Page 1

FANUC

3000C

1.

2.

OUTLINE

SPECIFICATIONS

2.

2.

2.3

2.4

1

2

Basic

Basic

Additional

Outer

Unit

Option

View

CONTENTS

,

...

Options

.

OPERATOR’S

FUJITSU

..

FANUC

MANUAL

LTD

;

1

3

3

7

8

13

3.

1

PROGRAMMING

3.

3.

3.

3.4

3.

3.

3.7

3.8

3.9

3.

3.

3.11.1

3.11.2

3.11.3

1

2

3

5

6

10

11

General

Process

Tape

Increment

Buffer

Absolute

Maximum

Tape

Address

Function

Feed

Format

Code

Function

Rapid

1

-Digit

4

-Digit

,

.

Sheet

System

Register

and

Programmable

Codes

Codes

Traverse

F-Code

F-Code

. .

.

(Buffer)

Incremental

Speed

Unit

Unit

Programming

Dimensions

15

.

.

15

15

17

18

20

20

21

22

22

24

25

25

26

27

B-5

520E/06

1

Page 2

3.

12

Preparatory

Function

(G

Function)

30

3.

3.

3.

3.

3.

3.

3.

3.12.

3.

3.

3.

3.

3.

3.

3.

3.

3.

3.

3.

3.

3.

3.

3.

3.

3.

3.

3.23

3.

3.25

12.

12.

12.

12.4

12.

12.

12.

12.

12.

12.11

12.

12.

12.

12.

12.

13

14

15

16

17

18

19

20

21

22

24

1

Positioning

Linear

2

Circular

3

Dwell

Circle

5

6

Helical

G15),

7

Plane

8

Programming

9

10

12

13

14

Zero

Cutter

Tool

Tool

Canned

Absolute

G91)

Programming

15

Initial

16

D

Spindle

Tool

B

Miscellaneous

Automatic

Optional

Absolute

Mirror

Sequence

Label

Sub

Programming

H

and

Function

Function

Skip

Tape

-Speed

Interpolation

Interpolation

(G04)

Cutting

Interpolation

B(G02,G03)

Selection

Return

Compensation

Offset

Offset

Cycles

and

Level

Functions

Function

(T

Acceleration

Block

Rewind

image

Number

Function

Control

Examples

(GOO)

(G12,

Copy

(G27

B

(G43,

A

(G45

(G73,

Incremental

of

and

Function)

Function

Skip

Stop

Display

,

(G17

(G25)

,

G28,

to

Absolute

R

point

(S

(M

and

&

Reset

and

(G01)

(GO

G13)

Helical

G18,

G29)

(G38

G44,

G48)

G76,

Level

Function)

Function)

Deceleration

&

Search

Control

.....

2,

GO

3)

.

Interpolation

G19)

.

G42)

to

G49)

G80

Programming

Zero

In/Out

G89)

to

Point

(G98

and

.

(G90

(G92)

G99)

A(G14,

and

•

-

..

.

32

34

36

40

41

42

46

46

49

51

63

66

76

91

91

93

94

95

96

97

98

99

101

103

104

105

106

108

111

4.

:

;

i

1

OPERATION

4.1

4.1.1

4.1.2

4.1.

MDI

3

4.1.4

2

4.

4.

4.4

4.

3

5

4.5.

4.

4.5.3

5.

Position

1-Digit

Built-in

Tape

1

2

DPL

&

Display

Switch

Display

Manual

Display

F-Code

Type

Reader

Tape

Tape

Procedure

Reader

Reader

Unit

Section

and

Unit

Data

Button

Section

Input

Unit

Unit

Manual

without

with

of

Setting

Section

........

(MDI)

Operator's

Reels

Reels

NC

an

..

Section

.....

Tape

..

Panel

116

;

116

116

118

120

129

148

150

150

151

151

154

158

Page 3

4

4.7

Punch

6

.

Procedure

Operator's

of

Panel

Function

161

162

4.7.1

4.7.2

4.7.3

4.7.4

4.7.5

4.7.6

4.7.7

4.7.8

4.7.9

4.7.10

4.7.11

4.7.12

4.7.13

4.7.14

4.7.15

4.7.

4.7.

4.7.

4.7.

4.7.20

4.7.21

4.7.22

4.7.23

4.7.24

16

17

18

19

MODE

CYCLE

FEED

JOG

RAPID

DRY

OPTIONAL

F4

JOG

EMERGENCY

SINGLE

ZERO

Lamps

BLOCK

DISPLAY

Z-AXIS

MANUAL

SCALE

AUXILIARY

HANDLE

MANUAL

SEARCH

OVERRIDE

POWER

2ND

SELECT

HOLD

&

STEP

TRAVERSE

RUN

FEED

FEED

RETURN

L.S.

START

BLOCK

RETURN

FEED

RETURN

START

ON/OFF

Switch

Button

Button

Button

Switch

BLOCK

RATE

RATE

OVERRIDE

Dial

STOP

Switch

Switch

Switch

LOCK/MACHINE

NEGLECT

ABSOLUTE

Switch

FUNCTION

AXIS

and

PULSE

CANCEL

REMOVE

SELECT

MULTIPLY

Button

Button

Switch

...

SKIP

Button

and

Switch

Switch

Switch

..

.

.

.....

Switch

Switch

LOCK

Dial

ZERO

LOCK

Switch

.

Switch

Switch

.

.

.

.

.

POSITION

Switch

..

162

164

165

166

167

167

168

168

169

170

171

173

174

177

178

179

181

181

182

183

183

183

1

83

183

5.

*

6.

OPERATIONAL

1

5.

2

5.

5.

3

5.4

5

5.

6

5.

7

5.

5.8

5.9

10

5.

11

5.

MAINTENANCE

1

6.

2

6.

3

6.

Preparation

Power

Turning

Setting

Manual

Setting

Tape

NC

Manual

Operation

Operation

Preparation

Turning

Daily

P

ow

er

Fault

PROCEDURE

and

Inspection

....

.....

on

Power

T

ape

a

Operation

Zero

the

Point

Operation/Memory

Operation

MDI

by

the

by

before

Off

Power

Maintenance

Fuses

Causes

and

during

Unit

MDI

Remedies

before

. .

NC

.

Call

Tape

NC

Off

.....

during

Turning

Turning

.

Operation

Operation

Tape

Power

on

.

.

.

Operation

..........

......

.

185

.

185

185

185

.

188

190

191

192

192

.

.

192

192

192

193

193

194

195

Page 4

APPENDIXES

Appendix

Appendix

Appendix

Appendix

Appendix

Appendix

Appendix

1

2

3

List

Range

of

Nomographs

1

3.

Tape

of

3.2

4

5

6

7

Preparation

How

to

RESET

State

and

and

Operation

Join

Codes

Various

Error

Circular

Tool

of

NC

Display

in

Path

NC

Tape

Commands

the

Radius

Cutting

a

at

Corner

Tape

of

Control

Values

Direction

in

Unit/Mode

201

202

205

205

208

216

218

219

Selection

220

Page 5

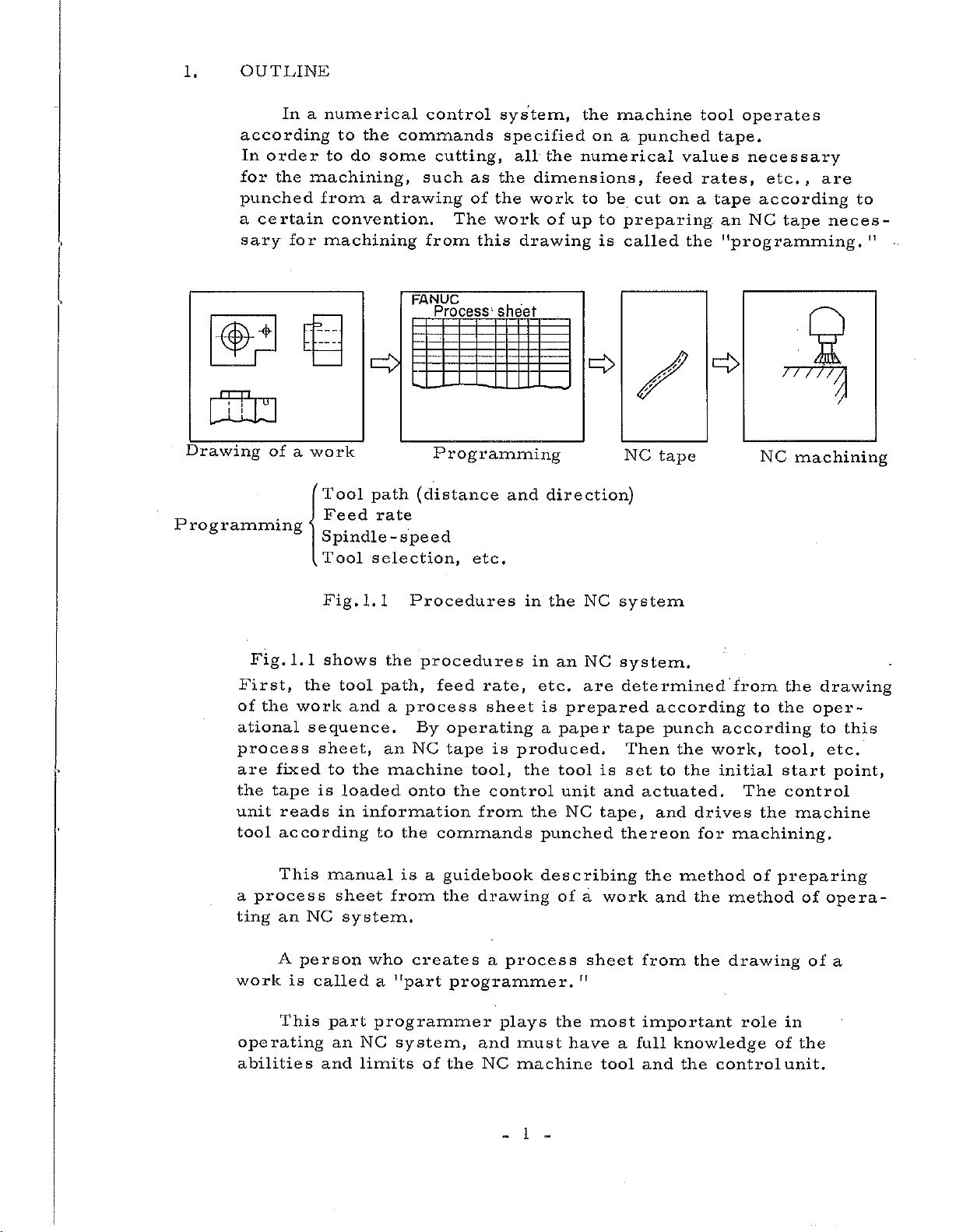

1.

OUTLINE

In

according

order

In

for

the

punched

certain

a

sary

for

a

numerical

to

the

to

do

machining,

from

convention.

machining

commands

some

a

drawing

ccmtrol

cutting,

such

The

from

FANUC

Process;

as

of

this

system,

specified

all

the

dimensions,

the

work

work

drawing

sheet

the

of

the

on

numerical

to

be

up

to

is

machine

punched

a

feed

cut

preparing

called

values

on

operates

tool

tape.

rates,

tape

a

an

the

"programming.

necessary

etc.,

according

tape

NC

are

neces¬

to

"

-

ura

Drawing

P

rog

(id

ramming

Fig.

First,

of

the

ational

process

are

the

unit

tool

d

of

work

a

1.1

the

work

sequence.

fixed

tape

reads

according

Tool

Feed

path

rate

Spindle-speed

1.1

tool

and

to

the

loaded

in

information

selection,

the

path,

a

an

machine

to

the

Tool

Fig.

shows

sheet,

is

Programming

(distance

Procedures

procedures

feed

process

By

operating

tape

NC

onto

the

commands

etc.

rate,

sheet

tool,

control

from

and

is

produced.

direction)

in

the

in

an

etc.

is

paper

a

the

tool

unit

the

punched

NC

NC

are

prepared

is

and

NC

tape,

NC

tape

system

system.

determined

according

tape

punch

Then

set

thereon

the

to

actuated.

and

the

drives

for

o

from

to

according

work,

initial

The

machining.

77777

NC

the

the

tool,

start

control

the

$

machining

drawing

oper¬

to

this

etc.

point,

machine

This

process

a

an

ting

A

work

This

operating

abilities

NC

person

is

manual

sheet

called

part

an

and

system.

who

a

programmer

NC

limits

is

from

creates

"part

system,

of

guidebook

a

the

drawing

programmer.

the

a

and

NC

process

plays

must

machine

1

describing

of

a

sheet

"

most

the

have

work

a

tool

the

method

and

from

important

full

knowledge

and

the

the

the

method

drawing

role

control

of

preparing

of

of

in

the

unit.

opera¬

of

a

Page 6

For

example,

he

must

select

(1)

select

(2)

effectively

(3)

(4)

(5)

the

give

point,

effectively

Also,

high-accuracy

tool,

Setting

to

setting

addition

the

(1)

resetting

Giving

(2)

(3)

Daily

such

the

tool

a

optimum

use

operator

,

etc.

use

operator

the

products,

the

usual

the

Cutter

the

because

instructions

maintenance

path

spindle

M

the

information

the

Canned

of

pay

operations

tape,

Compensation

the

of

about

(cleaning

as

to

function

NC

an

attention

operating

tool

regrinding

reduce

speed,

or

on

Cycle,

system

(loading

wear,

and

the

tool

and

function,

G

the

tool

etc.

must,

to

the

and

the

control

amount

etc.)

the

inspection)

machining

feed

change,

order

in

following

unloading

panel,

(requiring

tool

time,

rate,

machine

points

the

etc.)

the

to

work

produce

setup

in

and

periodical

The

front

its

Particularly

doors

outside

centers,

the

positioning

centers,

(including

This

machine

The

operator

and

enter

air

manual

milling

FANUC

and

etc,

back

in

a

that

tool

continuous

and

does

doors

usual

of

directly

discusses

machines,

builder

C

3000

used

not

need

open

operation,

the

tape

into

the

etc.

to

as

NC

are

cutting

FANUC

to

except

he

reader)

it.

equipment

Refer

which

equipped

for

DC

operate

for

rather

options

milling

servo

the

the

closed

with

the

to

with

motor

equipment

NC

maintenance.

operates

so

as

options

description

be

can

2-to

machines,

used

4-axis

series

with

it

not

for

machining

as

with

the

to

let

machining

issued

in

practice.

the

the

by

servo.

2

Page 7

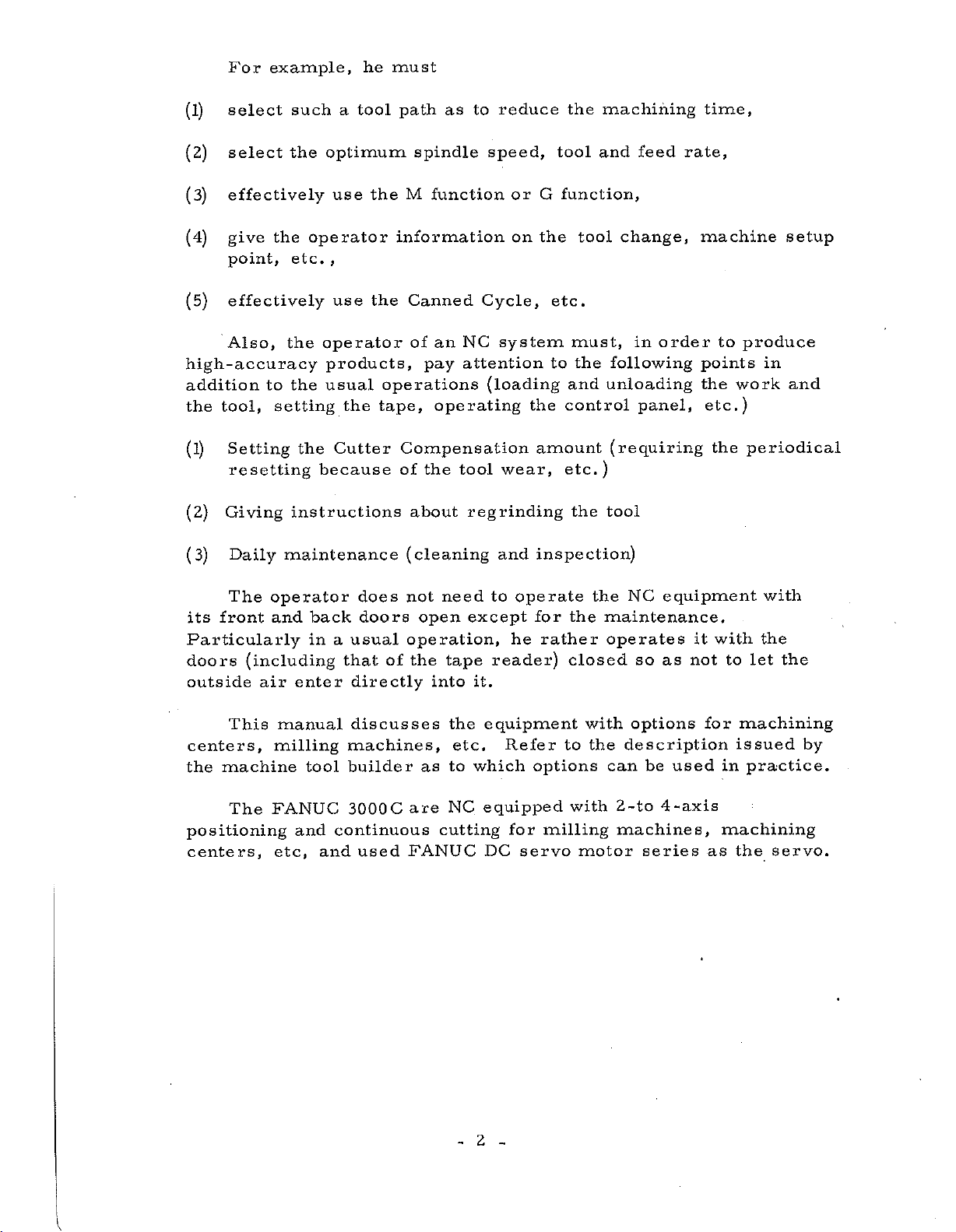

2.

