Page 1

Describes how to control the scanner and necessary information

when you develop applications.

Describes setup and installation of the product.

Describes how to handle the product.

Describes features and general specifications for the product.

Technical Reference Guide

Describes the interface and character code tables.

UV Model

Product Overview

Setup

Application Development Information

Handling

Appendix

M00086101

Rev. B

Page 2

Cautions

• No part of this document may be reproduced, stored in a retrieval system, or transmitted in any form

or by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior

written permission of Seiko Epson Corporation.

• The contents of this document are subject to change without notice. Please contact us for the latest

information.

• While every precaution has been taken in the preparation of this document, Seiko Epson Corporation assumes no responsibility for errors or omissions.

• Neither is any liability assumed for damages resulting from the use of the information contained

herein.

• Neither Seiko Epson Corporation nor its affiliates shall be liable to the purchaser of this product or third

parties for damages, losses, costs, or expenses incurred by the purchaser or third parties as a result of:

accident, misuse, or abuse of this product or unauthorized modifications, repairs, or alterations to this

product, or (excluding the U.S.) failure to strictly comply with Seiko Epson Corporation’s operating

and maintenance instructions.

• Seiko Epson Corporation shall not be liable against any damages or problems arising from the use of

any options or any consumable products other than those designated as Original Epson Products or

Epson Approved Products by Seiko Epson Corporation.

Trademarks

EEPSON is a registered trademark of Seiko Epson Corporation.

Exceed Your Vision is a registered trademark or trademark of Seiko Epson Corporation.

©Seiko Epson Corporation 2014-2017. All rights reserved.

2

Page 3

For Safety

Key to Symbols

The symbols in this manual are identified by their level of importance, as defined below. Read

the following carefully before handling the product.

You must follow warnings carefully to avoid serious bodily injury.

WARNING

Provides information that must be observed to prevent damage to the equipment or loss of

data.

CAUTION

Possibility of sustaining physical injuries.

Possibility of causing physical damage.

Possibility of causing information loss.

Provides information that must be observed to avoid damage to your equipment or a

malfunction.

Provides important information and useful tips.

3

Page 4

Warnings

WARNING

To avoid risk of electric shock, do not set up this product or handle cables during

a thunderstorm.

Never insert or disconnect the power plug with wet hands.

Doing so may result in severe shock.

Handle the power cable with care.

Improper handling may lead to fire or electric shock.

Do not modify or attempt to repair the cable.

Do not place any heavy object on top of the cable.

Avoid excessive bending, twisting, and pulling.

Do not place the cable near heating equipment.

Check that the plug is clean before plugging it in.

Be sure to push the plug all the way in.

Be sure to use the specified AC adapter.

Connection to an improper power source may cause fire or shock.

Do not place multiple loads on the power outlet.

Overloading the outlet may lead to fire.

Shut down your equipment immediately if it produces smoke, a strange odor, or

unusual noise.

Continued use may lead to fire. Immediately unplug the equipment and contact your

dealer or a Seiko Epson service center for advice.

Never attempt to repair this product yourself.

Improper repair work can be dangerous.

Never disassemble or modify this product.

Tampering with this product may result in injury or fire.

Do not allow foreign matter to fall into the equipment.

Penetration by foreign objects may lead to fire.

If water or other liquid spills into this equipment, do not continue to use it.

Continued use may lead to fire. Unplug the power cord immediately and contact your

dealer or a Seiko Epson service center for advice.

Do not use aerosol sprayers containing flammable gas inside or around this

product.

Doing so may cause fire.

4

Page 5

Cautions

Do not connect cables in ways other than those mentioned in this manual.

Different connections may cause equipment damage or fire.

CAUTION

Be sure to set this equipment on a firm, stable, horizontal surface.

The product may break or cause injury if it falls.

Do not use this product in locations subject to high humidity or dust levels.

Excessive humidity and dust may cause equipment damage or fire.

Do not place heavy objects on top of this product. Never stand or lean on this

product.

Equipment may fall or collapse, causing breakage and possible injury.

Before leaving the product unused for an extended period, make sure the ink

cartridge is installed, turn the product off using the power button, and unplug the

product to ensure safety.

Restriction of Use

When this product is used for applications requiring high reliability/safety such as

transportation devices related to aviation, rail, marine, automotive, etc.; disaster prevention

devices; various safety devices etc; or functional/precision

product only after giving consideration to including fail-safes and redundancies into your

design to maintain safety and total system reliability. Because this product was not intended for

use in applications requiring extremely high reliability/safety such as aerospace equipment,

main communication equipment, nuclear power control equipment, or medical equipment

related to direct medical care, etc., please make your own judgment on this product’s suitability

after a f

ull evaluation.

devices, etc., you should use this

5

Page 6

About this Manual

Aim of the Manual

This manual was created to provide information on development and design of scanner

applications for developers.

Manual Content

The manual is made up of the following sections:

Chapter 1

Chapter 2

Chapter 3

Chapter 4

Appendix

Product Overview

Setup

Application Development Information

Handling

Specifications of USB Interface

Character Code Tables

6

Page 7

Contents

■ For Safety...............................................................................................................................3

Key to Symbols ....................................................................................................................................... 3

Warnings ................................................................................................................................................. 4

Cautions.................................................................................................................................................. 5

■ Restriction of Use...................................................................................................................5

■ About this Manual ................................................................................................................6

Aim of the Manual................................................................................................................................. 6

Manual Content .................................................................................................................................... 6

■ Contents ................................................................................................................................7

Product Overview ........................................................................10

■ Features...............................................................................................................................10

■ Product Configuration........................................................................................................11

Color...................................................................................................................................................... 11

Attachments ........................................................................................................................................ 11

■ Part Names and Functions.................................................................................................12

Power Button ........................................................................................................................................ 13

Control Panel ....................................................................................................................................... 13

Connectors........................................................................................................................................... 15

■ Offline ..................................................................................................................................16

■ Processing Modes for Cut Sheet Paper ............................................................................17

High-Speed Mode ............................................................................................................................... 17

Confirmation Mode............................................................................................................................. 19

■ Selectable Functions for Processing Cut Sheet ...............................................................23

■ Error Status...........................................................................................................................25

Automatically Recoverable Errors ..................................................................................................... 25

Recoverable Errors .............................................................................................................................. 26

Unrecoverable Errors ........................................................................................................................... 27

■ NV Memory (Non-Volatile Memory) ................................................................................28

NV Graphics Memory.......................................................................................................................... 28

User NV Memory .................................................................................................................................. 28

Memory Switches................................................................................................................................. 28

User-defined Page............................................................................................................................... 29

Maintenance Counter ........................................................................................................................ 29

■ Maintenance Counter........................................................................................................30

■ Product Specifications .......................................................................................................31

Printing Specifications ......................................................................................................................... 33

Character Specifications.................................................................................................................... 34

7

Page 8

Scanner Specifications ........................................................................................................................35

Paper Specifications ............................................................................................................................37

Printable Area.......................................................................................................................................38

Scannable Area ...................................................................................................................................39

MICR Readable Area ..........................................................................................................................41

Area for Electronic Endorsement ....................................................................................................... 41

Environmental Conditions ...................................................................................................................42

Reliability................................................................................................................................................42

External Dimensions and Mass ............................................................................................................43

Setup .............................................................................................45

■ Flow of Setup ...................................................................................................................... 45

■ Installing the Product ......................................................................................................... 46

Important Notes on Installation ..........................................................................................................46

■ Connecting the Product to the Host Computer .............................................................. 47

■ Connecting the Power Supply Unit................................................................................... 48

■ Installing and Replacing the Ink Cartridge ..................................................................... 49

■ Setting the Memory Switches............................................................................................ 51

Functions ...............................................................................................................................................51

Application Development Information......................................53

■ Software .............................................................................................................................. 53

Operating Environment ....................................................................................................................... 53

Software for Windows .......................................................................................................................... 54

Software for Linux .................................................................................................................................55

How to Get Drivers, Utilities, and Manuals .........................................................................................55

■ Setting/Checking Modes .................................................................................................. 56

Self-test Mode.......................................................................................................................................56

NV Graphics Print Mode...................................................................................................................... 57

Handling .......................................................................................58

■ Turning On/Off the Product ............................................................................................... 58

Turning On .............................................................................................................................................58

Turning Off .............................................................................................................................................58

■ Opening Covers................................................................................................................. 59

Opening the Ink Cartridge Cover ......................................................................................................59

Opening the MICR Cover ...................................................................................................................59

Opening the Scanner Cover .............................................................................................................. 60

8

Page 9

■ Processing Cut Sheet Paper ..............................................................................................61

Flow of Single Pass Processing............................................................................................................ 61

Important Notes on Processing Cut Sheet Paper ............................................................................ 61

Inserting Cut Sheet Paper ................................................................................................................... 62

Ejecting Cut Sheet Paper ................................................................................................................... 63

■ Scanning ID Cards..............................................................................................................64

■ Cleaning..............................................................................................................................65

Cleaning the Ink-Jet Head ................................................................................................................. 65

Cleaning the MICR Head ................................................................................................................... 65

Cleaning the Scanner ......................................................................................................................... 66

Cleaning the Product Case ............................................................................................................... 67

■ Troubleshooting ..................................................................................................................68

Error LED Is On or Flashing ................................................................................................................... 68

Paper or ID Card Is Jammed.............................................................................................................. 68

Printout Is Faint ..................................................................................................................................... 68

Reading/Scanning Is not Normal....................................................................................................... 68

■ Preparing for Transport.......................................................................................................69

Install the transportation cartridge .................................................................................................... 69

Pack the scanner................................................................................................................................. 69

Appendix......................................................................................70

■ Specifications of USB Interface .........................................................................................70

USB Interface (Type B) ......................................................................................................................... 70

■ Character Code Tables .....................................................................................................71

Common to All Pages ......................................................................................................................... 72

Page 0 [PC437: USA, Standard Europe]............................................................................................73

Page 1 (Katakana).............................................................................................................................. 74

Page 2 (PC850: Multilingual) .............................................................................................................. 75

Page 3 (PC860: Portuguese) .............................................................................................................. 76

Page 4 (PC863: Canadian-French)................................................................................................... 77

Page 5 (PC865: Nordic) ...................................................................................................................... 78

Page 16 (WPC1252)............................................................................................................................. 79

Page 17 (PC866: Cyrillic #2)................................................................................................................ 80

Page 18 (PC852: Latin2)...................................................................................................................... 81

Page 19 (PC858: Euro) ..........................................................................................................

Page 255 (User-Defined Page) .......................................................................................................... 83

International Character Sets .............................................................................................................. 84

.............. 82

9

Page 10

Product Overview

This chapter describes features and specifications of the TM-S2000MJ.

Features

This compact, full-scale, up-grade hybrid product integrates functions of printing, check

computerization, and personal ID image reading required mainly for reception work at banks.

The main features are as follows.

•Small-footprint

•Check endorsement, cut sheet paper (cut sheet receipts, cashier’s check) printing

Ink-jet printing of multiple line and high resolution with 360 nozzle and 180 dpi

•Check magnetic ink character reader (E13B, CMC7) (supported by the driver.)

•Capturing image on the face and back of cut sheet paper and personal ID (such as driver’s

license)

Capability in obtaining binary (only cut sheet paper is supported.), grayscale, color, and infrared or

ultraviolet light source images.

•Auto sheet feeder

•Double feed detection for cut sheet paper

•Function to judge improper insertion of checks

•IQA (Image Quality Assurance) (supported by the driver)

•OCR (Optional Character Recognition) (OCR-A font, OCR-B font, barcodes) (supported by the

driver)

•High-speed USB (USB 2.0 compliant) port

•Maintenance counter tha

•Buzzer

•Low ink detection, notifications to request replacing the ink cartridge

•Paper separation using two exit pockets (supported by the two-pocket models only.)

t is convenient for remote maintenance

10

Page 11

Chapter 1 Product Overview

Product Configuration

The TM-S2000MJ differs in function and equipment depending on the following specifications.

Number of document exit pockets: 1 pocket or 2 pockets

Color

EDG (Epson Dark Gray)

Attachments

•USB cable

•2 dedicated ink cartridges (Model: SJIC18(K))

•AC cable*

•AC adapter

•Setup Guide

• User’s Manual

* May not be included depending on the product model.

