Page 1

FOT-930

Multifunction Loss Tester

User Guide

Page 2

Copyright © 2004–2013 EXFO Inc. All rights reserved. No part of this

publication may be reproduced, stored in a retrieval system or transmitted

in any form, be it electronically, mechanically, or by any other means such

as photocopying, recording or otherwise, without the prior written

permission of EXFO Inc. (EXFO).

Information provided by EXFO is believed to be accurate and reliable.

However, no responsibility is assumed by EXFO for its use nor for any

infringements of patents or other rights of third parties that may result from

its use. No license is granted by implication or otherwise under any patent

rights of EXFO.

EXFO’s Commerce And Government Entities (CAGE) code under the North

Atlantic Treaty Organization (NATO) is 0L8C3.

The information contained in this publication is subject to change without

notice.

Trademarks

EXFO’s trademarks have been identified as such. However, the presence

or absence of such identification does not affect the legal status of any

trademark.

Units of Measurement

Units of measurement in this publication conform to SI standards and

practices.

Version number: 8.0.0

ii FOT-930

Page 3

Contents

Contents

Certification Information ....................................................................................................... vi

1 Introducing the FOT-930 Multifunction Loss Tester ................................... 1

Main Features .........................................................................................................................1

Power Sources ........................................................................................................................4

Typical Applications ................................................................................................................4

Conventions ............................................................................................................................5

2 Safety Information ....................................................................................... 7

Other Safety Symbols on Your Unit .........................................................................................8

Laser Safety Information (Units without VFL) ..........................................................................9

Laser Safety Information (Units with VFL) ...............................................................................9

Electrical Safety Information .................................................................................................10

3 Getting Started with Your Multifunction Loss Tester .............................. 13

Turning the Unit On and Off .................................................................................................13

Using Menus and Keypad .....................................................................................................14

4 Customizing Your Multifunction Loss Tester ............................................ 17

Selecting the Language of Operation ...................................................................................17

Setting the Date and Time ....................................................................................................18

Adjusting the Brightness and Contrast .................................................................................19

Activating and Setting Screen Saver and Auto-Off ................................................................20

5 Setting Up Your Multifunction Loss Tester ............................................... 21

Installing the EXFO Universal Interface (EUI) .........................................................................21

Cleaning and Connecting Optical Fibers ...............................................................................22

Setting Autonaming Scheme ................................................................................................24

Setting Pass/Fail Thresholds ..................................................................................................26

6 Measuring Power or Loss .......................................................................... 29

Defining the List of Favorite Wavelengths .............................................................................30

Nulling Electrical Offsets .......................................................................................................32

Referencing Your Power Meter to a Source ...........................................................................33

Measuring Power or Loss ......................................................................................................36

Automatically Detecting Wavelength ....................................................................................39

7 Measuring Optical Return Loss ................................................................. 41

Performing ORL Reference and Setting ORL Zero Value ........................................................42

Performing and Saving ORL Measurements ..........................................................................43

Multifunction Loss Tester iii

Page 4

Contents

8 Performing Automated IL/ORL/Length Measurements (FASTEST) ...............47

Setting Up the FASTEST ........................................................................................................48

Referencing Units for FASTEST .............................................................................................49

Performing the FASTEST .......................................................................................................52

9 Managing Test Results ................................................................................55

Viewing and Deleting Results ...............................................................................................55

Checking Available Memory ..................................................................................................56

Transferring Test Results to a Computer ................................................................................56

10 Using a Light Source ...................................................................................59

11 Identifying Fiber Faults Visually ................................................................61

12 Inspecting Fibers with the FIP ....................................................................63

13 Communicating with Other Users .............................................................65

Sending and Receiving Text Messages ..................................................................................65

Communicating by Voice ......................................................................................................68

14 Maintenance ................................................................................................71

Cleaning EUI Connectors ......................................................................................................71

Cleaning Detector Ports ........................................................................................................74

Cleaning VFL-Type Connectors ..............................................................................................75

Recharging Main Batteries ....................................................................................................76

Replacing Batteries ...............................................................................................................77

Battery Safety Information ....................................................................................................78

Recalibrating the Unit ...........................................................................................................79

Upgrading the Embedded Software .....................................................................................80

Recycling and Disposal (Applies to European Union Only) ....................................................80

15 Troubleshooting ..........................................................................................81

Solving Common Problems ...................................................................................................81

Obtaining Online Help ..........................................................................................................85

Contacting the Technical Support Group ..............................................................................86

Transportation ......................................................................................................................87

16 Warranty ......................................................................................................89

General Information .............................................................................................................89

Liability .................................................................................................................................90

Exclusions .............................................................................................................................90

Certification ..........................................................................................................................90

Service and Repairs ...............................................................................................................91

EXFO Service Centers Worldwide ..........................................................................................92

iv FOT-930

Page 5

Contents

A Technical Specifications ............................................................................. 93

Index ................................................................................................................ 95

Multifunction Loss Tester v

Page 6

Certification Information

Certification Information

North America Regulatory Statement

This unit was certified by an agency approved in both Canada and the

United States of America. It has been evaluated according to applicable

North American approved standards for product safety for use in Canada

and the United States.

Electronic test and measurement equipment is exempt from FCC part 15,

subpart B compliance in the United States of America and from ICES-003

compliance in Canada. However, EXFO Inc. makes reasonable efforts to

ensure compliance to the applicable standards.

The limits set by these standards are designed to provide reasonable

protection against harmful interference when the equipment is operated in

a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance

with the user guide, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely

to cause harmful interference in which case the user will be required to

correct the interference at his own expense.

Modifications not expressly approved by the manufacturer could void the

user's authority to operate the equipment.

vi FOT-930

Page 7

DECLARATION OF CONFORMITY

Application of Council Directive(s): 1999/5/EC – The R&TTE Directive

2011/65/UE – Restriction of the use of certain hazardous substances (RoHS)

And their amendments

Manufacturer’s Name and Address:

EXFO Inc. EXFO Europe Ltd.

400 Godin Avenue Winchester House

Quebec City, Quebec School Lane, Chandlers Ford

G1M 2K2, CANADA SO53 4DG, UK

Tel.: +1 418 683-0211 Tel.: +44 2380 246 800

Equipment Type/Environment: Test & Measurement / Industrial

Trade Name/Model No.: Multifunction Loss Tester—FOT-930 MaxTester

Standard(s) to which Conformity is declared:

EN 61010-1:2010 Edition 3.0

Safety requirements for electrical equipment for measurement,

control, and laboratory use

– Part 1: General requirements

EN 61326-1:2006

Electrical equipment for measurement, control and laboratory use –

EMC requirements

– Part 1: General requirements

EN 60825-1:2007 Edition 2.0

Safety of laser products – Part 1: Equipment classification and

requirements

I, the undersigned, hereby declare that the equipment specified above conforms to the above Directive and Standards.

Manufacturer:

Stephen Bull, E. Eng

Vice-President Research and Development

400 Godin Avenue,

Quebec City, Quebec

G1M 2K2 CANADA

January 31, 2013

Certification Information

Multifunction Loss Tester vii

Page 8

Page 9

1 Introducing the FOT-930

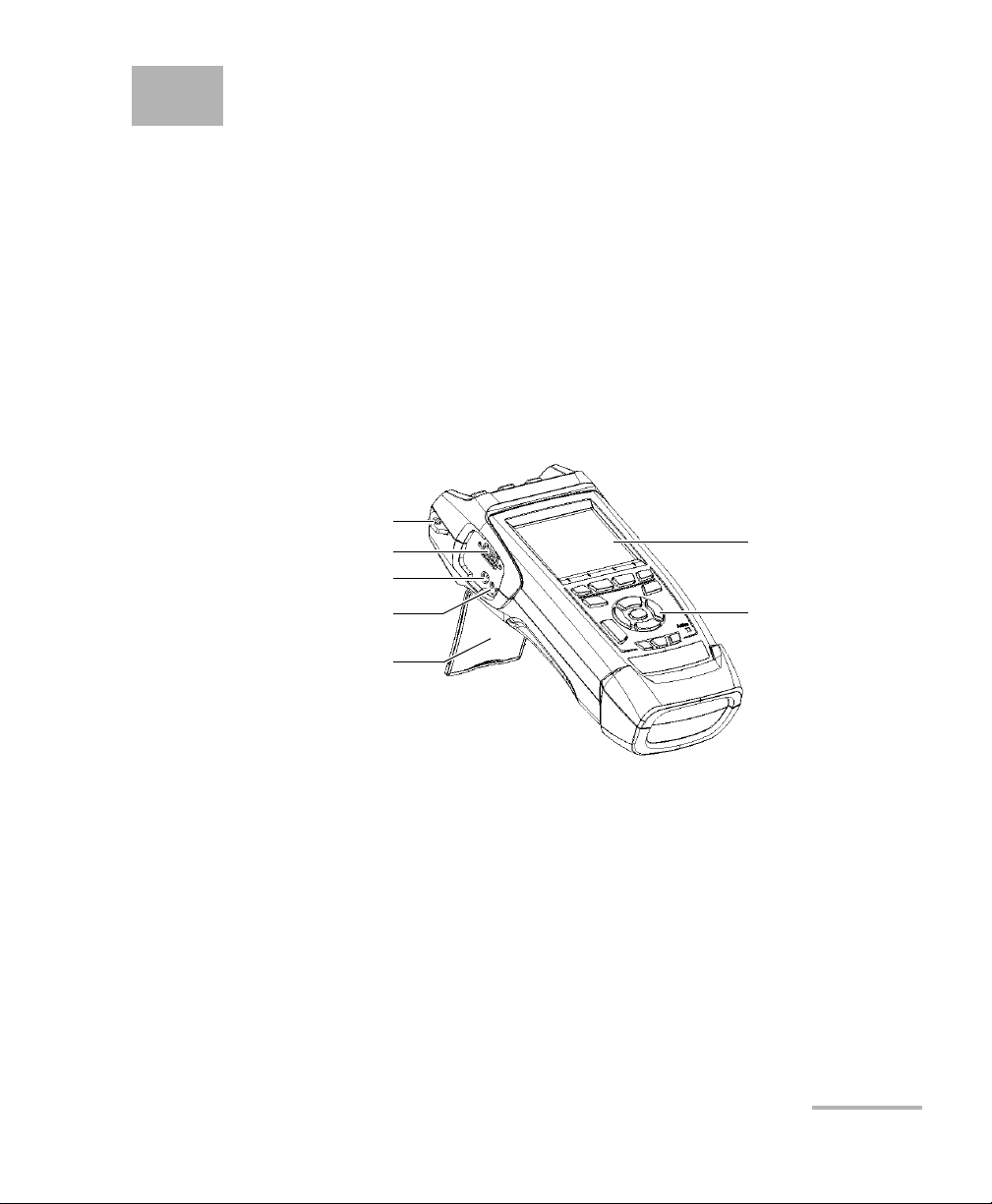

DC connector

Battery charge

status LEDs

RS-232 connector

Shoulder strap eyelet

Stand

Display

Keypad

Multifunction Loss Tester

The FOT-930 Multifunction Loss Tester integrates a power meter and light

sources with an optical return loss meter, optional talk set and visual fault

locator.

Main Features

The unit features FASTEST™, EXFO’s one-touch automated measurement.

In 10 seconds, you can simultaneously test IL and ORL at up to four

wavelengths, in both directions. During the same test, the unit also

determines fiber length.