SPECIFICATIONS

2.1

Item

(1)

(2)

(3)

(4)

(5)

(6)

Basic

Controlled

The

number

controllable

Maximum

dimension

Tape

Tape

Increment

Unit

Name

axes

of

axes

programmable

command

format

system

simultaneously

axes

3

options)

axes

2

additional

(4

axes

additional

manual

not

controlled

See

Section

-channel

8

RS-227)

See

Section

See

Section

Spe

(4

axes

_

axes

(3

options)

linear

for

options)

operation,

black

cifications

with

for

at

3.7.

3.3.

3.4.

additional

positioning

interpolation

In

three

time

a

paper

tape

case

axes

.

with

with

of

are

(EIA

(?)

(8)

(9)

(10)

(11)

(12)

EIA

code

ISO

code

Absolut

programming

Positioning

Linear

4-digit

Automatic

deceleration

/

e/lnc

interpolation

F-code

input

input

remental

feed

acceleration

See

Appendix

This

permits

Absolute

mixedly

Preparatory

The

identifies

Incremental

respectively.

permits

GOO

each

for

speed.

specifies

G01

to

tool

straight

end

See

See

be

point.

Section

Section

and

Incremental

one

in

the

programming,

individual

axis

controlled

line

up

3.11.

3.18.

1

.

specifying

block

function

Absolute

the

at

the

movement

to

a

the

dimensions

of

tape.

(G90,

the

and

positioning

Rapid

along

programmed

Traverse

a

of

G91)

a

(13)

Override

A

override

ment

a

panel

3

-

-

of

rotary

.

10%

switch

can

in

a

be

range

on

effected

0

the

operator's

to

in

incre¬

200%

by

Page 8

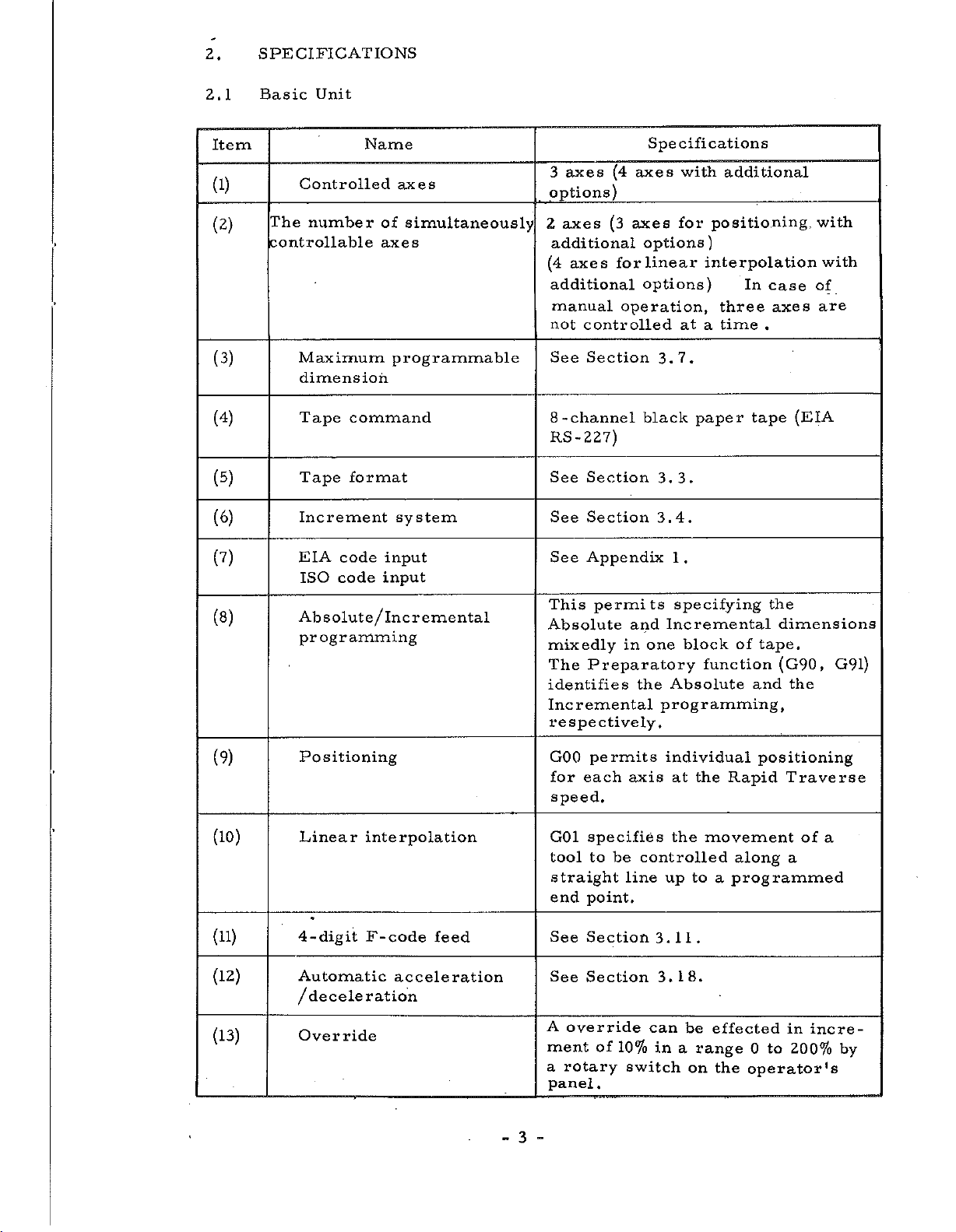

Item

(14)

Name

Programming

Zero

point

of

Absolute

permits

G92

ment

the

current

specified

such

Specifications

setting

a

coordinate

position

position

within

of

a

the

system

tool

equip¬

is

that

a

(15)

(16)

(17)

(18)

(19)

(20)

Miscellaneous

Backlash

Single

Label

Mirror

block

skip

image

/Remote

Interlock

function

compensation

mirror

image

This

specifies

M99.

this

By

pensated

a

in

range

This

executing

tape.

This

tape

place,

up

the

Symmetrical

with

is

function

or

the

to

tape.

respect

function.

This

axis

function

independently.

function,

in

of

a

function

only

for

ignores

and

first

the

backlash

increments

1

to

255

one

used

is

starting

EOB

cutting

to

any

stops

two-digit

pulses.

of

reading

block

for

the

the

information

code

can

axis

feed

the

is

one

of

of

naming

tape

in

be

performed

by

MOO

com¬

pulse

and

NC

at

reading

this

for

to

the

any

each

(21)

(22)

(23)

(24)

(25)

Dwell

Machine

Auxilliary

Display

Optional

lock

lock

Block

function

Skip

lock

G04

a

This

the

automatic

This

and

This

position

machine

This

skipping

punched

4

permits

specified

is

position

function

B

code

is

is

a

function

or

to

a

function

display

tool

function

a

block

a

with

stopping

period

display

manual

inhibits

Machine

is

"/"

of

time.

of

operating

unit

operation.

output

of

stopping

unit

while

operating

of

selectively

NC

of

(slash).

the

tape

feed

during

of

the

normally.

for

M,

the

only

an

S,

T

Page 9

Item

(26)

(27)

(28)

(29)

Manual

feed

JOG

STEP

MDI

feed

feed

h

Name

rapid

DPL

traverse

This

tool

TRAVERSE

in

by

This

tool

kept

mode

This

tool

when

in

SELECT

See

function

rapidly

the

the

function

while

pushed

function

to

the

Section

manual

MODE

by

XI,

the

step

Specifications

feed

can

while

button

continuous

SELECT

feed

can

the

JOG/

the

in

MODE

the

can

feed

,

X10

JOG/

feed

switch.

X100

STEP

mode

4.1.1

RAPID

the

is

kept

STEP

manual

SELECT

,

button

by

the

feed

switch.

the

button

the

X1000

the

machine

pushed

mode

machine

is

continuous

switch.

machine

pulses

is

pushed

MODE

(30)

(31)

(32)

(33)

(34)

(35)

Override

Z-axis

cancel

Tool

offset

Sequence

Remote

Remote

cancel

command

A

number

deceleration

power

search

ON/OFF

This

enable

Override

During

operation

can

be

This

for

This

to

number

This

rate

The

by

addition

button

panel.

is

a

feature

search

function

from

power

contact

a

a

made

a

cutter

on

on

the

fix

cycle

command

a

function

length.

any

tape.

outside,

is

signal

to

the

the

4

-digit

to

100%.

operation

to

be

ignored.

of

enables

following

decelerates

turned

POWER

control

F-code

or

the

for

compensating

operater

the

sequence

the

on

and

from

outside

ON/OFF

display

unit

feed

manual

Z-axis

feed

off

in

(36)

Buffer

register

5

-

This

mitting

executed,

ahead

NC

permits

tape.

pulses

during

continuously

between

by

reading

the

one

operation

blocks

block

trans¬

an

by

being

Page 10

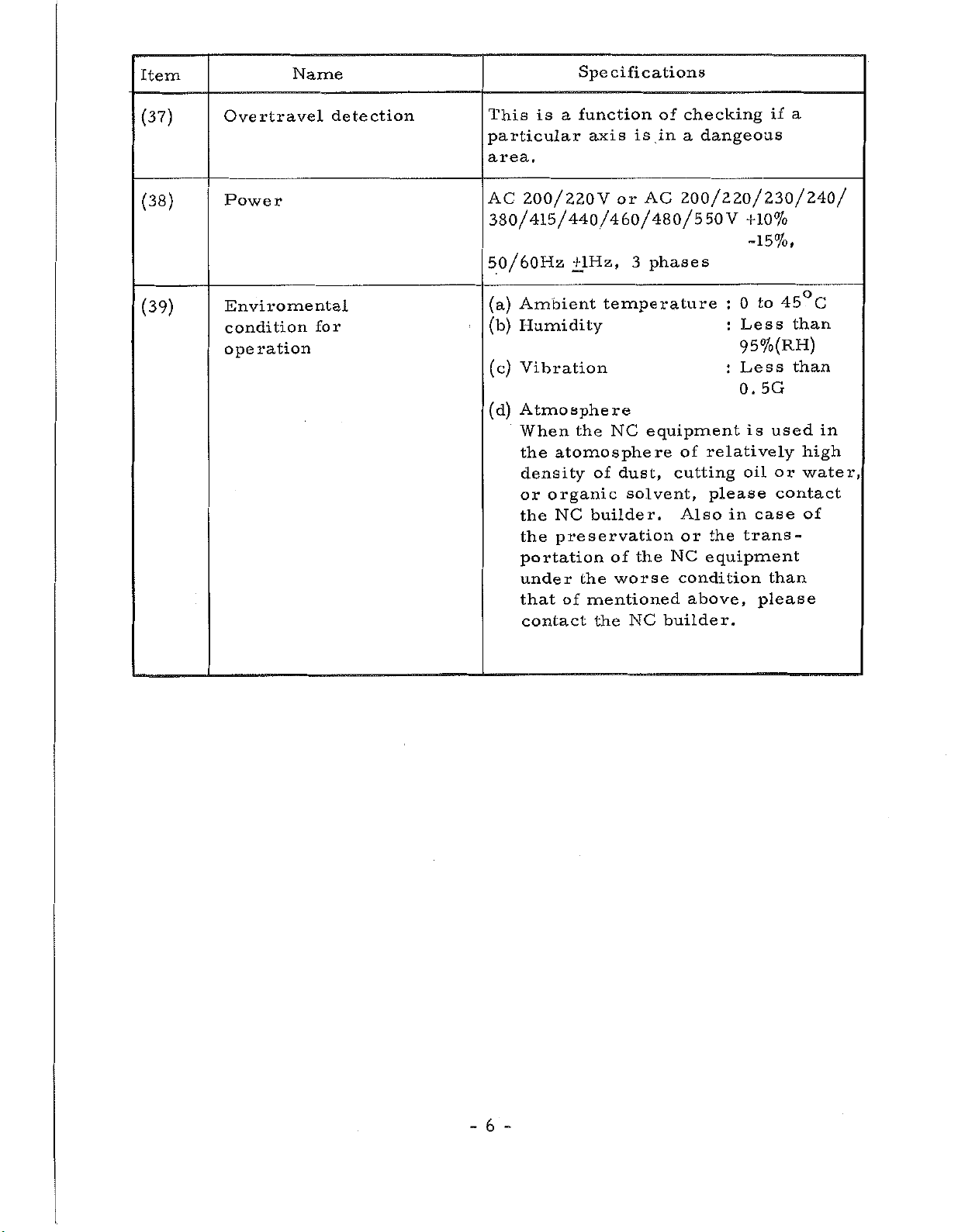

Item

(37)

Overtravel

Name

detection

This

particular

is

area.

Specifications

function

a

axis

a

checking

of

is

in

a

dangeous

if

(38)

(39)

Power

Enviromental

condition

operation

for

AC

200/220V

380/415/440/460/480/550V

or

AC

200/220/230/240/

+10%

-15%,

3

50/60Hz

Ambient

(a)

Humidity

(b)

+lHz,

temperature

phases

:

:

to

0

Less

45°C

than

95%(RH)

5G

is

case

please

than

used

or

contact

than

(c)

Vibration

Atmosphere

(d)

When

the

density

or

the

the

portation

under

that

contact

NC

the

atomo

organic

NC

preservation

of

sphere

of

builder.

of

the

mentioned

the

equipment

dust,

solvent,

the

worse

NC

of

cutting

Also

or

NC

equipment

condition

above,

builder.

Less

:

0.

relatively

oil

please

in

trans¬

the

in

high

water,

of

6

-

-

Page 11

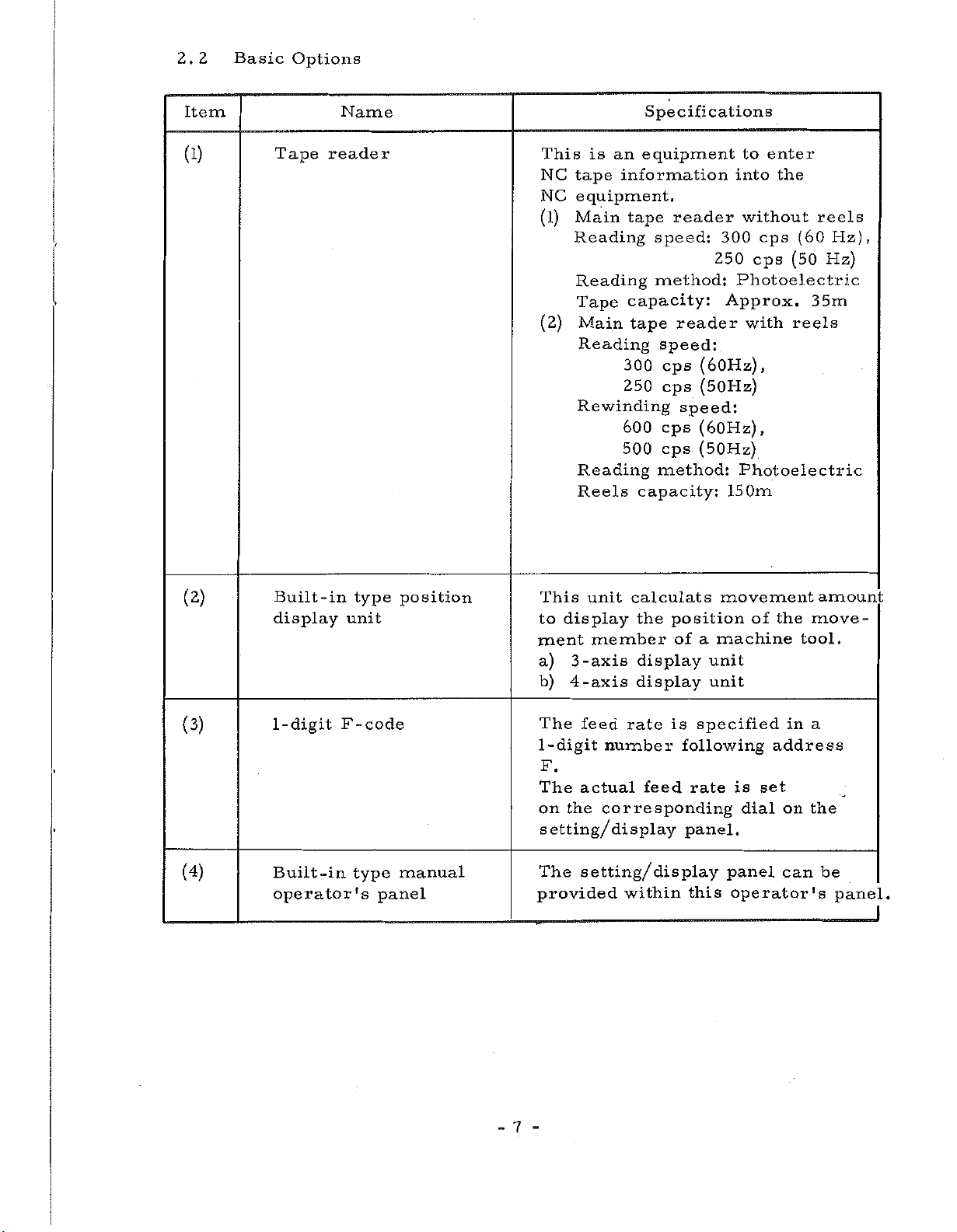

2.2

Basic

Options

Item

(1)

Tape

Name

reader

This

NC

NC

(1)

(2)

is

an

tape

information

equipment.

Main

Reading

Reading

Tape

Main

Reading

tape

capacity:

tape

300

250

Rewinding

600

500

Reading

Reels

Specifications

equipment

reader

speed:

250

method:

reader

speed:

cps

(60Hz),

(50Hz)

cps

speed:

cps

(60Hz)

(50Hz)

cps

method:

capacity:

to

enter

into

the

without

300

cps

cps

Photoelectric

Approx.

with

,

Photoelectric

150m

(60

(50

reels

reels

Hz),

Hz)

35m

(2)

(3)

(4)

Built-in

display

1-digit

Built-in

operator's

type

unit

F-code

type

position

manual

panel

This

to

ment

a)

b)

The

1

-digit

display

-axis

3

4

-axis

feed

calculats

unit

member

rate

number

the

display

display

F.

The

on

actual

the

feed

corresponding

setting/display

setting/

The

provided

within

position

of

is

following

rate

panel.

display

this

movement

machine

a

unit

unit

specified

is

dial

panel

operator's

of

set

move¬

the

tool.

a

in

address

on

the

can

amount

be

panel.

