Page 1

receipt printer

TM-T88/T88P

Operator’s Manual

400644802

Page 2

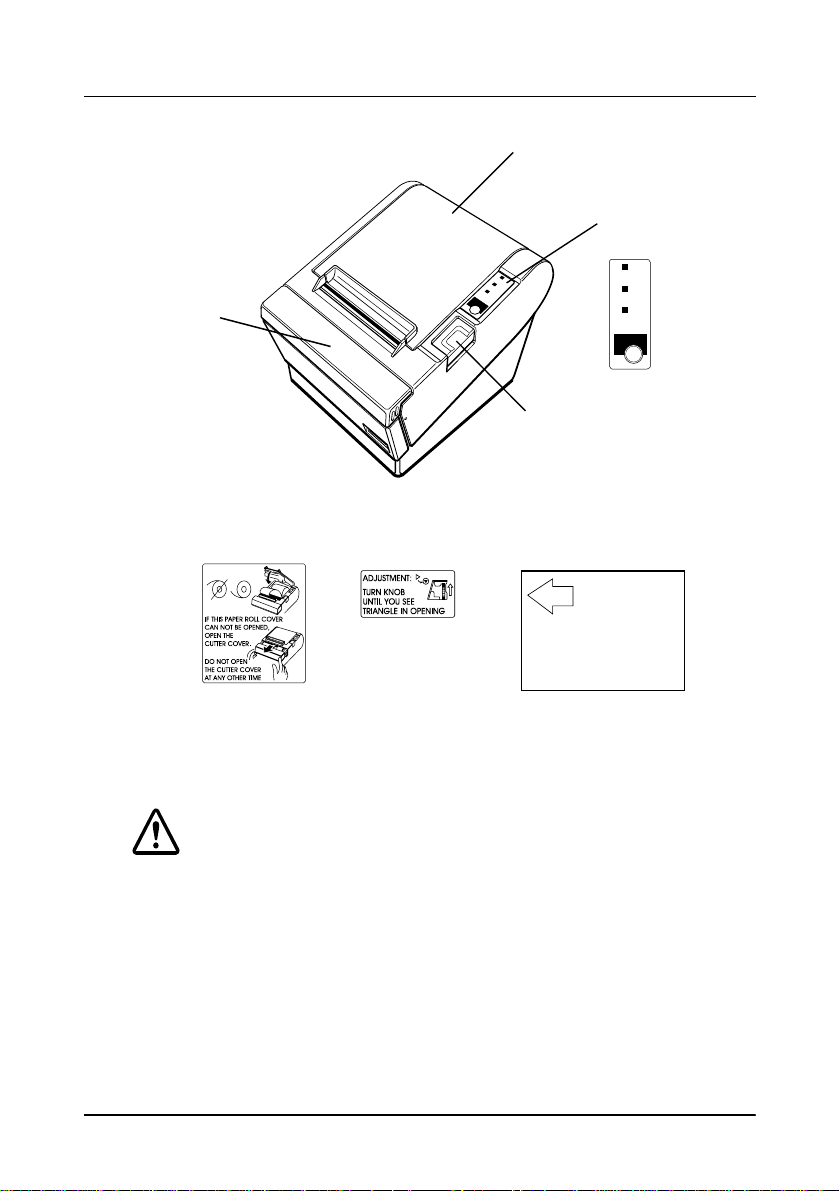

Printer Parts a nd Labels

Slide open this cutter cover

only when paper roll cover

cannot be opened.

Printer cover

Control panel

Cutter cover

Labels

Label inside

printer cover

Label inside

cutter section

POWER

ERROR

PAPER

OUT

FEED

Cover open button

Instruction label

for when cover

won’t open

POWER

ERROR

PAPER

OUT

FEED

Caution label above drawer kick-out connector.

Page 3

Quick Reference

This Quick Reference will direct you to key areas of this Operator’ s

Manual. For a complete listing of topics, see the Contents.

Printer Parts and Labels inside front cover

Ordering Paper page ix

Where to order paper

Setting Up the Printer page 1-1

How to set up the printer.

Installing and Replacing Paper page 1-7

How to load or change the paper roll.

Solving Problems page 3-1

How to correct problems.

Commands page 5-1

Descriptions of all the programming commands.

i

Page 4

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system, or transmitted in any form or by any means, electronic, mecha nical,

photocopying, recording, or otherwise, without the prior written permission of Seiko

Epson Corporation. No patent liability is assumed with respect to the use of the

information contained herein. While every precaution has been taken in the

preparation of this book, Seiko Epson Corporation assumes no responsibility for

errors or omissions. Neither is any liability assumed for damages resulting from the

use of the information contained herein.

Neither Seiko Epson Corporation nor its affiliates shall be liable to the purchaser of

this product or third parties for damages, losses, costs, or expenses incurred by

purchaser or third parties as a result of: accident, misuse, or abuse of this product or

unauthorized modifications, re pairs, or alterations to this product, or (excluding the

U.S.) failure to strictly comply with Seiko Epson Corporation’s operating and

maintenance instructions.

Seiko Epson Corporation shall not be liable against a ny damages or problems arising

from the use of any options or any consumable products other t han those desig nated

as Original Epson Products or Epson Approved Products by Seiko Epson

Corporation.

EPSON and ESC/POS are registered trademarks of Seiko Epson Corporation.

NOTICE: The contents of this manual are subject to change without notice.

Copyright © 1996 by Seiko Epson Corporation, Nagano, Japan.

ii

Page 5

FCC CLASS A

FCC Compliance Statement

For American Users

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interferen ce, in whic h case the user will b e required to

correct the interference at his own expense.

WARNING

The connection of a non- shielded print er interfac e cable to th is printer will i nvalidate

the FCC Verification of this device and may cause interference levels which exceed

the limits established by the FCC for this equipment.

You are cautioned that changes or modifications not expressly approved by the

party responsible for compliance could void your authority to operate the

equipment.

FOR CANADIAN USERS

This Class A digital apparatus meets all requirements of the Canadian Interfer enceCausing Equipment Regulations.

Cet appareil numérique de la classe A respecte toutes les exigenves du Règlement

sur le matériel brouileur du Canada.

GEREÄUSCHPEGEL

Gemäß der Dritten Verordnung zum Gerätesicherheitsgesetz

(Maschinenlärminformations- Verordnung-3. GSGV) ist der arbeitsplatzbezogene

Geräusch-Emissionswert kleiner als 70 dB(A) (basierend auf ISO 7779).

iii

Page 6

DECLARATION OF CONFORMITY

Product Name: Printer

Type Name: 129A

These printers conform to the following Directives and Norms

Directive 89/336/EEC

EN 55022 (1986 and 1994) Class B

EN 50082-1 (1992)

IEC 801-2 (1991)

IEC 801-3 (1984)

IEC 801-4 (1991)

Directive 90/384/EEC

EN45501: (1992)

iv

Page 7

EMI and Safety Standards Applied

The following standards are applied only to the printers that are so

labeled. (EMC is tested using the EPSON PS-170 power supply)

Europe: CE marking

EN55022

EN50082-1

EN45501

Safety Standard: TÜV (EN 60950)

North America: EMI: FCC Class A

Safety standards: UL 1950-2TH-D3

C-UL

Japan: EMI: VCCI Class 1

v

Page 8

About This Manual

Setting Up and Using

❏ Chapter 1 contains information on unpacking the printer and setting it up.

❏ Chapter 2 contains in formation on u sing the printer.

❏ Chapter 3 contains troubleshooting information.

Reference

❏ Chapter 4 contains specifications and character code tables.

❏ Chapter 5 contains the commands.

❏ Appendix A tells how to change the DIP switch and paper near end settings,

and Appendix B lists the EPSON Sales Subsidiaries and their addresses.

Warnings, Cautions, and Notes

WARNING:

Warnings must be followed carefully to avoi d serious bodily

injury.

CAUTION:

Cautions must be observed to avoid minor injury to yourself or

damage to your equipment.

Note:

Notes have important information and useful tips on the op eration of your

printer.

vi

Page 9

Introduction

Features

The TM-T88 and TM-T88P are high-quality POS printers that can print on a paper

roll. The printers have the following features:

Printing

❏ High speed printing: approximately 16.5 lines/second (1/6 inch feed).

❏ Low-noise thermal printing.

❏ High reliability due to a stable mechanism.

Application Software

❏ Command protocol is based on the ESC/POS® standard.

❏ Various layouts are possible by using page mode.

❏ Characters can be scaled up to 64 times as large as the standard size. S m oo thing

is also possible.

❏ Bar code printing is possible by using a bar code command. Bar codes can be

printed both in the vertical direction (fence bar code) and in the horizontal

direction (ladder bar code).

❏ Repeated operation and copy printing are possible by using macro definitions.

❏ Character font size (12 x 24 font or 9 x 24 font) can be selected using a command.

Printer Handling

❏ Easy paper roll loading.

❏ An auto-cutter is st andard.

❏ The printer allows easy maintenance for tasks such as head cleaning.

❏ Four different print densities can be selected by DIP switches.

❏ The built-in interface provides control capability for two drawers.

Introductionvii

Page 10

Options and Accessories

❏ EPSON power supply unit, PS-170.

❏ Affixing tapes (model : DF-10).

❏ RS-485 interface board can be equipped as a dealer option.

❏ Wall hanging bracke t se t (W H-1 0)

viii Introduction

Page 11

Ordering Paper and Supplies

Thermal roll paper can be ordered from the supplier in your area.

Specified Thermal Roll Paper: NTP080-80

In Japan: Nakagawa Seisakujo

2-5-21 Nishiki-Cho Warabi-Shi

Saitama-Ken 335 Japan

Tel: (048) 444-8211

Fax: (048) 443-6652

In U.S.A.: Nakagawa Mfg (USA) Inc.

2305 Lincoln Avenue

Hayward, CA 94545 USA

Tel: (510) 782-0197

Fax: (510) 782-7124

In Europe: Nakagawa Mfg (Europe) GmbH.

Krützpoort 16, 47804

Krefeld, Germany

Tel: 02151-711051

Fax: 02151-713293

In Southeast Asia: N.A.K. Mfg (Malaysia) SDN BHD

Lot 19-11, Bersatu Industrial Complexs,

Jalan Satu, Kaw Per. Cheras Jaya,.

Balakong Industrial Area, 43200 Cheras.

Selangor Darul Ehsan, Malaysia

Tel: 03-9047896, 9047900, 9047691

Fax: 03-9047889

Introduction ix

Page 12

Other Qualified Suppliers for Thermal Paper

The following suppliers sell thermal paper that may be used if

desired. Contact each company for information.

Original paper: TF50KS-E

Nippon Paper Industry Co., Ltd.

1-12-1, Yuraku-Cho, Chiyoda-Ku

Tokyo 100 Japan

Tel: 03-3218-8000

Fax: 03-3216-1375

Original paper: PD 160R

New Oji Paper Mfg. Co., Ltd.

