Page 1

FLS-2200

Broadband Source

User Guide

Page 2

Copyright © 2005–2013 EXFO Inc. All rights reserved. No part of this

publication may be reproduced, stored in a retrieval system or transmitted

in any form, be it electronically, mechanically, or by any other means such

as photocopying, recording or otherwise, without the prior written

permission of EXFO Inc. (EXFO).

Information provided by EXFO is believed to be accurate and reliable.

However, no responsibility is assumed by EXFO for its use nor for any

infringements of patents or other rights of third parties that may result from

its use. No license is granted by implication or otherwise under any patent

rights of EXFO.

EXFO’s Commerce And Government Entities (CAGE) code under the North

Atlantic Treaty Organization (NATO) is 0L8C3.

The information contained in this publication is subject to change without

notice.

Trademarks

EXFO’s trademarks have been identified as such. However, the presence

or absence of such identification does not affect the legal status of any

trademark.

Units of Measurement

Units of measurement in this publication conform to SI standards and

practices.

Patents

EXFO’s Universal Interface is protected by US patent 6,612,750.

Version number: 2.0.0

ii FLS-2200

Page 3

Contents

Certification information ....................................................................................................... vi

1 Introducing the FLS-2200 Broadband Source ............................................. 1

Main Features .........................................................................................................................1

Available Models ....................................................................................................................2

Typical Applications ................................................................................................................3

Conventions ............................................................................................................................4

2 Safety Information ....................................................................................... 5

Electrical Safety Information ...................................................................................................6

3 Getting Started with Your Broadband Source ............................................ 9

Installing the EXFO Universal Interface (EUI) .........................................................................11

Turning On/Off the Broadband Source ..................................................................................12

Installing EXFO LabVIEW Drivers ...........................................................................................14

4 Setting Up Your Broadband Source .......................................................... 17

Setting the Refresh Rate .......................................................................................................17

Activating or Deactivating the Backlight ...............................................................................18

Setting the Contrast .............................................................................................................18

Setting the Video Mode ........................................................................................................19

Setting the Drive Current ......................................................................................................20

Reverting the Broadband Source to Default Settings ............................................................21

5 Operating the Broadband Source ............................................................. 23

Cleaning and Connecting Optical Fibers ...............................................................................23

Activating or Deactivating a Source ......................................................................................25

6 Preparing for Remote Control ................................................................... 27

Linking Units with the GPIB Port ...........................................................................................27

Linking Units with the Serial Port ..........................................................................................28

Changing Communication Settings ......................................................................................29

Setting the Remote Control Mode ........................................................................................30

Setting GPIB Address ............................................................................................................31

Setting Baud Rate .................................................................................................................32

Setting Flow Control .............................................................................................................33

Broadband Source iii

Page 4

7 Using Your Broadband Source in an Automated Test Environment ........35

Message Management .........................................................................................................35

Standard Status Data Structure ............................................................................................39

SCPI Command Structure ......................................................................................................44

Consulting Data Types ..........................................................................................................49

Writing Remote Control Code ...............................................................................................49

Error Message Format ...........................................................................................................51

Working with EXFO LabVIEW Drivers ....................................................................................52

Using the EXFO Getting Started Applications .......................................................................54

Building and Using Custom VIs .............................................................................................59

8 Maintenance ................................................................................................65

Cleaning EUI Connectors ......................................................................................................66

Replacing Fuses ....................................................................................................................69

Upgrading the Embedded Software .....................................................................................70

Recycling and Disposal (Applies to European Union Only) ....................................................72

9 Troubleshooting ..........................................................................................73

Error Messages .....................................................................................................................73

Solving GPIB Common Problems ..........................................................................................77

Contacting the Technical Support Group ..............................................................................78

Transportation ......................................................................................................................78

10 Warranty ......................................................................................................79

General Information .............................................................................................................79

Liability .................................................................................................................................80

Exclusions .............................................................................................................................81

Certification ..........................................................................................................................81

Service and Repairs ...............................................................................................................82

EXFO Service Centers Worldwide ..........................................................................................83

A Technical Specifications ..............................................................................85

B Data Types ...................................................................................................89

Applicable Data Types for Input—IEEE 488.2 ........................................................................90

Applicable Data Types for Output—IEEE 488.2 .....................................................................99

Applicable Data Types for Input—SCPI ................................................................................109

Special Numeric Values Received on Output .......................................................................110

C IEEE 488.2 and Specific Command Reference .........................................111

IEEE 488.2 Commands—Quick Reference ...........................................................................111

IEEE 488.2 Commands—Description ..................................................................................112

Product-Specific Commands—Quick Reference ..................................................................135

Product-Specific Commands—Description ..........................................................................136

iv FLS-2200

Page 5

D SCPI-Based Errors ..................................................................................... 151

Index .............................................................................................................. 167

Broadband Source v

Page 6

Certification information

Certification information

North America Regulatory Statement

This unit was certified by an agency approved in both Canada and the

United States of America. It has been evaluated according to applicable

North American approved standards for product safety for use in Canada

and the United States.

Electronic test and measurement equipment is exempt from FCC part 15,

subpart B compliance in the United States of America and from ICES-003

compliance in Canada. However, EXFO Inc. makes reasonable efforts to

ensure compliance to the applicable standards.

The limits set by these standards are designed to provide reasonable

protection against harmful interference when the equipment is operated in

a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance

with the user guide, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely

to cause harmful interference in which case the user will be required to

correct the interference at his own expense.

Modifications not expressly approved by the manufacturer could void the

user's authority to operate the equipment.

IMPORTANT

Use of shielded remote I/O cables, with properly grounded shields

and metal connectors, is recommended in order to reduce radio

frequency interference that may emanate from these cables.

vi FLS-2200

Page 7

Certification information

Electro-Optical Engineerin

Application of Council Directive(s): 73/23/EEC - The Low Voltage Directive

89/336/EEC - The EMC Directive

Manufacturers Name: EXFO ELECTRO-OPTICAL ENG.

Manufacturers Address: 400 Godin Avenue

Vanier, Quebec

Canada G1M 2K2

(418) 683-0211

Equipment Type/Environment: Light Industrial Scientific Equipment

Trade Name/Model No.: FLS-2200 Broadband Light Source

Standard(s) to which Conformity is Declared:

EN 61010-1:1993/

A2: 1995

Safety Requirements for Electrical Equipment for Measurement, Control, and

Laboratory Use, Part 1: General Requirements

EN 55022:1998/

A1:2000

Limits and methods of measurement of radio disturbance characteristics of

industrial, scientific, and medical equipment

EN 61326:1997/ A2:

2001

Electrical Equipment for Measurement, Control and Laboratory

Use - EMC Requirements

EN 60825-1:1994/

A2: 2001

Safety of laser products-Part 1 :Equipment classifications, requirements and

users guide

I, the undersigned, hereby declare that the equipment specified above conforms to the above Directive and Standards.

Manufacturer

Signature:

Full Name: Stephen Bull, E. Eng

Position: Vice-President Research and

Development

Address: 465 Godin Avenue Vanier, Quebec,

Canada

Date: May 20 , 2003

DECLARATION OF CONFORMITY

g

Broadband Source vii

Page 8

Page 9

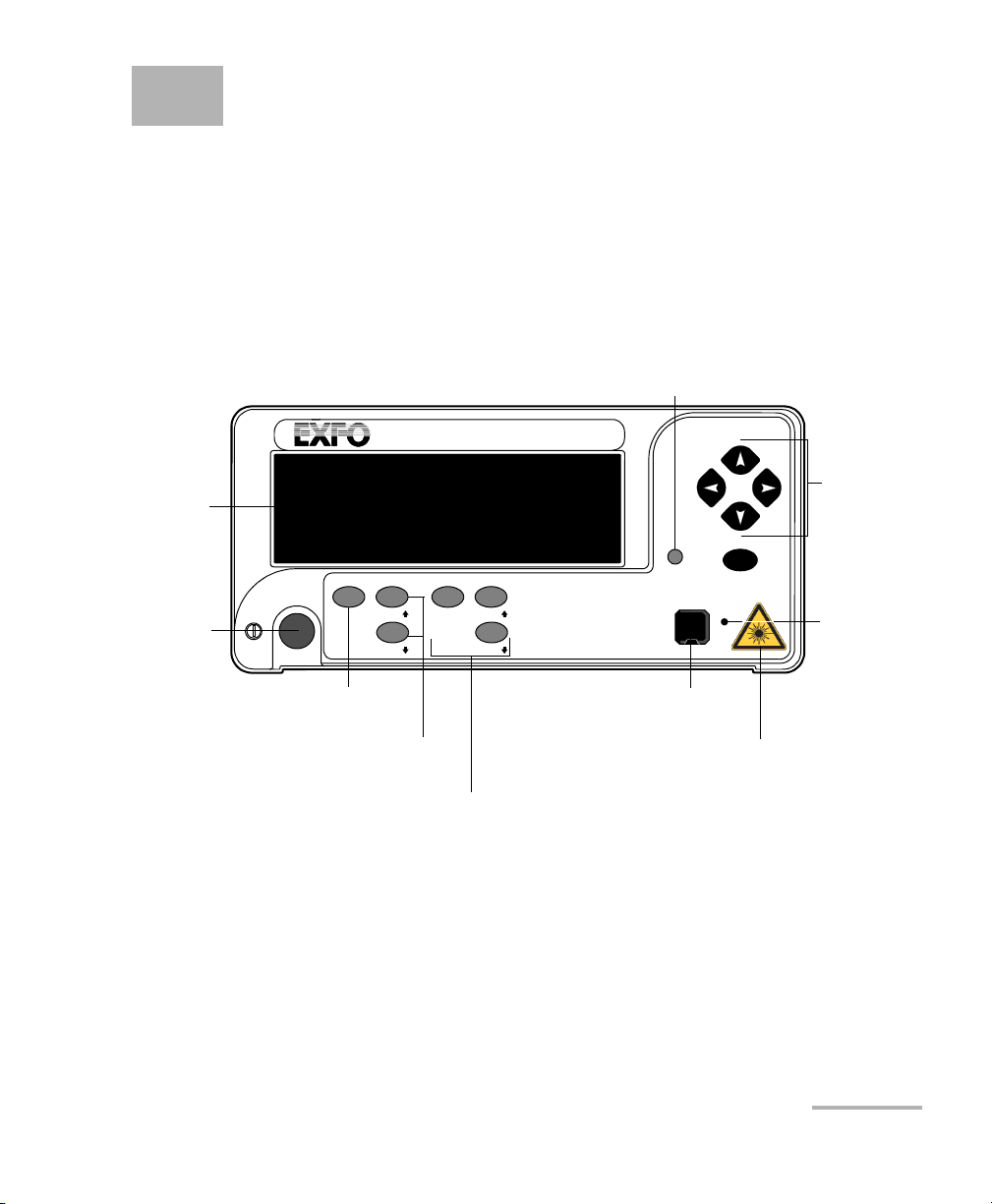

1 Introducing the FLS-2200

BROADBAND SOURCE

FLS-2200

ENTER

Setup

Active

Out

On/Off

Power

Power

Source 2

Navigation/

menu

setting

arrow keys

Setup menu access

Power

Source activation/

deactivation button

Display

Active LED

Output port

Drive-current increasing and

decreasing buttons

Second source control buttons

(on dual-source models only)

On/Off

Power

Power

Source 1

Laser radiation

hazard sticker

Broadband Source

Main Features

The FLS-2200 Broadband Source is a super-luminescent, light-emitting

diode (SLED) source covering all the bands needed for

telecommunications applications. It provides a broader spectral range and

more power density in a singlemode fiber than a white light source.