7

-

-

Page 12

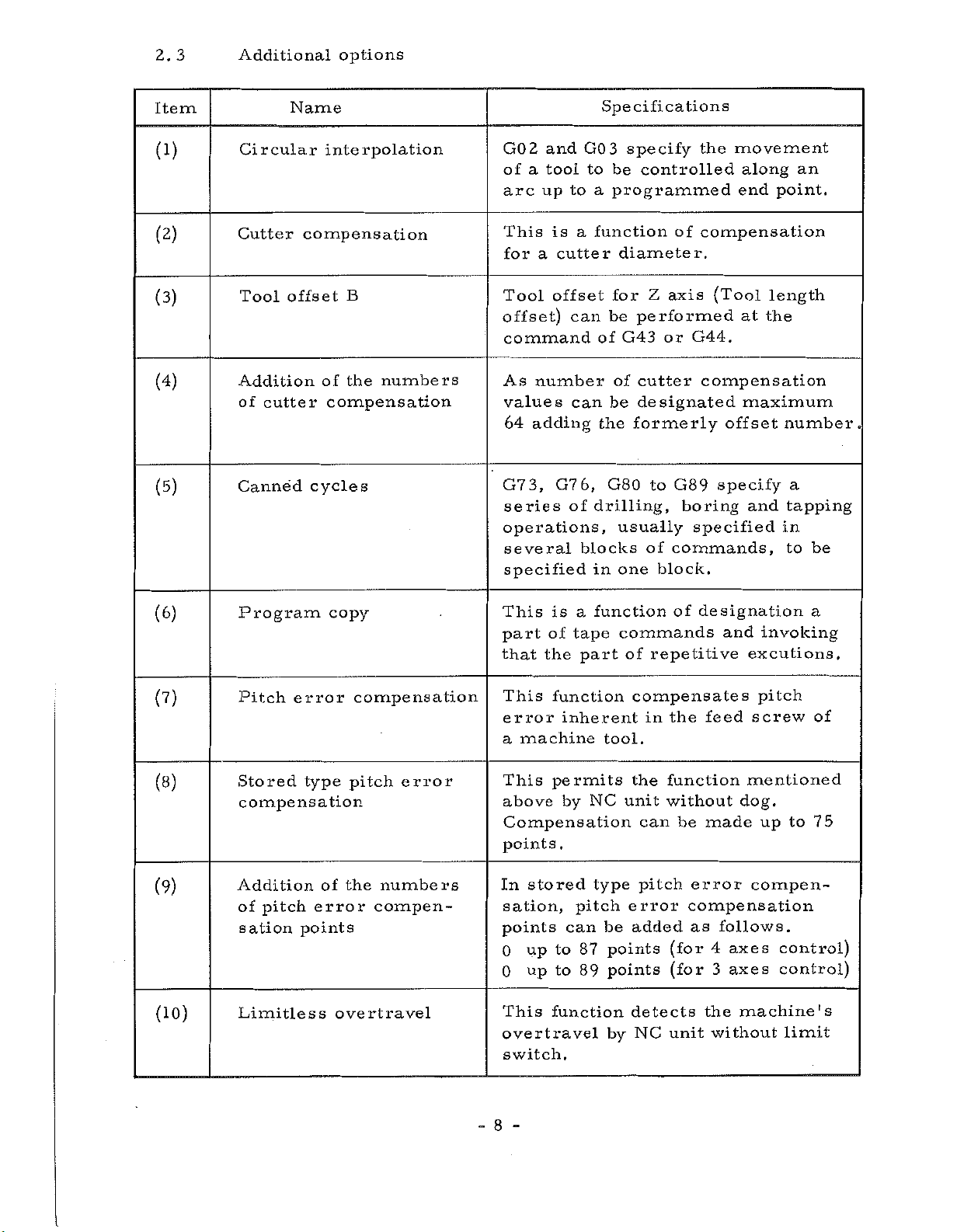

2.

3

Additional

options

Item

(1)

(2)

(3)

(4)

(5)

Circular

Cutter

Tool

Addition

cutter

of

Canned

Name

interpolation

compensation

offset

B

of

the

compensation

cycles

numbers

GO

2

and

of

tool

a

up

arc

This

for

Tool

a

is

cutter

offset

offset)

command

number

As

values

adding

64

3,

G7

series

operations,

several

specified

G7

Specifications

3

GO

to

be

a

to

programmed

function

a

diameter.

for

can

be

G43

of

of

be

can

the

6,

G80

of

drilling,

usually

blocks

in

one

specify

controlled

of

Z

axis

performed

or

cutter

designated

formerly

to

G89

commands,

of

block.

movement

the

along

end

compensation

(Tool

at

G44.

compensation

maximum

offset

specify

boring

specified

and

point.

length

the

number.

a

tapping

in

to

an

be

(6)

(?)

(8)

(9)

(10)

Program

Pitch

Stored

compensation

error

type

Addition

pitch

of

sation

Limitless

error

points

copy

compensation

pitch

the

of

overtravel

error

numbers

compen¬

This

part

that

This

error

a

This

above

Compensation

points

In

sation,

points

0

0

This

overtravel

switch.

is

of

the

function

inherent

machine

permits

by

.

stored

can

to

up

to

up

function

a

tape

part

pitch

87

89

function

commands

of

compensates

tool.

the

NC

unit

type

error

be

added

points

points

detects

by

repetitive

the

in

function

without

can

pitch

(for

(for

NC

unit

of

designation

and

feed

dog.

made

be

error

compensation

as

follows.

axes

4

3

axes

the

machine's

without

invoking

excutions.

pitch

screw

mentioned

to

up

compen¬

control)

control)

limit

a

of

75

8

-

-

Page 13

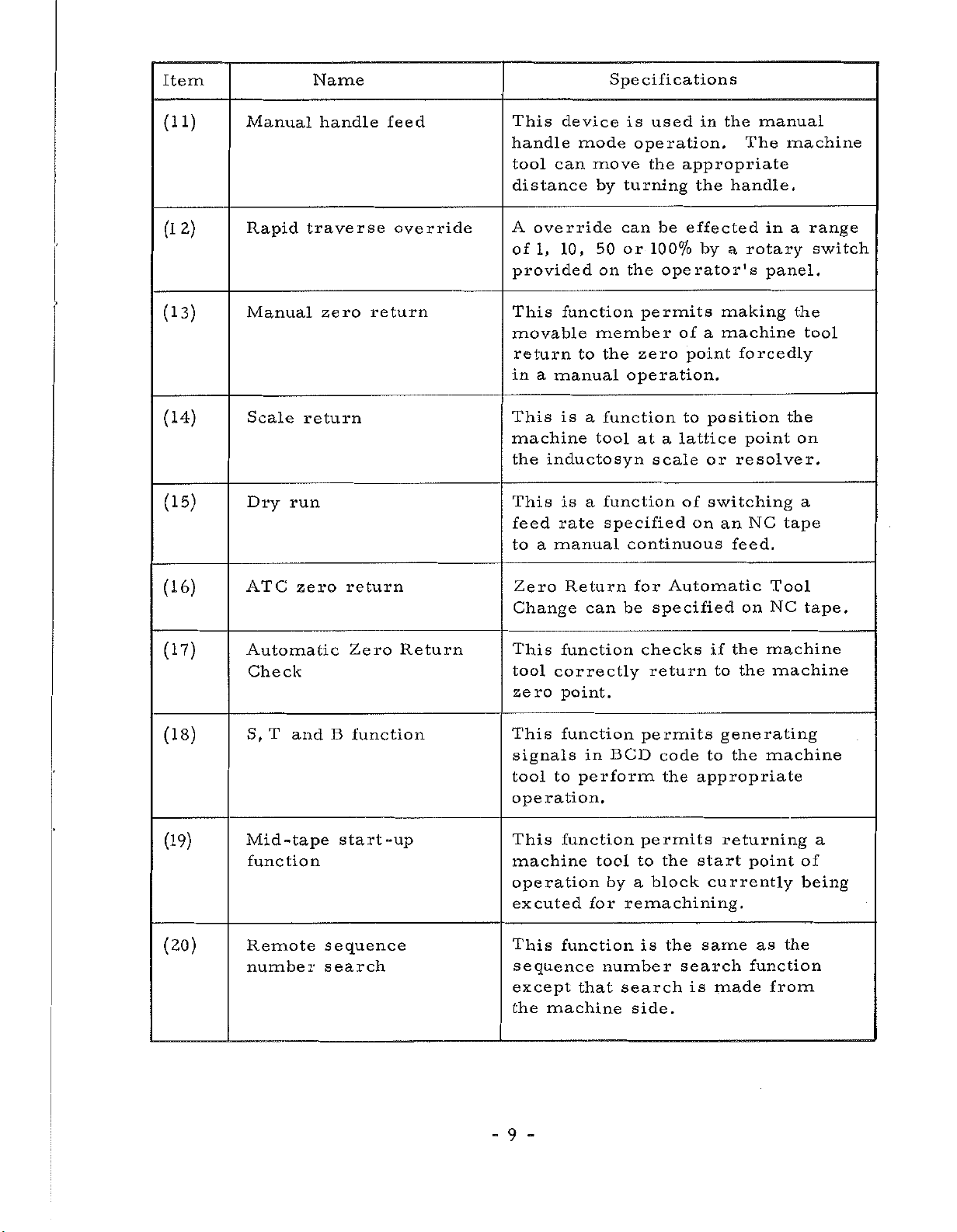

Item

Name

Specifications

(11)

2)

(1

(13)

(14)

(15)

Manual

Rapid

Manual

Scale

Dry

traverse

return

run

handle

zero

feed

override

return

This

handle

tool

can

distance

A

override

1,

of

provided

This

movable

return

a

in

manual

This

machine

inductosyn

the

This

feed

to

a

manual

device

mode

move

by

10,

50

on

function

member

to

is

function

a

tool

function

is

a

rate

is

used

operation.

the

turning

can

or

100%

the

permits

zero

the

operation.

at

scale

specified

continuous

in

appropriate

the

be

effected

by

operator's

of

a

point

to

position

lattice

a

or

of

switching

on

the

manual

The

handle.

rotary

a

making

machine

forcedly

point

resolver.

NC

an

feed.

machine

in

a

panel.

the

tape

range

switch

the

tool

on

a

(16)

(17)

(18)

(19)

(20)

ATC

zero

Automatic

Check

T

S,

Mid

and

-tape

function

Remote

number

return

Zero

B

function

start-up

sequence

search

Return

Zero

Change

This

tool

zero

This

signals

tool

operation.

This

machine

operation

excuted

This

Return

function

correctly

point.

function

to

function

function

sequence

except

the

machine

can

BCD

in

perform

tool

by

for

number

search

that

for

Automatic

be

specified

checks

return

permits

code

the

appropriate

permits

start

the

to

block

a

remachining.

is

the

search

is

side.

on

the

if

to

the

generating

to

the

returning

currently

same

made

Tool

NC

machine

machine

machine

point

the

as

function

from

tape.

a

of

being

-9-

Page 14

Item

Name

Specifications

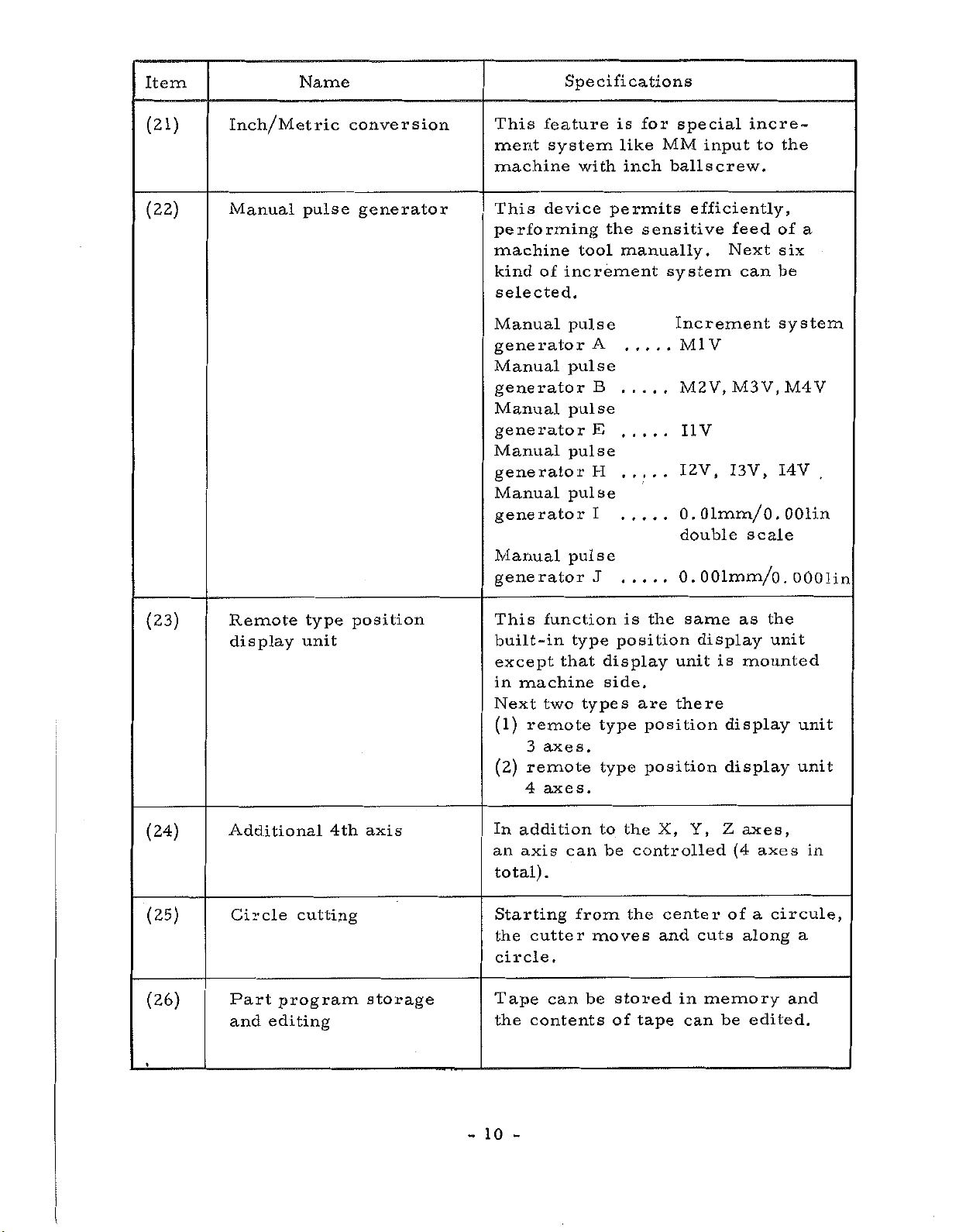

(21)

(22)

Inch/Metric

Manual

pulse

conversion

generator

This

ment

machine

This

performing

machine

kind

selected.

Manual

generator

Manual

feature

system

device

of

generator

Manual

generator

Manual

generator

Manual

generator

Manual

generator

is

with

permits

the

tool

increment

pulse

A

pulse

B

pulse

E

pulse

H

pulse

I

pulse

J

special

for

MM

like

inch

ballscrew.

sensitive

manually.

system

Increment

incre¬

input

efficiently,

to

feed

Next

can

V

Ml

M2V,

I1V

1

0

double

0.

M3V.M4V

2V,

I3V,

.

01mm/

scale

OOlmm/o.

the

of

six

be

system

I4V

.

OOlin

0

a

.

OOOlin

(23)

(24)

(25)

(26)

Remote

display

Additional

Circle

Part

and

program

editing

type

unit

4th

cutting

position

axis

storage

This

built-in

except

machine

in

Next

(1)

remote

3

remote

(2)

4

addition

In

axis

an

total)

Starting

cutter

the

circle.

Tape

contents

the

function

type

that

two

types

axes.

axes.

can

.

from

be

can

is

position

display

side.

type

type

to

the

be

the

moves

stored

of

same

the

unit

there

are

position

position

X,

controlled

center

and

in

can

tape

display

is

Y,

Z

cuts

memory

be

as

mounted

display

display

axes,

(4

axes

a

of

along

edited.

the

unit

unit

unit

in

circule,

a

and

-

10

-

Page 15

Item

Name

Specifications

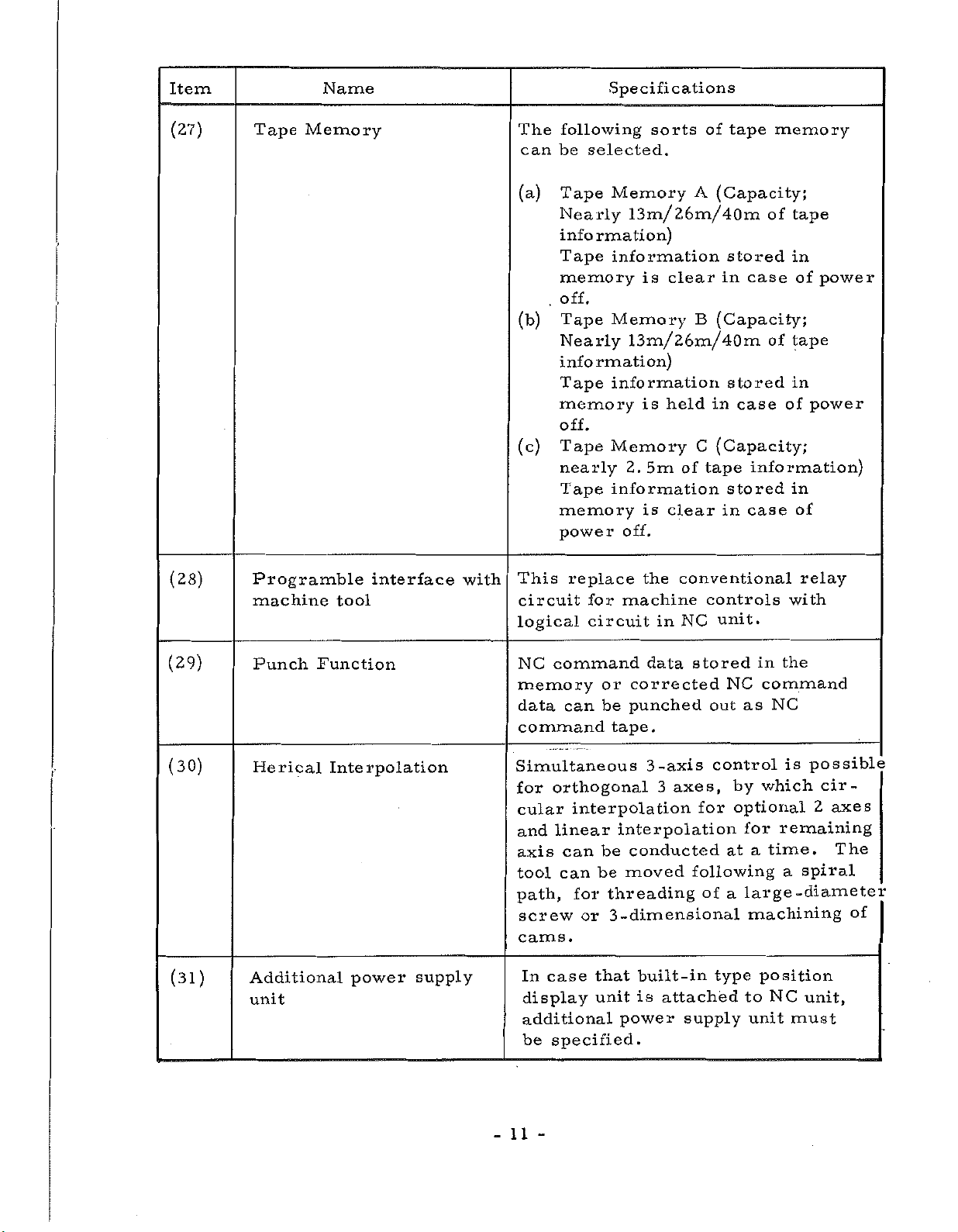

(27)

(28)

Tape

Prog

machine

ramble

Memory

tool

interface

with

The

following

can

be

(a)

Tape

Nearly

information)

Tape

memory

off.

