Page 1

FLS-2600B

Tunable Laser Source

User Guide

Page 2

Copyright © 2003–2011 EXFO Inc. All rights reserved. No part of this

publication may be reproduced, stored in a retrieval system or transmitted

in any form, be it electronically, mechanically, or by any other means such

as photocopying, recording or otherwise, without the prior written

permission of EXFO Inc. (EXFO).

Information provided by EXFO is believed to be accurate and reliable.

However, no responsibility is assumed by EXFO for its use nor for any

infringements of patents or other rights of third parties that may result from

its use. No license is granted by implication or otherwise under any patent

rights of EXFO.

EXFO’s Commerce And Government Entities (CAGE) code under the North

Atlantic Treaty Organization (NATO) is 0L8C3.

The information contained in this publication is subject to change without

notice.

Trademarks

EXFO’s trademarks have been identified as such. However, the presence

or absence of such identification does not affect the legal status of any

trademark.

Units of Measurement

Units of measurement in this publication conform to SI standards and

practices.

Version number: 3.0.0

ii FLS-2600B

Page 3

Contents

Contents

Certification Information ....................................................................................................... vi

1 Introducing the FLS-2600B Tunable Laser Source ...................................... 1

General Information ...............................................................................................................1

RS-232 Connector Pinout ........................................................................................................3

Typical Applications ................................................................................................................4

Conventions ............................................................................................................................5

2 Safety Information ....................................................................................... 7

Laser Safety Information .........................................................................................................7

Electrical Safety Information ...................................................................................................8

3 Getting Started with Your Tunable Laser Source ..................................... 11

Turning on the Unit ..............................................................................................................11

Positioning Your Unit Using the Support Stands ...................................................................13

4 Setting Standard Parameters .................................................................... 15

Setting the Display Intensity .................................................................................................15

Turning the Sound On or Off ................................................................................................16

Switching between Normal and High-Resolution (HR) Modes ..............................................17

Adjusting Decimals Using the Fine-Tune Feature ...................................................................17

Selecting the Display Unit .....................................................................................................18

Selecting a Wavelength ........................................................................................................19

Setting the Power .................................................................................................................21

Adding Items to Lists ............................................................................................................22

Deleting Items from Lists ......................................................................................................23

Using the Monitor Output ....................................................................................................24

Saving and Recalling Configurations .....................................................................................25

Reverting to Factory Settings ................................................................................................27

5 Setting Sweep Parameters ........................................................................ 29

Setting the Start and End Wavelengths ................................................................................29

Selecting the Sweep Mode ...................................................................................................30

Setting the Sweep Step ........................................................................................................31

Setting the Pauses ................................................................................................................32

Setting the Sweep Speed ......................................................................................................33

Selecting the Incoming Trigger Option .................................................................................35

Setting the Cycle Options .....................................................................................................36

Setting the Sweep Direction .................................................................................................37

Tunable Laser Source iii

Page 4

Contents

6 Operating your Tunable Laser Source .......................................................39

Cleaning and Connecting Optical Fibers ...............................................................................39

Installing the EXFO Universal Interface (EUI) .........................................................................41

Activating/Deactivating Light Emission .................................................................................42

Starting a Sweep ..................................................................................................................43

7 Maintenance ................................................................................................45

Cleaning Fixed Connectors ....................................................................................................46

Cleaning EUI Connectors ......................................................................................................48

Replacing the Fuse ................................................................................................................50

Software Upgrades ...............................................................................................................51

Adjusting Your Unit According to Wavelength .....................................................................54

Recalibrating the Unit ...........................................................................................................56

Recycling and Disposal (Applies to European Union Only) ....................................................56

8 Troubleshooting ..........................................................................................57

Solving Common Problems ...................................................................................................57

Contacting the Technical Support Group ..............................................................................58

Transportation ......................................................................................................................59

9 Warranty ......................................................................................................61

General Information .............................................................................................................61

Liability .................................................................................................................................62

Exclusions .............................................................................................................................63

Certification ..........................................................................................................................63

Service and Repairs ...............................................................................................................64

EXFO Service Centers Worldwide ..........................................................................................65

A Technical Specifications ..............................................................................67

B Trigger Option Theory ................................................................................69

Trigger Option in Continuous Mode .....................................................................................69

Trigger Option in Stepped Mode ..........................................................................................70

iv FLS-2600B

Page 5

Contents

C Remote Control .......................................................................................... 71

Setting the FLS-2600B for Remote Control ...........................................................................71

Setting the GPIB Primary Address .........................................................................................72

Changing the Baud Rate for RS-232 .....................................................................................73

Changing the Flow Control for RS-232 .................................................................................74

Communication Parameters ..................................................................................................75

Standard Status Data Structure ............................................................................................76

SCPI Commands ....................................................................................................................80

General Commands ..............................................................................................................82

Specific Commands ..............................................................................................................90

Programming Commands ...................................................................................................118

Other Commands ...............................................................................................................126

Quick Reference Command Tree .........................................................................................128

Error Messages ...................................................................................................................134

SCPI Management Errors (System Errors) ............................................................................135

FLS-2600B Error and Warning Messages .............................................................................137

GPIB Troubleshooting .........................................................................................................141

Index .............................................................................................................. 143

Tunable Laser Source v

Page 6

Certification Information

Certification Information

FCC Information

Electronic test equipment is exempt from Part 15 compliance (FCC) in

the United States. However, compliance verification tests are

systematically performed on most EXFO equipment.

Information

Electronic test equipment is subject to the EMC Directive in the European

Union. The IEC 61326-1 standard prescribes both emission and immunity

requirements for laboratory, measurement, and control equipment.

This unit has undergone extensive testing according to the European Union

Directive and Standards.

CSA Information

This unit is certified by the CSA (certificate number 162451) and was

evaluated according to applicable CSA standards (as confirmed by cCSAus

mark) as well as applicable IEC standards for use in Canada, the United

States, and other countries.

IMPORTANT

Use of shielded remote I/O cables, with properly grounded shields

and metal connectors, is recommended in order to reduce radio

frequency interference that may emanate from these cables.

vi FLS-2600B

Page 7

Certification Information

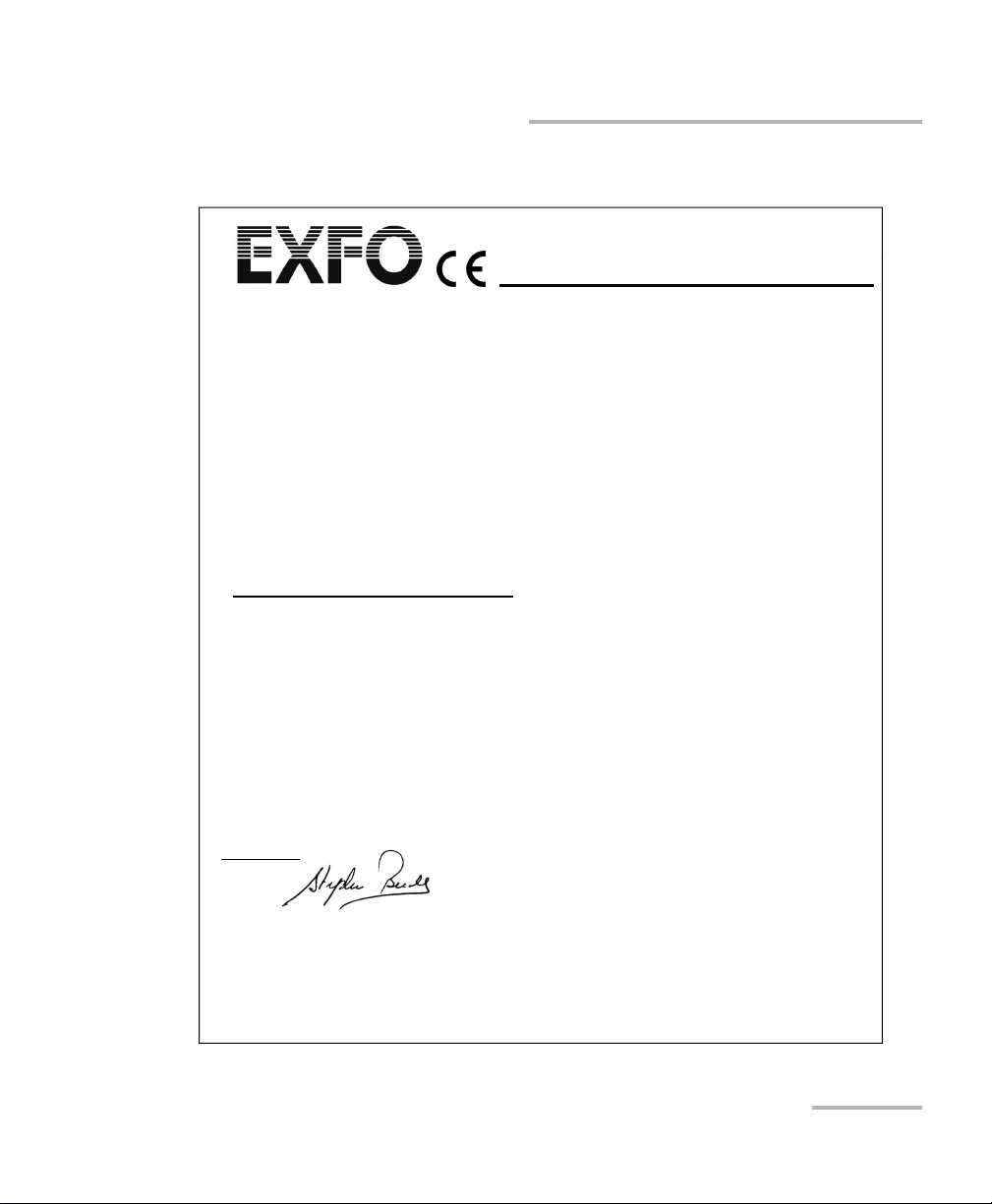

Application of Council Directive(s): 2006/95/EC - The Low Voltage Directive

2004/108/EC - The EMC Directive

93/68/EEC - CE Marking

And their amendments

0DQXIDFWXUHU¶V1DPH EXFO Inc. EXFO Europe

0DQXIDFWXUHU¶V$GGUHVV 400 Godin Avenue Omega Enterprise Park

Quebec, Quebec Electron Way,

Canada, G1M 2K2 Chandlers Ford,

(418) 683-0211 Hampshire, SO53 4SE,

UNITED KINGDOM

Equipment Type/Environment: Test & Measurement / Industrial

Trade Name/Model No.: Tunable Laser Source / FLS-2600B

Standard(s) to which Conformity is Declared:

EN 61010-1:2001 Edition 2.0

Safety requirements for electrical equipment for measurement,

control, and laboratory use ± Part 1: General requirements

EN 61326-1:2006

Electrical equipment for measurement, control and laboratory

use ± EMC requirements ± Part 1: General requirements

EN 60825-1:2007 Edition 2.0

Safety of laser products ± Part 1: Equipment classification and

requirements

I, the undersigned, hereby declare that the equipment specified above conforms to the above Directive and Standards.

Manufacturer

Signature:

Full Name:

Stephen Bull, E. Eng

Position:

Vice-President Research and

Development

Address:

400 Godin Avenue, Quebec (Quebec),

Canada, G1M 2K2

Date:

February 03, 2009

DECLARATION OF CONFORMITY

Tunable Laser Source vii

Page 8

Page 9

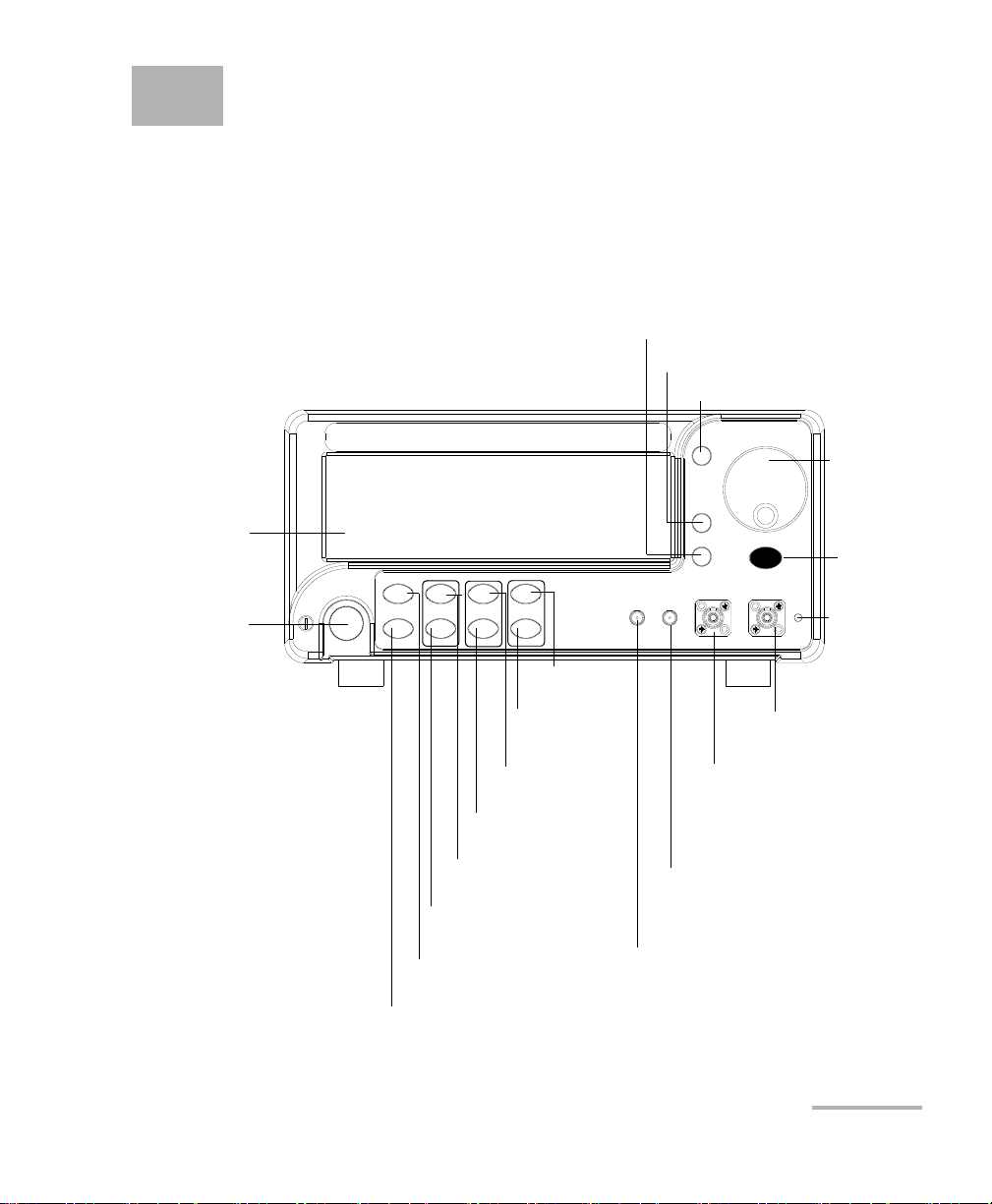

1 Introducing the FLS-2600B

FLS-2600B TUNABLE LASER SOURCE

Power

on/off

On/Off

Mode

/List

Power

List

Add

Del.

