Page 1

GE Fanuc Automation

Computer Numerical Control Products

Series 30i/300i/300is-MODEL A

Series 31i/310i/310is-MODEL A5

Series 31i/310i/310is-MODEL A

Series 32i/320i/320is-MODEL A

Connection Manual (Hardware)

GFZ-63943EN/02 June 2004

Page 2

Warnings, Cautions, and Notes

as Used in this Publication

Warning notices are used in this publication to emphasize that hazardous voltages, currents,

temperatures, or other conditions that could cause personal injury exist in this equipment or

may be associated with its use.

In situations where inattention could cause either personal injury or damage to equipment, a

Warning notice is used.

Caution notices are used where equipment might be damaged if care is not taken.

GFL-001

Warning

Caution

Note

Notes merely call attention to information that is especially significant to understanding and

operating the equipment.

This document is based on information available at the time of its publication. While efforts

have been made to be accurate, the information contained herein does not purport to cover all

details or variations in hardware or software, nor to provide for every possible contingency in

connection with installation, operation, or maintenance. Features may be described herein

which are not present in all hardware and software systems. GE Fanuc Automation assumes

no obligation of notice to holders of this document with respect to changes subsequently made.

GE Fanuc Automation makes no representation or warranty, expressed, implied, or statutory

with respect to, and assumes no responsibility for the accuracy, completeness, sufficiency, or

usefulness of the information contained herein. No warranties of merchantability or fitness for

purpose shall apply.

©Copyright 2004 GE Fanuc Automation North America, Inc.

All Rights Reserved.

Page 3

B-63943EN/02 DEFINITION OF WARNING, CAUTION, AND NOTE

DEFINITION OF WARNING, CAUTION, AND NOTE

This manual includes safety precautions for protecting the user and

preventing damage to the machine. Precautions are classified into

Warning and Caution according to their bearing on safety. Also,

supplementary information is described as a Note. Read the Warning,

Caution, and Note thoroughly before attempting to use the machine.

WARNING

Applied when there is a danger of the user being

injured or when there is a danger of both the user

being injured and the equipment being damaged if

the approved procedure is not observed.

CAUTION

Applied when there is a danger of the equipment

being damaged, if the approved procedure is not

observed.

NOTE

The Note is used to indicate supplementary

information other than Warning and Caution.

• Read this manual carefully, and store it in a safe place.

s-1

Page 4

Page 5

B-63943EN/02 PREFACE

PREFACE

This manual describes the electrical and structural specifications

required for connecting the CNC control unit to a machine tool. The

manual outlines the components commonly used for FANUC CNC

control units, as shown in the configuration diagram in Chapter 2, and

supplies additional information on using these components.

The manual outlines the I/O unit, servo, spindle, and other

components common to FANUC CNC control units, and supplies

additional information on using these components in this CNC control

unit. For detailed specifications, refer to the manuals of these

components.

For options not covered in this manual, also refer to the manuals of

these components.

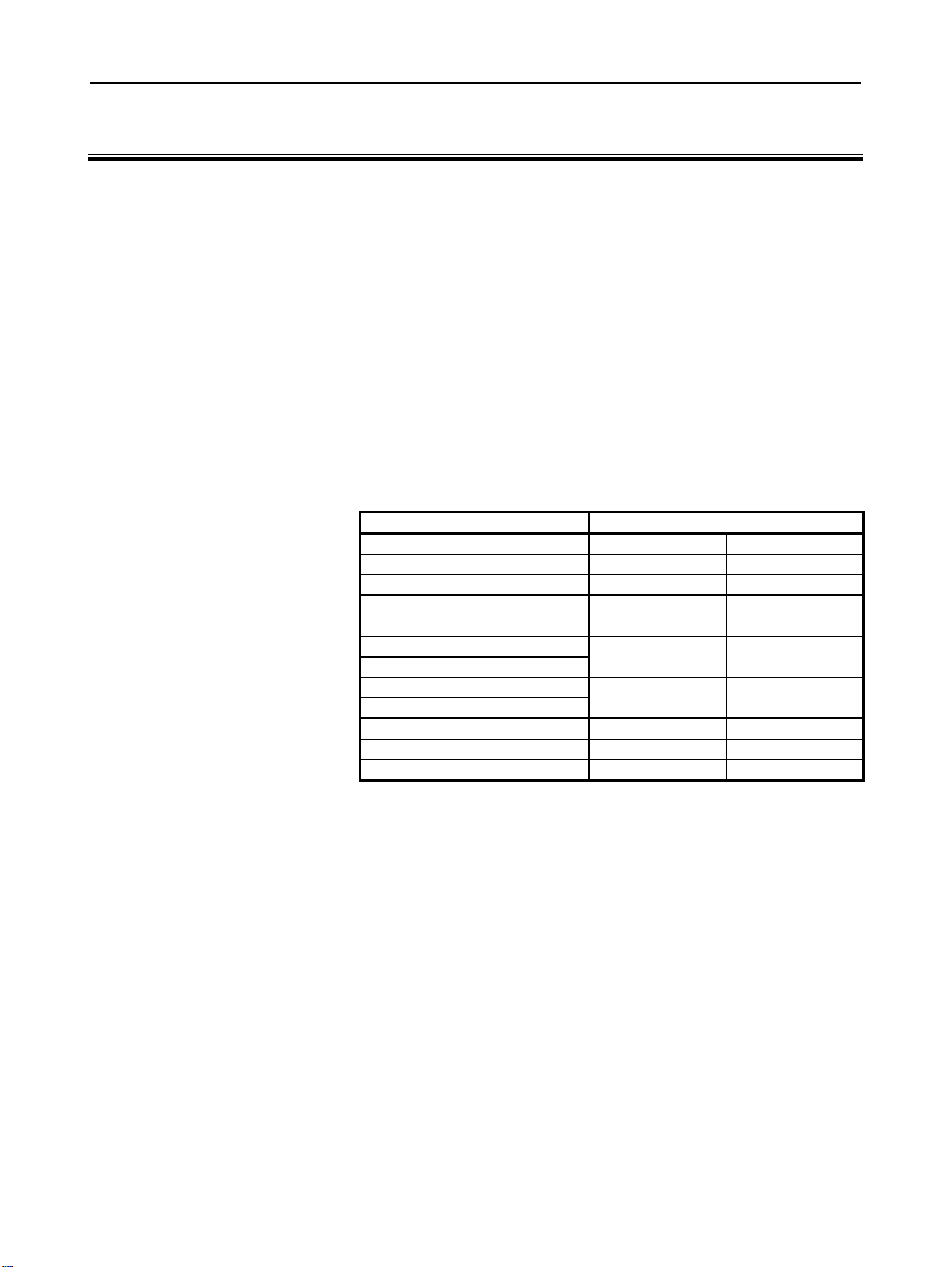

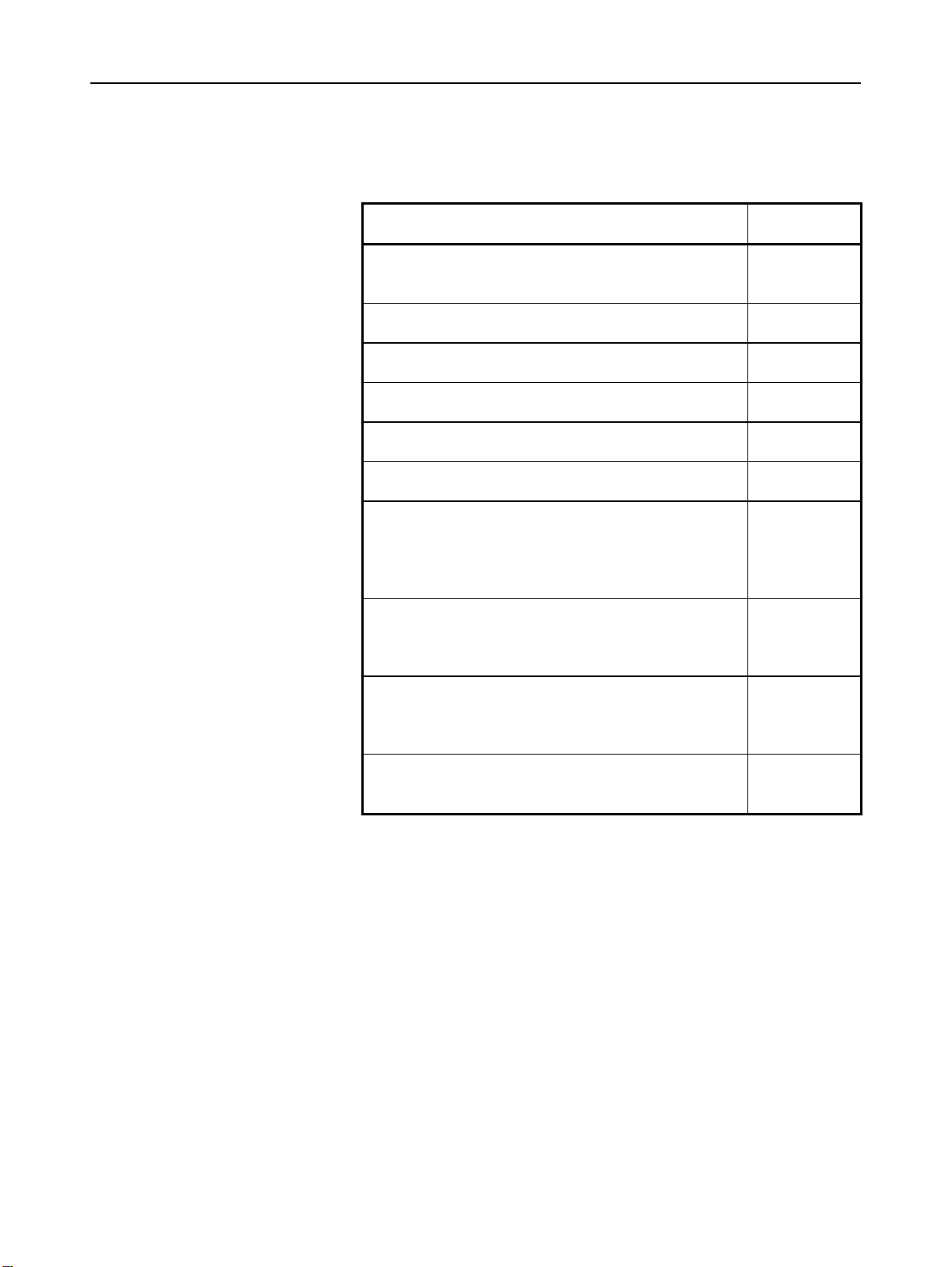

Applicable models

The models covered by this manual, and their abbreviations are :

Model name Abbreviation

FANUC Series 30i-MODEL A 30i Series 30i

FANUC Series 300i-MODEL A 300i Series 300i

FANUC Series 300is-MODEL A 300is Series 300is

FANUC Series 31i-MODEL A5

FANUC Series 31i-MODEL A

FANUC Series 310i-MODEL A5

FANUC Series 310i-MODEL A

FANUC Series 310is-MODEL A5

FANUC Series 310is-MODEL A

FANUC Series 32i-MODEL A 32i Series 32i

FANUC Series 320i-MODEL A 320i Series 320i

FANUC Series 320is-MODEL A 320is Series 320is

31i Series 31i

310i Series 310i

310is Series 310is

p-1

Page 6

PREFACE B-63943EN/02

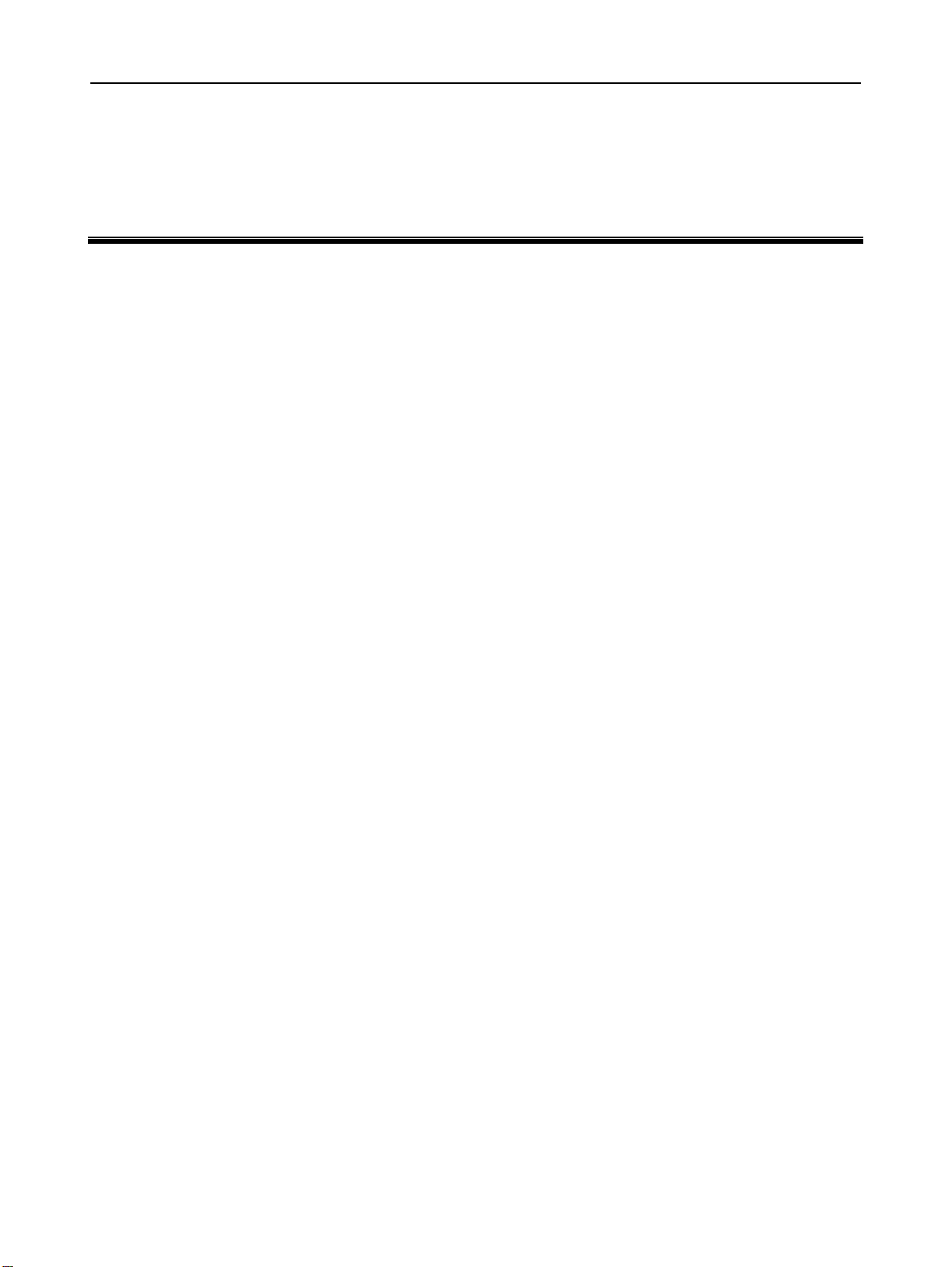

Organization of this manuals

This manual consists of chapters 1 to 13 and appendixes at the end of

the book.

