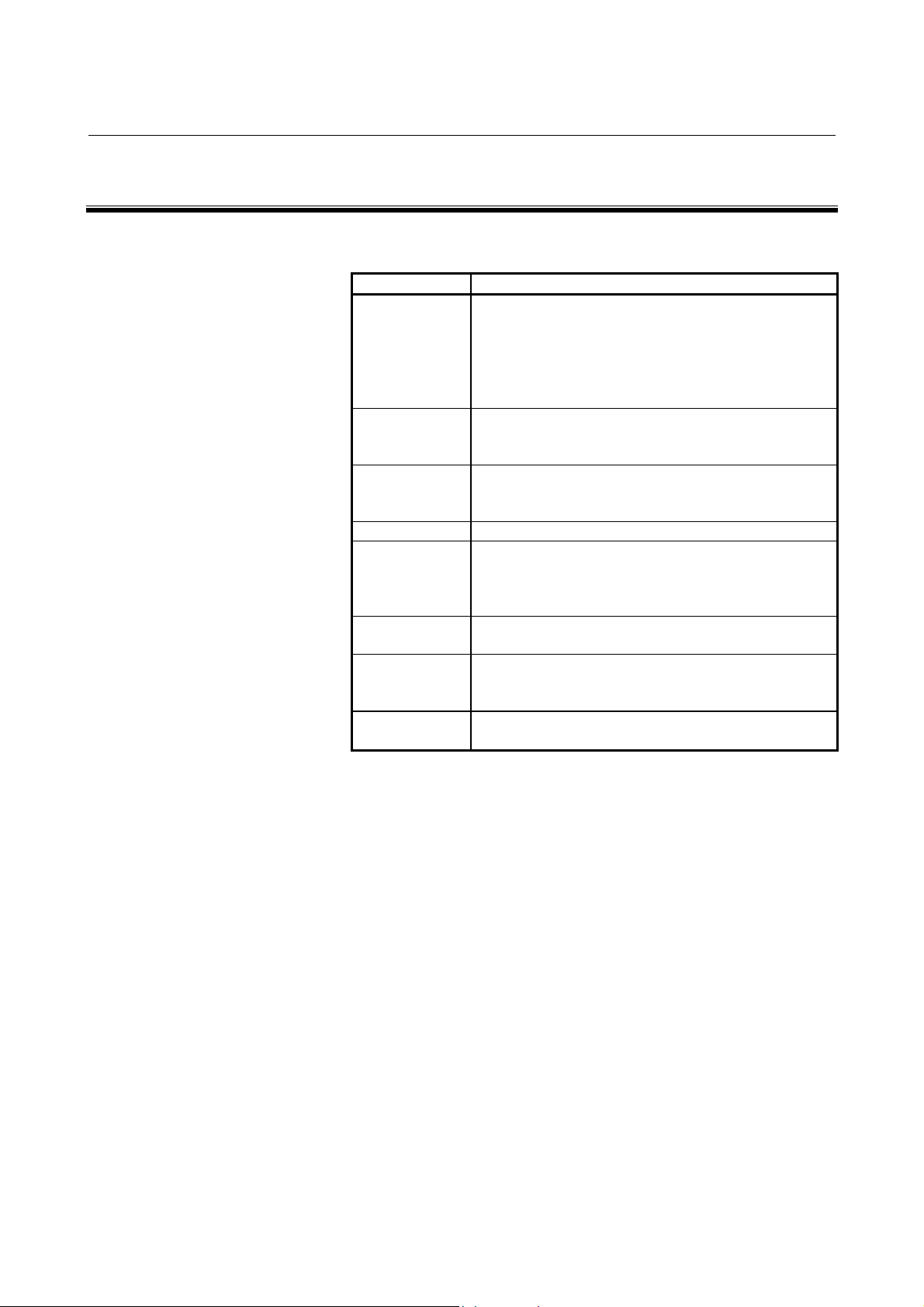

1.1 DEFINITION OF WARNING, CAUTION, AND NOTE

This manual includes safety precautions for protecting the user and

preventing damage to the machine. Precautions are classified into

Warning and Caution according to their bearing on safety. Also,

supplementary information is described as a Note. Read the Warning,

Caution, and Note thoroughly before attempting to use the machine.

WARNING

Applied when there is a danger of the user being

injured or when there is a damage of both the user

being injured and the equipment being damaged if

the approved procedure is not observed.

CAUTION

Applied when there is a danger of the equipment

being damaged, if the approved procedure is not

observed.

NOTE

The Note is used to indicate supplementary

information other than Warning and Caution.

- Read this manual carefully, and store it in a safe place.

s-2

Page 5

B-65272EN/04 SAFETY PRECAUTIONS

1.2 WARNING

WARNING

- Be safely dressed when handling a motor.

Wear safety shoes or gloves when handling a motor as you may get

hurt on any edge or protrusion on it or electric shocks.

- Use a crane or lift to move a motor from one place to another.

A motor is heavy. If you lift the motor by hand, you may get a

backache, or you may be seriously injured when you drop the motor.

A suitable crane or lift must be used to move the motor. (For the

weight of motors, refer to this manual.)

When moving a motor using a crane or lift, use a hanging bolt if the

motor has a corresponding tapped hole, or textile rope if it has no

tapped hole. If a motor is attached with a machine or any other heavy

stuff, do not use a hanging bolt to move the motor as the hanging bolt

and/or motor may get broken.

- Before starting to connect a motor to electric wires, make sure they are isolated

from an electric power source.

A failure to observe this caution is vary dangerous because you may

get electric shocks.

- Be sure to secure power wires.

If operation is performed with a terminal loose, the terminal block

may become abnormally hot, possibly causing a fire. Also, the

terminal may become disconnected, causing a ground fault or shortcircuit, and possibly giving you electric shocks. See the section in this

manual that gives the tightening torque for attaching power wires and

short-bars to the terminal block.

- Be sure to ground a motor frame.

To avoid electric shocks, be sure to connect the grounding terminal in

the terminal box to the grounding terminal of the machine.

- Do not ground a motor power wire terminal or short-circuit it to another power

wire terminal.

A failure to observe this caution may cause electric shocks or a

burned wiring.

* Some motors require a special connection such as a winding

switching. Refer to their respective motor specification manuals

for details.

- Do not supply the power to the motor while any terminal is exposed.

A failure to observe this caution is very dangerous because you may

get electric shocks if your body or any conductive stuff touches an

exposed terminal.

s-3

Page 6

SAFETY PRECAUTIONS B-65272EN/04

WARNING

- Do not bring any dangerous stuff near a motor.

Motors are connected to a power line, and may get hot. If a flammable

is placed near a motor, it may be ignited, catch fire, or explode.

- Do not get close to a rotary section of a motor when it is rotating.

You may get your clothes or fingers caught in a rotary section, and

may be injured. Before starting a motor, ensure that there is no stuff

that can fly away (such as a key) on the motor.

- Do not touch a motor with a wet hand.

A failure to observe this caution is vary dangerous because you may

get electric shocks.

- Before touching a motor, shut off the power to it.

Even if a motor is not rotating, there may be a voltage across the

terminals of the motor.

Especially before touching a power supply connection, take sufficient

precautions.

Otherwise you may get electric shocks.

- Do not touch any terminal of a motor for a while (at least 5 minutes) after the

power to the motor is shut off.

High voltage remains across power line terminals of a motor for a

while after the power to the motor is shut off. So, do not touch any

terminal or connect it to any other equipment. Otherwise, you may get

electric shocks or the motor and/or equipment may get damaged.

- To drive a motor, use a specified amplifier and parameters.

An incorrect combination of a motor, amplifier, and parameters may

cause the motor to behave unexpectedly. This is dangerous, and the

motor may get damaged.

- Before driving a motor, be sure to secure it.

If a motor is drove without being secured, it may roll over during

acceleration or deceleration, injuring the user.

s-4

Page 7

B-65272EN/04 SAFETY PRECAUTIONS

1.3 CAUTION

CAUTION

- Do not touch a motor when it is running or immediately after it stops.

A motor may get hot when it is running. Do not touch the motor

before it gets cool enough. Otherwise, you may get burned.

- Be careful not get your hair or cloths caught in a fan.

Be careful especially for a fan used to generate an inward air flow.

Be careful also for a fan even when the motor is stopped, because it

continues to rotate while the amplifier is turned on.

- Ensure that motors and related components are mounted securely.

If a motor or its component slips out of place or comes off when the

motor is running, it is very dangerous.

- FANUC motors are designed for use with machines. Do not use them for any other

purpose.

If a FANUC motor is used for an unintended purpose, it may cause an

unexpected symptom or trouble. If you want to use a motor for an

unintended purpose, previously consult with FANUC.

- Ensure that a base or frame on which a motor is mounted is strong enough.

Motors are heavy. If a base or frame on which a motor is mounted is

not strong enough, it is impossible to achieve the required precision.

- Be sure to connect motor cables correctly.

An incorrect connection of a cable cause abnormal heat generation,

equipment malfunction, or failure. Always use a cable with an

appropriate current carrying capacity (or thickness). For how to

connect cables to motors, refer to their

respective specification manuals.

- Ensure that motors are cooled if they are those that require forcible cooling.

If a motor that requires forcible cooling is not cooled normally, it may

cause a failure or trouble. For a fan-cooled motor, ensure that it is not

clogged or blocked with dust and dirt. For a liquid-cooled motor,

ensure that the amount of the liquid is appropriate and that the liquid

piping is not clogged. For both types, perform regular cleaning and

inspection.

- When attaching a component having inertia, such as a pulley, to a motor, ensure

that any imbalance between the motor and component is minimized.

If there is a large imbalance, the motor may vibrates abnormally,

resulting in the motor being broken.

s-5

Page 8

SAFETY PRECAUTIONS B-65272EN/04

CAUTION

- Be sure to attach a key to a motor with a keyed shaft.

If a motor with a keyed shaft runs with no key attached, it may impair

torque transmission or cause imbalance, resulting in the motor being

broken.With the αi series, a shaft with no key is used as standard.

s-6

Page 9

B-65272EN/04 SAFETY PRECAUTIONS

1.4 NOTE

NOTE

- Do not step or sit on a motor.

If you step or sit on a motor, it may get deformed or broken. Do not

put a motor on another unless they are in packages.