The power meter has the following characteristics:

Ge, GeX or InGaAs detector with 40 calibrated wavelengths to measure

absolute power or link loss

Editable list of favorite wavelengths for easy access

Modulated signal detection

Multifunction Loss Tester 1

Automatic wavelength detection from compatible sources

No offset nulling required in normal operation

Page 10

Introducing the FOT-930 Multifunction Loss Tester

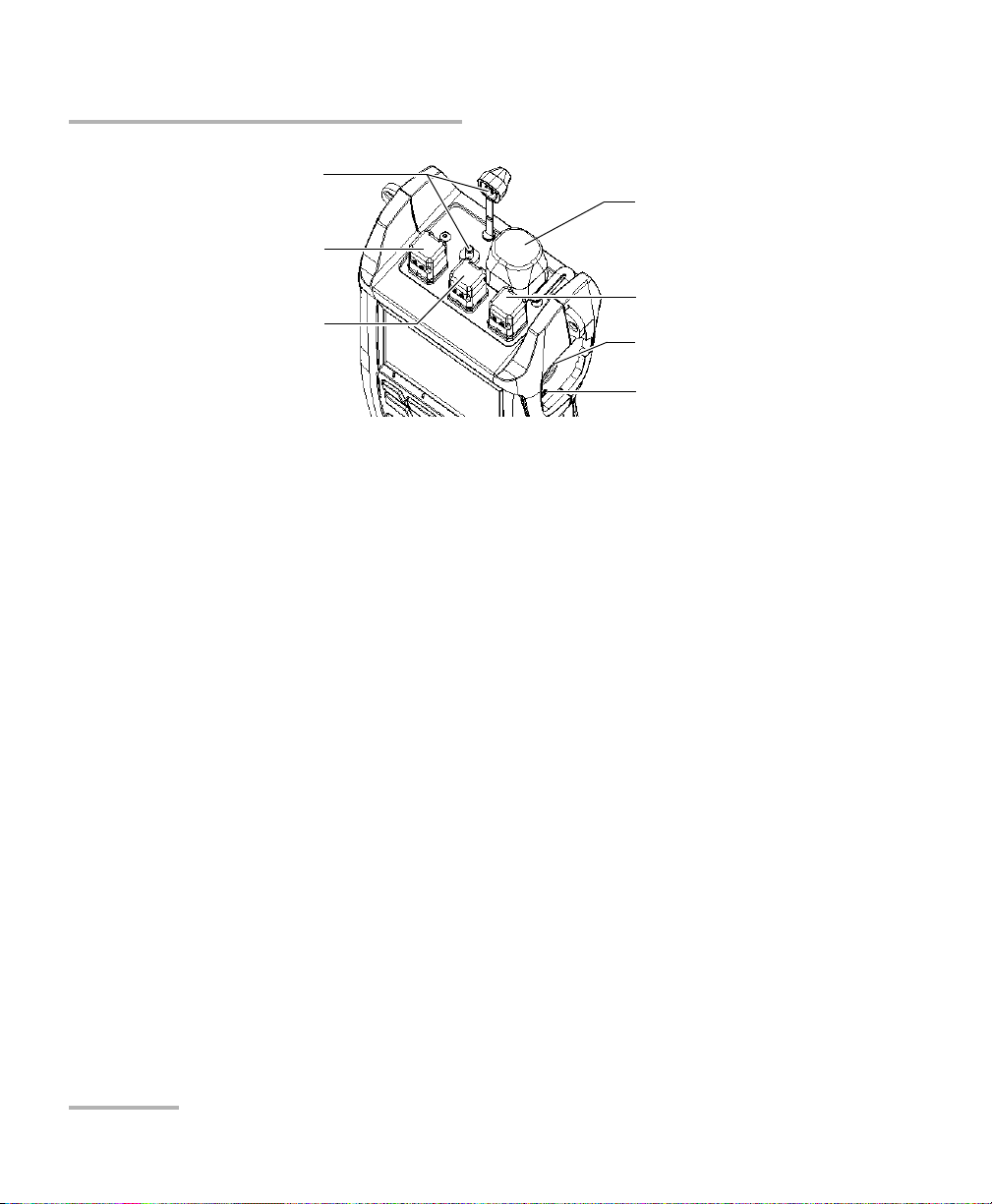

Headset connector

Inspection probe

connector

Ta l k set p o rt

Power meter detector port

Visual fault locator port

and soft cap

Singlemode port (F

ASTEST, light

source and ORL meter)

Multimode port

(F

ASTEST and light source)

Main Features

Note: Optical ports and connectors may differ from the illustration.

The light source has the following characteristics:

Singlemode port (two or three wavelengths), also used for FASTEST and

ORL.

AND/OR

Multimode port (two wavelengths), also used for F

ASTEST only.

Modulated or high-power signal compatible with other EXFO units

2 FOT-930

Page 11

Introducing the FOT-930 Multifunction Loss Tester

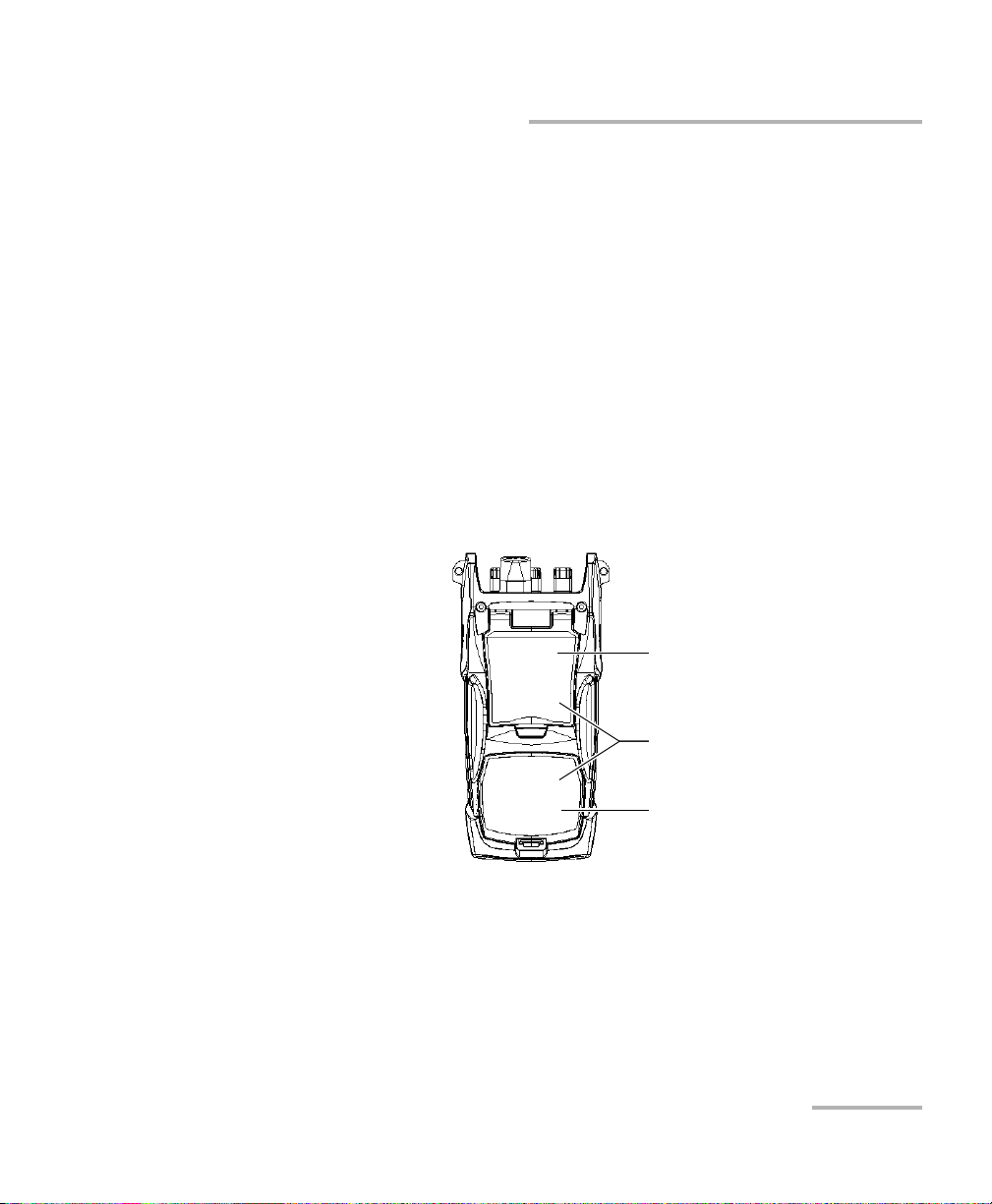

Safety label and serial number

(under the stand)

Battery compartment

(two rechargeable batteries)

Quick reference labels

Main Features

Other test utilities:

Text messaging

Full-duplex digital talk set (optional)

Visual fault locator to inspect or identify fibers (optional)

Video fiber inspection probe (optional)

Result processing and analysis features (also available in the Optical

Report Viewer application):

Customizable test thresholds with visual pass/fail analysis

Memory for 1024 results and possible data transfer to a computer for

analysis with the Optical Report Viewer software

FASTEST results displayed according to FTTx usage and terminology

Other useful characteristics:

Energy-saving features: automatic backlight or unit shutdown

Multilingual graphical user interface

Comprehensive online help available from each function and Quick

Reference labels affixed to back of unit

Multifunction Loss Tester 3

Page 12

Introducing the FOT-930 Multifunction Loss Tester

Pow er So urces

Power Sources

The unit operates with the following power sources:

AC adapter/charger (connected to standard power outlet—indoor use

only). Compatible car outlet adapter available upon request

One or two Lithium-Ion rechargeable batteries (automatically take

over if you unplug the AC adapter/charger)

Field-changeable without affecting operation

Automatic recharge when AC adapter/charger connected

CR2032-type Lithium cell battery (for clock only, used when

Lithium-Ion batteries and DC power are both unavailable)

IMPORTANT

Batteries are not charged at the factory. Fully charge them (about

4 hours) before using the unit for the first time.

Typical Applications

You can use the Multifunction Loss Tester for several applications, such as:

Fiber installation and maintenance applications

FTTx: testing of passive optical networks (PONs)

Absolute power or link loss measurements

Bidirectional loss and ORL testing

Length measurement

All-in-one tool for contractors

4 FOT-930

Page 13

Introducing the FOT-930 Multifunction Loss Tester

Conventions

Conventions

Before using the product described in this manual, you should understand

the following conventions:

WARNING

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury. Do not proceed unless you

understand and meet the required conditions.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury. Do not proceed unless you

understand and meet the required conditions.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in component damage. Do not proceed unless you

understand and meet the required conditions.

IMPORTANT

Refers to information about this product you should not overlook.

Multifunction Loss Tester 5

Page 14

Page 15

2 Safety Information

WARNING

Do not install or terminate fibers while a light source is active.

Never look directly into a live fiber and ensure that your eyes are

protected at all times.

WARNING

The use of controls, adjustments and procedures other than those

specified herein may result in exposure to hazardous situations or

impair the protection provided by this unit.

IMPORTANT

When you see the following symbol on your unit , make sure

that you refer to the instructions provided in your user

documentation. Ensure that you understand and meet the required

conditions before using your product.

IMPORTANT

Other safety instructions relevant for your product are located

throughout this documentation, depending on the action to

perform. Make sure to read them carefully when they apply to your

situation.

Multifunction Loss Tester 7

Page 16

Safety Information

Other Safety Symbols on Your Unit

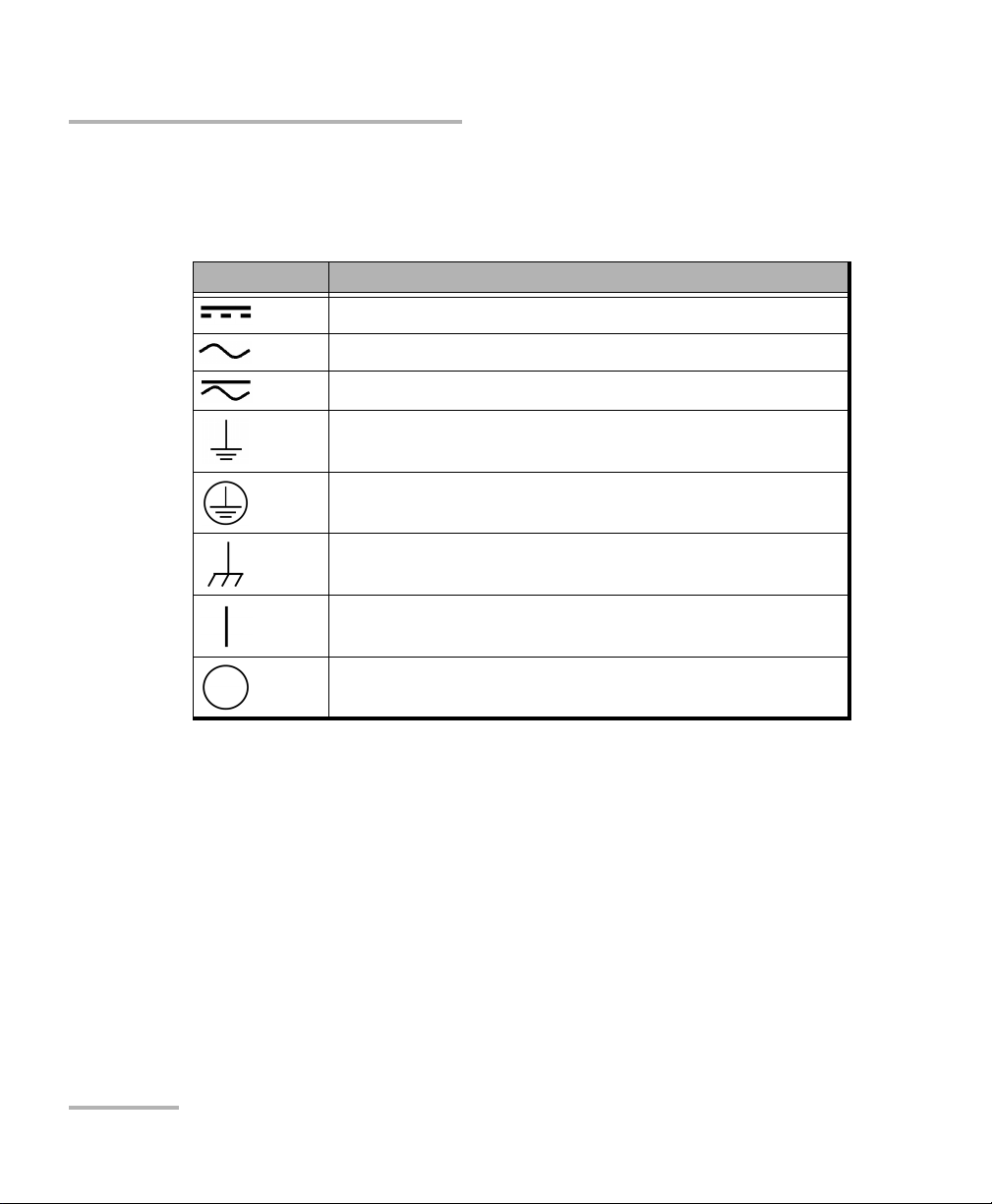

Other Safety Symbols on Your Unit

One or more of the following symbols may also appear on your unit.