.

(b)

Tape

Nearly

information)

Tape

memory

off.

(c)

Tape

nearly

Tape

memory

power

This

circuit

logical

selected.

replace

for

circuit

sorts

Memory

tape

of

A

(Capacity

13m/26m/40m

information

is

clear

Memory

stored

in

B

(Capacity;

case

13m/26m/40m

in

(Capacity;

C

tape

of

controls

unit.

NC

stored

case

stored

in

case

information

held

is

Memory

5m

2.

information

is

clear

off.

conventional

the

machine

in

memory-

;

tape

of

in

of

power

of

tape

in

power

of

information)

in

of

relay

with

(29)

(30)

(31)

Punch

Herical

Additional

unit

Function

Interpolation

power

supply

NC

command

memory

data

Simultaneous

for

cular

and

axis

tool

path,

can

command

orthogonal

interpolation

linear

can

can

for

screw

or

cams.

case

In

display

additional

be

that

unit

specified.

data

or

corrected

punched

be

tape.

-axis

3

3

interpolation

conducted

be

moved

be

threading

-dimensional

3

built-in

is

power

stored

axes,

for

following

of

attached

supply

NC

out

control

by

optional

at

a

type

the

in

command

NC

as

is

which

remaining

for

time.

a

a

position

NC

unit

-diameter

must

large

machining

to

possible

cir¬

2

axes

The

spiral

unit,

of

11

-

Page 16

Item

Name

Specifications

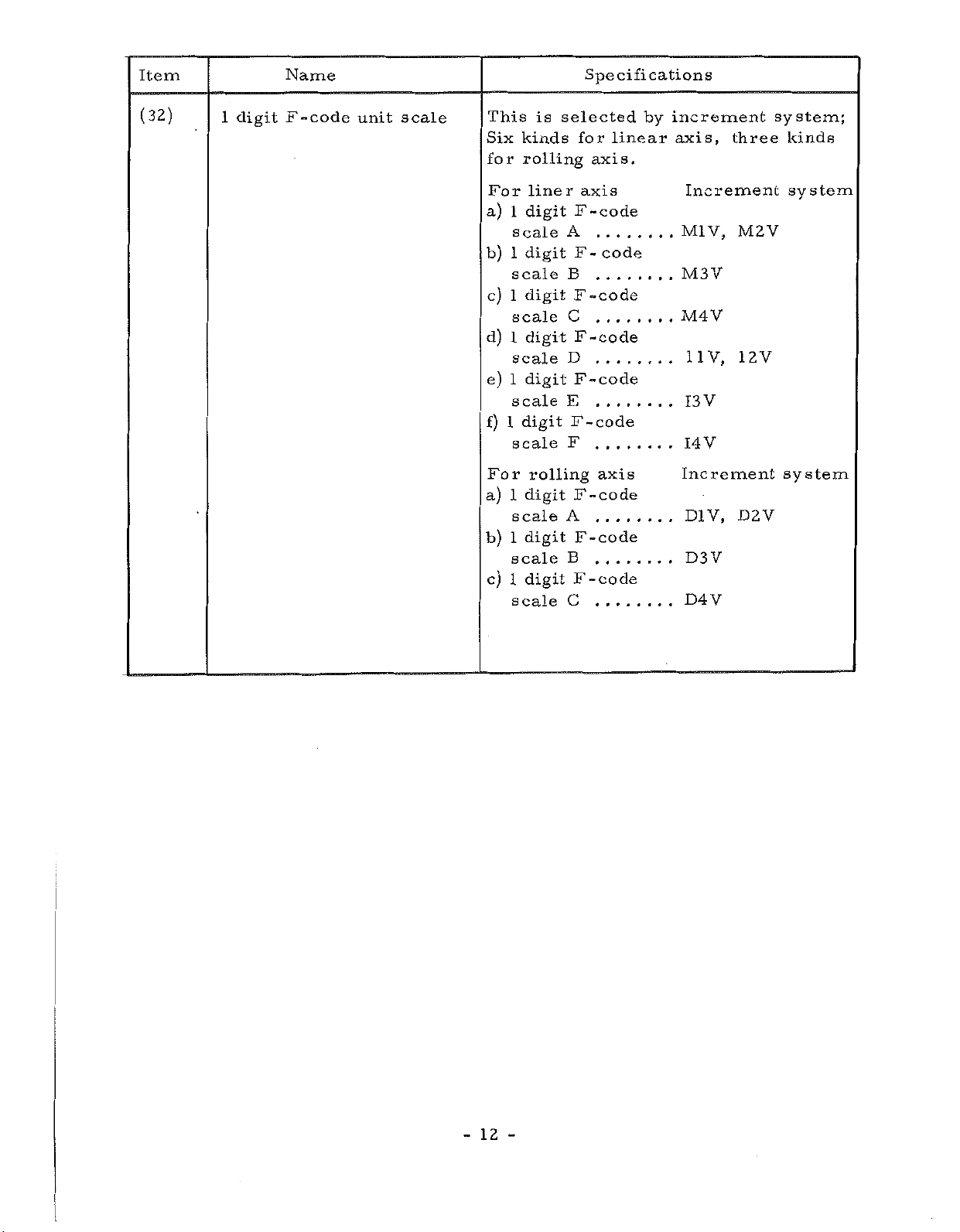

(32)

1

digit

F-code

unit

scale

This

Six

for

For

a)

b)

c)

d)

e)

f)

For

a)

b)

c)

1

1

1

1

1

1

1

1

is

kinds

rolling

lineraxis

digit

scale

digit

scale

1

digit

scale

digit

scale

digit

scale

digit

scale

rolling

digit

scale

digit

scale

digit

scale

selected

for

axis.

F

-code

A

.....

F

code

-

B

F

-code

C

.....

F-code

D

F

-code

E

F

-code

F

axis

F

-code

A

F-code

B

F

-code

C

linear

by

increment

axis,

Increment

V,

Ml

M3Y

M4V

11V,

V

13

V

14

Increment

D1V,

D3V

D4V

three

M2V

12V

D2V

system;

kinds

system

system

12

-

-

Page 17

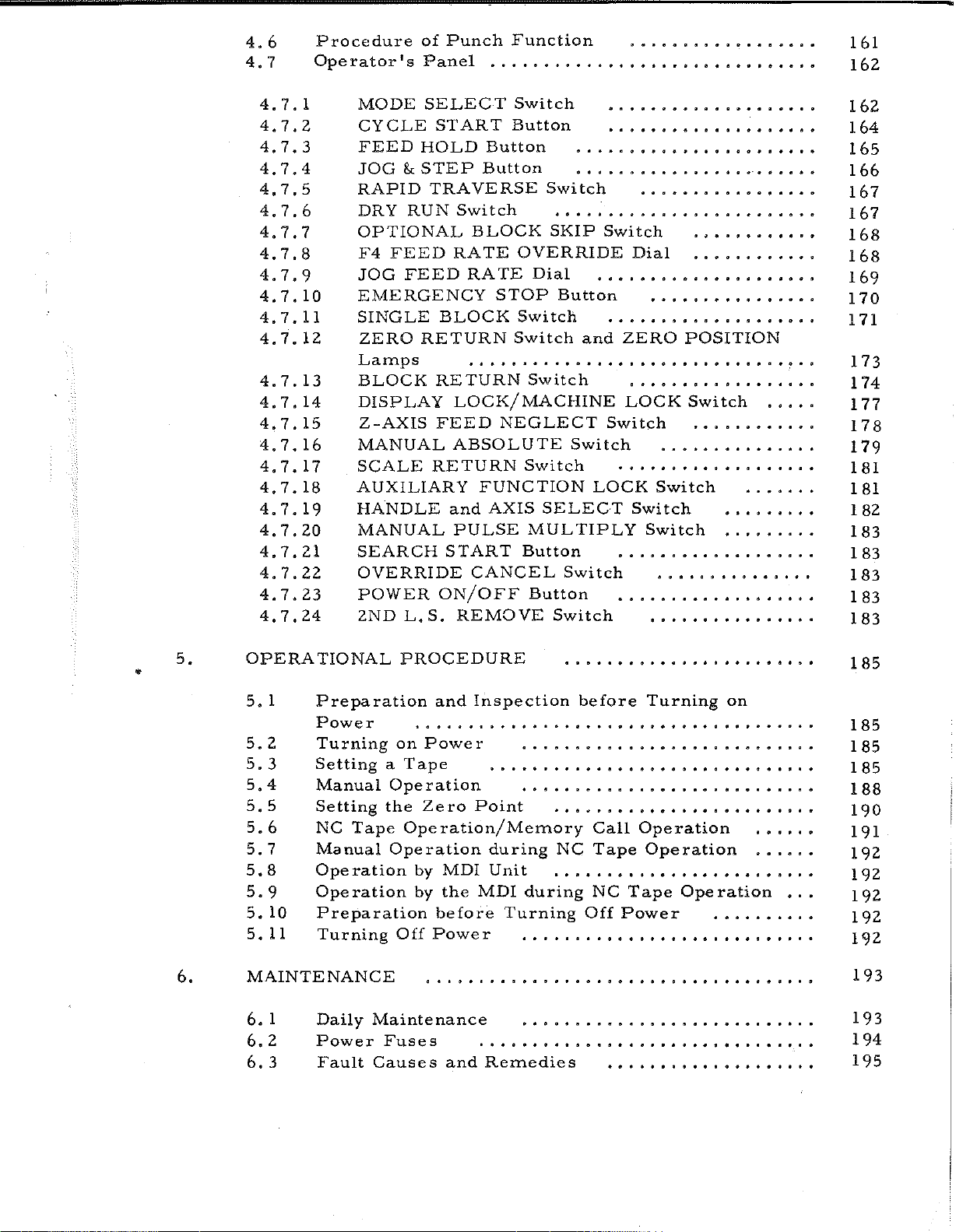

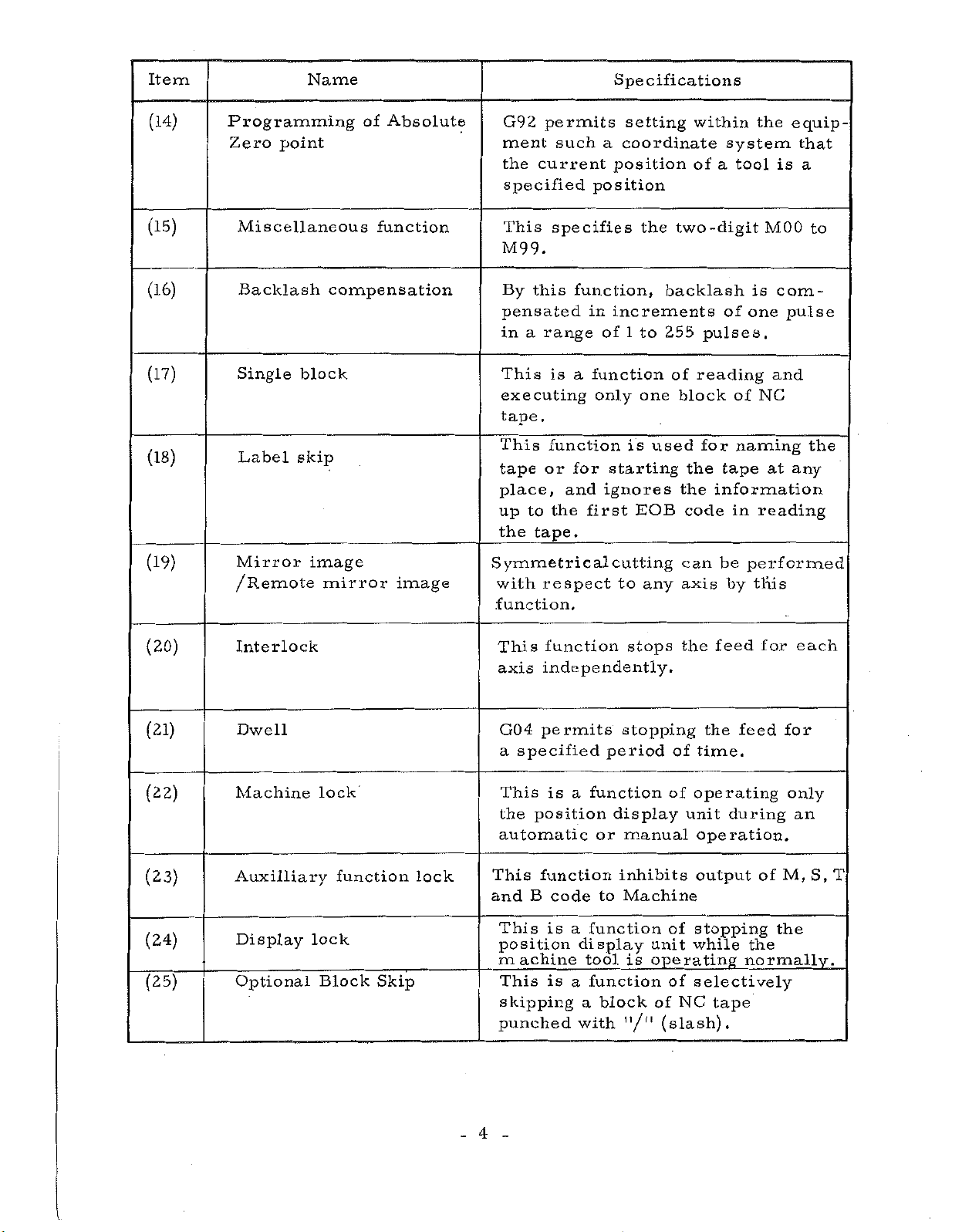

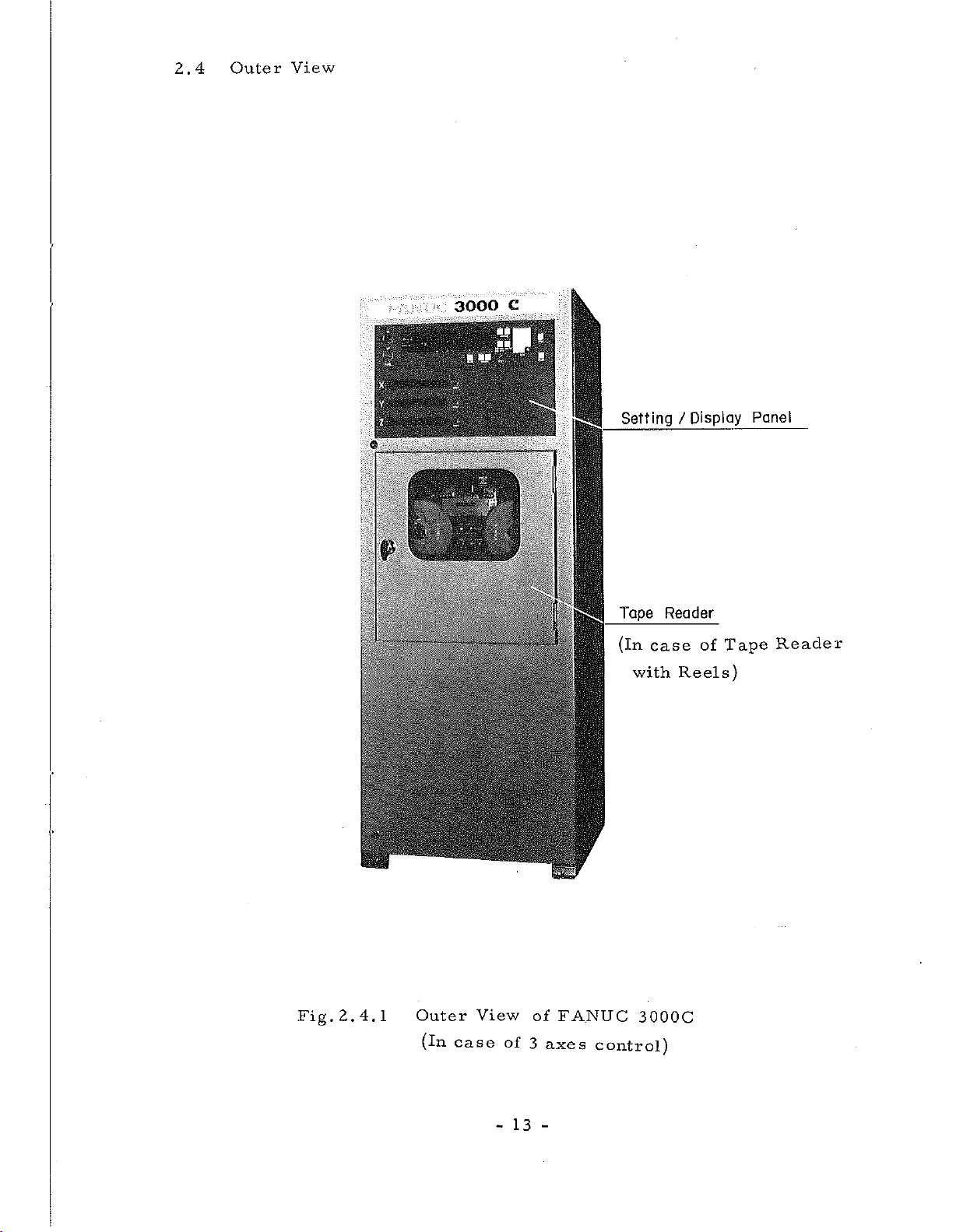

2.4

Outer

View

'4

x

p

1

•

—

:

P

.

