Page 1

Technical Reference Guide

Describes features of the product.

Describes setup and installation of the product and peripherals.

Describes advanced usage methods for the product.

Describes how to control the printer and necessary information

when you develop applications.

Describes how to handle the product.

Describes precautions for replacement.

Describes general specications and character code tables.

Product Overview

Setup

Advanced Usage

Application Development Information

Handling

Replacement of the TM-T88VI/TM-T88V

Appendix

M00138500

Rev. A

Page 2

Cautions

• No part of this document may be reproduced, stored in a retrieval system, or transmitted in any form or by

any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written

permission of Seiko Epson Corporation.

• The contents of this document are subject to change without notice. Please contact us for the latest

information.

• While every precaution has been taken in the preparation of this document, Seiko Epson Corporation

assumes no responsibility for errors or omissions.

• Neither is any liability assumed for damages resulting from the use of the information contained herein.

• Neither Seiko Epson Corporation nor its affiliates shall be liable to the purchaser of this product or third

parties for damages, losses, costs, or expenses incurred by the purchaser or third parties as a result of:

accident, misuse, or abuse of this product or unauthorized modifications, repairs, or alterations to this

product, or (excluding the U.S.) failure to strictly comply with Seiko Epson Corporation’s operating and

maintenance instructions.

• Seiko Epson Corporation shall not be liable against any damages or problems arising from the use of any

options or any consumable products other than those designated as Original Epson Products or Epson

Approved Products by Seiko Epson Corporation.

Trademarks

EPSON is a registered trademark of Seiko Epson Corporation.

Exceed Your Vision and ESC/POS are registered trademarks or trademarks of Seiko Epson Corporation.

Microsoft, Windows, and Windows Vista are registered trademarks of Microsoft Corporation in the United

States and/or other countries.

®

Wi-Fi

, WPATM, and WPA2TM are either registered trademarks or trademarks of Wi-Fi Alliance®.

The Bluetooth

®

word mark and logos are registered trademarks owned by Bluetooth SIG, Inc. and any use of

such marks by Seiko Epson Corporation is under license.

IOS is a trademark or registered trademark of Cisco in the U.S. and other countries and is used under license.

Apple, Apple TV, Apple Watch, iPad, iPad Air, iPad Pro, iPhone, and Lightning are trademarks of Apple Inc.,

registered in the U.S. and other countries. tvOS is a trademark of Apple Inc.

iBeacon is a trademark of Apple Inc.

Android

TM

is a trademark of Google LLC.

Google Play and the Google Play logo are trademarks of Google LLC.

All other trademarks are the property of their respective owners and used for identification purpose only.

ESC/POS® Command System

Epson ESC/POS is a proprietary POS printer command system that includes patented or patent-pending

commands. ESC/POS is compatible with most Epson POS printers and displays.

ESC/POS is designed to reduce the processing load on the host computer in POS environments. It comprises a

set of highly functional and efficient commands and also offers the flexibility to easily make future upgrades.

©Seiko Epson Corporation 2021.

Page 3

For Safety

Key to Symbols

The symbols in this manual are identified by their level of importance, as defined below. Read the following

carefully before handling the product.

You must follow warnings carefully to avoid serious bodily injury.

WARNING

Provides information that must be observed to prevent damage to the equipment or loss of data.

• Possibility of sustaining physical injuries.

CAUTION

• Possibility of causing physical damage.

• Possibility of causing information loss.

Provides information that must be observed to avoid damage to your equipment or a malfunction.

Provides important information and useful tips.

Warnings

WARNING

In the following cases, immediately unplug the AC cable and contact qualified service personnel.

Continued use may lead to fire or electric shock.

• If the product emits smoke, a strange odor, or unusual noises.

• If water or other liquid spills into the product.

• If the product is too hot to touch or the case is deformed.

Note the following points to avoid accidents such as fire, electric shock, or burn.

• Do not use this product where flammable fumes from gasoline, benzine, thinner, or other

flammable liquids may be in the air.

• Do not use aerosol sprayers containing flammable gas inside or around the product.

• Do not cover the product with cloth, or place the product in locations subject to high levels of

humidity or dust.

• Do not allow foreign objects or flammable objects to fall into the equipment.

• Do not touch the inside of the product except where mentioned in the manual.

• Do not use the product with any power supply or voltage other than the ones specified.

• Do not connect cables in ways other than those mentioned in the manual.

• Never disassemble or modify the product.

• Do not use the power plug if there is dust or foreign matter attached.

• Do not bend, twist, pull with excessive force, or place heavy object on the AC cable.

• Do not use the cables if they are damaged.

• Do not place multiple loads on the power outlet (wall outlet).

• Never insert or disconnect the power plug with wet hands.

3

Page 4

Cautions

CAUTION

Note the following points to avoid injury or malfunction.

• Setup the product on a firm, stable, horizontal surface.

• Do not place heavy objects on top of the product. Never stand or lean on the product.

• Do not press your hands or fingers against the cutter when removing printed paper or loading/

replacing roll paper.

• Do not put your hands between the cover and the body of the product when opening/closing

the cover.

• Never attempt to repair the product yourself.

• Do not connect a telephone line to the drawer kick connector.

To ensure safety, unplug this product before leaving it unused for an extended period.

4

Page 5

Caution Labels

The caution labels on the product indicate the following precautions.

CAUTION:

Do not touch the thermal head and the frame on its side because it can be very hot after printing.

CAUTION:

Touching the manual cutter may cause injury.

Restriction of Use

When this product is used for applications requiring high reliability/safety, such as transportation devices

related to aviation, rail, marine, automotive, etc.; disaster prevention devices; various safety devices, etc.; or

functional/precision devices, etc., you should use this product only after giving consideration to including failsafes and redundancies into your design to maintain safety and total system reliability. Because this product was

not intended for use in applications requiring extremely high reliability/safety, such as aerospace equipment,

main communication equipment, nuclear power control equipment, or medical equipment related to direct

medical care, etc., please make your own judgment on this product's suitability after a full evaluation.

Note about interference

•

This product generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications.

•

If this equipment does cause harmful interference to radio or television reception, which can be determined by

turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of the

following measures:

- Reorient or relocate the receiving antenna for the radio/TV.

- Increase the separation between the equipment and the radio/TV.

- Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

- Consult your dealer or an experienced radio/TV technician for help.

•

Never disassemble or modify this product.

•

Seiko Epson Corporation shall not be liable for interference to radio/TV resulting from changes or

modifications to this product not expressly approved by Seiko Epson Corporation.

Open Source Software License

This product uses open source software in addition to Epson proprietary software.

For information of the open source software used in this product, see the following URL.

http://xxx.xxx.xxx.xxx/PRESENTATION/ADVANCED/LICENSE/TOP

For “xxx.xxx.xxx.xxx” in the above URL, input your printer’s IP address.

5

Page 6

About this Manual

Aim of the Manual

This manual provides developers/engineers with all the necessary information for design, development and

installation of a POS system, and also design and development of a printer application.

Manual Content

The manual is made up of the following sections:

Chapter 1

Chapter 2

Chapter 3

Chapter 4

Chapter 5

Chapter 6

Appendix

Product Overview

Setup

Advanced Usage

Application Development Information

Handling

Replacement of the TM-T88VI/TM-T88V

Product Specifications

Specifications of Interfaces and Connectors

Bluetooth Low Energy Technology Advertising

Character Code Tables

6

Page 7

Contents

■ For Safety..................................................................................................................................3

Key to Symbols.................................................................................................................................................................... 3

Warnings ............................................................................................................................................................................... 3

Cautions................................................................................................................................................................................. 4

■ Caution Labels.........................................................................................................................5

■ Restriction of Use....................................................................................................................5

■ Note about interference ........................................................................................................5

■ Open Source Software License.............................................................................................5

■ About this Manual ..................................................................................................................6

Aim of the Manual ............................................................................................................................................................. 6

Manual Content .................................................................................................................................................................. 6

■ Contents....................................................................................................................................7

Product Overview ..........................................................................................12

■ Features ................................................................................................................................. 12

■ Product Configurations ...................................................................................................... 14

Models..................................................................................................................................................................................14

Accessories .........................................................................................................................................................................14

■ Part Names and Functions ................................................................................................. 15

Control Panel .....................................................................................................................................................................16

Connectors .........................................................................................................................................................................17

Online and Offline............................................................................................................................................................19

■ Status and Errors.................................................................................................................. 20

Status Display ....................................................................................................................................................................20

Network Connection Status .........................................................................................................................................21

Error Status .........................................................................................................................................................................21

■ NV Memory ........................................................................................................................... 24

NV Graphics Memory......................................................................................................................................................24

User NV Memory ..............................................................................................................................................................24

Memory Switches.............................................................................................................................................................24

R/E (Receipt Enhancement) ..........................................................................................................................................24

Maintenance Counter.....................................................................................................................................................25

■ Simple Setup for Wireless LAN .......................................................................................... 26

■ Useful Functions for Smart Devices.................................................................................. 27

NFC Tag................................................................................................................................................................................27

QR Code...............................................................................................................................................................................27

7

Page 8

■ Printing Using Multiple Interfaces.................................................................................... 28

Setup ...............................................................................................................29

■ Flow of Setup ........................................................................................................................ 29

■ Installing the Printer............................................................................................................ 30

Important Notes on Horizontal Installation ...........................................................................................................30

Important Notes on Wall Hanging.............................................................................................................................30

■ Adjusting the Paper Roll Near-End Sensor...................................................................... 31

■ Connecting the AC adapter................................................................................................ 33

Connecting the AC adapter..........................................................................................................................................33

■ Connecting the Printer to the Host................................................................................... 34

USB Interface .....................................................................................................................................................................34

Ethernet Interface............................................................................................................................................................34

Wireless LAN Interface (With OT-WL06)...................................................................................................................35

Serial Interface ..................................................................................................................................................................39

Parallel Interface ...............................................................................................................................................................39

USB Plus Power Interface ..............................................................................................................................................39

■ Connecting the Cash Drawer ............................................................................................. 40

Cash Drawer Requirements..........................................................................................................................................40

Connecting the drawer kick cable .............................................................................................................................41

■ Connecting the Optional External Buzzer....................................................................... 42

Attachment Position .......................................................................................................................................................42

■ Connecting the Optional Wireless LAN Unit................................................................... 43

■ Connecting the Optional Customer Display ................................................................... 43

■ Attaching the Connector Cover......................................................................................... 44

■ Arranging the Cables........................................................................................................... 46

■ Attaching the Power Switch Cover ................................................................................... 48

■ Changing the Paper Width................................................................................................. 49

■ RTC Settings .......................................................................................................................... 50

Advanced Usage ............................................................................................51

■ Setting the DIP Switches..................................................................................................... 51

Setting Procedure ............................................................................................................................................................51

Serial Model .......................................................................................................................................................................53

Parallel Model/Powered USB Model..........................................................................................................................55

Fixed Interface Model .....................................................................................................................................................57

Selecting the BUSY Status.............................................................................................................................................58

■ Software Settings................................................................................................................. 59

Functions.............................................................................................................................................................................61

8

Page 9

■ Setting/Checking Modes.................................................................................................... 69

Self-test Mode ...................................................................................................................................................................71

NV Graphics Information Print Mode........................................................................................................................71

Receipt Enhancement Information Print Mode ....................................................................................................72

Software Setting Mode..................................................................................................................................................73

Restore Default Values Mode.......................................................................................................................................75

Interface Setup Mode.....................................................................................................................................................76

TM-Intelligent Settings Information Print Mode ..................................................................................................77

Peripheral Device Information Print Mode.............................................................................................................77

Hexadecimal Dumping Mode .....................................................................................................................................78

■ Printing a Status Sheet........................................................................................................ 79

■ Network Connection Check ............................................................................................... 82

Printing a Network Connection Check Report ......................................................................................................82

List of Errors........................................................................................................................................................................82

■ Resetting the Interface Settings ....................................................................................... 83

■ TM-Intelligent Function ...................................................................................................... 84

Server direct print ............................................................................................................................................................84

Application Development Information.......................................................85

■ Controlling the Printer ........................................................................................................ 85

ePOS-Print XML.................................................................................................................................................................85

ePOS-Device XML.............................................................................................................................................................85

ESC/POS...............................................................................................................................................................................85

■ Controlling the Cash Drawer.............................................................................................. 87

■ Controlling the Built-in Buzzer .......................................................................................... 88

■ Controlling the Optional External Buzzer ....................................................................... 89