1

11

Page 12

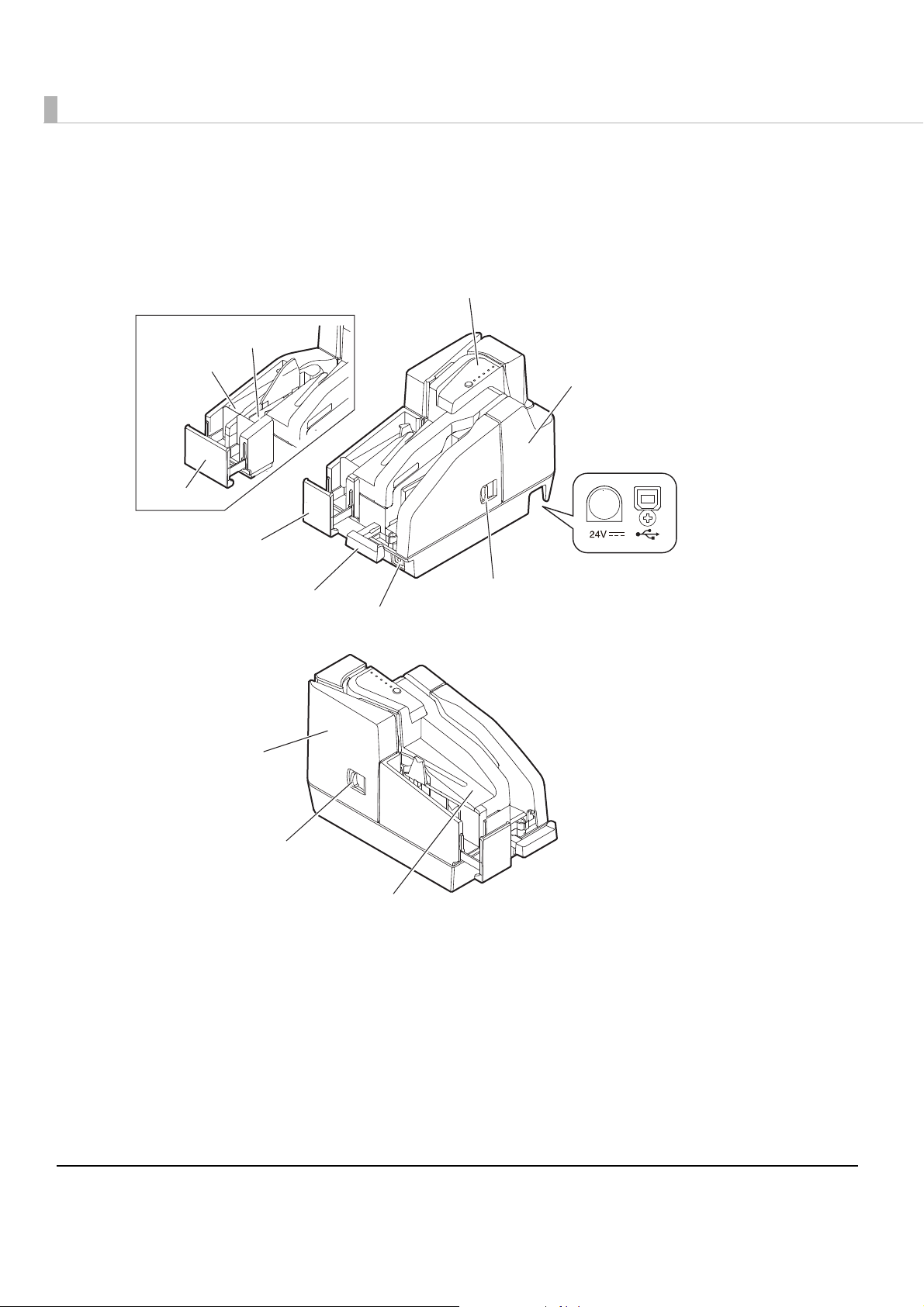

Part Names and Functions

(See "Control Panel" on page 13.)

(See

"Connectors" on page 15.)

Two-pocket model

Sub pocket

Main pocket

Pocket guide

Pocket guide

ASF guide

Power button

Control panel

MICR cover

Connectors

MICR cover open lever

12

Scanner cover

Scanner cover open lever

Ink cartridge cover

Page 13

Power Button

Turns the product on or off.

Be sure not to turn off the product or open the covers while the Power LED is flashing.

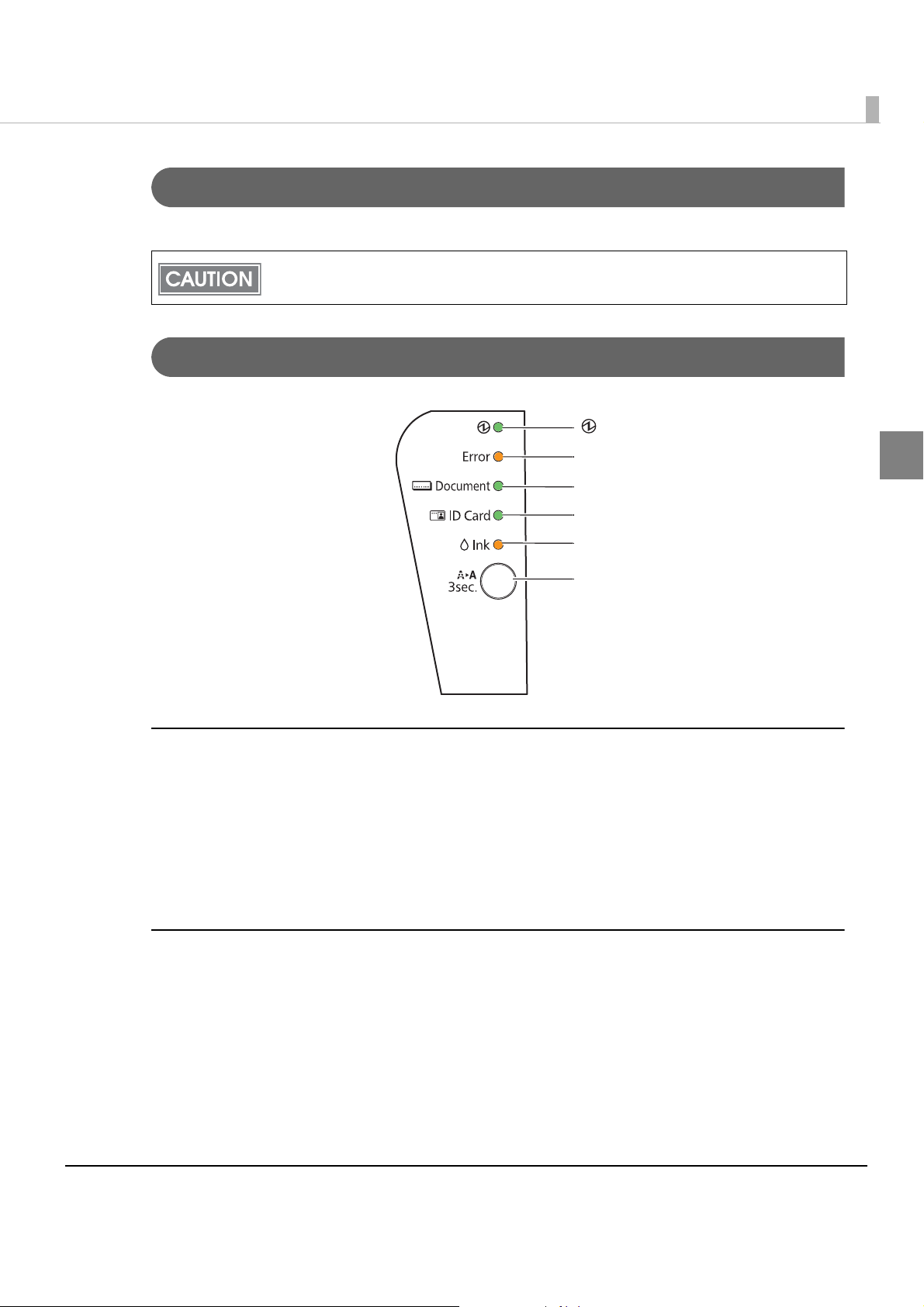

Control Panel

Chapter 1 Product Overview

(Power) LED

Error LED

Document LED

ID Card LED

Ink LED

Cleaning button

Power LED (Green)

•Lights when the power supply is on.

•Flashes rapidly while some operations such as turning power on, ink charging, or cleaning,

are executed.

• Flashes slowly while turning power off.

•Goes out when the power supply is turned off.

1

Error LED (Orange)

•Lights when the product is offline (except during self-test and during print head cleaning).

•Flashes when an error occurs. (For details about the flash codes, see "Error Status" on page 25.)

•Goes out during regular operation (online).

13

Page 14

Document LED (Green)

•Lights when the product is ready to process cut sheet paper in the ASF or while the product is

processing cut sheet paper.

•Flashes when the product is waiting for cut sheet paper insertion.

•Goes out except for the cases above.

ID Card LED (Green)

•Lights when ID card is set and the product is ready to process it.

•Flashes when the product is waiting for ID card insertion or removal.

•Goes out except for the cases above.

Ink LED (Orange)

•Lights when no ink cartridge is installed or it is time to replace the ink cartridge.

•Flashes when ink is low.

•Goes out when the ink cartridge is installed and remaining ink is enough.

Cleaning button

Pressing this button for 3 seconds or more starts the ink-jet head cleaning. (See "Cleaning the Ink-

Jet Head" on page 65

.)

14

Page 15

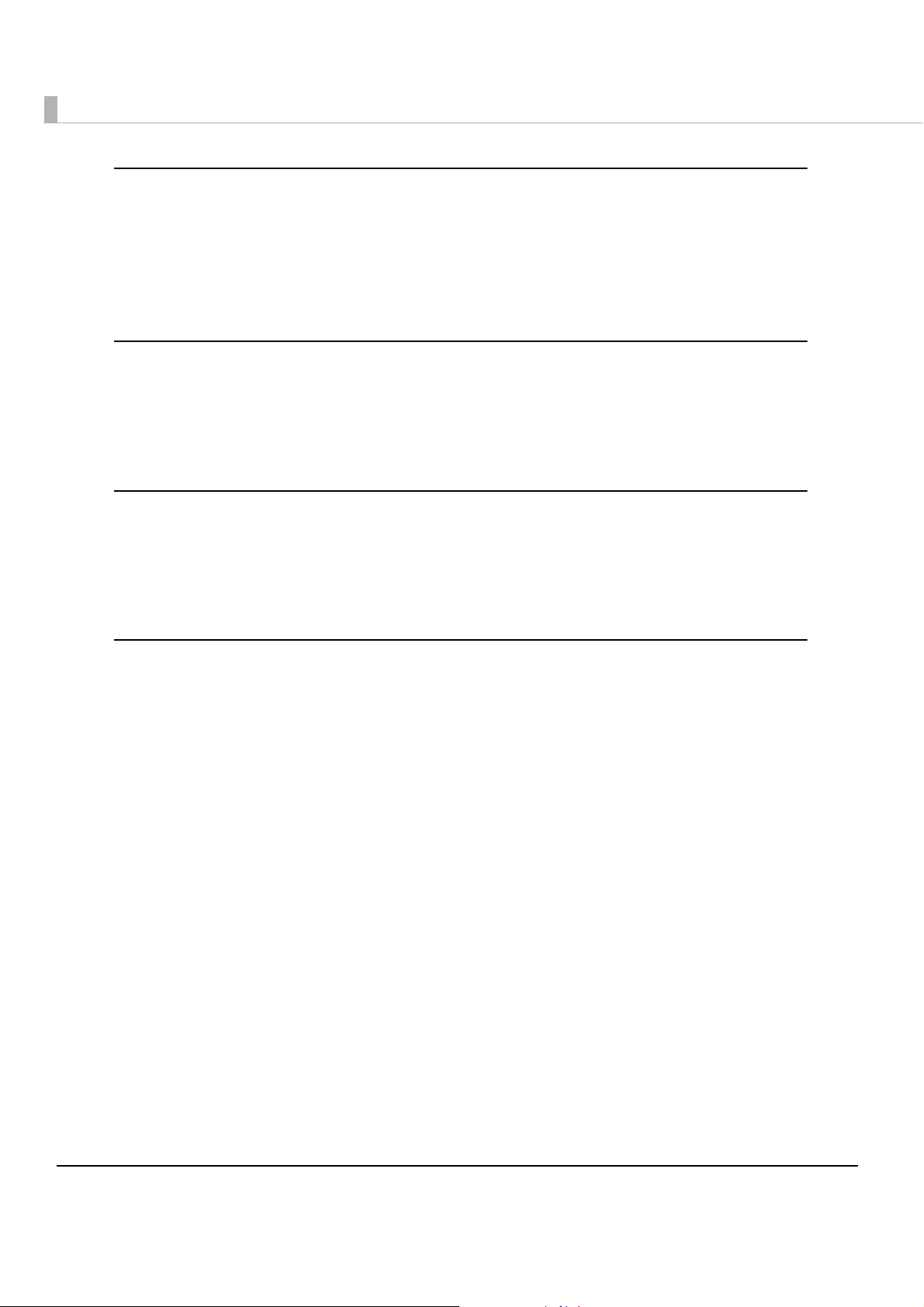

Chapter 1 Product Overview

Connectors

All cables are connected to the connector panel on the lower rear of the product.

1

•Power supply connector (

•USB connector (Type B) (➁): Connects the product with the host computer.

➀): Connects the power supply unit.