Chapter and title Contents

Chapter 1

CONFIGURATION

Chapter 2

TOTAL CONNECTION

DAIGRAMS

Chapter 3

INSTALLATION

Chapter 4

POWER SUPPLAY

CONNECTION

Chapter 5

CONNECTION TO CNC

PERIOHERALS

Chapter 6

SPINDLE CONNECTION

Chapter 7

SERVO INTERFACE

Chapter 8

CONNECTION TO FANUC I/O

Link

Chapter 9

STOP AND EMERGENCY

STOP

Chapter 10

CONNECTION TO OTHER

NETWORKS

Chapter 11

CONNECTION FOR Series

300is/310is/320is

Chapter 12

HIGH-SPEED SERIAL BUS

(HSSB)

Chapter 13

PANEL i

APPENDIX A) OUTLINE DRAWINGS OF UNITS

Provides general information related to the connection of the 30i series, as well as

an introduction to detailed information.

Describes how to connect peripheral units to the 30i series.

Describes the installation requirements for using the 30i series.

1) Required power supply capacity

2) Heat output

3) Locations of connectors on the control unit

4) Action against noise

Describes how to make connections related to the power supply of the 30i series.

Describes how to connect the following peripheral devices to the 30i series:

1) Display unit / MDI unit

2) I/O device (RS-232-C)

3) High-speed skip (HDI)

4) Embedded Ethernet

Describes how to connect spindle-related units to the 30i series.

Describes how to connect servo-related units to the 30i series.

Describes how to connect machine interface I/O with the FANUC I/O Link.

Describes how to handle the emergency stop signal.

Be sure to read this chapter.

Describes how to connect the 30i series to networks.

Describes connection for Series 300is/310is/320is.

Describes the high–speed serial bus (HSSB) that can be used with the 30i series.

Describes how to connect a PANEL i to the 30i series.

B) 20-PIN INTERFACE CONNECTORS AND CABLES

C) CONNECTION CABLE (SUPPLIED FROM US)

D) OPTICAL FIBER CABLE

E) LIQUID CRYSTAL DISPLAY (LCD)

F) MEMORY CARD INTERFACE

p-2

Page 7

B-63943EN/02 PREFACE

Related manuals of

Series 30i/300i/300is- MODEL A

Series 31i/310i/310is- MODEL A

Series 31i/310i/310is- MODEL A5

Series 32i/320i/320is- MODEL A

The following table lists the manuals related to Series 30i/300i

/300is-A, Series 31i/310i /310is-A, Series 31i/310i /310is-A5, Series

32i/320i /320is-A. This manual is indicated by an asterisk(*).

Table 1 Related manuals

Manual name Specification

number

DESCRIPTIONS B-63942EN

CONNECTION MANUAL (HARDWARE) B-63943EN *

CONNECTION MANUAL (FUNCTION) B-63943EN-1

USER’S MANUAL

(Common to Lathe System/Machining Center System)

USER’S MANUAL (For Lathe System) B-63944EN-1

USER’S MANUAL (For Machining Center System) B-63944EN-2

MAINTENANCE MANUAL B-63945EN

PARAMETER MANUAL B-65950EN

Programming

Macro Compiler / Macro Executor

PROGRAMMING MANUAL

Macro Compiler OPERATOR’S MANUAL B-66264EN

C Language Executor OPERATOR’S MANUAL B-63944EN-3

PMC

PMC PROGRAMMING MANUAL B-63983EN

Network

PROFIBUS-DP Board OPERATOR’S MANUAL B-63994EN

Fast Ethernet / Fast Data Server OPERATOR’S MANUAL B-64014EN

DeviceNet Board OPERATOR’S MANUAL B-64044EN

Operation guidance function

MANUAL GUIDE i OPERATOR’S MANUAL

MANUAL GUIDE i Set-up Guidance

OPERATOR’S MANUAL

B-63944EN

B-63943EN-2

B-63874EN

B-63874EN-1

p-3

Page 8

PREFACE B-63943EN/02

Related manuals of SERVO MOTOR αis/αi/βis/βi series

The following table lists the manuals related to SERVO MOTOR

αis/αi/βis/βi series

Table 2 Related manuals

Manual name

FANUC AC SERVO MOTOR αis series

FANUC AC SERVO MOTOR αi series

DESCRIPTIONS

FANUC AC SPINDLE MOTOR αi series

DESCRIPTIONS

FANUC AC SERVO MOTOR βis series

DESCRIPTIONS

FANUC AC SPINDLE MOTOR βi series

DESCRIPTIONS

FANUC SERVO AMPLIFIER αi series

DESCRIPTIONS

FANUC SERVO AMPLIFIER βi series

DESCRIPTIONS

FANUC SERVO MOTOR αis series

FANUC SERVO MOTOR αi series

FANUC AC SPINDLE MOTOR αi series

FANUC SERVO AMPLIFIER αi series

MAINTENANCE MANUAL

FANUC SERVO MOTOR βis series

FANUC AC SPINDLE MOTOR βi series

FANUC SERVO AMPLIFIER βi series

MAINTENANCE MANUAL

FANUC AC SERVO MOTOR αis series

FANUC AC SERVO MOTOR αi series

FANUC AC SERVO MOTOR βis series

PARAMETER MANUAL

FANUC AC SPINDLE MOTOR αi series

FANUC AC SPINDLE MOTOR βi series

PARAMETER MANUAL

Any of the servo motors and spindles listed above can be connected to

the CNC described in this manual. However, αi series servo amplifiers

can only be connected to αi series SVMs (for 30i/31i/32i).

This manual mainly assumes that the FANUC SERVO MOTOR αi

series of servo motor is used. For servo motor and spindle information,

refer to the manuals for the servo motor and spindle that are actually

connected.

Specification

number

B-65262EN

B-65272EN

B-65302EN

B-65312EN

B-65282EN

B-65322EN

B-65285EN

B-65325EN

B-65270EN

B-65280EN

p-4

Page 9

B-63943EN/02 TABLE OF CONTENTS

TABLE OF CONTENTS

DEFINITION OF WARNING, CAUTION, AND NOTE .................................s-1

PREFACE....................................................................................................p-1

1 CONFIGURATION ..................................................................................1

1.1 CONTROL UNIT CONFIGURATION AND COMPONENT NAMES ..............2

1.1.1 Configurations of LCD-mounted Type Control Units .............................................2

1.1.2 Configurations of Stand-alone Type Control Units..................................................5

1.1.3 Configurations of Optional Boards ..........................................................................9

1.2 HARDWARE OVERVIEW............................................................................ 11

1.2.1 LCD-mounted Type Control Unit Overview .........................................................11

1.2.2 Stand-alone Type Control Unit Overview..............................................................12

2 TOTAL CONNECTION DIAGRAMS .....................................................13

3 INSTALLATION ....................................................................................18

3.1 ENVIRONMENTAL REQUIREMENTS OUTSIDE THE CABINET............... 19

3.1.1 Environmental Conditions outside the Cabinet......................................................19

3.1.2 Installation Conditions of the CNC and Servo Unit in the Cabinet........................20

3.2 POWER SUPPLY CAPACITY .....................................................................21

3.2.1 Power Supply Capacities of CNC-related Units ....................................................21

3.3 DESIGN AND INSTALLATION CONDITIONS OF THE MACHINE TOOL

MAGNETIC CABINET ................................................................................. 23

3.4 THERMAL DESIGN OF THE MACHINE TOOL MAGNETIC CABINET ...... 25

3.4.1 Temperature Rise within the Machine Tool Magnetic Cabinet..............................25

3.4.2 Heat Output of Each Unit.......................................................................................26

3.4.3 Thermal Design of Operator's Panel.......................................................................27

3.5 ACTION AGAINST NOISE .......................................................................... 29

3.5.1 Separating Signal Lines..........................................................................................29

3.5.2 Ground....................................................................................................................31

3.5.3 Connecting the Signal Ground (SG) of the Control Unit.......................................34

3.5.4 Noise Suppressor....................................................................................................37

3.5.5 Cable Clamp and Shield Processing.......................................................................39

3.5.6 Measures Against Surges due to Lightning............................................................42

3.6 CONTROL UNIT.......................................................................................... 44

3.6.1 Installing the LCD-mounted Type Control Unit ....................................................44

3.6.2 Installing the Stand-alone Type Control Unit ........................................................45

c-1

Page 10

TABLE OF CONTENTS B-63943EN/02

3.7 CABLING DIAGRAM ...................................................................................46

3.8 DUSTPROOF MEASURES FOR CABINETS AND PENDANT BOXES ...... 47

4 POWER SUPPLY CONNECTION......................................................... 48

4.1 GENERAL ................................................................................................... 49

4.2 TURNING ON AND OFF THE POWER TO THE CONTROL UNIT............. 50

4.2.1 Power Supply for the Control Unit.........................................................................50

4.2.2 External 24 VDC Power Specification and Circuit Configuration.........................51

4.2.3 Power-on Sequence ................................................................................................55

4.2.4 Power-off Sequence ...............................................................................................55

4.3 CABLE FOR POWER SUPPLY TO CONTROL UNIT ................................. 57

4.4 BATTERIES................................................................................................. 58

4.4.1 Battery for Memory Backup in the CNC Control Unit (3 VDC)...........................58

4.4.1.1 Replacing the lithium battery............................................................................. 59

4.4.2 Batteries for PANEL i (3VDC)..............................................................................64

4.4.3 Battery for Separate Absolute Pulse Coders (6VDC) ............................................66

4.4.4 Battery for Absolute Pulse Coder Built into the Motor (6VDC)............................68

5 CONNECTION TO CNC PERIPHERALS .............................................69

5.1 CONNECTION WITH THE DISPLAY/MDI UNIT

(LCD- MOUNTED TYPE 30i SERIES) ........................................................70

5.1.1 Ovoerview ..............................................................................................................70

5.1.2 Connection to the MDI Unit (LCD-mounted Type 30i Series)..............................70

5.1.3 Connection with the Standard MDI Unit................................................................71

5.1.4 Key Layout of MDI................................................................................................72

5.2 CONNECTION WITH THE DISPLAY/MDI UNIT

(STAND-ALONE TYPE 30i SERIES) ..........................................................75

5.2.1 Overview ................................................................................................................75

5.2.2 Connection with an LCD Unit................................................................................75

5.3 CONNECTION WITH INPUT/OUTPUT DEVICES ......................................78

5.3.1 Overview ................................................................................................................78

5.3.2 Connecting I/O Devices .........................................................................................79

5.3.3 RS-232-C Serial Port..............................................................................................81

5.3.4 RS-232-C Interface Specification...........................................................................83

5.3.5 FANUC Handy FILE .............................................................................................92

5.4 CONNECTING THE HIGH-SPEED SKIP (HDI)........................................... 93

5.4.1 Connecting the High-speed Skip (HDI) .................................................................93

5.4.2 Input Signal Rules for the High-speed Skip (HDI) ................................................95

c-2

Page 11

B-63943EN/02 TABLE OF CONTENTS

5.5 Linking The EMBEDDED Ethernet Interface ............................................... 96

5.5.1 Connection to the Ethernet Interface......................................................................96

5.5.2 Specification of Twisted-Pair Cable.......................................................................98

5.5.3 Anti-Noise Measure .............................................................................................101

5.5.4 Network Installation .............................................................................................101

6 SPINDLE CONNECTION ....................................................................103

6.1 SERIAL SPINDLE...................................................................................... 104

6.1.1 Connection of One to Two Serial Spindles..........................................................104

6.1.2 Connecting One to Four Serial Spindles..............................................................107

6.1.3 Connecting Five or Six Serial Spindles................................................................114

6.1.4 Connecting Seven or Eight Serial spindles ..........................................................115

7 SERVO INTERFACE........................................................................... 116

7.1 CONNECTION TO THE SERVO AMPLIFIERS......................................... 117

7.1.1 Overview ..............................................................................................................118

7.1.2 Interface to the Servo Amplifiers .........................................................................118

7.2 SEPARATE DETECTOR INTERFACE...................................................... 121

7.2.1 Separate Detector Interface Unit Specification ....................................................123

7.2.2 Connection of Power Supply................................................................................124

7.2.3 Separate Detector Interface (Serial Interface) ......................................................126

7.2.4 Separate Detector Interface (Parallel interface)....................................................128

7.2.5 Input Signal Requirements (Parallel interface) ....................................................130

7.2.6 Connection of Battery for Absolute Position Detector.........................................132

7.2.7 Connection Between the Basic Unit and Additional Unit....................................134

7.2.8 Connector Locations.............................................................................................135

7.2.9 Installation............................................................................................................136

7.2.10 Notes on Installing a Separate Detector Interface Unit ........................................137

7.3 ANALOG INPUT SEPARATE DETECTOR INTERFACE .......................... 139

7.3.1 Overview ..............................................................................................................140

7.3.2 Analog Input Separate Detector Interface Unit Specification..............................143

7.3.3 Connection of Power Supply................................................................................143

7.3.4 Analog Input Separate Detector Interface (Analog 1Vp-p Interface) ..................145

7.3.5 Input Signal Specifications...................................................................................146

7.3.6 Connection of Battery for Absolute Position Detector.........................................147

7.3.7 Connection Between the Analog Input Separate Detector Interface Unit and

Additional Unit.....................................................................................................148