■ Software................................................................................................................................. 90

Development Kits ............................................................................................................................................................90

Drivers ..................................................................................................................................................................................91

Utilities .................................................................................................................................................................................91

Others...................................................................................................................................................................................92

Download ...........................................................................................................................................................................92

■ Notes on Printing Barcodes and Two-dimensional Symbols....................................... 93

Handling .........................................................................................................94

■ Installing and Replacing Roll Paper.................................................................................. 94

■ Removing Jammed Paper .................................................................................................. 97

■ If Roll Paper Cover does not Open.................................................................................... 99

■ Cleaning the Printer........................................................................................................... 100

Cleaning the Printer Case ...........................................................................................................................................100

9

Page 10

Cleaning the Thermal Head/Platen Roller ............................................................................................................ 100

■ Preparing for Transport..................................................................................................... 101

Replacement of the TM-T88VI/TM-T88V................................................... 102

■ Compatibility ...................................................................................................................... 102

Printing ............................................................................................................................................................................. 102

Print Density.................................................................................................................................................................... 102

Number of Head Energizing Parts........................................................................................................................... 102

Printable Area (for 80 mm Width Paper)............................................................................................................... 102

Cutting Method .............................................................................................................................................................102

Manual Paper Feed.......................................................................................................................................................103

Receive Buffer................................................................................................................................................................. 103

Memory Capacity.......................................................................................................................................................... 103

Electrical Characteristics............................................................................................................................................. 103

DIP Switches.................................................................................................................................................................... 103

Printer Status .................................................................................................................................................................. 103

Logo Registration.......................................................................................................................................................... 103

Driver Compatibility ..................................................................................................................................................... 103

USB Low Power Consumption Mode ..................................................................................................................... 103

Maintenance Counter.................................................................................................................................................. 104

Buzzer................................................................................................................................................................................ 104

NFC ..................................................................................................................................................................................... 104

Epson TM Utility for iOS/Android ............................................................................................................................ 104

Power Supply Box ......................................................................................................................................................... 104

Overall Dimensions ......................................................................................................................................................105

■ Additional Functions and Functional Improvements ................................................. 106

Print Speed ...................................................................................................................................................................... 106

Interface............................................................................................................................................................................ 106

SimpleAP Function .......................................................................................................................................................106

Noise .................................................................................................................................................................................. 106

LED Indicator .................................................................................................................................................................. 106

Appendix...................................................................................................... 107

■ Product Specifications ...................................................................................................... 107

Printing Specifications.................................................................................................................................................108

Character Specifications ............................................................................................................................................. 109

Printable Area................................................................................................................................................................. 110

Printing and Cutting Positions ................................................................................................................................. 112

Paper Specifications ..................................................................................................................................................... 113

Electrical Characteristics............................................................................................................................................. 114

Environmental Conditions ......................................................................................................................................... 115

External Dimensions and Mass ................................................................................................................................ 116

■ Specifications of Interfaces and Connectors ................................................................ 118

USB Interface .................................................................................................................................................................. 118

Network Interface ......................................................................................................................................................... 119

10

Page 11

RS-232 Serial Interface.................................................................................................................................................123

IEEE 1284 Parallel Interface........................................................................................................................................ 126

NFC Tag............................................................................................................................................................................. 128

■ Bluetooth Low Energy Technology Advertising........................................................... 129

Introduction .................................................................................................................................................................... 129

Dongle specifications .................................................................................................................................................. 129

Procedure......................................................................................................................................................................... 129

Changing the Bluetooth Low Energy Technology Advertising Packet...................................................... 130

■ Character Code Tables....................................................................................................... 141

■ Compatibility with USB Type-A ....................................................................................... 142

11

Page 12

Chapter 1 Product Overview

Product Overview

This chapter describes features of the product.

Features

Printing

• High speed printing (500 mm/s maximum).

• Shifting from 80 mm width paper printing to 58 mm width paper printing is available.

• Multi-tone graphic printing.

• Multiple languages are supported (ANK (includes Thai), Japanese (JIS Level 1, 2, 3, and 4), Simplified

Chinese, Traditional Chinese, Korean)

Handling

• Easy drop-in paper loading

Software

•

TM-Intelligent function is equipped.

Supports Server Direct Print that sends a request for print data from the product to the Web server at regular

intervals.

• Command protocol is based on the ESC/POS Proprietary Command System.

• OPOS ADK, OPOS ADK for .NET, JavaPOS ADK, and Windows printer drivers are available.

• In addition to supporting several kinds of bar code printing, DS1 DataBar printing and two-dimensional

symbol (PDF417, QR code, MaxiCode, Composite Symbology) printing are possible.

• A maintenance counter function is supported.

• Vari o u s ut i lity s oftw a r e are av a i lable .

A utility for iOS/AndroidTM (Epson TM Utility for iOS/Android) for making printer settings is also provided.

•

•

Indicates Ethernet and Wi-Fi network status separately with the two LED indicators.

Environment

• Paper saving function is available.

12

Page 13

Chapter 1 Product Overview

Functions

• NFC tag built into the printer unit for printing to a touched printer.

• Printing triggered by bar code scan by smart device camera.

• Supports printing using multiple interfaces.

• Enables HTTPS communication.

• Offers network connection check function.

Others

• Various interface models are available.

• Optional Wireless LAN cable set, customer display, external buzzer, and interface boards are available.

• Optional wall hanging bracket is available to attach the printer to a wall.

13

Page 14

Product Configurations

Models

• Serial model: equipped with serial, Ethernet, and built-in USB interfaces

• Parallel model: equipped with parallel, Ethernet, and built-in USB interfaces

• Powered USB model: equipped with USB Plus Power, Ethernet, and built-in USB interfaces

• Fixed Interface model: equipped with Ethernet and built-in USB interfaces

Accessories

Included

• Roll paper (for operation check)

• Power switch cover

• Connector cover

Chapter 1 Product Overview

• Screw for attaching the Connector cover (x1)

• Bottom cover for the Connector cover

• Screw for attaching the Bottom cover for the Connector cover (x2)

• Roll paper guide

• Screw for attaching the roll paper guide (x1)

• Cable lock band

• AC adapter*

• AC cable*

• TM-T88VII User's Guide

* May not be included depending on the model.

Options

• Power supply box (Model: OT-BX88VII)

• Wall hanging bracket (Model: WH-10)

• Interface boards (UB series)

• Optional external buzzer (Model: OT-BZ20)

• Wireless LAN cable set (Model: OT-WL06)

• Customer display (Model: DM-D30/DM-D70/DM-D110/DM-D210)

14

Page 15

Chapter 1 Product Overview

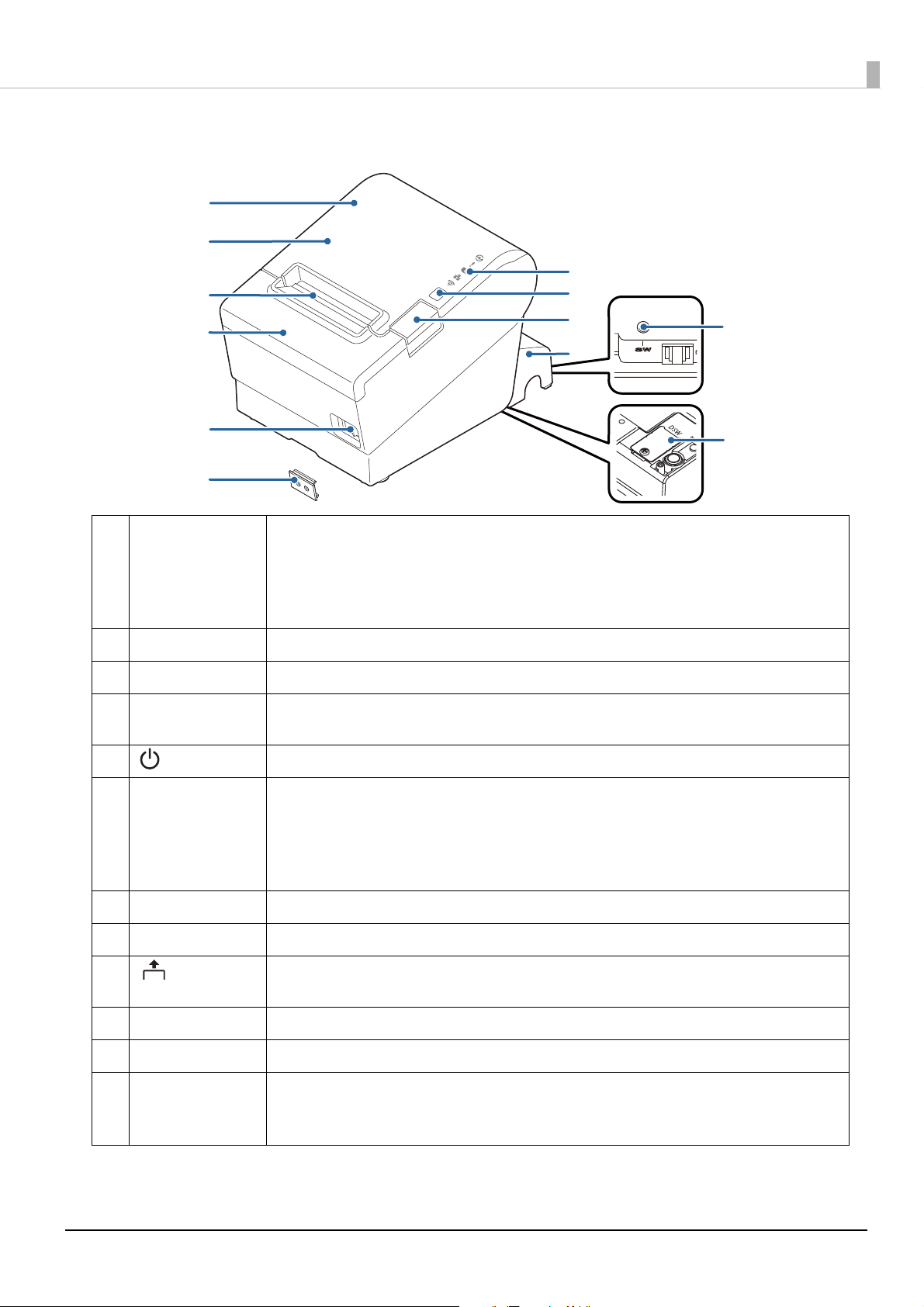

11

12

2

4

5

6

7

1

3

8

9

10

Part Names and Functions

.

1 NFC Tag A mark is printed here to indicate the position of the NFC tag. To establish communication with an

NFC device, bring the device close to this mark. For details on functions that use the NFC tag, refer

to "Useful Functions for Smart Devices" on page 27.

• Ther

e is no data rewriting function.

• Use Epson ePOS SDK to build this function into your application.

2 Roll paper cover Open this cover to install/replace the roll paper.

3 Manual cutter Use this cutter when you cut the roll paper manually.

4 Cutter cover Open this cover to unlock the autocutter blade when the roll paper cover does not open due to a

paper jam.

5 Power switch Turns the printer on or off.

6 Power switch cover Install the power switch cover onto the printer to prevent inadvertent changing of the power

switch, to prevent tampering, and to improve the appearance of the printer.

To operate the power switch, insert an object with a pointed tip such as a ballpoint pen into the

hole on the power switch cover.

For attaching the power switch cover, refer "Attaching the Power Switch Cover" on page 48.

7

Connector cover Use the printer with this cover attached to protect cables.

8 Cover open button Use this button to open the roll paper cover.

9 Feed button Pressing this button once feeds roll paper for one line. Hold down this button to continue feeding

roll paper.

10 Control Panel For details on LED, see "Control Panel" on page 16.

11

Dip switch cover Open the cover to view the dip switches for communication settings.

12 Status sheet button Use this button to print a status sheet on interfaces or initialize the settings on interfaces.

Fixed Interface models have the status sheet button on a different location. See "Fixed Interface

Mo

del" on page 18.

15

Page 16

Chapter 1 Product Overview

When turning off the printer without using the power switch, it is recommended to send a power-off

command to the printer. If you use the power-off sequence, the latest maintenance counter values are

saved. (Maintenance counter values are usually saved every two minutes.)

For information about ESC/POS commands, see the ESC/POS Command Reference.

Control Panel

Power LED

• Lights when the power supply is on.

• Off when the power supply is off.

• Flashes during the network to start up, when waiting for power off, or updating firmware.