7-5 Ginza 4-Chome Chuo-Ku

Tokyo 104 Japan

Tel: 03-3563-4800

Fax: 03-3563-1136

Original paper: AF50KS-E

Jujo Thermal Oy (Finland)

P.O. Box 92 FIN27501 Kauttua Finland

Original paper: F380

x Introduction

Tel: 38-3932900

Fax: 38-3932419

Kanzaki Specialty Papers, Inc.

Cummings Street

Ware, MA 01082 U.S.A.

Tel: (413)967-6204

Fax: (413) 734-5101

Page 13

Contents

Quick Reference. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Chapter 1 Setting Up the Printer

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Connecting the Cables and Grounding the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Installing or Replacing the Paper Roll . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Using the Power Switch Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Self Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Running the self test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Adjustments and Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Chapter 2 Using the Printer

Operating the Control Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Panel Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Chapter 3 Troubleshooting

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

General problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Printing problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Cleaning the print head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Paper handling problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Auto cutter problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Hexadecimal Dump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

xi

Page 14

Chapter 4 Reference Information

Printing Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Paper Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Electrical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Reliability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Character Code Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Chapter 5 Commands

Command Notation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Control Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Appendix A DIP Switch and Paper Near End Settings

Setting the DIP Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Adjusting the Paper Near End Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

Appendix B EPSON Sales Subsidiaries

xii

Page 15

Chapter 1

Setting Up the Printer

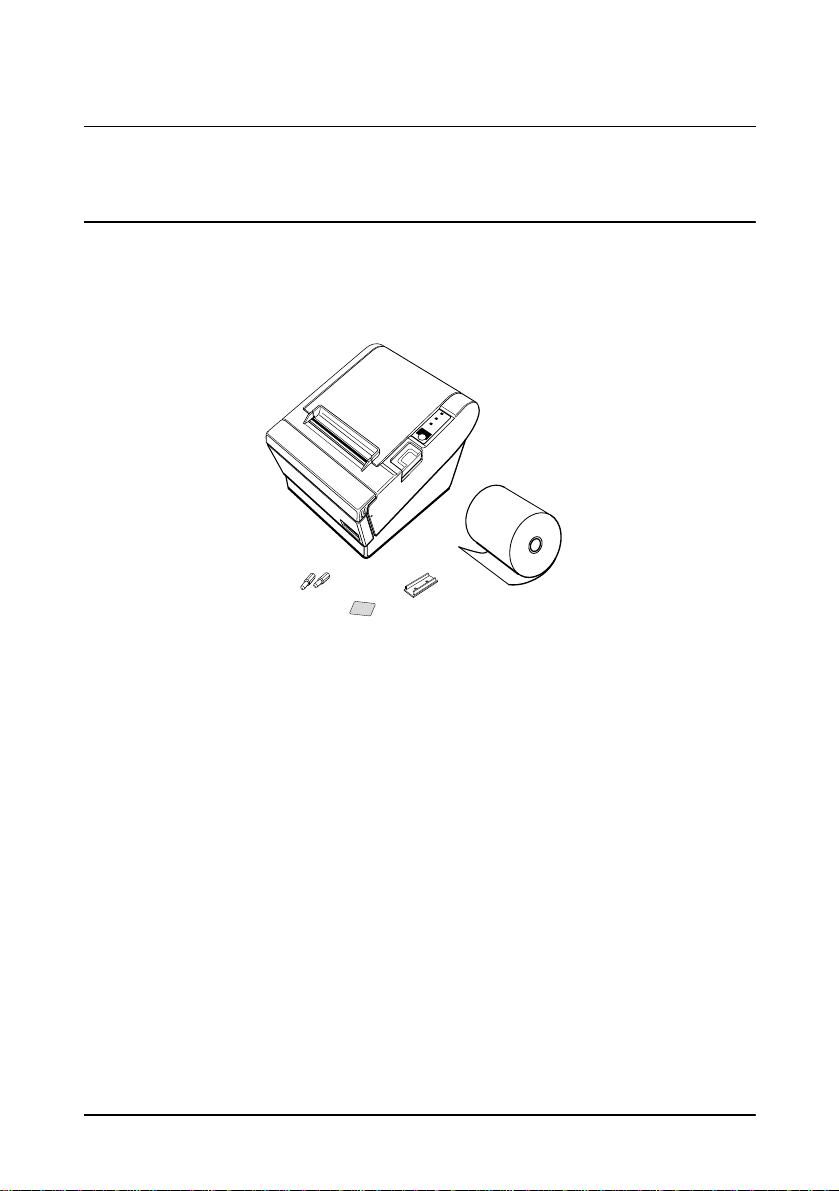

Unpacking

Your printer box should include these items. If any items are

damaged or missing, please contact your dealer for assistance.

Printer

POWER

ERROR

PAPER

OUT

FEED

Paper roll

Hexagonal

lock screws

Switch cover

Instruction label for

when paper roll cover

cannot be opened

See the note on page 1-3 for information abou t the hexag o na l lo ck screws.

Setting Up the Printer 1-1

Page 16

Connecting the Cables and Grounding the Printer

You can connect up to four c ables to the print er. The y a ll connect to

the connector panel on the back of the printer, which is shown

below:

FG

Interface

Grounding screw

FG

Drawer kick-out

DC24V

DK

Power supply

Notes:

There is a caution label above the drawer kick-out connector.

Depending on the interface installed, the interface connector on

your printer may look different from the one illustrated.

Before connecting any of the cables, make sure that both the printer

and the computer are turned off.

Connecting the compu t er

You need an appropriate interface cable.

1. Plug the cable connector securely into the printer’s interface

connector.

2. Tighten the screws on both sides of the cable connector.

1-2 Setting Up the Printer

Page 17

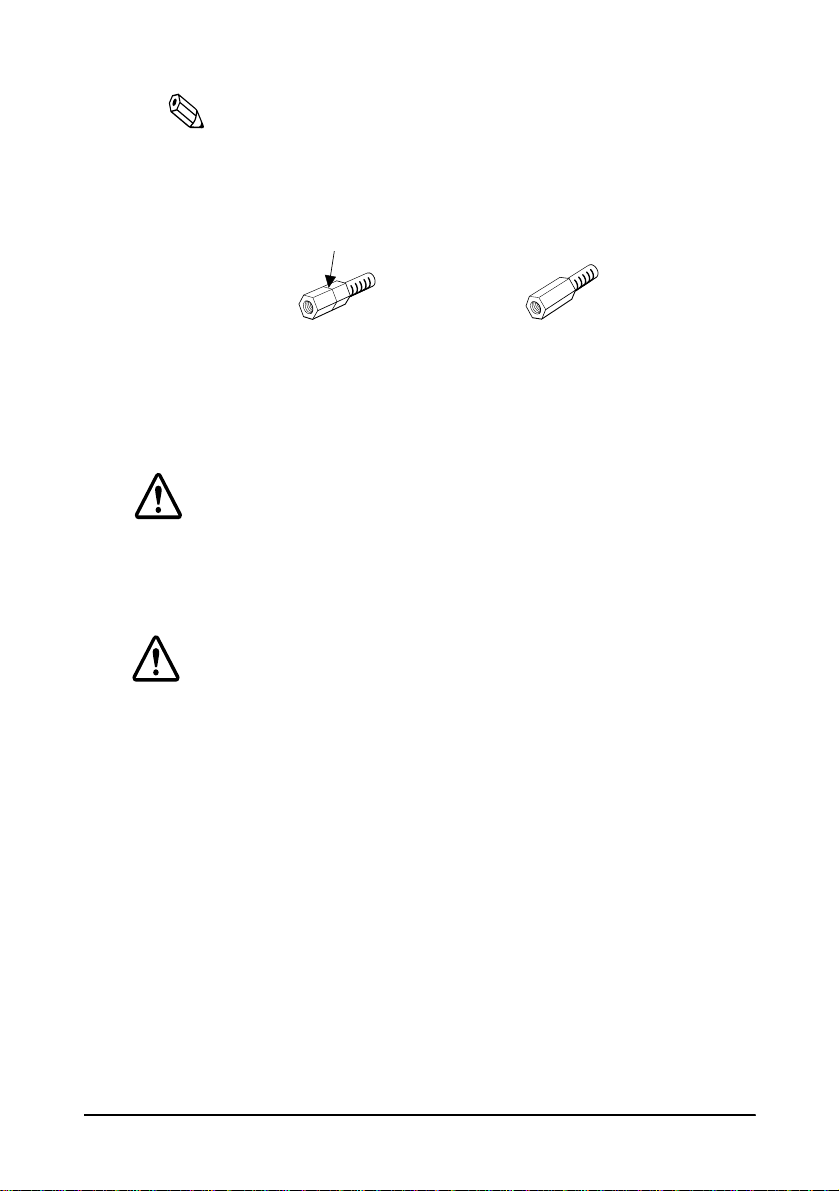

Note:

Your printer has inch-type hexagonal lock screws installed. If

your interface cable requires millimeter-type screws, replace the

inch-type screws with the enclosed millimeter-type screws using

a hex screwdriver (5 mm).

Inch screw

3. Attach the other end of the cable to the computer.

Millimeter screw

Connecting the Drawer

WARNING:

Use a drawer that matches th e prin te r sp eci ficat ion . Usi ng a n

improper drawer may damage the drawer as well as the

printer.

CAUTION:

Do not connect a telephone line to the drawer kick-out

connector; otherwise the printer and the telephone line may

be damaged.

