Page 1

CD/PMD ANALYZER SOURCE

R&D AND MANUFACTURING

FLS-5834A

USER GUIDE

Page 2

Copyright © 2003–2007 EXFO Electro-Optical Engineering Inc. All rights

reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted in any form, be it electronically,

mechanically, or by any other means such as photocopying, recording or

otherwise, without the prior written permission of EXFO Electro-Optical

Engineering Inc. (EXFO).

Information provided by EXFO is believed to be accurate and reliable.

However, no responsibility is assumed by EXFO for its use nor for any

infringements of patents or other rights of third parties that may result from

its use. No license is granted by implication or otherwise under any patent

rights of EXFO.

EXFO’s Commerce And Government Entities (CAGE) code under the North

Atlantic Treaty Organization (NATO) is 0L8C3.

The information contained in this publication is subject to change without

notice.

Trademarks

EXFO’s trademarks have been identified as such. However, the presence

or absence of such identification does not affect the legal status of any

trademark.

Units of Measurement

Units of measurement in this publication conform to SI standards and

practices.

Patents

EXFO’s Universal Interface is protected by US patent 6,612,750.

Version number 2.0.0.

ii FLS-5834A

Page 3

Contents

Contents

Certification Information ........................................................................................................v

1 Introducing the FLS-5834A CD/PMD Analyzer Source ................................ 1

Front Panel .............................................................................................................................1

Back Panel ..............................................................................................................................2

FLS-5834A Compatibility ........................................................................................................2

Conventions ............................................................................................................................3

2 Safety Information ....................................................................................... 5

LED Safety Information ...........................................................................................................5

Electrical Safety Information ...................................................................................................6

3 Getting Started with Your Light Source ..................................................... 9

Turning On and Off the CD/PMD Analyzer Source ...................................................................9

FLS-5834A CD/PMD Analyzer Source Display ........................................................................10

4 Setting CD/PMD Analyzer Source Parameters .......................................... 11

Setting the Refresh Rate .......................................................................................................12

Setting the Backlight ............................................................................................................13

Setting the Contrast .............................................................................................................13

Setting the Video Mode ........................................................................................................14

Resetting the CD/PMD Analyzer Source ................................................................................15

5 Operating the CD/PMD Analyzer Source ................................................... 17

Cleaning and Connecting Optical Fibers ...............................................................................17

Installing the EXFO Universal Interface (EUI) .........................................................................18

Activating or Deactivating the Source ...................................................................................19

6 Controlling the Source Remotely .............................................................. 21

Setting the Remote Command Mode ...................................................................................23

Setting the GPIB Address ......................................................................................................24

Setting the Baud Rate ...........................................................................................................25

Setting the Flow Control .......................................................................................................26

Communication Parameters ..................................................................................................27

Standard Status Data Structure ............................................................................................28

Command Structure .............................................................................................................33

Error Messages Format .........................................................................................................34

CD/PMD Analyzer Source iii

Page 4

Contents

7 Maintenance ................................................................................................35

Cleaning EUI Connectors ......................................................................................................36

Replacing Fuses ....................................................................................................................38

Recalibrating the Unit ...........................................................................................................39

Upgrading the Embedded Software .....................................................................................40

Recycling and Disposal (Applies to European Union Only) ....................................................42

8 Troubleshooting ..........................................................................................43

CD/PMD Analyzer Source Error Messages .............................................................................43

GPIB Troubleshooting ...........................................................................................................47

Finding Information on the EXFO Web Site ..........................................................................48

Contacting the Technical Support Group ..............................................................................49

Transportation ......................................................................................................................50

9 Warranty ......................................................................................................51

General Information .............................................................................................................51

Liability .................................................................................................................................52

Exclusions .............................................................................................................................52

Certification ..........................................................................................................................52

Service and Repairs ...............................................................................................................53

EXFO Service Centers Worldwide ..........................................................................................54

A Technical Specifications ..............................................................................55

B Rackmount Installation ..............................................................................57

C Remote Control Commands .......................................................................59

IEEE 488.2 Commands—Quick Reference .............................................................................59

IEEE 488.2 Commands—Description ....................................................................................60

Product-Specific Commands—Quick Reference ....................................................................81

Product-Specific Commands-Description ..............................................................................82

D SCPI-Based Errors ........................................................................................85

Index .................................................................................................................87

iv FLS-5834A

Page 5

Certification Information

Certification Information

F.C.C. Information

Electronic test equipment is exempt from Part 15 compliance (FCC) in

the United States. However, compliance verification tests are

systematically performed on most EXFO equipment.

Information

Electronic test equipment is subject to the EMC Directive in the European

Union. The EN61326 standard prescribes both emission and immunity

requirements for laboratory, measurement, and control equipment.

This unit has undergone extensive testing according to the European Union

Directive and Standards.

CSA Information

This unit is certified by the CSA (certificate number 162451) and was

evaluated according to applicable CSA and UL standards (as confirmed by

“C-US” mark) as well as applicable IEC standards for use in Canada, the

United States, and other countries.

CD/PMD Analyzer Source v

Page 6

Certification Information

DECLARATION OF CONFORMITY

Application of Council Directive(s): 73/23/EEC - The Low Voltage Directive

Manufacturer’s Name: EXFO ELECTRO-OPTICAL ENG.

Manufacturer’s Address: 400 Godin Avenue

Equipment Type/Environment: Light Industrial Scientific Equipment

Trade Name/Model No.: FLS-5800 Modulated Broadband Light Source

Standard(s) to which Conformity is Declared:

EN 61010-1:2001 Safety Requirements for Electrical Equipment for Measurement, Control,

EN 60825-1:1994 / A2: 2001 Safety of laser products – Part 1: Equipment classifications, requirements,

EN 61326:1997/ A3: 2003 Electrical Equipment for Measurement, Control and Laboratory

EN 55022: 1998/ A2: 2003 Limits and Methods of Measurement of Radio Disturbance Characteristics

I, the undersigned, hereby declare that the equipment specified above conforms to the above Directive and Standards.

Manufacturer

Signature:

and Laboratory Use, Part 1: General Requirements.

and user’s guide

Use - EMC Requirements

of Information Technology Equipment.

89/336/EEC - The EMC Directive

Quebec, Quebec

Canada G1M 2K2

(418) 683-0211

Full Name: Stephen Bull, E. Eng

Position: Vice-President Research and

Address: 400 Godin Avenue Quebec, Quebec,

Date: February 25, 2002

Development

Canada

vi FLS-5834A

Page 7

1 Introducing the FLS-5834A

CD/PMD Analyzer Source

The FLS-5834A CD/PMD Analyzer Source is a modulated, polarized

broadband fiber-optic source that has been especially designed to be used

with EXFO FTB-5800 Chromatic Dispersion Analyzer.