Do not turn on by using the power switch while waiting for the power to turn off (when the Power

LED is flashing). Otherwise, it may not startup correctly.

Error LED

• Lights or flashes when an error occurs. (For information about the flashing patterns, see "Status and Errors"

on page 20.)

ights after the power is turned on or after a reset (offline). Automatically goes out after a while to indicate

• L

that the printer is ready.

• Off when the printer is in standard mode (online).

Paper LED

• Lights when the roll paper is out.

• Flashes to urge user to operate the Feed button.

Wi-Fi LED

• Lights while the printer is connected to Wi-Fi.

• Off while the printer is not connected to Wi-Fi or while the printer is connected to a wired LAN.

• Flashes while communication is temporarily disabled because an IP address has not been acquired or for

other reason.

Ethernet LED

• Lights while the printer is connected to Ethernet.

• Off while the printer is not connected to Ethernet or while the printer is connected to Wi-Fi.

• Flashes while communication is temporarily disabled because an IP address has not been acquired or for

other reason.

16

Page 17

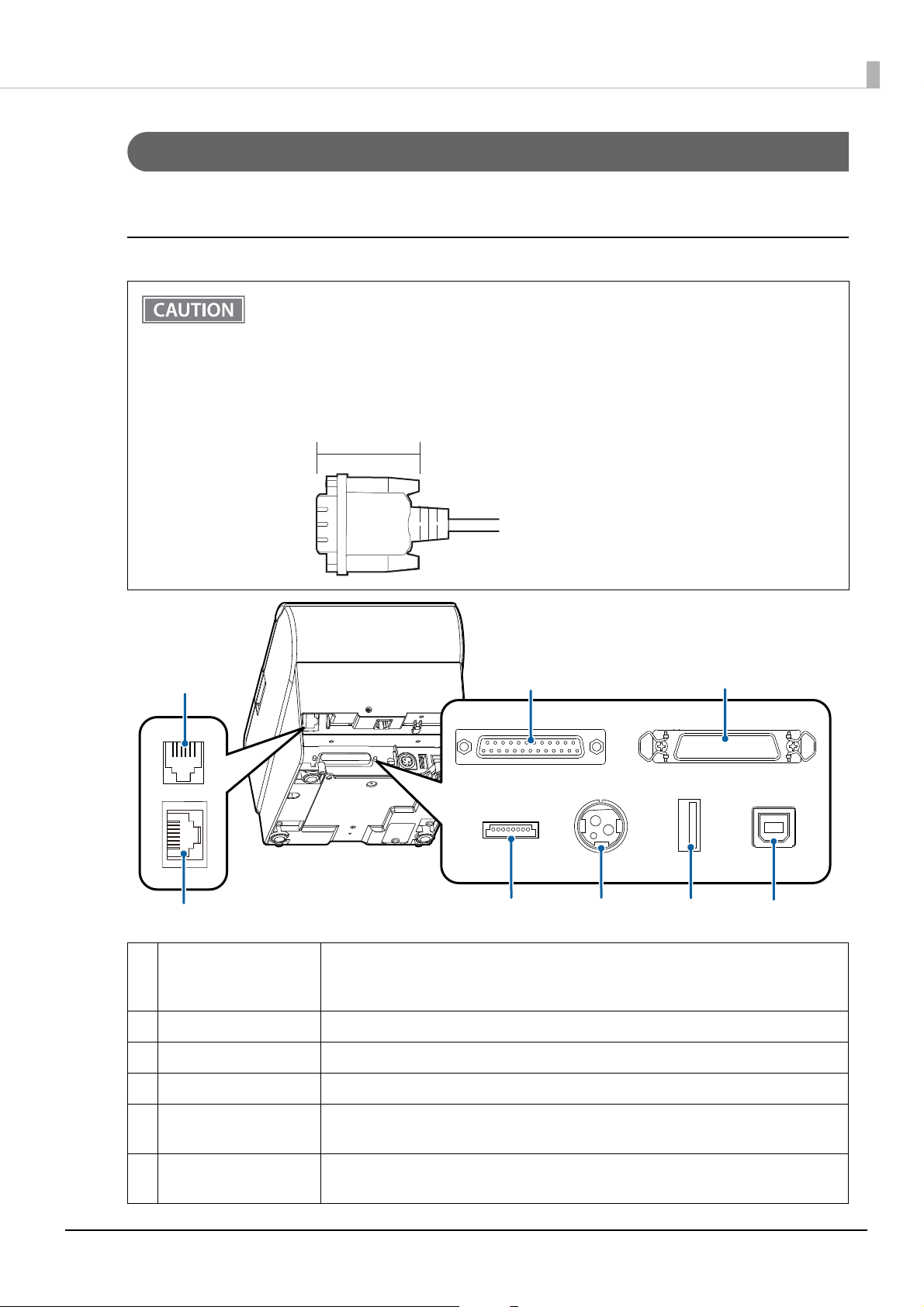

Connectors

All connectors are located on the lower rear of the printer.

Serial/Parallel/Powered USB Models

• The installed interface varies depending on the model.

• Do not insert a Type-B USB connector into the LAN connector or the drawer kick connector. If it

is inserted, the connector, printer, and the system may malfunction.

• If using the drawer kick connector and a serial/parallel connector simultaneously, we recommend

using either of the cables below to prevent the cables from interfering with one another.

* Flat-type drawer kick cable

* Serial/parallel cable with a connector (from the tip to the screw) that is within 34 mm {1.34"}.

Within 34 mm {1.34"}

Chapter 1 Product Overview

1

2

1 Drawer kick connector Connects the cash drawer or the optional external buzzer.

See "Connecting the Cash Drawer" on page 40, and "Connecting the Optional External

Buzz

er" on page 42.

2

Ethernet connector Connects the 10BASE-T/100BASE-TX Ethernet cable.

3 Serial interface Serial model only. Connects the serial cable for connecting to a computer.

4 Parallel interface Parallel model only. Connects the parallel cable for connecting to a computer.

5 USB Plus Power Interface Powered USB model only. Connects the USB Plus Power cable for connecting to a

computer.

3

5

6

4

7

8

6 Power supply connector Connect the AC adapter.

See "Connecting the AC adapter" on page 33.

17

Page 18

Chapter 1 Product Overview

2

1

3 4 5 6

7

7 USB connector Use only for connecting optional Wireless LAN unit and customer display.

CAUTION:

It may be hard to disconnect some types of USB cable. Do not forcibly pull the cable, or

the USB connector and USB cable may be damaged. Contact qualified service personnel

if you encounter the trouble.

8 USB connector (Type B) Connects the USB cable for connecting to a computer.

See "Connecting the Printer to the Host" on page 34.

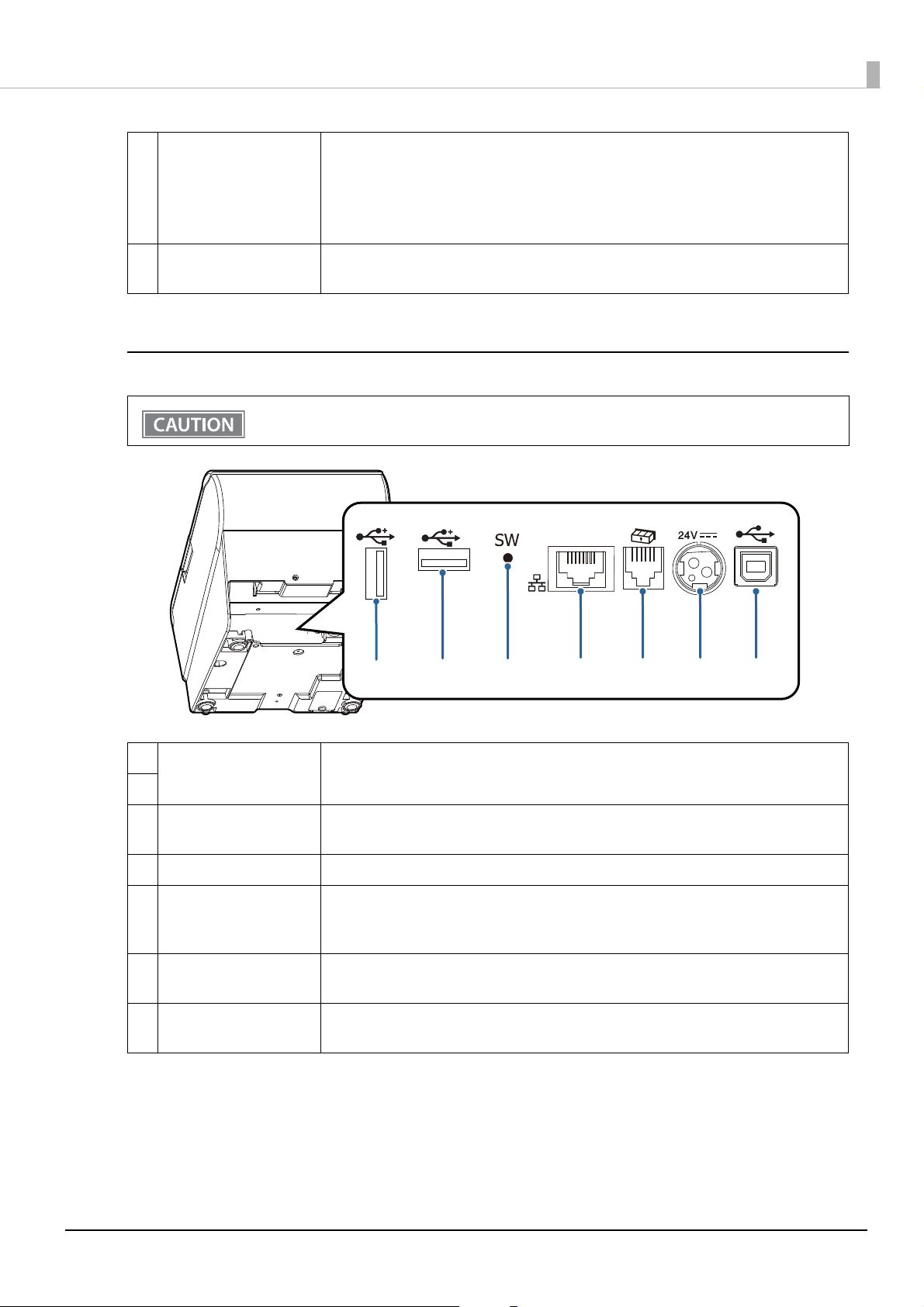

Fixed Interface Model

Do not

insert a Type-B USB connector into the LAN connector or the drawer kick connector. If it is

inserted, the connector, printer, and the system may malfunction.

1

USB connector (Type-A)

2

3 Status sheet button Use this button to print a status sheet on interfaces or initialize the settings on

4 Ethernet connector Connects the 10BASE-T/100BASE-TX Ethernet cable.

5 Drawer kick connector Connects the cash drawer or the optional external buzzer.

6

Power supply connector Connect the AC adapter.

7

USB connector (Type B) Connects the USB cable for connecting to a computer.

Connects a USB cable of a peripheral device such as an optional Wireless LAN cable set,

customer display, or handheld scanner.

interfaces.

See "Connecting the Cash Drawer" on page 40, and "Connecting the Optional External

Buzz

er" on page 42.

See "Connecting the AC adapter" on page 33.

See "Connecting the Printer to the Host" on page 34.

18

Page 19

Chapter 1 Product Overview

Online and Offline

Online

The printer is online and ready for normal printing unless there is a reason to go offline.