2

1

15

Page 16

Offline

The TM-S2000MJ automatically goes offline under the following conditions:

•During initialization after:

Power on (including resetting with the interface)

Removal of error causes

•When any of the following covers are opened:

Ink cartridge cover

MICR cover

Scanner cover

•When no ink cartridge is installed

•When it is time to replace the ink cartridge

•During self-test

•During the ink-jet head cleaning

•When an error has occurred

•During macro command execution

16

Page 17

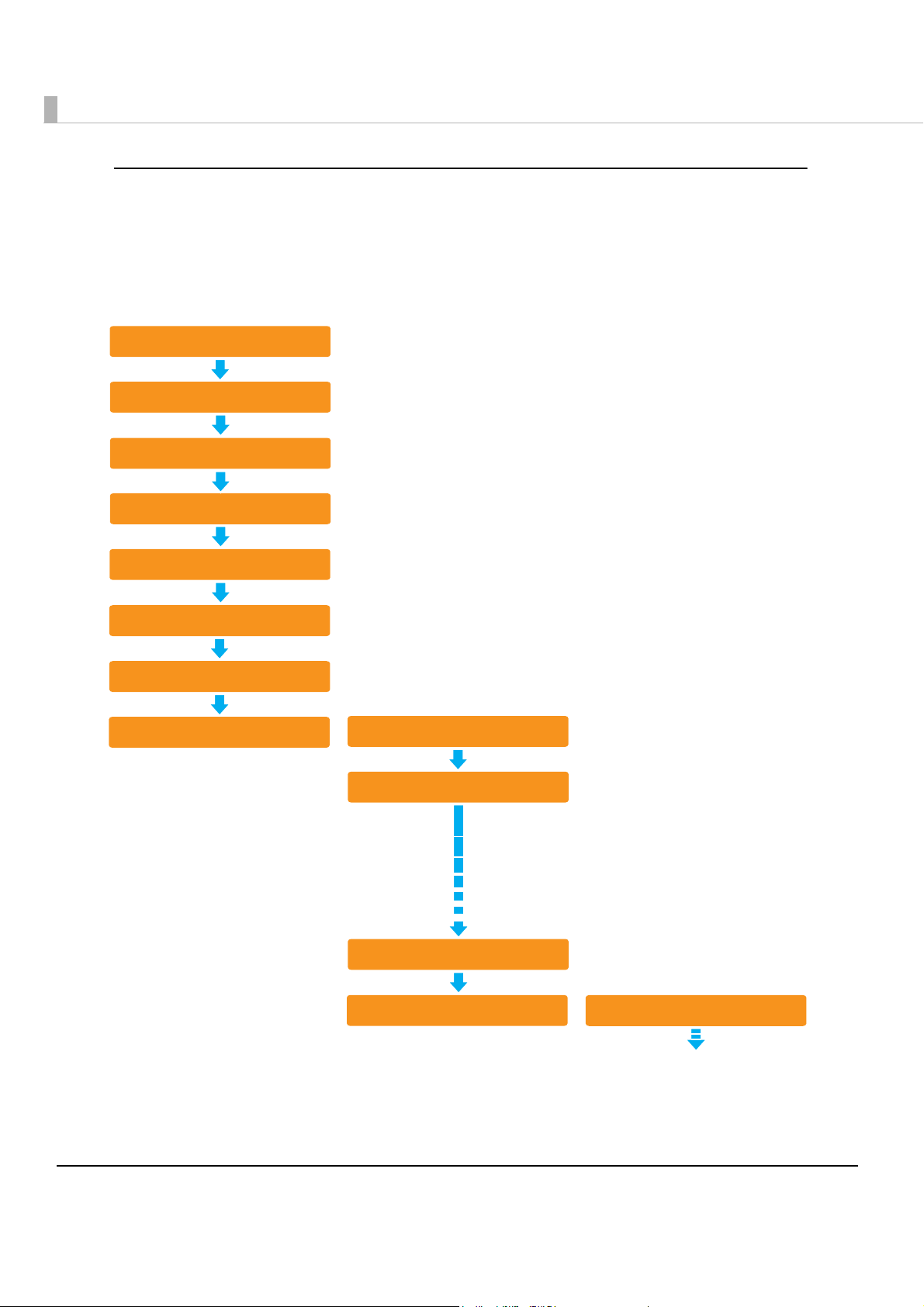

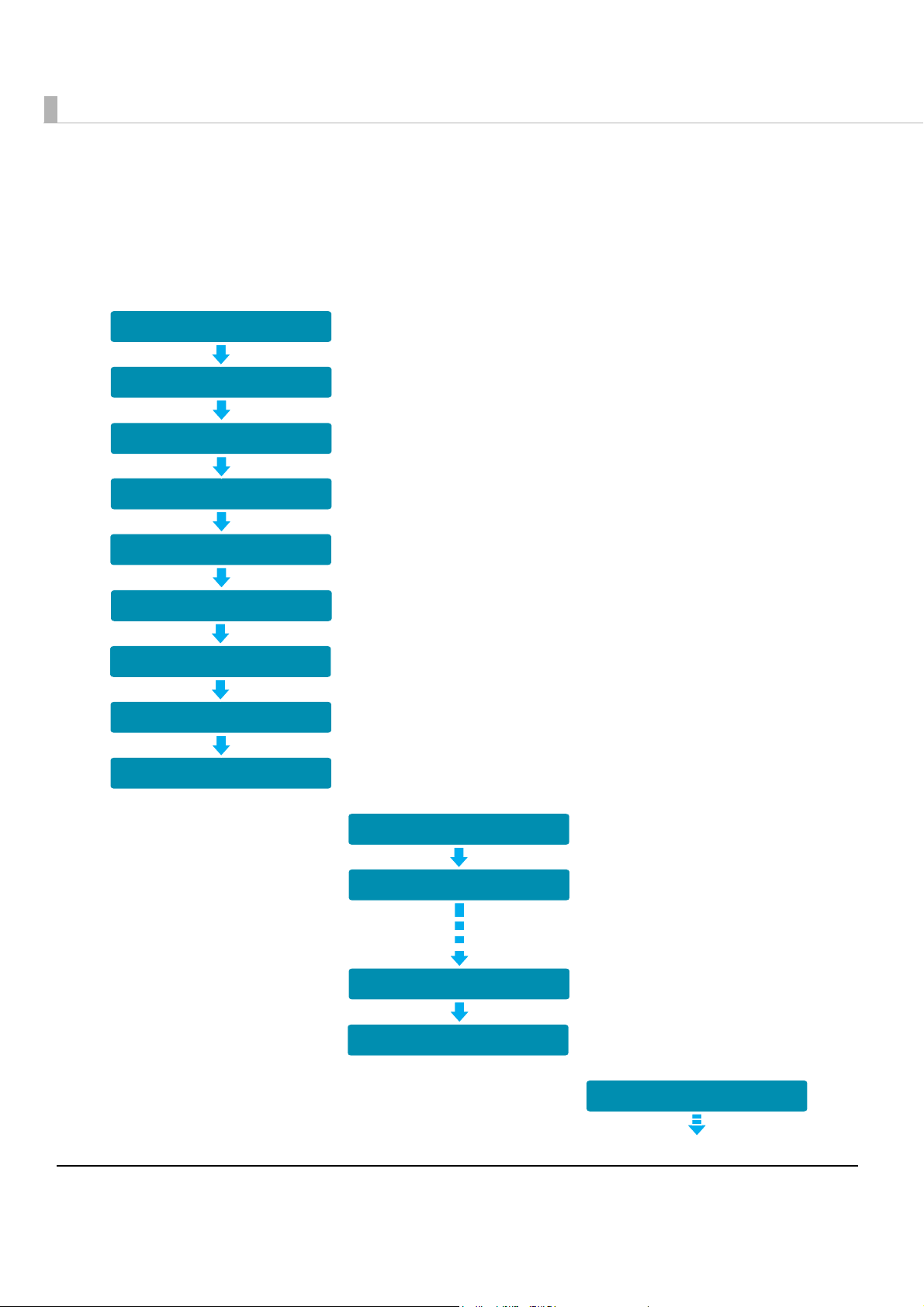

Chapter 1 Product Overview

Fed from the ASF

Check for double feeding

MICR reading

Ink jet printing

Capturing image on both sides

Ejection of the document

Fed from the ASF

Check for double feeding

MICR reading

Fed from the ASF

Check for double feeding

MICR reading

Ink jet printing

Capturing image on both sides

Ejection of the document

<First document>

<Second document>

<Third document>

Processing Modes for Cut Sheet Paper

The TM-S2000MJ has the following processing modes that are selectable with the driver in

accordance with how you want to use the product with cut sheet paper.

•High-speed mode

•Confirmation mode (with overlap/without overlap)

For detailed information about processing modes, see the TM-S2000MJ API Reference

Guide.

High-Speed Mode

This mode selects pockets and specifies whether to continue processing based on conditions

specified prior to scanning.

1

17

Page 18

When ejecting into the sub pocket (only for two-pocket models)

<First document>

Fed from the ASF

Check for double feeding

MICR reading

Ink jet printing

Capturing image on both sides

Backward paper feeding*

Switching of the pocket

Ejection of the document

<Second document>

<Third document>

Fed from the ASF

Check for double feeding

Ejection of the document

Fed from the ASF

Switching of the pockets

*: Occurs depending on some

conditions.

When documents are sorted into the two ejection pockets, a document is fed backward to the

pocket switching position and then ejected into a pocket if the ejection pocket is required to be

switched and the document is long. In that case, the processing slows down.

18

Page 19

Chapter 1 Product Overview

<First document>

Fed from the ASF

Check for double feeding

MICR reading

Ink jet printing

Capturing image on both sides

Stop of paper feeding*

Ejection of the document

<Second document>

<Third document>

Fed from the ASF

Check for double feeding

Ejection of the document

Fed from the ASF

Stop of paper feeding*

* Waits for an instruction from the

application.

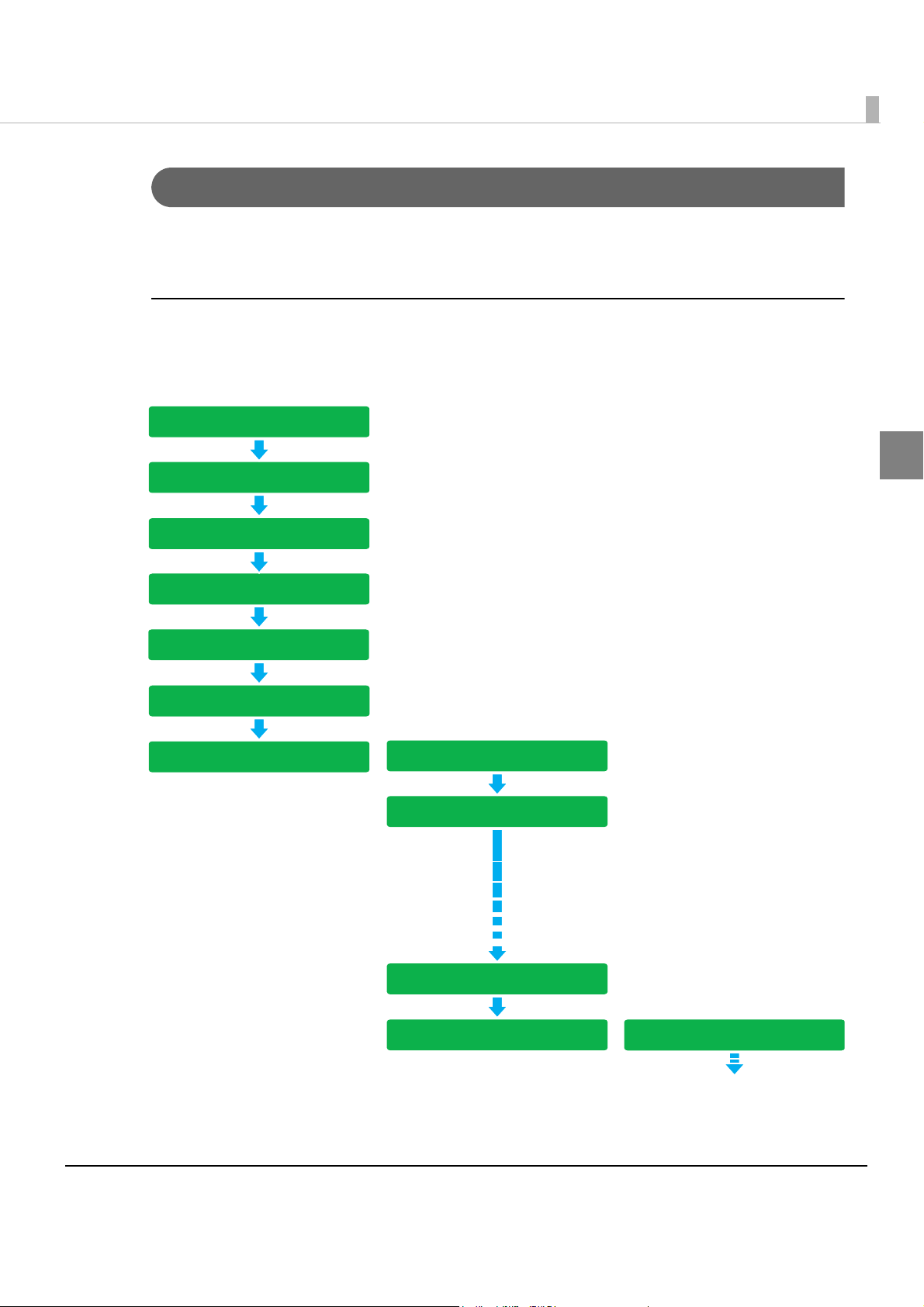

Confirmation Mode

This mode selects pockets and specifies whether to continue processing according to commands

from the application for each scan.