- When storing a motor, put it in a dry (non-condensing) place at room temperature

(0 to 40 °°°°C).

If a motor is stored in a humid or hot place, its components may get

damaged or deteriorated. In addition, keep a motor in such a position

that its shaft is held horizontal and its terminal box is at the top.

- Do not remove a nameplate from a motor.

If a nameplate comes off, be careful not to lose it. If the nameplate is

lost, the motor becomes unidentifiable, resulting in maintenance

becoming impossible. For a nameplate for a built-in spindle motor,

keep the nameplate with the spindle.

- Do not apply shocks to a motor or cause scratches to it.

If a motor is subjected to shocks or is scratched, its components may

be adversely affected, resulting in normal operation being impaired.

Be very careful when handling plastic portions, sensors, and windings,

because they are very liable to break. Especially, avoid lifting a motor

by pulling its plastic portion, winding, or power cable.

- Do not conduct dielectric strength or insulation test for a sensor.

Such a test can damage elements in the sensor.

- When testing the winding or insulation resistance of a motor, satisfy the

conditions stipulated in IEC34.

Testing a motor under a condition severer than those specified in

IEC34 may damage the motor.

- Do not disassemble a motor.

Disassembling a motor may cause a failure or trouble in it.

If disassembly is in need because of maintenance or repair, please

contact a service representative of FANUC.

- Do not modify a motor.

Do not modify a motor unless directed by FANUC. Modifying a

motor may cause a failure or trouble in it.

- Use a motor under an appropriate environmental condition.

Using a motor in an adverse environment may cause a failure or

trouble in it. Refer to their respective specification manuals for details

of the operating and environmental conditions for motors.

s-7

Page 10

SAFETY PRECAUTIONS B-65272EN/04

NOTE

- Do not apply a commercial power source voltage directly to a motor.

Applying a commercial power source voltage directly to a motor may

result in its windings being burned. Be sure to use a specified

amplifier for supplying voltage to the motor.

- For a motor with a terminal box, make a conduit hole for the terminal box in a

specified position.

When making a conduit hole, be careful not to break or damage

unspecified portions. Refer to an applicable specification manual.

- Before using a motor, measure its winding and insulation resistances, and make

sure they are normal.

Especially for a motor that has been stored for a prolonged period of

time, conduct these checks. A motor may deteriorate depending on the

condition under which it is stored or the time during which it is stored.

For the winding resistances of motors, refer to their respective

specification manuals, or ask FANUC. For insulation resistances, see

the following table.

- To use a motor as long as possible, perform periodic maintenance and inspection

for it, and check its winding and insulation resistances.

Note that extremely severe inspections (such as dielectric strength

tests) of a motor may damage its windings. For the winding

resistances of motors, refer to their respective specification manuals,

or ask FANUC. For insulation resistances, see the following table.

MOTOR INSULATION RESISTANCE MEASUREMENT

Measure an insulation resistance between each winding and

motor frame using an insulation resistance meter (500 VDC).

Judge the measurements according to the following table.

Insulation

resistance

100 MΩ or higher Acceptable

The winding has begun deteriorating. There is no

10 to 100 MΩ

1 to 10 MΩ

Lower than 1 MΩ Unacceptable. Replace the motor.

problem with the performance at present. Be

sure to perform periodic inspection.

The winding has considerably deteriorated.

Special care is in need. Be sure to perform

periodic inspection.

Judgment

s-8

Page 11

B-65272EN/04 PREFACE

PREFACE

The models covered by this manual, and their abbreviations are:

Series Model

α0.5/10000i, α1/10000i, α1.5/10000i, α2/10000i,

α3/10000i, α6/10000i, α8/8000i, α12/7000i, α15/7000i,

αi series

αiP series

αiT series

αiL series α8/20000iL, α15/15000iL, α26/15000iL

α(HV)i series

α(HV)iP

series

α(HV)iT

series

α(HV)iL

series

α18/7000i, α22/7000i, α30/6000i, α40/6000i, α50/4500i,

α1/15000i, α1.5/15000i, α2/15000i, α3/12000i, α6/12000i,

α8/10000i, α12/10000i, α15/10000i, α18/10000i,

α22/10000i

α12/6000i

α30/6000i

α12/8000i

α1.5/15000i

α8/12000i

α22/10000i

P, α15/6000iP, α18/6000iP, α22/6000iP,

P, α40/6000iP, α50/6000iP, α60/4500iP,

P, α15/8000iP, α18/8000iP, α22/8000iP

T, α2/15000iT, α3/12000iT, α6/12000iT,

T, α8/15000iT, α15/10000iT, α15/12000iT,

T

α0.5/10000HVi, α1/10000HVi, α1.5/10000HVi,

α2/10000HVi, α3/10000HVi, α6/10000HVi, α8/8000HVi,

α12/7000HVi, α15/7000HVi, α22/7000HVi, α30/6000HVi,

α40/6000HVi, α60/4500HVi, α100/4000HVi

α15/6000HViP, α22/6000HViP, α40/6000HViP,

α50/6000HVi

α1.5/15000HVi

α6/12000HVi

α15/10000HVi

α8/20000HVi

P, α60/4500HviP

T, α2/15000HViT, α3/12000HViT,

T, α8/12000HViT, α8/15000HViT,

T, α15/12000HViT, α22/10000HviT

L, α15/15000HViL, α26/15000HViL

p-1

Page 12

Page 13

B-65272EN/04 TABLE OF CONTENTS

TABLE OF CONTENTS

SAFETY PRECAUTIONS.......................................................................... s-1

I. DESCRIPTIONS FOR THE αi SERIES

1 GENERAL ..............................................................................................3

2 CONFIGURATION OF THE ααααi SERIES .................................................5

3 MOTOR TYPES .....................................................................................6

4 NOTES ON INSTALLATION ..................................................................7

4.1 COMMON ......................................................................................................8

4.2 POWER LEAD CONNECTION....................................................................19

4.3 FAN MOTOR CONNECTION ......................................................................24

4.4 WHEN A MOTOR IS CONNECTED TO A SPINDLE VIA A BELT ..............27

4.5 WHEN A MOTOR IS CONNECTED TO A SPINDLE VIA A GEAR.............30

4.6 WHEN A MOTOR IS DIRECTLY CONNECTED TO A SPINDLE VIA

A COUPLING...............................................................................................31

5 NOTES ON OPERATION.....................................................................32

6 DETERMINING THE ACCELERATION TIME ......................................33

7 DETERMINING THE ALLOWABLE DUTY CYCLE .............................39

8 DISPOSAL OF SPINDLE MOTORS BY MATERIAL TYPE .................42

II. FANUC AC SPINDLE MOTOR αi SERIES

1 GENERAL ............................................................................................45

2 SPECIFICATIONS................................................................................46

3 OUTPUT/TORQUE CHARACTERISTICS ............................................56

3.1 MODEL α0.5/10000i....................................................................................57

3.2 MODEL α1/10000i.......................................................................................57

3.3 MODEL α1.5/10000i....................................................................................58

3.4 MODEL α2/10000i.......................................................................................58

3.5 MODEL α3/10000i.......................................................................................59

3.6 MODEL α6/10000i.......................................................................................59

3.7 MODEL α8/8000i.........................................................................................60

3.8 MODEL α12/7000i.......................................................................................60

c-1

Page 14

TABLE OF CONTENTS B-65272EN/04

3.9 MODEL α15/7000i.......................................................................................61

3.10 MODEL α18/7000i.......................................................................................61

3.11 MODEL α22/7000i.......................................................................................62

3.12 MODEL α30/6000i.......................................................................................62

3.13 MODEL α40/6000i.......................................................................................63

3.14 MODEL α50/4500i.......................................................................................63

3.15 MODEL α1/15000i.......................................................................................64

3.16 MODEL α1.5/15000i....................................................................................65

3.17 MODEL α2/15000i.......................................................................................66

3.18 MODEL α3/12000i.......................................................................................67

3.19 MODEL α6/12000i.......................................................................................68

3.20 MODEL α8/10000i.......................................................................................69

3.21 MODEL α12/10000i.....................................................................................70

3.22 MODEL α15/10000i.....................................................................................71

3.23 MODEL α18/10000i.....................................................................................72

3.24 MODEL α22/10000i.....................................................................................73

4 CONNECTIONS ...................................................................................74

4.1 MODEL α0.5/10000i....................................................................................75

4.2 MODELS α1/10000i TO α50/4500i .............................................................77

4.3 CONNECTION OF SIGNAL LEAD ..............................................................78

5 ALLOWABLE RADIAL LOAD..............................................................79

6 ASSEMBLING ACCURACY.................................................................80

7 EXTERNAL DIMENSIONS...................................................................81

7.1 MODEL α0.5/10000i (FLANGE MOUNTING TYPE) ...................................82

7.2 MODELS α1/10000i AND α1/15000i (FLANGE MOUNTING TYPE) ..........83

7.3 MODEL α1/10000i (FOOT MOUNTING TYPE)...........................................84

7.4 MODEL α1.5/10000i (FLANGE MOUNTING TYPE) ...................................85

7.5 MODEL α1.5/15000i (FLANGE MOUNTING TYPE) ...................................86

7.6 MODEL α1.5/10000i (FOOT MOUNTING TYPE)........................................87

7.7 MODEL α2/10000i (FLANGE MOUNTING TYPE) ......................................88

7.8 MODEL α2/15000i (FLANGE MOUNTING TYPE) ......................................89

7.9 MODEL α2/10000i (FOOT MOUNTING TYPE)...........................................90

7.10 MODELS α3/10000i AND α3/12000i (FLANGE MOUNTING TYPE) ..........91

7.11 MODEL α3/10000i (FOOT MOUNTING TYPE)...........................................92

7.12 MODELS α6/10000i AND α6/12000i (FLANGE MOUNTING TYPE) ..........93

7.13 MODEL α6/10000i (FOOT MOUNTING TYPE)...........................................94

c-2

Page 15

B-65272EN/04 TABLE OF CONTENTS

7.14 MODELS α8/8000i AND α8/10000i (FLANGE MOUNTING TYPE) ............95

7.15 MODEL α8/8000i (FOOT MOUNTING TYPE).............................................96

7.16 MODELS α12/7000i AND α12/10000i (FLANGE MOUNTING TYPE) ........97

7.17 MODEL α12/7000i (FOOT MOUNTING TYPE)...........................................98

7.18 MODELS α15/7000i AND α15/10000i (FLANGE MOUNTING TYPE) ........99

7.19 MODEL α15/7000i (FOOT MOUNTING TYPE).........................................100

7.20 MODELS α18/7000i AND α18/10000i (FLANGE MOUNTING TYPE) ......101

7.21 MODEL α18/7000i (FOOT MOUNTING TYPE).........................................102

7.22 MODELS α22/7000i AND α22/10000i (FLANGE MOUNTING TYPE) ......103

7.23 MODEL α22/7000i (FOOT MOUNTING TYPE).........................................104

7.24 MODEL α30/6000i (FLANGE MOUNTING TYPE) ....................................105

7.25 MODEL α30/6000i (FOOT MOUNTING TYPE).........................................106

7.26 MODEL α40/6000i (FLANGE MOUNTING TYPE) ....................................107

7.27 MODEL α40/6000i (FOOT MOUNTING TYPE).........................................108

7.28 MODEL α50/4500i (FLANGE MOUNTING TYPE) ....................................109

7.29 MODEL α50/4500i (FOOT MOUNTING TYPE).........................................110

III. FANUC AC SPINDLE MOTOR αiP SERIES

1 GENERAL ..........................................................................................113

2 SPECIFICATIONS..............................................................................114

3 OUTPUT/TORQUE CHARACTERISTICS ..........................................120

3.1 MODEL α12/6000iP ...................................................................................121

3.2 MODEL α15/6000iP ...................................................................................122

3.3 MODEL α18/6000iP ...................................................................................123

3.4 MODEL α22/6000iP ...................................................................................124

3.5 MODEL α30/6000iP ...................................................................................125

3.6 MODEL α40/6000iP ...................................................................................126

3.7 MODEL α50/6000iP ...................................................................................127

3.8 MODEL α60/4500iP ...................................................................................128

3.9 MODEL α12/8000iP ...................................................................................129

3.10 MODEL α15/8000iP ...................................................................................130

3.11 MODEL α18/8000iP ...................................................................................131

3.12 MODEL α22/8000iP ...................................................................................132

4 CONNECTIONS .................................................................................133

4.1 MODELS α12/6000iP TO α60/4500iP ........................................................134

4.2 CONNECTION OF SIGNAL LEAD ............................................................135

c-3

Page 16

TABLE OF CONTENTS B-65272EN/04

5 ALLOWABLE RADIAL LOAD............................................................136

6 ASSEMBLING ACCURACY...............................................................137

7 EXTERNAL DIMENSIONS.................................................................138

7.1 MODELS α12/6000iP AND α12/8000iP (FRANGE MOUNTING TYPE).....139

7.2 MODEL α12/6000iP (FOOT MOUNTING TYPE) .......................................140

7.3 MODELS α15/6000i

7.4 MODEL α15/6000iP (FOOT MOUNTING TYPE) .......................................142

7.5 MODELS α18/6000i

7.6 MODEL α18/6000iP (FOOT MOUNTING TYPE) .......................................144

7.7 MODELS α22/6000iP AND α22/8000iP (FRANGE MOUNTING TYPE).....145

7.8 MODEL α22/6000iP (FOOT MOUNTING TYPE) .......................................146

7.9 MODELS α30/6000i

7.10 MODELS α30/6000iP AND α40/6000iP (FOOT MOUNTING TYPE) .........148

7.11 MODEL α50/6000iP (FRANGE MOUNTING TYPE) ..................................149

7.12 MODEL α50/6000iP (FOOT MOUNTING TYPE) .......................................150

7.13 MODEL α60/4500iP (FRANGE MOUNTING TYPE) ..................................151

7.14 MODEL α60/4500iP (FOOT MOUNTING TYPE) .......................................152

P AND α15/8000iP (FRANGE MOUNTING TYPE).....141

P AND α18/8000iP (FRANGE MOUNTING TYPE).....143

P AND α40/6000iP (FRANGE MOUNTING TYPE).....147

IV. FANUC AC SPINDLE MOTOR αiT SERIES

1 GENERAL ..........................................................................................155

2 SPECIFICATIONS..............................................................................157

3 OUTPUT/TORQUE CHARACTERISTICS ..........................................163

3.1 MODEL α1.5/15000iT ................................................................................164

3.2 MODEL α2/15000iT ...................................................................................165

3.3 MODEL α3/12000iT ...................................................................................166

3.4 MODEL α6/12000iT ...................................................................................167

3.5 MODEL α8/12000iT ...................................................................................168

3.6 MODEL α8/15000iT ...................................................................................169

3.7 MODEL α15/10000iT .................................................................................170

3.8 MODEL α15/12000iT .................................................................................171

3.9 MODEL α22/10000iT .................................................................................172

4 CONFIGURATION AND ORDERING NUMBER ................................173

4.1 CONFIGURATION.....................................................................................174

4.2 ORDERING NUMBER ...............................................................................175

5 CONNECTIONS .................................................................................176

c-4

Page 17

B-65272EN/04 TABLE OF CONTENTS

5.1 CONNECTION OF THE POWER, FAN MOTOR, AND MZi SENSOR

SIGNAL LEADS.........................................................................................177

5.2 CONNECTION OF SIGNAL LEAD ............................................................179

6 ASSEMBLING ACCURACY...............................................................180

7 EXTERNAL DIMENSIONS.................................................................181

7.1 MODEL α1.5/15000iT ................................................................................182

7.2 MODEL α2/15000iT ...................................................................................183

7.3 MODEL α3/12000i

7.4 MODEL α6/12000iT ...................................................................................185

7.5 MODELS α8/12000iT AND α8/15000iT......................................................186

7.6 MODEL α15/10000iT .................................................................................187

7.7 MODEL α15/12000i

7.8 MODEL α22/10000iT .................................................................................189

7.9 DISTANCE BLOCK TYPE 1.5iT................................................................190

7.10 DISTANCE BLOCK TYPE 2iT...................................................................191

7.11 DISTANCE BLOCK TYPE 6iT...................................................................192

7.12 DISTANCE BLOCK TYPE 15iT.................................................................193

T ...................................................................................184

T .................................................................................188

8 POINTS ABOUT DIRECT CONNECTION STRUCTURE...................194

9 NOTES ON MOTOR INSTALLATION................................................195

9.1 HIGHER-PRECISION MOUNTING FLANGE AND SHAFT .......................196

9.2 CENTERING USING CENTERING PLATES.............................................197