Set Sweep

Start

Stop

Trig In Trig Out Monitor

Output

Output

Setup

Sweep

Fine

tune

ENTER

Display

Source

on/off

Power

control

Access to Sweep menu

Monitor output

port

Add to

List

button

Switches between

and

List

Fine-Tuning button

Sweep Start

button

Trigger Out

SMA connector

Sweep Stop

button

Trigger In SMA

connector

Main output

port

Delete from List

button

Access to Setup menu

Switches between Normal and

High-Resolution modes

Selection

dial

Active LED

Enter

button

Tunable Laser Source

General Information

The FLS-2600B Tunable Laser Source addresses the testing requirements

for dense WDM component testing in the C- and L-bands.

Tunable Laser Source 1

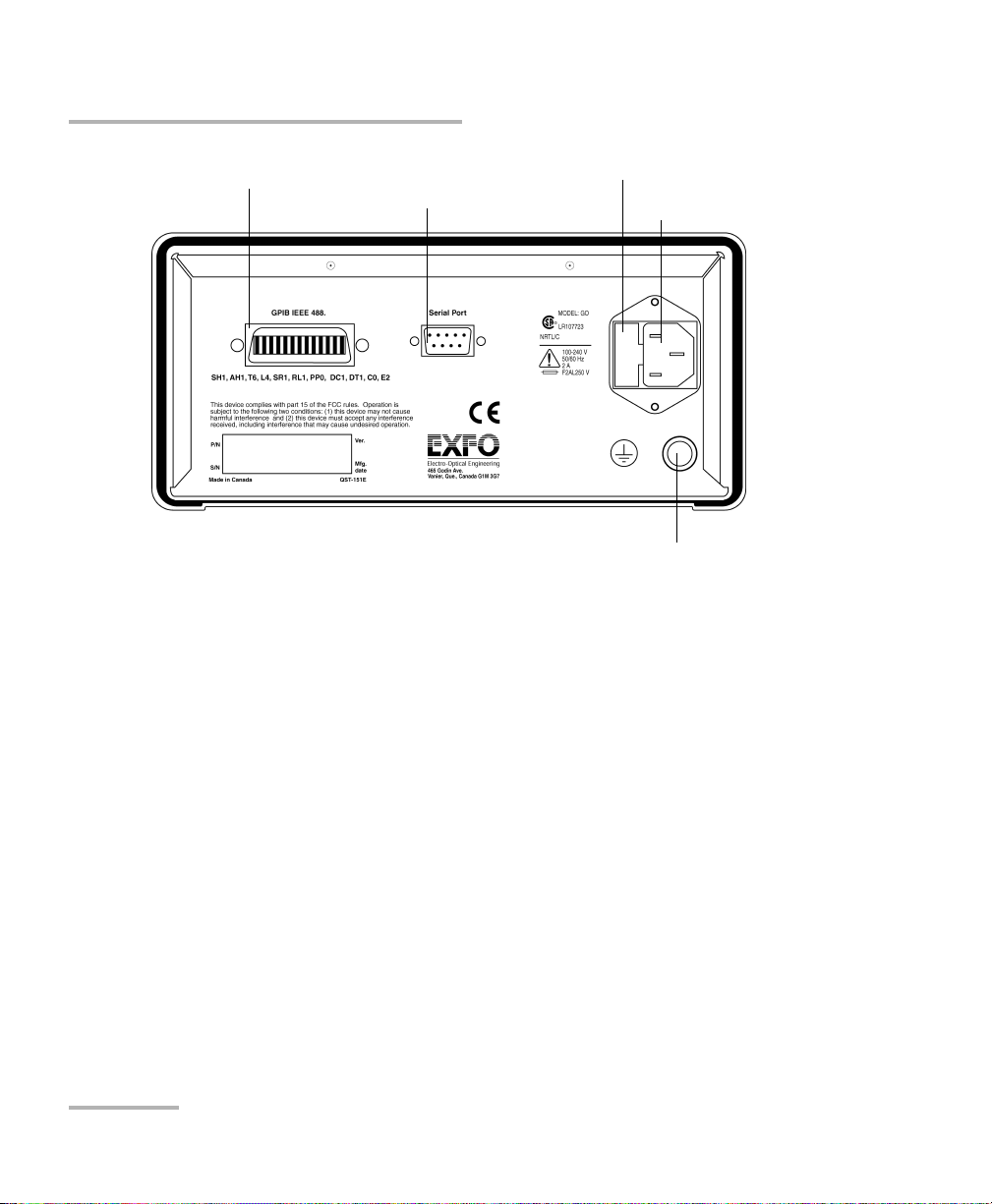

Page 10

Introducing the FLS-2600B Tunable Laser Source

GPIB port Serial port

(RS-232 DTE)

Fuse holder

Power inlet

2

Ground

General Information

2 FLS-2600B

Page 11

Introducing the FLS-2600B Tunable Laser Source

1234 5

6789

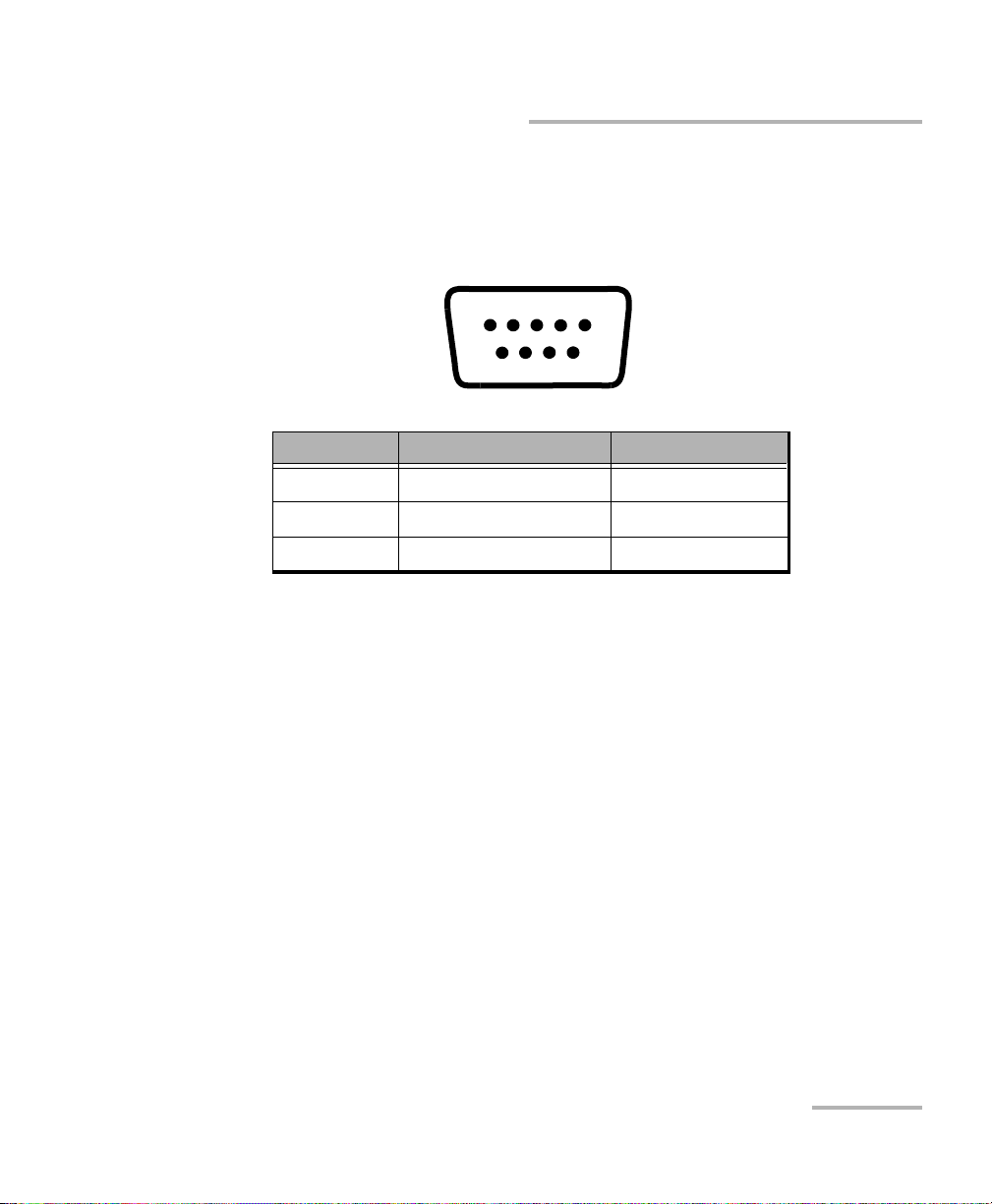

RS-232 Connector Pinout

RS-232 Connector Pinout

The RS-232 connector (serial port) at the back of the FLS-2600B uses a DTE

pinout configuration.

Pin Description Direction

2Receive (Rc) Input

3Transmit (Tx)Output

5 Signal ground (Gnd) —

The source has a medium coherence length that avoids problems such as

connector-induced interference and it is relatively immune to vibration. Its

linewidth is made up of several longitudinal modes that are present

simultaneously, resulting in no mode-hop-related measurement problems.

It also features a high-accuracy encoder for consistency in your results.

Tunable Laser Source 3

Your module may also feature the possibility to enable or disable the

automatic level control (ALC).

The FLS-2600B Tunable Laser Source supports local control (via its front

panel) and remote control (through GPIB or RS-232 using SCPI commands

or the provided LabVIEW drivers).

Page 12

Introducing the FLS-2600B Tunable Laser Source

Typic a l Ap pl ic ation s

Typical Applications

You can use your tunable laser source to perform several tasks, such as the

following:

characterizing filters, multiplexers, Bragg gratings, and other DWDM

components

checking wavelength-dependent gain, noise contribution and

saturation properties

determining the spectral sensitivity of receivers and detectors

performing high-loss tests on passive components

4 FLS-2600B

Page 13

Introducing the FLS-2600B Tunable Laser Source

Conventions

Conventions

Before using the product described in this manual, you should understand

the following conventions:

WARNING

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury. Do not proceed unless you

understand and meet the required conditions.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury. Do not proceed unless you

understand and meet the required conditions.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in component damage. Do not proceed unless you

understand and meet the required conditions.

IMPORTANT

Refers to information about this product you should not overlook.

Tunable Laser Source 5

Page 14

Page 15

2 Safety Information

Laser Safety Information

While handling optical fibers, laser radiation may be encountered at

source output ports and fiber ends. Avoid long-term exposure to laser

radiation.

WARNING

Do not install or terminate fibers while a light source is active.

Never look directly into a live fiber and ensure that your eyes are

protected at all times.

WARNING

Use of controls, adjustments and procedures for operation and

maintenance other than those specified herein may result in

hazardous radiation exposure or impair the protection provided by

this unit.

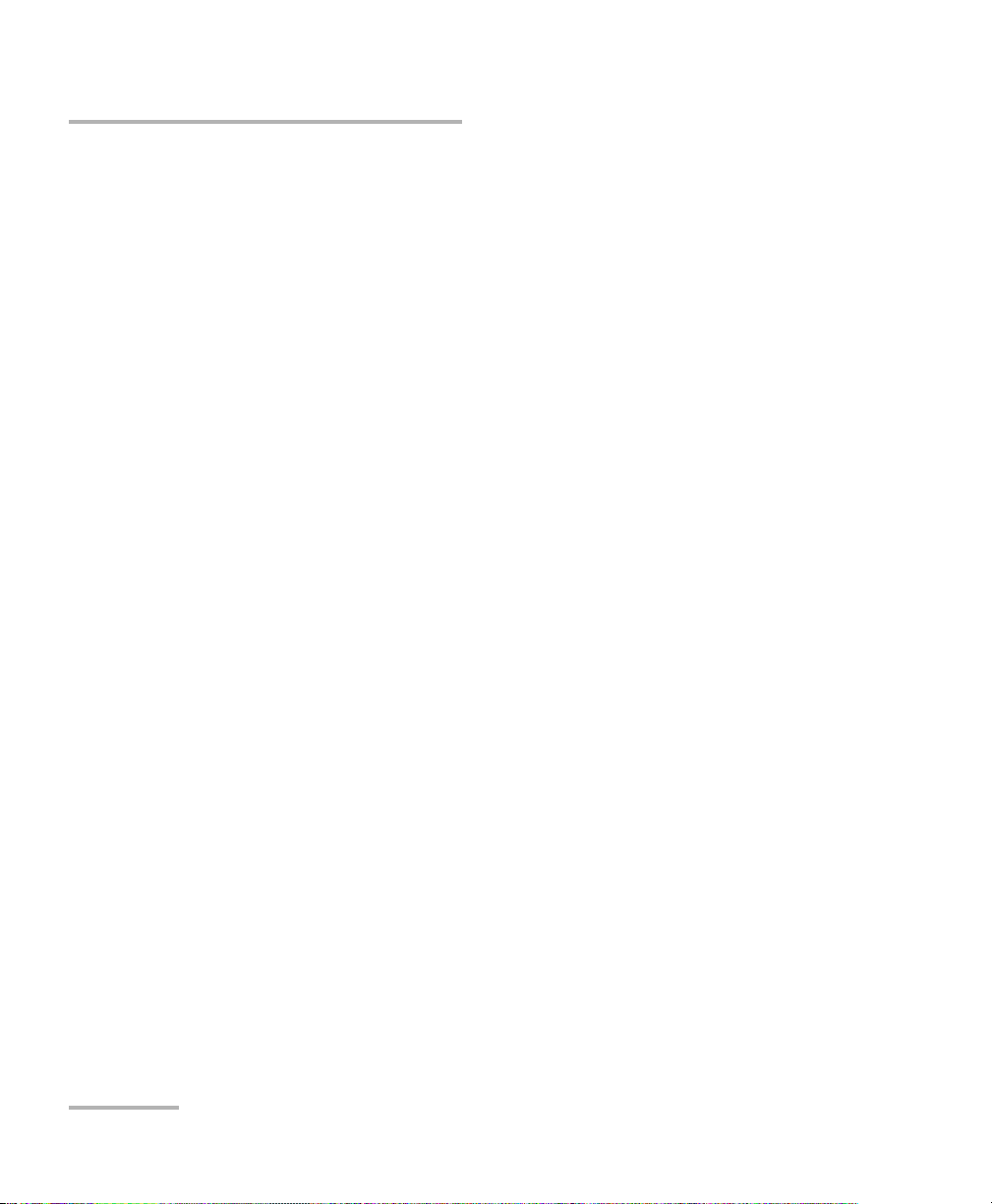

Your instrument is a Class 1M laser product in compliance with standards

IEC 60825-1 and 21 CFR 1040.10. Invisible laser radiation may be

encountered at the output port.