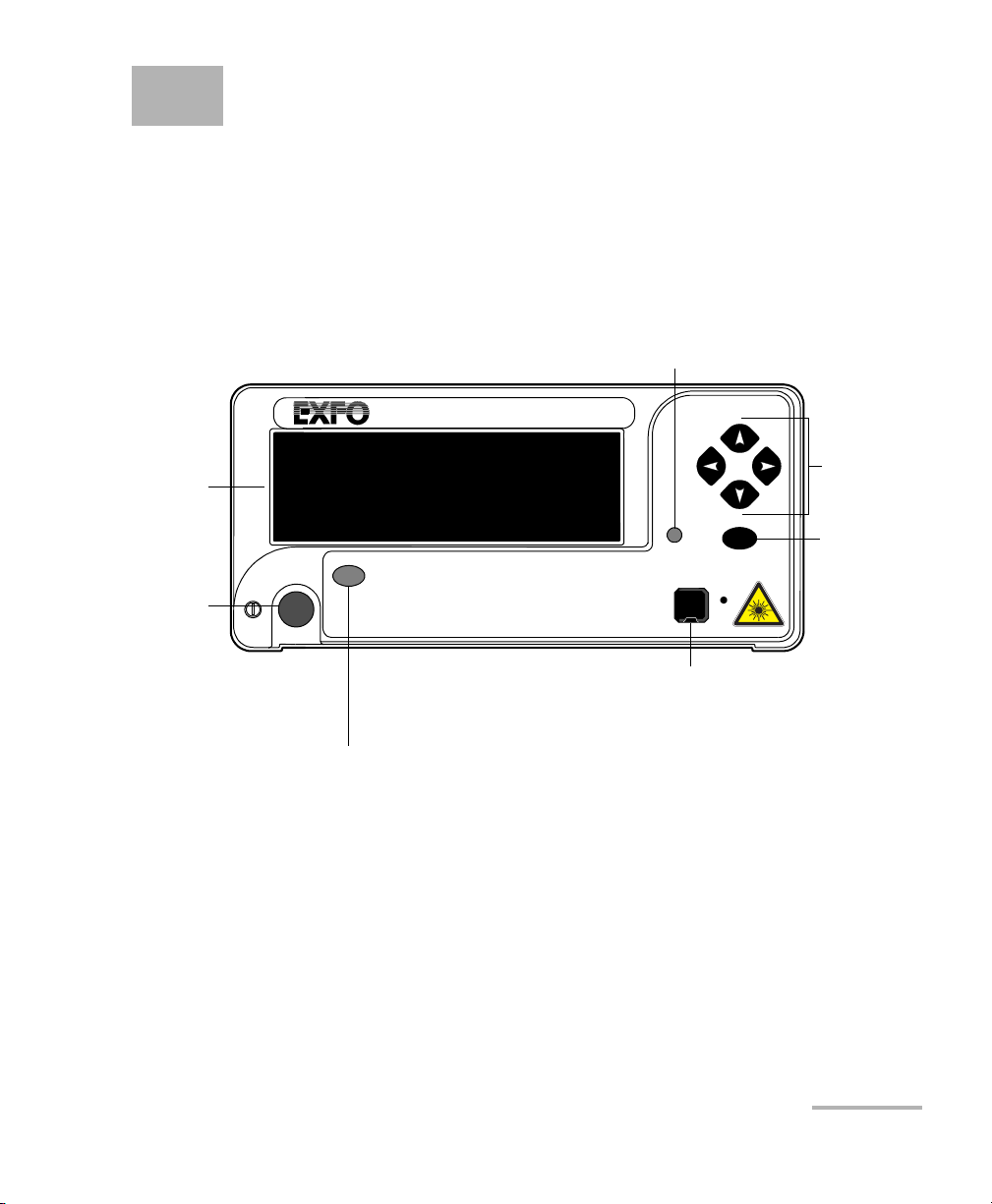

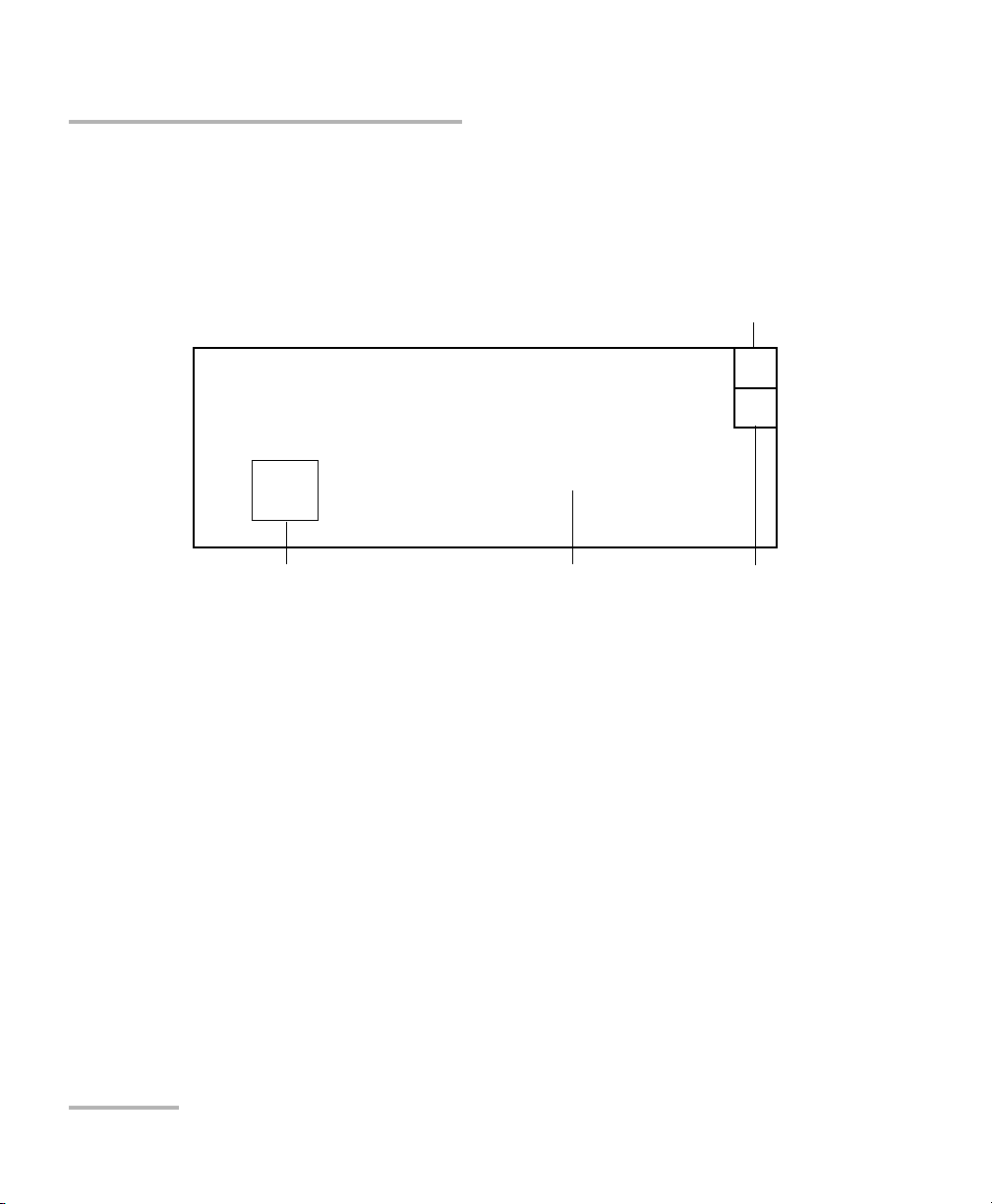

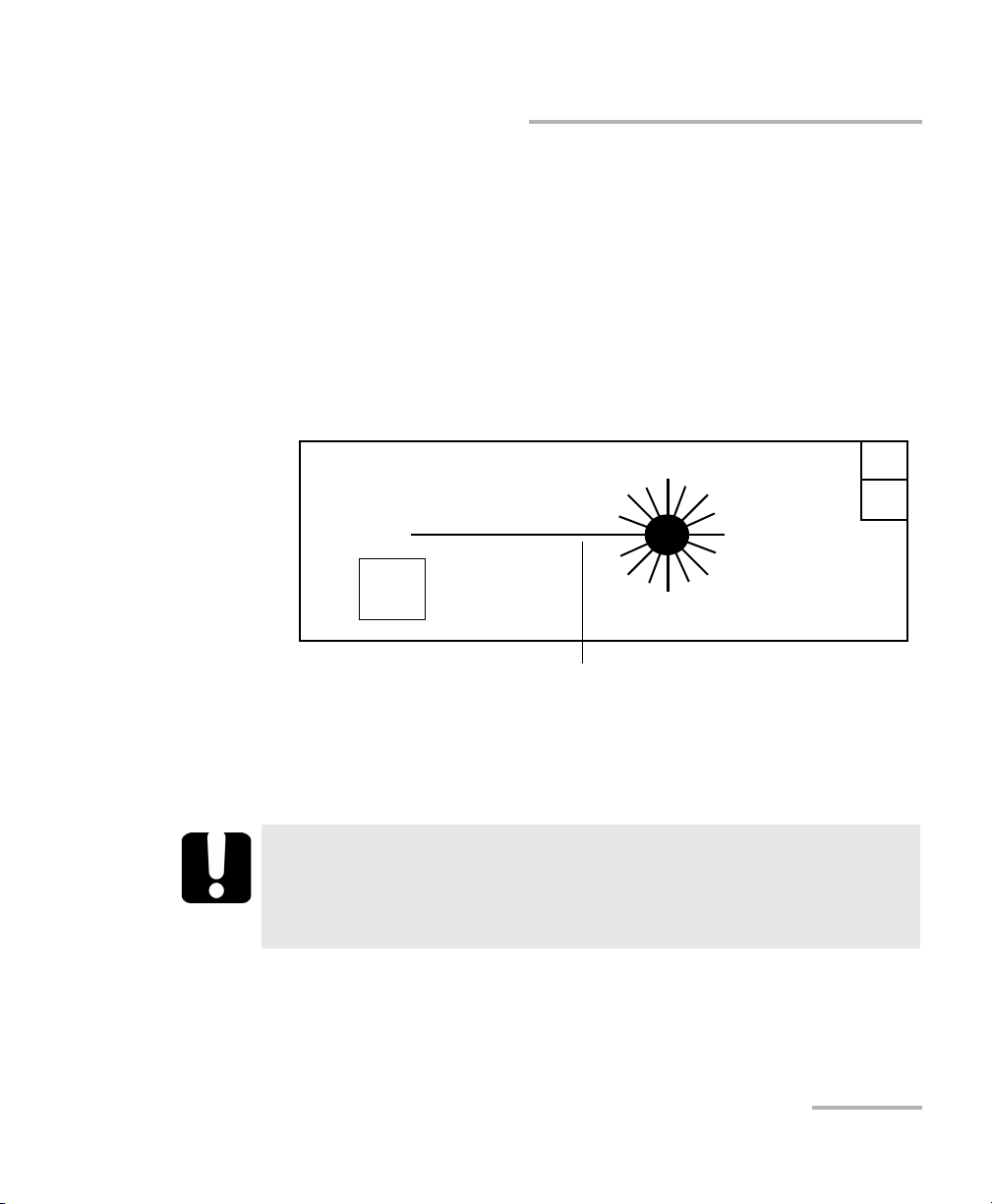

Front Panel

Setup menu access

Display

Turn

unit

ON/OFF

FLS-5834A

On/Off

Source activation/deactivation

button

CD/PMD ANALYZER SOURCE

Setup

Out

Active

Output port

ENTER

Navigation

keys

Confirmation

key

CD/PMD Analyzer Source 1

Page 8

Introducing the FLS-5834A CD/PMD Analyzer Source

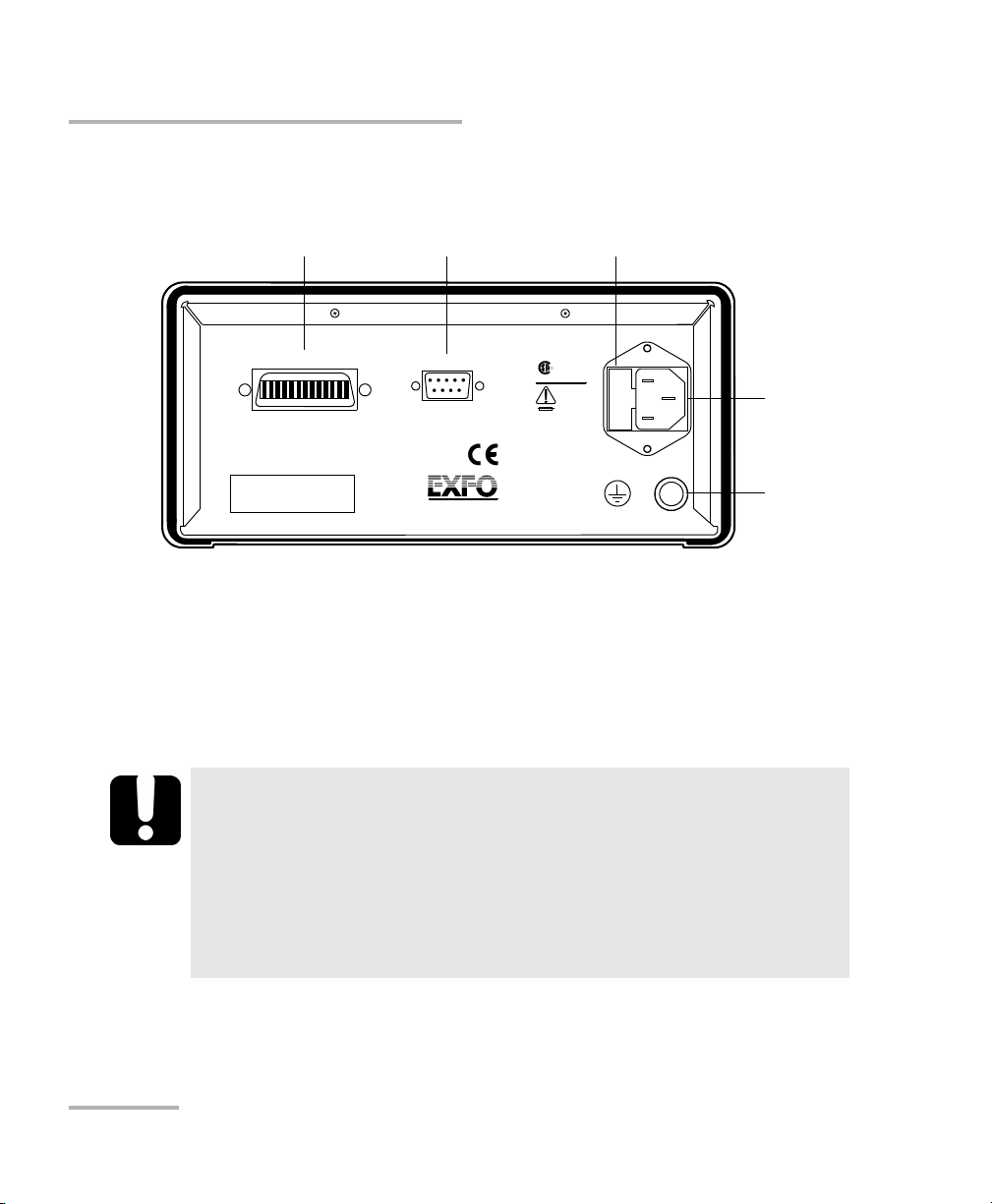

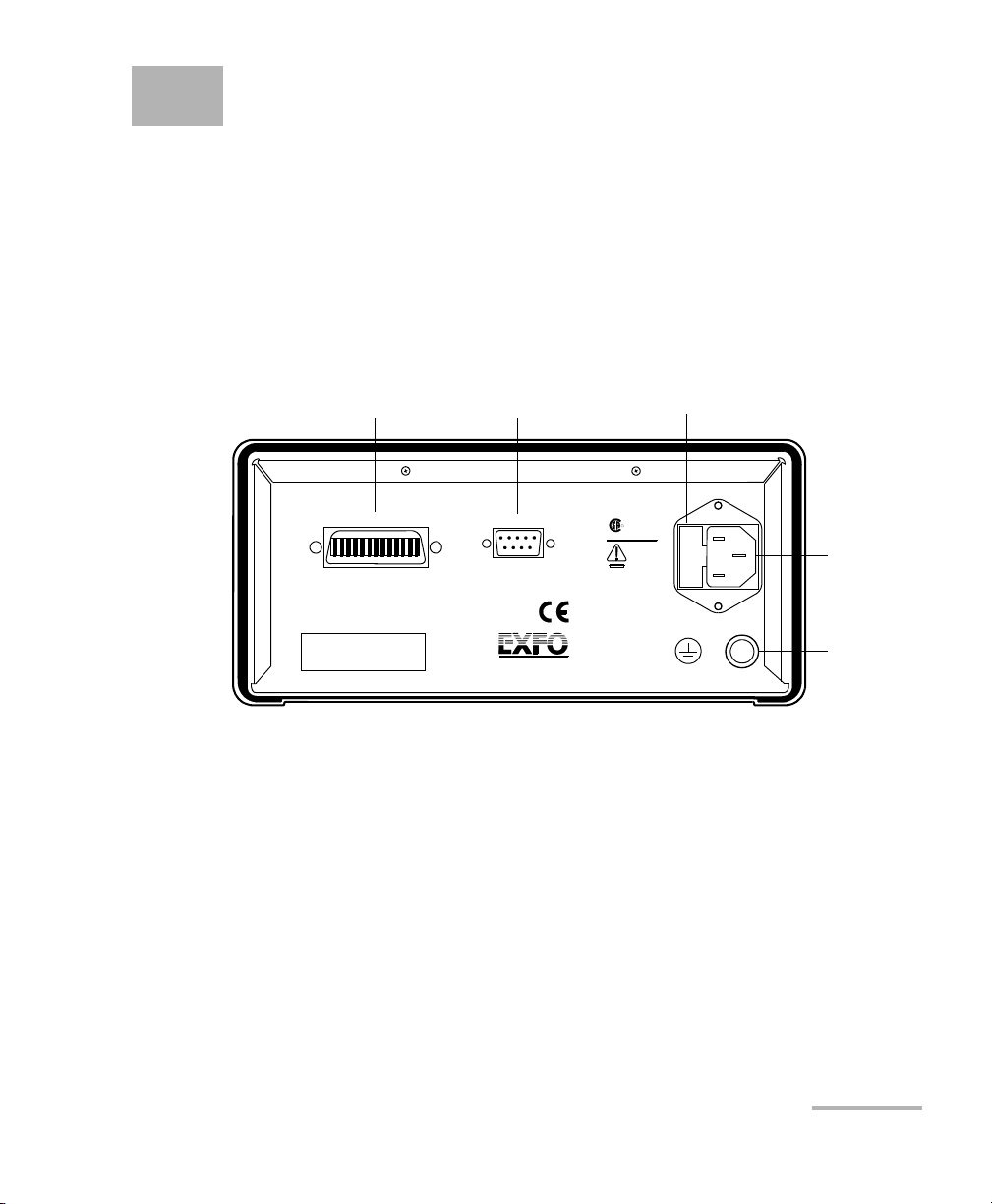

Back Panel

Back Panel

GPIB port

GPIB IEEE 488.2

SH1, AH1, T6, L4, SR1, RL1, PP0, DC1, DT1, C0, E2

This device complies with part 15 of the FCC rules. Operation is

subject to the following two conditions : (1) this device may not cause

harmful interference and (2) this device m ust accept any interference

received, including interference that may cause undesired operation.

P/N

S/N

Made in Canada

Serial port (RS-232 DTE) Fuse holder

CUS

MODEL: GO

LR107723

R

100-240 V

50/60 Hz

2 A

F2AL250 V

QST-151

Serial Port

Ver.

Mfg.

date

Electro-Optical Engineering

FLS-5834A Compatibility

The FLS-5834A is compatible with :

³ FTB-5500B PMD Analyzer

³ FTB-5800 Chromatic Dispersion Analyzer

IMPORTANT

Before using the FLS-5834A with the FTB-5800, you must install:

Power

inlet

Ground

³ ToolBox 6.28 or later.

³ The appropriate product pack (if applicable)

If you are using ToolBox 6.28, ensure to install ToolBox FTB-5800

6.28.1.17 Product Pack.

2 FLS-5834A

Page 9

Introducing the FLS-5834A CD/PMD Analyzer Source

Conventions

Conventions

Before using the product described in this manual, you should understand

the following conventions:

WARNING

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury. Do not proceed unless you

understand and meet the required conditions.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury. Do not proceed unless you

understand and meet the required conditions.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in component damage. Do not proceed unless you

understand and meet the required conditions.

IMPORTANT

Refers to information about this product you should not overlook.

CD/PMD Analyzer Source 3

Page 10

Page 11

2 Safety Information

WARNING

Do not install or terminate fibers while a light source is active.

Never look directly into a live fiber and ensure that your eyes are

protected at all times.

WARNING

Use of controls, adjustments and procedures for operation and

maintenance other than those specified herein may result in

hazardous radiation exposure.