9.3 CHECKING MOTOR VIBRATION (TO SEE WHETHER CENTERING

IS SUCCESSFUL) .....................................................................................198

9.4 COUPLING SELECTION...........................................................................199

9.5 ROTATION JOINT .....................................................................................202

9.6 COOLANT JOINT ......................................................................................203

9.7 ROTATION JOINT SUPPORT HOUSING .................................................205

V. FANUC AC SPINDLE MOTOR αiL SERIES

1 GENERAL ..........................................................................................209

2 SPECIFICATIONS..............................................................................210

3 OUTPUT/TORQUE CHARACTERISTICS ..........................................213

3.1 MODEL α8/20000iL....................................................................................214

3.2 MODEL α15/15000iL..................................................................................215

3.3 MODEL α26/15000iL..................................................................................216

c-5

Page 18

TABLE OF CONTENTS B-65272EN/04

4 CONNECTIONS .................................................................................217

4.1 TOTAL CONNECTION DIAGRAM ............................................................218

4.2 SIZE OF POWER LEAD ............................................................................219

4.3 CONNECTION OF SIGNAL LEAD ............................................................220

4.4 COOLING ..................................................................................................221

5 ASSEMBLING ACCURACY...............................................................223

6 EXTERNAL DIMENSIONS.................................................................224

6.1 MODEL α8/20000iL....................................................................................225

6.2 MODEL α15/15000iL..................................................................................226

6.3 MODEL α26/15000iL..................................................................................227

VI. FANUC AC SPINDLE MOTOR α(HV)i SERIES

1 GENERAL ..........................................................................................231

2 SPECIFICATIONS..............................................................................232

3 OUTPUT/TORQUE CHARACTERISTICS ..........................................238

3.1 MODEL α0.5/10000HVi.............................................................................239

3.2 MODEL α1/10000HVi................................................................................239

3.3 MODEL α1.5/10000HVi.............................................................................240

3.4 MODEL α2/10000HVi................................................................................240

3.5 MODEL α3/10000HVi................................................................................241

3.6 MODEL α6/10000HVi................................................................................241

3.7 MODEL α8/8000HVi..................................................................................242

3.8 MODEL α12/7000HVi................................................................................242

3.9 MODEL α15/7000HVi................................................................................243

3.10 MODEL α22/7000HVi................................................................................243

3.11 MODEL α30/6000HVi................................................................................244

3.12 MODEL α40/6000HVi................................................................................244

3.13 MODEL α60/4500HVi................................................................................245

3.14 MODEL α100/4000HVi..............................................................................246

4 CONNECTIONS .................................................................................247

4.1 MODEL α0.5/10000HVi.............................................................................248

4.2 MODELS α1/10000HVi TO α100/4000HVi ...............................................250

4.3 CONNECTION OF SIGNAL LEAD ............................................................251

5 ALLOWABLE RADIAL LOAD............................................................252

6 ASSEMBLING ACCURACY...............................................................253

c-6

Page 19

B-65272EN/04 TABLE OF CONTENTS

7 EXTERNAL DIMENSIONS.................................................................254

7.1 MODEL α0.5/10000HVi (FLANGE MOUNTING TYPE) ............................255

7.2 MODEL α1/10000HVi (FLANGE MOUNTING TYPE) ...............................256

7.3 MODEL α1/10000HVi (FOOT MOUNTING TYPE)....................................257

7.4 MODEL α1.5/10000HVi (FLANGE MOUNTING TYPE) ............................258

7.5 MODEL α1.5/10000HVi (FOOT MOUNTING TYPE).................................259

7.6 MODEL α2/10000HVi (FLANGE MOUNTING TYPE) ...............................260

7.7 MODEL α2/10000HVi (FOOT MOUNTING TYPE)....................................261

7.8 MODEL α3/10000HVi (FLANGE MOUNTING TYPE) ...............................262

7.9 MODEL α3/10000HVi (FOOT MOUNTING TYPE)....................................263

7.10 MODEL α6/10000HVi (FLANGE MOUNTING TYPE) ...............................264

7.11 MODEL α6/10000HVi (FOOT MOUNTING TYPE)....................................265

7.12 MODEL α8/8000HVi (FLANGE MOUNTING TYPE) .................................266

7.13 MODEL α8/8000HVi (FOOT MOUNTING TYPE)......................................267

7.14 MODEL α12/7000HVi (FLANGE MOUNTING TYPE) ...............................268

7.15 MODEL α12/7000HVi (FOOT MOUNTING TYPE)....................................269

7.16 MODEL α15/7000HVi (FLANGE MOUNTING TYPE) ...............................270

7.17 MODEL α15/7000HVi (FOOT MOUNTING TYPE)....................................271

7.18 MODEL α22/7000HVi (FLANGE MOUNTING TYPE) ...............................272

7.19 MODEL α22/7000HVi (FOOT MOUNTING TYPE)....................................273

7.20 MODEL α30/6000HVi (FLANGE MOUNTING TYPE) ...............................274

7.21 MODEL α30/6000HVi (FOOT MOUNTING TYPE)....................................275

7.22 MODEL α40/6000HVi (FLANGE MOUNTING TYPE) ...............................276

7.23 MODEL α40/6000HVi (FOOT MOUNTING TYPE)....................................277

7.24 MODEL α60/4500HVi (FLANGE MOUNTING TYPE) ...............................278

7.25 MODEL α60/4500HVi (FOOT MOUNTING TYPE)....................................279

7.26 MODEL α100/4000HVi (FOOT FLANGE MOUNTING TYPE) ..................280

VII. FANUC AC SPINDLE MOTOR α(HV)iP SERIES

1 GENERAL ..........................................................................................283

2 SPECIFICATIONS..............................................................................284

3 OUTPUT/TORQUE CHARACTERISTICS ..........................................289

3.1 MODEL α15/6000HViP ..............................................................................290

3.2 MODEL α22/6000HViP ..............................................................................291

3.3 MODEL α40/6000HViP ..............................................................................292

3.4 MODEL α50/6000HViP ..............................................................................293

c-7

Page 20

TABLE OF CONTENTS B-65272EN/04

3.5 MODEL α60/4500HViP ..............................................................................294

4 CONNECTIONS .................................................................................295

4.1 MODELS α15/6000HViP TO α60/4500HViP ..............................................296

4.2 CONNECTION OF SIGNAL LEAD ............................................................297

5 ALLOWABLE RADIAL LOAD............................................................298

6 ASSEMBLING ACCURACY...............................................................299

7 EXTERNAL DIMENSIONS.................................................................300

7.1 MODEL α15/6000HViP (FLANGE MOUNTING TYPE)..............................301

7.2 MODEL α15/6000HViP (FOOT MOUNTING TYPE) ..................................302

7.3 MODEL α22/6000HViP (FLANGE MOUNTING TYPE)..............................303

7.4 MODEL α22/6000HViP (FOOT MOUNTING TYPE) ..................................304

7.5 MODEL α40/6000HVi

7.6 MODEL α40/6000HViP (FOOT MOUNTING TYPE) ..................................306

7.7 MODEL α50/6000HViP (FLANGE MOUNTING TYPE)..............................307

7.8 MODEL α50/6000HViP (FOOT MOUNTING TYPE) ..................................308

7.9 MODEL α60/4500HViP (FLANGE MOUNTING TYPE)..............................309

7.10 MODEL α60/4500HViP (FOOT MOUNTING TYPE) ..................................310

P (FLANGE MOUNTING TYPE)..............................305

VIII. FANUC AC SPINDLE MOTOR α(HV)iT SERIES

1 GENERAL ..........................................................................................313

2 SPECIFICATIONS..............................................................................314

3 OUTPUT/TORQUE CHARACTERISTICS ..........................................320

3.1 MODEL α1.5/15000HViT ...........................................................................321

3.2 MODEL α2/15000HViT ..............................................................................322

3.3 MODEL α3/12000HViT ..............................................................................323

3.4 MODEL α6/12000HViT ..............................................................................324

3.5 MODEL α8/12000HViT ..............................................................................325

3.6 MODEL α8/15000HViT ..............................................................................326

3.7 MODEL α15/10000HViT ............................................................................327

3.8 MODEL α15/12000HViT ............................................................................328

3.9 MODEL α22/10000HViT ............................................................................329

4 CONFIGURATION AND ORDERING NUMBER ................................330

4.1 CONFIGURATION.....................................................................................331

4.2 ORDERING NUMBER ...............................................................................332

c-8

Page 21

B-65272EN/04 TABLE OF CONTENTS

5 CONNECTIONS .................................................................................333

5.1 CONNECTION OF THE POWER, FAN MOTOR, AND MZi SENSOR

SIGNAL LEADS.........................................................................................334

5.2 CONNECTION OF A SINGLE-PHASE FAN MOTOR ...............................335

5.3 CONNECTION OF SIGNAL LEAD ............................................................336

6 ASSEMBLING ACCURACY...............................................................337

7 EXTERNAL DIMENSIONS.................................................................338

7.1 MODEL α1.5/15000HViT ...........................................................................339

7.2 MODEL α2/15000HViT ..............................................................................340

7.3 MODEL α3/12000HViT ..............................................................................341

7.4 MODEL α6/12000HViT ..............................................................................342

7.5 MODELS α8/12000HVi

7.6 MODEL α15/10000HViT ............................................................................344

7.7 MODEL α15/12000HViT ............................................................................345

7.8 MODEL α22/10000HViT ............................................................................346

T AND α8/15000HViT ............................................343

IX. FANUC AC SPINDLE MOTOR α(HV)iL SERIES

1 GENERAL ..........................................................................................349

2 SPECIFICATIONS..............................................................................350

3 OUTPUT/TORQUE CHARACTERISTICS ..........................................353

3.1 MODEL α8/20000HViL...............................................................................354

3.2 MODEL α15/15000HViL.............................................................................355

3.3 MODEL α26/15000HViL.............................................................................356

4 CONNECTIONS .................................................................................357

4.1 POWER WIRE CRIMP TERMINAL SIZE ..................................................358

4.2 CONNECTION OF SIGNAL LEAD ............................................................359

4.3 COOLING ..................................................................................................360

5 ASSEMBLING ACCURACY...............................................................362

6 EXTERNAL DIMENSIONS.................................................................363

6.1 MODEL α8/20000HViL...............................................................................364

6.2 MODEL α15/15000HViL.............................................................................365

6.3 MODEL α26/15000HViL.............................................................................366

c-9

Page 22

Page 23

I. DESCRIPTIONS FOR THE ααααi SERIES

Page 24

Page 25

B-65272EN/04 SPECIFICATIONS FOR THE αi SERIES 1.GENERAL

α

α

1 GENERAL

As motors for driving the spindle of a CNC machine tool, the FANUC

AC Spindle Motor αi series has incorporated accumulated

technologies and employs the latest design and manufacturing

techniques to provide the features listed below.

Features

- The series provides a lineup of motors that satisfy various

spindle driving structures such as gear driving, belt driving, and

direct motor connection. So, the user can choose an optimal

motor that meets the spindle driving structure of the user.

- By employing winding switching, a wider rated output range

required for the spindle driving motor of a machine tool is

achieved. With the αi series, a high-speed winding is used to

remarkably increase the output level in the high-speed area, thus

reducing acceleration/deceleration time. With the αi

low-speed winding is used to increase the torque by a factor of

1.5.

- An up-to-date stator cooling method is employed for direct aircooling of the electromagnetic steel plate. So, a high power and

high torque are achieved with a compact size.

- By precision rotor aluminum casting and accurate rotor balance

correction, vibration grade V3 (option) is achieved even at high

speed.

- The user can select a motor fan exhaust direction: forward

direction or backward direction. An exhaust direction that

subjects the machine to less heat deformation can be selected.

With the αi series, the cooling air path is optimized to further

improve cooling performance.

- Two types of speed sensors built into the motor are available: Mi

sensor based on the A/B-phase signal and MZi sensor based on

the A/B-phase signal and one-rotation signal. The user can

choose between the two types according to the spindle

configuration and spindle function.

- This series employ waterproof and pressure-proof design

conforming to the international standard (IEC).