Setting Up the Printer 1-3

Page 18

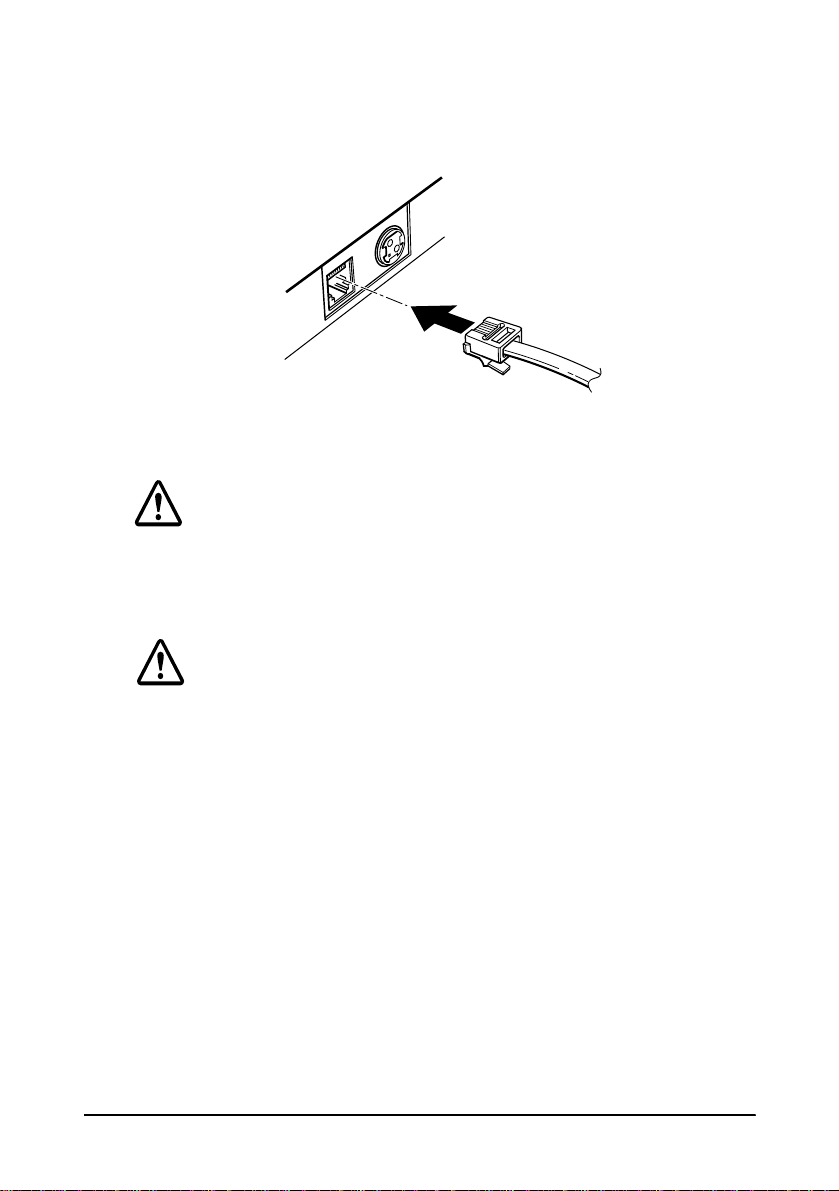

Plug the drawer cable into the drawer kick-out connector on the

back of the printer next to the power supply connector.

Anschließen der Lade

WARNUNG:

Eine für den Drucker geeignete Lade verwenden. Bei

Verwendung einer falschen Lade kann diese oder der

Drucker beschädigt werden.

ACHTUNG:

Kein Telefonkabel an die Schnappsteckerbuchse

anschließen, da sonst der Drucker und die Telef onkabel

beschädigt werden können.

1-4 Setting Up the Printer

Page 19

Das Kabel der Lade an die Schnappsteckerbuchse hinten am

Drucker neben dem Netßzanschluß

anschließen

.

Grounding the Printer

You need a ground wire to ground your printer. Make sure that the

wire is AWG 18 or equivalent.

1. Make sure that the printer is turned off.

2. Connect the ground wire to the printer using one of the the FG

screws on the back of the printer, as shown.

FG

FG

DC24V

DK

Connecting the Power Supply

Use the optional EPSON PS-170 or equivalent power supply for

your printer.

Setting Up the Printer 1-5

Page 20

WARNING:

Make sure that you use the EPSON PS-170 power supply or

equivalent. Usi ng an incorrect power supply may c ause fire or

electrical shock.

CAUTIONS:

When connecting or disconnecting the power supply from

the printer, make sure that the power supply is not plugged

into an electrical outlet. Otherwise you may damage the

power supply or the printer.

If the power supply’s rated voltage and your outlet’s voltage

do not match, contact your dealer for assistance. Do not

plug in the power cord. Otherwise, you may damage the

power supply or the printer.

1. Make sure that the printer’s power switch is turned off, and the

power supply’s power cord is unplugged from the electrical

outlet.

2. Check the label on the power supply to make sure that the

voltage required by the power supply matches that of your

electrical outlet.

3. Plug in the power supply’s cable as shown below. Notice that

the flat side of the plug faces down.

Note:

To remove the DC cable connector, make sure that the power

supply’s power cord is unplugged; then grasp the connector at the

arrow and pull it straight out.

1-6 Setting Up the Printer

Page 21

Installing or Replacing the Paper Roll

Note:

Be sure to use paper rolls that meet the specifications. Do not

use paper rolls that have the paper glued to the core because the

printer cannot detect the paper end correctly.

1. Make sure that the printer is not recei ving data; otherwi se, data

may be lost.

2. Open the paper roll cover by pressi ng the cove r-open butto n. If

the cover-open button will not open the cover, see page 3-4 or

3-6 in Troubleshooting.

POWER

ERROR

PAPER

OUT

FEED

3. Remove the used paper roll core if there is one.

Setting Up the Printer 1-7

Page 22

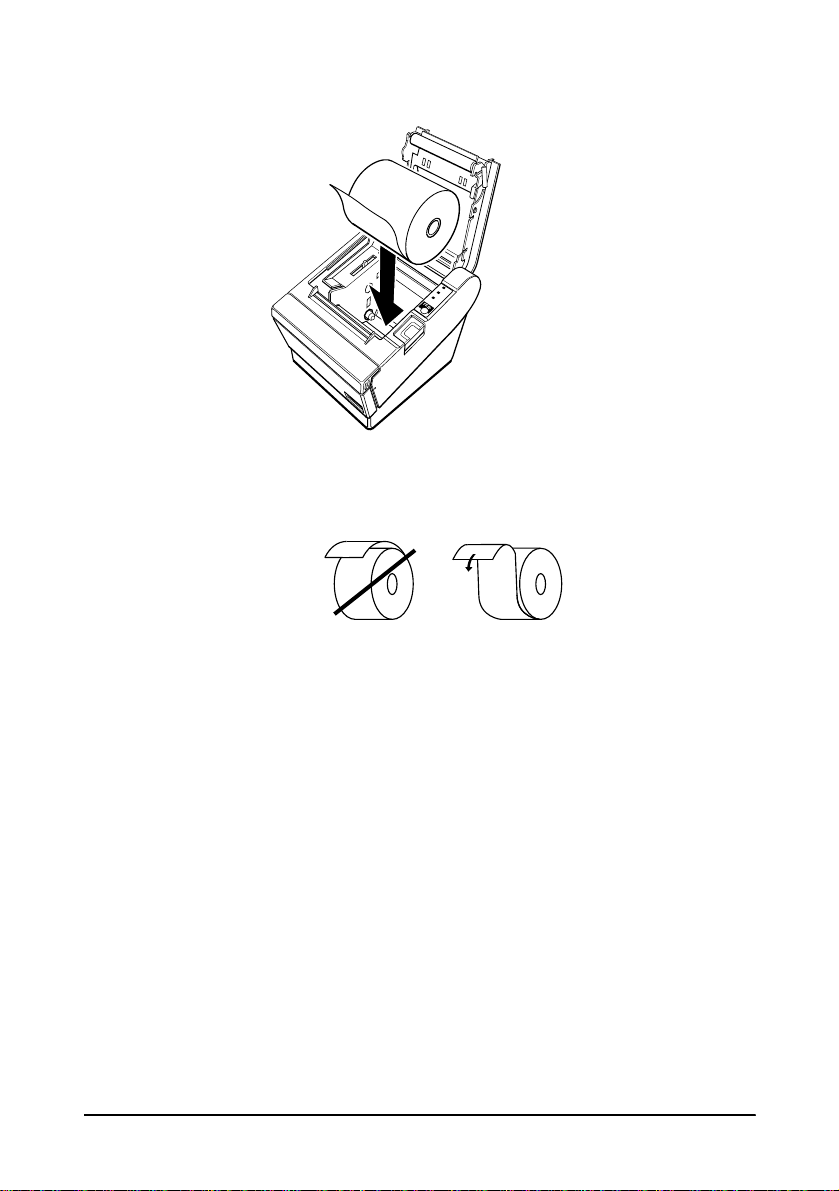

4. Insert the paper roll as shown.

POWER

ERROR

PAPER

OUT

FEED

5. Be sure to note the correct direction that the paper comes off the

roll.

1-8 Setting Up the Printer

Page 23

6. Pull out a small amount of paper, as shown. Then close the

cover.

POWER

ERROR

PAPER

OUT

FEED

7. Tear off the paper as shown.

POWER

ERROR

PAPER

OUT

FEED

Setting Up the Printer 1-9

Page 24

Using the Power Switch Cover

WARNING:

If an accident occurs when the power switch cover is

attached, unplug the power supply cord from the outlet

immediately. Continued usage may lead to fire or shock.

You can use the enclosed power swi tch cove r t o mak e sure that the

power switch is not accidentally pressed. If you want to use this

cover, install it as shown in the illustra tion below.

POWER

ERROR

PAPER

OUT

FEED

Self Test

The self test lets you know if your printer is operating properly. It

checks the control circuits , printer mechanisms, print quality, ROM

version, and DIP switch settin gs.

This test is independent of any other equipment or software.

Running the self test

1. Make sure the printer is turned off and the printer covers are

closed properly.

1-10 Setting Up the Printer

Page 25

2. While holding down the FEED button, turn on the printer using

the switch on the front of the printer to begin the self test. The

self test prints the printer settings and then prints the

following, cuts the paper, and pauses. (The PAPER OUT light

blinks.)

Self test printing.

Please press the PAPER FEED button.

3. Press the FEED button to continue printing. T he print er pri nts a

pattern using the built-in character set.

4. The self test automatically ends and cuts the paper after

printing the following:

*** completed ***

The printer is ready to receive data as soon as it completes the self

test.

Note:

If you want to pause the self test manually, press the FEED

button. Press the FEED button again to continue the self test.

Setting Up the Printer 1-11

Page 26

Adjustments and Settings

The TM-T88/T88P is set up at the factory to be appropriate for

almost all users. It does, however, offer some settings for users with

special requirements.

It has DIP switches that allow you to change communication

settings, such as handshaking and parity check, as well as print

density.

The TM-T88/T88P also has a near-end sensor for the paper. This

can give you a warning when the paper is almost out. If you find

that there is not en ough pap er remai ning on the roll when the nearend detector is triggered, you can change the near-end sensor

setting.

See Appendix A if you need to make any of these changes.

1-12 Setting Up the Printer

Page 27

Using the Printer

Chapter 2

Operating the Control Panels

You can control the basic paper feeding operations of the printer

with the button on the control panel. The indicator lights help you

monitor the printer’s status.

Control Panel

POWER

ERROR

PAPER

OUT

FEED

Button

The button can be disabled by the ESC c 5 command.

Press the FEED button onc e to ad vance pa per one l in e. You ca n also

hold down the FEED button to feed paper continuously.

Using the Printer 2-1

Page 28

Panel lights

POWER

The POWER light is on whenever the printer is on.

ERROR

This indicates an error. See Chapter 3 for informati on on what to do

when this light comes on.

PAPER OUT

This light in dicates the near end of the pape r roll. Install a new

paper roll and the printer will continue pr inting.

When the light blinks, it indicates the self-test printing standby

state or macro execution standby state when the macro execution

command is used.

2-2 Using the Printer

Page 29

Chapter 3

Troubleshooting

Troubleshooting

This chapter gives solutions to so me printer problems you may

have.

General problems

The lights on the control pane l do not come on.