LED Safety Information

Your instrument is a Class 1M LED product in compliance with standard

IEC 60825-1 Amendment 2: 2001. Invisible LED radiation may be

encountered at the output port.

The product is safe under reasonably foreseeable conditions of operation

but it may be hazardous if you use optics within a diverging or collimated

beam. Do not view directly with optical instruments.

³ Wavelength: 1520 to 1640 nm

³ Maximum output power at the connector: 10 mW

The unit has an active LED on its front panel. When lit, this LED indicates

that an optical signal is being emitted from the source port.

The active LED will turn on three seconds before the source starts emitting.

CD/PMD Analyzer Source 5

Page 12

Safety Information

Electrical Safety Information

Electrical Safety Information

This unit uses an international safety standard three-wire power cable. This

cable serves as a ground when connected to an appropriate AC power

outlet.

Note: If you need to ensure that the unit is completely powered off, disconnect the

power cable.

WARNING

³ Insert the power cable plug into a power outlet with a

protective ground contact. Do not use an extension cord

without a protective conductor.

³ Before powering on the unit, connect all grounding terminals,

extension cords and devices to a protective ground via a ground

socket. Any interruption of the protective grounding is a

potential shock hazard and may cause personal injury.

Whenever the ground protection is impaired, do not use the

unit and secure it against any accidental operation.

³ Do not tamper with the protective ground terminal.

The color coding used in the electric cable depends on the cable. New

plugs should meet the local safety requirements and include:

³ adequate load-carrying capacity

³ ground connection

³ cable clamp

IMPORTANT

EXFO assumes no liability if you attempt to perform internal service

on this unit.

6 FLS-5834A

Page 13

Safety Information

Electrical Safety Information

WARNING

³ Use this unit indoors only.

³ Position the unit so that the air can circulate freely around it.

³ Operation of any electrical instrument around flammable gases

or fumes constitutes a major safety hazard.

³ Do not remove unit covers during operation.

³ To avoid electrical shock, do not operate the unit if any part of

the outer surface (covers, panels, etc.) is damaged.

³ Only authorized personnel should carry out adjustments,

maintenance or repair of opened units under voltage. A person

qualified in first aid must also be present. Do not replace any

components while power cable are connected.

³ Use only fuses with the required rated current and specified

type (IEC, 5 mm x 20 mm (0.197 in x 0.787 in), fast-blow, 250 V,

2 A). Do not use repaired fuses or short-circuited fuse holders.

³ Capacitors inside the unit may be charged even if the unit has

been disconnected from its electrical supply.

CD/PMD Analyzer Source 7

Page 14

Safety Information

Electrical Safety Information

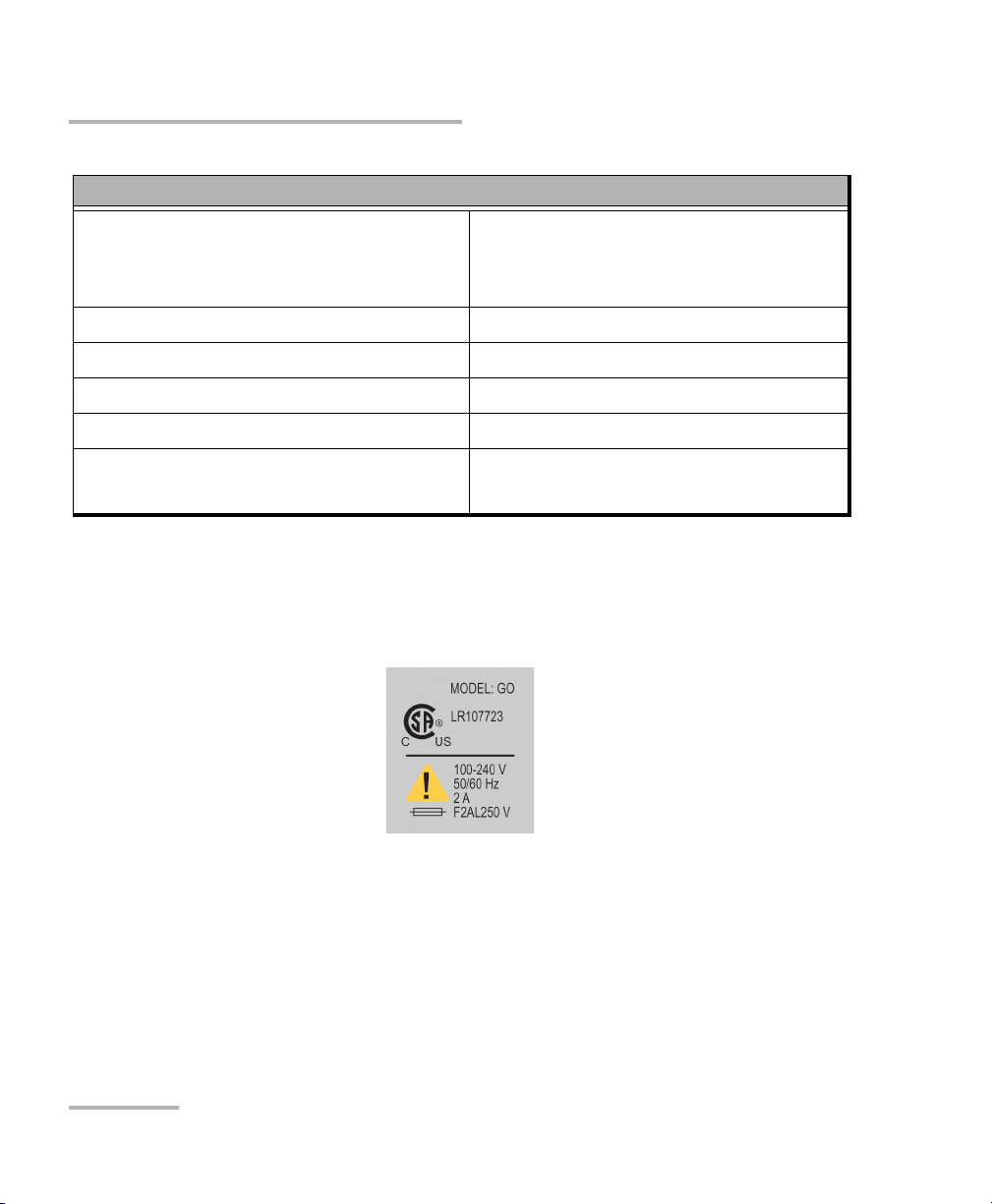

Equipment Ratings

Tem pe ra tu re

³ Operation

³ Storage

Relative humidity

a

0 °C to 40 °C (32 °F to 104 °F)

-40 °C to 70 °C (-40 °F to 158 °F)

0 % to 80 % non-condensing

Maximum operation altitude 2000 m (6562 ft)

Pollution degree 2

Installation category II

Power supply rating

b

100 V to 240 V (50 Hz/60 Hz)

maximum input power 2 A

a. Measured in 0 °C to 31 °C (32 °F to 87.8 °F) range, decreasing linearly to 50 % at 40 °C (104 °F).

b. Not exceeding

± 10 % of the nominal voltage.

The following label is located on the back panel of the unit:

8 FLS-5834A

Page 15

3 Getting Started with Your

Light Source

Turning On and Off the CD/PMD Analyzer Source

WARNING

Before turning on the source, please read the Electrical Safety

Information on page 6.

To turn on and off the CD/PMD Analyzer Source :

Press the red button located in the lower left-hand corner of the front

panel.

Upon startup, the unit beeps twice, performs a self-test and then displays

the main window with the source deactivated.

When the unit is turned off, the current Setup menu settings remain in a

storage device called non-volatile memory. These settings include display

features and remote control.

CD/PMD Analyzer Source 9

Page 16

Getting Started with Your Light Source

FLS-5834A CD/PMD Analyzer Source Display

FLS-5834A CD/PMD Analyzer Source Display

Form the main window of your unit, you can get important information on

the source with just one glance.

Remote control indicator

RM

Source

C+ L

OFF

LK

Band

Bandwith indicator

³ The source status indicator shows whether the source is active or not

(ON/OFF). In the case of an active source, a graphical element

representing a light beam is also displayed.

³ The remote control indicator (RM) appears when the unit is currently

controlled by remote commands (via GPIB or RS-232 communication

mode).

³ The locked keyboard indicator (LK) shows that a remote application

prevents you from using the keyboard of the unit.

Note: The term ‘‘keyboard‘‘ refers to all front panel buttons –except the red button

used to power the unit on or off.

Source status

Remotely-locked

keyboard indicator

10 FLS-5834A

Page 17

4 Setting CD/PMD Analyzer

Source Parameters

The blue button on the right side of the display provides access to the

single-level Setup menu. You can access the Setup menu even while the

source is active. The figure below shows Setup menu items.

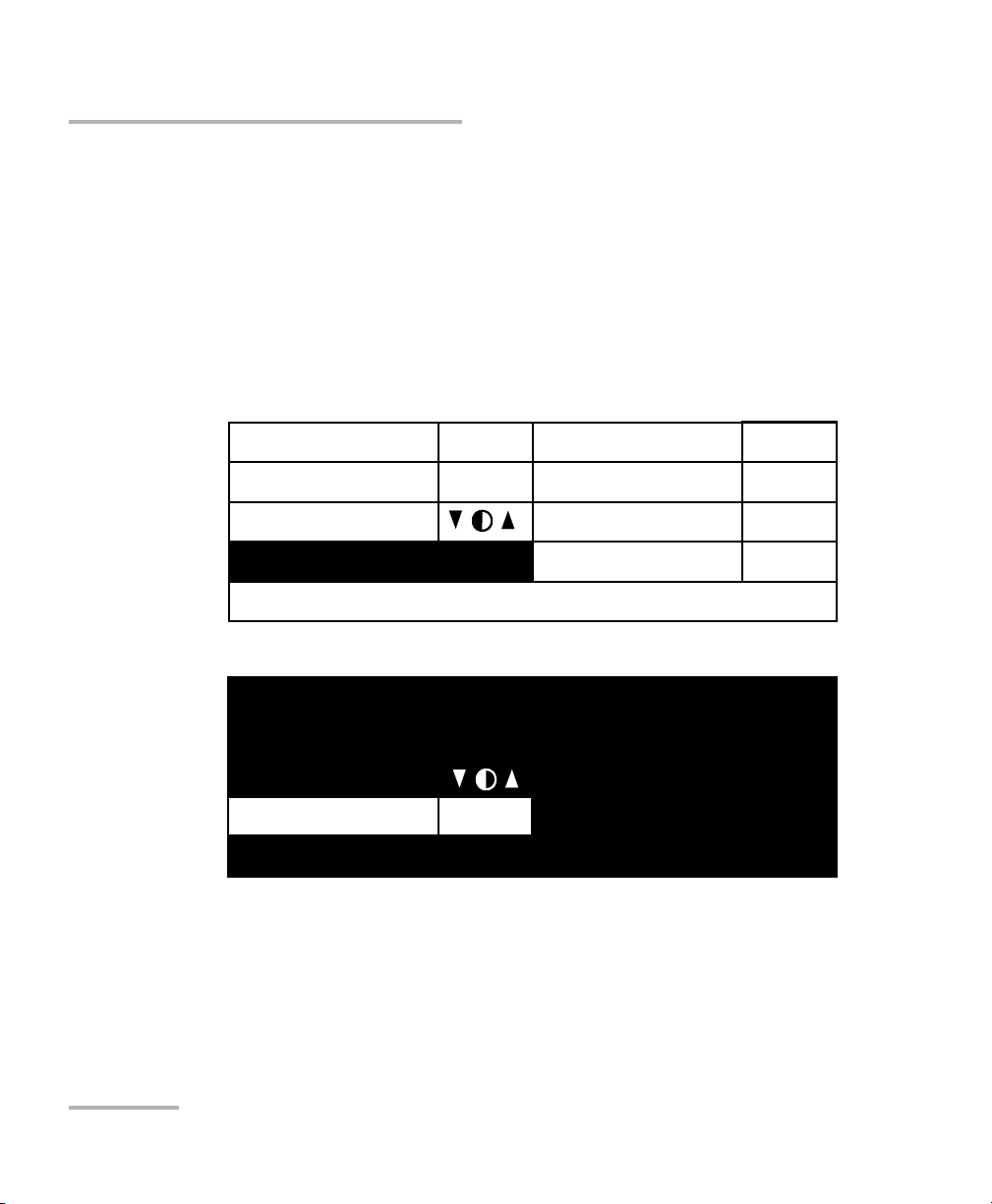

Refresh Rate

Backlight

Contrast

Video Mode

8 Hz

ON

STD

RS232 / GPIB

GPIB Addr.

Baud Rate

Flow Ctrl

GPIB

12

N.A.

N.A.

Exit

To set a parameter:

1. Use arrows on the front panel of the unit to select the parameter you

want to modify. The current selection is displayed in reverse video.

2. Press ENTER to edit the parameter. The cell containing the value will

turn to reverse video, indicating you can modify its contents.

3. Use the up/down arrows to select the appropriate value.

4. Confirm your selection by pressing ENTER. The display will return to

normal.

To exit the Setup menu, press the blue key providing access to the menu.

You can also select the Exit item from the Setup menu (last item at the

bottom of the window) and press ENTER. The CD/PMD Analyzer Source

will revert to its state prior to entering the menu.

ENTER

Note: The unit will beep whenever it does not allow an operation.

CD/PMD Analyzer Source 11

Page 18

Setting CD/PMD Analyzer Source Parameters

Setting the Refresh Rate

Setting the Refresh Rate

You can define the refresh rate of the display.

To set the refresh rate:

1. Press the Setup key.

2. Use the up/down or left/right arrow keys to select Refresh Rate (the

item will be displayed in reverse video).

Refresh Rate

Backlight

Contrast

Video Mode

8 Hz

ON

STD

RS232 / GPIB

GPIB Addr.

Baud Rate

Flow Ctrl

GPIB

12

N.A.

N.A.