P series, a

i series

- 3 -

iT series

Page 26

1.GENERAL SPECIFICATIONS FOR THE αi SERIES B-65272EN/04

α

α

α

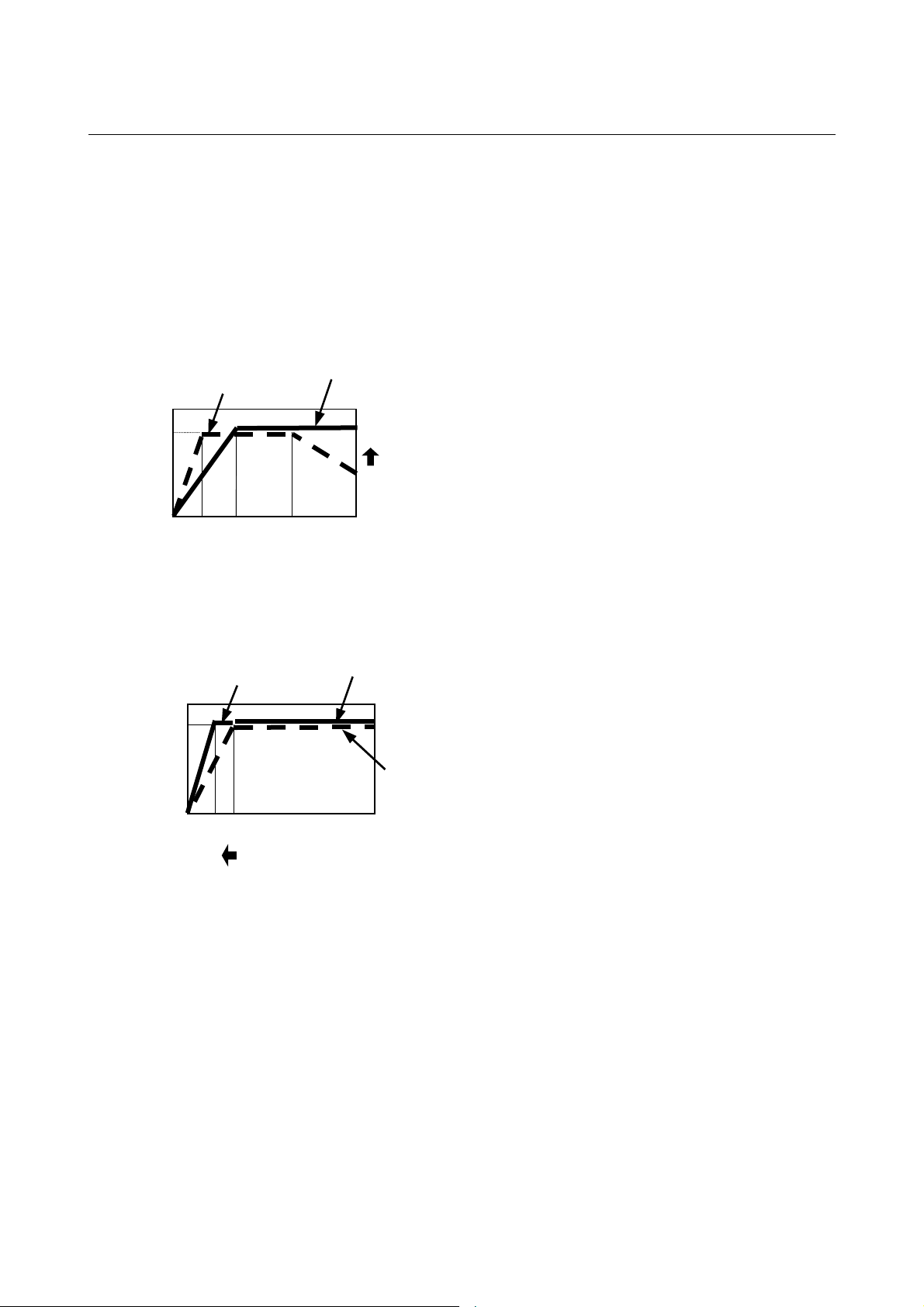

Features of ααααi

- Higher speed

- Increased rated output range by employing winding switching

i, αiT : Remarkable output increase in the high-speed area by employing a high-speed winding.

→ Enables highly efficient cutting and acceleration time reduction

α6/12000i

α6/12000i

(High-speed winding)

(Low-speed winding)

(kW)

7.5

0

4000

1500

Motor speed (min-1)

8000

7.5kW

Output : 2 times

3.7kW

12000

iP: Remarkable torque increase in the low-speed area by employing a low-speed winding

→ Enables optimal spindle speed selection and motor model downsizing

α12/6000iP

(Low-speed winding)

(kW)

7.5

α12/6000iP

(High-speed winding)

P12/6000

0

Torque : 1.5 times

750

500

Motor speed (min-1)

6000

- Low vibration: Vibration grade V3 (optional specification with the non-key type

only)

- 4 -

Page 27

B-65272EN/04 SPECIFICATIONS FOR THE αi SERIES 2.CONFIGURATION OF THE αi series

2 CONFIGURATION OF THE α

αi series

αα

The FANUC AC Spindle Motor αi series consists of the series listed

below with their features.

Feature

Series

αi

αiP

α(HV)i

αiT

αiL

Rated

output

0.55 to 45 Standard motors for machine-tool spindles

5.5 to 30

0.55 to 100

Motors with constant output over a wide range, which require no

reduction units

αi series directly connectable to a 400 V power supply

1.5 to 22 Model for direct spindle connection used with machining centers

7.5 to 30

Liquid-cooled model for direct spindle connection used with high

precision machining centers

Feature

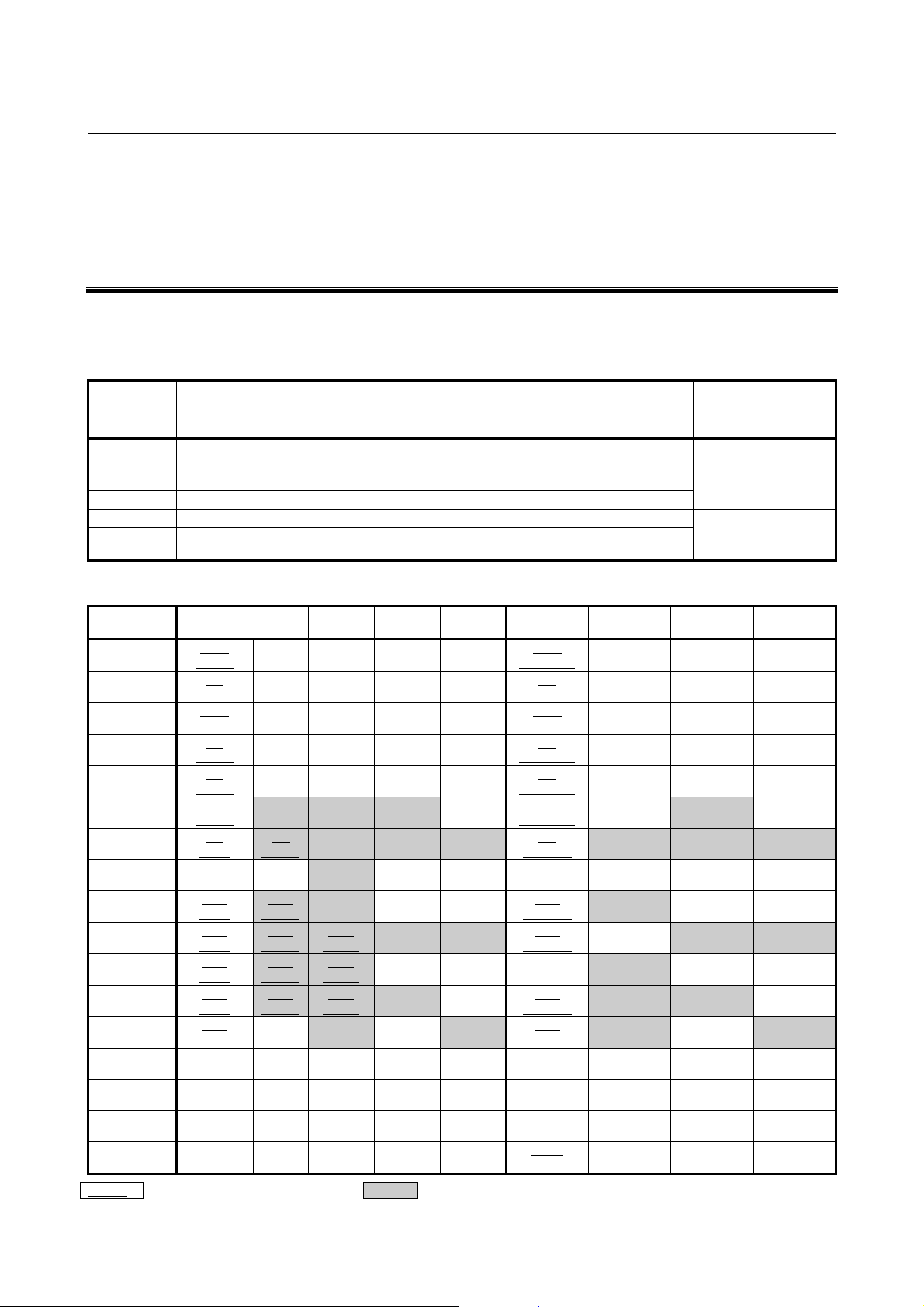

Lineup for ααααi series spindle motor

Continuous

rated output

0.55

1.1

1.5

2.2

3.7

5.5

7.5

9

11

15

18.5

22

30

37

45

60

100

15000 Highest-speed upgraded model Model supporting winding switching

ααααi ααααi

αααα0.5/

10000i

αααα1/

10000i

αααα1.5/

10000i

αααα2/

10000i

αααα3/

10000i

αααα6/

10000i

αααα8/

8000i

αααα12/

7000i

αααα15/

7000i

αααα18/

7000i

αααα22/

7000i

αααα30/

6000i

α40/

6000i

α50/

4500i

α1/

15000i

α1.5/

15000i

α2/

15000i

α3/

12000i

α6/

12000i

αααα8/

10000i

αααα12/

10000i

αααα15/

10000i

αααα18/

10000i

αααα22/

10000i

P α

α12/

6000iP

α15/

6000iP

α18/

6000iP

α22/

6000iP

αααα30/

6000iP

αααα40/

6000iP

αααα50/

6000iP

α60/

4500iP

αiT ααααiL αααα(HV)i αααα(HV)iP αααα(HV)iT αααα(HV)iL

αα

αααα0.5/

10000HVi

αααα1/

10000HVi

α1.5/

15000i

α2/

15000i

α3/

12000i

α6/

12000iT

α8/

12000iT

α15/

12000iT

α22/

10000iT

T

T

T

α8/

20000iL

α15/

15000iL

α26/

15000iL

αααα1.5/

10000HVi

αααα2/

10000HVi

αααα3/

10000HVi

αααα6/

10000HVi

αααα8/

8000HVi

αααα12/

7000HVi

αααα15/

7000HVi

αααα22/

7000HVi

αααα30/

6000HVi

α40/

6000HVi

α60/

4500HVi

αααα100/

4000HVi

α15/

6000HViP

α22/

6000HViP

α40/

6000HViP

α50/

6000HViP

α60/

4500HViP

Example of

applicable

machine

For Lathe and

Machining center

For Machining

center

α1.5/

15000HVi

15000HVi

12000HVi

12000HViT

12000HViT

12000HViT

10000HViT

T

α2/

T

α3/

T

α6/

α8/

α15/

α22/

α8/

20000HViL

α15/

15000HViL

α26/

15000HViL

- 5 -

Page 28

3.MOTOR TYPES SPECIFICATIONS FOR THE αi SERIES B-65272EN/04

3 MOTOR TYPES

Each model includes the types of motors listed below, and the user

can make an optimal choice according to the spindle driving structure.

See the ordering list (B-65271EN) for available motors.