I

3000

iv

J.

C

::p-

"

-

s

1

.

::

I

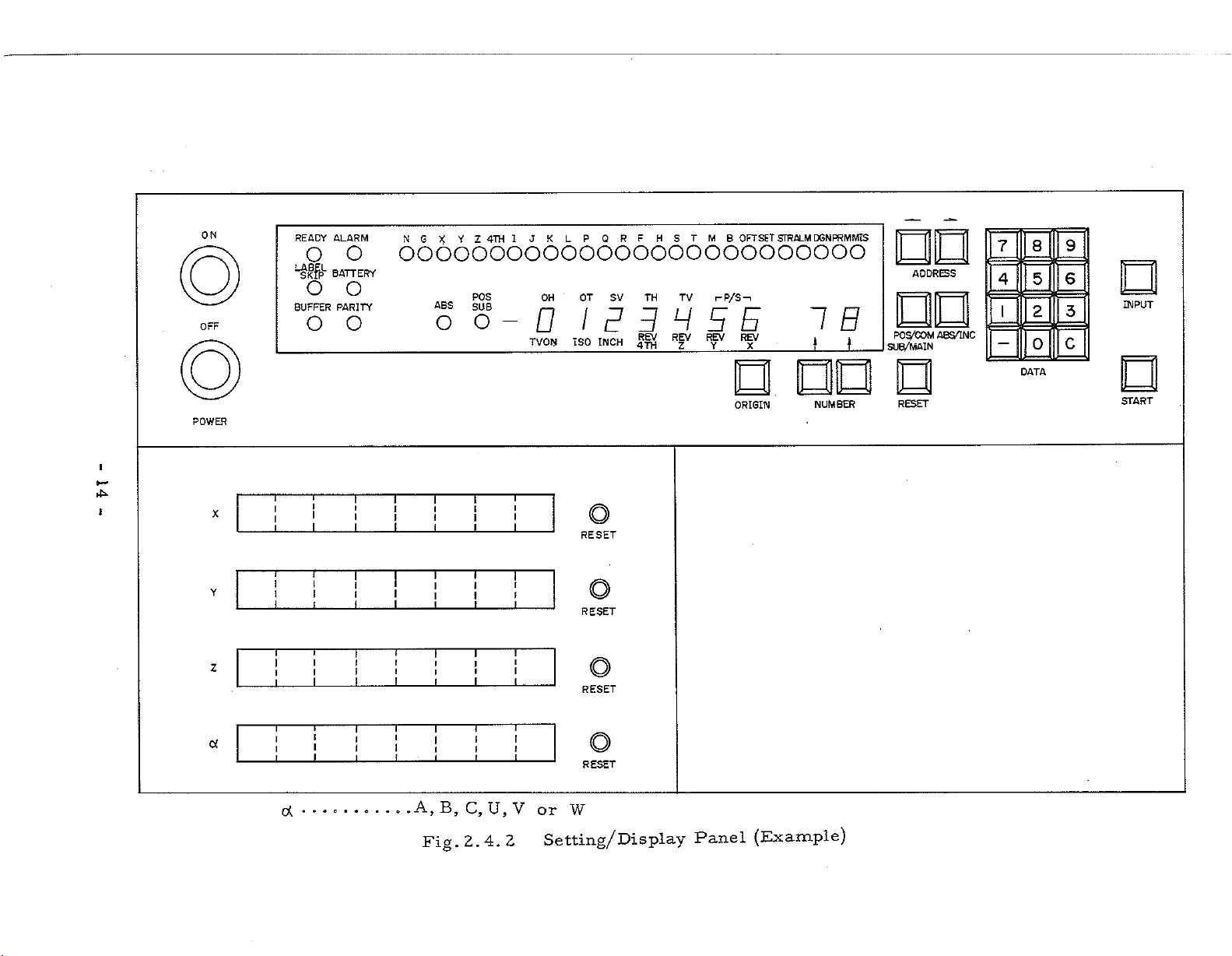

Setting

Tape

(in

case

with

Display

/

Reader

of

Reels)

Tape

Panel

Reader

Fig.

2.4.1

m

Outer

(in

case

View

-

of

13

of

3

-

FANUC

axes

3000C

control)

Page 18

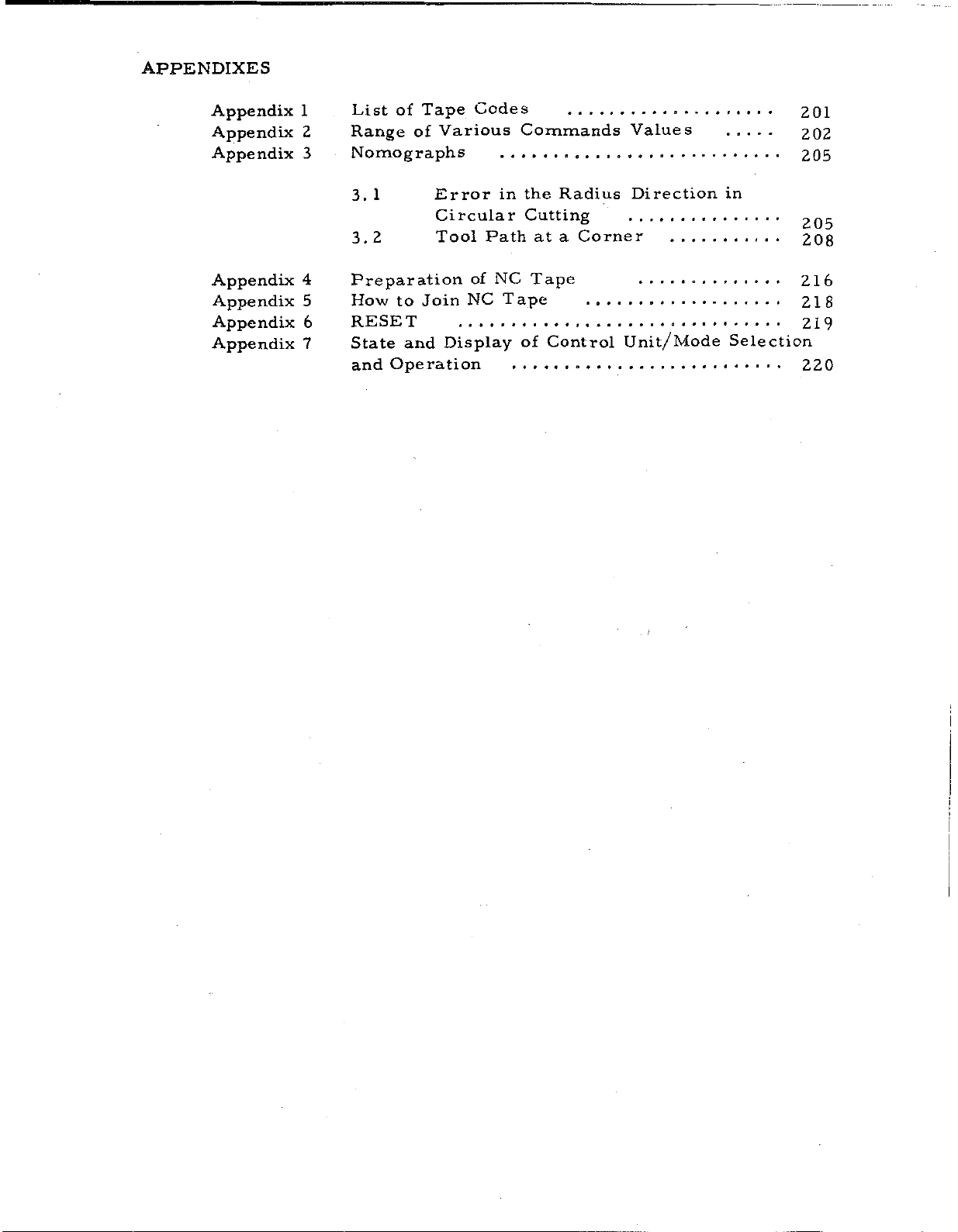

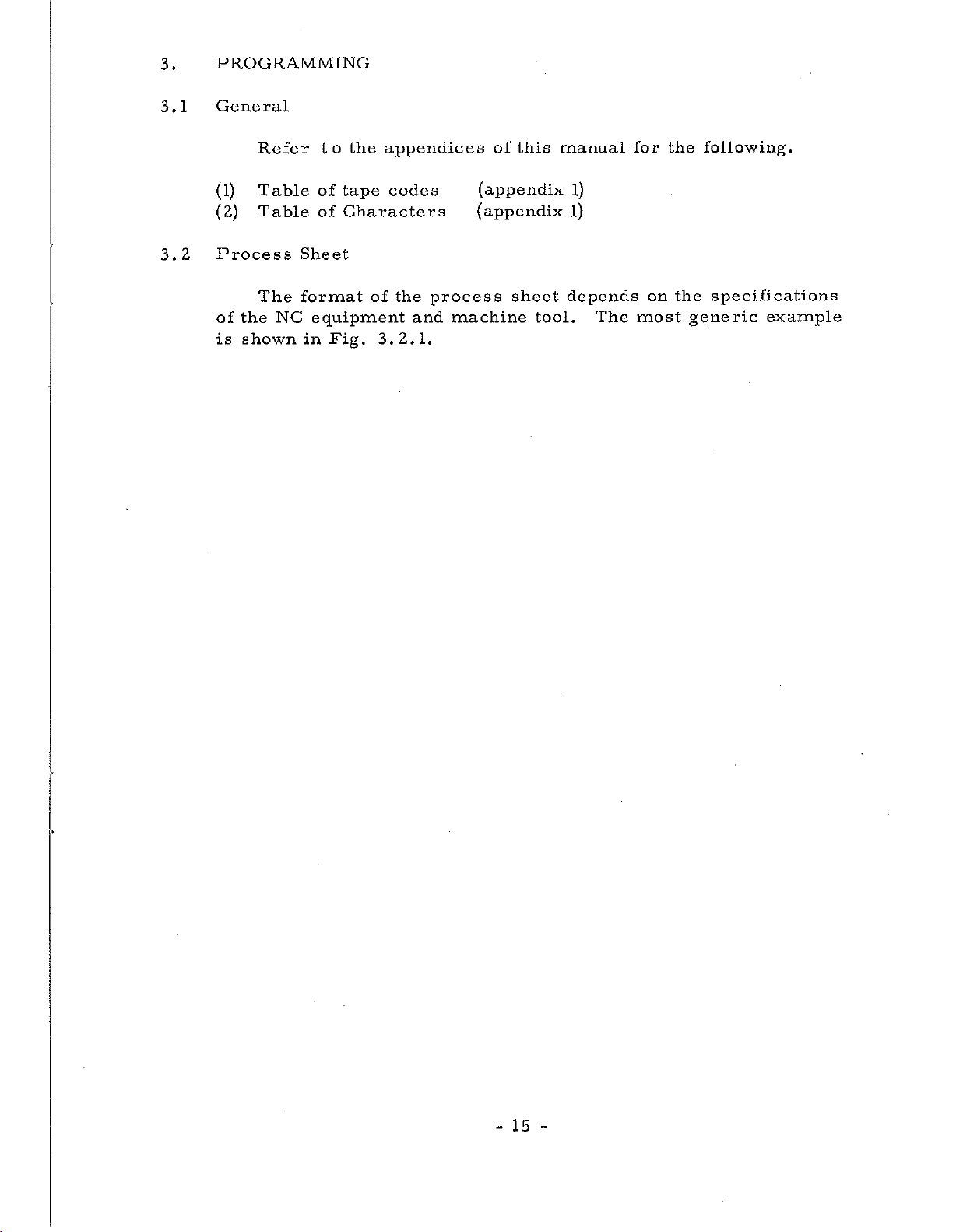

ON

OFF

READY

o

LABEL

SKIP

o

BUFFER

o

ALARM

o

BATTERY

o

PARITY

o

NG

XYZ

4TH

LP

QRF

HSTMB

OFTSET

JK

I

STRALM

DGNPRMMIS

oooooooooooooooooooooooooo

POS

OH

OT

SV

oo-OIPBHEE

ISO

TVON

INCH

TH

REV

4TH

TV

REV

Z

i-P/S-.

REV

Y

REV

X

IB

_

J

t

ADDRESS

PO

A8S/1NC

S/COM

SUB/MAIN

8

5

2

0

DATA

9

6

INPUT

E

c

7

4

I

NUMBER

Panel

ORIGIN

(Example)

POWER

I

4ÿ

!

X

Y

Z

a

T

T

I

1

T

1

1

T

I

l

1

I

i

1

(X

T T

i

I

i

I

T

1

1

I

f

I

i

1

T

T

i

f

f

I

I

T

T

I

J

i

i

I

1

T

1

I

I

1

I

T

II

I

T

T

r

r

l

f

I

1

T

I

i

I

I

1

A,

B,

2.4.

Fig,

T

1

I

T

I

f

I

i

T

\

F

1

C,U,V

T

RESET

I

i

I

I

T

i

1

T

I

i

2

RESET

RESET

RESET

W

or

Setting/Display

O

o

RESET

START

Page 19

3.

PROGRAMMING

3.1

3.2

General

Refer

(l)

Table

(2)

Table

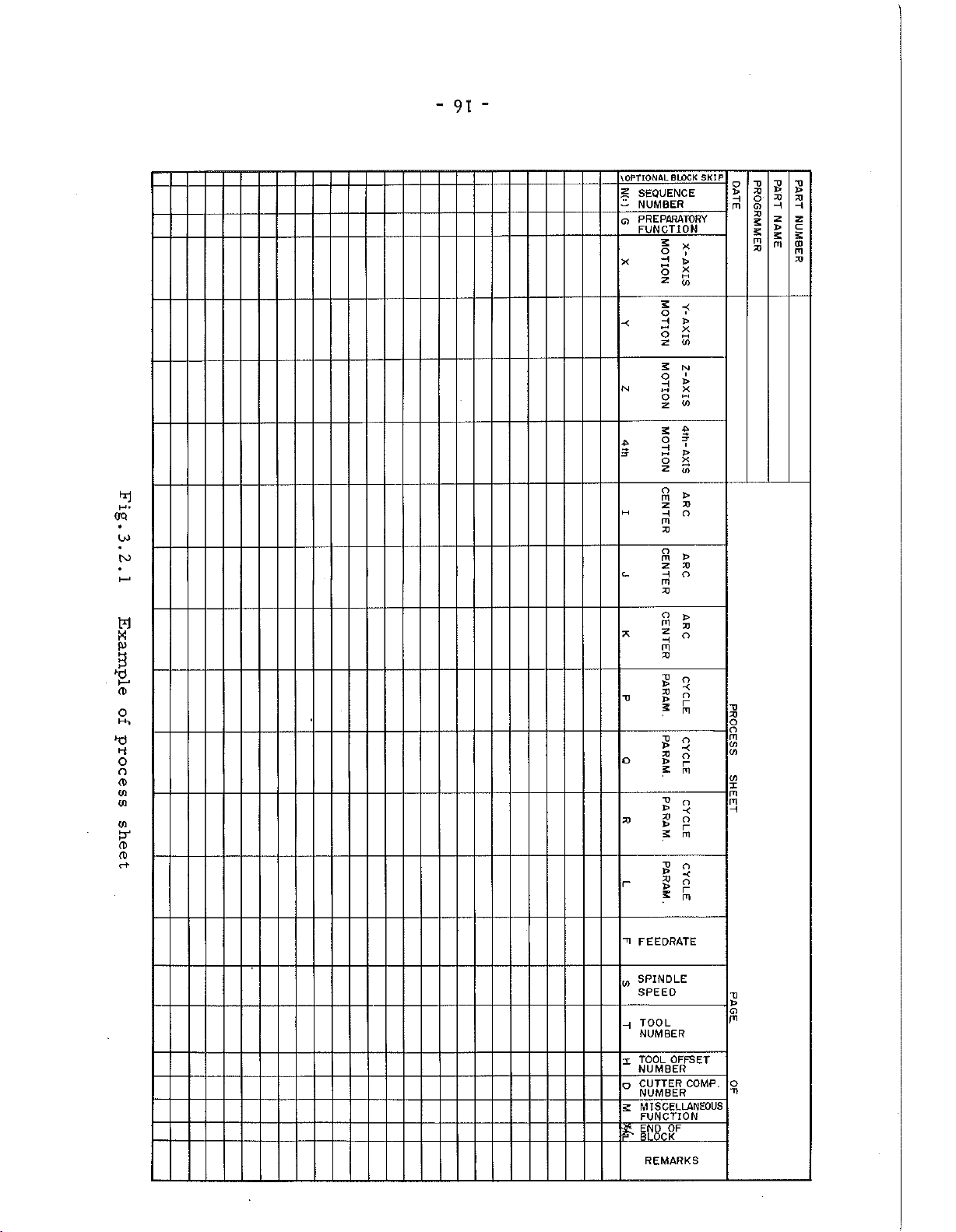

Process

The

of

the

shown

is

Sheet

format

NC

the

to

tape

of

Characters

of

equipment

in

Fig.

appendices

codes

of

the

and

3.2.1.

process

machine

this

of

(appendix

(appendix

sheet

tool.

manual

1)

l)

depends

The

for

on

most

the

following.

the

specifications

generic

example

15

-

Page 20

OQ

4

M-

u>

TO

w

B

CD

0

H-,

o

o

CD

03

03

03

CD

CD

c+

"

91

-

BLOCK

OPTIONAL

\

SEQUENCE

£

NUMBER

-

Q

PREPARATORY

FUNCTION

X

-<

N

M

c_

T3

o

23

r

SKIP

5

x

o

i

H

HH

X

o

S

X

O

'

H

>

X

o

CO

z

S

N

i

o

>

H

X

n

o

(0

z

s

$

p-

O

I

H

J>

hH

2

2

z

to

o

)>

m

2>

z

O

H

m

XJ

o

m

>

X)

z

O

H

m

X3

O

>

m

23

Z

o

H

m

23

V

o

X)

o

>

r

5

m

T>

O

>

X

X3

O

>

r

5

m

~o

O

>

X

X)

o

r

S

m

T3

o

X>

X

23

O

>

r

2

m

X)

X)

o

m

(O

CO

<o

x

rn

m

H

"0

o

S

t*

X3

->

2)

xt

o

H

G)

m

X>

5

n

X)

t

H

—

z

z

c

s

£

CD

m

m

X>

TI

FEEDRATE

SPINDLE

w

SPEED

TOOL

H

NUMBER

TOOL

X

o

S

ft

OFFSET

NUMBER

CUTTER

COMP.

