Page 1

Technical Reference Guide

Safety Precautions

Describes precautions that ensure safe use of the product. Read this first.

Product Overview

Describes product features.

Setup

Describes product and peripheral device installation

and setup procedures.

Advanced Product Use

Describes advanced product use.

Application Development Information

Provides information required for controlling this

product and application development.

Handling the Product

Describes the basic operating procedures of the product.

Troubleshooting

Describes what to do when problems occur.

Product Specifications

Provides product specifications, interface specifications, and character code tables.

M00110902

Rev. C

Page 2

Notes

• All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic, mechanical, photocopying, recording, or otherwise, without the

prior written permission of Seiko Epson Corporation.

• The content of this manual is subject to change without notice. Contact ESPON for the latest information.

• While every precaution has been taken in the preparation of this manual, Seiko Epson Corporation assumes

no responsibility for errors or omissions.

• Neither is any liability assumed for damages resulting from the use of the information contained herein.

• Neither Seiko Epson Corporation nor its affiliates shall be liable to the purchaser of this product or third par-

ties for damages, losses, costs, or expenses incurred by purchaser or third parties as a result of: accident, misuse, or abuse of this product or unauthorized modifications, repairs, or alterations to this product, or

(excluding the U.S.) failure to strictly comply with Seiko Epson Corporation's operating and maintenance

instructions.

• Seiko Epson Corporation shall not be liable for any damages or problems arising from the use of any options

or any consumable products other than those designated as Genuine Epson Products or Epson Approved

Products by Seiko Epson Corporation.

Copyrights

EPSON is a registered trademark of Seiko Epson Corporation.

Exceed Your Vision is a registered trademark or trademark of Seiko Epson Corporation.

Microsoft® and Windows® are registered trademarks of Microsoft Corporation in the United States, Japan,

and/or other countries.

All other trademarks are the property of their respective owners and used for identification purpose only.

©Seiko Epson Corporation 2018. All rights reserved.

2

Page 3

Table of Contents

■ Safety Precautions ..................................................................................................................7

Meanings of Symbols ....................................................................................................................................................... 7

Cautions on Installation ................................................................................................................................................... 7

Cautions on Power Supply.............................................................................................................................................. 7

Cautions on Handling....................................................................................................................................................... 8

Cautions on Ink Cartridges ............................................................................................................................................. 9

Caution Label.....................................................................................................................................................................10

■ Restriction of Use ................................................................................................................. 11

■ About This Manual ...............................................................................................................12

Purpose of This Manual..................................................................................................................................................12

Manual Organization ......................................................................................................................................................12

Manual Illustrations .........................................................................................................................................................12

Product Overview ..........................................................................................13

■ Features ................................................................................................................................. 13

■ Product Configuration ........................................................................................................ 14

Model....................................................................................................................................................................................14

Accessories .........................................................................................................................................................................14

■ Part Names and Functions ................................................................................................. 15

Front......................................................................................................................................................................................15

Operation Panel................................................................................................................................................................17

Rear .......................................................................................................................................................................................18

■ Checking the Product Status ............................................................................................. 19

Replacement Timing of Consumables......................................................................................................................19

Statuses and Errors ..........................................................................................................................................................20

■ Cut Sheet Processing Modes.............................................................................................. 24

High-speed Mode ............................................................................................................................................................24

Confirmation Mode .........................................................................................................................................................27

Speed of Each Processing Mode.................................................................................................................................31

■ NV Memory ........................................................................................................................... 33

NV Graphics Memory......................................................................................................................................................33

NV User Memory ..............................................................................................................................................................33

Memory Switch .................................................................................................................................................................33

R/E (Receipt Enhancement) ..........................................................................................................................................33

User-defined Page ...........................................................................................................................................................33

Maintenance Counters ...................................................................................................................................................34

3

Page 4

Setup............................................................................................................... 35

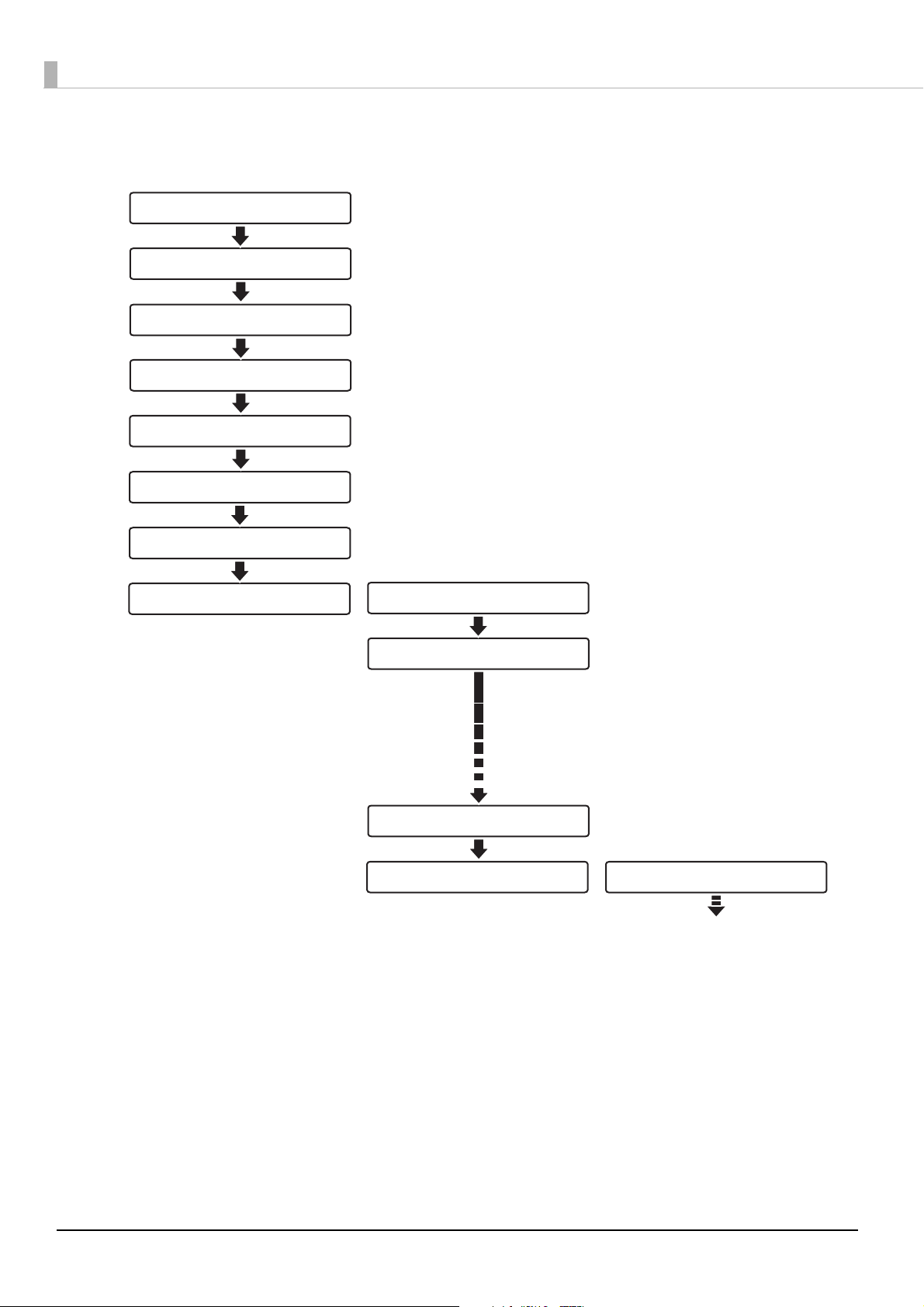

■ Setup Flow............................................................................................................................. 35

■ Product Installation ............................................................................................................. 36

Removing the Packing Materials ...............................................................................................................................36

Installation ......................................................................................................................................................................... 36

■ Connecting to a Host Computer........................................................................................ 37

■ Connecting a Cash Drawer ................................................................................................. 37

Specifications Required for a Cash Drawer............................................................................................................. 37

Connecting the Drawer Cable..................................................................................................................................... 38

■ Connecting a Power Supply............................................................................................... 39

■ Loading Roll Paper............................................................................................................... 40

■ Installing the Ink Cartridges............................................................................................... 41

■ Adjusting LCD Backlight Brightness................................................................................. 43

■ Test Printing .......................................................................................................................... 44

Advanced Product Use.................................................................................. 47

■ Software Settings ................................................................................................................. 47

Function .............................................................................................................................................................................. 48

■ Setting/Confirmation Mode............................................................................................... 53

Self-test Mode................................................................................................................................................................... 54

NV Graphics Information Print Mode ....................................................................................................................... 56

R/E Information Print Mode ......................................................................................................................................... 58

Software Setting Mode.................................................................................................................................................. 59

Application Development Information ...................................................... 61

■ Operating Environment...................................................................................................... 61

130 DPM Model ................................................................................................................................................................ 61

225 DPM Model ................................................................................................................................................................ 61

■ Driver ...................................................................................................................................... 62

For Windows Environment ........................................................................................................................................... 62

For Linux Environment .................................................................................................................................................. 63

■ Utilities ................................................................................................................................... 64

TM-S9000II Utility ............................................................................................................................................................ 64

Epson Deployment Tool................................................................................................................................................64

BmpToRaster ..................................................................................................................................................................... 64

4

Page 5

■ Downloading Software ....................................................................................................... 65

Handling the Product ....................................................................................67

■ Turning On/Off ..................................................................................................................... 67

Turning the Power On ....................................................................................................................................................67

Turning the Power Off ....................................................................................................................................................67

■ Opening a Cover................................................................................................................... 68

Opening the Ink Cartridge Cover ...............................................................................................................................68

Opening the Roll Paper Cover .....................................................................................................................................68

Opening the MICR Cover, Back Cover, and Scanner Cover................................................................................69

■ Replacing the Ink Cartridges ............................................................................................. 70

■ Replacing Roll Paper............................................................................................................70

■ Cut Sheet Processing........................................................................................................... 71

Process Flow.......................................................................................................................................................................71

Loading Cut Sheets .........................................................................................................................................................72

Removing Cut Sheets .....................................................................................................................................................73

■ ID Card Processing............................................................................................................... 74

■ Magnetic Stripe Card Processing ...................................................................................... 75

■ Cleaning the Product........................................................................................................... 76

Cleaning the Exterior ......................................................................................................................................................76

Cleaning the Thermal Head and Platen Roller.......................................................................................................76

Ink Head Cleaning............................................................................................................................................................77

Cleaning the Paper Feeding Path...............................................................................................................................77

Cleaning the Scanner .....................................................................................................................................................79

■ Preparing for Transport....................................................................................................... 80

Troubleshooting.............................................................................................81

■ The Product Does Not Turn On.......................................................................................... 82

■ Lit or Flashing ! (ERROR) LED.............................................................................................. 82

■ Error Message Displayed on the LCD ............................................................................... 82

Automatic Recovery Error .............................................................................................................................................82

Recoverable Error .............................................................................................................................................................83

Unrecoverable Error ........................................................................................................................................................85

■ Cut Sheet Jam ....................................................................................................................... 86

■ ID Card Does Not Come Out............................................................................................... 87

■ Roll Paper Jam ...................................................................................................................... 88

■ Cannot Open the Roll Paper Cover................................................................................... 89

■ Problems with Print Quality............................................................................................... 90

Printing on Roll Paper Is Blurred .................................................................................................................................90

5

Page 6

Printing on Cut Sheets Is Blurry.................................................................................................................................. 90

■ Problems with Reading Quality......................................................................................... 90

Cannot Read Magnetic Ink Characters Correctly ................................................................................................. 90

Poor Cut Sheet or ID Card Reading Quality............................................................................................................ 90

Product Specifications.................................................................................. 91

■ General Specifications......................................................................................................... 91

Electrical Specifications................................................................................................................................................. 92

Ink Cartridge...................................................................................................................................................................... 93

■ USB Interface Specifications .............................................................................................. 94

USB (Type-B)...................................................................................................................................................................... 94

USB (Type-A)...................................................................................................................................................................... 94

■ Printing Specifications ........................................................................................................ 95

Roll Paper Printing........................................................................................................................................................... 95

Cut Sheet Printing ........................................................................................................................................................... 96

■ Character Specifications ..................................................................................................... 97

■ Scanner Specifications ........................................................................................................ 98

■ MSR (Magnetic Stripe Reader) Specifications................................................................. 99

■ Paper Specifications .......................................................................................................... 100

Roll Paper..........................................................................................................................................................................100

Cut Sheet ..........................................................................................................................................................................101

■ Printable Area .....................................................................................................................101

Roll Paper..........................................................................................................................................................................101

Cut Sheet ..........................................................................................................................................................................102

■ Roll Paper Print Position and Cut Positions................................................................... 103

■ Scanner Scan Area.............................................................................................................. 104

Cut Sheet ..........................................................................................................................................................................104

ID Card ...............................................................................................................................................................................105

■ MICR Reading Area ............................................................................................................106

■ Electronic Endorsement Area ..........................................................................................106

■ Environmental Specifications.......................................................................................... 107

■ Reliability .............................................................................................................................108

■ Overall Dimensions............................................................................................................ 109

One-pocket Model ........................................................................................................................................................109

Two-pocket Model ........................................................................................................................................................110

■ Character Code Tables....................................................................................................... 111

6

Page 7

Safety Precautions

Meanings of Symbols

The symbols explained below are used in this manual. Be sure to take the time to understand the meaning of

each symbol before using the product.

Handling the product improperly by ignoring this symbol can lead to death or serious injury.

WARNING

Ignoring this symbol and using the product improperly can lead to the problems listed below.

• Personal injury

CAUTION

• Material damage

• Loss of data and other information

Indicates information with which you must comply when using the product. Mishandling due to

ignoring this information may cause the product to fail or malfunction.

Indicates supplementary explanations and information you should know.

Cautions on Installation

❏ Do not install/store the product in an unstable location or in a location subject to vibration from

other devices. Equipment may fall or collapse, causing breakage and possible injury.

CAUTION

❏ Do not install the product in a location exposed to oily smoke or dust, or in a humid location.

Doing so may cause electric shock or fire.

❏ Use the product under the environmental conditions specified in the manual. (U

tal Specifications” on page 107)

Cautions on Power Supply

❏ Do not use other than the specified AC adapter. In addition, do not use the specified

adapter with another device. Doing so may cause electric shock or fire.

WARNING

❏ Observe the following points when handling the AC adapter. Doing so may cause electric

shock or fire.

∗ Do not use in a location where rain or water will get on the AC adapter.

∗ Do not suspend the product by the power cord.

∗ Do not allow a clip or other metal object to touch the connectors.