Exit

3. Press ENTER to access the Refresh Rate edit box.

4. Use the up/down arrow keys to set the refresh rate between 1/2 Hz,

1Hz, 2Hz, 4Hz, 8Hz and 16Hz.

5. Press ENTER to confirm the new refresh rate.

12 FLS-5834A

Page 19

Setting CD/PMD Analyzer Source Parameters

Setting the Backlight

Setting the Backlight

In certain circumstances, you might want to deactivate the display

backlight.

To deactivate the backlight:

1. Press the Setup key.

2. Use the up/down or left/right arrow keys to select Backlight (the item

will be displayed in reverse video).

3. Press ENTER to access the Backlight edit box.

4. Use the up/down arrow keys until the backlight value changes to OFF.

5. Press ENTER to confirm the new backlight setting.

To reactivate the backlight:

³ Standing very close to the screen to see the information displayed,

repeat steps 1 to 4 above (but set the backlight value to ON).

OR

³ Reset the unit to the default factory parameters (see You may want to

reset the CD/PMD Analyzer Source parameters to their original values.

on page 15).

Setting the Contrast

To modify the contrast:

1. Press the Setup key.

2. Use the up/down or left/right arrow keys to select Contrast (item will

appear in reverse video).

3. Press ENTER to access the Contrast edit box.

4. Use the up/down arrow keys to adjust the contrast as required.

5. Press ENTER to confirm the contrast adjustment.

CD/PMD Analyzer Source 13

Page 20

Setting CD/PMD Analyzer Source Parameters

Setting the Video Mode

Setting the Video Mode

To change the video mode:

1. Press the Setup key.

2. Use the up/down or left/right arrow keys to select Video Mode (item

will appear in reverse video).

3. Press ENTER to access the Video Mode edit box.

4. Use the up/down arrow keys to set the required video mode.

Refresh Rate

Backlight

Contrast

Video Mode

8 Hz

ON

STD

RS232 / GPIB

GPIB Addr.

Baud Rate

Flow Ctrl

Exit

Refresh Rate

Backlight

8 Hz

ON

Contrast

Video Mode

Exit

Exit

5. Press ENTER to confirm the video mode.

INV

RS232 / GPIB

GPIB Addr.

Baud Rate

Baud Rate

Flow Ctrl

GPIB

12

N.A.

N.A.

GPIB

12

N.A.

N.A.

14 FLS-5834A

Page 21

Setting CD/PMD Analyzer Source Parameters

Resetting the CD/PMD Analyzer Source

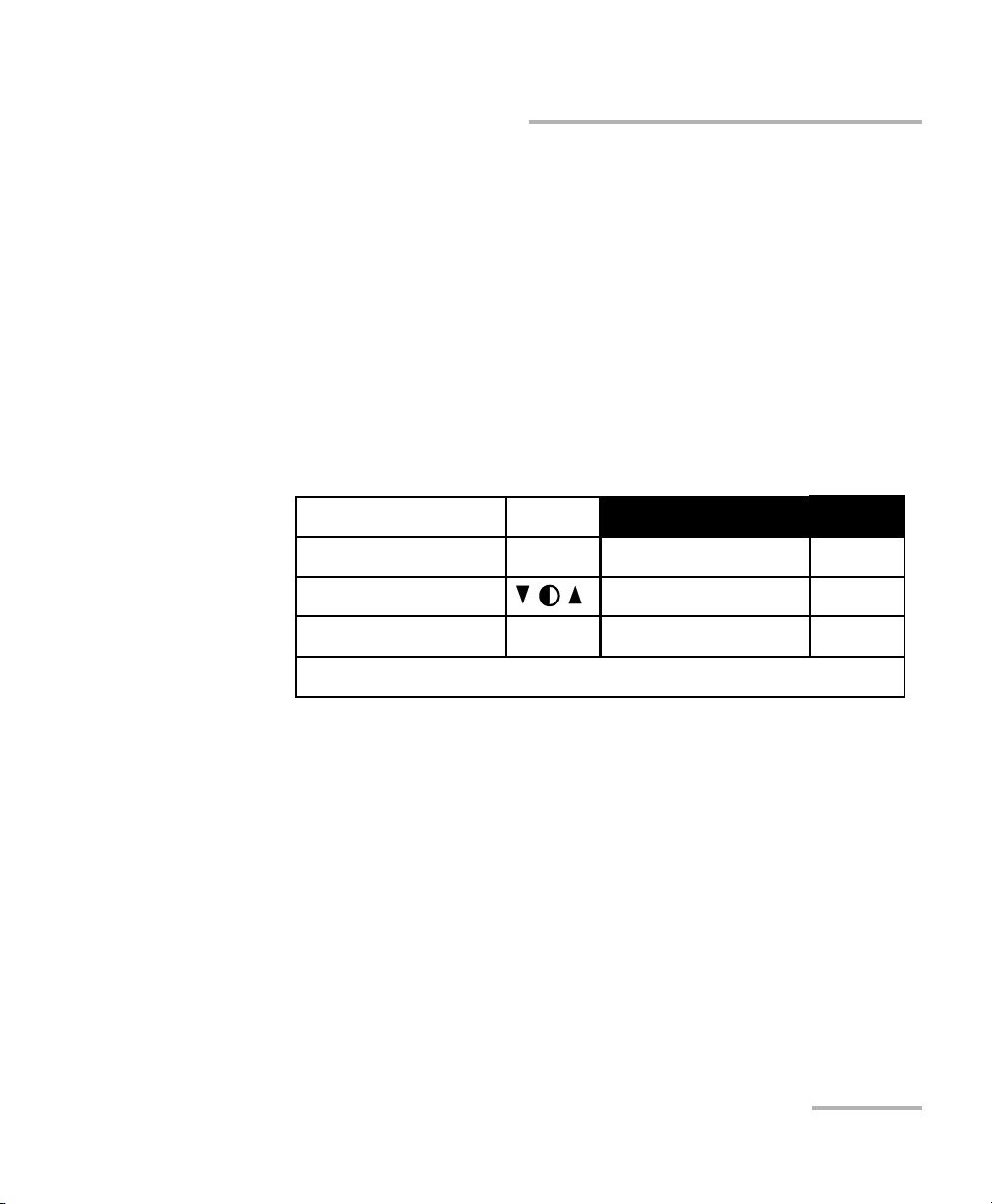

Resetting the CD/PMD Analyzer Source

You may want to reset the CD/PMD Analyzer Source parameters to their

original values.

To reset parameters to values at time of purchase, while turning

on the unit:

Press ENTER until the unit beeps three times.