Make sure that the power supply cables are correctly plugged into

the printer, the power unit, and to the pow er outlet.

Make sure that power is s upplied to the power outlet. If the outle t

is controlled by a switch or timer, use another outlet.

Printing problems

The ERROR light is on (not blinking) and nothing is printed.

If the PAPER OUT light is on, the paper roll is not installed or is at

or near the end. Install a new paper roll. See Chapter 1 for

instructions.

If the PAPER OUT light is off, make sure that the printer cover is

properly closed. Press the printer cover until the cover audibly

clicks into place.

The ERROR light is blinking and the printer does not print.

First, turn off the printer and check for a paper jam. (See the paper

jam description on page 3-3.)

Troubleshooting 3-1

Page 30

If there is no paper jam and the printer has been printi ng for quite a

while, the print head may be overheated. If the print head is

overheated, the printer will resume printing when the head has

cooled (usually within two or three minutes).

If there is no paper jam and the print head is not overheated, turn

off the printer and turn it back on after about 10 seconds. If the

ERROR light is still flashing, contact a qualified service person.

The ERROR light is off, but nothing is printed.

Try to run the self test to check that the printer works proper ly. See

the self test instructions in Chapter 1 to run the self test. If the self

test does not work, contact your dealer or a qualified service

person.

If the self test works properly, check the following:

1. Check the connection at both ends of the interface cable

between the printer and the computer. Also make sure that this

cable meets the specifications for both the printer and the

computer.

2. The data transmission settings may be different between the

printer and co mputer. Make sure that the printer’s DIP switch

settings for data transmission are the same as the computer’s.

You can print the printer’s interface settings using the self test.

If the printer still does not print, contact your dealer or a qualified

service person.

Printing is poor.

Paper dust on the heating element of the thermal print head can

lower the pr int quality. Try cleaning the print head as described

below:

3-2 Troubleshooting

Page 31

Cleaning the print head

CAUTIONS:

After printing, the print head can be very hot. Be careful not

to touch it. Also let it cool before you clean it.

Do not damage the print head by touching it with your

fingers or any hard object.

1. Open the printer cover.

2. Clean the thermal element of the print head with a cott on swab

moistened with an alcohol solvent (ethanol, methanol, or IPA).

Radiation plate

Head

Thermal element

Paper handling problems

Paper is jammed inside the printer.

CAUTIONS:

Do not touch the print head because it ca n b e ve ry ho t after

printing continuously for a long time.

Troubleshooting 3-3

Page 32

To clear a paper jam, follow the steps below:

1. Turn the printer off and press the cover open button to open

the cover.

2. Remove the jammed paper and put the roll back in the printer

and close the cover.

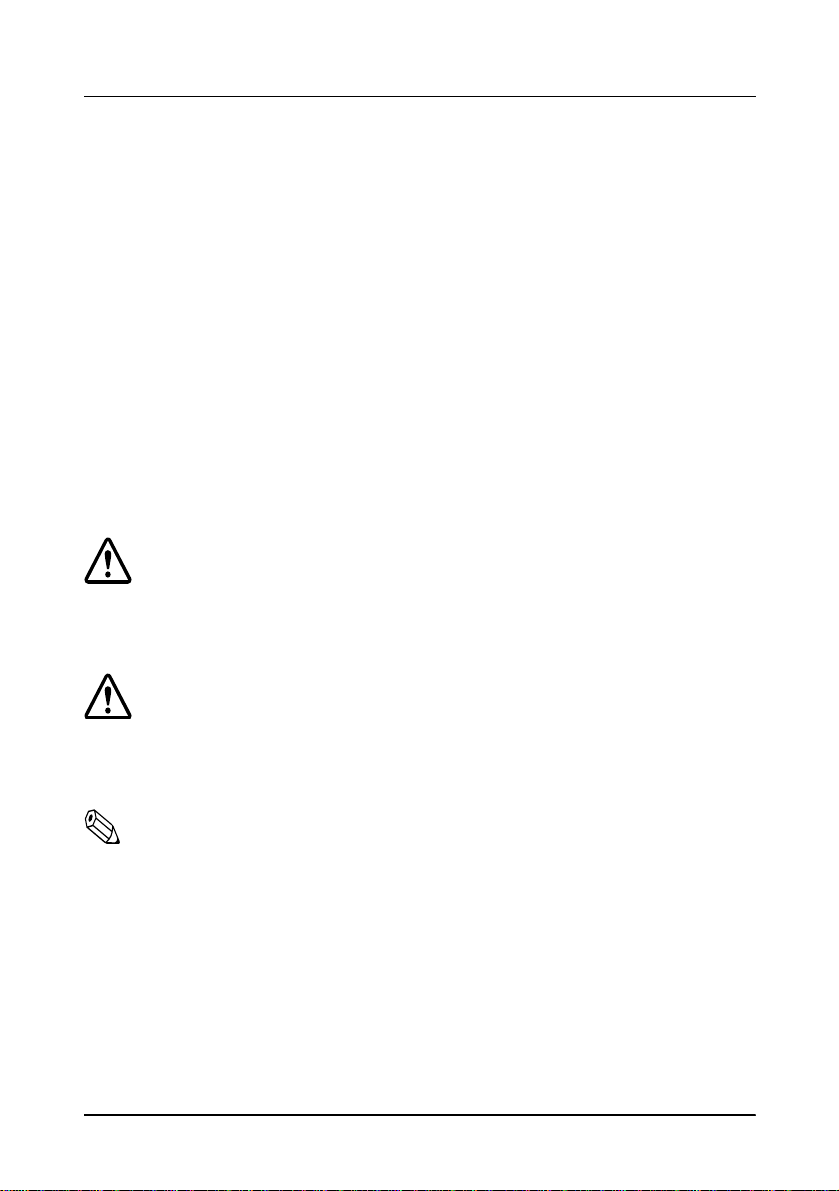

3. If paper is caught in the automatic cutter and the printer cover

cannot be opened, open the cutter cover as shown below.

POWER

ERROR

PAPER

OUT

FEED

3-4 Troubleshooting

Page 33

4. Then turn the knob until you see in the opening, as shown in

the illustrati on below. This returns the cutter bl ade to the

normal position. Also notice that there is a label near the cutter

to assist you.

ADJUSTMENT:

TURN KNOB

UNTIL YOU SEE

TRIANGLE IN OPENING

POWER

ERROR

PAPER

OUT

FEED

5. Close the cutter cover.

6. Open the printer cover.

7. Remove the jammed paper.

Auto cutter problems

The auto cutter is jammed.

If a foreign object such as a push pi n or pap er cli p dro ps in the auto

cutter and causes the auto cutter to lock up, the printer enters an

error state and begins the recovery operation automatically.

If the problem is not serious, the auto cutter returns to its normal

position without any intervention by th e user.

Troubleshooting 3-5

Page 34

If the auto cutter does not return to its normal position by itself,

follow the steps below to corre ct the problem:

1. Pull the cutter cover toward you so that you can rotate the

cutter motor knob.

POWER

ERROR

PAPER

OUT

FEED

2. Following the instructions on the label, rotate the knob until the

appears in the hole.

ADJUSTMENT:

TURN KNOB

UNTIL YOU SEE

TRIANGLE IN OPENING

3. Close the cutter cover.

3-6 Troubleshooting

POWER

ERROR

PAPER

OUT

FEED

Page 35

Hexadecimal Dump

This feature allows experienced users to see exactly what data is

coming to the printer. This can be useful in finding software

problems. When you turn on the hex dump function, the printer

prints all commands and other data in hexadecimal format along

with a guide section to help you find specific commands.

To use the hex dump feature, follow these steps:

1. After you make sure that the printer is off, open the cover.

2. Hold down the FEED button while you turn on the printer.

3. Close the cover.

4. Run any software program that sends data to the printer. The

printer prints “Hexadecimal Dump” and then all the codes it

receives in a two-column format. The first column contains the

hexadecimal codes and the second column gives the ASCII

characters that correspond to the codes.

Hexadecimal Dump

1B 21 00 1B 26 02 40 40 . ! . . & . @ @

1B 25 01 1B 63 34 00 1B . % . . c4 . .

41 42 43 44 45 46 47 48 ABCDEFGH

❏ A period (.) is printed for each code that has no ASCII

equivalent.

❏ During the hex dump all commands except DLE EOT and

DLE ENQ are disabled.

5. Open the cover to set the printer off line so that it will print the

last line.

6. Close the cover and turn of f the printe r or reset i t to turn off the

hex dump mode.

Troubleshooting 3-7

Page 36

Chapter 4

Reference Information

Printing Specifications

Printing method: Thermal line printing

Dot density: 180 dpi

25.4 mm (1”)]

Printing direction: Unidirectional with friction feed

Printing width: 72 mm (2.83”), 512 dot positions

Characters per line

(default):

Character spacing

(default):

Printing speed - High: Approximately 16.5 lines/second

Printing speed - Low: Approximately 11.8 lines/second (1/6”

42 (Font A)

56 (Font B)

0.28 mm (.01”) (2 dots) (Font A)

0.28 mm (.01”) (2 dots) (Font B)

Programmable by control command.

(1/6” inch feed, at 24V, 20° C,

density level 2)

Approximately 70 mm/second

(approximately 2.76”/second)

feed)

Approximately 50 mm/second

(approximately 2.0”/second)

High and low speeds are switched

automatically depending on the voltage

applied to the print er and t he temperat ure

of the environment.

Approximately 28 mm/second

(approximately 1.1”/second) when a

ladder bar code is printed.

×

180 dpi [the number of dots per

Reference Information 4-1

Page 37

Notes:

Printing speed may be slower, depending on the data transmission

speed and the combination of control commands.

The printer switches the mode of the printing speed automatically.

There may be variations in printing after switching the mode of the

printing speed. To prevent this for logo printing, using a

downloaded bit image is recommended. (Change in printing speed

does not occur during downloaded bit image printing).

Paper feeding speed: Approximately 70 mm/second

(approximately 2.76”/second) continuous

printing

Line spacing (default): 4.23 mm (1/6”)

Programmable by control command.

Number of characters: Alphanumeric characters: 95

International characters: 32

Character structure: Font A: 12

4-2 Reference Information

Extended graphics: 128

×

(including one space page)

×

24 (including 2-dot spacing

in horizontal)

Font B: 9

×

24 (including 2-dot spacing in

horizontal)

Font A is the default

7 pages

Page 38

CPL

80±

mm 3.15±

2

4

21

28

Double-width/

Double-height

W x H

(mm)

2.82 x 6.77

(.11” x .27”)

1.98 x 6.77

(.08” x .27”)

Standard Double-height Double-width

W x H

(mm)

Font A

12 x 24

Font B

9 x 24

* CPL = Characters Per Line

* Space between characters is not included

* Characters can be scaled up to 64 times as large as the standard sizes.