∗ Do not cover with bedding.

❏ Do not allow dust or other foreign material to adhere to the power plug. Doing so may

cause electric shock or fire.

❏ Insert the power plug securely all the way into the outlet. Doing so may cause electric

shock or fire.

❏ Be sure your AC power cord meets relevant safety standards of the area where you plan to

use it.

❏ Do not use a damaged power cable. Doing so may cause electric shock or fire.

“Environmen-

7

Page 8

❏ Contact qualified service personnel for advice if the power cable is damaged. Further-

more, observe the following points so as not to damage the power cable.

∗ Do not modify the power cable.

WARNING

∗ Do not place heavy objects on the power cable.

∗ Do not forcibly bend, twist, or pull the power cable.

∗ Do not lay the power cable near a heating appliance.

❏ Do not insert or remove the power plug with a wet hand. Doing so may cause electric

shock.

❏ Do not connect many power cables to one outlet. Doing so may cause fire.

❏ Regularly disconnect the power plug from the outlet and clean the base of the prongs and

between the prongs. Leaving the power plug connected to the outlet for a long period of

time may cause dust to accumulate on the base of the power plug prongs, resulting in a

short and fire.

❏ Hold the plug and do not pull the cable when disconnecting the power plug from the out-

let. Pulling the cable may damage the cable or deform the plug, causing electric shock or

fire.

❏ To ensure safety, unplug the product before leaving it unused for an extended period.

CAUTION

Cautions on Handling

WARNING

CAUTION

❏ Do not use the product in a location with volatile substances such as alcohol or paint thin-

ner present, or near fire. Doing so may cause electric shock or fire.

❏ Shut down the product immediately if it produces smoke, a strange odor, or unusual noise.

Doing so may cause electric shock or fire. If an abnormality occurs, immediately turn off

the power and remove the plug from the outlet, and then contact qualified service personnel for advice.

❏ Shut down the product immediately if a foreign object or water or other liquid gets inside

the product. Continued use may cause electric shock or fire. Immediately turn off the

power and remove the plug from the outlet, and then contact qualified service personnel

for advice.

❏ Never disassemble or repair the product by yourself as doing so is dangerous.

❏ Do not use the product in a location where inflammable gas, explosive gas, etc. is present

in the atmosphere. Furthermore, do not use aerosol sprayers containing flammable gas

inside or around the product. Doing so may cause fire.

❏ Do not connect cables in ways other than those mentioned in this manual. Doing so may

cause fire. It may also damage the other connected devices.

“Connecting a Power Supply” on page 39, “Connecting to a Host Computer”)

(U

❏ Do not touch the areas inside the product other than those mentioned in this manual.

Doing so may cause electric shock or burns.

❏ Do not insert metal or flammable materials, or allow them to fall into the product. Doing

so may cause electric shock or fire.

❏ Do not allow anyone to stand or place heavy objects on top of the product. Equipment may fall

or collapse, causing breakage and possible injury.

❏ Install the cables and optional products in the proper direction according to the proper proce-

dures. Failure to do so creates the risk of fire or electric shock. Follow the instructions in this manual to install them properly.

“Connecting a Power Supply” on page 39, “Connecting to a Host Computer”)

(U

❏ Before moving the product, shut down and unplug the product, and make sure that all the

cables are disconnected. Failure to do so may damage a cable, causing electric shock or fire.

❏ Do not store or transport the product while it is tilted, standing, or upside down. Doing so may

cause the ink to leak.

8

Page 9

Cautions on Ink Cartridges

❏ Do not touch the IC chip on an ink cartridge. Doing so may result in normal operation and print-

ing becoming no longer possible.

CAUTION

CAUTION

❏ The product uses ink cartridges equipped with IC chips to manage the amount of ink used and

other information so ink cartridges are usable even if they are removed and reinstalled. However,

if an ink cartridge with not much ink remaining is removed and reinstalled, it may not be usable.

Some ink is consumed each time cartridges are installed because the product automatically

checks their reliability.

❏ Since ink cartridges are designed to stop the operation before ink runs out completely to main-

tain the quality of the ink head, some ink remains in the used ink cartridges.

❏ In order to keep the ink head in good condition, ink is also consumed during such non-printing

maintenance operations such as ink cartridge replacement.

❏ Do not turn off the power or open the cover during ink charging (while the (Power) LED is

flashing). Opening the cover may cause the ink to be recharged, resulting in more ink being consumed. Also, it may result in normal printing becoming no longer possible.

❏ Do not disassemble an ink cartridge. Doing so may cause ink to get into eyes or onto skin.

❏ Do not disassemble or modify an ink cartridge. Doing so may cause printing malfunction.

❏ Use of old ink cartridges may result in reduced print quality. Use ink cartridges up within six

months after opening the packages. The usage period for ink cartridges is printed on the packaging of the individual ink cartridges.

❏ If ink contacts your skin, eyes, or mouth, take the following actions.

∗ When ink gets onto your skin, immediately wash the area with soap and water.

∗ When ink gets into your eyes, immediately flush them with water. Leaving the ink as is may

result in bloodshot eyes or mild inflammation. If something is wrong, immediately consult

with a doctor.

∗ When ink gets into your mouth, immediately spit it out and consult with a doctor.

❏ There may be some ink around the ink supply port on a removed ink cartridge. Take care so that

it does not stain the desk or other surface.

❏ Do not remove the ink cartridge except to replace it.

❏ Do not open an ink cartridge package until you are ready to install the ink cartridge in the prod-

uct.

❏ Do not shake an ink cartridge too hard. The ink cartridge may leak if you shake it around too

much or push the sides strongly.

❏ Do not allow foreign objects to fall into the cartridge installation section. Doing so may result in

normal printing becoming no longer possible. Remove any object that falls into the installation

section, taking care not to damage the section.

❏ When ink is charged the first time (right after purchase), ink is consumed for filling the ink head

nozzles (ink discharge holes) to get ready for printing. Because of this, the number of sheets that

can be printed by the first ink cartridge used in a new product may be lower than that of the second and subsequent ink cartridges.

❏ Turning off the product by performing a (POWER) button operation or by sending a com-

mand causes the ink head to be capped automatically to prevent the ink from drying. If you do

not plan to use the product after installing an ink cartridge, be sure to use either of the methods

above to turn off power. Do not pull out the power plug or turn off the breaker while the power

is on.

❏ Printing on water-repellent paper such as art paper, which is slow-drying, may cause print stains.

Also, if you print on glossy paper, fingerprints may get on the paper or ink may adhere to your

fingers when you touch the print surface. Select and use paper that will not cause print stains.

❏ Store the ink cartridges in a place out of reach of children.

❏ Epson recommends storing ink cartridges in a cool and dark place.

❏ If you wish to use ink cartridges that have been stored in a cold place for a long period of time,

leave them for at least 3 hours in a place that is at room temperature before use.

❏ Do not remove the ink cartridges from the product when storing the product.

9

Page 10

Caution Label

Thermal head

The labels affixed to the product indicate the following cautions.

!K CAUTION:

Do not touch the thermal head during or immediately after use. They may be very hot after a print operation.

10

Page 11

Restriction of Use

When this product is used for applications requiring high reliability/safety such as transportation devices

related to aviation, rail, marine, automotive etc.; disaster prevention devices; various safety devices etc.; or functional/precision devices etc., you should use this product only after giving consideration to including fail-safes

and redundancies into your design to maintain safety and total system reliability.

This product in not intended for use in aerospace equipment, main communication equipment, nuclear power

control equipment, medical equipment, or other applications that require a very high level of reliability and/or

safety. Be sure to check with the customer concerning these applications and judge applicability accordingly.

11

Page 12

About This Manual

Purpose of This Manual

This manual is intended to provide development engineers with information about product functions, operations, maintenance, and troubleshooting, and the information needed for application development and design.

Manual Organization

This manual is organized as shown below.

Chapter 1 Product Overview

Chapter 2 Setup

Chapter 3 Advanced Product Use

Chapter 4 Application Development Information

Chapter 5 Handling the Product

Chapter 6 Troubleshooting

Chapter 7 Product Specifications

Manual Illustrations

Unless specifically indicated otherwise, all illustrations in this manual show a model equipped with two pockets

and MSR.

12

Page 13

Chapter 1 Product Overview

Product Overview

This chapter describes the features and functions of the product.

Features

This product is a compact multifunction device that incorporates various functions required by banking

counter services.

❏ Roll paper printing

• Auto cutter as standard

• Roll Paper Reduction

❏ Cut sheet (check endorsement, single receipt, cashier's check) printing

• 360-nozzle inkjet printing enables 180 dpi multi-line, high-resolution output

[dpi: dot per inch]

❏ Check magnetic ink character recognition

❏ Cut sheets, personal ID (driver's license) two-side data acquisition

• Binary (cut sheets only), gray scale, color, IR (infrared) image acquisition

❏ Auto sheet feeder that automatically feeds cut sheets one sheet at a time

• Cut sheet overlap feed detector

• Check mis-insertion detector

• Image quality assessment (IQA) (supported by driver)

• Optical character recognition (OCR) (supported by driver)

❏ Two-pocket cut sheet separator

❏ Magnetic stripe card reader (MSR)

*2

*2

*1

1

❏ LCD for quick and easy determination of product status

❏ Equipped with USB-HUB

❏ Drawer connection allowed

❏ Counter that comes in handy for remote maintenance

❏ Built-in buzzer

*1: Supported fonts are OCR-A and OCR-B only

*2: Depends on model

*2

13

Page 14

Product Configuration

Functions and accessories for this product depend on the model.

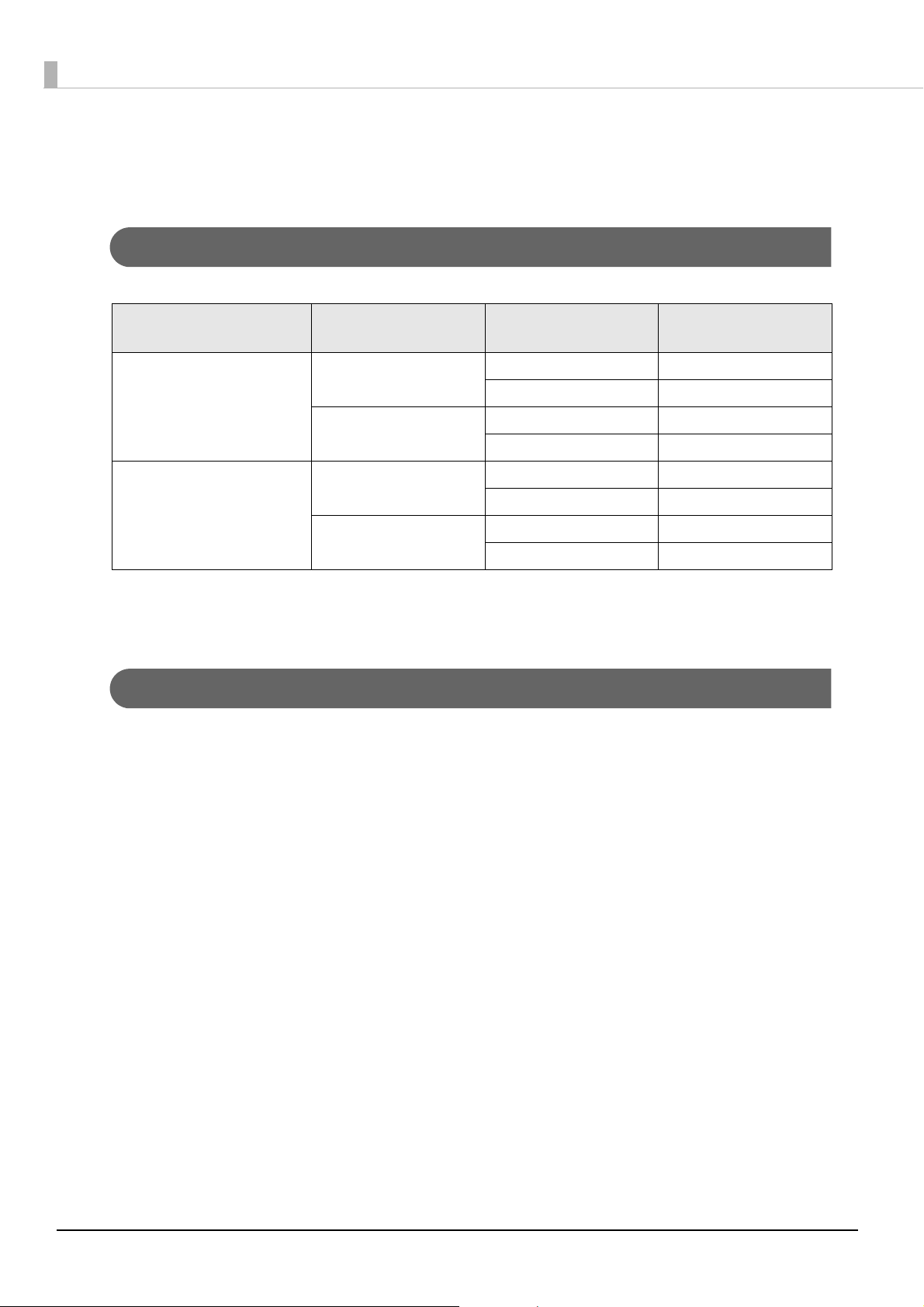

Model

Cut sheet print processing

speed

130 DPM One-pocket Unequipped Unequipped

225 DPM One-pocket Unequipped Unequipped

[DPM: Number of cut sheets processed per minute (Documents Per Minute)]

Number of cut sheet

pockets

Two-pocket Unequipped Unequipped

Two-pocket Unequipped Unequipped

MSR USB-HUB

Equipped Equipped

Equipped Equipped

Equipped Equipped

Equipped Equipped

Accessories

❏ Roll paper (for initial trial operation)

❏ Special ink cartridge SJIC18(K) x 2

❏ Dedicated AC adapter PS-180

❏ USB cable (length: 170 cm, color: black)