The product is safe under reasonably foreseeable conditions of operation

but it may be hazardous if you use optics within a diverging or collimated

beam. Do not view directly with optical instruments.

Tunable Laser Source 7

Page 16

Safety Information

Electrical Safety Information

Electrical Safety Information

The following safety precautions must be observed while operating and

servicing the unit. Failure to comply with these precautions or with specific

indications elsewhere in this manual violates safety standards of intended

use of the unit. EXFO assumes no liability for the user’s failure to comply

with these requirements.

This unit is intended for indoor use only.

Only fuses with the required rated current and specified type (IEC,

250 V, 2 A, fast blow, 0.197 in x 0.787 in/5 mm x 20 mm) may be used

for replacement. Do not use repaired fuses or short-circuited fuse

holders.

The power cable of the FLS-2600B Tunable Laser Source is the most

effective method to turn off the unit if a problem should occur.

Capacitors inside the unit may be charged, even if the unit has been

disconnected from its electrical supply.

Before turning on the unit, all grounding terminals, extensions cords,

and devices connected to it should also be connected to a protective

ground via a ground socket. Any interruption of the protective

grounding is a potential shock hazard and may cause personal injury.

Whenever the ground protection is impaired, the unit is not to be used,

and must be secured against any accidental or unintended operation.

Unit covers cannot be removed during operation.

Any adjustments, maintenance, and repair of opened units under

voltage should be avoided and carried out only by skilled personnel

aware of the hazards involved. Do not attempt internal service or

adjustment unless a person qualified to perform first aid is present.

Do not replace any components while power cable is connected.

8 FLS-2600B

Page 17

Safety Information

Electrical Safety Information

The unit must be positioned so as not to block the ventilation holes

located on each side of the unit and to allow easy disconnection of the

power cord if any problem should occur.

Operation of any electrical instrument around flammable gases or

fumes constitutes a major safety hazard.

Power Cable

This unit uses a three-wire power cable, which complies with international

safety standards. This cable serves as a ground when connected to an

appropriate AC power receptacle. The type of power cable supplied with

each unit is determined according to the country of destination.

Only qualified electricians should connect a new plug if needed. The color

coding used in the electrical cable depends on the cable. New plugs

should meet the local safety requirements and include the following

features:

adequate load-carrying capacity

ground connection

cable clamp

Tunable Laser Source 9

Page 18

Safety Information

Electrical Safety Information

To avoid electrical shock, do not operate the unit if there are signs

of damage to any part of the outer surface (covers, panels, etc.).

To avoid serious injury, you must observe the following precautions

before turning on the unit.

If the unit is to be powered via an auto-transformer for voltage

reduction, the common terminal must be connected to the

grounded power-source pole.

Insert the plug into a power outlet with a protective ground

contact. Do not use an extension cord without a protective

conductor.

Before turning on the unit, you must connect the protective

ground terminal of the unit to a protective conductor using the

unit power cord.

Do not tamper with the protective ground terminal.

WARNING

Equipment Ratings

Relative humidity 0 % to 80 % non-condensing

a

Maximum operation altitude 2000 m (6150 ft)

Pollution degree 2

Overvoltage category II

Power su p p ly ra ti ng

b

100 V to 240 V (50 Hz/60 Hz)

maximum 2 A

a. Measured in 0 °C to 31 °C (32 °F to 87.8 °F) range decreasing linearly to 50 % at 40 °C

(104 °F).

b. Not exceeding ± 10 % of the nominal voltage.

10 FLS-2600B

Page 19

3 Getting Started with Your

Tunable Laser Source

Turning on the Unit

Before turning on the FLS-2600B, please read the Safety Information on

page 7.

To turn the unit on and off, use the red button in the lower left-hand corner

of the front panel. The source is not active upon startup. To activate it, see

Activating/Deactivating Light Emission on page 42.

Upon startup, the unit beeps twice, performs a self-test, and then enters the

main menu with the same settings that were active when it was shut

down. When the unit is turned off, the following items remain in a storage

device called non-volatile memory:

current power setting

current wavelength setting

current mode (normal/high resolution)

current display mode (wavelength/power)

current Setup menu settings

shortlisted wavelengths (up to 100)

sweep parameters

saved sweep configurations (up to five)

Note: The power cord is the most effective disconnecting device. To ensure that

the unit is completely turned off, disconnect the power cord.

Tunable Laser Source 11

Page 20

Getting Started with Your Tunable Laser Source

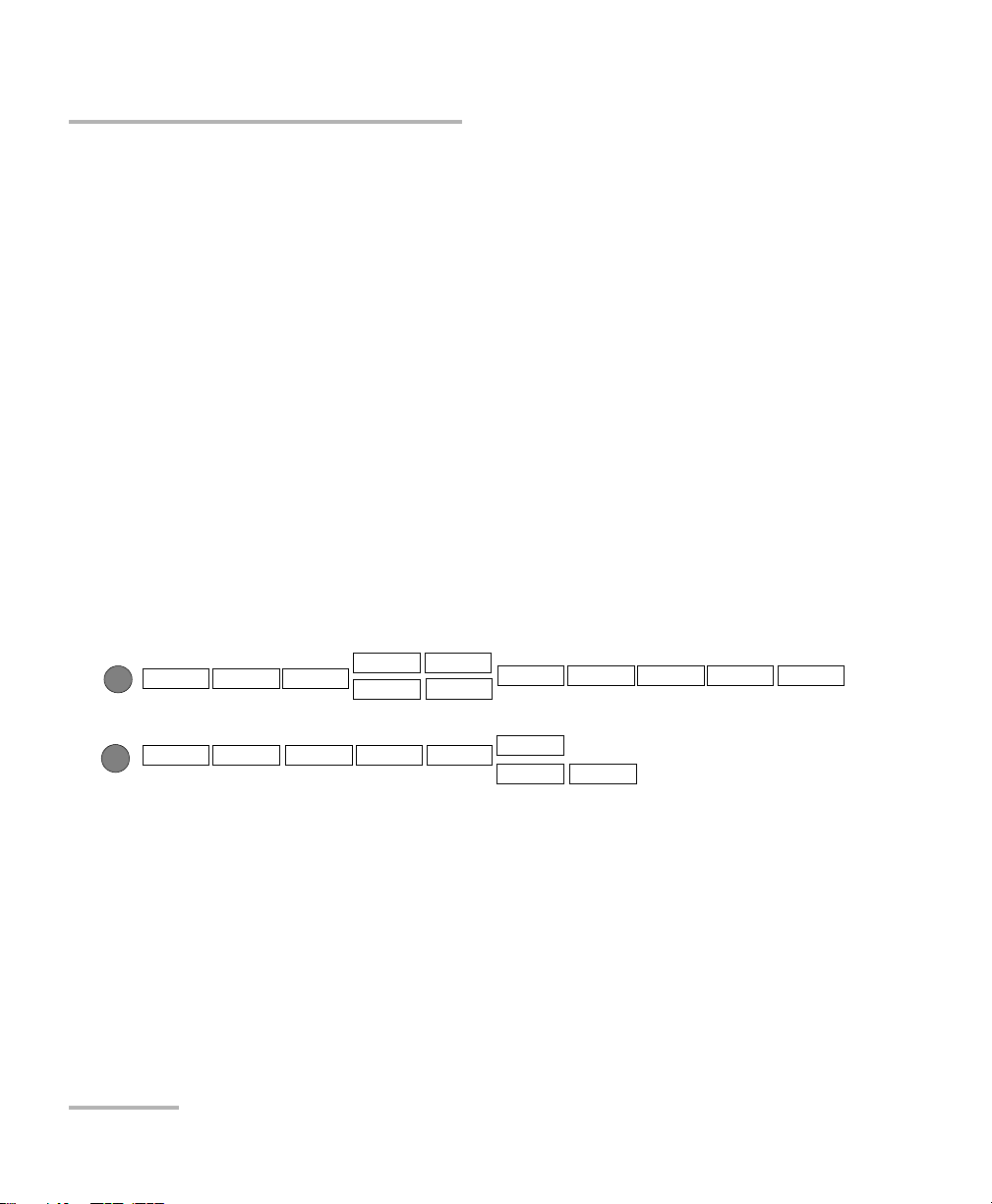

DURATION

Sweep

Setup

START

STOP

MODE

STEP PAUSE

CYCLE REVERSE TRIGGER

UNIT REMOTE

DEVICE

DIMMER

SAVE RECALL

SPEED

BAUD

FLOW

ADJUST

SOUND

Turning on the Unit

Some internal mechanisms can sometimes take several seconds to adjust,

depending on the operation.

The front panel control provides access to the following options:

source activation/deactivation

Normal or High-Resolution mode

wavelength editing

shortlisted wavelengths

power editing

shortlisted wavelength addition or deletion

start and stop sweep

The blue buttons to the right of the display give access to single-level

menus: Sweep and Setup. Unless a sweep is under way, these menus can

always be accessed, even while the source is active. The following

diagram shows these two menus and their items.

To move between the menu items, turn the selection dial. To exit a menu,

press the button that gave access to it (Sweep or Setup). The FLS-2600B

will return to its previous state.

Note: The unit will beep whenever the FLS-2600B does not allow an operation.

12 FLS-2600B

Page 21

Getting Started with Your Tunable Laser Source

Pos ition ing Your U nit Using the Support Stands

Positioning Your Unit Using the Support

Stands

To change the orientation of your unit, you can use the support stands

located on the bottom front part of the casing. Simply pull them down until

they lock into place.

Tunable Laser Source 13

Page 22

Page 23

4 Setting Standard Parameters

Edit

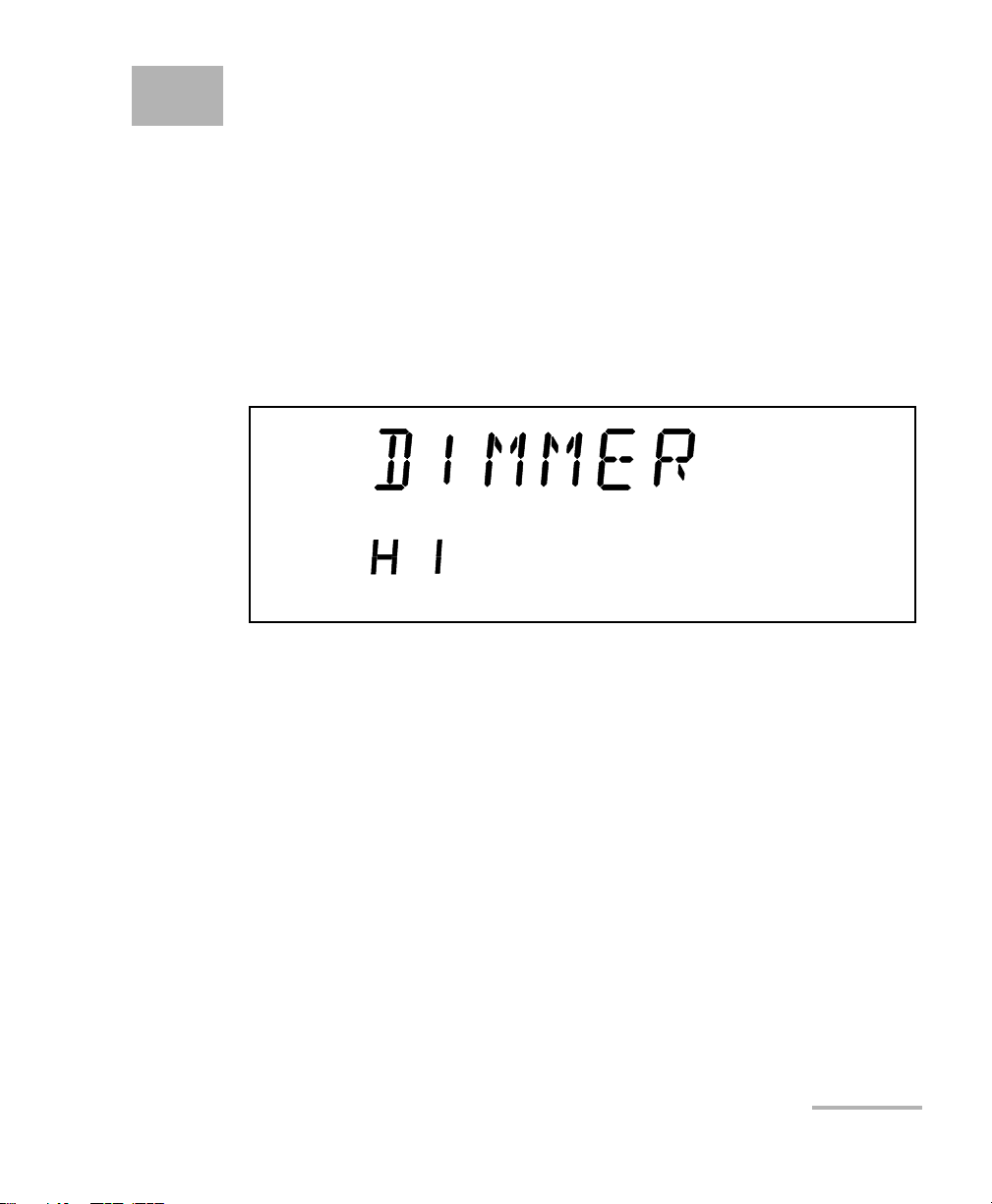

Setting the Display Intensity

You might want to set the display intensity of your unit, or turn the

display off.