7.3.8 Connector Locations.............................................................................................149

c-3

Page 12

TABLE OF CONTENTS B-63943EN/02

7.3.9 Installation............................................................................................................150

7.3.10 Notes on Installing an Analog Input Separate Detector Interface Unit................152

8 CONNECTION TO FANUC I/O Link ................................................... 154

8.1 OVERVIEW ............................................................................................... 155

8.2 CONNECTION........................................................................................... 156

8.2.1 Connection of FANUC I/O Link by Electric Cable.............................................158

8.2.2 Connection of FANUC I/O Link by Optical Fiber Cable ....................................159

8.2.3 Connection when Multiple Channels of FANUC I/O Links are Used.................162

8.3 UNITS THAT CAN BE CONNECTED USING FANUC I/O Link................. 173

8.4 CONNECTION OF CONNECTOR PANEL I/O MODULE.......................... 174

8.4.1 Configuration .......................................................................................................174

8.4.2 Connection Diagram.............................................................................................175

8.4.3 Module Specifications..........................................................................................176

8.4.4 DI/DO Connector Pin Assignment.......................................................................178

8.4.5 DI (Input Signal) Connection...............................................................................179

8.4.6 DO (Output Signal) Connection...........................................................................181

8.4.7 DI/DO Signal Specifications................................................................................182

8.4.8 2A Output Connector Pin Allocation...................................................................184

8.4.9 2A DO (Output Signal) Connection.....................................................................185

8.4.10 2A Output DO Signal Specifications ...................................................................186

8.4.11 Analog Input Connector Pin Allocation...............................................................187

8.4.12 Analog Input Signal Connections.........................................................................188

8.4.13 Analog Input Signal Specifications......................................................................189

8.4.14 Analog Input Specifications .................................................................................190

8.4.15 Manual Pulse Generator Connection....................................................................192

8.4.16 Cable Length for Manual Pulse Generator...........................................................193

8.4.17 Connection of Basic and Extension Modules.......................................................194

8.4.18 Module Installation...............................................................................................195

8.4.19 Other Notes...........................................................................................................200

8.4.20 Distribution I/O Setting........................................................................................204

8.5 CONNECTION OF OPERATOR'S PANEL I/O MODULE

(FOR MATRIX INPUT) .............................................................................. 206

8.5.1 Overall Connection Diagram................................................................................206

8.5.2 Power Connection ................................................................................................207

8.5.3 DI/DO Connector Pin Arrangement.....................................................................208

8.5.4 DI (General-purpose Input Signal) Connection ...................................................209

8.5.5 DI (Matrix Input Signal) Connection...................................................................211

c-4

Page 13

B-63943EN/02 TABLE OF CONTENTS

8.5.6 DO (Output Signal) Connection...........................................................................212

8.5.7 Manual Pulse Generator Connection....................................................................215

8.5.8 External View.......................................................................................................216

8.5.9 Specifications .......................................................................................................217

8.5.10 Other Notes...........................................................................................................219

8.6 CONNECTION OF OPERATOR'S PANEL I/O MODULE AND POWER

MAGNETICS CABINET I/O MODULE....................................................... 223

8.6.1 Overall Connection Diagram................................................................................223

8.6.2 Power Connection ................................................................................................224

8.6.3 DI/DO Connector Pin Arrangement.....................................................................225

8.6.4 DI (General-purpose Input Signal) Connection ...................................................226

8.6.5 DO (Output Signal) Connection...........................................................................230

8.6.6 Manual Pulse Generator Connection....................................................................232

8.6.7 External View.......................................................................................................232

8.6.8 Specifications .......................................................................................................233

8.6.9 Other Notes...........................................................................................................235

8.7 FANUC I/O LINK CONNECTION UNIT ..................................................... 239

8.7.1 Overview ..............................................................................................................239

8.7.2 Specification.........................................................................................................240

8.7.3 Connection ...........................................................................................................243

8.7.3.1 I/O Link interface ............................................................................................ 243

8.8 CONNECTING THE FANUC SERVO UNIT β SERIES WITH I/O LINK .... 246

8.8.1 Overview ..............................................................................................................246

8.8.2 Connection ...........................................................................................................246

8.8.3 Maximum Number of Units that can be Connected .............................................247

8.8.4 Address Assignment by Ladder............................................................................247

8.9 CONNECTION TO ATANDARD MACHINE OPERATOR'S PANEL.......... 248

8.9.1 Overview ..............................................................................................................248

8.9.2 Total Connection Diagram...................................................................................250

8.9.3 Each Connections.................................................................................................251

8.9.3.1 Pin assignment................................................................................................. 251

8.9.3.2 Power supply connection................................................................................. 252

8.9.3.3 I/O link connection .......................................................................................... 253

8.9.3.4 Emergency stop signal connection .................................................................. 254

8.9.3.5 Power ON/OFF control signal connection....................................................... 254

8.9.3.6 General-purpose DI signal connection ............................................................ 255

8.9.3.7 General-purpose DO signal connection........................................................... 257

8.9.3.8 Manual pulse generator connection ................................................................. 258

8.9.3.9 Connector (on the cable side) specifications ...................................................261

c-5

Page 14

TABLE OF CONTENTS B-63943EN/02

8.9.4 I/O Address...........................................................................................................262

8.9.4.1 Keyboard of main panel................................................................................... 262

8.9.4.2 Override signals............................................................................................... 263

8.9.5 I/O Mapping .........................................................................................................264

8.9.6 Outline..................................................................................................................265

8.9.6.1 Outline of main panel ......................................................................................265

8.9.6.2 Outline of sub panel A..................................................................................... 266

8.9.6.3 Outline of sub panel D..................................................................................... 267

8.9.6.4 Connector locations of main panel .................................................................. 268

8.9.7 Specifications .......................................................................................................269

8.9.7.1 Environmental requirement ............................................................................. 269

8.9.7.2 Order specification........................................................................................... 269

8.9.7.3 Main panel specification.................................................................................. 269

8.9.7.4 Sub panel A/D specification ............................................................................ 269

8.9.7.5 Power supply specification .............................................................................. 270

8.9.7.6 General-purpose DI signal definition .............................................................. 270

8.9.7.7 General-purpose DO signal definition............................................................. 270

8.9.8 Key Symbol Indication on Machine Operators Panel ..........................................271

8.9.8.1 Meaning of key symbols.................................................................................. 271

8.9.8.2 Detachable key top .......................................................................................... 273

8.9.9 Others ...................................................................................................................274

8.9.10 Maintenance Parts ................................................................................................277

9 STOP AND EMERGENCY STOP .......................................................278

9.1 STOP MODES........................................................................................... 279

9.2 SHUTTING OFF THE MOTOR POWER ................................................... 280

9.3 STOPPING THE SPINDLE MOTOR .........................................................281

9.4 STOPPING THE SERVO MOTOR ............................................................282

9.5 EMERGENCY STOP SIGNAL................................................................... 283

9.6 CAUTIONS ABOUT MULTIPATH CONTROL ...........................................286

10 CONNECTION TO OTHER NETWORKS ........................................... 287

11 CONNECTION FOR Series 300is/310is/320is..................................288

11.1 TOTAL CONNECTION DIAGRAMS .......................................................... 289

11.1.1 LCD-Mounted Type Series 300is/310is/320is Control Unit................................289

11.1.2 Display Unit for is Series CNC (Stand-Alone Type) ...........................................290

11.2 INSTALLATION .........................................................................................291

11.2.1 Connector Names and Connector Layout.............................................................291

11.2.1.1 LCD-mounted Type Series 300is/310is/320is................................................. 291

11.2.1.2 Display Unit for is Series................................................................................. 292

11.2.2 Environmental Conditions for Control Units .......................................................293

c-6

Page 15

B-63943EN/02 TABLE OF CONTENTS

11.2.3 Power Supply Capacity ........................................................................................294

11.3 CONNECTION TO CNC PERIPHERALS.................................................. 295

11.3.1 Main Power Input.................................................................................................295

11.3.2 Backup Unit..........................................................................................................296

11.3.3 Ethernet Interface (10BASE-T/ 100BASE-TX)...................................................300

11.3.4 Serial Port and USB Port......................................................................................308

11.3.4.1 Serial port 1 ..................................................................................................... 308

11.3.4.2 Serial port 2 ..................................................................................................... 311

11.3.4.3 USB port (rear side)......................................................................................... 313

11.3.4.4 USB port (front side) ....................................................................................... 314

11.3.5 High-speed Serial Bus (HSSB) [For Stand-alone Type]......................................315

11.3.6 Buzzer Output.......................................................................................................316

12 HIGH-SPEED SERIAL BUS (HSSB) ..................................................317

12.1 OVERVIEW ............................................................................................... 318

12.2 CAUTIONS ................................................................................................ 318

12.3 CONNECTION DIAGRAM......................................................................... 319

12.4 PERSONAL COMPUTER SPECIFICATION .............................................320

12.5 INSTALLATION ENVIRONMENT.............................................................. 320

12.6 PROCEDURE FOR INSTALLING PERSONAL COMPUTER

INTERFACE BOARDS .............................................................................. 321

12.7 HANDLING PRECAUTIONS .....................................................................321

12.8 RECOMMENDED CABLES....................................................................... 322

13 PANEL i............................................................................................... 323

13.1 OVERVIEW ............................................................................................... 324

13.2 CAUTIONS ................................................................................................ 324

13.3 TOTAL CONNECTION DIAGRAMS .......................................................... 325

13.4 SPECIFICATIONS..................................................................................... 326

13.4.1 Installation Environmental Conditions.................................................................326

13.4.2 Power Supply Specification .................................................................................328

13.4.3 Shutdown..............................................................................................................329

13.5 INSTALLATION SPACE ............................................................................ 330

13.5.1 Installation Space of the Basic Unit .....................................................................330

13.5.1.1 Installation space of the 10.4" LCD type basic unit ........................................ 330

13.5.1.2 Installation space of the 12.1" LCD type basic unit ........................................ 331

13.5.1.3 Installation space of the 15.0" LCD type basic unit ........................................ 332

13.5.2 Installation space of the HDD unit .......................................................................333

13.5.2.1 FA full keyboard and an MDI unit other than QWERTY MDI ...................... 333

13.5.2.2 When the QWERTY MDI and 10.4" LCD type basic unit are used ...............334

c-7

Page 16

TABLE OF CONTENTS B-63943EN/02

13.5.2.3 QWERTY MDI used in cases other than combination (2).............................. 334

13.5.3 Ground Terminal Connection of Units.................................................................335

13.6 PERIPHERAL EQUIPMENT AND CONNECTION .................................... 336

13.6.1 Connector Layout Diagram ..................................................................................336

13.6.2 Main Power Supply Input ....................................................................................337

13.6.3 Serial Port 1..........................................................................................................338

13.6.4 Serial Port 2..........................................................................................................340

13.6.5 Parallel Port ..........................................................................................................342

13.6.6 High-speed serial Bus (HSSB) .............................................................................344

13.6.7 Keyboard and Mouse............................................................................................345

13.6.8 Hard Disk Unit .....................................................................................................347

13.6.9 Floppy Disk Drive................................................................................................348

13.6.10 USB ....................................................................................................................350

13.6.11 Ethernet ................................................................................................................351

13.6.12 Video Port ............................................................................................................352

13.6.13 MDI ....................................................................................................................354

13.6.14 PCMCIA Card......................................................................................................355

13.6.15 PCI Extension Board............................................................................................356

13.7 Punch Panel for PANEL i .......................................................................... 358

13.7.1 Overview ..............................................................................................................358

13.7.2 Specifications .......................................................................................................358

13.7.3 Configuration .......................................................................................................359

13.7.4 Operating Environment ........................................................................................359

13.7.5 Connection to the PANEL i..................................................................................360

13.7.6 Connection to Peripheral Devices ........................................................................363

13.8 KEY CODES OF SOFT KEYS................................................................... 366

APPENDIX

A OUTLINE DRAWINGS OF UNITS ......................................................369

B 20-PIN INTERFACE CONNECTORS AND CABLES ......................... 439

B.1 BOARD-MOUNTED CONNECTORS ........................................................ 440

B.1.1 Vertical-type Connectors......................................................................................440

B.1.2 Straight and Right-angled Connectors

(for Spring and Screw-fixing Connector Housings).............................................440

B.2 CABLE CONNECTORS ............................................................................ 441

B.2.1 Strand Wire Press-mount Connector....................................................................441

B.2.2 Soldering Type Connector....................................................................................442

c-8

Page 17

B-63943EN/02 TABLE OF CONTENTS

B.3 RECOMMENDED CONNECTORS, APPLICABLE HOUSINGS, AND

CABLES .................................................................................................... 443

B.3.1 Recommended Connectors ...................................................................................444

B.3.2 Applicable Cables.................................................................................................445

C CONNECTION CABLE (SUPPLIED FROM US).................................454

D OPTICAL FIBER CABLE.................................................................... 457

E LIQUID CRYSTAL DISPLAY (LCD) ...................................................469

F MEMORY CARD INTERFACE............................................................472

c-9

Page 18

Page 19

B-63943EN/02 1.CONFIGURATION

1 CONFIGURATION

- 1 -

Page 20

1.CONFIGURATION B-63943EN/02

1.1 CONTROL UNIT CONFIGURATION AND COMPONENT

NAMES

The 30i series control units are divided into two types: the

LCD-mounted type and stand-alone type.

LCD-mounted type control units have a built-in display. Stand-alone

type control units have a separate display unit. In the following

sections, the LCD-mounted type is also referred to as the

LCD-mounted type, and the stand-alone type is also referred to as the

stand-alone type.

The configuration and component names of each type are shown in

the figures given below. This manual explains how to attach the

connectors shown in these figures to devices. The numbers in

parentheses () in the figures are keyed to the item numbers of the

descriptions in this manual. The numbers in brackets [] in the figures

are connector numbers.