Symbol Meaning

Direct current

Alternating current

Both direct and alternating current

The unit is equipped with an earth (ground) terminal.

The unit is equipped with a protective conductor terminal.

The unit is equipped with a frame or chassis terminal.

On (Power)

Off (Power)

8 FOT-930

Page 17

Safety Information

Affixed to back

(under the stand)

Indicated on

connector panel

Laser Safety Information (Units without VFL)

Laser Safety Information (Units without VFL)

Your instrument is a Class 1 laser product in compliance with standards

IEC 60825-1: 2007 and 21 CFR 1040.10, except for deviations pursuant to

Laser Notice No. 50, dated June 24, 2007. Invisible laser radiation may be

encountered at the output port.

The following label indicates that a product contains a Class 1 source:

Laser Safety Information (Units with VFL)

Your instrument is a Class 3R laser product in compliance with standards

IEC 60825-1: 2007 and 21 CFR 1040.10, except for deviations pursuant to

Laser Notice No. 50, dated June 24, 2007. Laser radiation is emitted at the

output port. It is potentially harmful in direct intrabeam viewing.

The following label(s) indicate that the product contains a Class 3R source:

Multifunction Loss Tester 9

Page 18

Safety Information

Electrical Safety Information

Electrical Safety Information

The AC adapter/charger provided with this unit is specifically designed to

work with your product.

Use only accessories that meet EXFO specifications.

EXFO guarantees the specifications and viability of the products

ONLY if they are used with chargers and batteries provided by

EXFO.

Use the external power supply indoors only.

WARNING

CAUTION

WARNING

Operation of any electrical instrument around flammable gases

or fumes constitutes a major safety hazard.

To avoid electrical shock, do not operate the unit if any part of

the outer surface (covers, panels, etc.) is damaged.

Use only the AC adapter/charger provided by EXFO with your

unit.

Use only the car outlet adapter designed for your unit and

approved by EXFO. The car outlet adapter contains a

replaceable fuse. Replace the damaged fuse ONLY with a fuse of

the same type: 3AG certified, 16 VDC, 3 A, with an I

2

40 A

sec and 80 A2sec.

When you use the unit outdoors, ensure that it is protected

from liquids, dust, direct sunlight, precipitation, and full wind

pressure.

10 FOT-930

2

t between

Page 19

Safety Information

Electrical Safety Information

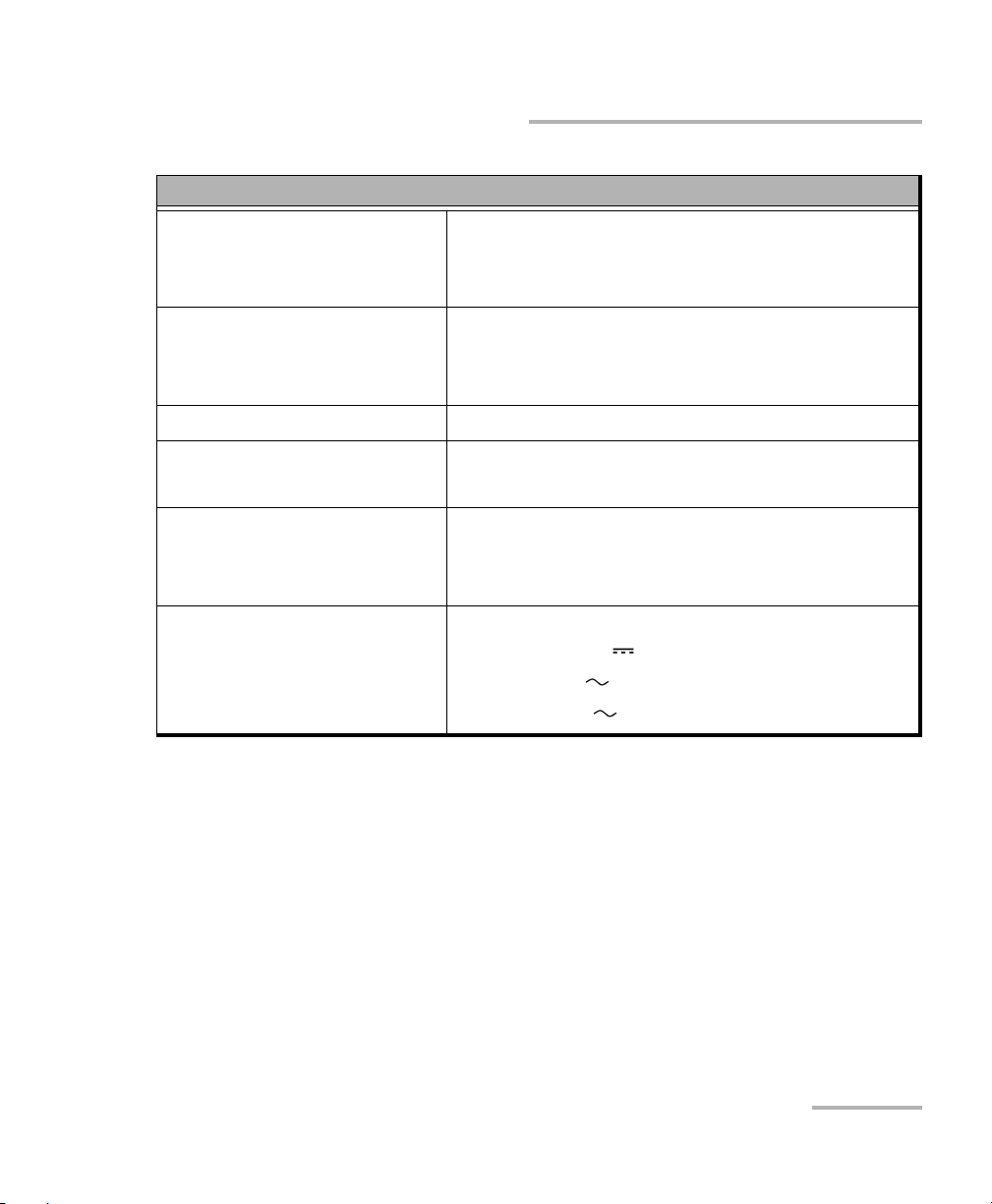

Equipment Ratings

Temp er at ur e

Operation

Storage

Relative humidity

unit

AC adapter

a

-0 °C to 40 °C (32 °F to 104 °F)

-40 °C to 70 °C (-40 °F to 158 °F)

95 % non-condensing

0 % to 80 % non-condensing

Maximum operation altitude 5000 m (6562 ft)

Pollution degree 2 (connected to AC mains)

3 (powered by batteries)

Overvoltage category

unit

AC adapter

Input power

unit

AC adapter

d

120 V, 14.4 W, 60 Hz

I

II

9 - 16 V; 12 W

230 V, 17 W, 50 Hz

b

c

a. Measured in 0 °C to 31 °C (32 °F to 87.8 °F) range, decreasing linearly to 50 % at 40 °C (104 °F)

b. For indoor use only.

c. Equipment is normally protected against exposure to direct sunlight, precipitations and full wind pressure.

d. Not exceeding ± 10 % of the nominal voltage

Multifunction Loss Tester 11

Page 20

Page 21

3 Getting Started with Your

Multifunction Loss Tester

CAUTION

To avoid damaging your unit, use it only with modules approved by

EXFO.

Turning the Unit On and Off

When you turn the unit on, you may use it immediately under normal

conditions (while the source offers good startup performance, you should

allow a 5-minute warmup).

When the unit is turned off, it keeps the following parameters in its internal

memory:

FASTEST parameters

Current power meter wavelength and list of favorite wavelengths

User-defined thresholds

Autonaming settings

Regional, LCD and energy-saving settings

Saved values and test results

IMPORTANT

If you remove batteries (and the AC adapter/charger is unplugged),

the unit will turn off without saving the above elements.

The date and time will be lost only if you remove the clock battery.

Note: To ensure that the power is completely turned off, disconnect the AC

adapter/charger and remove the batteries.

Multifunction Loss Tester 13

Page 22

Getting Started with Your Multifunction Loss Tester

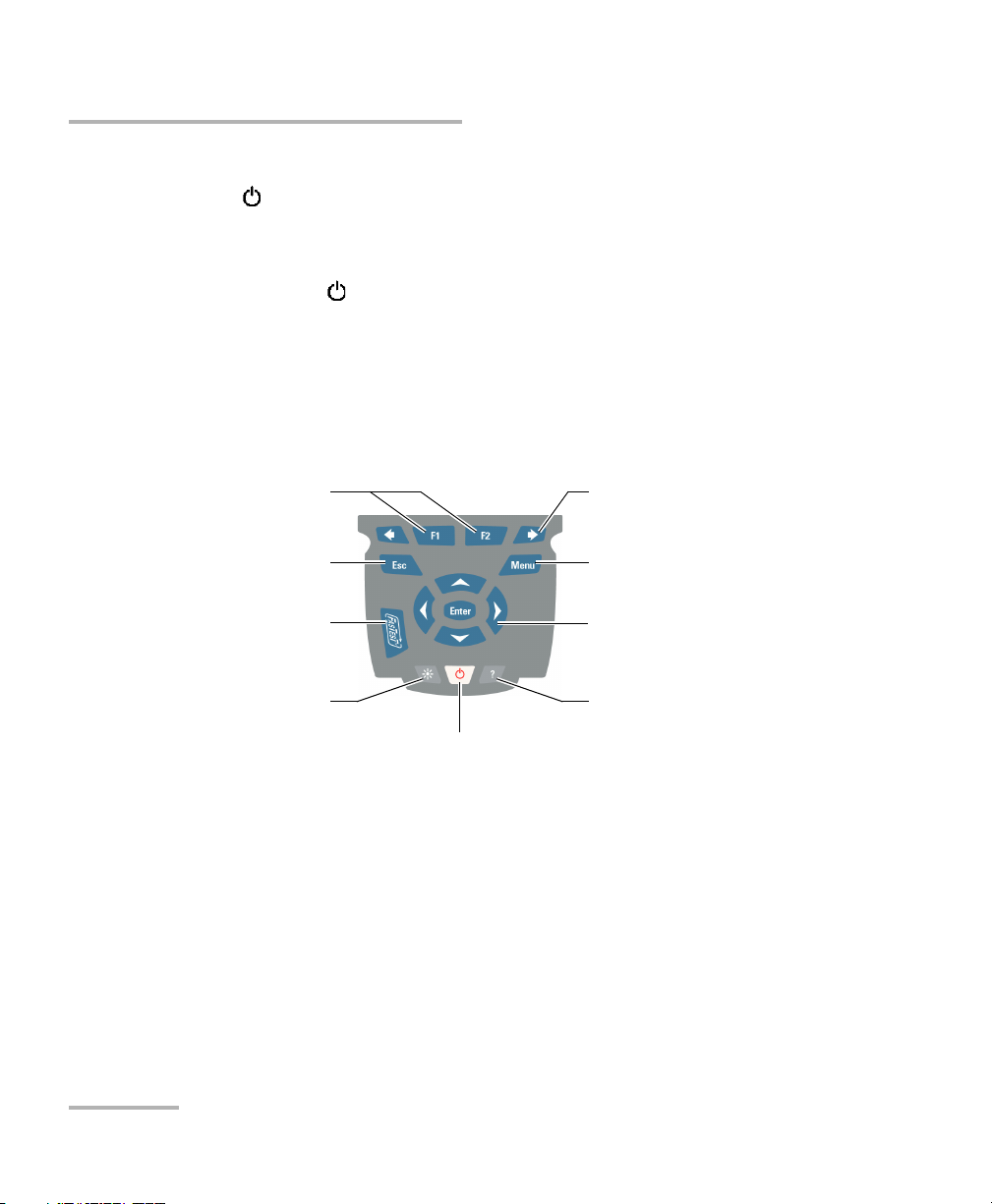

To activate the function

displayed directly above

To move around, select items,

and change parameters

To access F

ASTEST

To access the main menu

To access help about

current function

To adjust brightness (four levels)

To turn unit on/off

(blinks when idle or

when probe is active)

To cancel/exit current function

Keypad

To scroll through available

functions

Using Menus and Keypad

To turn the unit on:

Press . The unit initializes for a few seconds and displays the Power

Meter pane.

To turn the unit off:

Hold down the button for two seconds.

Using Menus and Keypad

You can access optical tools from the keypad or menu. Menu options may

differ depending on your unit configuration.