❏ AC cable*

❏ Instruction manuals

*: Not included with some models

14

Page 15

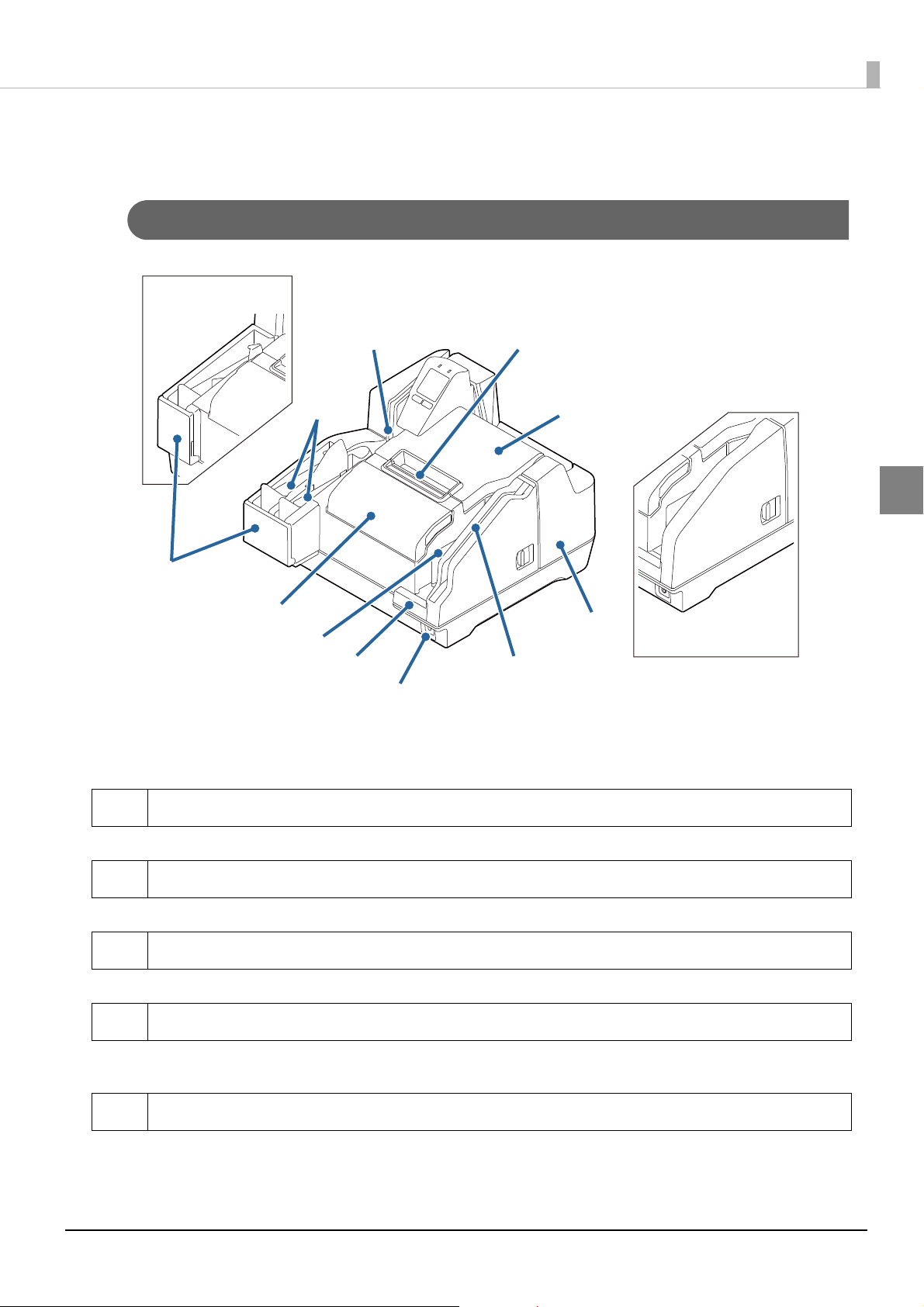

Part Names and Functions

1

4

6

3

One-pocket model

Model without MSR

5

7

8

10

9

2

11

Front

Chapter 1 Product Overview

1

1 ID card slot

To read an ID card, insert it. (U “ID Card Processing” on page 74)

2 Main pocket/Sub-pocket

Pockets hold cut sheets ejected after processing.

3 Pocket guides

Pull out the pocket guide to match the length of the cut sheets being used.

4 Ink cartridge cover

Open this cover to install/replace the ink cartridge. (U “Installing the Ink Cartridges” on page 41,

“Replacing the Ink Cartridges”

5 ASF (Auto-Sheet-Feeder)

Install the Auto-Sheet-Feeder to feed checks and other cut sheets. Up to 100 sheets can be fed. (U “Cut

Sheet Processing” on page 71

)

)

15

Page 16

6ASF guide

Pull out the pocket guide to match the length of the cut sheets being used.

7 (POWER) button

Turn the product on/off. (U “Turning On/Off” on page 67)

8 MSR (Magnetic Stripe Reader)

To read a magnetic strip card, insert the card and slide it. (U “Magnetic Stripe Card Processing” on page

75

)

9 MICR cover

Open this cover if cut sheets become jammed. (U “Opening the MICR Cover, Back Cover, and Scanner

Cover” on page 69

, “Cut Sheet Jam”)

10 Roll paper cover

Open this cover to load or replace the roll paper. (U “Loading Roll Paper” on page 40, “Replacing Roll

Paper”

)

11 Manual cutter

This cutter is for manually cutting roll paper.

16

Page 17

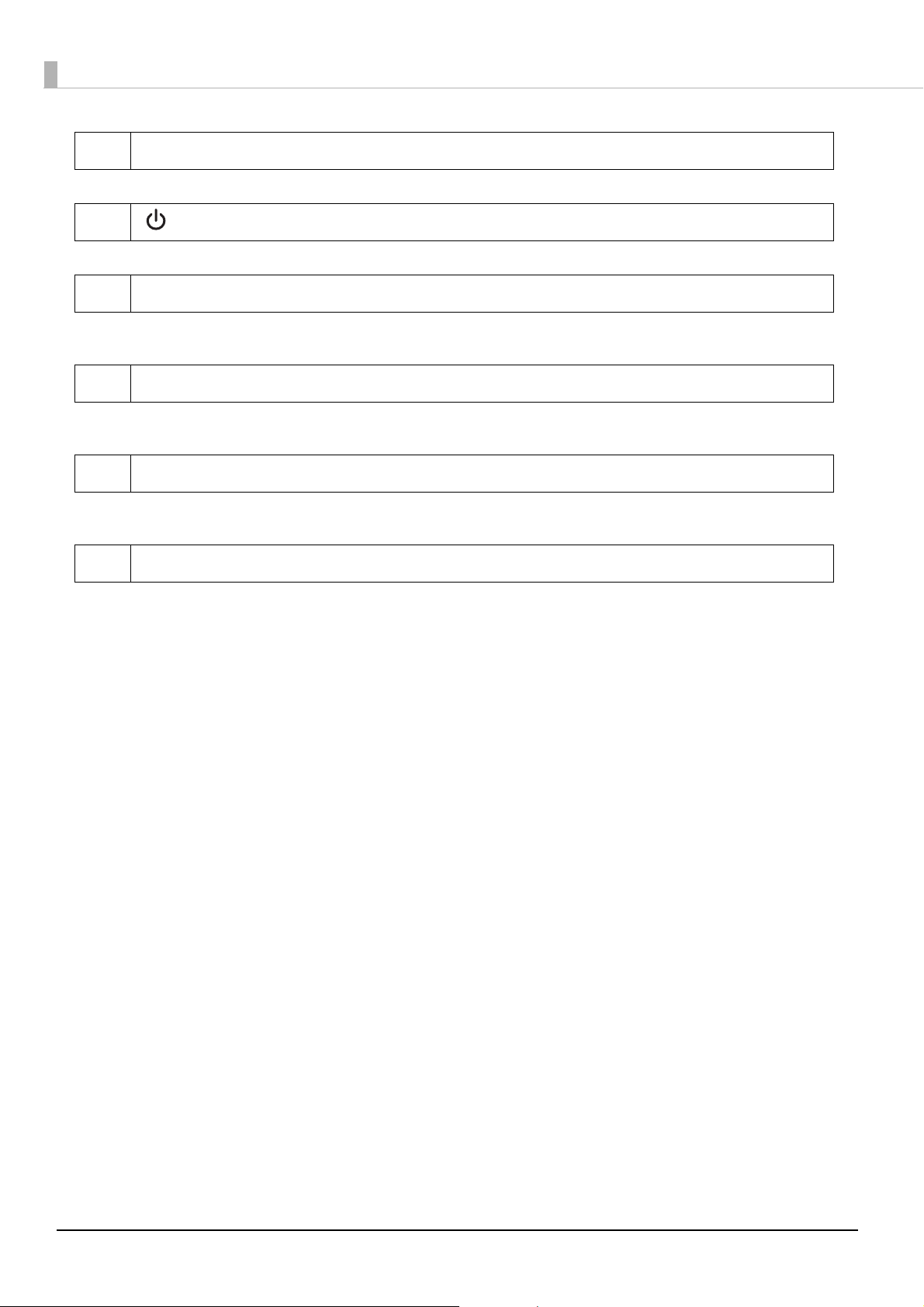

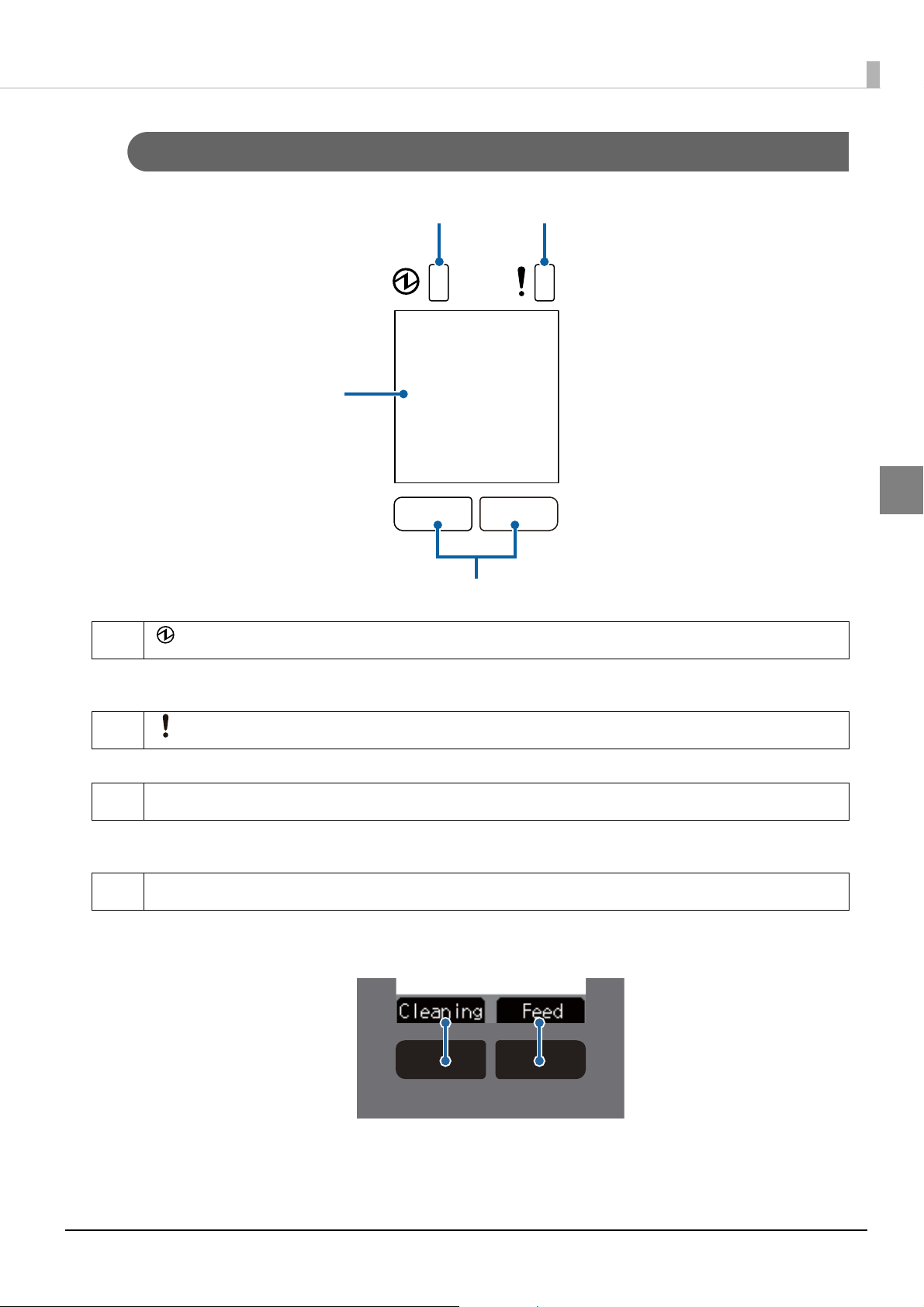

Operation Panel

1

2

3

4

Button 1 Button 2

Chapter 1 Product Overview

1

1 (POWER) LED

Lights when the product is turned on.

Flashes during printing and while ink is charging.

2 (ERROR) LED

Lights when an error occurs. (U “Checking the Product Status” on page 19)

3LCD

Shows the status of consumables and the product. (U “Checking the Product Status” on page 19)

LCD backlight brightness is adjustable. (U

4 Button 1 (Left) / Button 2 (Right)

Each button is assigned the corresponding function that appears at the bottom of the LCD. The function on

the lower left of the LCD is executed when Button 1 (left button) is pressed, while the function on the lower

right is executed when Button 2 (right button) is pressed.