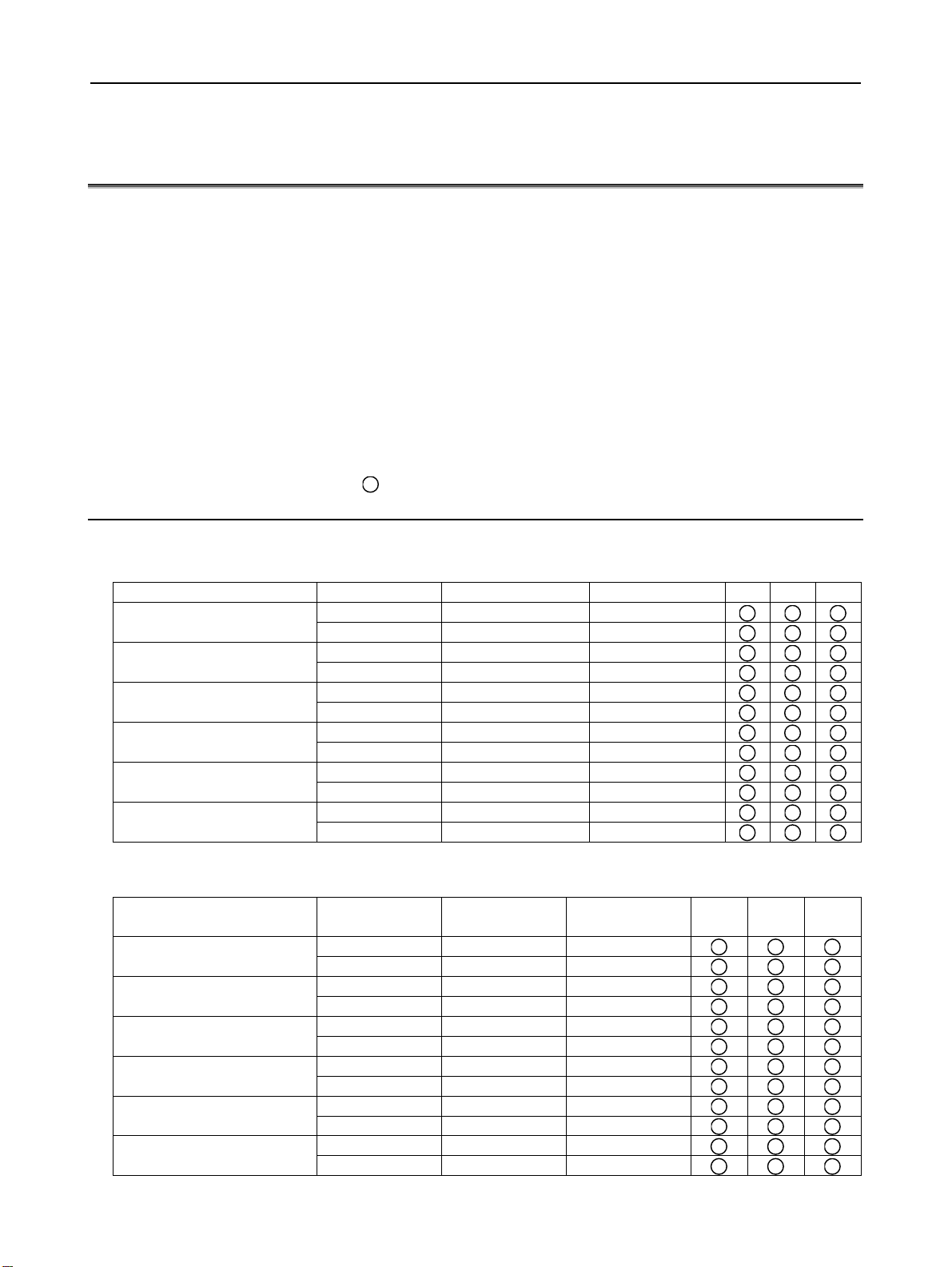

1.1.1 Configurations of LCD-mounted Type Control Units

LCD-mounted type Series 30i/31i/32i control units (A circle indicates

that the corresponding unit is available.)

Display unit Expansion slot Horizontal soft key Vertical soft key

7.2"STN monochrome LCD

8.4"TFT color LCD

10.4"TFT color LCD

10.4"TFT color LCD

(with touch panel)

15"TFT color LCD

15"TFT color LCD

(with touch panel)

None 5+2 None

2 5+2 None

None 5+2 None

2 5+2 None

None 10+2 8+1

2 10+2 8+1

None 10+2 8+1

2 10+2 8+1

None 10+2 8+1

2 10+2 8+1

None 10+2 8+1

2 10+2 8+1

LCD-mounted type Series 300is/310is/320is control units (A circle

indicates that the corresponding unit is available.)

Display unit Expansion slot

10.4"TFT color LCD

10.4"TFT color LCD

(with touch panel)

12.1"TFT color LCD

12.1"TFT color LCD

(with touch panel)

15"TFT color LCD

15"TFT color LCD

(with touch panel)

None 10+2 8+1

None 10+2 8+1

None 10+2 8+1

None 10+2 8+1

None 10+2 8+1

None 10+2 8+1

Horizontal soft

key

2 10+2 8+1

2 10+2 8+1

2 10+2 8+1

2 10+2 8+1

2 10+2 8+1

2 10+2 8+1

Vertical soft

key

30i 31i 32i

300is 310is 320is

- 2 -

Page 21

B-63943EN/02 1.CONFIGURATION

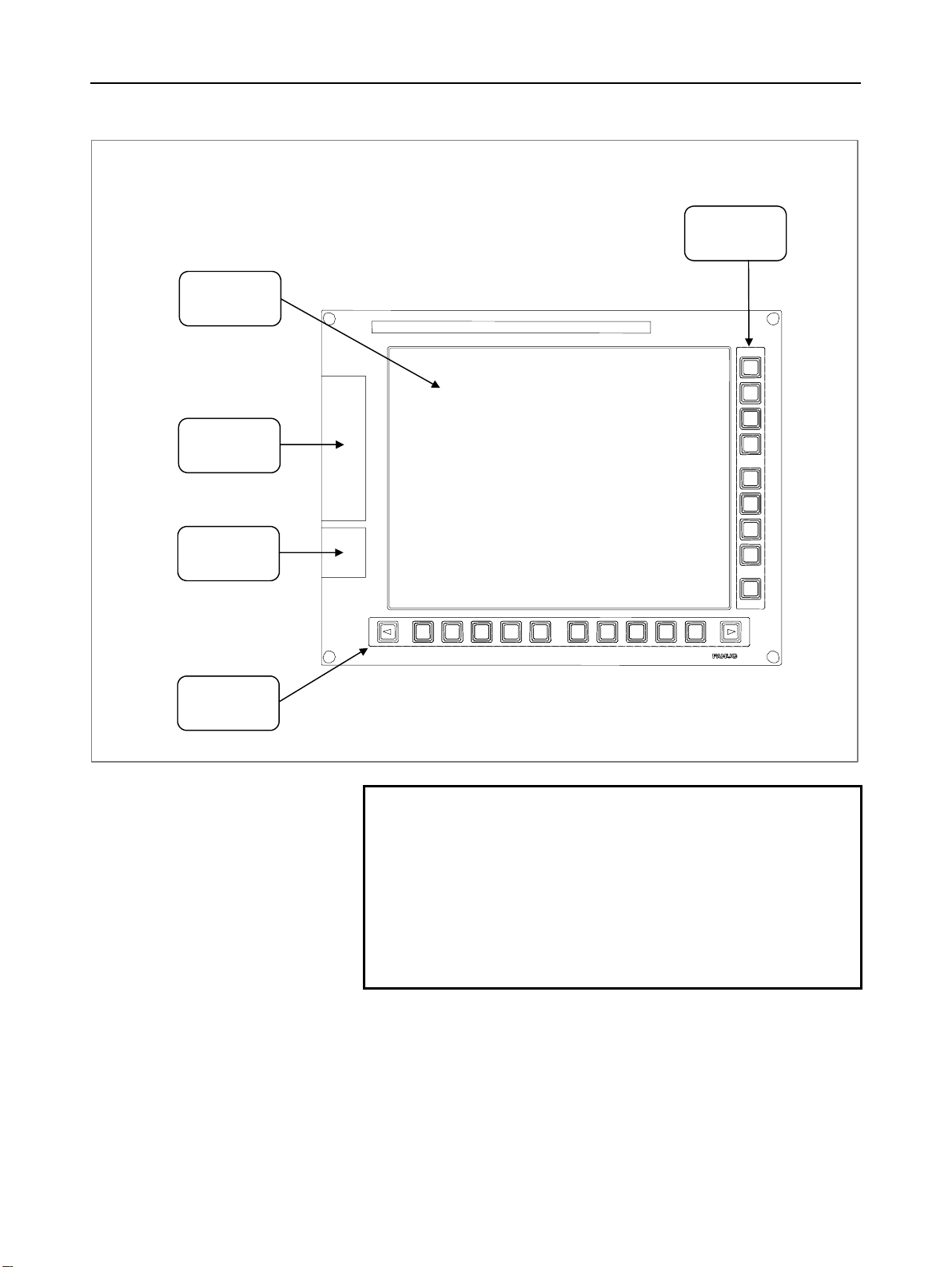

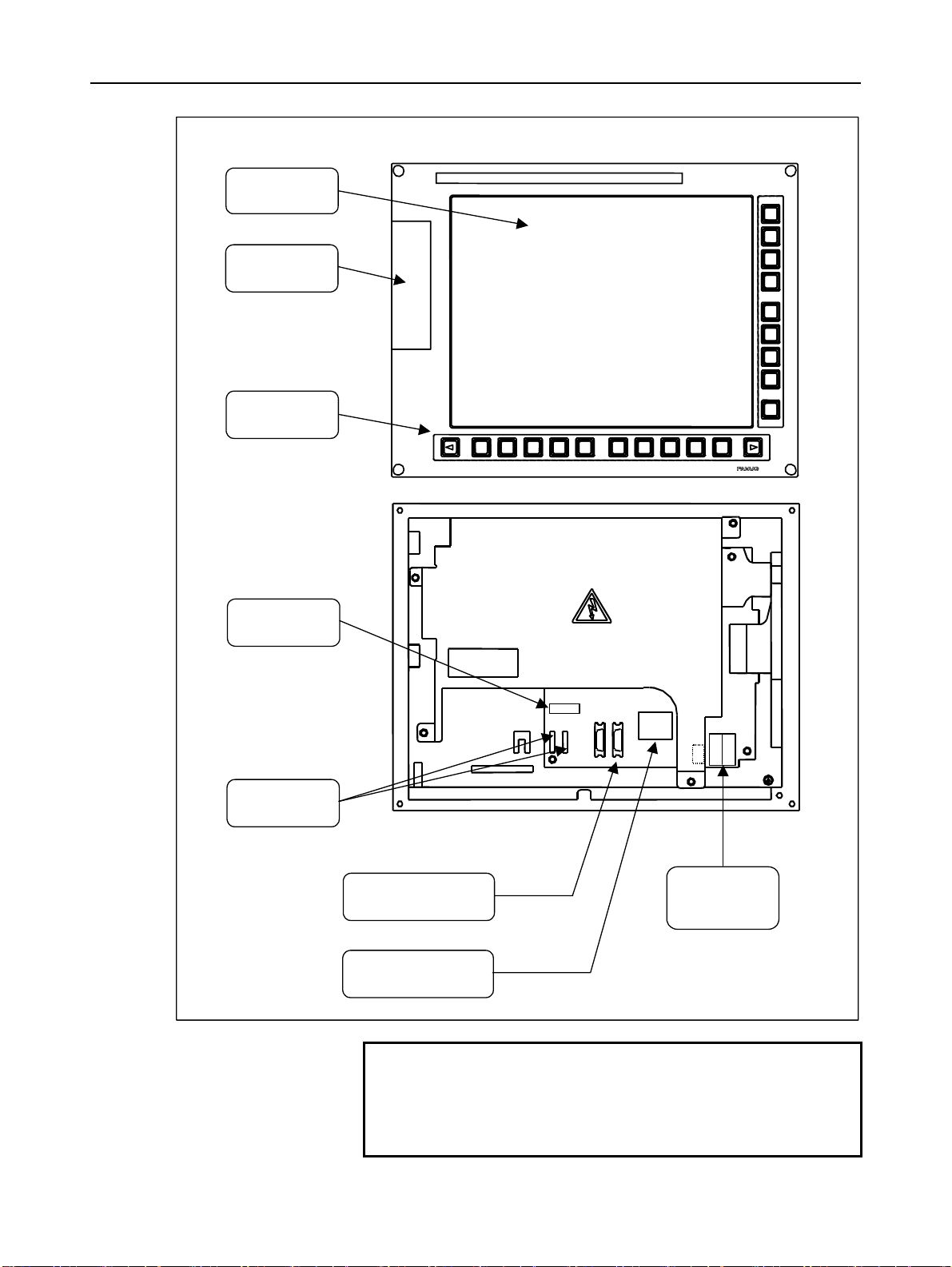

LCD-mounted type control unit

Vertical soft

keys

Liquid-crystal

display

Memory card

interface

USB port

Horizontal soft

keys

NOTE

1 This figure is a front view of the LCD-mounted type

control unit with an 10.4” TFT color liquid-crystal

display. The configurations of other control units

are basically the same as that shown above.

2 The Series 30i/31i/32i do not support the USB

port.

3 The 7.2” and 8.4” display units do not have vertical

soft keys.