14 FOT-930

Page 23

Getting Started with Your Multifunction Loss Tester

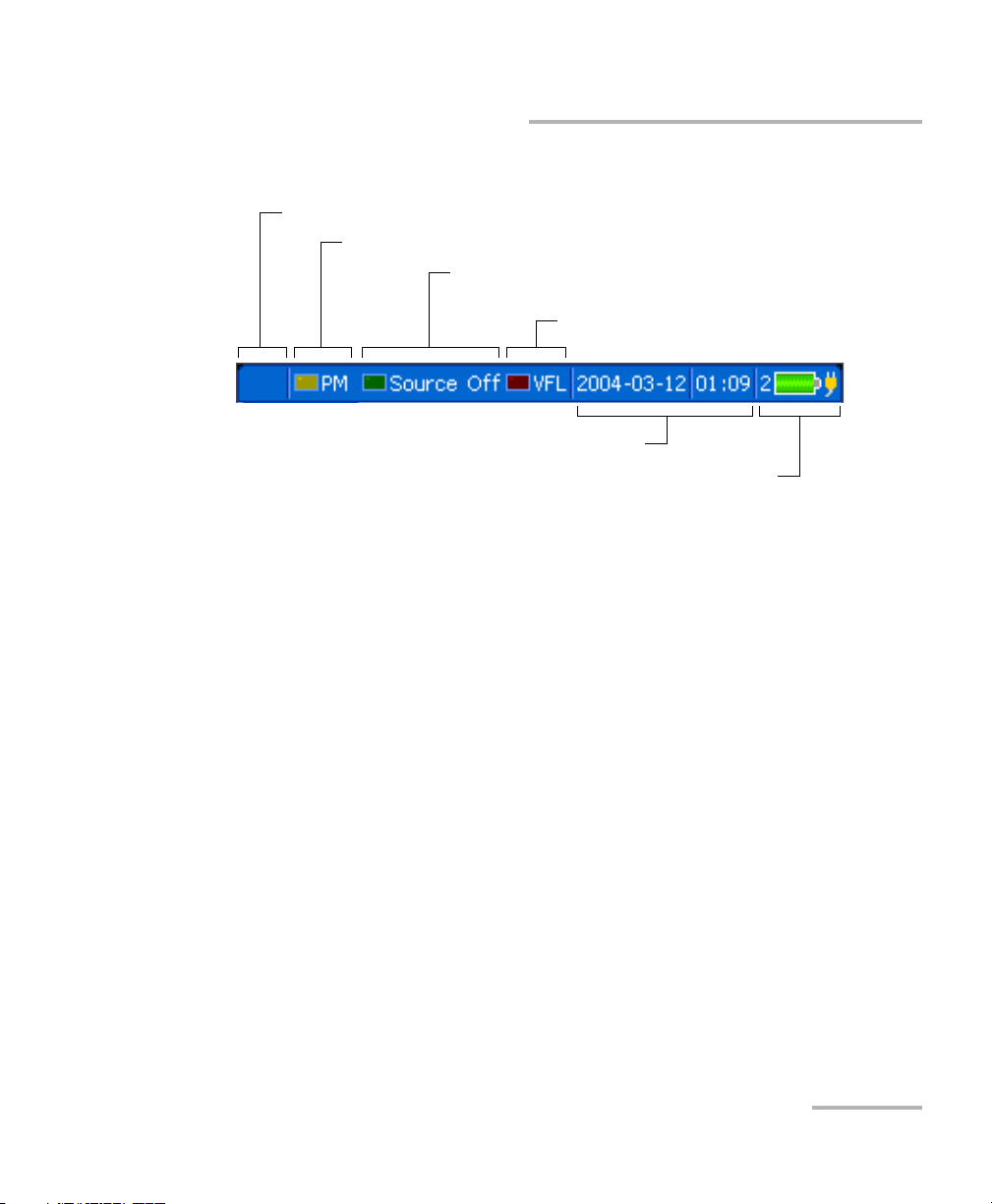

Power meter status (detected modulation)

Source/F

ASTEST/ORL meter status (active wavelength

or detected modulation)

VFL status (on/off)

Current date and time

Battery number/status and DC power status

Talk set status (seeking or connected)

Status Bar

Using Menus and Keypad

To access main features:

1. Press the Menu key.

2. Use the arrows to select feature and press Enter.

To activate F1/F2 functions:

1. Use the left/right function arrows (beside F1/F2 keys) to make the

desired function or parameter visible.

2. Press the F1 or F2 key located just below.

To access and modify on-screen parameters:

1. Use the arrows to select an on-screen item (drop-down list, keyboard,

check box, etc.).

2. Press Enter to activate or open it.

To enter text or numbers with an on-screen keyboard:

Multifunction Loss Tester 15

Use the left/right function arrows (beside F1/F2 keys) to move the

Use the up/down and left/right arrows to select a character, then press

Press OK (F1/F2 key) to accept the element and hide the keyboard.

cursor in the text.

Enter to add it.

Page 24

Page 25

4 Customizing Your

Multifunction Loss Tester

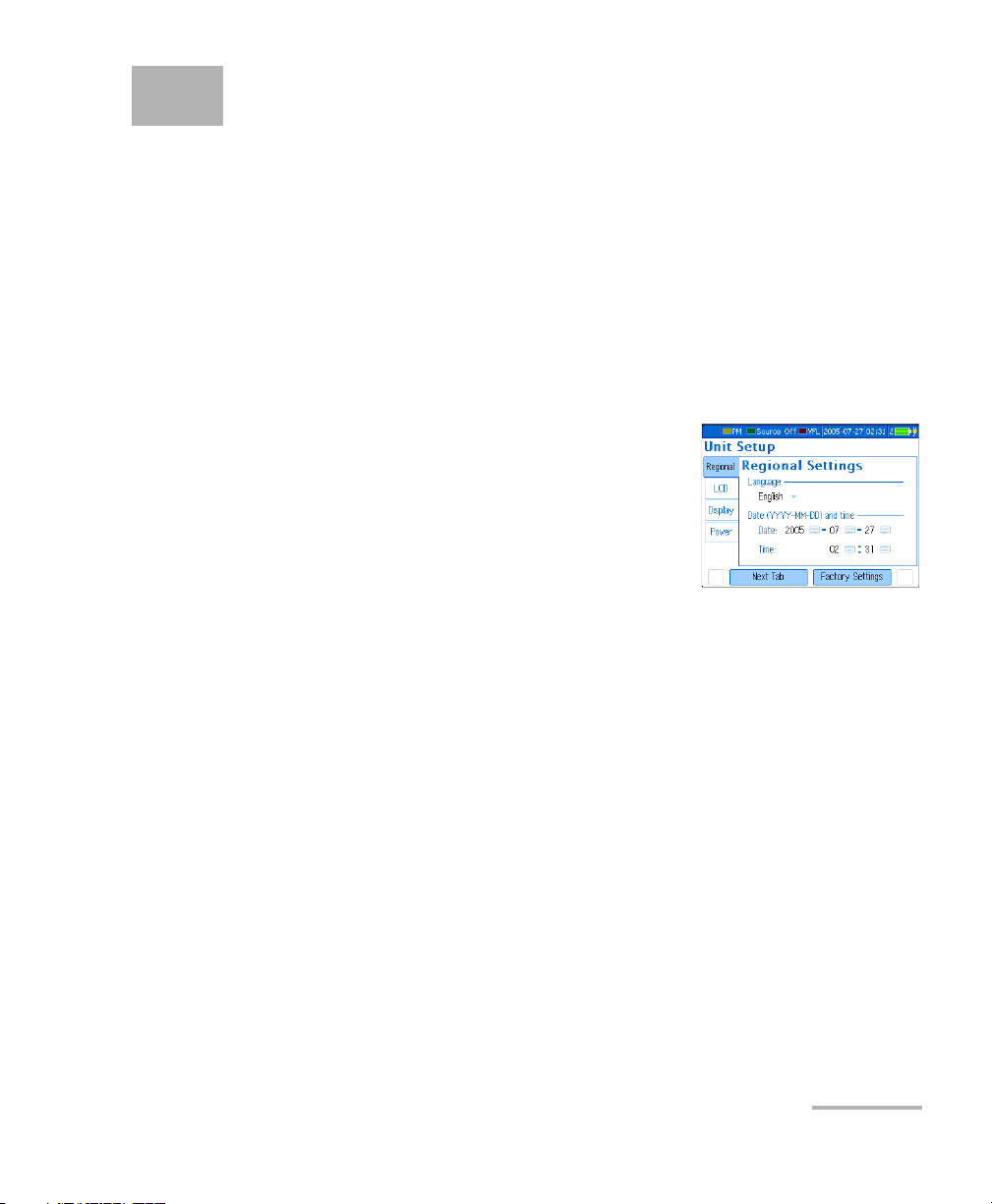

Selecting the Language of Operation

You may display the user interface in one of six languages (default is

English). If other languages become available in the future, you could

access them by replacing the unit software (see Upgrading the Embedded

Software on page 80). Values are kept in memory when you turn the unit

off. You may also revert to factory settings at any time.

To select a new interface language:

1. Press Menu, then select Setup > Unit.

2. Press Next Tab (F1/F2 key) until you get to

the Regional tab.

3. Use the arrows to select the Language list,

then press Enter to open it.

4. With the current language highlighted, use

the up/down arrows to select the desired language, then press Enter to

activate it.

To revert unit to factory-default settings:

1. Press Menu, then select Setup > Unit.

2. Press Factory Settings (F1/F2 key). Values on all tabs of the Unit Setup

pane are returned to factory settings.

Multifunction Loss Tester 17

Page 26

Customizing Your Multifunction Loss Tester

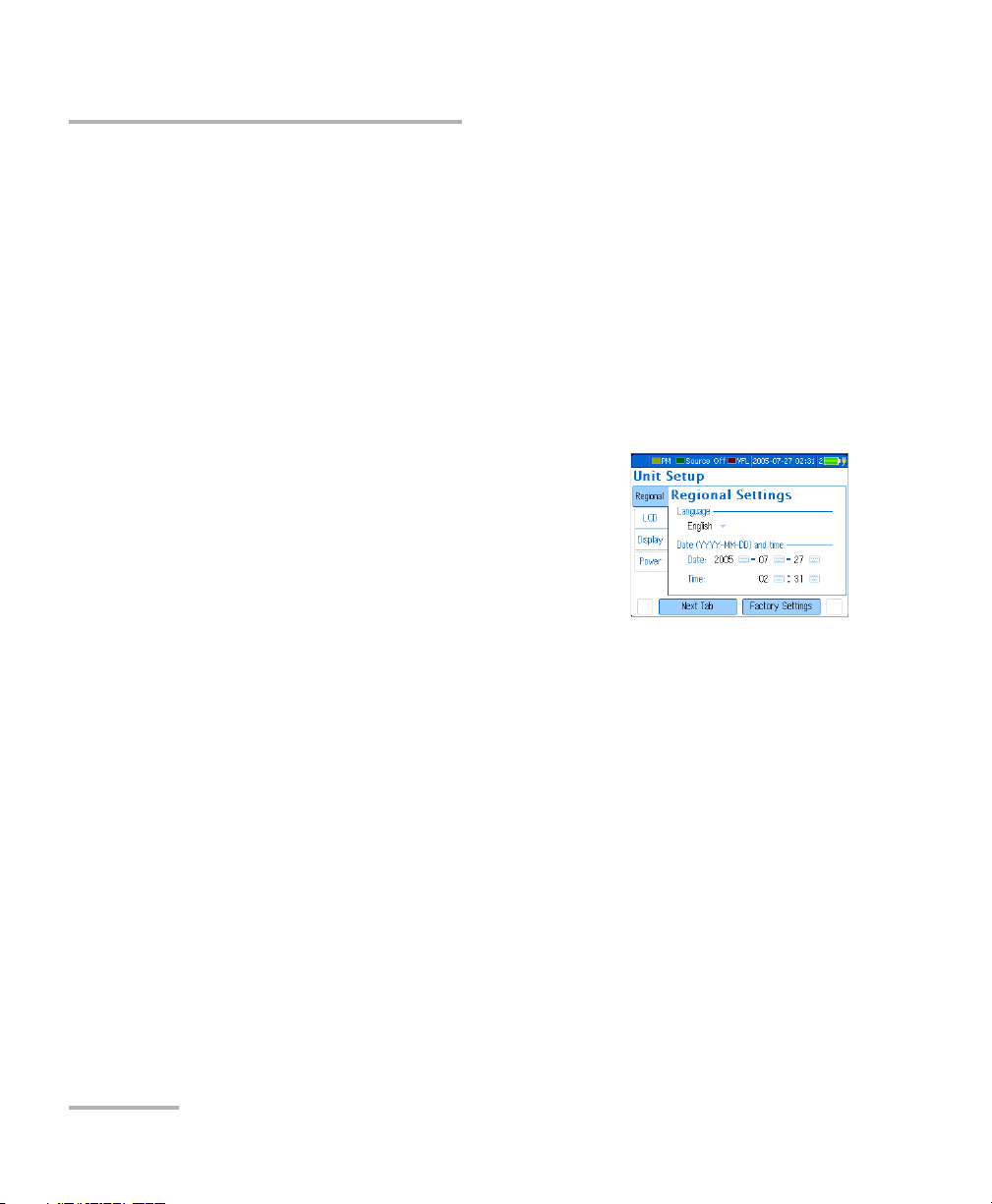

Setting the Date and Time

Setting the Date and Time

The current date and time are displayed on the status bar. When saving

results, the unit also saves the corresponding date and time.