Broadband Source 1

Page 10

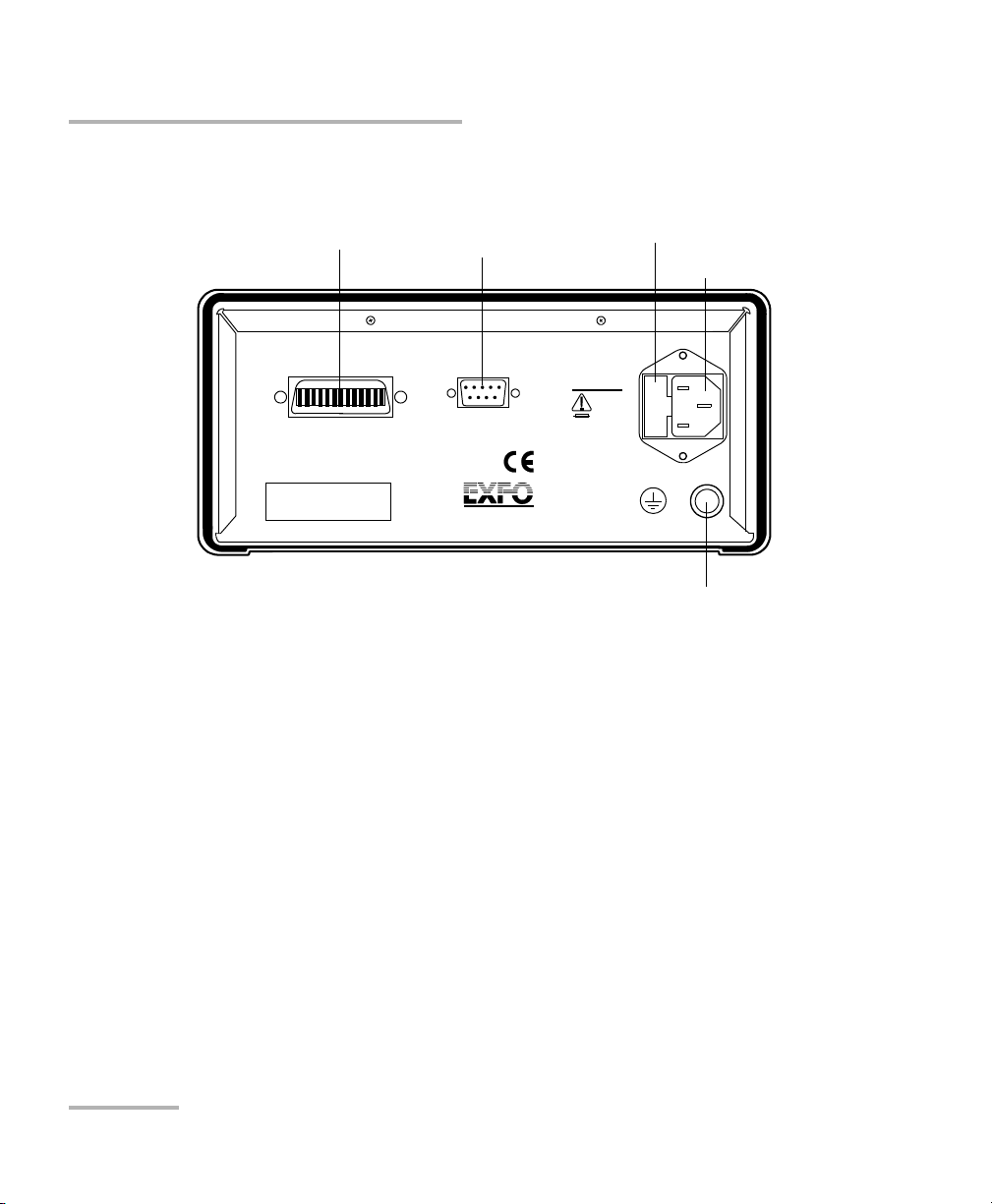

Introducing the FLS-2200 Broadband Source

Serial port (RS-232 DTE)

Fuse holder

Power inlet

GPIB port

400 Godin Ave.

Québec, Que., Canada G1M 2K2

GPIB IEEE 488.2

SH1, AH1, T6, L4, SR1, RL1, PP0, DC1, DT1, C0, E2

This device complies with part 15 of the FCC rules. Operation is

subject to the following two conditions: (1) this device may not cause

harmful interference and (2) this devic e must accept any interference

received, including interference that may cause undesired operation.

Made in Canada

P/N

S/N

Ver.

Mfg.

date

QST-151E

Serial Port

MODEL: GO

100-240 V

50/60 Hz

2 A

F2AL250 V

Ground

Available Models

On the back panel, you will find the ports for remote control, the power

inlet and fuse holder.

The FLS-2200 Broadband Source supports local control (via its front panel)

and remote control (through GPIB or RS-232 using SCPI commands or the

provided LabVIEW drivers).

Available Models

The FLS-2200 Broadband Source is available in the following models:

Models with a single super LED (SLED) covering a conventional

wavelength range (5 models).

Models with two SLEDs, covering a wider range for coarse

wavelength-division multiplexing (CWDM) and dual-window

applications (2 models).

2 FLS-2200

Page 11

Introducing the FLS-2200 Broadband Source

BROADBAND SOURCE

FLS-2200

ENTER

Setup

Active

Out

On/Off

Power

Power

Source 2

On/Off

Power

Power

Source 1

Optical Spectrum Analyzer

IQS-5250B

INPUT

DUT

Typical Applications

Typical Applications

You can use this light source to:

qualify components during development or to perform Pass/Fail tests

during production when you use the source with an optical spectrum

analyzer (OSA).

perform maintenance or troubleshooting tasks on a WDM network

when the source is combined with an OSA.

perform polarization mode dispersion (PMD) measurements when

you use the source with the FPMD-5600 Femtosecond PMD Analyzer

and the M9700 Passive Depolarizer.

perform polarization-dependent loss (PDL) measurements when you

use the source with an OSA.

The typical devices tested include passive optical network (PON)

components, CWDM components, attenuators, photonic switches,

broadband couplers, specialty couplers or multiplexers, Bragg gratings (the

source features a bandwidth large enough to test many Bragg gratings

simultaneously), etc.

A typical setup including both the FLS-2200 Broadband Source and an

IQS-5250B Optical Spectrum Analyzer is shown below.

Broadband Source 3

Page 12

Introducing the FLS-2200 Broadband Source

Conventions

Conventions

Before using the product described in this guide, you should understand

the following conventions:

WARNING

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury. Do not proceed unless you

understand and meet the required conditions.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury. Do not proceed unless you

understand and meet the required conditions.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in component damage. Do not proceed unless you

understand and meet the required conditions.

IMPORTANT

Refers to information about this product you should not overlook.

4 FLS-2200

Page 13

2 Safety Information

WARNING

Do not install or terminate fibers while a light source is active.

Never look directly into a live fiber and ensure that your eyes are

protected at all times.

WARNING

The use of controls, adjustments and procedures other than those

specified herein may result in exposure to hazardous situations or

impair the protection provided by this unit.

IMPORTANT

When you see the following symbol on your unit , make sure

that you refer to the instructions provided in your user

documentation. Ensure that you understand and meet the required

conditions before using your product.

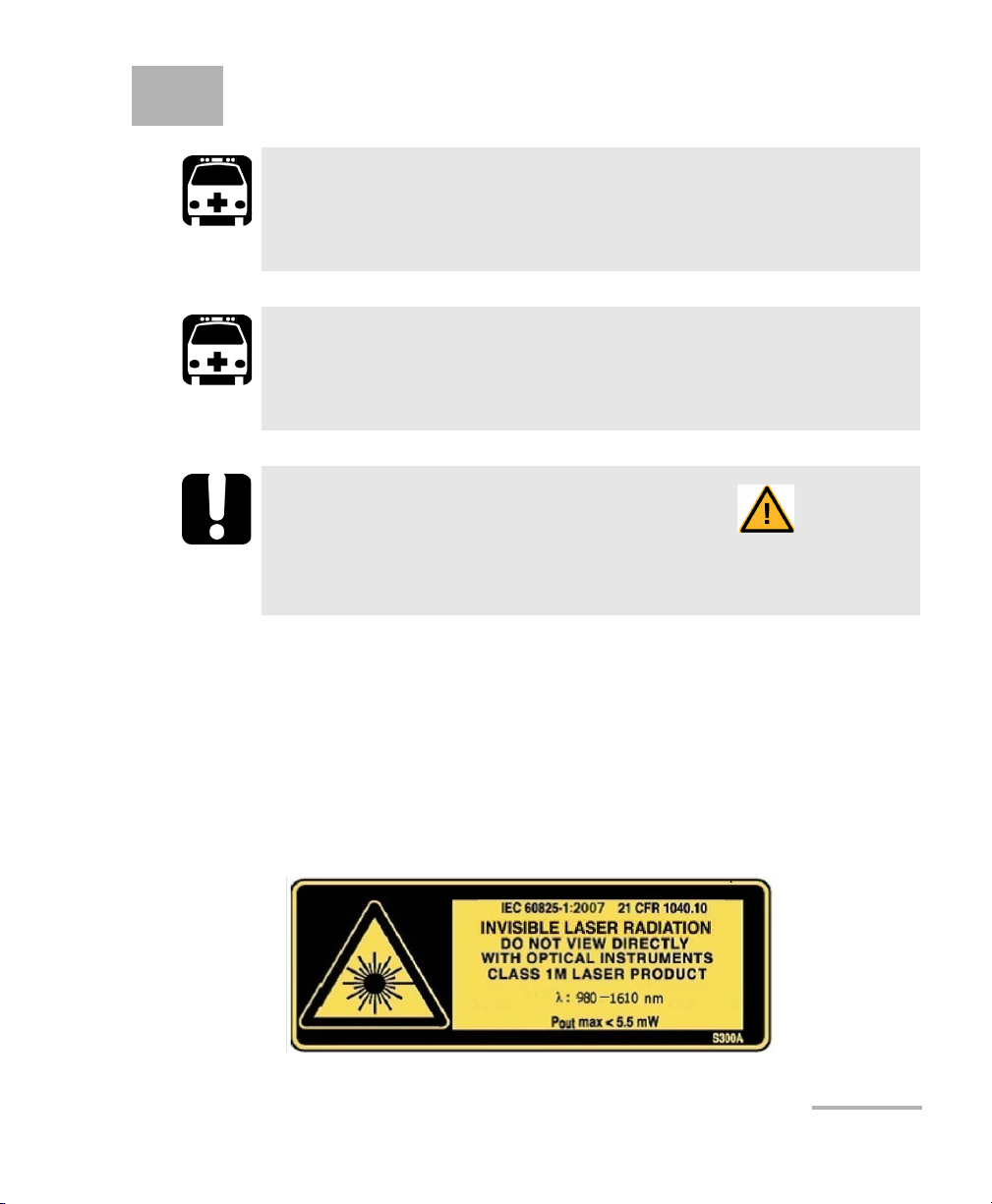

Your instrument is a Class 1M laser product in compliance with standards

IEC 60825-1 2007 and 21 CFR 1040.10. Invisible laser radiation may be

encountered at the output port.

The product is safe under reasonably foreseeable conditions of operation

but it may be hazardous if you use optics within a diverging or collimated

beam. Do not view directly with optical instruments.

The following label(s) indicate that the product contains a Class 1M source:

Broadband Source 5

Page 14

Safety Information

Electrical Safety Information

Electrical Safety Information

This unit uses an international safety standard three-wire power cable. This

cable serves as a ground when connected to an appropriate AC power

outlet.

Note: If you need to ensure that the unit is completely powered off, disconnect the

power cable.

WARNING

Insert the power cable plug into a power outlet with a

protective ground contact. Do not use an extension cord

without a protective conductor.

Before powering on the unit, connect all grounding terminals,

extension cords and devices to a protective ground via a ground

socket. Any interruption of the protective grounding is a

potential shock hazard and may cause personal injury.

Whenever the ground protection is impaired, do not use the

unit and secure it against any accidental operation.

Do not tamper with the protective ground terminal.

The color coding used in the electric cable depends on the cable. New

plugs should meet the local safety requirements and include:

adequate load-carrying capacity

ground connection

cable clamp

IMPORTANT

EXFO assumes no liability if you attempt to perform internal service

on this unit.

6 FLS-2200

Page 15

Safety Information

Electrical Safety Information

WARNING

Use this unit indoors only.

Position the unit so that the air can circulate freely around it.

Operation of any electrical instrument around flammable gases

or fumes constitutes a major safety hazard.

Do not remove unit covers during operation.

To avoid electrical shock, do not operate the unit if any part of

the outer surface (covers, panels, etc.) is damaged.

Only authorized personnel should carry out adjustments,

maintenance or repair of opened units under voltage. A person

qualified in first aid must also be present. Do not replace any

components while power cable are connected.

Use only fuses with the required rated current and specified

type (IEC, 5 mm x 20 mm (0.197 in x 0.787 in), fast-blow, 250 V,

2 A). Do not use repaired fuses or short-circuited fuse holders.

Capacitors inside the unit may be charged even if the unit has

been disconnected from its electrical supply.