All the user-defined parameters are automatically reset. The following

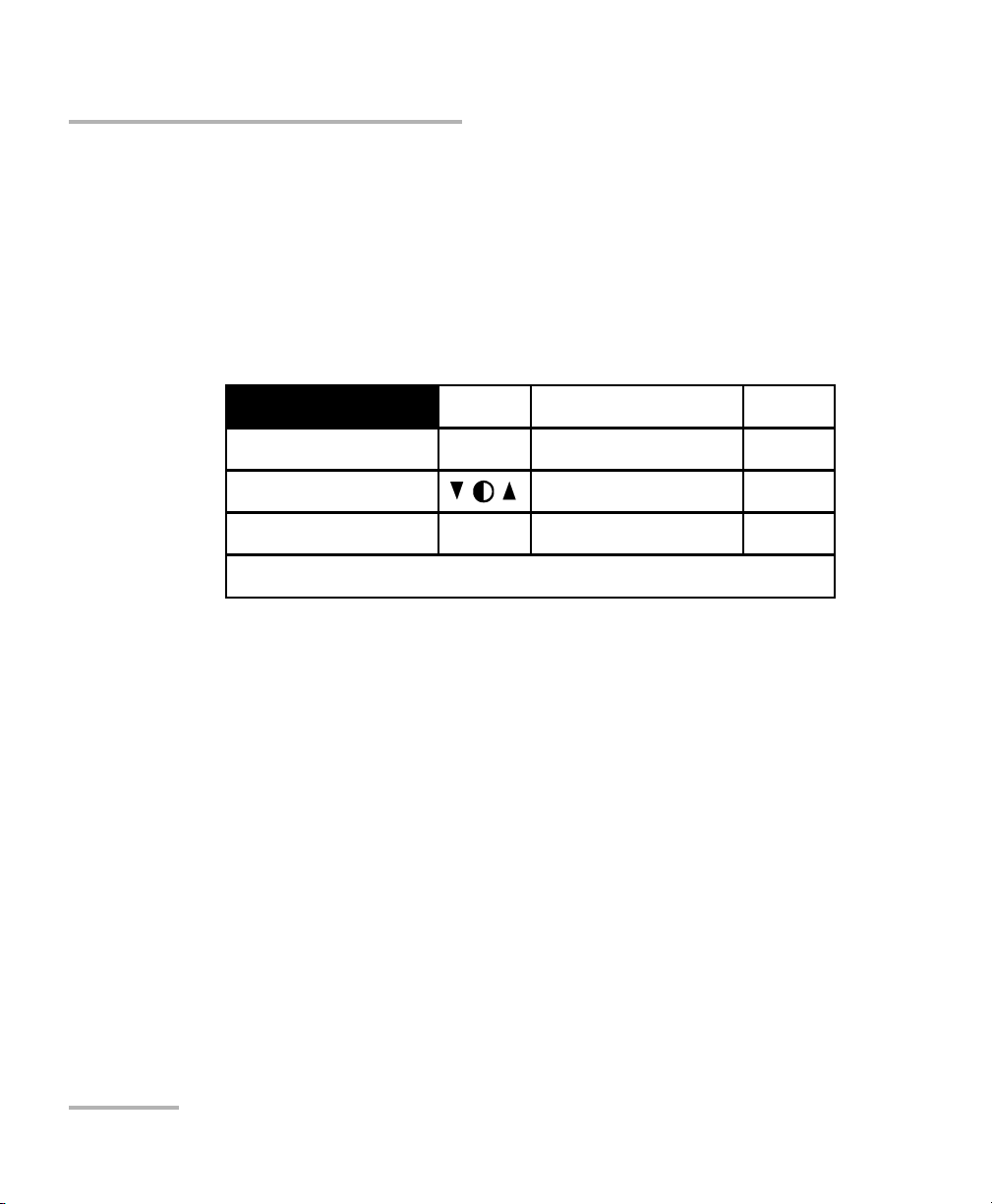

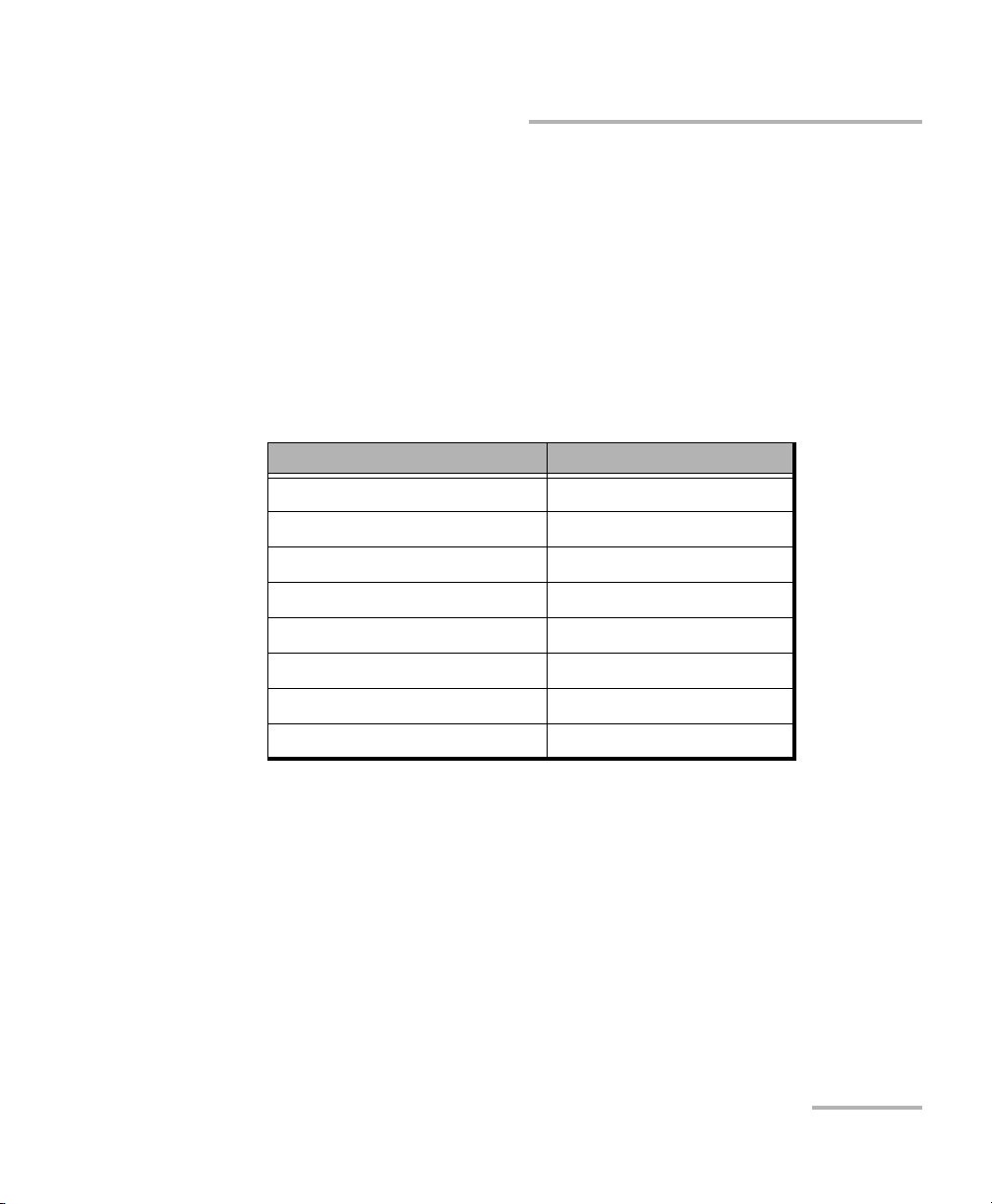

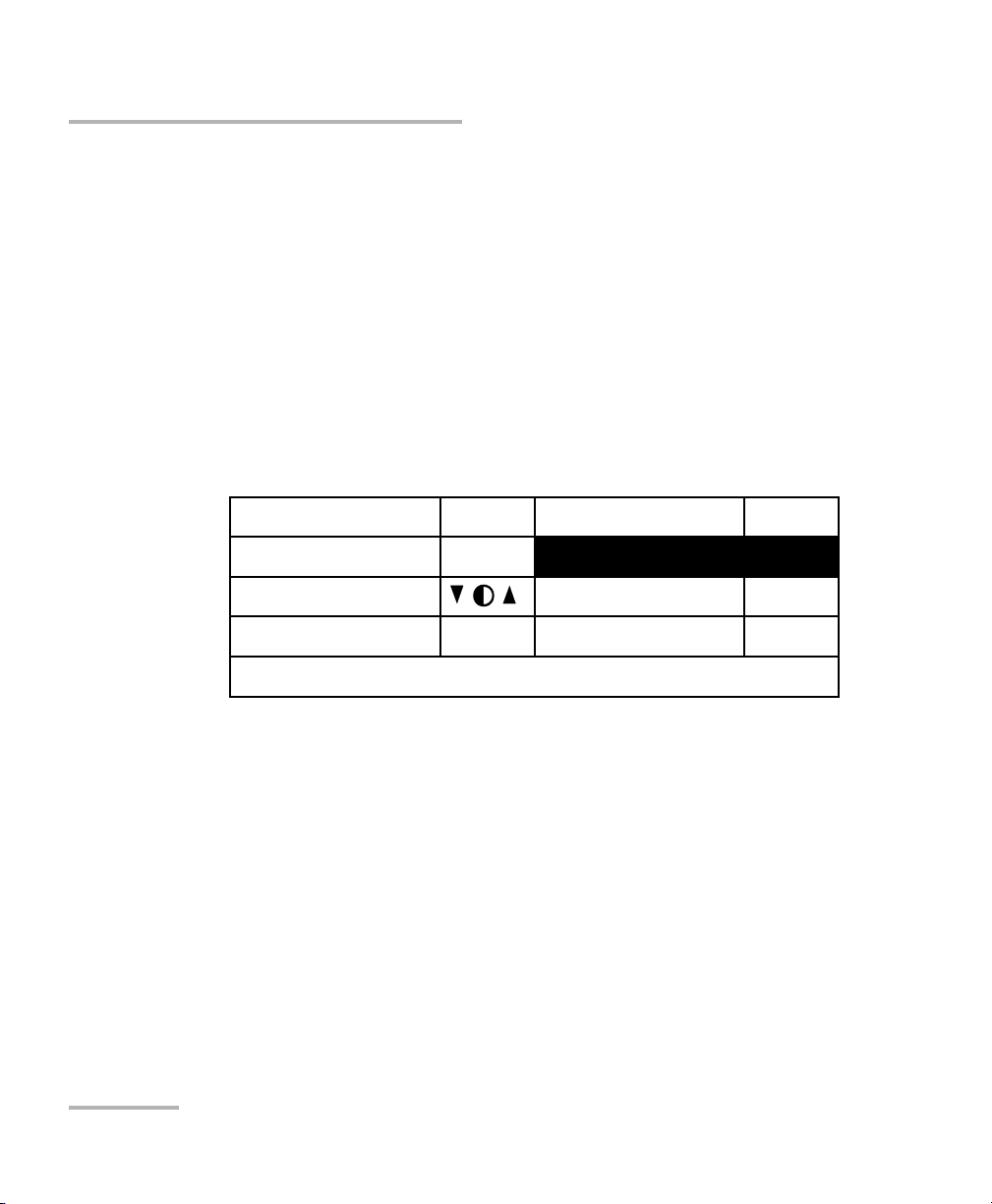

table presents the parameters and their default values.

Parameters Reset Value or State

Source OFF

Backlight ON

Video mode STD (standard)

Refresh rate 4 Hz

RS232/GPIB (remote control)

GPIB address

Baud rate

Flow ctrl

a

a

a

a

GPIB

12

N.A.

N.A.

a. Parameter cannot be reset by a remote control command.

CD/PMD Analyzer Source 15

Page 22

Page 23

5 Operating the CD/PMD

Analyzer Source

Cleaning and Connecting Optical Fibers

IMPORTANT

To ensure maximum power and to avoid erroneous readings:

³ Always clean fiber ends as explained below before inserting

them into the port. EXFO is not responsible for damage or

errors caused by bad fiber cleaning or handling.

³ Ensure that your patchcord has appropriate connectors. Joining

mismatched connectors will damage the ferrules.

To connect the fiber-optic cable to the port:

1. Clean the fiber ends as follows:

1a. Gently wipe the fiber end with a lint-free swab dipped in isopropyl

alcohol.

1b. Use compressed air to dry completely.

1c. Visually inspect the fiber end to ensure its cleanliness.

2. Carefully align the connector and port to prevent the fiber end from

touching the outside of the port or rubbing against other surfaces.

If your connector features a key, ensure that it is fully fitted into the

port’s corresponding notch.

3. Push the connector in so that the fiber-optic cable is firmly in place,

thus ensuring adequate contact.

If your connector features a screwsleeve, tighten the connector

enough to firmly maintain the fiber in place. Do not overtighten, as this

will damage the fiber and the port.

Note: If your fiber-optic cable is not properly aligned and/or connected, you will

notice heavy loss and reflection.

CD/PMD Analyzer Source 17

Page 24

Operating the CD/PMD Analyzer Source

Installing the EXFO Universal Interface (EUI)

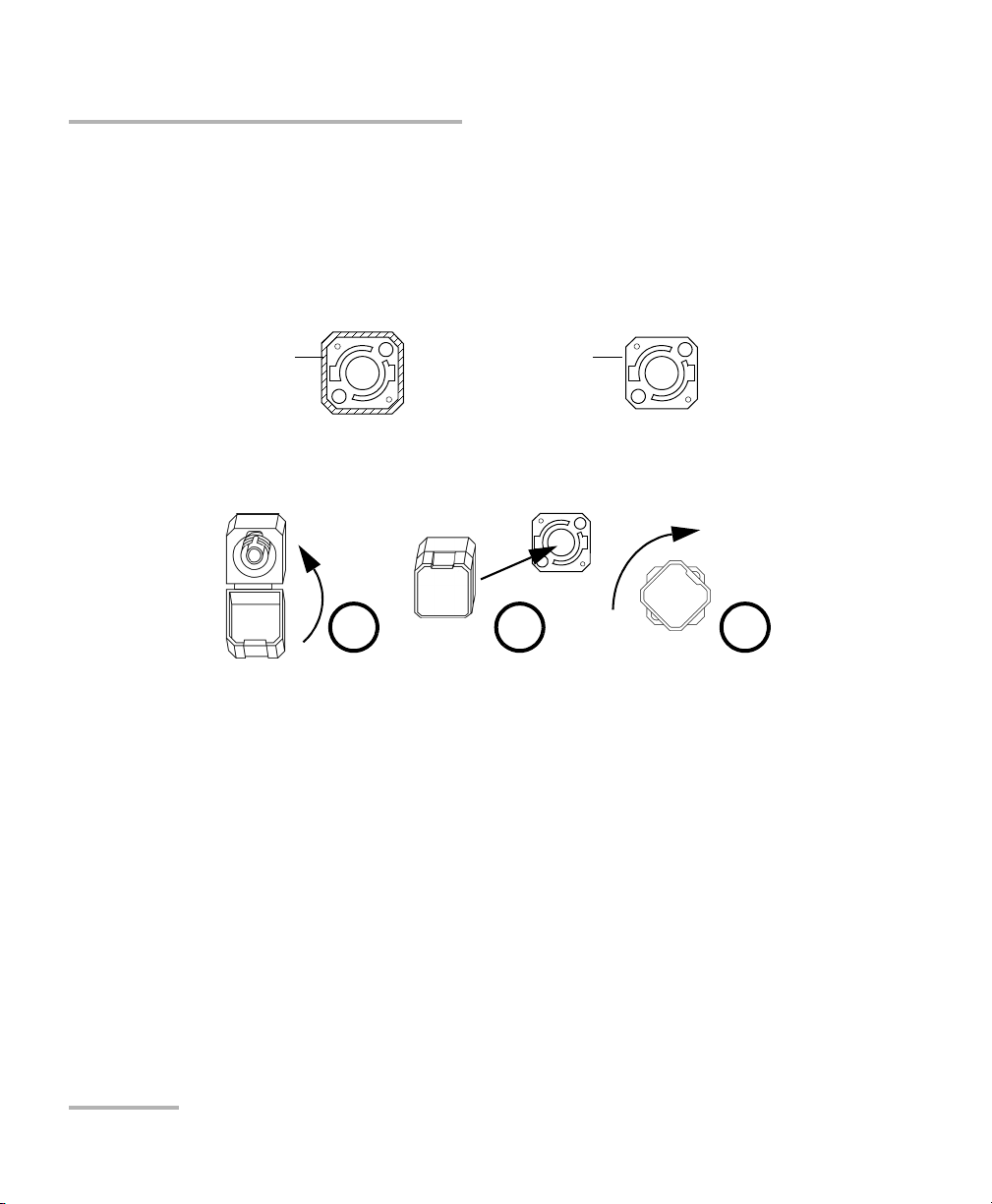

Installing the EXFO Universal Interface (EUI)

The EUI fixed baseplate is available for connectors with angled (APC) or

non-angled (UPC) polishing.A green border around the baseplate indicates

that it is for APC-type connectors.

Green border

indicates APC

option

Bare metal

(or blue border)

indicates UPC

option

To install an EUI connector adapter onto the EUI baseplate:

1. Hold the EUI connector adapter so the dust cap opens downwards.

2 3 4

2. Close the dust cap in order to hold the connector adapter more firmly.

3. Insert the connector adapter into the baseplate.

4. While pushing firmly, turn the connector adapter clockwise on the

baseplate to lock it in place.

18 FLS-5834A

Page 25

Operating the CD/PMD Analyzer Source

Activating or Deactivating the Source

Activating or Deactivating the Source

To activate the source:

1. Setup the source as explained in Setting CD/PMD Analyzer Source

Parameters on page 11.

2. To activate the source, press on the On/Off button. The active LED on

the module front will light up, and the front display will read "Source

ON", also showing a light beam icon.

The word "ON" will flash during the three-second safety delay.

RM

Source

C+ L

Band

Active source indicator

To deactivate the source:

To deactivate the source, press the On/Off button again. The active

LED on the module front will then turn off and the display will read

"Source OFF."

ON

LK

IMPORTANT

To obtain optimum stability, let the source warm up for 10 minutes.

If you do not respect this warmup time, the CD measurement will

present an uncertainty of 0.15 ps/nm.

CD/PMD Analyzer Source 19

Page 26

Page 27

6 Controlling the Source

Remotely

You can control the CD/PMD Analyzer Source remotely either by:

³ a GPIB interface (through a GPIB cable connected to the GPIB port)

or

³ an RS-232 interface (through a serial cable connected to the serial

port).

GPIB port

GPIB IEEE 488.2

SH1, AH1, T6, L4, SR1, RL1, PP0, DC1, DT1, C0, E2

This device complies with part 15 of the FCC rules. Operation is

subject to the following two conditions : (1) this device may not cause

harmful interference and (2) this devi ce must accept any interference

received, including interference that may cause undesired operation.

P/N

S/N

Made in Canada

Serial port (RS-232 DTE) Fuse holder

Ver.

Mfg.

date

QST-151

Serial Port

Electro-Optical Engineering

CUS

MODEL: GO

LR107723

R

100-240 V

50/60 Hz

2 A

F2AL250 V

Power

inlet

Ground

CD/PMD Analyzer Source 21

Page 28

Controlling the Source Remotely

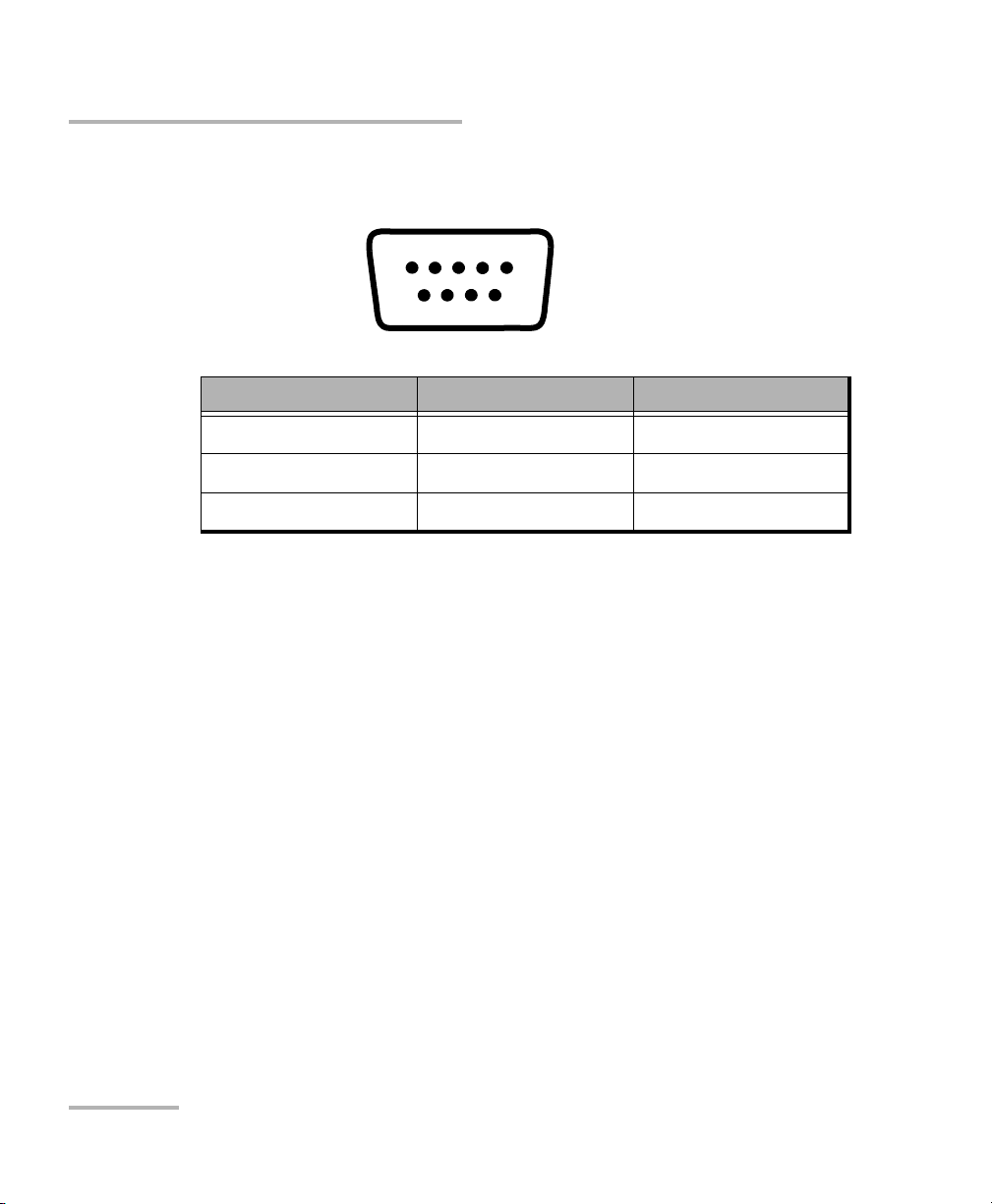

The RS-232 connector (serial port) at the back of the CD/PMD Analyzer

Source uses a DTE pinout configuration.