To change the display intensity:

1. Press Setup.

2. Turn the selection dial clockwise until DIMMER is displayed.

The current dimmer status appears.

3. Press ENTER. The Edit marker starts blinking in the lower part of the

display.

4. Turn the selection dial until you see the desired display intensity (LO,

HI, OFF, or Auto. OFF), then press ENTER.

Setting the dimmer to OFF turns off the display. Press any key to turn the

display back on.

Setting the dimmer to Auto. OFF also turns off the display. Press any key to

turn the display back on. However, after five seconds, the display will

automatically turn off again.

5. To e x i t the Setup menu, press Setup.

Tunable Laser Source 15

Page 24

Setting Standard Parameters

Edit

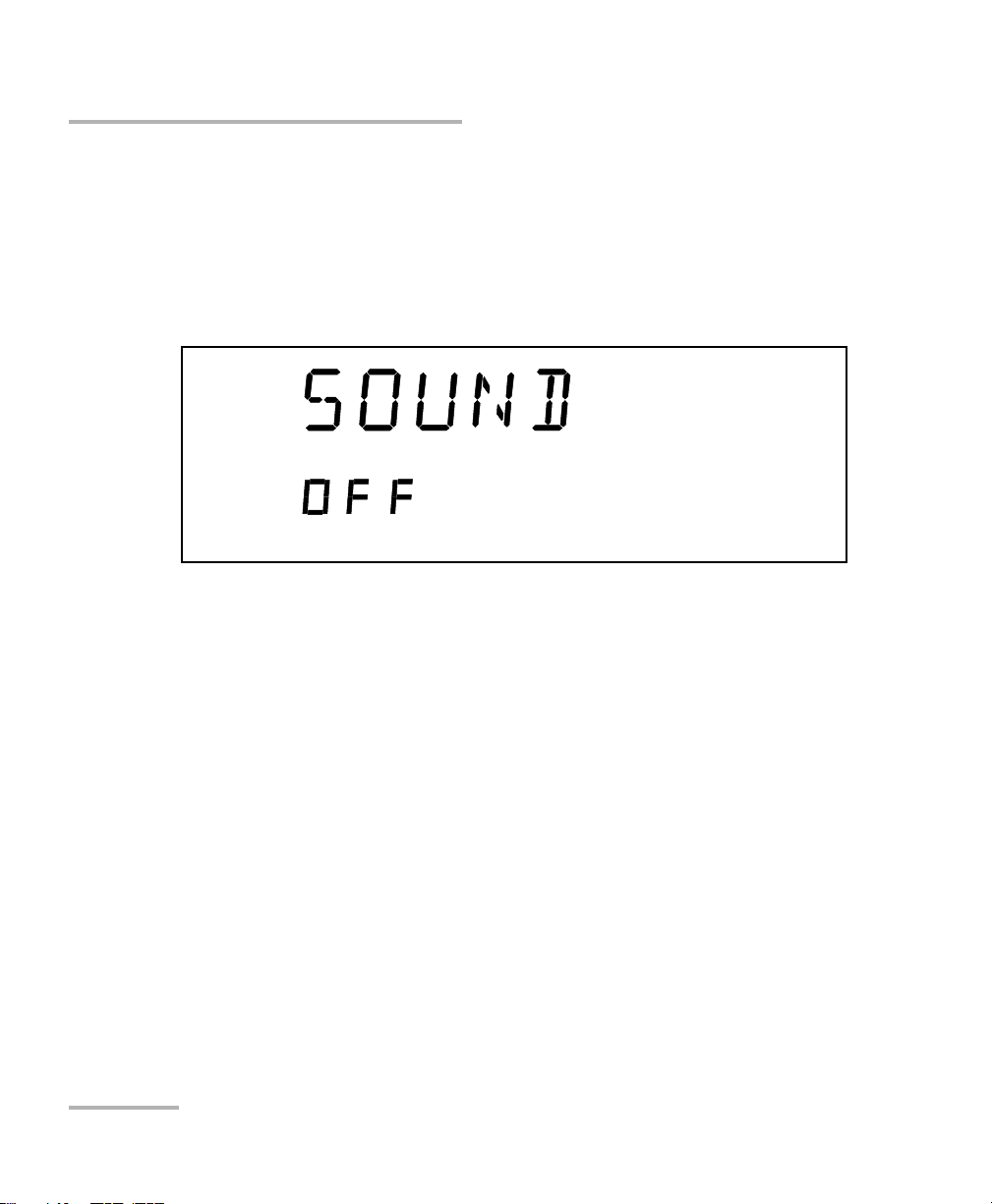

Turning the Sound On or Off

Turning the Sound On or Off

To turn the sound on your unit on or off:

1. Press Setup.

2. Turn the selection dial clockwise until SOUND is displayed. The current

sound status appears.

3. Press ENTER. The Edit marker starts blinking in the lower part of the

display.

4. Turn the selection dial until you reach the state you want (on or off),

then press ENTER.

To exi t the Setup menu, press Setup.

16 FLS-2600B

Page 25

Setting Standard Parameters

Switching between Normal and High-Resolution (HR) Modes

Switching between Normal and

High-Resolution (HR) Modes

In HR mode, the laser linewidth is reduced by a factor of 20 %. Typically, at

1550 nm, the Normal mode will produce a 1.6 GHz FWHM linewidth, while

the HR mode will produce a 1.4 GHz FWHM linewith. The tuning range

(or power at extreme wavelength) might be smaller in HR mode than in

Normal mode.

To select the operation mode:

Press the mode control button on the front panel.

Adjusting Decimals Using the Fine-Tune Feature

You can select values for your testing needs in two different ways:

Fine-tune and Coarse. If you press the Fine-tune button on the front panel,

Fine-tune appears on the display and you will be able to set the decimals.

If Fine-tune does not appear on the display, you are in Coarse mode and

can only adjust the numbers before the decimal point with the

selection dial.

Note: The Fine-tune feature applies to every numerical edition function with a

decimal point except in the Adjust submenu of the Setup menu.

See Adjusting Your Unit According to Wavelength on page 54 for more

information.

Tunable Laser Source 17

Page 26

Setting Standard Parameters

Selecting the Display Unit

Selecting the Display Unit

It is possible to select the display unit with which you want to work.

To select the display unit:

1. Press Setup.

2. The menu displays UNIT right away. Press ENTER to edit the units.

3. Turn the selection dial clockwise or counterclockwise to select the

desired unit (nm or THz).

4. Press ENTER to validate your choice and Setup to exit the Setup menu.

The selection affects all relevant wavelength settings, including those in the

Sweep.

18 FLS-2600B

Page 27

Setting Standard Parameters

Normal

nm

Fine-tune

dBm

Selecting a Wavelength

Selecting a Wavelength

There are several ways to select a wavelength for testing.

Entering a Wavelength Directly

To select a wavelength, make sure you are in Wavelength Edition mode.

To se l ect t h e Wavelength Edition mode, press the

front panel, so that

appears on the upper left-hand corner of the display.

/

List button on the

To select a specific wavelength, turn the selection dial clockwise or

counterclockwise until you reach the desired wavelength. The module will

then set the wavelength according to your selection.

If the set power cannot be maintained at the selected wavelength

(especially at extreme wavelengths), the displayed power value will flash,

a message appears in the status bar, and the power is no longer in constant

power mode. The output power stability and level will be the natural laser

emission.

To stop the power display from flashing and have the power regulation

work again, set the wavelength at an interval where the displayed power

can be reached, or decrease the power.

Tunable Laser Source 19

Page 28

Setting Standard Parameters

Normal

nm

list

Selecting a Wavelength

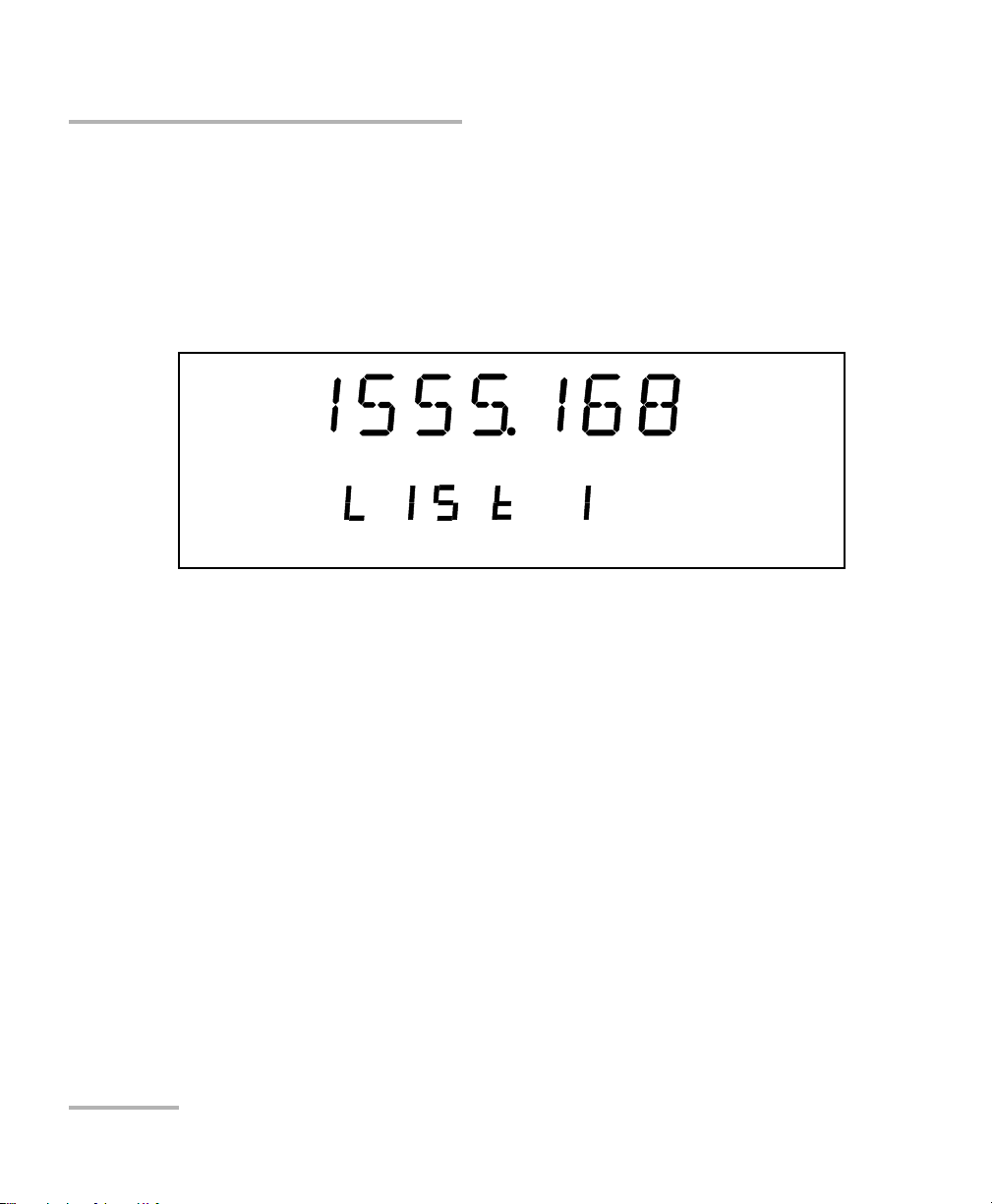

Retrieving a Wavelength from a Stored List

To select a wavelength from the list of wavelengths already

saved in the internal memory:

1. Ensure that you are in Wavelength List Edition mode. To select this

mode, press the

appears on the upper left-hand corner of the display.

2. Turn the selection dial clockwise or counterclockwise until you reach

the desired listed wavelength.

/

List button on the front panel so thatList

The list number corresponding to your wavelength selection will appear for

a few seconds, then the current power setting will reappear.

To add a wavelength to the list, see Adding Items to Lists on page 22.