1.41 x 3.39

(.06” x .13”)

0.99 x 3.39

(.04” x .13”)

CPL

42

56

W x H

(mm)

1.41 x 6.77

(.06” x .27”)

0.99 x 6.77

(.04” x .27”)

CPL

42

56

W x H

(mm)

2.82 x 3.39

(.11” x .13”)

1.98 x 3.39

(.08” x .13”)

Paper Specifications

Paper roll (single-ply): Size: Width: 79.5 mm ± 0.5 mm

(3.13” ± 0.02”)

CPL

21

28

Maximum

83 mm (3.27”)

outside

diameter:

Paper roll

spool

diameter:

Inside: 12 mm (0.47”)

Outside: 18 mm (0.71”)

Paper must not be pasted

to the paper roll spool.

Take up

paper roll

0.5

1.0

0.0

0.0

width:

Reference Information 4-3

Page 39

Electrical Characteristics

Supply voltag e: +24 VDC ± 7% (optional power supply: EPSON

PS-170)

Current

consumption: (at

24V, except for

drawer kick-out

driving)

Note:

Maximum 1A for drawer kick-out driving

Operating: Mean: approximately 1.5A

Standby: Mean: approximately 0.2A

(character font A α-N, capital

letters, 36-character rolling pat tern,

42 columns printing)

Peak: Approximately 5.0 A

4-4 Reference Information

Page 40

Reliability

Life: Mechanism: 15,000,000 lines

Thermal head: 100 million pulses,

100 km

Auto cutter: 1,000,000 cuts

(End of Life is defined as the point at

which the printer reaches the beginning of

the Wearout Period.)

MTBF: 180,000 hours

(Failure is defined as Random Failure

occurring at the time of the Random

Failure Period.)

MCBF: 37,000,000 lines

(This is an average failure interval based

on failures relating to wearout and

random failures up to the life of 15 mill io n

lines.)

Environmental Conditions

Temperature: Operating: 5° to 45°C (41° to 113°F)

Storage: -10° to 50°C (14° to 122°F)

(except for paper)

Humidity: Operating: 10 to 90% RH

Storage: 10 to 90% RH (except for

paper)

Reference Information 4-5

Page 41

Character Code Tables

The following pages show the character code tables. To find the

character corresponding t o a hexadecimal number, co unt across the

top of the table for the left digit and count down the left column of

the table for the right digit. For example, 4A = J.

Page 0 (PC437: U.S.A., Standard Europe)

(International character set: U.S.A.)

Note:

The character code tables show only which characters are printed.

They do not show the actual print pattern.

4-6 Reference Information

Page 42

Page 1 (Katakana)

Reference Information 4-7

Page 43

Page 2 (PC850: Multilingual)

4-8 Reference Information

Page 44

Page 3 (PC860: Portuguese)

Reference Information 4-9

Page 45

Page 255 (Space Page)

4-12 Reference Information

Page 46

International character set

ASCII code

Country

U. S.A. # $ @[ \

Fr a nce # $ à ° ç § ^ ` é ù è ¨

Germ a ny # $ § Ä Ö Ü ^ ` ä ö ü ß

U.K. £ $ @

Den mark I # $ @ Æ Ø Å ^ ` æ ø å

Swe den # ¤ É Ä Ö Å Ü é ä ö å ü

It a ly # $ @ ° \ é ^ ù à ò è ì

Sp ai n Pt $ @ ¡ Ñ ¿ ^ ` ¨ ñ }

Japan # $ @

Nor way # ¤ É Æ Ø Å Ü é æ ø å ü

Den mar k I I # $ É Æ Ø Å Ü é æ ø å ü

Hex 23 24 40 5B 5C 5D 5E 60 7B 7C 7D 7E

Dec 35 36 64 91 92 93 94 96 123 124 125 126

^` { ¦ }

]

\

[

¥

[

^` { ¦ }

]

^` { ¦ }

]

~

~

~

~

~

Reference Information 4-13

Page 47

Chapter 5

Commands

Command Notation

[Name] The name of the command.

[Format] The code sequence.

[Range] Gives the allowable ranges for the arguments.

[Description] Describes the function of the command.

Explanation of Terms

LSB Least Significant Bit

Control Commands

HT

[Name] Horizontal tab

[Format] ASCII HT

[Description] Moves the print position to the next horizontal tab position.

ASCII indicates the ASCII equivalents.

Hex indicates the hexadecimal equivalents.

Decimal indicates the decimal equivalents.

[ ]k indicates the contents of the [ ] should be repeated k times.

Hex 09

Decimal 9

LF

[Name] Print and line feed

[Format] ASCII LF

Hex 0A

Decimal 10

[Description] Prints the data in the print buffer an d f eeds o ne line based on the current

line spacing.

Commands 5-1

Page 48

FF

[Name] Print and return to standard mode (in page mode)

[Format] ASCII FF

Hex 0C

Decimal 12

[Description] In page mode, prints the data in the print buffer collectively and returns

to standard mo de .

CR

[Name] Print and carriage return

[Format] ASCII CR

Hex 0D

Decimal 13

[Description]

Paper

Paper roll Functions as same as LF Ignored

When automatic line feed

enabled

• This comma nd is se t acc ording to the DIP switch 1-1 setting at

power-on or re setting the pr inter with a para llel interface .

Automatic line feed disabled

CAN

[Name] Cancel print data in page mode

[Format] ASCII CAN

Hex 18

Decimal 24

[Description] In page mode, deletes all the print data in the current printable area.

DLE EOT

[Name] Real-time stat us tr an sm ission

[Format] ASCII DLE EOT

[Range] 1 ≤ n ≤ 4

n

Hex 10 04

Decimal 16 4

n

n

n

5-2 Commands

Page 49

[Description] Transmits the selected printer status specified by n in real time, according

to the following parameters:

n

= 1: Transmit printer status

n

= 2: Transmit off-line status

n

= 3: Transmit error status

n

= 4: Transmit paper roll sensor status

DLE ENQ

[Name] Real-time request t o prin t er

[Format] ASCII DLE ENQ

[Range] 1 ≤ n ≤ 2

[Description] Responds to a request from the host computer. n specifies the request as

nRequest

1 Recover from an error and restart printing from the line where the error occurred

2 Recover from an error after clearing the receive and print buffers

n

Hex 10 05

Decimal 16 5

follows:

n

n

n

ESC FF

[Name] Print data in page mode

[Format] ASCII ESC FF

Hex 1B 0C

Decimal 27 12

[Description] In p a g e mode, prints all b u ffe re d data in the prin ting area collectively.

ESC SP

[Name] Set right-side character spacing

[Format] ASCII ESC SP

[Range] 0 ≤ n ≤ 255

[Description] Sets the character spacing for the right side of the character to [n ×

n

Hex 1B 20

Decimal 27 32

horizontal or vertical motion units].

n

n

n

Commands 5-3

Page 50

ESC !

n

[Name] Select print mode(s)

[Format] ASCII ESC !

Hex 1B 21

Decimal 27 33

[Range] 0 ≤ n ≤ 255

[Description] Selects print mode(s) using n as follows:

Bit Off/On Hex Decimal Function

Off 00 0 Character font A (12 x 24).

0

On 01 1 Character font B (9 x 24).

1, 2 - - - Undefined.

Off 00 0 Emphasized mode not selected.

3

On 08 8 Emphasized mode selected.

Off 00 0 Double-height mode not selected.

4

On 10 16 Double-height mode selected.

Off 00 0 Double-width mode not selected.

5

On 20 32 Double-width mode selected.

6 - - - Undefined.

Off 00 0 Underline mode not selected.

7

On 80 128 Underline mod e selected.

n

n

n

• Determine the values of n by adding the values of all the

characteristics you w an t to se le c t .

ESC $

n

L nH

[Name] Set absolute print position

[Format] ASCII ESC $

Hex 1B 24

Decimal 27 36

0 ≤

n

n

≤ 255

L

≤ 255

H

[Range] 0 ≤

[Description] Sets the print starting position from the beginning of the line.

• The distance from the beginning of the line to the print

n

n

+

position is [(

× 256) × (vertical or horizontal motion

L

H

unit)].

5-4 Commands

n

n

n

L nH

L nH

L nH

Page 51

ESC %

[Name] Select/cancel user-defined character set

[Format] ASCII ESC %

[Range] 0 ≤ n ≤ 255

[Description] Selects or cancels the user-defined character set.

n

Hex 1B 25

Decimal 27 37

• When the LSB is 0, the user-defined character set is canceled

and the internal char act er se t is se le cted.

• When the LSB is 1, the user-defined character set is selected.

n

n

n

ESC &

[Name] Define user-define d ch ara ct ers

[Format] ASCII ESC &

[Range]

[Description] Defines user-defined characters.

y c1 c2 [x1 d1...d(y

Hex 1B 26

Decimal 27 38

y

= 3

32 ≤ c1 ≤ c2 ≤ 126

0 ≤ x ≤ 12 Font A (12 × 24)

0 ≤ x ≤ 9 Font B (9 × 24)

0 ≤

d1 ... d(y

×

xk)

×

x1)]...[xk d1...d(y × xk)]

y c1 c2 [x1 d1...d(y

[xk d1...d(y

y c1 c2 [x1 d1...d(y

[xk d1...d(y

y c1 c2 [x1 d1...d(y

[xk d1...d(y

≤ 255

•y specifies the number of bytes in the vertical direction.

•c1 specifies the beginning character code for the definition, and

c2

specifies the final code.

•x specifies the number of dots in the horizontal direction.

•d is the dot data for the characters. The dot pattern is in the

horizontal direction from the left side. Any remaining dots on

the right side are blank.

• The allowab le character code rang e is from ASCII code

20H(32) to 7EH(126).

• The data to defi ne a use r-defined character is

(y × x) bytes.

• Set a corresponding bit to 1 to print a dot o r 0 to not print a do t.

×

x1)]...

xk)]

×

x1)]...

×

xk)]

×

×

x1)]...

xk)]

×

Commands 5-5

Page 52

m n

L nH

d1 ...

dk

ESC ✻

[Name] Select bit -image mode

[Format] ASCII ESC *

Hex 1B 2A

Decimal 27 42

n

L

n

H

m

≤ 255

≤ 3

= 0, 1, 32, 33

[Range]

0 ≤

0 ≤

m n

m n

m n

L nH

L nH

L nH

d1 ...

d1 ...

d1 ...

k

k

k

0 ≤ d ≤ 255

[Description] Selects a bit-image mode using m for the number of dots specified by

n

n

and

L

mMode

0 8-dot single-density 8 60 DPI 90 DPI n

1 8-dot double-density 8 60 DPI 180 DPI n

32 24-dot single-density 24 180 DPI 90 DPI (n

33 24-dot double-density 24 180 DPI 180 DPI (n

, as follows:

H

•The

Vertical Direction Horizontal direction

n

and

L

Number of

Dots

n

indicate the number of dots of the bit image in

H

Dot

Density

Dot

Density

Number of Data

(K)

L

+ nH × 256

L

+ nH × 256

L

+ nH × 256) × 3

L

+ nH × 256) × 3

the horizontal direction. The number of dots is calculated by

n

n

+

× 256.