Offline

The printer automatically goes offline under the following conditions:

• While the printer power is turning on/off

• While a self-test is running

• While roll paper is fed using the Feed button

• When the printer stops printing due to a paper end (when the paper out detector detected the paper out)

• During an operation standby state

• When an error has occurred (See "Status and Errors" on page 20)

hile the roll paper cover is open

• W

19

Page 20

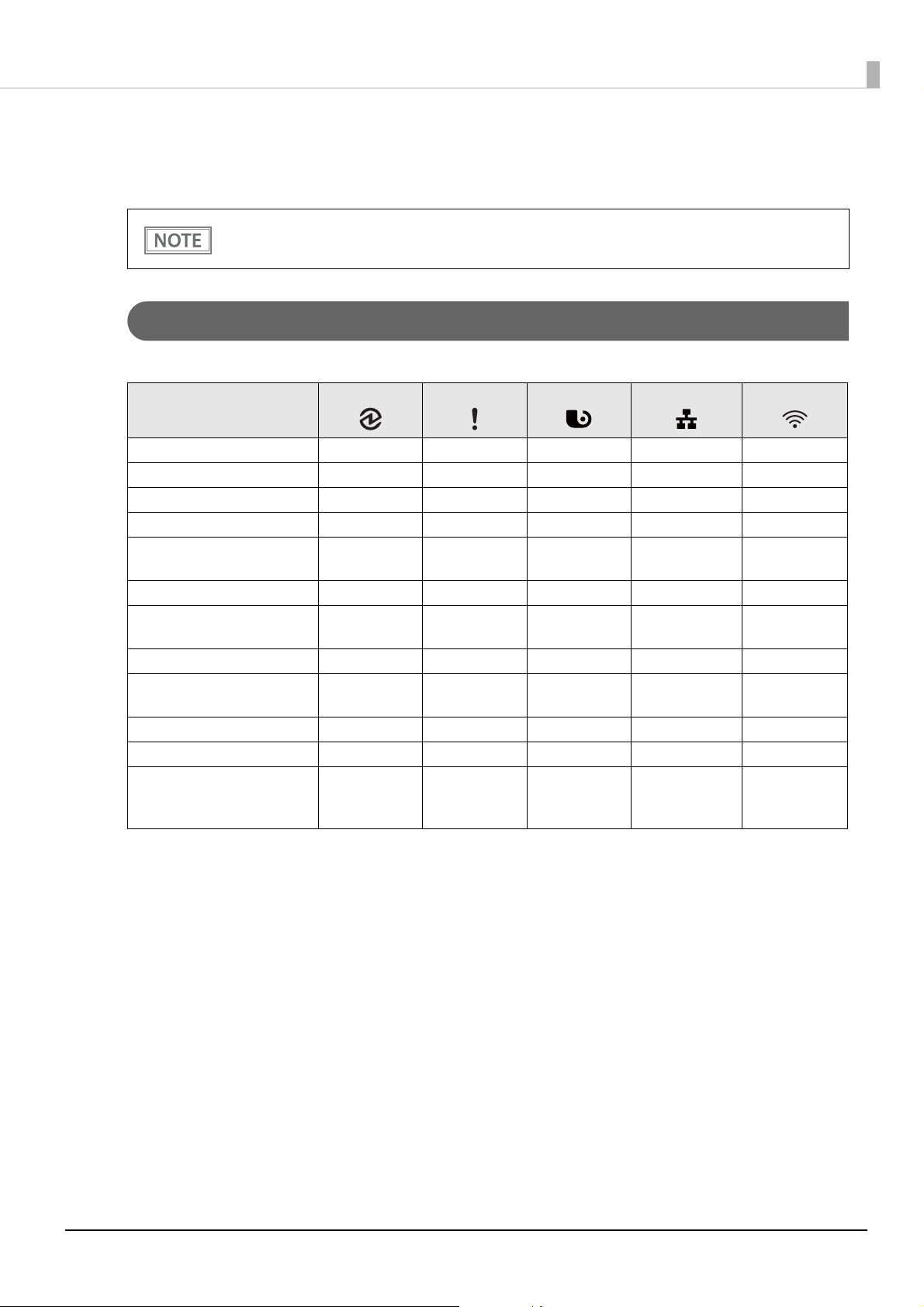

Status and Errors

The LEDs turn on or flash to indicate status of the printer.

Printing is impossible while an error is occurring.

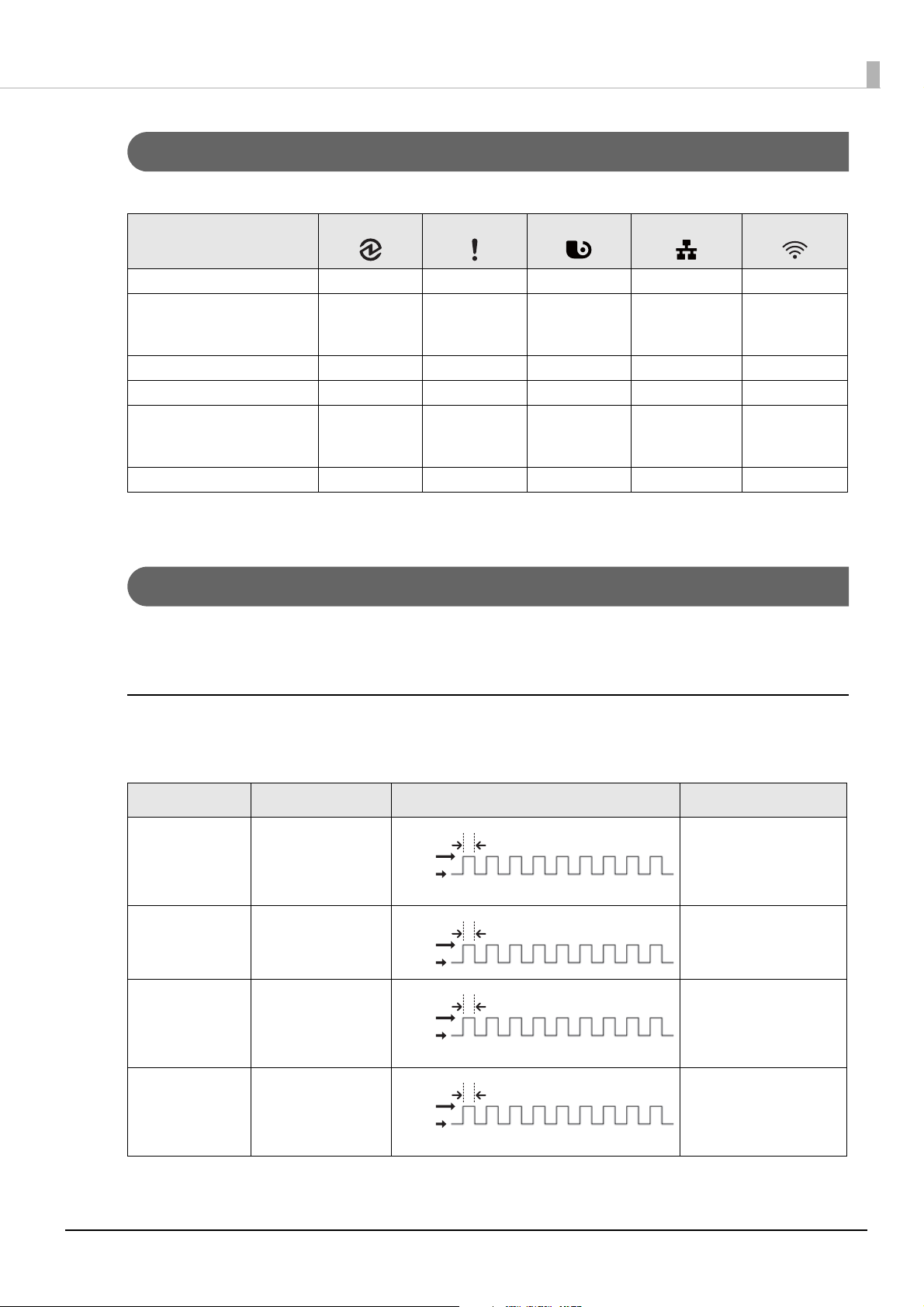

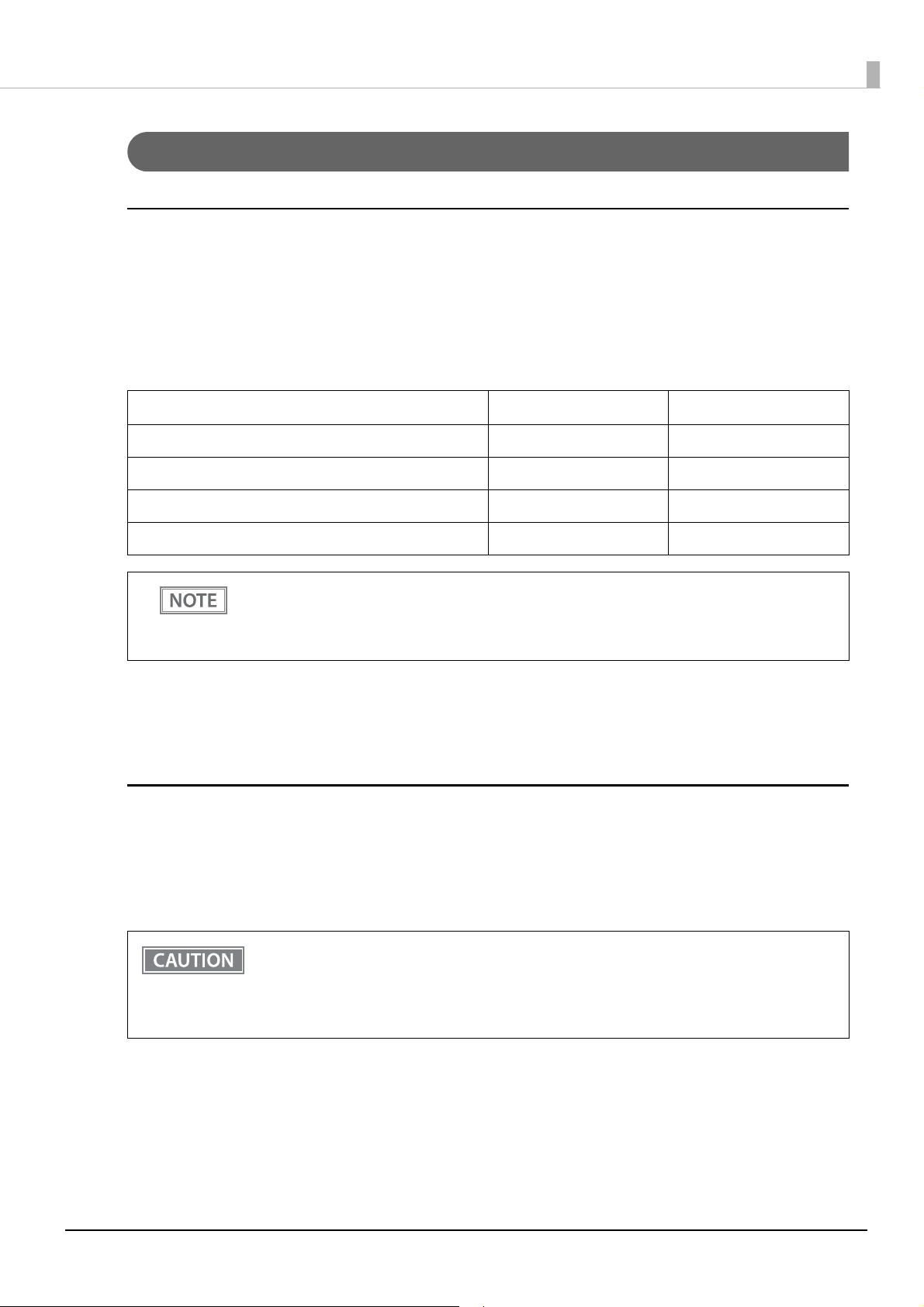

Status Display

Chapter 1 Product Overview

O: OFF N: ON F: Flashing - : Ignore the LED light

POWER LED

Normal state NOO --

Initializing after power-on NN ---

Running a self-test NO ---

Waiting to continue self-test NOF --

Feeding paper using the Feed

button

Waiting to execute a macro NOF --

Roll paper cover open while

not printing

No paper NNN --

Remaining amount of roll

paper is low

Updating firmware FOO --

During power-off process NNO --

Waiting for the roll paper

cover to be closed to print a

status sheet

NO ---

NN ---

NON --

NNF --

ERROR LED PAPER L ED Ethernet LED Wi-Fi LED

∗ -: Changes depending on whether or not paper is detected.

∗ The LED flashing pattern is: lighting for 0.32 s followed by a pause for 0.32 s.