- 3 -

Page 22

1.CONFIGURATION B-63943EN/02

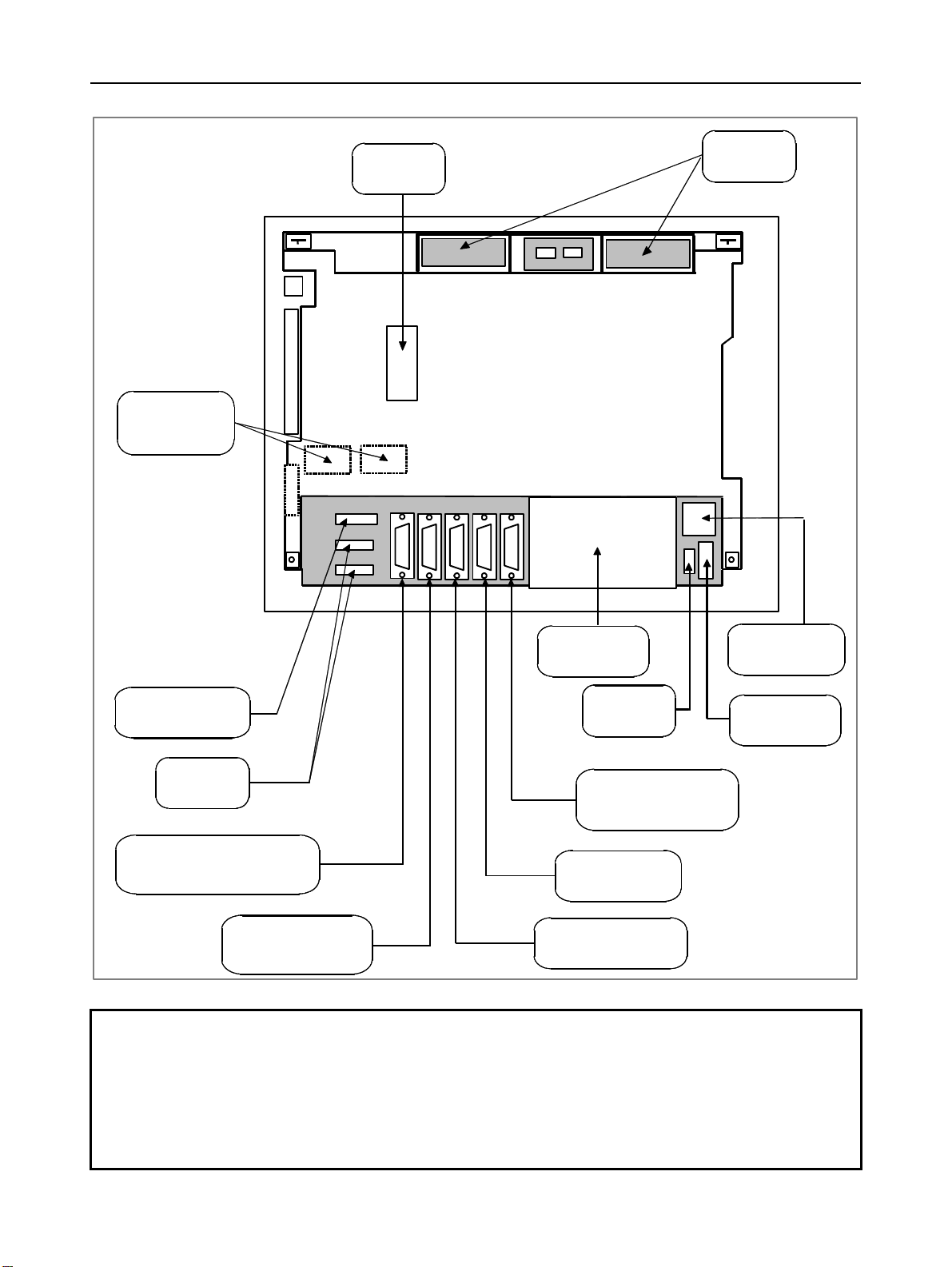

LCD-mounted type control unit

Battery

Unit rear panel

Servo unit

connector

[COP10A-1]

[COP10A-2] (7)

Fan unit

Ethernet

connector

[CD38A] (5.5)

Power supply

connector

[CPD16A]

MDI connector

[CA55] (5.1)

Soft key

I/O device interface (RS-232-C) or

serial spindle connector

[JD56A] (5.3, 6.1)

I/O device interface

connector (RS-232-C)

[JD36A/JD54] (5.3)

Power supply

module

Fuse

Serial spindle

connector

[JA41] (6.1)

I/O-Link connector

[JD51A] (8.2)

High-speed skip connector

[JA40] (5.4)

NOTE

This figure is a rear view of the 30i/31i/32i LCD-mounted type control unit without

option slots.

For the LCD-mounted type 300is/310is/320is control units, see Chapter 11.

The numbers in parentheses () in the figures are keyed to the item numbers of the

descriptions in this manual. The numbers in brackets [] in the figures are

connector numbers.

- 4 -

Page 23

B-63943EN/02 1.CONFIGURATION

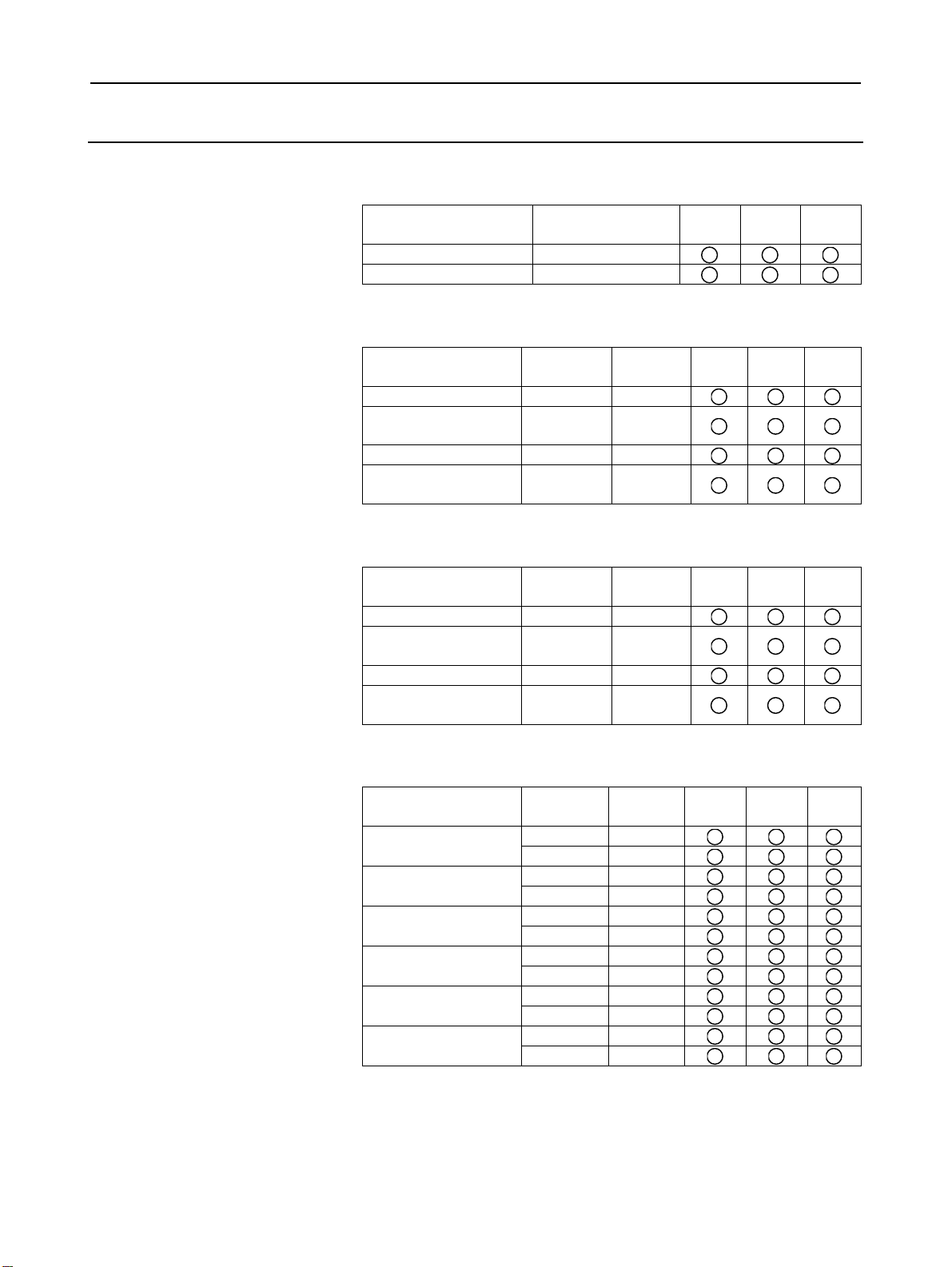

1.1.2 Configurations of Stand-alone Type Control Units

Stand-alone type Series 30i/31i/32i control units (A circle indicates

that the corresponding unit is available.)

Slot rack name

2-slot rack 2

4-slot rack 4

Expansion

slot

Series 30i/31i/32i display units (A circle indicates that the

corresponding unit is available.)

Display unit

10.4"TFT color LCD 10+2 8+1

10.4"TFT color LCD

(with touch panel)

15" TFT color LCD 10+2 8+1

15" TFT color LCD

(with touch panel)

Horizontal

soft key

10+2 8+1

10+2 8+1

Vertical

soft key

Series 300i/310i/320i PANEL i (A circle indicates that the

corresponding model is available.)

Display unit

10.4"TFT color LCD 10+2 8+1

10.4"TFT color LCD

(with touch panel)

15" TFT color LCD 10+2 8+1

15" TFT color LCD

(with touch panel)

Horizontal

soft key

10+2 8+1

10+2 8+1

Vertical

soft key

Series 300is/310is/320is CNC display units (A circle indicates that the

corresponding unit is available.)

Display unit

10.4"TFT color LCD

10.4"TFT color LCD

(with touch panel)

12.1"TFT color LCD

12.1"TFT color LCD

(with touch panel)

15"TFT color LCD

15"TFT color LCD

(with touch panel)

Horizontal

soft key

10+2 8+1

10+2 8+1

10+2 8+1

10+2 8+1

10+2 8+1

10+2 8+1

10+2 8+1

10+2 8+1

10+2 8+1

10+2 8+1

10+2 8+1

10+2 8+1

Vertical

soft key

30i 31i 32i

30i 31i 32i

30i 31i 32i

300is 310is 320is

- 5 -

Page 24

1.CONFIGURATION B-63943EN/02

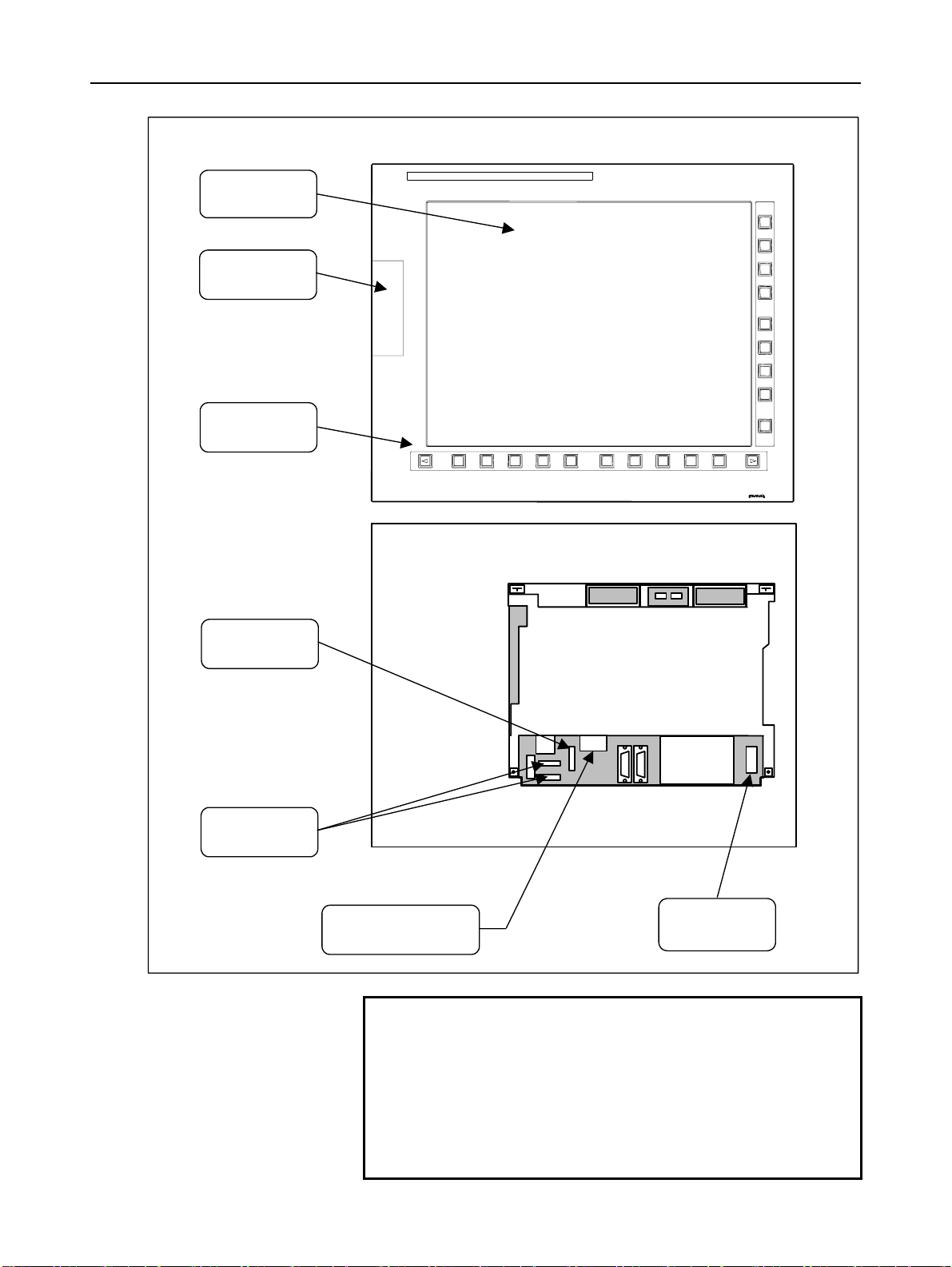

Stand-alone type control unit

Battery connector

Battery

I/O device interface

connector

Memory card interface

Ethernet LED

Ethernet connector

Optional slot 3

I/O device interface

connector

I/O Link connector

High-speed skip connector

Serial spindle connector

LED for blown fuse check

24-VDC power supply connector

[CPD19A] (right)

[CPD19B] (left)

Optional slot 1

Servo unit (FSSB)

connector

[COP10A-1] (lower)

[COP10A-2] (upper)

(7)

Optional slot 4

Optional slot 2

Display connector

2-slot rack

4-slot rack

LED for status indication

and maintenance

LED for alarm indication

Rotary switch for maintenance (upper),

Push switch for maintenance (lower)