NUMBER

MISCELLANEOUS

FUNCTION

OF

END

BLOCK

REMARKS

U

CD

PI

O

-n

Page 21

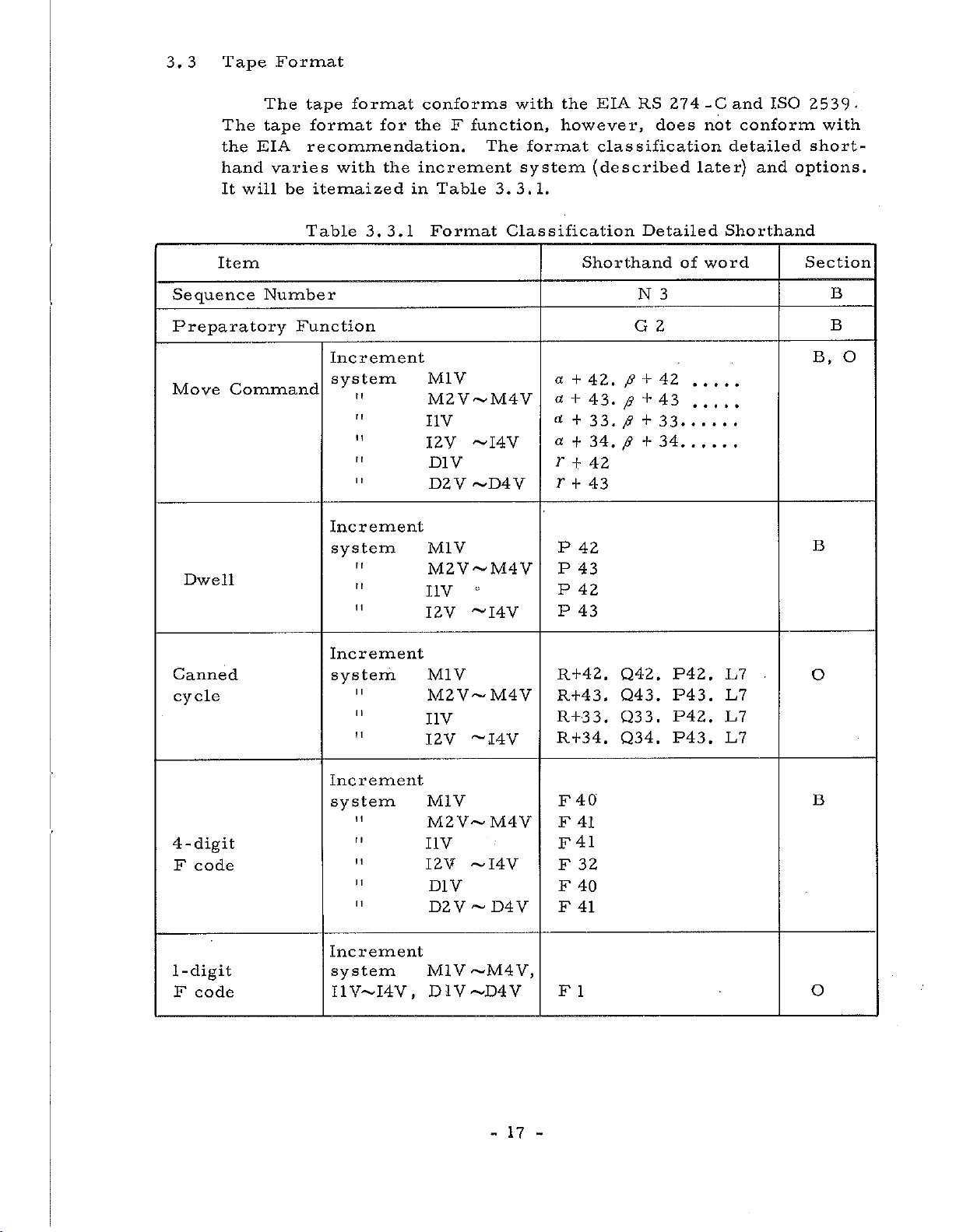

3.

Tape

3

Format

The

the

hand

It

Item

Sequence

Preparatory

Move

Command

Dwell

EIA

will

tape

The

format

tape

recommendation.

varies

itemaized

be

Table

Number

Function

format

for

with

the

3.3.1

Increment

system

"

Increment

system

t

r

(

r

1

1

conforms

the

F

increment

Table

in

Format

M1V

M2V~M4V

I1V

12V

D1V

D2V

M1V

M2V~M4V

I

IV

I2V

with

function,

The

3. 3.

Classification

~I4V

~D4V

~I4V

format

system

1.

a

a

«

cc

r

EIA

the

however,

classification

(described

Shorthand

+

42.

+

43.

+

33.

34,

+

42

+

r

43

+

P

42

P

43

P

42

P

43

RS

Detailed

N

G

p

+

+

p

p

+

p

+

274

does

3

2

42

43

33

34

of

-C

not

later)

Shorthand

word

ISO

and

conform

detailed

and

2539-

with

short¬

options.

Section

B

B

B,

B

O

Canned

cycle

4-digit

F

code

1-digit

code

F

Increment

system

I

I

1

I

!

1

Increment

system

"

Increment

system

I4V,

I1V—

M1V

M2V-M4V

IV

I

~I4V

I2V

M1V

M2V~M4V

I1V

I2V

~I4V

D1V

D2V

M1V

D1V-D4V

D4V

~

~M4

V,

R+42.

R+43.

R+3

R+34.

40

F

F

41

41

F

32

F

F

40

F

41

F

1

Q42.

Q43.

Q3

3

.

Q34.

P42.

P43

.

3

.

P42.

P43.

E7

L7

L7

L7

.

O

B

O

17

-

Page 22

Item

Shorthand

of

word

Section

Tool

Offset/Cutter

S

Function

T

Function

M

Function

B

Function

Note:

a

(1)

(2)

(3)

(4)

and

T

stands

Leading

Number

Both

Cutter

(0~63)

Compensation.

Compensation

p

stand

for

any

zeros

(N3)

.

D

and

H

Compensation

set

codes

can

for

of

can

be

commanded

any

A,

always

can

number.

of

B

be

and

be

HZ

or

S2

or

or

T2

M2

B3

X,

Y,

C.

omitted

specified

Maximum

for

D2

S4

T5

Z,

Tool

U,

except

on

V,

the

32

offset

W,

for

Tool

(0

I,

Sequence

Offset

~3l)

and

and

J

or

Cutter

B,

O

O

B

O

O

K

/

64

3.4

How

(5)

Among

B

With

(6)

can

the

{V

With

and

to

see

Example:

Increment

function,

the

be

expanded

B

function

the

program

detailed

a

System

S

function

optional

options

a

a

4-

is

5

means

point.

2

means

only

is

copy

shorthand.

52

+

any

is

a

sign.

4

of

function

one

B

function

to

up

not

effective.

of

circule

added,

the

of

a

maximum

two

digits

digits

five

addresses

and

added,

digits.

cutting,

above

of

below

T

selectable.

is

tape

five

function

the

In

helical

X,

digits

the

S

and

this

format

Y,

decimal

5

of

T

functions

case,

interpolation

changes.

Z

and

above

point.

digits

however,

etc.

the

decimal

and

The

increment

system

is

determined

18

-

by

the

following

elements:

Page 23

(1)

Least

input

increment

(2)

This

on

or

pulse

and

deg.

Least

This

is

NC

is

transmitted

is

mm/p,

of

Any

MDI

Increment

system

setting.

builder

M1V

M2V

the

least

tape

or

command

movement

the

the

least

inch/p

the

increment

the

for

unit

on

the

increment

unit

or

Refer

actual

Table

Least

inc

0.01

0.001

of

MDI

amount

from

in

deg./p.

systems

to

increment

3.4.1

rement

movement

unit.

NC

the

which

the

description

input

mm

mm

amount

This

machine

of

equipment

it

moves.

shown

system.

Increment

is

expressed

tool

to

This

in

Table

issued

Systems

Least

increment

0.001

0.001

that

can

for

the

is

3.4.1

by

command

mm/

mm/

be

specified

in

mm,

one

command

machine

expressed

is

the

machine

p

p

inch

tool,

selected

in

by

tool

M3V

M4V

I1V

I2V

I3V

I4V

D1V

D2V

D3V

D4V

When

the

increment

Increment

Therefore

speed

of

X-axis.

cutter

or

compensation

feed

number

the

0.001

0.001

0.001

0.

0

0.

0.01

0.001

0.

0.001

system

system

rate,

0001

0001

.

0001

001

of

offset

of

mm

mm

inch

inch

inch

inch

deg.

deg.

deg.

deg.

of

X,

X-axis

pulses

or

circular

Y

and

amount,

according

is

0.0005

0.0002

0.0001

0.0001

0.00005

0.00002

0.001

0.001

0.0005

0.0002

interpolation

Z-axis

regarded

are

etc

to

mm/

mm/

inch/p

inch/p

inch/p

inch/p

deg/p

deg/p

deg/p

deg/p

must

as

a

changed

the

increment

p

p

selected,

is

same.

be

fundamental.

into

pulse

system

for

Be

other

careful

than

the

of

X-axis.

designation

19

-

-

of

feed

rate

and

offset

amount

Page 24

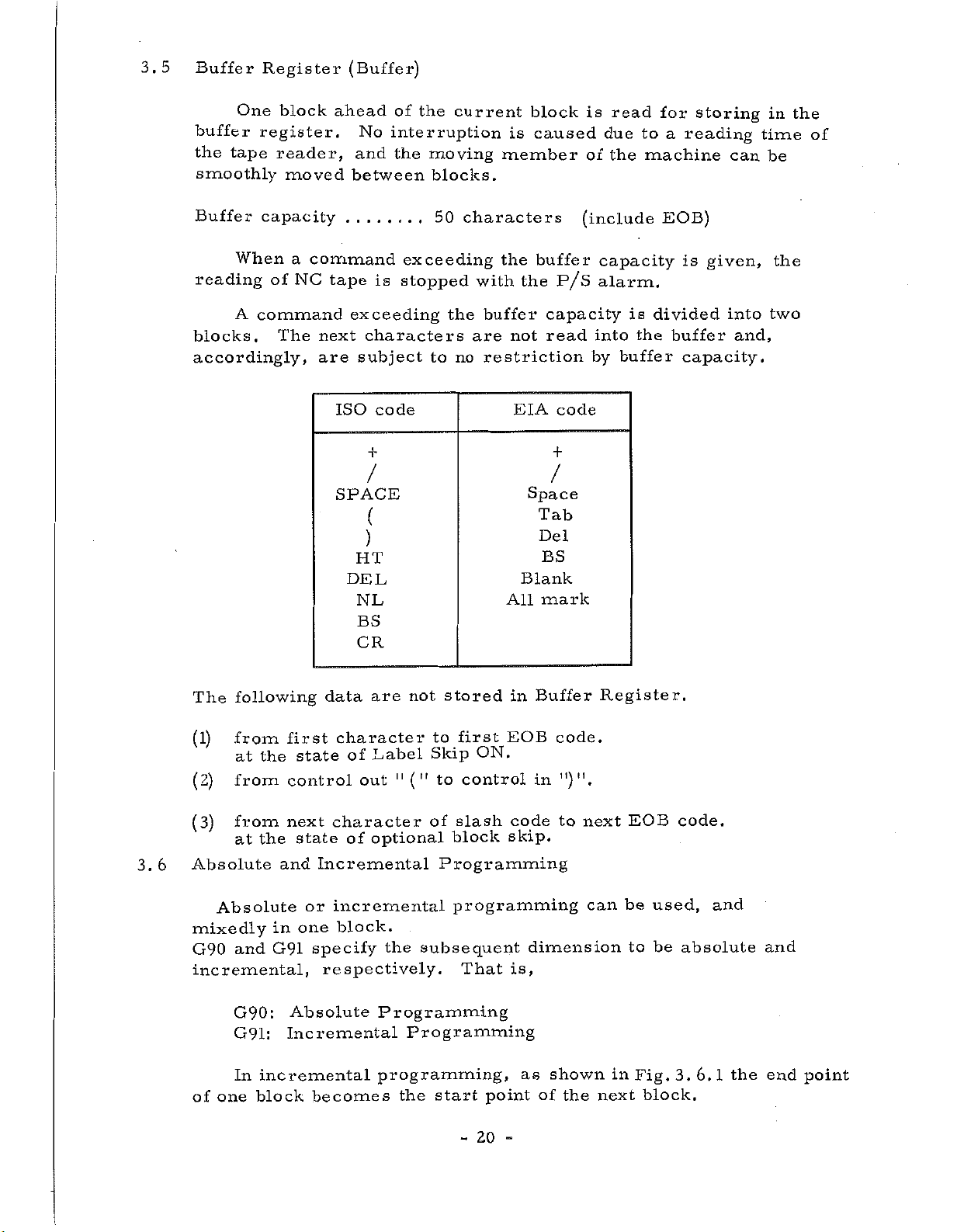

3.5

Buffer

One

buffer

the

tape

smoothly

Register

block

register.

reader,

moved

(Buffer)

ahead

No

and

between

of

the

current

interruption

the

moving

blocks.

block

is

caused

member

is

of

read

due

the

for

to

a

machine

storing

reading

can

in

time

be

the

of

Buffer

capacity

When

reading

A

command

blocks.

accordingly,

of

The

command

a

NC

next

are

tape

exceeding

characters

subject

ISO

/

SPACE

(

)

HT

DEL

NL

BS

CR

exceeding

is

stopped

code

to

50

the

no

characters

the

with

buffer

not

are

restriction

EIA

All

buffer

the

capacity

read

+

/

Space

Tab

Del

BS

Blank

mark

(include

P/S

code

capacity

alarm.

into

buffer

by

is

the

EOB)

is

divided

buffer

capacity.

given,

into

and,

the

two

3.6

following

The

from

(1)

at

from

(2)

from

(3)

the

at

Absolute

Absolute

mixedly

and

G90

incremental,

G90:

G91:

incremental

In

one

of

block

first

state

the

control

next

state

and

or

one

in

G91

Absolute

Incremental

are

data

character

Label

of

out

character

optional

of

Incremental

incremental

block.

specify

respectively.

becomes

stored

not

first

to

Skip

11

to

("

the

control

of

slash

block

Programming

programming

subsequent

That

Programming

Programming

programming,

the

start

-

ON.

point

20

Buffer

in

EOB

in

code

skip.

dimension

is,

as

of

code.

")".

to

shown

the

Register.

next

can

in

next

EOB

be

to

Fig.

used,

be

3.

block.

code.

and

absolute

6.1

the

and

end

point

Page 25

V3

Y

axis

which

the

In

zero

Fig.

Absolute

tool

a

point.

Y

Y2

VI

3.

is

3

Y]~~

KU1

6.1

programming,

to

Y

4-

Incremental

move,

axis

-xi

X2

—

i

i

J-U3-J

U2

coordinate

as

is

always

t

d

-

—

X3

shown

I

i

I

given

in

in

X

axis

values

Fig.

coordinate

a

X

axis

3.

6.

2

the

point

value

to

from

3.7

Increment

system

Maximum

M1V

M2V

M3V

M4V

I1V

12

V

programmable

the

Maximum

value

+

±

+

+

+

+

is

It

always

over

If

possibility

Fig.

Programmable

8388.

3.

6.

60

8388.607

4194.

303

1677.721

838.860

838.8607

forbidden

dimensions.

maximum

of

changing

2

Absolute

command

mm

mm

mm

mm

inch

inch

command

coordinate

Dimensions

to

give

value

the

sign.

Increment

system

I3V

14

V

D1V

D2V

D3V

D4V

the

command

is

values

over

commanded,

Maximum

value

+

419.4303

167.7721

±

8

388

+

8388.607

+

+

4194.303

1677.721

±

maximum

.

there

60

is

command

inch

inch

deg

deg

deg

deg

21

-

Page 26

3.