20

Page 21

Chapter 1 Product Overview

0.32 s

LED OFF

LED ON

0.32 s

LED OFF

LED ON

0.32 s

LED OFF

LED ON

0.32 s

LED OFF

LED ON

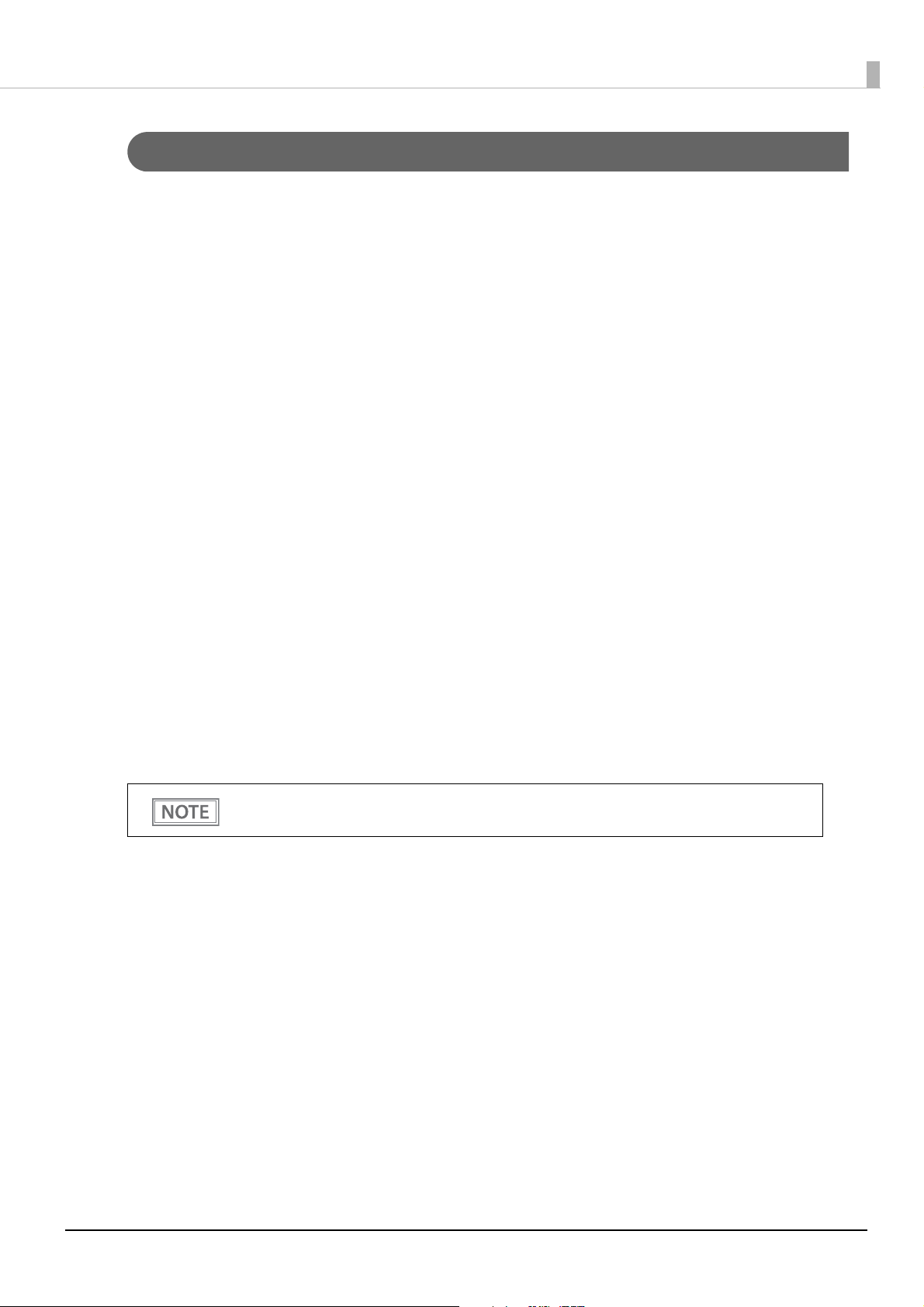

Network Connection Status

O: OFF N: ON F: Flashing - : Ignore the LED light

POWER LED ERROR LED PAPER LED Ethernet LED Wi-Fi LED

Connected to Ethernet NOO N -

In the process of connecting

to Ethernet (An IP address has

not been acquired)

Not connected to Ethernet NOO O -

Connected to Wi-Fi NOO - N

In the process of connecting

to Wi-Fi (An IP address has not

been acquired)

Not connected to Wi-Fi NOO - O

∗ -: Changes depending on whether or not paper is detected.

∗ The LED flashing pattern is: lighting for 0.32 s followed by a pause for 0.32 s.

NOO F -

NOO - F

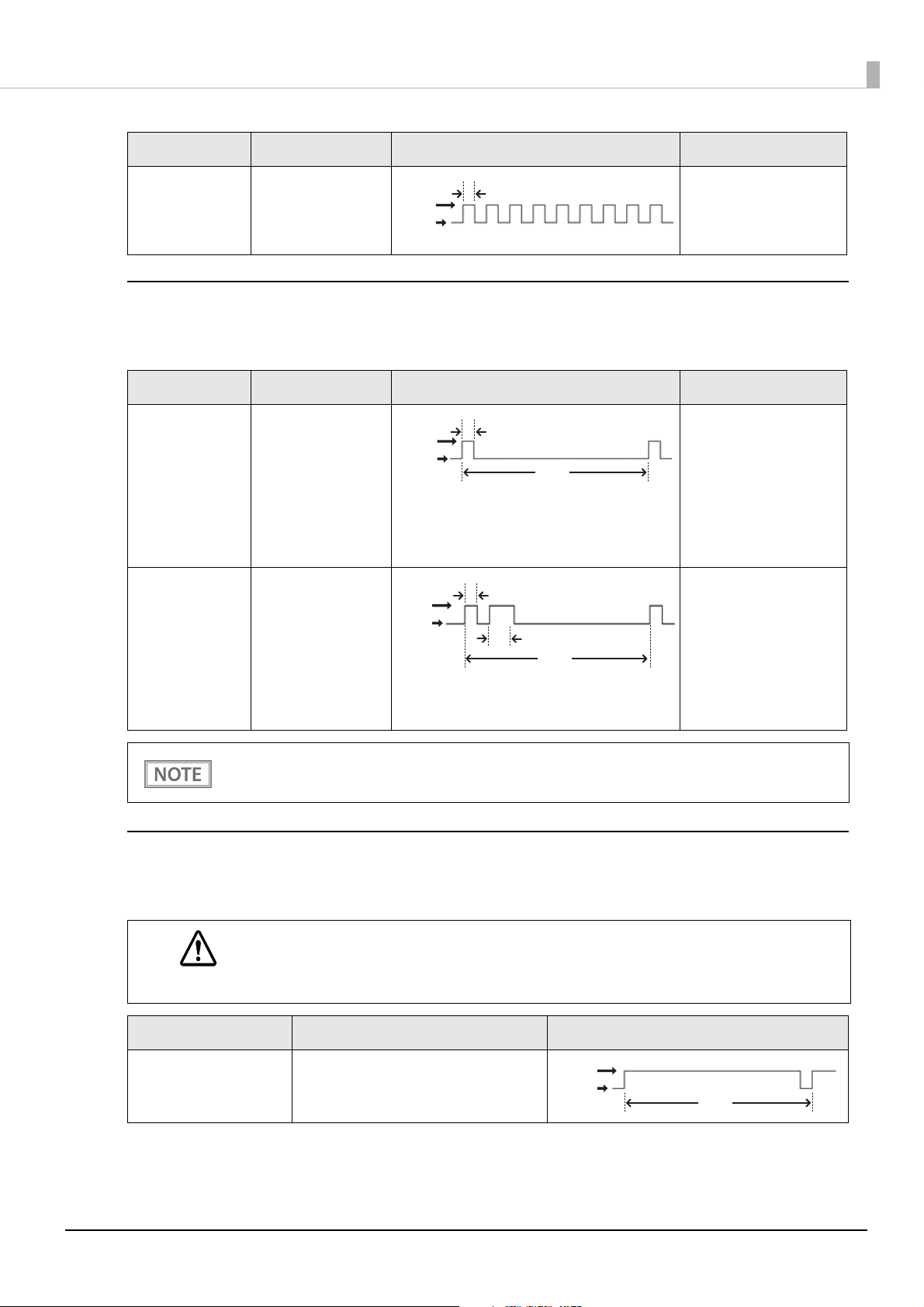

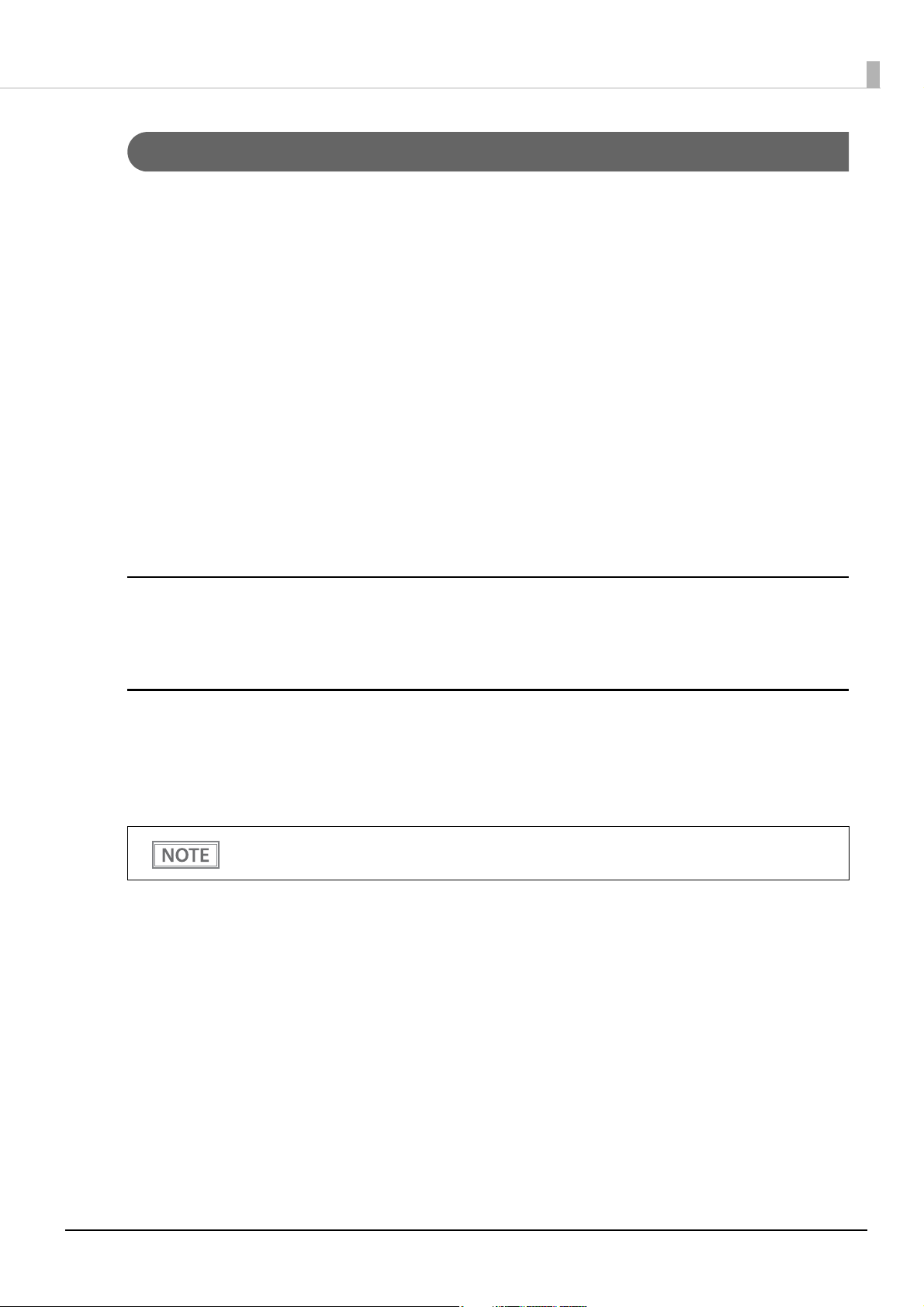

Error Status

There are three possible error types: automatically recoverable errors, recoverable errors, and unrecoverable

errors.

Automatically Recoverable Errors

Printing is impossible while an automatically recoverable error is occurring. The printer recovers from the error

as described below.

Error Explanation Error LED Flashing Pattern Recovery measure

Print head high

temperature error

Cover open error The roll paper cover

Motor driver IC

high temperature

error

A high temperature

beyond the standard

range for driving the

head is detected.

is opened during

printing.

A high temperature

beyond the standard

range for driving the

motor is detected.

The printer recovers from

the error when the head

temperature drops.

The printer recovers from

the error when the cover

is closed.

The printer recovers from

the error after the elapse

of a certain period of

time.

TM-i connection

error

The printer cannot

connect to the

server.