Broadband Source 7

Page 16

Safety Information

Electrical Safety Information

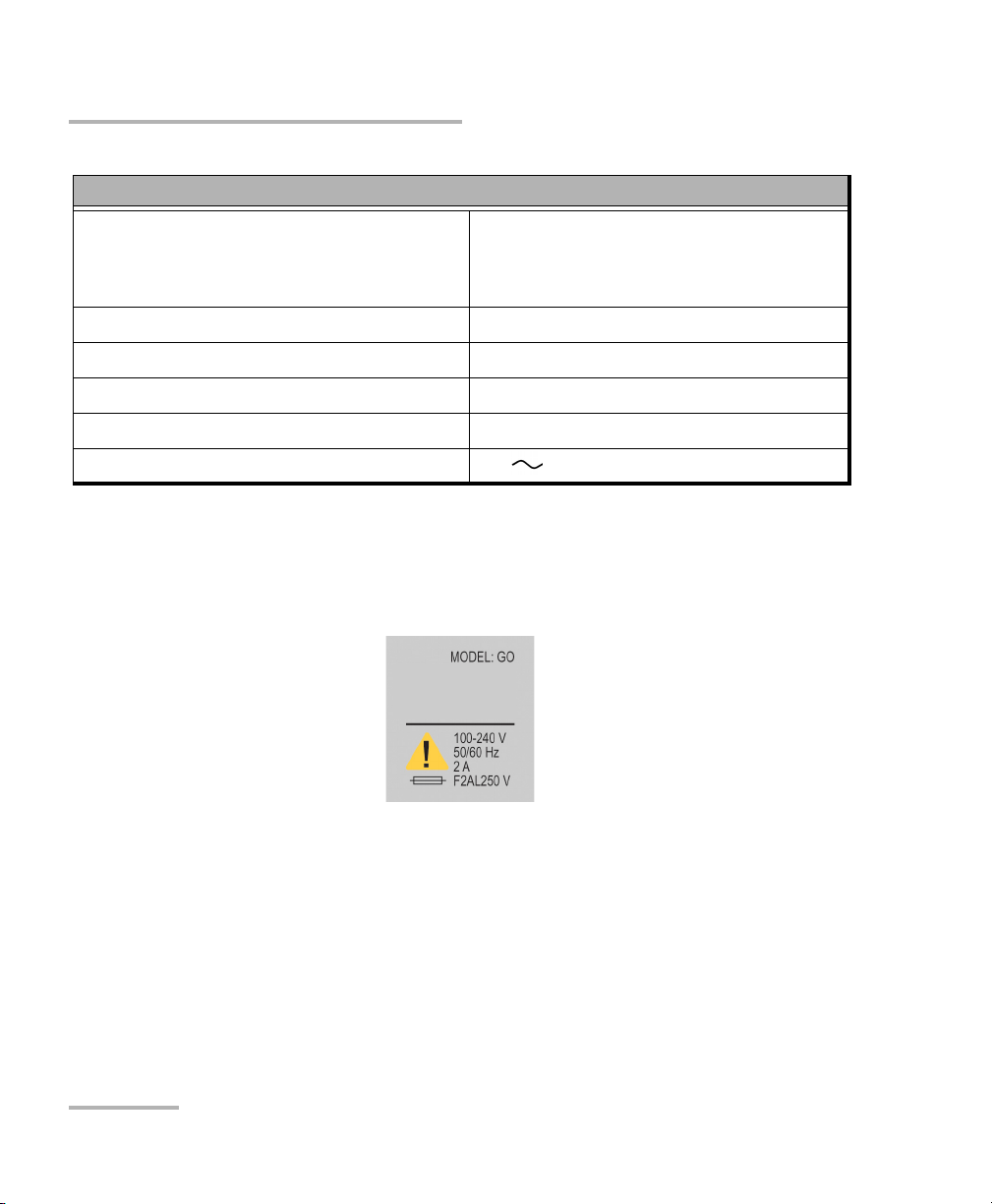

Equipment Ratings

Tem pe rat ur e

Operation

Storage

Relative humidity

a

0 °C to 40 °C (32 °F to 104 °F)

-40 °C to 70 °C (-40 °F to 158 °F)

0 % to 80 % non-condensing

Maximum operation altitude 2000 m (6562 ft)

Pollution degree 2

Overvoltage category II

Power supply rating

a. Measured in 0 °C to 31 °C (32 °F to 87.8 °F) range, decreasing linearly to 50 % at 40 °C (104 °F).

b. Not exceeding

b

± 10 % of the nominal voltage.

100 V - 240 V; 50 Hz/60 Hz; 2 A

The following label is located on the back panel of the unit:

8 FLS-2200

Page 17

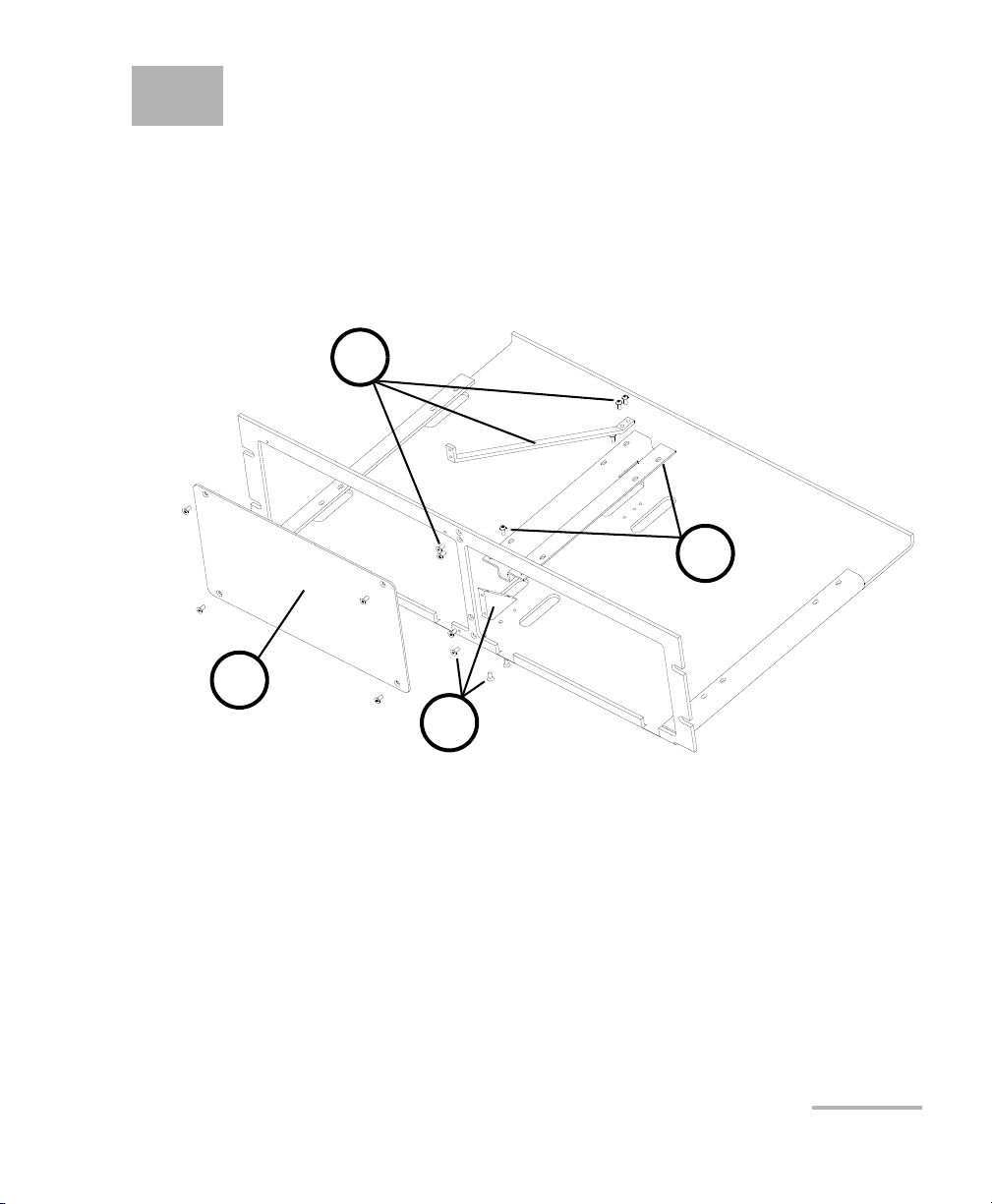

3 Getting Started with Your

2

3

4

1

Broadband Source

You can place your FLS-2200 Broadband Source in a rackmount to facilitate

its usage.

To install the rackmount:

1. Fix the angle iron using four flat Phillips screws.

2. Fix the rackmount bracket to the frame using two round Phillips

screws.

3. Fix the rackmount stiffener using two flat Phillips screws (for the front

panel) and two round Phillips screws.

4. If your rackmount will contain only one unit, fix the rackmount cover

plate to the empty part of the frame using four flat Phillips screws.

Broadband Source 9

Page 18

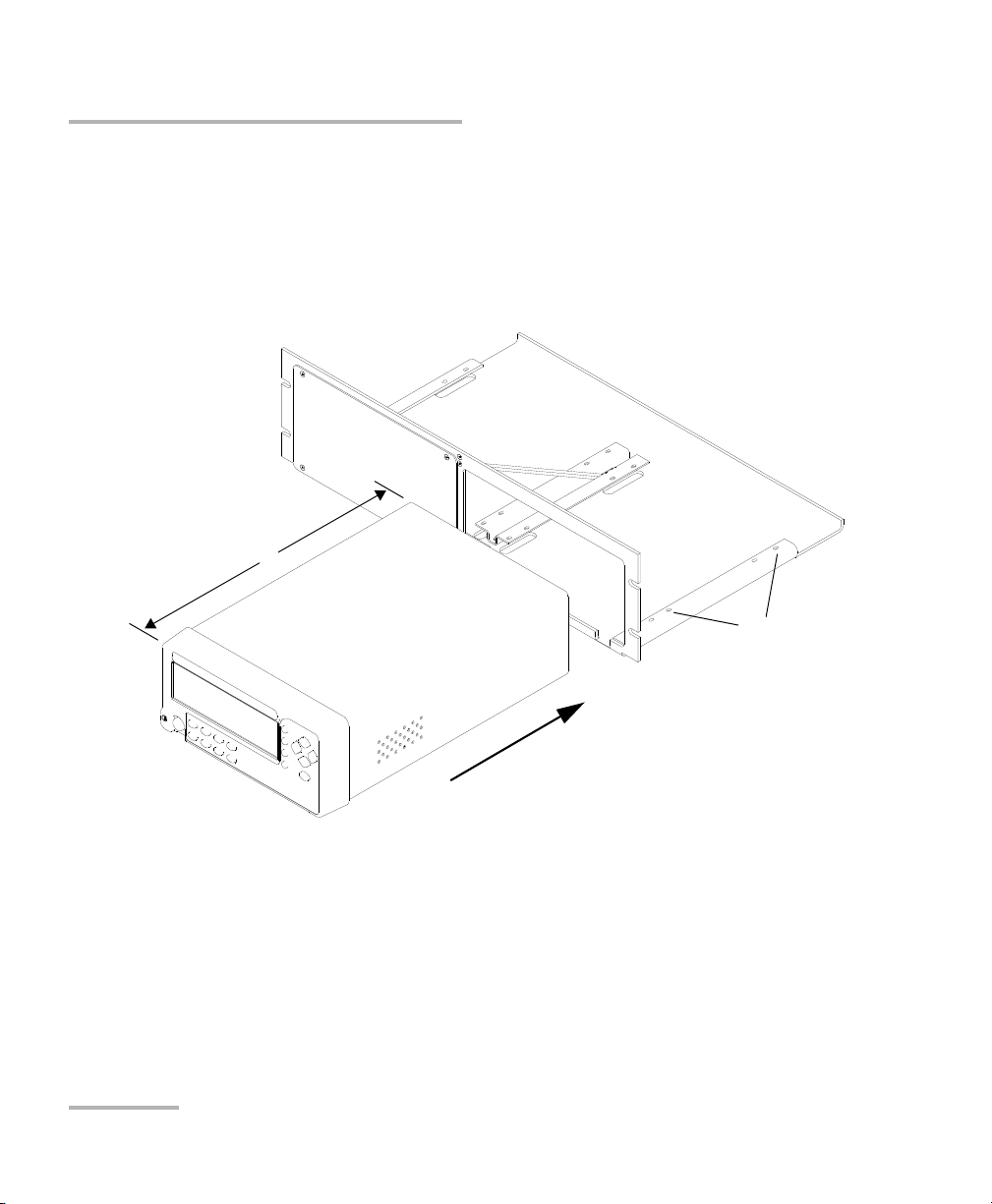

Getting Started with Your Broadband Source

X

A

To install your FLS-2200 Broadband Source in a rackmount:

1. Slide the benchtop unit into the rackmount and tighten it from

underneath using the four cover fixing screws.

If measurement X on the illustration exceeds 11.125 in., fix the unit into

the four holes identified as A. Otherwise, use the other four holes.

2. If a second benchtop is to be installed, remove the cover plate and

repeat step 1.