Pin Number Description Direction

2Receive (Rx)Input

3 Transmit (Tx) Output

5 Signal ground (Gnd) —

The commands used in both protocols are the same and are summarized

in two reference tables:

1234 5

6789

³ Common GPIB commands are listed in IEEE 488.2 Commands—Quick

Reference table on page 59.

³ Specific commands for the CD/PMD Analyzer Source are shown in the

Product-Specific Commands—Quick Reference table on page 81.

You can find detailed information in the Remonte Control Commands

appendix.

When the CD/PMD Analyzer Source is remotely controlled, RM appears in

the upper right-hand corner of the display.

22 FLS-5834A

Page 29

Controlling the Source Remotely

Setting the Remote Command Mode

Setting the Remote Command Mode

To remotely control the CD/PMD Analyzer Source, you must set a GPIB

address or activate the RS-232 port.

To set a remote command mode:

1. Press the Setup key.

2. Use the up/down or left/right arrow keys to select RS232 / GPIB. The

current setting is displayed.

Note: If GPIB is currently selected and you want to specify a GPIB address, see

Setting the GPIB Address on page 24.

Refresh Rate

Backlight

Contrast

Video Mode

8 Hz

ON

STD

RS232 / GPIB

GPIB Addr.

Baud Rate

Flow Ctrl

GPIB

12

N.A.

N.A.

Exit

3. Press ENTER to access the RS232 / GPIB edit box.

4. Use the up/down arrow keys to toggle between GPIB and RS232.

5. Press ENTER to confirm.

If you selected RS232, the GPIB Addr. menu option is deactivated (N.A. is

displayed).

If you selected GPIB, the Baud Rate and Flow Ctrl menu options are

disabled (N.A.is displayed). If necessary, you can change the GPIB address.

CD/PMD Analyzer Source 23

Page 30

Controlling the Source Remotely

Setting the GPIB Address

Setting the GPIB Address

If GPIB is selected as the remote command mode, you can select the GPIB

address you want to use from 1 to 30 (default value is 12).

To set a GPIB address:

1. Press the Setup key.

2. Use the up/down or left/right arrow keys to select GPIB Addr. The

current GPIB address is displayed.

Note: If you are in RS-232 mode, the GPIB address cell will display N.A. You m ust

change the communication mode to GPIB before setting an address.

Refresh Rate

Backlight

Contrast

Video Mode

8 Hz

ON

STD

RS232 / GPIB

GPIB Addr.

Baud Rate

Flow Ctrl

GPIB

12

N.A.

N.A.

Exit

3. Press ENTER, then use the up/down arrow keys to select a GPIB

address between 1 and 30.

4. Press ENTER to confirm your choice.

24 FLS-5834A

Page 31

Controlling the Source Remotely

Setting the Baud Rate

Setting the Baud Rate

The baud rate is a parameter related to RS-232 communication. It

determines the speed at which data is sent between the unit and a

computer, in bits per second (bps).

To change the baud rate for your remote communications:

1. Press the Setup key.

2. Use the up/down or left/right arrow keys to select Baud Rate. The

current setting is displayed.

Refresh Rate

Backlight

Contrast

Video Mode

8 Hz

ON

STD

RS232 / GPIB

GPIB Addr.

Baud Rate

Flow Ctrl

RS232

N.A.

19200

Soft

Exit

3. Press ENTER, then use the up/down arrow keys to select the baud rate.

You can select 1200, 2400, 4800, 9600 or 19200 bps.

4. Press ENTER to confirm.

CD/PMD Analyzer Source 25

Page 32

Controlling the Source Remotely

Setting the Flow Control

Setting the Flow Control

The flow control parameter applies only to RS-232 communication. This

parameter determines the type of serial communication used.

Choose Soft if you want the speed of data transmission to match the speed

at which the device can process it. This enables the computer and the

CD/PMD Analyzer Source to stop each other from transmitting by sending a

control character (Xoff). They will also be able to restart the transmission

by sending another control character (Xon). This is known as a software

handshake, a procedure requiring a special cable.

To set a flow control:

1. Press the Setup key.

2. Use the up/down or left/right arrow keys to select Flow Ctrl. The

current setting is displayed.

Refresh Rate

Backlight

Contrast

Video Mode

8 Hz

ON

STD

RS232 / GPIB

GPIB Addr.

Baud Rate

Flow Ctrl

RS232

N.A.

19200

Soft

Exit

3. Press ENTER, then use the up/down arrow keys to select the type of

flow you want. None means no flow control. Soft allows the unit or

computer controlling it, to turn the data transmission on or off.

4. Press ENTER to confirm.

26 FLS-5834A

Page 33

Controlling the Source Remotely

Communication Parameters

Communication Parameters

The communication parameters are used to set the communication port.

Note: EOS means “End of String.” EOI means “End or Identify.”

For GPIB Communication

Terminate Read on EOS Yes

Set EOI with EOS on Writes Yes

Type of compare on EOS 8 bits

EOS byte 0Ah

Send EOI at end of Writes Yes

GPIB primary address See Setting the GPIB Address on

page 24

GPIB secondary address None

For RS-232 Communication

EOS bytes 0Ah

Baud rate 1200/2400/4800/9600/ 19200 bps

Parity None

Data bits 8 bits

Stop bits 1 bit

Flow control Software (Xon/Xoff) or None

Activation See Setting the Remote Command

Mode on page 23

CD/PMD Analyzer Source 27

Page 34

Controlling the Source Remotely

Standard Status Data Structure

Standard Status Data Structure

The four tables below give information on the common status and enable

registers as defined by IEEE 488.2.

The diagram displayed on page 31 is a useful aid in understanding the

general commands and how a service request (SRQ) is generated.

³ Standard event status register (ESR)

Bits Mnemonics Bit Value

7 Power on 128

6Not used 0

5 Command error 32

4Execution error 16

3 Device dependent error 8

2Query error 4

1Not used 0

0 Operation complete 1

28 FLS-5834A

Page 35

Controlling the Source Remotely

³ Standard event status enable register (ESE)

Bits Mnemonics Bit Value

7 Power on 128

6Not used 0

5 Command error 32

4Execution error 16

3 Device dependent error 8

2Query error 4

1Not used 0

0 Operation complete 1

Standard Status Data Structure

CD/PMD Analyzer Source 29

Page 36

Controlling the Source Remotely

Standard Status Data Structure

³ Status byte register (STB)

Bits Mnemonics Bit Value

7Not used 0

6 Request service / Master

summary status

5 Event summary bit 32

4 Message available 16

3Not used 0

2 Error / Event queue 4

1Not used 0

0Not used 0

³ Service request enable register (SRE)

Bits Mnemonics Bit Value

7Not used 0

6Reserved 0

5 Event status byte 32

4 Message available 16

3Not used 0

64

2 Error / Event queue 4

1Not used 0

0Not used 0

30 FLS-5834A

Page 37

Controlling the Source Remotely

Standard Status Data Structure

Service Request

Generation

OR

OR

PON

7 6 5 4 3 2 1

EXECME

DDE

&

&

&

&

&

7 6 5 4 3 2 1 0

PON

7 6 5 4 3 2 1 0

{

RQS

MSS

6

EXECME

DDE

Message Output Queue not Empty

ESB MAV

&

&

&

&

OPC

QYE

Standard Event Status

0

Register (ESR)

&

&

&

Standard Event

Status Enable

Register (ESE)

OPC

QYE

Error / Event Ouput Queue not Empty

EEQ

Status Byte

Register

(STB)

&

&

&

read by serial poll

read by *STB?

7 5 4 3 2 1 0

{

ESB MAV EEQ

Service Request Enable

Register (SRE)

CD/PMD Analyzer Source 31

Page 38

Controlling the Source Remotely

Standard Status Data Structure

An SRQ is forced when a bit in the status byte register goes from 0 to 1 and

the corresponding SRE mask bit is set. If an SRQ is forced, the RQS bit is set

to 1 and will remain there until read by a serial poll –even if the reason or

condition causing the service request no longer exists. Similarly, if a serial

poll reads the RQS, it is reset to 0, whether or not the condition causing the

service request still exists.

32 FLS-5834A

Page 39

Controlling the Source Remotely

Command Structure

Command Structure

The GPIB and RS-232 commands follow the guidelines determined by the

Standard Commands for Programmable Instruments (SCPI) consortium.

For example, the following command syntax is used to activate or

deactivate the source.

SOUR:POW[:STAT]<wsp><Boolean>

³ SOUR, POW and STAT are keywords that define the function of the

command.

³ [ ] indicates that a keyword or parameter is optional.

³ <wsp> indicates that a space is required ("wsp" stands for "white

space").

³ <Boolean> indicates the command parameter.

³ Keywords must be separated by a colon.

To enter commands or queries you must use either the full word for the

command, or the three- or four-letter shortcut. Commands are not

case-sensitive, however spelling errors will cancel the command or query.

The command or query can be written using only shortcuts, only full

words, or a combination of both.

Other command syntax elements are:

³ The comma, which is used to separate values in a command or query.

³ The semi-colon, which is used to separate commands or queries,

when you send more than one at a time

Note: It is recommended that you retrieve the response immediately after

each query.

CD/PMD Analyzer Source 33

Page 40

Controlling the Source Remotely

Error Messages Format

Error Messages Format

System and device specific errors are managed by the FLS-5834A CD/PMD

Analyzer Source. The generic format for error messages is illustrated in the

following figure.

<Error number>

,

<Error

“

description>

<Device dependent

;

information>

As shown in the above figure, the message contains three parts:

³ Error number

³ Error description

³ Device dependent information

All error messages are stacked in a FIFO buffer. When there is at least one

message in the buffer, bit 2 of the status byte register is set to 1. Use the

SYST:ERR? command to read the most recent message. The error message

buffer is initialized when starting the CD/PMD Analyzer Source, when

executing the *CLS command, or by reading the last message stored in the

buffer.

Note: Error messages ending in a negative number are SCPI-based errors.

”

34 FLS-5834A

Page 41

7 Maintenance

To help ensure long, trouble-free operation:

³ Always clean fiber-optic connectors before using them.

³ Keep the unit free of dust.

³ Clean the unit casing and front panel with a cloth slightly dampened

with water.

³ Store unit at room temperature in a clean and dry area. Keep the unit

out of direct sunlight.

³ Avoid high humidity or significant temperature fluctuations.

³ Avoid unnecessary shocks and vibrations.

³ If any liquids are spilled on or into the unit, turn off the power

immediately and let the unit dry completely.

Use of controls, adjustments, and procedures for operation and

maintenance other than those specified herein may result in

hazardous radiation exposure.

WARNING

CD/PMD Analyzer Source 35

Page 42

Maintenance

Cleaning EUI Connectors

Cleaning EUI Connectors

Regular cleaning of EUI connectors will help maintain optimum

performance. There is no need to disassemble the unit.

If any damage occurs to internal connectors, the module casing will

have to be opened and a new calibration will be required.

To clean EUI connectors:

1. Remove the EUI from the instrument to expose the connector

baseplate and ferrule.

IMPORTANT

Turn

Push

2. Moisten a 2.5 mm cleaning tip with one drop of isopropyl alcohol

(alcohol may leave traces if used abundantly).

3. Slowly insert the cleaning tip into the EUI adapter until it comes out on

the other side (a slow clockwise rotating movement may help).

Pull

3

4

5

4. Gently turn the cleaning tip one full turn, then continue to turn as you

withdraw it.

36 FLS-5834A

Page 43

Cleaning EUI Connectors

5. Repeat steps 3 to 4 with a dry cleaning tip.

Note: Make sure you don’t touch the soft end of the cleaning tip.

6. Clean the ferrule in the connector port as follows:

6a. Deposit one drop of isopropyl alcohol on a lint-free wiping cloth.

IMPORTANT

Isopropyl alcohol may leave residues if used abundantly or left to

evaporate (about 10 seconds).

Avoid contact between the tip of the bottle and the wiping cloth,

and dry the surface quickly.

6b. Gently wipe the connector and ferrule.

6c. With a dry lint-free wiping cloth, gently wipe the same surfaces to

ensure that the connector and ferrule are perfectly dry.