8

In

maximum

In

command

Tape

Code

case

case

circular

of

command

of

inch/metric

value

is

also

value.

arc,

the

conversion

restricted.

radius

(See

is

is

4.1.4

necessary

selected,

under

maximum

(9))

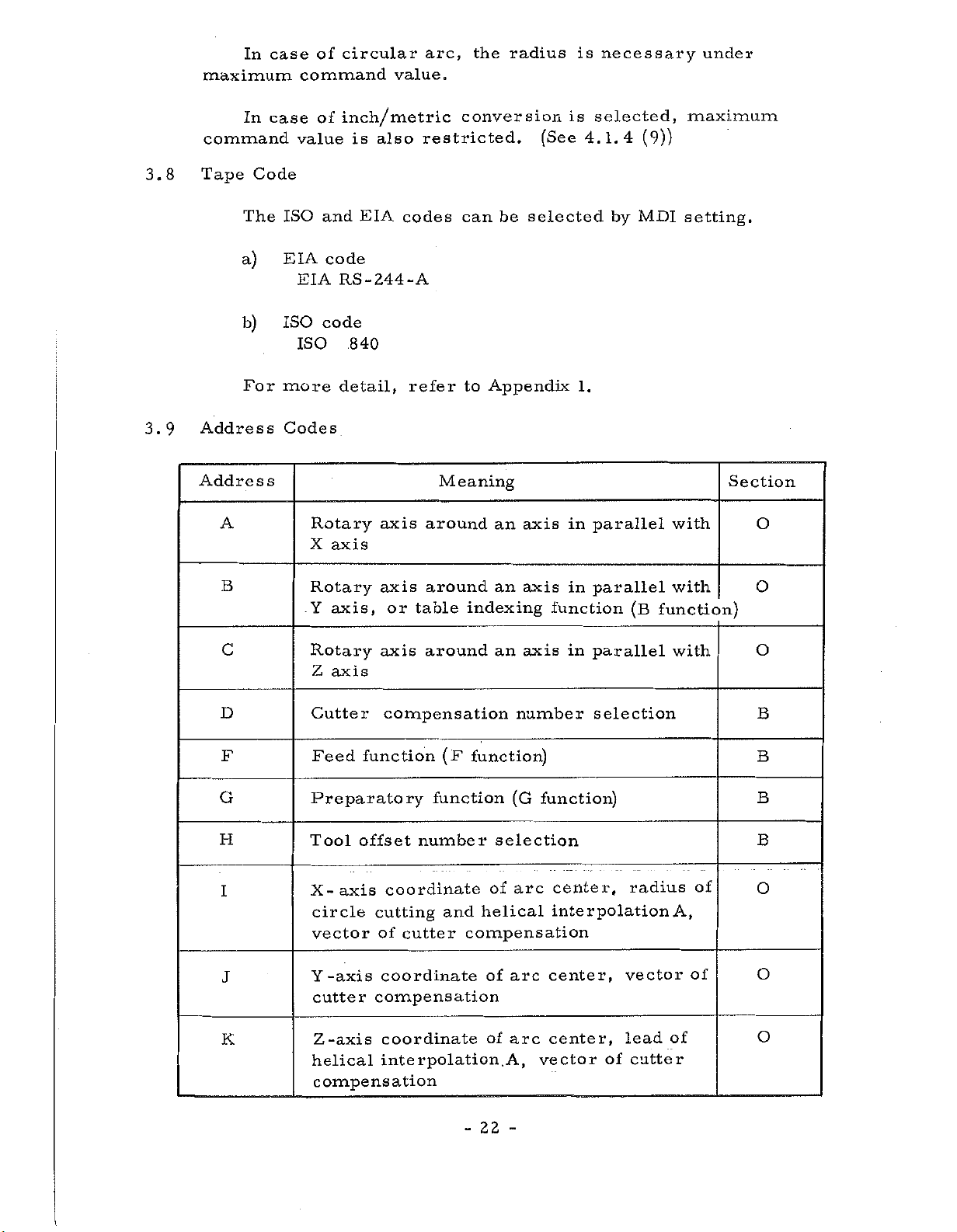

3.9

The

a)

b)

For

Address

Address

A

B

c

ISO

EIA

EIA

ISO

ISO

more

Codes

Rotary

X

Rotary

Y

Rotary

Z

EIA

and

code

RS-244-A

code

.840

detail,

axis

axis,

axis

axis

axis

or

axis

codes

refer

around

around

table

around

can

to

Appendix

Meaning

indexing

be

an

an

an

selected

axis

axis

function

axis

1.

in

in

in

by

parallel

parallel

parallel

MDI

(B

function)

setting.

with

with

with

Section

O

O

O

G

H

D

I

F

J

K

Cutter

Feed

compensation

function

Preparatory

Tool

X-axis

circle

Y

helical

offset

coordinate

cutting

vector

-axis

cutter

Z-axis

compensation

of

coordinate

compensation

coordinate

interpolation.

function

number

cutter

(F

function)

selection

of

helical

and

compensation

of

of

22

-

number

(G

arc

arc

arc

A,

-

selection

function)

center,

interpolation

center,

center,

vector

of

radius

vector

lead

cutter

of

A,

of

of

B

B

B

B

O

O

O

Page 27

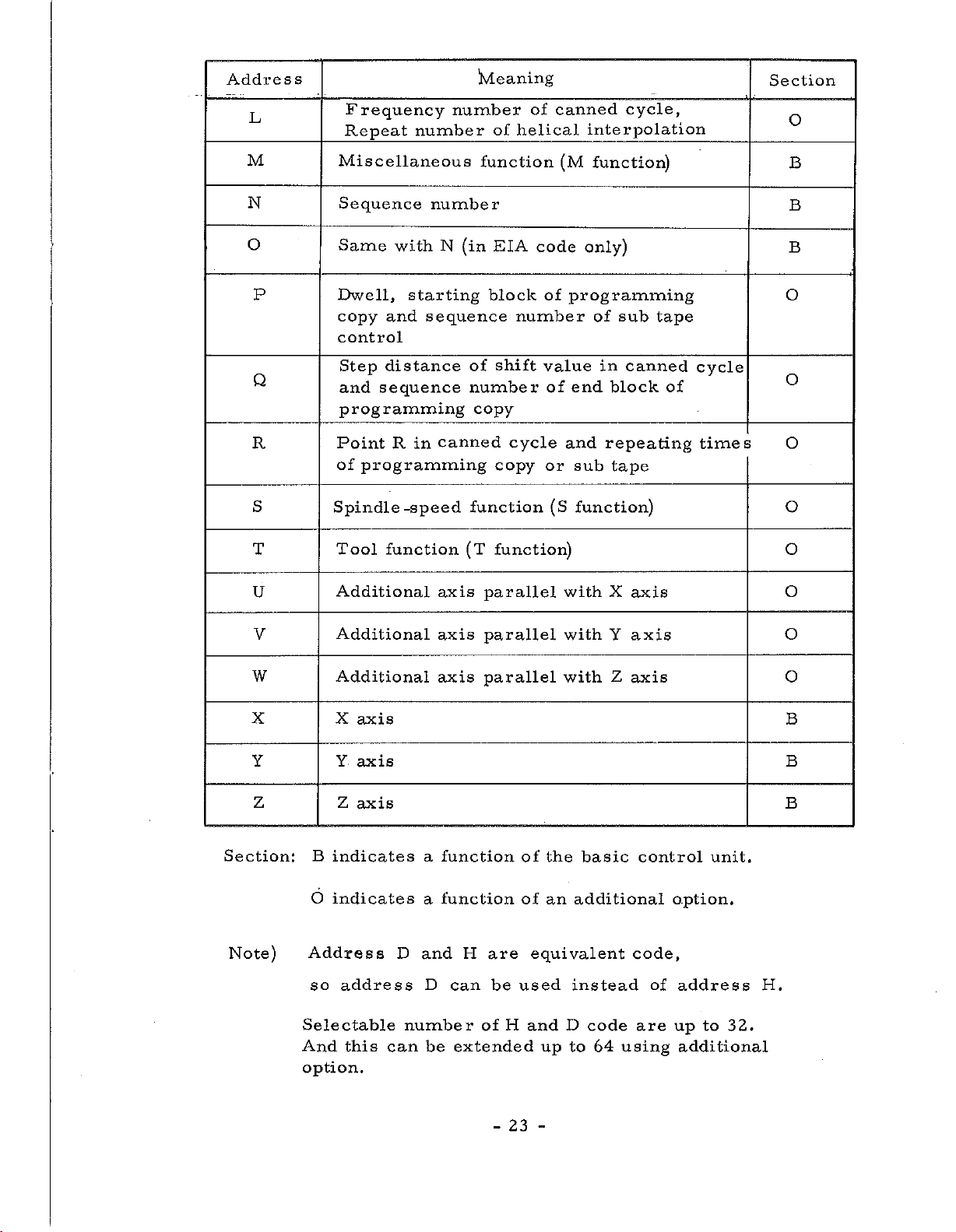

Address

Wteaning

Section

L

M

N

O

canned

of

of

helical

EIA

code

block

shift

of

number

value

cycle

copy

function)

(M

programming

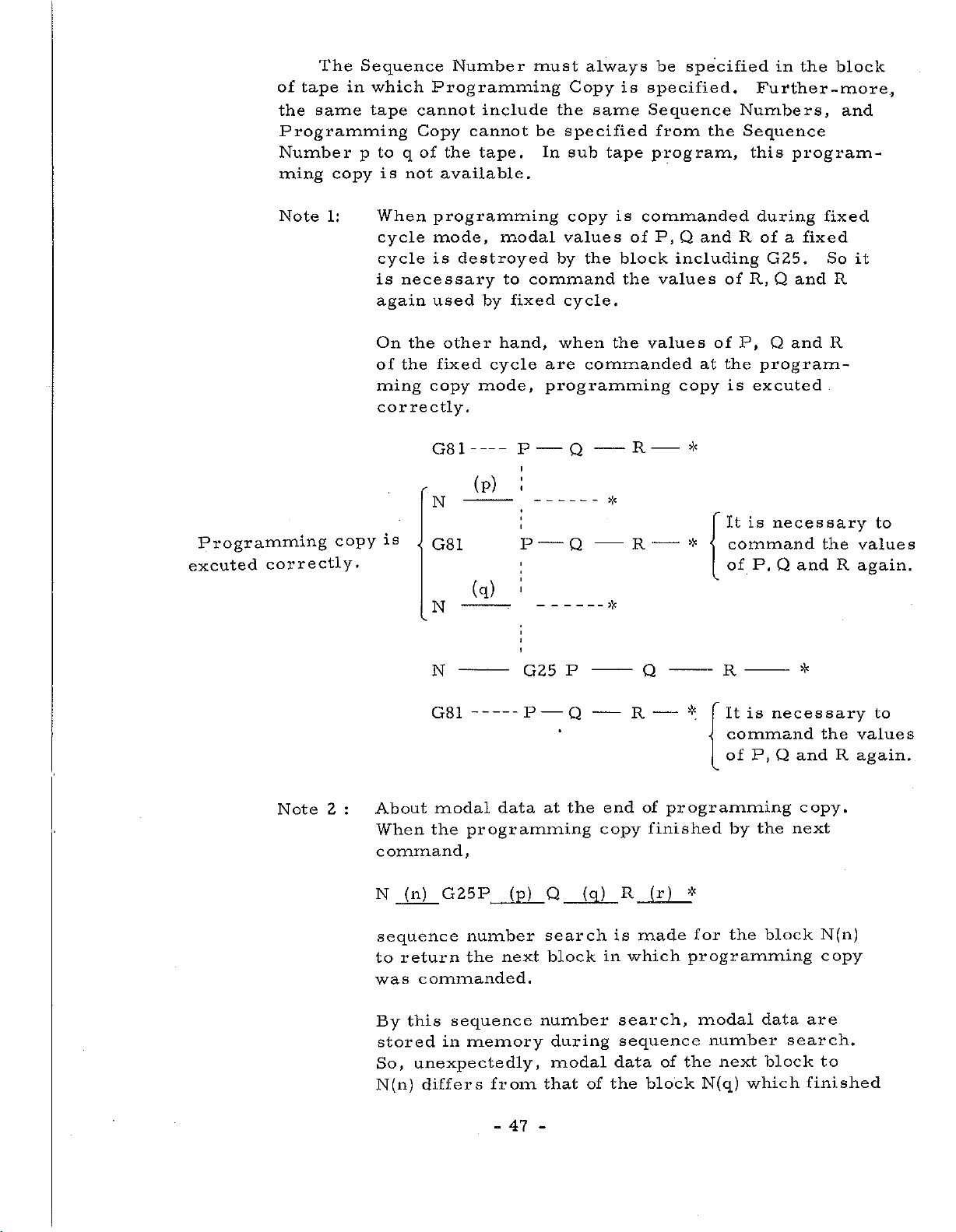

of

end

and

or

sub

(S

function)

number

number

N

starting

sequence

canned

in

number

function

(in

of

number

copy

function

(T

Frequency

Repeat

Miscellaneous

Sequence

Same

P

Dwell,

copy

control

Q

Step

and

with

and

distance

sequence

programming

R

S

T

Point

of

Spindle

Tool

R

programming

-speed

function

cycle,

interpolation

function)

only)

sub

canned

block

tape

tape

of

in

repeating

of

cycle

times

O

B

B

B

O

O

O

O

0

U

V

W

X X

Y

Z Z

Section:

Note)

Additional

Additional

Additional

axis

Y

axis

axis

B

indicates

6

indicates

Address

so

address

Selectable

And

this

option.

D

number

can

axis

axis

axis

a

function

function

a

and

D

be

parallel

parallel

parallel

H

are

can

be

of

extended

of

of

equivalent

used

H

and

with

with

with

the

an

D

up

X

Y

Z

basic

additional

instead

code

to

64

using

axis

axis

axis

control

code,

of

are

unit.

option.

address

to

up

additional

O

O

O

B

B

B

H.

32.

23

-

Page 28

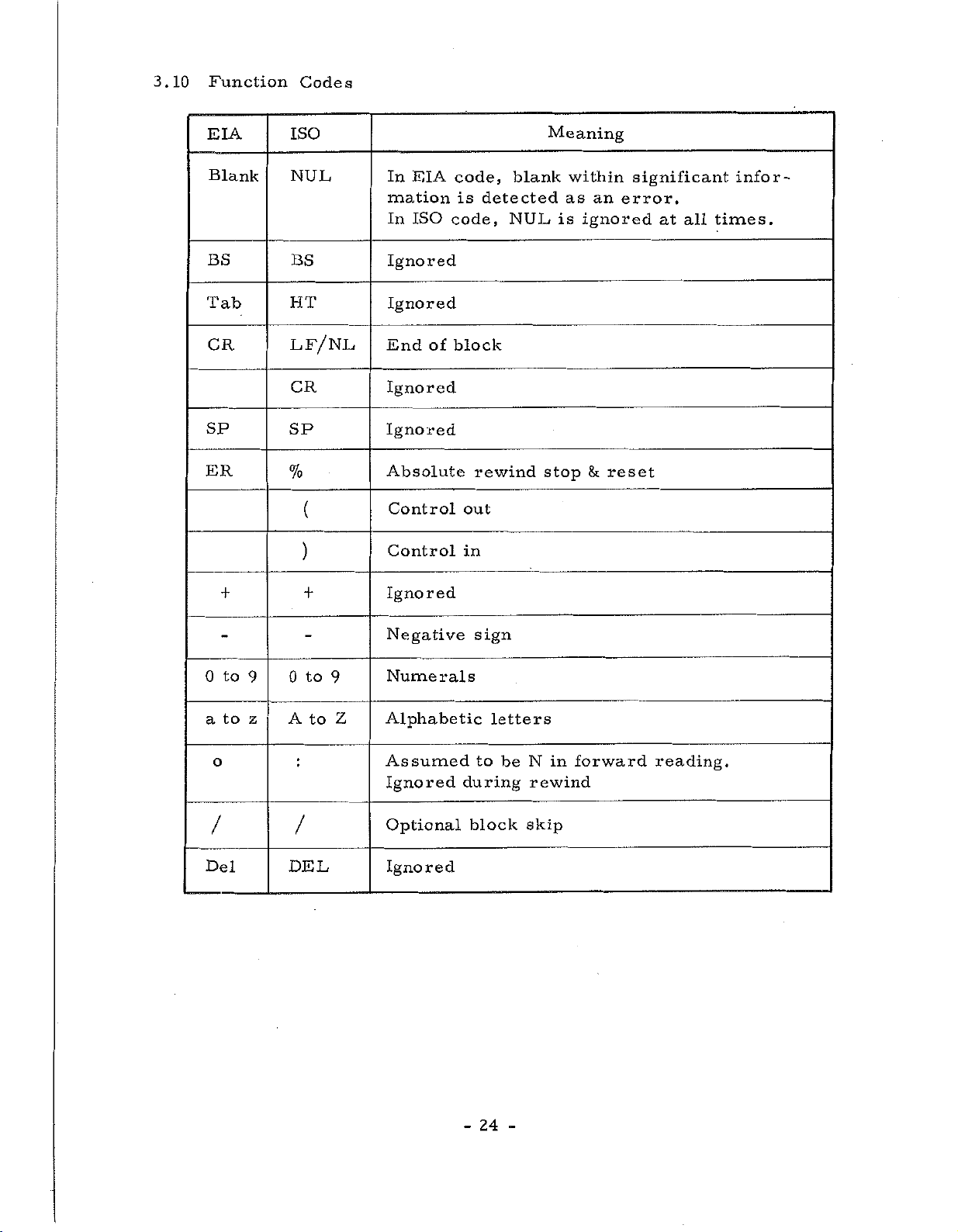

3.10

Function

Codes

EIA

Blank

BS

Tab

CR

SP

ER

ISO

NUL

BS

HT

LF/NL

CR

SP

%

(

)

EIA

In

mation

ISO

In

Ignored

Ignored

of

End

Ignored

Ignored

Absolute

Control

Control

code,

is

code,

block

out

in

blank

detected

NUL

rewind

Meaning

within

as

is

ignored

stop

fk

an

reset

significant

error.

at

all

infor¬

times.

0

a

o

/

Del

to

to

++

to

0

9

z

9

A

to

Z

/

DEL

Ignored

Negative

Numerals

Alphabetic

Assumed

Ignored

Optional

Ignored

sign

letters

to

during

block

be

in

N

rewind

skip

forward

reading.