To recover from the error,

correct the printer

settings. (

F

unction" on page 84)

"TM-Intelligent

21

Page 22

Chapter 1 Product Overview

0.32 s

LED OFF

LED ON

0.64 s

0.32 s

5.12 s

LED OFF

LED ON

5.12 s

LED OFF

LED ON

Error Explanation Error LED Flashing Pattern Recovery measure

DC motor heating

error

A high temperature

beyond the standard

range for driving the

motor is detected.

The printer recovers from

the error after the elapse

of a certain period of

time.

Recoverable Errors

Printing is impossible while a recoverable error is occurring. After the error cause is eliminated, the printer

recovers from the error when it is turned off and back on or receives an error recovery command.

Error Explanation Error LED Flashing Pattern Recovery measure

Auto cutter error The autocutter does

not work properly.

DC paper jam

error

The roll paper is

jammed.

LED ON

LED OFF

0.32 s

5.12 s

To recover from the error,

remove jammed paper or

foreign matter in the

printer, close the roll

paper cover, and then

send an error recovery

command, or turn the

printer back on.

To recover from the error,

remove jammed paper or

foreign matter in the

printer, close the roll

paper cover, and then

send an error recovery

command, or turn the

printer back on.

The error recovery command is valid only if a recoverable error (excluding automatically recoverable

errors) occurs.

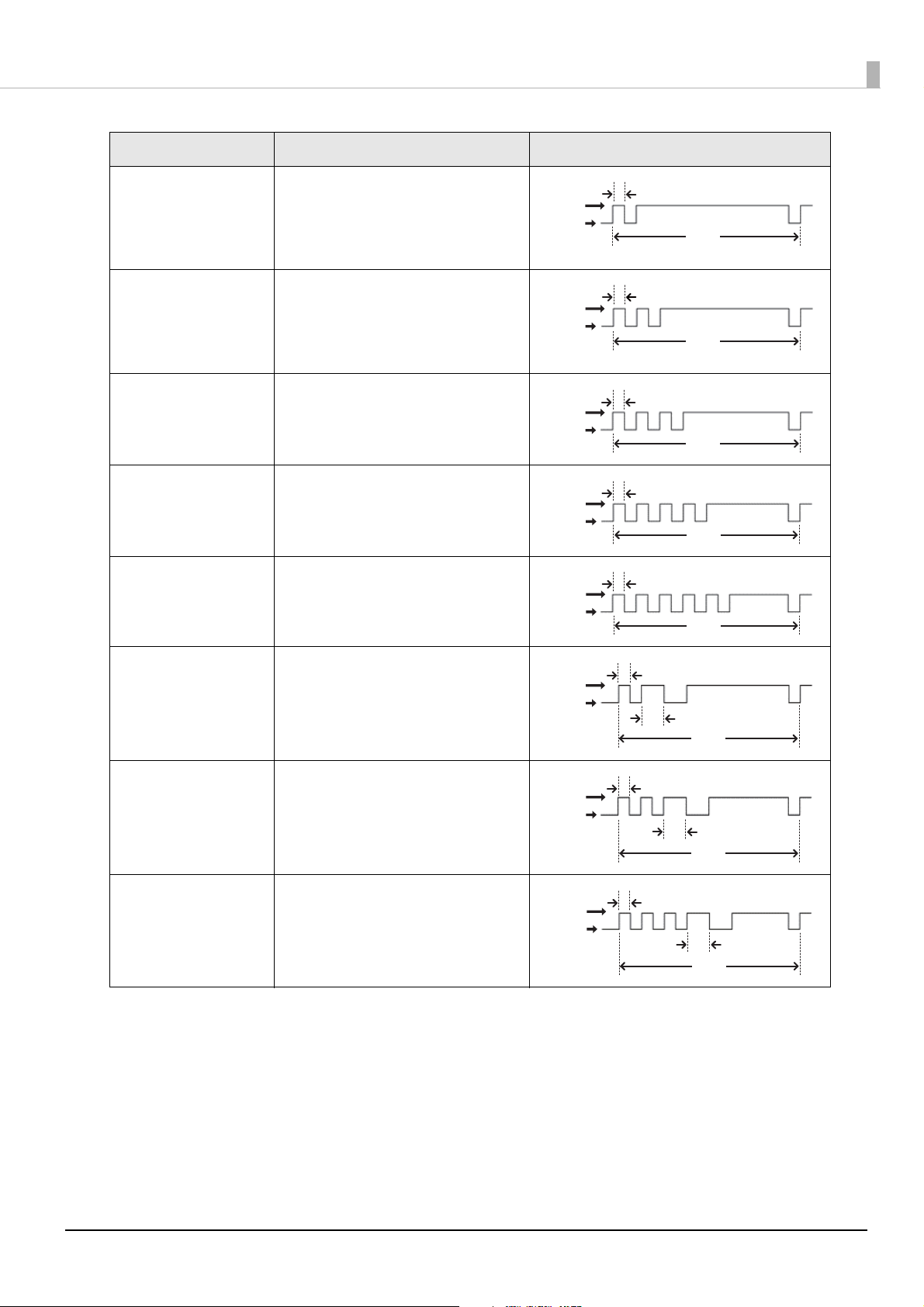

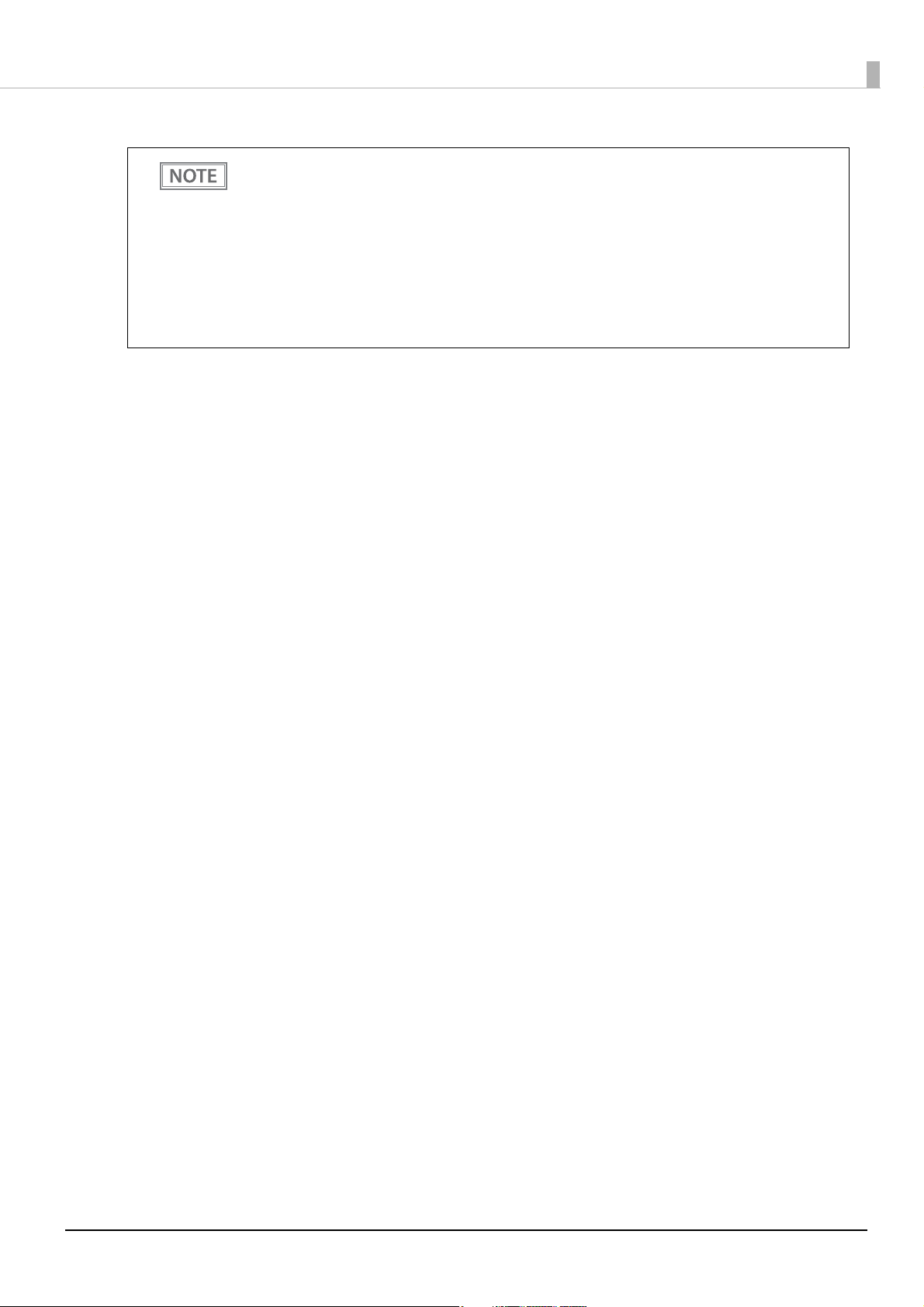

Unrecoverable Errors

Printing is impossible while an unrecoverable errors is occurring. If the error still occurs after turning the

printer off and then back on, the printer may be defective. Contact qualified service personnel.

Turn off the power immediately when unrecoverable errors occur.

CAUTION

Error Explanation Error LED Flashing Pattern

Internal circuit

connection error

Internal circuits are not connected

correctly.

22

Page 23

Chapter 1 Product Overview

0.32 s

5.12 s

LED OFF

LED ON

0.32 s

5.12s

LED OFF

LED ON

0.64 s

0.32 s

5.12 s

LED OFF

LED ON

0.32 s

5.12 s

0.64 s

LED OFF

LED ON

0.32 s

5.12 s

0.64 s

LED OFF

LED ON

Error Explanation Error LED Flashing Pattern

Memory reading/writing

error

After a reading/writing check of the

memory, the printer does not work

correctly.

High voltage error The power supply voltage is extremely

high.

Low voltage error The power supply voltage is extremely

low.

CPU execution error The CPU is executing an incorrect

address.

Communication unit

error

An error has occurred in the

communication unit.

LED ON

LED OFF

LED ON

LED OFF

LED ON

LED OFF

0.32 s

5.12 s

0.32 s

5.12 s

0.32 s

5.12 s

DC reversing error The DC motor is reversing.

DC driving time error DC motor driving time has exceeded the

limit.

DC oscillation error The DC motor is oscillating.

23

Page 24

Chapter 1 Product Overview

NV Memory

The printer's NV memory (Non-Volatile Memory) stores data even after the printer power is turned off. NV

memory contains the following memory areas for the user:

• NV graphics memory

• User NV memory

• Memory switches

• R/E (Receipt Enhancement)

• Maintenance counter

NV memory can be rewritten about 100,000 times. As a guide, NV memory rewriting should be 10

times or less a day when you program applications.

CAUTION

NV Graphics Memory

Graphics, such as shop logos to be printed on receipts, can be stored. Even with a serial interface model whose

communication speed is low, high speed graphics printing is possible.

To register your graphics data, use TM-T88VII Utility or ESC/POS commands.

You can check registered graphics data using TM-T88VII Utility or by printing the data in the NV graphics

information print mode.

User NV Memory

You can store and read text data for multiple purposes, such as for storing a note including customizing or

maintenance information of the printer.

Memory Switches

With the memory switches, which are software switches for the printer, you can configure various settings of the

printer. For information about the memory switch, see "Software Settings" on page 59.

R/E (Receipt Enhancement)

You can set the graphics data, such as a shop logo, registered in the NV graphics memory to be printed on the

top of each receipt or to be printed on the bottom of each receipt just before the paper is cut.

To make the settings, use TM-T88VII Utility or ESC/POS commands.

You can check the settings using TM-T88VII Utility or by printing the settings information in the Receipt

enhancement information print mode.

24

Page 25

Chapter 1 Product Overview

Maintenance Counter

With this function, printer information, such as the number of lines printed, the number of autocuts, and

printer operation time after the printer starts working, is automatically stored in NV memory.

• You can also check the head running length and number of times of autocutting with the self-test

(see "Self-test Mode" on page 71).

• T

he maintenance counter values are automatically saved in the NV memory usually every two

minutes (up to four minutes). However, the values are not saved when the printer is in powersaving mode or when it is turned off without the use of the power switch.

25

Page 26

Chapter 1 Product Overview

SimpleAP Start

SSID : DIR ECT-T M-T88V II- XXXXXXXXXX

Serial number of the printer

Simple Setup for Wireless LAN

The printer has "SimpleAP" mode that allows a device to directly connect to the printer without using an access

point. You can configure wireless LAN settings using the printer setting tool and print on the printer using the

direct connection.