6d. Verify connector surface with a portable fiber-optic microscope

(e.g., EXFO’s FOMS) or fiber inspection probe (e.g., EXFO’s FIP).

Maintenance

WARNING

Verifying the surface of the connector WHILE THE UNIT IS ACTIVE

WILL result in permanent eye damage.

7. Put the EUI back onto the instrument (push and turn clockwise).

8. Throw out cleaning tips and wiping cloths after one use.

CD/PMD Analyzer Source 37

Page 44

Maintenance

Replacing Fuses

Replacing Fuses

The FLS-5834A CD/PMD Analyzer Source contains two F2.0L250V-type fuses

(IEC, 5 mm x 20 mm (0.197 in x 0.787 in), fast-acting, low breaking

capacity, 250 V). The fuse holder is located at the back of the CD/PMD

Analyzer Source, just beside the power inlet.

To replace a fuse:

1. Turn off the unit and disconnect the power cord.

2. Using a flat-head screwdriver as a lever, pull out the fuse holder.

Fuse holder

3. Verify and replace the fuses as necessary.

38 FLS-5834A

Page 45

Maintenance

Recalibrating the Unit

4. Insert the new fuses into the fuse holder.

Fuse

Fuse holder

5. Ensure the fuses are placed firmly in the holder before reinstalling it in

the unit.

6. Firmly push the fuse holder back into place.

Recalibrating the Unit

Manufacturing and service center calibrations are based on the

ISO/IEC 17025 Standard, which states that calibration documents must not

contain a recommended calibration interval, unless this has been

previously agreed upon with the customer.

Validity of specifications depends on operating conditions. For example,

the calibration validity period can be longer or shorter depending on the

intensity of use, environmental conditions and unit maintenance. You

should determine the adequate calibration interval for your unit according

to your accuracy requirements.

Under normal use, EXFO recommends calibrating your unit every year.

CD/PMD Analyzer Source 39

Page 46

Maintenance

Upgrading the Embedded Software

Upgrading the Embedded Software

To upgrade the CD/PMD Analyzer Source embedded software, you will

need to obtain the upgrade files from EXFO’s Technical Support Group. You

will also need a null-modem cable.

You may upgrade software under DOS, Windows 3.1, Windows 9x,

or Windows 2000. With some notebook computers, you may need

to be under a DOS environment. If problems occur, contact EXFO.

To upgrade the embedded software:

1. Turn off the CD/PMD Analyzer Source.

2. Connect a null-modem cable to the CD/PMD Analyzer Source RS-232

port and to an unused serial communication port on your computer.

3. On your computer’s hard disk, create a folder named “Test” (C:\Test).

4. Unzip or copy the upgrade files into the newly created folder.

IMPORTANT

5. If the software upgrade is performed under Windows 98, you must

restart your computer in DOS mode before starting the upgrade

program. In other cases, simply exit to DOS.

6. Go to the “C:\Test” folder and start the upgrade program by typing the

following line (spaces are required between parameters):

Lo0006.exe /C:2 /F:c:\test\filename.hex /S:19200

Parameters can be decoded as follows:

³ /C: serial port number (COM2 in the above example)

³ /F: file to copy on your unit (replace “filename” with the actual

name of the .hex file on your hard disk)

³ /S: computer-to-unit transfer speed (if “19200” does not work, try

“56700”)

40 FLS-5834A

Page 47

Maintenance

Upgrading the Embedded Software

7. When a message about waiting for a evice handshake appears, turn on

the CD/PMD Analyzer Source.

The unit display remains off, the unit beeps once and the upgrade

program starts automatically. A progress bar on the computer screen

indicates the upgrade status. Once the software upgrade is complete,

the message about restarting the unit appears.

8. If the software upgrade was performed under Windows 2000, an error

message to the effect that the LO0006 NTVDM has encountered a

system error and to select close to terminate the application is

displayed. Click Close to hide the dialog box.

9. Turn the CD/PMD Analyzer Source off, and then on again.

Some units will display the new version number at startup, otherwise

press the up and right arrow keys together while the unit is turned on.

CD/PMD Analyzer Source 41

Page 48

Maintenance

Recycling and Disposal (Applies to European Union Only)

Recycling and Disposal

(Applies to European Union Only)

Recycle or dispose of your product (including electric and

electronic accessories) properly, in accordance with local

regulations. Do not dispose of it in ordinary garbage receptacles.

This equipment was sold after August 13, 2005 (as identified by

the black rectangle).

³ Unless otherwise noted in a separate agreement between EXFO and a

customer, distributor or commercial partner, EXFO will cover costs

related to the collection, treatment, recovery and disposal of

end-of-lifecycle waste generated by electronic equipment introduced

after August 13, 2005 to an European Union member state with

legislation regarding Directive 2002/96/EC.

³ Except for reasons of safety or environmental benefit, equipment

manufactured by EXFO, under its brand name, is generally designed to

facilitate dismantling and reclamation.

For complete recycling/disposal procedures and contact information, visit

the EXFO Web site at www.exfo.com/recycle.

42 FLS-5834A

Page 49

8 Troubleshooting

CD/PMD Analyzer Source Error Messages

Warning/Error

Number

-11 Module reset error:

The nulling was not performed

correctly.

-12 Wrong module ID:

The module returns the wrong ID.

-20 Module communication error:

Communication error with the

module.

-25 Checksum error:

Checksum error while reading the

module’s FIFO.

-30 Command not accepted:

The command that caused the

warning will be lost. The unit may

continue with the program even if the

command was not performed.

-31 Module setting error:

One of the settings sent to the unit is

wrong.

Description Recommended Action

Restart your unit to solve the

problem.

Call EXFO for assistance.

Restart your unit to solve the

problem.

Restart your unit to solve the

problem.

If problem persists, call EXFO for

assistance.

Review your command before

sending it again.

-32 Action currently in progress:

You cannot send a command while

the unit is already active.

-34 Command overflow:

Too many commands were sent to

the unit at a time.

CD/PMD Analyzer Source 43

Wait until the unit is done before

sending the command.

Wait until the unit is done before

sending more commands.

Page 50

Troubleshooting

CD/PMD Analyzer Source Error Messages

Warning/Error

Number

Description Recommended Action

-40 FIFO not ready for reading:

The unit’s FIFO is not ready for

reading. Commands sent will be

ignored.

-60 Laser over-current:

A problem occurred with the current

going to the laser.

-64 EEPROM error:

The EEPROM was not detected.

-65 EEPROM checksum error:

A checksum error was detected by

the unit.

-68 Temperature error:

The operating temperature of the unit

is from 10 °C to 40 °C (50 °F to 104 °F).

-69 FPGA problem:

An FPGA problem was detected.

If problem persists, call EXFO for

assistance.

Call EXFO for assistance.

Call EXFO for assistance.

Call EXFO for assistance.

Make sure the ambient

temperature remains within the

specified temperature range.

Call EXFO for assistance.

-73 Supply voltage error:

Call EXFO for assistance.

Internal voltage values are out of the

operation range.

-74 Laser pump failure:

Call EXFO for assistance.

A problem occurred in the output

(optical) power of the laser pump.

-75 Laser temperature problem:

Laser temperature is out of the

operation range.

44 FLS-5834A

Make sure the ambient

temperature remains within the

specified temperature range.

Page 51

Troubleshooting

CD/PMD Analyzer Source Error Messages

Warning/Error

Number

Description Recommended Action

-76 Thermo-electric cooler over-current:

A problem occurred with the current

going to the thermo-electric cooler.

-79 EEPROM access error:

A problem occurred when accessing

the EEPROM memory (read or write).

100 No more room in the command pipe:

A command could not be added to

the command pipe.

101 Timeout error:

The command request was not

performed in the set time amount.

102 Runtime error:

The command was not performed by

the unit due to a runtime error.

103 Invalid response:

A command has triggered an invalid

response from the unit.

Call EXFO for assistance.

Call EXFO for assistance.

If problem persists, call EXFO for

assistance.

Call EXFO for assistance.

Call EXFO for assistance.

Call EXFO for assistance.

200 Decompression error:

Call EXFO for assistance.

An error occurred while

decompressing the software.

32244 Floating exception:

There is an overflow while running a

Restart your unit to solve the

problem.

command.

32245 Stack overflow:

Not enough RAM to run the

Restart your unit to solve the

problem.

command.

CD/PMD Analyzer Source 45

Page 52

Troubleshooting

CD/PMD Analyzer Source Error Messages

Warning/Error

Number

Description Recommended Action

32246 Abort called in firmware:

The unit used a command which it is

not intended to.

32300 Heap overflow:

Not enough space in the heap.

32301

32302

Malloc overflow:

Not enough RAM to run the

command.

32303 Divide by zero:

The unit attempted to perform a

division by zero, which gives an

infinite answer.

32304 Array boundary error:

A table index is outside the

boundaries set by the array.

32305 Invalid Opcode:

The unit did not recognize the binary

code.

Restart your unit to solve the

problem.

Restart your unit to solve the

problem.

Restart your unit to solve the

problem.

Restart your unit to solve the

problem.

Restart your unit to solve the

problem.

Restart your unit to solve the

problem.

46 FLS-5834A

Page 53

Troubleshooting

GPIB Troubleshooting

GPIB Troubleshooting

Problem Probable Cause Solution

Unable to communicate

with CD/PMD Analyzer

Source (no response from

*IDN? command).

Receive “Undefined

header” error.

Unstable communication. Incorrect termination

Incorrect

communication type

selected.

Incorrect

communication

parameters.

Incorrect termination

characters.

Poor bus connection. Ensure the functionning of the

Improper configuration. Verify that the GPIB interface is

Incorrect command

syntax.

character.

Select the correct

communication type: RS-232 or

GPIB.

Check the communication

parameters: bus address, baud

rate, flow control, etc., as

required.

Synchronize termination

characters between the GPIB

controller and the SCPI manager.

controller card and make sure

that the bus cable is properly

connected.

properly configured.

Verify and correct syntax.

Synchronize termination

characters between the GPIB

controller and the SCPI manager.

CD/PMD Analyzer Source 47

Page 54

Troubleshooting

Finding Information on the EXFO Web Site

Finding Information on the EXFO Web Site

The EXFO Web site provides answers to frequently asked questions (FAQs)

regarding the use of your FLS-5834A CD/PMD Analyzer Source.

To access FAQs:

1. Ty pe http://www.exfo.com in your Internet browser.

2. Click the Support tab.

3. Click FAQs and follow the on-screen instructions. You will be given a

list of questions pertaining to your subject.

The EXFO Web site also provides the product’s most recent technical

specifications.

48 FLS-5834A

Page 55

Troubleshooting

Contacting the Technical Support Group

Contacting the Technical Support Group

To obtain after-sales service or technical support for this product, contact

EXFO at one of the following numbers. The Technical Support Group is

available to take your calls from Monday to Friday, 7:30 a.m. to 8:00 p.m.

(Eastern Time in North America).

Technical Support Group

400 Godin Avenue

Quebec (Quebec) G1M 2K2

CANADA

To accelerate the process, please have information such as the name and

the serial number (see the product identification label—an example is

shown below), as well as a description of your problem, close at hand.

1 866 683-0155 (USA and Canada)

Tel.: 1 418 683-5498

Fax: 1 418 683-9224

support@exfo.com

P/N

**************** A

542392-3D

S/N

Made in Canada QST442B

January 2020

Ver.

Mfg.

date

465 Godin Avenue

Vanier (Quebec) G1M 3G7 CANADA

FLS-5834A-XX

Connector

CD/PMD Analyzer Source 49

Page 56

Troubleshooting

Transportation

Transportation

Maintain a temperature range within specifications when transporting the

unit. Transportation damage can occur from improper handling. The

following steps are recommended to minimize the possibility of damage:

³ Pack the unit in its original packing material when shipping.

³ Avoid high humidity or large temperature fluctuations.

³ Keep the unit out of direct sunlight.

³ Avoid unnecessary shocks and vibrations.

50 FLS-5834A

Page 57

9 Warranty

General Information

EXFO Electro-Optical Engineering Inc. (EXFO) warrants this equipment

against defects in material and workmanship for a period oftwo years from

the date of original shipment. EXFO also warrants that this equipment will

meet applicable specifications under normal use.

During the warranty period, EXFO will, at its discretion, repair, replace,

or issue credit for any defective product, as well as verify and adjust the

product free of charge should the equipment need to be repaired or if the

original calibration is erroneous. If the equipment is sent back for

verification of calibration during the warranty period and found to meet all

published specifications, EXFO will charge standard calibration fees.

The warranty can become null and void if:

³ unit has been tampered with, repaired, or worked upon by

unauthorized individuals or non-EXFO personnel.

³ warranty sticker has been removed.

IMPORTANT

³ case screws, other than those specified in this guide, have been

removed.

³ case has been opened, other than as explained in this guide.

³ unit serial number has been altered, erased, or removed.

³ unit has been misused, neglected, or damaged by accident.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES EXPRESSED,

IMPLIED, OR STATUTORY, INCLUDING, BUT NOT LIMITED TO, THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE. IN NO EVENT SHALL EXFO BE LIABLE FOR

SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES.

CD/PMD Analyzer Source 51

Page 58

Warranty

Liability

Liability

EXFO shall not be liable for damages resulting from the use of the product,

nor shall be responsible for any failure in the performance of other items to

which the product is connected or the operation of any system of which

the product may be a part.

EXFO shall not be liable for damages resulting from improper usage or

unauthorized modification of the product, its accompanying accessories

and software.

Exclusions

EXFO reserves the right to make changes in the design or construction of

any of its products at any time without incurring obligation to make any

changes whatsoever on units purchased. Accessories, including but not

limited to fuses, pilot lamps, batteries and universal interfaces (EUI) used

with EXFO products are not covered by this warranty.

This warranty excludes failure resulting from: improper use or installation,

normal wear and tear, accident, abuse, neglect, fire, water, lightning or

other acts of nature, causes external to the product or other factors beyond

EXFO’s control.