You must enter the date according to the year-month-day format and the

time according to the 24-hour format.

Note: A dedicated clock battery keeps the date and time accurate. For details, see

Replacing Batteries on page 77.

To set the date and time:

1. Press Menu, then select Setup > Unit.

2. Press Next Tab (F1/F2 key) until you get to

the Regional tab.

3. Use the arrows to select any of the date or

time settings, then press Enter to display the

on-screen keyboard (for details about using

keyboards, see Using Menus and Keypad on page 14).

4. Set the new value and press OK (F1/F2 key).

18 FOT-930

Page 27

Customizing Your Multifunction Loss Tester

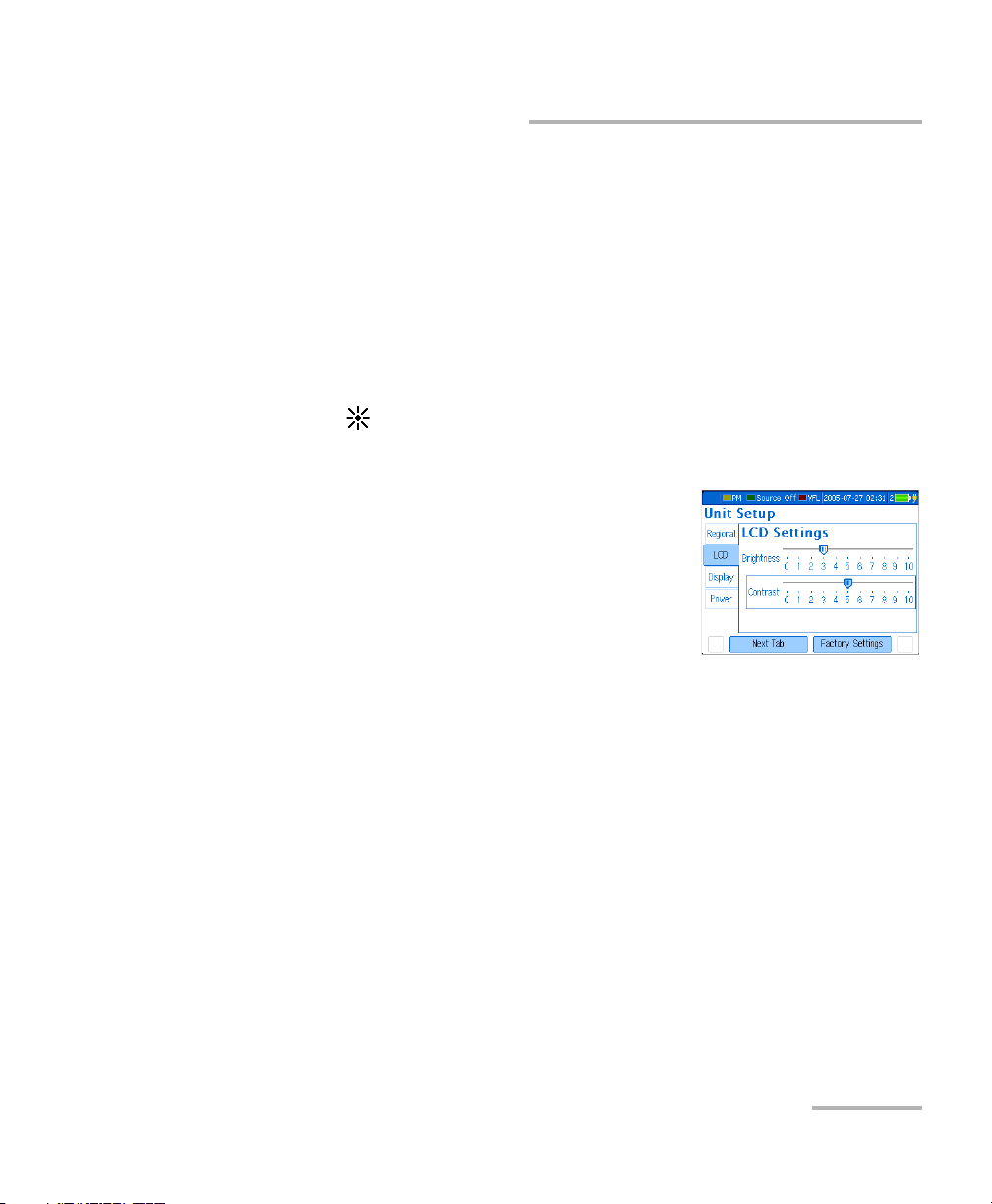

Adjusting the Brightness and Contrast

Adjusting the Brightness and Contrast

To fit your work environment, you may adjust the LCD brightness and

contrast. Values are kept in memory when you turn the unit off. You may

also revert to factory settings at any time.

Note: These settings do not apply to the Fiber Inspection Probe display. For

details, see Inspecting Fibers with the FIP on page 63.

To adjust the display brightness and contrast:

Press the key repeatedly to switch between brightness levels (0-4-7-10).

OR

1. Press Menu, then select Setup > Unit.

2. Press Next Tab (F1/F2 key) until you get to

the LCD tab.

3. Use the up/down arrows to select the

Brightness or Contrast slider.

4. Use the left/right arrows to adjust the

brightness or contrast level.

To revert unit to factory-default settings:

1. Press Menu, then select Setup > Unit.

2. Press Factory Settings (F1/F2 key). Values on all tabs of the Unit Setup

pane are returned to factory settings.

Multifunction Loss Tester 19

Page 28

Customizing Your Multifunction Loss Tester

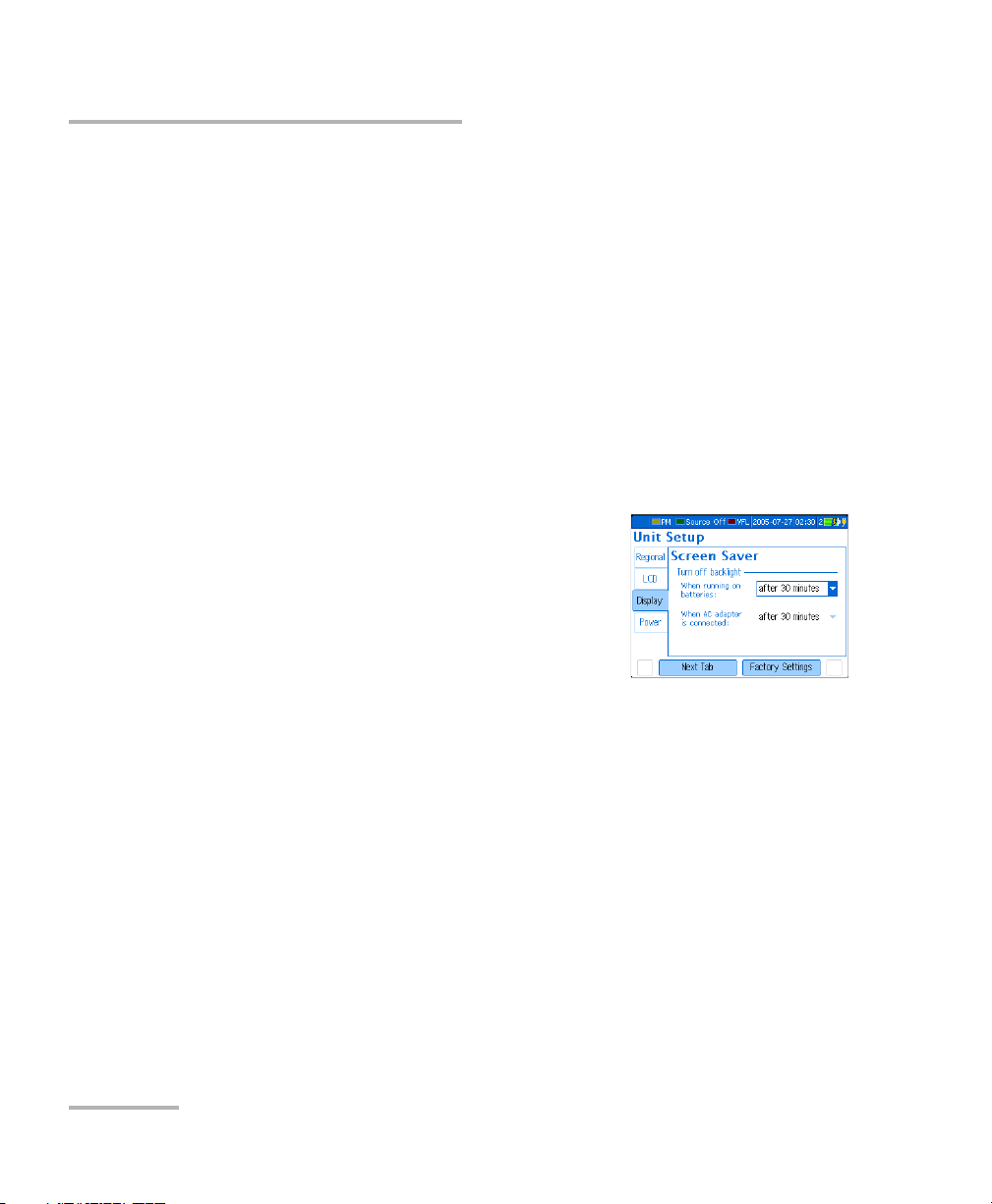

Activating and Setting Screen Saver and Auto-Off

Activating and Setting Screen Saver and

Auto-Off

When you do not use the unit for a while, the display may be dimmed to

save power. Your unit may also turn itself off completely.

You can set idle durations for DC and battery operation. Values are kept in

memory when you turn the unit off. You may also revert to factory settings

at any time.

Note: The ON/OFF button blinks to indicate screen saver activation, but unit

operation is not interrupted. Press any key to deactivate the screen saver.

To activate/deactivate the screen saver or auto-off:

1. Press Menu, then select Setup > Unit.

2. Press Next Tab (F1/F2 key) until you get to

the Power tab (for auto-off) or Display tab

(for screen saver).

3. Use the up/down arrows to select the battery

or AC adapter duration list, then press Enter

to open the list.

4. With the current duration highlighted, use the up/down arrows to

select the desired duration (or Never), then press Enter to confirm.

To revert unit to factory-default settings:

1. Press Menu, then select Setup > Unit.

2. Press Factor y Settings (F1/F2 key). Values on all tabs of the Unit Setup

pane are returned to factory settings.

20 FOT-930

Page 29

5 Setting Up Your Multifunction

Bare metal

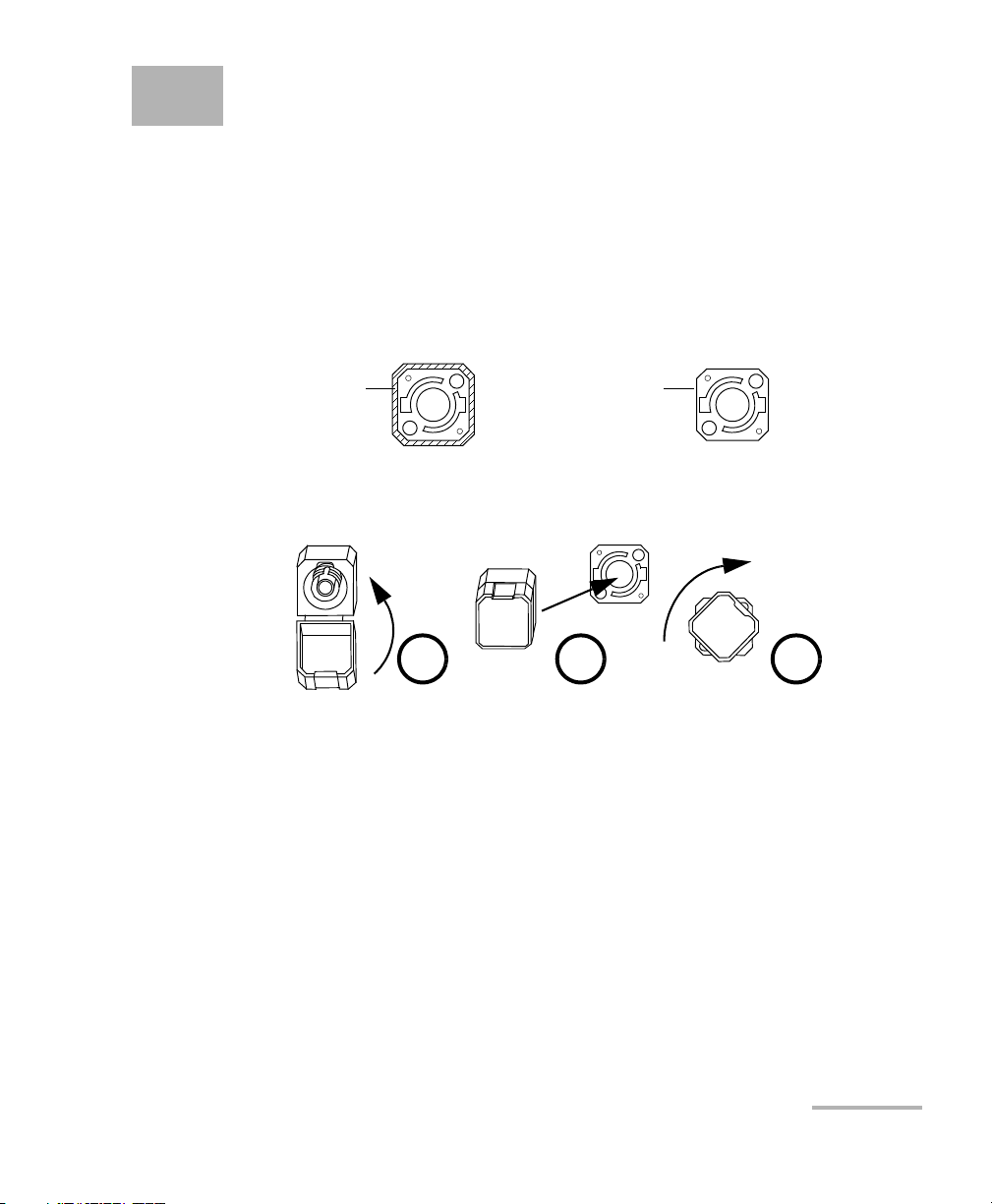

(or blue border)

indicates UPC

option

Green border

indicates APC

option

2 3 4

Loss Tester

Installing the EXFO Universal Interface (EUI)

The EUI fixed baseplate is available for connectors with angled (APC) or

non-angled (UPC) polishing. A green border around the baseplate

indicates that it is for APC-type connectors.