“Adjusting LCD Backlight Brightness” on page 43)

17

Page 18

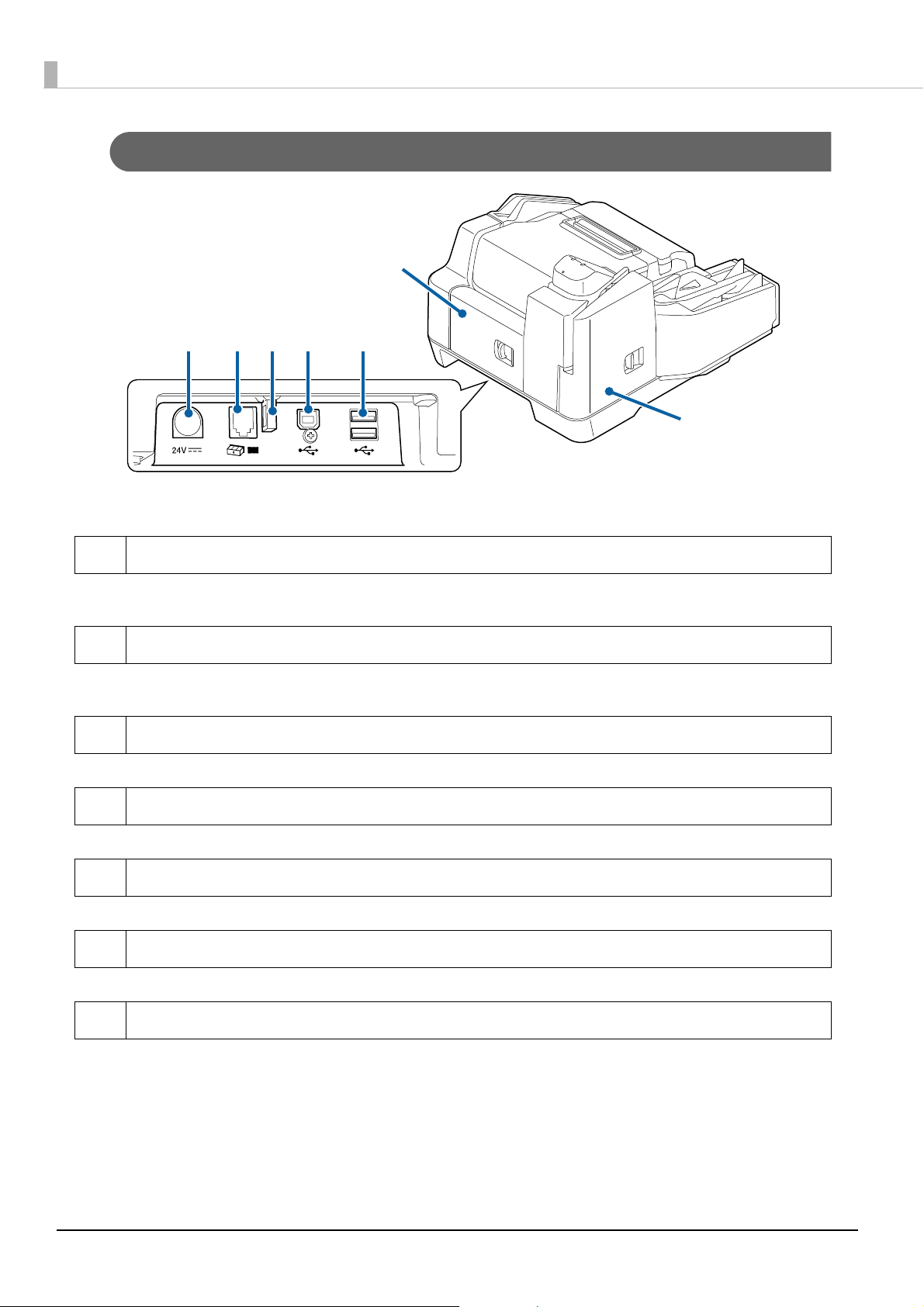

Rear

1

2

35467

1 Back cover

Open this cover if cut sheets become jammed. (U “Opening the MICR Cover, Back Cover, and Scanner

Cover” on page 69

, “Cut Sheet Jam”)

2 Scanner cover

Open this cover if cut sheets or an ID card becomes jammed. (U “Opening the MICR Cover, Back Cover,

and Scanner Cover” on page 69

3 DC-IN connector

Connect a DC cable.

4 Drawer kick connector

Connect the drawer cable.

5 Wire saddle

Pass the USB cable through this saddle to prevent disconnection of the cable.

6 USB connector (Type B)

Connect a USB cable (Type B).

7 USB connector (Type A)

Connect a USB cable (Type A).

, “Cut Sheet Jam”, “ID Card Does Not Come Out”)

18

Page 19

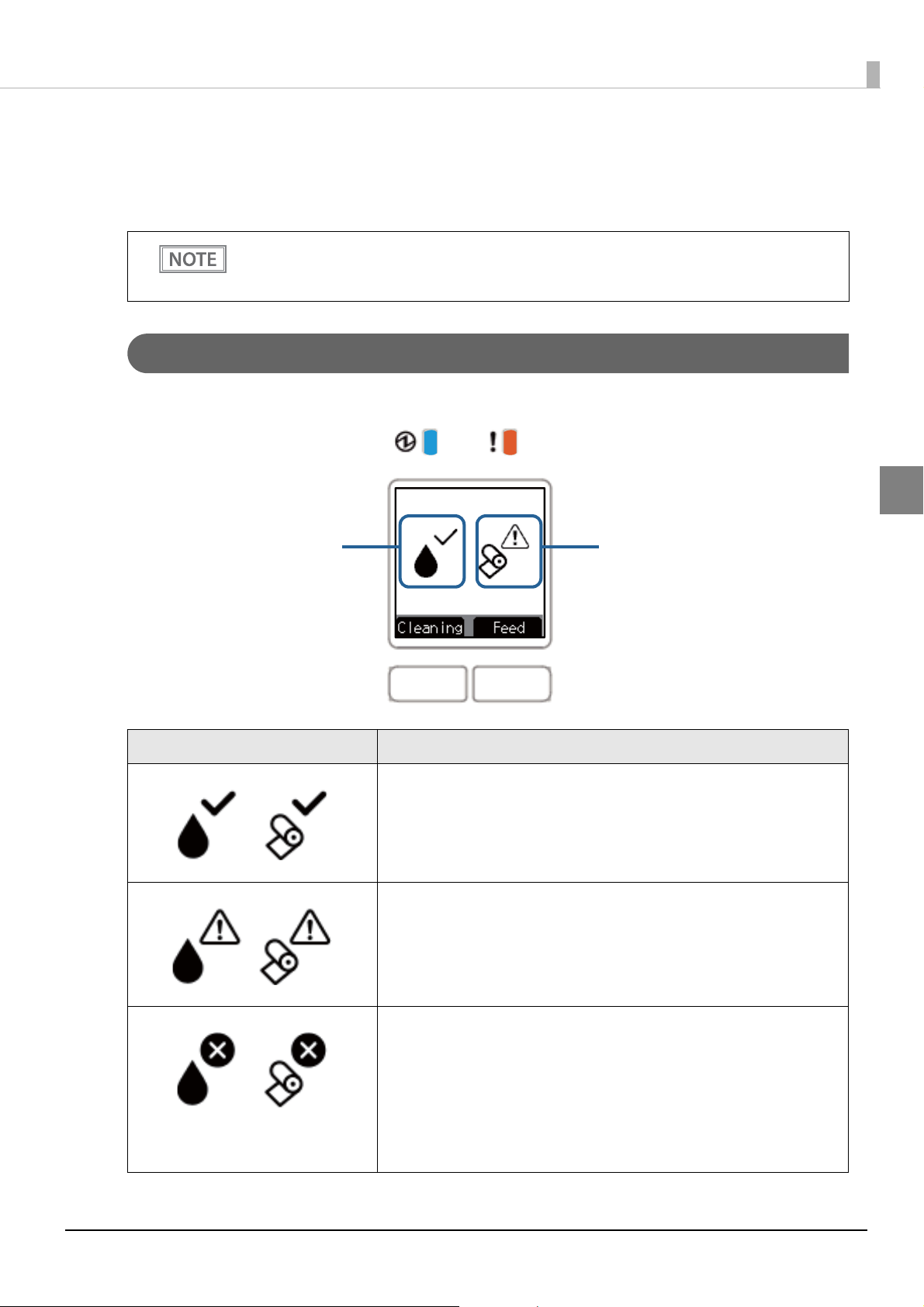

Chapter 1 Product Overview

Roll paper statusInk status

Checking the Product Status

The status of the product can be checked from a combination of the LEDs lighting/flashing and the LCD display.

The error type cannot be distinguished by the LED pattern. Develop an application that reads the

status from the application and identifies the error, and lets the user know the required recovery

procedure.

Replacement Timing of Consumables

The ink cartridge and roll paper status can be checked on the LCD home screen.

1

LCD display Status

• There is sufficient ink remaining.

• There is sufficient roll paper remaining.

• There is not much ink remaining so nearly time to replace the ink cartridge.

Prepare a new ink cartridge.

• Roll paper is low, and the time to replace the roll paper is approaching. Prepare new roll paper.

• Ink cartridge is expended. Loading or replacement of the ink cartridge is

required. Printing on cut sheet is not possible until a new ink cartridge is

installed. (Ink cartridge replacement guidance appears on the LCD.

U

“Replacing the Ink Cartridges” on page 70)

• Roll paper is not loaded or remaining roll paper is low. To print on roll paper,

loading or replacement of the roll paper is required. Printing on roll paper is

not possible until new roll paper is loaded. (Ink roll paper replacement guidance appears on the LCD. U

“Replacing Roll Paper” on page 70)

19

Page 20

LCD display Status

An ink cartridge is not installed. An ink cartridge must be loaded to print on

cut sheets.

There is not enough ink for periodic ink head cleaning. The ink cartridge needs

to be replaced to perform cleaning.

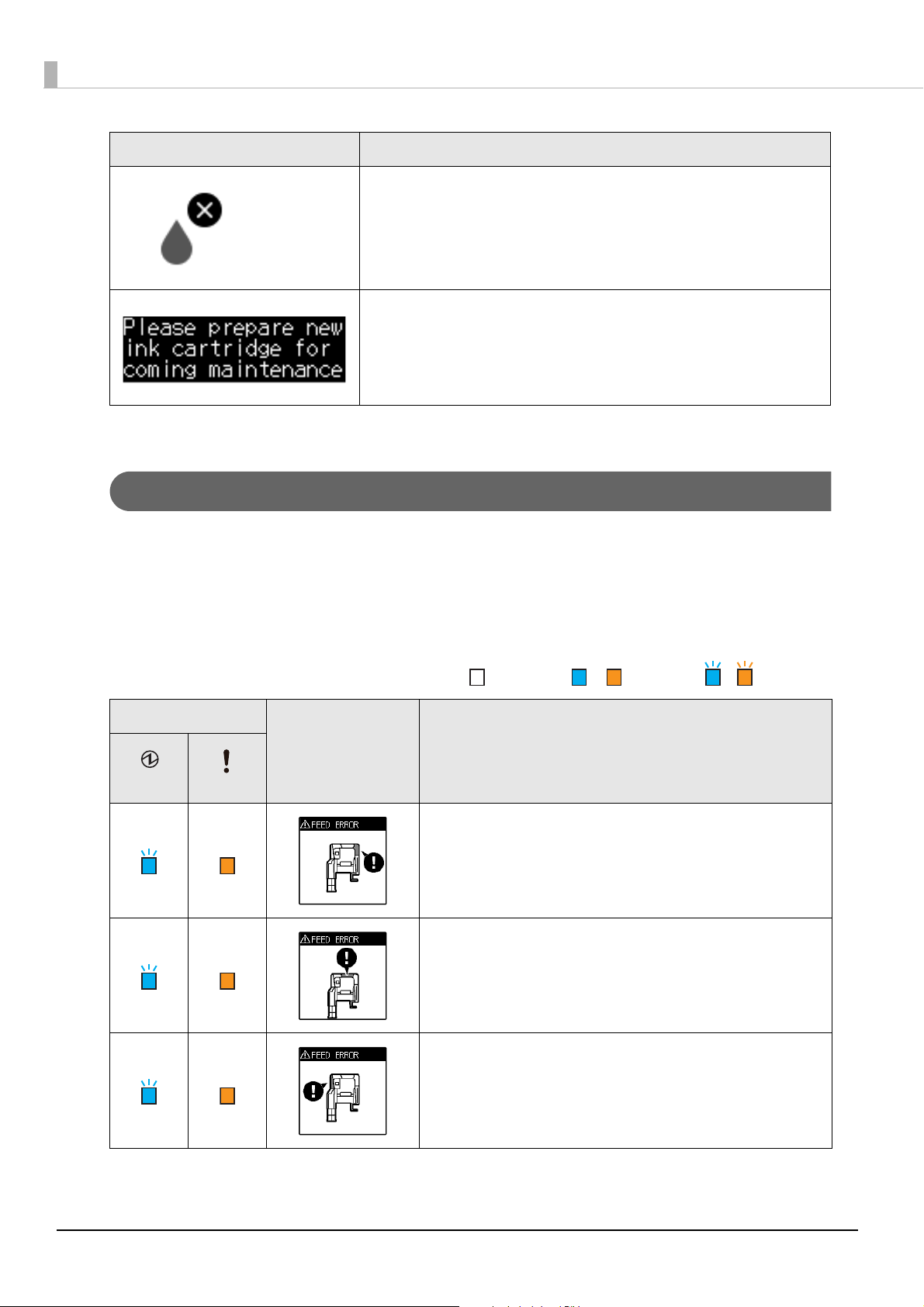

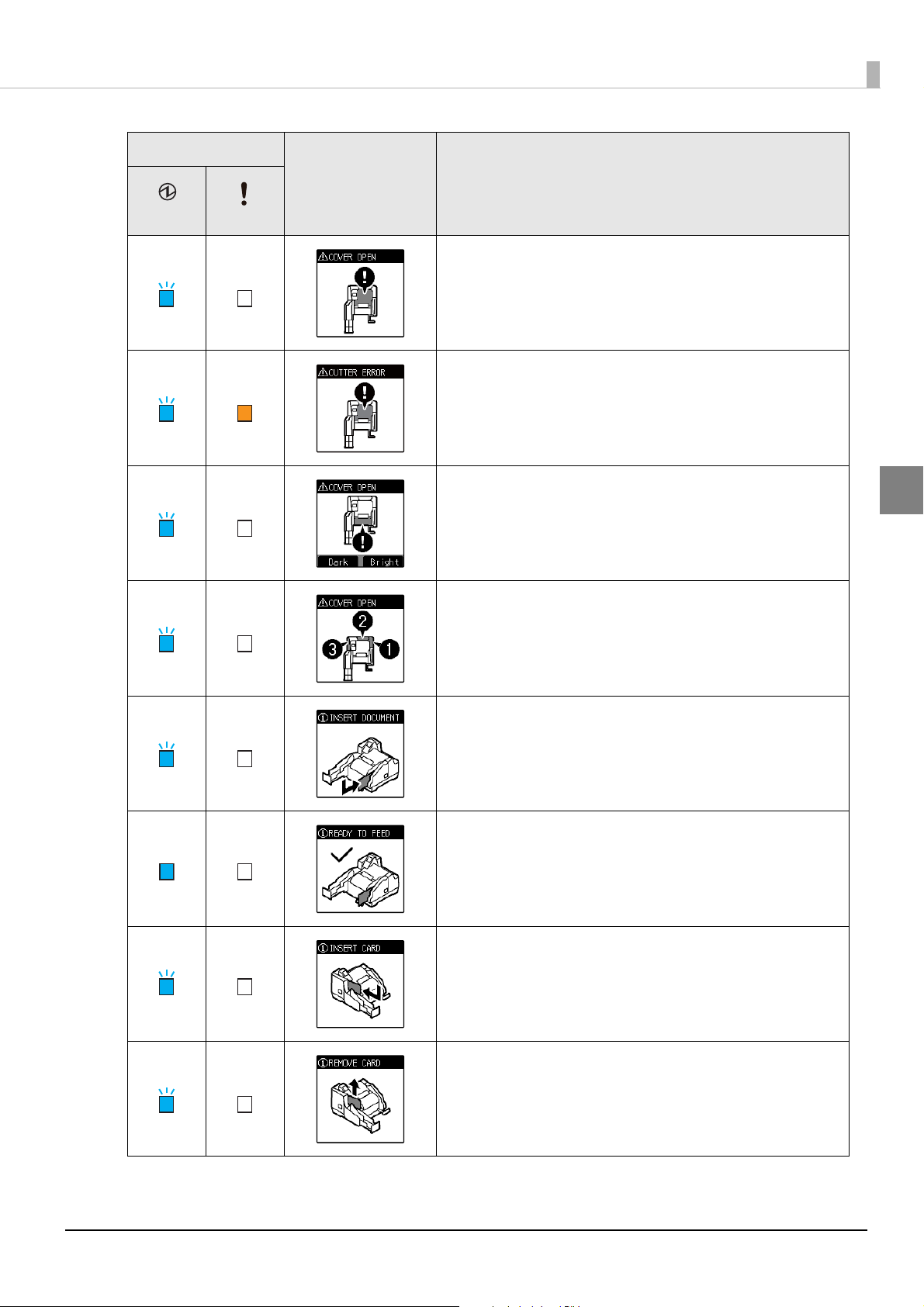

Statuses and Errors

The status of the product can be checked from a combination of the LEDs lighting/flashing and the LCD display.