L

H

• If the bit-image data input exceeds the number of dots to be

printed on a line , t he e xcess data is ignored.

•d indicates the bit-image data. Set a corresponding bit to 1 to

print a dot or to 0 to not print a dot.

ESC - n

[Name] Turn underl in e mode on/off

[Format] ASCII ESC -

Hex 1B 2D

Decimal 27 45

n

n

n

[Range] 0 ≤ n ≤ 2, 48 ≤ n ≤ 50

[Description] Turns under line mode on or off, based on th e fo llowing values of n:

n Function

0, 48 Turns off underline mode

1, 49 Turns on underline mode (1-dot thick)

2, 50 Turns on underline mode (2-dots thick)

5-6 Commands

Page 53

ESC 2

[Name] Select default line spacing

[Format] ASCII ESC 2

Hex 1B 32

Decimal 27 50

[Description] Sets the line spacing to 1/6 inch.

ESC 3

n

[Name] Set line spacing

[Format] ASCII ESC 3

Hex 1B 33

Decimal 27 51

[Range] 0 ≤ n ≤ 255

[Description] Sets the line spacing to [n × vertical or horizontal motion unit].

ESC =

n

[Name] Set peripheral device

[Format] ASCII ESC =

Hex 1B 3D

Decimal 27 61

[Range] 1 ≤ n ≤ 255

[Description] Selects device to which host computer sends data, using n as follows:

Bit Off/On Hex Decimal Function

Off 00 0 Printer disabled.

0

On 01 1 Printer enabled

1-7 - - - Undefined.

n

n

n

n

n

n

ESC ?

n

[Name] Cancel user-defined characters

[Format] ASCII ESC ?

Hex 1B 3F

Decimal 27 63

[Range] 32 ≤ n ≤ 126

[Description] Cancels user-defined characters.

n

n

n

ESC @

[Name] Initialize printer

[Format] ASCII ESC @

Hex 1B 40

Decimal 27 64

[Description] Clears the data in the print buffer and resets the printer mode to the

mode that was in effect wh en t he p ow e r was turned on.

Commands 5-7

Page 54

ESC D n1 ... nk NUL

[Name] Set horizontal tab positions

[Format] ASCII ESC D

Hex 1B 44

Decimal 27 68

[Range] 1 ≤ n ≤ 255

0≤ k ≤ 32

[Description] Sets horizontal tab posit io n s.

•n specifies the column number for setting a horizontal tab

position from the beginning of the line.

•k indicates the total n umber of horizontal tab positi on s t o b e

set.

ESC E

n

[Name] Turn emphasized mode on/off

[Format] ASCII ESC E

Hex 1B 45

Decimal 27 69

[Range] 0 ≤ n ≤ 255

[Description] Turns emphasized mode on or off

• When the LSB is 0, emphasized mode is turned off.

• When the LSB is 1, emphasized mode is turned on.

ESC G

[Name] Turn double-strike mode on/off

[Format] ASCII ESC G

[Range] 0 ≤ n ≤ 255

[Description] Turns double -strike mode on or off.

ESC J

[Name] Print and feed paper

[Format] ASCII ESC J

[Range] 0 ≤ n ≤ 255

[Description] Prints the data in the pri nt b u ffe r an d fe eds t h e pape r n × vertical or

n

Hex 1B 47

Decimal 27 71

• When the LSB is 0, double-strike mode is tur ned off.

• When the LS B is 1, double-strike mode is turned on.

n

Hex 1B 4A

Decimal 27 74

horizontal motion unit.

n

1 ... nkNUL

n

1 ... nk00

n

1 ... nk0

n

n

n

n

n

n

n

n

n

5-8 Commands

Page 55

ESC L

[Name] Select page mode

[Format] ASCII ESC L

Hex 1B 4C

Decimal 27 76

[Description] Switches from st an d ard mode to page mode.

ESC R

n

[Name] Select an intern at ion al character set

[Format] ASCII ESC R

Hex 1B 52

Decimal 27 82

[Range] 0 ≤ n ≤ 10

[Description] Selects an in t e rnational character set n from the following t able:

nCharacter set

0 U.S.A.

1France

2Germany

3U.K.

4Denmark I

5 Sweden

6Italy

7 Spain

8 Japan

9 Norway

10 Denmark II

n

n

n

ESC S

[Name] Select standard mode

[Format] ASCII ESC S

Hex 1B 53

Decimal 27 83

[Description] Switches from page mode to standard mode.

ESC T

n

[Name] Select print direction in page mode

[Format] ASCII ESC T

Hex 1B 54

Decimal 27 84

[Range] 0 ≤ n ≤ 3

48 ≤ n ≤ 51

[Description] Selects the print direction and starting position in page mode.

n

n

n

Commands 5-9

Page 56

n

specifies the print direction an d starting position as follows:

n Print Direction Starting Position

0, 48 Left to right Upper left

1, 49 Bottom to top Lower left

2, 50 Right to left Lower right

3, 51 Top to bottom Upper right

ESC V

n

[Name] Turn 90° clockwise rotation mode on/off

[Format] ASCII ESC V

Hex 1B 56

Decimal 27 86

n

n

n

[Range] n = 0, 1, 48, 49

[Description] Turns 90° clockwise rotation mode on/off

n

is used as follows:

n Function

0, 48 Turns off 90° clockwise rotation mode

1, 49 Turns on 90° clockwise rotation mode

ESC W

L xH yL yH

x

dxL dxH dyL dy

H

[Name] Set printing area in page mode

[Format] ASC II ESC W

Hex 1B 57

Decimal 27 87

x

, xH, yL, yH, dxL, dxH, dyL, dy

[Range] 0 ≤

L

(except

dx

=dxH=0 or dyL=dyH=

L

H

0)

x

L xH yL yH

x

L xH yL yH

x

L xH yL yH

≤ 255

dxL dxH dyL dy

dxL dxH dyL dy

dxL dxH dyL dy

H

H

H

[Description] • The horizontal starting position, vertical starting position,

printing area width, and prin ting a rea h eight are defin ed as x0 ,

y0, dx, dy, respectively.

Each setting for the printing area is calculated as fol lows:

x

x

L

H

+

x0 = [(

y0 = [(

dx = [

dy = [

( 256) × (horizontal motion unit)]

y

y

L

H

+

( 256) × (vertical mo t ion unit)]

dx

dx

L

H

+

( 256) × (horizontal motion unit)]

dy

dy

L

H

+

( 256) × (vertical motion unit)]

5-10 Commands

Page 57

ESC \

nL nH

[Name] Set relative print position

n

n

n

L nH

L nH

L nH

[Format] ASCII ESC \

Hex 1B 5C

Decimal 27 92

n

[Range] 0 ≤

0 ≤

L

n

H

≤ 255

≤ 255

[Description] Sets the print starting position based on the current position.

• This command set s th e di st ance from the current pos it ion to [(

n

H

× 256) × horizontal or vertical motion unit]

ESC a

n

[Name] Select justification

[Format] ASCII ESC a

Hex 1B 61

Decimal 27 97

n

n

n

[Range] 0 ≤ n ≤ 2, 48 ≤ n ≤ 50

[Description] Aligns all the data in one lin e to t h e specified position

n

selects the justifica t ion as follows

n Justification

0, 48 Left justification

1, 49 Center i ng

2, 50 Right justification

:

n

L

+

ESC c 3

n

[Name] Select paper sensor(s) to output paper end signals

[Format] ASCII ESC c 3

Hex 1B 63 33

Decimal 27 99 51

n

n

n

[Range] 0 ≤ n ≤ 255

[Description] Selects the paper sensor(s) to output paper end signals

This command is available only with a parallel inte rface and is ignored with ser ial

interface.

• Each bit of n is used as follows:

Bit Off/On Hex Decimal Function

Off 00 0 Paper roll near-end sensor disabled.

0

On 01 1 Paper roll near-end sensor enabled.

Off 00 0 Paper roll near-end sensor disabled.

1

On 02 2 Paper roll near-end sensor enabled.

Commands 5-11

Page 58

Bit Off/On Hex Decimal Function

Off 00 0 Paper roll end sensor disabled.

2

On 04 4 Paper roll end sensor enabled.

Off 00 0 Paper roll end sensor disabled.

3

On 08 8 Paper roll end sensor enabled.

4-7 - - - Undefined.

ESC c 4

n

[Name] Select paper sensor(s) to stop printing

[Format] ASCII ESC c 4

Hex 1B 63 34

Decimal 27 99 52

n

n

n

[Range] 0 ≤ n ≤ 255

[Description] Selects the paper sensor(s) used to stop printing when a paper-end is

detected, using n as follows:

Bit Off/On Hex Decimal Function

Off 00 0 Paper roll near-end sensor disabled.

0

On 01 1 Paper roll near-end sensor enabled.

Off 00 0 Paper roll near-end sensor disabled.

1

On 02 2 Paper roll near-end sensor enabled.

2-7 - - - Undefined.

ESC c 5

n

[Name] Enable/disa b le pan e l buttons

[Format] ASCII ESC c 5

Hex 1B 63 35

Decimal 27 99 53

n

n

n

[Range] 0 ≤ n ≤ 255

[Description] Enables or disables the panel buttons.

• When the LSB is 0, the panel buttons are enabled.

• When the LSB is 1, the panel buttons are disabled.

ESC d

n

[Name] Print and feed n lines

[Format] ASCII ESC d

Hex 1B 64

Decimal 27 100

n

n

n

[Range] 0 ≤ n ≤ 255

[Description] Prints the dat a in th e pri nt b uffe r an d feeds n lines.

5-12 Commands

Page 59

ESC p

m t1 t2

[Name] Generate pulse

[Format] ASCII ESC p

Hex 1B 70

Decimal 27 112

[Range]

m

= 0, 1, 48, 49

mt1 t2

mt1 t2

mt1 t2

0 ≤ t1 ≤ 255, 0≤ t2 ≤ 255

[Description] Outputs the pulse specified by t1 and t2 to connector pin m as follows:

m Connector pin

0, 48 Drawer kick-out connector pin 2.

1, 49 Drawer kick-out connector pin 5.

ESC t

n

[Name] Select character code table

[Format] ASCII ESC t

Hex 1B 74

Decimal 27 116

n

n

n

[Range] 0 ≤ n ≤ 5, n = 255

[Description] Selects a page n from the character code table.

nPage

0 0 (PC437 [U.S.A., Standard Eutope])

1 1 (Katakana)

2 2 (PC850 [Multilingual])

3 3 (PC860 [Portuguese])

4 4 (PC863 [Canadian-French])

5 5 (PC865 [Nordic])

255 Space page

Commands 5-13

Page 60

ESC {

n

[Name] Turns upside-do wn printing mode on/off

[Format] ASCII ESC {

Hex 1B 7B

Decimal 27 123

n

n

n

[Range] 0 ≤ n ≤ 255

[Description] Turns upside-d own printing mode on or off.