20 FLS-2600B

Page 29

Setting Standard Parameters

Normal

nm

Fine-tune

Power

dBm

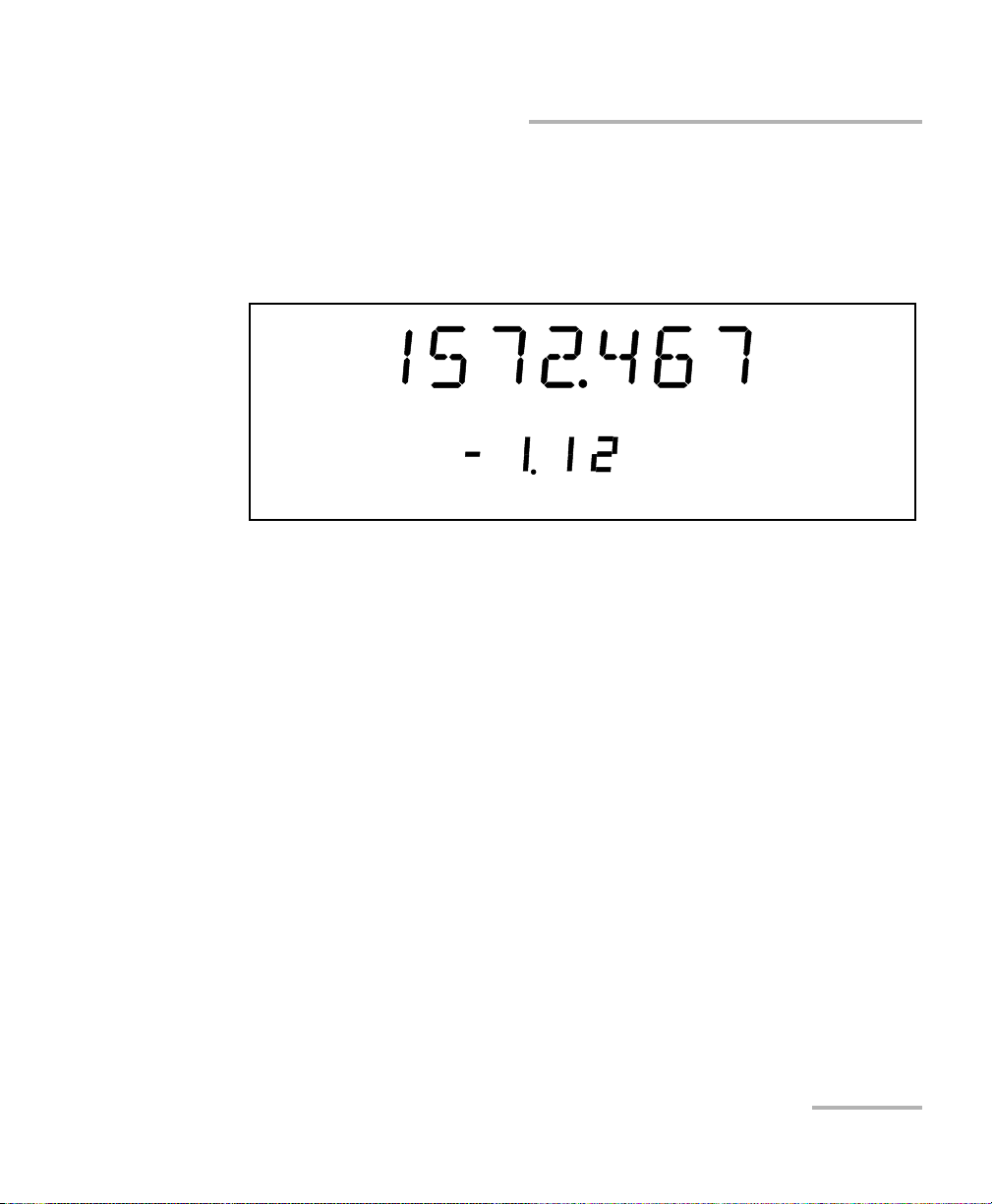

Setting the Power

Setting the Power

To set the output power, you must be in Power Edition mode. To select the

Power Edition mode, press the Power button on the front panel, so that

Power appears in the left part of the display.

To select a specific power value, turn the selection dial clockwise or

counterclockwise until you reach the desired power value. The source will

then send the command to set the power according to your selection.

Note: If the set power cannot be maintained at the selected wavelength

(especially at extreme wavelengths), the displayed power value will flash

and you will no longer be in Constant Power mode. The output power

stability and level will be the natural laser emission. To stop the power

display from flashing and have the power regulation work again, set the

wavelengths at an interval where the displayed power can be reached or

select a lower power for your wavelength. For more information on how to

set a specific wavelength, see Entering a Wavelength Directly on page 19.

Your source can either be in Normal Power mode (where the ALC is

enabled), or in Max. Power mode (where the ALC is disabled).

To ch a nge t h e Automatic Level Control status, press on the Power/Pmax.

button. If you see Power on the left side of the display, you are in Normal

Pow er mode. If you see Max. Power on the right side of the display, you are

in Max. Power mode. Once you have selected Max. Power, the unit reverts

to or List mode, according to the one you used last.

Tunable Laser Source 21

Page 30

Setting Standard Parameters

Adding Items to Lists

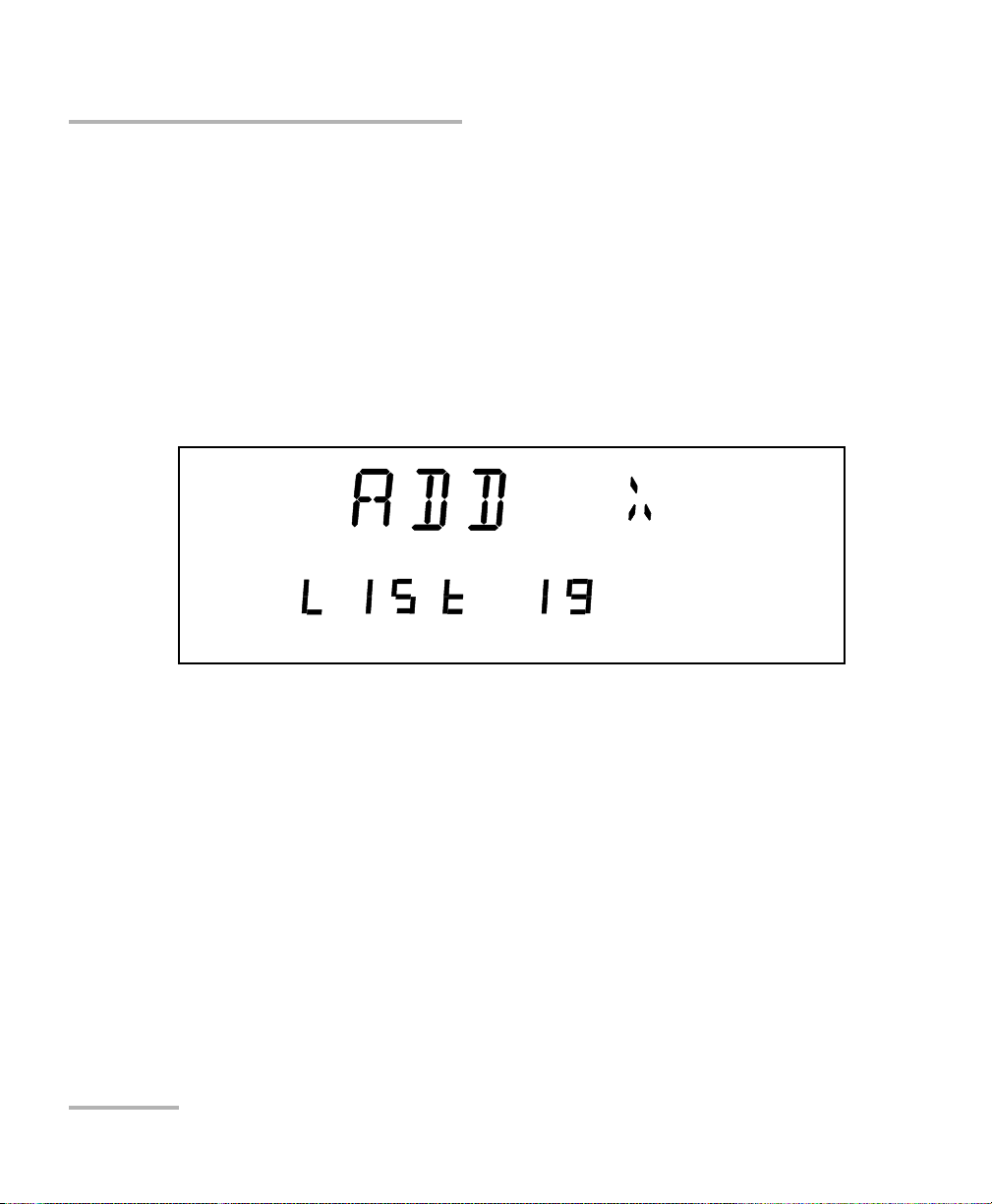

Adding Items to Lists

You can add items to the current list of wavelengths.

To add items:

1. Make sure you are in Wavelength Edition mode (

the Wavelength Edition mode, see Selecting a Wavelength on page 19.

2. Turn the selection dial clockwise or counterclockwise until you reach

the desired wavelength.

3. Press the Add button on the front panel.

mode). To select

To indicate that the new wavelength was saved, a number between

1 and 100, stating the wavelength’s rank in the list, as well as the

ADD mention, will appear. If the list is full, the display will indicate FULL,

and you will hear a beep. You will need to delete some wavelengths before

adding more to the list.

The new wavelength is always added to the end of the list, regardless of its

value, using the next available list number. This means that your entries will

not be in ascending or descending numerical order if not entered as such.

To create an ascending list of wavelengths, enter your values beginning

with the lowest and finishing with the highest. To create a descending list

of wavelengths, simply enter your values from highest to lowest.

22 FLS-2600B

Page 31

Setting Standard Parameters

Deleting Items from Lists

Deleting Items from Lists

You can delete items from the current list of wavelengths.

To d el e te it e ms :

1. Make sure you are in Wavelength List Edition mode (

To se l ect t h e Wavelength List Edition mode, see Retrieving a

Wavelength from a Stored List on page 20.

2. Turn the selection dial clockwise or counterclockwise until you reach

the desired listed wavelength.

3. Press the Del button on the front panel.

List mode).

To indicate that the wavelength was deleted, a number between 1 and 100,

stating the wavelength’s rank in the list, as well as the DEL

appear. If the list is empty, the display will indicate EMPTY, and you will

hear a beep.

Note: Deleting a wavelength will shift the ranking of the other entries.

For example, if you delete entry number 3 in a list of five items, number 4

will become 3 and number 5 will become 4.

Tunable Laser Source 23

mention will

Page 32

Setting Standard Parameters

Using the Monitor Output

Using the Monitor Output

The monitor output of the FLS-2600B, located on the front of the unit, is

mainly used to monitor the wavelength of the emitted signal with a

wavelength meter. The power available through the monitor corresponds

to approximately 10 % of the total power output, even though neither this

fraction nor the power stability emitted are guaranteed.

You cannot deactivate the monitor output.

IMPORTANT

24 FLS-2600B

Page 33

Setting Standard Parameters

Saving and Recalling Configurations

Saving and Recalling Configurations

Once you have set the FLS-2600B Tunable Laser Source parameters, you

can save your custom configuration and recall it at any time. You can also

recall the factory-defined settings.

Note: You can save or recall up to five configurations.

Saved parameters are

Start wavelength of the sweep

End wavelength of the sweep

Number of sweeps (1-99 or loop)

Sweep speed (Continuous mode)

Sweep duration (Continuous mode)

Step size (Step-by-Step mode)

Pause length (Step-by-Step mode)

Reverse status (ON/OFF)

Trigger status (ON/OFF)

Tunable Laser Source 25

Page 34

Setting Standard Parameters

Edit

Edit

Saving and Recalling Configurations

To save or recall a sweep configuration:

1. Press Sweep.

2. Turn the selection dial clockwise until SAVE or RECALL is displayed,

depending on the action you want to perform.

3. Press ENTER. The Edit marker starts blinking in the lower left-hand

corner of the display.

4. Turn the selection dial clockwise or counterclockwise to select the

desired number where you want to save your configuration.

5. Press ENTER to validate your choice, and Sweep to exit the Sweep

menu.

26 FLS-2600B

Page 35

Setting Standard Parameters

Reverting to Factory Settings

Reverting to Factory Settings

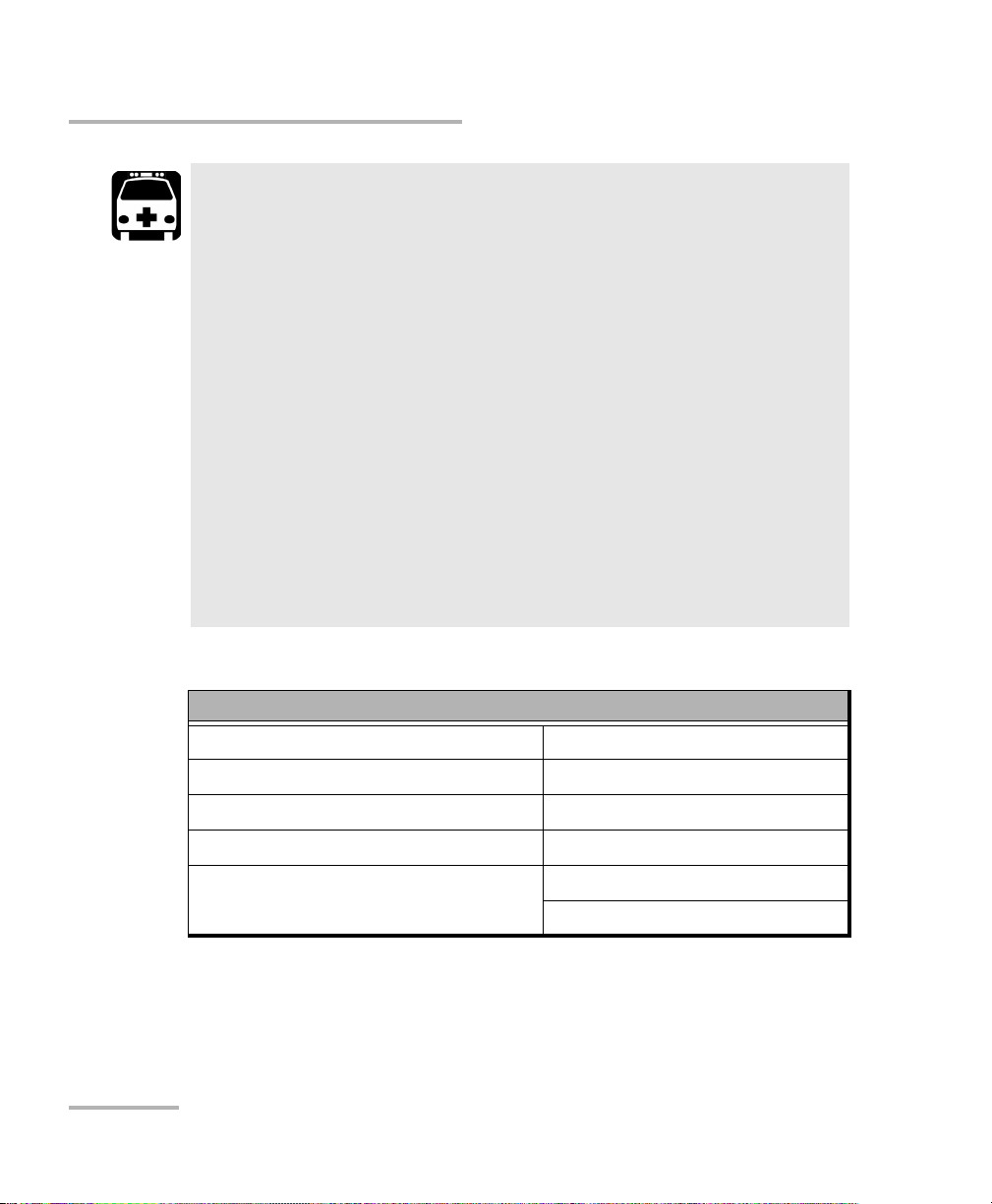

Turning on the unit and pressing ENTER at the same time until it beeps

three times will reset the unit to the following default values:

Parameters Reset Value or State

Edit mode (/ list)|(Power)

Source mode (Normal|HR) Normal

Lambda unit (nm|THz) nm

Fine-tune (Active|Inactive) Active

Lambda 1550.000 nm

Power 0.0 d Bm

Lambda list Empty

Lambda list index (0-100) 1

Sweep program (1-5) 1

Dimmer status (Hi, Low, Off, Auto. Off) Hi

Key sound (On|Off) Off

Sweep range 1540.000 nm to 1560.000 nm

Sweep mode Continuous

Speed 10.000 nm/s

Step 10.000 nm

Pause 1000 ms (1 second)

Cycles (1-99 or Loop) Loop

Reverse (Active|Inactive) Inactive

Trigger (Active|Inactive) Inactive

GPIB Address

RS-232/GPIB

a. This setting will only change with a local reset.