Product operation stops when an error occurs. For details on resolving errors, refer to

played on the LCD” on page 82

.

“Error Message Dis-

LED

POWER ERROR

:Off / :On / :Flashing

LCD display Product status

Cut sheets are jammed in the MICR reader. (U “Cut Sheet Jam” on

page 86

Cut sheets are jammed in the back of the product

(U

Cut sheets are jammed in the scanner

(U

)

“Cut Sheet Jam” on page 86)

“Cut Sheet Jam” on page 86)

20

Page 21

LED

POWER ERROR

LCD display Product status

The roll paper cover is open

Auto cutter position error

(U

“Recoverable Error” on page 83)

Ink cover is open

Chapter 1 Product Overview

1

One or more of the following covers are open: MICR cover, back

cover, scanner cover

Standing by for insertion of cut sheets

Cut sheet detection

Card insertion standby

Card removal standby

21

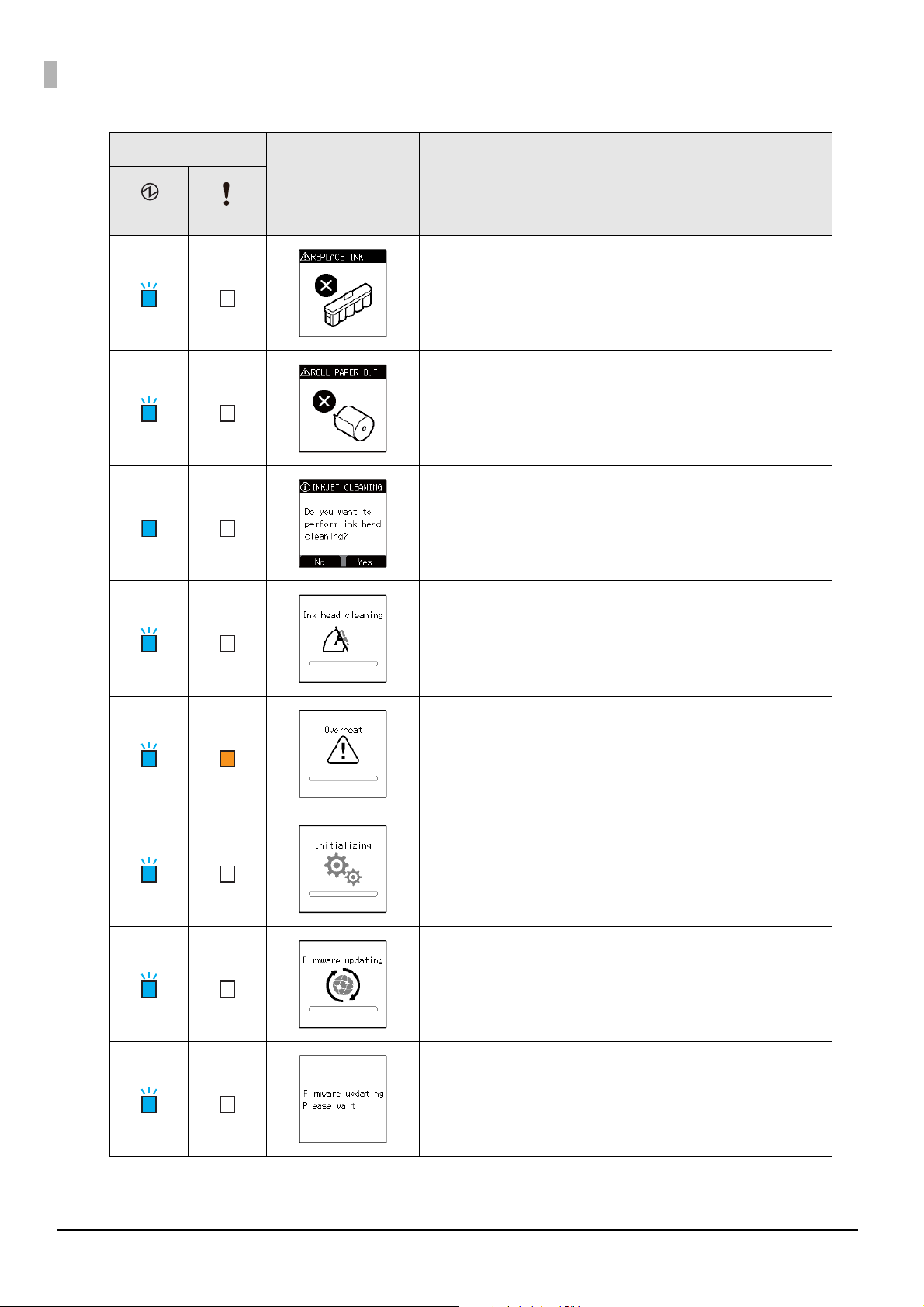

Page 22

LED

POWER ERROR

LCD display Product status

Cartridge loading or replacement required

(U “Installing the Ink Cartridges” on page 41

Roll paper loading or replacement required

(U

“Loading Roll Paper” on page 40)

Ink head cleaning standby

(U

“Ink Head Cleaning” on page 77)

)

Ink head cleaning

• Thermal head high temperature

• Ink head high temperature

• Motor driver high temperature

(U

“Automatic Recovery Error” on page 82)

• In power-on sequence

• In power-off sequence

Firmware rewriting (data receive in progress)

22

Firmware rewriting (data writing, restoration in progress)

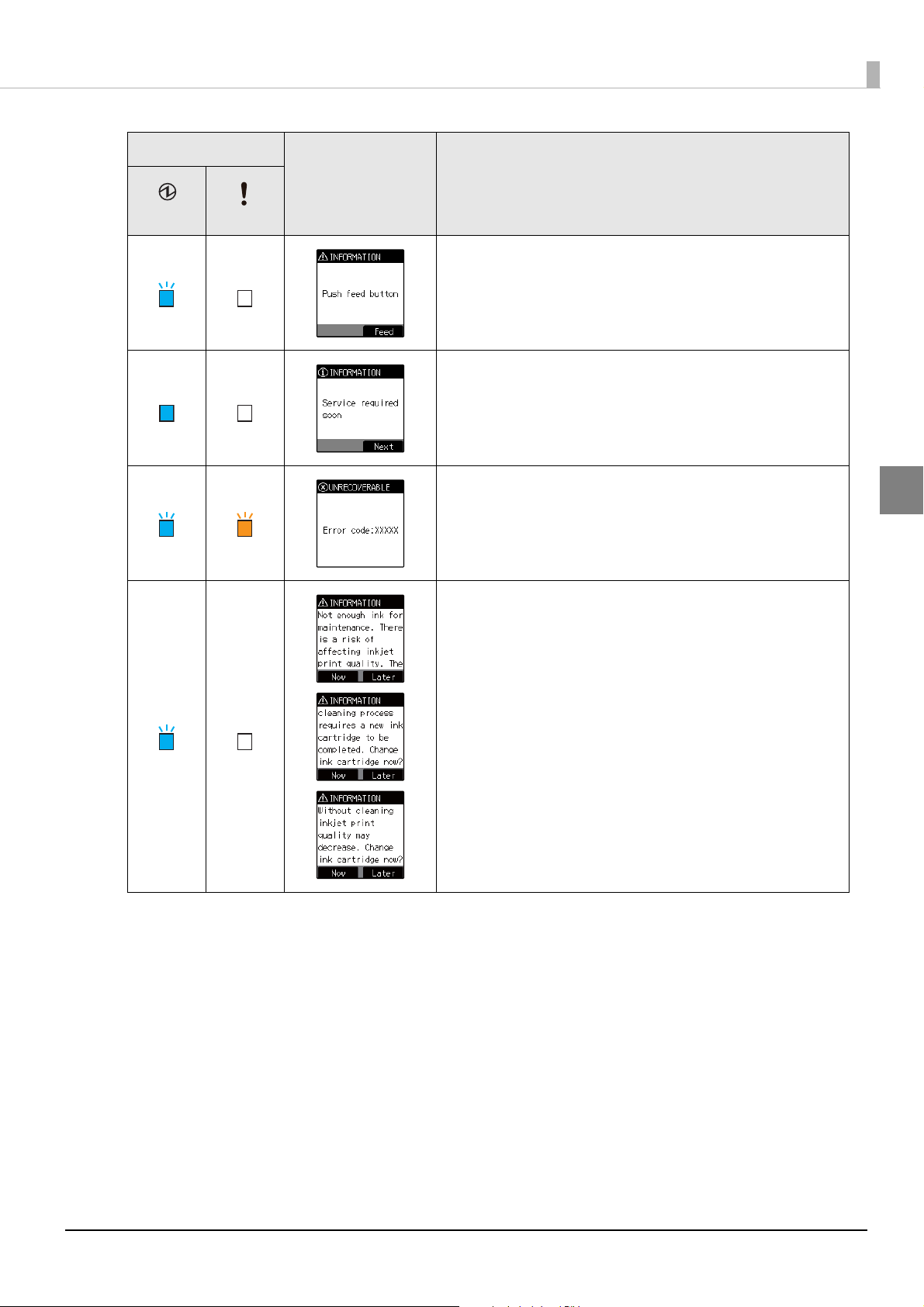

Page 23

LED

POWER ERROR

Chapter 1 Product Overview

LCD display Product status

Macro execution function operation standby

The pump unit is near the end of it's service life

Unrecoverable error

(U “Unrecoverable Error” on page 85)

Insufficient ink for periodic ink head cleaning

1

23

Page 24

Cut Sheet Processing Modes

There are two modes for processing cut sheets. Select the method most suitable for your environment.

• High-speed mode (U “High-speed Mode” on page 24

• Confirmation mode (U

For details on processing modes, refer to the TM-S9000MJ API Reference Guide.

“Confirmation Mode” on page 27)

)

High-speed Mode

Use this mode to specify processing conditions from the firmware or driver.

Table of Judgment Subjects and Criteria

Judgment made by: Criteria

Firmware • Overlapping feeding detection result

• Incorrect insertion detection result (Check paper)

• Magnetic waveform detection result

• External noise detection result

• Printing result of exceeded media length

Driver • MICR “?” detection result

• IQA judgment result

• Barcode recognition result

24

Page 25

Chapter 1 Product Overview

Fed from the ASF

Check for double feeding

MICR reading

Ink jet printing

Capturing image on both sides

Ejection of the cut sheet

Fed from the ASF

Check for double feeding

MICR reading

Fed from the ASF

Check for double feeding

MICR reading

Ink jet printing

Caputuring image on both sides

Ejection of the cut sheet

<First cut sheet>

<Second cut sheet>

<Third cut sheet>

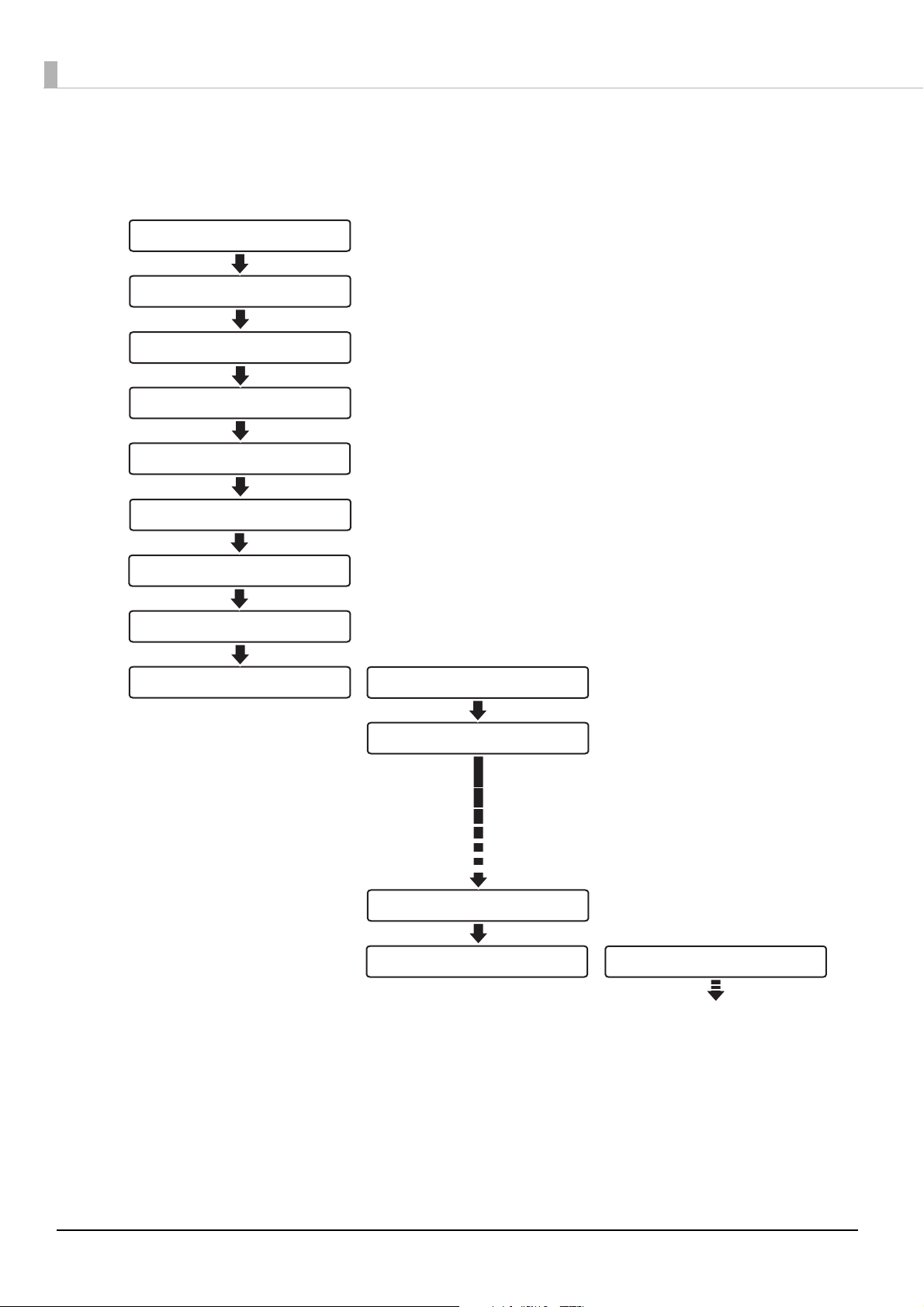

Document Processing Sequence

The processing sequence depends on the number of pockets and whether or not back feeding is being performed.

When back feeding is not necessary with 1-pocket models/2-pocket models

1

25

Page 26

When back feeding is required with 2-pocket models

<First cut sheet>

Fed from the ASF

Check for double feeding

MICR reading

Ink jet printing

Capturing image on both sides

Backward paper feeding*

Switching of the pocket

Ejection of the

cut sheet

<Second cut sheet>

<Third cut sheet>

Fed from the ASF

Check for double feeding

Ejection of the cut sheet

Fed from the ASF

Switching of the pockets

∗ Occurs depending on some conditions.

26

Page 27

Chapter 1 Product Overview

∗ Waits for a command from the

application.

Confirmation Mode

Use this mode to specify processing conditions from the application.

This mode stops the process that starts with cut sheet feeding is from the ASF and ends with cut sheet output to

a pocket, in order to receive an instruction from the application. It then restarts the process. It also can be used

to configure the no-overlap/overlap setting from the application.

No-overlap: Starts send of the next cut sheet after the current cut sheet is fully in the pocket

Overlap: Starts feeding of the next cut sheet while the current cut sheet is being output to the

pocket

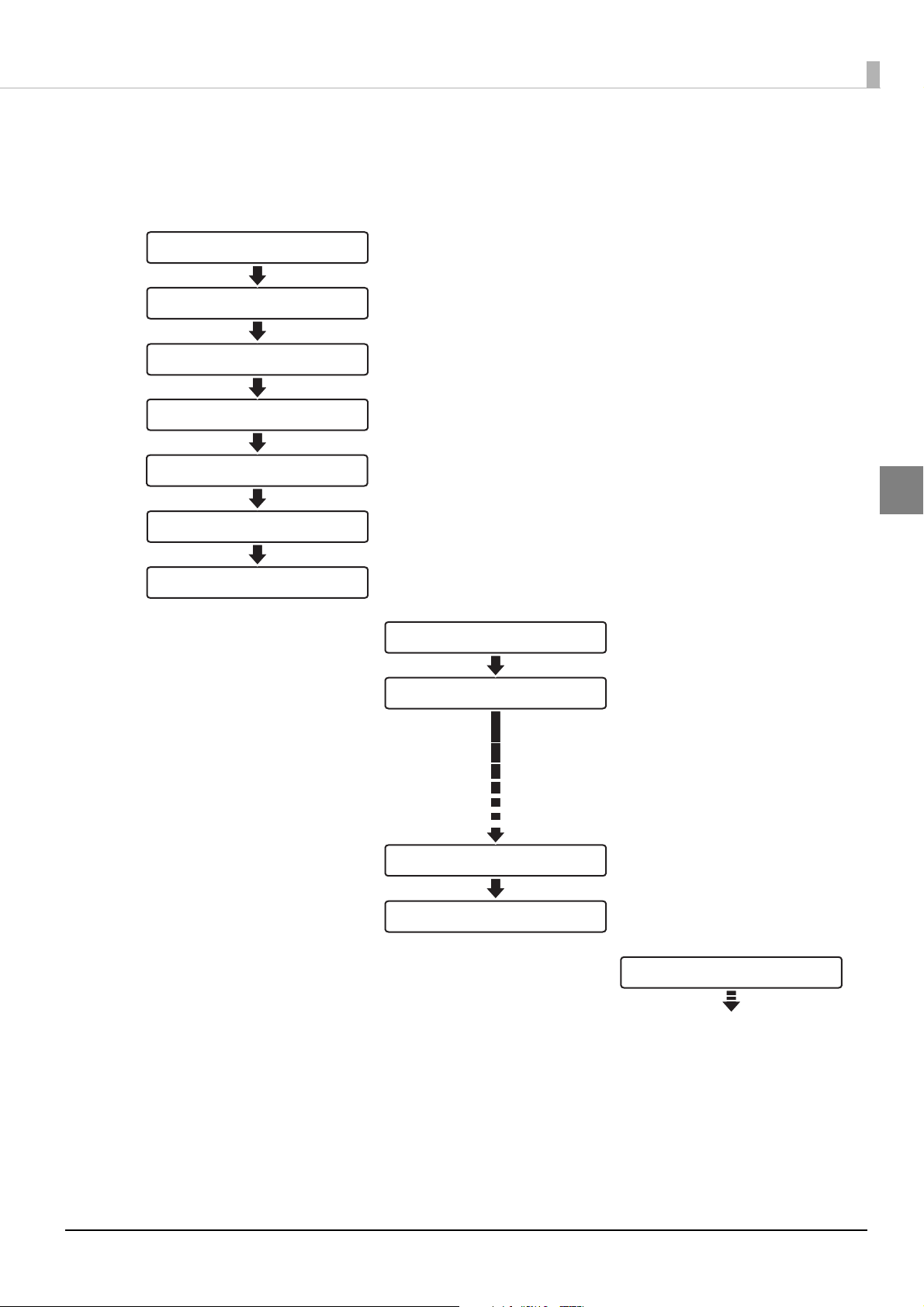

Document Processing Sequence

The processing sequence depends on the number of pockets and whether or not back feeding is being performed.

With overlap

When back feeding is not necessary with 1-pocket models/2-pocket models

<First cut sheet>

1

Fed from the ASF

Check for double feeding

MICR reading

Ink jet printing

Capturing image on both sides

Stop of paper feeding*

Ejection of the cut sheet

<Second cut sheet>

Fed from the ASF

Check for double feeding

Stop of paper feeding*

Ejection of the cut sheet

<Third cut sheet>

Fed from the ASF

27

Page 28

With overlap

<First cut sheet>

<Second cut sheet>

<Third cut sheet>

Fed from the ASF

Check for double feeding

MICR reading

Ink jet printing

Capturing image on both sides

Stop of paper feeding*

Backward paper feeding*

Switching of the pockets

Ejection of the cut sheet

Fed from the ASF

Check for double feeding

Ejection of the cut sheet

Fed from the ASF

Switching of the pockets

1

2

∗1: Waits for a command from the

application.

∗2: Occurs depending on some conditions.

When back feeding is required with 2-pocket models

28

Page 29

Chapter 1 Product Overview

<First cut sheet>

Fed from the ASF

Check for double feeding

MICR reading

Ink jet printing

Capturing image on both sides

Stop of paper feeding*

Ejection of the cut sheet

<Second cut sheet>

<Third cut sheet>

Fed from the ASF

Check for double feeding

Ejection of the cut sheet

Fed from the ASF

Stop of paper feeding*

Ejection of the document

∗ Waits for a command from the

application.

Without overlap

When back feeding is not necessary with 1-pocket models/2-pocket models

1

29

Page 30

With overlap

<First cut sheet>

Fed from the ASF

Check for double feeding

MICR reading

Ink jet printing

Capturing image on both sides

Stop of paper feeding*

Backward paper feeding*

Switching of the pockets

Ejection of the cut sheet

<Second cut sheet>

<Third cut sheet>

Fed from the ASF

Check for double feeding

Ejection of the cut sheet

Fed from the ASF

Switching of the pockets

2

1

∗1: Waits for a command from the

application.

∗2: Occurs depending on some conditions.

When back feeding is required with 2-pocket models

30

Page 31

Chapter 1 Product Overview

Speed of Each Processing Mode

This is the processing speed from the point that the first cut sheet is sent from the ASF until receipt of the image

data of the 100th cut sheet (highest value).

Processing Speed Conditions

The processing speed may be reduced by the conditions described below.

• Host computer operating environment (U

• Software that coexists on the computer

• Image resolution, light source settings

When the resolution of the captured image is 240 dpi or 300 dpi, or when the acquired image is 24-bit

color or infrared (IR)

• Driver IQA, OCR, bar code recognition settings

• Data transfer, save, and other application processing

• Cut sheet status

• Processing mode and judgment subject

Processing modes Judgment made by Condition details

High-speed mode Firmware Operation based on firmware judgments, without instruction

Driver When driver judgment is required, processing speed is slower

Confirmation mode Application Since the product stands by for instructions from the applica-

“Operating Environment” on page 61)

from the host computer, for high-speed processing. However,

when cut sheets are output to the sub-pocket in the case of 2pocket models, processing is slower due to generation of back

feeding.

compared to operation according to judgment conditions by

firmware only.

tion for each cut sheet scan, processing speed depends on

control from the application. Also, processing speed depends

on whether or not overlap is performed.

1

31

Page 32

Processing Modes

Resolution of captured image: 200 dpi, grayscale/black and white

Processing speed

Processing mode and

judgment subject

High-speed mode

Firmware judgment

High-speed mode

Driver judgment

Confirmation mode

Application judgment

*2

Media size

Main-pocket

Personal check 225 DPM 180 DPM 130 DPM 130 DPM

Business check 175 DPM 152 DPM 130 DPM 130 DPM

Personal check 79 DPM 61 DPM 79 DPM 61 DPM

Business check 65 DPM 52 DPM 65 DPM 52 DPM

Personal check 65 DPM 53 DPM 65 DPM 53 DPM

Business check 51 DPM 44 DPM 51 DPM 44 DPM

225 DPM 130 DPM

ejection

∗1: When 50 of the 100 sheets are in the sub-pocket

∗2: Does not take application processing time into consideration

Sub-pocket

ejection

*1

50%

Main-pocket

ejection

Sub-pocket

ejection

*1

50%

32

Page 33

Chapter 1 Product Overview

NV Memory

This product is equipped with nonvolatile memory (NV), which maintains stored data even if the product is

turned off. The memory areas below are available in NV memory for use by the user.

• NV graphics memory

• NV user memory

• Memory switch

• R/E (receipt enhancement)

• User-defined page

• Maintenance counters

As a general rule for the number of writes to NV memory, create an application that writes no more

than 10 times a day.

NV Graphics Memory

Multiple store logos and other graphics can be registered for printing on logos.

Registered graphics can be viewed using the TM-S9000II Utility or the NV graphics information print mode.

For details on the NV graphics information printing mode, refer to the TM-S9000II Utility User's

Manual and

“NV Graphics Information Print Mode” on page 56.

NV User Memory

Custom product settings and maintenance information can be saved as text data and read as required.

Memory Switch

This switch can be used to configure various product settings.

For details on memory switches, refer to

“Software Settings” on page 47.

R/E (Receipt Enhancement)

1

Settings can be configured to have the store logo and other graphics printed automatically at the beginning and

the end of receipts.

For details on R/E (receipt enhancement), refer to

“R/E Information Print Mode” on page 58.

User-defined Page

Character that is not registered on the product can be printed by registering it on a user-defined page (Character Code Table: page 255).

33

Page 34

Maintenance Counters

This function automatically registers the number of print lines, the number of auto cutter operations, product

running time, and other maintenance counter information in product memory. Counter information can be

referenced to support periodic inspections, consumable replacement and others.

The head travel distance and the number of auto cutter operations (U “Self-test Mode” on page

54

).