10 FLS-2200

Page 19

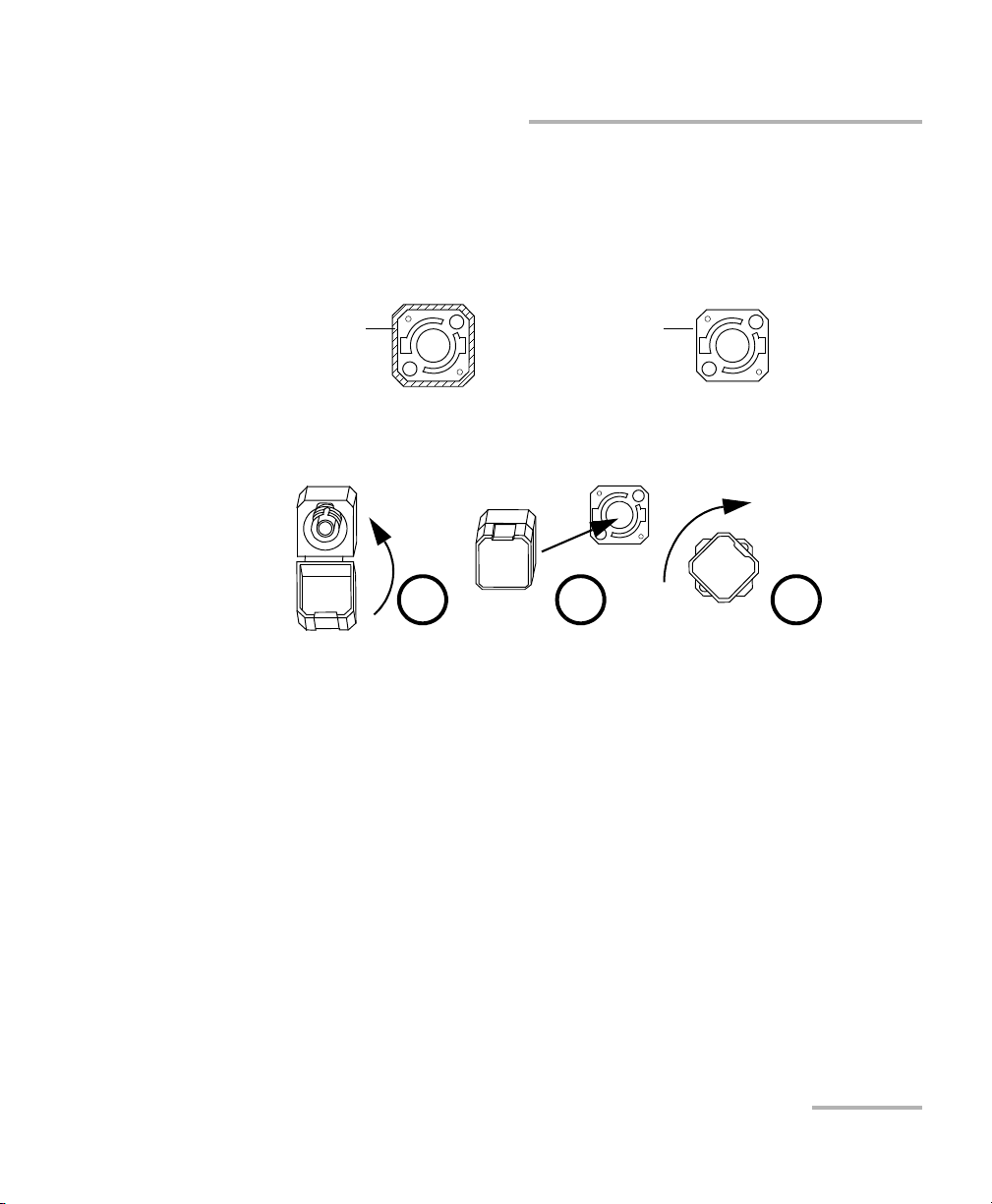

Getting Started with Your Broadband Source

Bare metal

(or blue border)

indicates UPC

option

Green border

indicates APC

option

2 3 4

Installing the EXFO Universal Interface (EUI)

Installing the EXFO Universal Interface (EUI)

The EUI fixed baseplate is available for connectors with angled (APC) or

non-angled (UPC) polishing. A green border around the baseplate

indicates that it is for APC-type connectors.

To install an EUI connector adapter onto the EUI baseplate:

1. Hold the EUI connector adapter so the dust cap opens downwards.

2. Close the dust cap in order to hold the connector adapter more firmly.

3. Insert the connector adapter into the baseplate.

4. While pushing firmly, turn the connector adapter clockwise on the

baseplate to lock it in place.

Broadband Source 11

Page 20

Getting Started with Your Broadband Source

RM

LK

Source 1

OFF

1300 nm 210 mA

Source 2

OFF

1550 nm 191 mA

Remote control

Remotely-locked front panel

Wavelength

and drive

current

Source status

Information on second source

(dual-source models only)

Source number (dual-source

models only)

Turning On/Off the Broadband Source

Turning On/Off the Broadband Source

WARNING

Before turning on the source, read Electrical Safety Information on

page 6.

To turn the Broadband Source on and off:

Press the red button located in the lower left-hand corner of the front

panel.

Upon startup, the unit beeps twice, performs a self-test and then displays

the main window, indicating that all sources are deactivated (OFF).

12 FLS-2200

Page 21

Getting Started with Your Broadband Source

Turning On/Off the Broadband Source

The source status indicator shows whether the source is active or not

(ON/OFF). In the case of an active source, a graphical element

representing a light beam is also displayed.

The wavelength and drive current indicator shows the source’s

nominal wavelength (in nanometers) and the selected drive current

(in milliamperes).

The remote control indicator (RM) appears when the unit is currently

controlled by remote commands (via GPIB or RS-232 communication).

Note: You must set the GPIB bus line to True in GPIB or send the *REM command

in RS-232 for the remote control indicator to be displayed.

The remotely-locked keyboard indicator (LK) shows that a remote

application is preventing you from using the unit’s front panel buttons

(keyboard)—except the red button used to turn the unit on or off.

When the unit is turned off, the current Setup menu settings remain in the

unit’s memory. These settings include display features and remote control.

Broadband Source 13

Page 22

Getting Started with Your Broadband Source

Installing EXFO LabVIEW Drivers

Installing EXFO LabVIEW Drivers

Before being able to work with EXFO LabVIEW drivers, you must install the

following elements on your computer:

National Instruments LabVIEW software and the corresponding

patches.

EXFO LabVIEW drivers (including demo applications to help you get

started with the drivers)

For information on these applications, see Working with EXFO LabVIEW

Drivers on page 52.

Note: Only administrator-level users can install software under Windows XP.

To install the LabVIEW software:

1. Insert the LabVIEW CD in the CD-ROM drive.

2. The installation process should start automatically. If not, start it

manually as follows:

2a. On the Windows taskbar, click Start and select Run.

2b. In the Open box locate the autorun.exe file.

2c. Click OK to start the installation procedure and follow the

on-screen instructions.

You should keep the default names and paths suggested by the

installation program.

3. Once the software installation is complete, install the patches available

for your LabVIEW version.

If the patches are not included on your LabVIEW CD, you may

download them from National Instruments’ Web site at www.ni.com.

3a. On the Windows taskbar, click Start and select Run.

3b. In the Open box, locate Updates\setup.exe.

14 FLS-2200

Page 23

Getting Started with Your Broadband Source

Installing EXFO LabVIEW Drivers

3c. Click OK to start the installation procedure and follow the

on-screen instructions.

To install the EXFO LabVIEW drivers:

1. Insert the installation CD in the CD-ROM drive.

2. Start the installation process as follows:

2a. On the Windows taskbar, click Start and select Run.

2b. In the Open box, locate Labview Drivers\setup.exe on the storage

device where the drivers are located.

2c. Click OK to start the InstallShield Wizard and follow the on-screen

instructions.

For easier use, the drivers will be installed in LabVIEW’s default

instrument library folder:

C:\Program Files\National Instruments\LabVIEW 6\instr.lib\EXFO.

Broadband Source 15

Page 24

Page 25

4 Setting Up Your Broadband

Refresh Rate

Backlight

Contrast

Video Mode

8 Hz

ON

STD

Exit

RS232 / GPIB

GPIB Addr.

Baud Rate

Flow Ctrl

GPIB

12

N.A.

N.A.

Source

The blue button on the right of the display provides access to the

single-level Setup menu. You can access this menu even while the source

is active to set up the various parameters.

Setting the Refresh Rate

To set the refresh rate:

1. Press the Setup button.

2. Use the up/down or left/right arrow keys to select Refresh Rate (the

item will be displayed in reverse video).

3. Press ENTER to access the Refresh Rate edit box.

4. Use the up/down arrow keys to set the refresh rate between 1/2 Hz,

1Hz, 2Hz, 4Hz, 8Hz and 16Hz.

5. Press ENTER to confirm the new refresh rate.

Broadband Source 17

Page 26

Setting Up Your Broadband Source

Activating or Deactivating the Backlight

Activating or Deactivating the Backlight

To deactivate the backlight:

1. Press the Setup button.

2. Use the up/down or left/right arrow keys to select Backlight (the item

will be displayed in reverse video).

3. Press ENTER to access the Backlight edit box.

4. Use the up/down arrow keys until the backlight value changes to OFF.

5. Press ENTER to confirm the new backlight setting.

To reactivate the backlight:

Stand very close to the unit to see the information displayed. Repeat

steps 1 to 4 above—except that you must set the backlight value to ON.

OR

Reset the unit to the default parameters (see Reverting the Broadband

Source to Default Settings on page 21).

Setting the Contrast

To set the contrast:

1. Press the Setup button.

2. Use the up/down or left/right arrow keys to select Contrast (item will

appear in reverse video).

3. Press ENTER to access the Contrast edit box.

4. Use the up/down arrow keys to adjust the contrast as required.

5. Press ENTER to confirm the contrast adjustment.

18 FLS-2200

Page 27

Setting Up Your Broadband Source

Refresh Rate

Backlight

Contrast

Video Mode

Exit

8 Hz

ON

STD

RS232 / GPIB

GPIB Addr.

Baud Rate

Flow Ctrl

GPIB

12

N.A.

N.A.

Refresh Rate

Backlight

Contrast

Video Mode

Exit

ON

INV

RS232 / GPIB

GPIB Addr.

Flow Ctrl

GPIB

12

N.A.

N.A.

Baud Rate

Exit

8 Hz

Baud Rate

Setting the Video Mode

Setting the Video Mode

To set the video mode:

1. Press the Setup button.

2. Use the up/down or left/right arrow keys to select Video Mode (item

will appear in reverse video).

3. Press ENTER to access the Video Mode edit box.

4. Use the up/down arrow keys to set the required video mode (standard

or reverse).

5. Press ENTER to confirm the video mode.

Broadband Source 19

Page 28

Setting Up Your Broadband Source

BROADBAND SOURCE

FLS-2200

ENTER

Setup

Active

Out

On/Off

Power

Power

Source 2

Increasing and decreasing buttons

On/Off

Power

Power

Source 1

Power

Power

Setting the Drive Current

Setting the Drive Current

You can adjust the source’s drive current to better suit your needs. The

drive current can be increased or decreased by steps of 1 mA or 10 mA.

On a dual-source, each one has its own set of control buttons and has an

independent drive current value.

Note: You can set the drive current even while the source is not emitting.

To set the drive current:

1. Press the button to increase the value by steps of 1 mA.

OR

Press the button to decrease the value by steps of 1 mA.

2. To increase or decrease the value by steps of 10 mA, hold the

corresponding button down.

The displayed current value on the screen changes accordingly.

3. If you have a dual-source, you can repeat the above steps to set the

drive current for the second source.

20 FLS-2200

Page 29

Setting Up Your Broadband Source

Reverting the Broadband Source to Default Settings

Reverting the Broadband Source to Default

Settings

You may want to revert the Broadband Source to the factory settings.

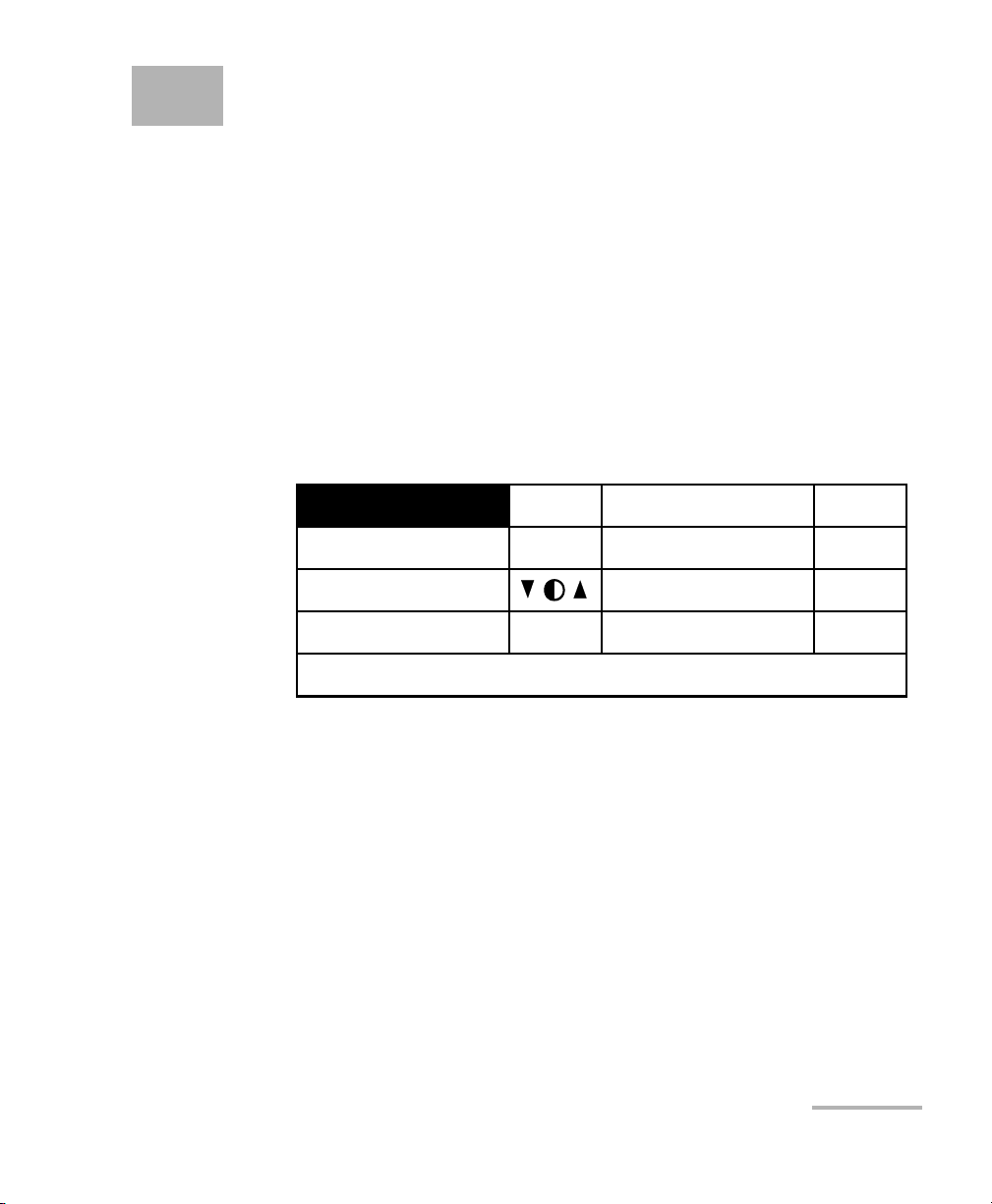

The following table presents the parameters and their default values.