• The printer acts as an access point in the SimpleAP mode and allows up to eight devices to connect

to the printer.

• Connection to a wireless LAN or wired LAN and connection using the SimpleAP mode can be made

at the same time.

• Communication between devices connected to the printer in the SimpleAP mode is impossible.

• If the printer is already connected to a wireless LAN and setting using the SimpleAP mode is

started, the wireless LAN connection is temporarily disconnected.

• If you change the passphrase, connection using SimpleAP from an Android 10 device is disabled. It

may also occur with a device running other OS. If that happens, delete the printer's SimpleAP SSID

profile in the Wi-Fi settings of the Windows, iOS, or Android device, and then connect to the printer

again.

SimpleAP is enabled by default. The printer automatically prints the information shown below when it is turned

on with the following conditions; SimpleAP enabled, not connected to a wireless LAN/wired LAN/USB device,

and wireless LAN settings have not been configured.

The printer activates SimpleAP when it is turned on for the first time, however, if you change the printer

settings using TM-T88VII Utility for Windows or EpsonNet Config, SimpleAP is disabled.

To activate SimpleAP again, start it by selecting the SimpleAP menu that is available after printing a status sheet,

or reset the network settings.

"Setting up from a Windows Computer using SimpleAP" on page 36

"Resetting the Interface Settings" on page 83

26

Page 27

Chapter 1 Product Overview

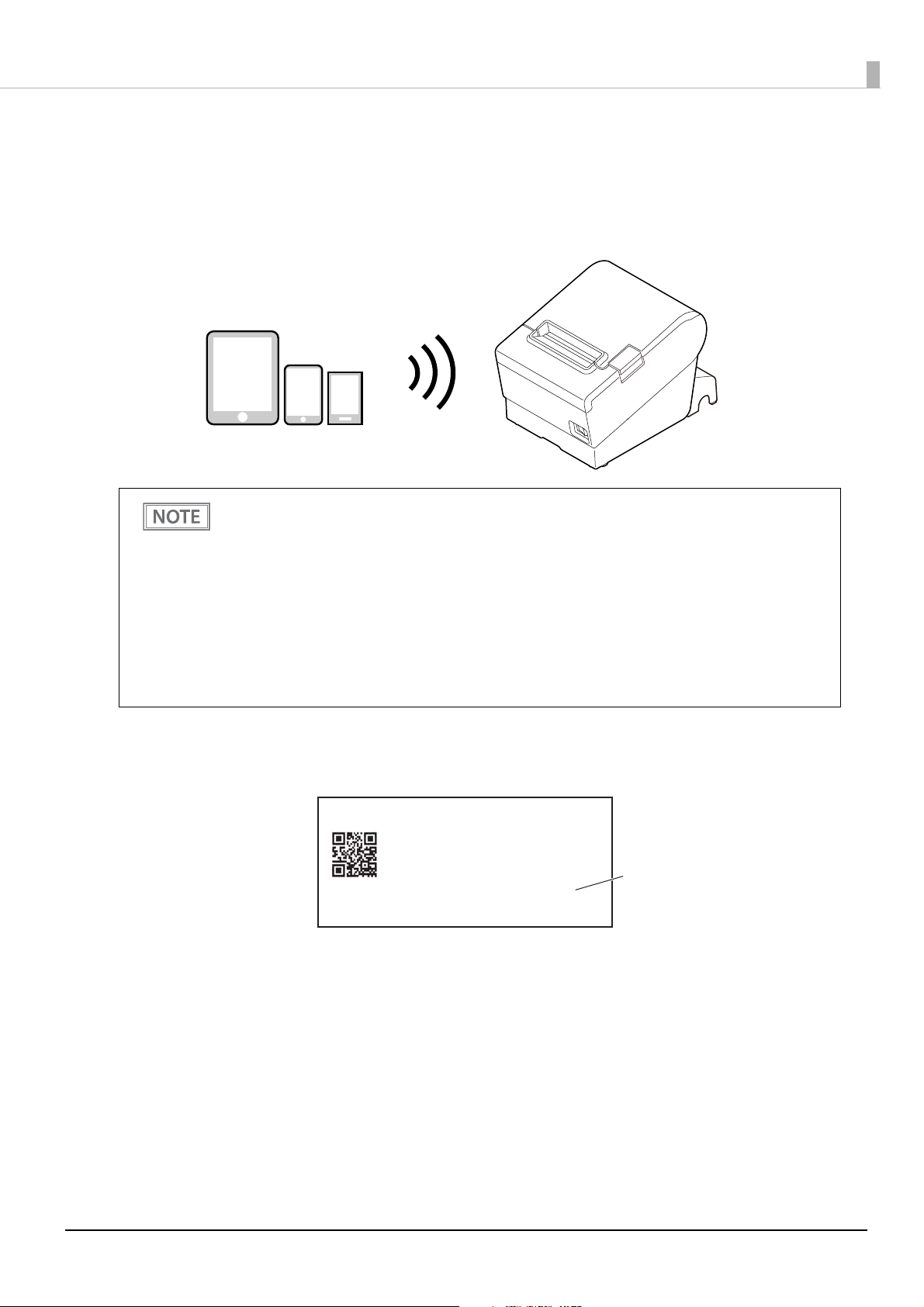

Useful Functions for Smart Devices

You can easily connect this product to the network by using the NFC tag built-in to the printer or the QR code

printed on the status sheet.

NFC Tag

Bring a smart device that supports NFC close to the NFC tag to acquire the printer information (information

for specifying the device).

Specify the target printer using the acquired information to connect to the network.

QR Code

Capture the QR code printed on the status sheet with the camera on your smart device to acquire the printer

information (information for specifying the device).

Specify the target printer using the acquired information to connect to the network.

• Programming using Epson ePOS SDK is required to use these functions. These functions are

created by combining NFC touch and QR code capturing operations and the target printer

specifications using Printer Easy Select API.

See the "Epson ePOS SDK for Android/iOS User's Manual" and the Epson ePOS SDK sample

program for more details. The sample program also contains a sample implementation method for

reading an NFC tag and capturing a QR code.

• You can try a demo of these functions by using Epson TM Utility for iOS/Android.

27

Page 28

Chapter 1 Product Overview

Printing Using Multiple Interfaces

In printers with multiple interfaces, you can use all interfaces without any limitations on which interface is to be

used. You can use this function to temporarily connect a smart device to a nearby printer and print.

The printer provides each interface with an independent receive buffer and switches the active interface

depending on the priority, while handling data in each receive buffer.

You can set one interface for the main connection. Data received from the main connection interface is handled

with the highest priority.

By default, the interface that receives the first data transfer is set as the main connection interface; however, you

can select the main connection interface in advance.

In the status where all receive buffers are empty for more than the set time (1 second by default), interface

switching is enabled. The interface that receives the data in this status becomes active.

You cannot use wired and wireless LANs at the same time. When a LAN cable is connected, wireless

LAN is disabled.

You can select the main connection interface and set the time to enable interface switching from the

software settings. For details on software settings, see "Software Settings" on page 59.

28

Page 29

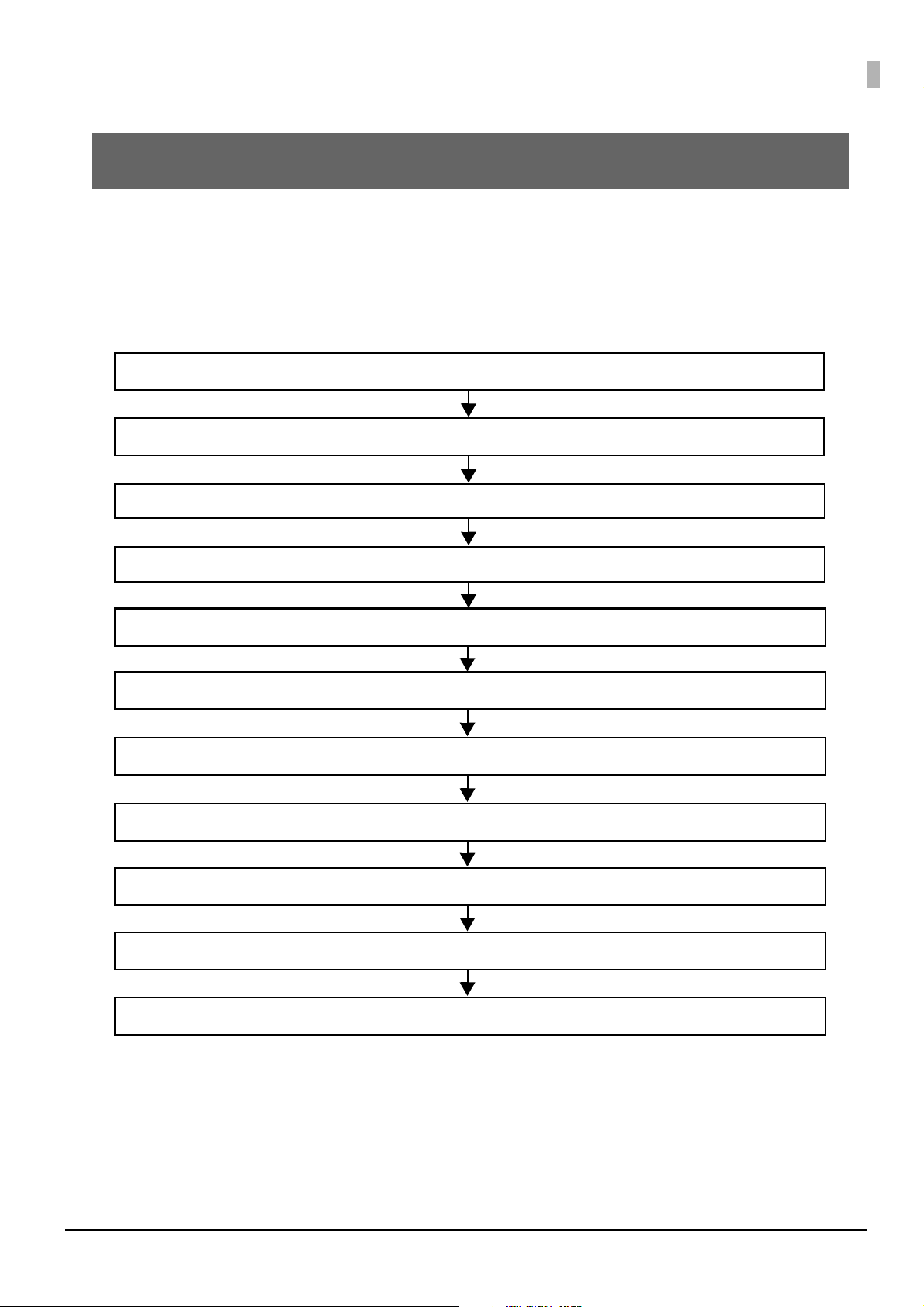

Setup

2. Adjusting the Paper Roll Near-End Sensor (page 31)

5. Connecting the Cash Drawer (page 40)

4. Connecting the Printer to the Host (page 34)

6. Connecting the Optional External Buzzer (page 42)

1. Installing the Printer (page 30)

7. Attaching the Connector Cover (page 44)

8. Arranging the Cables (page 46)

9. Attaching the Power Switch Cover (page 48)

10. Changing the Paper Width (page 49)

3. Connecting the AC adapter (page 33)

11. RTC Settings (page 50)

This chapter describes setup and installation of the product and peripherals.

Flow of Setup

This chapter consists of the following sections along with the setup flow of the product and peripherals.

Chapter 2 Setup

29

Page 30

Chapter 2 Setup

Installing the Printer

You can install this printer horizontally. With an optional hanging bracket (WH-10), you can also attach the

printer to a wall.

Important Notes on Horizontal Installation

• The printer must be installed horizontally on a flat surface (not tilted).

• Do not place the printer in dusty locations.

• Do not catch cables or place foreign matter under the printer.

Important Notes on Wall Hanging

You need to perform the following tasks to install the printer on a wall. For more details, see the installation

manual for the optional wall hanging bracket (WH-10).

• Installing the roll-paper stoppers

• Changing the location of the roll paper near-end sensor

• Attaching the connector cover

• Attaching the wall hanging bracket (WH-10)

For the other notes, see the installation manual for the optional wall hanging bracket (WH-10).

• Be sure to attach the connector cover when you install the printer on a wall using the wall hanging

bracket.