• When the LSB is 0, upsid e -down printing mode is turned off.

• When the LSB is 1, upside-down printing mode is turned on.

GS !

n

[Name] Select charac ter size

[Format] ASCII GS !

Hex 1D 21

Decimal 29 33

n

n

n

[Range] 0 ≤ n ≤ 255

(1 ≤ vertical number of times ≤ 8, 1 ≤ horizontal number of tim e s ≤ 8)

[Description] Selects the character height using bits 0 to 2 and se le ct s t h e character

width using bits 4 to 7, as foll ows:

Bit Off/On Hex Decimal Function

0

1

Character height selection. See Table 2.

2

3

4

5

Character width selection. See Table 1.

6

7

Table 1

Character Width Selection

Hex Decimal Width Hex Decimal Height

00 0 1 (normal) 00 0 1(normal)

10 16 2 (dou bl e-w idt h) 01 1 2 (double-height)

20 32 3 02 2 3

30 48 4 03 3 4

Table 2

Character Height Selection

5-14 Commands

Page 61

Table 1

Character Width Selection

Hex Decimal Width Hex Decimal Height

40 64 5 04 4 5

50 80 6 05 5 6

60 96 7 06 6 7

70 112 8 07 7 8

GS $

L nH

n

Table 2

Character Height Selection

[Name] Set absolute vertical print position in page mode

n

[Format] ASCII GS $

Hex 1D 24

Decimal 29 36

[Range] 0 ≤

n

≤ 255, 0 ≤

L

n

≤ 255

H

L nH

n

L nH

n

L nH

[Description] • Sets the absolute vert ic al print starting position for buffer

character data in page mode .

n

n

• This command sets the absolute print position to [(

+

L

256) × (vertical or horizontal motion unit)] in ches.

×

H

GS ✻

... d(x × y × 8)

x y d1

[Name] Define downloaded bit-image

[Format] ASCII GS *

Hex 1D 2A

Decimal 29 42

x y d1 ... d(x

x y d1 ... d(x

x y d1 ... d(x

× y × 8)

× y × 8)

× y × 8)

[Range]

1 ≤ x ≤ 255

1 ≤ y ≤ 48

0 ≤ d ≤ 255

[Description] Defines a downloaded bit-image using the number of dots specified

by x and

y

• The number of dots in the horizontal dire ction is x × 8 .

• The number of dots in the vertical direction y × 8.

•If x × y is out of the specified range, this command is ignored.

•The d indicates bit-image data. Data (d) specifies a bit printed

to 1 and not printed to 0.

• After a downloaded bit-image is de f i ned, it is availab le until

ESC @ or ESC & is executed; the printer is reset; or the power

is turned off.

Commands 5-15

Page 62

GS /

m

[Name] Print downloaded bit-image

[Format] ASCII GS /

Hex 1D 2F

Decimal 29 47

m

m

m

[Range] 0 ≤ m ≤ 3, 48 ≤ m ≤ 51

[Description] Prints a downloaded bit -im age using the mode specified by m.

m

selects a mode from the tab le b elow:

m Mode Vertical Dot Density (DPI) Horizontal Dot Density (DPI)

0, 48

1, 49

2, 50

3, 51

Normal

Double-width

Double-height

Quadruple

180

180

90

90

180

90

180

90

GS :

[Name] Start/end macro definition

[Format] ASCII GS :

Hex 1D 3A

Decimal 29 58

[Description] Starts or ends macro definition.

GS B

n

[Name] Turn white/black reverse printing mod e on /off

[Format] ASCII GS B

Hex 1D 42

Decimal 29 66

[Range] 0 ≤ n ≤ 255

[Description] Turns on or off white/black reverse p rinting mode.

• When the LSB is 0, white/black rev e rse mode is turned off.

• When the LSB is 1, white/black rev e rse mode is turned on.

n

n

n

GS H

n

[Name] Select printing position of HRI characters

[Format] ASCII GS H

Hex 1D 48

Decimal 29 72

n

n

n

[Range] 0 ≤ n ≤ 3, 48 ≤ n ≤ 51

[Description] Selects the printing position of HRI characters when printing a bar code.

5-16 Commands

Page 63

n

selects the printing position as follows:

n Printing posiition

0, 48 Not printed.

1, 49 Above bar code.

2, 50 Belo w bar code.

3, 51 Both above and below the bar code.

• HRI indicates Human Readable Interpretation.

GS I

n

[Name] Transmit printer ID

[Format] ASCII GS I

Hex 1D 49

Decimal 29 73

n

n

n

[Range] 1 ≤ n ≤ 3, 49 ≤ n ≤ 51

[Description] Transmits the printer ID specified by n as follows:

n Printer ID Specification ID (hexidecimal)

1, 49 Printer model ID TM-T88/T88P 20

2, 50 Type ID See table below.

3, 51 ROM version ID Depends on ROM version.

n

=2, Type ID

Bit Off/On Hex Decimal Function

0 Off 00 0 Two-byte character code not supported.

1 On 02 2 Auto-cutter equipped.

2, 3 - - - Undefined

4 Off 00 0 Not used. Fixed to Off.

5, 6 - - - Undefined.

7 Off 00 0 Not used. Fixed to Off.

GS L

L nH

n

[Name] Set left margin

[Format] ASCII GS L

Hex 1D 4C

Decimal 29 76

0 ≤

n

n

≤ 255

L

≤ 255

H

[Range] 0 ≤

n

L

n

L

n

L

n

H

n

H

n

H

Commands 5-17

Page 64

n

[Description] Sets the left margin using

• The left margin is set to [(

and

L

n

in standard mode.

H

n

n

+

× 256) × horizontal motion

L

H

unit)] from the beginning of the line.

GS P

x y

[Name] Set horizontal and vertical motion units

[Format] ASCII GS P

Hex 1D 50

Decimal 29 80

xy

xy

xy

[Range] 0 ≤ x ≤ 255

0 ≤ y ≤ 255

[Description] Sets the horizontal and vertical motion units to 1/x inch and 1/

y

inches, respectively.

When x and y are set to 0, the default setting of eac h val u e is use d .

➀

GS V m ➁ GS V

m n

[Name] Select cut mode and cut p aper

[Format]

[Range]

➀

ASCII GS V

Hex 1D 56

Decimal 29 86

➁

ASCII GS V

Hex 1D 56

Decimal 29 86

➀

m = 1, 49

m =

➁

66, 0 ≤ n ≤ 255

m

m

m

mn

mn

mn

[Description] Selects a mode for cutting paper and executes paper cutting. The

value of m selects the mode as fo llows:

m Print mode

1, 49 Partial cut (one point left uncut)

66

Feeds paper (cutting position + [n × (vertical motion unit)]), and cuts the paper

partially (one point left uncut)

GS W

n

L nH

[Name] Set printing area width

[Format] ASCII GS W

Hex 1D 57

Decimal 29 87

0 ≤

n

n

≤ 255

L

≤ 255

H

[Range] 0 ≤

n

L

n

L

n

L

[Description] Sets the printing area width to the area specified by

standard mode

The printing area width is set to [(

•

.

n

motion unit)] inches from the left margin.

5-18 Commands

n

H

n

H

n

H

+

× 256) × horizontal

L

H

n

n

and

L

in

H

n

Page 65

L nH

GS \

[Name] Set relative vertical print position in page mode

[Format] ASCII GS \

[Range] 0 ≤

[Description] Sets the relative vertical print starting position from the current

GS ^

[Name] Execute macro

[Format] ASCII GS ^

[Range] 0 ≤ r ≤ 255

[Description] Executes a ma c ro.

n

Hex 1D 5C

Decimal 29 92

n

≤ 255

L

n

≤ 255

0 ≤

H

position in page mode.

This command sets the distance from the current position to

•

[(

+

L

n

r t m

Hex 1D 5E

Decimal 29 94

0 ≤ t ≤ 255

m

= 0, 1

specifies the number of times to execute the macro.

•

r

specifies the waiting time for executing the macro.

•

t

n

L nH

n

L nH

n

L nH

× 256) × vertical or horizontal motion unit].

H

n

r t m

r t m

r t m

The waiting time is t × 100 msec for every macro execution.

m specifies macro executing mode.

•

When m = 0:

•

The macro executes r times continuously with interval specified by t.

When m = 1:

•

After waiting for the period specified by t, the PAPER OUT LED

indicator blinks and the printer waits for the FEED button to be

pressed. After the button is pressed, the printer executes the macro

once. The printer repe at s t he op e ration r times.

GS a

n

[Name] Enable/Disable Automatic Status Back (ASB)

[Format] ASCII GS a

Hex 1D 61

Decimal 29 97

[Range] 0 ≤ n ≤ 255

n

n

n

Commands 5-19

Page 66

[Description] E nables or di sables ASB an d specifies t he status items to include, using

n

as follows:

Bit Off/On Hex Decimal Status for ASB

Off 00 0 Drawer kick-out connector pin 3 status disabled.

0

On 01 1 Drawer kick-out connector pin 3 status enabled.

Off 00 0 On-line/off-line status disabled.

1

On 02 2 On-line/off-line status enabled .

Off 00 0 Error status disabled.

2

On 04 4 Error status enabled.

Off 00 0 Paper roll sensor status disabled.

3

On 08 8 Paper roll sensor status enabled.

4-7 - - - Undefined.

GS b

n

[Name] Turns smoothing m od e on /off

[Format] ASCII GS b

Hex 1D 62

Decimal 29 98

n

n

n

[Range] 0 ≤ n ≤ 255

[Description] Turns smoothing mode on or off.

When the LSB is 0, smoothing m od e is tur n ed off.

When the LSB is 1, smooth in g mode is turned on.

GS f

n

[Name] Select font for Human Readable Interpretat i on (HRI) characters

[Format] ASCII GS f

Hex 1D 66

Decimal 29 102

[Range]

n

= 0, 1, 48, 49

n

n

n

[Description] Selects a font for the HRI characters used w hen printing a bar code.

n

selects a font from the foll owing table:

n Font

0, 48 Font A (12 × 24)

1, 49 Font B (9 × 24)

HRI indicates Human Readable Interpretation.

•

5-20 Commands

Page 67

GS h

n

[Name] Set bar code heig ht

[Format] ASCII GS h

Hex 1D 68

Decimal 29 104

[Range] 1 ≤ n ≤ 255

[Description] Sets the height of the bar code.

n

specifies the number of dots in the vertical direction.

n

n

n

➀ GS k m

d1...dk NUL

➁ GS k

m n d1...dn

[Name] Print bar code

[Format]

[Range]

➀ ASCII GS k

Hex 1D 6B

Decimal 29 107

➁ ASCII GS k

Hex 1D 6B

Decimal 29 107

m

➀ 0 ≤

≤ 6 (k and d depends on the bar code system used)

m

➁ 65 ≤

≤ 73 (n and d depends on the bar code syst e m use d )

m d

m d

m d

m n d

m n d

m n d

1...dkNUL

1...dk 00

1...dk 0

dn

1...

dn

1...

dn

1...