To install an EUI connector adapter onto the EUI baseplate:

1. Hold the EUI connector adapter so the dust cap opens downwards.

2. Close the dust cap in order to hold the connector adapter more firmly.

3. Insert the connector adapter into the baseplate.

4. While pushing firmly, turn the connector adapter clockwise on the

baseplate to lock it in place.

Multifunction Loss Tester 21

Page 30

Setting Up Your Multifunction Loss Tester

Cleaning and Connecting Optical Fibers

Cleaning and Connecting Optical Fibers

IMPORTANT

To ensure maximum power and to avoid erroneous readings:

Always inspect fiber ends and make sure that they are clean as

explained below before inserting them into the port. EXFO is

not responsible for damage or errors caused by bad fiber

cleaning or handling.

Ensure that your patchcord has appropriate connectors. Joining

mismatched connectors will damage the ferrules.

To connect the fiber-optic cable to the port:

1. Inspect the fiber using a fiber inspection microscope. If the fiber is

clean, proceed to connecting it to the port. If the fiber is dirty, clean it as

explained below.

2. Clean the fiber ends as follows:

2a. Gently wipe the fiber end with a lint-free swab dipped in isopropyl

alcohol.

2b. Use compressed air to dry completely.

2c. Visually inspect the fiber end to ensure its cleanliness.

22 FOT-930

Page 31

Setting Up Your Multifunction Loss Tester

Cleaning and Connecting Optical Fibers

3. Carefully align the connector and port to prevent the fiber end from

touching the outside of the port or rubbing against other surfaces.

If your connector features a key, ensure that it is fully fitted into the

port’s corresponding notch.

4. Push the connector in so that the fiber-optic cable is firmly in place,

thus ensuring adequate contact.

If your connector features a screwsleeve, tighten the connector

enough to firmly maintain the fiber in place. Do not overtighten, as this

will damage the fiber and the port.

Note: If your fiber-optic cable is not properly aligned and/or connected, you will

notice heavy loss and reflection.

EXFO uses good quality connectors in compliance with EIA-455-21A

standards.

To keep connectors clean and in good condition, EXFO strongly

recommends inspecting them with a fiber inspection probe before

connecting them. Failure to do so will result in permanent damage to the

connectors and degradation in measurements.

Multifunction Loss Tester 23

Page 32

Setting Autonaming Scheme

Setting Autonaming Scheme

Initially, the unit suggests cable and fiber names based on autonaming

settings. After saving a result, the unit prepares the next fiber name by

incrementing the suffix (or by adding “001” to a name with no suffix).

When you manually change the name for the first time (in Power Meter,

ORL Meter or F

ASTEST), the unit then ignores autonaming settings.

IMPORTANT

To start using new autonaming settings, you must delete all cables

from memory.

Cable names: maximum 21 characters for prefix, 3 digits for number

(or 24 characters when name is manually set)

Fiber names: maximum 12 characters for prefix, plus 3-digit suffix

(duplicate names allowed when name is manually set)

Note: If you manually change a fiber name, then turn the unit off without saving

at least one result, this name will be discarded.

24 FOT-930

Page 33

Setting Autonaming Scheme

To set the autonaming scheme:

1. Press Menu, then select Setup > Data

Autonaming.

2. Use the arrows to select the cable prefix,

cable number or fiber prefix.

3. Press Enter to display the on-screen

keyboard (for details about using keyboards, see Using Menus and

Keypad on page 14).

4. Set the name/value, then press OK (F1/F2 key) to hide the keyboard.

To revert to the factory-default autonaming scheme:

1. Press Menu, then select Setup > Data Autonaming.

2. Press Factory Settings (F1/F2 key).

Multifunction Loss Tester 25

Page 34

Setting Pass/Fail Thresholds

Setting Pass/Fail Thresholds

You can define five groups of thresholds to specify acceptable loss (in dB

and dB per distance unit) and ORL values (in dB) for each wavelength, for

both singlemode and multimode fibers.

Thresholds are supplied by system manufacturers and depend on the

system deployed.

Each time a measurement exceeds a threshold, the result is shown with a

red background and an exclamation mark in the table.

IMPORTANT

Thresholds are not saved with measurements. Results are compared

to the threshold group currently active on the unit where results

are viewed (for F

Note: When transferring results from handheld unit to computer, thresholds are

not transferred along with results. However, you can define thresholds in

the Optical Report Viewer application.

ASTEST results, not necessarily the master unit).

26 FOT-930

Page 35

Setting Pass/Fail Thresholds

To set loss or ORL thresholds:

1. Press Menu, then select Setup >

Thresholds.

2. Use the arrows to select a threshold group in

the Current list. Select None to deactivate all

thresholds.

3. Use the arrows to select:

a fiber mode (singlemode or multimode)

loss units (dB or dB/distance; distance units are selected in FASTEST

setup)

Note: When feet is the current distance unit, you must set thresholds in dB/kft to

obtain meaningful values.

4. Use the arrows to select a value in the table (under the Loss or ORL

columns), then press Enter to display the on-screen keyboard (for

details about keyboards, see Using Menus and Keypad on page 14).

5. Set the threshold, then press OK (F1/F2 key) to hide the keyboard. The

value must be within your unit’s loss/ORL range.

Thresholds are saved only when you turn the unit off.

To rename a threshold group:

1. From the Thresholds pane, use the arrows to select the Current list,

then press Enter to open it.

2. With the current group highlighted, use the up/down arrows to select

the desired group, then press Enter to activate it.

3. Press Rename (F1/F2 key) to display the on-screen keyboard (for

details about keyboards, see Using Menus and Keypad on page 14).

4. Set the new group name (maximum 10 characters), then press OK

(F1/F2 key).

Multifunction Loss Tester 27

Page 36

Page 37

6 Measuring Power or Loss

Power meter port

Open list or press Wavelength to

switch between favorite wavelengths.

Press Setup to modify the list

of favorite wavelengths

or activate auto-detection.

Measured power/loss

Modulation detected

(PM if no modulation)

Open list or press W/dBm/dB to

display power (W or dBm) or

loss (dB).

Press Reference to set new

reference for loss measurement.

Open lists to change cable/fiber

name of next saved data.

Press Store to save current value

under displayed name.

The FOT-930 Multifunction Loss Tester is equipped with an optical power

meter to measure absolute power (in dBm or W) or insertion loss (in dB).

The power meter port is independent of the F

The following functions are available on your power meter:

ASTEST port.

Multifunction Loss Tester 29

Page 38

Measuring Power or Loss

Defining the List of Favorite Wavelengths

Defining the List of Favorite Wavelengths

You must put the wavelengths you want to use on a list of favorite

wavelengths. Only wavelengths selected from this list are available for

measurements.

By default, the list contains 22 of the 40 calibrated wavelengths. It can

contain a maximum of 30 wavelengths.

Specifications are guaranteed for calibrated wavelengths only. For other

wavelengths, the unit will determine values based on the calibrated

wavelengths (3-point interpolation).

Detector

Type

InGaAs

Ge

800, 820, 830, 840, 850, 860, 870,

880, 910, 980, 1270, 1280, 1290,

1300, 1310, 1320, 1330, 1340, 1390,

1450, 1460, 1470, 1480, 1490, 1500,

1510, 1520, 1530, 1540, 1550, 1560,

1570, 1580, 1590, 1600, 1610, 1620,

1630, 1640, 1650.

GeX All the above, plus 1370 and 1060. Same as above.

Calibrated

Wavelengths (nm)

Default Favorite

Wavelengths (nm)

800, 840, 850,

860, 910, 980,

1280, 1300, 1310,

1320, 1450,

1470, 1480, 1490,

1510, 1520, 1530, 1540,

1550, 1560,1570, 1625.

Note: The list must always contain at least one selected wavelength.

30 FOT-930

Page 39

Measuring Power or Loss

Defining the List of Favorite Wavelengths

To customize the list of favorite and selected wavelengths:

1. Press Menu, then select Setup >

Power Meter.

OR

From the Power Meter pane, press Setup

(F1/F2 key).

2. Using the up/down arrows, scroll through the

list.

3. Press Enter to select/deselect the highlighted wavelength. An X

appears beside selected wavelengths.

4. If a wavelength does not appear on the list, you can add it by pressing

Add Wavelength (F1/F2 key). You can also remove a wavelength from

the list by pressing Remove Wavelength (F1/F2 key).

5. Repeat these steps for other wavelengths as necessary.

To revert to the factory-default list:

1. Press Menu, then select Setup > Power Meter.

OR

From the Power Meter pane, press Setup (F1/F2 key).

2. Press Factory Settings (F1/F2 key).

Multifunction Loss Tester 31

Page 40

Measuring Power or Loss

Nulling Electrical Offsets

Nulling Electrical Offsets

Temperature and humidity variations affect the performance of electronic

circuits and optical detectors. Nulling the electrical offsets eliminate these

effects.

Your unit has been designed not to require offset nulling under normal

operation, but you should perform it whenever environmental conditions

change significantly or when measuring very low power values.

IMPORTANT

Light must not reach detectors when nulling offsets. Always use an

EUI or protective screw cap. Do not use a soft rubber cover.

Note: Starting a nulling automatically deactivates all light sources on the unit.

To perform an offset nulling:

1. Press Menu, then select Setup > Power Meter.

OR

From the Power Meter pane, press Setup (F1/F2 key).

2. Press Nulling (F1/F2 key).

3. Tighten the protective caps on the power

meter and F

The nulling process takes approximately 10

seconds. Check marks appear next to nulled

detectors. If light is still detected, you will

need to place the caps properly and restart.

32 FOT-930

ASTEST ports, then press OK.

Page 41

Measuring Power or Loss

Referencing Your Power Meter to a Source

Referencing Your Power Meter to a Source

In reference mode, your unit displays the loss

created by the fiber under test only, since it

subtracts a reference value from the measured

power.

In the illustration, the reference value

(-36.87 dBm) is subtracted from the actual power

measured (-7.89 dBm).

Note: The reference value you set for each wavelength remains in memory until a

new one is set for the same wavelength, even when you turn the unit off.

Compatible sources (such as FOT-300 and FLS-300) can transmit a

reference value to your power meter, avoiding the need for manual

referencing. This value is not the source’s actual power. It is a user-defined

value that may not take the link loss into account.

Multifunction Loss Tester 33

Page 42

Measuring Power or Loss

Light

source

Power

meter

Adapter

Reference

patchcord

Light

source

Power

meter

Adapter

Reference

patchcord

Bulkhead

adapter

Reference

patchcord

Referencing Your Power Meter to a Source

To reference the power meter to a source:

1. Press Menu, then select Power Meter.

2. Check your fibers and clean them properly for optimum performance

(see Cleaning and Connecting Optical Fibers on page 22).

3. Using one of the following methods, connect a light source to the

power meter port of your unit.

One single reference patchcord

Two reference patchcords and a bulkhead adapter

4. Activate the source at the desired wavelength.

5. Match the power meter wavelength with the

source wavelength as follows:

Press Wave l e n g t h (F1/F2 key) to switch

between favorite wavelengths of your

power meter (see Defining the List of

Favorite Wavelengths on page 30).

OR

If the source emits an auto-wavelength signal and auto-detection is

enabled (see Automatically Detecting Wavelength on page 39), the

power meter automatically matches the source wavelength.

34 FOT-930

Page 43

Measuring Power or Loss

Referencing Your Power Meter to a Source

6. Press W/dBm/dB (F1/F2 key) until you get

dB units to retrieve the last saved reference.