Parameters Default Values

Source OFF

Drive current Minimum value

Backlight ON

Videomode STD (standard)

Refresh rate 4 Hz

RS232/GPIB (Remote control)

GPIB address

Baud rate

Flow ctrl

a

a

a

a

GPIB

12

N.A.

N.A.

a. Parameter cannot be reset by a remote control command.

To revert the source to default settings:

1. Turn off the unit.

2. Turn on the unit and press ENTER at the same time until the unit beeps

three times.

Broadband Source 21

Page 30

Page 31

5 Operating the Broadband

Source

Cleaning and Connecting Optical Fibers

IMPORTANT

To ensure maximum power and to avoid erroneous readings:

Always inspect fiber ends and make sure that they are clean as

explained below before inserting them into the port. EXFO is

not responsible for damage or errors caused by bad fiber

cleaning or handling.

Ensure that your patchcord has appropriate connectors. Joining

mismatched connectors will damage the ferrules.

To connect the fiber-optic cable to the port:

1. Inspect the fiber using a fiber inspection microscope. If the fiber is

clean, proceed to connecting it to the port. If the fiber is dirty, clean it as

explained below.

2. Clean the fiber ends as follows:

2a. Gently wipe the fiber end with a lint-free swab dipped in isopropyl

alcohol.

2b. Use compressed air to dry completely.

2c. Visually inspect the fiber end to ensure its cleanliness.

Broadband Source 23

Page 32

Operating the Broadband Source

Cleaning and Connecting Optical Fibers

3. Carefully align the connector and port to prevent the fiber end from

touching the outside of the port or rubbing against other surfaces.

If your connector features a key, ensure that it is fully fitted into the

port’s corresponding notch.

4. Push the connector in so that the fiber-optic cable is firmly in place,

thus ensuring adequate contact.

If your connector features a screwsleeve, tighten the connector

enough to firmly maintain the fiber in place. Do not overtighten, as this

will damage the fiber and the port.

Note: If your fiber-optic cable is not properly aligned and/or connected, you will

notice heavy loss and reflection.

EXFO uses good quality connectors in compliance with EIA-455-21A

standards.

To keep connectors clean and in good condition, EXFO strongly

recommends inspecting them with a fiber inspection probe before

connecting them. Failure to do so will result in permanent damage to the

connectors and degradation in measurements.

24 FLS-2200

Page 33

Operating the Broadband Source

BROADBAND SOURCE

FLS-2200

ENTER

On/Off

Power

Setup

Active

Out

On/Off

Power

Power

Power

Source 1

Source 2

Source activation/

deactivation button

Activating or Deactivating a Source

Activating or Deactivating a Source

On a dual-source, each one has its own set of control buttons and can be

activated or deactivated separately (both ON, both OFF, one ON and one

OFF).

When lit, the active LED indicates that an optical signal is being emitted

from the source port.

For your safety, the Broadband Source provides a three-second safety delay

between the source activation and actual light emission. You can also stop

light emission at any time by pressing on the activation/deactivation button.

Broadband Source 25

Page 34

Operating the Broadband Source

Active source

RM

LK

Source 1

ON

1300 nm 210 mA

Source 2

OFF

1550 nm 191 mA

Information

on second

source

(dual-source

models only)

Activating or Deactivating a Source

To activate a source:

1. Press the activation/deactivation button (labeled On/Off).

Note: If you have a dual-source, make sure you use the appropriate set of buttons

(Source 1 or Source 2).

The active LED on the unit front panel will light up, and the display will

read “Source x ON”, also showing a light beam icon. The word “ON”

will flash during the three-second safety delay.

2. If you have a dual-source, you can repeat step 1 to activate the second

one.

IMPORTANT

To obtain optimum stability, let the source warm up for 30 minutes.

To deactivate a source:

1. Press the activation/deactivation button (labeled On/Off).

The active LED on the module front will turn off and the display will

read “Source x OFF”.

2. If you have a dual-source, you can repeat the above step to deactivate

the second one source.

26 FLS-2200

Page 35

6 Preparing for Remote Control

GPIB port

The Broadband Source can be controlled remotely either by GPIB or

RS-232.

Note: When the Broadband Source is being controlled remotely, RM appears in

the upper right corner of the display.

EXFO supplies commands that follow the guidelines determined by the

SCPI consortium. The same commands are used in both GPIB and RS-232

communication. You can find detailed information about these commands

in the IEEE 488.2 and Specific Command Reference appendix.

Linking Units with the GPIB Port

Your FLS-2200 Broadband Source is equipped with a GPIB port. You can

simply use a GPIB cable to link it to the other unit with which you want to

perform remote control. The GPIB port is located at the back of Broadband

Source, as shown below.

Broadband Source 27

Page 36

Preparing for Remote Control

Serial port

1234 5

6789

Linking Units with the Serial Port

Linking Units with the Serial Port

Your FLS-2200 Broadband Source is equipped with a serial (RS-232) port to

send and receive data. You can simply use a null-modem (serial) cable to

link it to the other unit with which you want to perform remote control. The

RS-232 port is located at the back of Broadband Source, as shown below.

The RS-232 connector uses a DTE pinout configuration.

Pin Description Direction

2 Receive (Rx) Input

3 Transmit (Tx) Output

5 Ground (Gnd) —

28 FLS-2200

Page 37

Preparing for Remote Control

Changing Communication Settings

Changing Communication Settings

To re m ot el y c on tr ol yo ur Broadband Source, you must set a GPIB address

or activate the RS-232 port.

Note: Communication settings cannot be modified without turning on your unit.

The tables present the different parameters for GPIB and RS-232

communication and their corresponding values.

Note: EOS means “End of String.” EOI means “End of Identify.”

Parameters for GPIB Communication

Terminate Read on EOS Yes

Set EOI with EOS on Writes Yes

Type of compare on EOS 8 bits

EOS byte 0Ah

Send EOI at end of Writes Yes

GPIB primary address Value between 1 and 30 (default value: 12)

GPIB secondary address None

Parameters for RS-232 Communication

EOS bytes 0Ah

Baud rate 1200/2400/4800/9600/19200 bps

Parity None

Data bits 8 bits

Stop bits 1 bit

Flow control Software (Xon/Xoff) or None

Broadband Source 29

Page 38

Preparing for Remote Control

Refresh Rate

Backlight

Contrast

Video Mode

Exit

8 Hz

ON

STD

RS232 / GPIB

GPIB Addr.

Baud Rate

Flow Ctrl

GPIB

12

N.A.

N.A.

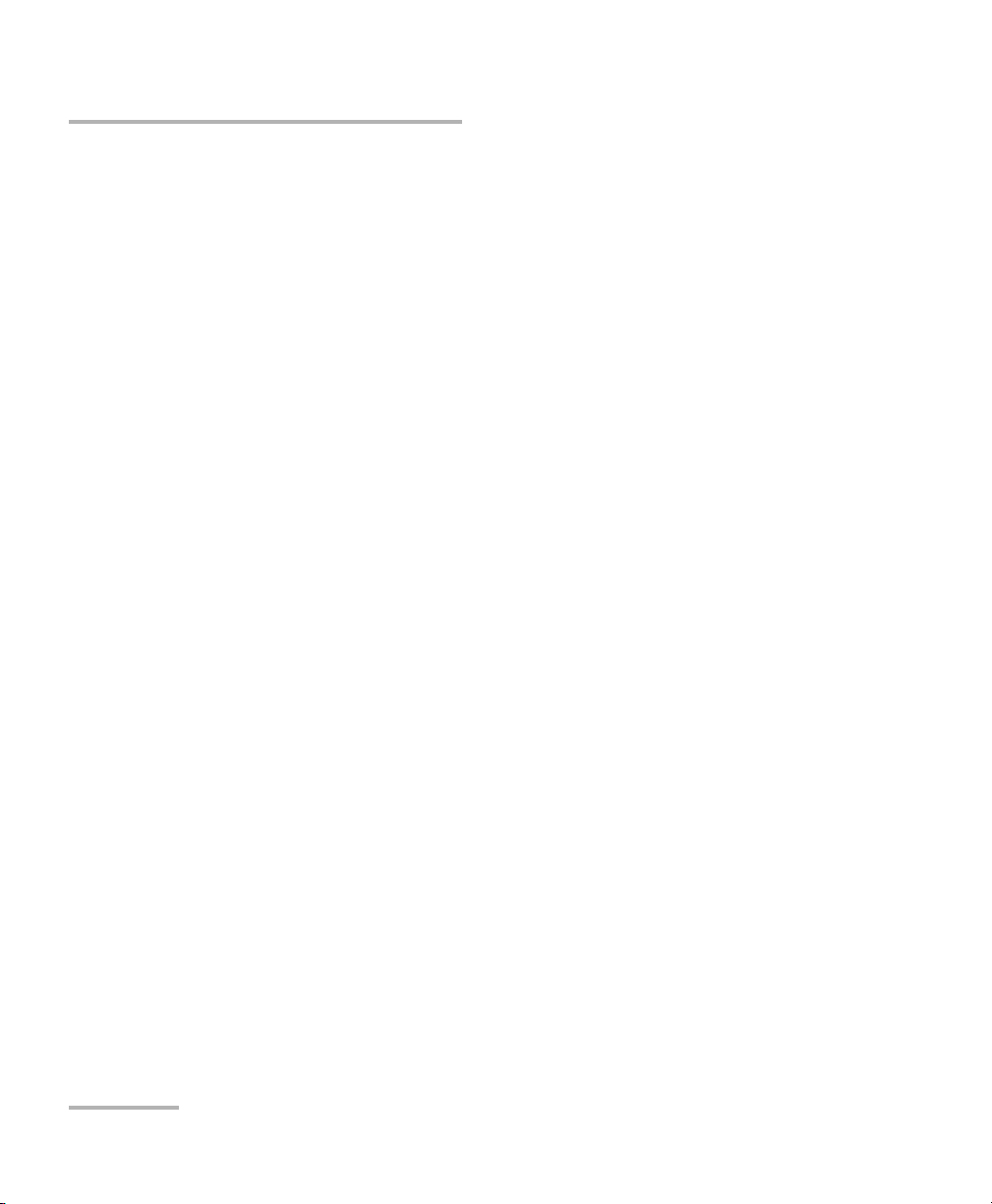

Setting the Remote Control Mode

Setting the Remote Control Mode

To remotely control the Broadband Source, you must either

select the GPIB mode by setting a GPIB address, or

activate the RS-232 port and set its parameters (see Setting Baud Rate

on page 32 and Setting Flow Control on page 33).

To set a remote control mode:

1. Press the Setup button.

2. Use the up/down or left/right arrow buttons to select RS232/GPIB.

Note: If GPIB is currently selected and you want to specify a GPIB address, see

Setting GPIB Address on page 31.

3. Press ENTER to access the RS232 / GPIB edit box.

4. Use the up/down arrow keys to toggle between GPIB and RS232.

5. Press ENTER to confirm.

If you selected RS232, the GPIB Addr. menu option is deactivated (“N.A.”is

displayed).

If you selected GPIB, the Baud Rate and Flow Ctrl menu options are

disabled (“N.A.” is displayed). If the currently selected GPIB address

doesn’t suit your needs, you can change it.

30 FLS-2200

Page 39

Preparing for Remote Control

Refresh Rate

Backlight

Contrast

Video Mode

Exit

8 Hz

ON

STD

RS232 / GPIB

GPIB Addr.

Baud Rate

Flow Ctrl

GPIB

12

N.A.