GND connection terminal

- 6 -

Page 25

B-63943EN/02 1.CONFIGURATION

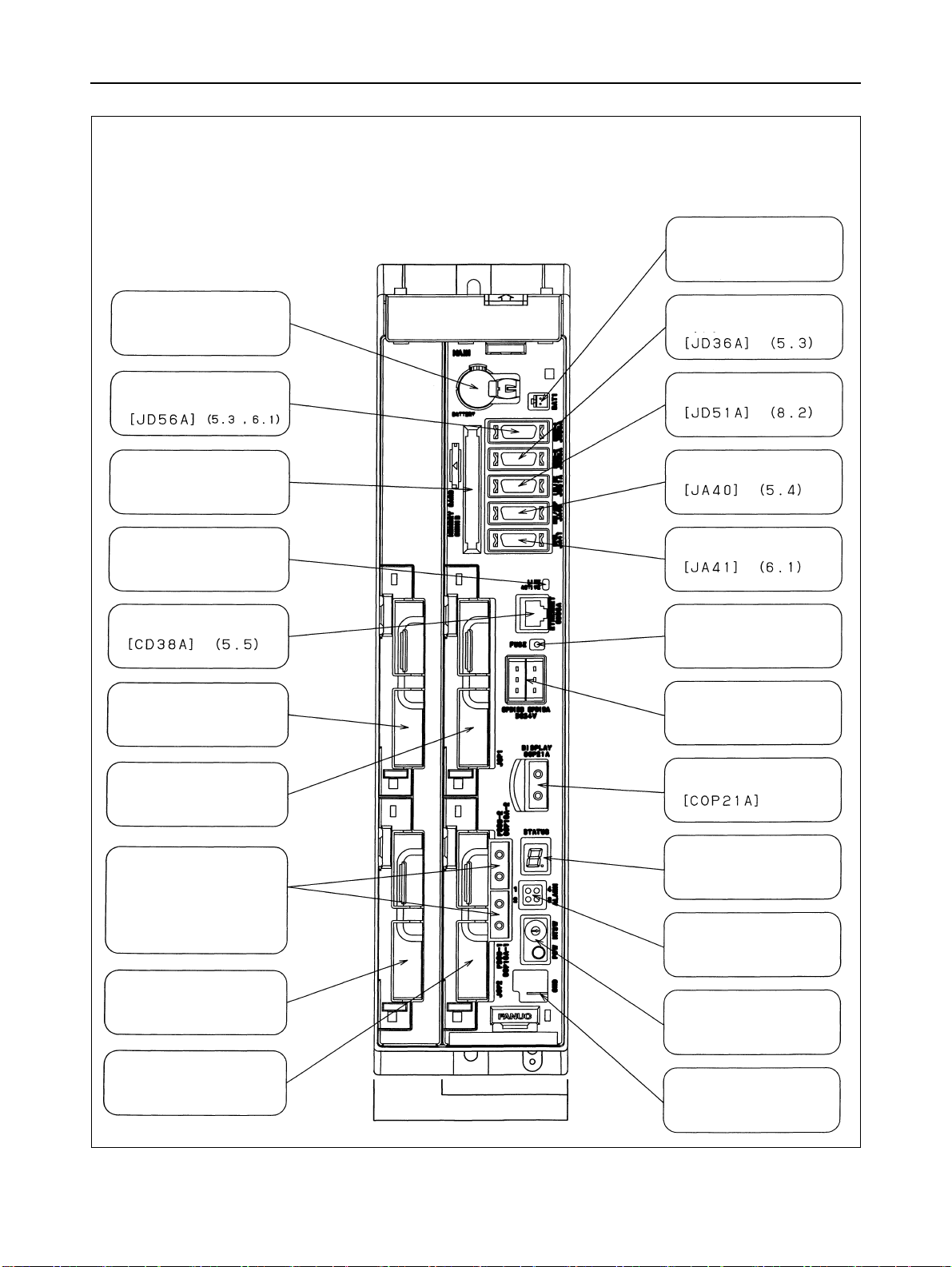

10.4” LCD unit for the stand-alone type Series 30i/31i/32i control unit

Liquid-crystal

display

Memory card

interface

Soft keys

MDI connector

[CA55] (5.1)

Soft key

connectors

Touch panel connector

Optical connector for

display control

[COP21A] (5.2)

Power supply

connectors

[CP1A]

[CP1B] (5.2)

NOTE

The numbers in parentheses () in the figures are

keyed to the item numbers of the descriptions in

this manual. The numbers in brackets [] in the

figures are connector numbers.

- 7 -

Page 26

1.CONFIGURATION B-63943EN/02

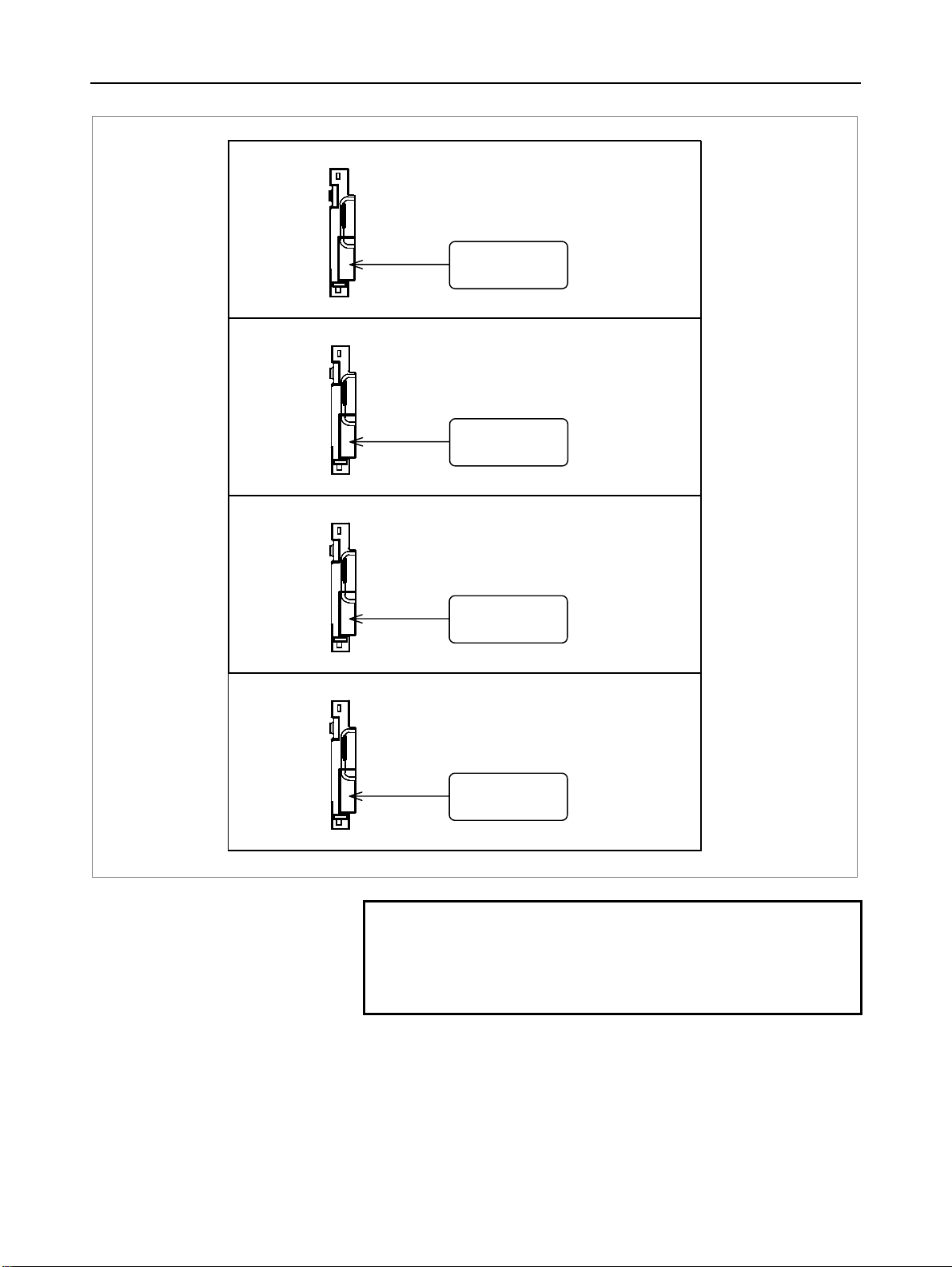

w

15” LCD unit for the stand-alone type Series 30i/31i/32i control unit

Liquid-crystal

display

Memory card

interface

Soft keys

MDI connector

[CA55] (5.1)

Soft key

connectors

Optical connector for

display control

[COP21M] (5.2)

Fan motor

Rear vie

Fan motor

Power supply

connector

[CPD18] (5.2)

NOTE

The numbers in parentheses () in the figures are

keyed to the item numbers of the descriptions in

this manual. The numbers in brackets [] in the

figures are connector numbers.

For the display units for the Series 300i/310i/320i,

see Chapter 13. For the display units for the

Series 300is/310is/320is, see Chapter 11.

- 8 -

Page 27

B-63943EN/02 1.CONFIGURATION

[

]

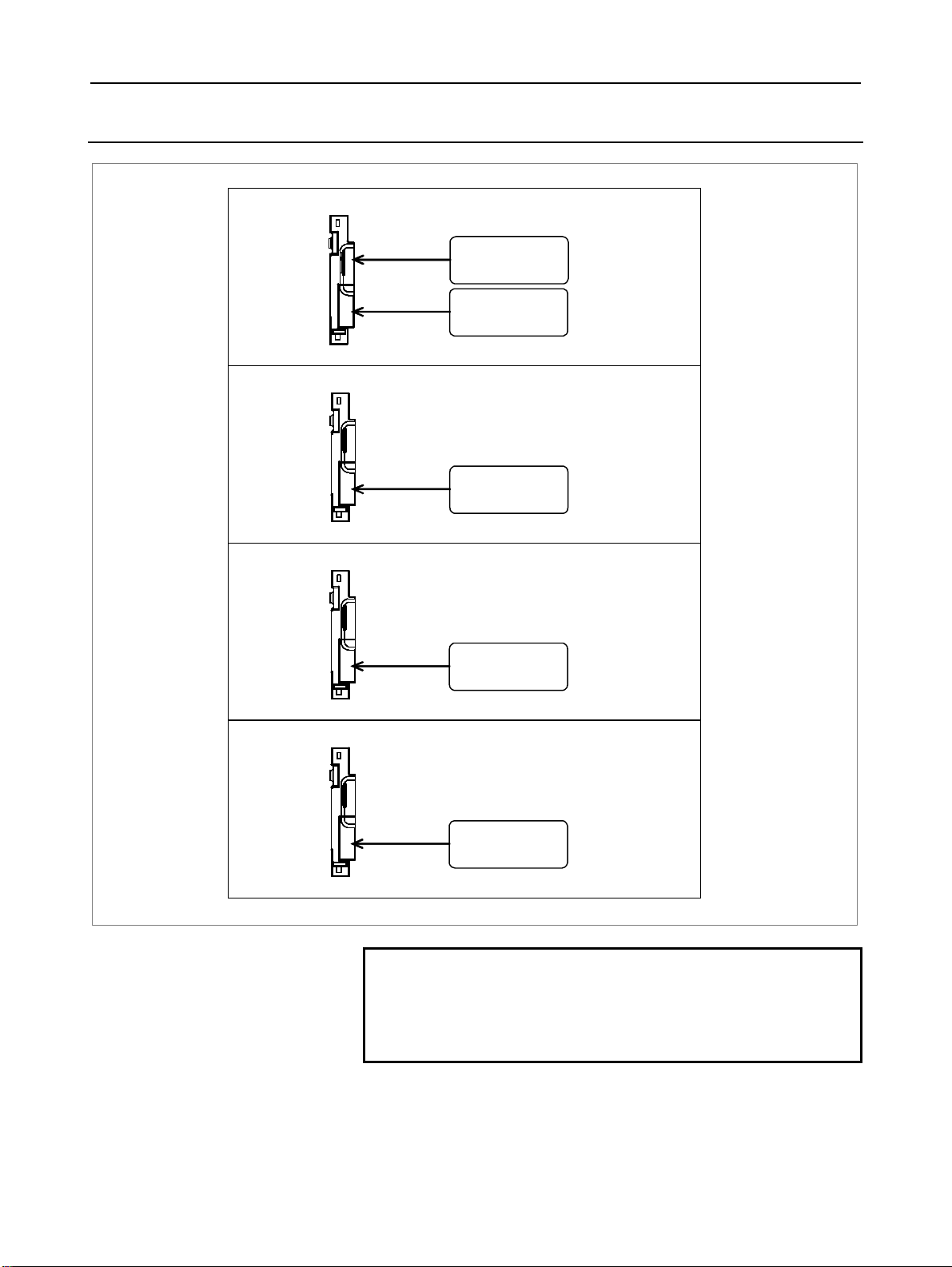

1.1.3 Configurations of Optional Boards

Additional axis board

For I/O-Link

[JD1A] (8.2)

For ser vo unit

[COP10A] (7)

Additional spindle board

For serial spindle

[JA41L] (6.1)

Fast data server board

HSSB board

For Ethernet

[CD38R] (5.5)

HSSB optical

connector

COP21N

NOTE

The numbers in parentheses () in the figures are

keyed to the item numbers of the descriptions in

this manual. The numbers in brackets [] in the

figures are connector numbers.

- 9 -

Page 28

1.CONFIGURATION B-63943EN/02

Profibus master board

For Profibus

[CN1]

Profibus slave board

For Profibus

[CN2]

DeviceNet board

FL-net board

For DeviceNet

[TBL]

For FL-net

[CD38N]

NOTE

The numbers in parentheses () in the figures are

keyed to the item numbers of the descriptions in

this manual. The numbers in brackets [] in the

figures are connector numbers.