Tunable Laser Source 27

a

a

12

GPIB

Page 36

Page 37

5 Setting Sweep Parameters

Fine-tune

Edit

nm

Your tunable laser source allows you to perform automatic wavelength

scans according to user-defined parameters. You can perform a

continuous sweep (the source will make one or several continuous

passes), or you can perform a step-by-step sweep (the signal wavelength

changes according to preset increments or steps).

Setting the Start and End Wavelengths

The wavelength scans and their lengths (or duration) depend on the start

and end wavelengths you set.

To set the wavelengths for your scans:

1. Press Sweep. You will be in the START

menu.

2. Press ENTER. The Edit marker starts blinking in the lower part of the

display.

3. Tu r n t h e se l e cti o n dia l clockwise or counterclockwise until the desired

wavelength is displayed.

4. Press ENTER. You can select a wavelength at a resolution of 0.001 nm.

5. To e x i t the Sweep menu, press Sweep.

OR

Tunable Laser Source 29

Turn the dial clockwise or counterclockwise until EXIT is displayed,

then press ENTER.

Page 38

Setting Sweep Parameters

Edit

Selecting the Sweep Mode

To set the end wavelength, repeat the process, but after pressing on

Sweep, turn the selection dial clockwise until

Note: The start and end wavelengths of the sweep can be set in ascending or

descending order, with a minimum value of 1.0 nm. The sweep will be

performed accordingly.

STOP is displayed.

Selecting the Sweep Mode

You can select the sweep mode you want to perform in the Sweep menu.

The source will use either the Continuous or Stepped mode.

To set the sweep mode you want to use:

1. Press Sweep.

2. Turn the selection dial clockwise until

3. Press ENTER. The Edit marker starts blinking in the bottom left-hand

corner of the display.

4. Turn the selection dial clockwise or counterclockwise until the desired

mode is displayed: Continuous (Cont.) or Step-by-Step (Step).

5. Press ENTER to confirm your choice, and then Sweep to exit the

Sweep menu.

The sweeps will now be performed according to the mode you have

selected.

MODE is displayed.

30 FLS-2600B

Page 39

Setting Sweep Parameters

Edit

nm

Setting the Sweep Step

Setting the Sweep Step

You can set the size of the step (in nm or THz) for your step-by-step sweep.

Your tunable laser source unit was designed to give a constant step value

using nm as units. When steps are given in THz, the selected step value

represents the average value of the steps during the sweep, since an

interval in nm does not always have the save equivalent value in THz

according to the wavelength bandwidth you have selected.

To set the step:

1. Make sure you have selected the step-by-step sweeping mode (as seen

in Selecting the Sweep Mode on page 30).

2. Press Sweep.

3. Turn the selection dial clockwise until STEP is displayed.

4. Press ENTER. The Edit marker starts blinking in the lower part of the

display.

5. Turn the selection dial clockwise or counterclockwise to select the

desired size for the step.

Tunable Laser Source 31

Page 40

Setting Sweep Parameters

Setting the Pauses

6. Press ENTER to validate your choice, and Sweep to exit the menu.

OR

Turn the dial clockwise or counterclockwise until EXIT is displayed,

then press ENTER.

Note: If the sweep wavelength range is not a multiple of the step value selected,

the stop wavelength will be truncated to the nearest possible value, thus

reducing the range.

Setting the Pauses

You can set a time interval or pauses between steps. First, make sure you

have selected the Step-by-Step sweep mode. For more information, see

Selecting the Sweep Mode on page 30.

To set the length of the pauses between the steps:

1. Press Sweep.

2. Turn the selection dial clockwise until PAUSE is displayed.

3. Press ENTER. The Edit marker starts blinking in bottom left-hand

corner of the display.

32 FLS-2600B

Page 41

Setting Sweep Parameters

Fine-tune

Edit

m/s/ms

Setting the Sweep Speed

4. Turn the selection dial clockwise or counterclockwise to select the

desired length of time for the pause. The pause range goes from

0.050 to 60.000 seconds.

5. Press ENTER to validate your choice, and Sweep to exit the Sweep

menu.

Setting the Sweep Speed

You can change the sweep speed when you are in Continuous mode.

For more information on setting the mode to Continuous, see Selecting the

Sweep Mode on page 30.

To change the speed:

1. Press Sweep.

2. Turn the selection dial clockwise until SPEED is displayed.

3. Press ENTER. The Edit marker starts blinking in the bottom left-hand

corner of the display.

Tunable Laser Source 33

Page 42

Setting Sweep Parameters

Fine-tune

Edit nm/s

Setting the Sweep Speed

4. Turn the selection dial clockwise or counterclockwise to select the

desired speed of the sweep.

.

5. Press ENTER to validate your choice, and Sweep to exit the Sweep

menu.

Note: Setting the speed will automatically determine the duration of one pass

according to the selected range.

Your FLS-2600B unit was designed to give a constant speed value using nm

as units. When the speed is given in a THz environment, the selected

speed value represents the average value during the sweep, since an

interval in nm does not always have the same equivalent value in THz

according to the wavelength bandwidth you have selected.

Note: You cannot edit the duration of the scan. It will be automatically calculated

according to the speed and wavelength range.

To add or delete steps from the lists, see Adding Items to Lists on page 22

and Deleting Items from Lists on page 23.

34 FLS-2600B

Page 43

Setting Sweep Parameters

Edit

Selecting the Incoming Trigger Option

Selecting the Incoming Trigger Option

The incoming trigger option allows you to synchronize your sweeps with

signals from other units.

To switch the incoming trigger option on or off:

1. Press Sweep.

2. Turn the selection dial clockwise until TRIGGER is displayed.

3. Press ENTER. The Edit marker starts blinking in the lower part of the

display.

4. Turn the selection dial clockwise or counterclockwise to turn the

Trigger option on or off.

5. Press ENTER to validate your choice and Sweep to exit the Sweep

menu.

For more information about the trigger option on your tunable laser source,

see Trigger Option Theory on page 69.

Tunable Laser Source 35

Page 44

Setting Sweep Parameters

Edit

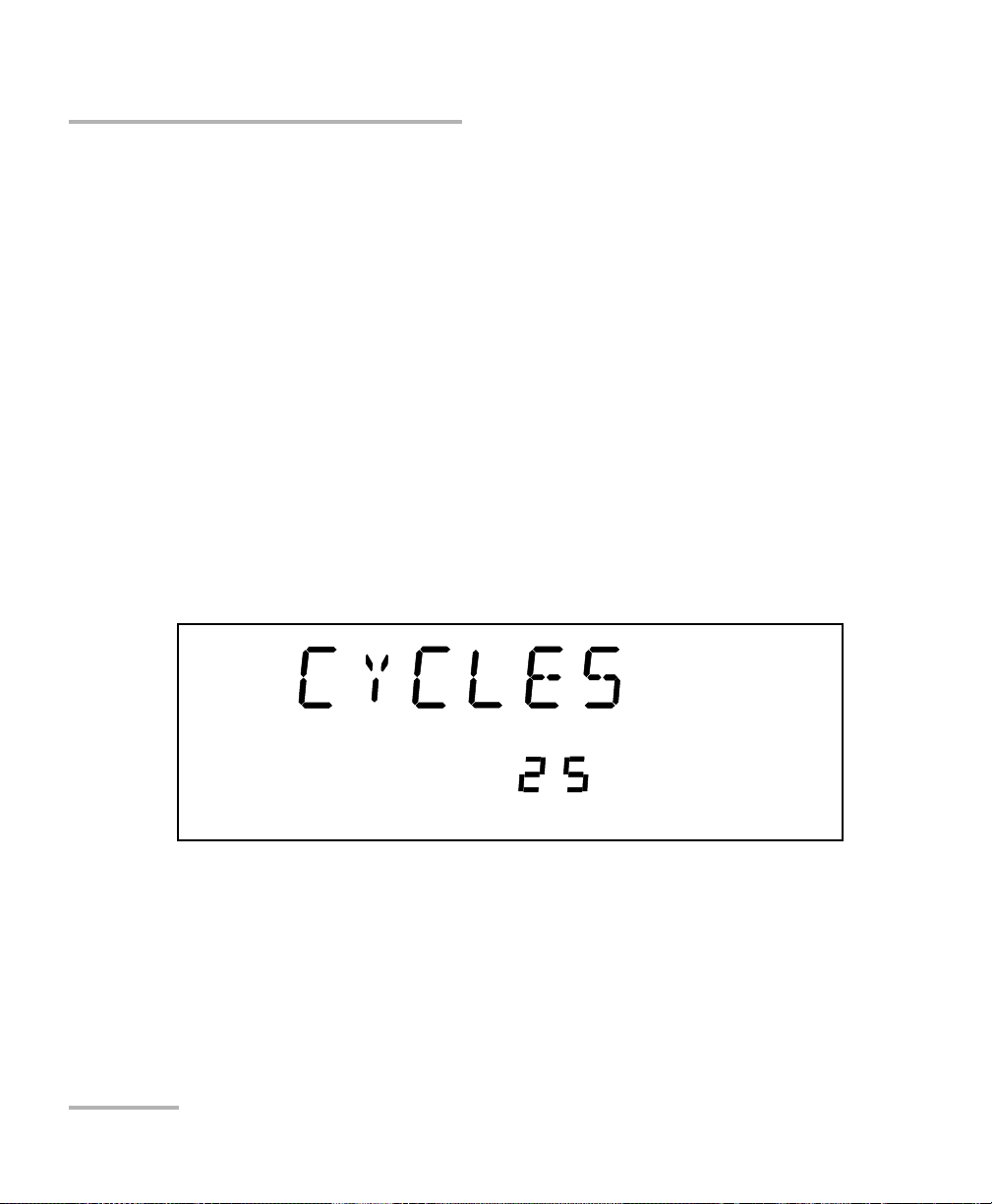

Setting the Cycle Options

Setting the Cycle Options

The cycle options allow you to specify settings in both continuous and

stepped sweep modes.

You can set a specific number of cycles for the sweep to perform.

To set the number of cycles:

1. Press Sweep.

2. Turn the selection dial clockwise until CYCLES is displayed.

3. Press ENTER. The Edit marker starts blinking in the bottom left-hand

corner of the display.

4. Turn the selection dial clockwise or counterclockwise to select the

desired number of sweep cycles. You can select a number from

1 to 99. You can also select Continuous cycling by turning the selection

dial counterclockwise until you pass 1. The display will then indicate

Loop.

5. Press ENTER to validate your choice, and Sweep to exit the Sweep

menu.

36 FLS-2600B

Page 45

Setting Sweep Parameters

Edit

Setting the Sweep Direction

Setting the Sweep Direction

The sweep can be either unidirectional, meaning that it will only go in one

direction, or bidirectional, sweeping back and forth. This is set through the

Reverse feature of your FLS-2600B.

To set the direction of the sweep:

1. Press Sweep.

2. Turn the selection dial clockwise until REVERSE is displayed.

3. Press ENTER. The Edit marker starts blinking in the bottom left-hand

corner of the display.

4. Turn the selection dial clockwise or counterclockwise to turn the

Reverse option on or off.

5. Press ENTER to validate your choice, and Sweep to exit the Sweep

menu.

Tunable Laser Source 37

Page 46

Page 47

6 Operating your Tunable Laser

Source

Cleaning and Connecting Optical Fibers

IMPORTANT

To ensure maximum power and to avoid erroneous readings:

Always inspect fiber ends and make sure that they are clean as

explained below before inserting them into the port. EXFO is

not responsible for damage or errors caused by bad fiber

cleaning or handling.

Ensure that your patchcord has appropriate connectors. Joining

mismatched connectors will damage the ferrules.

To connect the fiber-optic cable to the port:

1. Inspect the fiber using a fiber inspection microscope. If the fiber is

clean, proceed to connecting it to the port. If the fiber is dirty, clean it as

explained below.

2. Clean the fiber ends as follows:

2a. Gently wipe the fiber end with a lint-free swab dipped in isopropyl

alcohol.

2b. Use compressed air to dry completely.

2c. Visually inspect the fiber end to ensure its cleanliness.