N.A.

Setting GPIB Address

Setting GPIB Address

If GPIB is selected as the remote command mode, you can select the GPIB

address you want to use from 1 to 30 (default value is 12).

To set a GPIB address:

1. Press the Setup button.

2. Use the up/down or left/right arrow keys to select GPIB Addr. The

current GPIB address is displayed.

Note: If you are in RS-232 mode, the GPIB address cell will display “N.A.” You

must change the communication mode to GPIB before setting an address.

3. Press ENTER, then use the up/down arrow keys to select a GPIB

address between 1 and 30.

4. Press ENTER to confirm your choice.

Broadband Source 31

Page 40

Preparing for Remote Control

Refresh Rate

Backlight

Contrast

Video Mode

Exit

8 Hz

ON

STD

RS232 / GPIB

GPIB Addr.

Baud Rate

Flow Ctrl

RS232

N.A.

19200

Soft

Setting Baud Rate

Setting Baud Rate

The baud rate is a parameter related to RS-232 communication. It

determines the speed at which data is sent between the unit and a

computer, in bits per second (bps).

To change the baud rate for your remote communications:

1. Press the Setup button.

2. Use the up/down or left/right arrow keys to select Baud Rate. The

current setting is displayed.

Note: If you are in GPIB mode, the Baud Rate cell will display “N.A.” You must

change the communication mode to RS-232 before setting the baud rate.

3. Press ENTER, then use the up/down arrow keys to select the baud rate.

You can select 1200, 2400, 4800, 9600 or 19200 bps.

4. Press ENTER to confirm.

32 FLS-2200

Page 41

Preparing for Remote Control

Refresh Rate

Backlight

Contrast

Video Mode

Exit

8 Hz

ON

STD

RS232 / GPIB

GPIB Addr.

Baud Rate

Flow Ctrl

RS232

N.A.

19200

Soft

Setting Flow Control

Setting Flow Control

The flow control parameter applies only to RS-232 communication. This

parameter allows you to select the type of serial communication used.

You can choose the Soft option if you want the rate of data transmission to

match the rate at which it can be processed by the device. This enables the

computer and the Broadband Source to stop each other from transmitting

by sending a control character (Xoff). They will also be able to restart the

transmission by sending another control character (Xon). This is known as

a “software handshake”.

To set a flow control:

1. Press the Setup button.

2. Use the up/down or left/right arrow keys to select Flow Ctrl. The

current setting is displayed.

Note: If you are in GPIB mode, the Flow Ctrl cell will display “N.A.” You must

change the communication mode to RS-232 before setting the flow control.

3. Press ENTER, then use the up/down arrow keys to select the type of

flow you want. “None” means no flow control. “Soft” allows the unit or

computer controlling it, to turn the data transmission on or off.

4. Press ENTER to confirm.

Broadband Source 33

Page 42

Page 43

7 Using Your Broadband Source

in an Automated Test

Environment

EXFO supplies commands that follow the guidelines determined by the

SCPI consortium and LabVIEW drivers for your FLS-2200 Broadband

Source. Your application can be developed using LabVIEW.

The present chapter gives you information to help you use the provided

commands and drivers to remotely control your Broadband Source.

Message Management

Each device that is physically connected to the GPIB link has its own input

buffer, output queue and error/event queue. These data structures allow

storage of incoming messages (single or compound commands that are

sent to an instrument), responses from queries, errors and events that may

occur.

Data structure Characteristics Clearing

Input buffer Consists of a First-In, First-Out

(FIFO) data structure.

Stores Data Bytes (DABs) and END

messages.

Delivers messages to the parser in

the order that they were received

from the I/O control.

Maximum message length:

unlimited in DABs (the input

buffer size is only limited to the

total size of the device memory).

Broadband Source 35

The buffer will be cleared

by:

Turning off the power.

Sending a Device Clear

(DCL) message to the

instrument.

Sending a

Selected Device Clear

(SDC) message to the

instrument.

Page 44

Using Your Broadband Source in an Automated Test Environment

Message Management

Data structure Characteristics Clearing

An incoming byte empties the

output queue. An error will be

raised if the output queue

contained data. Consequently, it

clears the Message AVailable bit

(bit number 4 –MAV from the

Status Byte register).

Except for the string and binary

block contents, the following

transformations are made on the

incoming data:

character conversion from lower

case to upper case.

conversion of “<wsp>”

characters to spaces.

conversion of multiple blanks to a

single blank.

Parser begins to process messages

when the <PROGRAM MESSAGE

TERMINATOR> is received or if

the input buffer is full.

36 FLS-2200

Page 45

Using Your Broadband Source in an Automated Test Environment

Message Management

Data structure Characteristics Clearing

Output queue Consists of a First-In, First-Out

(FIFO) data structure.

When the instrument acts as a

talker, it sends response messages

(from the output queue) to the

controller. Response messages all

end with a <RESPONSE MESSAGE

TERMINATOR>, see the appendix

on data types.

Total storage capacity: only limited

to the device’s memory.

As soon as there is data in the

output queue, the Message

AVailable bit (bit number 4 –MAV

from the Status Byte register) is set

to 1.

Remains empty if no query is

received or if the query contains

an error.

The Output queue will be

cleared by:

Reading all the items it

contains.

Turning off the power.

Sending a Device Clear

(DCL) message to the

instrument.

Sending a

Selected Device Clear

(SDC) message to the

instrument.

Attempting to send a

command before

reading the responses to

previous queries (an

error will also be

raised).

Broadband Source 37

Page 46

Using Your Broadband Source in an Automated Test Environment

Message Management

Data structure Characteristics Clearing

Error/Event

queue

Consists of a First-In, First-Out

(FIFO) data structure.

Total storage capacity: 50 errors or

events.

Errors or events can be retrieved,

one at a time, with

:SYSTem:ERRor[:NEXT]?.

When an error or event occurs

and the Error/Event queue is full,

the last item in the queue (the

most recent) is removed and the

Queue overflow error

(error –350) is added. No new

items will be stored into the queue

until there will be room available.

As soon as there is data in the

output queue, the Error AVailable

bit (bit number 2 –EAV from the

Status Byte register) is set to 1.

The Error/Event queue will

be cleared when:

Reading all the items it

contains.

Turning off the power.

Sending a Device Clear

(DCL) message to the

instrument.

Sending a

Selected Device Clear

(SDC) message to the

instrument.

Using the *CLS

command.

38 FLS-2200

Page 47

Using Your Broadband Source in an Automated Test Environment

Standard Status Data Structure

Standard Status Data Structure

Each device that is physically connected to the GPIB bus has four status

registers with a structure complying with the IEEE 488.2 standard. These

registers allow the controller to monitor events and get useful information

on the status of the devices it controls.

Standard Event Status Register (ESR)

Bits Mnemonics Bit Value

7 Power On 128

6Not used 0

5 Command Error 32

4Execution Error 16

3 Device Dependent Error 8

2Query Error 4

1Not used 0

0Operation Complete 1

Broadband Source 39

Page 48

Using Your Broadband Source in an Automated Test Environment

Standard Status Data Structure

Standard Event Status Enable Register (ESE)

Bits Mnemonics Bit Value

7 Power on 128

6Not used 0

5 Command error 32

4Execution error 16

3 Device dependent error 8

2Query error 4

1Not used 0

0 Operation complete 1

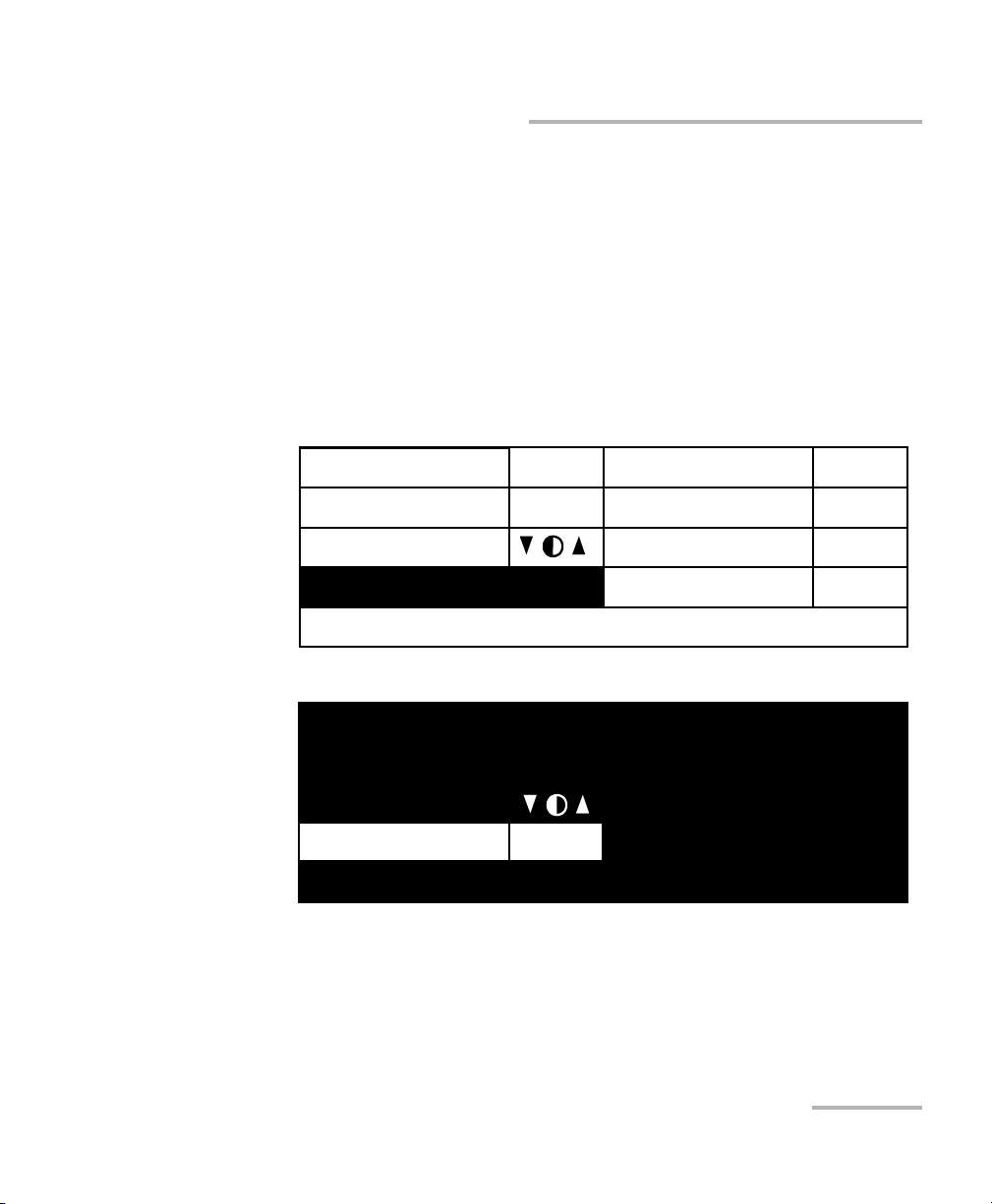

The following table presents a summary of the possible operations on ESR

and ESE registers.

Register Read Write Clear

ESR Use *ESR?. Impossible to write. Use *CLS.

Read the register.

ESE Use *ESE?. Use *ESE. Use *ESE with a value

equal to 0.

40 FLS-2200

Page 49

Using Your Broadband Source in an Automated Test Environment

Standard Status Data Structure

Status Byte Register (STB)

Bits Mnemonics Bit Value

7Not used 0

6 Request service / Master summary status 64

5 Event summary bit 32

4 Message available 16

3Not used 0

2 Error / Event queue 4

1Not used 0

0Not used 0

Service Request Enable Register (SRE)

Bits Mnemonics Bit Value

7Not used 0

6 Reserved 0

5 Event status byte 32

4 Message available 16

3Not used 0

2 Error / Event queue 4

1Not used 0

0Not used 0

Broadband Source 41

Page 50

Using Your Broadband Source in an Automated Test Environment

Standard Status Data Structure

The following table presents a summary of the possible operations on STB

and SRE registers.

Register Read Write Clear

STB Use *STB?.

Use serial poll (GPIB

bus sequence that

allows retrieval of the

value without

Impossible to write;

the register’s contents

is only modified when

the Event registers or

Queues are modified.

interrupting the current

process).

SRE Use *SRE? Use *SRE with a value

equal to 0 to disable

the register or with a

value equal to 1 to

enable it.

The diagram displayed on the next page is a useful aid in understanding

the general commands and how a service request (SRQ) is generated.

Using a service request, a device notifies the controller that an event

requiring special attention occurred. The controller will then find which

device generated a SRQ (its RQS bit is set) and the causes of it.

Use *CLS before

sending a query (to

clear the Event registers

and Queues and by the

same token clear the

STB register).

Use *SRE with a value

equal to 0.