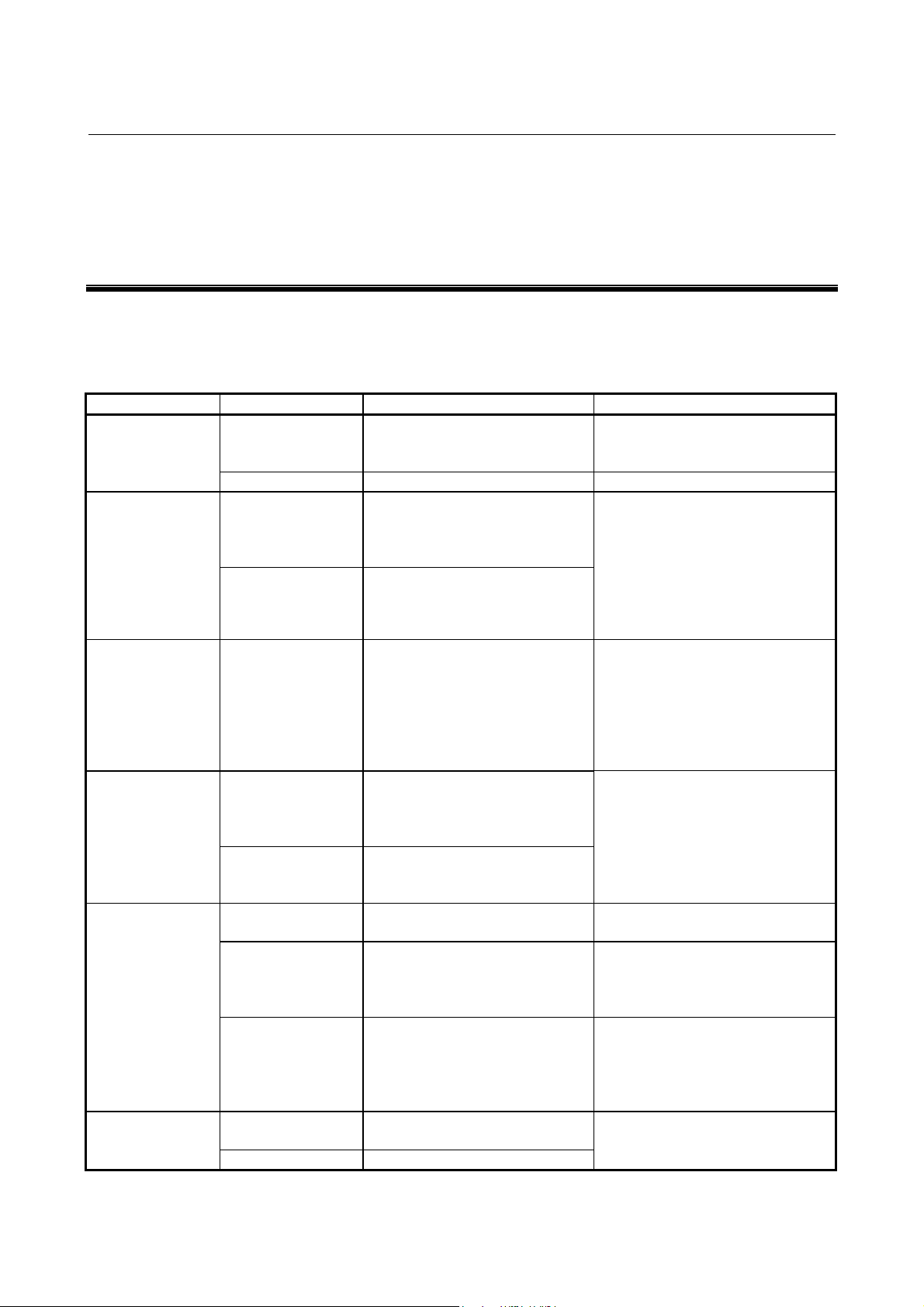

Item Type Use Remarks

Mounting types

Built-in sensor

Connected to spindle via a gear

Flange mounting type

Foot mounting type Connected to spindle via a belt

Mi sensor

MZi sensor

Directly connected to a spindle

Connected to spindle via a belt

When connected to the spindle via a

belt or gear at a deceleration ratio

other than 1:1

(When the spindle has a sensor)

When connected to the spindle via a

belt, gear, or coupling on a 1:1 basis

(When the spindle has no sensor)

The motor can be positioned

accurately.

For a detailed explanation, refer to the

following descriptions:

Subsection, “Spindle Amplifier Module

(SPM)” in the SERVO AMPLIFIER αi

series DESCRIPTIONS (B-65282EN)

Shaft figure With no key Connected to a pulley

Rearward exhaust

Cooling air exhaust

direction

Output shaft seal

Maximum speed

(Exhaust from side

opposite the output

shaft)

Forward exhaust

(Exhaust from the

output shaft side)

Oil seal

Labyrinth

No seal

Standard-speed

model

High-speed model -

When the machine is positioned at

the output shaft side

When the machine is positioned at

the side opposite the output shaft

Gear connection, direct connection,

and belt driving

Belt driving and direct connection

(Only when no lubricant or coolant

splashes onto the flange surface of

the motor)

Belt driving

(Only when no lubricant splashes

onto the flange surface of the motor)

-

A shaft with no key is used as

standard to facilitate pulley and gear

balance correction and acceleration/

deceleration operation.

When a shaft with a key is needed,

contact your FANUC sales

representative.

Direct the exhaust out and away from

the machine.

Used in flange mounting type

standard-speed models.

Used in flange mounting type highspeed models. (Some high-speed

models have an oil seal.)

Foot-mounting type models have no

output shaft seal, but can be changed

to a model with an oil seal or labyrinth.

For the models that can be changed,

refer to "Order List" (B-65271EN).

Consider the maximum speed of each

model and select a model accordingly.

- 6 -

Page 29

B-65272EN/04 SPECIFICATIONS FOR THE αi SERIES 4.NOTES ON INSTALLATION

4 NOTES ON INSTALLATION

- 7 -

Page 30

4.NOTES ON INSTALLATION SPECIFICATIONS FOR THE αi SERIES B-65272EN/04

4.1 COMMON

Be sure to observe the following, regardless of the connection method

of the motor:

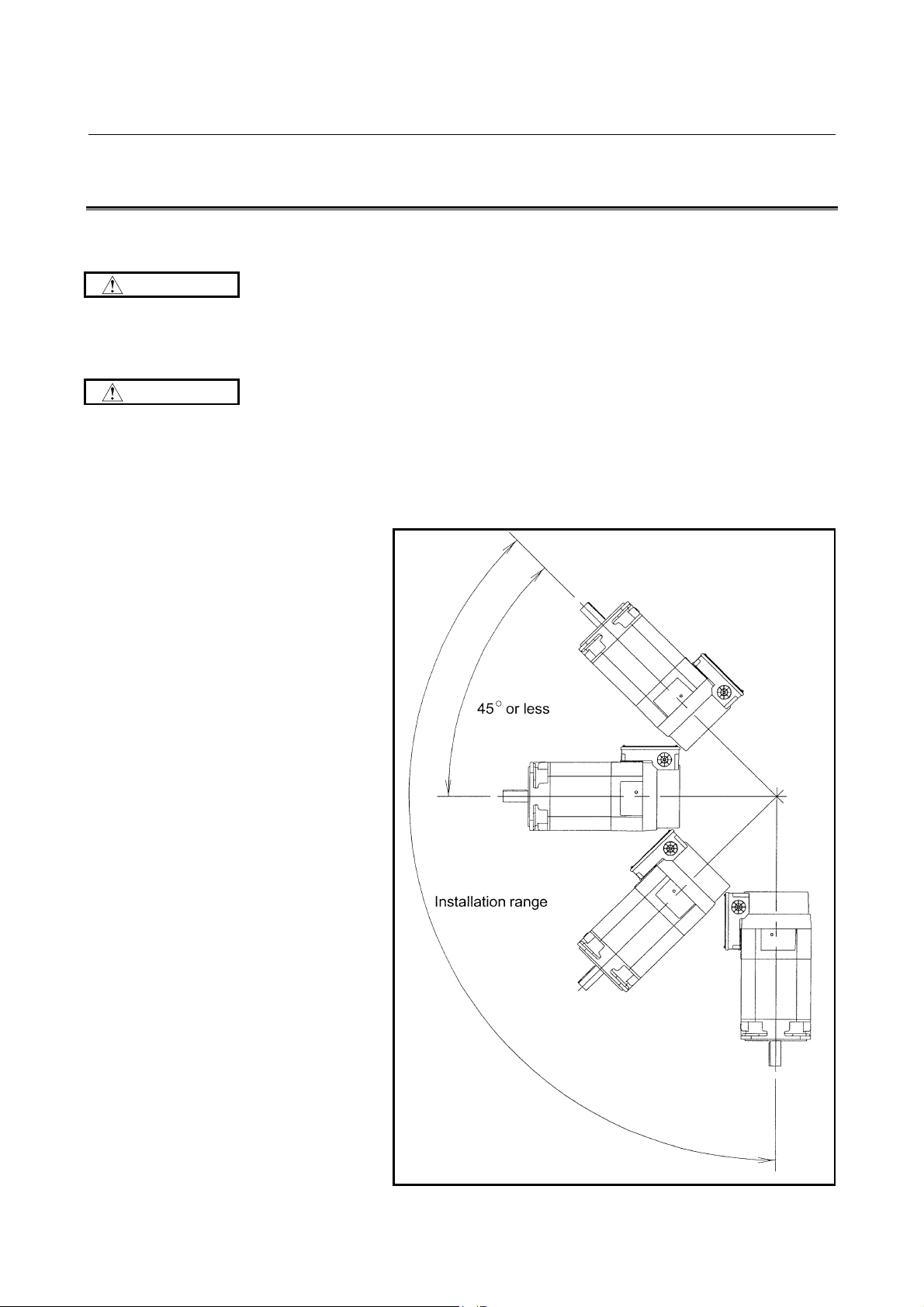

WARNING

When connecting a metallic conduit to a plastic terminal box, connect

the conduit to ground on the power magnetics cabinet side.

CAUTION

1 Mount the motor so that the output shaft points in a direction

ranging within 45° degrees above the horizontal to vertically

downwards.

2 When the motor needs to be pointed to more than 45° degrees

above the horizontal, consult you FANUC representative.