Tunable Laser Source 39

Page 48

Operating your Tunable Laser Source

Cleaning and Connecting Optical Fibers

3. Carefully align the connector and port to prevent the fiber end from

touching the outside of the port or rubbing against other surfaces.

If your connector features a key, ensure that it is fully fitted into the

port’s corresponding notch.

4. Push the connector in so that the fiber-optic cable is firmly in place,

thus ensuring adequate contact.

If your connector features a screwsleeve, tighten the connector

enough to firmly maintain the fiber in place. Do not overtighten, as this

will damage the fiber and the port.

Note: If your fiber-optic cable is not properly aligned and/or connected, you will

notice heavy loss and reflection.

40 FLS-2600B

Page 49

Operating your Tunable Laser Source

Bare metal

(or blue border)

indicates UPC

option

Green border

indicates APC

option

2 3 4

Installing the EXFO Universal Interface (EUI)

Installing the EXFO Universal Interface (EUI)

The EUI fixed baseplate is available for connectors with angled (APC) or

non-angled (UPC) polishing. A green border around the baseplate

indicates that it is for APC-type connectors.

To install an EUI connector adapter onto the EUI baseplate:

1. Hold the EUI connector adapter so the dust cap opens downwards.

2. Close the dust cap in order to hold the connector adapter more firmly.

3. Insert the connector adapter into the baseplate.

4. While pushing firmly, turn the connector adapter clockwise on the

baseplate to lock it in place.

Tunable Laser Source 41

Page 50

Operating your Tunable Laser Source

Activating/Deactivating Light Emission

Activating/Deactivating Light Emission

Before turning on the Tunable Laser Source, please read the Safety

Information on page 7.

If the source has been exposed to extreme conditions or if you feel that a

calibration would help you achieve better results, you can perform an

offset calibration as described in Adjusting Your Unit According to

Wavelength on page 54.

To activate or deactivate the light emission:

1. Press the On/Off button. The Source init. marker appears on the

display.

2. The Active LED lights up on the module front panel to indicate that the

source is active at the wavelength, output power, and mode currently

selected.

3. To deactivate the source, press On/Off again.

The Active LED usually lights up immediately, but the laser power is

ramped to its maximum in about five seconds. If an error occured

with the power prior to the source initialization, the active LED can

take up to three seconds to light up.

IMPORTANT

IMPORTANT

To obtain optimum stability, a laser source should be allowed to

warm up for 60 minutes.

42 FLS-2600B

Page 51

Operating your Tunable Laser Source

Starting a Sweep

Starting a Sweep

After setting your sweep parameters as explained in Setting Sweep

Parameters on page 29 and that your source is turned on, you are ready to

start your sweep.

To start the sweep, press the Start button on the front panel. The system

will perform the sweep according to the settings you have entered.

To stop the sweep before it is completed, press the Stop button on the

front panel.

Note: You can stop the sweep at any time. Turning the laser on or off will also

stop the sweep.

Tunable Laser Source 43

Page 52

Page 53

7 Maintenance

To help ensure long, trouble-free operation:

Always inspect fiber-optic connectors before using them and clean

them if necessary.

Keep the unit free of dust.

Clean the unit casing and front panel with a cloth slightly dampened

with water.

Store unit at room temperature in a clean and dry area. Keep the unit

out of direct sunlight.

Avoid high humidity or significant temperature fluctuations.

Avoid unnecessary shocks and vibrations.

If any liquids are spilled on or into the unit, turn off the power

immediately, disconnect from any external power source, remove the

batteries and let the unit dry completely.

Use of controls, adjustments, and procedures for operation and

maintenance other than those specified herein may result in

hazardous radiation exposure.

WARNING

Tunable Laser Source 45

Page 54

Maintenance

Cleaning Fixed Connectors

Cleaning Fixed Connectors

Regular cleaning of connectors will help maintain optimum performance.

Do not try to disassemble the unit. Doing so would break the connector.

To clean fixed connectors:

1. Fold a lint-free wiping cloth in four to form a square.

2. Moisten the center of the lint-free wiping cloth with only one drop of

isopropyl alcohol.

Alcohol may leave traces if used abundantly. Avoid contact between

the tip of the bottle and the wiping cloth, and do not use bottles

that distribute too much alcohol at a time.

3. Gently wipe the connector threads three times with the folded and

moistened section of the wiping cloth.

IMPORTANT

IMPORTANT

Isopropyl alcohol takes approximately ten seconds to evaporate.

Since isopropyl alcohol is not absolutely pure, evaporation will

leave microscopic residue. Make sure you dry the surfaces before

evaporation occurs.

4. With a dry lint-free wiping cloth, gently wipe the same surfaces three

times with a rotating movement.

5. Throw out the wiping cloths after one use.

6. Moisten a cleaning tip (2.5 mm tip) with only one drop of isopropyl

alcohol.

46 FLS-2600B

Page 55

Maintenance

7

8

9

Cleaning Fixed Connectors

IMPORTANT

Alcohol may leave traces if used abundantly. Avoid contact between

the tip of the bottle and the cleaning tip, and do not use bottles

that distribute too much alcohol at a time.

7. Slowly insert the cleaning tip into the connector until it reaches the

ferrule inside (a slow clockwise rotating movement may help).

8. Gently turn the cleaning tip one full turn.

9. Continue to turn as you withdraw the cleaning tip.

10. Repeat steps 7 to 9, but this time with a dry cleaning tip (2.5 mm tip

provided by EXFO).

Note: Make sure you don’t touch the soft end of the cleaning tip and verify the

cleanliness of the cotton tip.

11. Throw out the cleaning tips after one use.

Tunable Laser Source 47

Page 56

Maintenance

Push

Tur n

Pull

3

4

5

Cleaning EUI Connectors

Cleaning EUI Connectors

Regular cleaning of EUI connectors will help maintain optimum

performance. There is no need to disassemble the unit.

If any damage occurs to internal connectors, the module casing will

have to be opened and a new calibration will be required.

To clean EUI connectors:

1. Remove the EUI from the instrument to expose the connector

baseplate and ferrule.

IMPORTANT

2. Moisten a 2.5 mm cleaning tip with one drop of isopropyl alcohol

(alcohol may leave traces if used abundantly).

3. Slowly insert the cleaning tip into the EUI adapter until it comes out on

the other side (a slow clockwise rotating movement may help).

4. Gently turn the cleaning tip one full turn, then continue to turn as you

withdraw it.

48 FLS-2600B

Page 57

Cleaning EUI Connectors

5. Repeat steps 3 to 4 with a dry cleaning tip.

Note: Make sure you don’t touch the soft end of the cleaning tip.

6. Clean the ferrule in the connector port as follows:

6a. Deposit one drop of isopropyl alcohol on a lint-free wiping cloth.

IMPORTANT

Isopropyl alcohol may leave residues if used abundantly or left to

evaporate (about 10 seconds).

Avoid contact between the tip of the bottle and the wiping cloth,

and dry the surface quickly.

6b. Gently wipe the connector and ferrule.

6c. With a dry lint-free wiping cloth, gently wipe the same surfaces to

ensure that the connector and ferrule are perfectly dry.

6d. Verify connector surface with a portable fiber-optic microscope

(for example, EXFO’s FOMS) or fiber inspection probe (for

example, EXFO’s FIP).

Maintenance

WARNING

Verifying the surface of the connector WHILE THE UNIT IS ACTIVE

WILL result in permanent eye damage.

7. Put the EUI back onto the instrument (push and turn clockwise).

8. Throw out cleaning tips and wiping cloths after one use.

Tunable Laser Source 49

Page 58

Maintenance

Replacing the Fuse

Replacing the Fuse

The FLS-2600B contains two fuses of type IEC, 250 V, 2 A, fast blow

0.197 in x 0.787 in/5 mm x 20 mm. The fuse holder is located at the back of

the FLS-2600B, just beside the power inlet.

To replace the fuses:

1. Unplug the power cord from the FLS-2600B.

2. Pull the fuse holder out of the FLS-2600B.

3. Check and replace the fuses if necessary.

Employer uniquement avec

Use only with a 250V fuse

un fusible de 250V

4. Make sure the fuses are placed firmly in the holder prior to its

reinsertion.

5. Firmly push the holder into place.

50 FLS-2600B

Page 59

Maintenance

Software Upgrades

Software Upgrades

To upgrade the FLS-2600B embedded software using a diskette, you must

connect your FLS-2600B to a computer through a null modem cable.

Note: Software upgrades may be performed in DOS, Windows 3.1, Windows 95,

Windows 98 or Windows 2000. If problems occur, please contact EXFO.

IMPORTANT

When using a notebook computer to upgrade the FLS-2600B

software, you should perform the upgrade in a DOS environment.

Proceed with the software upgrade only if the version indicated on

the diskette is greater than the software version currently installed

in your unit. To check the software version currently installed on

your unit, see the information displayed at startup.

Tunable Laser Source 51

Page 60

Maintenance

Software Upgrades

To perform a software upgrade:

1. Turn off the FLS-2600B.

2. If it is not already done, turn on the computer.

3. On the hard disk of your computer, create a directory named "Tes t"

4. Insert the upgrade diskette into the computer’s floppy disk drive and

5. Connect one end of a null modem cable to the FLS-2600B RS-232 serial

6. If the software upgrade is performed in Windows 98, you have to

(C:\Test).

copy the *.hex file into the new directory (if necessary, unzip the file).

port and the other end to an unused communication port on your

computer (ex. COM2).

restart your computer in DOS mode before starting the upgrade

program. Otherwise, simply exit to DOS.

From C:\Te st directory, type LO0006.exe /c:2 /F:C:\Test\*.hex,

which can be decoded as follows:

2 represents the serial port number. In this case, it means COM2.

There is a space between LO0006.exe and /.

There is a space between c:2 and /F.

* represents the name of the file. Do not type *.hex, but rather the

actual name of the file you copied to your hard disk.

7. Press Enter.

52 FLS-2600B

Page 61

Maintenance

Software Upgrades

8. When the Waiting for device handshake message appears, turn on the

FLS-2600B. The FLS-2600B screen will remain off; the unit will beep

once and the update program will start automatically. A progress bar

on the computer screen will indicate the status of the software

upgrade.

9. Once the software upgrade is complete, the Reboot device for self-test

message will appear. If the software upgrade was performed in

Windows 2000, the following error message will be displayed: LO0006

NTVDM has encountered a System Error. The parameter is incorrect.

Select “Close” to terminate the application. Click Close to hide the

dialog box.

10. You must turn the FLS-2600B off, and then on again, to use the

upgraded software. During self-test execution, the FLS-2600B should

display the new software version number.

Tunable Laser Source 53

Page 62

Maintenance

Edit

nm

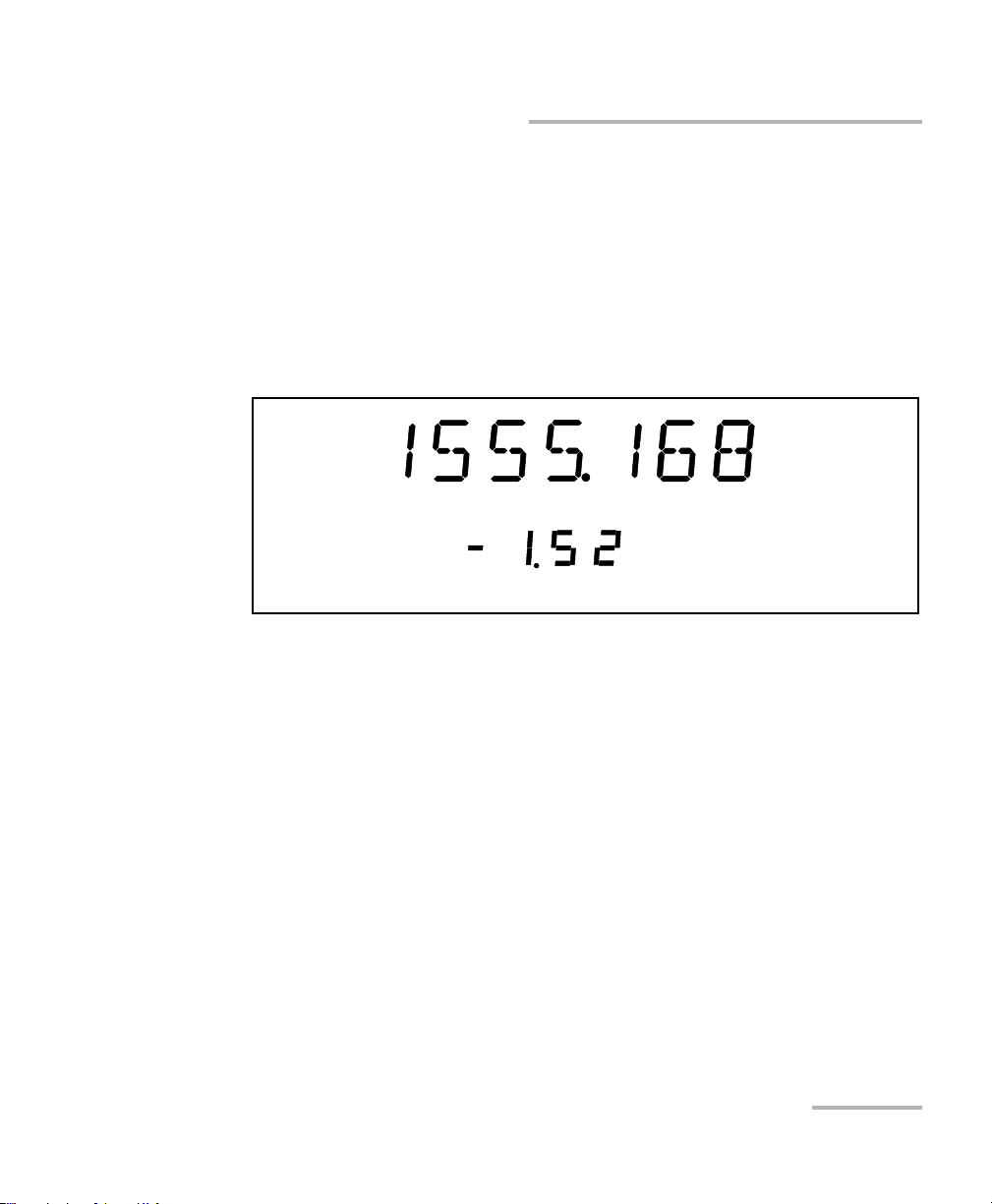

Adjusting Your Unit According to Wavelength

Adjusting Your Unit According to Wavelength

It is possible to introduce an offset in your Tunable Laser Source to correct

a wavelength deviation as measured by a reference wavelength meter.