Confirmation mode with overlap

The product starts feeding the next document while ejecting the current document into a pocket.

1

19

Page 20

When ejecting into the sub pocket (only for two-pocket models)

*1 Waits for an instruction from

the application.

*

2

Occurs depending on some

conditions.

When the two-pocket model receives a command to eject a document into a pocket, the

processing slows down because it feeds the document backward to the pocket switching

position and ejects it into a pocket.

<First document>

Fed from the ASF

Check for double feeding

MICR reading

Ink jet printing

Capturing image on both sides

Stop of paper feeding*

Backward paper feeding*

Switching of the pockets

Ejection of the document

1

2

<Second document>

Fed from the ASF

Check for double feeding

Switching of the pockets

<Third document>

Ejection of the document

Fed from the ASF

20

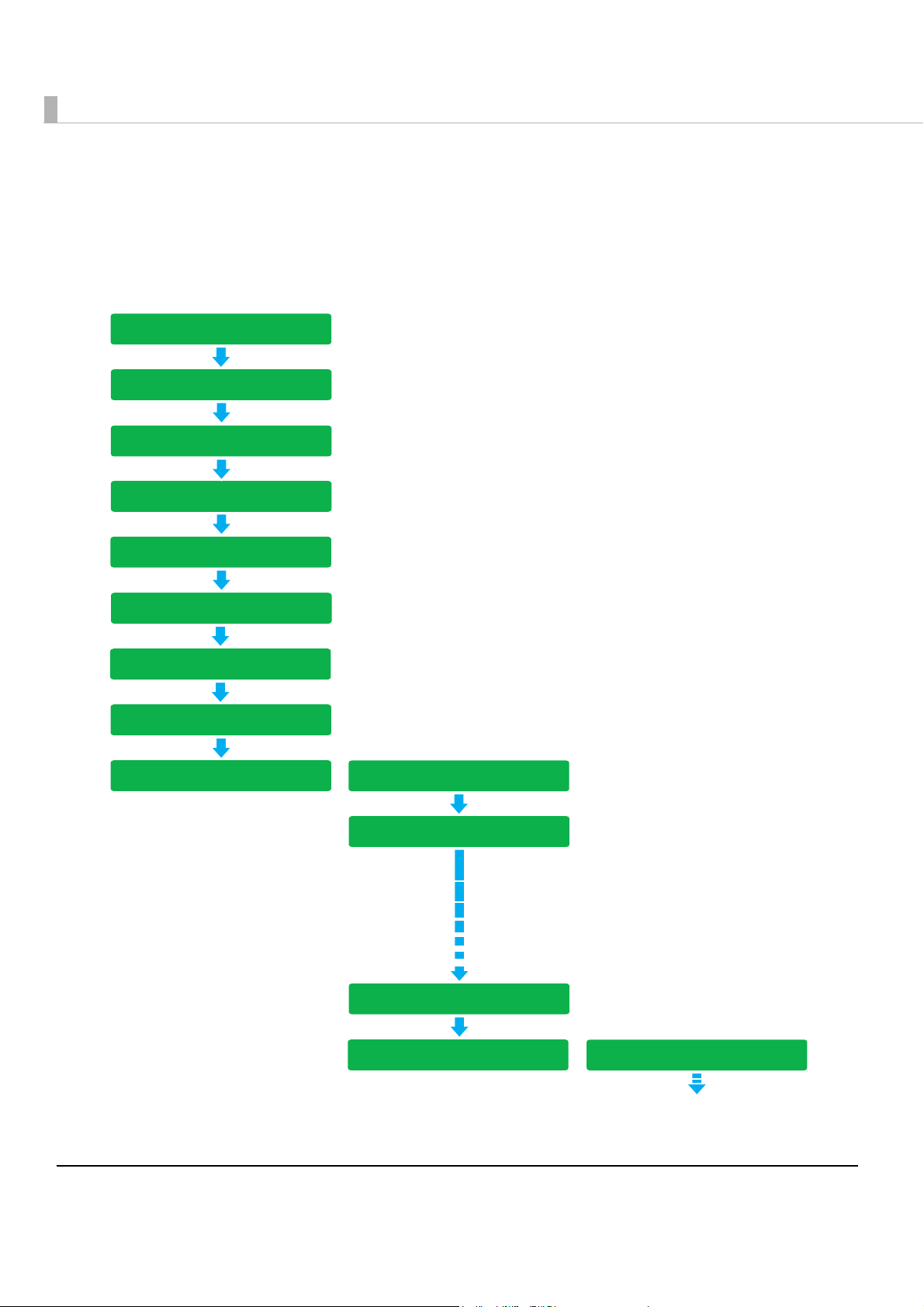

Page 21

Confirmation mode without overlap

<First document>

Fed from the ASF

Check for double feeding

MICR reading

Ink jet printing

Capturing image on both sides

Stop of paper feeding*

Ejection of the document

<Second document>

<Third document>

Fed from the ASF

Check for double feeding

Ejection of the document

Fed from the ASF

Stop of paper feeding*

Ejection of the document

* Waits for an instruction from the

application.

The product starts feeding the next cut sheet paper after the current cut sheet paper has been

stored completely into the pocket.

Chapter 1 Product Overview

1

21

Page 22

When ejecting into the sub pocket (only for two-pocket models)

<First document>

Fed from the ASF

Check for double feeding

MICR reading

Ink jet printing

Capturing image on both sides

Stop of paper feeding*

Backward paper feeding*

Switching of the pockets

Ejection of the document

<Second document>

<Third document>

Fed from the ASF

Check for double feeding

Ejection of the document

Fed from the ASF

Switching of the pockets

2

1

*1 Waits for an instruction from

the application.

*

2

Occurs depending on some

conditions.

When the two-pocket model receives a command to eject the document into the sub pocket, the

processing slows down because it feeds the cut sheet paper backward to the pocket switching

position and ejects it into the sub pocket.

22

Page 23

Chapter 1 Product Overview

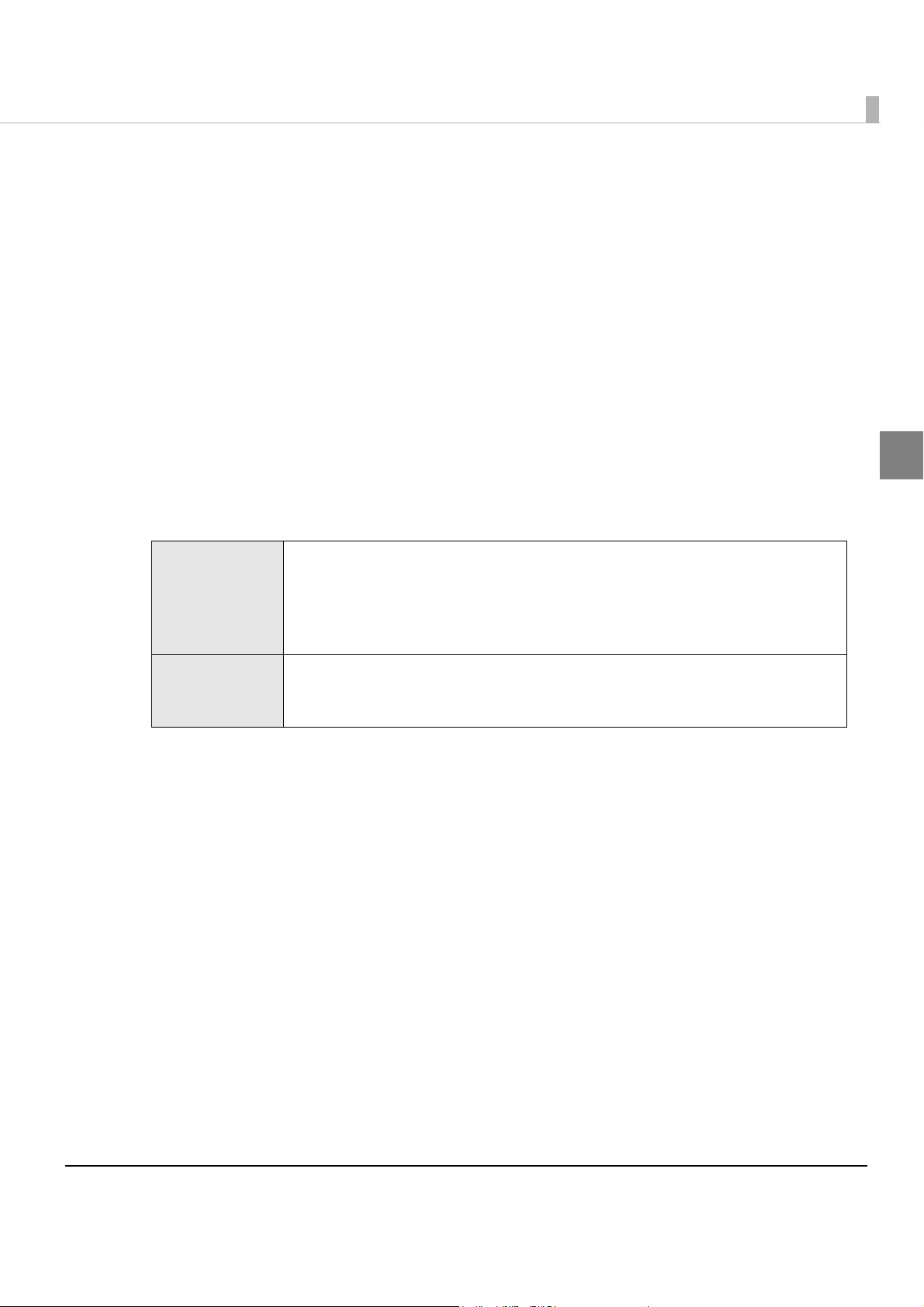

Selectable Functions for Processing Cut Sheet

The TM-S2000MJ has the following functions that are selectable with the driver in accordance

with how you want to use the product with cut sheet paper. Settings with an application are also

available for the pocket ejection and processing continuance in the confirmation mode.

•Pocket ejection (on

Ejects the document to the Main pocket

Ejects the document to the Sub pocket

Waterfall*

•Processing continuance

Continues processing

Ejects the document and stops processing

Stops processing without ejecting the document

* When the ejection pocket is near-full, the documents are automatically ejected to the other pocket.

Processing Mode:

High-speed

mode

Confirmation

mode

ly for two-pocket models)

This mode specifies whether or not to use Pocket ejection or Processing continuance

depending on the conditions set before scanning starts.

This allows the application to operate at high speed as it does not need to specify

operations for the next document for each scan. These conditions can be judged by the

host computer (processing in the driver) or by the firmware.

This mode specifies whether or not to use Pocket ejection or Processing continuance

depending on the instructions from the application. If there are no instructions from the

application, operations can also be performed by using the settings made beforehand.

1

23

Page 24

Functions and Judgment Conditions to be Selected in Each Processing Mode:

Processing

Modes

Judgment Selectable Functions

Judged by F/W When judgments are made from the following conditions only.

High-speed

mode

Judged by Driver The following conditions are judged at the same time as well as the

Confirmation

mode

Judged by

Application

Processing speed limitation:

Processing

Modes

Judgment Description

Detecting double feeding

Detecting incorrect insertion

(Check paper)

Detecting magnetic waveform

Detecting external noise

Print result that exceeds the paper length

conditions in the cell above.

“?” in MICR reading

IQA judgment

Barcode recognition result

Functions are judged by application software

High-speed

mode

Confirmation

mode

Judged by F/W Since operations can be performed with judgment by the firmware,

without judgment by the host computer, operations can be

performed at a high speed.

However, back feeding occurs when ejecting the document into the

sub pocket for two-pocket models. Therefore, the speed decreases

when the number of sub pocket ejections increases.

Judged by Driver Performance declines when the conditions need to be judged by

the driver.

Judged by

Application

When conditions for scanned images, MICR text strings, and so on

are judged by the application, since the product waits for

instructions from the application, the processing speed changes for

each scan as the application returns instructions to the driver.

Furthermore, performance changes depending on whether or not

to overlap the next document upon instructions from the

applications.