34

Page 35

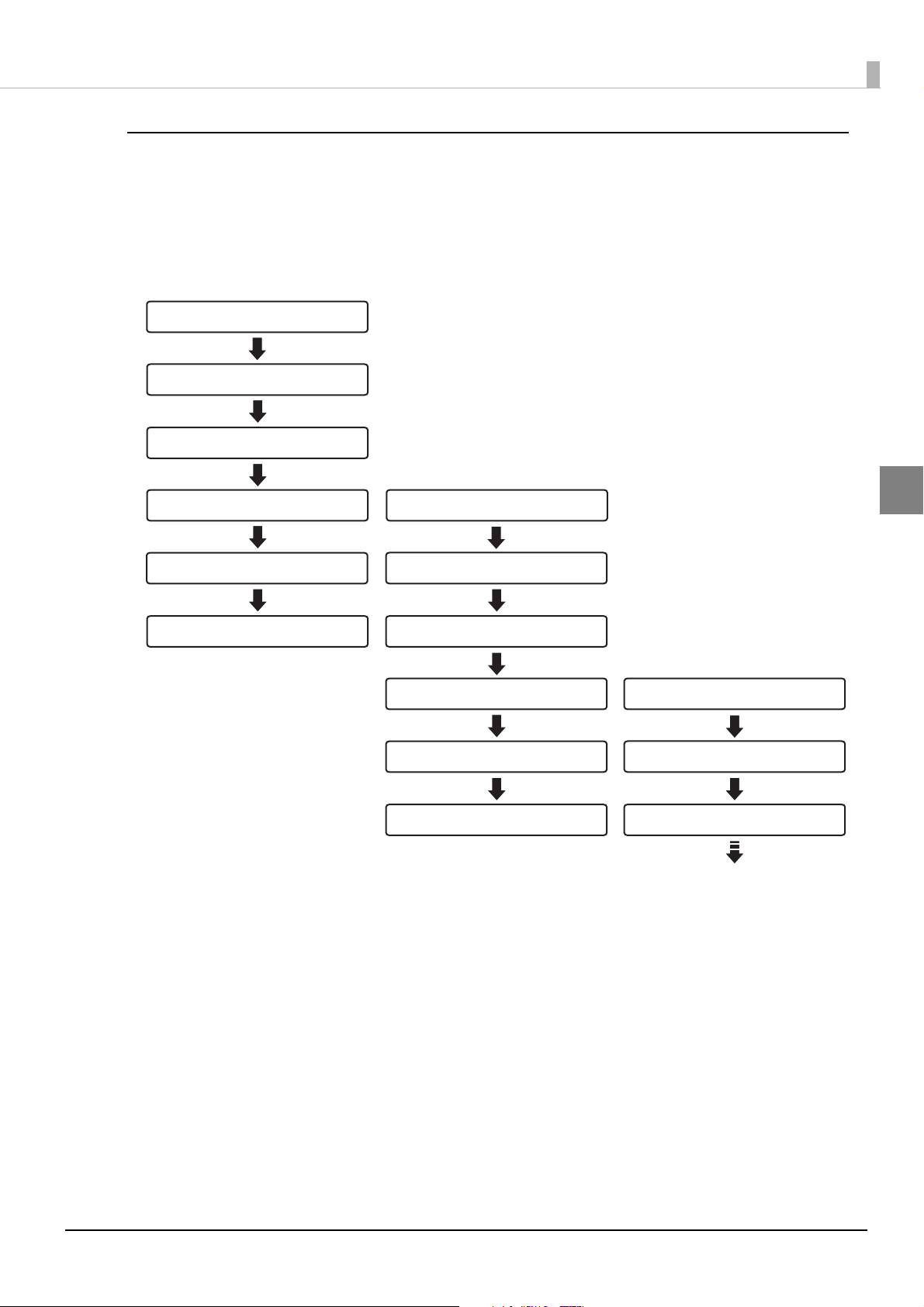

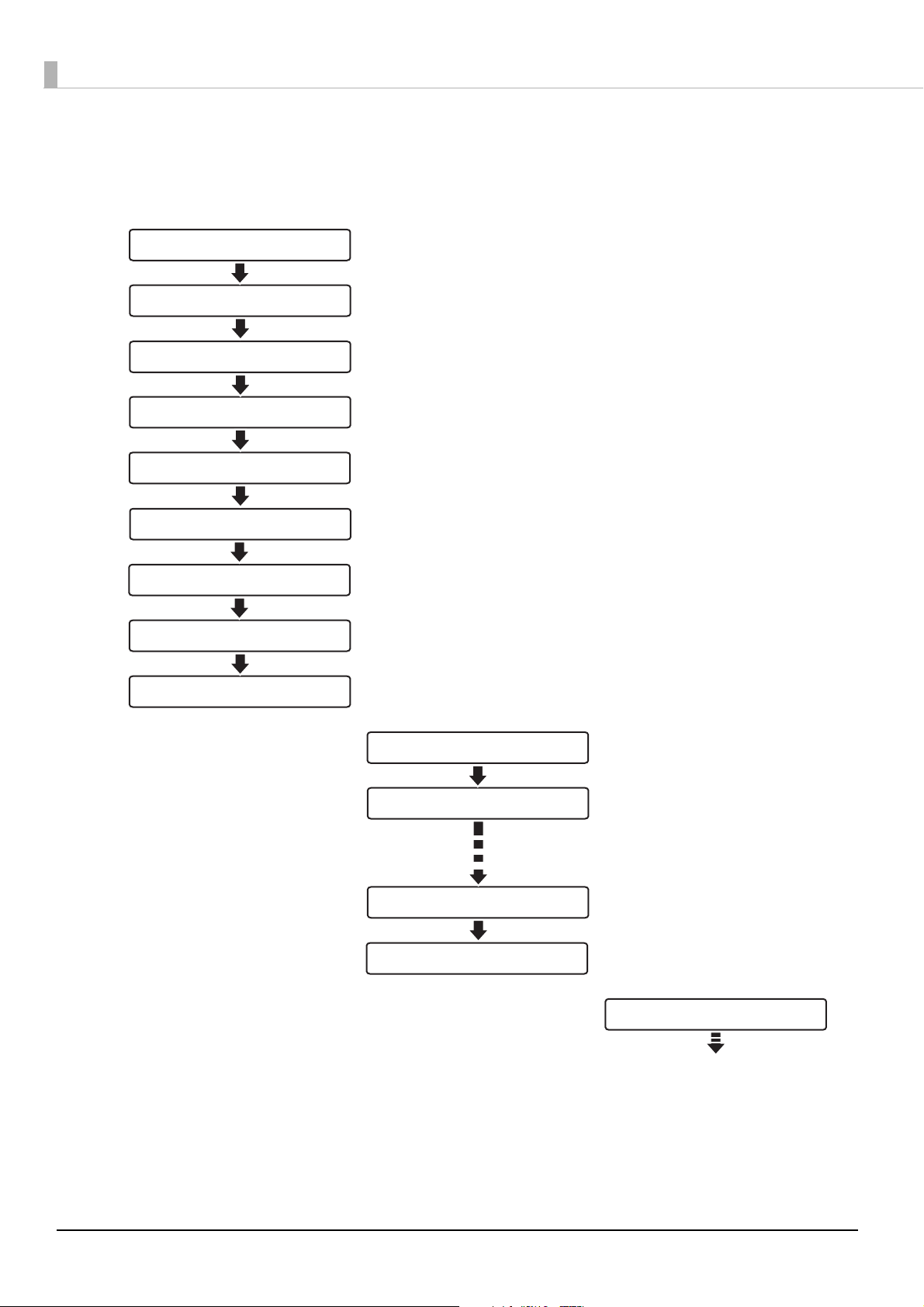

Chapter 2 Setup

3. Connecting a Cash Drawer (page 37)

4. Connecting a Power Supply (page 39)

2. Connecting to a Host Computer (page 37)

1. Product Installation (page 36)

5. Loading Roll Paper (page 40)

6. Installing the Ink Cartridges (page 41)

7. Adjusting LCD Backlight Brightness (page 43)

8. Test Printing (page 44)

Setup

This chapter describes the product and peripheral device installation and setup procedures that need to be performed before using the product.

Setup Flow

The information in this chapter follows the flow of product and its peripheral device setup as shown below.

2

35

Page 36

Product Installation

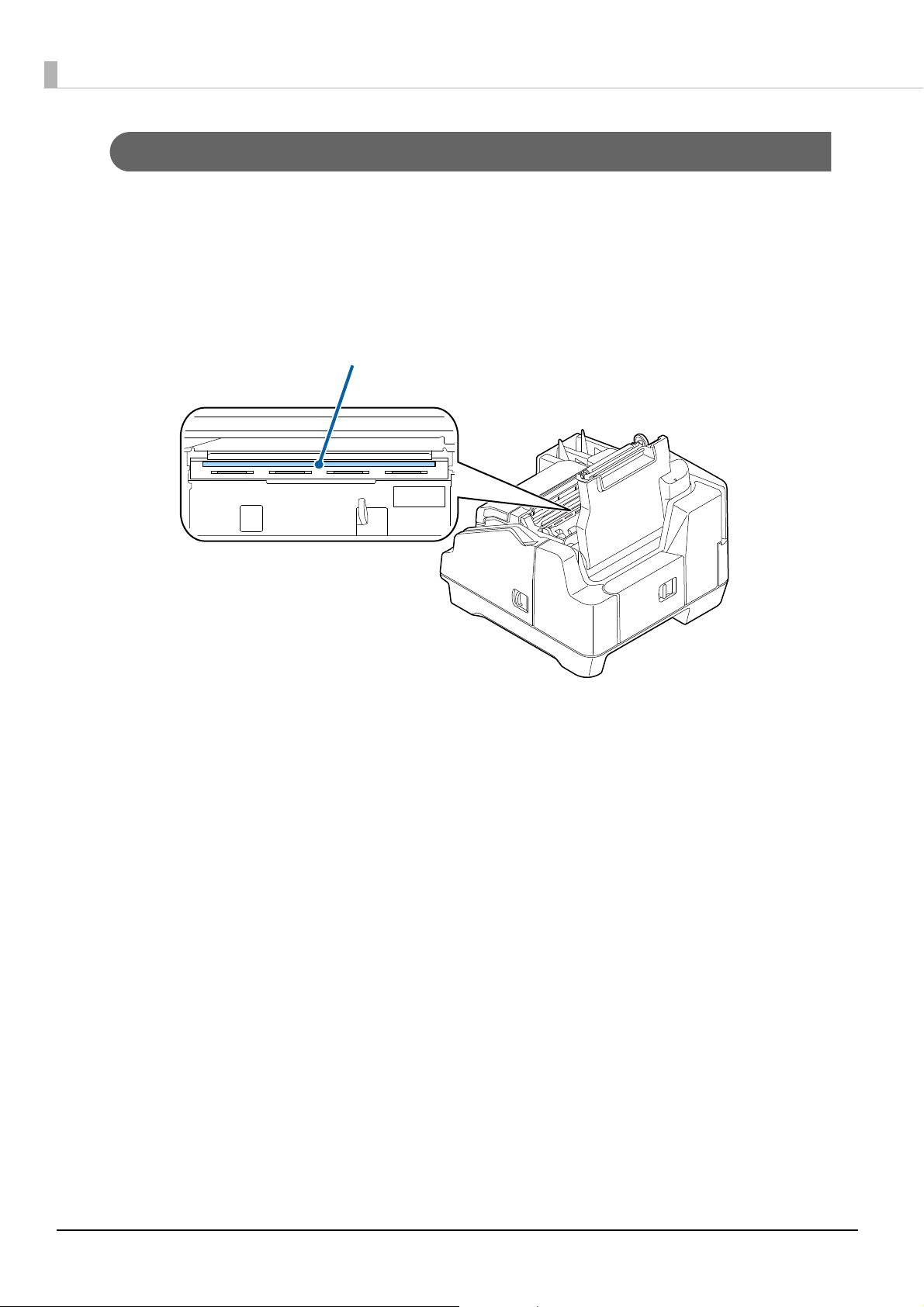

Removing the Packing Materials

Packing materials are affixed for protection against shock during transportation. Remove the packing materials

shown below before installing the product.

The packing materials and packaging box are required for future transportation. Keep them in a

safe place.

Installation

Provide sufficient space in a location appropriate for installation.

Location Appropriate for Installation

• On an area larger than the bottom surface of the product (U “Overall Dimensions” on page 109)

• In a level and stable location

• In a location free of vibration and impacts

• In a location where a dedicated power outlet is available

• In a location with sufficient space around the product to allow for replacement of consumable products, and

daily cleaning.

• In a location meeting the guaranteed environmental conditions (U

)

107

• When moving the product, lift it up by grasping at the depressions on either side.

• Make sure that cords or other objects are not being pinched by the product.

• To avoid deterioration of the MICR recognition rate, do not install the product near a magnetic

field. In particular, check the MICR reader recognition rate when the product is installed near a

display device.

“Environmental Specifications” on page

36

Page 37

Chapter 2 Setup

Connecting to a Host Computer

Connect the USB for connecting with the host computer to the port on the back of the product. (U “Rear” on

page 18

)

• Pass the USB cable through the wire saddle to prevent accidental disconnection.

• Use of the included USB cable is recommended. Use of another USB cable can result in improper

operation during large-volume data processing when scanning a series of documents.

Connecting a Cash Drawer

• Simultaneous operation of two drives is not supported.

• When sending consecutive drawer drive pulses, allow an interval between pulses that is at least

four times that of the drawer drive pulse.

Specifications Required for a Cash Drawer

Cash drawer specifications vary widely according to manufacturer and model. Whenever connecting a drawer

that is not one specified for this product, check to make sure that it meets the drawer specifications below.

Connecting a drawer that does not meet these specifications creates the risk of damage to the product.

• Drawer kick solenoid or other load between pins 4 and 2 or pins 4 and 5 of the drawer kick connector

• When using a drawer open/close signal, a switch must be provided between drawer kick connector pins 3

and 6

• Load resistance (by a drawer kick solenoid or others) of at least 24 Ω, and input current of no more than 1 A

• Use of only the 24 V output of drawer kick connector pin 4 for the drawer power supply

2

37

Page 38

Drawer Kick Connector Connection Diagram

Shielded

Drawer kick connector

Product

User (drawer)

Drawer open/

close switch

Drawer kick

solenoid

1

2

3

4

5

6

6 5 4 3 2 1

F. G

+24V

Connecting the Drawer Cable

• Use a shielded cable for the drawer cable.

• Be sure to use product power (connector pin 4) for drawer power.

WARNING

• Do not plug a general public phone line or other similar connector to the drawer kick connector.

Doing so can damage the public phone line or product.

Insert the drawer cable into the product's drawer kick connector until you hear it click into place.

38

Page 39

Connecting a Power Supply

• Use only the specified AC adapter. Not doing so may cause a fire or electric shock. (U “Electrical

Specifications” on page 92

WARNING

Insert the DC connector of the AC adapter firmly all the way into the DC-IN connector

1

of the product.

Insert the connector of the AC cable firmly all the way into the AC inlet of the AC

2

adapter.

Insert the power plug firmly all the way into an outlet with a ground.

3

• Do not plug the AC cable into a power outlet whose voltage does not match the input voltage of

the AC adapter. Doing so can damage the product.

• If you discover an abnormality immediately turn off the product and unplug AC cable from the

power outlet.

• Use only the AC cable that comes with the product.

Chapter 2 Setup

)

Place the AC adapter with its label facing downward.

4

2

39

Page 40

Loading Roll Paper

Take care not to press on the manual cutter with your hand or fingers. Doing so may cause injury.

CAUTION

Open the roll paper cover. (U “Opening the Roll Paper Cover” on page 68)

1

Load roll paper, making sure it is oriented correctly.

2

Pull out the leading edge of the roll paper a little, and close the roll paper cover.

3

If the product is turned on, the roll paper will be cut automatically.

40

Page 41

Chapter 2 Setup

IC chip

Installing the Ink Cartridges

This section describes the procedure for installing the ink cartridges and performing ink charging for the first

time.

When replacing an ink cartridge, refer to

dure in this section.

Read the precautions on handling carefully before installing the ink cartridges.

(U

“Cautions on Ink Cartridges” on page 9)

CAUTION

Check that the product is powered on. (U “Turning the Power On” on page 67)

1

Open the ink cartridge cover. (U “Opening the Ink Cartridge Cover” on page 68)

2

Remove a new ink cartridge from its bag.

3

“Replacing the Ink Cartridges” on page 70, and then follow the proce-

Peel the yellow film from the ink cartridge.

4

• Do not remove the other label.

• Do not touch the IC chip.

CAUTION

2

41

Page 42

Gently press the ink cartridge into the product.

PUSH

5

Close the ink cartridge cover.

6

Ink charging starts. The (POWER) LED flashes during ink charging. It takes up to 4 minutes to charge the

ink the first time ink cartridges are installed in the product.

When ink charging completes, the (POWER) LED changes from flashing to on.

CAUTION

Never open any cover of the printer or turn off the printer during ink charging (while the

(POWER) LED is flashing). Doing so will consume a large amount of ink, which may result in the

need to replace the ink cartridges before the completion of charging.

The ink cartridges included in the product package are used for initial charging. The product uses

ink to prepare for printing (ink charging) when the ink cartridges are installed for the first time.

The installing of ink cartridges is now complete.