- 10 -

Page 29

B-63943EN/02 1.CONFIGURATION

A

A

1.2 HARDWARE OVERVIEW

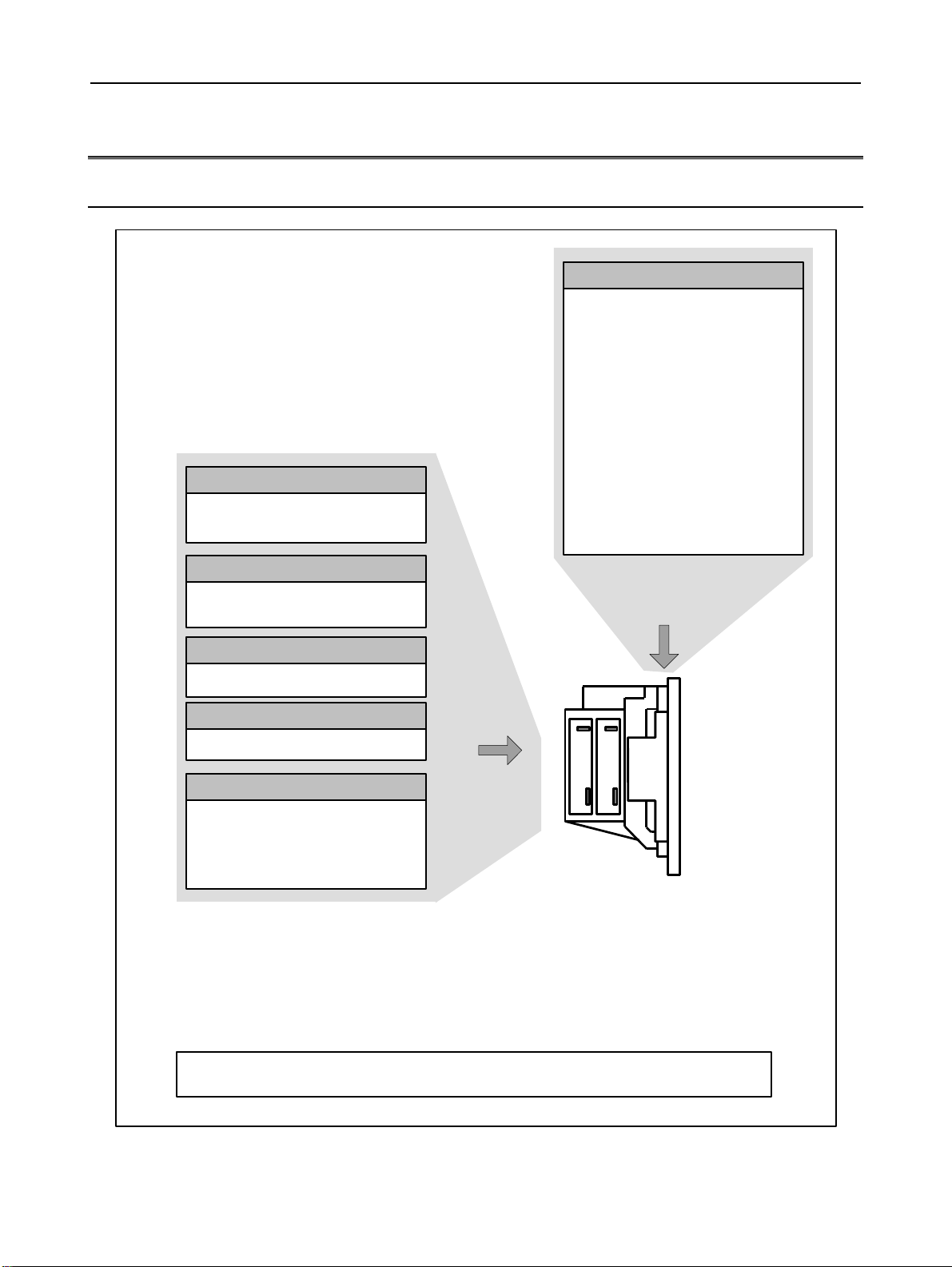

1.2.1 LCD-mounted Type Control Unit Overview

Main board

- CPU for controlling CNC

- Power supply

- 2-axis to 24-axis control

- Spindle interface

- LCD/MDI interface

- I/O Link

- PMC control function

- High-speed DI

- RS-232C

- Memory card interface

- PC function

300is/310is/320is)

(

Data server board

Data server function

Ethernet communication function

Additional axis board

dditional axis control function

I/O Link

Additional spindle board

dditional spindle control function

HSSB interface board

High-speed serial bus interface

Various types of network boards

FL-net board

Profibus master board

Profibus slave board

Device Net board

Basic system

Options

Unit without optional slots

or

Unit having two optional slots

On a unit with optional slots, as many optional boards as the slots can be mounted.

- 11 -

Page 30

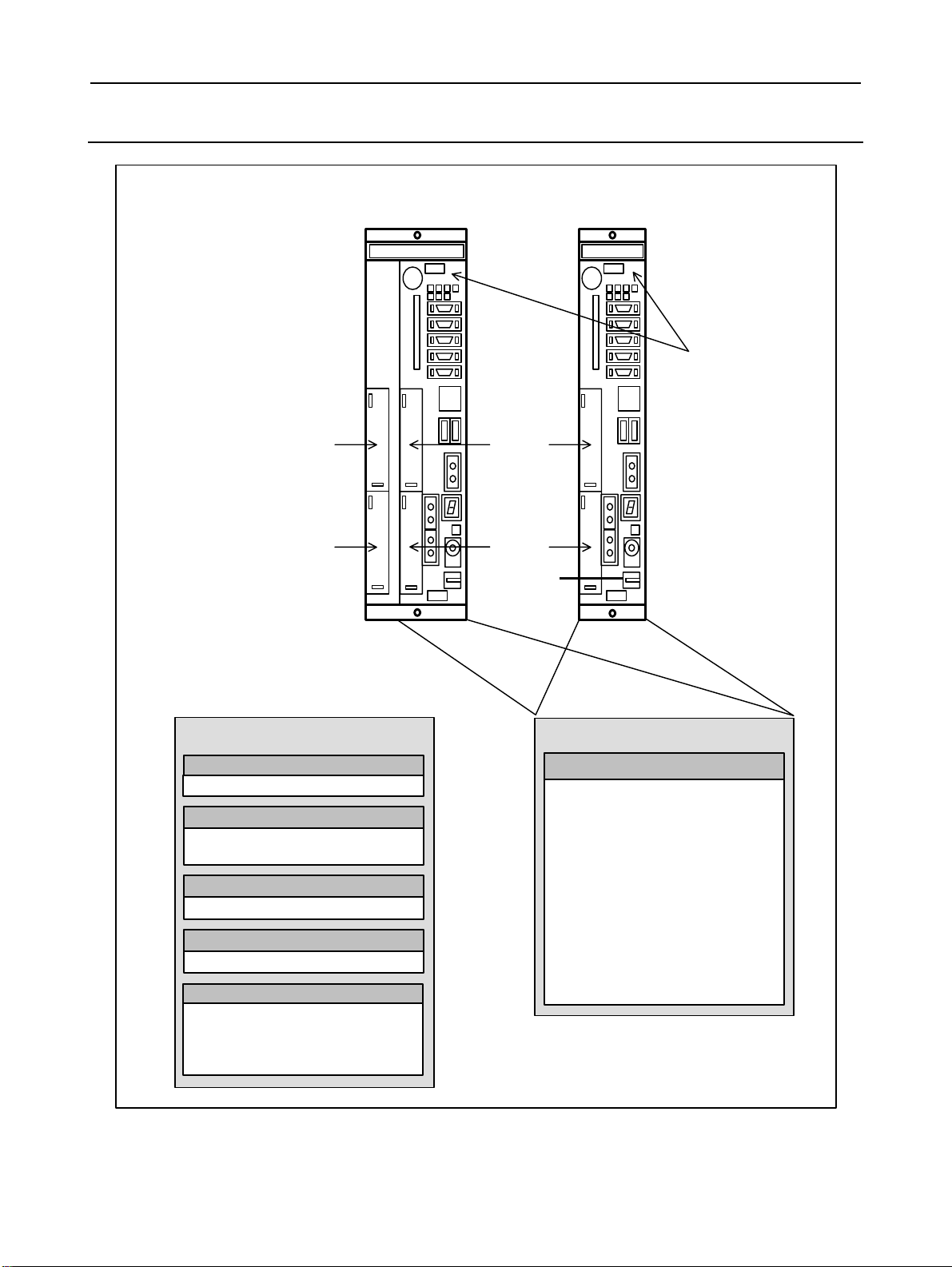

1.CONFIGURATION B-63943EN/02

A

A

1.2.2 Stand-alone Type Control Unit Overview

2 slot rack 4 slot rack

Main board

Slot 3

Slot 4

Options (Slot 1 to 4)

Data server board

Data server function

Additional axis board

dditional axis control function

I/O Link

Additional spindle board

dditional spindle control function

HSSB interface board

High-speed serial bus interface board

Slot 1

Slot 2

Basic system

Main board

- CPU for controlling CNC

- Power supply

- 2-axis to 24-axis control

- Spindle interface

- DISPLAY interface

- I/O Link

- PMC control function

- High-speed DI

- RS-232C

- Memory card interface

Various types of network boards

FL-net board

Profibus master board

Profibus slave board

Device Net board

- 12 -

Page 31

B-63943EN/02 2.TOTAL CONNECTION DIAGRAMS

2 TOTAL CONNECTION DIAGRAMS

- 13 -

Page 32

2.TOTAL CONNECTION DIAGRAMS B-63943EN/02

p

A

A

r

LCD-mounted type control unit

LCD display unit

Main board

24V-IN(CPD16A)

MDI(CA55)

R232-1(JD56A)

R232-2(JD36A)

HDI(JA40)

I/O Link(JD51A)

SPDL(JA41)

24VDC

24VDC

3rd and 4th

serial

spindles

MDI UNIT

CK27

RS-232-C I/O unit

5th and 6th serial spindles

RS-232-C I/O unit

Touch panel

High-peed skip input

Distributed I/O

board

JA3

CPD1

JD1B

JD1A

CPD1

Distributed

I/O board,

JD1B

I/O unit, etc.

JD1A

CX1A

TB2

PSM

TB1

CX1B

C reacto

CX3

CX4

JX1B

24 VDC power supply

Manual pulse generator

Operator's

anel

Power

magnetics

cabinet

Circuit breaker

200VAC

MCC

Position coder

200VAC

Circuit breaker

FSSB(COP10A-1)

FSSB(COP10A-2)

ETHERNET(CD38A)

To 2nd spindle

24VDC

CX1A

JA7B

JA7A

COP10B

COP10A

COP10B

COP10A

COP10B

COP10A

COP10B

COP10A

(In this figure, a 1-axisamplifier is used.)

Separate detector interface unit 1

CP11A

COP10B

COP10A

CNF1

Separate detector interface unit 2

CP11A

Ethernet

CX2A

TB1

SPM

TB1

CX2B

CX2A JX1A

TB1

SVM

TB1 CX2B

SVM

SVM

SVM

JF101

JF102

JF103

JF104

JA4A

JF101

JF102

JF103

JF104

JX1A

JY2

TB2

JX1B

Serial spindle mot or

TB2

JF1

JX1B

Linear scale, axis 1

Linear scale, axis 2

Linear scale, axis 3

Linear scale, axis 4

bsolute scale battery

(Required only when an absolute scale is used)

Linear scale, axis 1

Linear scale, axis 2

Linear scale, axis 3

Linear scale, axis 4

Servo motor

Servo motor

Servo motor

Servo motor

- 14 -

Page 33

B-63943EN/02 2.TOTAL CONNECTION DIAGRAMS

β

A

A

A

A

A

Stand-alone type control unit

Main board

Slot 1

24V-IN(CPD19A)

24V-OUT(CPD19B)

DISPLAY(COP21A)

HDI(JA40)

I/O Link(JD51A)

To I/O device

Optical fiber ccable

24VDC

DC24V

DC24V

LCD UNIT

COP21A,B,M

CA55 CK27

CP1A

CP1B

(Touch panel)

High-peed skip input

Distributed

I/O board

JA3

CPD1

JD1B

JD1A

Distributed

CPD1

I/O board,

JD1B

I/O unit,

JD1A

etc.

JD1B

amplifier

with I/O Link

JD1A

Memory card

24 VDC power supply

MDI UNIT

PANEL i or personal computer

Manual pulse generator

Operator's

panel

Power

magnetics

cabinet

Servo motor

R232-1(JD56A)

R232-2(JD36A)

SPDL(JA41)

Servo card

FSSB(COP10A-1)

FSSB(COP10A-2)

ETHERNET(CD38A)

3rd, 4th

spindles

To 2nd spindle

Optical fiber cable

24VDC

Separate detector

interface unit 2

5th, 6th spindles

CX1A

TB2

PSM

TB1

CX1B

CX1A

JA7B

JA7A

COP10B

COP10A

COP10B

COP10A

COP10B

COP10A

COP10B

COP10A

(In this figure, a 1-axis amplifier is used.)

Separate detector interface unit 1

CP11A

COP10B

COP10A

CNF1

Ethernet

CX2A JX1A

TB1

SPM

TB1

CX2B JX1B

CX2A JX1A

TB1

SVM

TB1 CX2B

SVM

SVM

SVM

JF101

JF102

JF103

JF104

JA4A

RS-232-C I/O device

RS-232-C I/O device

C reactor

CX3

CX4

JX1B

JY2

TB2

TB2

JF1

JX1B

MCC

Position coder

Serial spindle mot or

Linear scale, axis 1

Linear scale, axis 2

Linear scale, axis 3

Linear scale, axis 4

Battery for absolute scale

(Required only when an absolute scale is used)

Circuit breaker

200VAC

200VAC

Circuit breaker

xis 1

servo motor

xis 2

servo motor

xis 3

servo motor

xis 4

servo motor

- 15 -

Page 34

2.TOTAL CONNECTION DIAGRAMS B-63943EN/02

A

A

When optional functions are provided

dditional spindle board

Optional slot

SPDL(JA41L)

dditional axis board

FSSB(COP10A-3)

To 8th spindle

COP10B

COP10A

COP10B

COP10A

COP10B

COP10A

COP10B

COP10A

PSM

SPM

SVM

SVM

SVM

SVM

Position coder

7th spindle

Servo motor

Servo motor

Servo motor

Servo motor

Manual pulse generator

Operator's

panel

Power

magnetics

cabinet

I/O Link(JD1A)

24VDC

24VDC

Distributed

I/O board

CPD1

JD1B

JD1A

CPD1

JD1B

JD1A

JA3

Distributed I/O

board, I/O unit,

etc.

- 16 -

Page 35

B-63943EN/02 2.TOTAL CONNECTION DIAGRAMS

A

A

A

When optional functions are provided

Fast data server

Optional slot

board

ATA card

ETHERNET(CD38R)

HSSB ボード

HSSB(COP21N)

Profibus master

board

Profibus slave

board

PROFI(CN1)

PROFI(CN2)

The user should provide an ATA card.