24

-

Page 29

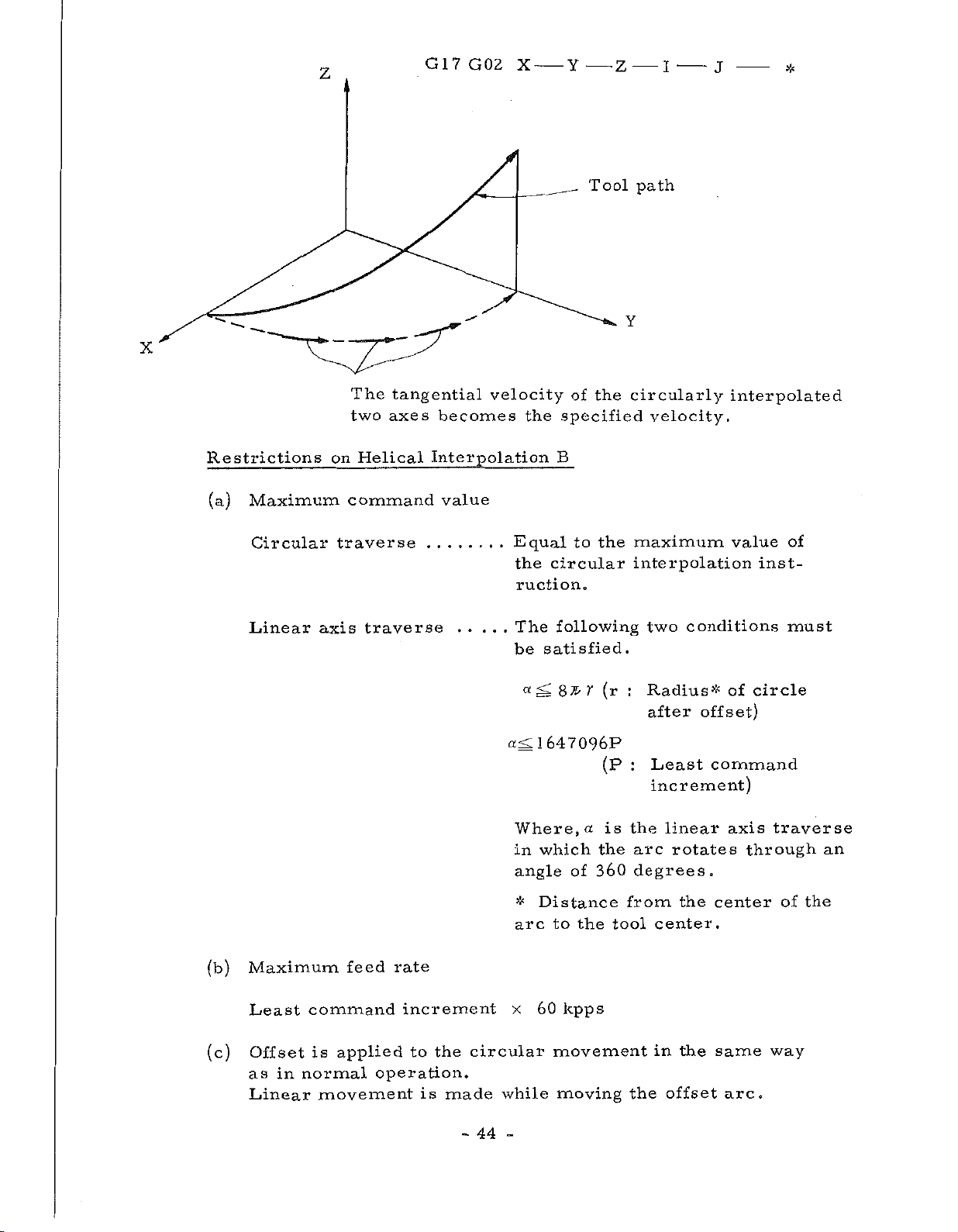

(1)

Label

Skip

Function

(2)

(3)

a

tape

If

mation

information

The

EOB

mation.

The

display

a)

b)

Control

All

parenthesis

formed.

reset,

Stop

has

Absolute

The

this

reset.

reader

code

label

the

the

information

and

no

code

code

is

read

is

ignored

has

And

skip

panel

power

equipment

Out/in

code

When

Control

Reset

effects

Rewind

means

read

is

this

If

with

reels,

in

until

been

this

at

function

lights

is

(Only

including

is

the

In

is

this

in

Stop

an

within

code

with

until

read,

up

turned

is

ignored,

power

is

effected.

not

absolute

is

the

the

the

reset

a

state

becomes

when

on,

reset

at

EOB

used

section.

and

Significant

read

tape

Label

End

is

Label

in

ISO

is

in

Reset

during

feed

of

command

called

on

or

a

mode

code)

between

and

turned

However

this

rewind

is

Skip

Block

the

lamp

skip

and

other

TH

and

on,

section.

stop,

Information,

manual

stopped

Function

code

is

Tape

the

left

or

(EOB)

read

Significant

turns

lamp

than

parenthesis

TV

checks

when

Absolute

And

in

and

operation

unconditionally.

on,

after

off.

on

MDI

the

Rewind

EOB

addition,

means

it

all

infor¬

is

read.

first

the

Infor¬

the

mode.

and

are

not

equipment

code

when

a

the

tape

on

right

per¬

is

3.11

3.11.1

Feed

Function

Rapid

kpps.

for

the

Traverse

The

The

each

type

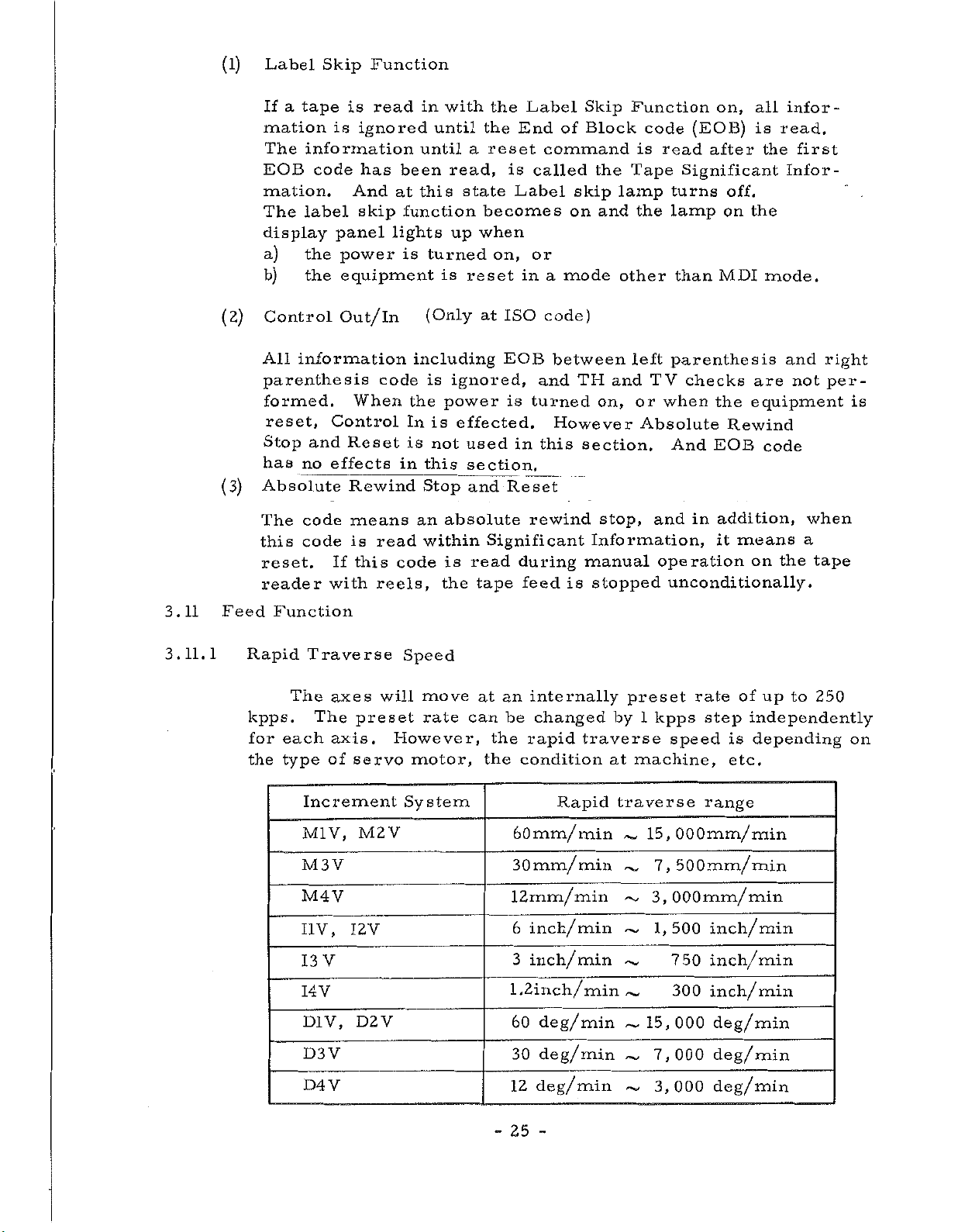

Increment

M1V,

M3

M4V

I1V,

V

13

I4V

D1V,

D3V

D4V

axes

axis.

of

V

preset

servo

M2

I2V

D2V

Speed

will

However,

motor,

System

V

move

rate

an

the

the

internally

be

rapid

condition

at

can

60mm/

30mm/

12mm/min

6

inch/min

3

inch/min

1.2inch/minÿ,

60

30

12

changed

traverse

Rapid

min

min

deg/min

deg/min

deg/min

preset

by

1

at

machine,

traverse

15,

~~

~

~

~~

15,

~

~

~

up

of

independently

is

depending

etc.

kpps

speed

rate

step

range

OOOmm/min

7,

500mm/

3,

OOOmm/min

1,500

750

300

000

7,000

3,000

min

inch/min

inch/min

inch/min

deg/min

deg/min

deg/min

to

250

on

-

25

-

Page 30

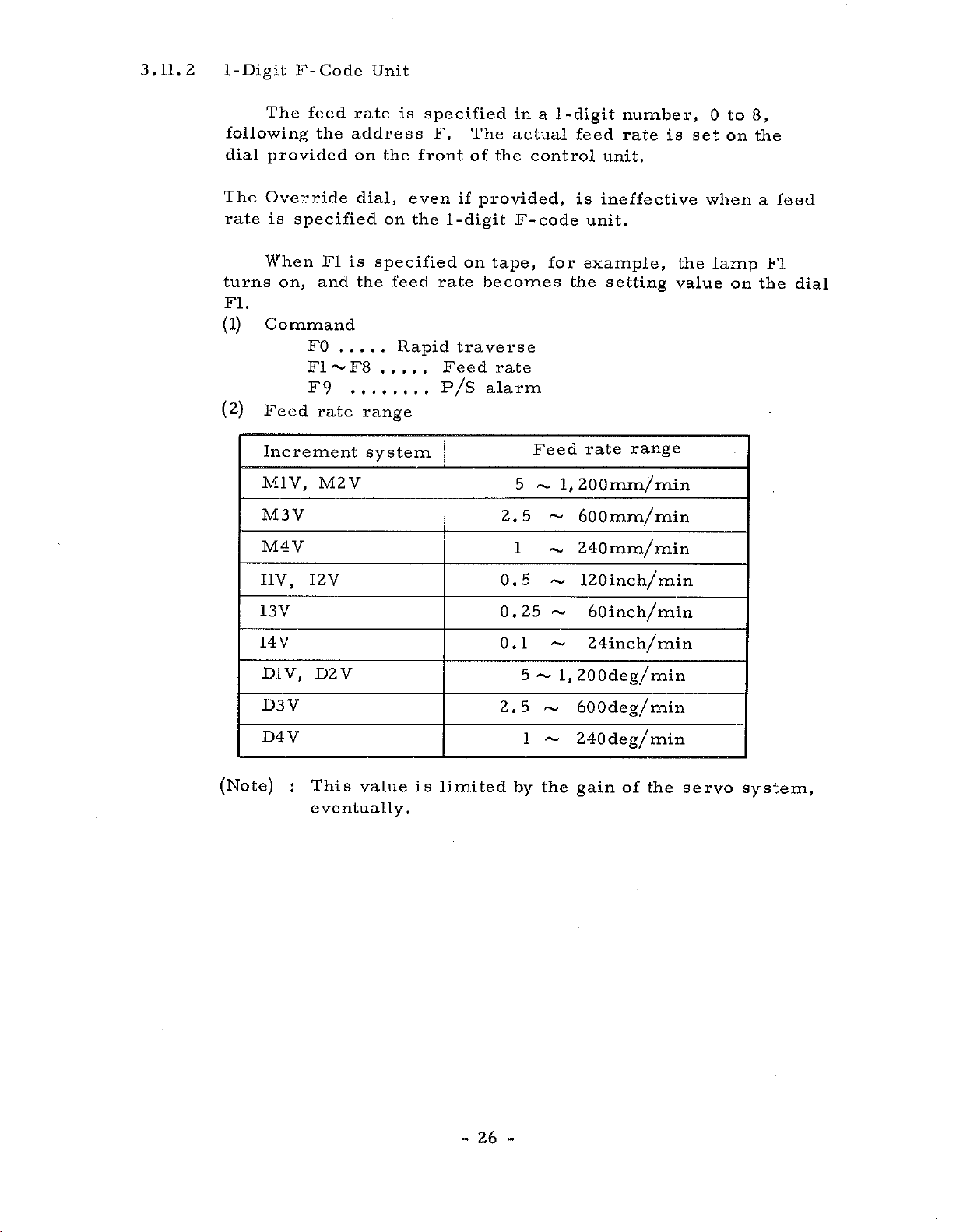

3.11.2

1-Digit

The

following

provided

dial

F-Code

feed

the

Unit

rate

address

on

the

is

specified

front

F.

The

of

the

in

a

actual

control

-digit

1

feed

number,

rate

unit.

to

8,

0

is

set

on

the

The

rate

turns

FI.

(l)

(2)

Override

is

specified

When

on,

and

Command

FO

F1~F8

F9

Feed

Increment

M1V,

M3V

M4Y

I1V,

I3V

I4V

D1Y,

D3V

D4V

I2V

D2V

FI

rate

M2V

dial,

is

the

even

on

specified

feed

Rapid

.....

the

if

1

-digit

rate

traverse

Feed

on

P/S

range

system

provided,

F-code

tape,

becomes

rate

alarm

5

2.5

1

0.5

0.25

0.1

5

2.5

1

is

ineffective

unit.

for

example,

the

setting

Feed

~

~

rate

1,

200mm/min

~

600mm/

240mm/

~

120inch/min

~

~

60inch/min

~

24inch/min

l,200deg/min

600deg/min

~

240deg/min

~

range

min

min

the

value

when

lamp

on

a

FI

the

feed

dial

(Note)

This

:

eventually.

value

is

limited

-

26

-

by

the

gain

of

the

servo

system,

Page 31

3.11.

4

3

-Digit

F-Code

Unit

min

that

actual

of

the

and

issued

feed

The

or

inch/min

can

be

feed

motor

is

usually

the

by

Increment

system

M1V

M2V

V

M3

M4V

I

V

1

V

I

2

V

3

I

V

I

4

rate

specified

rate,

used,

lower

machine

Table

is

specified

following

is

however,

or

the

than

tool

3.11.1

Format

as

F40

F41

F41

F41

F41

F32

F32

F32

address

in

is

time

these

builder

F

directly

Table

limited

constant,

values.

code

F.

3.11.1.

as

range

F

code

FOll

FOll

1

FO'l

FO'l

I

FOjl

F|01~

-4—

F'01~,F

i

F]01~F

a

in

The

the

by

etc.

Refer

to

what

range

F3600

~

F3600I0

~

F

~

F

~

F

~

F

number

range

The

type

of

to

the

1800|0

7

20b

600

3

360100

1

180

of

upper

and

the

the

upper

—

00

code

---

00

72|

in

feed

servo

rates

limit

load

condition

description

limit

mm/

of

the

system,

is,

of

0

on

the

In

a

CEL

ignored

4

-digit

in

order

D

1

D2

D3

D4

Override

An

to

200%

operator's

With

Fixed

switch

F-code

V

V

V

V

to

the

dial

Cycle

on

(assumed

to

distinguish

can

this

panel.

at

(tapping

the

to

should

F40

F41

F41

F41

applied

be

feed

operator's

100%,

be

100%).

be

from

rate

in

on

the

the

feed

cycle

commanded

G84),

panel

1-digit

FOll

FO'l

F01!

F01

~

+

~

~

.

1

~

L

increments

FEED

rate

is

and

ON,

at

more

F-code.

F

360*0

F3600i0

F1800I0

720,0

F

Decimal

in

or

with

*

mm/

deg/min

of

RATE

same

the

the

however,

than

point

min.,

10%

OVERRIDE

OVERRIDE

2-digit

expressed

inch/min

in

the

as

specified.

the

range

dial

CAN¬

Override

is

27

-

-

Page 32

Example

F

F450

code

3.11.

1

Correspondence

Rates

Increment

V

Ml

M2V~M4V

V

II

V

12

~

14

system

V

between

the

Feed

450

mm/min

45

.

0

45

0

.

4.50

F

Codes

rate

mm/

inch/

inch/

min

min

min

and

Feed

Notes

Note

on

the

The

1:

mixedly,

a

(Examples)

Feed

1-,

number

F3

F23

F3545

DIV

D2V

function

and

and

code

~

4

o

o

D4V

-Digit

are

F-Code

identified

following

With

the

Without

the

effected.

The

the

1-Digit

4

-Digit

4-Digit

address

1-Digit

F-Code

the

1-Digit

F-Code

Increment

45

45

Feed

the

by

F-Code

0

deg

deg/min

.

0

functions

number

F.

F-Code

Feed

F-Code

Feed

/min

system

Feed

can

of

Feed

(F3)

Feed

(3

mm/min)

is

effected.

be

digits

option,

is

effected.

MIV

used

of

option,

is

Note

2:

Feed

FO

F1-F8

4-digit

F

code

-

rate

is

GOO

RT

RT

RT

as

follows

,

1

GO

G81

~G89

28

-

by

G73,

RT

Cutting

F-code

Cutting

F

-code

RT:

G

code

G76

feed

feedrate

Rapid

command.

GO2,G03

G12-G15,

S

Alarm

P/

rate

by

by

Traverse

G39

l-digit

4-digit

Page 33

Note

Acceleration

3:

by

move

ration

the

command.

speed-up

and

Deceleration

and

circuit

deceleration

near

Refer

to

for

are

the

Section

details.

effected

start

3.

and

Automatic

18

automatically

end

points

Accele¬

of

a

becomes

F

code

F

rate

code

is

of

each

the

modal,

is

axis

specified

once

specified.

is

controlled

feed

specified,

rate.

it

so

is

the

that

effective

tangent

until

Note

Note

4:

5:

The

speed

The

another

feed

I

29

-

-

Page 34

3.12

Preparatory

Function

(G

Function)

Table

G

code

GOO

G01

GO

GO

3

4

GO

G12

G13

G14

G15

G17

G18

G19

G25

G27

G28

G29

G38

G39

G40

G41

G42

G43

G44

G45

G46

G47

G48

G49

G73

G7

G80

G81

G82

G83

G84

G85

G86

G87

G88

G89

3,12.1

2

lists

Group

A

A

A

A

>1'

*

A

A

B

B