• When installing on a wall using a wall mounting bracket, the status of the wireless signal for the

wireless LAN unit may decline. In this situation, use an extension cable.

30

Page 31

Adjusting the Paper Roll Near-End Sensor

Detection lever

Positioning plate

Adjustment screw

Adjustment screw

Positioning plate

Detection lever

For wall-hanging

For horizontal installation

Knob

Below are two situations where a roll paper NE sensor adjustment is required.

• To adjust the detection position to suit the diameter of the roll paper core used.

• To adjust the detection position of remaining amount of paper.

• Since roll paper cores vary slightly in shape, depending on paper roll design and manufacturing

tolerances, it is impossible to detect the remaining paper exactly.

• To let the NE sensor detect remaining amount of paper accurately, it is recommended to use a roll

paper with a core inner diameter of 12 mm {0.47"} and outer diameter of 18 mm {0.71"}.

• An outer diameter of a paper roll that is detected as near-end varies by usage environment, and/or

paper specifications. Please check operation of the NE sensor by yourself.

Follow the steps below to adjust the roll paper near-end sensor.

Open the roll paper cover, and remove the roll paper.

1

Loosen the adjustment screw fastening the sensor, and then operate the knob to

2

align the top edge of the positioning plate with the upper or lower level.

Chapter 2 Setup

Adjustment position Upper Lower

Outer diameter of a roll to

be detected as near-end

Position of the positioning

plate

Approx. 27 {1.06"} Approx. 23 {0.97"}

31

Page 32

Tighten the adjustment screw.

3

After adjustment, make sure that the detection lever operates smoothly.

4

Chapter 2 Setup

32

Page 33

Connecting the AC adapter

AC adapter

AC cable

Use the Epson PS-180 or an equivalent product as the AC adapter.

• Never insert the AC cable plug into a socket that does not meet the input voltage of the AC

adapter.

WARNING

Connecting the AC adapter

Make sure the printer is turned off.

1

Connect the AC cable to the AC adapter.

2

Doing so may result in damage to the printer.

• Should a fault ever occur, immediately turn off the power to the printer and unplug the AC

cable from the socket.

Chapter 2 Setup

Connect the DC cable of the AC adapter to the power supply connector (stamped

3

24V).

The optional power supply box (OT-BX88VII) is available. You can store the power supply unit in

the box attached to the printer.

33

Page 34

Connecting the Printer to the Host

• Be sure to install the driver before connecting the printer to the host computer.

• The printer uses modular connectors specifically designed for the cash drawer. Do not connect

these connectors to an ordinary telephone line.

USB Interface

When using USB cable to connect with host device, connect the USB cable to the printer, and after starting the

host device, turn the printer on.

• Do not place any weight or stress on the cable when using. Doing so could damage the cable and

connectors.

• Make sure to use a USB 2.0 compliant cable.

• When the printer is connected to an Android device via USB, the connection may be disabled after

changing the printer settings using TM Utility. In that case, restart TM Utility.

Chapter 2 Setup

Ethernet Interface

Use ethernet cable to connect the printer to network via a hub.

Use Epson TM-T88VII Utility for Windows to set network.

For details on Epson TM-T88VII Utility for Windows, refer to TM-T88VII Utility User's Manual.

• When LAN cables are installed outdoors, make sure they are connected through devices that have

surge protection.

Otherwise, the devices can be damaged by lightning.

• Never attempt to connect the drawer kick cable or a standard telephone line cable to the LAN

connector.

As same with Conventional models, you can use WebConfig in the same way.

Start up a web browser and then input the printer's IP address in the address bar.

On the authentication screen, input password as described below.

The default password is the serial number of the printer. You can check the serial number by running a

self-test ("Self-test Mode" on page 71) or on the product ID plate attached to the product.

34

Page 35

Chapter 2 Setup

Wireless LAN Interface (With OT-WL06)

You can connect using a wired cable (LAN/USB), or connect using SimpleAP mode, and setup a wireless LAN

using a network configuration tool. When setting up multiple printers, you can connect using a wired cable

(LAN/USB) and setup a wireless LAN using the Epson Deployment Tool.

Using Epson TM Utility for iOS/Android, you can easily connect the printer to the network from an iOS or

Android devices.

• When using wireless LAN, make sure you disconnect the LAN cable. If a LAN cable is connected,

wireless LAN is disabled.

• When you set up the access point at the same time, set the access point in advance and check that

it operates correctly.

• Examine the radio wave situation in the surrounding area before use.

• Avoid using the same channel that is used in the neighboring shops where Wireless LAN is used.

• Wireless LANs with a frequency band of 2.4 GHz interfere with Bluetooth communication. When

using Bluetooth and Wi-Fi at the same time, we recommend using 5 GHz.

• When using the printer in environments where kitchen microwaves and other devices that may

interfere radio waves are installed, observe the following points.

∗ Keep the printer away from the devices, such as kitchen microwaves, that may cause radio wave

interference.

∗ Use channels that are away from the frequency bands that may cause radio wave interference.

∗ Place shields between the printer and the devices that may cause radio wave interference.

∗ Select either 2.4 GHz or 5 GHz, whichever is free from radio wave interference.

∗ In auto channel setting for the access point, do not select a channel in which the devices may

cause radio wave interference.

For SimpleAP mode, see

"Simple Setup for Wireless LAN" on page 26.

35

Page 36

Setting up from a Windows Computer using SimpleAP

Necessary Items

Prepare the following items.

• Computer for setting: Windows 10/8/7/Vista

Computer equipped with a wireless LAN function

• Utility for setting: Epson TM-T88VII Utility for Windows

Follow the steps below to connect the printer.

Check that the Wireless LAN unit is connected to the printer.

1

Activate SimpleAP on the printer.

2

Check that SSID and QR code is printed. How to activate SimpleAP differs depending on whether network settings have been done or not.

When network settings have Not been done:

The printer activates SimpleAP when it is turned on.

Chapter 2 Setup

After starting the printer, check that the "SimpleAP Start" is printed. If nothing is printed after

70 seconds, you need to enable SimpleAP in interface settings mode.

When network settings have been done:

Activate SimpleAP from the setting menu available after printing the status sheet.

1) Print the status sheet. "Printing a Status Sheet" on page 79

2) Press the Feed button briefly (less than one sec

"SimpleAP mode" is selected in the setting menu.

3) Hold down the Feed button for at least one second.

SimpleAP is activated.

Start TM-T88VII Utility for Windows.

3

The Feed button is disabled when the utility is started.

Connect the printer using SimpleAP.

4

Click [Add port] - [Network] - [Wi-Fi Direct (SimpleAP)], and then add the printer.

When the printer is connected, make the wireless LAN settings.

5

For information about the settings, see TM-T88VII Utility User's Manual.

ond) three times.

When the setting is completed, turn off and back on the printer.

6

36

Page 37

Setting up Using a USB Connection from a Windows Computer

Necessary Items

Prepare the following items.

• Computer for setting: Windows 10/8/7/Vista

• Utility for setting: TM-T88VII Utility for Windows

• USB cable

Follow the steps below to connect the printer.

Connect the printer to a PC via the USB cable.

1

Turn on the host computer.

2

Turn on the printer.

3

Chapter 2 Setup

Start up the TM-T88VII Utility for Windows.

4

When TM-T88VII Utility for Windows starts, the Feed button is disabled.

Select the printer, and then press the [OK] button.

5

If the printer is not displayed, press the "Add Port" button, and then add the printer connected by

USB.

Perform network I/F as well as TCP/IP settings.

6

For details on the settings, see the TM-T88VII Utility User's Manual.

When you have finished making settings, disconnect the USB cable, turn off the

7

printer, and then turn it back on.

37

Page 38

Chapter 2 Setup

Setting up from a Smart Device using Epson TM Utility for iOS/Android

Necessary Items

Prepare the following items.

• Device for setting: iOS or Android device

• Utility for setting: Epson TM Utility for iOS/Android

Run the Epson TM Utility for iOS/Android.

1

Set from “Wi-Fi Setup Wizard” in the menu.

2

Follow the on-screen instructions to complete the settings.

38

Page 39

Chapter 2 Setup

Serial Interface

When connecting to the host computer through a serial interface (RS-232), connect a serial cable to the printer,

start the host computer, and then turn on the printer.

• When using connectors equipped with screws, tighten the screws on both sides to secure the

connectors firmly.

• When using interface cables equipped with a ground line, attach the ground line to the screw hole

marked "FG" on the printer.

Parallel Interface

When connecting to the host computer using a parallel interface, connect the parallel cable to the printer, start

the host computer, and then turn on the printer.

When using interface cables equipped with a ground line, attach the ground line to the screw hole

marked "FG" on the printer.

USB Plus Power Interface

When using a USB Plus Power cable to connect with the host device, connect the flat connector of the USB Plus

Power cable to the printer, and the square connector to the device. After starting the host device, turn the

printer on.

When using USB Plus Power Interface, be careful of the following points.

• Do not connect an AC adapter and USB (Type-B) simultaneously.

• Do not remove or insert the USB Plus Power cable while the printer is still on.

39

Page 40

Chapter 2 Setup

With shielded

Drawer kick connector

Printer side

User side

[Drawer kick side]

Drawer open/

close switch

Drawer kick

solenoid

1

2

3

4

5

6

Connecting the Cash Drawer

• Do not connect both the optional external buzzer and the cash drawer to the printer at the same

time by using a branched connector.

• When the optional external buzzer is enabled with the memory switch (customized values) (see

"Software Settings" on page 59), a cash drawer cannot be used. Be sure to disable it when you use a

cas

h drawer.

• Two driver transistors cannot be energized simultaneously.

• Leave intervals longer than 4 times the drawer driving pulse when sending it continuously.

Cash Drawer Requirements

Specifications of drawers differ depending on makers or models. When you use a drawer other than specified,

make sure its specification meets the following conditions.

Otherwise, devices may be damaged.

• The load, such as a drawer kick solenoid, must be connected between pins 4 and 2 or pins 4 and 5 of the

drawer kick connector.

• When the drawer open/close signal is used, a switch must be provided between drawer kick connector pins 3

and 6.

• The resistance of the load, such as a drawer kick solenoid, must be 24

Ω or more or the input current must be

1A or less.

• Be sure to use the 24V power output on drawer kick connector pin 4 for driving the equipment.

Drawer Connection Diagram

F. G

+24V

Adaptable Connector

RJ12 modular connector

40

Page 41

Pin assignments

Pin number Signal name Direction

1Frame GND -

2 Drawer kick drive signal 1 Output

3 Drawer kick open/close signal Input

4 +24 V -

5 Drawer kick drive signal 2 Output

Chapter 2 Setup

6Signal GND -

6 5 4 3 2 1

Connecting the drawer kick cable

• Use a shield cable for the drawer kick cable.

• When using cash drawer, make sure to use the power supply for printer (connector pins 4).

WARNING

Connect the drawer kick cable to the drawer kick connector by pressing firmly until the connector clicks into

place.

• Do not insert a telephone line into the drawer kick connector.

Doing so may damage the telephone line or printer.

41

Page 42

Chapter 2 Setup

Volume adjustment knob

Connecting the Optional External Buzzer

When the optional external buzzer (model: OT-BZ20) is connected to the drawer kick connector of the printer,

you can set the printer so that it beeps when you send commands, when an error occurs, when executed

autocutting, and when detected paper end. Settings for sound patterns and frequency depending on the

occasions the buzzer beeps are also available.

You need to set with the memory switch (customized values) for buzzer enable/disable setting, sound pattern

setting, and frequency setting. For information about the memory switch (customized values), see "Software

Settings" on page 59.

• Be sure to turn off the printer before you connect/disconnect the optional external buzzer.

• Do not connect both the optional external buzzer and the cash drawer to the printer at the

same time by using a branched connector.

Attachment Position

The optional external buzzer is recommended to be installed in the following positions.

• Do not install the optional external buzzer at the roll paper exit.

• To prevent liquid from entering inside, it is recommended to install the optional external buzzer

so that the volume adjustment knob is positioned sideways or downward.

42

Page 43

Connecting the Optional Wireless LAN Unit

The optional Wireless LAN cable set (OT-WL06) enables you to use the product with a Wi-Fi connection.

For more information, refer to Technical Reference Guide of the Wireless LAN cable set.

• Be sure to turn off the printer when connecting the Wireless LAN unit.

• Depending on the installation conditions of the printer and the routing for cables connected to it,