Note: A calibrated wavelength meter is required to perform a user calibration on

your unit.

To adjust your module at a certain wavelength:

1. Turn your Tunable Laser Source on.

2. Press Setup.

3. Turn the selection dial until ADJUST is displayed. The default

pre-selected wavelength appears.

4. Press ENTER. The Edit marker starts blinking in the lower part of the

display.

5. Connect your FLS-2600B to a calibrated wavelength meter.

6. Turn the selection dial until you reach the wavelength value read on

the wavelength meter, then press ENTER to validate it.

Note: The Fine-tune feature is not available in this submenu.

54 FLS-2600B

Page 63

Maintenance

Adjusting Your Unit According to Wavelength

7. To ex it th e Setup menu, press Setup.

Note: The difference between the pre-selected wavelength and the measured

wavelength cannot be greater than ± 0.200 nm or ± 0.0250 THz.

This user-performed calibration feature can help you achieve better

absolute wavelength accuracy if, for example, you feel that conditions

outside the unit may have affected the calibration.

The difference between the pre-selected wavelength and the measured

wavelength cannot be greater than ± 0.200 nm. If the difference between

the measured and preselected wavelengths is greater than ± 0.200 nm

(for example, if you have entered the wrong value), an error message will

be generated.

IMPORTANT

Note that the offset introduced into the Tunable Laser Source with

this software feature cannot be disabled. To correct for a handling

error during the procedure, you must repeat the steps described

above with a calibrated wavelength meter.

Tunable Laser Source 55

Page 64

Maintenance

Recalibrating the Unit

Recalibrating the Unit

Manufacturing and service center calibrations are based on the

ISO/IEC 17025 Standard, which states that calibration documents must not

contain a recommended calibration interval, unless this has been

previously agreed upon with the customer.

Validity of specifications depends on operating conditions. For example,

the calibration validity period can be longer or shorter depending on the

intensity of use, environmental conditions and unit maintenance. You

should determine the adequate calibration interval for your unit according

to your accuracy requirements.

Under normal use, EXFO recommends calibrating your unit every year.

Recycling and Disposal (Applies to European Union Only)

For complete recycling/disposal information as per European Directive

WEEE 2002/96/EC, visit the EXFO Web site at www.exfo.com/recycle.

56 FLS-2600B

Page 65

8 Troubleshooting

Solving Common Problems

If you encounter one of the problems listed below, try to solve it first with

the given information. In all cases, if the problem persists after performing

a recommended action, contact EXFO immediately.

Problem Probable Cause Recommended Action

Source appears unstable. Stabilization time

was insufficient.

Reflection is

destabilizing the

source.

There was an

ambient

temperature

variation.

Wait at least 60 minutes for

optimum stabilization.

Use an optical isolator with

your source.

Control ambient

temperature.

Tunable Laser Source 57

Page 66

Troubleshooting

Ver.

Mfg.

date

P/N

S/N

Made in Canada QST442B

465 Godin Avenue

Vanier (Quebec) G1M 3G7 CANADA

**************** A

January 2020

542392-3D

FLS-2600B-XX-XX

Connector code

Fiber type

Contacting the Technical Support Group

Contacting the Technical Support Group

To obtain after-sales service or technical support for this product, contact

EXFO at one of the following numbers. The Technical Support Group is

available to take your calls from Monday to Friday, 8:00 a.m. to 7:00 p.m.

(Eastern Time in North America).

For detailed information about technical support, visit the EXFO Web site at

www.exfo.com.

Technical Support Group

400 Godin Avenue

Quebec (Quebec) G1M 2K2

CANADA

To accelerate the process, please have information such as the name and

the serial number (see the product identification label—an example is

shown below), as well as a description of your problem, close at hand.

1 866 683-0155 (USA and Canada)

Tel.: 1 418 683-5498

Fax: 1 418 683-9224

support@exfo.com

58 FLS-2600B

Page 67

Troubleshooting

Transportation

Transportation

Maintain a temperature range within specifications when transporting the

unit. Transportation damage can occur from improper handling. The

following steps are recommended to minimize the possibility of damage:

Pack the unit in its original packing material when shipping.

Avoid high humidity or large temperature fluctuations.

Keep the unit out of direct sunlight.

Avoid unnecessary shocks and vibrations.

Tunable Laser Source 59

Page 68

Page 69

9 Warranty

General Information

EXFO Inc. (EXFO) warrants this equipment against defects in material and

workmanship for a period oftwo years from the date of original shipment.

EXFO also warrants that this equipment will meet applicable specifications

under normal use.

During the warranty period, EXFO will, at its discretion, repair, replace,

or issue credit for any defective product, as well as verify and adjust the

product free of charge should the equipment need to be repaired or if the

original calibration is erroneous. If the equipment is sent back for

verification of calibration during the warranty period and found to meet all

published specifications, EXFO will charge standard calibration fees.

The warranty can become null and void if:

unit has been tampered with, repaired, or worked upon by

unauthorized individuals or non-EXFO personnel.

warranty sticker has been removed.

IMPORTANT

case screws, other than those specified in this guide, have been

removed.

case has been opened, other than as explained in this guide.

unit serial number has been altered, erased, or removed.

unit has been misused, neglected, or damaged by accident.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES EXPRESSED,

IMPLIED, OR STATUTORY, INCLUDING, BUT NOT LIMITED TO, THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE. IN NO EVENT SHALL EXFO BE LIABLE FOR

SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES.

Tunable Laser Source 61

Page 70

Warranty

Liability

Liability

EXFO shall not be liable for damages resulting from the use of the product,

nor shall be responsible for any failure in the performance of other items to

which the product is connected or the operation of any system of which

the product may be a part.

EXFO shall not be liable for damages resulting from improper usage or

unauthorized modification of the product, its accompanying accessories

and software.

62 FLS-2600B

Page 71

Warranty

Exclusions

EXFO reserves the right to make changes in the design or construction of

any of its products at any time without incurring obligation to make any

changes whatsoever on units purchased. Accessories, including but not

limited to fuses, pilot lamps, batteries and universal interfaces (EUI) used

with EXFO products are not covered by this warranty.

This warranty excludes failure resulting from: improper use or installation,

normal wear and tear, accident, abuse, neglect, fire, water, lightning or

other acts of nature, causes external to the product or other factors beyond

the control of EXFO.

IMPORTANT

EXFO will charge a fee for replacing optical connectors that were

damaged due to misuse or bad cleaning.

Certification

Exclusions

EXFO certifies that this equipment met its published specifications at the

time of shipment from the factory.

Tunable Laser Source 63

Page 72

Warranty

Service and Repairs

Service and Repairs

EXFO commits to providing product service and repair for five years

following the date of purchase.

To send any equipment for service or repair:

1. Call one of EXFO’s authorized service centers (see EXFO Service

2. If equipment must be returned to EXFO or an authorized service

3. If possible, back up your data before sending the unit for repair.

4. Pack the equipment in its original shipping material. Be sure to include

5. Return the equipment, prepaid, to the address given to you by support

Centers Worldwide on page 65). Support personnel will determine if

the equipment requires service, repair, or calibration.

center, support personnel will issue a Return Merchandise

Authorization (RMA) number and provide an address for return.

a statement or report fully detailing the defect and the conditions under

which it was observed.

personnel. Be sure to write the RMA number on the shipping slip. EXFO

will refuse and return any package that does not bear an RMA number.

Note: A test setup fee will apply to any returned unit that, after test, is found to

meet the applicable specifications.

After repair, the equipment will be returned with a repair report. If the

equipment is not under warranty, you will be invoiced for the cost

appearing on this report. EXFO will pay return-to-customer shipping costs

for equipment under warranty. Shipping insurance is at your expense.

Routine recalibration is not included in any of the warranty plans. Since

calibrations/verifications are not covered by the basic or extended

warranties, you may elect to purchase FlexCare Calibration/Verification

Packages for a definite period of time. Contact an authorized service center

(see EXFO Service Centers Worldwide on page 65).

64 FLS-2600B

Page 73

Warranty

EXFO Service Centers Worldwide

EXFO Service Centers Worldwide

If your product requires servicing, contact your nearest authorized service

center.

EXFO Headquarters Service Center

400 Godin Avenue

Quebec (Quebec) G1M 2K2

CANADA

EXFO Europe Service Center

Omega Enterprise Park, Electron Way

Chandlers Ford, Hampshire S053 4SE

ENGLAND

EXFO Telecom Equipment

(Shenzhen) Ltd.

3rd Floor, Building 10,

Yu Sheng Industrial Park (Gu Shu

Crossing), No. 467,

National Highway 107,

Xixiang, Bao An District,

Shenzhen, China, 518126

1 866 683-0155 (USA and Canada)

Tel.: 1 418 683-5498

Fax: 1 418 683-9224

quebec.service@exfo.com

Tel.: +44 2380 246810

Fax: +44 2380 246801

europe.service@exfo.com

Tel: +86 (755) 2955 3100

Fax: +86 (755) 2955 3101

beijing.service@exfo.com

Tunable Laser Source 65

Page 74

Page 75

A Technical Specifications

WAVELENGTH

Range (nm) 1510 to 1612

Display resolution (pm) 1

Effective spectral linewidth FWHM

b

(GHz) 1.3 (typical)

Repeatability

c

(pm) 10 measurements ±2.5 (6 = 5)

Stability

c

(pm) 1 hour ±6 (6 = 12)

Uncertainty

d

(pm) ±15

Sweep rate

e

(nm/s) Maximum 50

Minimum 2

Tuning time

f

(ms) 75 (typical)

Notes

a. Specifications are valid at 23 °C ± 1 °C after one-hour warmup time.

b. FWHM: full width at half maximum. The specification is valid at 1580 nm, where

it corresponds to 12 pm.

Given in HR mode.

Typical 700 MHz at 1610 nm and 2 GHz at 1520 nm.

Linewidth is Gaussian-like and produces a coherence length of about 15 cm

when propagating into SMF-28 fiber type.

c. Expressed as ± half the difference between the maximum and

minimum values measured.

d. User calibration may be required.

e. Operating in continuous sweep.

f. 1 nm step, one complete step through GPIB in manual mode with FLS-2600B.

g. In normal mode. Operating in high-resolution mode (HR) typically reduces power level

at extreme wavelengths, therefore shortening the tuning range by a few nanometers.

h. At connector output of the source.

i. In the 1515 nm to 1610 nm range.

SSE: source spontaneous emission

RBW: spectral resolution bandwidth

j. ALC: Automatic level (or power) control.

k. For 1 dB step 10 % to 90 % response time.

POWER

Output power

g, h

(dBm) From 1515 nm to 1610 nm * 0

From 1510 nm to 1612 nm * —10

Stability

c

(dB) 15 minutes ±0.005 (6 = 0.01)

1 hour ±0.01 (6 = 0.02)

Repeatability for a wavelength change

c

(dB) 10 measurements ±0.015 (6 = 0.03)

Signal to SSE

g, i

(dB) From 1515 nm to 1610 nm * 75 (typical)

±1 nm from peak with RBW 0.1 nm From 1550 nm to 1610 nm * 80 (typical)

Signal to total SSE (dB) * 45

50 (typical)

INTERNAL VARIABLE ATTENUATOR

Attenuation range (dB) 10

Linearity with attenuation (dB) ±0.3 (typical)

Repeatability for specific wavelength

c

(dB) ±0.005 (6 = 0.010) (typical)

Response time

k

(s) 0.5 (typical

)

IMPORTANT

The following technical specifications can change without notice.

The information presented in this section is provided as a reference

only. To obtain this product’s most recent technical specifications,

visit the EXFO Web site at www.exfo.com.

Tunable Laser Source 67

Page 76

Technical Specifications

GENERAL SPECIFICATIONS

Output fiber type SMF-28

Operating temperature 10 °C to 40 °C (50 °F to 104 °F)

Storage temperature —10 °C to 50 °C (14 °F to 122 °F)

Dimensions (H x W x D)

IQS 125 mm x 74 mm x 282 mm (4

15

/16 in x 2 15/16 in x 11 1/8 in)

FLS 117 mm x 222 mm x 333 mm (4

5

/8 in x 8 3/4 in x 13 3/8 in)

Weight 1.4 kg (3.1 lb) 3.4 kg (7.4 lb)

Instruments Drivers

LabVIEW™ drivers and SCPI commands

Remote Control

With FLS-2600B: GPIB (IEEE-488.1, IEEE-488.2) and RS-232.

With IQS-500 or IQS-600: GPIB (IEEE-488.1, IEEE-488.2), Ethernet and RS-232.

Standard Accessories

User Guide, Certificate of Compliance and AC power cord

68 FLS-2600B

Page 77

B Trigger Option Theory

(a) sweep start

(b) second sweep trigger

(c) trig received during the

second sweep; kept in

memory and will trigger the

third sweep

(d) trig received during the

third sweep kept in memory

and will trigger the fourth

sweep

(e) lost trig

Your Tunable Laser Source features Trigger In and Out connectors. When

the trigger option is set to On, the Trigger In will wait for signals. The Trigger

Out is always active and emits a signal for each one-way pass (Continuous

mode) or step (Stepped mode) the system performs during the sweep.

The synchronization feature uses a TTL, 5 V signal. It is achieved on the

signal’s rising edge. The pulse width of the Trigger In signal must be larger

than 1 μs. The pulse width of the Trigger Out signal is 8 μs.

Trigger Option in Continuous Mode

The sweep will begin when the first synchronization signal is received at

the In port. When a pass (one way) is completed, the system waits for

another synchronization signal to move again.

If the synchronization signal arrives before the sweep is completed, it is

kept in memory to be used on the next pass. The memory keeps only one

synchronization signal on standby; if the system receives more than one