- 8 -

Page 31

B-65272EN/04 SPECIFICATIONS FOR THE αi SERIES 4.NOTES ON INSTALLATION

3 Use the eyebolt of the motor to lift only a single motor, (gear and

pulley may be attached).

4 Place a cover over an air-cooled motor to prevent the motor from

being exposed to coolant or lubricant.

5 Limit the vibration acceleration at the rear bracket of the motor

to 0.5 G (4.9 m/s

2

) to ensure the long-term reliability of each part

of the motor.

In particular, to limit the acceleration in the case of direct

connection to 0.5 G, carefully perform centering with the mating

spindle and make the motor shaft parallel with the spindle.

Details of the measuring method

Measuring instrument:

Equivalent to the VM-3314A or VM-3304 manufactured by

IMV CORPORATION.

Condition: At the time of highest-speed rotation with no load

Measurement frequency range with no load at the highest speed:

10 to 1000 Hz

Criteria: 0.5 G (4.9 m/s

1. Using a pickup

A. Pressing a pickup against

the side of the rear bracket

2

) or less at the rear bracket

B. Screwing a block into the eyebolt

internal thread on the rear

bracket, then screwing a pickup

into the block.

Block

Pickup

Side of the rear bracket

2. Vibration measurement position (rear bracket)

Eyebolt

internal thread

- 9 -

Pickup

Eyebolt internal thread

Side of the rear bracket

Page 32

4.NOTES ON INSTALLATION SPECIFICATIONS FOR THE αi SERIES B-65272EN/04

6 Dynamic balance

During high-speed operation, a small imbalance may cause a

large vibration, resulting in an unusual sound, premature bearing

damage, or some other abnormality.

Therefore, reduce the amount of the imbalance with the dynamic

balance of the other rotation shafts, as well as the gear and

pulley mounted on the output shaft of the motor, as much as

possible.

- Balance correction

With the αi series, a shaft with no key is used as standard to

facilitate the balance correction of a pulley, gear, and

coupling attached to the shaft. Use a completely symmetric

pulley, gear, or coupling, and use a backlash-less tightening

part such as a SPANN ELEMENTE to secure a pulley, gear,

or coupling to the shaft. When attaching a pulley to a shaft,

for example, adjust the periphery vibration to within 20 µm.

This basically eliminates the need for balance correction.

To further reduce the vibration level, make a field balance

correction, for example, by tightening a screw into the

tapped hole for balance correction provided on a

component such as a pulley.

NOTE

When a shaft with a key is required, contact your

FANUC sales representative.

- 10 -

Page 33

B-65272EN/04 SPECIFICATIONS FOR THE αi SERIES 4.NOTES ON INSTALLATION

7 Output shaft seal

To prevent cutting lubricant or dust from penetrating inside the

motor, one of the following output shaft seals is provided on the

output shaft. (For the use and applicable motors, see Chapter 3,

"MOTOR TYPES.")

For those models with an oil seal, ensure that the surface of the

lubricant is below the lip of the oil seal.

If a simple labyrinth is used as the output shaft seal (high-speed

model) or if no seal is provided (foot mounting type), ensure that

lubricant does not splash onto the flange surface. (If such a

motor is directly mounted on a gear box, the lubricant may

gradually penetrate inside the motor even when no lubricant

splashes on flange surface, thus resulting in motor failure.

Therefore, do not mount such a motor on a gear box directly.

- 11 -

Page 34

4.NOTES ON INSTALLATION SPECIFICATIONS FOR THE αi SERIES B-65272EN/04

8 The lid of the terminal box is provided with rubber gasket to

make it waterproof.

Check that the lid has this gasket, then mount it on the terminal

box.

9 The edge of the fauset joint to mount the flange mounting type

motor should be chamfered about C1.

10 Please space 30 mm or more between the fan cover and the

partition to keep the cooling ability well.

We recommend to take a structure such as you can clean air

holes and the fan cover easily.

- 12 -

Page 35

B-65272EN/04 SPECIFICATIONS FOR THE αi SERIES 4.NOTES ON INSTALLATION

11 If much oil mist, dust, or other foreign matter settles on the

motor, the cooling performance is degraded, resulting in

degraded performance of the motor. Design the machine such

that only clean cooling air is drawn into the motor.

Example)

When a duct with a filter is installed on a flange mounting

type motor with a rear exhaust (The filter requires periodic

cleaning.)

- 13 -

Page 36

4.NOTES ON INSTALLATION SPECIFICATIONS FOR THE αi SERIES B-65272EN/04

NOTE

1 A foot mounting type motor has no oil seal. When an oil seal is

required, add #0002 to the drawing number of the motor. An oil

seal cannot be attached to any high-speed model, however. For

details, refer to "Order List" (B-65271EN).

Example)

Model α12/7000i (foot mounting type, with no key,

rearward exhaust)

A06B-1408-B200

A06B-1408-B200#0002 (with oil seal)

2 When the oil seal is not exposed to lubricant, remove the coil

spring of the oil seal to decrease the friction between the lip and

shaft.

There is no problem with dry dust sealing.

If the motor is turned at high speed with the contact section

between the oil seal and shaft being dry, the contact section can

make an abnormal sound (interfering sound), or the lip can be

damaged.

- 14 -

Page 37

B-65272EN/04 SPECIFICATIONS FOR THE αi SERIES 4.NOTES ON INSTALLATION

3 Cable wiring

Follow the procedure below to install the cable.

(1) Use a hammer to strike the portion for the cable hole on the

terminal box and open the hole.

This time, pay attention not to break the other place except

hole. (In some models, it is not necessary to make a hole.)

(2) Thread the cable through a conduit. Connect the conduit

with the connector. (*1)

(3) Tighten the connector at the cable hole of the terminal box

using a nut. (*2, *3)

(4) Connect each terminal appropriately in the terminal box

with screws.

When a hole once made is not used, purchase the following

rubber bushing and mount it at the hole.

Do not open a hole where it is not required.

Break the thin plastic plate to make a hole.

Model Ordering number

α1i to α15i , α12iP to α22iP

α1.5/15000iT to α15/10000iT

α6HVi to α22HVi

α15HVi

α1.5/15000HViT to α22/10000HViT

α8/20000iL , α8/20000HViL

α18i, α22i, α30iP, α40iP, α50iP

α40HViP , α50HViP

α15/12000iT, α22/10000iT

α15/15000iL, α26/15000iL

α15/15000HViL, α26/15000HViL

P , α22HViP

A06B-0754-K001

A06B-0731-K001

High-speed models are same as above.

- 15 -

Page 38

4.NOTES ON INSTALLATION SPECIFICATIONS FOR THE αi SERIES B-65272EN/04

*1 If a 90° connector is used on any of the following models,

the mounting orientation of its conduit is limited as shown

below to avoid interference between the conduit and motor.

If you want to mount the conduit in any orientation, use a

45° connector. (For any model other than listed below, the

conduit for a 90° connector can be mounted in any

orientation.)

Applicable models :

α12i to α15i, α12i

α12HVi to α22HVi, α15/6000HVi

α15/10000HVi

Conduit mounting orientation for a 90° connector

Conduit mounting orientation for a 45° connector

P to α22iP, α15/10000iT,

P to α22/6000HViP,

T, α15/12000HViT, α22/10000HViT

*2 The nut used to fasten the connector to the terminal box

must be smaller than the size listed below. (Any larger nut

interferes with the terminal box.) For the diameter of the

cable hole in each model, refer to the outside dimension

drawing of the respective models.

Cable hole

diameter

φ42.5 mm 53 mm (maximum) 9 mm (maximum)

φ61 mm 80 mm (maximum) 15 mm (maximum)

Outside dimensions of the conduit-connector retaining nut

Outside diameter e Width t

e

t

- 16 -

Page 39

B-65272EN/04 SPECIFICATIONS FOR THE αi SERIES 4.NOTES ON INSTALLATION

*3 If the connector you want to use is smaller than the cable

hole on the terminal box, prepare the bushing, nut, and O-

ring shown below.

O-ring

Connector

Bushing

diameter

φφφφD

φ42.5 mm P46 C0462G

φ61 mm P65 C0650G

Nut

O-ring codeCable hole

JIS B 2401 ISO 3601-1

* For the diameter of the cable hole in each model, refer

to the outside dimension drawing of the respective

models.

- 17 -

Page 40

4.NOTES ON INSTALLATION SPECIFICATIONS FOR THE αi SERIES B-65272EN/04

4 Center of gravity

The distance L from the flange end face to the center of gravity

in each model is listed below.

Center

of gravity

L

ααααi

series

α0.5/10000i

α1/10000i

α1/15000i

α1.5/10000i

α1.5/15000i

α2/10000i

α2/15000i

α3/10000i

α3/12000i

α6/10000i

α6/12000i

α8/8000i

α8/10000i

α12/7000i

α12/10000i

α15/7000i

α15/10000i

α18/7000i

α18/10000i

α22/7000i

α22/10000i

α30/6000i α30/6000iP α30/6000HVi

α40/6000i α40/6000iP α40/6000HVi α40/6000HViP

-

α50/4500i

-

--

ααααiP

series

-

-

-

-

-

-

-

α12/6000iP

α12/8000iP

α15/6000iP

α15/8000iP

α18/6000iP

α18/6000iP

α22/6000iP

α22/8000iP

α50/4500i

α60/4500i

P

---

P α60/4500HVi α60/4500HViP

αααα (HV)i

series

α0.5/10000HVi

α1/10000HVi

α1.5/10000HVi

α2/10000HVi

α3/10000HVi

α6/10000HVi

α8/8000HVi

α12/7000HVi

α15/7000HVi α15/6000HViP

--

α22/7000HVi α22/6000HViP

-

α100/4000HVi

αααα(HV)iP

series

- 95±5

- 125±5

- 145±5

- 125±5

- 170±5

- 150±5

- 185±5

- 160±5

-

α50/6000HVi

-

Center of gravity [mm]

P

- 18 -

Page 41

B-65272EN/04 SPECIFICATIONS FOR THE αi SERIES 4.NOTES ON INSTALLATION

4.2 POWER LEAD CONNECTION

WARNING

To attach the power leads and jumpers, follow the procedure

described in this section to make connections with specified torque.

Driving a motor with terminals loosened could result in the terminal

board overheating and causing a fire. In addition, it may remove

terminal to cause a ground fault, short circuit, or electric shock.