IMPORTANT

EXFO will charge a fee for replacing optical connectors that were

damaged due to misuse or bad cleaning.

Certification

EXFO certifies that this equipment met its published specifications at the

time of shipment from the factory.

52 FLS-5834A

Page 59

Warranty

Service and Repairs

Service and Repairs

EXFO commits to providing product service and repair for five years

following the date of purchase.

To send any equipment for service or repair:

1. Call one of EXFO’s authorized service centers (see EXFO Service

Centers Worldwide on page 54). Support personnel will determine if

the equipment requires service, repair, or calibration.

2. If equipment must be returned to EXFO or an authorized service

center, support personnel will issue a Return Merchandise

Authorization (RMA) number and provide an address for return.

3. If possible, back up your data before sending the unit for repair.

4. Pack the equipment in its original shipping material. Be sure to include

a statement or report fully detailing the defect and the conditions under

which it was observed.

5. Return the equipment, prepaid, to the address given to you by support

personnel. Be sure to write the RMA number on the shipping slip. EXFO

will refuse and return any package that does not bear an RMA number.

Note: A test setup fee will apply to any returned unit that, after test, is found to

meet the applicable specifications.

After repair, the equipment will be returned with a repair report. If the

equipment is not under warranty, you will be invoiced for the cost

appearing on this report. EXFO will pay return-to-customer shipping costs

for equipment under warranty. Shipping insurance is at your expense.

Routine recalibration is not included in any of the warranty plans. Since

calibrations/verifications are not covered by the basic or extended

warranties, you may elect to purchase FlexCare Calibration/Verification

Packages for a definite period of time. Contact an authorized service center

(see EXFO Service Centers Worldwide on page 54).

CD/PMD Analyzer Source 53

Page 60

Warranty

EXFO Service Centers Worldwide

EXFO Service Centers Worldwide

If your product requires servicing, contact your nearest authorized service

center.

EXFO Headquarters Service Center

400 Godin Avenue

Quebec (Quebec) G1M 2K2

CANADA

EXFO Europe Service Center

Omega Enterprise Park, Electron Way

Chandlers Ford, Hampshire S053 4SE

ENGLAND

EXFO China Service Center/

Beijing OSIC

Beijing New Century Hotel

Office Tower, Room 1754-1755

No. 6 Southern Capital Gym Road

Beijing 100044

P. R . C H I N A

1 866 683-0155 (USA and Canada)

Tel.: 1 418 683-5498

Fax: 1 418 683-9224

quebec.service@exfo.com

Tel.: +44 2380 246810

Fax: +44 2380 246801

europe.service@exfo.com

Tel.: +86 (10) 6849 2738

Fax: +86 (10) 6849 2662

beijing.service@exfo.com

54 FLS-5834A

Page 61

A Technical Specifications

SPECIFICATIONS

a

GENERAL SPECIF ICATIONS

a

NOTES

a. Typical

SPECIFICATIONS

a

Center wavelength (nm) 1580 ±20

Output power (dBm) 4

Peak spectral density (dBm/nm)

>—12.5

Power stability (15 minutes) (dB)

< 0.075

Modulation frequency (MHz) 100

GENERAL SPECI FICATIONS

Temperature

operating 0 °C to 40 °C (32 °F to 104 °F)

storing —20 °C to 50 °C (—4 °F to 122 °F)

Relative humidity (non-condensing) 0 % to 90 %

Size (H x W x D) 116 mm x 218 mm x 340 mm (

45/8in x 83/4in x 131/8in

)

Weight (without transceivers) 3.2 kg (7.1 lb)

IMPORTANT

The following technical specifications can change without notice.

The information presented in this section is provided as a reference

only. To obtain this product’s most recent technical specifications,

visit the EXFO Web site at www.exfo.com.

CD/PMD Analyzer Source 55

Page 62

Page 63

B Rackmount Installation

You can place your FLS-5834A CD/PMD Analyzer Source in a rackmount to

facilitate its usage.

To install the rackmount:

1. Fix the angle iron using four flat Phillips screws.

3

2

4

1

2. Fix the rackmount bracket to the frame using two round Phillips

screws.

3. Fix the rackmount stiffener using two flat Phillips screws (for the front

panel) and two round Phillips screws.

4. If your rackmount will contain only one unit, fix the rackmount cover

plate to the empty part of the frame using four flat Phillips screws.

CD/PMD Analyzer Source 57

Page 64

Rackmount Installation

To install your FLS-5834A CD/PMD Analyzer Source in a

rackmount:

1. Slide the benchtop unit into the rackmount and tighten it from

underneath using the four cover fixing screws.

If measurement X on the illustration exceeds 11.125 in., fix the unit into

the four holes identified as A. Otherwise, use the other four holes.

X

A

2. If a second benchtop is to be installed, remove the cover plate and

repeat step 1.

58 FLS-5834A

Page 65

C Remote Control Commands

IEEE 488.2 Commands—Quick Reference

The CD/PMD Analyzer Source recognizes the required commands

identified in IEEE 488.2. The table below summarizes these commands.

Command Function

*CLS Clear status command

*ESE Standard event status enable command

*ESE? Standard event status enable query

*ESR? Standard event status register query

*IDN? Identification query

a

*LOK

a

*LOK?

*OPC Operation complete command

*OPC? Operation complete query

a

*REM

Set Remote Lockout programming state

Remote Lockout programming state query

Set Remote programming state

*RST Reset command

*SRE Service request enable command

*SRE? Service request enable query

*STB? Read status byte query

*TST? Self-test query

*WAI Wait for pending operations to be completed

a. This command can only be used with RS-232 communication.

CD/PMD Analyzer Source 59

Page 66

Remote Control Commands

IEEE 488.2 Commands—Description

IEEE 488.2 Commands—Description

Description The *CLS command clears the Standard Event

Syntax *CLS

Parameter(s) None

Description The *ESE command sets the Standard Event

*CLS

Status Register and the Error/Event Queue.

*ESE

Status Enable Register bits, as defined in the

table below. This register contains a mask value

for the bits to be enabled in the Standard Event

Status Register.

MSB LSBStandard Event Status Enable Register

PON CME EXE DDE QYE N.U. OPC

N.U.

Syntax *ESE<wsp><RegisterValue>

Parameter(s) RegisterValue:

The program data syntax for <RegisterValue> is

defined as a <DECIMAL NUMERIC PROGRAM

DATA> element.

The <RegisterValue>, expressed in base 2,

represents the bit values of the Standard Event

Status Enable Register.

60 FLS-5834A

Page 67

Remote Control Commands

IEEE 488.2 Commands—Description

*ESE

The table below shows the contents of this

register.

Bit Weight Meaning

PON 128 Power ON Enable

N.U. 64 Not used

CMD 32 CoMmanD Error Enable

EXE 16 Execution Error Enable

DDE 8 Device Dependent Error Enable

QRY 4 QueRry Error Enable

N.U. 2 Not used

OPC 1 Operation Complete Enable

A value of 1 in the Enable Register enables the

corresponding bit in the Status Register, a value

of 0 disables the bit. The value of the

<RegisterValue> shall be in the range of 0

through 255.

Example(s) *ESE 25

where 25 = (bit EXE, bit DDE and bit OPC)

*ESE 0

clears the content of the Standard Event Status

Enable register

See Also *ESE?

*ESR?

CD/PMD Analyzer Source 61

Page 68

Remote Control Commands

IEEE 488.2 Commands—Description

Description The *ESE? query allows the programmer to

Syntax *ESE?

Parameter(s) None

Response Syntax <RegisterValue>

*ESE?

determine the current contents of the Standard

Event Status Enable Register. See the contents of

this register below.

MSB LSBStandard Event Status Enable Register

PON CME EXE DDE QYE N.U. OPC

N.U.

62 FLS-5834A

Page 69

Response(s) RegisterValue:

The response data syntax for <RegisterValue> is

defined as a <NR1 NUMERIC RESPONSE DATA>

element.

The <RegisterValue> ranges from 0 through 255.

The <RegisterValue> value expressed in base 2

(binary) represents the bit values of the Standard

Event Status Enable register. See below.

Bit Weight Meaning

PON 128 Power ON Enable

N.U. 64 Not used

CMD 32 CoMmanD Error Enable

EXE 16 Execution Error Enable

DDE 8 Device Dependent Error Enable

Remote Control Commands

IEEE 488.2 Commands—Description

*ESE?

QRY 4 QueRry Error Enable

N.U. 2 Not used

OPC 1 Operation Complete Enable

Example(s) *ESE? returns 133

where 133 = (bit PON, bit QYE and bit OPC)

See Also *ESE

*ESR?

CD/PMD Analyzer Source 63

Page 70

Remote Control Commands

IEEE 488.2 Commands—Description

Description The *ESR? query allows the programmer to

Syntax *ESR?

Parameter(s) None

Response Syntax <RegisterValue>

*ESR?

determine the current contents of the Standard

Event Status Register. Reading the Standard

Event Status Register clears it. See the contents of

this register below.

MSB LSBStandard Event Status Enable Register

PON CME EXE DDE QYE N.U. OPC

N.U.

64 FLS-5834A

Page 71

Response(s) RegisterValue:

The response data syntax for <RegisterValue> is

defined as a <NR1 NUMERIC RESPONSE DATA>

element.

The <RegisterValue> ranges from 0 through 255.

The <RegisterValue> value expressed in base 2

(binary) represents the bit values of the Standard

Event Status register. See below.

Bit Weight Meaning

PON 128 Power ON Enable

N.U. 64 Not used

CMD 32 CoMmanD Error Enable

EXE 16 Execution Error Enable

DDE 8 Device Dependent Error Enable

Remote Control Commands

IEEE 488.2 Commands—Description

*ESR?

QRY 4 QueRry Error Enable

N.U. 2 Not used

OPC 1 Operation Complete Enable

Example(s) *ESR? returns 33

where 33 = (bit CME and bit OPC)

See Also *ESE

*ESE?

CD/PMD Analyzer Source 65

Page 72

Remote Control Commands

IEEE 488.2 Commands—Description

Description The intent of the *IDN? query is for the unique

Syntax *IDN?

Response(s) “EXFO E.-O. Engineering,FLS-5834A,xxxxxxxxxx,

Description This command is used to set the Remote

*IDN?

identification of devices over the system

interface.

2.0r0”, where

– xxxxxxxx is the serial number

– 2.0r0 is the Firmware level.

*LOK

Lockout programming state.

Syntax *LOK<wsp><LockoutState>

Parameter(s) LockoutState:

The program data syntax for <LockoutState> is

defined as a <Boolean Program Data> element.

The <LockoutState>special forms ON and OFF

are accepted on input for increased readibility.

ON corresponds to 1 and OFF to 0.

The <LockoutState> parameter is the new

lockout state of the CD/PMD Analyzer Source:

“0”- Removing the Lockout state of the source.

“1”- Enabling the Lockout state of the source.

66 FLS-5834A

Page 73

Remote Control Commands

IEEE 488.2 Commands—Description

*LOK

Example(s) *LOK 1

Notes This command can only be used when working

with RS-232 communication.

See Also *LOK?

CD/PMD Analyzer Source 67

Page 74

Remote Control Commands

IEEE 488.2 Commands—Description

Description This query returns the Remote Lockout

Syntax *LOK?

Parameter(s) None

Response Syntax <LockoutState>

Response LockoutState:

*LOK?

programming state indicating if the CD/PMD

Analyzer Source has been locked out by a

remote application.

The response data syntax for <LockoutState> is

defined as an <NR1 NUMERIC RESPONSE

DATA> element.

The <LockoutState> response corresponds to

the remote lockout state of the CD/PMD Analyzer

Source:

“0”- The source is unlocked.

“1”- The source is locked.

Example(s) *LOK? returns 1

Notes This command can only be used when working

with RS-232 communication.

See Also *LOK

68 FLS-5834A

Page 75

Remote Control Commands

IEEE 488.2 Commands—Description

*OPC

Description The *OPC command allows synchronization

between the instrument and an external

controller.

The *OPC command causes the instrument to

set bit 0 (Operation Complete) in the Standard

Event Status Register to the TRUE (logic 1) state

when the instrument completes all pending

operations.

Detection of the Operation Complete message

can be accomplished by continuous polling of

the Standard Event Status Register using the

*ESR? common query command. However,

using a service request eliminates the need to

poll the Standard Event Status Register thereby

freeing the controller to do other useful work.

Syntax *OPC

Parameter(s) None

See Also *OPC?

*WAI

CD/PMD Analyzer Source 69

Page 76

Remote Control Commands

IEEE 488.2 Commands—Description

Description The *OPC? query allows synchronization

Syntax *OPC?

Parameter(s) None

Response Syntax <Acknowledge>

*OPC?

between the instrument and an external

controller by reading the Output Queue or by

waiting for a service request on the Message

Available (MAV) bit in the Status Byte Register.

The *OPC? query causes the instrument to place

an ASCII character, 1, into its Output Queue

when the device completes all pending

operations. A consequence of this action is that

the MAV bit in the Status Byte Register is set to

state 1.

Response(s) Acknowledge:

The response data syntax for <Acknowledge> is

defined as a <NR1 NUMERIC RESPONSE DATA>

element.

The <Acknowledge> response is a single

ASCII-encoded byte corresponding to 1.

The receipt of an <Acknowledge> response

indicates that all pending selected device

operations have been completed.

Example(s) *OPC? Return 1

See Also *OPC

*WAI

70 FLS-5834A

Page 77

Remote Control Commands

IEEE 488.2 Commands—Description

Description This command is used to set the Remote

programming state that determines if the source

will be controlled locally or remotely.

Syntax *REM<wsp><RemoteState>

Parameter(s) RemoteState:

The program syntax data for <RemoteState> is

defined as a <Boolean Program Data> element.

The <RemoteState> special forms ON and OFF

are accepted on input for increased readibility.

ON corresponds to 1 and OFF to 0.

The <RemoteState> parameter is the new

remote state of the CD/PMD Analyzer Source: