Page 1

FIP-400B

Fiber Inspection Probe and

ConnectorMax2 Mobile

User Guide

Page 2

Copyright © 2015 EXFO Inc. All rights reserved. No part of this publication

may be reproduced, stored in a retrieval system or transmitted in any form,

be it electronically, mechanically, or by any other means such as

photocopying, recording or otherwise, without the prior written permission

of EXFO Inc. (EXFO).

Information provided by EXFO is believed to be accurate and reliable.

However, no responsibility is assumed by EXFO for its use nor for any

infringements of patents or other rights of third parties that may result from

its use. No license is granted by implication or otherwise under any patent

rights of EXFO.

EXFO’s Commerce And Government Entities (CAGE) code under the North

Atlantic Treaty Organization (NATO) is 0L8C3.

The information contained in this publication is subject to change without

notice.

Trademarks

EXFO’s trademarks have been identified as such. However, the presence

or absence of such identification does not affect the legal status of any

trademark.

Units of Measurement

Units of measurement in this publication conform to SI standards and

practices.

Patents

Feature(s) of this product is/are protected by pending design patents.

Version number: 6.0.0.1

ii FIP-400B

Page 3

Contents

Certification Information ........................................................................................................v

1 Introducing the FIP-400B Fiber Inspection Probe and

ConnectorMax2 Mobile ................................................................................ 1

Probe ......................................................................................................................................1

Available Models ....................................................................................................................3

Probe Tips ...............................................................................................................................3

LED Indicators .........................................................................................................................4

ConnectorMax2 Mobile Software ..........................................................................................6

Conventions ............................................................................................................................7

2 Safety Information ....................................................................................... 9

Other Safety Symbols on Your Unit .......................................................................................10

Electrical Safety Information .................................................................................................11

3 Setting up Your Fiber Inspection Probe and ConnectorMax2 Mobile ..... 13

Preparing to Use the Mobile Application ..............................................................................13

Connecting or Disconnecting the Wireless Probe ..................................................................14

Changing the Fiber Inspection Probe Tip ..............................................................................17

Setting up Autonaming ........................................................................................................18

Setting up Identification .......................................................................................................22

Setting up the Increment ......................................................................................................25

Setting Up Auto Capture ......................................................................................................29

Selecting Test Configurations ...............................................................................................31

Modifying the File Format .....................................................................................................36

Selecting the Sharing Application .........................................................................................38

Sharing Data When No Connection Is Available ....................................................................40

Restoring to Default Settings ................................................................................................43

4 Inspecting Fiber Ends ................................................................................. 45

Inspecting Fiber Ends ...........................................................................................................45

Saving Files ...........................................................................................................................48

Managing Files .....................................................................................................................52

Analyzing Captures ...............................................................................................................56

Transferring Results With Third-Party Applications ................................................................60

Fiber Inspection Probe iii

Page 4

5 Maintenance ................................................................................................65

General Maintenance ............................................................................................................65

Recycling and Disposal (Applies to European Union Only) ....................................................65

Recharging the Battery .........................................................................................................66

Replacing the Battery ............................................................................................................68

6 Troubleshooting ..........................................................................................71

Solving Common Problems ...................................................................................................71

Contacting the Technical Support Group ..............................................................................74

Viewing Information About ConnectorMax2 Mobile ...........................................................75

Viewing Online Help .............................................................................................................76

Transportation ......................................................................................................................77

7 Warranty ......................................................................................................79

General Information .............................................................................................................79

Liability .................................................................................................................................80

Exclusions .............................................................................................................................80

Certification ..........................................................................................................................80

Service and Repairs ...............................................................................................................81

EXFO Service Centers Worldwide ..........................................................................................82

A Technical Specifications ..............................................................................83

B Fiber Inspection Probe Tip Compatibility Chart .......................................85

Index .................................................................................................................89

iv FIP-400B

Page 5

Certification Information

Certification Information

North America Regulatory Statement

This unit was certified by an agency approved in both Canada and the

United States of America. It has been evaluated according to applicable

North American approved standards for product safety for use in Canada

and the United States.

Electronic test and measurement equipment is exempt from FCC part 15,

subpart B compliance in the United States of America and from ICES-003

compliance in Canada. However, EXFO Inc. makes reasonable efforts to

ensure compliance to the applicable standards.

The limits set by these standards are designed to provide reasonable

protection against harmful interference when the equipment is operated in

a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance

with the user guide, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely

to cause harmful interference in which case the user will be required to

correct the interference at his own expense.

Modifications not expressly approved by the manufacturer could void the

user's authority to operate the equipment.

Fiber Inspection Probe v

Page 6

Certification Information

Your unit comes with an internal wireless module and antenna for which

the following information applies:

This equipment has been tested and found to comply with the limits

for a Class A digital device, pursuant to Part 15 of the FCC Rules.

Operation is subject to the following two conditions: (1) This device

may not cause harmful interference, and (2) this device must accept

any interference received, including interference that may cause

undesired operation.

This device complies with Industry Canada license-exempt RSS

standard(s). Operation is subject to the following two conditions: (1)

this device may not cause interference, and (2) this device must

accept any interference, including interference that may cause

undesired operation of the device.

This device complies with the US/Canada portable RF exposure limit

set forth for an uncontrolled environment and is safe for intended

operation as described in this user documentation. The further RF

exposure reduction can be achieved if the device can be kept as far as

possible from the user’s body.

This device does not contain any user-serviceable components. Any

unauthorized product changes or modifications will invalidate

warranty and all applicable regulatory certifications and approvals.

vi FIP-400B

Page 7

Certification Information

European Community Declaration of Conformity

Warning: This is a class A product. In a domestic environment, this product

may cause radio interference in which case the user may be required to

take adequate measures.

Hereby, EXFO declares that the radio equipment type “Wide Band Data

Transmission” is in compliance with Directive 2014/53/EU.

An electronic version of the complete declaration of conformity for your

product is available on our website at www.exfo.com. Refer to the

product’s page on the Web site for details.

The information about the Wi-Fi frequency bands is as follows:

Between the frequencies 2400.0 MHz - 2483.5 MHz.

The maximum output power is 15 dBm.

This device is a 2.4 GHz wideband transmission system (transceiver),

intended for use in all EU member states and EFTA countries, except in

France and Italy where restrictive use applies.

In Italy, the end-user should apply for a license at the national spectrum

authorities in order to obtain authorization to use the device for setting up

outdoor radio links and/or for supplying access to telecommunications

and/or network services.

This device may not be used for setting up radio links in France, and in

some areas the RF output power may be limited to 10 mW EIRP in the

frequency range of 2454 - 2483.5 MHz. For detailed information, the

end-user should contact the national spectrum authority in France.

Fiber Inspection Probe vii

Page 8

Page 9

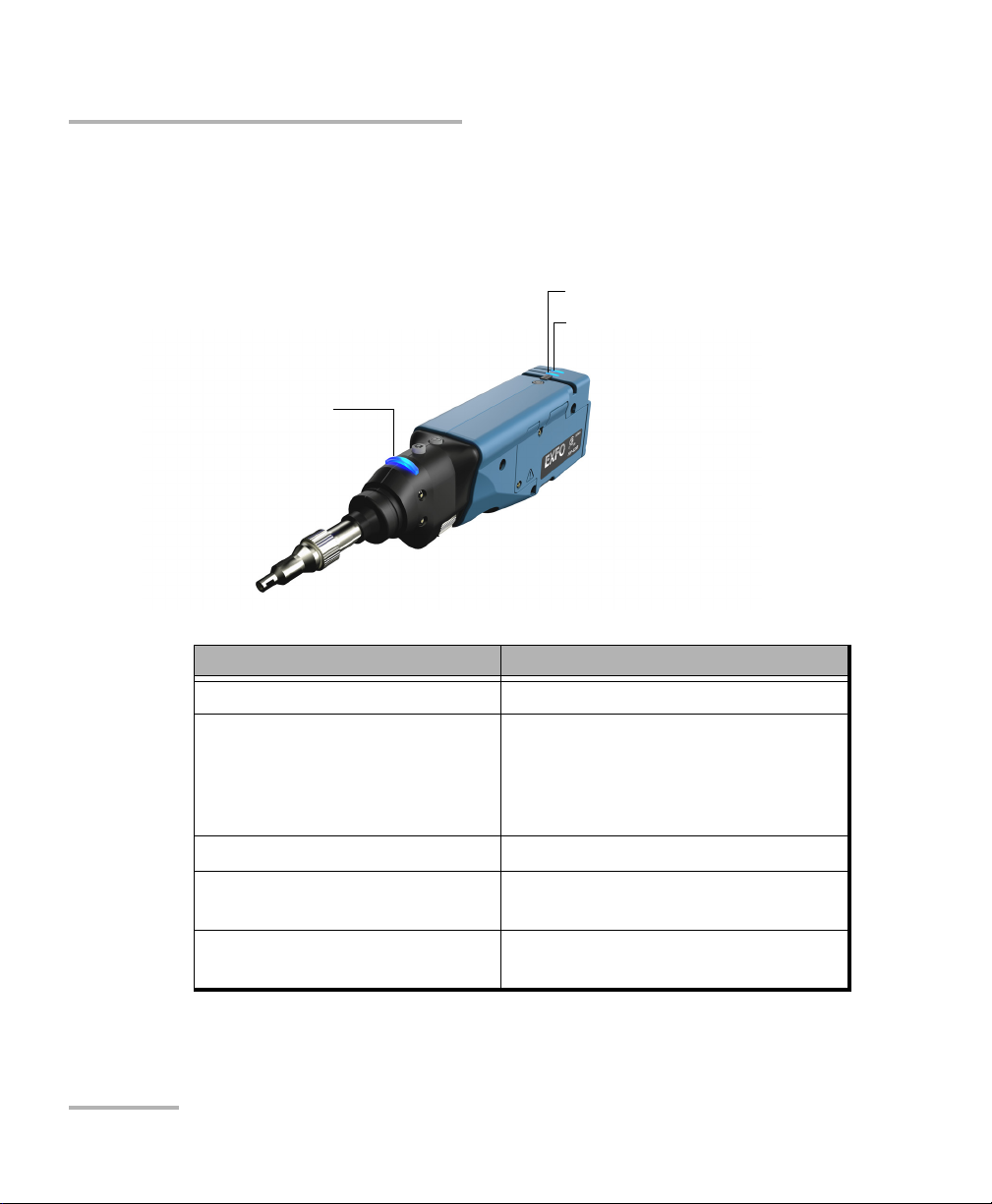

1 Introducing the FIP-400B Fiber

Status LED

Retaining nut

Focus

Magnification control

Capture control

Interchangeable

adapter tips

Micro USB adapter

connector

Battery compartment door

Battery LED

Wi-Fi LED

Inspection Probe and

ConnectorMax2 Mobile

The FIP-400B Fiber Inspection Probe is a portable video microscope used

to inspect fiber ends. Unlike traditional microscopes, the FIP-400B

facilitates the examination of patchcord connectors and also hard-to-reach

connectors on the back of patch panels and bulkhead adapters.

Probe

The FIP-400B is designed to be an intuitive, easy-to-use piece of

equipment. This video microscope is used for inspecting fiber ends.

Fiber Inspection Probe 1

The focus knob can be turned in either direction to focus the image.

The magnification control button allows you to shift between three

levels of magnification. When pressed for one second, it activates the

auto focus.

Page 10

Introducing the FIP-400B Fiber Inspection Probe and ConnectorMax2 Mobile

Probe

The capture control button allows you to capture an image, perform an

analysis, or return to the Live Video mode.

The retaining nut holds tips securely in place, ensuring they are always

fastened in the correct position.

The status LED gives you information about the probe or the analysis

results.

The interchangeable adapter tips give you the possibility to use various

tips depending on the type of connector you are inspecting.

The micro USB adapter connector recharges the battery of the probe

when it is low. You can recharge the battery with the provided USB

cable and the adapter/charger that you connect to a power outlet. You

can also use the provided USB cable alone that you connect to a USB

port of a computer.

When the probe is connected to a power outlet or to a USB port, it still

works via Wi-Fi.

The battery compartment door is for battery replacement.

The probe comes equipped with a protective cap that fits over basic tips;

therefore, you do not need to remove the tip before putting the cap on.

2 FIP-400B

Page 11

Introducing the FIP-400B Fiber Inspection Probe and ConnectorMax2 Mobile

Available Models

Available Models

The features available for your probe are automatically detected when you

connect it to your smart device. The table below shows which feature is

available for each model.

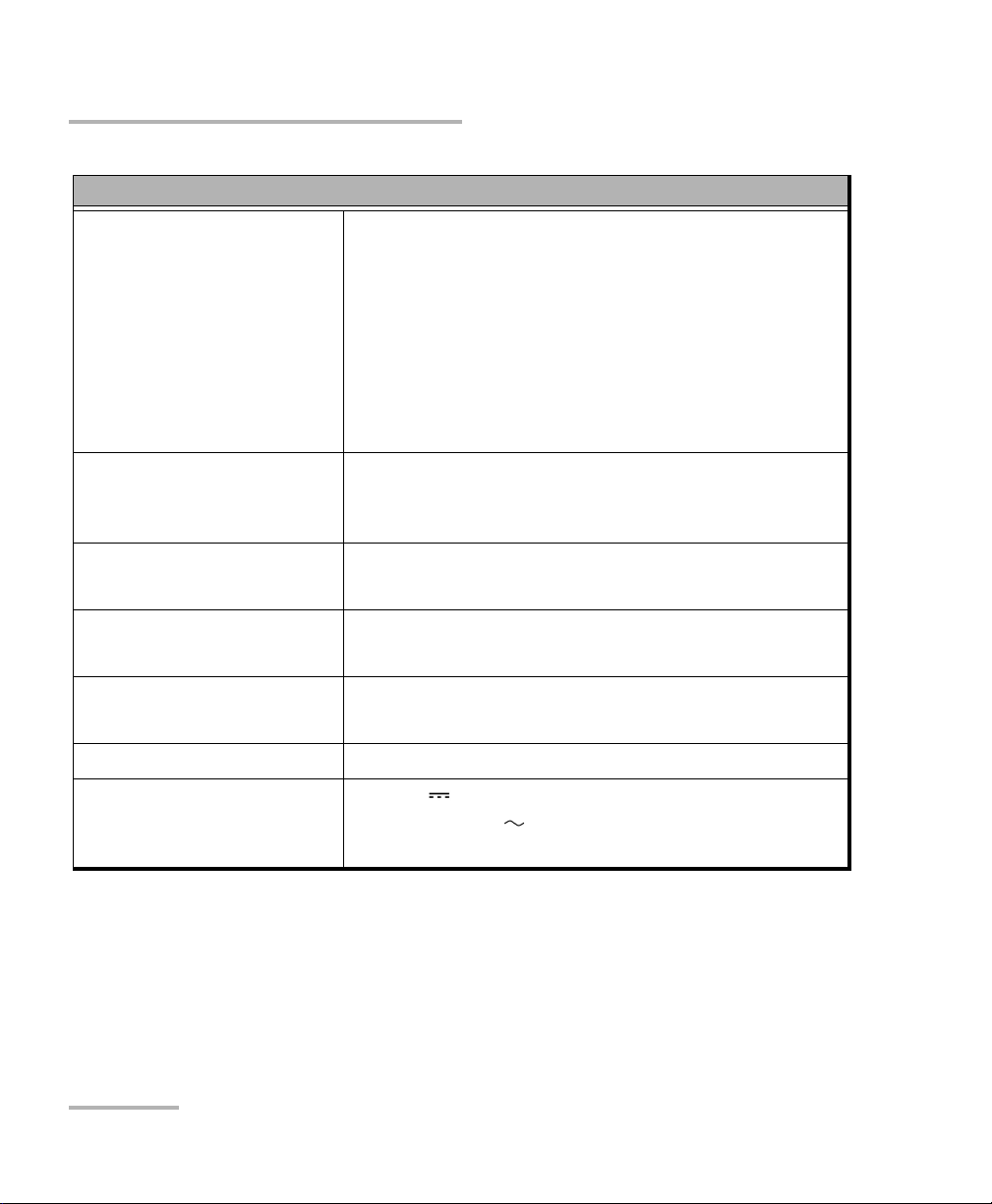

Models Inspection Auto analysis Auto centering Auto focus Auto capture

FIP-425B X X X - -

FIP-435B X X X X X

Note: When the internal temperature of the FIP-435B is too low, the probe

performs a warm-up that can last up to a minute.

Probe Tips

The FIP-400B comes with two interchangeable tips included in two

different packages (UPC or APC). Additional models are also available.

UPC package:

FIPT-400-FC-SC: FC-SC Bulkhead tip

FIPT-400-U25M: Universal patchcord tip (2.5 mm ferrule)

APC package:

FIPT-400-SC-APC: SC APC tip for bulkhead adapter

FIPT-400-U25MA: Universal patchcord tip for 2.5 mm ferrules

Other tip models are available for various bulkhead adapters and

patchcord connectors. For more information about tips and their use, see

the Fiber Inspection Probe Tip Compatibility Chart on page 85, or visit the

EXFO Web site.

Fiber Inspection Probe 3

Page 12

Introducing the FIP-400B Fiber Inspection Probe and ConnectorMax2 Mobile

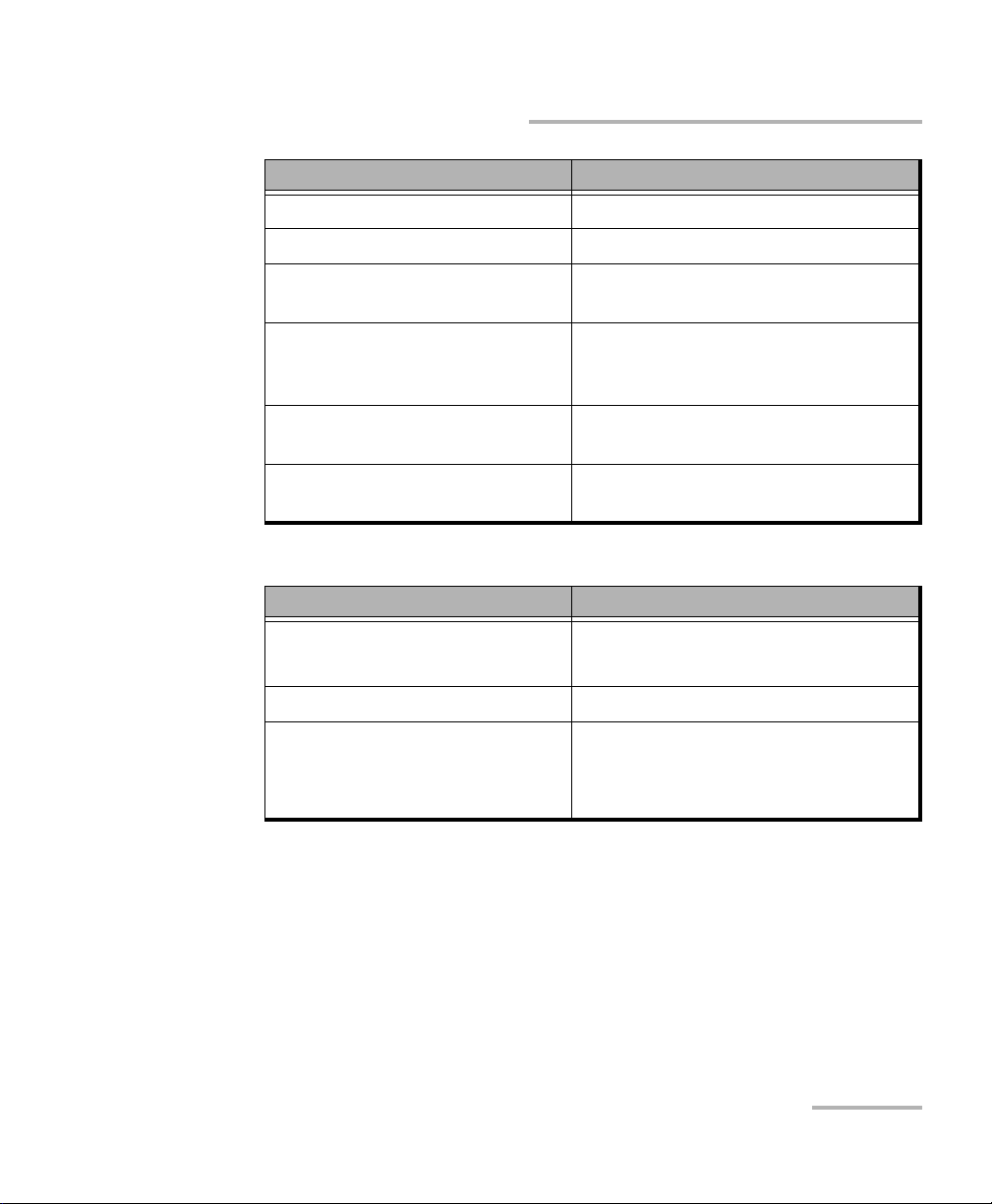

Status LED

Battery LED

Wi-Fi LED

LED Indicators

LED Indicators

The LED located on the probe gives you information about the probe or the

analysis results.

Status LED Status

Flashing blue Processing in progress

Flashing red

There is a problem with the probe.

Follow the instructions on screen.

The auto focus is in timeout

There is an analysis error

Blue The probe is ready and operational

Red In Capture mode, current FIP result

status is Fail

Green In Capture mode, current FIP result

status is Pass

4 FIP-400B

Page 13

Introducing the FIP-400B Fiber Inspection Probe and ConnectorMax2 Mobile

LED Indicators

Battery LED Status

Flashing blue USB connected, battery charging

Blue USB connected, battery fully charged

Red Battery error (only visible when

connected to a USB cable)

Flashing yellow USB connected, battery not charging

because the battery temperature does

not allow the battery to charge

Yellow USB not connected, critical battery

level

Not lit USB not connected, battery above low

level

Wi-Fi LED Status

Blue Ready to transmit

Wireless transmission in progress

Red Transmission error

Not lit

Probe is off

OR

Probe is initializing

Fiber Inspection Probe 5

Page 14

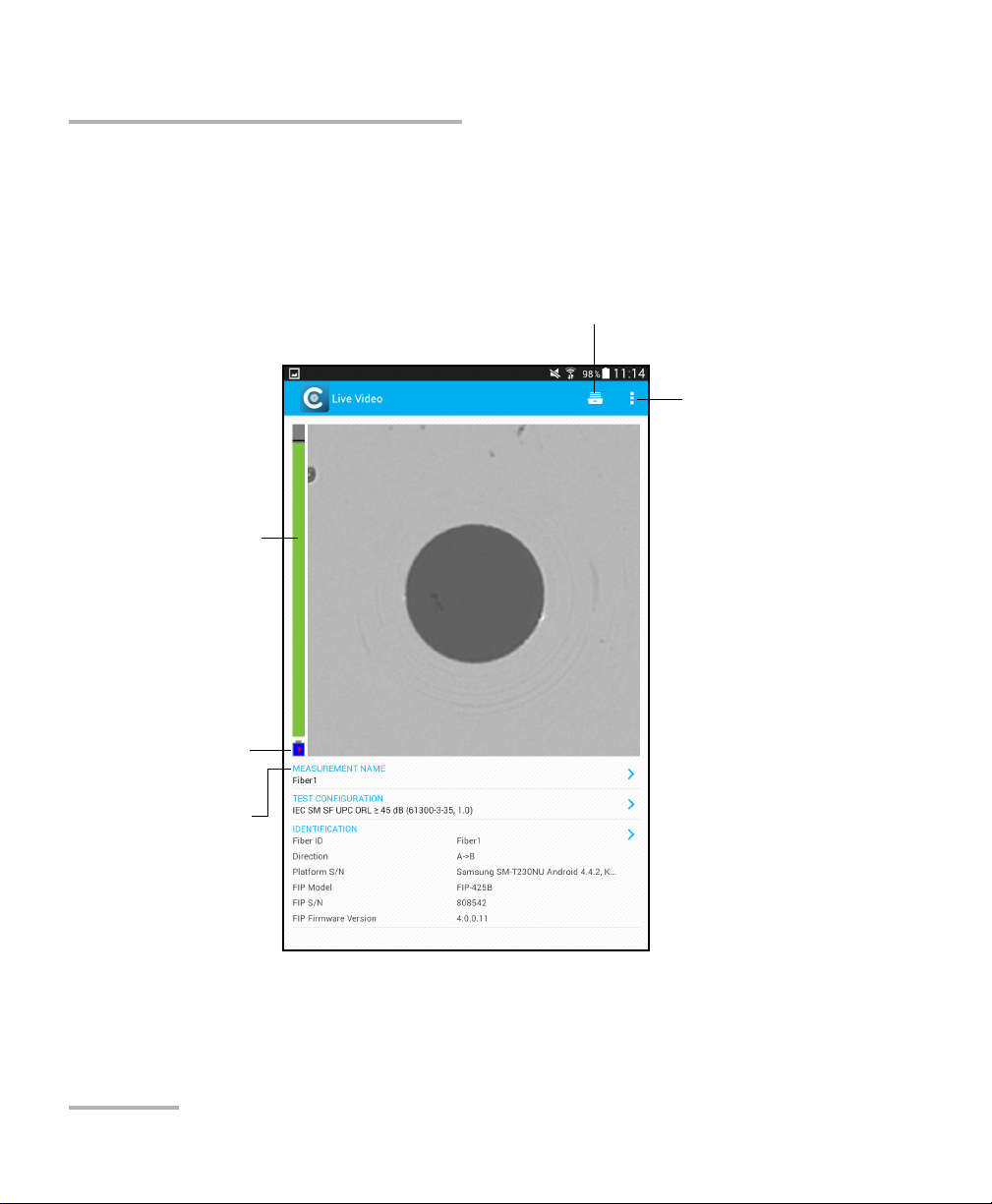

Introducing the FIP-400B Fiber Inspection Probe and ConnectorMax2 Mobile

Battery status

Name of the file

resulting from the

autonaming

Archive icon

User Preferences

Can be found in

the menu button

depending on the

smart device used.

Auto focus

ConnectorMax2 Mobile Software

ConnectorMax2 Mobile Software

ConnectorMax2 Mobile is the application used to view the fiber

inspections. You can also use specific test configurations and analyze the

fibers automatically upon capturing a picture.

6 FIP-400B

Page 15

Introducing the FIP-400B Fiber Inspection Probe and ConnectorMax2 Mobile

Conventions

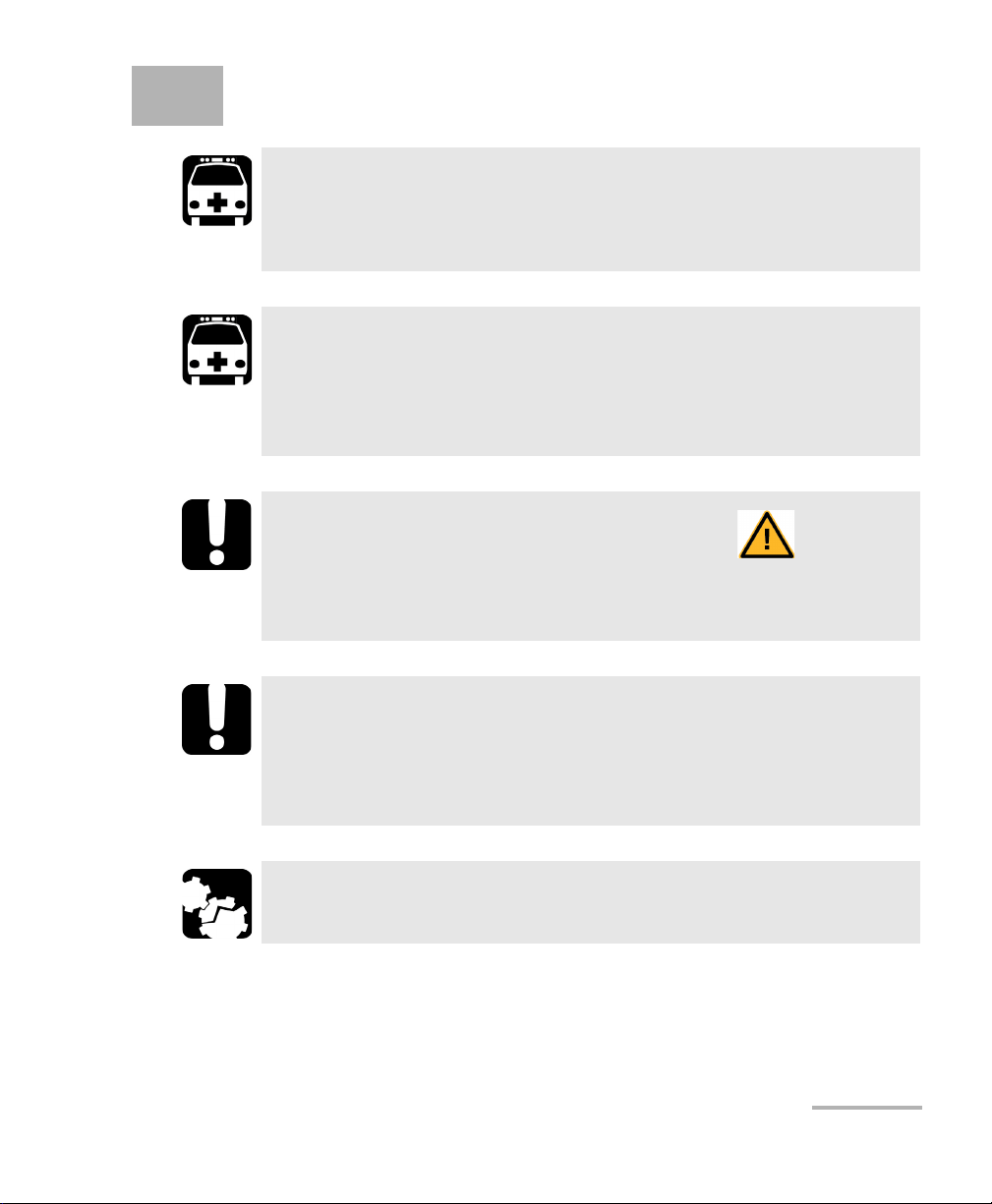

Conventions

Before using the product described in this guide, you should understand

the following conventions:

WARNING

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury. Do not proceed unless you

understand and meet the required conditions.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury. Do not proceed unless you

understand and meet the required conditions.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in component damage. Do not proceed unless you

understand and meet the required conditions.

IMPORTANT

Refers to information about this product you should not overlook.

Note: The appearance and the orientation (portrait or landscape) of the

application may vary depending on the smart device used.

Fiber Inspection Probe 7

Page 16

Page 17

2 Safety Information

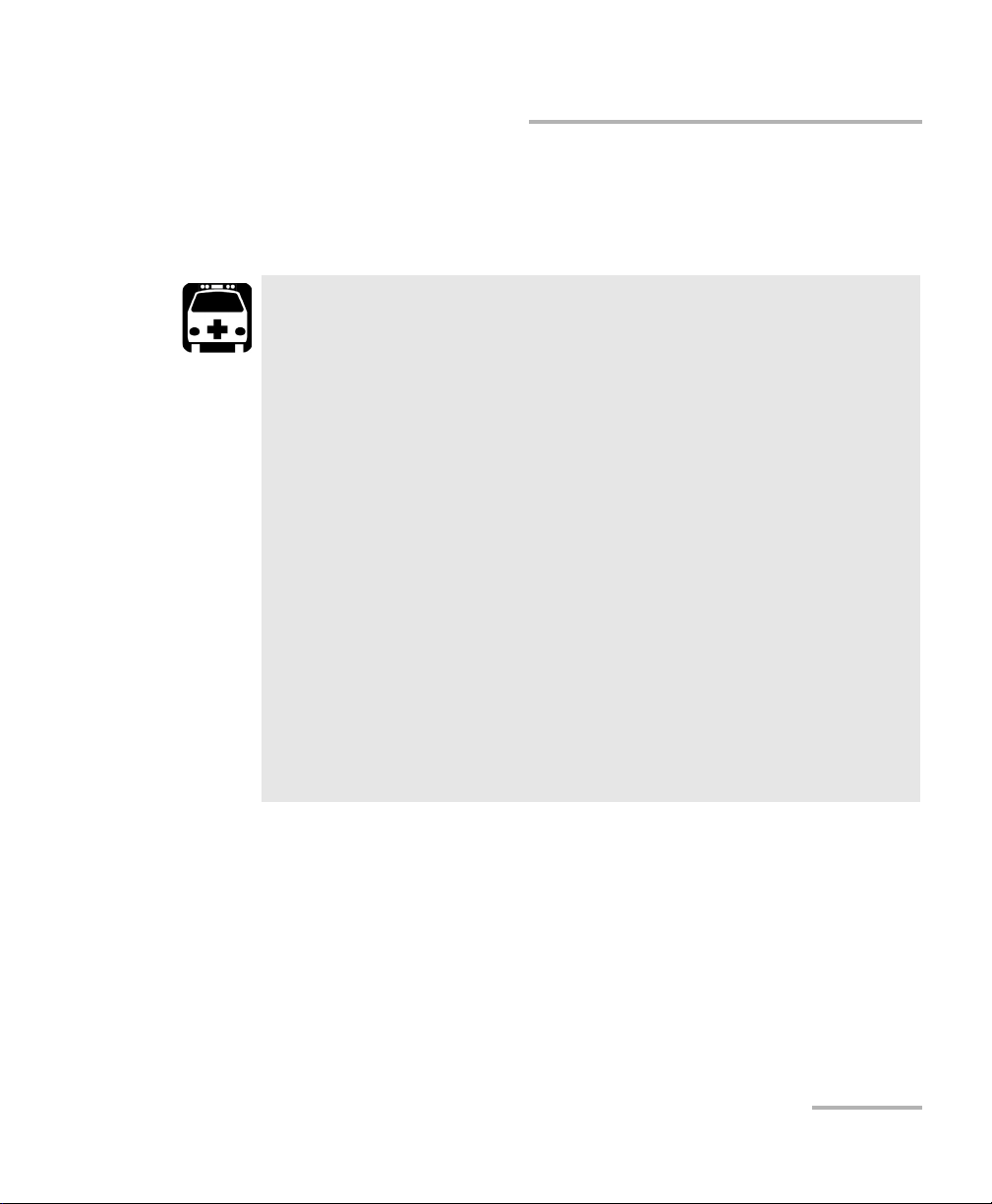

WARNING

Do not install or terminate fibers while a light source is active.

Never look directly into a live fiber and ensure that your eyes are

protected at all times.

WARNING

The use of controls, adjustments and procedures, namely for

operation and maintenance, other than those specified herein may

result in hazardous radiation exposure or impair the protection

provided by this unit.

IMPORTANT

When you see the following symbol on your unit , make sure

that you refer to the instructions provided in your user

documentation. Ensure that you understand and meet the required

conditions before using your product.

IMPORTANT

Other safety instructions relevant for your product are located

throughout this documentation, depending on the action to

perform. Make sure to read them carefully when they apply to your

situation.

CAUTION

Do not use the fiber probe outdoors in wet locations.

Fiber Inspection Probe 9

Page 18

Safety Information

Other Safety Symbols on Your Unit

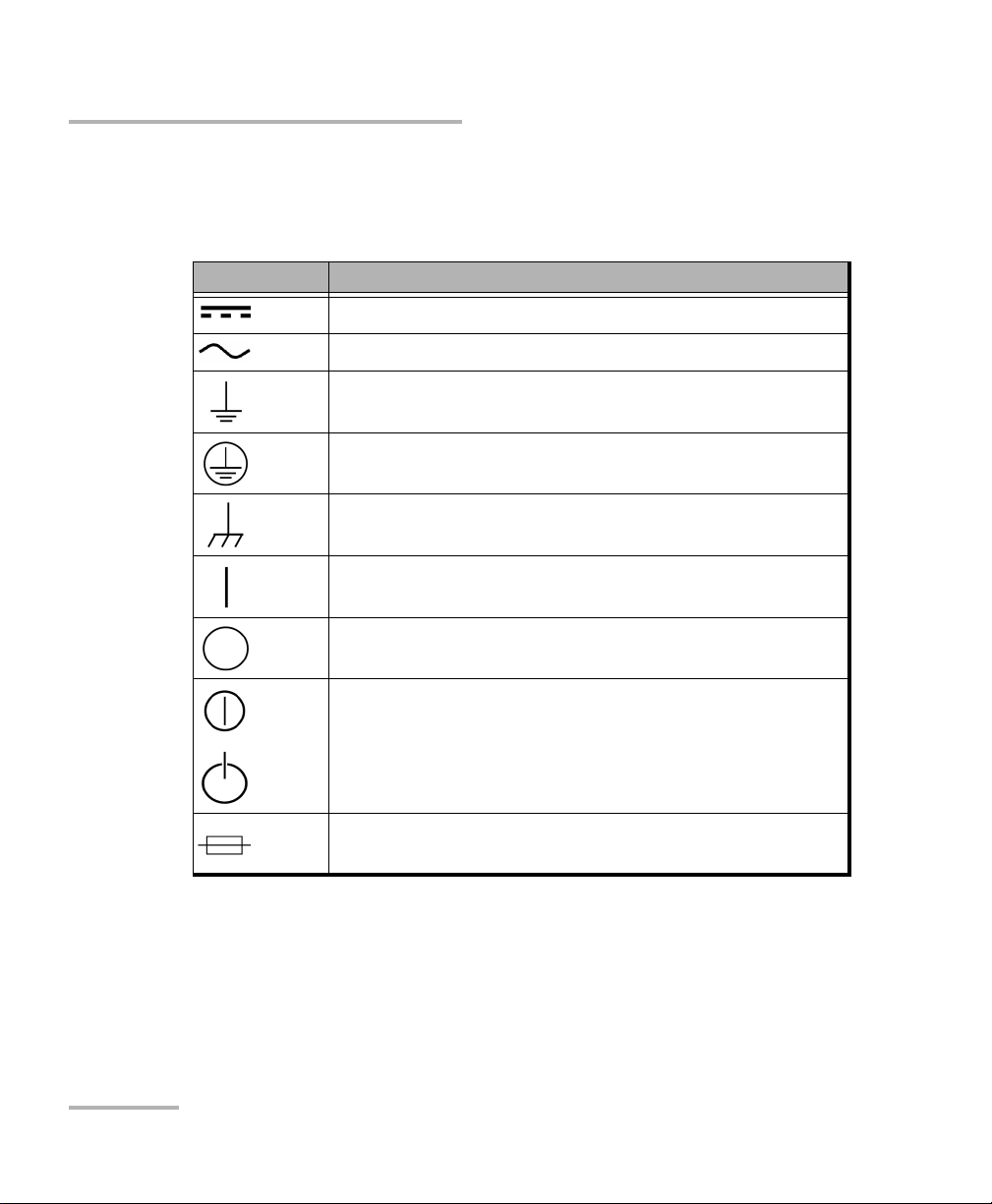

Other Safety Symbols on Your Unit

One or more of the following symbols may also appear on your unit.

Symbol Meaning

Direct current

Alternating current

The unit is equipped with an earth (ground) terminal.

The unit is equipped with a protective conductor terminal.

The unit is equipped with a frame or chassis terminal.

On (Power)

Off (Power)

OR On/Off (Power)

Fuse

10 FIP-400B

Page 19

Safety Information

Electrical Safety Information

Electrical Safety Information

If you need to ensure that the unit is completely turned off, disconnect the

power cable and remove the battery.

WARNING

Use the external electrical power supply indoors only.

Position the unit so that the air can circulate freely around it.

Operation of any electrical instrument around flammable gases

or fumes constitutes a major safety hazard.

To avoid electrical shock, do not operate the unit if any part of

the outer surface (covers, panels, etc.) is damaged.

Only authorized personnel should carry out adjustments,

maintenance or repair of opened units under voltage. A person

qualified in first aid must also be present. Do not replace any

components while the power cable and battery are connected.

Capacitors inside the unit may be charged even if the unit has

been disconnected from its electrical supply.

Use only the listed and certified AC adapter/charger provided by

EXFO with your unit. It provides reinforced insulation between

primary and secondary, and is suitably rated for the country

where the unit is sold.

Fiber Inspection Probe 11

Page 20

Safety Information

Electrical Safety Information

Equipment Ratings

Tem pe ra tu re

Operation

Unit powered by batteries: -10 °C to 40 °C

(14 °F to 104 °F)

Unit connected to USB adapter: 0 °C to 40 °C

(32 °F to 104 °F)

Storage Unit without batteries: -40 °C to 70 °C

(-40 °F to 158 °F)

Unit with batteries: -20 °C to 60 °C

(-4 °F to 140 °F)

Relative humidity

a

unit: 95 % non-condensing

USB adapter: 5 % to 95 % for storage and 8 % to 90 %

for operating temperature

Maximum operation altitude

Pollution degree

2000 m (6562 ft) (unit connected to USB adapter)

3000 m (9843 ft) (unit operated from batteries)

2 (unit connected to external power supply)

3 (unit operated from batteries)

b

Overvoltage category unit: I

AC adapter: II

Measurement category Not rated for measurement categories II, III, or IV

Input power

c

unit: 5 VDC; 1.8 A

USB adapter: 100 - 240 Vac; 50 Hz to 60 Hz;

0.4 A Max

a. Measured in 0 °C to 31 °C (32 °F to 87.8 °F) range, decreasing linearly to 50 % at 40 °C (104 °F).

b. Equipment must be normally protected against exposure to direct sunlight, precipitation and full wind

pressure.

c. Not exceeding ± 10 % of the nominal voltage.

12 FIP-400B

Page 21

3 Setting up Your Fiber

Inspection Probe and

ConnectorMax2 Mobile

When you receive your wireless probe, and before you start working, you

need to download the ConnectorMax2 Mobile application on your smart

device. The application is available for smart devices supporting

Android 4.2, mainly Samsung Galaxy Note 3 and 4, as well as Samsung

Galaxy Tab 4 with an 8-inch screen.

You can change various settings in ConnectorMax2 Mobile, such as the

automated file name or the way you want to share files with third party

applications. These settings are kept for future work sessions.

Preparing to Use the Mobile Application

Before you start working with your wireless probe, there are two steps to

perform.

You need to install ConnectorMax2 Mobile on your smart device.

IMPORTANT

The ConnectorMax2 Mobile application is available for free in

Google Play Store. You need to have a Google account to download

the application. For more information, refer to www.google.com.

Once the application is installed, you have to connect your wireless

probe by Wi-Fi.

When your wireless probe is connected, it is added to the list of the

available probes. It remains available for future tests.

Note: You need to have access to an external Wi-Fi network to install

ConnectorMax2 Mobile. The Wi-Fi needs to be set to ON on your smart

device.

Fiber Inspection Probe 13

Page 22

Setting up Your Fiber Inspection Probe and ConnectorMax2 Mobile

Connecting or Disconnecting the Wireless Probe

To install ConnectorMax2 Mobile:

1. Ensure you have access to an Internet connection.

2. Ta p th e Google Play Store icon.

3. In the Google Play Store (or Play Store) application, search for EXFO

or ConnectorMax2 Mobile.

4. Follow the instructions on-screen.

Once the ConnectorMax2 Mobile is installed, you can now activate the

wireless probe.

Connecting or Disconnecting the Wireless

Probe

When the ConnectorMax2 Mobile is installed on your smart device, you

have to connect your wireless probe by Wi-Fi. When your wireless probe is

connected it is added to the list of the available probes. It remains available

for future tests.

You have to disconnect the probe first if you want to perform the following:

work with another probe

use the probe with another smart device

share files with third-party applications

14 FIP-400B

Page 23

Setting up Your Fiber Inspection Probe and ConnectorMax2 Mobile

Connecting or Disconnecting the Wireless Probe

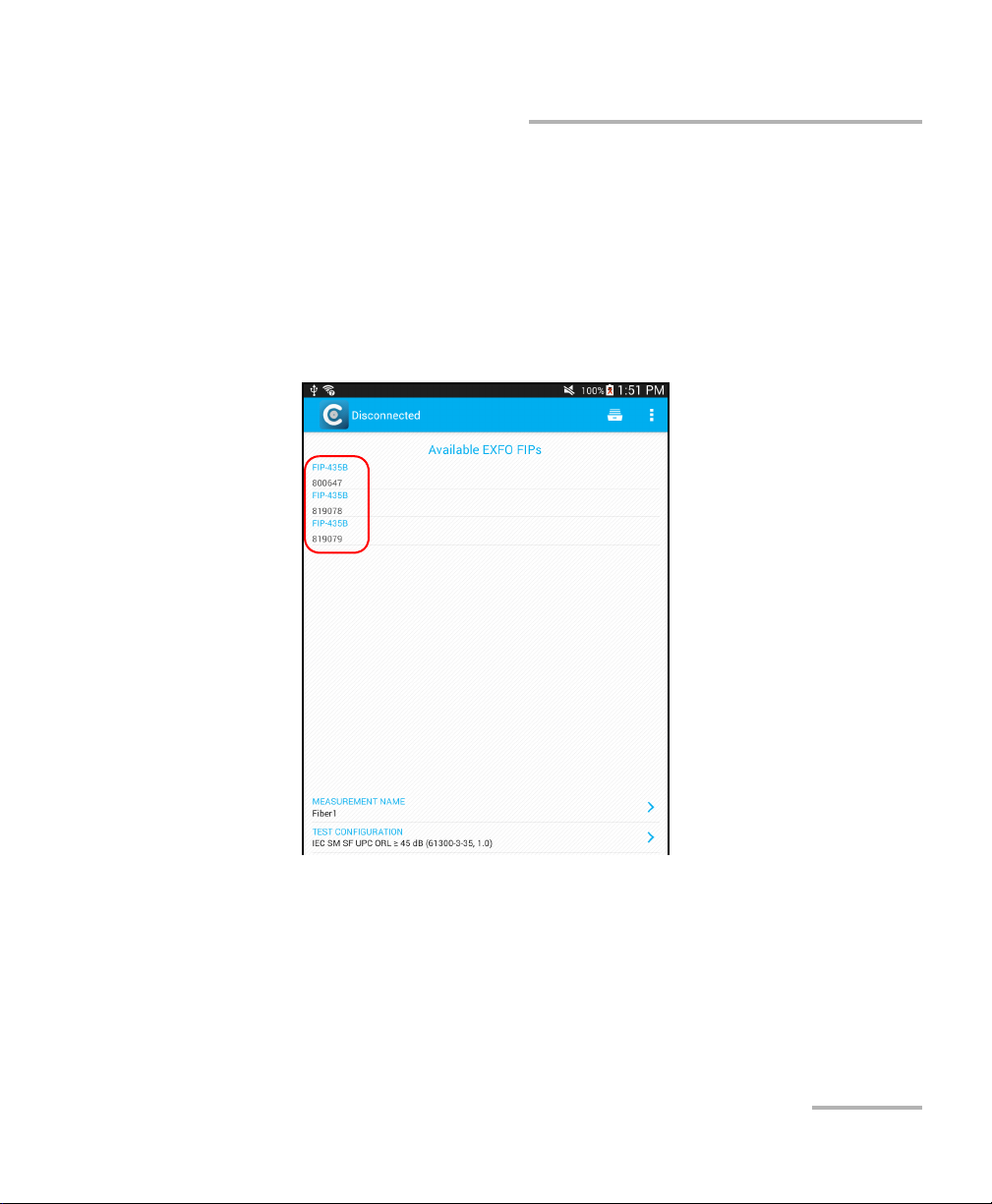

To connect the wireless probe:

1. Ensure the power saving mode is disabled on your smart device.

2. Turn on the probe by pressing the ON button.

3. Ensure the Wi-Fi is activated on your smart device.

4. Start the ConnectorMax2 Mobile application.

5. Select the wireless probe you want to work with.

Note: When a wireless probe is selected, the 3G, 4G and LTE communications are

disabled automatically.

Note: The probes are identified by their serial numbers and type.

Note: The probe can be selected from the Wi-Fi configuration on the smart

device.

Fiber Inspection Probe 15

Page 24

Setting up Your Fiber Inspection Probe and ConnectorMax2 Mobile

Connecting or Disconnecting the Wireless Probe

To disconnect the wireless probe:

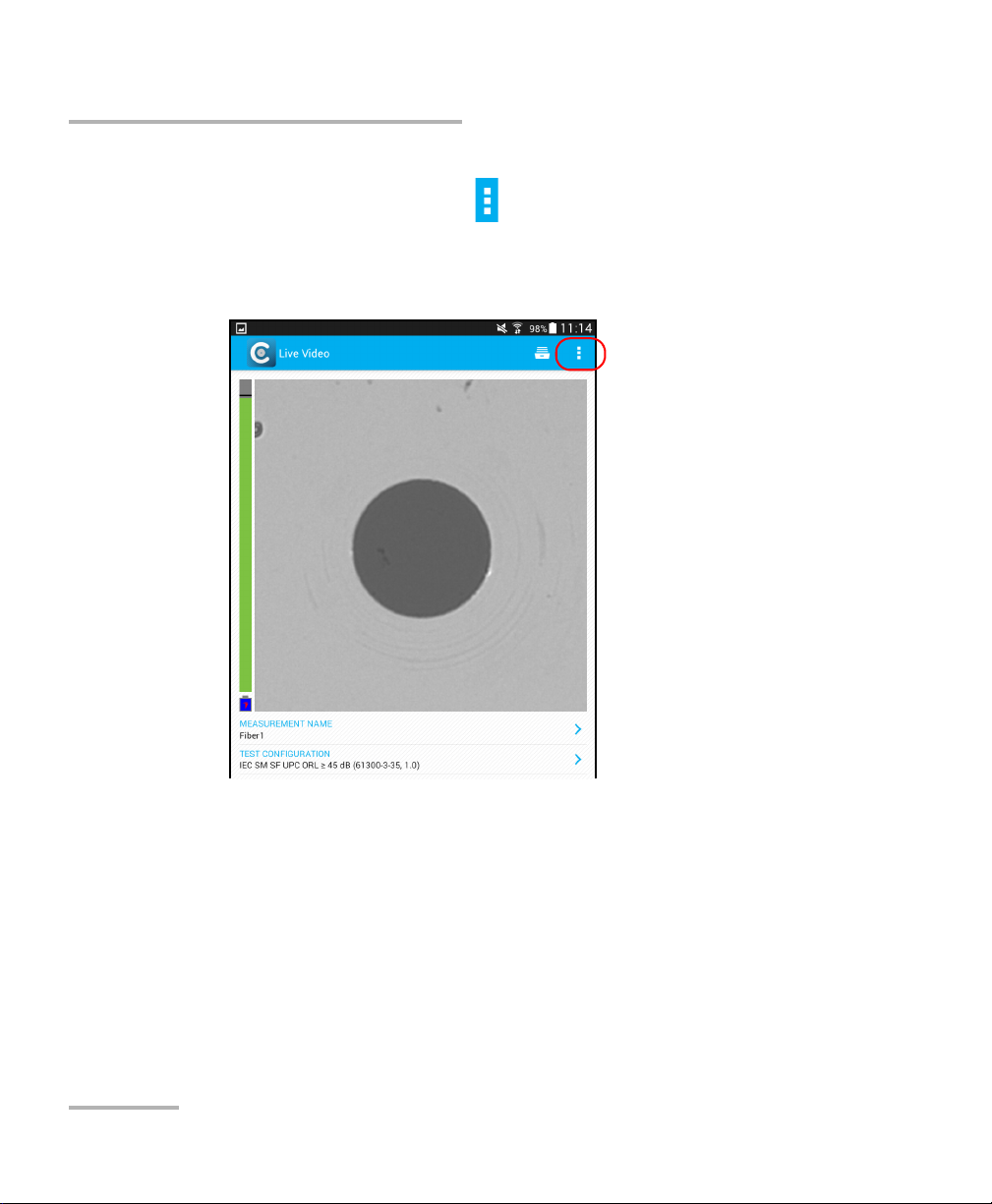

1. From the main window, tap .

Note: Depending on the smart device you are using, the application settings can

be found in the menu button instead.

2. Select Disconnect probe.

16 FIP-400B

Page 25

Setting up Your Fiber Inspection Probe and ConnectorMax2 Mobile

Changing the Fiber Inspection Probe Tip

Changing the Fiber Inspection Probe Tip

You can use various tips depending on the type of connector you are

inspecting. For more information about tips you can use, see the Fiber

Inspection Probe Tip Compatibility Chart on page 85, or contact your

vendor for additional information.

To change a tip:

1. Untighten the tip’s retaining nut.

2. Remove the tip.

3. Insert a new tip.

4. Adjust the tip to the notch.

5. Retighten the retaining nut.

Fiber Inspection Probe 17

Page 26

Setting up Your Fiber Inspection Probe and ConnectorMax2 Mobile

Setting up Autonaming

Setting up Autonaming

The autonaming feature is useful to make a relevant naming scheme for

your tests. This also ensures that you do not overwrite files by mistake. You

can select which item goes in the file name, as well as the type of separator

you want to use in between.

A preview is available to show you the final output of the file name.

In Live Video mode, the autonaming parameters can be set. You will only

see the parameters for the current and next capture (when the test is done

but not saved yet), or for the next capture only (test is not done yet).

Otherwise, the parameters will not be displayed.

In Capture and Archive modes, it is possible to change the name of the file

without changing the settings.

18 FIP-400B

Page 27

Setting up Your Fiber Inspection Probe and ConnectorMax2 Mobile

Setting up Autonaming

To configure the automatic file naming:

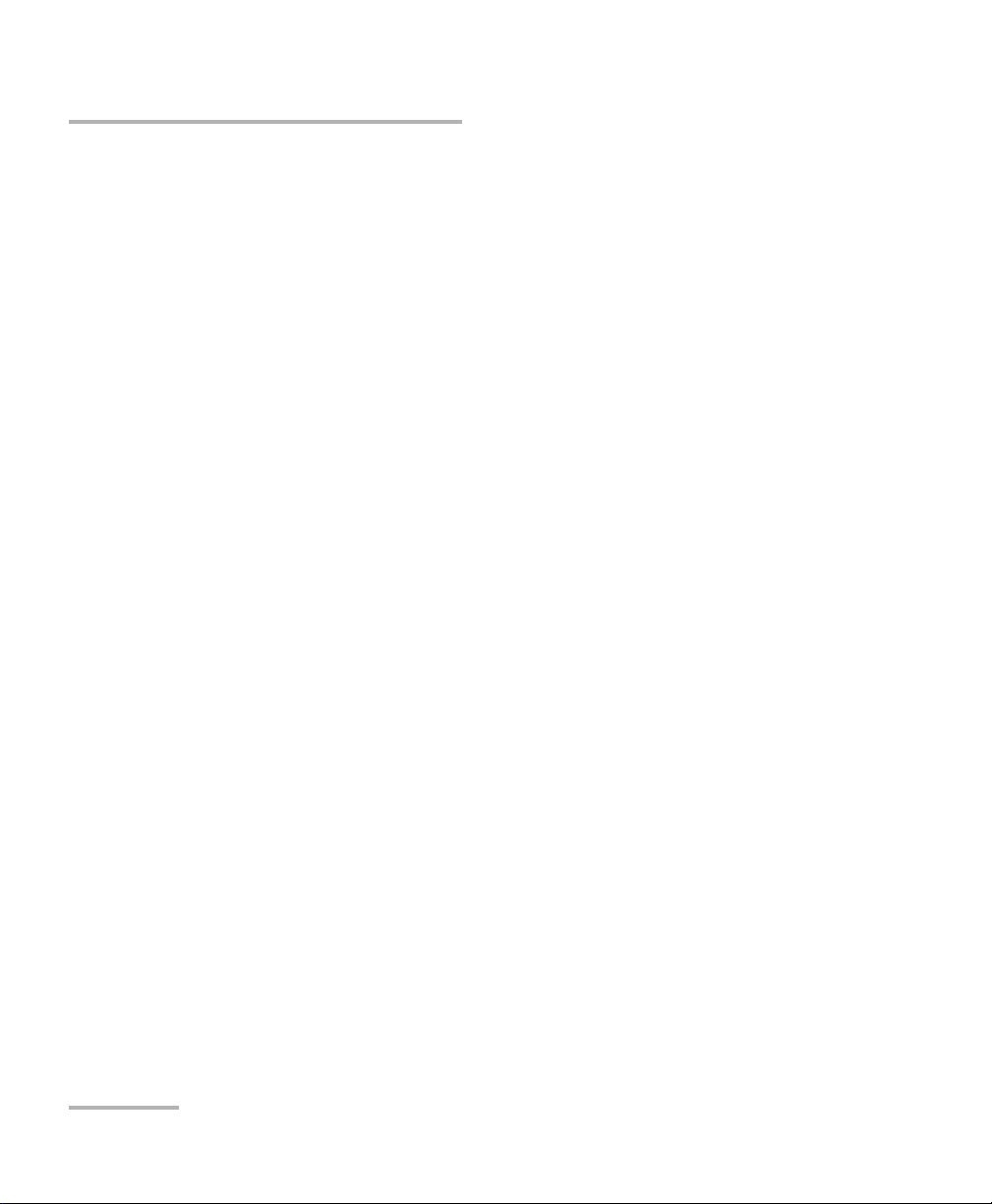

1. From the main window, tap the at the end of the Identification row.

Note: You can also tap the at the end of the Measurement Name row.

Fiber Inspection Probe 19

Page 28

Setting up Your Fiber Inspection Probe and ConnectorMax2 Mobile

Setting up Autonaming

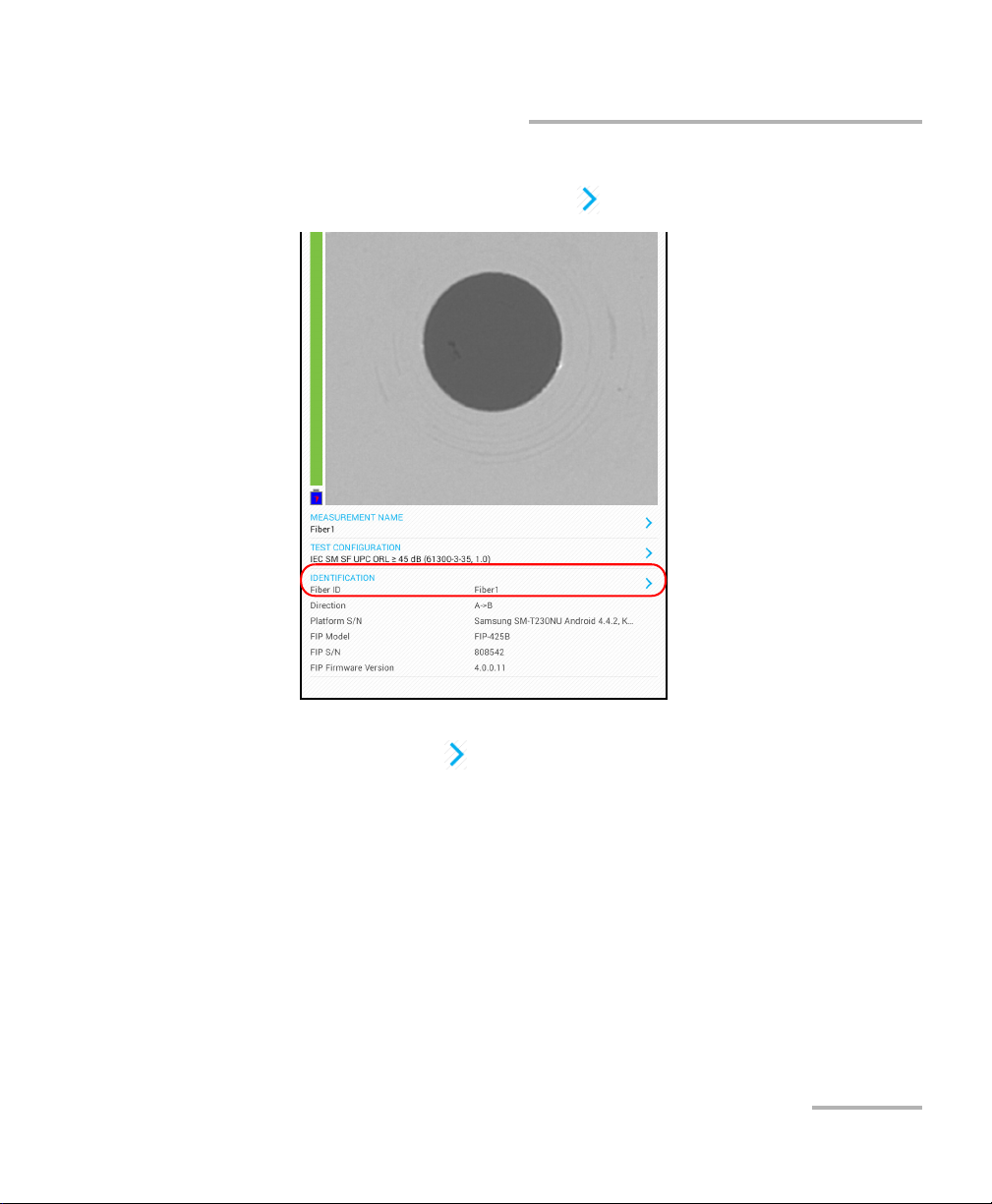

2. Select the Autonaming tab.

3. Move the identifiers from the Inactive Identifiers to the Active

Identifiers space by tapping . You can remove the identifiers by

tapping . You can also move the identifiers with the drag and drop

gesture.

Note: Only the identifiers with values are displayed.

4. Under Filename Edition, you can customize the information displayed

next to Custom Filename.

Note: You can edit information either with the virtual keyboard or with the

microphone. A microphone is part of the virtual keyboard on your smart

device.

20 FIP-400B

Page 29

Setting up Your Fiber Inspection Probe and ConnectorMax2 Mobile

Setting up Autonaming

5. If you want to select the separator in the automatic numbering section,

tap the line next to Separator.

5a. Navigate through the separators by scrolling through the words

that are greyed.

5b. Tap OK to confirm your choice.

6. Tap to confirm your new settings and to return to the main window.

The new settings will apply the next time you perform a capture.

Fiber Inspection Probe 21

Page 30

Setting up Your Fiber Inspection Probe and ConnectorMax2 Mobile

Setting up Identification

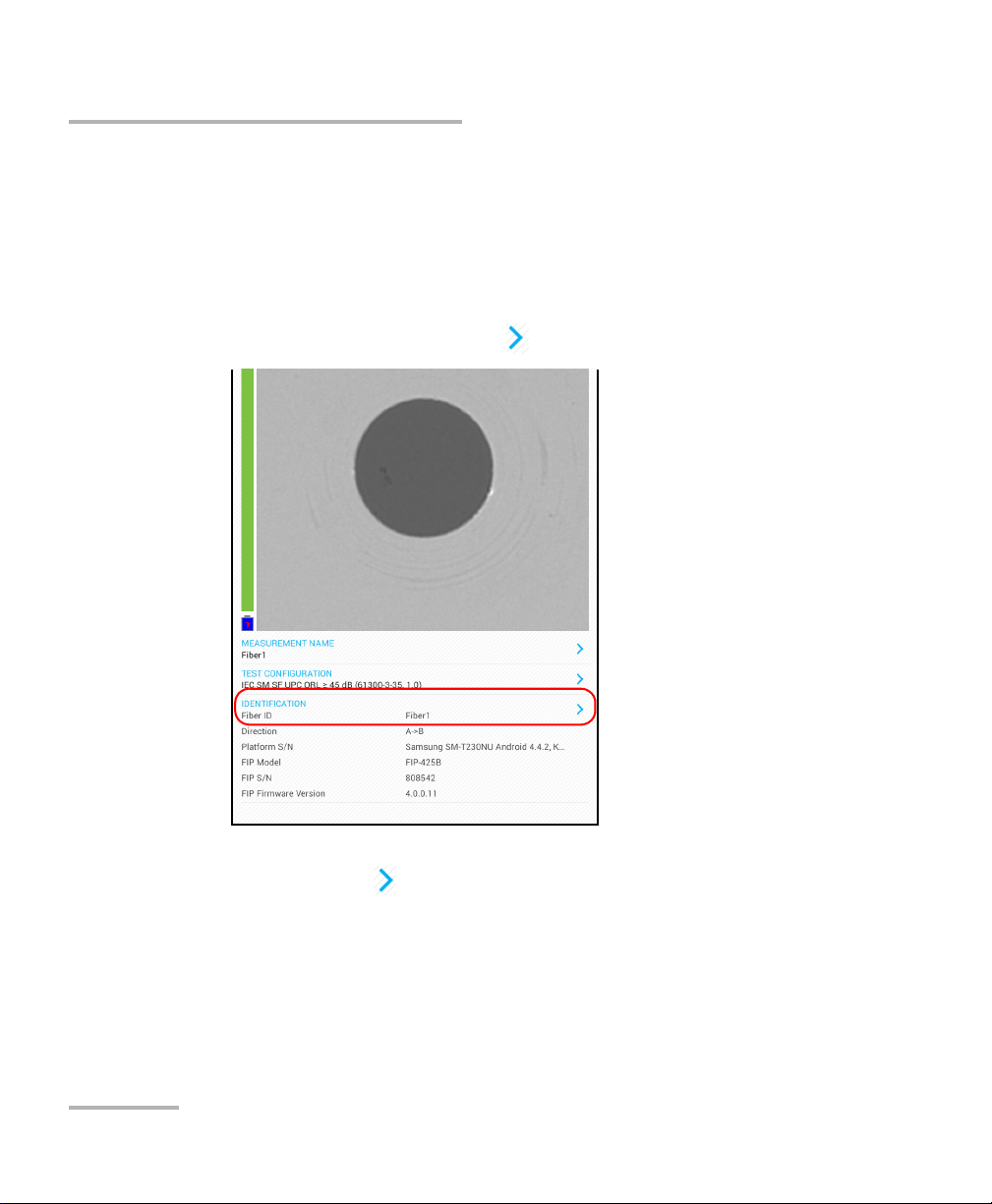

Setting up Identification

In order to have information on the tests to be performed, it is possible to

customize some fields such as the cable ID, the fiber ID, the location (A

and/or B), the Connector ID, or the Frame.

To configure the identification:

1. From the main window, tap the at the end of the Identification row.

Note: You can also tap the at the end of the Measurement Name row.

22 FIP-400B

Page 31

Setting up Your Fiber Inspection Probe and ConnectorMax2 Mobile

Setting up Identification

2. If necessary, select the Identification tab.

Fiber Inspection Probe 23

Page 32

Setting up Your Fiber Inspection Probe and ConnectorMax2 Mobile

Setting up Identification

3. Enter all the information as follows:

3a. Locate the row corresponding to the identifier that you want to

modify.

3b. Tap on the line next to the identifier that you want to modify and

enter the information.

Note: You can edit information either with the virtual keyboard or with the

microphone. A microphone is part of the virtual keyboard on your smart

device.

4. Tap to confirm your new settings and to return to the main window.

The new settings will apply the next time you perform a capture.

Note: Some identifiers are also displayed as read-only information.

24 FIP-400B

Page 33

Setting up Your Fiber Inspection Probe and ConnectorMax2 Mobile

Setting up the Increment

Setting up the Increment

The file name is made of one or more static parts (alphanumeric) and one

or more variable parts (numeric) that will be incremented or

decremented, according to your selection, as follows:

If you choose incrementation... If you choose decrementation...

Variable part increases until it

reaches the highest possible value

with the selected number of digits,

then restarts at 1.

Note: To decrement values, the start number must be higher than the stop

number.

The file name can be incremented using one or more identifiers. Selecting

a single identifier will follow the incrementation (or decrementation) value

you have set.

When selecting more than one identifier, the latter appear sequentially in

the order that you have set, and the incrementation will start with the last

item in the list (the one with the farthest indentation). For example, if you

have a file name with the Location, Cable and Fiber identifiers, in that

order, the first item to be incremented is the Fiber identifier, then Cable,

then Location:

Location 1, Cable 1, Fiber 1

Location 1, Cable 1, Fiber 2

Location 1, Cable 2, Fiber 1

Variable part decreases until it

reaches 1, then restarts at the highest

possible value with the selected

number of digits.

Location 1, Cable 2, Fiber 2

and so forth.

Fiber Inspection Probe 25

Page 34

Setting up Your Fiber Inspection Probe and ConnectorMax2 Mobile

Setting up the Increment

After a result is saved, you have to return to the Live Video mode so that the

application prepares the next file name by incrementing (or decrementing)

the suffix.

Note: If you choose not to save a particular file, the suggested file name remains

available for the next capture. This applies to all type of connectors.

You can select the number of digits displayed for the incremented or

decremented values.

Select "#" if you want to keep the value exactly in the same format as

defined in the start and stop values. If a value is to be incremented from 1

to 10, it becomes 1, 2, 3, ... 9, 10. One "#" is the default format.

Select two, three, or four "#" if you want all values to be expressed with the

same number of digits. The application fills the empty spaces with zeros

before the increment or decrement to ensure the appropriate format is

displayed. For example, if you select two "#" and the value is to be

incremented from 1 to 10, it becomes 01, 02, 03, ... 09, 10.

26 FIP-400B

Page 35

Setting up Your Fiber Inspection Probe and ConnectorMax2 Mobile

Setting up the Increment

To configure the incrementation:

1. From the main window, tap the at the end of the Identification row.

Note: You can also tap the at the end of the Measurement Name row.

Note: Setting up the increment is only possible in Live Video mode.

Fiber Inspection Probe 27

Page 36

Setting up Your Fiber Inspection Probe and ConnectorMax2 Mobile

Setting up the Increment

2. If necessary, select the Increment tab.

3. Move the increments from the Inactive Increments to the Active

Increments space by tapping . You can remove the identifiers by

tapping . You can also move the identifiers with the drag and drop

gesture.

Note: Only the identifiers with values are displayed.

4. When an increment is moved to the Active Increments, enter the start,

stop and increment values as desired.

Note: To decrement values, the start number must be higher than the stop

number.

5. Tap to confirm your new settings and to return to the main window.

The new settings will apply the next time you perform a capture.

28 FIP-400B

Page 37

Setting up Your Fiber Inspection Probe and ConnectorMax2 Mobile

Setting Up Auto Capture

Setting Up Auto Capture

Note: The auto capture is a feature available for FIP-435B probes only.

As soon as the application detects that you are working in Live Video

mode, the feature is enabled in the Application Settings, and if the focus

level is acceptable, a capture is made automatically. This is known as the

auto capture.

Note: The auto capture is possible only in high magnification.

To enable the auto capture:

1. From the main window, tap .

Note: Depending on the smart device you are using, the application settings can

be found in the menu button instead.

Fiber Inspection Probe 29

Page 38

Setting up Your Fiber Inspection Probe and ConnectorMax2 Mobile

Setting Up Auto Capture

2. Select Application Settings.

3. Under Probe, active the ON button next to Auto capture.

4. Tap to return to the main window.

30 FIP-400B

Page 39

Setting up Your Fiber Inspection Probe and ConnectorMax2 Mobile

Selecting Test Configurations

Selecting Test Configurations

If you are testing single fibers, you can select specific test configurations

according to the type of fiber you are analyzing, the connector type or the

type of anomaly you are looking for.

When working with the smart device, you can hide some test

configurations with the eye icon.

Note: You cannot hide the current test configuration.

To select a test configuration:

1. From the main window, tap the at the end of the Tes t

Configuration row.

Fiber Inspection Probe 31

Page 40

Setting up Your Fiber Inspection Probe and ConnectorMax2 Mobile

Selecting Test Configurations

2. Select the configuration you want to use in the list of available choices

and tap the On or Off button.

Note: If you want to select more than one test configurations at a time, press and

hold the desired test configurations.

Note: You cannot select the current test configuration.

3. Tap to return to the main window.

32 FIP-400B

Page 41

Setting up Your Fiber Inspection Probe and ConnectorMax2 Mobile

Selecting Test Configurations

To show or hide test configurations:

1. From the main window, tap the at the end of the Tes t

Configuration row.

Fiber Inspection Probe 33

Page 42

Setting up Your Fiber Inspection Probe and ConnectorMax2 Mobile

Selecting Test Configurations

2. In the Test Configuration window, tap the test configuration you want

to hide.

Note: If you want to select more than one test configurations at a time, press and

hold the desired test configurations.

Note: You cannot select the current test configuration.

34 FIP-400B

Page 43

Setting up Your Fiber Inspection Probe and ConnectorMax2 Mobile

Selecting Test Configurations

3. Tap the icon to hide the test configurations.

4. Tap the icon to show all test configurations.

5. Tap to return to the main window.

Fiber Inspection Probe 35

Page 44

Setting up Your Fiber Inspection Probe and ConnectorMax2 Mobile

Modifying the File Format

Modifying the File Format

The data that can be shared with third-party applications are measurement

files (.cmax2) and images (.png).

By default, you will be prompted to select the file format with which you

want to work.

To modify the file format:

1. From the main window, tap .

Note: Depending on the smart device you are using, the application settings can

be found in the menu button instead.

2. Select Application Settings.

36 FIP-400B

Page 45

Setting up Your Fiber Inspection Probe and ConnectorMax2 Mobile

Modifying the File Format

3. Under Sharing, tap Preferred file format.

4. Navigate through the preferred file format by scrolling through the

words that are greyed.

5. Ta p OK to confirm your choice.

6. Tap to return to the main window.

Fiber Inspection Probe 37

Page 46

Setting up Your Fiber Inspection Probe and ConnectorMax2 Mobile

Selecting the Sharing Application

Selecting the Sharing Application

Third-party applications, such as Google Drive and DropBox, are useful

when you want to share measurement files with other users. For more

information, see Transferring Results With Third-Party Applications on

page 60.

By default, you will be prompted to select the application with which you

want to work. You can configure the unit to always start your favorite

application directly instead.

To select the sharing application:

1. From the main window, tap .

Note: Depending on the smart device you are using, the application settings can

be found in the menu button instead.

38 FIP-400B

Page 47

Setting up Your Fiber Inspection Probe and ConnectorMax2 Mobile

Selecting the Sharing Application

2. Select Application Settings.

3. Under Sharing, tap Preferred application.

4. Navigate through the preferred application by scrolling through the

words that are greyed.

5. Ta p OK to confirm your choice.

6. Tap to return to the main window.

Fiber Inspection Probe 39

Page 48

Setting up Your Fiber Inspection Probe and ConnectorMax2 Mobile

Sharing Data When No Connection Is Available

Sharing Data When No Connection Is Available

By default, the application will prompt you to define the action to perform

when there is no 3G, 4G or Wi-Fi external connection available. You can let

the application buffer the files, or you can modify the wireless or mobile

settings and try sharing the files again.

If the FIP measurements are buffered, the application will transmit them

sequentially as soon as the network is available again.

Note: You need to disconnect the probe before trying to share data. Otherwise,

the data will be buffered anyway.

If you prefer not to be prompted each time no connection is available, you

can configure the application to always send the files to the buffer directly

instead.

40 FIP-400B

Page 49

Setting up Your Fiber Inspection Probe and ConnectorMax2 Mobile

Sharing Data When No Connection Is Available

To share data when no connection is available:

1. From the main window, tap .

Note: Depending on the smart device you are using, the application settings can

be found in the menu button instead.

2. Select Application Settings.

Fiber Inspection Probe 41

Page 50

Setting up Your Fiber Inspection Probe and ConnectorMax2 Mobile

Sharing Data When No Connection Is Available

3. Under Sharing, tap Preferred behavior when no connection is

available.

4. Navigate through the preferred behavior by scrolling through the words

that are greyed.

5. Ta p OK to confirm your choice.

6. Tap to return to the main window.

42 FIP-400B

Page 51

Setting up Your Fiber Inspection Probe and ConnectorMax2 Mobile

Restoring to Default Settings

Restoring to Default Settings

At any time, you can restore to default settings in your smart device. The

Restore default settings button restores all values that were changed in

the Application Settings.

To restore to default settings:

1. From the main window, tap .

Note: Depending on the smart device you are using, the application settings can

be found in the menu button instead.

2. Select Application Settings.

Fiber Inspection Probe 43

Page 52

Setting up Your Fiber Inspection Probe and ConnectorMax2 Mobile

Restoring to Default Settings

3. Ta p th e Restore Default Settings button.

4. Tap to return to the main window.

44 FIP-400B

Page 53

4 Inspecting Fiber Ends

Viewing the fiber inspection is done using ConnectorMax2 Mobile. You can

start the application before or after connecting the probe, and the view

on-screen will be automatically updated.

WARNING

Never look directly into a live fiber. It could cause serious eye

damage. Always use your FIP-400B Fiber Inspection Probe.

Inspecting Fiber Ends

When you connect the FIP-400B Fiber Inspection Probe to your smart

device, you can view and inspect fiber ends right away. This direct viewing

mode is known as the Live Video mode.

Note: When the internal temperature of the FIP-435B is too low, the probe

performs a warm-up that can last up to a minute.

You can also capture images of your inspections to save them for future

analyses. This is known as the Capture mode.

A digital watermark is added to the images generated by the application.

Fiber Inspection Probe 45

Page 54

Inspecting Fiber Ends

Inspecting Fiber Ends

The focus indicator, which is displayed in the left part of the main window,

indicates whether the current view is optimized for a capture. A green

indicator shows a picture that can be captured and analyzed. Analysis will

be more difficult with a yellow indicator, and impossible with a red

indicator. A vertical black bar displays the peak focus level.

Note: The peak focus level is shown only when the auto focus sequence is

complete.

For more information on analysis, see Analyzing Captures on page 56.

46 FIP-400B

Page 55

Inspecting Fiber Ends

Inspecting Fiber Ends

To inspect fiber ends (single fiber) in Live Video mode:

1. Install a probe tip (see Changing the Fiber Inspection Probe Tip on

page 17).

2. Insert the fiber into the probe tip.

3. Start ConnectorMax2 Mobile if it is not already started.

4. Ensure to configure the automatic file naming (see Setting up

Autonaming on page 18).

5. Depending on the probe you are using, proceed as follows:

If you have an FIP-425B, the auto analysis and the auto centering

(enabled by default) adjust automatically.

If you have an FIP-435B, the auto analysis, the auto centering, the

auto focus (all enabled by default), and the auto capture adjust

automatically.

For more information, see Analyzing Captures on page 56.

Note: With your fingers, you can stretch to zoom in on the image of the connector

on screen and pinch to zoom out of it.

6. If the fiber end is dirty, remove it from the probe, clean it and

reinspect it.

7. Once you are satisfied with the inspection, when in high magnification

level, press and hold the image of the connector on screen.

OR

Press the Fiber Inspection Probe handset button.

8. Go to the next connector or close the application.

Fiber Inspection Probe 47

Page 56

Inspecting Fiber Ends

Saving Files

Saving Files

In Capture mode, you can save the acquisition files manually for future

reference.

You can also set ConnectorMax2 Mobile so that it saves the capture

automatically only if the result is Pass, only if the result is Fail, or regardless

of the status. When it is not possible to save a file, the application displays a

message.

All the files (saved manually or automatically) are sent to the following

folder: Storage/Emulated/0/Documents/EXFO/cmax2. For smart devices

supporting Android 4.4 (kit kat) and above, the files are sent to the

following folder: /Android/data/com.exfo.cmax2.mobile.android/files/.

Note: When you return to the Live Video mode, your file name structure will be

automatically incremented or decremented so that you do not overwrite

your work.

48 FIP-400B

Page 57

Inspecting Fiber Ends

To s av e a fi l e:

1. In Live Video mode, press and hold the image on screen.

2. In Capture mode, tap .

Saving Files

Fiber Inspection Probe 49

Page 58

Inspecting Fiber Ends

Saving Files

To save file automatically:

1. From the main window, tap .

Note: Depending on the smart device you are using, the application settings can

be found in the menu button instead.

2. Select Application Settings.

50 FIP-400B

Page 59

Inspecting Fiber Ends

Saving Files

3. Under Saving, select the type of auto save you want to use by

activating the ON button.

4. Tap to return to the main window.

Fiber Inspection Probe 51

Page 60

Inspecting Fiber Ends

Managing Files

Managing Files

You can open captured files directly from the smart device to view them.

All saved measurements are available in Archive mode. The application

scans the smart device periodically and store the .cmax2 files here:

Storage/Emulated/0/Documents/EXFO/cmax2. For smart devices

supporting Android 4.4 (kit kat) and above, the files are sent to the

following folder: /Android/data/com.exfo.cmax2.mobile.android/files/.

You can also delete unwanted files. By default, all files are highlighted but

you can unselect the files you want to keep by pressing and holding the

screen. Otherwise, all files will be deleted.

To share files, see Transferring Results With Third-Party Applications on

page 60.

The .cmax2 files, when saved with the ConnectorMax 2 smart device, are

compatible with any EXFO applications.

To o pe n a fi le :

1. From the main window, tap .

52 FIP-400B

Page 61

2. In the Archive window, select a file.

Inspecting Fiber Ends

Managing Files

3. Tap the selected file to open it.

Fiber Inspection Probe 53

Page 62

Inspecting Fiber Ends

Managing Files

To delete a file:

1. From the main window, tap .

54 FIP-400B

Page 63

2. In the Archive window, tap .

Inspecting Fiber Ends

Managing Files

3. By default, all files are highlighted but you can unselect the files you

want to keep by pressing and holding the screen.

IMPORTANT

All highlighted files will be deleted. Ensure to unselect the files you

want to keep.

4. Tap to delete the file.

Fiber Inspection Probe 55

Page 64

Inspecting Fiber Ends

Analyzing Captures

Analyzing Captures

With the capture analysis option (FIP-425B and FIP-435B), you can perform

automated pass/fail analyses according to the criteria you have set.

Depending on the fiber probe that you have, you may have access to the

following features:

Auto centering: displays the fiber in the middle of the image. It is

compatible with all connector types and fibers with a cladding of

125 μm. The auto centering is enabled only in high magnification.

Working with the auto centering feature can be useful with standard

connectors.

Auto focus: focuses on the connector image. It is enabled only in high

magnification. The auto focus is only possible in Live Video mode, and

if the focus is not done manually. It starts automatically when you insert

an optical fiber connector. For more information, see Fiber Inspection

Probe Tip Compatibility Chart on page 85.

Auto capture: is possible with an acceptable focus level. It is enabled if

the auto centering and auto focus are activated. The auto capture is

possible only in high magnification. For more information, see Setting

Up Auto Capture on page 29.

Auto analysis: displays 4 inspection zones: core, cladding, adhesive,

and contact. It is enabled only in high magnification.

The analysis results are available as soon as you press and hold your finger

on the image on-screen, when you press the capture button on the probe,

or when the auto capture feature is selected. For more information, see

Setting Up Auto Capture on page 29.

The global status is displayed in the upper right part of the window after an

analysis. The Results are displayed when a capture is made. When you are

ready to inspect another fiber, you have to return to the Live Video mode

first.

The results are available as an image or in a detailed table.

56 FIP-400B

Page 65

Inspecting Fiber Ends

Analyzing Captures

The Image shows the snapshot of the fiber when you captured it. You

can see all the anomalies that have been detected.

The overlay shows the status of the analysis, the status per zone, the

analysis zones, any anomaly (defects, scratches) found on the fiber

endface, and the global status in the upper right part of the main

window. The color of the circles shows the status of the analysis zone:

Green: pass

Blue: no analysis was performed or the function is disabled

Red: fail

Fiber Inspection Probe 57

Page 66

Inspecting Fiber Ends

Analyzing Captures

By default, the overlay is shown after an analysis, but you can hide it by

tapping the image on screen.

The Results show detailed information for scratches and defects

detected in each test zone and the corresponding test status.

58 FIP-400B

Page 67

Inspecting Fiber Ends

Analyzing Captures

To view the results:

1. In Live Video mode, press and hold your finger on the screen.

2. In Capture mode, tap the at the end of the Inspection Results row.

OR

Tap the pass or fail icon located on the upper right part of the main

window.

3. From the Inspection Results window, tap to return to the Capture

window.

Fiber Inspection Probe 59

Page 68

Inspecting Fiber Ends

Transferring Results With Third-Party Applications

Transferring Results With Third-Party

Applications

Third-party applications, such as Google Drive and DropBox, are useful

when you want to share measurement files with other users. The data that

can be shared are measurement files (.cmax2) and images (.png). The

third-party applications allow you to delete files also.

By default, you will be prompted to select the application with which you

want to work. If you prefer, you can configure the unit to always start your

favorite application directly instead (see Selecting the Sharing Application

on page 38).

It is possible to share the FIP measurements in Capture mode and in

Archive modes only. The Live Video mode does not allow it.

When there is no 3G, 4G or Wi-Fi external connection available, the

application buffers the FIP measurements that need to be shared. As soon

as the network is available, the application transmits the data sequentially.

You need to disconnect the probe first if you want to share data with the

smart device. Otherwise, the application buffers the FIP measurements.

IMPORTANT

If you want to transfer results with the DropBox third-party

application, you need to open a DropBox account first.

60 FIP-400B

Page 69

Inspecting Fiber Ends

Transferring Results With Third-Party Applications

To transfer results with third-party applications:

1. Ensure the Wi-Fi is activated on your smart device.

2. Ensure you are connected to a Wi-Fi network.

3. From the main window, tap .

Fiber Inspection Probe 61

Page 70

Inspecting Fiber Ends

Transferring Results With Third-Party Applications

4. In the Archive window, select the measurement files you want to share

by pressing and holding your finger on the screen.

62 FIP-400B

Page 71

Inspecting Fiber Ends

Transferring Results With Third-Party Applications

5. Ta p .

6.

Select the type of file (.cmax2 or .png) you want to share.

7.

Select the third-party application you want to work with (Google Drive

or Drop Box for example).

8. Follow the instructions on-screen.

Fiber Inspection Probe 63

Page 72

Page 73

5 Maintenance

General Maintenance

To help ensure long, trouble-free operation:

Always inspect fiber-optic connectors before using them and clean

them if necessary.

Keep the unit free of dust.

Clean the unit casing with a cloth slightly dampened with water.

Store unit at room temperature in a clean and dry area. Keep the unit

out of direct sunlight.

Avoid high humidity or significant temperature fluctuations.

Avoid unnecessary shocks and vibrations.

If any liquids are spilled on or into the unit, turn off the power

immediately, disconnect from any external power source, remove the

batteries and let the unit dry completely.

The use of controls, adjustments and procedures, namely for

operation and maintenance, other than those specified herein may

result in hazardous radiation exposure or impair the protection

provided by this unit.

WARNING

Recycling and Disposal (Applies to European Union Only)

For complete recycling/disposal information as per European Directive

WEEE 2012/19/UE, visit the EXFO Web site at www.exfo.com/recycle.

Fiber Inspection Probe 65

Page 74

Maintenance

Recharging the Battery

Recharging the Battery

The battery in your Fiber Inspection Probe is a Li-ion polymer battery with

three-cell format. The charge status is shown with the LEDs on the Fiber

Inspection Probe. The ConnectorMax2 Mobile software application also

indicates the charge status.

Only charge the battery with the USB cable and adapter/charger

provided by EXFO with your unit.

You can purchase a new battery from EXFO.

The battery is not charged at the factory. You must fully charge

CAUTION

IMPORTANT

it before using the unit for the first time. The battery is fully

charged after a few hours or when the battery LED indicator

stops flashing. The charge cycle starts and stops automatically.

The time required to charge the battery depends on various

factors such as the ambient temperature.

To ensure that the battery functions or charges properly, keep it

within operation and storage temperature range.

66 FIP-400B

Page 75

Maintenance

Recharging the Battery

The micro USB adapter connector recharges the battery of the probe when

it is low. You can recharge the battery with the provided USB cable and the

adapter/charger that you connect to a power outlet. You can also use the

provided USB cable alone that you connect to a USB port of a computer.

When the probe is connected to a power outlet or to a USB port, it still

works via Wi-Fi.

When the probe is connected to the USB port of a computer (500 mA),

here are the possible cases for the charging process:

Status FIP-425B FIP-435B

Live Video mode Charging Not charging

Capture/Archive Charging Charging

OFF Charging Charging

Fiber Inspection Probe 67

Page 76

Maintenance

Replacing the Battery

Replacing the Battery

Your probe is powered by a Li-ion polymer rechargeable battery.

Your unit uses a three-cell battery that has been especially

Battery replacement should only be done by a qualified

Do not throw the battery into fire or water and do not

To avoid irremediable damage to the battery, always remove the

battery compartment door carefully, ensuring that the battery does

not fall.

WARNING

designed for EXFO. For this reason, you can only replace it with

a battery of the same type and model. The use of other

batteries may damage your unit and compromise your safety.

technician with the appropriate tools on an electronic bench or

similar environment.

short-circuit the battery electrical contacts. Do not disassemble.

CAUTION

68 FIP-400B

Page 77

Maintenance

Screws

Battery compartment door

Replacing the Battery

To replace the battery:

1. Turn off the probe.

2. Unplug any power cable.

3. Using a screwdriver, remove the two screws that are located on the

side of the probe.

4. Remove the battery compartment door.

CAUTION

Gently pull on the battery to avoid damaging the wires.

Fiber Inspection Probe 69

Page 78

Maintenance

Battery

Wires

Replacing the Battery

5. Remove the battery.

6. Replace the battery, respecting the polarity (black, yellow, and red

7. Close the battery compartment door.

8. Using a screwdriver, put the screws that you have removed at step 3

wires).

back in place.

70 FIP-400B

Page 79

6 Troubleshooting

Solving Common Problems

The table below presents common problems and their solutions.

Problem Solution

I cannot analyze an

image

I cannot see the fiber

on-screen

The FIP internal

temperature is too high

Violation of EXFO

embedded software

copyright

The auto centering does

not function properly

The image is not focused properly; use the focus knob on

the probe until the focus indicator displays the best value

available. Yellow indicates an acceptable range, and

green shows the preferred range.

Ensure that the probe is connected properly.

Ensure that the connector is aligned properly.

Ensure that the focus value is sufficient to perform the

analysis.

Ensure that you are using a high magnitude level.

Verify the probe connection status to see if

ConnectorMax2 Mobile is detecting the probe properly. If

the probe is connected properly, close ConnectorMax2

Mobile and open it again.

Ensure the Wi-Fi is on.

Ensure the probe is on.

Let the FIP cool down.

Contact EXFO for technical support.

Clean the connector.

Adjust the image focus.

A connection error

occurred

Fiber Inspection Probe 71

Ensure that the probe is not currently in use by another

application.

Try to connect the probe again.

Page 80

Troubleshooting

Solving Common Problems

Problem Solution

An APC fiber is

connected to an

FIP-435B probe, the blue

LED is blinking and the

motor is not running

Refresh rate is very low

The FIP status LED blinks

red for 2 seconds in Live

Video mode and turns

back to blue (auto focus

timeout)

The FIP LED blinks red

for 2 seconds in Capture

mode and no analysis

results are available

The user interface

displayed in the

application is truncated.

When the fiber connector is detected, this will then initiate

the auto-focus sequence.

Ensure that the power saving mode is deactivated.

On your smart device, close the applications that are not

in use.

Reduce the number of probes operating in the vicinity.

Bring the probe and the smart device closer together.

Capture the image again.

There was an analysis error. Repeat the inspection process.

Change font size in the smart device settings to facilitate

reading comprehension.

72 FIP-400B

Page 81

Problem Solution

Troubleshooting

Solving Common Problems

The list of available FIPs

is empty.

The FIP measurement is

corrupted when it is

imported from a

computer to the smart

device via a USB cable.

The ConnectorMax2

Mobile application icon

is not available in the list

of the applications

displayed.

Ensure the Wi-Fi is on.

Ensure the probe is on.

The corruption seems to be caused by the smart device

drivers. This is not caused by the ConnectorMax2 Mobile

application.

Try to transfer the files to the smart device using a cloud

application such as Google Drive.

Ensure the smart device is not in Safe Mode. If so, restart

the smart device.

Ensure the ConnectorMax2 Mobile application was

installed from the current user account (not from another

account).

Fiber Inspection Probe 73

Page 82

Troubleshooting

Contacting the Technical Support Group

Contacting the Technical Support Group

To obtain after-sales service or technical support for this product, contact

EXFO at one of the following numbers. The Technical Support Group is

available to take your calls from Monday to Friday, 8:00 a.m. to 7:00 p.m.

(Eastern Time in North America).

Technical Support Group

400 Godin Avenue

Quebec (Quebec) G1M 2K2

CANADA

For detailed information about technical support, and for a list of other

worldwide locations, visit the EXFO Web site at www.exfo.com.

If you have comments or suggestions about this user documentation, you

can send them to customer.feedback.manual@exfo.com.

To accelerate the process, please have information such as the name and

the serial number (see the product identification label), as well as a

description of your problem, close at hand.

1 866 683-0155 (USA and Canada)

Tel.: 1 418 683-5498

Fax: 1 418 683-9224

support@exfo.com

74 FIP-400B

Page 83

Troubleshooting

Viewing Information About ConnectorMax2 Mobile

Viewing Information About ConnectorMax2

Mobile

You can view information about ConnectorMax2 Mobile such as the

version number and different policies on your smart device.

To view ConnectorMax2 Mobile information:

1. From the main window, tap .

Note: Depending on the smart device you are using, the about button can be

found in the menu button instead.

2. Select About.

3. Under Version Information and General Information, select the

information you want to view.

4. Tap to return to the main window.

Fiber Inspection Probe 75

Page 84

Troubleshooting

Viewing Online Help

Viewing Online Help

You can view the online help for ConnectorMax2 Mobile at any time.

To view the online help:

1. From the main window, tap .

Note: Depending on the smart device you are using, the online help can be found

in the menu button instead.

2. Select Help.

3. Under Guides, select the document you want to view.

4. Tap to return to the main window.

76 FIP-400B

Page 85

Troubleshooting

Transportation

Transportation

Maintain a temperature range within specifications when transporting the

unit. Transportation damage can occur from improper handling. The

following steps are recommended to minimize the possibility of damage:

Pack the unit in its original packing material when shipping.

Avoid high humidity or large temperature fluctuations.

Keep the unit out of direct sunlight.

Avoid unnecessary shocks and vibrations.

Fiber Inspection Probe 77

Page 86

Page 87

7 Warranty

General Information

EXFO Inc. (EXFO) warrants this equipment against defects in material and

workmanship for a period of one year from the date of original shipment.

EXFO also warrants that this equipment will meet applicable specifications

under normal use.

During the warranty period, EXFO will, at its discretion, repair, replace,

or issue credit for any defective product, as well as verify and adjust the

product free of charge should the equipment need to be repaired or if the

original calibration is erroneous. If the equipment is sent back for

verification of calibration during the warranty period and found to meet all

published specifications, EXFO will charge standard calibration fees.

The warranty can become null and void if:

unit has been tampered with, repaired, or worked upon by

unauthorized individuals or non-EXFO personnel.

warranty sticker has been removed.

IMPORTANT

case screws, other than those specified in this guide, have been

removed.

case has been opened, other than as explained in this guide.

unit serial number has been altered, erased, or removed.

unit has been misused, neglected, or damaged by accident.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES EXPRESSED,

IMPLIED, OR STATUTORY, INCLUDING, BUT NOT LIMITED TO, THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE. IN NO EVENT SHALL EXFO BE LIABLE FOR

SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES.

Fiber Inspection Probe 79

Page 88

Warranty

Liability

Liability

EXFO shall not be liable for damages resulting from the use of the product,

nor shall be responsible for any failure in the performance of other items to

which the product is connected or the operation of any system of which

the product may be a part.

EXFO shall not be liable for damages resulting from improper usage or

unauthorized modification of the product, its accompanying accessories

and software.

Exclusions

EXFO reserves the right to make changes in the design or construction of

any of its products at any time without incurring obligation to make any

changes whatsoever on units purchased. Accessories, including but not

limited to fuses, pilot lamps, batteries and universal interfaces (EUI) used

with EXFO products are not covered by this warranty.

This warranty excludes failure resulting from: improper use or installation,

normal wear and tear, accident, abuse, neglect, fire, water, lightning or

other acts of nature, causes external to the product or other factors beyond

the control of EXFO.

IMPORTANT

In the case of products equipped with optical connectors, EXFO will

charge a fee for replacing connectors that were damaged due to

misuse or bad cleaning.

Certification

EXFO certifies that this equipment met its published specifications at the

time of shipment from the factory.

80 FIP-400B

Page 89

Warranty

Service and Repairs

Service and Repairs

EXFO commits to providing product service and repair for five years

following the date of purchase.

To send any equipment for service or repair:

1. Call one of EXFO’s authorized service centers (see EXFO Service

Centers Worldwide on page 82). Support personnel will determine if

the equipment requires service, repair, or calibration.

2. If equipment must be returned to EXFO or an authorized service

center, support personnel will issue a Return Merchandise

Authorization (RMA) number and provide an address for return.

3. If possible, back up your data before sending the unit for repair.

4. Pack the equipment in its original shipping material. Be sure to include

a statement or report fully detailing the defect and the conditions under

which it was observed.

5. Return the equipment, prepaid, to the address given to you by support

personnel. Be sure to write the RMA number on the shipping slip. EXFO

will refuse and return any package that does not bear an RMA number.

Note: A test setup fee will apply to any returned unit that, after test, is found to

meet the applicable specifications.

After repair, the equipment will be returned with a repair report. If the

equipment is not under warranty, you will be invoiced for the cost

appearing on this report. EXFO will pay return-to-customer shipping costs

for equipment under warranty. Shipping insurance is at your expense.

Routine recalibration is not included in any of the warranty plans. Since

calibrations/verifications are not covered by the basic or extended

warranties, you may elect to purchase FlexCare Calibration/Verification

Packages for a definite period of time. Contact an authorized service center

(see EXFO Service Centers Worldwide on page 82).

Fiber Inspection Probe 81

Page 90

Warranty

EXFO Service Centers Worldwide

EXFO Service Centers Worldwide

If your product requires servicing, contact your nearest authorized service

center.

EXFO Headquarters Service Center

400 Godin Avenue

Quebec (Quebec) G1M 2K2

CANADA

EXFO Europe Service Center

Winchester House, School Lane

Chandlers Ford, Hampshire S053 4DG

ENGLAND

EXFO Telecom Equipment

(Shenzhen) Ltd.

3rd Floor, Building 10,

Yu Sheng Industrial Park (Gu Shu

Crossing), No. 467,

National Highway 107,

Xixiang, Bao An District,

Shenzhen, China, 518126

1 866 683-0155 (USA and Canada)

Tel.: 1 418 683-5498

Fax: 1 418 683-9224

support@exfo.com

Tel.: +44 2380 246800

Fax: +44 2380 246801

support.europe@exfo.com

Tel: +86 (755) 2955 3100

Fax: +86 (755) 2955 3101

support.asia@exfo.com

To view EXFO's network of partner-operated Certified Service Centers

nearest you, please consult EXFO's corporate website for the complete list

of service partners:

http://www.exfo.com/support/services/instrument-services/

exfo-service-centers.

82 FIP-400B

Page 91

A Technical Specifications

PRELIMINARY SPECIFICATIONS

a

Size (H x W x D) 55 mm x 39 mm x 207 mm (2 3/16 in x 1 1/2 in x 8 1/8 in)

b

Weight 0.3 kg (0.7 lb)

Resolution 0.55 μm

Camera sensor Five-megapixel CMOS

Visual detection capability <1 μm

Field of view

304 μm x 304 μm (high magnification)

608 μm x 608 μm (mid magnification)

912 μm x 912 μm (low magnification)

Light source Blue LED

Lighting technique Coaxial

Capture button Available on all models

Magnification button Available on all models

Digital magnification Three levels

Connector Micro USB

Connectivity Wi-Fi 802.11

Frequency band 2.4 GHz

Smart device OS compatibility

c

Android™ 4.2 and above

Power 1 x removable battery

Autonomy

d

FIP-425B: *8 hours

FIP-435B: *6 hours

Recharge time

e

)4 h

Distance range

f

2.5 m (8.2 ft)

Notes

a. Typical.

b. Measurement excluding tip.

c. Software qualified with Samsung Galaxy™ device. Other Android models are not guaranteed to be 100% compatible.

d. One (1) test per minute. The probe remains in live mode for 20 seconds during each test.

e. When probe is in use the recharge time may take longer.

f. Wi-Fi interferences and physical obstacles may affect distance range.

IMPORTANT

The following technical specifications can change without notice.

The information presented in this section is provided as a reference

only. To obtain this product’s most recent technical specifications,

visit the EXFO Web site at www.exfo.com.

Fiber Inspection Probe 83

Page 92

Technical Specifications

GENERAL SPECIFICATIONS

Temperature operating

Unit powered by batteries: –10

o

C to 40 oC (14 oF to 104 oF)

Unit connected to USB adapter: 0

o

C to 40 oC (32 oF to 104 oF)

Temperature storage

Unit without batteries: –40

o

C to 70 oC (–40 oF to 158 oF)

Unit with batteries: –20

o

C to 60 oC (–4 oF to 140 oF)

Relative humidity

Unit : 0% to 95% non-condensing

USB Adapter : 5% to 95% non-condensing for storage. 8% to 90% for operating temperature.

ACCESSORIES

Includes:

Video inspection probe (FIP-425B/435B)

Bulkhead and patch cord tips

GP-2175: Protective cap and cord assembly

FIPT-BOX: Compartmentalized plastic case for tips

GP-10-094: Soft pouch for FIP-400 and FIP-400B

GP-2225: USB to Micro USB cable

GP-2226: Rechargeable battery (qty:1)

GP-2227: USB AC Adapter

84 FIP-400B

Page 93

B Fiber Inspection Probe Tip

Compatibility Chart

With some tips that include lenses, and before performing an automatic

focus, you must adjust the focus manually for the first inspection.

Note: The tips for which the probe requires a manual focus before the first

inspection are listed in the table below.

To reach the focus level manually:

1. Bring the focus manually close to the focal point.

2. Activate the auto focus or press the magnification control button on the

probe and hold it down until the auto focus is activated again.

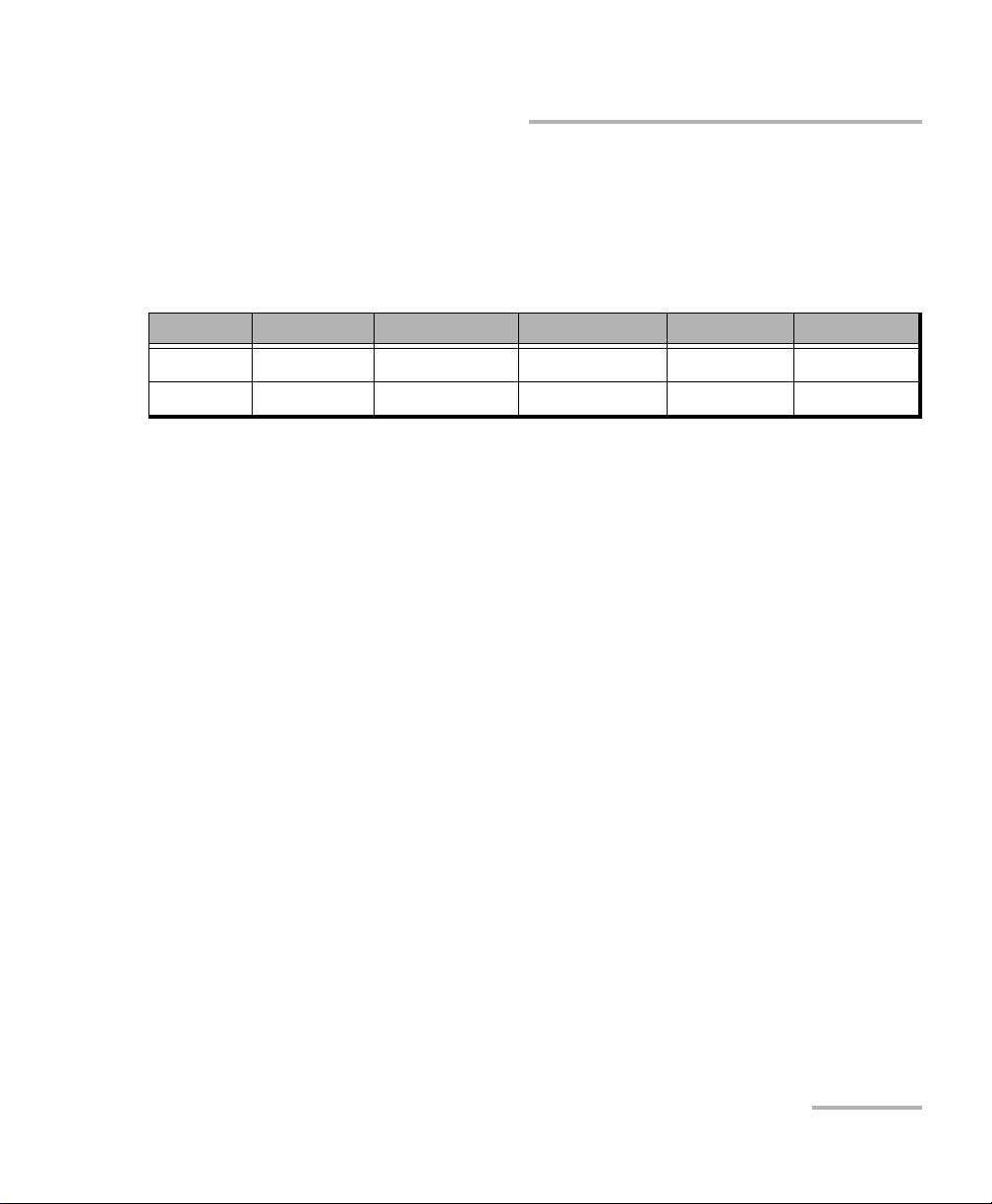

The table below establishes the Fiber Inspection Probe tip compatibility

with the different operations: fiber inspection, auto analysis (option), auto

focus (option), and auto detection (option) provided with the

ConnectorMax2 Mobile application:

Analysis

Tip Description Tip Code

Uni.2.5mm for PC

connector

Uni.2.5mm for APC

connector

Uni.1.25mm for PC

Connector

Uni.1.25mm for

APC connector

FC APC tip for

bulkhead adapter

FC and SC tip for

bulkhead adapter

Fiber Inspection Probe 85

FIPT-400-U25M OK OK OK OK

FIPT-400-U25MA OK OK OK OK

FIPT-400-U12M OK OK OK OK

FIPT-400-U12MA OK OK OK OK

FIPT-400-FC-APC OK OK OK OK

FIPT-400-FC-SC OK OK OK OK

Inspection

(all models)

(FIP-425B

and

FIP-435B)

Auto focus

(FIP-435B)

Connector

Auto

detection

(FIP-435B)

Page 94

Fiber Inspection Probe Tip Compatibility Chart

Tip Description Tip Code

ST for UPC

FIPT-400-ST OK OK OK OK

bulkhead adapter

E-2000 for PC

FIPT-400-E2000 OK OK OK NO

bulkhead