42

Page 43

Chapter 2 Setup

Adjusting LCD Backlight Brightness

Adjust the brightness of the LCD to suit the environment where the product is being used. The changed setting

is retained even if the power is turned off. Available brightness settings are bright, normal, and dark.

Open the ink cartridge cover. (U “Opening the Ink Cartridge Cover” on page 68)

1

Press Button 1 (dark) to make the display dark, or Button 2 (bright) to make the dis-

2

play bright.

Close the ink cartridge cover.

3

2

43

Page 44

Test Printing

Firmware version 1.02 ESC/POS

Buer Capacity

4K bytes (xed)

Handshaking operation (busy condition)

Receive buer full (xed)

Automatic line feed (CR command function)

Disabled

Resident character

Alphanumeric

Power on status

Disabled

Receipt cover open

Auto recoverable error

Remote wakeup

Enabled

Nozzle check pattern

Maintenance information

Thermal head : 0.000 km

Autocutter : 1 cut

Inkjet head(nozzle1) : 234 shots

Inkjet head(nozzle1) : 130 shots

MICR head : 92 sheets

Memory switches

Self-test printing can be used to check product settings. Self-test printing on cut sheets can be used to check for

missing dots and other printing irregularities.

For printing procedure, refer to “Self-test Mode” on page 54

.

44

Page 45

Chapter 2 Setup

<Normal>

<Clogging>

If the test print shows that the nozzle check pattern is blurred, it means that ink head cleaning is required.

(U

“Ink Head Cleaning” on page 77)

2

45

Page 46

46

Page 47

Chapter 3 Advanced Product Use

Advanced Product Use

Software Settings

The product has memory switches and customize values as software setting functions, which can be used for

configuring various product settings.

Refer to the following section for an overview of each function. Settings can be configured using one of the

methods (ESC/POS command, software setting mode, TM-S9000II Utility) shown in the table below.

Setting item/setting methods

Transmits the power ON information ✔✔

Auto line feed ✔✔

Remote wake-up ✔✔

Roll paper cover open during printing ✔✔

Roll paper print density ✔✔

Paper autocutting after closing the roll paper cover ✔✔

Roll Paper Reduction ✔✔

Print density when multiple tone printing ✔✔

Sets time to check ink head cleaning

Memory switch

Validation settings

Cut sheet settings

Time to enter power saving mode

Customize value

Function to prevent printing on the back side of documents (endorse) without magnetic ink characters

Software setting

mode

TM-S9000II Utility

✔

✔

✔

✔

✔

3

MICR appearance judgment position using the function to prevent printing on the back side of documents (endorse) without magnetic ink characters

Settings for auto Top Logo /

Bottom Logo printing

R/E

Extended settings for auto Top Logo /

Bottom Logo printing

• For information on the software setting mode, refer to “Software Setting Mode” on page 59.

• For details on the TM-S9000II Utility, refer to the TM-S9000II Utility User's Manual.

✔

✔

✔

47

Page 48

Function

Transmits the power ON information

• No send (default setting)

• Send

Auto line feed

• Always disabled (default setting)

• Always enabled

Remote wake-up

• Enabled (default setting)

• Disabled

Roll paper cover open during printing

• Automatic recovery error (default setting)

• Recoverable error

Roll paper print density

Selectable level 1 to 13 (70 to 130%)

Default setting: Level 7 (standard)

In order to ensure high print quality, setting the print density is recommended in accordance with the type of

paper being used as shown in the table below.

Original paper type Density

AF50KS-E 4 (85%)

TF50KS-EY, P220AGB-1 5 (90%)

TF60KS-E, PD160R, PD190R, KT48FA, KT55FA, F5041(55), F5041(48) 7 (100%)

P30521, P30523, P31523, P35524 8 (105%)

The higher the print density, the lower the printing speed.

Paper autocutting after closing the roll paper cover

• Cut (default setting)

• No cut (not recommended)

48

Page 49

Roll Paper Reduction

Reduction of top margin

• Does not reduce (default setting)

• Reduces

Reduction of bottom margin

• Does not reduce (default setting)

• Reduces

Line space reduction rate

• Does not reduce (default setting)

• 25%

• 50%

• 75%

Chapter 3 Advanced Product Use

Line feed reduction rate

• Does not reduce (default setting)

• 25%

• 50%

• 75%

Bar code height reduction rate

• Does not reduce (default setting)

• 25%

• 50%

• 75%

Print density when multiple tone printing

Selectable level 1 to 13 (70 to 130%)

Default setting: Level 7

In order to ensure high print quality, setting the print density is recommended in accordance with the type of

paper being used.

3

The higher the print density, the lower the printing speed.

Sets time to check ink head cleaning

Time (hh:mm) can be specified

Default setting: 20:00

49

Page 50

Validation settings

Paper feed direction

Top mar gin (dot s)

Left margin

(dots)

Allowable printing area

50.8 mm

18 mm

10 mm

10 mm

Paper feed direction

Top margin (dots)

Left margin

(dots)

Allowable printing area

50.8 mm

18 mm

10 mm

10 mm

Top margin (default setting: 0) and left margin (default setting: 0) settings are configurable

Cut sheet settings

Top margin (default setting: 0) and left margin (default setting: 0) settings are configurable

Time to enter power saving mode

This time can be set within the range of 100 ms [0.1 second] to 3600 s [60 minutes]

Default setting: 300 s [5 minutes]

50

Page 51

Chapter 3 Advanced Product Use

Paper length 160 mm

MICR line detection position (0.1 mm units)

MICR character start position

50.8 mm

18 mm

10 mm

10 mm

Paper feed direction

Function to prevent printing on the back side of documents (endorse) without magnetic ink characters

• Disabled (default setting)

• Enabled

Magnetic ink characters appearance judgment position

The MICR line judgment location (default: 0) can be specified in 0.1 mm units

Settings for auto Top Logo / Bottom Logo printing

Key codes

You can select from among the key codes of pre-registered logos

Alignment

• Align left

• Align center

• Align right

3

51

Page 52

Extended settings for auto Top Logo / Bottom Logo printing

Top Logo printing when feeding is up to the cut position

• Disabled

• Enabled (default setting)

Top Logo printing when the product is turned on

• Disabled (default setting)

• Enabled

Top Logo printing when covers are closed

• Disabled

• Enabled (default setting)

52

Page 53

Chapter 3 Advanced Product Use

Open the roll paper cover and hold down Button 2 as you turn on the product

Close the roll paper cover

Software setting mode

Short-press Button 2 once

+

Close the roll paper cover

NV graphics information

print mode

Short-press Button 2 four times

+

Close the roll paper cover

R/E information print mode

Close all covers and hold down Button 2 as you turn on the product

Short-press Button 2 once

Self-test mode

<Printing on roll paper>

Close all covers and hold down Button 1 as

you turn on the product

Load the cut sheet

Self-test mode

Open the ink cartridge cover and hold down

Button 1 as you turn on the product

Short-press Button 1 twice

+

Close the ink cartridge cover

+

Load the cut sheet

NV graphics information print mode

<Printing on cut sheet>

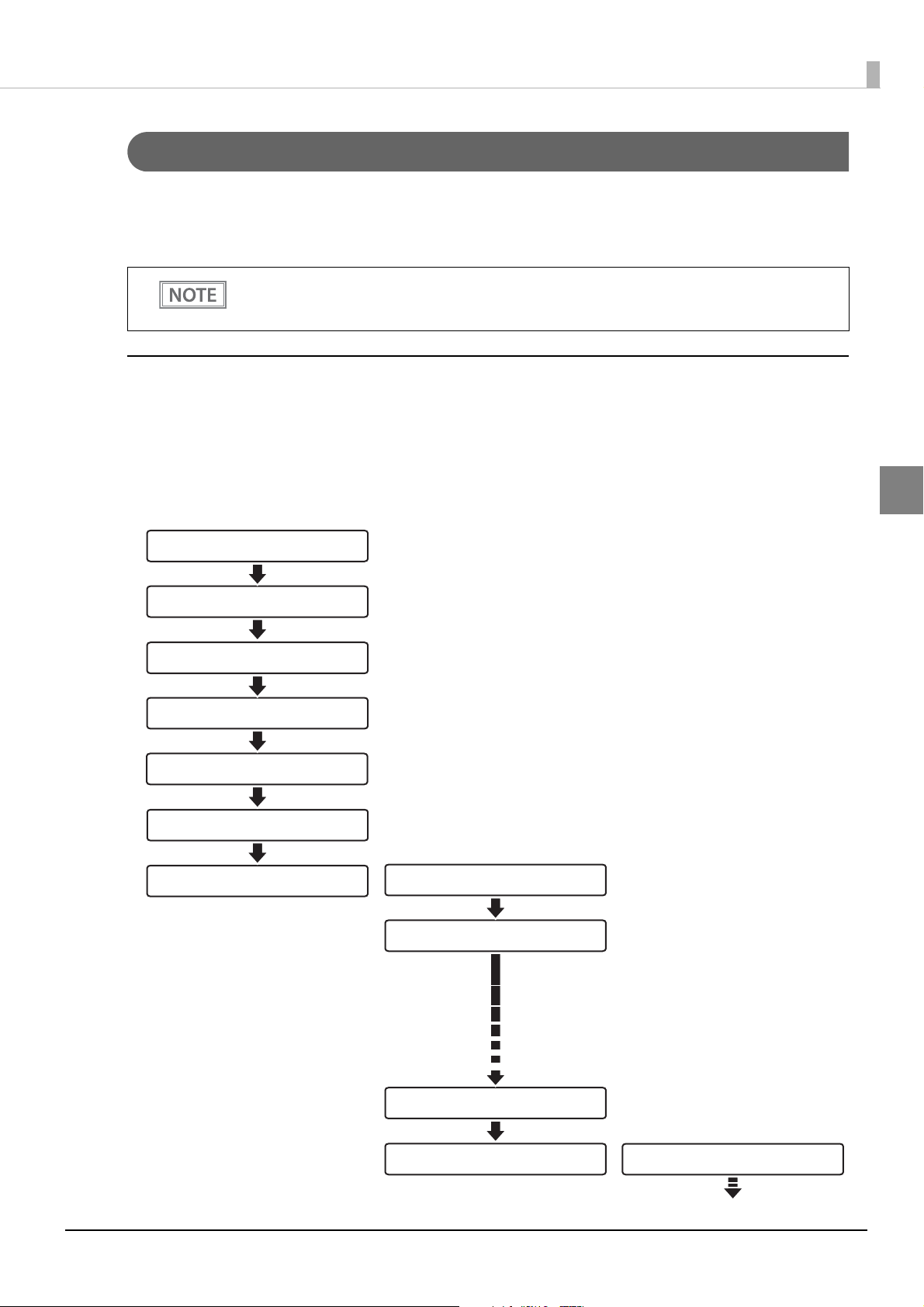

Setting/Confirmation Mode

In addition to the normal printing modes, the product also includes the modes below for configuring settings

and checking the status of functions.

• Self-test mode

• NV graphics information print mode

• R/E information print mode

• Software setting mode

Each mode is selected in accordance with the button that is pressed when the product is turned on and whether

a cover is opened or closed.

3

53

Page 54

Self-test Mode

You can use the self-test to check the items below.

• Control circuit function

• Printer mechanism function

• Print quality

• Control ROM version

• Memory switch setting function

Perform the procedures below.

Printing to Roll Paper

Turn off the product and confirm that all covers are closed.

1

While holding down Button 2, press the (POWER) button to turn on the product.

2

This starts test printing on the roll paper.

ON

+

Press Button 2 (Feed) again.

3

This restarts test printing. Printing is complete when “*** completed ***” is printed.

54

Page 55

Chapter 3 Advanced Product Use

ON

+

Self-Test Printing on Cut Sheets

When test printing on cut sheets, use the included cut sheet paper or cut sheets with dimensions of at least

70 mm wide by 152 mm long.

Turn off the product and confirm that all covers are closed.

1

While holding down Button 1, press the (POWER) button to turn on the product.

2

Load three cut sheets into the ASF. (U “Loading Cut Sheets” on page 72)

3

Test printing begins. Printing is complete when “*** completed ***” is printed.

• Self-test printing uses three cut sheets. The product stands by for insertion of cut sheets until

printing is complete.

• If the check doesn’t feed correctly, perform the self-test using 3 of the provided new cut sheets.

If the printer has not been used for three months or more, please perform this self-test print procedure, and repeat until the unit feeds correctly.

3

55

Page 56

NV Graphics Information Print Mode

This mode prints the NV graphics information below, which is registered on the product.

• NV graphics capacity

• NV graphics capacity usage

• NV graphics remaining free space

• NV number of graphics registrations

• Key code of each data, X-direction dots and Y-direction dots

• NV graphics data

For details on NV graphics, refer to “NV Memory” on page 33.

Printing to Roll Paper

Turn off the product and open the roll paper cover.

1

While holding down Button 2, press the (POWER) button to turn on the product.

2

Press Button 2 twice.

3

Close the roll paper cover.

4

This starts printing of NV graphics information.

Initialization starts after printing is complete. Next, the product transitions to its normal state (printing/scanning enabled).

ON

+

56

Page 57

Chapter 3 Advanced Product Use

ON

+

Printing on Cut Sheets

When test printing on cut sheets, use the included cut sheet paper or cut sheets with dimensions of at least

70 mm wide by 152 mm long.

Turn off the product and open the ink cartridge cover.

1

While holding down Button 1, press the (POWER) button to turn on the product.

2

Press Button 1 twice.

3

Close the ink cartridge cover.

4

This starts printing of NV graphics information.

Initialization starts after printing is complete. Next, the product transitions to its normal state (printing/scanning enabled).

3

57

Page 58

R/E Information Print Mode

ON

+

This mode prints the receipt enhancement information below, which is registered on the product.

• Auto Top Logo setting

• Auto Bottom Logo setting

• Auto Top Logo/auto Bottom Logo extended settings

Perform the procedures below.

Turn off the product and open the roll paper cover.

1

While holding down Button 2, press the (POWER) button to turn on the product.

2

Press Button 2 four times.

3

Close the roll paper cover.

4

This starts R/E (receipt enhancement) information printing.

Initialization starts after printing is complete. Next, the product transitions to its normal state (printing/scanning enabled).

58

Page 59

Chapter 3 Advanced Product Use

Software Setting Mode

Use this mode to configure settings for the product's memory switches and customize values.

• Roll paper print density

• Auto paper use reduction

• Paper auto cutting after closing the roll paper cover

• Error operation setting

• Transmits the power ON information

• Communication settings

For details on memory switches and customize values, refer to “Software Settings” on page 47.

Perform the procedures below.

Turn off the product and open the roll paper cover.

1

While holding down Button 2, press the (POWER) button to turn on the product.

2

ON