42 FLS-2200

Page 51

Using Your Broadband Source in an Automated Test Environment

Standard Status Data Structure

Broadband Source 43

Page 52

Using Your Broadband Source in an Automated Test Environment

SOUR:POW[:STAT]<wsp><Boolean Program Data>

Mandatory

keywords

Optional keyword

(in square brackets)

Required

space

ParameterKeyword

separators

SCPI Command Structure

SCPI Command Structure

The information presented in this section provides an overview of GPIB

programming. If you need detailed information, refer to:

The International Institute of Electrical and Electronics Engineers. IEEE

Standard 488.1-1987, IEEE Standard Digital Interface for Programmable

Instrumentation. New York, 1987.

The International Institute of Electrical and Electronics Engineers. IEEE

Standard 488.2-1992, IEEE Standard Codes, Formats, Protocols and

Common Commands For Use with ANSI/IEEE Std. 488.1-1987. New

York, 1992.

Standard Commands for Programmable Instruments (SCPI). Volume

1: Syntax and Style. Vers. 1999.0 May, U.S.A, 1999.

The provided commands follow the guidelines determined by the Standard

Commands for Programmable Instruments (SCPI) consortium. A program

message consists of one or more commands (and/or queries) with their

appropriate parameters.

Note: The command provided below is for guidance only; your Broadband

Source may not support it.

For example, a program message could contain a command used to

activate or deactivate a source. The corresponding command syntax

would be:

When sending a message containing the previous command, you would

44 FLS-2200

actually type: SOUR:POW ON.

Page 53

Using Your Broadband Source in an Automated Test Environment

SCPI Command Structure

The following table shows elements that are commonly used in the

commands or queries syntax.

Item Meaning

[ ] Enclose optional keywords or parameters.

Do not include square brackets in your program message.

[1..n] Indicates that the instrument provides multiple capabilities and that you

have to specify which one you want to use. If you omit the value, the

command will take effect on the first capability.

Multiple capabilities can be found at any branch of the command tree

(root, intermediate node or terminal node).

Example: If the command is :SENSe[1..n]:CORRection:COLLect:ZERO

and you want it to take effect on the second SENSe (sensor) capability

of the instrument, you may send this:

:SENSe2:CORRection:COLLect:ZERO.

Do not include square brackets in your program message; simply enter

the number.

<wsp> Indicates that a space is required (“wsp” stands for “white space”).

Corresponds to ASCII character codes (0 to 9 and 11 to 32, in decimal).

Do not include “<wsp>” in your program message; simply type a space.

<digit> Element used in the construction of various numeric data types. Can

take any value between 0 and 9 inclusively (corresponds to ASCII

character codes 48 to 57, in decimal).

Broadband Source 45

Page 54

Using Your Broadband Source in an Automated Test Environment

<Upper/lo wer

cas e alpha>

<Upper/l ower

cas e alpha>

_

<digi t>

SCPI Command Structure

Item Meaning

<mnemonic> Element used in the construction of certain data types and program

messages.

In the diagram above,

“<Upper/lower case alpha>” corresponds to ASCII character codes

(65 to 90 and 97 to 122, in decimal).

“_” corresponds to an underscore character (code 95, in decimal).

< > Text appearing between angled brackets specifies the command

parameter to be sent or the response you will receive from an

instrument.

Do not include angled brackets in your program message.

| Indicates that one, and only one, value must be selected from the

available choices.

Example: If the list is 0|1, you can only select 0 or 1.

Do not include the pipe character in your program message.

{ } Indicate that the enclosed parameters can appear 0 to n times when the

command is used.

Do not include braces in your program message.

: Mandatory to separate keywords. Can be omitted at the beginning of a

program message. For example, you can use either :SYST:ERR or

SYST:ERR.

46 FLS-2200

Page 55

Using Your Broadband Source in an Automated Test Environment

:SYSTem:ERRor?

:SYST:ERR?

:syst:err?

Long form

Short form (small words

represented by the capital letters

of the long form)

Item Meaning

SCPI Command Structure

;

Mandatory to separate the different commands of a program

message when more than one command is sent at a time. In this

case, it is called <PROGRAM MESSAGE UNIT SEPARATOR>.

Also used to separate responses when multiple queries were sent in

a single program message. In this case, it is called <RESPONSE

MESSAGE UNIT SEPARATOR>.

,

Mandatory to separate parameters in a command or a query. In this

case, it is called <PROGRAM DATA SEPARATOR>.

Also used to separate the various responses from a query. In this

case, it is called <RESPONSE DATA SEPARATOR>.

There are also several conventions regarding command syntax:

Spelling errors will cancel the command or query.

Commands and queries are not case-sensitive. You can type your

program messages using either lower-case or upper-case letters.

The command or query can be written using only the three- or

four-letter shortcuts, only full words, or a combination of both.

The example below shows the long and the short forms of a same

query.

For readability reasons, you can use extra spaces in your program

messages but they won’t be taken into account. For more information,

see Message Management on page 35.

Broadband Source 47

Page 56

Using Your Broadband Source in an Automated Test Environment

:system:version?;:system:error:next?

:system:version?;error:next?

other<mnemonic> path

<mnemonic> path

omitted –also correct

saved <mnemonic> path

:system:error:next?;:system:version?

:system:error:next?;version?

Incorrect; :version? is not in

the :system:error branch

other<mnemonic> pathsaved <mnemonic> path

SCPI Command Structure

You can build program messages allowing you to send more than one

command at a time. Sometimes, you can omit the leading

<mnemonic> path to simplify the program messages and speed up

the search time (the parser saves the last position in the command

tree).

Paths cannot be omitted in all cases. The example below would cause

an error.

IEEE 488.2 required commands or queries (beginning with a *) that are

part of the program message have no effect on the paths.

Example:

:system:version?;*idn?;:system:error:next? is equivalent to

:system:version?;*idn?;error:next?

Note: Omitting the leading <mnemonic> path is only possible when you have

more than one command or query in the program message that you send.

A program message must be ended with a <PROGRAM MESSAGE

TERMINATOR>. For more information, see the appendix on data types.

48 FLS-2200

Page 57

Using Your Broadband Source in an Automated Test Environment

Consulting Data Types

Consulting Data Types

If you need information about data types used in EXFO’s documentation,

see the appendix on data types.

Writing Remote Control Code

Complex measurement programs may be written using any programming

environment that supports GPIB communication. GPIB development kits

are available for most of the popular commercial programming languages.

You can find all the commands and queries supported by the Broadband

Source in the IEEE 488.2 and Specific Commands appendix.

Broadband Source 49

Page 58

Using Your Broadband Source in an Automated Test Environment

Writing Remote Control Code

When you write code, you must follow these rules on message reception

and transmission:

The controller must have sent a complete message to the instrument

(including the message terminator) before retrieving a response.

The controller must retrieve all the responses from previous queries

(including the response terminator) before sending a new message to

an instrument.

The controller must not try to retrieve a response from an instrument if

the corresponding query has not been previously sent to the

instrument.

You must pay special attention to queries that return an indefinite ASCII

response. To avoid any confusion, the IEEE 488.2 standard requires that

this data type be immediately followed by a response termination

character. For this reason, when working with compound queries, you

must ensure that a query sending an indefinite ASCII response is the

last query of the series.

Be careful when sending program messages containing multiple

queries that return large amounts of data. Since the controller can only

retrieve data when the instrument has finished processing the queries,

it could result in problems ranging from a saturation of the output

queue to the complete blocking of the whole system.

50 FLS-2200

Page 59

Using Your Broadband Source in an Automated Test Environment

<Error

number>

, "

<Error

description>

; "

<Device

dependent

information>

Error Message Format

Error Message Format

System and device-specific errors are managed by the FLS-2200

Broadband Source. The generic format for error messages is illustrated in

the following figure.

As shown in the above figure, the message contains three parts:

error number

error description

device-dependent information

Error messages ending in a negative number are SCPI-based errors.

For more information on errors, see Message Management on page 35. For

a complete list of possible errors, seethe appendix on SCPI-based errors.

Broadband Source 51

Page 60

Using Your Broadband Source in an Automated Test Environment

Perform all operations on

instrument

Set up communication

parameters

Open communication

Close communication

Working with EXFO LabVIEW Drivers

Working with EXFO LabVIEW Drivers

EXFO provides you with custom drivers that you can use to program

commands for your inspection instruments.

IMPORTANT

You need to be familiar with the LabVIEW environment and

programming methods to work with EXFO drivers.

Regardless of whether you work with the provided Getting Started

applications or your own VIs (using EXFO drivers), the steps remain the

same.

Before configuring the communication parameters via LabVIEW (provided

applications or new VI), you must configure the FLS-2200 Broadband

Source for remote control. For more information, see the section on

preparing your unit for automation or remote control in this user

documentation.

52 FLS-2200

Page 61

Using Your Broadband Source in an Automated Test Environment

Working with EXFO LabVIEW Drivers

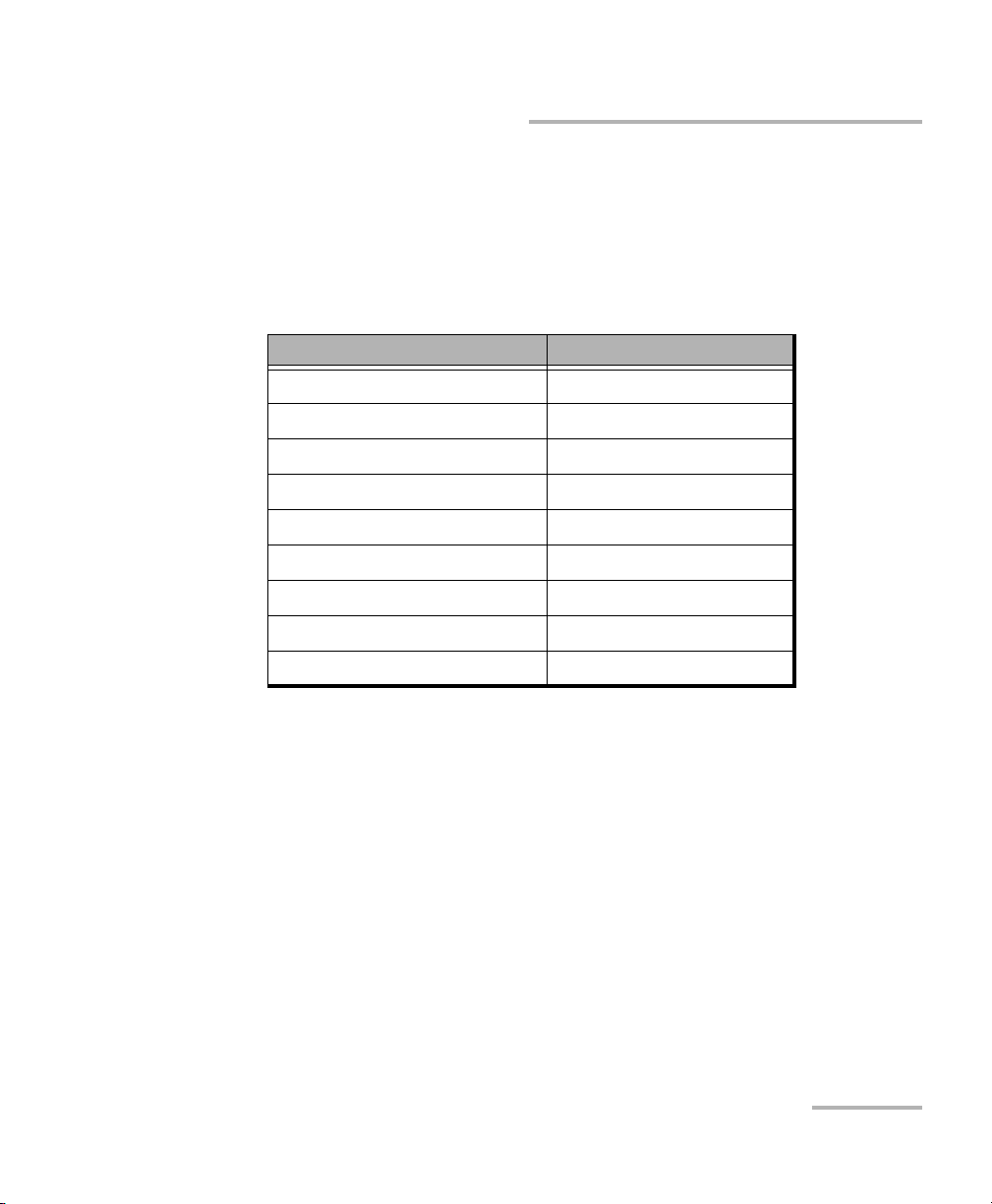

The following table presents the possible settings for communication

parameters. These parameters must be set from LabVIEW for each

instrument.

Parameter RS-232 GPIB

Communication type RS232 GPIB

VISA resource name Select the serial port

from the list

Select the GPIB device

from the list

Broadband Source 53

Page 62

Using Your Broadband Source in an Automated Test Environment

Getting Started file

Using the EXFO Getting Started Applications

Using the EXFO Getting Started Applications

Once the LabVIEW drivers are installed, the Getting Started demo

applications are available to demonstrate the following:

How to open and close the communication link between the remote

computer and the device.