CAUTION

1. When attaching the power leads and jumpers to the terminal

board of a motor, tighten the screws with torque specified in the

table. For the terminal size of a terminal board, refer to Chapter

4, "CONNECTIONS" in the manual of the corresponding series.

Terminal size

M4 1.1 to 1.5

M5 2.0 to 2.5

M6 3.5 to 4.5

M8 8 to 10

M10 15 to 16

Tightening torque

[N⋅⋅⋅⋅m]

2. To maintain the required isolation distance, observe the

following:

• When attaching a crimp terminal at the end of a power lead,

cover the crimped portion of the crimp terminal with

insulating tube.

• If the terminal board is provided with an insulating cover,

fasten the power leads with the screws, and then put back

the insulating cover in place.

3. If you want to energize an output switching type motor only with

the low- or high-speed winding rather than switching its output,

jumper the low- or high-speed winding, whichever is applicable,

and then connect three power leads (the U-, V-, and W-phase

wires) to the motor (except for the α15/12000i

T and αiL series

motors).

The output switching type motors in the αi series, αi

α(HV)i

P series come standard with jumpers in the terminal box.

P series, and

If you want to any other output switching type motor, place an

order for jumpers according to the following list.

- 19 -

Page 42

4.NOTES ON INSTALLATION SPECIFICATIONS FOR THE αi SERIES B-65272EN/04

Terminal

size

M5 Low-speed winding A65L-0001-0630/SS 1

M5 High-speed winding A65L-0001-0630/SD 3

M6 Low-speed winding A290-1410-X416 1

M6 High-speed winding A290-1410-X417 3

Specification of the

winding to be used

Ordering number

Required

quantity

- 20 -

Page 43

B-65272EN/04 SPECIFICATIONS FOR THE αi SERIES 4.NOTES ON INSTALLATION

X

X

4. How to connect power leads to output switching type motors

For output switching type motors, six power leads (the U-, V-,

W-, X-, Y-, and Z-phase wires) can be connected on the terminal

board.

•••• Detailed descriptions of an

M5 type terminal board

The terminal board has two

rows. The U-, V-, and W-phase

leads can be connected to the

upper row, while the Z-, X-, and

Y-phase wires can be

connected to the lower row.

1) Using the motor by switching its output

To use the motor by switching its output, connect the six

power leads (the U-, V-, W-, X-, Y-, and Z-phase wires)

respectively to the terminal board screws marked U, V, W,

X, Y, and Z.

(For the α15/12000i

board screws are marked U

•••• Connecting power wires to

an M5 type terminal board

<1> Connecting power leads to

the lower row

Attach the Z-, X-, and Yphase power leads to the

lower row and fasten them

with the screws.

Screws (six M5 screws)

Cover

Z

Y

T and αiL series motors, the terminal

, V1, W1, U2, V2, and W2.)

1

Power lead

U

V

W

Te r m in a l bo a r d

Z

Y

U

<2> Attaching power leads to

the upper row

After putting the cover on

the lower row, attach the

U-, V-, and W-phase power

leads to the upper row and

fasten them with the

Cover

V

W

- 21 -

Page 44

4.NOTES ON INSTALLATION SPECIFICATIONS FOR THE αi SERIES B-65272EN/04

X

X

Y

2) Using the motor by energizing it only with the low-speed

winding (Y connection) rather than switching its output

•••• Connecting power leads to an M5

type terminal board

<1> Mounting a jumper

Mount a jumper on the lower row to

make electric connections (Z-X-Y)

among the three terminals on the

lower row.

The jumper must be mounted in the

specified orientation. See the figure

at the right.

Jumper

(A65L-0001-0630/SS)

Z

Y

<2> Attaching power leads

After putting the cover on the

lower row, attach the U-, V-, and

W-phase power leads to the

upper row and fasten them with

the screws.

•••• Connecting power leads to an M6 type

terminal board

<1> Mounting a jumper

Mount a jumper on the lower row to

make electric connections among the

Z, X, and Y terminals.

The jumper must be mounted in the

specified orientation. See the figure at

the right.

Jumper

(A290-1410-X416)

Cover

Power lead

U

V

W

Power leads (six)

on the motor side

Z

<2> Attaching power leads

Attach the U-, V-, and W-phase

power leads and fasten them with

the screws.

Power lead

U

V

W

- 22 -

Page 45

B-65272EN/04 SPECIFICATIONS FOR THE αi SERIES 4.NOTES ON INSTALLATION

(

A

)

3) Using the motor by energizing it only with the high-speed

winding (∆ connection) rather than switching its output

•••• Connecting power leads to an M5

type terminal board

<1> Mounting jumpers

Mount three jumpers between the

upper and lower rows to make

electric connections between U

and Z, between V and X, and

between W and Y.

The jumpers must be mounted in

the specified orientation. See the

figure at the right.

<2> Attaching power leads

Attach the U-, V-, and Wphase power leads to the

upper row and fasten them

with the screws.

No cover need be put on

the lower row.

Jumper

65L-0001-0630/SD

U

Z

U

V

W

Power lead

•••• Connecting power leads to an M6

type terminal board

<1> Mounting jumpers

Mount three jumpers to make an

electric connection in each pair of

adjacent terminals (between U

and Z, between V and X, and

between W and Y).

The jumper must be mounted in

the specified orientation. See the

figure at the right.

<2> Attaching power leads

Attach the U-, V-, and Wphase power leads and

fasten them with the

screws.

Power lead

Power leads (six)

on the motor side

U

Z

Jumper

(A290-1410-X417)

U

V

W

- 23 -

Page 46

4.NOTES ON INSTALLATION SPECIFICATIONS FOR THE αi SERIES B-65272EN/04

4.3 FAN MOTOR CONNECTION

50Hz 60Hz

ααααi, ααααiP, ααααiT series

spindle motor models

α1i, α1.5i, α1.5iT

α2i, α3i, α2iT, α3iT

α6i, α8i, α6iT, α8iT

α12i to α22i,

α12i

P to α22iP,

α15i

T, α22iT

α30i, α40i,

α30i

P, α40iP, α50iP

α50i, α60i, α60iP

αααα(HV)i, αααα(HV)iP, αααα(HV)iT series

spindle motor models

α1HVi, α1.5HVi, α1.5HViT

Rated

voltage

[V]

240 0.15 0.47 240 0.12 0.48

200 0.10 0.41 200 0.10 0.40

200 0.13 0.50 200 0.14 0.51

200 0.22 1.15 200 0.32 1.10

200 0.65 3.12 200 0.8 3.06

200 0.75 3.96 200 0.75 3.68

Rated

voltage

[V]

200 0.09 230 0.11

Rated

current

[A]

50Hz 60Hz

Rated

current

[A]

Surge

current

[Ap-p]

Surge

current

[Ap-p]

Rated

voltage

[V]

Rated

voltage

[V]

Rated

current

[A]

Rated

current

[A]

Surge

current

[Ap-p]

Surge

current

[Ap-p]

α2HVi, α3HVi,

α2HVi

T, α3HViT

α6HVi, α8HVi,

α6HVi

T, α8HViT

α12HVi to α22HVi,

α15HVi

α100HVi (circumference fan),

α100HVi (back fan)

P, α22HViP,

α15HVi

α40HVi

T, α22HViT

α30HVi, α40HVi,

P, α50HViP

α60HVi, α60HViP

NOTE

1 The term "surge current" represents a peak-to-peak

2 The values listed below are a rough standard. They

200 0.11 230 0.13

400 0.07 0.31 480 0.08 0.37

400 0.20 0.97 480 0.24 1.22

380 0.30 1.86 380 0.35 1.82

380 0.30 2.18 380 0.30 1.98

400 0.30 400 0.36

current that flows when the power is turned on.

are not guaranteed.

- 24 -

Page 47

B-65272EN/04 SPECIFICATIONS FOR THE αi SERIES 4.NOTES ON INSTALLATION

Cable for the fan motor

The machine tool builder is to prepare the following cable for the fan

motor:

Vinyl heavy-duty power cord JIS C 3312 3-conductor

Conductor: 37/0.26 (2 mm

2

)

Sheath: PVCφ11

Crimp terminal: T2-4S

<1> For a non-screw terminal block (Peel off each wire sheath on the

motor side by 8 to 9 mm.)

11

φ

<2> For an M4 or M3.5 screw terminal block (Attach crimp terminals

to the both ends.)

11

φ

- 25 -

Page 48

4.NOTES ON INSTALLATION SPECIFICATIONS FOR THE αi SERIES B-65272EN/04

Method of connection to a non-screw terminal for the fan motor

<4>

<2>

Conductor

8 to 9mm

ConductorSheath

<3>

Screwdriver

<1>

Spring

Conductive plate

Peel-off length of a wire sheath

By using an appropriate tool, peel off each wire sheath by 8 to 9

mm.

Screwdriver

Use a flat-blade screwdriver with a blade size of 3.5 × 0.5 mm.

(210-120J (standard type), 210-350J (short type) manufactured

by WAGO)

Connection procedure

<1> Insert the tip of the screwdriver into the screwdriver insertion

slot (small rectangular hole) until the tip touches the spring. Next,

while tilting the screwdriver toward the inside of the terminal

block, push the screwdriver until it butts the conductive plate. In

this state, the spring is opened completely, and the screwdriver is

held in the terminal block. Ensure that the screwdriver is secured.

Otherwise, the next step (wire insertion) cannot be conducted

easily.

<2> Check the peel-off length (8 to 9 mm), then insert the wire into

the wire insertion slot (large rectangular hole) until it stops, by

sliding the wire along the outer side of the hole slowly so that

the conductor does not become loose. Be careful not to push a

thin wire excessively.

<3> While holding down the inserted wire by one hand, extract the

screwdriver. The spring is closed to make a connection.

<4> By slightly pulling the wire, check that the wire is connected

firmly. The wire need not be pulled intensely.

Inside the terminal box

Cautions

- Only one wire must be connected to one spring.

- A wire, which may be a stranded wire or single conductor, can

Non-screw

terminal block

be directly connected without performing terminal processing if

its sheath is peeled off. A wire after ferrule processing can also

be connected.

Screwdriver

Conductor

Non-screw terminal block

(cross section)