OR

Press Reference (F1/F2 key) to save the

current power as the new reference.

Reference power appears (in dBm) and

current loss is automatically switched to dB.

7. Repeat the procedure for each wavelength you want to reference.

To receive the reference value from a compatible source:

1. Connect the source to your power meter (with or without a fiber under

test).

2. Use the source to emit the special signal that contains its power value.

For more information, refer to the source’s user guide.

When it detects the special signal, the power meter beeps. The

new reference power is displayed (in dBm) and current loss

reading is automatically switched to dB.

You cannot change the power meter wavelength, units or

reference power manually.

Multifunction Loss Tester 35

Page 44

Measuring Power or Loss

Measuring Power or Loss

Measuring Power or Loss

Measuring absolute power or link loss is done the same way, except for the

referencing step. You can take power or loss measurements and save them

for further analysis.

Connect high-power live fiber to the power meter port only.

To perform power or loss measurements:

1. If necessary, perform an offset nulling (see Nulling Electrical Offsets on

page 32).

2. Press Menu, then select Power Meter.

3. Check your fibers and clean them properly (see Cleaning and

Connecting Optical Fibers on page 22).

4. For loss measurements, reference your power meter to a light source

(see Referencing Your Power Meter to a Source on page 33), then

deactivate the light source.

CAUTION

5. If you have used a single reference patchcord, disconnect it from the

power meter port only, then attach a second reference patchcord to

the power meter.

OR

If you have used two reference patchcords, disconnect both of them at

the bulkhead.

36 FOT-930

Page 45

Measuring Power or Loss

Light

source

Power

meter

Adapter

Reference

patchcord

Fiber

under test

Reference

patchcord

Bulkhead

adapter

Bulkhead

adapter

Measuring Power or Loss

6. Using bulkhead adapters or the system patch panels, connect a fiber

under test to reference patchcords attached to the light source and

power meter.

7. Activate the source at the desired wavelength.

8. Match the power meter wavelength with the source wavelength as

follows:

Press Wave l e n g t h (F1/F2 key) to switch between favorite

wavelengths of your power meter (see Defining the List of Favorite

Wavelengths on page 30).

OR

If the source emits an auto-wavelength signal and auto-detection is

enabled (see Automatically Detecting Wavelength on page 39), the

power meter automatically matches the source wavelength.

If the unit detects a modulated signal, it beeps and the signal frequency

is indicated in the status bar, next to a yellow LED: 2k indicates a 2-kHz

signal, 1k a 1-kHz signal, and 270 a 270-Hz signal.

9. Press W/dBm/dB (F1/F2 key) to select the desired power (W or dBm)

or loss (dB) unit.

Multifunction Loss Tester 37

Page 46

Measuring Power or Loss

Measuring Power or Loss

10. Save the displayed values, if desired.

10a.Change the displayed cable and fiber

names as needed.

10b.Press Store (F1/F2 key) to save the

value along with wavelength, reference

power, date and time. The fiber name

will increment automatically, ready to save the next value.

For details about viewing results, see Managing Test Results on

page 55.

11. Repeat the procedure for other wavelengths.

38 FOT-930

Page 47

Measuring Power or Loss

Automatically Detecting Wavelength

Automatically Detecting Wavelength

Compatible sources (such as FOT-930, FOT-300 and FLS-300) can transmit

their wavelength values through the fiber, avoiding the need to manually

match the source and power meter wavelengths.

Note: When receiving an auto-wavelength (or Auto-ID) signal, you cannot

manually change the power meter wavelength.

To receive an auto-wavelength signal from a source:

1. Press Menu, then select Setup > Power

Meter.

OR

From the Power Meter pane, press Setup

(F1/F2 key).

2. Use the arrows to select Automatic

wavelength detection, then press Enter.

3. Connect a compatible source to your unit’s power meter port.

4. Activate the source in Auto-ID mode (FOT-930: see Using a Light

Source on page 59).

Your power meter automatically matches the source wavelength.

Multifunction Loss Tester 39

Page 48

Page 49

7 Measuring Optical Return Loss

ORL meter port

Open lists to change cable/fiber

name of next saved data.

Press Store to save current ORL

value under displayed name.

Measured ORL

(positive value)

Current ORL wavelength

Open list or press Wavelength

to switch between singlemode

wavelengths.

Press ORL Zero to calibrate

the ORL meter sensitivity.

Press Default ORL Zero to revert to

factory-default sensitivity.

Press ORL Reference to set reference

using ORL calibrated patchcord (best).

Press Loopback Ref. to use

any other patchcord.

Optical return loss (ORL) is the total effect of multiple reflections and

scattering events within a fiber-optic system.

The FOT-930 Multifunction Loss Tester is equipped with an ORL meter to

measure ORL for singlemode fibers. The ORL meter uses the F

(singlemode) port only.

The following functions are available on your ORL meter:

ASTEST SM

Multifunction Loss Tester 41

Page 50

Measuring Optical Return Loss

Set

ORL zero

Measure

ORL

Save

results

Perform

ORL reference

Set up thresholds

(see page 26)

Null offsets

(see page 32)

Select

wavelength

Termination Component

under test

Performing ORL Reference and Setting ORL Zero Value

The ORL measurement procedure is outlined below:

Performing ORL Reference and Setting ORL

Zero Value

The ORL zero measurement eliminates the effects of backreflection on the

link before the component under test, so your unit displays only the

backreflection of this component.

You should set a new ORL zero:

when you change the measurement patchcord (the one connected to

the DUT, not the reference patchcord)

when you remove a connection between the unit and mandrel

To set the ORL zero value (all wavelengths at once):

1. Press Menu, then select ORL Meter.

2. Press ORL Zero (F1/F2 key).

3. Connect a patchcord to the F

42 FOT-930

ASTEST SM port.

Page 51

Measuring Optical Return Loss

Per f orming and S aving ORL Measurements

4. Terminate the fiber as close as possible before the component under

test. Wrap it at least 10 turns around a mandrel or small diameter tool,

adding turns until the reading stabilizes.

5. Press OK to save the ORL zero value, then remove the termination.

To revert to the factory-default ORL zero value:

1. Press Menu, then select ORL Meter.

2. Press Default ORL Zero (F1/F2 key).

Performing and Saving ORL Measurements

You can define ORL thresholds (see Setting Pass/Fail Thresholds on

page 26) before or after measuring ORL. ORL values below thresholds are

displayed in red.

To m ea s ur e O R L:

1. If necessary, perform an offset nulling (see Nulling Electrical Offsets on

page 32).

2. Press Menu, then select ORL Meter.

3. Press Wavelength (F1/F2 key) to select a singlemode wavelength.

4. Verify your patchcords and clean them properly (see Cleaning and

Connecting Optical Fibers on page 22).

Note: If the F

EXFO’s optional ORL calibrated patchcord.

Multifunction Loss Tester 43

ASTEST SM port of your unit is equipped with an APC connector, use

Page 52

Measuring Optical Return Loss

Performing and Saving ORL Measurements

5. Connect one end of a patchcord to the FASTEST SM port of your unit

leaving the other end unconnected.

6. Perform an ORL reference as follows:

Note: During the reference, the patchcord end should remain in the air;

reflections occurring at a fiber-to-air interface correspond to a constant of

14.7 dB.

Use the left/right function arrows to display

ORL Reference and press the F1 or F2 key

to select it.

In the ORL Reference message box, press

OK (Enter).

44 FOT-930

Page 53

Measuring Optical Return Loss

Te rm i n at i o nComponent

under test

Per f orming and S aving ORL Measurements

7. Pe rfor m an ORL zero measurement (see Performing ORL Reference

and Setting ORL Zero Value on page 42).

8. Terminate the fiber as close as possible after the component under

test. Wrap it at least 10 turns around a mandrel or small diameter tool,

adding turns until the reading stabilizes.

Note: Avoid bending the fiber between the unit and the termination point.

The displayed value represents the ORL of the component under test.

9. Save the displayed values, if desired.

9a. Change the displayed cable and fiber

names as needed.

9b. Press Store (F1/F2 key) to save the

value along with wavelength, date and

time. The fiber name will increment

automatically, ready to save the next value.

For details about viewing results, see Managing Test Results on

page 55.

10. Repeat procedure for other wavelengths if necessary.

Multifunction Loss Tester 45

Page 54

Page 55

8 Performing Automated

FASTEST singlemode (SM) and

multimode (MM) ports

Perform

F

ASTEST

Perform

reference

Save

results

Set ORL zero

(see page 42)

Null offsets

(see page 32)

Set up

F

ASTEST

Set up thresholds

(see page 26)

IL/ORL/Length Measurements

ASTEST)

(F

FASTEST allows you to perform 2- or 3-wavelength bidirectional loss and

ORL tests for singlemode fibers, or 2-wavelength loss tests for multimode

fibers, in 10 seconds (including fiber length measurement).

F

ASTEST is useful in high-fiber-count installations. Activated at the touch of a

button, F

ASTEST cuts down on training time and provides error-free results.

To use F

ASTEST, you need a compatible unit (such as FTB-3930, FOT-930,

FOT-920 or FTB-3920, but not the FOT-910). The unit at the remote end is

only used to establish references. It then waits for commands from the unit

initiating F

The F

ASTEST (master).

ASTEST procedure is outlined below:

Multifunction Loss Tester 47

Page 56

Performing Automated IL/ORL/Length Measurements (FASTEST)

(standard wavelengths)

(FTTx wavelengths)

Setting Up the FASTEST

Setting Up the FASTEST

You can configure the FASTEST on the master unit only. The remote unit will

automatically adapt to these parameters (F

unit are ignored).

Setup includes the following elements:

Port and DUT (fiber) type: multimode

F

ASTEST will not include ORL.

Compatibility: select FOT-930 for fast, two-

or three-wavelength testing including ORL (it

requires two FOT-930/FTB-3930). Use

FOT-920 when other unit is an FOT-920 or

FTB-3920.

Length units: affects thresholds and fiber length only.

Mode/wavelengths: select one or more wavelengths for the FASTEST.

Depending on your choice, the F

measurements. Selecting FTTx Custom or FTTx All allows you to

define upstream and downstream wavelengths.

ASTEST parameters on remote

ASTEST will include loss and/or ORL

Automatic saving of results: select where results are automatically

stored (remote saving not available with FOT-920). Fiber name

automatically increments after each F

Unit location: in FTTx mode, you specify if the master unit is closer to

ASTEST.

the CO (or to the premises) than the remote unit.

To set up the F

ASTEST:

1. Press Menu, then select Setup > FasTesT.

2. Select the F

48 FOT-930

ASTEST parameters.

Page 57

Performing Automated IL/ORL/Length Measurements (FASTES T)

System

under test

Connector

mating

Connector

mating

System

under test

Connector

mating

Referencing Units for FASTEST

Referencing Units for FASTEST

Referencing subtracts the loss caused by the test setup components from

the overall loss measured during F

loss inserted by the system under test alone.

Two referencing methods are available:

Side-by-Side Method (Best) Loopback Method

ASTEST. The final result represents the

Description Reference taken with both units

together using their F

ASTEST ports.

Slightly more accurate value than

Reference taken separately on

each unit (F

ASTEST port connected

to power meter port).

loopback method.

Location of units Must be at same location. Can be at different locations.

Loss included in

F

ASTEST result

Elements to

consider

Loss due to system under test and

one connector mating.

Includes neither an ORL

reference nor an ORL zero

measurement. To obtain them,

use the ORL Meter pane (see

Performing ORL Reference and

Loss due to system under test and

the two connector matings.

When measuring ORL (F

ASTEST or

ORL meter), accounts for

connector loss and adjusts ORL

calibration accordingly.

Not recommended for short links.

Setting ORL Zero Value on

page 42).

With multiple referencing, you

may coordinate an FTB-3930 with

up to 10 FOT-930 units.

Multifunction Loss Tester 49

Page 58

Performing Automated IL/ORL/Length Measurements (FASTEST)

Reference

patchcord

Bulkhead

adapter

Reference

patchcord

Referencing Units for FASTEST

To perform a side-by-side reference:

1. On the master unit (the one initiating the

test), press F

ASTEST.

2. In the Ref. Type list, select the Side-by-side

reference type, then press Enter. An

illustration of the connection is shown with

previous reference values (if any).

3. Connect both units through their F

ASTEST ports, using two reference

patchcords and a bulkhead adapter.

4. Press Take Reference (F1/F2 key). After a few seconds, the unit

displays new reference values for each wavelength on both units. If

values are not acceptable, try to clean connectors and repeat this step.

5. Disconnect the two patchcords from the bulkhead only and connect

them to the fiber under test (using bulkhead adapters or the system

patch panels).

IMPORTANT

You can turn off the unit without losing the reference.

If you disconnect the patchcords from the FASTEST ports, you

must take a new reference.

50 FOT-930

Page 59

Performing Automated IL/ORL/Length Measurements (FASTES T)

Reference

patchcord

Adapter

Referencing Units for FASTEST

To perform a loopback reference:

1. Press F

ASTEST.

2. In the Ref. Type list, select the Loopback

reference type, then press Enter. An

illustration of the connection is shown with

previous reference values (if any).

