Page 1

Technical Reference Guide

Describes features of the product.

Describes advanced usage methods for the product.

Describes precautions for replacement.

Describes how to handle the product.

Describes setup and installation of the product and

peripherals.

Describes how to control the printer and necessary

information when you develop applications.

Describes general specications and character code tables.

Product Overview

Setup

Advanced Usage

Application Development Information

Handling

Replacement of the TM-T82

Appendix

M00121903

Rev. D

Page 2

Cautions

• No part of this document may be reproduced, stored in a retrieval system, or transmitted in any form or by

any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written

permission of Seiko Epson Corporation.

• The contents of this document are subject to change without notice. Please contact us for the latest

information.

• While every precaution has been taken in the preparation of this document, Seiko Epson Corporation

assumes no responsibility for errors or omissions.

• Neither is any liability assumed for damages resulting from the use of the information contained herein.

• Neither Seiko Epson Corporation nor its affiliates shall be liable to the purchaser of this product or third

parties for damages, losses, costs, or expenses incurred by the purchaser or third parties as a result of:

accident, misuse, or abuse of this product or unauthorized modifications, repairs, or alterations to this

product, or (excluding the U.S.) failure to strictly comply with Seiko Epson Corporation's operating and

maintenance instructions.

• Seiko Epson Corporation shall not be liable against any damages or problems arising from the use of any

options or any consumable products other than those designated as Original Epson Products or Epson

Approved Products by Seiko Epson Corporation.

Trademarks

EPSON is a registered trademark of Seiko Epson Corporation. Exceed Your Vision and ESC/POS are registered

trademarks or trademarks of Seiko Epson Corporation.

Microsoft and Windows are registered trademarks of Microsoft Corporation in the United States and/or other

countries.

IOS is a trademark or registered trademark of Cisco in the U.S. and other countries and is used under license.

Android™ is a trademark of Google LLC.

All other trademarks are the property of their respective owners and used for identification purpose only.

ESC/POS® Command System

EPSON ESC/POS is a proprietary POS printer command system that includes patented or patent-pending

commands. ESC/POS is compatible with most EPSON POS printers and displays. ESC/POS is designed to

reduce the processing load on the host computer in POS environments. It comprises a set of highly functional

and efficient commands and also offers the flexibility to easily make future upgrades.

©Seiko Epson Corporation 2019-2020. All rights reserved.

Page 3

For Safety

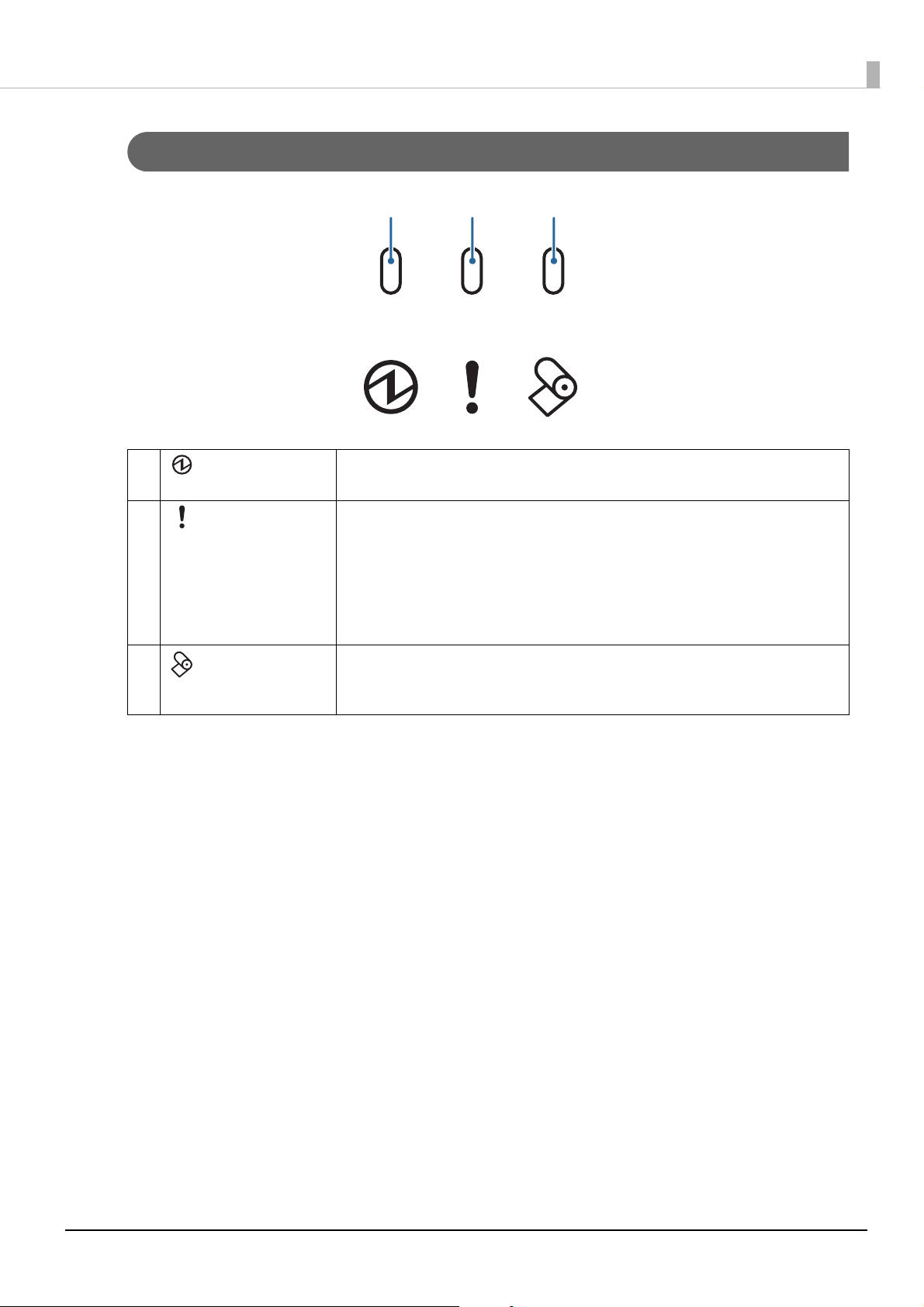

Key to Symbols

The symbols in this manual are identified by their level of importance, as defined below. Read the following

carefully before handling the product.

You must follow warnings carefully to avoid serious bodily injury.

WARNING

Provides information that must be observed to prevent damage to the equipment or loss of data.

• Possibility of sustaining physical injuries.

CAUTION

• Possibility of causing physical damage.

• Possibility of causing information loss.

Provides information that must be observed to avoid damage to your equipment or a malfunction.

Provides important information and useful tips.

Warnings

WARNING

• To avoid risk of electric shock, do not set up this product or handle cables during a

thunderstorm

• Never insert or disconnect the power plug with wet hands.

Doing so may result in severe shock.

• Handle the power cable with care.

Improper handling may lead to fire or electric shock.

∗ Do not modify or attempt to repair the cable.

∗ Do not place any heavy object on top of the cable.

∗ Avoid excessive bending, twisting, and pulling.

∗ Do not place the cable near heating equipment.

∗ Check that the plug is clean before plugging it in.

∗ Be sure to push the plug all the way in.

• Be sure to use the specified power source.

Connection to an improper power source may cause fire or shock.

• Do not place multiple loads on the power outlet.

Overloading the outlet may lead to fire. Plug the power cord directly into the household power

outlet (100-240 VAC).

• Shut down your equipment immediately if it produces smoke, a strange odor, or unusual noise.

Continued use may lead to fire. Immediately unplug the equipment and contact qualified

service personnel.

• Never attempt to repair this product yourself.

Improper repair work can be dangerous.

• Never disassemble or modify this product.

Tampering with this product may result in injury or fire.

• Do not allow foreign matter to fall into the equipment.

Penetration by foreign objects may lead to fire.

3

Page 4

WARNING

Cautions

CAUTION

• If water or other liquid spills into this equipment, do not continue to use it.

Continued use may lead to fire. Unplug the power cord immediately and contact qualified

service personnel.

• Do not use aerosol sprayers containing flammable gas inside or around this product.

Doing so may cause fire.

• Do not connect cables in ways other than those mentioned in this manual.

Different connections may cause equipment damage or fire.

• Be sure to set this equipment on a firm, stable, horizontal surface.

The product may break or cause injury if it falls.

• Do not use this product in locations subject to high humidity or dust levels.

Excessive humidity and dust may cause equipment damage or fire.

• Do not place heavy objects on top of this product. Never stand or lean on this product.

Equipment may fall or collapse, causing breakage and possible injury.

• Take care not to push your hand or finger against the manual cutter. Doing so may injure your

hand or finger.

∗ When you remove printed paper

∗ When you perform other operations such as loading/replacing roll paper

• Do not open the roll paper cover without taking the necessary precautions, as this can result in

injury from the autocutter fixed blade.

• To ensure safety, unplug this product before leaving it unused for an extended period.

Caution Labels

The caution labels on the product indicate the following precautions.

CAUTION:

Do not touch the thermal head and the frame on its side during or immediately after use. After printing, the thermal head

and its surroundings can be very hot.

Restriction of Use

When this product is used for applications requiring high reliability/safety, such as transportation devices

related to aviation, rail, marine, automotive, etc.; disaster prevention devices; various safety devices, etc.; or

functional/precision devices, etc., you should use this product only after giving consideration to including failsafes and redundancies into your design to maintain safety and total system reliability.

Because this product was not intended for use in applications requiring extremely high reliability/safety, such as

aerospace equipment, main communication equipment, nuclear power control equipment, or medical

equipment related to direct medical care, etc., please make your own judgment on this product's suitability after

a full evaluation.

4

Page 5

About this Manual

Aim of the Manual

This manual provides developers/engineers with all the necessary information for design, development and

installation of a POS system, and also design and development of a printer application.

Manual Content

The manual is made up of the following sections:

Chapter 1 Product Overview

Chapter 2 Setup

Chapter 3 Advanced Usage

Chapter 4 Application Development Information

Chapter 5 Handling

Chapter 6 Replacement of the TM-T82

Appendix

Product Specifications

Specifications of Interfaces and Connectors

Character Code Tables

5

Page 6

Contents

■ For Safety.................................................................................................................................3

Key to Symbols.................................................................................................................................................................. 3

Warnings ............................................................................................................................................................................. 3

Cautions............................................................................................................................................................................... 4

■ Caution Labels ........................................................................................................................4

■ Restriction of Use ...................................................................................................................4

■ About this Manual .................................................................................................................5

Aim of the Manual ........................................................................................................................................................... 5

Manual Content ................................................................................................................................................................ 5

■ Contents...................................................................................................................................6

Product Overview ............................................................................................ 9

■ Features ...................................................................................................................................9

■ Product Configurations ..................................................................................................... 10

Models................................................................................................................................................................................10

Accessories .......................................................................................................................................................................10

■ Part Names and Functions ................................................................................................ 11

LED Lights .........................................................................................................................................................................12

Connectors .......................................................................................................................................................................13

■ Status and Errors ................................................................................................................. 14

Online and Offline..........................................................................................................................................................14

Automatically Recoverable Errors ............................................................................................................................14

Recoverable Errors .........................................................................................................................................................15

Unrecoverable Errors ....................................................................................................................................................15

Status Display ..................................................................................................................................................................16

■ NV Memory .......................................................................................................................... 17

NV Graphics Memory....................................................................................................................................................17

User NV Memory ............................................................................................................................................................17

Memory Switches (Customized Value)...................................................................................................................17

R/E (Receipt Enhancement) ........................................................................................................................................17

User-defined Page .........................................................................................................................................................18

Maintenance Counter...................................................................................................................................................18

Setup ............................................................................................................... 19

■ Flow of Setup ....................................................................................................................... 19

■ Installing the Printer........................................................................................................... 20

■ Connecting the Printer to the Host ................................................................................. 20

USB Interface ...................................................................................................................................................................20

6

Page 7

Serial Interface ................................................................................................................................................................21

Ethernet Interface ..........................................................................................................................................................21

■ Connecting the AC cable ................................................................................................... 22

Connecting Procedure .................................................................................................................................................22

■ Connecting the Cash Drawer............................................................................................ 23

Cash Drawer Requirements ........................................................................................................................................23

Connecting the Drawer Kick Cable..........................................................................................................................24

■ Connecting the Optional External Buzzer...................................................................... 25

Connecting Procedure .................................................................................................................................................25

Advanced Usage ............................................................................................ 26

■ Software Settings................................................................................................................ 26

Feature ...............................................................................................................................................................................27

■ Setting/Checking Modes ................................................................................................... 34

Self-test Mode .................................................................................................................................................................36

NV Graphics Information Print Mode......................................................................................................................36

Receipt Enhancement Information Print Mode ..................................................................................................37

Software Setting Mode ................................................................................................................................................37

Restore Default Values Mode.....................................................................................................................................39

Interface Setup Mode (Ethernet model only) ......................................................................................................40

Hexadecimal Dumping Mode ...................................................................................................................................40

■ Printing a Status Sheet....................................................................................................... 42

■ Resetting the Interface Settings ...................................................................................... 43

Application Development Information....................................................... 44

■ Controlling the Printer....................................................................................................... 44

ESC/POS.............................................................................................................................................................................44

■ Controlling the Cash Drawer............................................................................................. 45

■ Controlling the Optional External Buzzer ...................................................................... 46

■ Software................................................................................................................................ 47

Development Kits ..........................................................................................................................................................47

Drivers ................................................................................................................................................................................48

Utilities ...............................................................................................................................................................................49

Download .........................................................................................................................................................................49

■ Notes on Printing Barcodes and Two-dimensional Symbols...................................... 50

Handling ......................................................................................................... 51

■ Installing and Replacing Roll Paper................................................................................. 51

7

Page 8

■ Removing Jammed Paper ................................................................................................. 53

When the Roll Paper Cover Cannot be Opened..................................................................................................53

■ Cleaning the Printer............................................................................................................54

Cleaning the Printer Case............................................................................................................................................54

Cleaning the Thermal Head/Platen Roller .............................................................................................................54

■ Preparing for Transport ..................................................................................................... 55

Replacement of the TM-T82.......................................................................... 56

■ Compatibility ....................................................................................................................... 56

Printing ..............................................................................................................................................................................56

Print Speed .......................................................................................................................................................................56

Cutting Method ..............................................................................................................................................................56

Logo Registration...........................................................................................................................................................56

Driver Compatibility......................................................................................................................................................56

USB Low Power Consumption Mode ......................................................................................................................56

Paper Width......................................................................................................................................................................57

IP Address Setting..........................................................................................................................................................57

If Connecting as a Peripheral Device of the TM-i/DT Printer ..........................................................................57

Overall Dimensions .......................................................................................................................................................58

Appendix......................................................................................................... 59

■ Product Specifications ....................................................................................................... 59

Printing Specifications .................................................................................................................................................61

Character Specifications ..............................................................................................................................................62

Paper Specifications ......................................................................................................................................................63

Printable Area..................................................................................................................................................................64

Printing and Cutting Positions ..................................................................................................................................64

Electrical Characteristics..............................................................................................................................................65

Environmental Conditions..........................................................................................................................................66

External Dimensions and Mass .................................................................................................................................67

■ Specifications of Interfaces and Connectors ................................................................. 68

USB Interface ...................................................................................................................................................................68

RS-232 Serial Interface .................................................................................................................................................69

Ethernet Interface ..........................................................................................................................................................72

■ Character Code Tables........................................................................................................ 74

8

Page 9

Product Overview

This chapter describes features of the product.

Features

Printing

High speed receipt printing is possible (200 mm/s maximum).

Handling

Easy drop-in paper loading

Software

Chapter 1 Product Overview

• Command protocol is based on the ESC/POS® Proprietary Command System.

• Windows printer drivers, OPOS ADK, and OPOS ADK for .NET are available.

• Printing of various types of bar codes, GS1-DataBar, and two-dimensional symbols (PDF417, QR code,

MaxiCode, Composite Symbology) is supported.

• A maintenance counter function is supported.

• Multiple languages are supported for code pages, Windows drivers, and utility software.

Interface

The interface is selectable when purchasing the product.

Environment

Paper reduction function is available.

Others

Optional external buzzer is available.

9

Page 10

Product Configurations

Models

• Serial (RS-232C)/USB interface model

• Ethernet interface model

Accessories

Included

• Roll paper (for operation check)

• Interface cable (Serial/USB model only)

• AC cable

Chapter 1 Product Overview

• User's Guide

Options

• Affixing tape for fixing the printer (Model: DF-10)

• External buzzer (Model: OT-BZ20)

10

Page 11

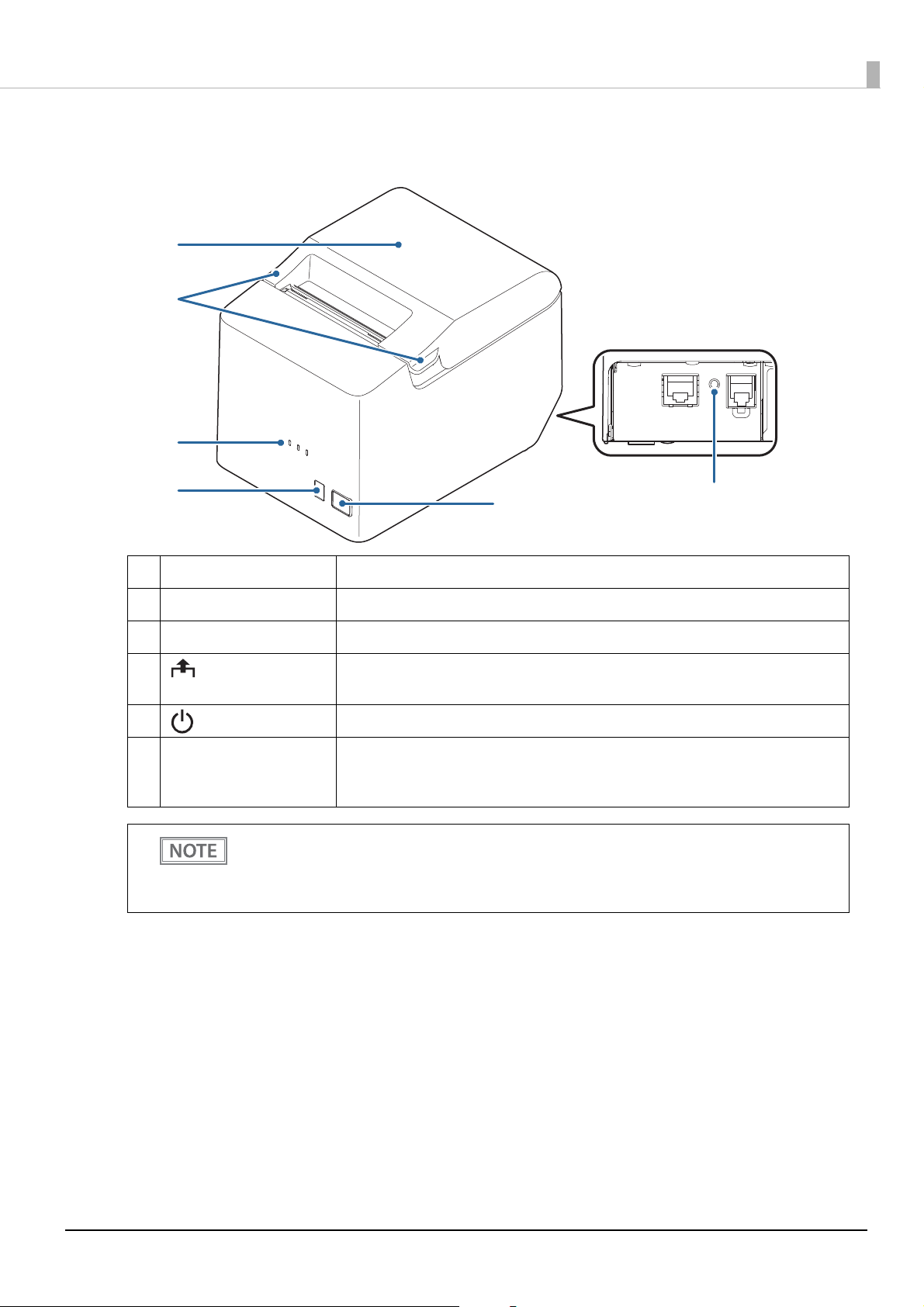

Part Names and Functions

5

6

3

2

1

4

Chapter 1 Product Overview

1 Roll paper cover Open this cover to install/replace the roll paper.

2 Cover open lever Use this button to open the roll paper cover.

3 LED lights For details on the LED lights, see "LED Lights" on page 12

4 Feed button Press this button to feed the roll paper by one line. Hold down this button to feed the

roll paper continuously.

5 Power button Press this button to turn the printer on or off.

6 Status sheet button

(Ethernet interface model

only)

When turning off the printer without using the power button, it is recommended to send a

power-off command to the printer. If you use the power-off sequence, the latest maintenance

counter values are saved. (Maintenance counter values are usually saved every two minutes.)

For information about ESC/POS commands, see the ESC/POS Command Reference.

Press this button to print the interface status sheet, or to reset the interface settings.

.

11

Page 12

Chapter 1 Product Overview

12 3

LED Lights

1 Power LED • On when the power supply is on.

• Off when the power supply is off.

2 Error LED Lights or flashes when the printer is offline. (For information about the lighting and

flashing patterns, see

• Lights after the power is turned on or after a reset (offline). Automatically goes out

after a while to indicate that the printer is ready.

• Lights when the end of the roll paper is detected, and when printing has stopped

(offline). If this happens, replace the roll paper.

• Off when the printer is in standard mode (online).

"Status and Errors" on page 14.)

3 Paper LED • Lights when there is no more roll paper.

• Off when there is a sufficient amount of roll paper remaining.

• Flashes when a self-test is in progress or when macro execution standby state.

12

Page 13

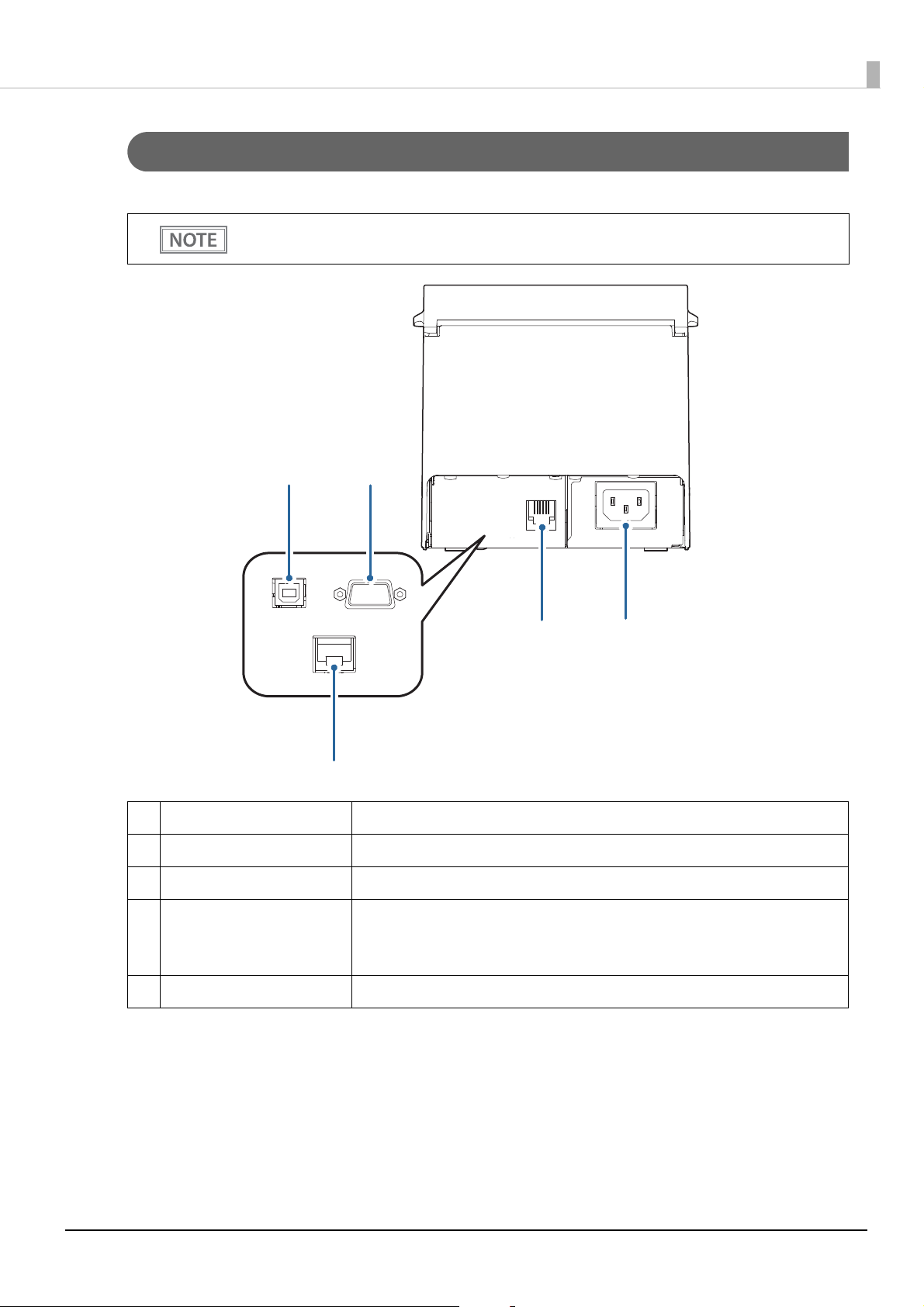

Connectors

4

5

1

3

2

All connectors are located on the lower rear of the printer.

Available interface may vary depending on the model.

Chapter 1 Product Overview

1 USB connector Connects the USB cable for connecting to a computer.

2 Serial interface Connects the serial cable for connecting to a computer.

3 Ethernet connector Connects the 10BASE-T/100BASE-TX Ethernet cable.

4 Drawer kick connector Connects the cash drawer or the optional external buzzer.

"Connecting the Cash Drawer" on page 23

"Connecting the Optional External Buzzer" on page 25

5 Power supply connector Connects the AC cable.

13

Page 14

Status and Errors

The LEDs light or flash to indicate the printer status.

The printer cannot print while an error is left unsolved.

Online and Offline

Online

The printer is online and ready for normal printing unless there is a reason to go offline.

Offline

The printer automatically goes offline under the following conditions:

Chapter 1 Product Overview

• While the printer power is turning on/off

• While a self-test is running

• While roll paper is fed using the Feed button

• When the printer stops printing due to a paper end (when the paper out detector detected the paper out)

• During an operation standby state

• When an error has occurred (See

• While the roll paper cover is open

"Status and Errors" on page 14)

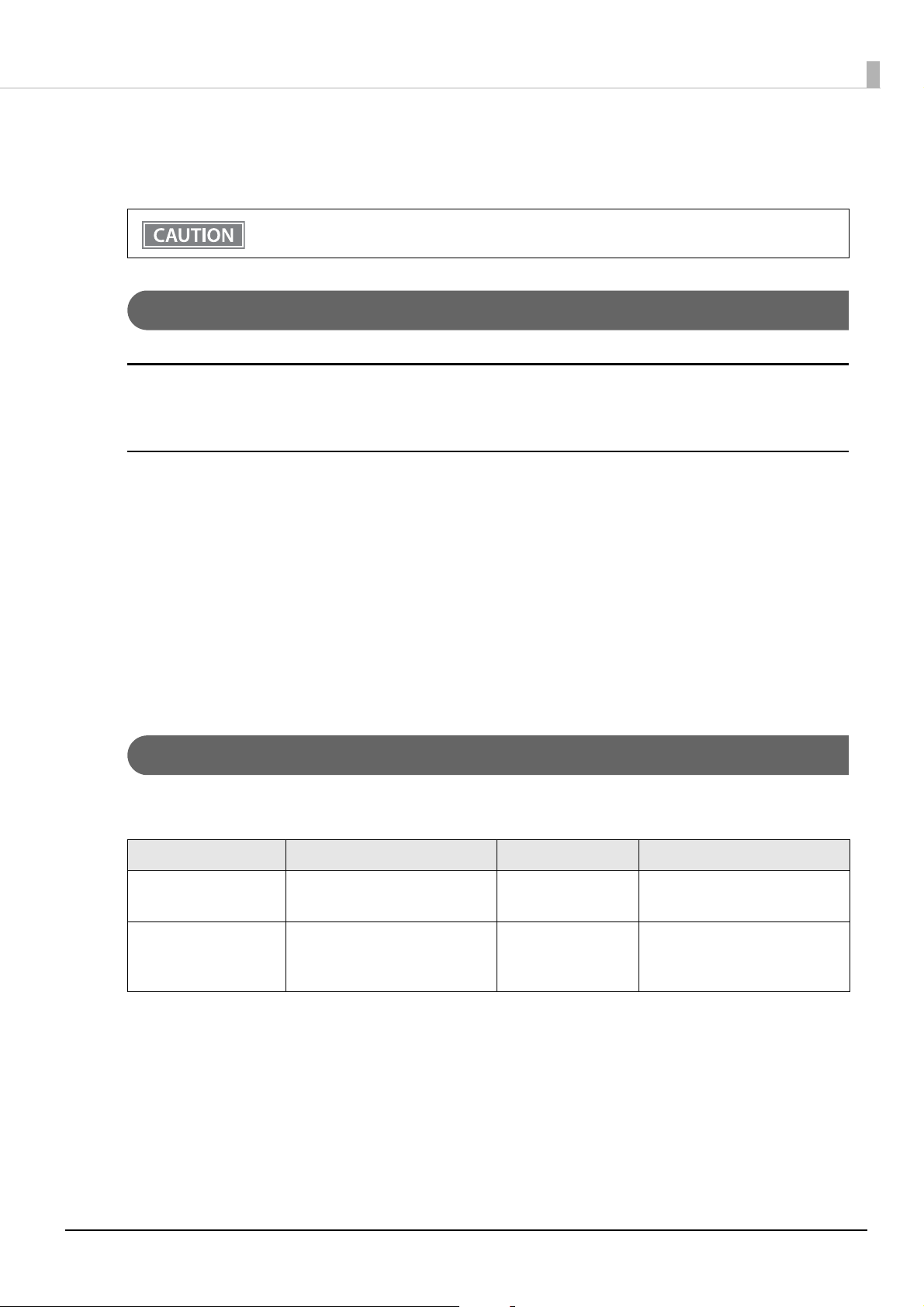

Automatically Recoverable Errors

The printer cannot print when automatically recoverable errors occur. They can be recovered easily, as

described below.

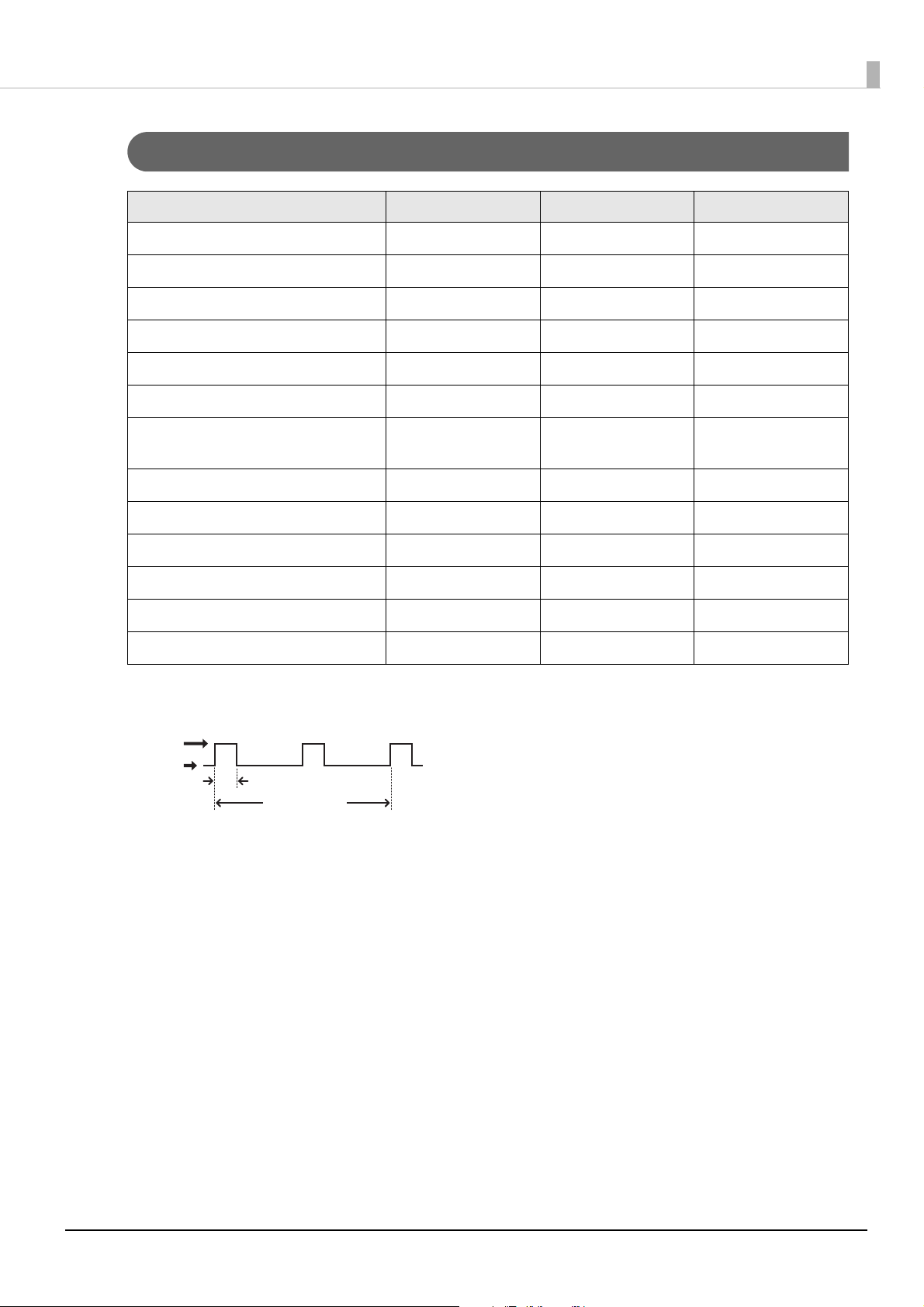

Error Error description Error LED status Condition for Recovery

Roll paper cover

open error

Head temperature error A high temperature outside the

The roll paper cover was opened

during printing

thermal head drive operating

range was detected

ON Recovers automatically when the

roll paper cover is closed

ON Recovers automatically when the

thermal head cools.

14

Page 15

Chapter 1 Product Overview

LED OFF

LED ON

Approx. 320 ms

Recoverable Errors

The printer cannot print when a recoverable error occurs. It can be recovered easily by turning the power on

again or sending an error recovery command from the driver after eliminating the cause of the error.

Error Error description Error LED status Condition for Recovery

Autocutter

error

Autocutter does not work

correctly

The error recovery command is valid only if a recoverable error (excluding automatically

recoverable errors) occurs.

Use the TM-T100 Utility to change the condition for recovery. For details, see the TM-T100 Utility

User's Manual.

ON Recovers from the error when

the jammed paper or foreign

matter is removed, and the roll

paper cover is closed.

Unrecoverable Errors

The printer cannot print when an unrecoverable error occurs. If the error persists after turning the printer off

and then on again, the printer may be defective. Contact qualified service personnel.

Turn off the power immediately when an unrecoverable error occurs.

CAUTION

Error Error description Error LED flash code

R/W error in memory After R/W checking, the printer does not work

correctly.

High voltage error The power supply voltage is extremely high.

Low voltage error The power supply voltage is extremely low.

CPU execution error The CPU is executing an incorrect address.

Internal circuit

connection error

Internal circuits are not connected correctly.

15

Page 16

Chapter 1 Product Overview

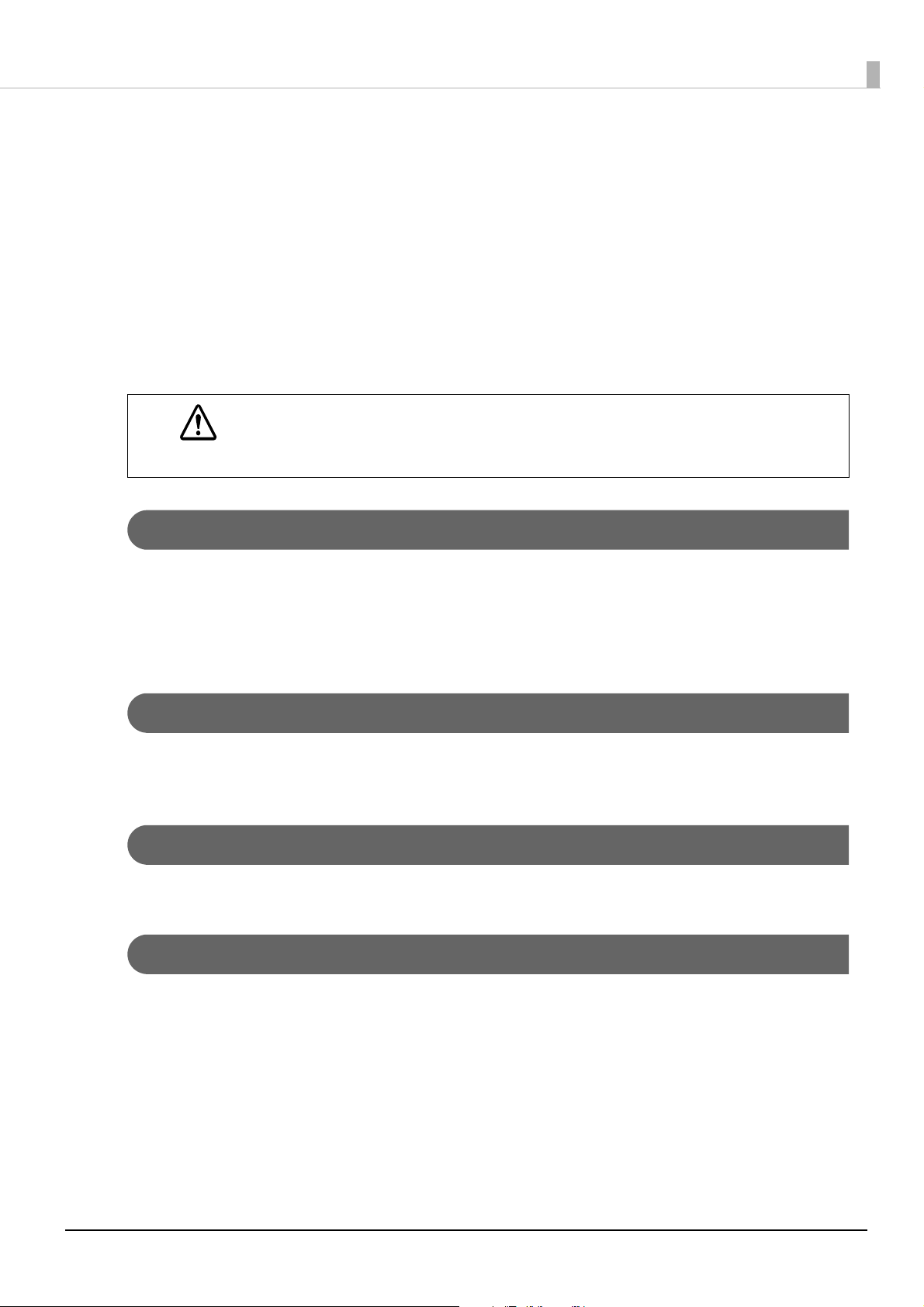

Status Display

Power LED Error LED Paper LED

Online ON OFF OFF

Initializing after power-on ON ON -

Running a self-test ON OFF -

Waiting to continue self-test ON OFF Flashing

Feeding using the Feed button ON OFF -

Waiting to execute a macro ON OFF Flashing

Roll paper cover open while the printer is

not printing

No paper ON ON ON

While updating firmware (Main) ON Flashing Flashing

While updating firmware (Boot) ON ON ON

Power off standing by ON OFF Flashing

The network link is down ON Flashing* -

Waiting to print status sheet ON ON Flashing

ON ON -

-: Changes depending on whether or not paper is detected.

*: The error LED flashing patterns are as follows.

LED ON

LED OFF

Approx. 640 ms

Approx. 5,120 ms

16

Page 17

Chapter 1 Product Overview

NV Memory

The printer is equipped with the NV memory (Nonvolatile Memory) to store data even after the printer power

is turned off. NV memory contains the following memory areas for the user:

• NV graphics memory

• User NV memory

• Memory switches

• R/E (Receipt Enhancement)

• User-defined page

• Maintenance counter

As a guide, NV memory rewriting should be 10 times or less a day when you program applications.

CAUTION

NV Graphics Memory

Graphics, such as shop logos to be printed on receipts, can be stored. Even with a serial interface model whose

transmission speed is low, high speed graphics printing is possible.

TM-T100 Utility or ESC/POS commands can be used for the graphic registration.

TM-T100 Utility or NV Graphics Information Print Mode can be used for the confirmation.

User NV Memory

You can store and read text data for multiple purposes, such as for storing a note including customizing or

maintenance information of the printer.

Memory Switches (Customized Value)

You can configure various settings of the printer. For more information, see "Software Settings" on page 26.

R/E (Receipt Enhancement)

Registered graphics in the NV Graphics Memory can be printed automatically, as a top logo before receipt

printing or as a bottom logo before cutting paper.

TM-T100 Utility or ESC/POS commands can be used for the settings.

TM-T100 Utility or Receipt Enhancement Information Print Mode can be used for the confirmation.

17

Page 18

Chapter 1 Product Overview

User-defined Page

You can store character data in the user-defined page (character code table: page 255) so that you can also print

characters not resident in the printer.

Maintenance Counter

With this function, printer information, such as the number of lines printed, the number of autocuts, and

printer operation time after the printer starts working, is automatically stored in NV memory. You can use the

counter information for periodical checks or part replacement.

• You can also check the print head running length and number of times of auto-cutting with the

self-test (see

• The maintenance counter value is normally saved in the NV memory every 2 minutes (maximum

of 4 minutes). However, it is not automatically saved when the product is in the power-saving

mode or when the power is turned off without using the power switch.

"Self-test Mode" on page 36).

18

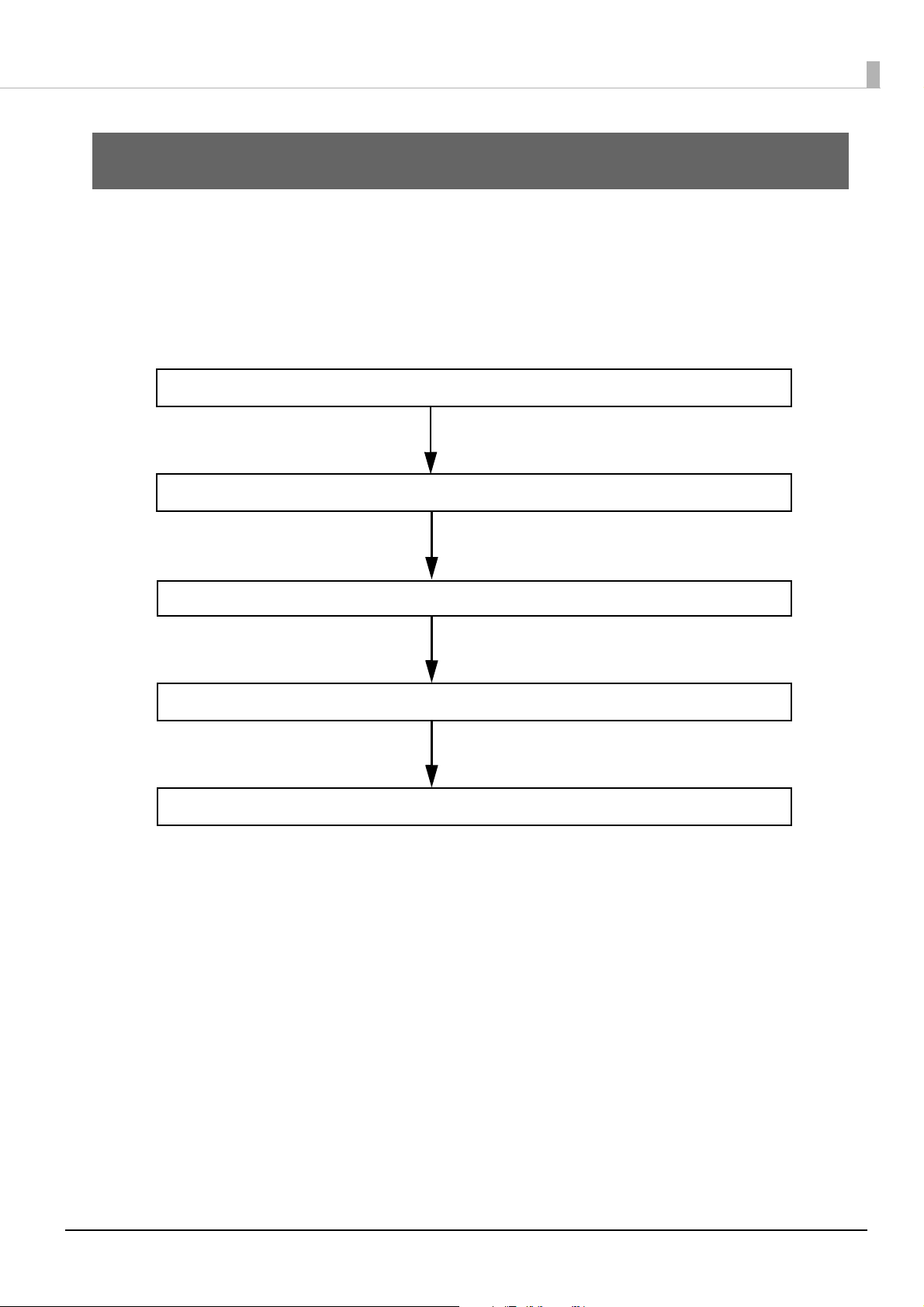

Page 19

Setup

2. Connecting the Printer to the Host (page 20)

5. Connecting the Optional External Buzzer (page 25)

3. Connecting the AC cable (page 22)

1. Installing the Printer (page 20)

4. Connecting the Cash Drawer (page 23)

This chapter describes setup and installation of the product and peripherals.

Flow of Setup

This chapter consists of the following sections along with the setup flow of the product and peripherals.

Chapter 2 Setup

19

Page 20

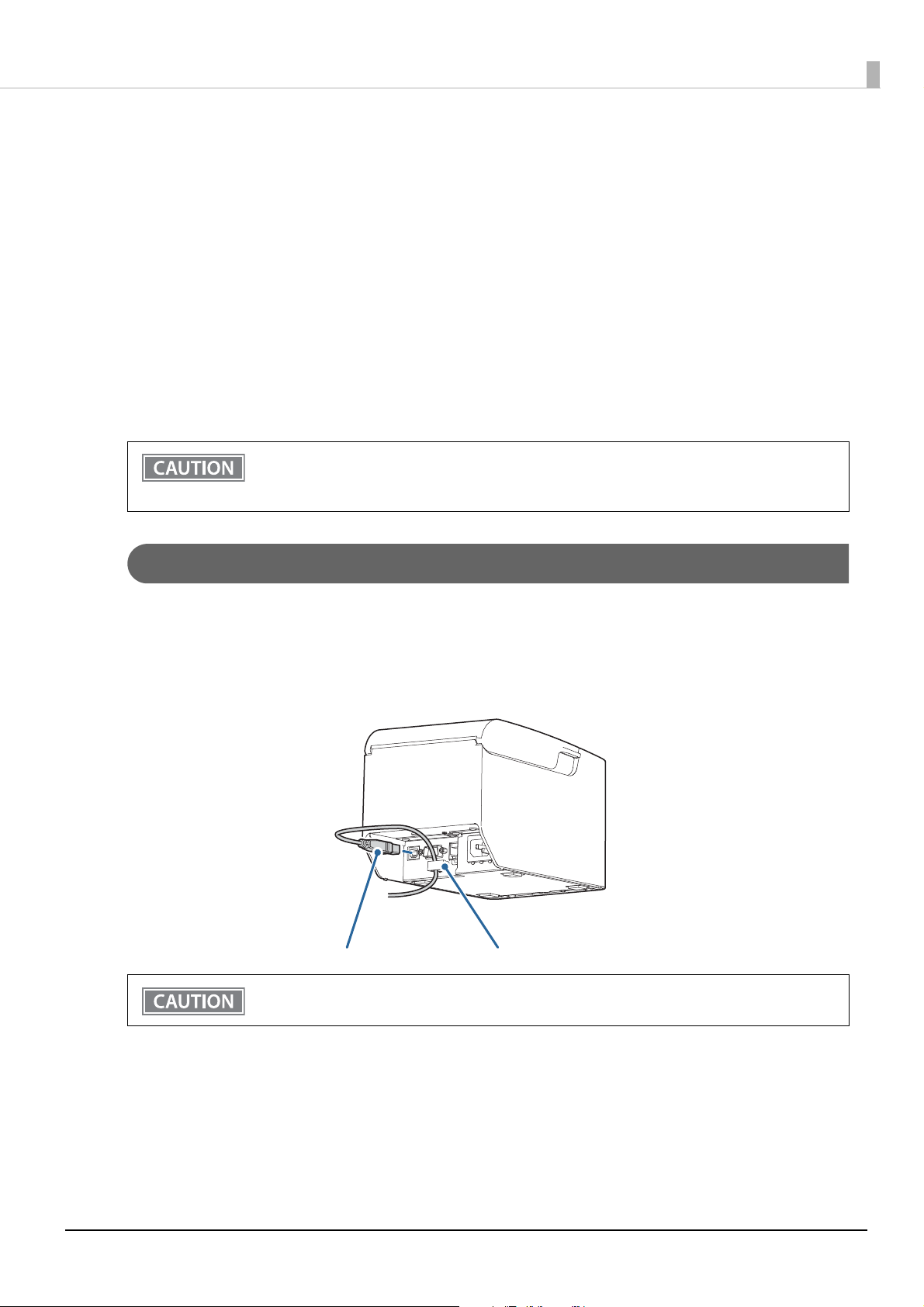

Installing the Printer

Wire saddle

USB cable

Observe the following precautions when installing the printer.

• The printer must be installed horizontally.

• Do not place the printer in a dusty location.

• Do not knock or strike the printer. This may cause defective print.

• Do not catch cables or place foreign matter under the printer.

• Take measures to prevent the printer from moving by vibration during paper cutting and when using a

drawer. Affixing tape (Model: DF-10) is provided as an option.

Connecting the Printer to the Host

• Be sure to install the driver before connecting the printer to the host computer.

• The printer uses a modular connector specifically designed for the cash drawer. Do not connect

the connector to an ordinary telephone line.

Chapter 2 Setup

USB Interface

When using USB cable to connect with host device, connect the USB cable to the printer, and after starting the

host device, turn the printer on.

When connecting the USB cable to the printer, fix the cable with the wire saddle to prevent it from being

disconnected.

Do not place any weight or stress on the cable when using. Doing so could damage the cable and

connectors.

20

Page 21

Chapter 2 Setup

Serial Interface

When connecting to the host computer through a serial interface (RS-232), connect a serial cable to the printer,

start the host computer, and then turn on the printer.

When using connectors equipped with screws, tighten the screws on both sides to secure the

connectors firmly.

Ethernet Interface

Use an Ethernet cable to connect the printer to network via a hub.

Use Epson TM-T100 Utility or EpsonNet Config to set network.

For details on Epson TM-T100 Utility, refer to TM-T100 Utility User's Manual.

For details on EpsonNet Config, refer to EpsonNet Config User's Guide.

• When LAN cables are installed outdoors, make sure they are connected through devices that

have surge protection.

Otherwise, the devices can be damaged by lightning.

• Never attempt to connect the drawer kick cable or a standard telephone line cable to the LAN

connector.

As same with Conventional models, you can use EpsonNet Config (Web version) in the same way.

Start up a web browser and then input the printer's IP address in the address bar.

On the authentication screen, input your user name and password.

The default setting for the password varies depending on the firmware version.

Firmware version User name

Before 13.04 ESC/POS

13.04 ESC/POS or later

You can check the firmware version using the self-test (

You can check the product's serial number using a self-test (

manufacturing nameplate attached to the product.

"epson"

"epson"

Password

"epson"

Product serial number

(10 alphanumeric characters, case sensitive)

"Self-test Mode" on page 36).

"Self-test Mode" on page 36) or on the

21

Page 22

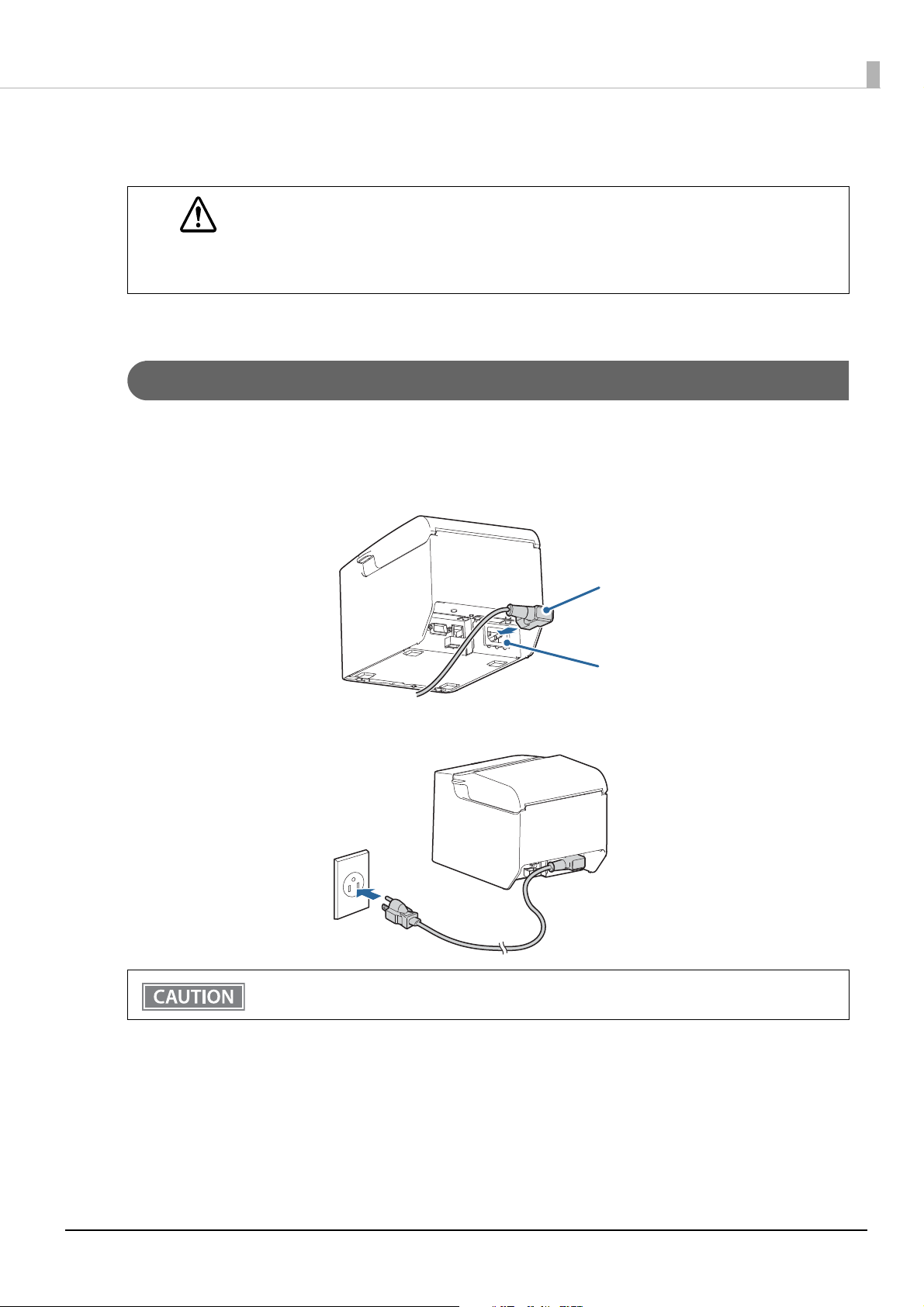

Connecting the AC cable

Power supply connector

AC cable

• Never insert the AC cable plug into a socket that does not meet the rated voltage requirements

of the printer.

WARNING

Be sure to use the included AC cable.

Connecting Procedure

Make sure the printer is turned off.

1

Connect the AC cable to the power supply connector.

2

Doing so may result in damage to the printer.

• Should a fault ever occur, immediately turn off the power to the printer and unplug the AC cable

from the wall socket.

Chapter 2 Setup

Insert the AC plug into a wall socket.

3

Do not turn on the printer before installing the printer driver.

22

Page 23

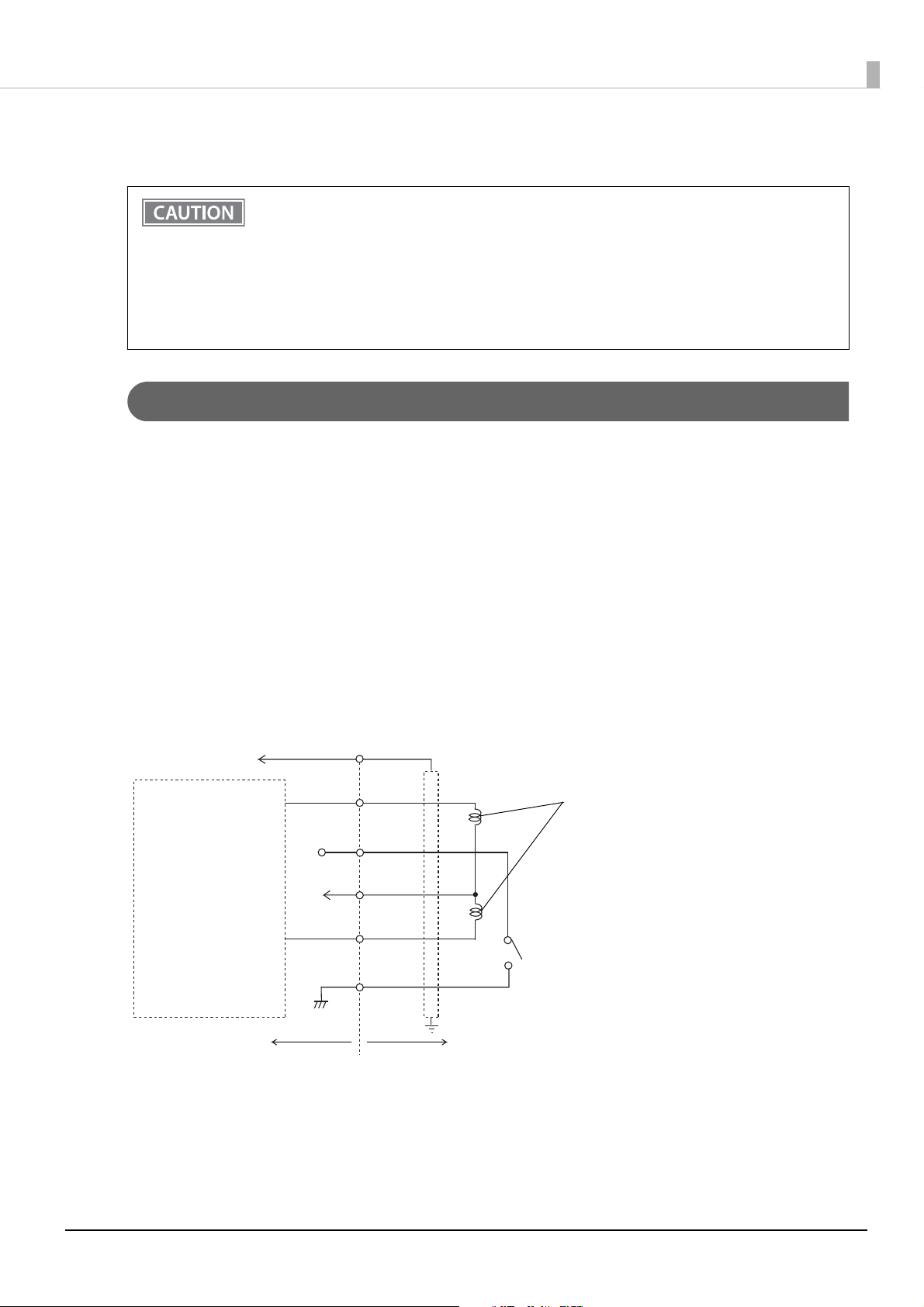

Chapter 2 Setup

F. G

+24V

With shielded

Drawer kick connector

Printer side

User side [Drawer kick side]

Drawer open/ close switch

Drawer kick solenoid

1

2

3

4

5

6

Connecting the Cash Drawer

• The optional external buzzer and the cash drawer cannot be used simultaneously. Do not

connect both the optional external buzzer and the cash drawer to the printer at the same time

by using a branched connector.

• The cash drawer cannot be used If the enable/disable setting for the optional external buzzer is

set to “enable”. When using the cash drawer, be sure to set it to “disable” using the Epson TMT100 Utility.

• Two driver transistors cannot be energized simultaneously.

• Leave intervals longer than 4 times the drawer driving pulse when sending it continuously.

Cash Drawer Requirements

Specifications of drawers differ depending on makers or models. When you use a drawer other than specified,

make sure its specification meets the following conditions.

Otherwise, devices may be damaged.

• The load, such as a drawer kick solenoid, must be connected between pins 4 and 2 or pins 4 and 5 of the

drawer kick connector.

• When the drawer open/close signal is used, a switch must be provided between drawer kick connector pins 3

and 6.

• The resistance of the load, such as a drawer kick solenoid, must be 24 ohms or more or the input current

must be 1A or less.

• Be sure to use the 24V power output on drawer kick connector pin 4 for driving the equipment.

Drawer Connection Diagram

Adaptable Connector

Modular connector RJ12

23

Page 24

Pin assignments

6 5 4 3 2 1

Pin number Signal name Direction

1Frame GND -

2 Drawer kick drive signal 1 Output

3 Drawer kick open/close signal Input

4 +24 V -

5 Drawer kick drive signal 2 Output

6Signal GND -

Connecting the Drawer Kick Cable

• Use a shield cable for the drawer kick cable.

• When using cash drawer, make sure to use the power supply for printer (connector pins 4).

WARNING

• Do not insert a telephone line into the drawer kick connector.

Doing so may damage the telephone line or printer.

Chapter 2 Setup

Connect the drawer kick cable to the drawer kick connector by pressing firmly until the connector clicks into

place.

24

Page 25

Chapter 2 Setup

Volume adjustment knob

Connecting the Optional External Buzzer

When the optional external buzzer (model: OT-BZ20) is connected to the drawer kick connector of the printer,

you can set the printer so that it beeps when you send commands, when an error occurs, when executed auto

cutting, and when detected paper end. Settings for sound patterns and frequency depending on the occasions

the buzzer beeps are also available.

Use the TM-T100 Utility to make the buzzer settings: enable/disable setting, sound pattern setting, and

frequency setting.

• Be sure to turn off the printer before you connect/disconnect the optional external buzzer.

• The optional external buzzer and the cash drawer cannot be used simultaneously. Do not

connect both the optional external buzzer and the cash drawer to the printer at the same time

by using a branched connector.

Connecting Procedure

The optional external buzzer is recommended to be installed in the following positions.

• Do not install the optional external buzzer at the roll paper exit.

• To prevent liquid from entering inside, it is recommended to install the optional external buzzer

so that the volume adjustment knob is positioned sideways or downward.

25

Page 26

Chapter 3 Advanced Usage

Advanced Usage

Software Settings

With the memory switches and customized values, which are software settings for this printer, you can set the

various functions. For an outline of the functions, see the following pages. Software settings are performed

using the TM-T100 Utility, Software Setting Mode, or ESC/POS Commands.

Item/Method

Automatic line feed ✔

USB power-saving function ✔

Pre-feed before next print ✔

Error signal output ✔

Data processing with reception error ✔

Recovery conditions from receive buffer BUSY ✔

Memory Switches

Paper sensors to output paper end signal ✔

Receive buffer capacity ✔✔

Condition for BUSY ✔✔

Print density ✔✔

Print speed ✔✔

Automatic paper reduction ✔✔

Character code table defaults ✔✔

International character defaults ✔✔

Software Setting Mode Epson TM-T100 Utility

Thai characters print method ✔✔

Column emulation mode ✔✔

Autocutting after closing the roll paper cover ✔

Customized Values

Buzzer function ✔

Shrinking/Expanding graphics data ✔

USB class ✔✔

Serial Interface Communication Condition ✔✔

Autocutter error recovery condition ✔

Auto top logo printing ✔

Auto bottom logo printing ✔

Extended settings for auto top logo/bottom logo printing ✔

• For information about the TM-T100 Utility, see the TM-T100 Utility User's Manual.

• For information about how to use the Software Setting Mode, see

page 37

.

"Software Setting Mode" on

26

Page 27

Feature

Automatic line feed

• Always disabled (default setting)

• Always enabled

USB power-saving function

• Disabled

• Enabled (default setting)

The USB power-saving function is valid only when the USB interface communication condition is

set to the vendor-defined class and the system configuration is set so that the USB driver can

support the USB power-saving function.

Chapter 3 Advanced Usage

Error signal output

• Enabled (default setting)

• Disabled

Data processing with reception error

• Prints “?” (default setting)

• Ignored

Recovery conditions from receive buffer BUSY

• Releases the BUSY state when the remaining receive buffer capacity reaches 256 bytes (default setting)

• Releases the BUSY state when the remaining capacity of the receive buffer reaches 138 bytes.

Receive buffer capacity

• 4 KB (default setting)

• 45 bytes

27

Page 28

Chapter 3 Advanced Usage

Condition for BUSY

• Receive buffer full/Offline (default setting)

• Receive buffer full

• In either case above, the printer enters the BUSY state after power is turned on, and when a self-

test is being run.

• If BUSY condition is set to “Receive buffer full,” the printer will not become BUSY

∗ When the roll paper cover is open

∗ When paper is fed by the FEED button

∗ When printing has stopped for a paper out

∗ When macro execution ready state

∗ When error has occurred

Print density

Selectable from levels 1 to 7 (Light ~ Dark)

Default setting: Level 4

Depending on the paper type, it is recommended to set the print density as shown in the table below for the best

print quality.

Original Paper type Density

TF50KS-EY Level 4

PD160R Level 4

KT48FA Level 4

When the print density level is increased, print speed may be reduced.

Print speed

Selectable from levels 1 to 13 (Slow ~ Fast)

Default setting: Level 13

Depending on print conditions, such as print duty, thermal head temperature, and data

transmission speed, print speed is automatically adjusted, which may cause white lines due to

intermittent print (the motor sometimes stops). To avoid this, keep the print speed constant by

setting it lower.

USB class

• Vendor-defined class (default setting)

• Printer class

28

Page 29

Serial Interface Communication Condition

Baud rate

• 2400 bps

• 4800 bps

• 9600 bps

• 19200 bps

• 38400 bps (default setting)

• 57600 bps

• 115200 bps

Parity

• No parity (default setting)

• Odd parity

• Even parity

Chapter 3 Advanced Usage

Handshaking

• DTR/DSR (default setting)

• XON/XOFF

Bit length

• 7 bits

• 8 bits (default setting)

Paper reduction

Extra upper space reduction

• Disabled (default setting)

• Enabled

Extra lower space reduction

• Disabled (default setting)

• Enabled

Line space reduction rate

• Disabled (default setting)

• 25%

• 50%

• 75%

29

Page 30

Line feed reduction rate

• Disabled (default setting)

• 25%

• 50%

• 75%

Barcode height reduction rate

• Disabled (default setting)

• 25%

• 50%

• 75%

Amount of reduction in character height

• Disabled (default setting)

• Extra character space reduction by 25%

Chapter 3 Advanced Usage

• Extra character space reduction by 50%

• Extra character space reduction by 75%

• Paper reduction is not performed for space dot lines of graphics printing data.

• When reducing barcode height, reading of the barcode is not guaranteed. Be sure to check that

the barcode can be read with a user’s barcode reader in advance.

Character code table defaults

Selectable from 43 pages including user-defined page

Default setting: PC437: USA, Standard Europe

International character defaults

Selectable from 18 sets

Default setting: China

Thai characters print method

• 3 Pass

• 1 Pass (default setting)

Column emulation mode

• 48 column mode (default setting)

• 42 column mode

Autocutting after closing the roll paper cover

• Cuts (default setting)

• Does not cut

30

Page 31

Optional buzzer

• For information about how to connect the optional external buzzer, see "Connecting the

Optional External Buzzer" on page 25

• When the optional external buzzer is enabled, a cash drawer cannot be used. Be sure to disable

it when you use a cash drawer.

Enables/disables

• Disabled (default setting)

• Enabled

Buzzer frequency (Error)

• Does not sound

• Sounds 1 time

• Sounds continuously (default setting)

Sound pattern (Autocut)

Chapter 3 Advanced Usage

.

Selectable from Patterns A to E

Default setting: Pattern A

Buzzer frequency (Autocut)

• Does not sound

• Sounds 1 time (default setting)

Sound pattern (Pulse 1)

Selectable from Patterns A to E

Default setting: Pattern A

Buzzer frequency (Pulse 1)

• Does not sound

• Sounds 1 time (default setting)

Sound pattern (Pulse 2)

Selectable from Patterns A to E

Default setting: Pattern B

Buzzer frequency (Pulse 2)

• Does not sound

• Sounds 1 time (default setting)

31

Page 32

Shrinking/Expanding graphics data

Resizing

• No resizing (default setting)

• Automatic shrinking

• Manual adjustment

Algorithm

• Thinning out method

• Nearest neighbor method (default setting)

• Bilinear method

• Bicubic method

Scaling factor (manual adjustment)

50% to 200%

Chapter 3 Advanced Usage

Auto top logo printing

TM-T100 Utility does not support the setting for Number of lines to be deleted below top logo.

Key-code

Selectable from key-codes of registered logos

Alignment

• Left

• Center

• Right

Number of lines to be deleted below top logo

32

Page 33

Auto bottom logo printing

Key-code

Selectable from key-codes of registered logos

Alignment

• Left

• Center

• Right

Extended settings for auto top logo/bottom logo printing

TM-T100 Utility does not support the following settings.

• Top logo print while paper feeding to the cutting position

• Top logo print while clearing the buffer to recover from a recoverable error

• Top logo print after paper feeding with the Feed button has finished

Chapter 3 Advanced Usage

Top logo print while paper feeding to the cutting position

• Disabled (default setting)

• Enabled

Top logo print when printer is powered on

• Disabled (default setting)

• Enabled

Top logo print when roll paper cover is closed

• Disabled

• Enabled (default setting)

Top logo print while clearing the buffer to recover from a recoverable error

• Disabled

• Enabled (default setting)

Top logo print after paper feeding with the Feed button has finished

• Disabled (default setting)

• Enabled

33

Page 34

Chapter 3 Advanced Usage

Close the roll paper cover, and turn on the printer while pressing the Feed button.

Self-test

Briefly press the Feed button.

Continuing the self-test

Hold down the Feed button

Mode selection guidance

Open the roll paper cover, turn on the printer while pressing the Feed button,

and then close the roll paper cover.

Hexadecimal Dumping

Press the Feed button

once briefly and then

hold it down

Press the Feed button

two times briefly and

then hold it down

Press the Feed button

three times briefly and

then hold it down

(1)

(2)

Press the Feed button

four times briefly and

then hold it down

Press the Feed button

five times briefly and

then hold it down

NV Graphics

Information

Receipt Enhancement

Information

Software Setting

Restore Default

Val ues

Interface Setup Mode

(Ethernet model only)

Setting/Checking Modes

As well as print mode, the following modes are also provided for making various printer settings and checking

items.

• Self-test mode

• NV graphics information print mode

• Receipt Enhancement information print mode

• Software setting mode

• Restore default values mode

• Interface setup mode (Ethernet model only)

• Hexadecimal dumping mode

To enter the Self-test mode or the Hexadecimal dumping mode, turn the printer on with the special operations

as described below.

To enter one of the other modes, first enter the Self-test mode, and then select one mode by operating the Feed

button as described below.

34

Page 35

Chapter 3 Advanced Usage

In (1) and (2), the following guidances are printed, the Paper LED flashes, and instructs the user's operations.

1. Continuing self-test guidance

2. Mode selection guidance

35

Page 36

Chapter 3 Advanced Usage

Self-test Mode

You can check the following items using the self-test.

• Product name

• Firmware version

• Product serial number

• Interface information

• Resident fonts

• Maintenance counter information (print head running length, number of times of auto-cutting)

Follow the steps below. The self-test can also be executed using ESC/POS Commands.

Close the roll paper cover.

1

While pressing the Feed button, turn on the printer.

2

(Hold down the Feed button until printing starts.)

After printing the current print status, a Continuing self-test guidance is printed, and the Power LED

flashes.

Briefly press the Feed button (less than one second) to continue the self-test.

3

The printer prints a rolling pattern on the roll paper, using the built-in character set.

After “*** completed ***” is printed, the printer initializes and switches to standard mode.

NV Graphics Information Print Mode

Prints the following NV graphics information registered to the printer.

• Capacity of the NV graphics

• Used capacity of the NV graphics

• Unused capacity of the NV graphics

• Number of NV graphics that are registered

• Key code, number of dots in X direction, number of dots in Y direction to be defined.

• NV graphics data

For details on NV graphics, see "NV Graphics Memory" on page 17.

Follow the steps below.

After running a self-test, hold down the Feed button for at least one second to enter

1

the Mode selection.

The Mode selection guidance is printed, and the Paper LED flashes.

36

Page 37

Chapter 3 Advanced Usage

After briefly (less than one second) pressing the Feed button once, hold it down for at

2

least one second, to print the NV graphics information.

After information printing, the Mode selection guidance is printed again.

To finish, turn off the power, or select “Exit and Reboot Printer”.

3

Receipt Enhancement Information Print Mode

You can check the following items using the R/E information mode:

• Auto top logo printing setting

• Auto bottom logo printing setting

• Extended settings for auto top/bottom logo printing

Follow the steps below.

After running a self-test, hold down the Feed button for at least one second to enter

1

the Mode selection.

The Mode selection guidance is printed, and the Paper LED flashes.

After briefly (less than one second) pressing the Feed button twice, hold it down for

2

at least one second, to print the R/E information.

After information printing, the Mode selection guidance is printed again.

To finish, turn off the power, or select “Exit and Reboot Printer”.

3

Software Setting Mode

You can change the printer settings. For information on available setting items, see "Software Settings" on page 26.

Follow the steps below.

After running a self-test, hold down the Feed button for at least one second to enter

1

the Mode selection.

The Mode selection guidance is printed, and the Paper LED flashes.

37

Page 38

Chapter 3 Advanced Usage

Briefly press the Feed button three times (less than one second), hold it down for at

2

least one second to enter the Software setting mode (Customize Value Settings).

The Software setting mode guidance is printed, and the Paper LED flashes.

Customize Value Settings

Modes

0: Exit

1: Print Current Settings

2: Interface Settings

3: Print Density

4: Print Speed

Automatic Reduction of Paper

5:

6: Character Settings

Select Modes by executing following

procedure.

step 1. Press the Feed button less

than 1 second as many times

as the selected mode number.

step 2. Press Feed button for 1

second or more.

After briefly pressing the Feed button (less than one second) for the number of times

3

shown in the print result, hold down the button for more than one second to select

the setting items.

The setting selected as the setting item, the current settings and default settings are printed.

Depending on the setting item, you may need to continue selecting the setting item before the

settings are printed. For details on setting items, see "Software Settings" on page 26

When set to a value other than those in the software setting mode, the current settings are

not printed.

Select a setting by briefly pressing the Feed button (less than one second) for the

4

number of times applicable to the setting, and then hold down the button for more

.

than one second to confirm your selection.

After saving the settings, the Software setting mode guidance is printed, and the Paper LED flashes.

To close Software setting mode, turn off the printer, or select “Exit” to return to Mode

5

selection guidance, and then select “Exit and Reboot Printer”.

• To select 0 as the item number, hold down the Feed button until printing starts.

• If the button is pressed a number of times that is not displayed by the Setup guidance, the

operation is invalid and the same guidance is printed.

38

Page 39

Chapter 3 Advanced Usage

Restore Default Values Mode

In Restore default values mode, following values saved on NV Memory will be set back to default settings.

When any error occurs, you can use to specify the reason.

Setting Contents Setting Items

Customized value ✔✔

Memory switches ✔✔

R/E (Receipt Enhancement) settings ✔✔

Communication condition of USB interface ✔✔

Communication condition of serial interface ✔✔

Communication condition of network interface ✔✔

NV graphics - ✔

NV bit image - ✔

User-defined page - ✔

User NV Memory - ✔

Follow the steps below.

Restore Default Values and

Delete Defined Data

After running a self-test, hold down the Feed button for at least one second to enter

1

the Mode selection.

The Mode selection guidance is printed, and the Paper LED flashes.

Briefly press the Feed button four times (less than one second), hold it down for at

2

least one second to enter the Restore Default Values.

The guidance is printed.

When only restoring the default settings:

3

Briefly press the Feed button once (less than one second), hold it down for at least

one second. (Hold down the Feed button until the restoration complete message is

printed.)

When restoring default settings and deleting user defined data:

Briefly press the Feed button twice (less than one second), and then hold it down for

at least one second. (Hold down the Feed button until the restoration complete

message is printed.)

To finish, turn off the power.

4

39

Page 40

Chapter 3 Advanced Usage

Interface Setup Mode (Ethernet model only)

Use this mode to setup the interface and other settings.

Follow the steps below.

After running a self-test, hold down the Feed button for at least one second to enter

1

the Mode selection.

The Mode selection guidance is printed, and the Paper LED flashes.

Briefly press the Feed button five times (less than one second), hold it down for at

2

least one second to enter the Interface Setup mode.

The guidance is printed.

After briefly pressing the Feed button (less than one second) for the number of times

3

shown in the print result, hold down the button for more than one second to select

the setting items.

Initialize

Select [Ethernet Setup] and select [Initialize] to initialize the network setting parameter. The printer is reset and

restarted.

Hexadecimal Dumping Mode

In the hexadecimal dumping mode, the printer prints the data transmitted from a host computer in

hexadecimal numbers and their corresponding characters. It enables you to check if data is transmitted to the

printer correctly.

• If there is no character corresponding to print data, “ . ” is printed.

• If you press the Feed button when there is less than one line of print data, one line is printed.

• During hexadecimal dumping mode, applications that check the printer status may not operate

correctly. The printer only returns the status for the “Real-time transmission status” command.

Follow the steps below. Hexadecimal Dumping Mode can also be executed using ESC/POS Commands.

Open the roll paper cover.

1

While pressing the Feed button, turn on the printer. (Hold down the Feed button

2

until the Error LED turns on.)

Close the roll paper cover.

3

The printer starts printing data received from then on in hexadecimal numbers and their

corresponding ASCII characters.

40

Page 41

Chapter 3 Advanced Usage

Example of printing in hexadecimal dumping mode:

To close hexadecimal dumping mode, turn off the printer after printing is complete,

4

or press the Feed button for three times.

41

Page 42

Printing a Status Sheet

Follow the steps below to check the Ethernet interface settings.

When the power LED is flashing, wait until it remains lit to start printing.

Using the Status Sheet Button

Check that the printer is turned on.

1

Make sure the roll paper cover is closed.

Hold down the status sheet button (for 3 seconds or longer).

2

The status sheet is printed. After printing, the printer returns to the standard mode.

Using the Feed button

Chapter 3 Advanced Usage

Check that the printer is turned on.

1

Open the roll paper cover.

2

Hold down the Feed button (for 1 seconds or longer).

3

Close the roll paper cover.

4

The status sheet is printed. After printing, the printer returns to the standard mode.

* * * Ethernet Interface * * *

the

E

rnet Status

MAC Address

Physical Layer

Link Status

Ethernet

: XXXXXXXXXXXX

:WFDN

Network

Soft Version : XX.XX

TCP/IP Status

Acquiring

IP Address

Subnet Mask

Default Gateway

Other Status

TimeServer

Stored Date/Time

TM-T100

: XX-XX-XX-XX-XX-XX

: Auto-negotiation

: Connect

:

XXXX

: XXX.XXX.XXX.XX

: XXX.XXX.XXX.X

: X.X.X.X

: Invalid

: 20XX/XX/XX 00:00:00

42

Page 43

Resetting the Interface Settings

Follow the steps below to reset the interface settings.

• You can return the interface settings to their defaults from the Interface Setup mode. For details

on the Interface Setup mode, see "Interface Setup Mode (Ethernet model only)" on page 40

• Only network settings are returned to their defaults.

Turn off the printer and close the roll paper cover.

1

Hold down the status sheet button while turning on the printer.

2

A message is printed indicating that resetting is being performed, and the printer restarts.

Hold down the status sheet button until the initialization execution message is printed.

Chapter 3 Advanced Usage

.

43

Page 44

Chapter 4 Application Development Information

Application Development Information

This chapter describes how to control the printer and gives information useful for printer application

development.

Controlling the Printer

The printer supports the ESC/POS commands.

Users can control the printer by using the aforementioned command, or the following development kits or

drivers.

• EPSON Advanced Printer Driver (APD)

• OPOS ADK

• OPOS ADK for .NET

• Epson ePOS SDK

ESC/POS

ESC/POS is the Epson original printer command system for POS printers and customer display.

With ESC/POS commands, you can directly control all the printer functions, but detailed knowledge of printer

specifications or combination of commands is required, compared to using drivers and applications.

For details of ESC/POS, see the ESC/POS Command Reference. The ESC/POS Command Reference can be

accessed at the following URL.

www.epson-biz.com/pos/reference/

44

Page 45

Chapter 4 Application Development Information

Controlling the Cash Drawer

A pulse output is sent to drawer kick connector pin 2 or pin 5, and you can open the drawer.

You can also check the open/close status of the drawer by checking the signal level of the drawer kick connector

pin 3.

These controls are executed by a driver or by commands.

ESC/POS Commands

Prepare the output command for the specified pulse and the status transmission command.

For details, see the ESC/POS Command Reference.

For Windows Printer Drivers (APD)

You can set so that the drawer opens at the start of printing. For details, see the manual for drivers.

For details on control, see the manual for Status API of the driver.

OPOS (OCX Driver)

Register a cash drawer using the SetupPOS Utility, and control using the OpenDrawer method or

the DirectIO function.

For details, see the “EPSON OPOS ADK MANUAL APPLICATION DEVELOPMENT GUIDE

Cash Drawer” and the “UnifiedPOS Specification”.

OPOS for .NET

Register a cash drawer using the SetupPOS Utility, and control using the OpenDrawer method or

the DirectIO function.

For details, see the “EPSON OPOS ADK for .NET MANUAL Application Development Guide Cash

Drawer (EPSON Standard)” and the “UnifiedPOS Specification”.

Epson ePOS SDK

The output command for the drawer kick pulse and the status transmission command are provided

in each SDK library. For details, see the user's manuals provided with each SDK.

• Whether or not pin 2 or pin 5 operates the drawer kick connector depends on the connected

cash drawer.

• You can acquire documents regarding the UnifiedPOS from the following link.

https://www.omg.org/retail/unified-pos.htm

45

Page 46

Chapter 4 Application Development Information

Controlling the Optional External Buzzer

You can set the optional external buzzer to buzz when an error occurs and when an automatic cut off occurs.

The buzzer can be buzzed at any time using a driver or a command.

You can also set the timing and the beep pattern for the buzzer.

ESC/POS Commands

Use the buzzer control command or the output command for the specified pulse.

For details, see the ESC/POS Command Reference.

For Windows Printer Drivers (APD)

Use the DirectIO function or the API for opening the drawer. For details, see the manual for Status

API of the drivers.

OPOS (OCX Driver)

Register a POS printer using the SetupPOS Utility and control using the DirectIO function.

For details, see the “EPSON OPOS ADK MANUAL APPLICATION DEVELOPMENT GUIDE

POSPrinter (TM Series)”.

OPOS for .NET

Register a POS printer using the SetupPOS Utility and control using the DirectIO function.

For details, see the “EPSON OPOS ADK for .NET MANUAL Application Development Guide POS Printer

(TM-T100)”.

Epson ePOS SDK

The command for the buzzer function is provided in each SDK library. For details, see the user's

manuals provided with each SDK.

For details on setting the optional external buzzer, see "Connecting the Optional External Buzzer"

on page 25

.

46

Page 47

Chapter 4 Application Development Information

Software

The following software is provided for application development.

Development Kits

Software Description

EPSON OPOS ADK This OCX driver can control POS peripherals using OLE technology.* Because

controlling POS peripherals with original commands is not required on the

application side, efficient system development is possible.

EPSON OPOS ADK for .NET The OPOS ADK for .NET is a POS industry standard printer driver compatible with

Microsoft POS for .NET.

It allows you to develop applications that are compatible with the UPOS (Unified

POS) specification.

When developing applications, use a separate development environment such

as Microsoft Visual Studio .NET.

EPSON JavaPOS ADK

(Windows/Linux)

Epson ePOS SDK This is a developer kit to control applications, native applications for smart

for Android

for iOS

JavaPOS is the standard specification which defines an architecture and device

interface (API) to access various POS devices from a Java based system. Using

JavaPOS standard API allows control with Java based applications of functions

inherent to each device. A flexible design with Java language and JavaPOS

enables many different types of computer systems, such as stand alone or

network configuration, to use a same application. You can use JavaPOS to build

applications and drivers independently of platforms. This allows flexible

configurations using thin clients to meet the system requirements.

devices, and printers. This includes libraries, manuals, and sample programs.

* OLE technology developed by Microsoft divides software into part blocks. The OPOS driver is presupposed

to be used with a development environment, such as Visual Basic, unlike ordinary Windows printer drivers.

It is not a driver to be used for printing from commercial applications.

You can acquire documents regarding the UnifiedPOS from the following link.

https://www.omg.org/retail/unified-pos.htm

47

Page 48

Drivers

Chapter 4 Application Development Information

Software Description

EPSON Advanced Printer Driver

(APD)

EPSON TM Virtual Port Driver This is a serial/parallel-USB/LAN conversion driver to make an

Mac Printer Driver Mac printer driver allows you to control the printer using

Epson TM/BA Series Thermal

Printer Driver

In addition to ordinary Windows printer driver functions, this

driver has controls specific to POS. The Status API (Epson original

DLL) that monitors printer status and sends ESC/POS commands

is also attached to this driver.

Epson TM/BA/EU printer connected via USB or LAN accessible

from a POS application through a virtual serial or parallel port.

It allows you to directly control devices connected via USB or LAN

with ESC/POS commands without making changes in the POS

application that controls devices connected via a serial or parallel

interface.

Common UNIX Printing System (CUPS) on Mac OS X.

This is a full raster printer driver. It is able to print images, text, and

vector graphics etc., that an application displays. With this driver

many printer controls are possible, such as paper cut timing

control, cash drawer control, printing speed control, blank line

skip, and upside-down printing. It also provides API and dialogues

for print setting, sample applications, and logo setting utility.

This driver allows you to control the printer using Common UNIX

Printing System (CUPS) on GNU/Linux.

This is a full raster printer driver. It is able to print images, text, and

vector graphics etc., that an application displays. With this driver

many printer control are possible, such as paper cut timing

control, cash drawer control, printing speed control, blank line

skip, and upside-down printing.

Operating

environment

Windows

Windows

Mac OS X

GNU/Linux

48

Page 49

Utilities

Chapter 4 Application Development Information

Software Description

TM-T100 Utility A utility for checking and changing various printer settings. Use

this utility to:

• Check the current settings

• Test oper a tion

• Store logos

• Set paper reduction

• Set printing control

• Set communication interfaces

• Set the network

• Save/restore settings

EpsonNet Config A network setting tool for Epson network products. Windows, Mac

Epson Deployment Tool Use to make network and printer settings simultaneously. Allows

you to make settings efficiently at the time of introducing TM

printers for the first time, or when configuring multiple TM

printers at the same time.

Epson Monitoring Tool Use to check a list of status for the Epson printers connected to

the network.

You can also update certificates for multiple printers in a batch.

Operating

environment

Windows

Windows

Windows

Download

You can obtain software and manuals from one of the following URLs.

For customers in North America, go to the following web site and follow the on-screen instructions.

www.epson.com/support/

For customers in other countries, go to the following web site:

www.epson-biz.com

49

Page 50

Chapter 4 Application Development Information

Notes on Printing Barcodes and Two-dimensional Symbols

• The user must set the quiet zone, depending on the barcode standards.

• When printing PDF417 (two-dimensional symbols), the following are recommended:

Module height: 3 to 5 times the module width

Vertical size of the symbol: approximately 5 mm {0.20"} or more

• The recognition rate of ladder barcodes and two-dimensional symbols may vary depending on widths of the

modules, print density, environmental temperature, type of paper, and characteristics of the reader.

Therefore, the user must check the recognition rate before setting the use conditions so that the restrictions

of the reader are satisfied.

• Reading quality of barcodes and two-dimensional symbols in graphics multiple tone printing is not

guaranteed.

• When printing ladder barcodes or two-dimensional symbols with graphics printing, set the print speed to

speed level 2.

50

Page 51

Handling

Cover open lever

This chapter describes basic handling of the printer.

Installing and Replacing Roll Paper

• Do not open the roll paper cover during printing.

The printer may be damaged.

CAUTION

• Do not touch the manual cutter with your hands when installing or replacing the roll paper.

Otherwise, you may be injured because the manual cutter blade is sharp.

• Use roll paper that meets the printer specification. For details about paper specification, see

"Paper Specifications" on page 63.

• Paper must not be pasted to the roll paper spool.

Chapter 5 Handling

Press the cover open lever to open the roll paper cover.

1

Remove the used roll paper core, if any.

2

51

Page 52

Install the roll paper in the correct direction.

1

2

3

Chapter 5 Handling