24

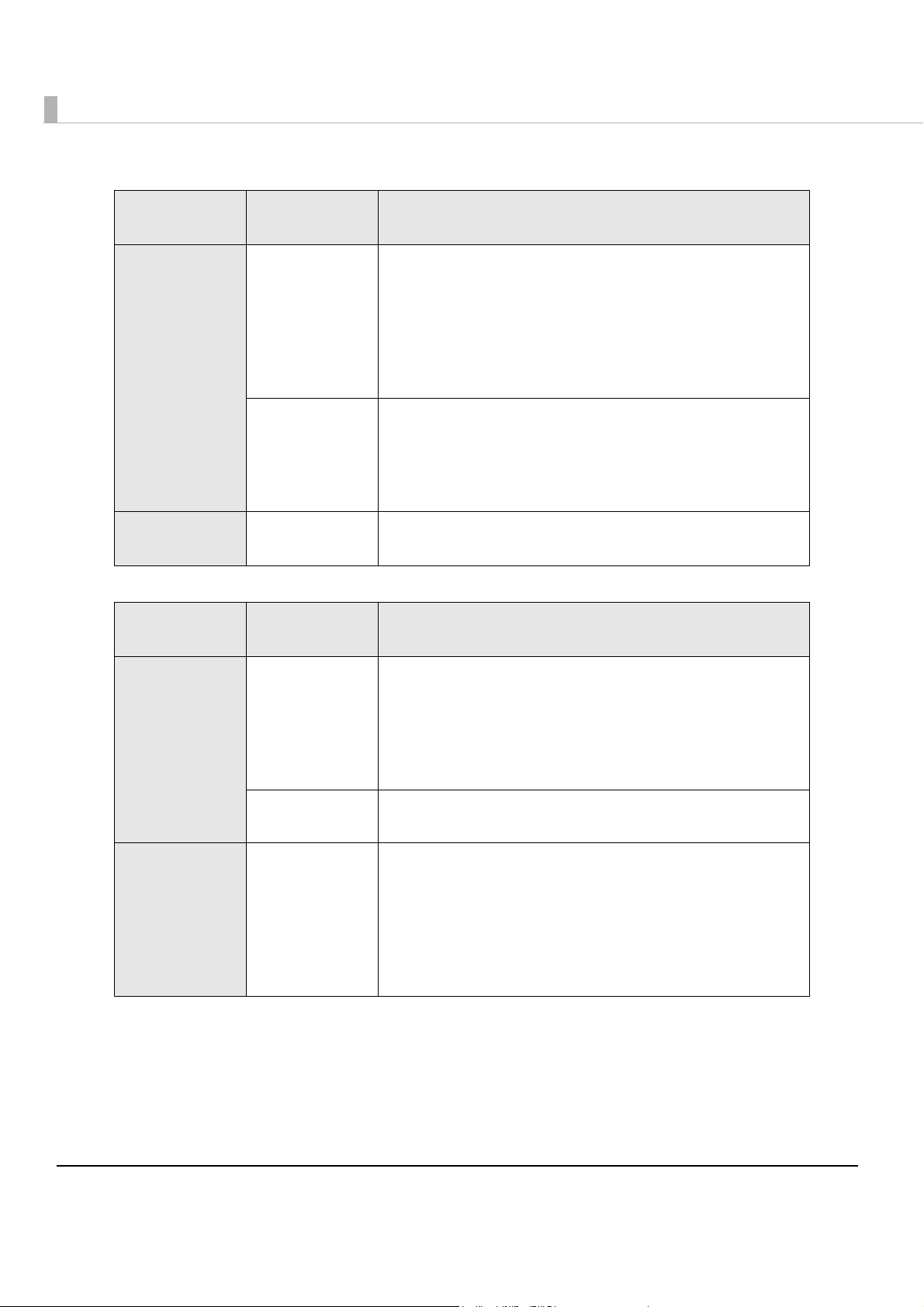

Page 25

Chapter 1 Product Overview

Approx. 320 ms

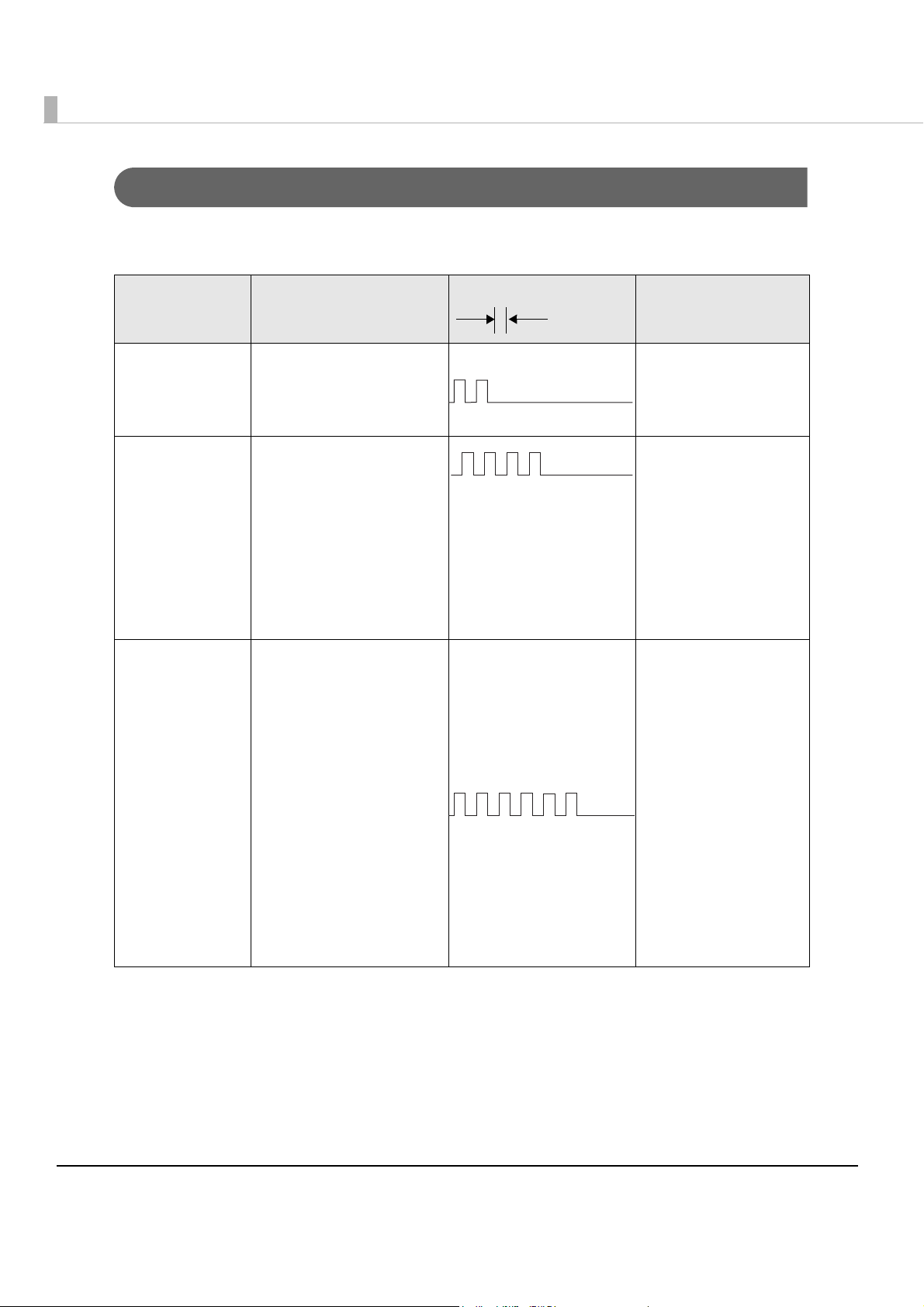

Error Status

When an error occurs, the printer stops operating, goes offline, and the Error LED flashes.

There are three possible error types: automatically recoverable errors, recoverable errors, and

unrecoverable errors.

Automatically Recoverable Errors

Printing is no longer possible when automatically recoverable errors occur. They can be

recovered easily, as described below.

Error LED flash code

Error Error description

Recovery measure

1

Print head high

temperature

r*

erro

Print head low

temperature

r*

erro

* If a drive circuit error occurs because of extreme temperatures, it is an unrecoverable error.

The temperature of the

print head is extremely

high.

The temperature of the

print head is extremely

low.

Recovers

automatically when

the print head cools.

Recovers

automatically when

the print head warms.

25

Page 26

Recoverable Errors

Approx.320 ms

Processing is no longer possible when recoverable errors occur. They can be recovered easily by

sending an error recovery command from the driver after eliminating the cause of the error.

Error LED flash code

Error Error description

Recovery measure

Mechanism

position error

Cut sheet paper

jam error

Cut sheet paper

feed error

The home position of the

hopper or the pocket

switching board cannot

be detected.

The check is not ejected

after feeding a specified

amount of paper.

Feeding from the ASF

failed.

A cut sheet paper/card

jam was detected.

Too short/long paper

was detected.

Double feeding of cut

sheet paper occurred.

Cut sheet paper was

inserted upside down or

back to front.

Selected that incorrect

cut sheet paper feeding

to cause an error in

confirmation mode.

Data that is longer than

the length of the cut

sheet paper was

specified.

Noise was detected

during MICR reading.

Recovers with a

command after the

error cause is

eliminated.

Recovers with a

command after the

error cause is

eliminated.

Recovers with a

command after the

error cause is

eliminated.

26

Page 27

Chapter 1 Product Overview

Approx. 320 ms

Unrecoverable Errors

Processing is no longer possible when unrecoverable errors occur. The scanner must be repaired.

Turn off the power immediately when unrecoverable errors occur.

CAUTION

Error LED flash code

Error Error description

Drive circuit error Internal circuit does not work correctly.

There is an abnormality in the thermistor.

Read/Write error After R/W checking, the printer does not

work correctly.

High voltage error The power supply voltage is extremely

high.

1

Low voltage error The power supply voltage is extremely low.

CPU execution error The CPU executes an incorrect address.

Communication

device error

IJ mechanism error Ink jet print mechanism does not work

Double feeding

detector noise error

Double feeding

detector error

Maintenance error The pump rotates more times than

USB does not work correctly.

correctly.

The double feeding detector detected a

noise.

The double feeding detector does not

work correctly.

specified.

The absorbed amount of the ink

absorber is more than specified.

27

Page 28

NV Memory (Non-Volatile Memory)

The printer's NV memory stores data even after the printer power is turned off. NV memory

contains the following memory areas for the user:

•NV graphics memory

• User NV memory

•Memory switches

•User-defined page

•Maintenance counter

As a guide when you program applications, NV memory should be rewritten 10 or fewer

times a day.

NV Graphics Memory

Graphics, such as logos to be printed on receipts, can be stored to enable high speed graphic

printing.

Use the TM-S2000 Utility to register graphics. You can also print and confirm the registered

graphics in the TM-S2000 Utility or NV graphics memory print mode.

For detailed information about the TM-S2000 Utility, see the TM-S2000 Utility User’s

Manual.

For information about how to use the NV graphics memory print mode, see

Graphics Print Mode" on page 57.

"NV

User NV Memory

You can store and read text data for multiple purposes, such as for storing a note including

customizing or maintenance information of the printer.

Memory Switches

With the memory switches, which are software switches for the printer, you can configure

various settings of the printer.

For information about the memory switches, see

"Setting the Memory Switches" on page 51.

28

Page 29

Chapter 1 Product Overview

User-defined Page

You can store character data in the user-defined page (character code table: page 255) so that you

can also print characters not resident in the printer.

Maintenance Counter

With this function, printer information, such as the number of head shots for ink jet , the count of

ASF feeding, and printer operation time after the printer starts working, is automatically stored

in NV memory. You can read or reset the information with the TM-S2000 Utility or the API of the

TM-S2000 Driver

to use it for periodical checks or part replacement.

For information about maintenance counter, see

"Maintenance Counter" on page 30.

1

29

Page 30

Maintenance Counter

The TM-S2000MJ has the maintenance counter to get the following counts.

Counter Counter type Unit

Number of head shots for ink jet (Column A) Resettable/Cumulative 1000 shots

Number of head shots for ink jet (Column B) Resettable/Cumulative 1000 shots

Count of pump motor operations Resettable/Cumulative Count

Count of ASF feeding Resettable/Cumulative Count

Count of cut sheet paper scanning Resettable/Cumulative Count

Count of card scanning Resettable/Cumulative Count

Count of magnetic ink character read Resettable/Cumulative Count

Count of pocket switch Resettable/Cumulative Count

Count of hopper open/close Resettable/Cumulative Count

Duration of product operation Resettable/Cumulative Hours

30

Page 31

Chapter 1 Product Overview

Product Specifications

ASF paper supply Number of sheets that can be loaded: 100 sheets or fewer

(when the paper thickness is 0.13 mm or less).

total thickness must be 13 mm or less including warps.

However, the

Pocket storage One-pocket

model

Two-pocket

model

MICR reader Reading method Permanent magnetic bias

Supported fonts E13B, CMC7 (Alphabetic characters are not supported.)

Recognition rate 99% or more (at 25C {77F} using check paper conforming to

OCR/ barcode

reader

Supported OCR

fonts

100 sheets or fewer (when the paper thickness is 0.13 mm or

less). However, the total thickness must be 13 mm or less

including warps.

Main pocket: 100 sheets or fewer (when the paper thickness is

0.13 mm or less).

or less including warps.

Sub pocket: 50 sheets or fewer (when the paper thickness is

0.13 mm or less). However, the total thickness must be 6.5 mm

or less including warps.

ANSI standards)

E13B, CMC7

OCR A

However, the total thickness must be 13 mm

1

OCR B (The characters, %, /, and & are available by driver

setting.)

Supported

barcode fonts

Interface USB (Type B) [compliance: USB 2.0 communication speed: Hi-

UPC-A, UPC-E, Code39, Code128, ITF, JAN8(EAN),

JAN13(EAN)

Speed (480 Mbps)/Full-Speed (12 Mbps)]

31

Page 32

Ink cartridge Exclusive ink cartridge: SJIC18(K)

Color of ink: Black

Power supply Specified AC adapter

Operating voltage DC24V ± 7%

The specified processing speed is not achievable when using USB Full-Speed.