Some of the available functions (by loading the necessary .vi files).

All the .vi files related to an instrument are presented in the same folder. By

default, they can be found under:

C:\Program Files\EXFO\LabVIEW Getting Started\Getting Started xxxx

(where xxxx corresponds to the product code).

You can also directly start a demo application this way:

From the Windows task bar, click the Start button, then point to All

Programs > EXFO > LabVIEW Getting Started Applications, and click

Getting Started xxxx (where xxxx corresponds to the product code).

Each Getting Started application offers a user interface (called Front Panel

and a design view (called Block Diagram).

54 FLS-2200

Page 63

Using Your Broadband Source in an Automated Test Environment

Communication

indicator

(light green when

connected)

Communication

parameters

Function examples

Using the EXFO Getting Started Applications

On the Front Panel, you can set communication parameters between the

computer and the current instrument. It also offers various controls and

buttons to use the instrument easily. In fact, the application performs the

necessary calls to the instrument’s drivers so it is transparent to the user.

Broadband Source 55

The application state (called State Machine) changes whenever an action

is performed on the instrument. If you toggle to Block Diagram view, you

can see the list of possible states. The application is always in one of the

predefined states.

Page 64

Using Your Broadband Source in an Automated Test Environment

State Machine

Instrument2200_SetSourceState.vi

Using the EXFO Getting Started Applications

The following figure illustrates the State Machine after the user has clicked

on the button allowing you to set the source state (from the Front Panel).

When the State Machine changes to “SetSourceState”, the application calls

“Instrument2200_PowerSource.vi”, which, in turn, calls the

“SourcePower.vi”sub VI that will perform the appropriate action on the

instrument.

56 FLS-2200

Page 65

Using Your Broadband Source in an Automated Test Environment

Instrument driver VI

Using the EXFO Getting Started Applications

The detail of this sub VI gives precious information on how to call an

instrument driver VI.

To use a Getting Started application:

1. Turn on the computer and ensure that all the remote-control

parameters are set correctly.

2. Open the desired Getting Started application and run it from LabVIEW.

3. From the application’s Front Panel, set the communication parameters.

For information on communication parameters, see Working with

EXFO LabVIEW Drivers on page 52.

4. Once the parameters are configured, click Initialize Communication.

5. Using the provided buttons and controls, perform the desired actions.

Broadband Source 57

Page 66

Using Your Broadband Source in an Automated Test Environment

Using the EXFO Getting Started Applications

6. When you are finished, select Close to end the communication.

7. Close LabVIEW.

IMPORTANT

To avoid losing the original version of the Getting Started

applications, do not save changes when prompted by LabVIEW.

58 FLS-2200

Page 67

Using Your Broadband Source in an Automated Test Environment

To open and close the

communication link

To send IEEE 488.2

commands and control

the instrument

Building and Using Custom VIs

Building and Using Custom VIs

EXFO LabVIEW drivers have been designed to let you control the various

instruments according to your needs, by building your own VIs in LabVIEW.

You can access EXFO drivers

directly from

C:\Program Files\National Instruments\LabVIEW 6\instr.lib\EXFO

from the LabVIEW function palettes

The EXFO palette gives you access to a sub-palette in which each icon

corresponds to a set of drivers that allow you to either

communicate with the FLS-2200 Broadband Source

open and close communication links with the FLS-2200 Broadband

Source

send IEEE 488.2 (common) commands

Broadband Source 59

Page 68

Using Your Broadband Source in an Automated Test Environment

Red background:

write-only

command (Set)

Blue background:

read-and-write

command (Get/Set)

Yellow background:

read-only command

(Get)

Symbols: refer to first keyword

of associated SCPI command

To send IEEE 488.2

commands

Building and Using Custom VIs

When you click an icon in the palette, the corresponding sub-palette

opens, giving you access to the different functions.

60 FLS-2200

Page 69

Using Your Broadband Source in an Automated Test Environment

2b

2c

2e

2d

Building and Using Custom VIs

To build a custom VI:

1. Start LabVIEW and create a new VI.

2. Open the EXFO palette.

2a. From LabVIEW, open the Diagram Block view.

2b. Display the Functions palette and select Instrument I/O.

2c. From the Instrument I/O palette, select Instrument Drivers.

2d. From the Instrument Drivers palette, select EXFO.

2e. From the EXFO palette, select the icon corresponding to the

FLS-2200 Broadband Source.

Broadband Source 61

Page 70

Using Your Broadband Source in an Automated Test Environment

Building and Using Custom VIs

3. Select EXFO Communication 2200.

4. From the EXFO Communication 2200 palette, select

Communication2200_OpenComm.vi and add it to your new VI.

5. Set the communication parameters. For information on

communication parameters, see Working with EXFO LabVIEW Drivers

on page 52.

6. From the EXFO palette, select the icon corresponding to the functions

of the FLS-2200 Broadband Source.

7. From the displayed palette, select the function you need and add the

corresponding driver to your VI.

62 FLS-2200

Page 71

Using Your Broadband Source in an Automated Test Environment

Building and Using Custom VIs

8. Set the required parameters and connect the instrument

Communication ID in parameter to the Communication ID out

parameter from CommunicationXXXX_OpenComm.vi.

The example below shows how to configure the

SourcePowerState_GSet.vi to turn on the source.In this example, Set

was chosen and the PowerState parameter was set to True.

9. Repeat steps 7 and 8 for each of the functions you want to use.

However, you have to link Communication ID in of the new driver to

Communication ID out of the preceding driver.

Note: If you want to use IEEE 488.2 commands, add the desired driver to your VI

and configure its parameters exactly as you would do with any instrument

function.

Broadband Source 63

Page 72

Using Your Broadband Source in an Automated Test Environment

Building and Using Custom VIs

10. When you are finished, add CommunicationXXXX_CloseComm.vi to

your VI.

Connect the Communication ID out parameter of the last function to

the Communication ID in parameter of

CommunicationXXXX_CloseComm.vi.

Note: You only have to open communication once at the beginning, and close it

when all of the desired functions will have been added.

11. Save your work.

To use your new VI:

1. Turn on the computer and ensure that all the remote-control

parameters are set correctly.

2. From LabVIEW, run the VI.

64 FLS-2200

Page 73

8 Maintenance

To help ensure long, trouble-free operation:

Always inspect fiber-optic connectors before using them and clean

them if necessary.

Keep the unit free of dust.

Clean the unit casing and front panel with a cloth slightly dampened

with water.

Store unit at room temperature in a clean and dry area. Keep the unit

out of direct sunlight.

Avoid high humidity or significant temperature fluctuations.

Avoid unnecessary shocks and vibrations.

If any liquids are spilled on or into the unit, turn off the power

immediately, disconnect from any external power source, remove the

batteries and let the unit dry completely.

The use of controls, adjustments and procedures other than those

specified herein may result in exposure to hazardous situations or

impair the protection provided by this unit.

WARNING

Cleaning EUI Connectors

Regular cleaning of EUI connectors will help maintain optimum

performance. There is no need to disassemble the unit.

IMPORTANT

If any damage occurs to internal connectors, the module casing will

have to be opened and a new calibration will be required.

Broadband Source 65

Page 74

Maintenance

Push

Tur n

Pull

3

4

5

Cleaning EUI Connectors

Looking into the optical connector while the light source is active

WILL result in permanent eye damage. EXFO strongly recommends

to TURN OFF the unit before proceeding with the cleaning

procedure.

To clean EUI connectors:

1. Remove the EUI from the instrument to expose the connector

baseplate and ferrule.

2. Moisten a 2.5 mm cleaning tip with one drop of isopropyl alcohol

(alcohol may leave traces if used abundantly).

WARNING

3. Slowly insert the cleaning tip into the EUI adapter until it comes out on

the other side (a slow clockwise rotating movement may help).

4. Gently turn the cleaning tip one full turn, then continue to turn as you

withdraw it.

5. Repeat steps ? to ? with a dry cleaning tip.

Note: Make sure you don’t touch the soft end of the cleaning tip.

66 FLS-2200

Page 75

Maintenance

Cleaning EUI Connectors

6. Clean the ferrule in the connector port as follows:

6a. Deposit one drop of isopropyl alcohol on a lint-free wiping cloth.

IMPORTANT

Isopropyl alcohol may leave residues if used abundantly or left to

evaporate (about 10 seconds).

Avoid contact between the tip of the bottle and the wiping cloth,

and dry the surface quickly.

6b. Gently wipe the connector and ferrule.

6c. With a dry lint-free wiping cloth, gently wipe the same surfaces to

ensure that the connector and ferrule are perfectly dry.

6d. Verify connector surface with a portable fiber-optic microscope

(for example, EXFO’s FOMS) or fiber inspection probe (for

example, EXFO’s FIP).

7. Put the EUI back onto the instrument (push and turn clockwise).

8. Throw out cleaning tips and wiping cloths after one use.

Broadband Source 67

Page 76

Maintenance

Fuse holder

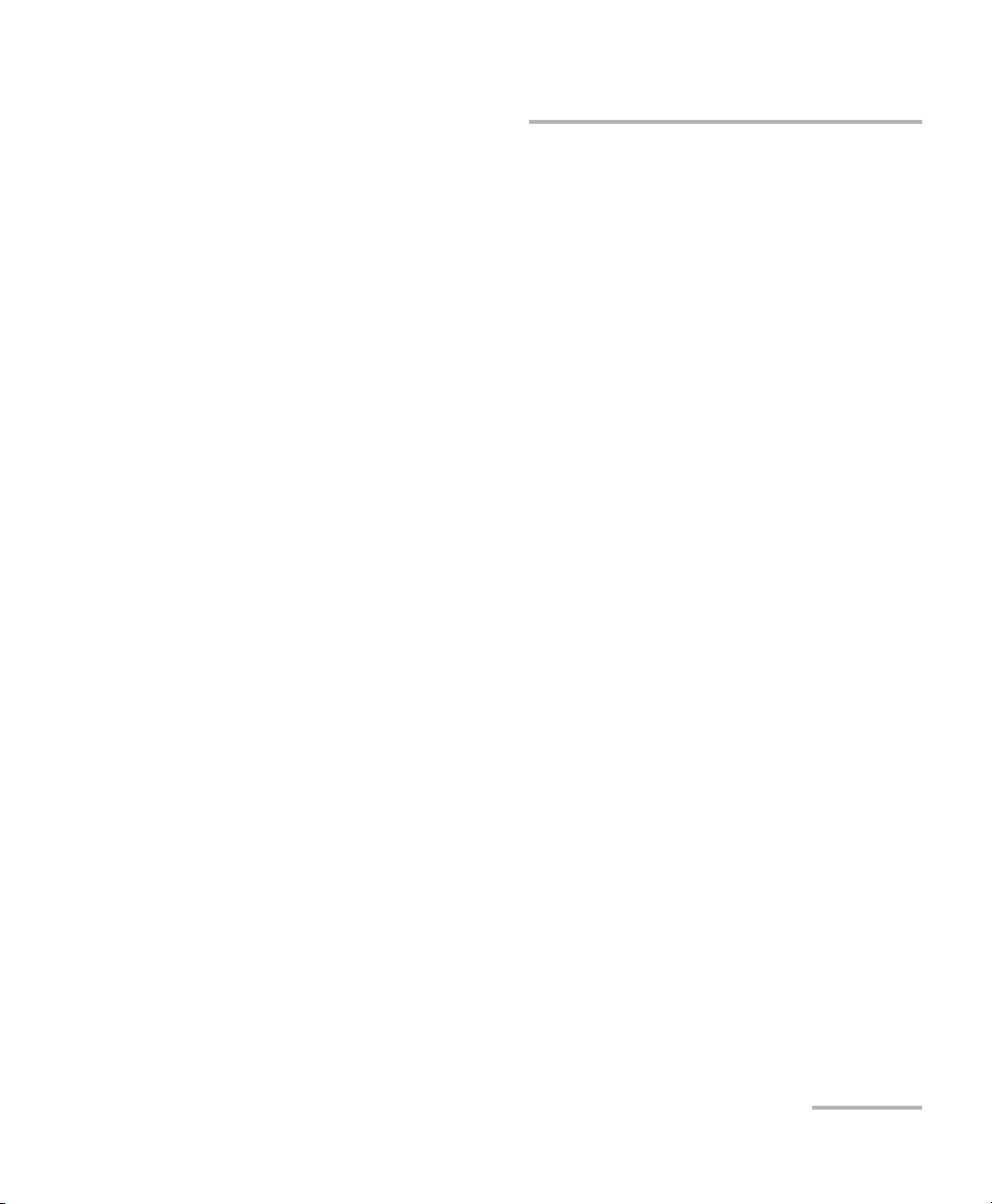

Replacing Fuses

Replacing Fuses

The FLS-2200 Broadband Source contains two F2.0L250V-type fuses

(5 mm x 20 mm (0.197 in x 0.787 in), fast-acting, low breaking capacity,

250 V). The fuse holder is located at the back of the Broadband Source, just

beside the power inlet.

To replace a fuse:

1. Turn off the unit and disconnect the power cord.