[Description] Selects a bar code system and prints the bar code.

m

selects a bar code system as follows:

m Bar Code System Number of Characters Remarks

0UPC-A 11 ≤ k

➀

1UPC-E 11 ≤ k

2 JAN13 (EAN 13) 12 ≤ k

3 JAN 8 (EAN 8) 7 ≤ k

4 CODE39 1 ≤ k

5ITF 1

6 CODABAR 1 ≤ k48

≤

12 48 ≤ d ≤ 57

≤

12 48 ≤ d ≤ 57

≤

13 48 ≤ d ≤ 57

≤

848

≤

k (even number) 48 ≤ d ≤ 57

≤

d ≤ 57

48 ≤ d ≤ 57, 65 ≤ d ≤ 90

d = 32, 36, 37, 43, 45, 46,

47

≤

d ≤ 57, 65 ≤ d ≤ 68

d = 32, 36, 37, 43, 45, 46,

47, 58

Commands 5-21

Page 68

m Bar Code System Number of Characters Remarks

65 UPC-A 11 ≤ n

➁

66 UPC-E 11 ≤ n

67 JAN13 (EAN 13) 12 ≤ n

68 JAN 8 (EAN 8) 7 ≤ n

69 CODE39 1 ≤ n

70 ITF 1 ≤ n ≤ 255 (even number) 48 ≤ d ≤ 57

71 CODABAR 1 ≤ n ≤ 255 48 ≤ d ≤ 57, 65 ≤ d ≤ 68

72 CODE93 1 ≤ n ≤ 255 0 ≤ d ≤ 127

73 CODE128 2 ≤ n ≤ 255 0 ≤ d ≤ 127

≤

12 48 ≤ d ≤ 57

≤

12 48 ≤ d ≤ 57

≤

13 48 ≤ d ≤ 57

≤

848

≤

255 48 ≤ d ≤ 57, 65 ≤ d ≤ 90

≤

d ≤ 57

d = 32, 36, 37, 43, 45, 46,

47

d = 32, 36, 37, 43, 45, 46,

47, 58

[Description for ➀]

indicates the character code to be printed and k indicates the

•

d

number of characters to be printed.

[Description for ➁]

indicates the number of bar code data, and the printer processes

•

n

bytes from the next character data as bar code data.

n

indicates the character code to be printed.

•

d

GS r

n

[Name] Transmit status

[Format] ASCII GS r

Hex 1D 72

Decimal 29 114

n

n

n

[Range] 1 ≤ n ≤ 2, 49 ≤ n ≤ 50

[Description] Transmits t h e stat us specified by n as follows:

n Function

1, 49 Transmits paper sensor status

2, 50 Transmits drawer kick-out connector status

5-22 Commands

Page 69

GS w

n

[Name] Set bar code width

[Format] ASCII GS w

Hex 1D 77

Decimal 29 119

n

n

n

[Range] 2 ≤ n ≤ 6

[Description] Set the horizontal size of the bar code.

n

specifies the bar code width as follows::

Module Width (mm)

n

for Multi-level Bar Code

2 0.282 0.282 0.706

3 0.423 0.423 1.129

4 0.564 0.564 1.411

5 0.706 0.706 1.834

6 0.847 0.847 2.258

Multi-level bar codes are as follows:

•

Binary-level Bar Code

Thin element width (mm) Thick element width (mm)

UPC-A, UPC-E, JAN13 (EAN 13), JAN 8 (EAN 8), CODE93,

CODE128

Binary-level bar codes are as follows:

•

CODE39, ITF, CODABAR

Commands 5-23

Page 70

Appendix A

Dip Switch and Paper Near End Settings

Although the factory settings are best for almost all uses, if you

have special requirements, y ou can ch ange the DIP switch o r paper

near end settings.

Setting the DIP Switches

DIP switch functions

Your printer has two sets of DIP switches. The functions of the

switches are shown in the following tables.

Serial interface specification

Set 1

SW Function ON OFF

1-1 Data receive error Ignored P rin ts “? ”

1-2 Receiv e buffer capacity 45 bytes 4K bytes

1-3 Handshaking XON/XOFF DTR/DSR

1-4 Data word length 7 bits 8 bits

1-5 Parity check Enabled Disabled

1-6 Parity selection Even Odd

1-7

Transmission speed (See the table below)

1-8

Dip Switch and Paper Near End Settings A-1

Page 71

Transmission Speed

Transmission Speed (BPS)-bits per second 1-7 1-8

2400 ON ON

4800 OFF ON

9600 ON OFF

19200 OFF OFF

Set 2

SW Function ON OFF

Handshaking (BUSY

2-1

condition)

Reserved: do not

2-2

change settings

2-3

Selects print density Refer to table below

2-4

Reserved: do not

2-5

change settings

Reserved: do not

2-6

change settings

2-7 I/F pin 6 reset signal Enabled D isa ble d

2-8 I/F pin 25 reset signal Enabled Disabled

Receive buffer full

Fixed to OFF

Fixed to OFF

Fixed to OFF

Off line or

receive buffer full

A-2 Dip Switch and Paper Near End Settings

Page 72

Print Density Selection

Print Density SW 2-3 SW 2-4

1 (Light) ON ON

2OFFOFF

3ONOFF

4 (Dark) OFF ON

Notes:

With the optional RS-485 interface, DIP switches 2-7 and 2-8 are disabled.

•

Changes in DIP switch settings (excluding switches 2-7 and 2-8 interface reset

•

signals) are recognized only when the printer power is turned on or when the

printer is reset by using the interface. If the DIP switch setting is chan g ed after

the printer power is turned on, the change doe s not take effec t until th e

printer is turned on again or is reset.

If you turn on DIP switch 2-7 or 2-8 while the printer is turned on, the printer may

•

be reset, depending on the signal state. DI P switches should not be changed

while the printer power is on.

If the print density is set to level 3 or 4, the printing will be at th e lo w sp eed .

•

Dip Switch and Paper Near End Settings A-3

Page 73

Parallel interface specification

Set 1

SW Function ON OFF

1-1 Auto line feed Always enabled Always disabled

1-2 Receive buffer capacity 45 bytes 4K bytes

1-3~

1-8

Set 2

SW Function ON OFF

2-1

2-2

2-3

2-4

2-5~

2-7

2-8

Undefined – –

Handshaking

(BUSY condit io n)

Reserved

(Do not cha nge settings )

Selects print density Refer to table below

Reserved

(Do not cha nge settings )

I/F pin 31 reset signal

(Do not cha nge settins)

• Receive buffer full

• Reading data

Fixed to Off

Fixed to Off

Fixed to On

• Off-line

• Receive buffer full

• Reading data

Print Density Selection

Print Density SW 2-3 SW 2-4

1 (Light) ON ON

2OFFON

3ONOFF

4 (Dark) OFF OFF

A-4 Dip Switch and Paper Near End Settings

Page 74

Notes:

Changes in DIP switch settings (excluding switch 2-8 interface reset signal) are

•

recognized only when the printer po wer is turned on or when t he printer is

reset by using the interface. If the DIP switch setting is changed after the

printer power is turned on, the change does no t take effec t until the prin t er is

turned on again or is reset.

If you turn on DIP switch 2-8 while the printer is turned on, the printer may be

•

reset, depending on the signal state. DIP switches should not be changed

while the printer power is on.

If the print density is set to level 3 or 4, the printing will be at th e lo w sp eed .

•

Dip Switch and Paper Near End Settings A-5

Page 75

Changing the DIP switch settings

If you need to change set tings, fol low the steps bel ow to make y our

changes:

CAUTION:

Turn off the printer while removing the DIP switch cover to

prevent an electric short, which can damage the printer.

1. Make sure the printer is turned off.

2. Remove the screw from the DIP switch cov er. The n t ake off t he

DIP switch cover, as shown in the illustration below.

DSW1

DSW2

3. Set the switches using a pointed tool, such as tweezers or a

small screwdriver.

4. Replace the DIP switch cover. Then secure it with the screw.

The new settings take effect when you turn on the printer.

A-6 Dip Switch and Paper Near End Settings

Page 76

ACHTUNG:

Schalten Sie den Drucker aus, während Sie di e die DIPSchalterabdeckung abnehmen, um elektrische Kurzschlüsse

zu verhindern, die den Drucker beschädigen können.

1. Stellen Sie sicher, daß der Drucker ausgeschaltet ist.

2. Entfernen Sie die Schraube von der DIP-Schalterabdeckung.

Dann nehmen Sie die DIP-Schalterabdeckung ab, wie in der

Abbildung unten gezeigt.

DSW1

DSW2

3. Stellen Sie die Schalter mit einem spitzen Gegenstand wie einer

Pinzette oder einem kleinen Schraubenzieher in die

gewünschte Stellung.

4. Setzen Sie die DIP-Schalterabdeckung wieder auf.

Anschließend befestigen Sie sie mit der Schraube.

Die neuen Einstellungen werden gültig, wenn der Drucker wieder

eingeschaltet wird.

Dip Switch and Paper Near End Settings A-7

Page 77

Adjusting the Paper Near End Detector

The paper near end detector detects when paper is almost gone by

measuring the diameter of the paper roll. The detector has two

settings.

Because of variations in paper roll cores, it is not possible for the

detector to measure exactly the length of paper left on the roll when

the detector is triggered. Of the two settings, th e factory setting

(lower) leaves the least amount of paper on the roll when the

sensor is triggered. If you want more paper left, change the setting

as described belo w.

Note:

The factory setting is based on a paper roll core with an outside

diameter of 18mm and an inside diameter of 12mm. If you use a

paper roll with a core with an outside diameter of more than 18mm,

it is better to change to the upper setting, as described below.

1. Open the printer cover, and remove the paper roll.

2. Loosen the adjusting screw and move the tab up to the upper

setting.

Tab

Screw

POWER

ERROR

PAPER

OUT

FEED

3. Tighten the adjusting screw , and check to be sure that the

detecting lever moves freely.

4. Replace the paper roll.

A-8 Dip Switch and Paper Near End Settings

Page 78

Appendix B

EPSON

EPSON AMERICA INC./OEM DIV. 20770 Madrona Ave.

EPSON EUROPE B.V. Prof. J.H. Bavincklaan 5

EPSON Deutschland GmbH Zülpicher Strasse 6, 40549

EPSON U.K. LIMITED Campus 100 Maylands Ave.

EPSON FRANCE S.A. 68 Bis Rue Marjolin B.P. 320 92305

Sales Subsidiaries

Torrance, CA 90559-2842 U.S.A.

Tel : 1-310-787-6300

Fax : 1-310-782-5350

1183 AT Amstelveen The Netherlands

Tel : 31-(0)20-5475-251

Fax : 31-(0)20-6454-315

Düsseldorf 11, Germany