32

Page 33

Chapter 1 Product Overview

Printing Specifications

Printing method Line ink jet printing with ink jet head

Nozzle arrangement 360 nozzles in 2 lines

Dot density 180 180 dpi

Printing direction Fixed stroke control

Print height 50.80 mm {2.00 in}

Printable lines Font A 12 lines maximum

Font B 16 lines maximum

Line spacing* Default: Approx. 4.23 mm {1/6 in}

Print width 100 to 215 mm {3.94 to 8.46 in} (depends on the

paper width)

Characters per line Font A 59 to 126 (depends on the paper width)

Font B 78 to 169 (depends on the paper width)

Character spacing* Font A 0.28 mm {0.01 in} (2 dots)

Font B 0.28 mm {0.01 in} (2 dots)

Maximum printing speed Approx. 800 mm/s {31.50 in/s} (When not obtaining

images)

dpi: dots per inch (number of dots per 25.4 mm {1.00 in})

* Programmable by control command.

1

33

Page 34

Character Specifications

Number of characters Alphanumeric characters 95 characters

Extended graphics 128 characters 11 pages (including user-

defined page)

International characters 37 characters

Character structure Font A 12 24 (including 2-dot horizontal spacing)

Font B 9 17 (including 2-dot horizontal spacing)

Character size (W H) Font A Standard: 1.41 3.39

Double-height: 1.41 6.77

Double-width: 2.82 3.39

Double-height/Double-width: 2.82 6.77

Font B Standard: 0.99 2.40

Double-height: 0.99 4.80

Double-width: 1.98 2.40

Double-height/Double-width: 1.98 4.80

Characters per line Font A Standard: 42

Double-height: 42

Double-width: 21

Double-height/Double-width: 21

Font B Standard: 56

Double-height: 56

Double-width: 28

Double-height/Double-width: 28

Space between characters is not included.

Characters can be scaled up to 64 times as large as the standard sizes.

When using Font B with a font style such as emphasized, some words may be hard to read. Check the font style in advance

when using Font B.

34

Page 35

Chapter 1 Product Overview

Scanner Specifications

Image Scanner CIS (Contact Image Sensor)

Resolution (H W) Cut sheet paper 300 300 dpi, 240 240 dpi, 200 200 dpi,

120 120 dpi, 100 100 dpi

ID cards 600 600 dpi, 300 300 dpi, 200 200 dpi

Gradation Binary (black and white)*

24-bit color, Binary and 256-level grayscale using

infrared or ultraviolet*

Data compression

format

Data format Binary (black and white)*

Image size (H W) Max. 109.728 mm {4.32 in}*

256-level grayscale

24-bit color

Binary (black and white) CCITT/group 4

256-level grayscale TIFF, JPEG, BMP, Raster

24-bit color TIFF, JPEG, BMP

Infrared light source

image

Ultraviolet light source

image

JPEG

3

TIFF*4, BMP

Binary (black and white): TIFF, BMP

256-level grayscale: TIFF, JPEG, BMP, Raster

Binary (black and white): TIFF, BMP

256-level grayscale: TIFF, JPEG, BMP, Raster

6

{10.04 in}*

function, the scanning area is approximately

equivalent to the document size.)

(When using the driver’s auto size

2

light source

1

, 256-level grayscale,

5

Max. 255.0 mm

1

Image quality Complies with IQA (Image Quality Assurance)

formulated by FSTC (Financial Services

Technology Consortium).

Deskewing images Deskews the image on the skewing document,

according to the TM-S2000 driver settings.

Auto size adjustment Crops the image and adjusts the size to the

document size, according to the TM-S2000 driver

settings.

35

Page 36

Scanning speed Cut sheet paper Approx. 800 mm/s {31.50 in/s}, Approx. 600 mm/s

{23.62 in/s}, Approx. 400 mm/s {15.75 in/s}, Approx.

240 mm/s {9.45 in/s} (Depends on the image to

read)

ID card Approx. 118 mm/s

Approx. 88 mm/s (when 24-bit color with infrared

or ultraviolet)

Cut sheet paper See "Paper Specifications" on page 37

.

ID card Type ISO/IEC7810 compliant (without embossed

effect)

Size (H W) 53.92 to 54.18 mm {2.12 to 2.13 in} 85.47 to 85.90

mm {3.36 to 3.38 in}

Thickness 0.5 to 0.84 mm {0.02 to 2.13 in}

Warpage 2 mm maximum (ISO/IEC7810)

dpi: dots per inch (25.4 mm)

1

Binary is supported by cut sheet paper only.

*

2

Scanning with an ultraviolet light source is only available for the front side of the check.

*

3

The background on the check is eliminated automatically when the TM-S2000 driver binarizes grayscale image.

*

4

The TIFF format of resolution 200 dpi, binary, CCITT-Group 4 compression complies with ANSI X9.100-181-2007.

*

5

Image sensor height is 109.728 mm {4.32 in}. As the image sensor attaching portion is included, the actual obtainable height

*

of the image is maximum 107.358 {4.23 in}.

6

Maximum document width in which image can be obtained is maximum 235 mm {9.25 in} + margin to ensure image

*

obtainment.

36

Page 37

Chapter 1 Product Overview

55 mm

20 mm

Diameter: 6 mm or less

Paper Specifications

Type Normal paper (single-ply only)

Size (H W) 60 to 120 mm {2.36 to 4.72 in} 100 to 235 mm {3.94 to 9.25 in}

Thickness 0.075 to 0.2 mm {0.003 to 0.008 in} (single-ply only)

Weight 60 to 120 g/m

Make sure that the paper has no curl, folds (especially at the top edges), warps, or

wrinkles. Otherwise a paper jam may occur.

Since the paper sensors use a reflective photo sensor, do not use paper that has holes,

translucency, or areas whose reflection ratio is less than 40% in the area shown in the

figure below.

Do not insert paper that has clips, staples, or other objects. Doing so may cause a paper

jam, MICR reading error, or damage to the MICR head or scanner head.

The paper sensors ignore the range indicated in the figure below for the guide holes in

fan-folded paper.

2

{16 to 32 lb}

1

37

Page 38

Printable Area

50.8 mm

18 mm

10 mm

10 mm

Check insertion direction

50.8 mm

18 mm

10 mm

Check insertion direction

60.8 mm

When the printing position is set from the top of the paper

When the printing position is set from the end of the paper

38

In the area that is 40 mm away from the end of the paper, print may be deformed.

Page 39

Chapter 1 Product Overview

Image height: Max. 109.728

Image width: Max. 255.0 mm

c=2.37

a=10.0b=10.0

Paper inserting direction

Image width: Max. 255.0 mm

Image height: Max. 109.728

c=2.37

a=10.0

Paper inserting direction

b=10.0

<

Front>

<Back>

All the numeric values are typical,

Scannable Area

Cut sheet paper

Image scanning may not be possible in the area a and b in the figures below. The quality of the

scanned image may be decreased in the area c.

No. 12345

pay to

the order of

MICR character

$

Dollars

1

39

Page 40

ID card

Insertion direction (Backward feeding)

107.357 mm

Max 116 mm

10 mm

49.3 mm

10 mm

Scanning direction

Paper path for check

3.9 mm

61.976 mm

109.728 mm

40

Page 41

MICR Readable Area

MICR read width: Max. 241 mm

Reading starting position of MICR:

3 mm from the paper edge

Max. 12.7 mm

Readable width of paper: Max. 235 mm

Readable MICR width: Max. 225 mm

Paper inserting direction

100 ~ 235

[Units: mm]

60 ~ 106.4 mm

<Front or Back>

Area for Electronic Endorsement

Chapter 1 Product Overview

1

41

Page 42

Environmental Conditions

°C

Temperature/

humidity

Operating 10 ~ 35°C {50 ~ 95°F}, 20 ~ 80% RH without condensation (See

the operating temperature and humidity range below.)

Storage

(Factory packing)

Maximum

absolute rated

temperature

-20 ~ 60°C {-4 ~ 140°F}, 5 ~ 85% RH without condensation (120

hours or less at -20 {-4°F} or 60°C {140°F})

70°C {158°F} (This temperature must never be exceeded

during operation or storage.)

80

55

Humidity (%)

20

10 27 35

Temperature ( )

Reliability

Life including reading of checks

and ID cards

ASF 2 million sheets

Print head 6 billion shots/nozzles

MTBF 180,000 hours

MCBF 4,940,000 processes

2 million sheets

42

Page 43

External Dimensions and Mass

[Unit: mm]

The values below are when the pocket guide is fully pulled out.

One-pocket model

Height

Approximately 177.0 mm {6.97 in}

Width

Approximately 142.0 mm {5.59 in}

Chapter 1 Product Overview

Depth

Approximately 374.8 mm {14.76 in}

Mass

Approximately 4.5kg {9.92 lb}

1

43

Page 44

Two-pocket model

[Unit: mm]