Ethernet

Personal Computer

or PANEL i

nother NC

(another Profibus unit)

nother NC

(another Profibus unit)

(Note 1)

DeviceNet board

DVNET(TBL)

FL-net board

FLNET(CD38N)

nother NC

(another DeviceNet unit)

FL-net unit

Note 1 The 30i/31i/32imodel is still used when a

personal computer or PANEL i is

connected using an HSSB interface.

- 17 -

Page 36

3.INSTALLATION B-63943EN/02

3 INSTALLATION

- 18 -

Page 37

B-63943EN/02 3.INSTALLATION

3.1 ENVIRONMENTAL REQUIREMENTS OUTSIDE THE

CABINET

3.1.1 Environmental Conditions outside the Cabinet

The peripheral units and the control unit have been designed on the

assumption that they are housed in closed cabinets. In this manual

"cabinet" refers to the following:

• Cabinet manufactured by the machine tool builder for housing

the control unit or peripheral units;

• Operation pendant, manufactured by the machine tool builder,

for housing the LCD/MDI unit or operator's panel.

• Equivalent to the above.

The environmental conditions when installing these cabinets shall

conform to the following table. Section 3.3 describes the installation

and design conditions of a cabinet satisfying these conditions.

Ambient

temperature of

the cabinet

Humidity

Vibration

sea level

Environment

NOTE

If the CNC is installed 1000 m or higher above sea level, the allowable upper

ambient temperature of the CNC in the cabinet is changed as follows.

Assume that the allowable upper ambient temperature of the CNC in the cabinet

installed 1000 m or higher above sea level decreases by 1.0°C for every 100 m rise

in altitude.

Example)

The upper allowable ambient temperature of the CNC in the cabinet installed

1750 m above sea level is:

55°C - 1750/100 × 1.0°C = 47.5°C

Therefore, the allowable ambient temperature range is from 0°C to 47.5°C.

When a hard disk is used, there are the following installation conditions:

Meters above sea level (operating): -60 to 3000 m

Meters above sea level (non-operating): -60 to 12000 m

Operating 0°C to 45°C

Storage, Transport -20°C to 60°C

Temperature change 0.3°C/minute or less

Normal 75%RH or less, no condensation

Short period

(less than 1 month)

Operating 0.5G or less

Non-operating 1.0G or less

Operating Up to 1000 m (Note) Meters above

Non-operating Up to 12000 m

Normal machine shop environment

(The environment must be considered if the cabinets

are in a location where the density of dust, coolant,

organic solvent, and/or corrosive gas is relatively high.)

95%RH or less, no condensation

- 19 -

Page 38

3.INSTALLATION B-63943EN/02

3.1.2 Installation Conditions of the CNC and Servo Unit in the

Cabinet

Condition

Operating 0°C to 58°C 0°C to 55°C

Ambient

temperature

Humidity

Vibration

above sea

level

Environment

Storage,

Transport

Temperature

change

Normal 75%RH or less, no condensation

Short period

(less than 1

month)

Operating

Non-operating 1.0G or less

Operating Up to 1000 m (Note in Subsection 3.1.1) Meters

Non-operating Up to 12000 m

LCD-mounted type control unit

and display unit

−20°C to 60°C

0.3°C/minute or less

95%RH or less, no condensation

0.5G or less

FANUC conducted an evaluation test under the

following conditions:

10 to 58 Hz: 0.075 mm (amplitude)

58 to 500Hz: 1G

Direction of vibration: Each of the X, Y, and Z directions

Number of sweep cycles: 10

Conforming to IEC68-2-6

Coolant, lubricant, or cutting chips shall not be sprinkled

directly over the CNC or servo unit. No corrosive gas

shall be allowed.

NOTE

If you want to use a PANEL i, see also Chapter 13.

Stand-alone type

control unit

- 20 -

Page 39

B-63943EN/02 3.INSTALLATION

3.2 POWER SUPPLY CAPACITY

3.2.1 Power Supply Capacities of CNC-related Units

The following CNC-related units require an input power supply that

satisfies the indicated current capacities with a power supply voltage

of 24 VDC ±10%. Here, note that momentary voltage changes and

ripples are also within ±10% of the power supply voltage.

Table 3.2.1 (a) Power supply capacity

Power

Unit

7.2”/8.4”/10.4” type display unit

type control

unit

Stand-alone

type control

unit

Optional board

15” type display unit

Control unit (alone)

10.4” display unit

15” display unit

Additional axis board

Additional spindle board

Fast data server board

HSSB board

Profibus master board

Profibus slave board

FL-net board

DeviceNet (master) board

NOTE

1 The liquid-crystal display and MDI unit are

included. Optional boards are not included.

2 When an RS-232C unit (with power supplied from

the NC) is connected to the RS-232C port, +0.2 A

is further required.

3 Use memory cards that consume no more than 2

W.

4 For the PANEL i, see Chapter 13.

5 For the FS300i/310is/320is, see Chapter 11.

6 For other peripheral units (such as I/O units), see

Table 3.2.1 (b) and also refer to the relevant

manuals.

7 When you select the input DC power supply for the

CNC control section, consider the restrictions other

than the power supply capacity. Be sure to see

also Subsection 4.4.2.

supply

capacity

1.6A

2.2A

1.6A

0.7A

1.5A

0.3A

0.2A

0.2A

0.2A

0.2A

0.1A

0.2A

0.1A

Remarks

Note 1) LCD-mounted

Note 1)

- 21 -

Page 40

3.INSTALLATION B-63943EN/02

Table 3.2.1 (b) Power supply rating (peripheral units)

Unit

MDI unit 0A

Standard machine operator’s panel 0.4A

Operator's panel I/O module 0.3A+7.3mA×DI

Connector panel I/O module (basic) 0.2A+7.3mA×DI

Connector panel I/O module

(additional)

Separate detector interface unit 0.9A Basic 4-axis unit

Separate detector interface unit 1.5A Basic 4 axes +

Power supply

capacity

0.1A+7.3mA×DI

Remarks

only

additional 4 axes

- 22 -

Page 41

B-63943EN/02 3.INSTALLATION

3.3 DESIGN AND INSTALLATION CONDITIONS OF THE

MACHINE TOOL MAGNETIC CABINET

When a cabinet is designed, it must satisfy the environmental

conditions described in Section 3.1. In addition, the magnetic

interference on the screen, noise resistance, and maintenance

requirements must be considered. The cabinet design must meet the

following conditions :

(1) The cabinet must be fully closed.

The cabinet must be designed to prevent the entry of airborne

dust, coolant, and organic solvent.

(2) The cabinet must be designed so that the permissible temperature

of each unit is not exceeded. For actual heat design, see Section

3.4.

(3) A closed cabinet must be equipped with a fan to circulate the air

within. (This is not necessary for a unit with fan.)

The fan must be adjusted so that the air moves at 0.5 m/sec along

the surface of each installed unit.

CAUTION

If the air blows directly from the fan to the unit, dust

easily adheres to the unit. This may cause the

unit to fail. (This is not necessary for a unit with

fan.)

(4) For the air to move easily, a clearance of 100 mm is required

between each unit and the wall of the cabinet.

(5) Packing materials must be used for the cable port and the door in

order to seal the cabinet.

(6) The display unit must not be installed in such a place that coolant

would directly fall onto the unit. The control unit has a

dust-proof front panel, but the unit should not be placed in a

location where coolant would directly fall onto it.

(7) Noise must be minimized.

As the machine and the CNC unit are reduced in size, the parts

that generate noise may be placed near noise-sensitive parts in

the magnetics cabinet.

The CNC unit is built to protect it from external noise. Cabinet

design to minimize noise generation and to prevent it from being

transmitted to the CNC unit is necessary. See section 3.5 for

details of noise elimination/management.

(8) When placing units in the cabinet, also consider ease of

maintenance.

The units should be placed so that they can be checked and

replaced easily when maintenance is performed.

(9) The hard disk drive and floppy disk drive must not be installed

near the source of a strong magnetic field.

(10) The installation conditions of the I/O unit and connector panel

I/O module must be satisfied.

- 23 -

Page 42

3.INSTALLATION B-63943EN/02

To obtain good ventilation in the module, the I/O unit and

connector panel I/O module must be installed in the direction

shown in the following figure. Clearances of 100 mm or more

both above and below the I/O unit are required for wiring and

ventilation.

Equipment radiating too much heat must not be put below the

I/O unit and connector panel I/O module.

Top

Bottom

Connector panel I/O module or

I/O base unit

(No screws or protrusions shall extend

from the bottom of this unit.)

- 24 -

Page 43

B-63943EN/02 3.INSTALLATION

3.4 THERMAL DESIGN OF THE MACHINE TOOL MAGNETIC

CABINET

The internal air temperature of the cabinet increases when the units

and parts installed in the cabinet generate heat. Since the generated

heat is radiated from the surface of the cabinet, the temperature of the

air in the cabinet and the outside air balance at certain heat levels.

If the amount of heat generated is constant, the larger the surface

area of the cabinet, the less the internal temperature rises. The

thermal design of the cabinet refers to calculating the heat generated in

the cabinet, evaluating the surface area of the cabinet, and enlarging

that surface area by installing heat exchangers in the cabinet, if

necessary. Such a design method is described in the following

subsections.

3.4.1 Temperature Rise within the Machine Tool Magnetic Cabinet

The cooling capacity of a cabinet made of sheet metal is generally 6

W/°C per 1m

contained in a cabinet having a surface area of 1 m

of the air in the cabinet rises by 1°C. In this case the surface area of

the cabinet refers to the area useful in cooling , that is, the area

obtained by subtracting the area of the cabinet touching the floor from

the total surface area of the cabinet. There are two preconditions :

The air in the cabinet must be circuited by the fun, and the

temperature of the air in the cabinet must be almost constant. For

example, the operator’s panel cabinet may contain an LCD-mounted

type control unit or the display of a stand-alone type control unit. To

keep the temperature in the cabinet at 58°C or below when the

ambient temperature is 45°C, the equation below must be satisfied.

Internal heat loss P [W] ≤

6[W/m

(A cooling capacity of 6 W/°C assumes the cabinet is so large that

agitation with the fan motor does not make the temperature

distribution uniform. For a small cabinet like the operator's panel, a

cooling capacity of 8 W/°C, indicated in Subsection 3.4.4, may be

used.)

For example, a cabinet having a surface area of 4m

capacity of 24W/°C. To limit the internal temperature increase to

13°C under these conditions, the internal heat must not exceed

312W. If the actual internal heat is 360W, however, the temperature

in the cabinet rises by 15°C or more. When this happens, the cooling

capacity of the cabinet must be improved using the heat exchanger.

For the power magnetic cabinet containing a stand-alone type control

unit, the internal temperature rise must be suppressed to 55°C or less,

instead of 58°C.

2

surface area, that is, when the 6W heat source is

2

⋅°C] × surface area S[m2] × 13[°C] of rise in temperature

2

, the temperature

2

has a cooling

- 25 -

Page 44

3.INSTALLATION B-63943EN/02

3.4.2 Heat Output of Each Unit

Table 3.4.2 (a) Heat output

Heat

output

33W

49W

30W

13W

34W

4W

3W

3W

4W

5W

2W

5W

2W

type control unit

Stand-alone type

control unit

Optional board

Unit

7.2”/8.4”/10.4” type display unit

15” type display unit

Control unit (alone)

10.4” display unit

15” display unit

Additional axis board

Additional spindle board

Fast data server board

HSSB board

Profibus master board

Profibus slave board

FL-net board

DeviceNet (master) board

NOTE

The liquid-crystal display and MDI unit are

included. Optional boards are not included.

Table 3.4.2 (b) Heat output

Unit

MDI unit 0W

Standard machine operator’s

panel

Operator's panel I/O module 12W Note 1)

Connector panel I/O module

(basic)

Connector panel I/O module

(additional)

Separate detector interface unit 9W Basic 4-axis unit only

Separate detector interface unit 14W Basic 4 axes + additional 4 axes

Heat

output

15W Note 1)

8W Note 1)

5W Note 1)

Note 2)

Note 2)

Remarks

NOTE

1 The indicated values are when 50% of the module

input signals are ON.

2 Heat output generated within the separate detector

is not included.

Remarks

(Note) LCD-mounted

(Note)

- 26 -

Page 45

B-63943EN/02 3.INSTALLATION

3.4.3 Thermal Design of Operator's Panel

With a small cabinet like the operator's panel, the heat dissipating

capacity of the cabinet is as shown below, assuming that there is

sufficient mixing of the air inside the cabinet.

Coated metal surfaces: 8 W/m

Plastic surfaces: 3.7 W/m

An example of the thermal design for the cabinet shown in Fig. 3.4.3

is shown below.

2

°C

2

°C

Fig. 3.4.3

Assume the following.

Thermal exchange rates

2

Coated metal surfaces : 8 W/m

Plastic surfaces : 3.7 W/m

⋅°C

2

⋅°C

Allowable temperature rise : 13°C higher than the exterior

temperature

Also, assume the following.

Dimensions of pendant type cabinet shown in Fig. 3.4.3:

560(W) × 470(H) × 150(D) mm

Surface area of metallic sections : 0.5722 m

Surface area of plastic sections : 0.2632 m

2

2

- 27 -

Page 46

3.INSTALLATION B-63943EN/02

In this case, the allowable total heat dissipation for the cabinet is:

8 × 0.5722 × 13 + 3.7 × 0.2632 × 13 = 72 W.

In consequence, it can be concluded that the units shown in Table

3.4.3 on the next page can be installed in this cabinet.

Table 3.4.3

LCD-mounted type control unit (10.4” LCD) 33W

Optional board (Fast data server board) 3W

Optional board (Additional axis board) 4W

Standard machine operator's panel 15W

120-mm square fan motor for air mixing 8W

Total heat dissipation of the above 63W

NOTE

The 15 W quoted for the standard machine

operator's panel represents an example heat

output value when half of all the input signals are

turned on. This value varies, depending on the

mechanical configuration.

- 28 -

Page 47

B-63943EN/02 3.INSTALLATION

3.5 ACTION AGAINST NOISE

The CNC has been steadily reduced in size using surface-mount and