3. Connect a reference patchcord from the F

ASTEST

port to the power meter adapter.

4. Press Take Reference (F1/F2 key). After a few

seconds, the unit displays new reference values

for each wavelength. If values are not acceptable,

try to clean connectors and repeat this step.

5. Disconnect the reference patchcord from the

power meter adapter only and connect it to the fiber under test.

IMPORTANT

You can turn off the unit without losing the reference.

If you disconnect the patchcord from the FASTEST port, you must

take a new reference.

6. Repeat the procedure with the second unit.

Multifunction Loss Tester 51

Page 60

Performing Automated IL/ORL/Length Measurements (FASTEST)

Reference

patchcord

Fiber

under test

Reference

patchcord

Bulkhead

adapter

Bulkhead

adapter

Per for ming th e FASTEST

Performing the FASTEST

Although FASTEST requires two units (one at each end of the fiber under

test), you initiate it from only one (the master). Both units use F

settings from the master unit.

ASTEST

To p er f or m a F

Unit A (Master) Unit B

ASTEST:

1. If necessary, null the offsets (see

Nulling Electrical Offsets on page 32).

2. Clean your fibers properly (see

Cleaning and Connecting Optical

Fibers on page 22).

3. Set up the F

ASTEST (see Setting Up the

FasTesT on page 48).

4. If you are testing ORL, perform an

ORL zero measurement from the ORL

Meter pane (see Performing ORL

Reference and Setting ORL Zero Value

on page 42).

5. Reference your unit (see Referencing

Units for FasTesT on page 49).

6. Connect reference patchcord to fiber

under test (as shown):

1. If necessary, null the offsets.

2. Clean your fibers properly.

3. If you are testing ORL, perform an

ORL zero measurement from the ORL

Meter pane.

4. Reference your unit.

5. Connect reference patchcord to fiber

under test (as shown):

52 FOT-930

Page 61

Performing Automated IL/ORL/Length Measurements (FASTES T)

Open lists to select cable/fiber

name for data to be saved.

Press Store to save results under

displayed name.

Press Next Tab to switch

to next result type.

Red/exclamation mark indicates

result that exceeds threshold.

Disk icon would indicate

unsaved results.

Press Setup to modify

F

ASTEST parameters.

(FTTx view)

Performing the FASTEST

Unit A (Master) Unit B

7. From the F

ASTEST pane, set the next

cable/fiber names as needed (used

for automatic save).

8. Press the F

ASTEST key or press Start

Test (F1/F2 key).

The units establish communication and automated tests begin. Measurements

appear on both units as they are taken.

9. Save the displayed values if you want.

If Auto save was activated for one or

both units, results are already saved.

9a. Change the displayed cable and

fiber names as needed.

9b. Press Store (F1/F2 key) to save

the values. The fiber name

increments automatically, ready

to save the next value.

If you are not satisfied with the results,

press F

For details about viewing FASTEST results, see Managing Test Results on page 55.

Multifunction Loss Tester 53

ASTEST and redo the test.

Page 62

Page 63

9 Managing Test Results

Open lists to select cable/fiber name

of data to recall.

Press Next Fiber or Next Cable to

switch between available results.

Press Next Tab to switch

to next result type.

Red/exclamation mark indicates

result that exceeds threshold.

Press Delete Fiber or Delete Cable to

remove data from list.

Press Delete All Cables to free

memory.

(standard view)

Viewing and Deleting Results

You can save up to 1024 results (FASTEST, power/loss and ORL) in your unit,

along with references and date/time of tests. You will save and recall this

data according to cable and fiber names.

IMPORTANT

The date and time of FASTEST references are not saved. They are

displayed with the results immediately after the test only.

To view and process test results:

Press Menu, then select Results/Information > Cable Results. The

following functions are available when viewing results:

IMPORTANT

You cannot recover deleted results. Ensure that you transfer

your data to a computer if you intend to use it later.

Deleting a single cable/fiber does not free memory. To free

memory, you must delete all cables at once.

Note: For more accuracy, the average is always calculated from loss values in W

and then converted to dB.

Multifunction Loss Tester 55

Page 64

Managing Test Results

Serial port

(male DB9)

RS-232

connector

Checking Available Memory

Checking Available Memory

You can save up to 1024 results in the unit memory.

To view the available memory on your unit:

Press Menu, then select Results/Information > Unit Info.

Transferring Test Results to a Computer

Using an appropriate serial cable and the Handheld Data Transfer software,

you can transfer results from your handheld unit to a computer or FTB-500.

This way, you can increase storage capacity, perform better analyses on

test results and create reports.

Transferred files are not automatically deleted from your unit.

To transfer test results to a computer:

1. Using the serial cable, connect your unit to an available COM port of

the computer.

IMPORTANT

Note: If your computer is not equipped with an RS-232 port, you can use a USB

adapter. After installing the proper drivers, your computer should associate

the adapter to an available COM port.

56 FOT-930

Page 65

Managing Test Results

Transferring Test Results to a Computer

2. Turn on both the computer and your handheld unit. Ensure that your

unit will remain on during the transfer (connect it to a power outlet and

deactivate auto-off).

3. On the computer, launch the Handheld Data Transfer application and

start the operation.

Note: For details about setting up the software and transferring data, refer to the

Handheld Data Transfer online help.

Multifunction Loss Tester 57

Page 66

Page 67

10 Using a Light Source

Source singlemode (SM) and

multimode (MM) ports

Your unit may contain two source ports: a 2- or 3-wavelength singlemode

port and a 2-wavelength multimode port, depending on the configuration

(see Technical Specifications on page 93).

The source signal can be continuous (CW or high-power) or modulated

(270 Hz, 1 kHz or 2 kHz) and uses the F

CW signal (the default): constant power over the temperature range,

but about 3 dB lower than maximum.

High-power signal: reaches maximum power, but its power slightly

varies over the temperature range.

A special Auto ID signal can transmit its wavelength value, to facilitate

wavelength detection by a compatible unit.

WARNING

When a source is active, its port emits invisible laser radiation.

Avoid exposure and do not stare directly into the beam. Ensure that

any unused port is properly protected with a cap.

ASTEST ports.

The Power Meter pane remains displayed

when you use the source.

If you switch to power meter or VFL while a

source is active, the Source pane remains

displayed.

When you switch sources, the modulation

remains the same. It is indicated in the Source pane.

Multifunction Loss Tester 59

Page 68

Using a Light Source

Only one source/wavelength may be active at a time. The active port

(SM or MM) is indicated in the Source pane.

The source status is indicated with a LED in the status bar and with the

Active indicator under the keypad.

Note: The Active indicator always shows the source, VFL, ORL meter or talk set

port status (even in FIP or idle mode).

To activate a light source:

1. Connect the fiber under test to the source port (see Cleaning and

Connecting Optical Fibers on page 22).

2. Press Menu, then select Source/VFL > Source (units with a VFL) or

Source (units with no VFL).

3. Press Wavelength (F1/F2 key) to activate each available source in turn.

OR

Use the arrows to open the wavelength/status list and select the

desired wavelength.

To deactivate a light source:

Press Wave l e n g t h (F1/F2 key) until you get past the last source. The list

displays Off.

OR

Use the arrows to open the wavelength list and select Off.

To change the signal modulation:

1. Activate the source if you want.

2. Press Modulation (F1/F2 key) to switch

between available modulations.

OR

3. Use the arrows to open the list and select the

desired modulation.

60 FOT-930

Page 69

11 Identifying Fiber Faults

Visually

The visual fault locator (VFL) helps you identify bends, faulty connectors,

splices and other causes of signal loss.

From its dedicated port, the VFL emits a red signal which becomes visible

at the location of a fault on the fiber. This signal can be continuous

(CW, the default) or blinking (1 Hz).

WARNING

When the VFL is active, the VFL port emits visible laser radiation.

Avoid exposure and do not stare directly into the beam. Ensure that

any unused port is properly protected with a cap.

The Power Meter pane remains displayed

when you use the VFL.

If you switch to source or power meter while

the VFL is active, the VFL pane remains

displayed.

The VFL status is indicated with a LED in the

status bar and with the Active indicator under the keypad.

Note: The Active indicator always shows the source, VFL, ORL meter or talk set

port status (even in FIP or idle mode).

Multifunction Loss Tester 61

Page 70

Identifying Fiber Faults Visually

The red light indicates

that the VFL is on.

To activate the VFL and inspect a fiber:

1. Connect the fiber under test to the VFL port

(see Cleaning and Connecting Optical Fibers

on page 22).

2. Press Menu, then select Source/VFL > VFL.

3. Press VFL On/Off (F1/F2 key) to activate the VFL (list displays On).

OR

Use the arrows to open the VFL status list and select On.

4. To switch between blinking (1 Hz) and continuous (CW) signals, press

Modulation (F1/F2 key).

OR

Use the arrows to open the list and select the desired modulation.

5. Without looking directly into the beam, examine the fiber. If light is

coming out of the rubber jacket or on the side of the ferrule, the fiber is

defective.

6. Deactivate the VFL by pressing VFL On/Off (F1/F2 key).

62 FOT-930

Page 71

12 Inspecting Fibers with the FIP

The fiber inspection probe allows you to find dirty or damaged connectors

by displaying an enlarged view of the connector surface.

The following common features of video fiber inspection probes are

compatible with your unit:

Magnification control: supports 200x, 400x or other zoom factors.

Focus control: allows you to fine-tune the display quality.

Image capture: freezes the image on the FOT-930 display by pressing a

button.

For more information, refer to the user guide that came with your probe.

IMPORTANT

When another unit requests a FASTEST with your unit, the FASTEST

takes over and Probe mode is interrupted.

You cannot receive text messages or talk set calls while using

Probe mode.

To access Probe mode on your unit:

1. Connect the probe to the right side of the unit, using an adapter if

necessary.

2. Activate the probe display using one of the following:

Press Menu, then select Probe.

Press the button on the probe (some models only).

To adjust brightness or contrast:

Brightness: use up/down arrows.

Contrast: use left/right arrows.

To exit Probe mode and return to the regular display:

Press Esc or Menu.

Multifunction Loss Tester 63

Page 72

Page 73

13 Communicating with Other

Users

Your Multifunction Loss Tester offers two ways to communicate:

text messages

voice (via the optional talk set)

Sending and Receiving Text Messages

To facilitate communication between opposite ends of a fiber (especially

on models with no talk set), you may send text messages to compatible

units (such as FOT-930, FTB-3930, FOT-920 or FTB-3920) through their

F

ASTEST ports.

It is possible to send a predefined message or to write one of your own

(maximum 30 characters). However, custom messages are deleted when

you turn the unit off.

IMPORTANT

The messaging feature does not work with the talk set port.

The messaging feature will not work if both units try to send a

message at the same time.

You cannot use other features while sending or receiving a

message.

You cannot cancel the operation.

Multifunction Loss Tester 65

Page 74

Communicating with Other Users

Sending and Receiving Text Messages

To add a custom text message to the list:

1. Press Menu, then select

Talk Set/Messages > Messages (units with a

talk set) or Messages (units with no talk set).

2. Using the up/down arrows, scroll through the

list and select a message to use as a basis.

3. Press New Message (F1/F2 key).

4. Enter or change the message text using the on-screen keyboard and

press OK (F1/F2 key). The message is added to the list.

To send a text message:

1. Connect the units at each end of the same fiber via their F

2. On the sending unit, press Menu, then select

Talk Set/Messages > Messages (units with a

talk set) or Messages (units with no talk set).

ASTEST ports.

66 FOT-930

Page 75

Communicating with Other Users

Sending and Receiving Text Messages

3. Ensure that the port indicated (SM or MM) is the one you use.

Otherwise, press Port Setup (F1/F2 key) and change it, then return to

the Messages pane.

4. Using the up/down arrows, scroll through the list and select the

message.

5. Press Send (F1/F2 key).

After a few seconds, your message will automatically appear on the

receiving unit. If an incompatible unit (or no unit) is detected at the other

end, or if the F

ASTEST port of the receiving unit is in use, an error message

will appear.

When you receive a message:

Your unit emits a short beep and displays the received message.

Press OK to clear the display and return to your previous function.

Press Reply to access the Messages pane and reply to the message.

You will then need to use the menu to return to your previous function.

However, your last readings will be lost.

Note: If the message was written with a language not supported by your unit, you

will see unreadable characters only.

Multifunction Loss Tester 67

Page 76

Communicating with Other Users

Tal k s e t po r t

Communicating by Voice

Communicating by Voice

With the optional talk set, you can establish full-duplex digital voice

communication over a dedicated fiber, even while other functions are in

use.

The talk set provides adjustable headset volume and uses a dedicated port.

It is not compatible with the FOT-920 or FTB-3920 talk sets.

Note: You may use any commercially available headset equipped with a

microphone.

While communication is established, the actions and displays of

each unit may differ as follows:

You can send or receive a call at any time, except during a FASTEST.

Once communication is established, it will be maintained even if you

use the unit’s other test tools (including F

If communication is lost, calling unit will automatically try to

ASTEST).

reestablish communication.

68 FOT-930

Page 77

Communicating with Other Users

Communicating by Voice