Height

Approximately 177.0 mm {6.97 in}

Width

Approximately 167.0 mm {6.57 in}

Depth

Approximately 409.8 mm {16.13 in}

Mass

Approximately 4.5 kg {9.92 lb}

44

Page 45

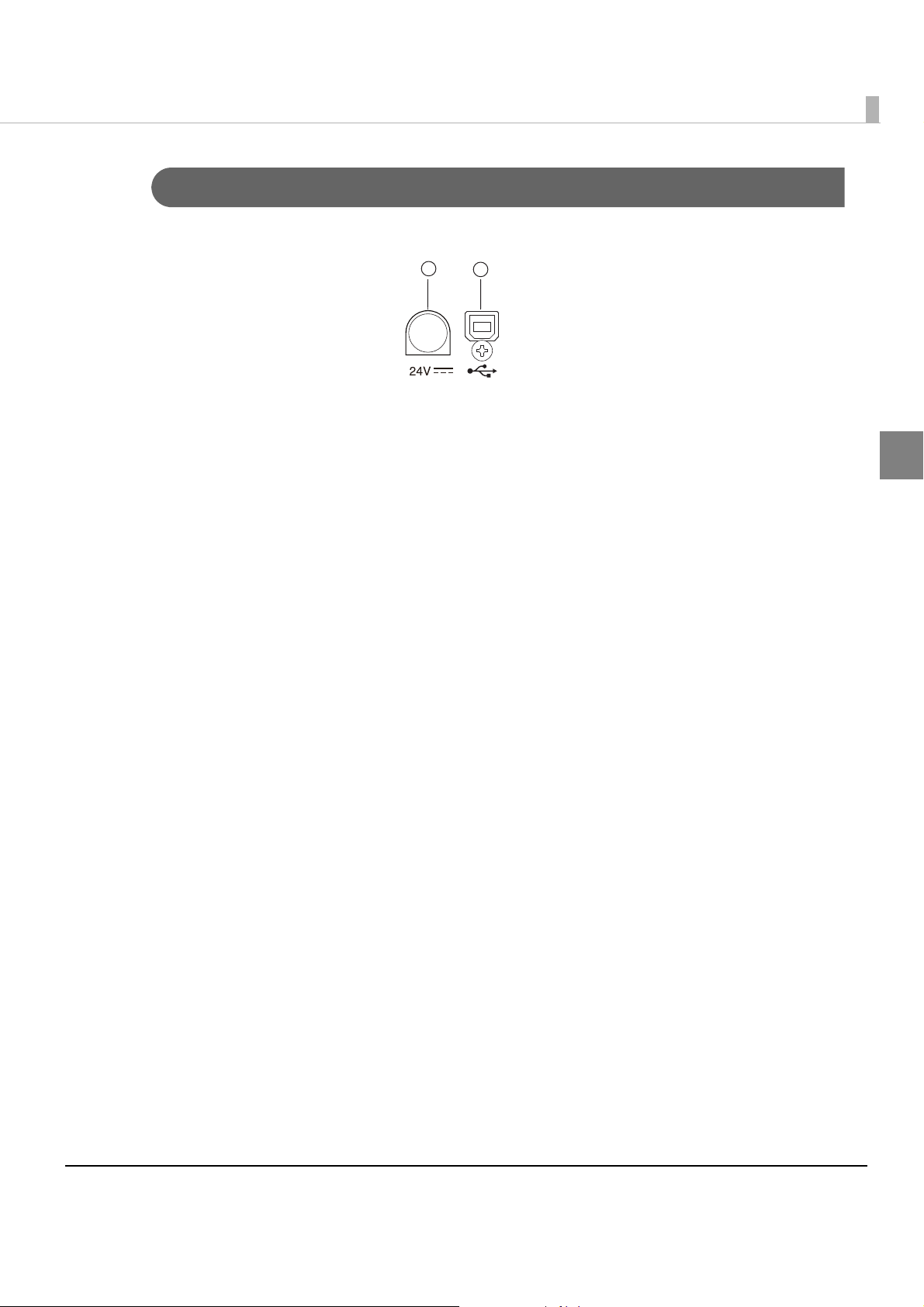

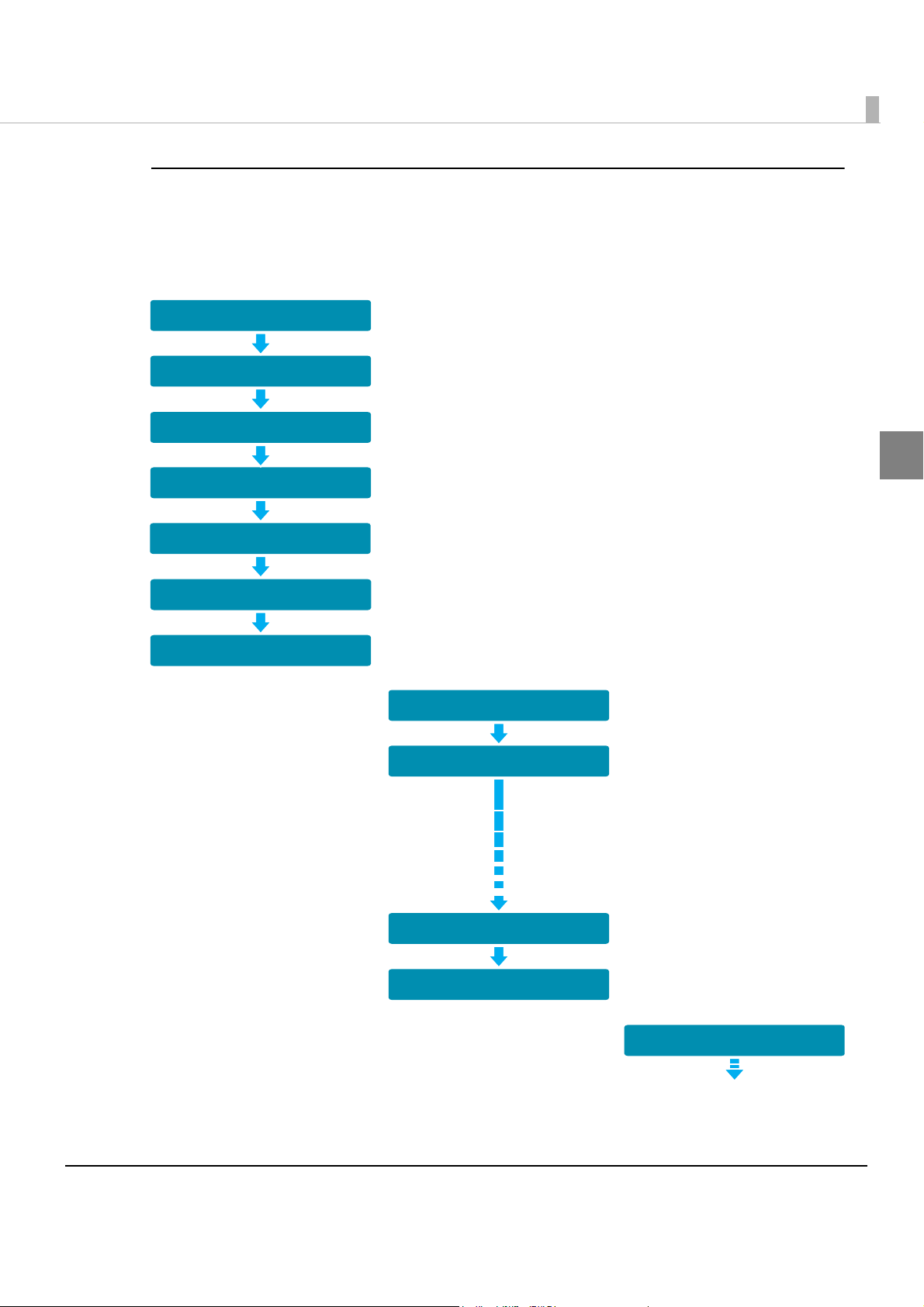

Setup

1. Installing the Product (page 46)

3. Connecting the Power Supply Unit (page 48)

2. Connecting the Product to the Host Computer (page 47)

4. Installing and Replacing the Ink Cartridge (page 49)

5. Setting the Memory Switches (page 51)

This chapter describes setup and installation of the product.

Flow of Setup

This chapter consists of the following sections along with the setup flow of the product.

Chapter 2 Setup

2

45

Page 46

Installing the Product

Important Notes on Installation

•Install the product horizontally.

•Make sure that the product is not subjected to any impact or vibration.

•Do not place the product near any magnetic fields to avoid decreasing the MICR recognition

rate. Especially, when you install the product near a display device, check the recognition rate

of the MICR reader.

•Leave enough space around the product to open the covers, the pocket guide, and the ASF

guide.

•To prevent a paper jam, do not prevent paper from being ejected from the paper exit.

•Make sure cords and foreign objects are not caught in the product.

•Do not put any food or drink on the product case.

•Remove the cushions in the product and fixing tape before use.

46

Page 47

Chapter 2 Setup

Connecting the Product to the Host Computer

Follow the steps below to connect the product to a host computer.

Be sure to install the driver before connecting the product to the host computer.

Be sure to use the USB cable that is included with the product.

Connect the USB cable to the USB (Type B) connector.

1

Fix the USB cable with the cable hook to prevent the USB cable from falling off.

Connect the USB cable to the host computer.

2

2

47

Page 48

Connecting the Power Supply Unit

Follow the steps below to connect the power supply unit to the product.

Be sure to use the specified AC adapter only.

Connection to an improper power source may cause fire or shock.

WARNING

Connect the AC cable to the AC adapter.

1

Connect the DC cable of the AC adapter to the power supply

2

connector on the product.

Should a fault ever occur in the AC adapter immediately turn off the power to the

product and remove the power supply cable from the wall socket.

48

Insert the AC cable plug into a socket.

3

Page 49

Chapter 2 Setup

Installing and Replacing the Ink Cartridge

Follow the steps below to install the ink cartridge into the product for the first time or replace it

with a new one.

Do not open the ink cartridge until you are ready to install it.

Do not touch the green IC chip on the side of the ink cartridge.

Do not puncture the convex part of the bottom of the ink cartridge or remove the

transparent film on the bottom of the ink cartridge.

Do not remove the ink cartridge except when replacing it with a new one.

After installing an ink cartridge, use it up within 6 months.

Use the ink cartridge before the expiration date printed on its package and on the ink

cartridge itself.

A used cartridge may have some ink on the convex part of the bottom of the cartridge.

Avoid touching that part to keep your hands clean.

Dispose of the used ink cartridges according to the laws or regulations in your country

and region.

To transport or store this product for a long period after once using this product, make

sure the ink cartridge is installed in the product.

2

When the ink cartridge is installed for the first time, the product uses ink to prepare for

printing (ink charging). Make sure to use a new ink cartridge.

Cartridge yields vary based on such usage environment and conditions.

To insure print quality, some ink remains in the cartridge after the Ink LED comes on.

This printer may automatically run maintenance operations at night or when the power is

turned on to maintain print quality. As a result of these maintenance operations, you may

need to replace the ink cartridge. In this case, replace the ink cartridge with a new one.

Turn on the product.

1

See "Turning On" on page 58.

Open the ink cartridge cover.

2

See "Opening the Ink Cartridge Cover" on page 59.

49

Page 50

If there is a used ink cartridge, remove it by pulling up the tab on the top

3

of the cartridge while holding the product.

Remove a new ink cartridge from its package.

4

Install the ink cartridge in the correct direction, and push it until it clicks in

5

place.

50

Close the ink cartridge cover.

6

When you first use the product, installing an ink cartridge begins charging the ink supply.

Ink charging takes approximately four minutes and Power LED flashes during that time.

Do not tilt the product during ink charging to avoid ink leakage.

Be sure not to turn off the product or open the covers while the Power LED is flashing.

This restarts the ink charging, which wastes ink.

Make sure the Power LED turns on after flashing.

7

Page 51

Chapter 2 Setup

Setting the Memory Switches

With the memory switches function, which are software settings for the printer, you can set the

various functions.

Use TM-S2000 Utility to set the memory switches.

For detailed information about the TM-S2000 Utility, see the TM-S2000 Utility User’s

Manual.

Functions

Power ON information

•Do not transmit (initial setting)

•Transmit

Auto line feed

•Always disabled (initial setting)

•Always enabled

Remote wake-up

•Enabled (initial setting)

•Disabled

Time to check ink head cleaning

Time (hh:mm) is settable. (initial setting: 20:00)

2

51

Page 52

Validation settings

Top margin (dots)

Left margin

(dots)

50.8 mm

18 mm

Print Area

10 mm

10 mm

Paper feed direction

Top margin (dots)

Left margin

(dots)

50.8 mm

18 mm

Print Area

10 mm10 mm

Paper feed direction

•Top margin (initial setting: 0)

•Left margin (initial setting: 0)

Slip settings

•Top margin (initial setting: 0)

•Left margin (initial setting: 0)

Time to enter power saving mode

Settable from 100ms ~ 3600s. (initial setting: 3000 [5 minutes])

52

Page 53

Chapter 3 Application Development Information

Application Development Information

This chapter describes software and gives information useful for printer application

development.

Software

Operating Environment

Minimum Specification

•CPU: At least a Pentium 4, 2.0 GHz or the equivalent

•Memory: At least 512 MB or above the minimum operating system requirement

• HDD: Free space of more than 30 MB (before installing the driver)

•Interface: USB 2.0 Hi-speed

Recommended Specification

•CPU: At least Intel Core 2 Duo 1.8 GHz or the equivalent

•Memory: At least 1 GB or above the minimum operating system requirement

• HDD: Free space of more than 30 MB (before installing the driver)

•Interface: USB 2.0 Hi-speed

3

53

Page 54

Software for Windows

Current Settings

Operation Check

Storing Logos

Backup/Restore

Printing Control

Device Settings

Software Description

TM-S2000 Driver Use this API (Application Program Interface) to fully use functions of

the TM-S2000MJ, such as the scanner function, endorsement printing

function, cut sheet paper printing function, and to monitor the status

of the TM-S2000MJ. Programming can be done in Visual C++, Basic, or

other programming languages.

Printer Driver for TM-S2000 This is the standard printer driver for Windows. Printing is possible using

the print function of commercially available software.

TM Virtual Port Driver for TM-S This driver changes the interface so that a printer connected with the

USB interface acts as if it is connected with the serial/parallel

interface. Use this driver when you use applications that directly send

control commands to printers connected with the serial/parallel

interface. This driver supports the print function only. The scanner

function is not available.

TM-S2000 TWAIN Wrapper Use this software to control the TM-S2000MJ using TWAIN, the standard

interface for scanners. Use it together with the TM-S2000 Driver.

TM-S2000 Java Wrapper Use this software to control the TM-S2000MJ from Java applications.

Use it together with the TM-S2000 Driver.

TM-S2000 Utility Use this software to use or set the following functions of the

TM-S2000MJ.

TWAIN App.

TM-S2000

TWAIN Driver

Im ag e A p p.and Print App.

TM-S2000 Driver

TM-S2000MJ

Print App.

Printer D river

54

Page 55

Chapter 3 Application Development Information

Core API Layer

CUPSSANE Back End

TM-S2000MJ

SANE Front End

(Image App.)

Print App.

Software for Linux

Software Description

SANE Backend Use this software to control the TM-S2000MJ using the main scanner

interface for Linux.

CUPS Driver This is a printer driver for Linux.

3

How to Get Drivers, Utilities, and Manuals

You can obtain drivers, utilities, and manuals from one of the following URLs.

For customers in North America, go to the following web site:

http://www.epson.com/support/

For customers in other countries, go to the following web site:

http://download.epson-biz.com/?service=pos

55

Page 56

Setting/Checking Modes

•Firmware version

•Buffer capacity

•Handshaking operation (busy condition)

•Automatic line feed (CR command function)

•Resident character

•Power on status

•Remote wake-up

• Nozzle check pattern

•Maintenance information

•Memory switches

Besides the ordinary print mode, the printer has the following modes to set or check settings of

the printer.

•Self-test Mode

•NV Graphics Print Mode

Self-test Mode

In the self-test mode, the printer prints the current status of the printer and resident characters as

a test print.

You can confirm the following information with the status print.

Starting the test print

Follow the steps below to start a test print.

Close all covers.

1

While pressing the Cleaning button, turn on the printer. (Keep pressing

2

the Cleaning button until the Document LED starts flashing.)

The printer goes into the insertion waiting status for cut sheet paper.

Insert the cut sheet paper.

3

The printer starts printing the current status of the printer on the cut sheet paper.

After ejecting the cut sheet paper, the printer goes into the paper insertion waiting status

again and again until printing the current status of the printer and a test print of a rolling

pattern using only the built-in character set complete.

After printing the following message, the printer is initialized and returned to the normal

mode.

*** completed***

56

Page 57

Chapter 3 Application Development Information

NV Graphics Print Mode

You can confirm the following information by running NV graphics print mode:

•Capacity of the NV graphics

•Used amount of the NV graphics

•Unused capacity of the NV graphics

•Number of NV graphics that are registered

•Key code, number of dots in X direction, number of dots in Y direction

•NV graphics dat

a

For detailed information about NV graphics, see "NV Graphics Memory" on page 28.

Starting the NV graphics print mode

Follow the steps below to run this mode.

With the ink cartridge cover opened, while pressing the Cleaning

1

button, turn on the printer. (Keep pressing the button until the Error LED

lights.)

Press the Cleaning button twice.

2

Close the ink cartridge cover.

3

The printer starts printing the NV graphics information.

Turn the power off.

4

The printer returns to the normal mode.

3

57

Page 58

Handling

Power button

This chapter describes basic handling of the scanner.

Turning On/Off the Product

Turning On

To turn on the product, press the power button on the front side of the product.

Turning Off

When turning off the product, make sure the AC cable is connected to the product and a

wall socket, and always use the power button.

To turn off the product, press the power button for 3 seconds or more until Power LED goes off.

58

Page 59

Opening Covers

Do not open the covers while processing is in progress.

Opening the Ink Cartridge Cover

Put your finger under the left side of the ink cartridge cover and pull it up to open it.

Chapter 4 Handling

Opening the MICR Cover

Pull the MICR cover open lever and pull the MICR cover outward to open it.

4

59

Page 60

Opening the Scanner Cover

Pull the scanner cover open lever and pull the scanner cover outward to open it.

60

Page 61

Chapter 4 Handling

1

2

3

4

5

Processing Cut Sheet Paper

The TM-S2000MJ is capable of performing the following actions on cut sheet paper in a single

pass.

Flow of Single Pass Processing

Auto sheet feeder (ASF) section feeds the cut sheet paper. (➀)

MICR reader section reads magnetic ink characters on the cut sheet paper. (

Printer section prints on the cut sheet paper.(

Scanner section scans both sides of the cut sheet paper.(

Pocket section ejects the processed cut sheet paper.(

➂)

➃)

➄)

➁)

4

Important Notes on Processing Cut Sheet Paper

•Use cut sheet paper that meets the specifications. (See "Paper Specifications" on page 37.)

•Do not use copy paper or other multi-ply paper.

•Make sure that the cut sheet paper has no curl, bending (especially on the corners), warpage,

or wrinkles.

•Do not use checks with paper clips, staples, adhesive tape, or other foreign materials attached.

•Be sure to let cut sheet paper go as soon as the scanner starts feeding. Ot

a paper skew, paper jam, or MICR reading error.

•Do not open the covers while processing is in progress.

herwise, there may be

61

Page 62

Inserting Cut Sheet Paper

1

2

347

8

0

1

2

345

6

7

8

90

1

2

3

4

780

1

2

3

4

5

6

7

8

9

0

You can put up to 100 sheets of cut sheet paper in the ASF to be fed automatically.

Pull out the ASF guide and the pocket guide appropriately for the size of

1

the cut sheet paper to be set.

Set the cut sheet paper in the ASF with the edges aligned to the paper

2

setting mark on the right side of the ink cartridge cover.

Set the sheets with the face on which you want to print facing inside.

To scan checks or read the magnetic ink characters with MICR, set the sheets with the

part of the magnetic ink characters facing outside and down.

To set multiple sheets, align them neatly on the bottom-right (insertion side) corner.

If the sheets are inserted without being aligned, they may not be fed at all, or a paper

jam or incorrect feeding of multiple sheets may result.

62

After setting the cut sheet paper, release it immediately.

3

Do not insert an ID card into the ID card insertion slot while processing cut sheet paper.

Page 63

Ejecting Cut Sheet Paper

Remove the cut sheet paper when it is ejected.

To prevent a paper jam, do not leave more than 100 sheets in the pocket (for two-pocket

models, 100 sheets in the main pocket and 50 sheets in the sub pocket) while processing

cut sheet paper.

1234780 1234567890

Chapter 4 Handling

For two-pocket models, paper may be ejected separately into the main pocket and the sub

pocket depending on your application.

4

63

Page 64

Scanning ID Cards

Follow the steps below to scan both sides of an ID card.

Use an ID card that meets the specifications. (See "Paper Specifications" on page 37.)

Make sure that the ID card is flat and does not have excessive bending, cracks, folds, or

embossing.

Do not touch the external terminal when using an IC card.

Put the ID card in the insertion slot on the right side of the pocket with its

1

photo side facing the pocket, and slide it along the bottom of the slot.

When the card starts feeding, release it immediately.

2

When the ID card is feeding, a part of it comes out of the card carrier slit at the back of

the product. Be sure not to block this slit.

Do not touch the ID card when it is being ejected. Doing so may cause distortion and

other problems with the scanned data.

Do not open the covers while processing is in progress.

When the ID card is ejected and the ID Card LED flashes, remove the ID

3

card from the slot.

64

Page 65

Chapter 4 Handling

Cleaning

Cleaning the Ink-Jet Head

When printing on cut sheet paper becomes faint or uneven, the ink-jet head may need to be

cleaned.

The cleaning process uses some ink. Do not run cleaning when it is unnecessary.

To start the ink-jet head cleaning, press the cleaning button on the control panel for 3 seconds or

more. During the cleaning, Power LED flashes.

When Power LED comes on after flashing, the ink-jet head cleaning is completed.

Cleaning the MICR Head

When the MICR head becomes dirty, the product cannot read the magnetic ink characters

normally.

Clean the MICR head every 6 months or every 100,000 passes by setting the following cleaning

sheet in the same way as cut sheet paper. (See

•KIC Team, Inc. “Waffletechnology® cleaning card” (CS1B15WS)

•KIC Team, Inc. "Epson Check Scanner Cleaning Kit" (Model: KWEPS-KCS2)

Use a cleaning sheet only one time; then discard it.

It is recommended to clean the MICR head once per week or once every 2,000 sheets

for good reading results.

It is recommended to clean the scanner after cleaning the MICR head.

"Inserting Cut Sheet Paper" on page 62.)

4

65

Page 66

Cleaning the Scanner

If the glass of the scanner gets soiled from ink or paper dust, the quality of scanned data may

deteriorate. Clean the glass every 6 months or every 100,000 passes by following the steps below.

Do not use synthetic detergent, benzine, water, or other liquid for cleaning.

Doing so may result in a stain.

CAUTION

Open the scanner cover.

1

See "Opening the Scanner Cover" on page 60.

Lightly wipe 2 parts of glass areas shown in the picture below with a soft,

2

dry cloth.

When the glass of the scanner is smeared with oil, grease or other unremovable substance,

wipe it with a cloth lightly dipped in alcohol. However, never apply any liquid directly to

the glass of the scanner.

Never apply any liquid directly to the glass of the scanner.

66

Close the scanner cover firmly until it clicks in place.

3

It is recommended to clean the scanner once per week or once every 2,000 sheets for good

reading results.

Page 67

Chapter 4 Handling

Cleaning the Product Case

Be sure to turn off the product, and wipe the dirt off the product case with a dry cloth or a damp

cloth.

Never clean the product with alcohol, benzine, thinner, or other such solvents.

Doing so may damage or break the parts made of plastic and rubber.

CAUTION

67

4

Page 68

Troubleshooting

Error LED Is On or Flashing

See "Error Status" on page 25.

Paper or ID Card Is Jammed

When cut sheet paper is jammed

Open the MICR cover or scanner cover to remove the jammed paper in the paper path.

"Opening the MICR Cover" on page 59 or "Opening the Scanner Cover" on page 60.

See

When an ID card is jammed

Open the scanner cover to remove the jammed ID card.

"Opening the Scanner Cover" on page 60.

See

Printout Is Faint

The ink-jet head may be dirty.

"Cleaning the Ink-Jet Head" on page 65 to clean the ink-jet head.

See

Reading/Scanning Is not Normal

Magnetic ink character cannot be read normally

The MICR head may be dirty.

"Cleaning the MICR Head" on page 65 to clean the MICR head.

See

Scanned data is not normal

The scanner glass may be dirty.

"Cleaning the Scanner" on page 66 to clean the scanner glass.

See

68

Page 69

Chapter 4 Handling

Preparing for Transport

Follow the steps below to transport the product.

Keep the product upright and horizontal during transportation.

Install the transportation cartridge

If transporting a product for which the initial ink filling has been done, install the transportation

cartridge and transport it. Failure to do so may cause ink leaks.

Transportation cartridge: TRANSPORTATION CARTRIDGE, SJIC18, UNIT

Turn on the product.

1

See "Turning On" on page 58.

Open the ink cartridge cover.

2

See "Opening the Ink Cartridge Cover" on page 59.

Remove it by pulling up the tab on the top of the cartridge while holding

3

the product.

Install the transportation ink cartridge in the correct direction, and push

4

it until it clicks in place.

Close the ink cartridge cover.

5

Pack the scanner

Turn off the product.

1

See "Turning Off" on page 58.

Confirm that Power LED is off.

2

4

Remove the power supply connector.

3

Store the ASF guide and the pocket guide inside the scanner.

4

Pack the scanner upright.

5

69

Page 70

Appendix

Specifications of USB Interface

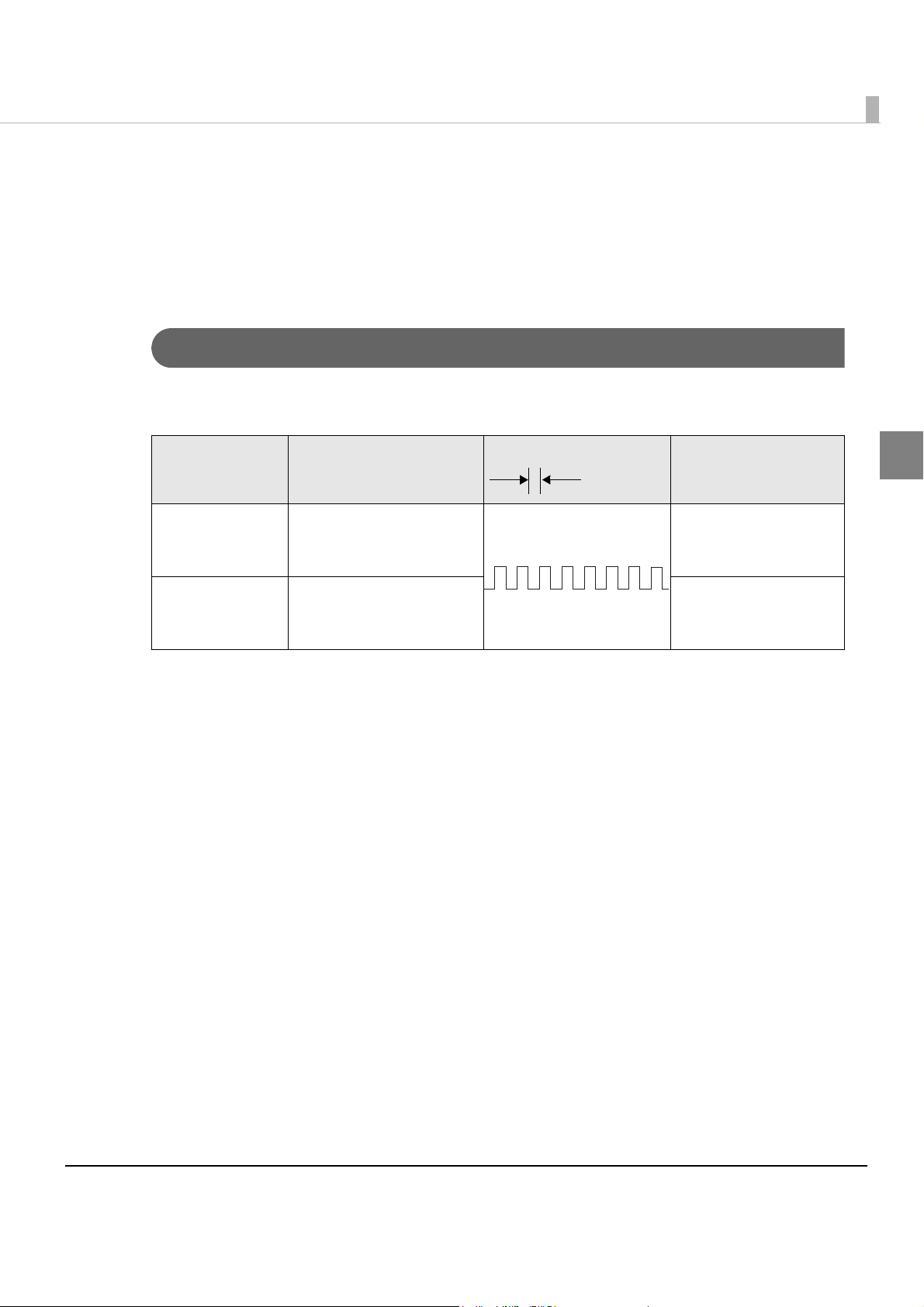

USB Interface (Type B)

Outline

•High-speed transmission at 480 Mbps [bps: bits per second]

•Plug & Play, Hot Insertion & Removal

USB transmission specifications

Overall specifications According to USB 2.0 specifications

Transmission speed USB High-Speed (480 Mbps)

USB Full-Speed (12 Mbps)

Transmission method USB bulk/USB interrupt transmission

Power supply specifications USB self power supply function

Current consumed by USB bus 0 mA

If the printer does not work even if it is connected with a USB 2.0 compliant cable, this could

be due to one of the following reasons.

1) An impact has damaged the quality of the USB cable.

2) An impact has damaged the USB connector built in the PC.

70

Page 71

Character Code Tables

The character code tables show only character configurations. They do not show the

actual print pattern.

“SP” in the table shows a space.

Appendix

71

Page 72

Common to All Pages